Page 1

KEEPING THE WORLD SEWING™

User's Guide

Page 2

Please note that on disposal, this product must be safely

recycled in accordance with relevant National legislation

relating to electrical/electronic products. If in doubt please

contact your retailer for guidance.

This householdsewing machine is designed to comply with IEC/EN 60335-2-28 and UL 1594

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following:

Read all instructions before using this household sewing machine.

DANGER - To reduce the risk of electric

shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing machine from

the electric outlet immediately after using and before cleaning.

• Always unplug before relamping. Replace bulb with same type rated 5 Watt.

WARNING - To reduce the risk of burns,

fi re, electric shock, or injury to persons:

•

This sewing machine is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the sewing machine by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the sewing machine.

•

Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

•

Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer or

service center for examination, repair, electrical or mechanical adjustment.

•

Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing

machine and foot controller free from the accumulation of lint, dust, and loose cloth.

•

Keep fi ngers away from all moving parts. Special care is required around the sewing machine needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

•

Do not use bent needles.

•

Do not pull or push fabric while stitching. It may defl ect the needle causing it to break.

•

Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as threading needle,

changing needle, threading bobbin, or changing presser foot, etc.

• Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when making

any other user servicing adjustments mentioned in the instruction manual.

•

Never drop or insert any object into any opening.

•

Do not use outdoors.

•

Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

•

To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

•

Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

•

Keep fi ngers away from moving parts, especially the area near the blades.

SAVE THESE INSTRUCTIONS

For the USA and Canada

This sewing machine has a polarized plug (one blade wider than the other). To reduce the risk of electric shock,

this plug is intended to fi t in a polarized outlet only one way. If the plug does not fi t fully in the outlet, reverse the

plug. If it still does not fi t, contact a qualifi ed electrician to install the proper outlet. Do not modify the plug in any

way.

Page 3

Table of contents

1. SUMMARY ...............................................................................................1

1 - 1. Name of parts .......................................................................................... 1

1 - 2. Accessories ............................................................................................. 2

1 - 3. Preparation .............................................................................................. 3~4

1 - 4. Sewing speed .......................................................................................... 5

1 - 5. Telescopic thread stand ...........................................................................5

1 - 6. Replacing the needle ...............................................................................6

1 - 7. Changing threads .................................................................................... 7

1 - 8. Stitch fi nger lever ..................................................................................... 8

1 - 9. Presser foot lift .........................................................................................8

1-10. Disengaging the upper cutter ..................................................................8

1-11. Free arm .................................................................................................. 8

2. SEWING ADVISOR DISPLAY GUIDE ..................................................... 9

2 - 1. Selection buttons ..................................................................................... 9

2 - 2. Sewing Advisor display function .............................................................. 10

2 - 3. Choice of language ..................................................................................11

2 - 4. Auto Mode ............................................................................................... 11~12

2 - 5. Manual Mode ........................................................................................... 12

2 - 6. Memory Mode .........................................................................................13~14

2 - 7. Stitch table ............................................................................................... 15

2 - 8. Table of fabric type ................................................................................... 15

2 - 9. Error messages ....................................................................................... 15

3. THREADING ............................................................................................16

3 - 1. Upper looper threading (A) ...................................................................... 16

3 - 2. Lower looper threading (B) ...................................................................... 17

3 - 3. Needle threading (C) (D) ......................................................................... 18

3 - 4. Preparations and control .........................................................................19

3 - 5. Presser foot pressure .............................................................................. 19

3 - 6. Thread tension table ................................................................................ 19

3 - 7. Thread tension .........................................................................................20~21

3 - 8. Adjusting the stitch width / cutting width .................................................. 22

3 - 9. Stitch length ............................................................................................. 23

3-10. Differential feed ........................................................................................23~24

Page 4

4. SEWING ...................................................................................................25

4 - 1. Four thread overlock stitch with 2 needles ..............................................25

Before sewing ..........................................................................................25

Insert the fabric .......................................................................................25

Start sewing and chain off .......................................................................25~26

Cording thread / Decorative thread ......................................................... 27

Serging curves ........................................................................................ 28

4 - 2. Three thread overlock ..............................................................................29~30

4 - 3. Two thread overlock .................................................................................31

4 - 4. Stitch selection table two-thread sewing ..................................................32

4 - 5. Rolled edge .............................................................................................33~34

4 - 6. Flatlock .................................................................................................... 35

4 - 7. Pin tuck .................................................................................................... 36

4 - 8. Five thread overlock stitch and Double chain stitch .................................37~39

4 - 9. Cover stitch ..............................................................................................40~48

5. MAINTENANCE .......................................................................................49

5 - 1. Changing the light bulb ............................................................................ 49

5 - 2. Cleaning after sewing .............................................................................. 50

5 - 3. Storage .................................................................................................... 50

5 - 4. Replacing the lower cutter ....................................................................... 50

5 - 5. Lubrication ............................................................................................... 50

6. STITCH TABLE ........................................................................................ 51~54

7. TABLE OF SEWING MATERIALS, NEEDLES AND THREADS ............. 55

8. TROUBLE SHOOTING ............................................................................56

9. SPECIFICATIONS ...................................................................................57

10. OPTIONAL ACCESSORIES ....................................................................58

10-1. Presser feet-optional accessories ...........................................................58~66

10-2. Waste tray ...............................................................................................67

11. NOTE ....................................................................................................... 68~71

12. INDEX ......................................................................................................72

Page 5

—1—

1. SUMMARY

1-1. Name of parts

1. Presser foot pressure adjustment dial

2. Spool pin

3. Thread take-up lever cover

4. Thread guides

5. Telescopic thread stand

6. Thread tension dials

7. Presser foot lift lever

8. Thread cutter

9. Thread guides A for decorative thread /

cording thread

10. Upper cutter knob

11. Presser foot

12. Sewing surface, fl at bed cover

13. Cutting width / stitch width adjusting dial

14. Cutter cover

15. Front panel

16. Front cover

17. Handwheel

18. Sewing Advisor™ liquid crystal display

(LCD)

19. Stitch fi nger

20. Upper cutter

21. Stitch fi nger lever

22. Thread guides B for decorative thread

Needle plate

123456 7

18

9

8 1011 1213141516 17

224

19 20 21

Page 6

#

80

#

90

—2—

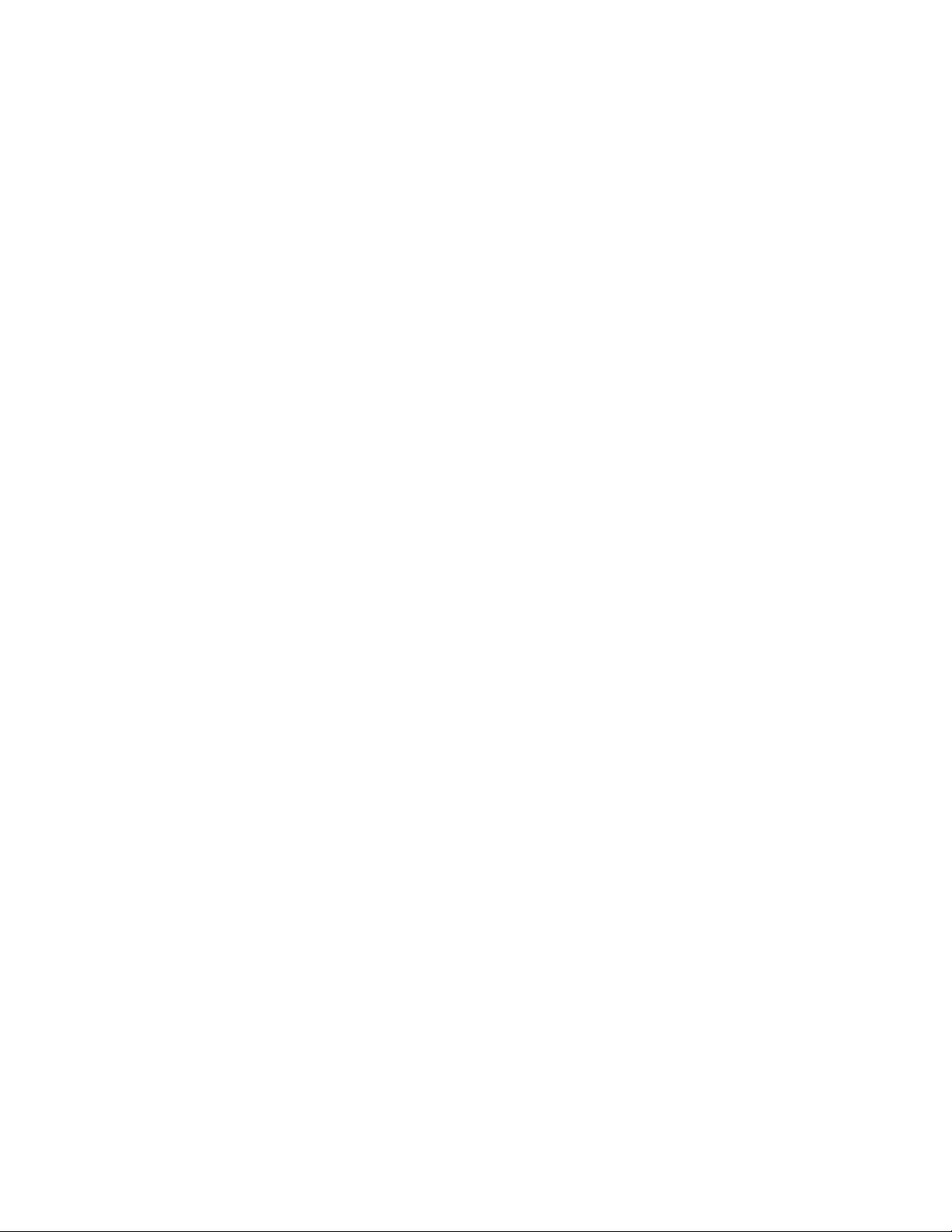

1-2. Accessories

Screw driver

Allen wrench (1.5mm)

Oiler

Tweezers

Spool holder

Light bulb changer Presser foot (C)

for Cover stitch

Needle plate (C)

for Cover stitch

and double

chain stitch

Needle threader

Multipurpose foot Vinyl cover

Cutter cover (C)

for Cover stitch

and double

chain stitch

Net for thread spools

By pass for thread guide EWaste tray

Needles (SCHMETZ 130/705H)

Cleaning brush

Page 7

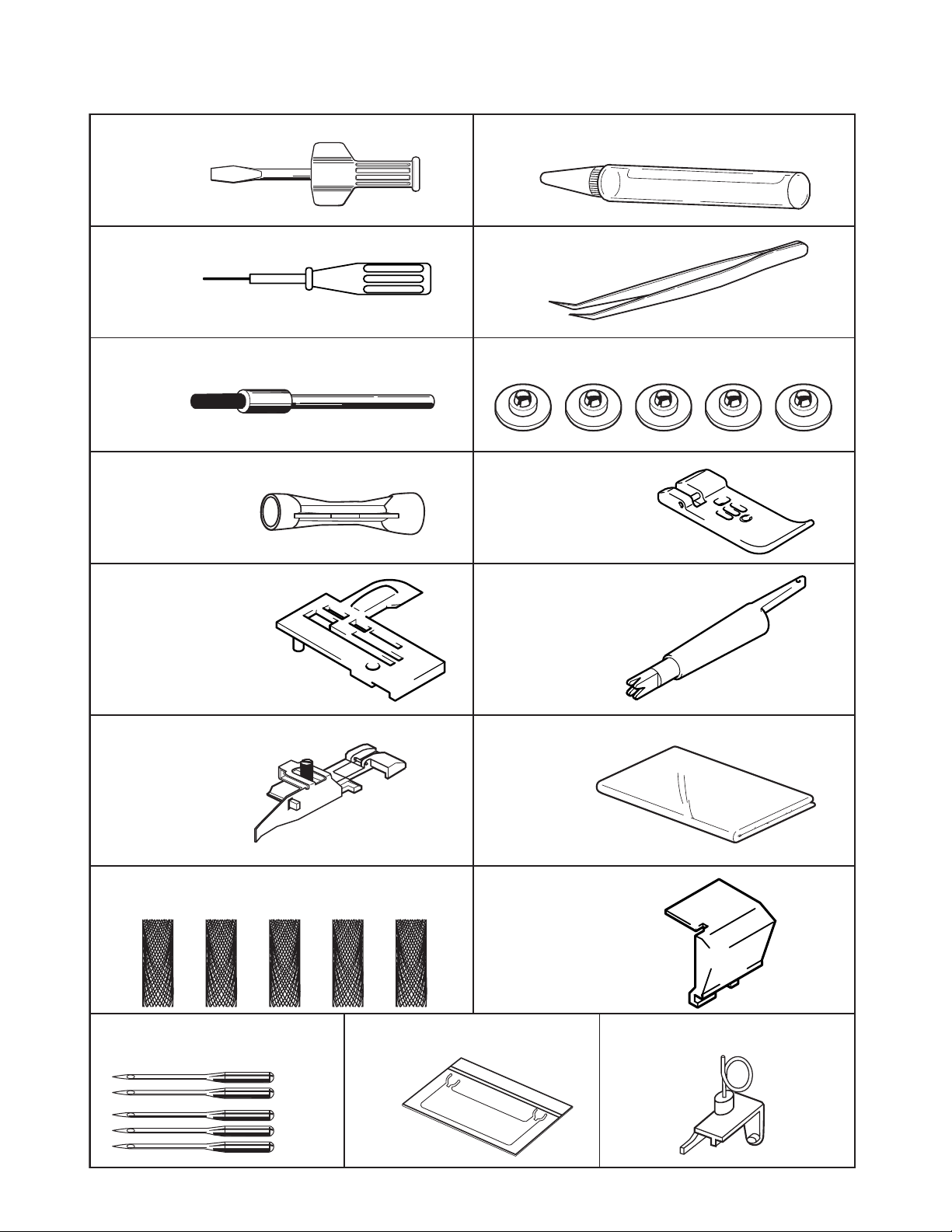

—3—

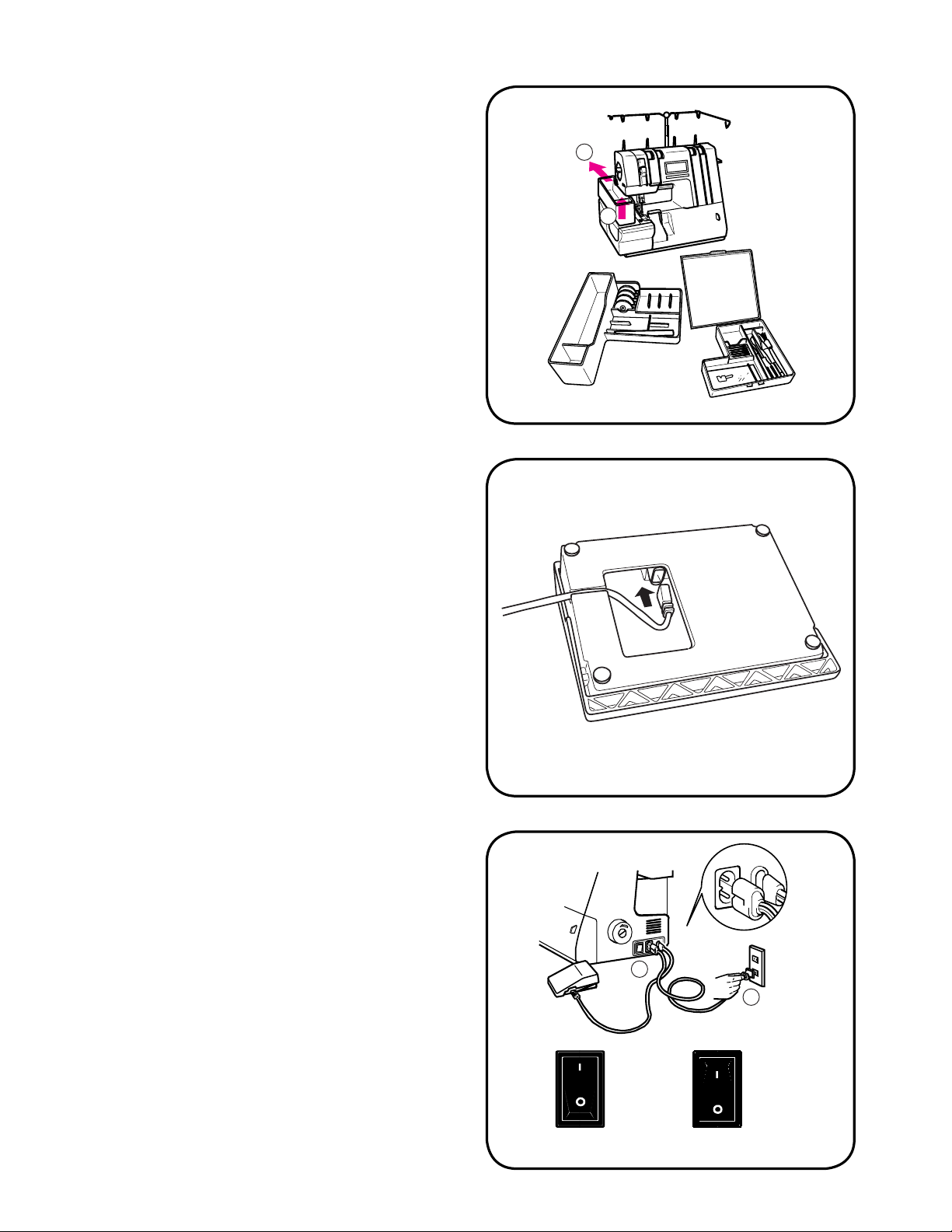

Attach

Remove

Front cover

Cutter cover

A

B

Change the presser foot

Turn the main power switch off.

(See page 4)

1. Raise presser foot.

2. Raise needle to its highest position by turning

the handwheel toward you.

3. Push button (A) and the foot will come off.

4. Position the new foot with the pin beneath

the groove of the ankle. Lower the presser

foot lever to mark the ankle snap on to the

presser foot.

1-3. Preparation

Handwheel

Always turn handwheel toward you.

Open the front cover

Push part (B) - at the arrow - to the right and

pull the cover down toward you.

Close the front cover

Close the cover with caution. The front cover

must be closed while sewing. The front cover

has a safety switch. If the front cover is not

closed, the machine will not sew.

Page 8

—4—

2

1

2

1

ON

OFF

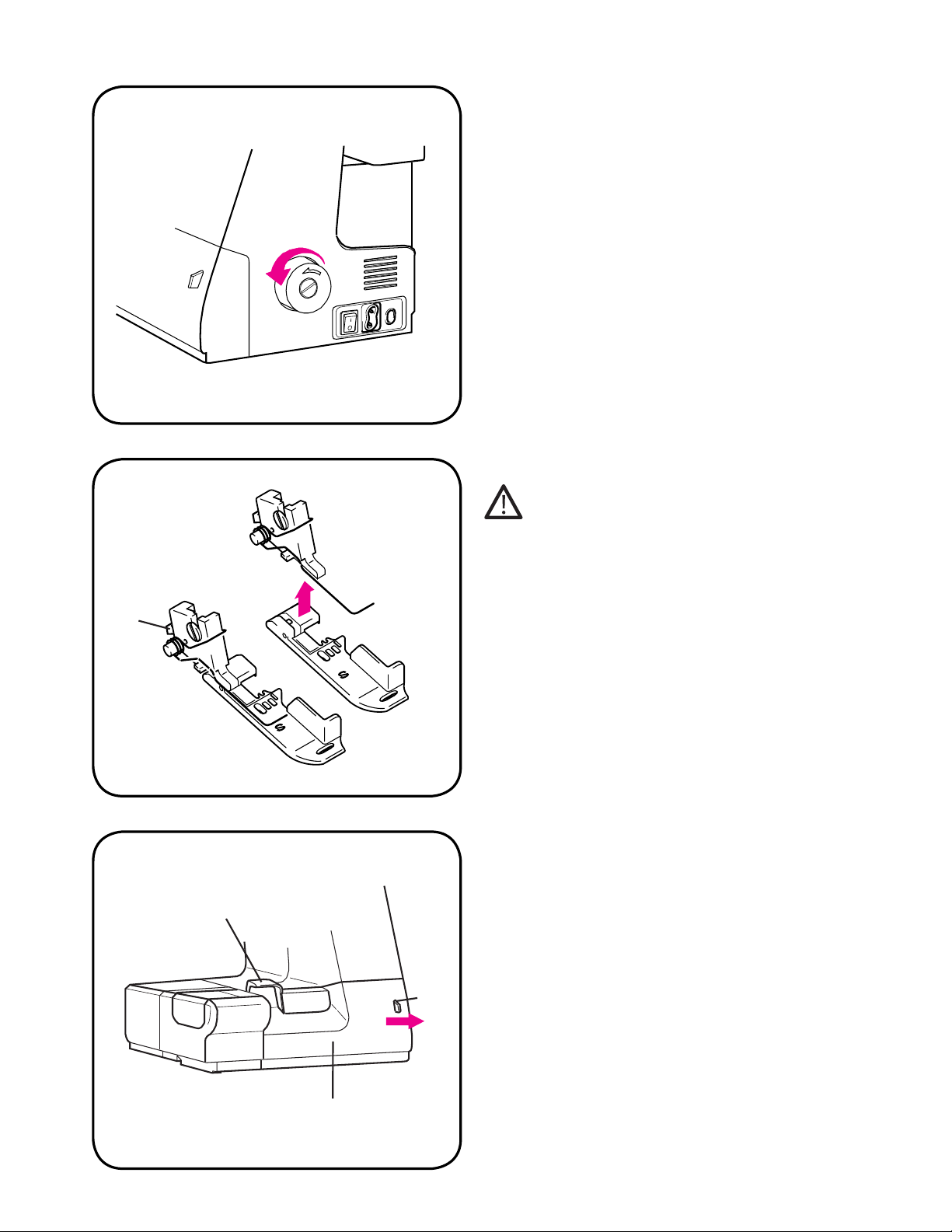

Accessory box

Lift the accessory box slightly

➀ and slide it in

the direction of the arrow

➁.

The accessory box consists of two parts. It

holds the foot control and other accessories. To

slide the box back on, reverse the steps from

above.

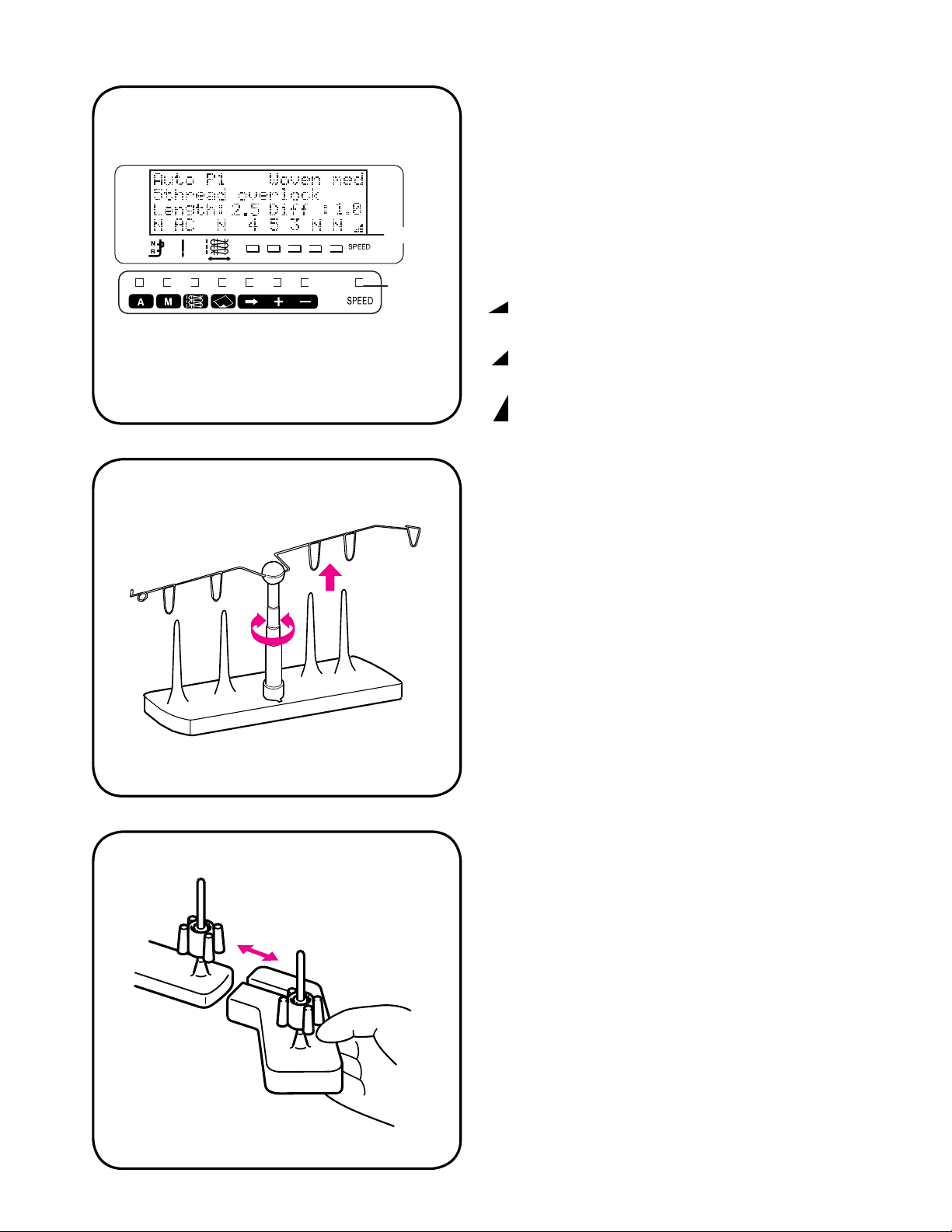

Connection

Note: Turn the main power switch off.

Among the accessories you will fi nd the foot

control cord and the main cord.

1. Place the foot control on its narrow side. Fit

the plug into the socket inside the foot control

compartment.

2. Push it fi rmly to make sure it is properly connected. This operation only necessary the

very fi rst time you are going to use the

machine.

3. To correctly turn away the cord, place it into

the slot, see picture.

Note: Before plugging in, check to ensure that

the foot control is of “FR-4”.

On the back of the machine, there is information about the voltage. Before plugging in your

machine, make sure that these values correspond to power supply. The specifi cations vary

from country to country.

Connect foot control and power cord

➀ ➁.

When pressing the main switch, both machine

and sewing light are turned on.

• Always turn off and unplug the machine

when not in use.

• When the power switch is turned off, the ma-

chine will not start even if you press the foot

control.

• Never leave anything on the foot control.

Page 9

—5—

1-4. Sewing speed

The harder you press the foot control, the faster

the machine will sew. You can choose between

three sewing speeds, (slow, medium, fast) with

the speed selector.

When you turn on the machine, the medium

speed mode is selected. Indicated symbol and

maximum speed modes are as follows:

:0-500 Slow speed mode

(max. speed 500 stitches/min)

:0-1000 Medium speed mode

(max. speed 1000 stitches/min)

:0-1300 Fast speed mode

(max. speed 1300 stitches/min)

Note: While “Chain stitch”, “Cover stitch wide”,

“Cover stitch narrow” and “Triple cover

stitch” are selected, the maximum speed

mode is limited to slow and medium only.

1-5. Telescopic thread stand

Extend the telescopic thread stand to its full

height and turn until it locks against the stop.

Make sure the round loop is to the left.

Indicato

r

Speed

selector

Page 10

—6—

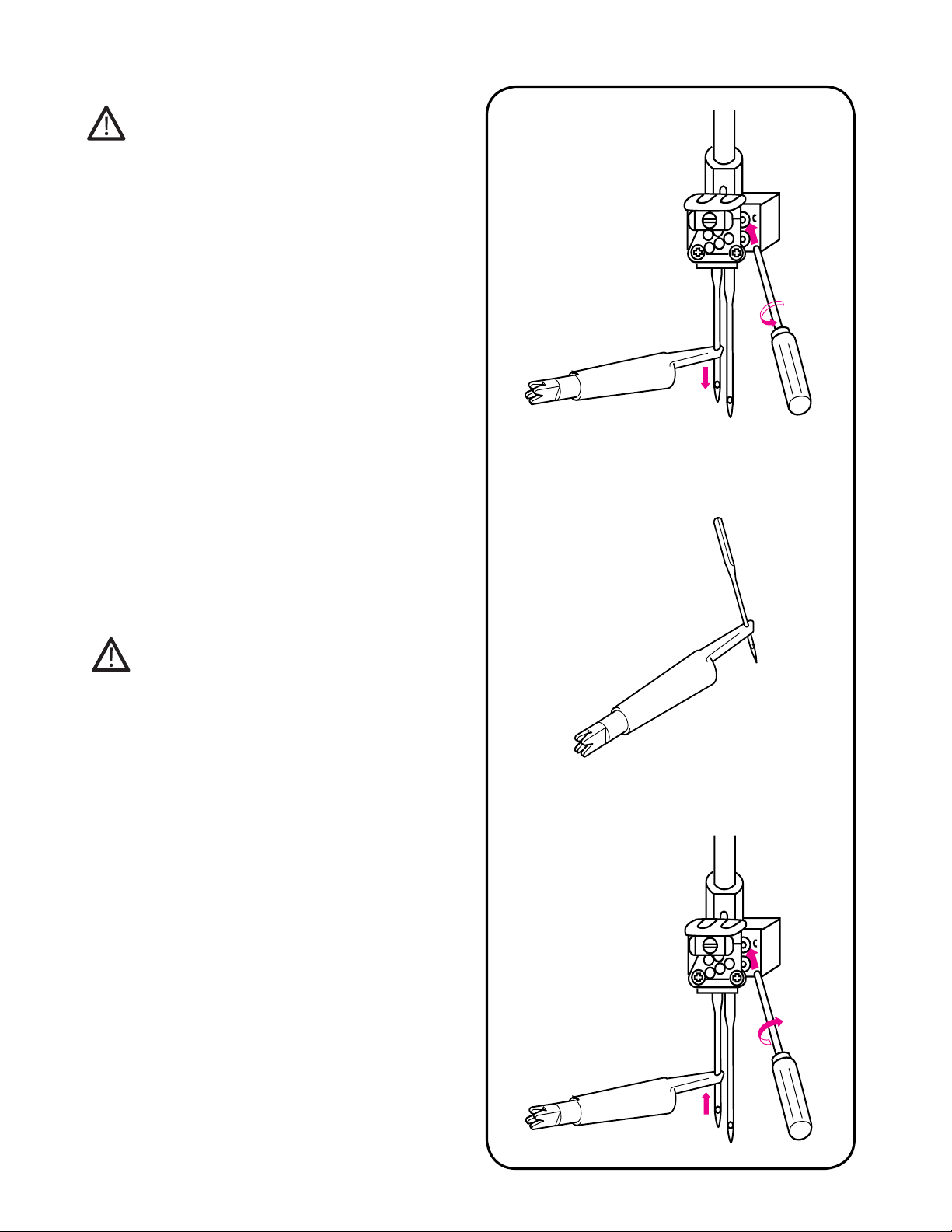

1-6. Replacing the needle

Turn the main power switch off.

1. Turn the handwheel toward you

(counterclockwise) by hand until the needle

is in its highest position.

2. Insert the needle into the opposite side

needle hole of Needle threader.

3.

Loosen the needle set screw with allenwrench

and remove the needle.

Please be sure to tighten loosen set screws

after removing the needle.

Note: Please use the allenwrench included in

the standard accessories for the proper

installation.

IMPORTANT

Lightly tighten the screw at the unused needle

position, so it does not fall out while sewing.

To insert the needle

Turn the main power switch off.

1. Turn the handwheel until the needle bar is in

its highest position.

2. Insert the needle into the opposite side

needle hole of Needle threader as far as it

goes with holding the fl at side of needle away

from you.

3.

Tighten the needle set screw with allenwrench.

4. If a needle does not go up all the way it may

be necessary to loosen the adjacent needle

screw slightly.

Page 11

—7—

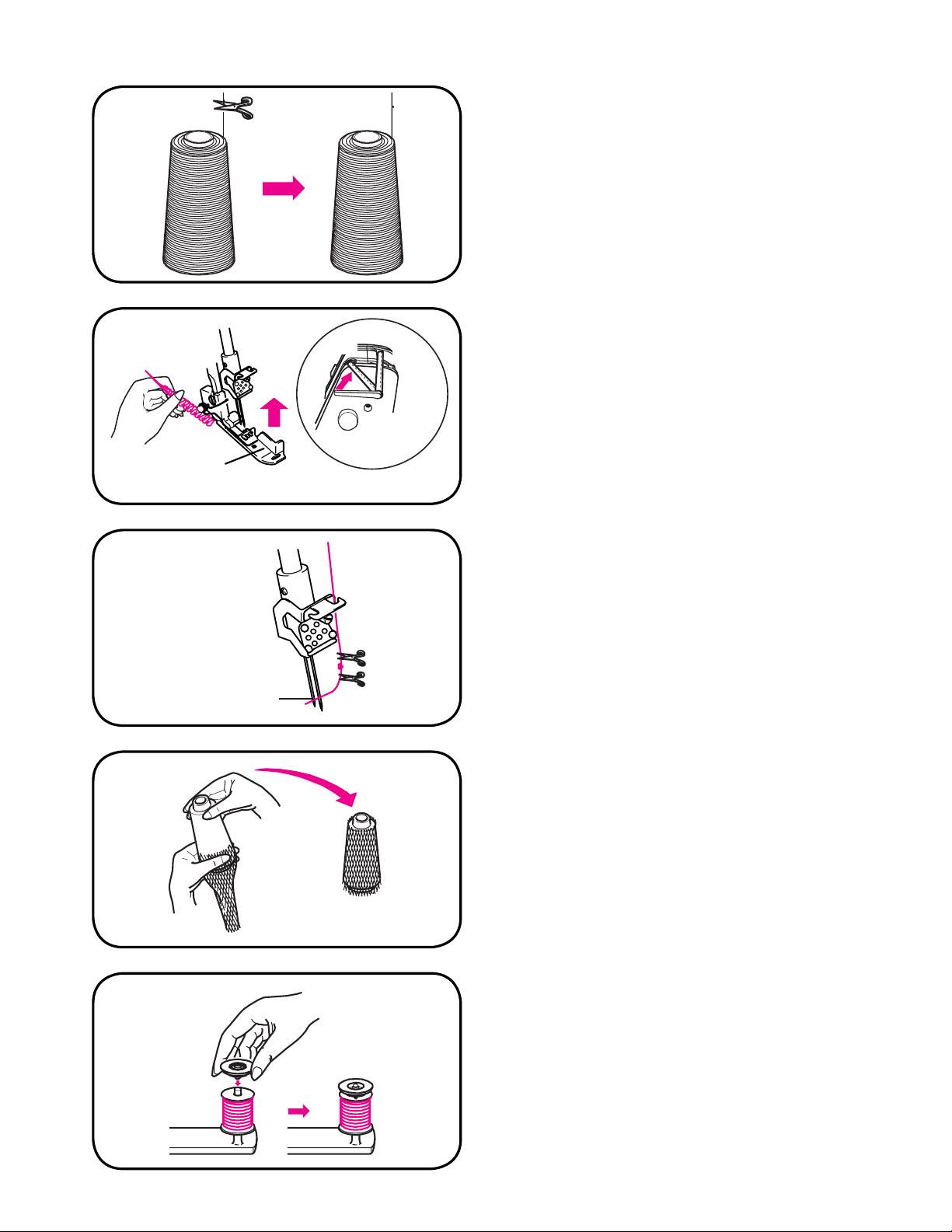

Cut the thread

Tie the thread

Presser

foot lift

Presser foot

Eye of the needle

1-7. Changing threads

The machine comes threaded with overlock

thread. To change thread follow the easy

threading as explained on page 16~18 or to tie

on:

1. Cut the thread in use near the thread spool

(in front of the telescopic thread stand). Place

the new thread spool on the spool pin and tie

the thread ends together.

2. Raise the presser foot with the presser foot

lift up to release the thread tension, so the

knot can easily pass through the thread ten-

sion discs.

3. Pull out the looper thread until the thread

knot comes about 10 cm (3” to 4”) behind the

presser foot.

4. When changing the needle thread, cut the

thread knot before it reaches the eye of the

needle to avoid bending the needle.

Thread net

In some cases cover the spool with the net

to prevent threads from slipping off the spool.

Slide on the net so that it covers the spool

entirely.

Spool holder

When using standard thread spools, place the

spool holders as shown to hold spool in place.

And prevent thread from getting caught on edge

of spool.

A

B

Page 12

—8—

Stitch fi nger lever

Presser foot

Needle plate

Presser foot lift

Front cover

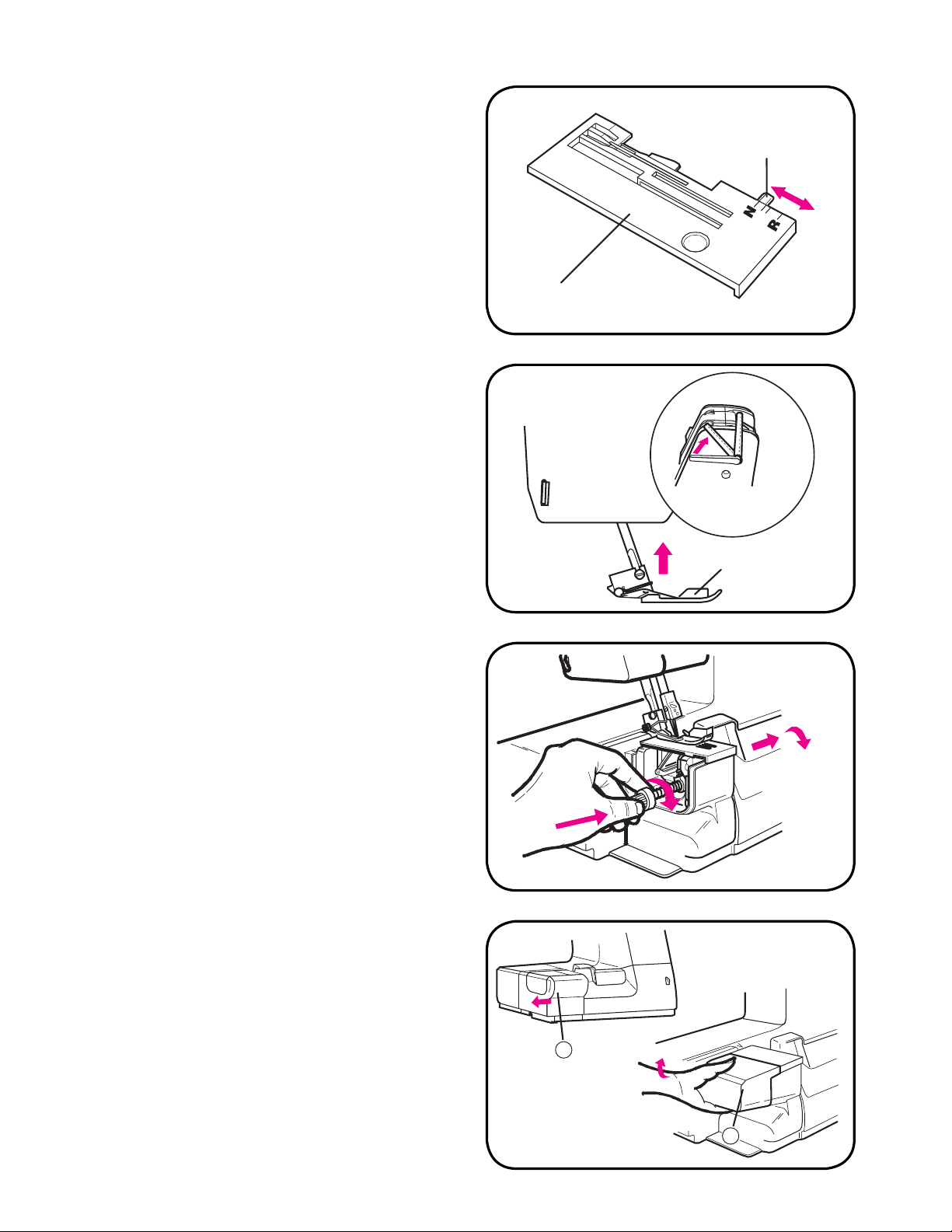

1-8. Stitch fi nger lever

(Convert from overlock stitch to rolled edge)

Raise the needle to its highest position by turning the handwheel toward you.

Overlock

Push the stitch fi nger lever to align it with “N” on

the needle plate.

Rolled edge

Pull the stitch fi nger lever toward you to align it

with “R” on the needle plate.

1-9. Presser foot lift

Lift up the presser foot lift to raise the presser

foot. The presser foot lift stops at position “A”.

When replacing the presser foot or when inserting very thick fabrics under the presser foot,

the lift height can be increased by pushing the

presser foot lift to position “B” and holding it

there. Make sure that the upper looper is in its

lowest position.

Note: Never sew with the presser foot up.

1-10. Disengaging the upper cutter

For Cover stitch or to sew along the edge of the

fabric, the upper cutter can be disengaged.

1. Remove the fl at bed cover

a and the free arm

cover

b pulling the respective cover in the

direction of the arrow.

2. Open the front cover.

3. Push the knob to its maximum point and turn

the knob to lower according to the arrow.

Since the cutter is sharp, be careful when

disengaging it.

4. Replace free arm and fl at bed cover .

Note: Be sure to put the cutter fully down before

sewing.

Note: You must sew along the edge of the fabric

when the cutter is disengaged or set for

Cover stitch.

1-11. Free arm

Pull out the fl at bed cover

a in the direction of

the arrow. The free arm is convenient for sewing

trousers legs, cuffs, and other small areas such

as children’s garments.

How to remove the free arm:

Hold the free arm cover

b as shown in the

picture.

1. Lift it up to release the clamps.

2. Pull it to the left.

A

B

a

b

Page 13

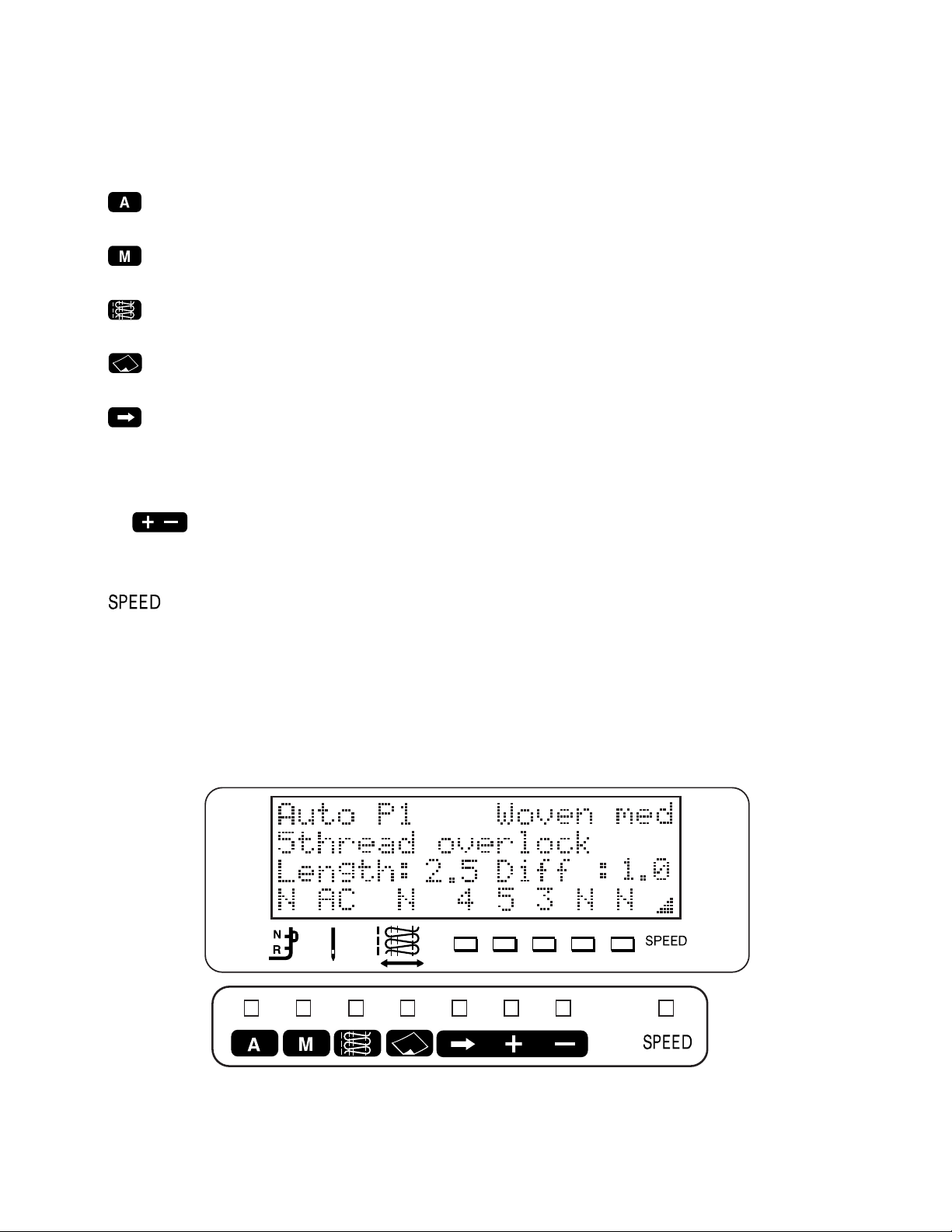

2. SEWING ADVISOR DISPLAY GUIDE

2-1. Selection buttons

The buttons below can either be pressed one step at a time or held until the desired setting is

obtained.

1. : Auto button

Press for Auto Mode. Standard settings are displayed.

2. : Memory button

Press to retrieve stored settings or store new setting preference in memory.

3. : Stitch selection button

Retrieve the 16 pre-set stitches in Auto Mode.

4. : Fabric selection button

Select fabric type in Auto Mode.

5. : Cursor button

Access Manual Mode to enter and or alter settings.

Cursor moves as follows:

Stitch length - Differential feed ratio - Cutting width(if applicable) - Thread tension

6.-7. : Plus(+) and Minus(-) button

In Manual Mode, settings increase(+) or decrease(-).

In Memory Mode, cursor moves to stored memories.

8. : Speed selection button

Select maximum speed mode. Refer to “1-4. Sewing speed (page 5)”.

9. Sewing Advisor display

All stitch settings can be shown in the display.

—9—

Page 14

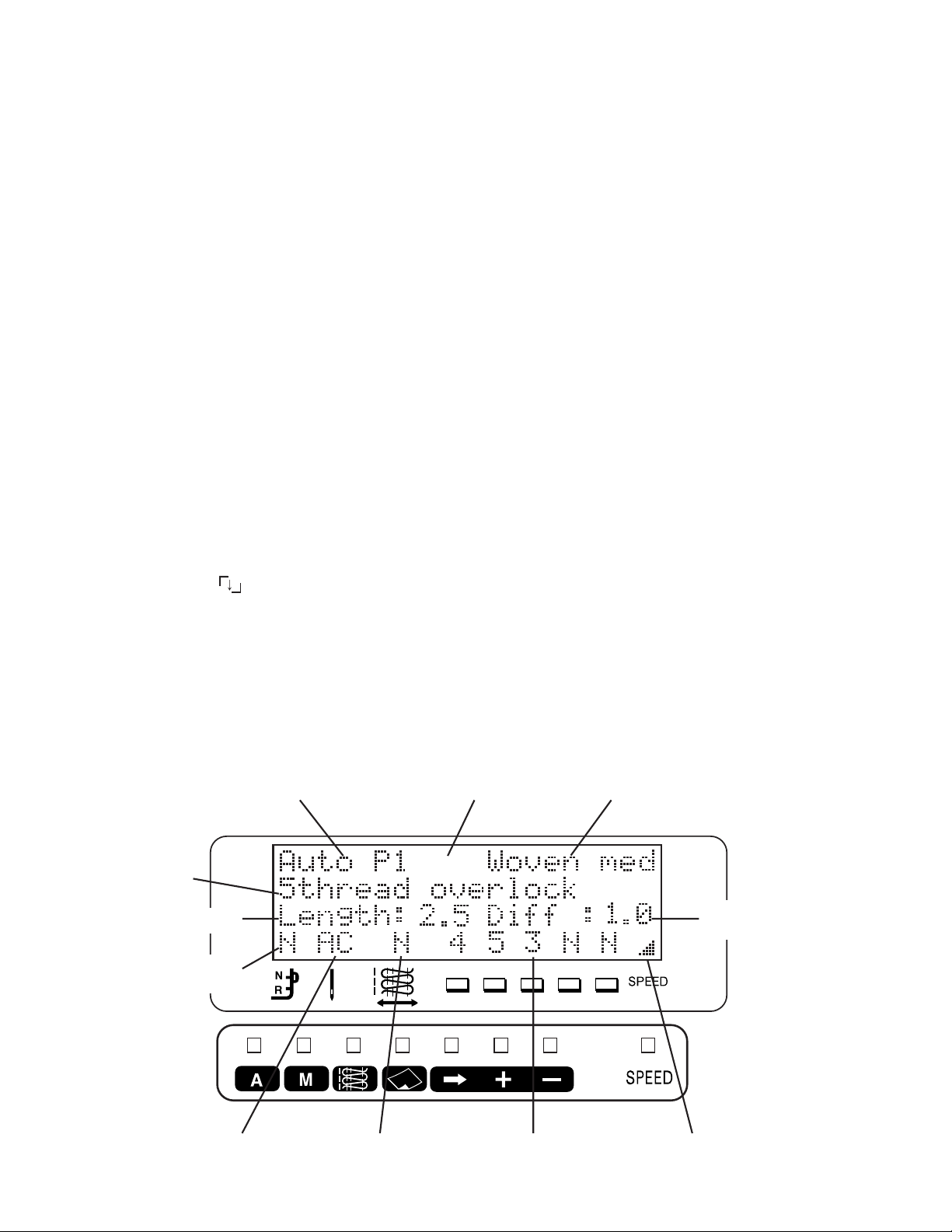

2-2. Sewing Advisor display function

Mode and stitch number :

Mode and pre-set stitch are displayed.

Memory number :

In Memory Mode, stored memory number is displayed.

Fabric :

Fabric type is displayed.

Stitch :

Stitch description is displayed.

Stitch length :

The recommended stitch length is displayed.

Differential feed ratio :

Standard ratio is displayed.

Stitch fi nger position :

Recommended position is displayed which corresponds to marking on the needle plate.

Needle position :

Recommended needle position is displayed which corresponds to marking on the needle clamp.

Cutting width :

The recommended cutting width is displayed.

When marking apperas on the Sewing Advisor, it means to lower the upper cutter.

Thread tension :

The recommended thread tension is displayed.

Each thread tension dial corresponds to color symbols from left to right.

Speed indicator :

Selected maximum speed mode is displayed. Refer to “1-4. Sewing speed (page 5)”.

—10—

Mode and stitch number Memory number Fabric

Needle

p

osition Cutting width Speed indicatorThread tension

Stitch

Stitch length

Stitch finger

position

Differential

feed ratio

Page 15

2-3. Choice of language

You can select the following languages :

American English, British English, French, Italian, German, Swedish, Norwegian, Danish, Finnish,

Dutch, Spanish, Czech, Polish, and Russian.

Select the language as follows:

1. Turn on the machine while pressing the auto button and cursor button simultane-

ously. The pre-set language is displayed.

2. Press the plus button or minus button until the desired language is displayed.

3. Press the memory button .

4. The selected language is now stored and stays in memory even if you turn off the machine.

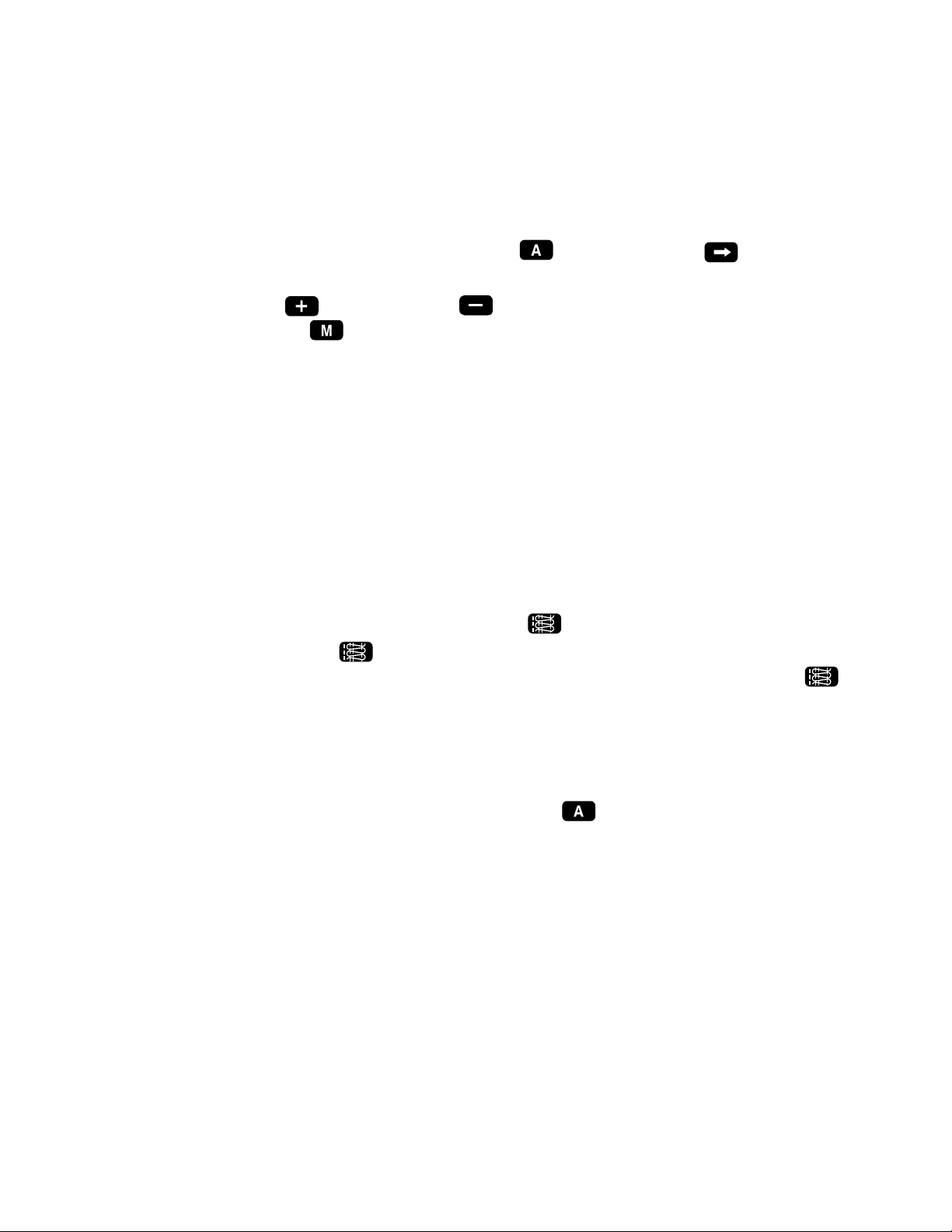

2-4. Auto Mode

The recommended settings are displayed for perfect stitching.

Note: Fabric and thread may vary. Therefore try the setting on scraps fi rst.

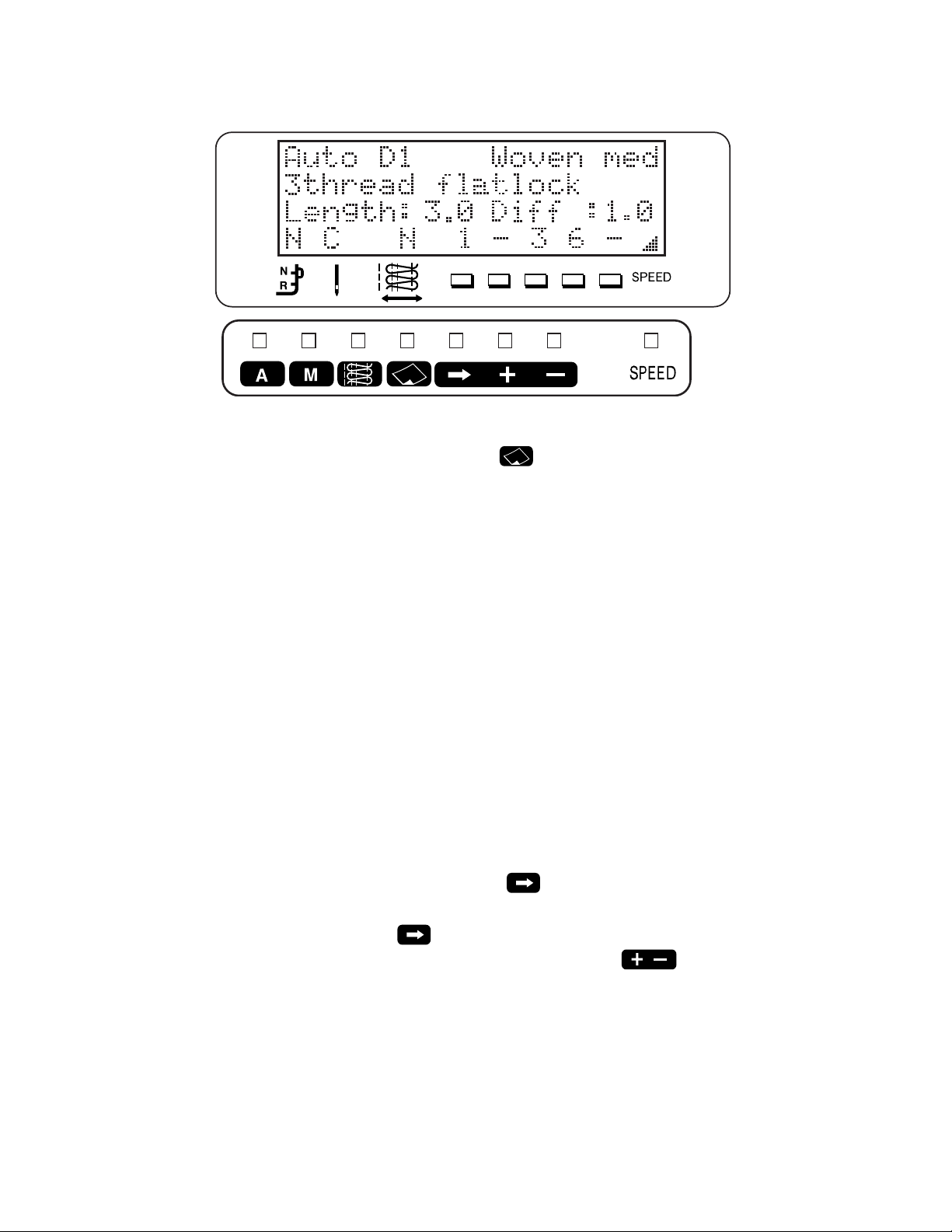

(1) Stitch selection

Turn on the machine, then “Auto A1” type of fabric “Woven med” (for woven medium)

and stitch “4-thread overlock” appears.

Change the stitch by pressing the stitch selection button .

Each time you press the button , the recommended settings are displayed.

Compare with “2-7. Stitch table (page 15)” and continue pressing the stitch selection button

until the desired stitch is displayed.

When the display shows “—” for the thread tension, it means “Do not thread here”.

Note: When it is necessary to change the accessory type, the accessory alert message is dis-

played. To cancel this message, press the auto button . For accessory type, see “4.

Sewing (page 25)”.

—11—

Page 16

(2) Selection of fabric

Select the fabric type with the fabric selection button .

The recommended setting then appears on the Sewing Advisor.

The message “Not advised” appears when the setting is not recommended.

See “2-8. Table of fabric type (page 15)”.

Set up your Huskylock™ as advised by the Sewing Advisor.

The machine is now ready for sewing.

Note: Fabric and thread may vary. Always test sew before starting on your garments.

Note: The stitch length and the differential ratio are adjusted automatically in accordance with the

displayed numbers.

2-5. Manual Mode

Manual Mode allows you to alter the auto setting. Your own setting can be stored in Memory

Mode. See below.

Manual setting as follows :

1. Enter Manual Mode by pressing the cursor button .

2. The changeable number starts to blink.

3. Move by means of the cursor button to the number to be changed.

4. Selected number can be altered by pressing plus or minus button .

5. Continue pressing these buttons until the desired numbers appear.

6. To save this setting, store it in Memory Mode.

Note: The stitch length and the differential ratio are adjusted automatically in accordance with the

displayed numbers.

The other settings may be adjusted with each dial or knob.

—12—

Example: If you press the stitch selection button 3 times, the following will be displayed:

Page 17

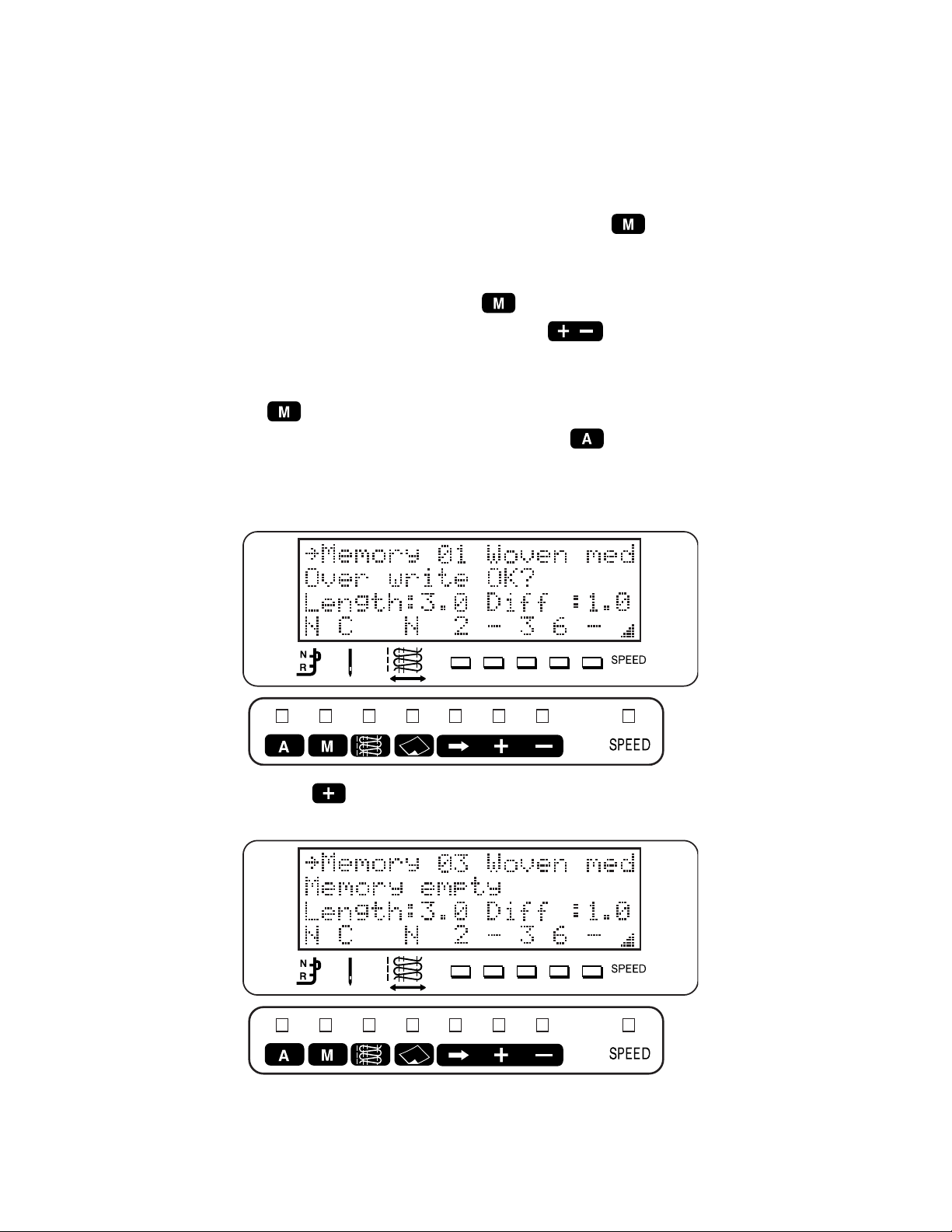

Example: Press plus button twice and memory number 03, which is empty, will be displayed.

2-6. Memory Mode

After making new settings in Manual Mode, you can store your settings or retrieve them in this

mode.

(1) Store new setting in memory

After changing the settings in Manual Mode, press memory button and then memory number

blinks. If the blinking memory number is used already, the message “Over write OK?” appears and

blinks.

If you want to overwrite, press the memory button again.

If you do not want to overwrite, press plus or minus button until you reach an empty

memory.

When the memory is empty, the message “Memory empty” appears and blinks.

Press memory button to store.

If you do not want to overwrite or store, press the auto button to leave Memory Mode.

Example: Memory number 01 is full.

—13—

Note: There are 50 memories available. On the last page of this instruction book, there is space for

your notes about what you have stored.

Page 18

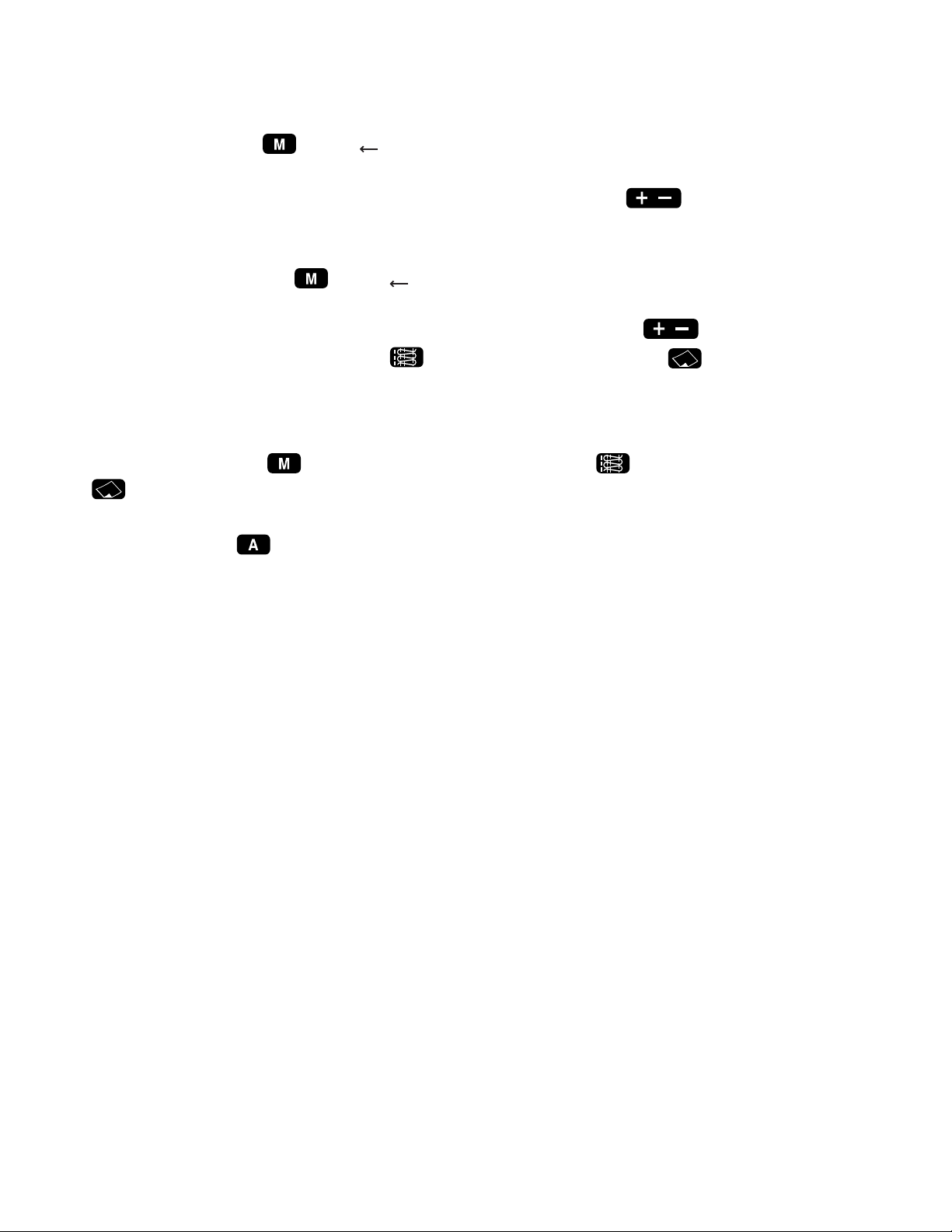

(2) Retrieve from memory

When turning the machine on, the recommended standard settings are displayed.

Press memory button . Now “ Memory” appears with the last setting you made before turn-

ing off the machine.

Select the memory you want to use by pressing plus or minus button .

(3) Delete from memory

Press the memory button . Now “ Memory” appears with the last setting you made before

turning off the machine.

Select the memory you wish to delete by pressing plus or minus button .

Then press the stitch selection button and the fabric selection button simultaneously.

Now message “Memory will clear” appears and starts to blink.

Note: If you want to cancel the deletion, release both buttons.

Press memory button while pressing stitch selection button and fabric selection button

at the same time to execute the deletion.

The message “Memory empty” appears and now the deletion is completed.

Press auto button for standard setting.

—14—

Page 19

—15—

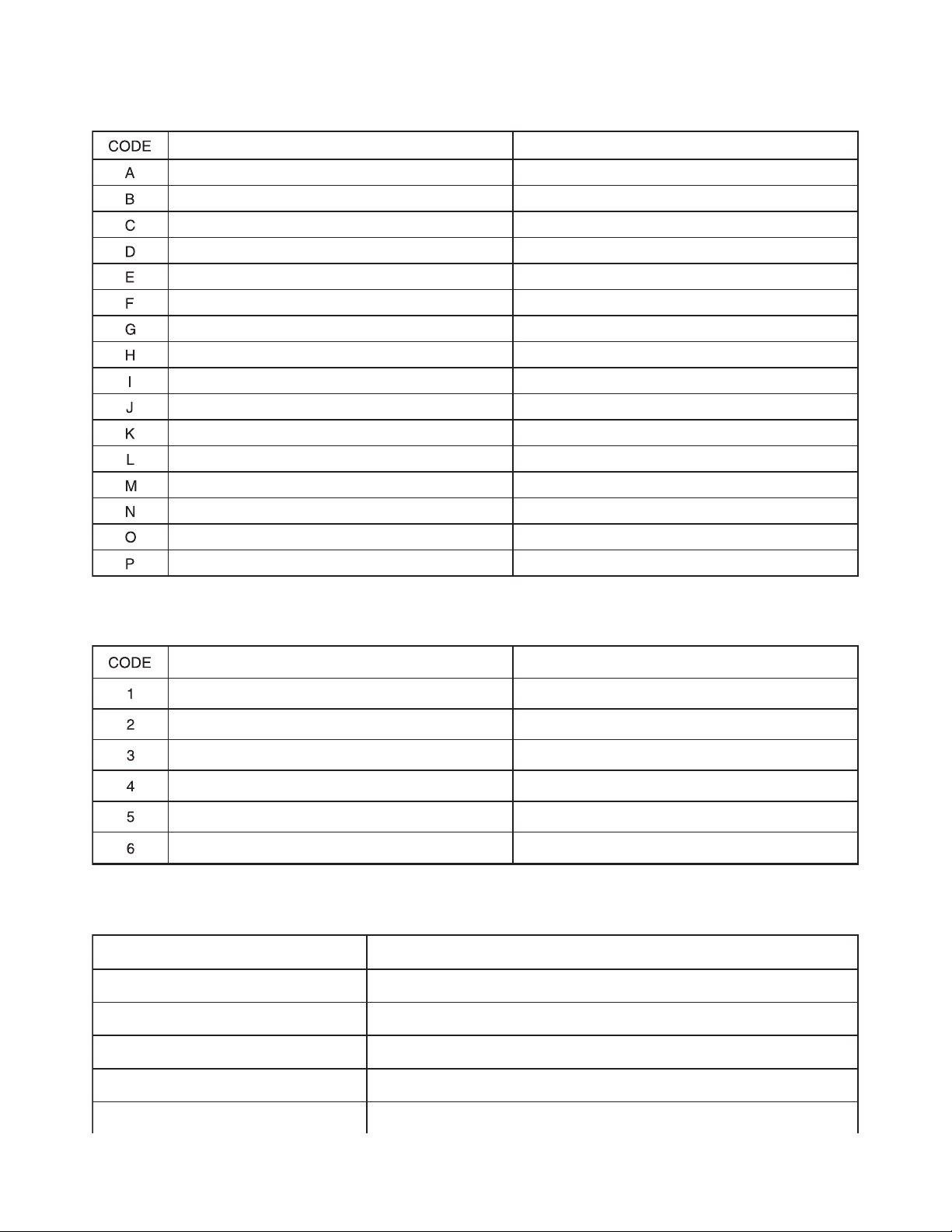

2-7. Stitch table

The following 16 stitches are programmed in the Husqvarna Viking® Huskylock 936

Stitch

4-thread overlock

3-thread wide overlock

3-thread narrow overlock

3-thread fl atlock

3-thread rolled edge

3-thread narrow rolled edge

2-thread wide overlock

2-thread narrow overlock

2-thread fl atlock

2-thread rolled edge

2-thread narrow rolled edge

Chainstitch

Cover stitch wide

Cover stitch narrow

Triple cover stitch

5-thread overlock

Display text

4thread overlock

3thread wide o/l

3thread narrow o/l

3thread fl atlock

3thread rolled edge

3thread narrow edge

2thread wide o/l

2thread narrow o/l

2thread fl atlock

2thread rolled edge

2thread narrow edge

Chainstitch

Cover stitch wide

Cover stitch narrow

Triple cover stitch

5thread overlock

Fabric type

Medium woven

Heavy woven

Light woven

Medium stretch knit

Heavy stretch knit

Light stretch knit

Display text

Woven med

Woven hvy

Woven It

Knit med

Knit hvy

Knit It

Message

Lower presser foot

Close front cover

Overloaded

Use other memory

Call service

Meanings

The presser foot must be down while sewing.

The front cover must be closed while sewing.

Remover fabric, then begin sewing again.

Select another memory.

No access to memories.

2-8. Table of fabric type

Code fabric display abbreviations.

2-9. Error messages

When the following messages are displayed, correct the troubles.

Page 20

1

2

3

4

5

6

7

8

9

DABC

DNDN

—16—

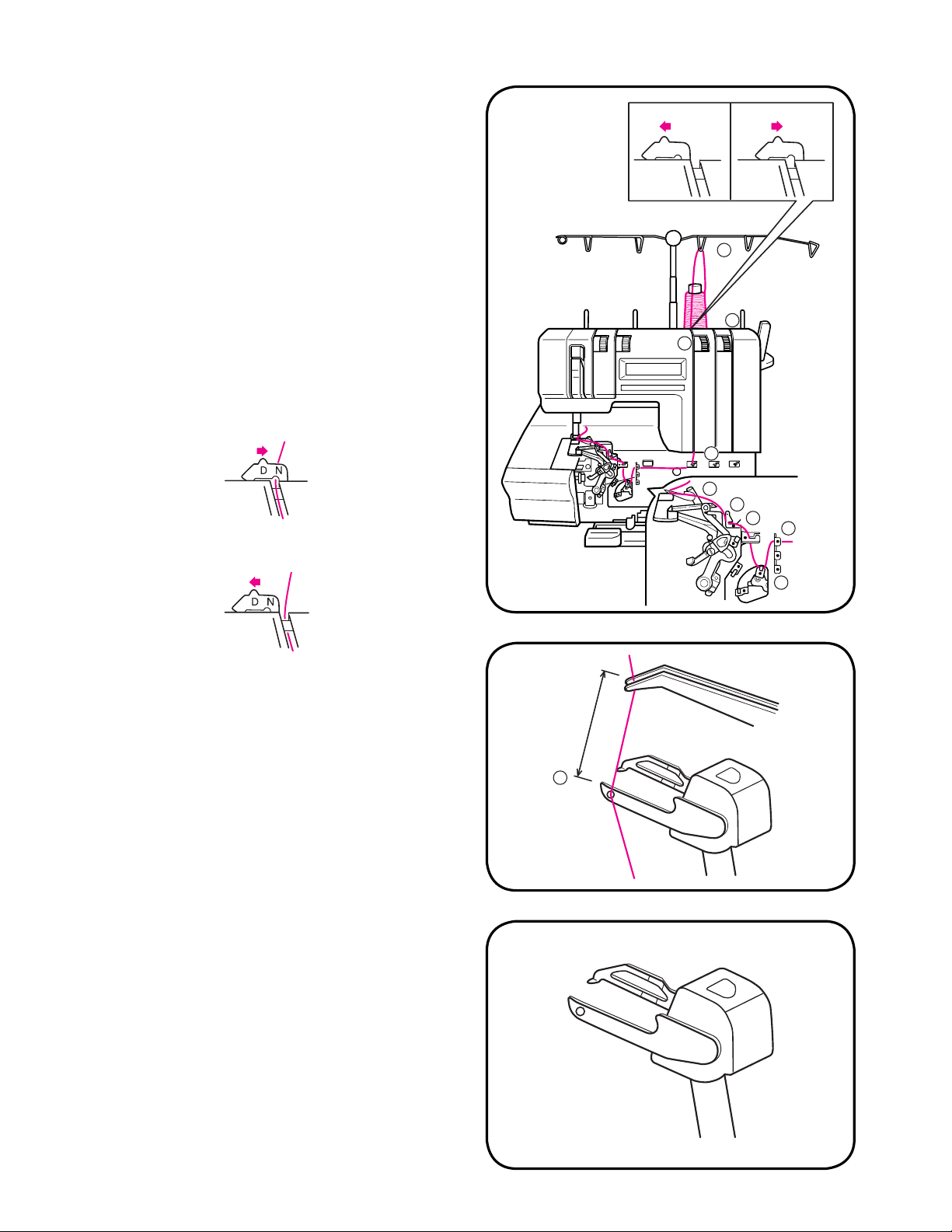

Thread the machine in the following order:

Upper looper ( A )

Lower looper ( B )

Needles ( C,D )

3-1. Upper looper threading ( A )

1. Set the upper looper to the highest position

by turning the handwheel toward you.

2. Raise the presser foot.

3. Open front cover.

4. Pull thread from spool through guide

➀ of the

thread stand and then through guides

➁ to

➈.

When using decorative thread, move the thread

guide for decorative thread (B) to the right(D),

then thread through thread guide.

When using regular thread, move the thread

guide for decorative thread (B) to the left(N).

5. Thread the eye

➈ of the upper looper.

6. Pull a thread tail leaving about 10 cm (3” to

4”) long.

Note:

For all sewing except 2-thread sewing, set the

2-thread converter as illustrated.

3. THREADING (For four thread overlock stitch)

Spun thread

Decorative thread

10 cm

9

Page 21

a

DNDN

DABC

1

2

3

4

5

6

7

8

9

10

—17—

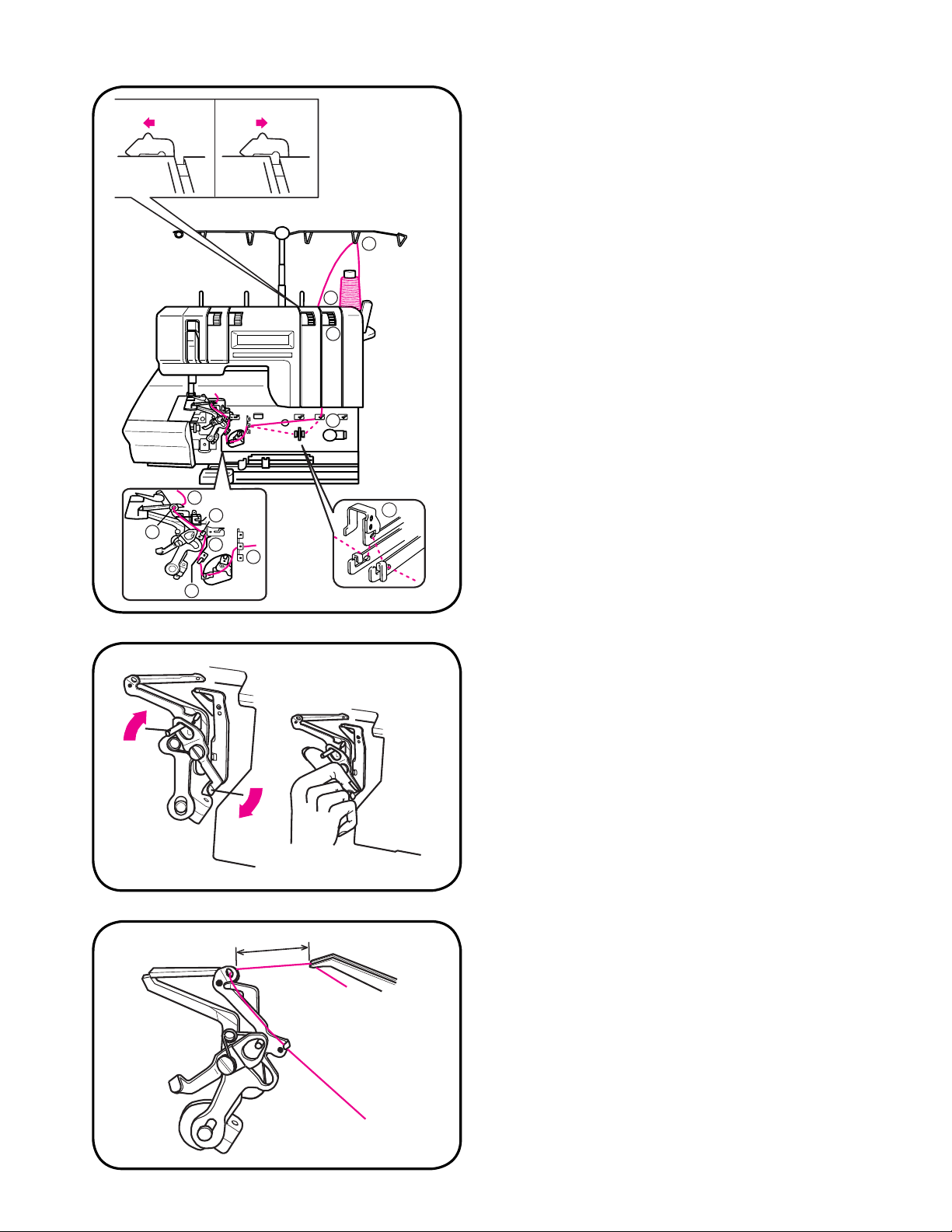

3-2. Lower looper threading ( B )

1. Raise the presser foot.

2. Open front cover.

3. Pull thread from spool through guide

➀ of the

thread stand and then through guide

➁.

Note: Make sure the thread snaps into the slot

of guide

➁, and between the thread ten-

sions discs

➂.

4. Turn the handwheel toward you and position

the lower looper to the far right.

5. Then thread through guides

④ to ➇.

Note: For best result in sewing narrow edge,

thread through guide

a.

6. Push lever (A) in the direction of the arrow

until the thread holes

➈ and ➉ are in lined

up each other. Pull the thread through eye

➈,

➉ of the lower looper.

7. Leave about 10 cm (4”) of the thread.

8. The lower looper threader automatically

returns to its original position by turning the

handwheel once toward you.

Spun thread Decorative thread

(A)

10 cm

Page 22

7. Pull the thread through the needle eye ➆,

with tweezers leaving about 10 cm (4”) of

thread tail.

3-3. Needle threading ( C ) ( D )

1. Raise the presser foot.

2. Raise the needle to its highest position by

turning the handwheel toward you.

3. Pull thread from spool through guide

➀.

Note: Make sure the thread snaps into the slot

of guide

➁ and between the thread ten-

sion discs

➂.

4. Pull the thread through guides

④, ➄, ➅ for

the right needle and through guides

➄, ➅

for the left needle.

Note: Make sure that right needle thread (D)

passes to the right of the guide

➄ and

left needle thread (C) to the left.

5. Slide the thread into the ditch of needle

threader.

6. Hold the needle threader to the needle with

the mark on top and bottom side. Slide

it along the needle to the needle eye. The

thread will loop through the eye of the needle.

—18—

DABC

1

2

3

4

5

6

7

10cm

Page 23

—19—

3-4. Preparations and control

Check that thread has not slipped off the guides

nor has broken. Make sure the upper cutter

moves correctly against the lower cutter by

slowly turning the handwheel toward you.

Check that there are no pieces of fabric or

thread between the cutters. Turn the handwheel

toward you and make sure the threads form the

stitch on the stitch fi nger of the needle plate. If

not, check threading.

When the machine has been threaded, close

the front cover and lower the presser foot.

3-5. Presser foot pressure

You can change the presser foot pressure with

the numbered dial on the left side of the machine.

Position “N” is for normal fabrics. A lower number is for thin fabrics. A higher number is for

thick fabrics.

3-6. Thread tension table

Left

needle

Right

needle

Upper

looper

Lower

looper

Stitch

length

Stitch/Cutting

width

Overlock

Narrow edging

Rolled edge

The thread tension is only a recommendation according to the chart above.

See recommendation in the Sewing Advisor display.

Since the numbers in the chart are average it may be necessary to adjust the tension somewhat

according to different types of fabric and threads.

Note: Fabric and thread structure may vary between different weights and types. Therefore try the

best setting for your machine.

The differential feed ratio is normally “1.0”.

N

1

5

Page 24

2

3 4

1

—20—

Lower looper

thread

Upper looper

thread

Left needle

thread

Right needle

thread

Wrong side

Right side

Lower looper

thread

Wrong side

Right side

Upper looper

thread

Left needle

thread

Right needle

thread

3-7. Thread tension

Start from normal position. Change and thereaf-

ter check one dial at a time until you obtain the

desired result. Turn the dial to a higher number

to increase tension. Turn the dial to a lower

number to decrease tension.

➀ Left needle thread

➁ Right needle thread

➂ Upper looper thread

④ Lower looper thread

4-thread stitch

Correct tension

Lower and upper looper threads should be well

balanced with the same thread tension (both

looper threads should meet at the edge of the

fabric). The needle thread should not slacken or

be pulled.

Unbalanced upper looper thread is wrapped

around and over the back side

Increase the thread tension of the upper looper

(dial

➂) or reduce the thread tension of the

lower looper thread (dial

④).

1

2

3 4

Page 25

2

3 4

1

2

3 4

1

2

3 4

1

—21—

Lower looper

thread

Wrong side

Right side

Upper looper

thread

Left needle

thread

Right needle

thread

Lower looper

thread

Wrong side

Right side

Upper looper

thread

Left needle

thread

Right needle

thread

Lower looper

thread

Wrong side

Right side

Upper looper

thread

Left needle

thread

Right needle

thread

Unbalanced lower thread is wrapped around

and over the top side

Increase the thread tension of the lower looper

(dial

④) or reduce the thread tension of the up-

per looper thread (dial

➂).

Left needle thread too loose

Increase the thread tension of the left needle

dial

➀ or reduce the thread tension of both

looper threads- dial

➂ and ④.

Right needle thread too loose

Increase the thread tension of the right needle

thread, dial ➁.

Page 26

—22—

3-8. Adjusting the stitch width / cutting

width

The distance between the needle and the outer

edge of the fabric is called stitch width / cutting

width.

• The cutting width can be set between 5-7mm

depending on the type of fabric.

• Normal stitch width / cutting width is 5.5mm,

which corresponds to “N” on the dial.

• Turn dial

a to set the cutting width.

Note: There is an index mark on the machine.

cutting width

stitch width

Stitch fi nger

Stitch fi nger

lever

Needle plate

When you experience loops off the edge of the

fabric, slide the stitch fi nger toward you for fi ne

tune width adjustment.

To adjust, move the stitch fi nger lever toward

you from “N” position to the mark —. There are

two fi ne tune settings.

After adjusting, test your stitch.

a

Page 27

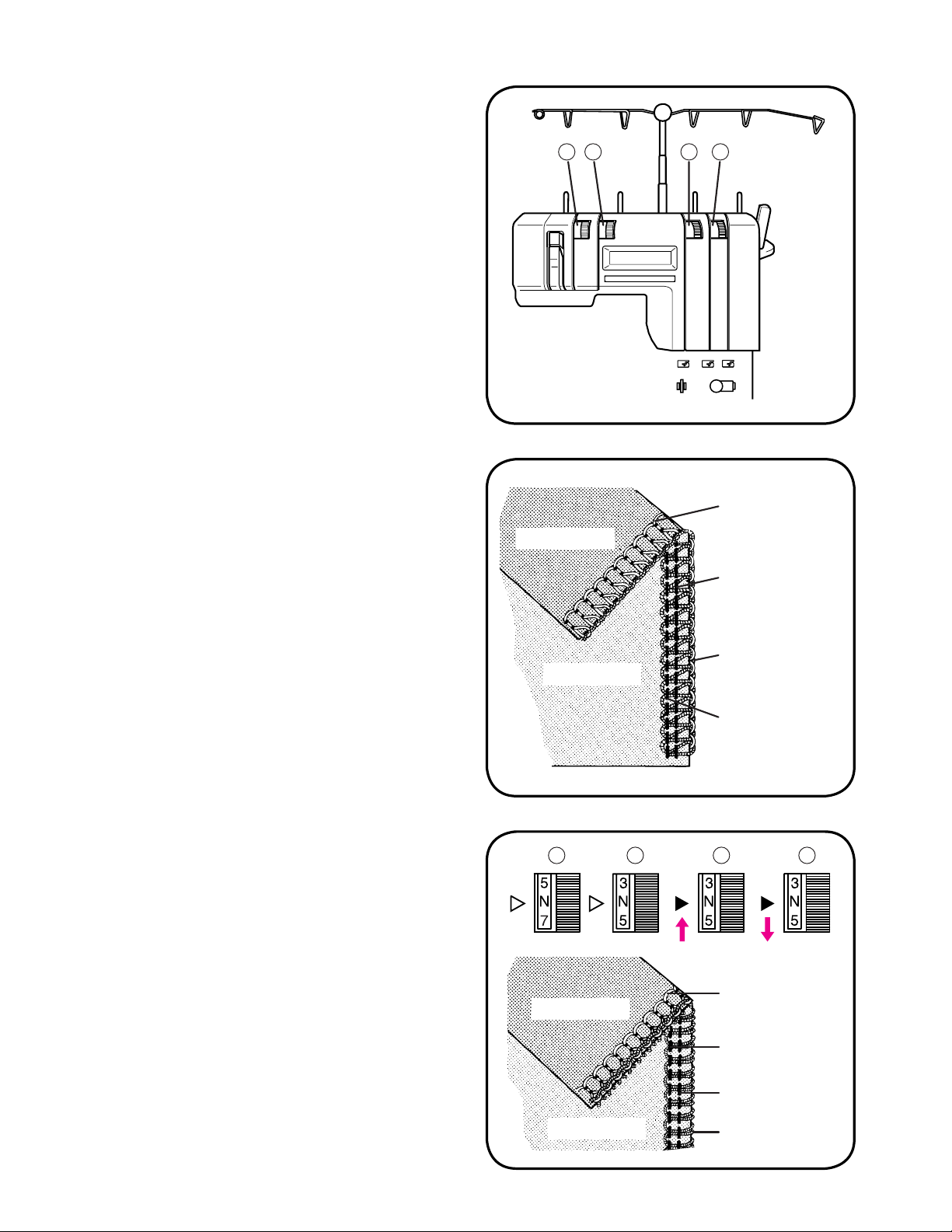

Model 936 features automatic Stitch length and Differential feed. You can override the automatic

settings as follows:

3-9. Stitch length

Normal stitch length is 2.5 mm. You may change the stitch length between 0.8 (for rolled edge) and

5 mm, using the Sewing Advisor’s manual function.

Change the stitch length as follows:

1. Press cursor button until the setting number for the stitch length blinks.

2. Press plus or minus button to select the desired length number.

3. Start to sew. The stitch length is adjusted automatically to the number.

4. If you want to store this setting, you can use the memory function.

See “2-5. Manual Mode (page 12)”.

3-10. Differential feed

Differential feed helps you to sew perfect seams on all kinds of fabric from light woven to heavy

knits.

This Huskylock has two feed teeth. The front teeth (for differential feed) can be adjusted to feed

more or less in proportion to the rear.

The ratio can be set between 0.5 and 2.5.

For light weight fabrics, set closer to 0.5. The front teeth move slower to hold fabric taut. For heavy

weight one, set closer to 2.5. The front feed teeth move faster to prevent distortion and stretching of

fabric.

The differential feed also helps to gather woven fabrics.

For maximum gathers, set to 2.5 and increase stitch length.

Change the differential feed as follows:

1. Press cursor button until the setting number for the differential feed blinks.

2. Press plus or minus button until the number becomes to what you want to change.

3. Start to sew. The differential feed is adjusted automatically to the number value.

4. If you want to store this setting, you can use the memory function.

See “2-5. Manual Mode (page 12)”.

Note: First sew a few test stitches on a piece of fabric you are going to use, referring the chart

below.

Note: The differential feed ratio and the stitch length are related to each other. Their minimum and

maximum values may be limited by their combinations and selected stitch patterns.

—23—

Page 28

—24—

First sew a few test stitches on a piece of fabric you are going to use, referring to the chart below.

Stitch length Diff

Speed

0.8-4

4.5-5

Stretch

material

Min-5.0

Low-High

Low-High

Differential feed “1.0”

Stitch length ✕ Diff =

5.1-Max

Low-Med

Low-Med

Min. 0.5-Max. 2.5

Min. 0.6-Max. 2.0

Fabric

ResultSetting

Non-stretch

material

Very thin

material

Silk-silky

knitwear

Normal

thick

woven

fabrics

Knit

Jersey

1.0-2.5

1.0

0.5-0.9

Page 29

—25—

Presser

foot lift

4. SEWING

4-1. Four thread overlock stitch with 2 needles

Before sewing

Once you have fi nished threading, place the

four threads under and behind the presser foot.

Turn the handwheel toward you 2-3 turns so

that the stitches are formed on the stitch fi nger.

Warning:

Keep fi ngers away from all moving parts. Special care is required around the sewing area

and lower looper. Do not touch light bulb while

operating machine as it is hot and may burn

your fi ngers.

Insert the fabric

When you are ready to sew, place the fabric

under the front part of the presser foot, the

presser foot does not have to be raised. When

sewing with very heavy fabrics the extra presser

foot lift may be necessary. Place the fabric un-

derneath the foot with the raw edge of the fabric

in front of the cutter. Lower the presser foot.

Start sewing

Slowly sew the fi rst stitches by turning the

handwheel toward you. The fabric feeds auto-

matically. Guide it toward the presser foot, trim-

ming as necessary.

Page 30

—26—

Chain off

When you reach the end of fabric, chain off for

several inches.

Note: Do not pull the threads out roughly, be-

cause the needle might bend or break.

• Cut off the thread chain using the thread cut-

ter on the left of the machine.

Note: Lay thread chain into thread cutter from

back to front, then pull toward you.

Page 31

—27—

Cording thread / Decorative thread

Cording thread / decorative thread can be used

to strengthen and stabilize stitches when seam-

ing stretch fabrics and for decorative effects.

Listed below are two ways of using corded

thread:

• Thread cord through the loop at the extreme

left of the telescopic stand and through the

guide on the left of the machine.

1. Place the narrow cord (about 3 mm) into the

front hole of the presser foot and back under

the foot, then sew so the right needle stitches

through the cord.

2. Thread a narrow cord through the small hole

on the right side of the presser foot near the

needles according to the illustration. Make

sure that the thread runs along the edge of

the fabric, then sew over the thread.

2.1.

Page 32

—28—

Serging curves

For inside curves, guide the fabric lightly and

place the fabric under the right front of the

presser foot. Applying pressure to the fabric

with your left hand at the same time, apply a

little pressure in the opposite direction with your

right hand to hold it against the cutter as shown.

For outside curves, apply pressure in the op-

posite direction of the above.

Page 33

—29—

4-2. Three thread overlock

To sew three thread overlock, simply remove

one needle.

1. Remove the right needle for wide three

thread

Use dial

➀ for the tension of the left needle

thread, stitch width / cutting width is normally

5.5 mm. The differential feed ratio is normally

“1.0”.

2. Remove the left needle for narrow three

thread

The right needle sews a narrow width. Use dial

➁ for the tension of the right needle thread,

stitch width / cutting width is normally 3.5 mm.

The differential feed ratio is normally “1.0”.

Right needle

Left needle

2

1

2

1

Page 34

2

3 4

1

a

—30—

Wrong side

Right side

Wrong side

Right side

3-thread stitch

Correct tension

The needle thread lies fl at and straight, to the

left, and locks with the upper looper thread on

the top and the lower looper thread on the bot-

tom side of the fabric.

Unbalanced lower looper thread is wrapped

around and over the top side

Increase the thread tension of the lower looper

(dial

④) or reduce the thread tension of the up-

per looper thread (dial

➂).

Page 35

—31—

2-thread converter

4-3. Two thread overlock

1. Open the front cover.

2. Use one needle thread (left or right needle)

and lower looper thread.

3. Turn the handwheel toward you to move the

upper looper to the right side of the needle.

4. Hold the 2-thread converter by hand and

gently push it down.

Warning:

Pushing converter down too hard may bend

converter.

5. Insert the tip

➀ of the 2-thread converter into

the eye

➁ of the upper looper.

6. Close the front cover.

For 3-thread/4-thread overlock sewing, set 2-

thread overlock converter in the up position as

illustrated, by removing the tip

➀ out of the eye

➁ of the upper looper.

2

1

Page 36

1

2

3

4

5

6

7

3

N

5

1

2

3

0

1

2

1

2

3

4

5

6

7

3

N

5

1

2

3

0

1

2

—32—

Set tension according to the table above. Since the fi gures in the table are average, it may be

necessary to adjust the tension according to the type of fabric, fabric thickness and thread.

Note: Fabric and thread may vary. Stitch a sample on scraps before sewing your garment. The

differential feed ratio is normally set to “1.0” (see page 24).

4-4. Stitch selection table two-thread sewing

Thread tension adjustment / Correct thread

tension

Unbalanced lower looper thread-stitches are

wrapped around and over the wrong side

Increase the thread tension of the lower looper

thread (dial

④) or reduce the tension of the

right needle thread (dial

➁).

Wrong side

Right side

Wrong side

Right side

Lower looper

thread

Needle thread

Lower looper

thread

Needle thread

Unbalanced needle thread tension-stitches

too loose

Increase the thread tension of the right needle

thread (dial

➁) or reduce the tension of the

looper thread (dial

④).

Stitch

Finger

Thread

Tension

Stitches

Stitch

Length

Cutting

Width

Dial

Lower

Looper

Tension

Upper

Looper

Tension

Right

Needle

Tension

Left

Needle

Tension

Material

Not advised

Not advised

Light

Medium

Heavy

Light

Medium

Heavy

Light

Medium

Heavy

Light

Medium

Heavy

2-thread

Rolled

Edge

2-thread

Narrow

Edge

2-thread

Overlock

(Narrow)

2-thread

Overlock

(Wide)

Page 37

—33—

4-5. Rolled edge

Three thread rolled edge

The two edges described above are suitable for light weight fabrics.

3-thread narrow edge

The fabric is rolled by adjusting.

The thread tension and is overlocked with

upper looper thread.

3-thread narrow edge

The fabric is overlocked with upper and

lower looper thread.

3. Sew along edge of fabric, cutting desired

amount for a beautiful fi nish on table linens

or hems.

Note: For best result in sewing narrow edge,

thread through guide

a. (See page 17)

1. Remove the left needle (only sew with right

needle).

2. Pull the stitch fi nger lever toward you to posi-

tion “R” on the needle plate.

2mm

2

3

4

2mm

2

3

4

Page 38

—34—

Table for three thread rolled edge and narrow edge

Rolled edge

Narrow edge

Thread tension

Adjust thread tension according to type of fabric and thread.

Two thread rolled edge

1. Convert to 2-thread overlock, see page 31.

2. Use right needle only and pull stitch fi nger lever toward you to align with “R” on the needle

plate.

Thread tension

Table for two thread rolled edge and narrow edge

Right needle thread (2)

Upper looper thread (3)

Lower looper thread (4)

Cutting width

Stitch length

Differential feed ratio

Right needle thread (2)

Upper looper thread (3)

Lower looper thread (4)

Cutting width

Stitch length

Differential feed ratio

Rolled edge

Narrow edge

Page 39

—35—

A.

B.

C.

Right side of fabric

Adjusting screw

Material guide

4-6. Flatlock

There are two ways to sew a fl atlock stitch, with

wrong sides folded together to create a decora-

tive look and with right sides folded together to

create ladder stitch as used for lingerie.

1. Fold the material with wrong sides together.

Then raise the presser foot, set the material

so that it is under the needle, and then lower

the presser foot. Set the stitch width control

dial to (5-7). Sew, allowing the thread to loop

off the edge (C).

4. Pull the material open (fl at) as shown. This

method is not recommended for thin materi-

als. To adjust the position of the material

guide, the same piece of material can be

used to make a test sewing.

Note: For use of decorative threads in looper,

decrease looper tension experiment,

and program your settings in one of the

memories for future use.

Flatlock with multipurpose foot:

2. Adjust with the adjusting screw so that the

needle moves down to a position 2.5~3.0 mm

(0.1~0.12 in.) inside the folded edge of the

material so that some of the stitching loops

over the edge.

3. While guiding the material with your hand,

sew at a constant speed.

Note: This foot will make it easier to sew along

the folded edge without cutting the fabric.

2.5~3mm

Page 40

—36—

The side of

the needles

plate.

Tuck edge

4-7. Pin tuck

Pin tucks are stitched along a folded edge. To

avoid cutting the fabric, use the multipurpose

foot. Pin tucks are suitable for children’s clothes

and lady’s blouses.

1. Use the left needle for wide tucks, the right

needle for narrow.

2. Snap on multipurpose foot and adjust guide.

(page 35)

3. Raise the presser foot.

4. The tension is set for normal overlock “N”.

Mark and press the pin tucks before sewing.

The differential feed ratio is normally “1.0”.

5. Place the fabric under the presser foot with

the edge in line with the side of the needle

plate, or guide on the multipurpose foot,

lower the presser foot and start serging.

Serge off the fabric at the end.

6. The tuck is pressed to one side when serging

is fi nished.

Page 41

4-8. Five thread over lock stitch and Double

chain stitch

Double chain stitch looper threading (E)

1. Raise the presser foot.

2. Open front cover.

3. Pull thread from spool through guide

➀ of the

thread stand and then through guide

➁.

Note: Make sure the thread snaps into the slot

of guide

➁, and then thread through ➂

to

➅.

4. Turn the handwheel toward you and position

the double chain stitch looper to the far right.

5. When you push the looper threading knob in

the direction of the knob arrow as shown, the

double chain stitch looper moves to the right,

and you can pass thread into the thread hole

at the end of the looper more easily.

6. Then thread through guides

➆

to ➉.

Note: Make sure the thread snaps into the slot

of guide

➇.

7. Pull out the thread leaving about 10 cm.

8. When you start stitching after threading, the

knob returns to the original position automatically.

—37—

Thread guide E

Note: When using decorative thread by Five

thread overlock stitch and Double chain

stitch as illustrated.

Insert Thread guide E from the back to-

ward the front as illustrated, then thread

a decorative thread into Thread guide E.

When carrying the sewing machine, take off

Thread guide E from the machine.

1

2

56

7

8

9

10

4

3

CD A B

E

7

8

9

10

Page 42

—38—

5-thread overlock Double chain stitch

CD AB

1

2

5

6

7

8

4

3

E

DAB

CD AB

E

DAB

Page 43

#

80

#

90

#

90

#

80

#

90

1

4

5

N

5

a

—39—

Double chain stitch

5-thread overlock stitch

Wrong side

Right side

Wrong side

Right side

Wrong side

Right side

Chainstitch

Correct tension

The chainstitch needle thread lies on the top

side of the fabric, and is just visible in the

chainstitch looper thread on the underside of

the fabric.

The needle thread is too loose

Increase the thread tension of the needle

thread dial

➀.

(The needle thread

a is too loose.)

Note: Thread tension adjustment for 5-thread

overlock, see above and “3-7” thread ten-

sion (page 20).

A fi ve thread overlock stitch is the combination

of chainstitch and three thread overlock stitch.

For concerning thread tension adjustment,

please refer to above mentioned explanation

for the chainstitch and page 30 for three thread

stitch.

Note: Insert SCHMETZ needle(s) into the

needle clamp in the position(s) advised

by the Sewing Advisor.

Five thread overlock (oneword)

Needle position A · · · #90

Needle position C · · · #80

Double chain stitch

Needle position A · · · #90

Five thread overlock Double chain stitch

Page 44

—40—

3

2

1

4-9. Cover stitch

Set up for Cover stitch and Chainstitch

When sewing cover stitches or double chain

stitches, change the following parts:

1. Cutter cover ( C )

2. Needle plate ( C )

3. Needle (SCHMETZ #90)

4. Presser foot ( C )

Change the parts in the following order.

Cut and remove each thread before beginning

to change the parts:

1. To position the upper looper:

1) Tap the foot controller once to stop the

needle in the lower stop position.

2) Open the front cover to reveal select lever.

3) To ensure safety, turn off the power switch.

4) While pushing down the select lever, move

it from “S” to “C”.

5) Turn the handwheel toward you by hand

to stop the needle bar in the upper stop

position.

2. To remove the standard cutter cover, slide

cutter cover (S) to the left and remove.

3. Remove the fl atbed cover and free arm cover

and lower the cutter. (Refer to Page 8)

Front cover

OFF

Page 45

—41—

4

5,6

7

8

10

11

9

Screw

Cutting width

adjust dial

4. Remove the rear needle(s) from the needle

clamp.

7. Turn the cutting width dial to 7.

Note: If it is not set to width “7”, the cutter will

not allow the Cover Stitch needle plate

(C) to be put on.

8. Put on the needle plate ( C ).

(Use the screw removed in above step 6 for

the needle plate ( C ).)

9. Insert SCHMETZ (#90) needle(s) into the

needle clamp in the position(s) advised by

the Sewing Advisor.

10. Snap on the presser foot ( C ).

11. Slide on the cutter cover ( C ).

Note: To change from Cover / Chain stitch to

standard overlock, reverse the steps

above.

12. Close the front cover.

13. Slide on the free arm cover and fl atbed

cover.

5. Set the stitch fi nger lever to “R”. (See Page 8)

and remove the presser foot ( S ).

6. Remove the standard needle plate ( S ). (Re-

move one screw.)

Page 46

—42—

5

4

3

1

2

To change from Cover or Double chain stitch

sewing to standard sewing, reverse the order

of set up for Cover stitches. However, always

remove the needle plate ( C ) before moving the

lever from “C” to “S”.

The order is given below:

To ensure safety, turn off the power switch.

Also, cut and remove the thread before chang-

ing parts below.

1. Open the front cover.

2. Remove the cutter cover ( C ). (as explained

on page 40)

3. Turn the handwheel toward you to set the

needle to the highest position.

4. Raise the presser foot, and snap off presser

foot ( C ).

5. Remove the front needle(s) from the needle

clamp.

6. Remove the fl atbed and free arm covers.

OFF

Page 47

—43—

7

8

11

13

14

7. Remove the needle plate ( C ).

8. Put on the standard needle plate ( S ).

9. Raise the cutter.

10. Replace the needles according to desired

stitch.

11. Snap on the standard presser foot ( S ).

12. Turn the handwheel by hand to set the

needle to the lowest position.

13. Move the Chain / Cover select lever from “C”

to “S”.

(Turn the handwheel by hand to make sure that

the upper looper moves.)

14. Slide on the standard cover ( S ) to the front

cover.

15. Close the front cover.

16. Put on the fl atbed and free arm cover.

Page 48

Cover stitch looper threading (B)

1. Raise the presser foot.

2. Open front cover.

3. Pull thread from spool through guide

➀ of the

thread stand and then through guide

➁.

Note: Make sure the thread snaps into the slot

of guide

➁, and then thread through ➂

to

➅.

4. Turn the handwheel toward you and position

the double chain stitch looper to the far right.

5. When you push the looper threading knob in

the direction of the knob arrow as shown, the

double chain stitch looper moves to the right,

and you can pass thread into the thread hole

at the end of the looper more easily.

6. Then thread through guides

➆

to ➈.

7. Pull out the thread leaving about 10 cm.

8. When you start stitching after threading, the

knob returns to the original position automati-

cally.

—44—

CD A B

E

1

2

5

6

7

8

9

4

3

7

8

9

Page 49

—45—

Cover stitch wide Cover stitch narrow

CD AB

CD AB

E

DAB

E

DAB

Page 50

—46—

Triple cover stitch

CD AB

E

DAB

Page 51

—47—

Triple coverstitch

Correct tension

The picture shows the correct tension of 3

needle threads and chainstitch looper thread.

When needle thread is too loose

Increase thread tension dial

➀ (➁ , ➂), or

decrease the chainstitch looper thread tension

dial

④.

When chainstitch looper thread is too loose

Increase the chainstitch looper thread tension

dial

④.

1

2

3

4

5

N

7

5

6

7

5

6

7

2

3

N

1

2

3

4

5

N

7

5

6

7

5

6

7

2

3

N

Page 52

1

2

3

4

5

N

7

5

6

7

5

6

7

2

3

N

1

2

3

4

5

N

7

5

6

7

5

6

7

2

3

N

—48—

Wrong side

Right side

Wrong side

Right side

Wrong side

Right side

Cover stitch wide and Cover stitch narrow.

The picture shows the correct tension of both

Needle threads and the chainstitch looper

thread.

The right needle thread is too loose

Increase the thread tension of the right needle

thread dial

➂ or reduce the tension of looper

threads- dial

④.

Both needle threads are too tight

Reduce the thread tension of both needle

threads- dial ➁ and ➂.

Page 53

—49—

3

2,4

1,5

5. MAINTENANCE

5-1. Changing the light bulb

Warning:

Let the light bulb cool down before replacing it

to avoid burning your fi ngers.

Note: The maximum power of the light bulb is

12V, 5W.

Unplug the machine.

1. Lay machine on its back.

2. Place the rubber sleeve with its deep hole

(found in the accessory box) around the bulb.

3. Do not turn the bulb, just pull it down to re-

move the bulb.

4. When inserting, place the rubber sleeve with

its shallow hole around the new bulb, insert

the bulb by pushing it up.

5. Check with fi nger tips that the new bulb is

properly fi tted.

Page 54

1~2mm

—50—

Lower cutter

Lowest position

Upper cutter

Set screw

5-2. Cleaning after sewing

Unplug the machine.

1. Open the front cover (page 3) and free arm

cover (page 8).

2. Remove all the lint with the brush from the

accessory box.

5-3. Storage

1. When the machine is not in use, disconnect it

from the power supply.

2. Cover the machine with the vinyl cover when

you have fi nished sewing.

3. Store the machine so that it is not directly

exposed to sunlight or humidity.

5-4. Replacing the lower cutter

Cutters are available as an accessory at your

authorized Husqvarna dealer.

Unplug the machine

1. Open the front cover (See page 8).

2. Disengage upper cutter and turn to lowest

position.

3. Loosen the screw of the lower cutter and

remove the cutter.

4. Mount the new cutter.

5. Re-position the upper cutter.

6. Turn the handwheel so that the needles are

in their lowest position.

7. Make sure that the front edge of the cutter is

1~2 mm lower than the cutting edge of the

lower cutter.

8. Tighten the new cutter with the screw.

9. Always clean with the brush.

5-5. Lubrication

To make the machine run smoothly and quietly

some of the moving parts must be lubricated

once or twice a month when using the machine normally and once a week when using it

frequently. Always remember to unplug the machine for service. Remove all excess oil before

you start sewing to avoid staining your project.

Page 55

—51—

6. STITCH TABLE

Combination Thread tension

Sewing Program Material

Stitch

Length

Stitch

Finger

Cutting

Width

Needle

Pos.

Needle

Plate

Presser

Foot

Diff

Feed

Upper

Knife

Pos.

Cutting

Knife

Cover

Clutch

Lever

Pos.

Woven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

2.5

3.0

2.0

2.5

3.0

2.0

Up

Up

UpUpUp

Up

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

N

N

N

N

N

N

N

N

N

N

N

N

-

-

-

-

-

-

N

N

N

N

3

3

N

N

N

3

3

3

1.0

0.8

NN

CD

1.5

2.0

1.0

Woven Med 2.5

3.0

2.0

2.5

3.0

2.0

Up

Up

Up

Up

Up

Up

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

N

N

N

N

N

N

N

N

N

3

3

3

3

3

3

-

-

-

-

-

-

-

-

-

-

-

-

3

4

3

1.0

0.8

NNC

C

1.5

2.0

1.0

Woven Med 2.5

3.0

2.0

2.5

3.0

3.0

2.0

Up

Up

UpUpUp

Up

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

N

N

N

N

N

N

N

N

N

N

3

3

N

5

3

3

3

3

3

3

3

-

-

-

-

-

-

-

-

-

-

-

-

1.0

0.8

NN

D

1.5

2.0

1.0

Woven Med Up

Up

Up

Up

Up

Up

S

S

S

S

S

S

M

M

M

M

M

M

S

S

S

S

S

S

S

S

S

S

S

S

6

7

6

7

7

N

N

73

-

-

-

-

-

-

-

-

-

-

-

-

1

1

1

1

1

1

1.0

0.8

NN

1.5

2.0

1.0

A:4-thread overlock

W

oven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

B:3-thread wide overlock

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

C:3-thread narrow overlock

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

D:3-thread flatlock

YRGBP

Sewing Advisor display data reference sheet (For 5-thread mode)

Page 56

—52—

Combination Thread tension

Sewing Program Material

Stitch

Length

Stitch

Finger

Cutting

Width

Needle

Pos.

Needle

Plate

Presser

Foot

Diff

Feed

Upper

Knife

Pos.

Cutting

Knife

Cover

Clutch

Lever

Pos.

Woven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

E:3-thread rolled edge

Woven Med

Woven Hvy

Woven Lt

1.0

0.8

0.9

1.0

0.8

6.0

6.0

6.0

6.0

6.0

R

R

R

R

R

Up

Up

Up

Up

Up

Up

Up

Up

Up

Up

Up

Up

Up

Up

Up

Up

Up

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

1

1

1

1

1

1

5

5

6

6

6

6

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

S

S

S

S

S

S

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

2

2

2

2

2

2

6

7

6

6

6

6

D

D

D

D

D

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

-

-

-

-

-

-

-

-

6

6

6

-

-

N

3

N

N

N

N

N

3

N

3

5

6

1.0

1.0

1.0

1.0

3.0

3.0

N

N

C

D

N

N

1.0

Knit Med

Knit Hvy

Not advised

Not advised

Not advised

Not advised

Knit Lt

F:3-thread narrow edge

W

oven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

G:2-thread wide overlock

Woven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

1.0

0.8

1.5

2.0

1.0

1.0

0.8

1.5

2.0

1.0

H:2-thread narrow overlock

YR

GBP

Page 57

—53—

Combination Thread tension

Sewing Program Material

Stitch

Length

Stitch

Finger

Cutting

Width

Needle

Pos.

Needle

Plate

Presser

Foot

Diff

Feed

Upper

Knife

Pos.

Cutting

Knife

Cover

Clutch

Lever

Pos.

Woven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

I:2-thread flatlock

Woven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

J:2-thread rolled edge

Woven Med

0.9

1.0

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

K:2-thread narrow edge

Woven Med

Woven Hvy

Woven Lt

Knit Med

1.0

0.8

1.5

2.0

1.0

1.0

0.8

0.8

0.9

1.0

1.0

Up

Up

UpUpUp

Up

UpUpUp

Up

Up

Up

1.0

1.0

1.0

3.0

3.0

1.0

1.0

1.0

3.0

R

R

R

N

R

R

R

R

5.0

N

N

N

7

5.0

5.0

N

R

D

D

D

C

A

D

D

D

A7

Do

wn

Down

S

S

SSS

S

S

S

S

S

S

S

5

6

555

5

5

5

5

5

6

6

C

C

-

-

111

1

1

1

-

--

-

-

-

-

-

-

-

5

5

4

N

N

2

N

3

---

-

-

-

---

-

-

-

-

-

-

-

-

-

---

-

-

-

N

N

2

2

-

-

-

-

-

-

-

-

-

S

S

SSS

S

S

S

S

S

S

S

C

C

S

S

SSS

S

S

S

S

S

S

S

C

C

S

S

MMM

M

M

M

S

S

S

S

C

C

Knit Hvy

Knit Lt

Not advised

Not advised

Not advised

Not advised

Not advised

Not advised

Not advised

L:Chainstitch

YR

GBP

Page 58

—54—

Combination Thread tension

Sewing Program Material

Stitch

Length

Stitch

Finger

Cutting

Width

Needle

Pos.

Needle

Plate

Presser

Foot

Diff

Feed

Upper

Knife

Pos.

Cutting

Knife

Cover

Clutch

Lever

Pos.

Woven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

M:Cover stitch wide

Woven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

N:Cover stitch narrow

Woven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

Not advised

Not advised

Not advised

Not advised

O:Triple cover stitch

Woven Med

Woven Hvy

Woven Lt

Knit Med

Knit Hvy

Knit Lt

-

-

-

-

-

-

-

-

-

-

-

-

-

-

N

N

N

3

3

3

3

N

3

3

3

3

3

3

3

3

3

3

3

3

N

N

N

N

N

N

7

7

6

6

6

6

6

5

5

5

6

6

5

5

3

3

3

3

3

2

6

6

6

6

6

6

6

5

5

5

6

6

5

5

5

5

N

N

N

N

-

-

-

-

-

-

-

-

-

-

N

N

5

5

4

5

4

4

4

4

1.0

1.0

1.0

0.8

1.0

1.0

0.9

1.0

1.0

1.0

0.8

1.5

2.0

1.0

3.5

4.0

4.5

3.5

4.0

4.0

4.5

4.0

3.5

4.0

4.5

2.5

R

R

R

R

R

R

R

R

N

C

C

C

C

C

C

C

C

S

C

C

C

C

C

C

C

C

S

C

C

C

C

C

C

C

C

S

C

C

C

C

C

C

C

C

S

A

E

A

E

EB

EB

EB

EB

AB

E

AB

E

CA

7

7

7

7

7

7

7

7

N

Down

Down

Down

Down

Down

Down

Down

Down

Up

P:5-thread overlock

YRGBP

Page 59

—55—

7. TABLE OF SEWING MATERIALS, NEEDLES AND THREADS

Use ball point needles for stretch fabrics.

Thin materials

(crepe, georgette)

Thick materials

(thick denim)

Medium materials

(chino, gabardine, etc.)

Twisted thread

#50/2~#60/2

Twisted thread

#60/2

Medium

Stitch length

Tight

Loose

Overedging width

(Between left needle

and edge)

Thread tension

(Needle thread)

Thread

Polyester (spun

fi lament)

Twisted thread

#60/2~#100/3

(Twisted thread

#80/3~#100/3)

2.0 ~ 2.25 mm 2.5 ~ 3.0 mm 2.5 ~ 3.0 mm

5.0 ~ 5.5 mm 5.0 ~ 5.5 mm 5.5 ~ 6.0 mm

#80 #80 ~ #90 #90

HA*1

Needle (SCHMETZ

130/705H)

(For home-use

sewing machine)

Page 60

—56—

8. TROUBLE SHOOTING

Under normal conditions, if you carefully follow instruction for operating, no diffi cult or special ad-

justment is necessary for this machine.

Following cases are not failure of machine. Check your machine before you call service.

PROBLEM CORRECTION

REFERENCE

PAG E

CAUSE

• Plug cord into electrical outlet and

machine properly

• Increase pressure by setting lever to

(N~5)

• Adjust differential feed

• Insert new needle

• Reset needle

• Do not pull fabric

• Re-thread machine

• Reset thread tension(s)

• Reset needle / change to new needle

• Insert new needle

• Reset needle

• Re-thread machine

• Check thread tensions

• Loosen needle thread tensions

• Re-thread machine

• Set differential feed 0.5-N

• Not plugged in properly

• Pressure on presser foot