Page 1

HB 445, HB 445 R

HB 560, HB 585, HB 685

EN

Instruction manual

NO

Bruksanvisning

SV

Bruksanvisning

FI

Käyttöopas

DA

Betjeningsvejledning

SL

Navodila za uporabo

SK

Návod na obsluhu

TR

Kullanım kılavuzu

HU

Használati útmutató

SR

Uputstvo za upotrebu

HR

Upute za uporabu

BG

Инструкция за експлоатация

UK

Посібник з експлуатації

ET

Kasutusjuhend

MK

Упатство за употреба

AZ

İstifadə üzrə təlimat

KK

Пайдаланушының

нұсқаулығы

HB 445.2 HB 445.2 R HB 560.1 HB 585.1 HB 685.1

www.viking-garden.comC

Page 2

0478 403 9801 C. I16. Eco. DS-2016-03 © 2016 VIKING GmbH, A-6336 Langkampfen / Kufstein

Page 3

1

0478 403 9801 C

1

Page 4

2

2

0478 403 9801 C

Page 5

3

4

0478 403 9801 C

3

Page 6

5

6

4

0478 403 9801 C

Page 7

7

0478 403 9801 C

5

Page 8

8

6

0478 403 9801 C

Page 9

9

0478 403 9801 C

7

Page 10

10

11

8

0478 403 9801 C

Page 11

12

13

0478 403 9801 C

9

Page 12

14

10

15

0478 403 9801 C

Page 13

16

17

18

0478 403 9801 C

11

Page 14

19

20

12

21

0478 403 9801 C

Page 15

22

23

0478 403 9801 C

13

Page 16

24 25

26

14

27

0478 403 9801 C

Page 17

28

29 30

0478 403 9801 C

15

Page 18

31

16

0478 403 9801 C

Page 19

32

0478 403 9801 C

17

Page 20

18

0478 403 9801 C

Page 21

Dear Customer,

Thank you for choosing a VIKING quality

product.

This product has been produced using

state-of-the-art production methods and

extensive quality assurance procedures,

because our goal is only achieved if you,

the customer, are satisfied with your

machine.

If you have any questions concerning your

machine, please contact your dealer or our

sales agency directly.

I hope that your VIKING machine will

give you great enjoyment.

Management

1. Table of contents

Notes on the instruction manual 20

General 20

Instructions for reading the

instruction manual 20

Machine overview 21

For your safety 21

General 21

Refilling the tank – handling petrol 22

Clothing and equipment 22

Transporting the machine 22

Before operation 23

Working with your machine 24

Maintenance and repairs 25

Storage for prolonged periods

without operation 26

Disposal 27

Description of symbols 27

Standard equipment 27

Preparing the machine for

operation 28

Installation instructions 28

Attaching the chassis 28

Installing the brake spur 28

Assembling the handlebar 29

Folding up the handlebar 29

Installing impact protectors 29

Mounting the hoes: HB 445,

HB 445 R 29

Mounting the hoes: HB 560,

HB 585, HB 685 30

Installing the plant protection disc 31

Installing the self-propulsion levers 31

Routing the drive cables 31

Attaching the drive cables 31

Routing and installing the throttle

cable 31

Fastening the cables to the

handlebar 31

Fuel and engine oil 32

Controls 32

Throttle lever 32

Self-propulsion levers 32

Safety devices 33

Self-propulsion lever lock 33

Safety devices 33

Notes on working with the

machine 33

Working area for operator 33

Working position of the machine 33

Hoe combinations 33

Ideal body position when working 33

Operating the machine 34

Preparatory measures 34

Height adjustment of the upper

handlebar 34

Lateral adjustment of the

handlebar 34

Folding the transport chassis in

and out 34

Adjusting the brake spur 34

Starting the engine 35

Stopping the engine 35

Engaging and disengaging self-

propulsion (forwards) 35

Engaging and disengaging self-

propulsion (reverse) (HB 445 R,

HB 560, HB 585, HB 685) 35

Tilling 35

Maintenance 36

Removing the hoes 36

Cleaning the machine 36

Combustion engine 36

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

Printed on chlorine-free bleached paper. Paper is recyclable. Cover is halogen free.

19

Page 22

Service intervals 37

Storage and periods of inoperation

(winter break) 37

Transport 37

Transporting the tiller 37

Environmental protection 38

Disposal 38

Minimising wear and preventing

damage 38

Standard spare parts 39

CE - manufacturer's declaration of

conformity 39

Technical specifications 40

Troubleshooting 41

Service schedule 42

Handover confirmation 42

Service confirmation 42

2. Notes on the instruction manual

2.1 General

This instruction manual constitutes

original manufacturer's instructions in

the sense of EC Directive 2006/42/EC.

VIKING is continually striving to further

develop its range of products; we therefore

reserve the right to make alterations to the

form, technical specifications and

equipment level of our standard

equipment.

For this reason, the information and

illustrations in this manual are subject to

alterations.

This instruction manual is protected by

copyright. All rights reserved, especially

the right of reproduction, translation and

processing using electronic systems.

2.2 Instructions for reading the instruction manual

Illustrations and texts describe specific

operating steps.

All symbols which are affixed to the

machine are explained in this instruction

manual.

Viewing direction:

Viewing direction when "left" and "right"

are used in the instruction manual:

the user is standing behind the machine

and is looking forwards in the direction of

travel.

Section reference:

References to relevant sections and

subsections for further descriptions are

made using arrows. The following example

shows a reference to a section: (Ö 2.1)

Designation of text passages:

The instructions described can be

identified as in the following examples.

Operating steps which require intervention

on the part of the user:

● Release bolt (1) using a screwdriver,

operate lever (2)...

General lists:

– Use of the product for sporting or

competitive events

Texts with added significance:

Text passages with added significance are

identified using the symbols described

below in order to especially emphasise

them in the instruction manual:

Danger

Risk of accident and severe injury

to persons. A certain type of

behaviour is necessary or must be

avoided.

Warning

Risk of injury to persons. A certain

type of behaviour prevents possible

or probable injuries.

Caution

Minor injuries or material damage

can be prevented by a certain type

of behaviour.

Note

Information for better use of the

machine and in order to avoid

possible operating errors.

Texts relating to illustrations:

Illustrations relating to use of the machine

can be found in the front of this instruction

manual.

The camera symbol serves to link

the figures on the illustration pages

with the corresponding text

passages in the instruction manual.

1

20

0478 403 9801 C - EN

Page 23

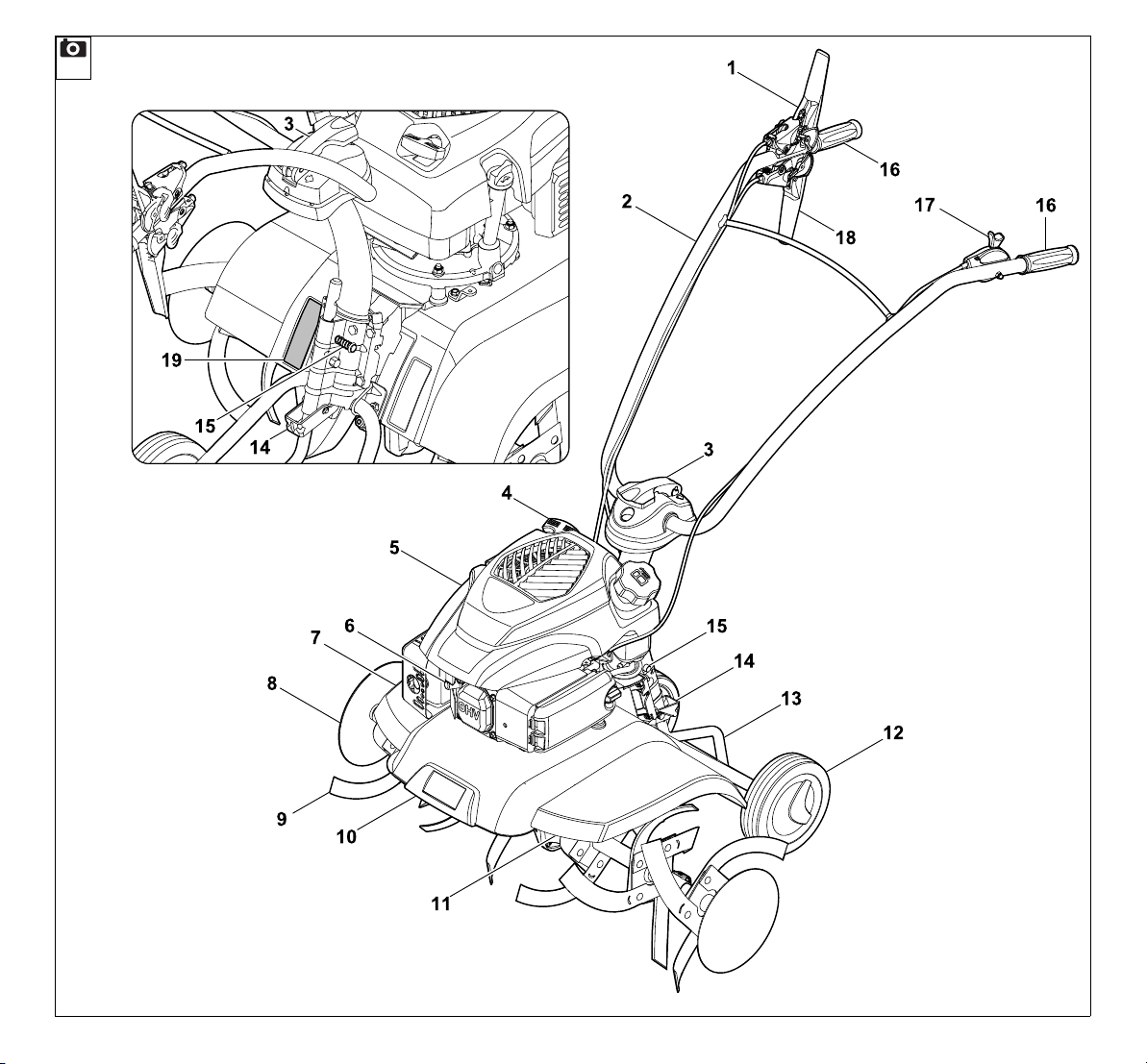

3. Machine overview

1 Self-propulsion lever (forwards)

2 Upper handlebar

3 Tension lever

4 Recoil starter rope

5 Engine

6 Spark plug socket

7 Right impact protector

8 Plant protection disc

9 Hoes

10 Carrying handle

11 Right impact protector

12 Transport chassis

13 Brake spur

14 Release lever (transport chassis)

15 Release pin (brake spur)

16 Handle

17 Throttle lever

18 HB 445 R, HB 560, HB 585, HB 685:

Self-propulsion lever (reverse)

19 Identification plate with serial number

4. For your safety

4.1 General

These safety regulations must

be observed when working with

the machine.

Read the entire instruction

manual before using the

machine for the first time. Keep

the instruction manual in a safe

place for future reference.

1

Observe the operating and maintenance

instructions contained in the separate

engine instruction manual.

These safety precautions are essential for

your safety, however the list is not

exhaustive. Always use the machine in a

reasonable and responsible manner and

be aware that the user is responsible for

accidents involving third parties or their

property.

Make sure that you are familiar with the

controls and operation of the machine. In

particular, the user must know how the

work tools and engine can be stopped

quickly.

The machine must only be used by

persons who have read the instruction

manual and are familiar with operation of

the machine. The user should seek expert

and practical instruction prior to initial

operation. The user must receive

instruction on safe use of the machine

from the vendor or another expert.

During this instruction, the user should be

made aware that the utmost care and

concentration are required for working with

the machine.

Risk of death from suffocation!

Packaging material is not a toy danger of suffocation! Keep

packaging material away from

children.

Only give or lend the machine, including

any accessories, to persons who are

familiar with this model and how to operate

it. The instruction manual forms part of the

machine and must always be provided to

persons borrowing it.

The machine must only be operated by

persons who are well rested and in good

physical and mental condition. If your

health is impaired, you should consult your

doctor to determine whether working with

the machine is possible. The machine

should not be operated after the

consumption of alcohol, drugs or

medications which impair reactions.

Children, persons with impaired physical,

sensory or mental faculties or those

lacking the appropriate experience, or

persons who are not familiar with the

instructions, must never be allowed to use

the machine.

Never allow children under the age of 16 to

use the machine. Local regulations may

specify a minimum age for users.

Caution – risk of accident:

The tiller is only suitable for tilling

operations such as the sowing, cultivation

or care of plants. It must only be used as

described in this instruction manual –

improper use is prohibited. Use for other

purposes is not permitted and may be

dangerous. Such use could result in injury

to persons or damage to the machine.

Due to physical danger to the user, the

tiller must not be used for the following

applications (incomplete list):

– working on lawn roofs and in balcony

boxes,

– for shredding or chopping tree or hedge

cuttings.

It is not permitted to transport objects,

animals or persons, particularly children,

on the machine.

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

21

Page 24

For safety reasons, any modification to the

machine, except the proper installation of

accessories approved by VIKING is

forbidden and results in voiding of the

warranty cover. Information regarding

approved accessories can be obtained

from your VIKING specialist dealer.

In particular, any tampering with the

machine which increases the power output

or the engine speed is forbidden.

Particular care is required during use in

public green spaces, parks, sports fields,

along roads and in agricultural and forestry

businesses.

Caution: Danger to health due

to vibrations!

Excessive exposure to

vibrations can result in damage

to the cardiovascular or nervous system,

particularly in persons with cardiovascular

problems. Please consult a physician if

you experience symptoms that may have

been caused by vibrational loads.

Symptoms of this kind principally affect the

fingers, hands or wrists and include

(incomplete list):

– numbness,

– pain,

– muscular weakness,

– skin discolouration,

– unpleasant tingling sensation.

When using the tiller, plan for work breaks

and avoid using the machine for

excessively long periods, as this may be

damaging to health due to vibration.

4.2 Refilling the tank – handling petrol Danger to life!

Petrol is poisonous and extremely

inflammable.

Petrol must only be stored in appropriate,

tested containers (canisters). Always

screw on the fuel tank and canister caps

properly and tightly. Defective caps must

be replaced for safety reasons.

Never use beverage bottles or similar for

disposal or storage of fuels and lubricants.

Persons, particularly children, could be

tempted to drink out of them.

Keep petrol away from sparks,

naked flames, pilot lights, heat

sources, and other ignition

sources. Do not smoke!

Refill the tank out-of-doors and do not

smoke during refilling.

Before refilling the tank, stop the engine

and allow it to cool.

Refilling with petrol must be performed

before the engine is started. When the

engine is running or is hot, the tank cap

must not be removed and the tank must

not be refilled with petrol.

Do not overfill the fuel tank!

To give the fuel room to expand,

never fill the fuel tank past the

lower edge of the filler neck.

Observe the additional

instructions in the engine

instruction manual.

If petrol is spilled, the engine

must only be started after the petrolcontaminated area has been cleaned. All

attempts at starting must be avoided until

the petrol fumes have dispersed (wipe

dry).

Any spilt fuel must be wiped up

immediately.

Clothing must be changed if it comes into

contact with petrol.

Never store the machine with petrol in the

tank inside a building. The resulting petrol

fumes could come into contact with naked

flames or sparks and could be ignited.

If it is necessary to drain the tank, this must

be done out of doors.

4.3 Clothing and equipment

Always wear sturdy footwear

with high-grip soles when

working. Never work barefoot

or, for example, in sandals.

Also always wear sturdy gloves

and tie up and secure long hair

(headscarf, cap, etc.) when

performing maintenance and

cleaning work or when transporting the

machine.

Wear suitable, close-fitting

clothing when working with the

machine, e.g. overalls, but not

work coats. Do not wear

scarves, ties, jewellery, clothing with

dangling straps or cords or other

protruding articles of clothing when

working with the machine.

Hair, clothing or parts of clothing could

become caught or entangled in the rotating

parts. This can result in serious injury.

4.4 Transporting the machine

Always wear gloves in order to prevent

injuries due to sharp-edged and hot

components.

22

0478 403 9801 C - EN

Page 25

Do not transport the machine with the

engine running. Before transport, switch

off the engine, allow the work tool to come

to a complete standstill and detach the

spark plug socket.

Only transport the machine once the

engine has cooled down and with an

empty fuel tank.

Observe the information in the section

"Transport". It describes how to lift and

lash the machine. (Ö 13.)

Always carry the machine with two people

– use the appropriate lifting points.

Use suitable loading aids (loading ramps,

lifters).

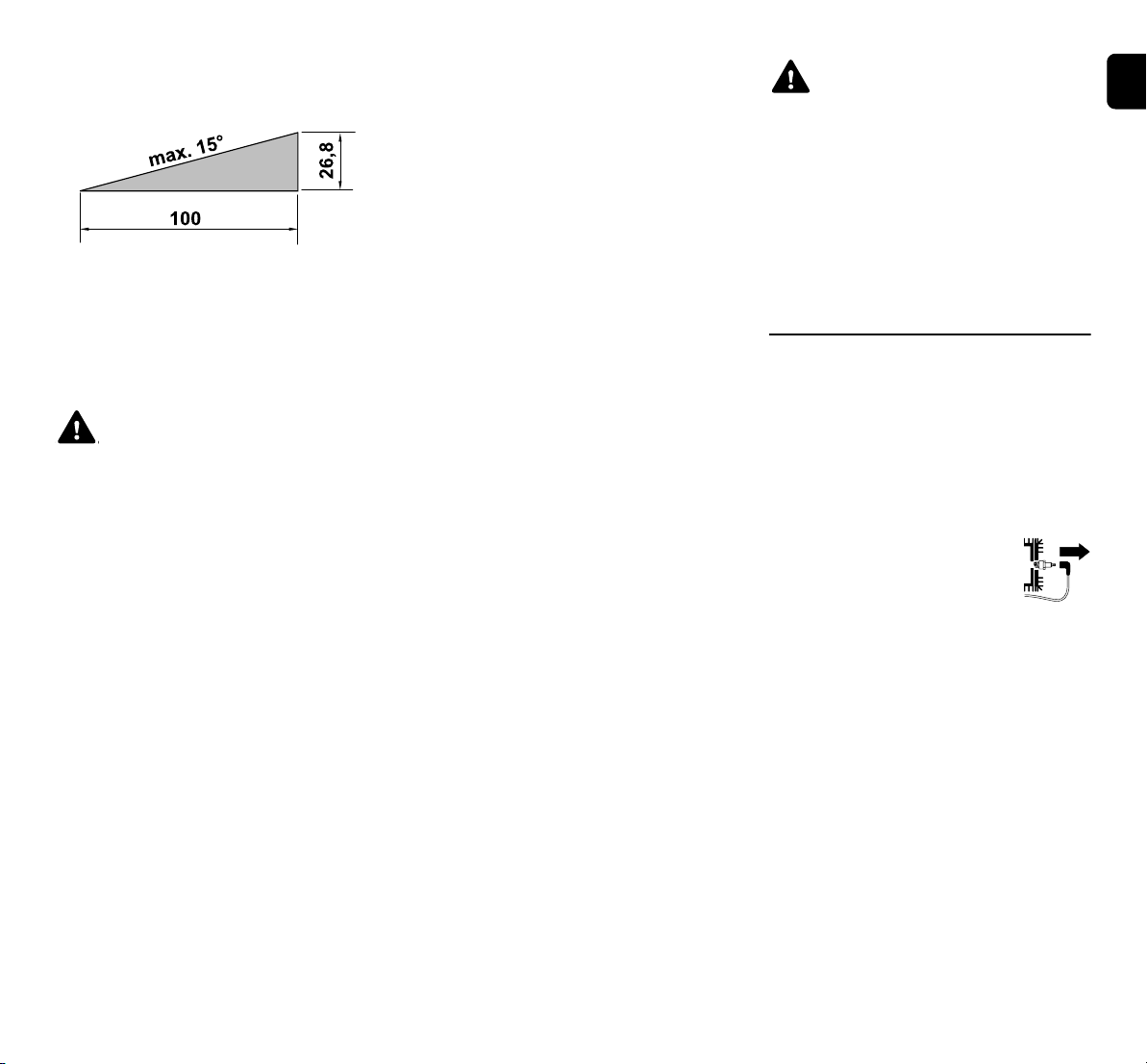

For safety reasons, a tilt angle of 15° must

not be exceeded when transporting and

loading the machine, especially when

using loading ramps.

Secure the machine and any machine

components being transported on the load

floor using adequately-dimensioned

fastening material (belts, ropes, etc.).

Never transport the machine unsecured.

VIKING recommends transporting the tiller

using a suitable trailer or on a suitable load

floor and not inside a vehicle (e.g. luggage

compartment).

When transporting the machine, always

observe regional legislation, especially

regarding load security and the transport

of objects on load floors.

4.5 Before operation

Make sure that only persons who are

familiar with the instruction manual are

permitted to use the machine.

Check the fuel system (particularly visible

parts such as e.g. tank, tank cap, hose

connections) before operating the

machine. In the event of any leaks or

damage, do not start the engine – fire

hazard!

Have the machine repaired by a specialist

dealer prior to operation.

Observe the local regulations regarding

permitted operating times for gardening

power tools with combustion engines.

Carefully inspect the complete area on

which the machine is to be used and

remove any large stones, sticks, wires,

bones or other foreign objects which could

be thrown up by the machine.

Objects hidden in the ground (lawn

sprinkler systems, posts, water valves,

foundations, electrical wires, etc.) must be

clearly marked before working with the

machine and avoided during operation.

Never run over any such foreign objects.

Defective and all other worn or damaged

parts must be removed before using the

machine. Replace any illegible or

damaged danger signs and warnings on

the machine. Your VIKING specialist has a

supply of replacement stickers and all the

other spare parts.

Check secure seating of the spark plug

socket on the spark plug before using the

machine.

The machine must only be used in good

operating condition. Before each use,

check whether:

– The entire machine is properly

assembled.

– The safety devices (e.g. self-propulsion

lever, impact protectors, protective

covers, handlebar, protective grille) are

in good condition and working properly.

Never use the machine with missing,

damaged or worn safety devices.

– The work tools (hoes), fastening bolts

and retaining pins are fitted and are not

worn or damaged (notches, cracks).

Worn or damaged parts must be

replaced.

– The work tools (hoes) are secure and

firmly installed.

– The self-propulsion levers are working

and are easy to operate.

– The tank cap is properly attached.

– The tank and fuel-carrying parts, as well

as the tank cap are in good condition.

– The oil closure screw is properly

attached.

– The accessories used are complete

and are properly installed on the

machine. All the components included

in the scope of delivery of the accessory

must be installed/used.

Carry out any necessary work or consult a

specialist dealer. VIKING recommends

VIKING specialist dealers.

The left and right impact protectors are

adapted to the relevant working width and

must always be properly installed. If, on

models HB 445 and HB 445 R, the

working width is increased using additional

hoes (VIKING accessories), the larger

impact protectors (supplied in the scope of

delivery of the accessories) must also be

installed.

Push or pull the machine to the area to be

worked with the aid of the transport

wheels.

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

23

Page 26

Before operating, remove any foreign

objects (tools, cloths, etc.) placed on the

machine.

4.6 Working with your machine

Keep other persons out of the

danger area. Never work when

animals or persons, particularly

children, are in the danger area.

Caution: Objects such as soil, stones, etc.

can be thrown up or thrown out sideways

during working.

The machine may only be operated by one

person. The operator must stay within the

working area when the engine is running.

(Ö 10.1)

During operation, the machine must not be

lifted, pushed or pulled at the transport

handle, guard plate or at other machine

parts except for the handles of the

handlebar – and especially not by a

second person.

The switch and safety devices installed in

the machine must not be removed or

bypassed. In particular, never secure the

self-propulsion lever to the upper

handlebar (e.g. by tying it).

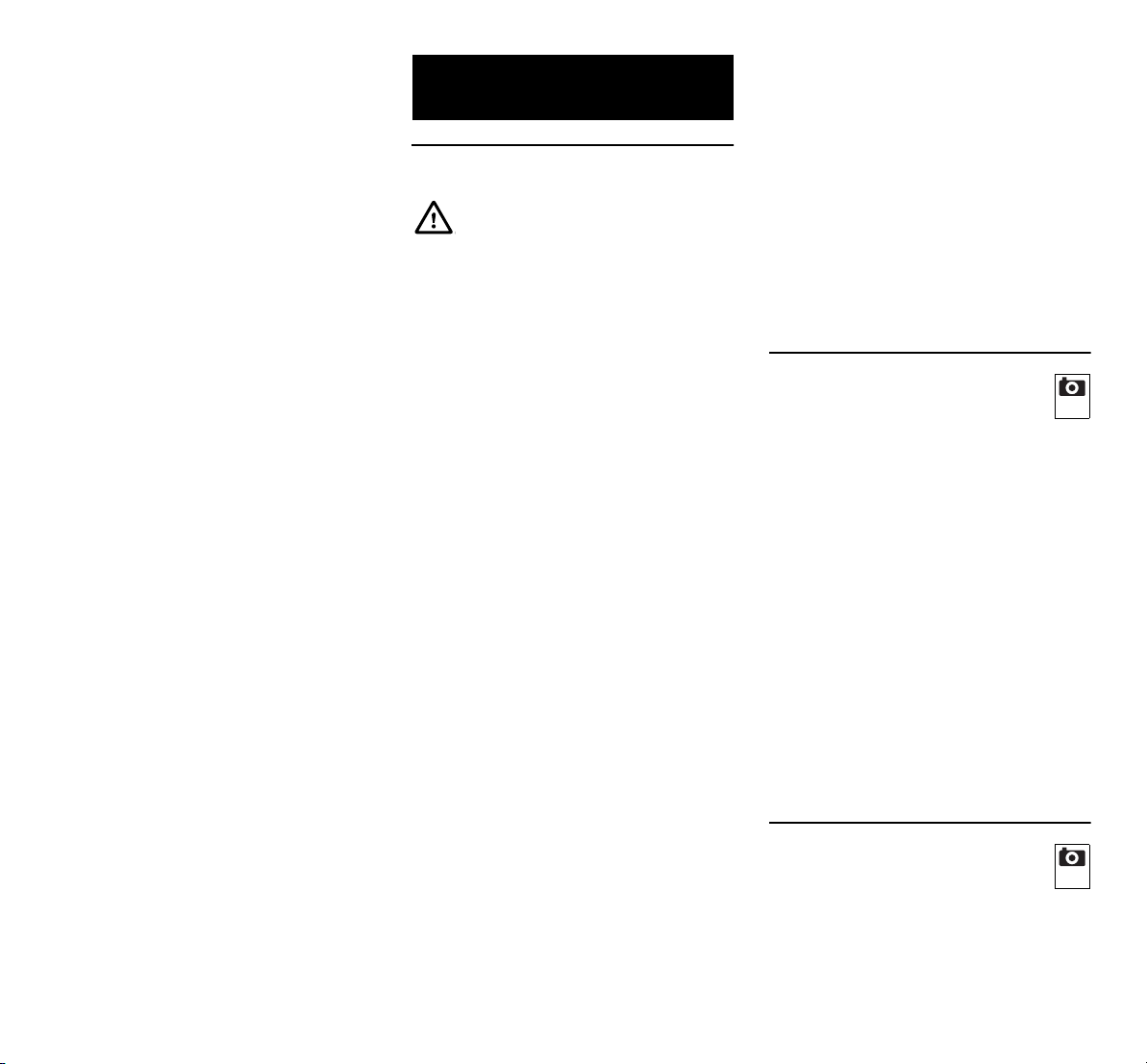

Caution – risk of injury!

Never put hands or feet on or

underneath rotating parts.

Always observe the safety

distance provided by the

handlebar. This safety distance

corresponds to the length of the properly

installed and folded-out handlebar. Do not

modify the handlebar and never operate

the machine with the handlebar folded

down.

Never attach any objects to the handlebar

(e.g. work clothing).

Only work during the day or with good

artificial light.

Do not operate the machine in the rain or

during thunder storms, particularly when

there is a risk of lightning strike.

The risk of accidents is higher if the ground

is damp due to increased danger of

slipping.

Particular caution should be exercised

during working in order to prevent slipping.

If possible, avoid using the machine when

the ground is damp.

Do not operate the machine on tarmac or

paved areas, etc. with the hoes attached.

Use the machine with great care when

working near slopes, terraces, ditches and

embankments. In particular, ensure that

you maintain sufficient distance to such

danger areas.

Exhaust gases:

Danger to life through poisoning!

In the case of nausea, headache,

impaired vision (e.g. decreasing

field of view) hearing disorder,

dizziness, decreasing power of

concentration, stop working

immediately. These symptoms may

be caused by excessively high

exhaust gas concentrations.

The machine generates

poisonous exhaust gases when

the engine is running. The

gases contain poisonous

carbon monoxide, a colourless and

odourless gas, as well as other pollutants.

The engine must never be operated in

closed or poorly ventilated spaces.

Observe discharge direction of exhaust

gases. Never point the exhaust towards

persons.

Starting:

Exercise care when starting the machine

and observe the instructions contained in

the section entitled "Operating the

machine" (Ö 11.6). Starting the machine

in accordance with these instructions

reduces the risk of injury.

Risk of injury!

If the starter rope recoils at speed, the

hand and arm will be pulled towards the

engine faster than the starter rope can be

released. This kickback can result in

broken bones, crush injuries and sprains.

Ensure that you keep your feet far enough

away from the work tools.

The machine must not be tilted during

start-up.

The self-propulsion levers must not be

pressed when starting.

Working on slopes:

Always work across and back on slopes,

never up and down.

The operator must never stand below the

running machine on a slope. If the user

loses control, there is a risk of being run

over by the machine.

Be particularly careful when changing

direction on a slope.

Always ensure good stability on slopes

and avoid mowing on excessively steep

slopes.

The machine can tip over when used on

slopes. For safety reasons, the machine

must not be used on slopes with an

inclination of more than 15° (26.8 %). Risk

of injury!

24

0478 403 9801 C - EN

Page 27

A slope inclination of 15° corresponds to a

vertical height increase of 26.8 cm for a

100 cm horizontal distance.

In order to ensure an adequate oil supply

for the engine, the information in the

accompanying engine instruction manual

must be additionally observed when using

the machine on slopes.

Working:

Risk of injury!

Never place your hands or feet

above, underneath or on rotating

parts.

For safety reasons, the machine must

always be operated using both hands,

which must be kept on the handles of the

handlebar at all times during operation.

Never work using only one hand.

Only control the working depth by applying

pressure to the brake spur.

Use the machine with particular care when

operating on difficult (e.g. stony and hard)

ground. Reduce the rotational speed of the

work tools (fuel control).

Only operate the machine at walking

speed – never run when working with the

machine. Working quickly with the

machine increases the risk of injury due to

stumbling, slipping, etc.

Caution – risk of injury!

Exercise particular caution and ensure that

there is sufficient distance between the

work tools (hoes) and your feet when

turning the machine around, pulling it

towards you, or using reverse gear.

Caution – Risk of stumbling!

Watch out for obstacles behind the

operator when moving the machine

backwards.

If the machine becomes stuck, stop the

engine and detach the spark plug socket.

Lift the machine with the help of a second

person and free it.

Stop the engine

– when the machine has to be tilted for

transportation

– when pushing or pulling the machine to

and from the area to be worked

– when leaving the machine unattended

– before re-filling the tank. Allow the

engine to cool down before re-filling the

tank. Fire hazard!

– when pushing or pulling the machine on

an area that is not to be worked.

Stop the engine and detach the spark plug

socket:

– before remedying blockages

– before lifting or carrying the machine

– before transporting the machine

– before checking or cleaning the

machine or before carrying out any

other work (e.g. adjusting the

handlebar, folding out the transport

chassis) on it

– after hitting a foreign object or if the

machine vibrates excessively. In these

cases, check the machine, in particular

the work tools (hoes, hoe retainers,

drive shaft), for damage and carry out

the necessary repairs before restarting

and working with the machine.

Risk of injury!

Strong vibration is normally an

indication of a fault.

In particular, the tiller must not be

operated with a damaged or bent

drive shaft or with damaged work

tools.

If you do not have the appropriate

expertise, have the necessary

repairs carried out by a specialist

dealer (VIKING recommends

VIKING specialist dealers).

4.7 Maintenance and repairs

Before beginning cleaning, adjustment,

repair and maintenance operations:

● Park the machine on firm and level

ground

● Stop the engine and allow it to cool

down

● Detach the spark plug

socket.

Caution – risk of injury!

Keep the spark plug socket

away from the spark plug; an inadvertent

ignition spark can result in fires or electric

shocks.

Inadvertent contact between the spark

plug and the spark plug socket can result

in unwanted starting of the engine.

Set the machine down on its back only for

cleaning and maintenance work. If

machine is set onto its side or front, this

may cause damage to the engine and

other machine parts, resulting in

expensive repairs.

Allow the machine to cool down before

performing maintenance operations on the

gearbox, engine, exhaust manifold or

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

25

Page 28

muffler in particular. Temperatures of

80° C and above can be reached. Danger

of burns!

Direct contact with engine oil can be

dangerous. Engine oil must not be spilled.

VIKING recommends leaving the task of

topping up engine oil or performing engine

oil changes to a VIKING specialist dealer.

Check the entire machine for wear or

damage on a regular basis, particularly

before extended periods when the

machine is not in use (e.g. over winter).

For safety reasons, worn or damaged

parts must be replaced immediately to

ensure that the machine is always in a safe

operating condition.

Cleaning:

The complete machine must be cleaned

thoroughly following use. (Ö 12.2)

Remove accumulated clipping deposits

using a stick. Clean the underside of the

machine with water and a brush.

Do not use aggressive cleaning agents.

These can damage plastics and metals,

impairing the safe operation of your

VIKING machine.

The underside of the machine (everything

below the guard plate) can be cleaned

using a high-pressure cleaner or steam

cleaner. Maintain a distance of at least 1 m

and never direct the water jet directly at the

bearing points or seals – especially the

seal between the gearbox housing and

guard plate.

In order to prevent fire hazards, keep the

area around the air vents, cooling ribs and

the area of the exhaust free from

e.g. grass, straw, moss, leaves or

escaping grease.

Maintenance operations:

Only maintenance operations described in

this instruction manual may be carried out.

Have all other work performed by a

specialist dealer.

If you do not have the necessary expertise

or auxiliary equipment, please always

contact a specialist dealer.

VIKING recommends that you have

maintenance operations and repairs

performed exclusively by a VIKING

specialist dealer.

VIKING specialist dealers regularly attend

training courses and are provided with

technical information.

Only use tools, accessories or

attachments approved for this machine by

VIKING or technically identical parts.

Otherwise, there may be a risk of

accidents resulting in personal injury or

damage to the machine. If you have any

questions, please consult a specialist

dealer.

The characteristics of original VIKING

tools, accessories and spare parts are

optimally adapted to the machine and the

user's requirements. Genuine VIKING

spare parts can be recognised by the

VIKING spare parts number, by the

VIKING lettering and, if present, by the

VIKING spare parts symbol. On smaller

parts, only the symbol may be present.

For safety reasons, fuel-carrying

components (fuel line, fuel cock, fuel tank,

tank cap, connections, etc.) must be

checked regularly for damage and leaks

and replaced by a technician if necessary

(VIKING recommends VIKING specialist

dealers).

Always keep warning and information

stickers clean and readable. Damaged or

missing stickers must be replaced by new,

original plates from your VIKING specialist

dealer. If a component is replaced with a

new component, ensure that the new

component is provided with the same

stickers.

Ensure that all nuts, pins, bolts and screws

are securely tightened, so that the

machine is in a safe operating condition.

Never alter the basic setting of the engine

or run at excessive engine speeds.

Components or guards that are removed

for maintenance operations must be

properly reinstalled immediately.

When replacing the work tools (hoes),

ensure that the correct hoe type and hoe

combination are installed – only those

versions approved by VIKING are

permitted.

4.8 Storage for prolonged periods without operation

Allow the engine to cool before storing the

machine in an enclosed space.

Store the machine with empty fuel tank

and the fuel reserve in a lockable and wellventilated room.

Ensure that the machine is protected from

unauthorised use (e.g. by children).

Never store the machine with petrol in the

tank inside a building. The resulting petrol

fumes could come into contact with naked

flames or sparks and could be ignited.

If the tank has to be emptied (e.g.

immobilisation before the winter break),

the fuel tank must be emptied out of doors

only (empty the tank by running the

engine, for example).

Thoroughly clean the machine before

storage (e.g. winter break).

26

0478 403 9801 C - EN

Page 29

Only store the machine with the spark plug

socket disconnected.

Store the machine in good operational

condition.

Allow the machine to cool down

completely before covering it.

4.9 Disposal

Waste products such as used engine oil or

fuel, used lubricants, filters, batteries and

similar wearing parts can be harmful to

people, animals and the environment, and

must consequently be disposed of

properly.

Consult your recycling centre or your

specialist dealer for information on the

proper disposal of waste products. VIKING

recommends VIKING specialist dealers.

Ensure that old machines are properly

disposed of. Read the information in the

"Environmental protection" section.

(Ö 14.)

5. Description of symbols

Caution: –

Risk of injury!

Read and follow the instruction manual and the safety

instructions before initial

use.

Rotating tools: Keep your

hands and feet away from

rotating tools. Only operate

with protective covers.

Maintain a safety

distance.

Detach the spark plug

socket before performing

any maintenance and cleaning operations.

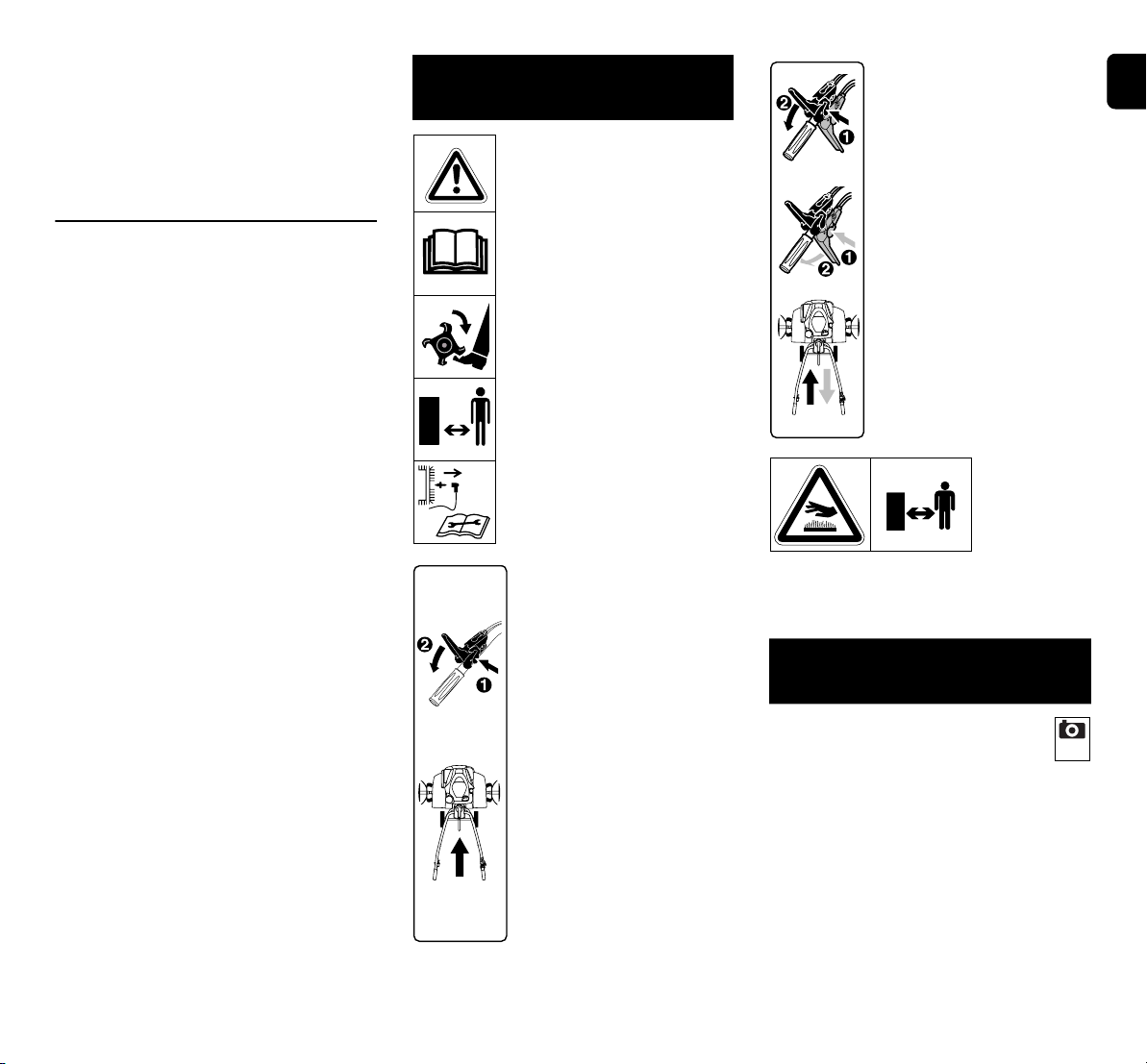

HB 445:

For safety reasons, the

release lever must be

pressed before actuation of

the self-propulsion lever.

This prevents inadvertent

actuation of the self-propulsion lever.

HB 445 R, HB 560, HB 585,

HB 685:

For safety reasons, the relevant release lever must be

pressed before actuation of

the self-propulsion lever.

This prevents inadvertent

actuation of a self-propulsion lever. The black selfpropulsion lever is for the

forward gear and the red

self-propulsion lever is for

the reverse gear.

Danger of burns:

Do not touch hot surfaces. Gearbox

housing becomes extremely hot.

6. Standard equipment

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

2

Item Designation Qty.

A Basic unit 1

B Handlebar 1

C Tension lever 1

D Transport chassis 1

E Brake spur 1

F Left impact protector 1

G Right impact protector 1

27

Page 30

Item Designation Qty.

H HB 445, HB 445 R:

Hoe 4

I HB 560, HB 585, HB 685:

Dual hoe 2

J HB 585, HB 685:

Single hoe 2

K Protection ring 2

L Plant protection disc 2

M Self-propulsion lever

(forwards) black 1

N HB 445 R, HB 560,

HB 585, HB 685:

Self-propulsion lever

(reverse) red 1

O HB 445:

Lock nut M6 1

P HB 445:

Cover

Q Lock nut M6 1

R Flat head bolt M6 1

S HB 445, HB 445 R,

HB 585, HB 685:

Folding retainer 10x40

HB 560:

Folding retainer 10x40

T Flat head bolt M8 2

U Hexagon nut M8 2

V Cable tie 2

– Instruction manual 1

– Instruction manual

Engine 1

– HB 560, HB 585, HB 685:

Spark plug wrench 1

7. Preparing the machine for operation

7.1 Installation instructions

Risk of injury!

Observe the safety instructions in

the "For your safety" section. (Ö 4.)

In particular, detach the spark plug

socket and always wear thick

gloves when carrying out any work

on the hoes.

Observe the specified torque.

Only route and attach drive cables

and throttle cable as described.

Incorrectly installed cables (e.g.

1

6

4

incorrect routing or attaching to the

wrong self-propulsion lever) may

cause malfunctions.

● Perform all the operations described on

a clean, flat, level and firm surface.

● Observe installation position – always

ensure that the machine is standing

stably and securely.

● Strictly observe instructions for cable

installation. In particular, fasten all

cables to the handlebar using cable

ties in order to prevent damage to the

machine (e.g. when folding down the

handlebar) or possible malfunctions.

Self-propulsion levers, drive cables

HB 445:

– Black self-propulsion lever on the upper

side of the handlebar.

– One drive cable (forwards).

HB 445 R, HB 560, HB 585, HB 685:

– Black self-propulsion lever on the upper

side of the handlebar.

– Red self-propulsion lever on the

underside of the handlebar.

– One drive cable (forwards). The cable is

fitted with a black cap and must be

attached to the black self-propulsion

lever.

– One drive cable (reverse). The cable is

fitted with a red cap and must be

attached to the red self-propulsion

lever.

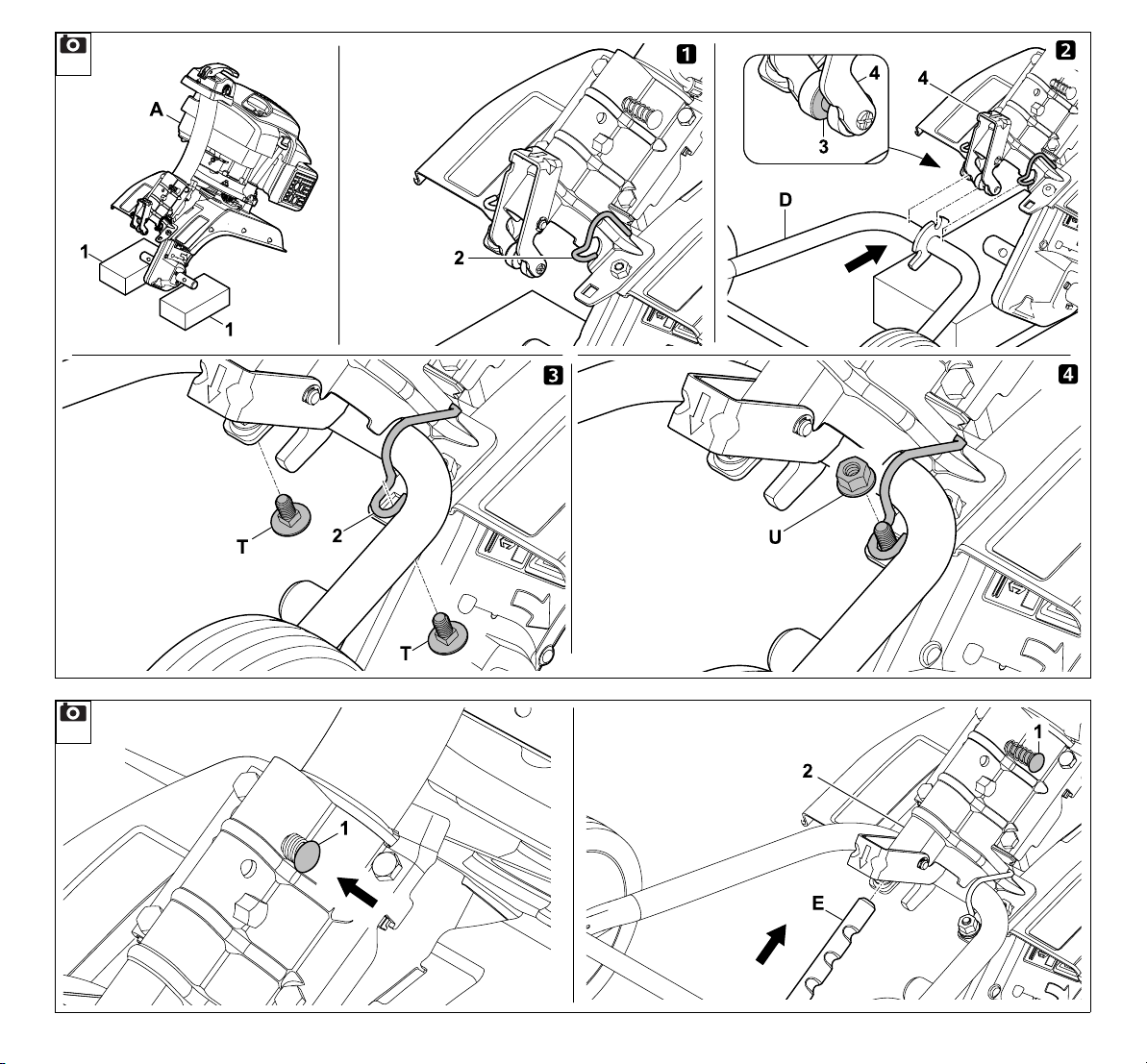

7.2 Attaching the chassis

● Installation position:

Tilt basic unit (A) forwards as

shown and support at both drive shafts

using suitable wooden blocks (1)

(height 50 - 60 mm, width/length

approx. 100 mm).

● 1 Press retaining clasp (2) upwards

and hold.

● 2 Insert transport chassis (D) into

recess (3) in the pin of release lever (4).

● Press transport chassis (D) upwards to

the stop and hold.

● 3 Press retaining clasp (2)

downwards. Insert bolts (T) on both

sides from below.

● 4 Secure retaining clasp (2) by

tightening both nuts (U).

7.3 Installing the brake spur

● Installation position:

see "Attaching the chassis"

(Ö 7.2)

● Press release pin (1) and hold.

3

4

28

0478 403 9801 C - EN

Page 31

● Insert brake spur (E) into adapter (2)

from below and push upwards to the

stop.

● Release the pressure on release pin (1)

and pull brake spur (E) downwards until

it engages.

● Check that brake spur (E) is seated

securely.

7.4 Assembling the handlebar

● 1 Installation position:

see "Attaching the chassis"

(Ö 7.2)

● Remove rubber band (1).

● 2 Lift up console (2) and hold.

● 3 Insert handlebar (B) centrally

between console (2) and lower

handlebar (3) to the stop and hold. The

legs of spring (4) must run along

notched adjustment mechanism (5) as

shown.

Check the illustrated position of

spring (4) in adjustment element (6),

attach the spring if necessary.

● 4 Tighten screw (7).

● 5 Unscrew nut (8) at tension lever (C)

and remove together with spring (9).

● Push tension lever (C) with integrated

bolt from above through console (2)

and lower handlebar (3). Push

spring (9) onto tension lever (C). Screw

on nut (8) one to two turns.

Note:

Install tension lever (C) so that it

must be pressed forwards towards

the engine to apply tension.

● 6 Move upper handlebar (3) to the

central position. (Ö 11.3)

5

● Press tension lever (C) forwards with

the hand.

● Screw on nut (8) to 5 Nm (not to the

stop).

● Check clamping:

Tension lever (C) is correctly installed if

it can be operated with the hand while

the handlebar is securely attached to

the basic unit.

● Adjusting the tensioning force:

If the handlebar is not sufficiently

clamped or if the tension lever cannot

be operated with the hand, loosen the

tension lever and adjust the tensioning

force by tightening or loosening nut (8).

Then press the tension lever forwards

again.

Risk of injury!

The machine must only be pushed

or pulled with a handlebar securely

attached to the basic unit

(handlebar must not be loose under

tension).

7.5 Folding up the handlebar

● Pull tension lever (1) upwards.

Fold up upper handlebar (2) in

the direction of the arrow.

● Press tension lever (1) forwards to the

stop.

● Adjust the height of the handlebar.

(Ö 11.2)

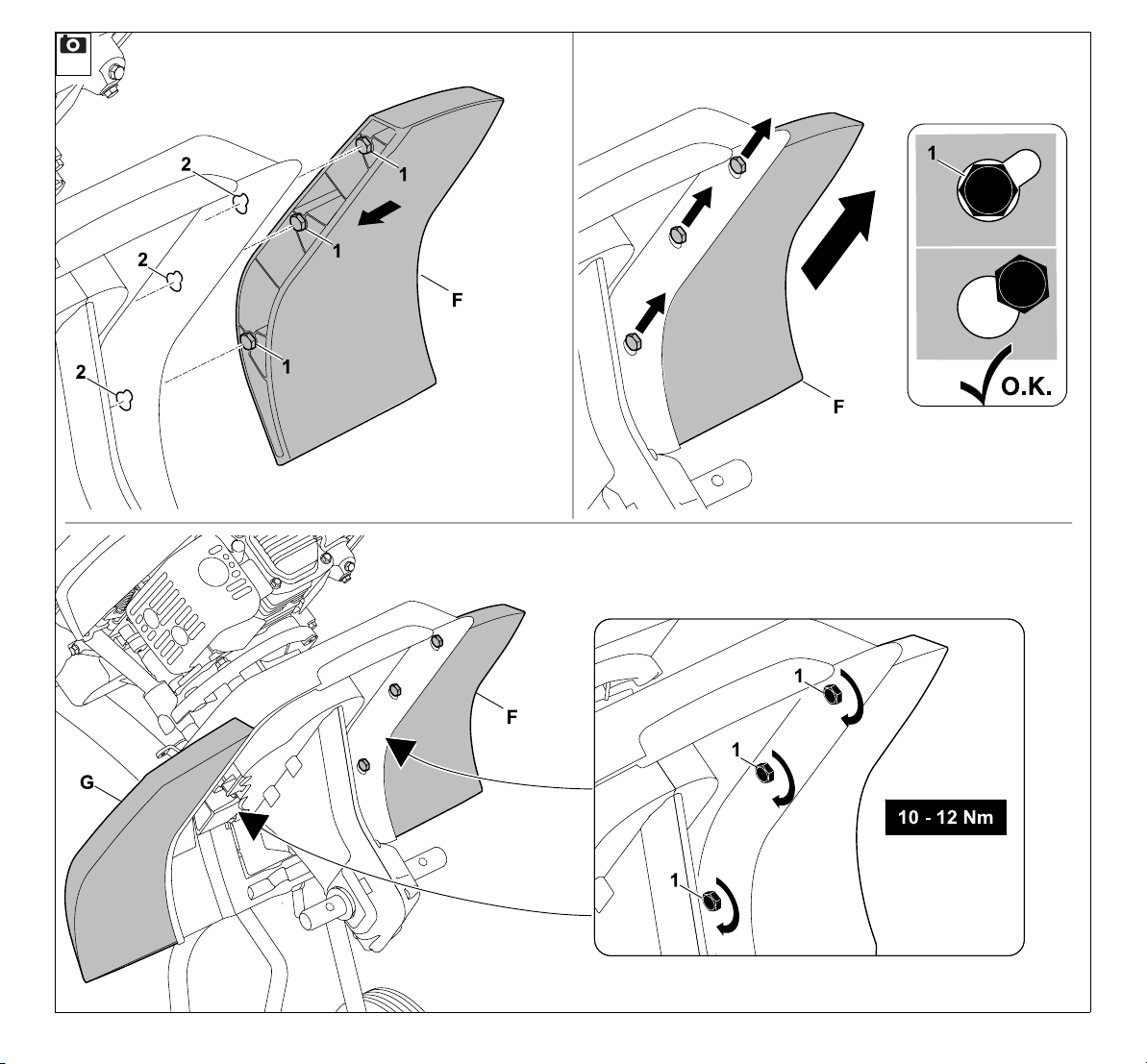

7.6 Installing impact protectors

● Check pre-installed screws (1) in

impact protectors (F, G) – do not

fully unscrew.

6

7

● Place the tiller in the cleaning position.

(Ö 12.2)

● Insert the three pre-installed screws (1)

of left impact protector (F) into the three

bores (2) in the cover plate.

● Push impact protector (F) forwards and

hold.

● Screw in screws (1) and tighten to 10 -

12 Nm.

● Check for secure seating of impact

protector (F) and then install right

impact protector (G) in the same way.

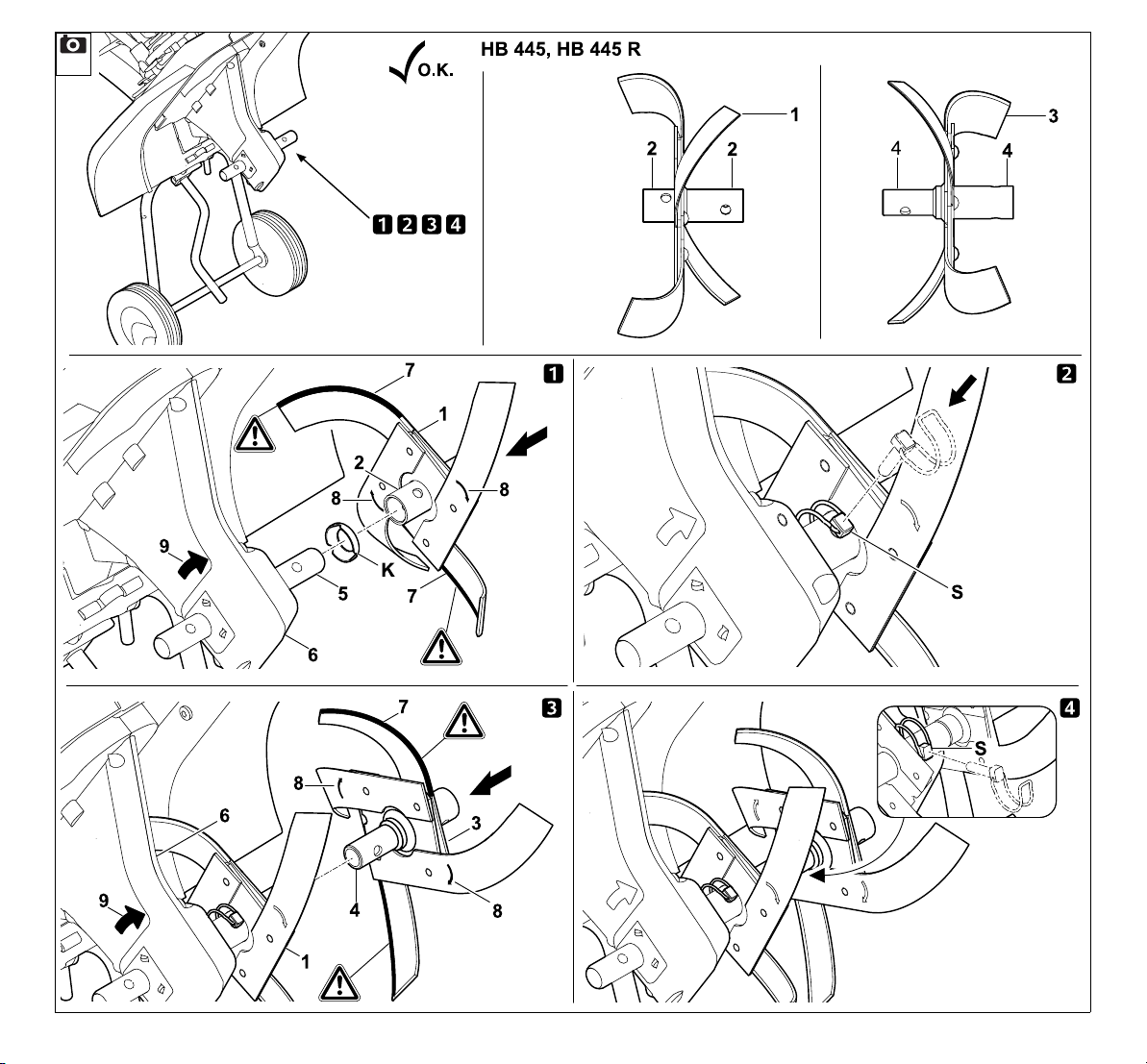

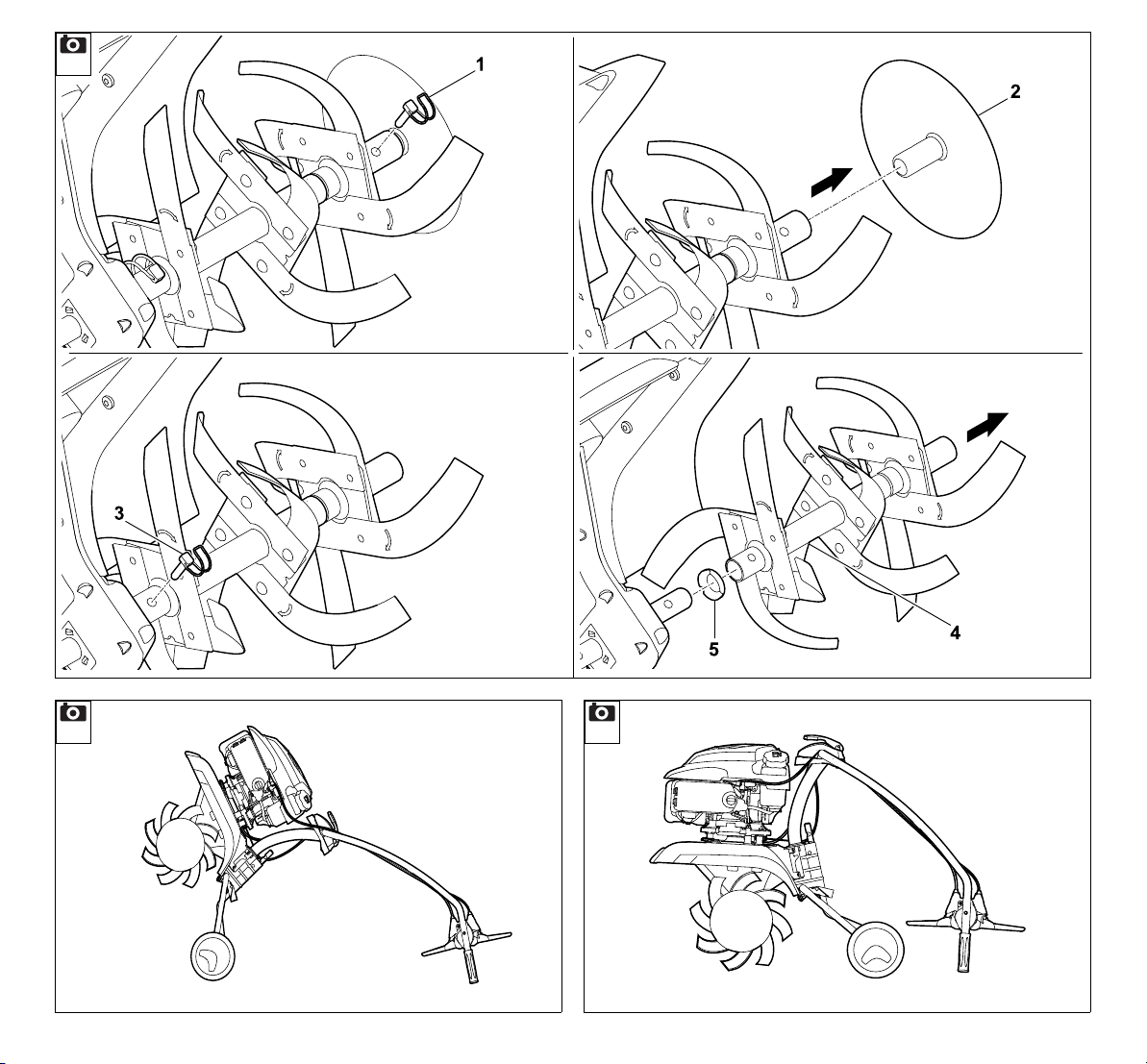

7.7 Mounting the hoes: HB 445, HB 445 R

● Place the tiller in the cleaning

position. (Ö 12.2)

Strictly observe the assembly

instructions. In particular, observe

the installation sequence and install

protection rings, hoes and folding

retainers completely as described.

When installing the folding retainer,

strictly observe the correct direction

of insertion and positioning of the

securing clip, as shown. In the case

of incorrect or rotated installation,

the folding retainer may come loose

and be lost.

For good working results, the

cutting edges of the hoes must

point forwards (not towards the

handlebar) – observe arrow

markings.

Definition of hoes:

– Hoe (1):

same sized outer diameter of shaft

mount (2).

8

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

29

Page 32

–Hoe(3):

different outer diameters of shaft

mount (4).

1

● Push protection ring (K) to the stop on

drive shaft (5). The recesses in the

protection ring must engage on the

three locating lugs of gearbox

housing (6).

● Position hoe (1) so that the shorter

shaft mount (2) faces the gearbox

housing and cutting edges (7) point

forwards. Arrows (8) on the hoe and

arrow (9) on gearbox housing (6) must

point in the same direction.

● Push hoe (1) onto drive shaft (5).

● Turn hoe (1) so that the bores in the

shaft mount and the drive shaft align.

2

● Insert folding retainer (S) through the

bores and close the securing clip.

3

● Position hoe (3) so that the smaller

outer diameter of shaft mount (4) faces

the already mounted hoe (1) and

cutting edges (7) point forwards.

Arrows (8) on the hoe and arrow (9) on

gearbox housing (6) must point in the

same direction.

● Push hoe (3) into the already mounted

hoe (1).

● Turn hoe (3) so that the bores in both

hoes align.

4

● Insert folding retainer (S) through the

bores and close the securing clip.

● Install the plant protection disc if

necessary. (Ö 7.9)

● Repeat the hoe mounting procedure on

the other side.

7.8 Mounting the hoes: HB 560, HB 585, HB 685

9

● Place the tiller in the cleaning

position. (Ö 12.2)

Strictly observe the assembly

instructions. In particular, observe

the installation sequence and install

protection rings, hoes and folding

retainers completely as described.

When installing the folding retainer,

strictly observe the correct direction

of insertion and positioning of the

securing clip, as shown. In the case

of incorrect or rotated installation,

the folding retainer may come loose

and be lost.

For good working results, the

cutting edges of the hoes must

point forwards (not towards the

handlebar) – observe arrow

markings.

Definition of hoes:

– Hoe (I):

dual-row hoe.

–Hoe(J):

single-row hoe.

1 HB 560, HB 585, HB 685

● Push protection ring (K) to the stop on

drive shaft (1). The recesses in the

protection ring must engage on the

three locating lugs of gearbox

housing (2).

● Position hoe (I) so that the shorter

shaft mount (3) faces the gearbox

housing and cutting edges (4) point

forwards. Arrows (5) on the hoe and

arrow (6) on gearbox housing (2) must

point in the same direction.

● Push hoe (I) onto drive shaft (1).

● Turn hoe (I) so that the bores in the

shaft mount and the drive shaft align.

2 HB 560, HB 585, HB 685

● Insert folding retainer (S) through the

bores and close the securing clip.

3 HB 585, HB 685

● Position hoe (J) so that the smaller

outer diameter of shaft mount (7) faces

the already mounted hoe (I) and cutting

edges (4) point forwards. Arrows (5) on

the hoe and arrow (6) on gearbox

housing (2) must point in the same

direction.

● Push hoe (J) into the already mounted

hoe (I).

● Turn hoe (J) so that the bores in both

hoes align.

4 HB 585, HB 685

● Insert folding retainer (S) through the

bores and close the securing clip.

HB 560, HB 585, HB 685

● Install the plant protection disc if

necessary. (Ö 7.9)

● Repeat the hoe mounting procedure on

the other side.

30

0478 403 9801 C - EN

Page 33

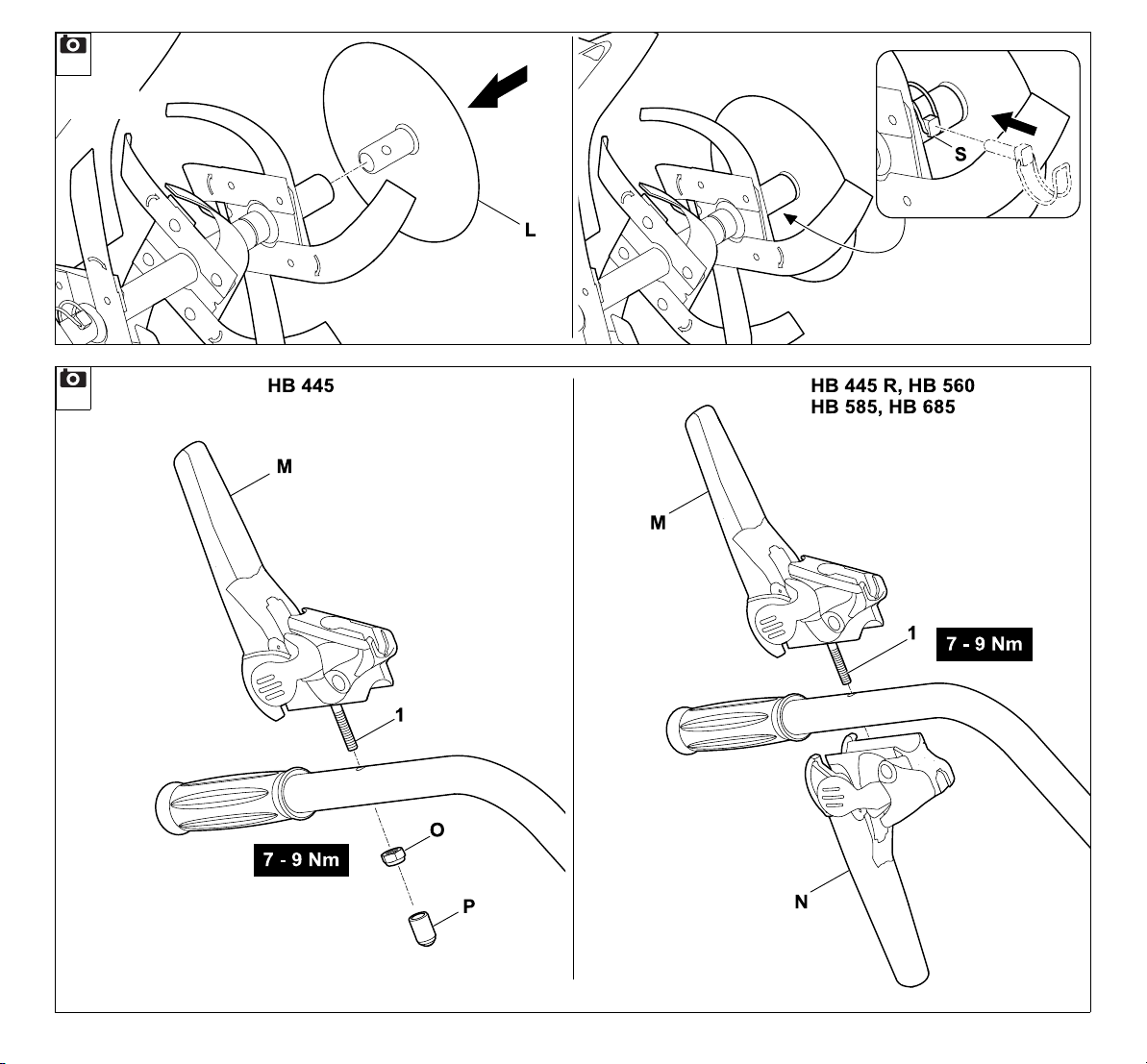

7.9 Installing the plant protection disc

When installing the folding retainer,

strictly observe the correct direction

of insertion and positioning of the

securing clip, as shown. In the case

of incorrect or rotated installation,

the folding retainer may come loose

and be lost.

● Install plant protection disc (L) on the

outer hoe. Turn the plant protection disc

so that the bores in the disc and the hoe

align.

● Insert folding retainer (S) through the

bores and close the securing clip.

● Repeat this procedure on the other

side.

7.10 Installing the selfpropulsion levers

● Observe the installation

instructions. (Ö 7.1)

● Insert black self-propulsion lever (M)

with integrated bolt (1) from above into

the bore in the upper handlebar.

● HB 445:

Screw on lock nut (O) and tighten to 7 9 Nm. Fit cover (P).

● HB 445 R, HB 560, HB 585, HB 685:

Position red self-propulsion lever (N) so

that the bolt of the black lever can be

screwed into the nut integrated in the

red lever.

Press red self-propulsion lever (N)

upwards against the handlebar. Screw

in bolt (1) and tighten to 7 - 9 Nm.

10

11

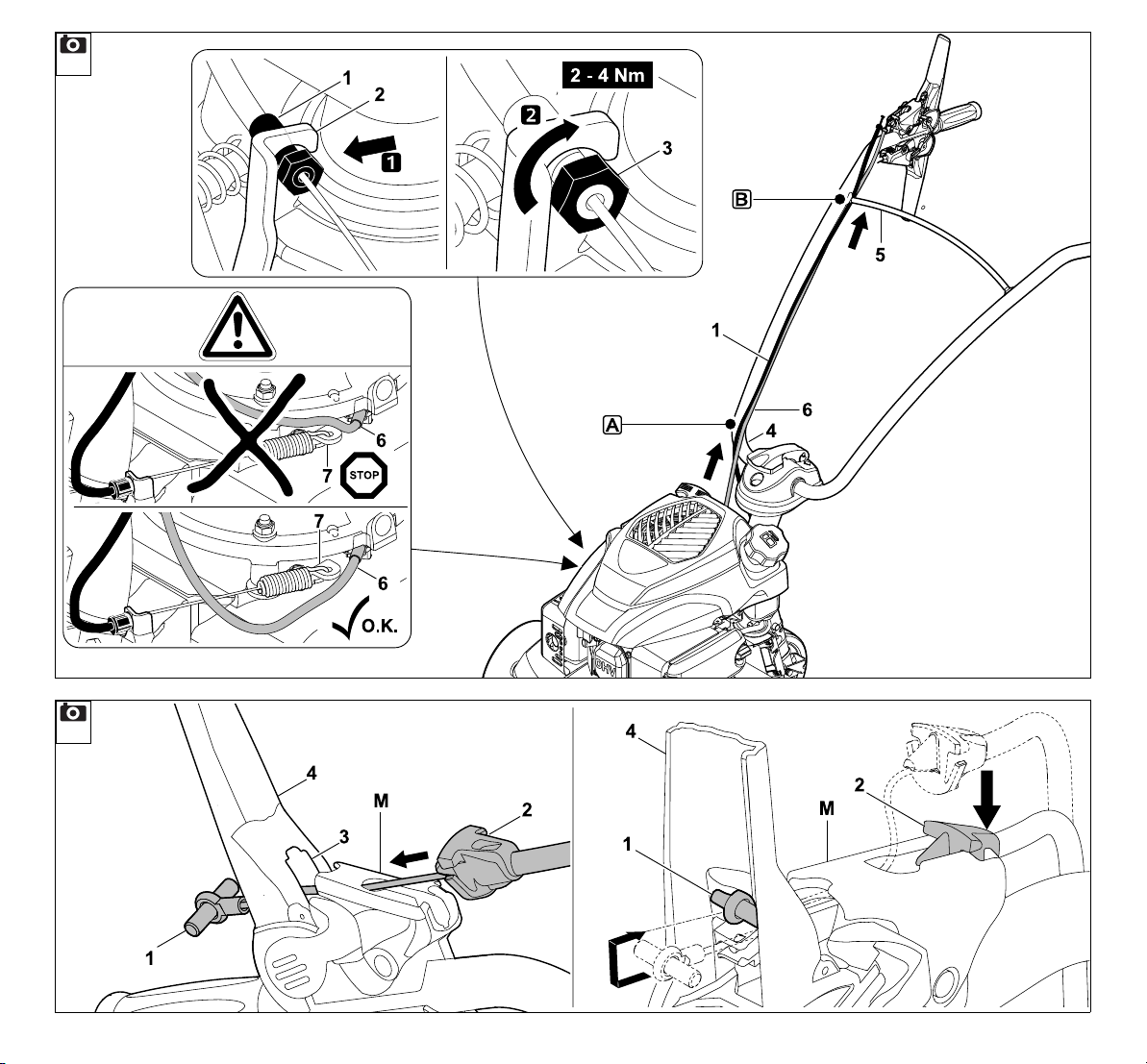

7.11 Routing the drive cables

● Observe the installation

instructions. (Ö 7.1)

● 1 Unwind (forward) drive cable (1) and

fit into bracket (2).

● 2 Tighten nut (3) to 2 - 4 Nm.

● Guide (forward) drive cable (1) upwards

as follows:

A Guide (forward) drive cable (1) over

upper handlebar (4).

B Route (forward) drive cable (1)

under crossbar (5) of the upper

handlebar.

● HB 445 R, HB 560, HB 585, HB 685:

Route (reverse) drive cable (6) on the

right side of the engine below relay

lever (7). Guide the cable upwards

along the handlebar as with the

(forward) drive cable.

7.12 Attaching the drive cables

● Observe the installation

instructions. (Ö 7.1)

Drive cable (forwards):

● Insert toggle (1) of the drive cable with

black cap (2) into black self-propulsion

lever (M).

● Guide toggle (1) through opening (3) of

lever (4). Use suitable pliers if

necessary.

● Using suitable pliers, pull toggle (1) and

engage it in lever (4) as shown.

● Press cap (2) onto self-propulsion

lever (4) and allow it to engage.

12

13

● Operation checks:

Actuate the self-propulsion lever.

(Ö 11.8)

The self-propulsion lever must be easy

to operate.

Drive cable (reverse)

HB 445 R, HB 560, HB 585, HB 685:

● Insert toggle of the drive cable with red

cap into the red self-propulsion lever.

● Further installation is identical to that of

the drive cable (forwards).

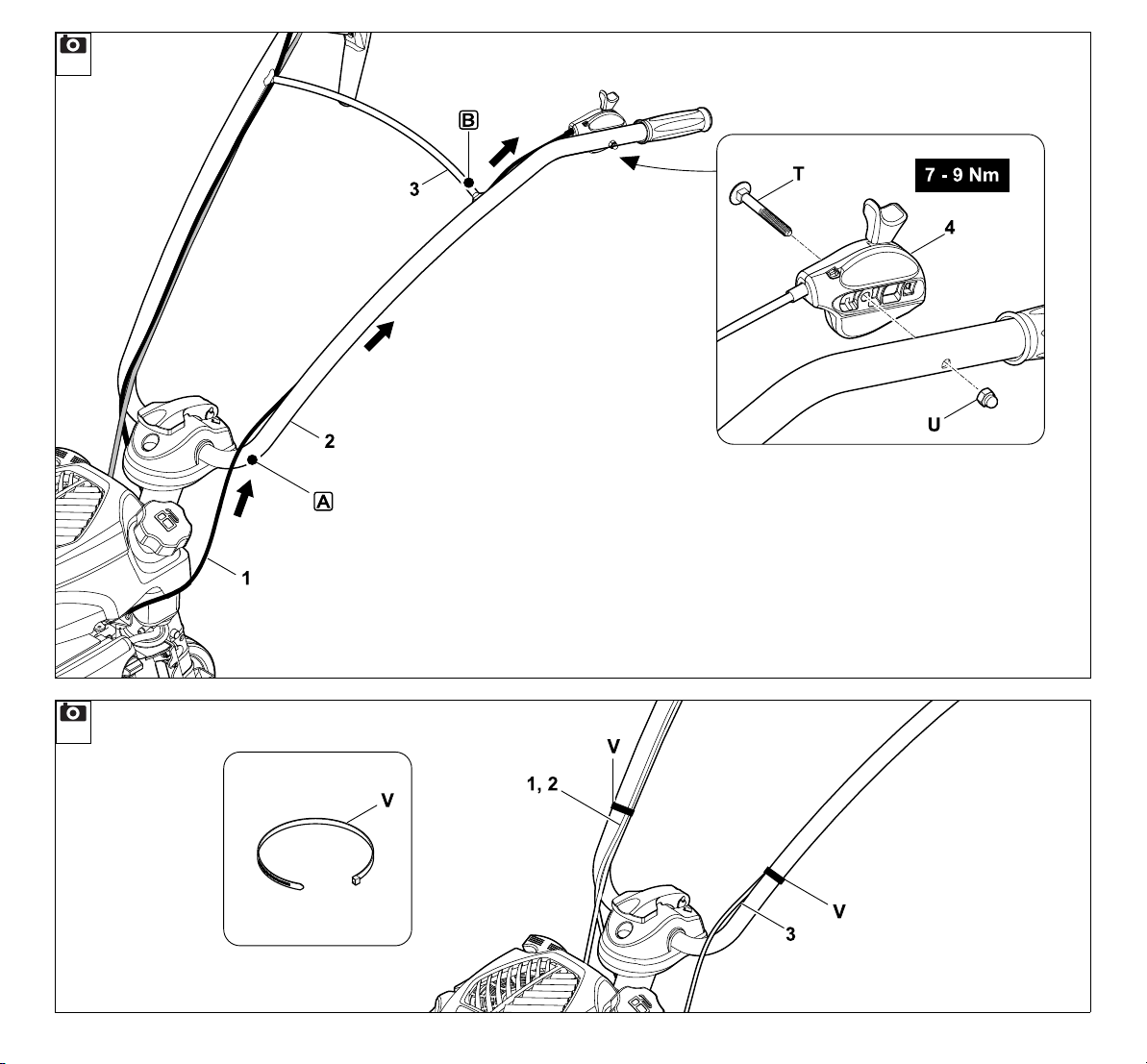

7.13 Routing and installing the throttle cable

● Observe the installation

instructions. (Ö 7.1)

● Unwind throttle cable (1) and route as

follows:

A Guide the throttle cable along upper

handlebar (2).

B Route the throttle cable under

crossbar (3) of the upper handlebar.

● Insert bolt (T) into bore (4) of the throttle

cable housing. Fit the throttle cable

housing with inserted bolt onto the

upper handlebar from the inside and

hold. Screw on lock nut (U) and tighten

to 7 - 9 Nm.

7.14 Fastening the cables to the handlebar

● Observe the installation

instructions. (Ö 7.1)

● HB 445:

Fasten drive cable (1) to the right side

of the upper handlebar using a cable

tie (V).

14

15

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

31

Page 34

● HB 445 R, HB 560, HB 585, HB 685:

Fasten both drive cables (1, 2) to the

right side of the upper handlebar using

a cable tie (V).

● Fasten throttle cable (3) to the left side

of the upper handlebar using a cable

tie (V).

● Check for secure seating of the cable

ties. Cut off the excess length of the

cable ties.

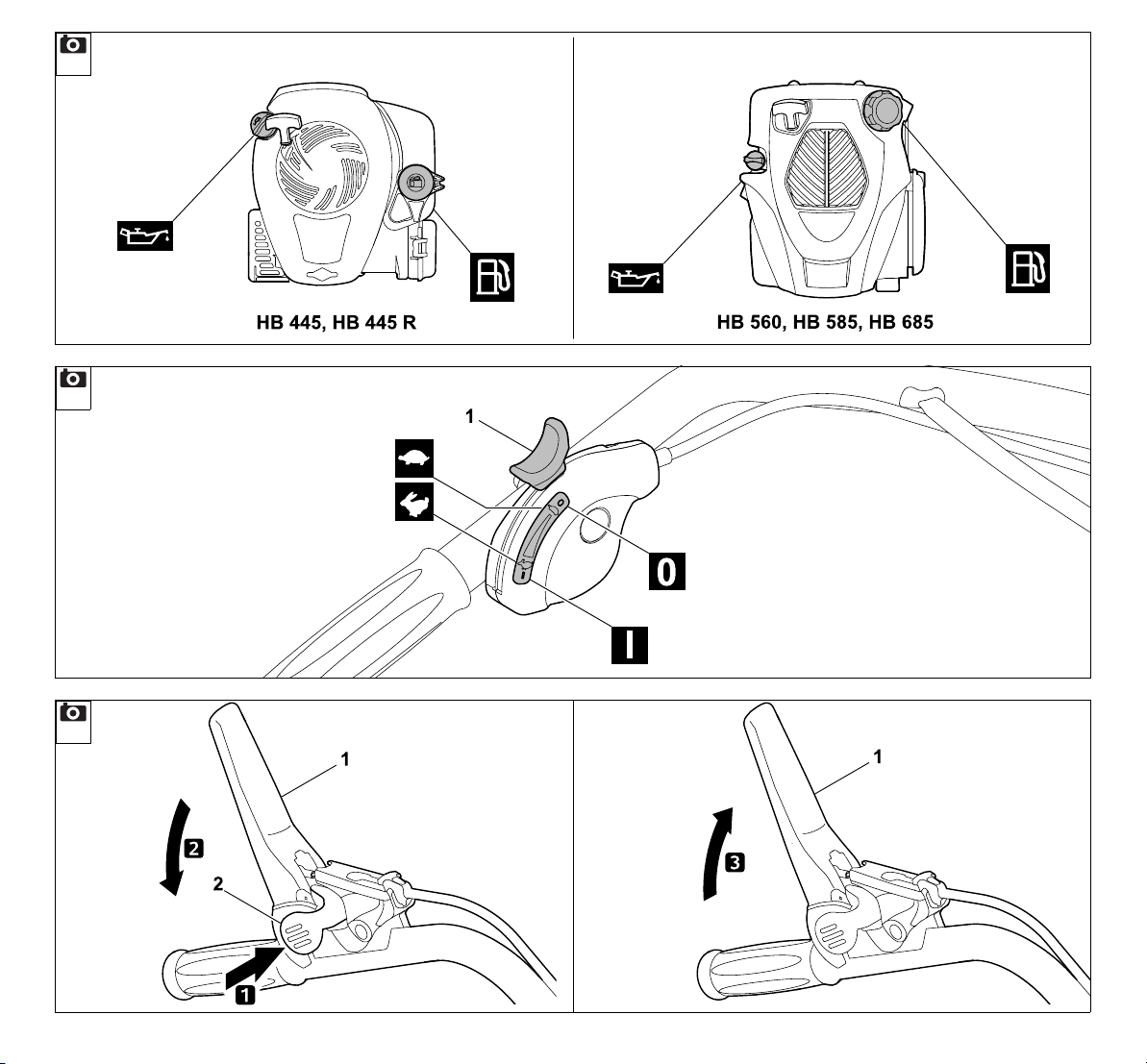

7.15 Fuel and engine oil

16

Avoid damage to the machine

Top up engine oil before starting for

the first time. Use a suitable filling

aid when topping up the engine oil

and when refuelling (e.g. funnel).

Engine oil:

Please consult the engine

instruction manual for the type of

engine oil to be used and the oil capacity.

Check the oil filling level at regular

intervals (see engine instruction manual).

Avoid exceeding or falling below the

correct oil level.

Screw on the oil tank cap properly before

operating the engine.

Fuel:

Recommendation:

Fresh good quality fuels,

unleaded petrol.

Please consult the engine instruction

manual for details on the fuel quality

(octane rating).

8. Controls

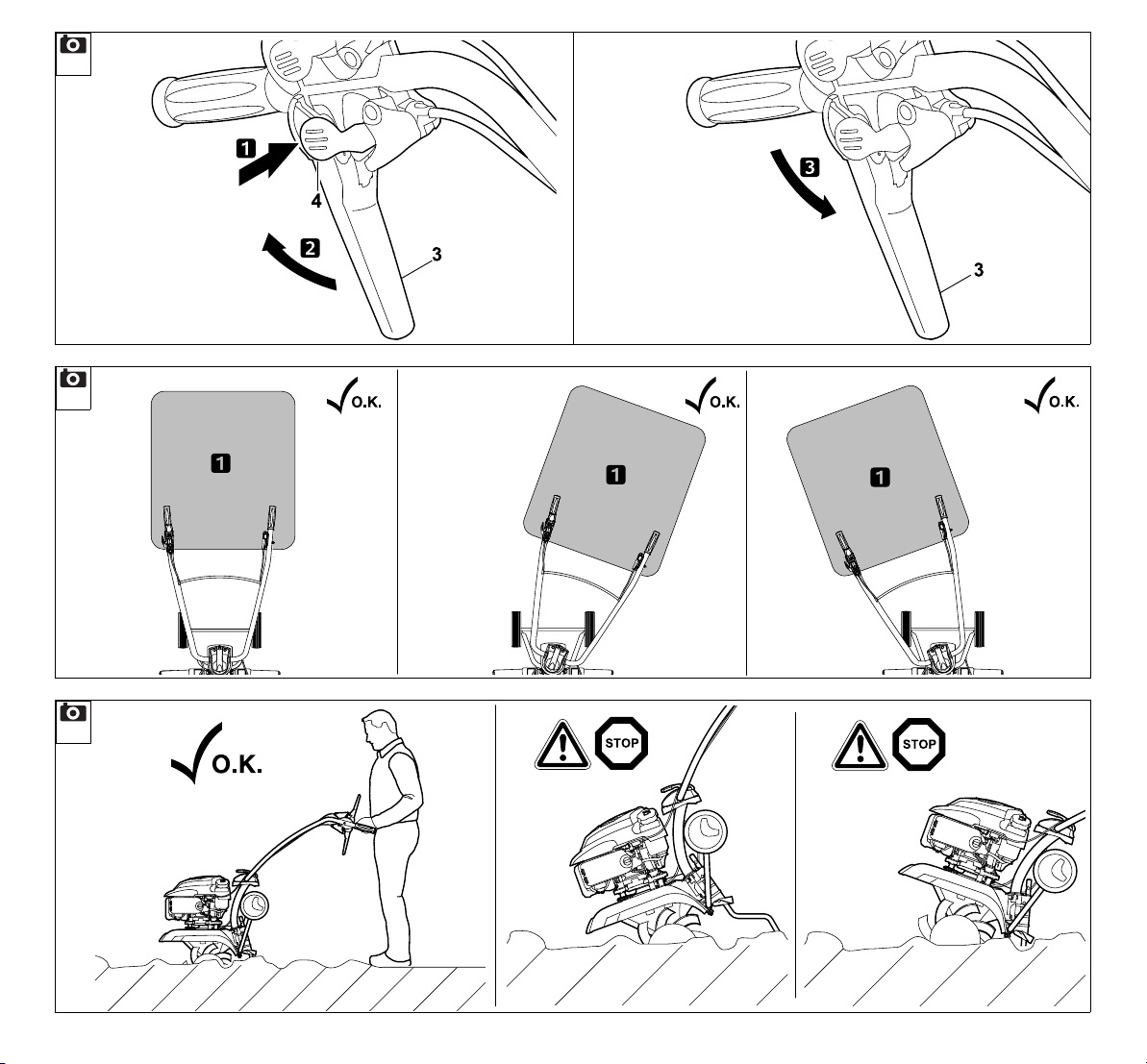

8.1 Throttle lever

The engine speed can be controlled

via throttle lever (1).

Start position:

● Pull throttle lever (1) back to the

stop.

● The engine can be started. (Ö 11.6)

Stop position:

● Push throttle lever (1) forwards

to the stop (note detent).

● The engine stops after a few seconds.

Engine speed control:

● Move throttle lever (1) when the engine

is running.

Engine speed:

Fast

Slow

8.2 Self-propulsion levers

The drive is engaged or disengaged

by actuation of a self-propulsion

lever (1, 3) when the engine is

running – the drive shaft begins to rotate or

is stopped.

When the black self-propulsion lever

(forwards) (1) is actuated and with the

hoes installed, the tiller moves forwards

upon contact with the ground.

17

18

19

When the red self-propulsion lever

(reverse) (3) is actuated and with the hoes

installed, the tiller moves backwards upon

contact with the ground.

The self-propulsion levers and are

mechanically locked for safety reasons.

This prevents inadvertent actuation.

(Ö 9.1)

Furthermore, on models HB 445 R,

HB 560, HB 585 and HB 685, only one

self-propulsion lever can be depressed at

a time due to a mechanical locking device

– either the self-propulsion lever

(forwards) or the self-propulsion lever

(reverse).

Avoid damage to the machine!

Actuation of the self-propulsion

lever should be performed quickly

and promptly. Do not dwell in the

half-pressed position – prevent

excessive wear to the V-belt.

Actuating self-propulsion lever

(forwards):

● 1 Press and hold release

lever (2) to the stop against selfpropulsion lever (forwards) (1).

● 2 Press self-propulsion lever

(forwards) (1) quickly to the stop and

hold.

● Release the release lever (2).

The drive is engaged and the drive

shaft rotates.

● 3 Disengaging the drive:

Release self-propulsion lever

(forwards) (1).

18

32

0478 403 9801 C - EN

Page 35

Actuating self-propulsion lever

(reverse) (HB 445 R, HB 560,

HB 585, HB 685):

● 1 Press and hold release lever (4) to

the stop against self-propulsion lever

(reverse) (3).

● 2 Press self-propulsion lever

(reverse) (3) quickly to the stop and

hold.

● Release the release lever (4).

The drive is engaged and the drive

shaft rotates.

● 3 Disengaging the drive:

Release self-propulsion lever

(reverse) (3).

19

9. Safety devices

The machine is equipped with several

safety devices for safe operation and for

the prevention of improper use.

Risk of injury!

Safety devices must not be

removed, bypassed, modified or

damaged. If a safety device is

found to be defective, the machine

must not be operated. Consult a

specialist dealer; VIKING

recommends VIKING specialist

dealers.

9.1 Self-propulsion lever lock

The self-propulsion levers are

mechanically locked for safety reasons.

This prevents inadvertent actuation.

The relevant release lever must be

pressed before the self-propulsion lever

can be actuated. (Ö 8.2)

9.2 Safety devices

The tiller is equipped with safety devices,

which prevent inadvertent contact with the

work tools and protect against objects

thrown up by the machine.

These include the side impact protectors,

guard plate and correctly-installed

handlebar.

10. Notes on working with the machine

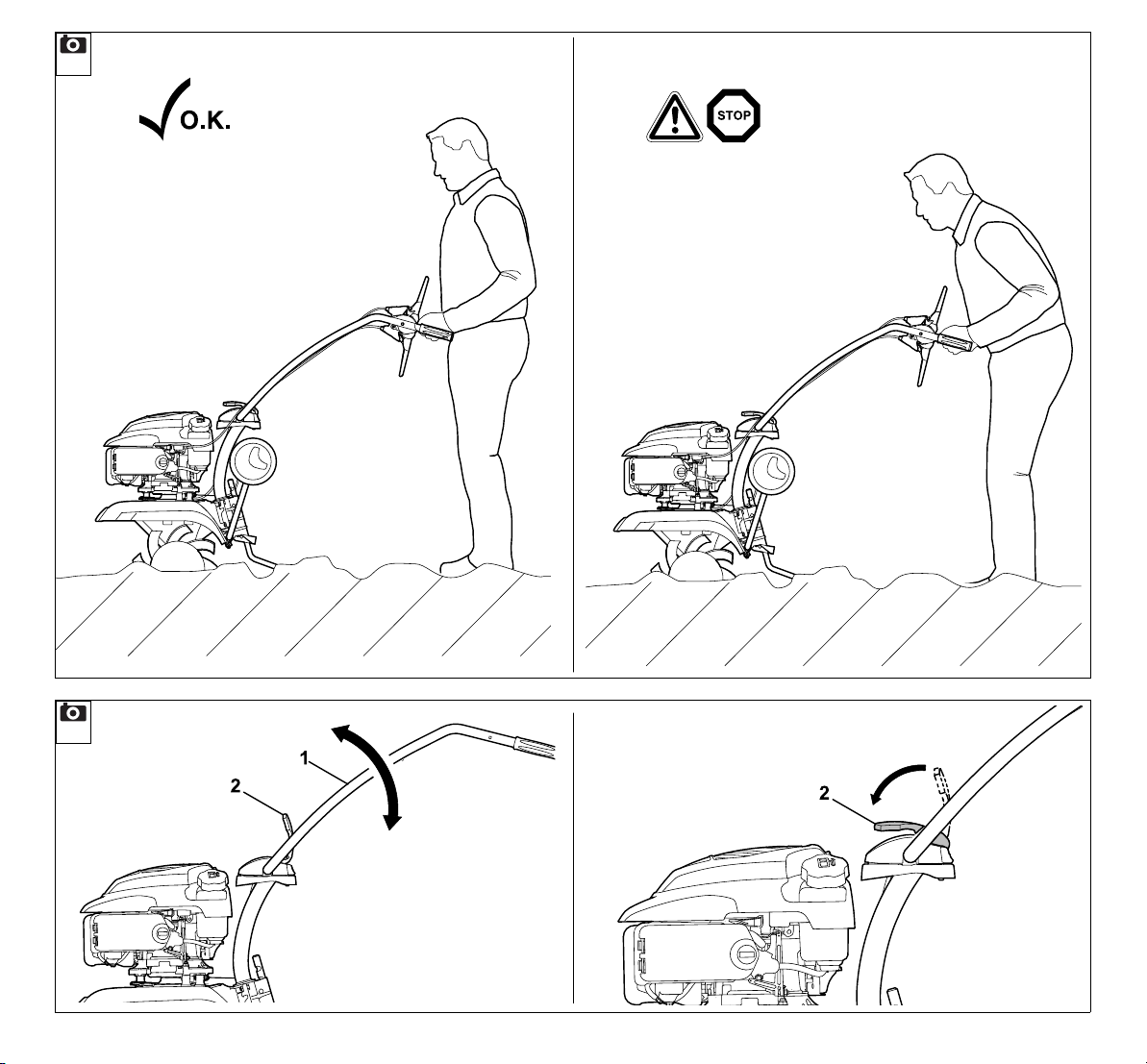

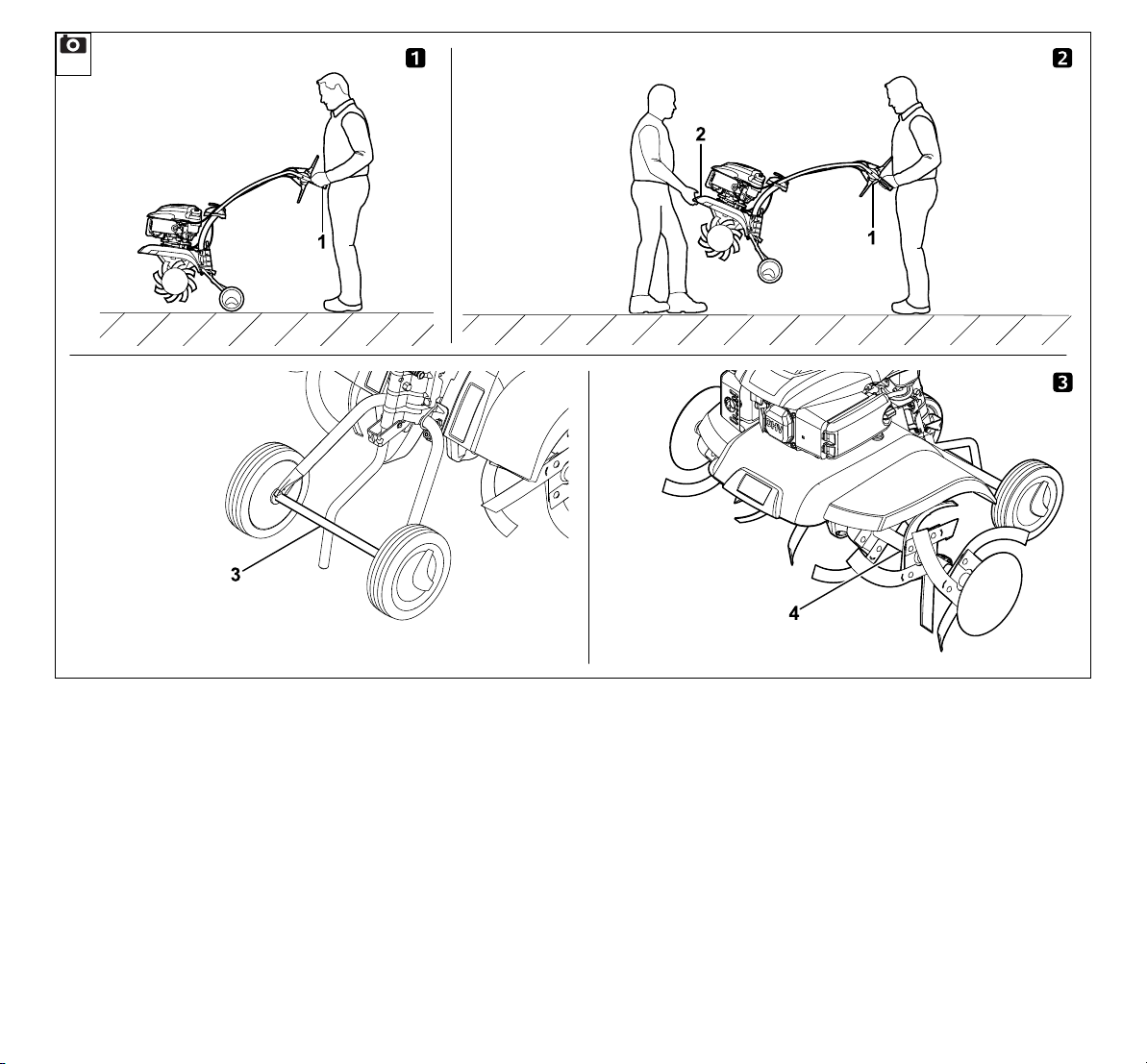

10.1 Working area for operator

● For safety reasons, the operator

must stay within the working area

(grey area 1) for the entire operating

period (when the engine is running).

● The tiller must only be operated by one

person. Other persons must keep out of

the danger area. (Ö 4.)

10.2 Working position of the machine

● The tiller must only be operated

when it is standing on the ground

(engine at the top). The tiller must be

kept as horizontal as possible during

the entire operating period. Avoid

excessive tilting or tipping.

20

21

10.3 Hoe combinations

Always mount the same number of

hoes on the left and right drive

shafts.

The plant protection disc can be

installed in conjunction with all the

hoe combinations described. This

protects the surrounding plants –

when tilling in a narrow bed, for

example.

Possible combinations

HB 445, HB 445 R:

– 2 hoes:

one single-row hoe per drive shaft

– 4 hoes:

two single-row hoes per drive shaft

Possible combinations

HB 560:

– 2 hoes:

one dual-row hoe per drive shaft

Possible combinations

HB 585, HB 685:

– 2 hoes:

one dual-row hoe per drive shaft

– 4 hoes:

one dual-row hoe and one single-row

hoe per drive shaft

10.4 Ideal body position when working

The ideal body position helps to

reduce fatigue during working.

For this purpose, the machine settings

(handlebar height adjustment, brake spur

adjustment) should be selected so that a

straight posture (back) can be maintained

during the entire operating period.

22

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

33

Page 36

Ideal body position:

– straight back

– straight legs

– lower arms bent slightly downwards

11. Operating the machine

11.1 Preparatory measures

Risk of injury!

Please observe the safety

instructions in the "For your safety"

section (Ö 4.) and familiarise

yourself with the controls of the

tiller. (Ö 8.)

● Check engine oil level and refill tank.

(Ö 7.15)

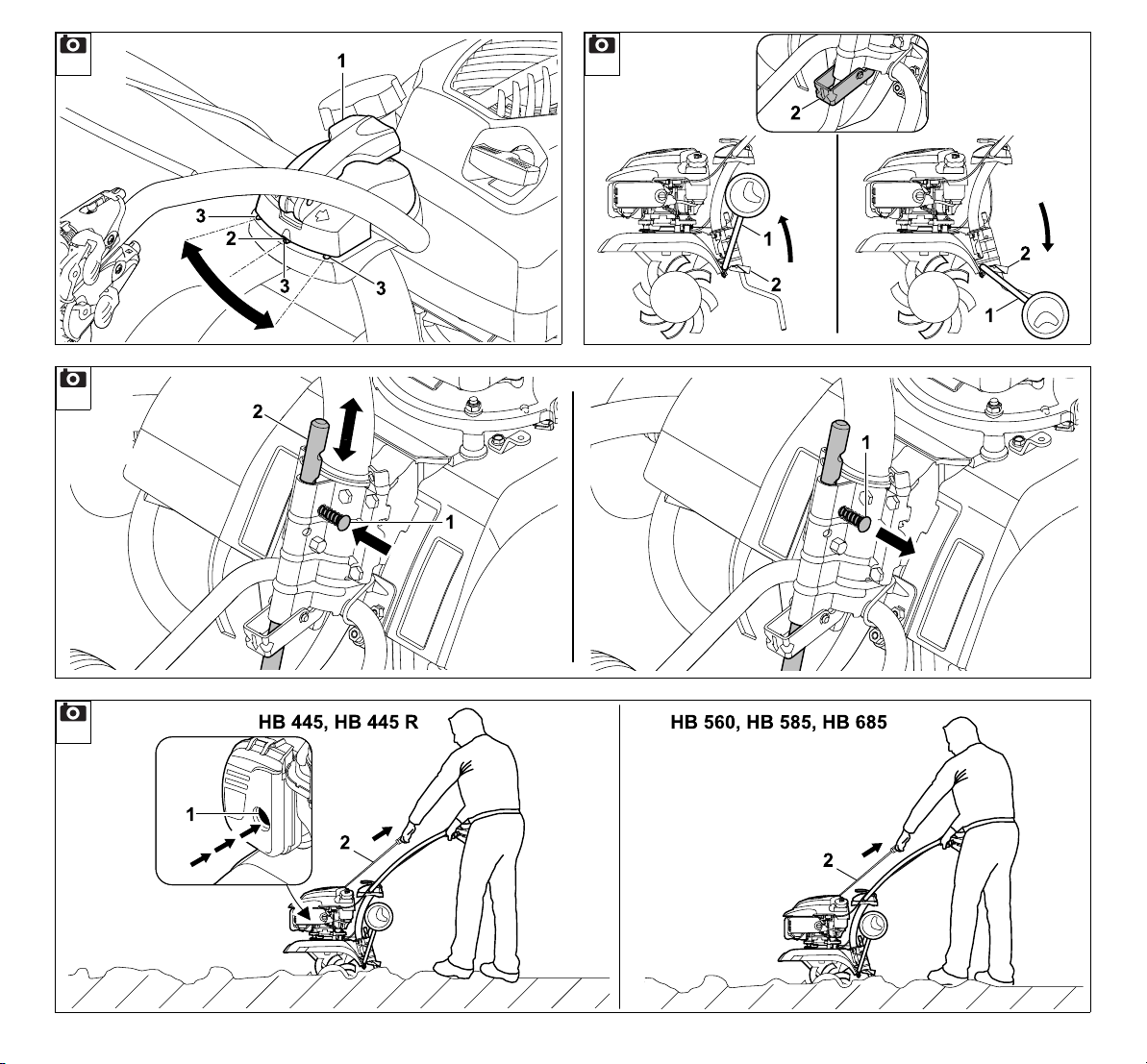

11.2 Height adjustment of the upper handlebar

The height of the upper handlebar

can be adjusted.

● Fold out the transport chassis. (Ö 11.4)

● Firmly grasp upper handlebar (1) at

handle (2) with one hand and hold.

● With the other hand, pull tension

lever (3) towards the rear and hold.

● Set upper handlebar (1) to the required

position.

● Press tension lever (3) forwards and

ensure that the upper handlebar is fully

engaged and fastened.

● Fold in the transport chassis if

necessary. (Ö 11.4)

23

11.3 Lateral adjustment of the handlebar

The handlebar can be adjusted

laterally to three positions.

● Fold out the transport chassis. (Ö 11.4)

● Hold the upper handlebar at a handle

with one hand.

● Pull tension lever (1) upwards with the

hand.

● Move the handlebar into the required

position. Ensure that retaining lug (2) is

located above one of the three

holes (3).

● Press tension lever (1) forwards with

the hand and clamp the handlebar.

● Check the handlebar for secure

seating.

● Fold in the transport chassis if

necessary. (Ö 11.4)

11.4 Folding the transport chassis in and out

With the aid of the transport chassis,

the tiller can be transported by pushing or

pulling.

Risk of injury!

If the transport chassis is in the

working position (folded upwards)

and the release lever is pushed, the

transport chassis can automatically

drop into the transport position.

Folding out the transport chassis –

transport position:

● Raise transport chassis (1) slightly with

one hand and hold.

● Press release lever (2).

24

25

● Fold transport chassis (1) downwards

to the stop and release the pressure on

release lever (2). The transport chassis

engages and is locked in place.

Folding in the transport chassis –

working position:

● Hold transport chassis (1) with the hand

and relieve the weight by lifting slightly.

● Press release lever (2) and fold the

transport chassis upwards.

● Release the pressure on release

lever (2) and fold the transport chassis

upwards to the stop. The transport

chassis engages and is locked in place

in the working position.

11.5 Adjusting the brake spur

The brake spur is used to regulate

the resistance and consequently the

speed of propulsion during tilling. The

brake spur can be adjusted in three stages

for better control.

Adjusting the brake spur:

● Fold out the transport chassis into the

transport position. (Ö 11.4)

Ensure that the machine is standing

stably and securely.

● Press release pin (1) and hold.

● Move brake spur (2) to the desired

position.

● Release the pressure on release pin (1)

and ensure that the brake spur

engages.

26

34

0478 403 9801 C - EN

Page 37

11.6 Starting the engine

Models HB 445 and HB 445 R are

equipped with a primer for cold

starting.

Models HB 560, HB 585 and HB 685

feature an automatic choke (Smart

Choke).

● Set the throttle lever to the start

position. (Ö 8.1)

● Only HB 445, HB 445 R:

if the engine is cold, press primer (1)

three times.

If the engine is warm, do not

actuate the primer.

Operating in very cold weather:

If necessary, actuate the primer

following a work break, as the

engine can cool down quickly.

● Grasp the handle of the recoil starter

rope (2) firmly with one hand and hold.

● Slowly pull out the recoil starter rope (2)

to the point of compression resistance.

Then pull forcefully with one swift tug to

arm's length. Slowly return the recoil

starter rope (2) so that it is rolled up

again.

Repeat the procedure until the engine

starts.

11.7 Stopping the engine

● In order to stop the engine, move the

throttle lever to the Stop position.

(Ö 8.1)

The engine comes to a stop after a

short run-down time.

27

11.8 Engaging and disengaging selfpropulsion (forwards)

Engaging self-propulsion (forwards):

● Move the tiller to the area to be tilled

with the engine stopped. (Ö 13.)

● Start the engine. (Ö 11.6)

● Hold the tiller firmly at the handles with

both hands.

● Actuate and hold the black self-

propulsion lever (forwards). (Ö 8.2)

The drive shaft with the installed work

tools begins to rotate and the tiller

moves forwards.

Disengaging self-propulsion

(forwards):

● Release self-propulsion lever

(forwards). (Ö 8.2)

The drive shaft with the installed work

tools stops.

11.9 Engaging and disengaging selfpropulsion (reverse) (HB 445 R,

HB 560, HB 585, HB 685)

The HB 445 R, HB 560, HB 585 and

HB 685 tillers are equipped with a reverse

gear.

During tilling, the reverse gear serves

exclusively to free the tiller more easily

when it has become stuck. Reverse gear is

not intended for tilling purposes.

Risk of injury!

Ensure sufficient space between

the operator's body and the

handlebar before engaging selfpropulsion (reverse).

Engaging self-propulsion (reverse):

● Move the tiller to the area to be tilled

with the engine stopped. (Ö 13.)

● Start the engine. (Ö 11.6)

● Hold the tiller firmly at the handles with

both hands.

● Actuate and hold the red self-

propulsion lever (reverse). (Ö 8.2)

The drive shaft with the installed work

tools begins to rotate and the tiller

moves backwards.

Disengaging self-propulsion (reverse):

● Release self-propulsion lever (reverse).

(Ö 8.2)

The drive shaft with the installed work

tools stops.

11.10 Tilling

During tilling, rotating hoes are used to

loosen the soil and prepare it for the

sowing, cultivation or care of plants.

Risk of injury!

Only work in a forward direction.

Beware of obstacles (e.g. stone

slabs of paths), which must not be

run over.

● Move the tiller to the area to be tilled

with the engine stopped. (Ö 13.1)

● Fold in the transport chassis. (Ö 11.4)

● Start the engine. (Ö 11.6)

● Hold the tiller firmly at the handles with

both hands and maintain a secure

footing – note working area for

operator. (Ö 10.1)

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

35

Page 38

● Actuate and hold self-propulsion lever

(forwards). (Ö 11.8)

The hoes start to rotate and tilling can

begin.

● After work is completed, disengage

self-propulsion (Ö 11.8), stop the

engine (Ö 11.7) and clean the machine

(Ö 12.2).

12. Maintenance

Risk of injury!

Carefully read the section "For your

safety" (Ö 4.), particularly the

subsection "Maintenance and

repairs" (Ö 4.7), and follow all

safety instructions exactly before

performing any maintenance or

cleaning operations on the

machine.

Detach the spark plug

socket before performing

any maintenance or

cleaning operations.

12.1 Removing the hoes

28

The complete hoe set together with

the plant protection disc can be

removed from the drive shaft by

removing the folding retainer next

to the gearbox housing. For

assembly work on the hoes, follow

the instructions in the "Mounting the

hoes" (Ö 7.7), (Ö 7.8) and "Hoe

combinations" (Ö 10.3) sections.

● Allow the machine (engine, gearbox) to

cool down completely.

● Place the tiller in the cleaning position.

(Ö 12.2)

● Removing the plant protection discs:

Fold open the securing clip of folding

retainer (1) and remove the folding

retainer. Remove plant protection

disc (2).

● Removing the hoes:

Fold open the securing clip of folding

retainer (3) and remove the folding

retainer. Remove the hoe assembly (4).

● Remove the protection rings (5) and

store safely – do not lose!

12.2 Cleaning the machine Maintenance interval:

After each use

● Clean the entire machine thoroughly

after each use. Care of the machine will

protect it against damage and extend its

service life.

● Before cleaning, allow the machine to

cool down completely, detach the spark

plug socket and wear long sleeves and

thick gloves during cleaning work on the

gearbox and hoes.

Cleaning position:

Avoid damage to the machine!

Only place the tiller in the illustrated

position for short periods (cleaning

and maintenance operations).

Place the machine in the upright

position during storage.

● Fold out the transport chassis. (Ö 11.4)

● Move the upper handlebar to the

uppermost position. (Ö 11.2)

● Move the tiller onto firm and level

ground.

29

● Tip the machine backwards until the

handlebar rests on the ground.

Notes on cleaning:

● Remove the dirt and accumulated

deposits using a brush, a damp cloth or

a stick – do not use aggressive cleaning

agents. VIKING recommends the use of

a special cleaner (e.g. STIHL special

cleaner).

● Never spray water onto the handlebar,

engine components, seals or bearing

points. This would result in expensive

repairs.

● Engine:

Remove dirt from the cooling ribs, fan

wheel, area around the air filter,

exhaust, etc. to ensure that the engine

is adequately cooled.

● Gearbox housing, chassis and hoes

can be cleaned using a water jet or

high-pressure cleaner.

Avoid damage to the machine!

When using a high-pressure

cleaner, maintain a distance of at

least 1 m and never direct the

water jet directly at bearing points,

drive shaft or seals – especially the

seal between the gearbox housing

and guard plate.

12.3 Combustion engine Maintenance interval:

Before each use

Check the engine oil level (see engine

instruction manual).

Observe the operating and maintenance

instructions contained in the attached

engine instruction manual.

36

0478 403 9801 C - EN

Page 39

12.4 Service intervals Service by the specialist dealer:

For private use, annually

Maintenance of the tiller should be

performed by a specialist dealer. VIKING

recommends VIKING specialist dealers.

Maintenance by the user:

● Before each use

Check the engine oil level (see engine

instruction manual)

● After each use

Clean the machine. (Ö 12.2)

12.5 Storage and periods of inoperation (winter break)

Store the tiller in the normal position

(transport chassis folded out). For spacesaving storage, fold the handlebar

downwards as shown.

Danger of tipping over!

The tiller can tip over forwards if the

hoes are poorly positioned. For that

reason, always check that the tiller

is stable.

If necessary, turn the hoes slightly

to reduce the top-heaviness.

Alternatively support the tiller in the

area of the carrying handle during

storage.

Store the machine in a dry, locked, dustfree room. Make sure that it is out of the

reach of children.

Any faults must always be remedied prior

to storage. The machine must always be in

a safe operating condition. Keep all nuts,

pins and screws tightly fastened, replace

danger signs and warnings on the

machine that have become illegible and

30

check the entire machine for wear and

damage. Replace all worn and damaged

parts.

Also note the following points when storing

the machine for long periods (winter

break):

● Clean all external parts of the machine

with care.

● Empty the fuel tank and carburettor.

● Thoroughly lubricate/grease all moving

parts.

● Unscrew the spark plug (see engine

instruction manual) and pour approx.

3 cm³ of engine oil into the engine via

the spark plug hole. Turn the engine

several times with the spark plug

removed (pull the recoil starter rope).

Fire hazard!

Keep the spark plug socket away

from the spark plug hole due to the

danger of ignition.

● Screw the spark plug back in (see

engine instruction manual).

● Perform an oil change (see engine

instruction manual).

● Cover the engine and store the

machine in the normal position.

13. Transport

13.1 Transporting the tiller

31

Risk of injury!

Observe the safety instructions in

the "For your safety" section (Ö 4.),

especially the "Transport" section

(Ö 4.4).

Prior to transporting, stop the

engine, detach the spark plug

socket and put on suitable safety

clothing (safety shoes, gloves,

overall covering hands and legs).

Take weight into account! (Ö 18.)

1 Pulling or pushing the tiller:

● Set the brake spur to the highest

position. (Ö 11.5)

● Fold out the transport chassis. (Ö 11.4)

● Hold the tiller at both handles (1) and tilt

backwards until the machine is standing

on the transport wheels.

● Push or pull the tiller slowly (walking

pace).

On firm and level ground, push the

machine. On rough and uneven ground,

it is advisable to pull the machine.

ENNO

SVFIDASLSKTRHUSRHRBGUKETMK

0478 403 9801 C - EN

37

Page 40

Risk of injury!

Due to the heavy weight of the

machine, particular care must be

taken at steps, kerbs, sloping

ramps and other raised areas.

The user must always stand higher

than the machine, in order to avoid

being run over by the machine in

the case of loss of control – i.e.

push the machine down or pull the

machine up steps and slopes.

Do not push or pull the machine

over more than two or three steps.

Where there are more steps, carry

the tiller with the help of a second

person.

2 Lifting or carrying the tiller:

● Check that the upper handlebar is

seated securely.

● Lift and carry the tiller with at least two

persons and always maintain a

sufficient distance from the hoes.

Lifting points:

Handles (1) and carrying handle (2)

3 Transporting the tiller on a load

floor:

● Always transport the tiller in the upright

position – on the transport chassis and

hoes. Never place the machine on its

side.

● To ensure stability, fold out the

transport chassis (Ö 11.4) and mount

the hoes (Ö 7.7), (Ö 7.8).

● Secure the tiller on the load floor using

ropes or straps to prevent it from

slipping.

Lashing points:

Transport chassis axle (3) and hoe

axle (4).

14. Environmental protection

The machine, its packaging and

accessories are all produced

from recyclable materials and

must be disposed of

accordingly.

By disposing of materials separately and in

an environmentally-friendly manner,

valuable resources can be re-used. For

this reason, the machine should be

disposed of for recycling at the end of its

useful life.

14.1 Disposal

Waste products such as used oil (engine

oil, gearbox oil) and fuel must always be

disposed of properly.

Render the engine unusable prior to

disposal. In particular, remove the ignition

lead, empty the fuel tank and drain the

engine oil.

Risk of injury from the hoes!

Always store an old tiller in a safe place

prior to scrapping. Make sure that the

machine and the hoes are kept out of the

reach of children.

15. Minimising wear and preventing damage

Important information on maintenance

and care of the product group

Petrol tillers (HB)

VIKING assumes no liability for material or

personal damage caused by the nonobservance of information contained in the

operating instructions, in particular with

regard to safety, operation and

maintenance, or which arise through the

use of unauthorised attachment or spare

parts.

Please always observe the following

important information for the prevention of

damage or excessive wear to your VIKING

machine:

1. Wearing parts

Some parts of the VIKING machine are

subject to normal wear even when used

properly and must be replaced in due time

depending on type and duration of use.

These include:

–V-belt

–Hoe

– Brake spur

2. Compliance with the information in

this instruction manual

The VIKING machine must be used,

maintained and stored with the care

described in this instruction manual. Any

damage caused by non-compliance with

the safety, operating and maintenance

instructions is the sole responsibility of the

user.

This applies in particular to:

– Product modifications not approved by

VIKING.

– Use of fuel and lubricants not approved

by VIKING (lubricants, petrol and

engine oil, see engine manufacturer's

specifications).

– The use of tools or accessories which

are not approved or suitable for the

machine, or are of inferior quality.

– Improper use of the product.

38

0478 403 9801 C - EN

Page 41

– Use of the product for sporting or

competitive events.

– Resultant damage due to continued use

of the product with defective

components.

3. Maintenance operations

All operations listed in the section

"Maintenance" must be performed

regularly.

If these maintenance operations cannot be

carried out by the user, a specialist dealer

must be commissioned to perform them.

VIKING recommends that you have

maintenance operations and repairs

performed exclusively by a VIKING

specialist dealer.

VIKING specialist dealers regularly attend

training courses and are provided with

technical information.

If these operations are neglected, faults

may arise which are the responsibility of

the user.

These include: