Vertex Standard VX-1400 series Service Manual

VERTEX STANDARD CO., LTD.

4-8-8 Nakameguro, Meguro-Ku, Tokyo 153-8644, Japan

VERTEX STANDARD

US Headquarters

VX-1400 Series

HF Multi Mode Mobile Radio

Service Manual

©2009 VERTEX STANDARD CO., LTD. EC091H90A

10900 Walker Street, Cypress, CA 90630, U.S.A.

YAESU UK LTD.

Unit 12, Sun Valley Business Park, Winnall Close

Winchester, Hampshire, SO23 0LB, U.K.

VERTEX STANDARD HK LTD.

Unit 5, 20/F., Seaview Centre, 139-141 Hoi Bun Road,

Kwun Tong, Kowloon, Hong Kong

VERTEX STANDARD (AUSTRALIA) PTY., LTD.

Normanby Business Park, Unit 14/45 Normanby Road

Notting Hill 3168, Victoria, Australia

Introduction

This manual provides the technical information necessary for

servicing the VX-1400 HF Transceiver.

Servicing this equipment requires expertise in handing sur-

face-mount chip components. Attempts by non-qualified per-

sons to service this equipment may result in permanent dam-

age not covered by the warranty, and may be illegal in some

countries.

Two PCB layout diagrams are provided for each double-sided

board in this transceiver. Each side of the board is referred to

by the type of the majority of components installed on that side (“Side A” or “Side B”). In most cases one side

has only chip components (surface-mount devices), and the other has either a mixture of both chip and leaded

components (trimmers, coils, electrolytic capacitors, ICs, etc.), or leaded components only.

As described in the pages to follow, the advanced microprocessor design of the VX-1400 Transceiver allows a

complete alignment of this transceiver to be performed without opening the case of the radio; all adjustments

can be performed from the front panel, using the “Alignment Mode” menu.

While we believe the information in this manual to be correct, VERTEX STANDARD assumes no liability for

damage that may occur as a result of typographical or other errors that may be present. Your cooperation in

pointing out any inconsistencies in the technical information would be appreciated.

Important Note

1) This transceiver was assembled using Pb (lead) free solder, based on the RoHS specification.

Only lead-free solder (Alloy Composition: Sn-3.0Ag-0.5Cu) should be used for repairs performed on this apparatus. The

solder stated above utilizes the alloy composition required for compliance with the lead-free specification, and any solder

with the above alloy composition may be used.

2) Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries according to the instructions.

Contents

Specifications ...................................................................................................................................................... 2

Exploded View & Miscellaneous Parts .......................................................................................................... 3

Block Diagram.....................................................................................................................................................5

Connection Diagram ..........................................................................................................................................6

Alignment ............................................................................................................................................................ 7

Board Units (Schematics, Layouts & Parts)

PANEL Unit ................................................................................................................................................ 15

MAIN Unit .................................................................................................................................................. 23

PA Unit ........................................................................................................................................................ 47

ALE-2 Unit (Option) ..................................................................................................................................59

1VX-1400 Series Service Manual

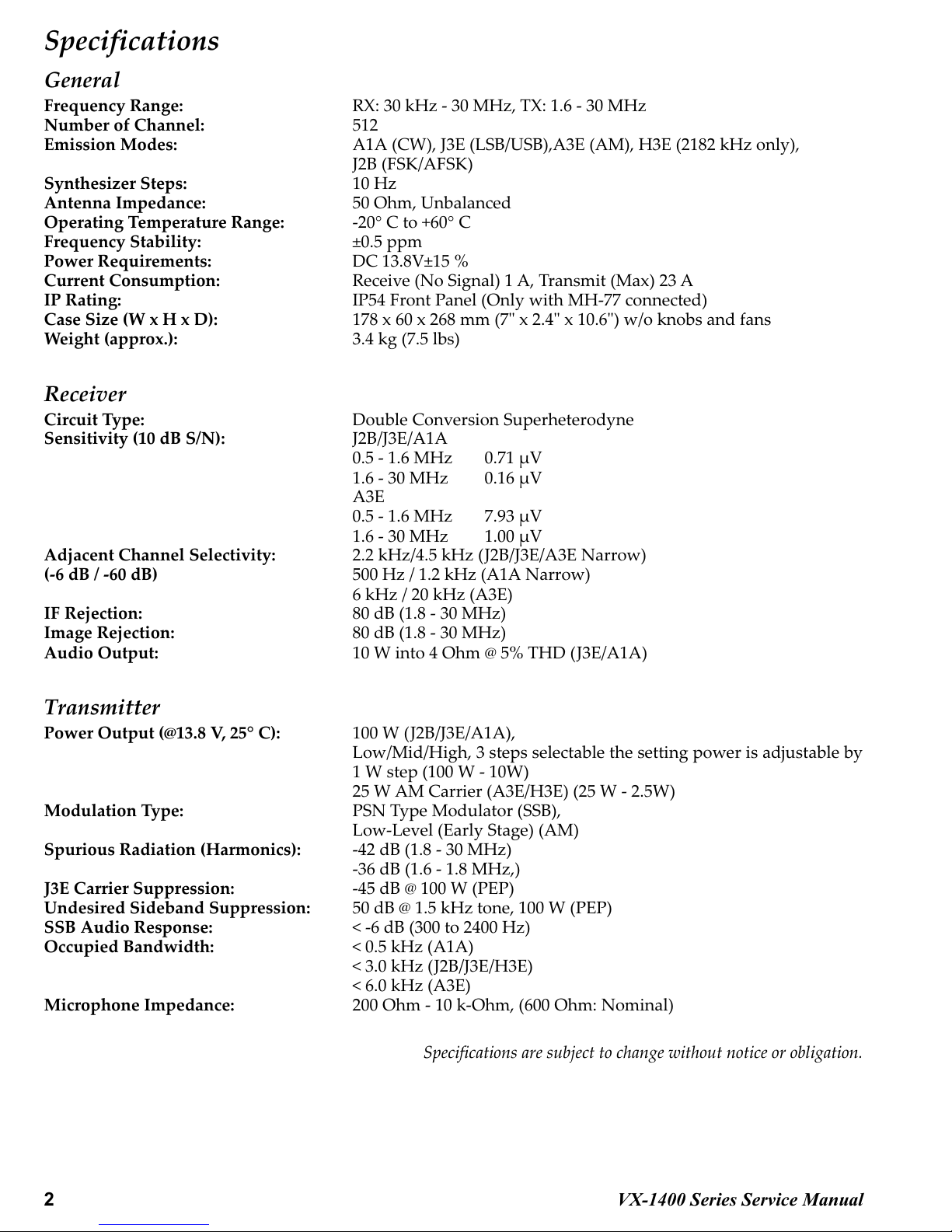

Specifications

General

Frequency Range: RX: 30 kHz - 30 MHz, TX: 1.6 - 30 MHz

Number of Channel: 512

Emission Modes: A1A (CW), J3E (LSB/USB),A3E (AM), H3E (2182 kHz only),

J2B (FSK/AFSK)

Synthesizer Steps: 10 Hz

Antenna Impedance: 50 Ohm, Unbalanced

Operating Temperature Range: -20° C to +60° C

Frequency Stability: ±0.5 ppm

Power Requirements: DC 13.8V±15 %

Current Consumption: Receive (No Signal) 1 A, Transmit (Max) 23 A

IP Rating: IP54 Front Panel (Only with MH-77 connected)

Case Size (W x H x D): 178 x 60 x 268 mm (7" x 2.4" x 10.6") w/o knobs and fans

Weight (approx.): 3.4 kg (7.5 lbs)

Receiver

Circuit Type: Double Conversion Superheterodyne

Sensitivity (10 dB S/N): J2B/J3E/A1A

0.5 - 1.6 MHz 0.71 µV

1.6 - 30 MHz 0.16 µV

A3E

0.5 - 1.6 MHz 7.93 µV

1.6 - 30 MHz 1.00 µV

Adjacent Channel Selectivity: 2.2 kHz/4.5 kHz (J2B/J3E/A3E Narrow)

(-6 dB / -60 dB) 500 Hz / 1.2 kHz (A1A Narrow)

6 kHz / 20 kHz (A3E)

IF Rejection: 80 dB (1.8 - 30 MHz)

Image Rejection: 80 dB (1.8 - 30 MHz)

Audio Output: 10 W into 4 Ohm @ 5% THD (J3E/A1A)

Transmitter

Power Output (@13.8 V, 25° C): 100 W (J2B/J3E/A1A),

Low/Mid/High, 3 steps selectable the setting power is adjustable by

1 W step (100 W - 10W)

25 W AM Carrier (A3E/H3E) (25 W - 2.5W)

Modulation Type: PSN Type Modulator (SSB),

Low-Level (Early Stage) (AM)

Spurious Radiation (Harmonics): -42 dB (1.8 - 30 MHz)

-36 dB (1.6 - 1.8 MHz,)

J3E Carrier Suppression: -45 dB @ 100 W (PEP)

Undesired Sideband Suppression: 50 dB @ 1.5 kHz tone, 100 W (PEP)

SSB Audio Response: < -6 dB (300 to 2400 Hz)

Occupied Bandwidth: < 0.5 kHz (A1A)

< 3.0 kHz (J2B/J3E/H3E)

< 6.0 kHz (A3E)

Microphone Impedance: 200 Ohm - 10 k-Ohm, (600 Ohm: Nominal)

Specifications are subject to change without notice or obligation.

2 VX-1400 Series Service Manual

3

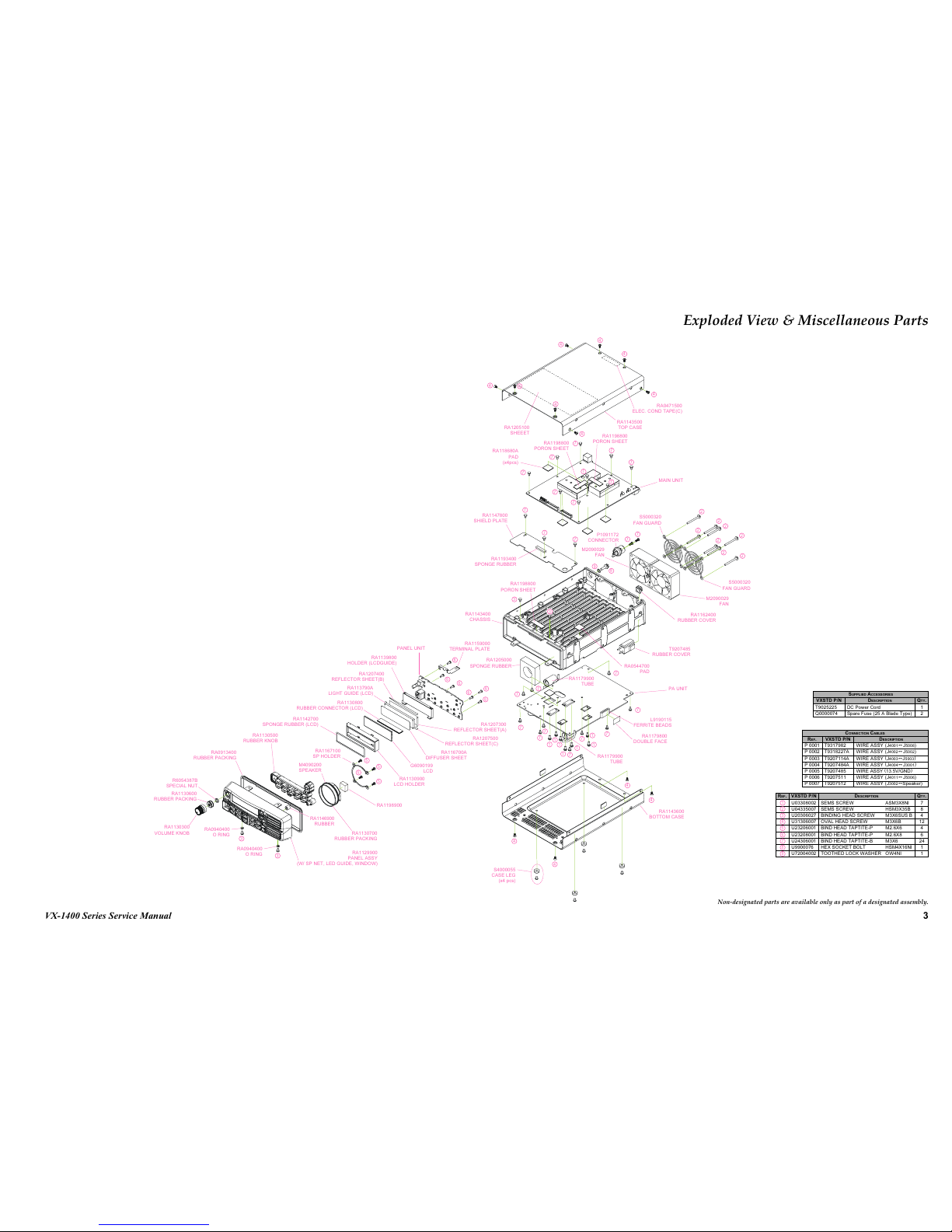

Exploded View & Miscellaneous Parts

VX-1400 Series Service Manual

VXSTD P/N

U03308002

U04335007

U20306027

U31306007

U23206001

U23208001

U24306001

U9900076

U72004002

SEMS SCREW

SEMS SCREW

BINDING HEAD SCREW

OVAL HEAD SCREW

BIND HEAD TAPTITE-P

BIND HEAD TAPTITE-P

BIND HEAD TAPTITE-B

HEX SOCKET BOLT

TOOTHED LOCK WASHER

ASM3X8NI

HSM3X35B

M3X6SUS B

M3X6B

M2.6X6

M2.6X8

M3X6

HSM4X16NI

OW4NI

QTY.

7

8

4

12

4

6

24

1

1

REF.

1

2

3

4

5

6

7

8

9

DESCRIPTION

Non-designated parts are available only as part of a designated assembly.

VXSTD P/N

T9317982

T9318227A

T9207114A

T9207484A

T9207485

T9207511

T9207512

DESCRIPTION

WIRE ASSY (J4001 J 5008

)

WIRE ASSY (J4002 J 5002

)

WIRE ASSY (J4003 J5003

)

WIRE ASSY (J4004 J 3001

)

WIRE ASSY (13.5V/GND

)

WIRE ASSY (J4011 J 5006

)

WIRE ASSY (J3002 Speaker

)

CONNECTION CABLES

REF.

P 0001

P 0002

P 0003

P 0004

P 0005

P 0006

P 0007

VXSTD P/N

T9025225

Q0000074

DESCRIPTION

DC Power Cord

Spare Fuse (25 A Blade Type)

QTY.

1

2

SUPPLIED ACCESSORIES

M4090200

SPEAKER

S5000320

FAN GUARD

S5000320

FAN GUARD

RA1130300

VOLUME KNOB

RA1143500

TOP CASE

RA1143600

BOTTOM CASE

PANEL UNIT

MAIN UNIT

PA UNIT

RA1129900

PANEL ASSY

(W/ SP NET, LED GUIDE, WINDOW)

RA1167100

SP HOLDER

RA1146900

RUBBER

RA1159000

TERMINAL PLATE

RA1130500

RUBBER KNOB

RA1130600

RUBBER PACKING

RA0913400

RUBBER PACKING

RA0940400

O RING

RA1143400

CHASSIS

RA1147800

SHIELD PLATE

RA0544700

PAD

R6054387B

SPECIAL NUT

RA1179800

DOUBLE FACE

RA1179900

TUBE

RA1162400

RUBBER COVER

S4000055

CASE LEG

(x4 pcs)

RA116700A

DIFFUSER SHEET

RA113790A

LIGHT GUIDE (LCD)

RA1139800

HOLDER (LCDGUIDE)

RA1207300

REFLECTOR SHEET(A)

RA1130800

RUBBER CONNECTOR (LCD)

RA1130900

LCD HOLDER

RA1142700

SPONGE RUBBER (LCD)

G6090199

LCD

M2090029

FAN

M2090029

FAN

2

2

2

2

2

2

2

2

8

9

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

P1091172

CONNECTOR

7

7

L9190115

FERRITE BEADS

1

1

1

1

1

1

1

3

3

3

RA1130700

RUBBER PACKING

RA0940400

O RING

4

6

6

6

6

5

5

4

4

4

4

4

4

4

4

4

4

4

5

5

6

6

RA1198900

RA1205000

SPONGE RUBBER

RA1198800

PORON SHEET

RA1193400

SPONGE RUBBER

RA1205100

SHEEET

RA0471500

ELEC. COND TAPE(C)

RA1198800

PORON SHEET

RA1198800

PORON SHEET

RA118680A

PAD

(x4pcs)

3

T9207485

RUBBER COVER

RA1207400

REFLECTOR SHEET(B)

RA1207500

REFLECTOR SHEET(C)

RA1179900

TUBE

4

Exploded View & Miscellaneous Parts

VX-1400 Series Service Manual

Note

5

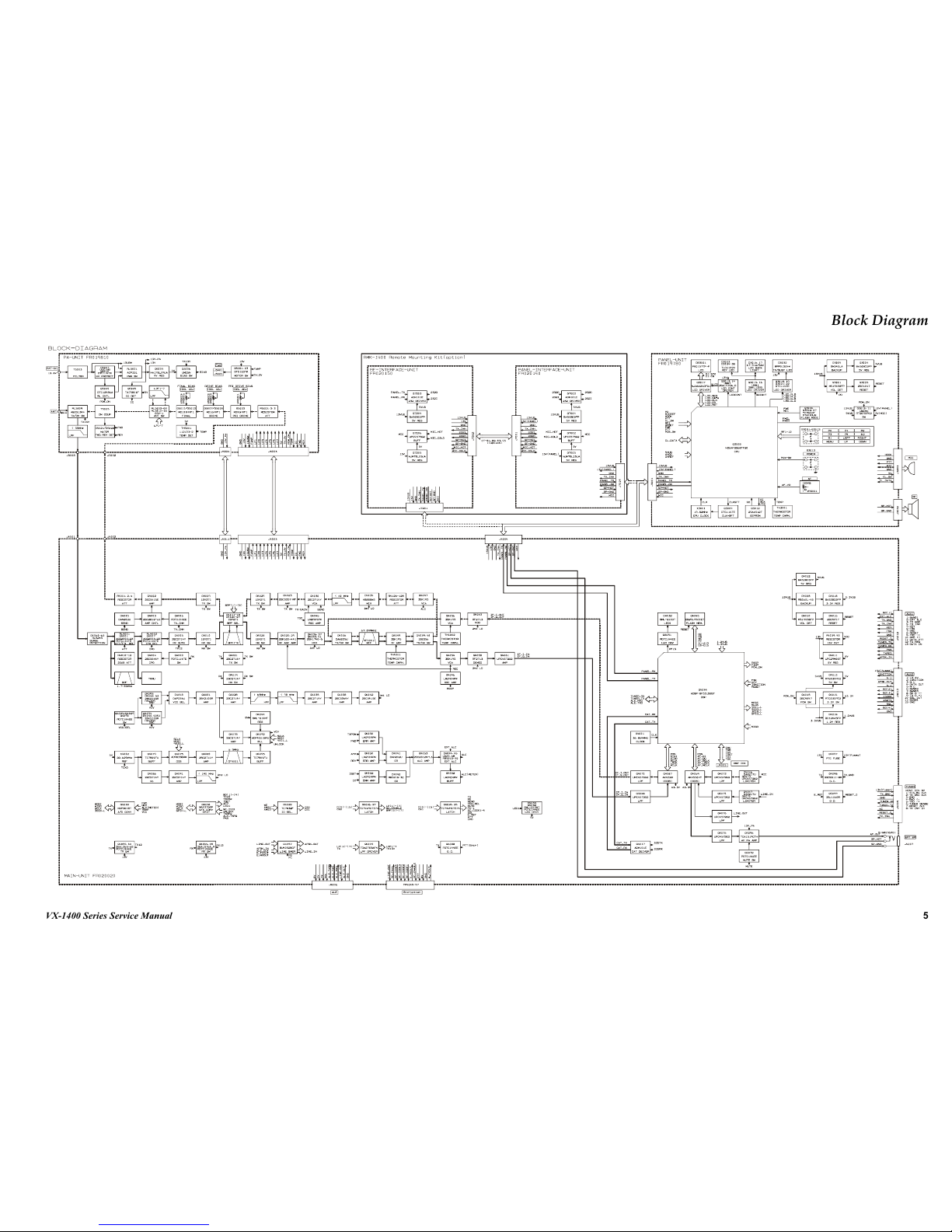

Block Diagram

VX-1400 Series Service Manual

6

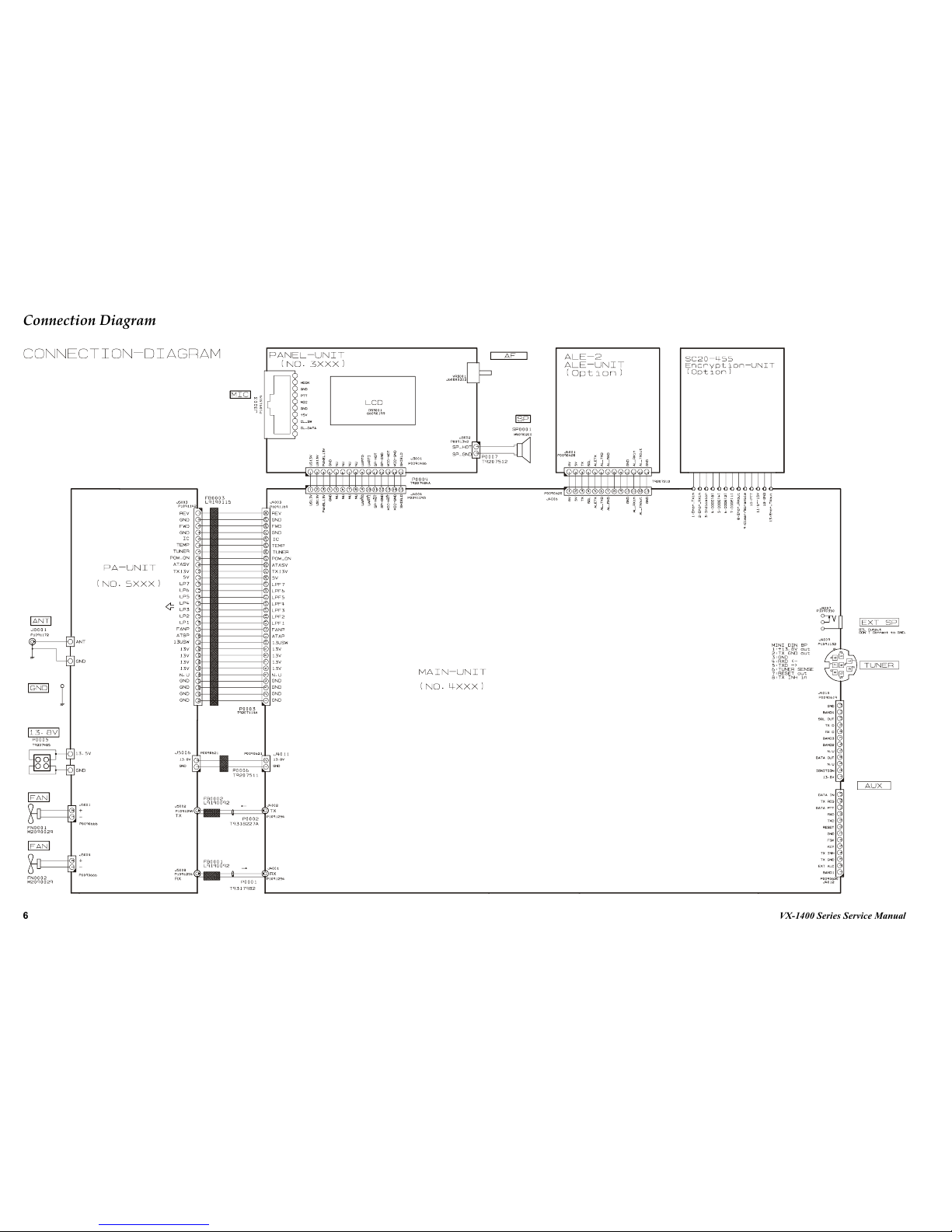

Connection Diagram

VX-1400 Series Service Manual

Alignment

Introduction and Precautions

The following procedures cover adjustments that are not

normally required once the transceiver has left the facto-

ry. However, if a problem occurs during normal opera-

tion due to component failure; realignment may be re-

quired after the faulty components have been replaced.

We recommend that authorized Vertex Standard Techni-

cians, who are experienced with the circuitry and fully

equipped to repair and align our products, perform re-

pairs. If a fault is suspected, contact the selling dealer for

instructions regarding repair. Authorized Vertex Standard

Technicians have the latest information to align all cir-

cuits and make complete performance checks to ensure

compliance with factory specifications after repairs.

Those who undertake the following alignments are cau-

tioned to proceed at their own risk. Problems caused by

unauthorized attempts at realignment are not covered by

the warranty policy.

Vertex Standard must reserve the right to change circuits

and alignment procedures in the interest of improved

performance, without notifying owners.

Under no circumstances should any alignment be at-

tempted unless the normal functions and operation of the

transceiver are clearly understood, the cause of the mal-

function has been clearly identified and all faulty compo-

nents replaced. The need for realignment should be de-

termined to be necessary.

The following test equipment (and a thorough familiari-

ty with its correct use) is necessary for correct alignment.

Most steps do not require all of the equipment listed. The

interactions of some adjustments may require that sever-

al adjustments be performed in a sequence. Do not at-

tempt to perform only a single step unless it is clearly

isolated electrically from all other steps. Have all test

equipment ready before beginning, and follow all of the

steps in a section in the order they are presented.

Required Test Equipment

RF Signal Generator

AF Signal Generator

Spectrum Analyzer good to at least 1 GHz.

Frequency Counter

RF Millivoltmeter

Digital DC Voltmeter (high-Z, 1 M-Ohm/V)

DC Voltmeter

DC Ammeter (20 A)

Ohmmeter

50-Ohm Dummy Load (150 watts)

150-Ohm Dummy Load (150 watts)

In-Line Wattmeter (100 watts, 50-Ohm)

RF Sampling Coupler

4-Ohm AF Dummy Load (15 watts)

IBM® PC / compatible Computer with Windows

Vista/XP/2000

Vertex Standard VPL-1 or FIF-10 + CT-104A Pro-

gramming Cable & CE111 Programming Soft-

ware

Alignment Preparation & Precautions

A 50-ohm RF Dummy load and in-line wattmeter must

be connected to the "ANT" jack in all procedures that call

for transmission, except where specified otherwise. Cor-

rect alignment is not possible with an antenna.

After completing one step, read the following step to de-

termine whether the same test equipment will be required.

If not, remove the unneeded test equipment before pro-

ceeding (except the dummy load and wattmeter).

Correct alignment requires that the ambient temperature

be maintained constant between 68 °F ~ 86 °F (20 °C ~ 30

°C). When the transceiver is brought into the shop from a

hot or cold environment, it should be allowed time to come

to room temperature before alignment. Also, the test

equipment must be thoroughly warmed up before begin-

ning.

®

Whenever possible, alignments should be made with os-

cillator shields and circuit boards firmly affixed in place.

Note: Signal levels in dB referred to in this procedure

are based on 0 dBµ = 0.5 µV (closed circuit).

Caution: Do not connect the audio output line to ground,

and be certain that the speaker has adequate ca-

pability to handle the audio output from the

radio.

7VX-1400 Series Service Manual

Alignment

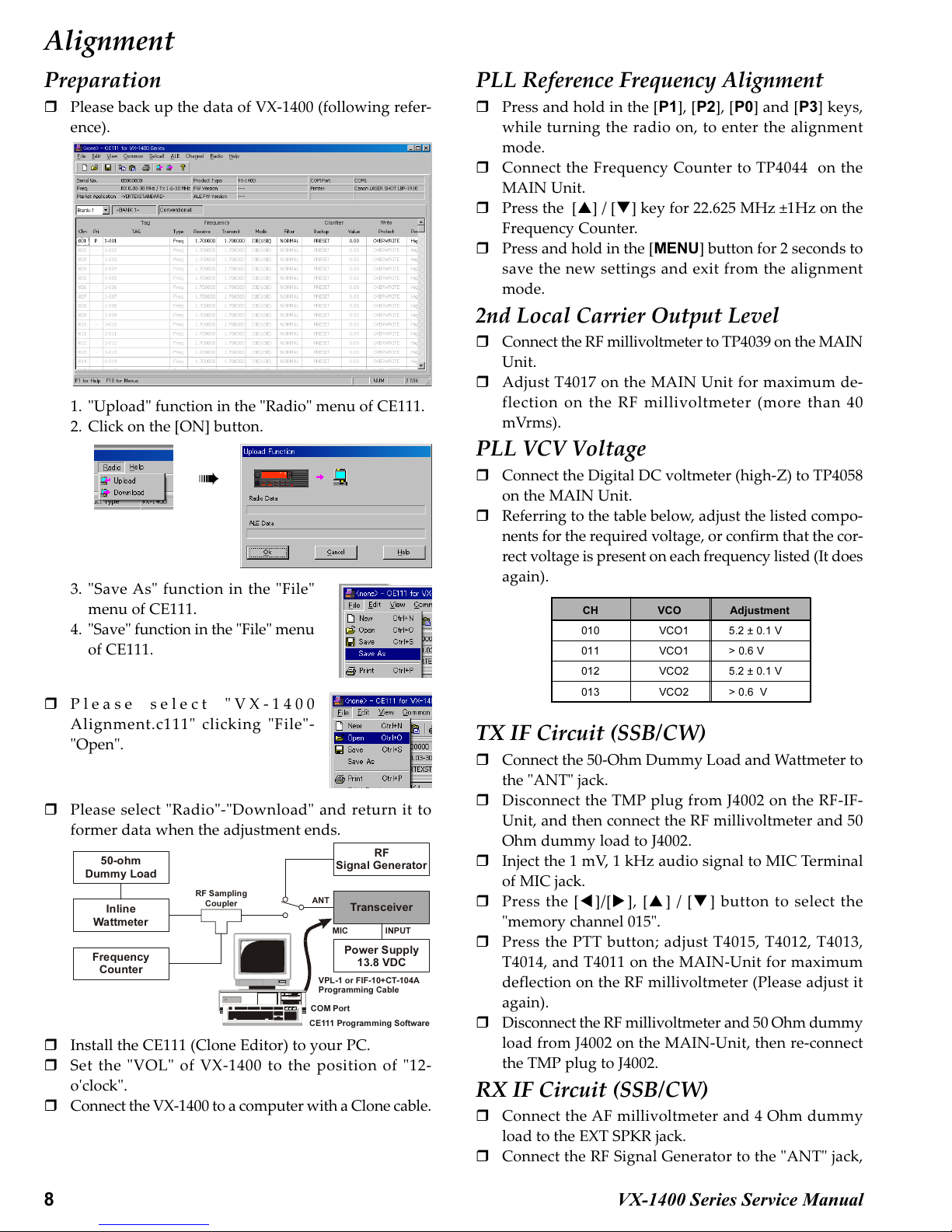

Preparation

Please back up the data of VX-1400 (following refer-

ence).

1. "Upload" function in the "Radio" menu of CE111.

2. Click on the [ON] button.

➠

3. "Save As" function in the "File"

menu of CE111.

4. "Save" function in the "File" menu

of CE111.

Please select "VX-1400

Alignment.c111" clicking "File"-

"Open".

Please select "Radio"-"Download" and return it to

former data when the adjustment ends.

50-ohm

Dummy Load

Inline

Wattmeter

Frequency

Counter

RF Sampling

Coupler

ANT

VPL-1 or FIF-10+CT-104A

Programming Cable

COM Port

CE111 Programming Software

Install the CE111 (Clone Editor) to your PC.

Set the "VOL" of VX-1400 to the position of "12-

o'clock".

Connect the VX-1400 to a computer with a Clone cable.

RF

Signal Generator

Transceiver

MIC

INPUT

Power Supply

13.8 VDC

PLL Reference Frequency Alignment

Press and hold in the [P1], [P2], [P0] and [P3] keys,

while turning the radio on, to enter the alignment

mode.

Connect the Frequency Counter to TP4044 on the

MAIN Unit.

Press the [] / [] key for 22.625 MHz ±1Hz on the

Frequency Counter.

Press and hold in the [MENU] button for 2 seconds to

save the new settings and exit from the alignment

mode.

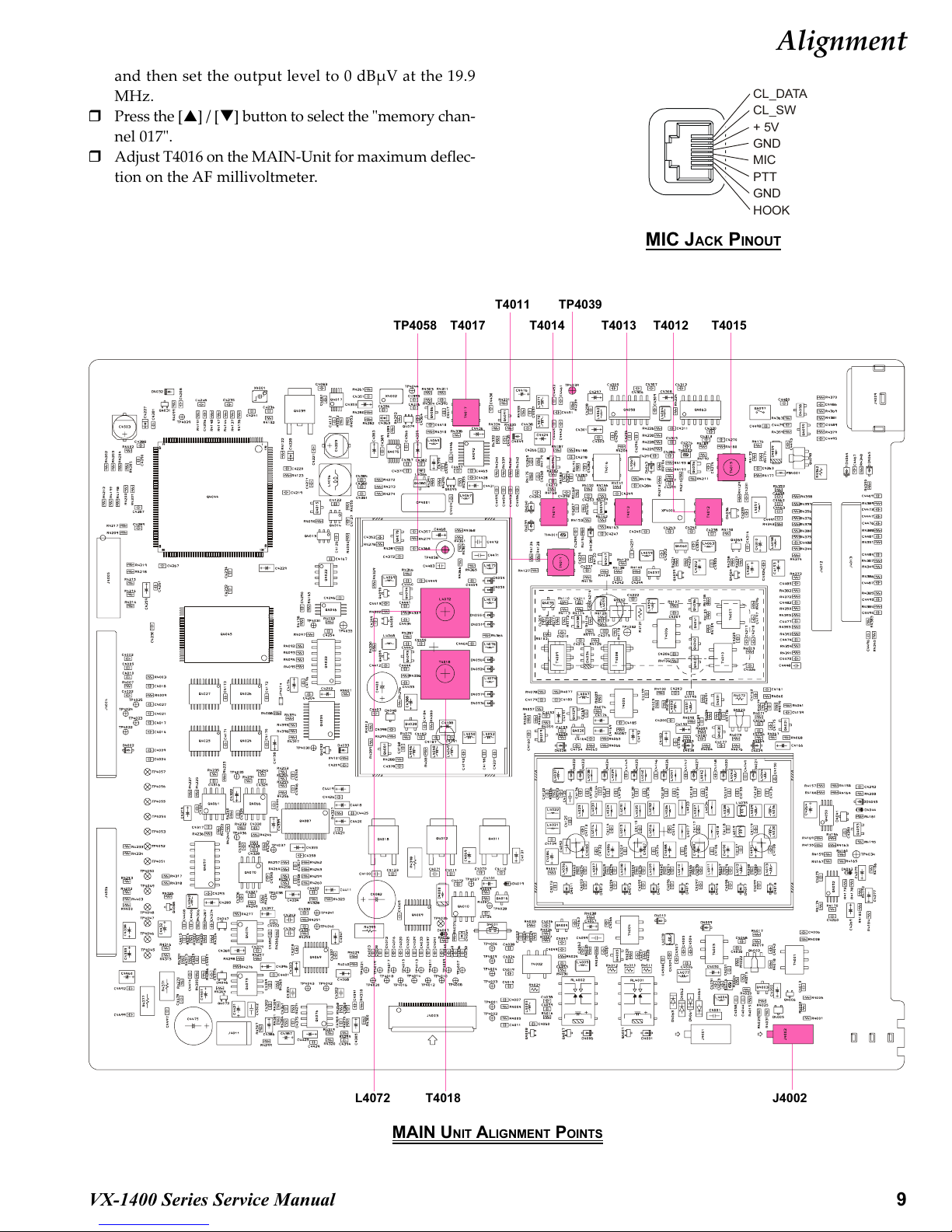

2nd Local Carrier Output Level

Connect the RF millivoltmeter to TP4039 on the MAIN

Unit.

Adjust T4017 on the MAIN Unit for maximum de-

flection on the RF millivoltmeter (more than 40

mVrms).

PLL VCV Voltage

Connect the Digital DC voltmeter (high-Z) to TP4058

on the MAIN Unit.

Referring to the table below, adjust the listed compo-

nents for the required voltage, or confirm that the cor-

rect voltage is present on each frequency listed (It does

again).

CH

010

011

012

013

VCO

VCO1

VCO1

VCO2

VCO2

Adjustment

5.2 ± 0.1 V

> 0.6 V

5.2 ± 0.1 V

> 0.6 V

TX IF Circuit (SSB/CW)

Connect the 50-Ohm Dummy Load and Wattmeter to

the "ANT" jack.

Disconnect the TMP plug from J4002 on the RF-IF-

Unit, and then connect the RF millivoltmeter and 50

Ohm dummy load to J4002.

Inject the 1 mV, 1 kHz audio signal to MIC Terminal

of MIC jack.

Press the [⊳ ]/[ ], [] / [ ] button to select the

"memory channel 015".

Press the PTT button; adjust T4015, T4012, T4013,

T4014, and T4011 on the MAIN-Unit for maximum

deflection on the RF millivoltmeter (Please adjust it

again).

Disconnect the RF millivoltmeter and 50 Ohm dummy

load from J4002 on the MAIN-Unit, then re-connect

the TMP plug to J4002.

RX IF Circuit (SSB/CW)

Connect the AF millivoltmeter and 4 Ohm dummy

load to the EXT SPKR jack.

Connect the RF Signal Generator to the "ANT" jack,

8 VX-1400 Series Service Manual

and then set the output level to 0 dBµV at the 19.9

MHz.

Press the [] / [] button to select the "memory chan-

nel 017".

Adjust T4016 on the MAIN-Unit for maximum deflec-

tion on the AF millivoltmeter.

Alignment

CL_DATA

CL_SW

+ 5V

GND

MIC

PTT

GND

HOOK

MIC JACK PINOUT

TP4058

T4011

T4017 T4015T4014 T4013 T4012

TP4039

T4018L4072

MAIN UNIT ALIGNMENT POINTS

J4002

9VX-1400 Series Service Manual

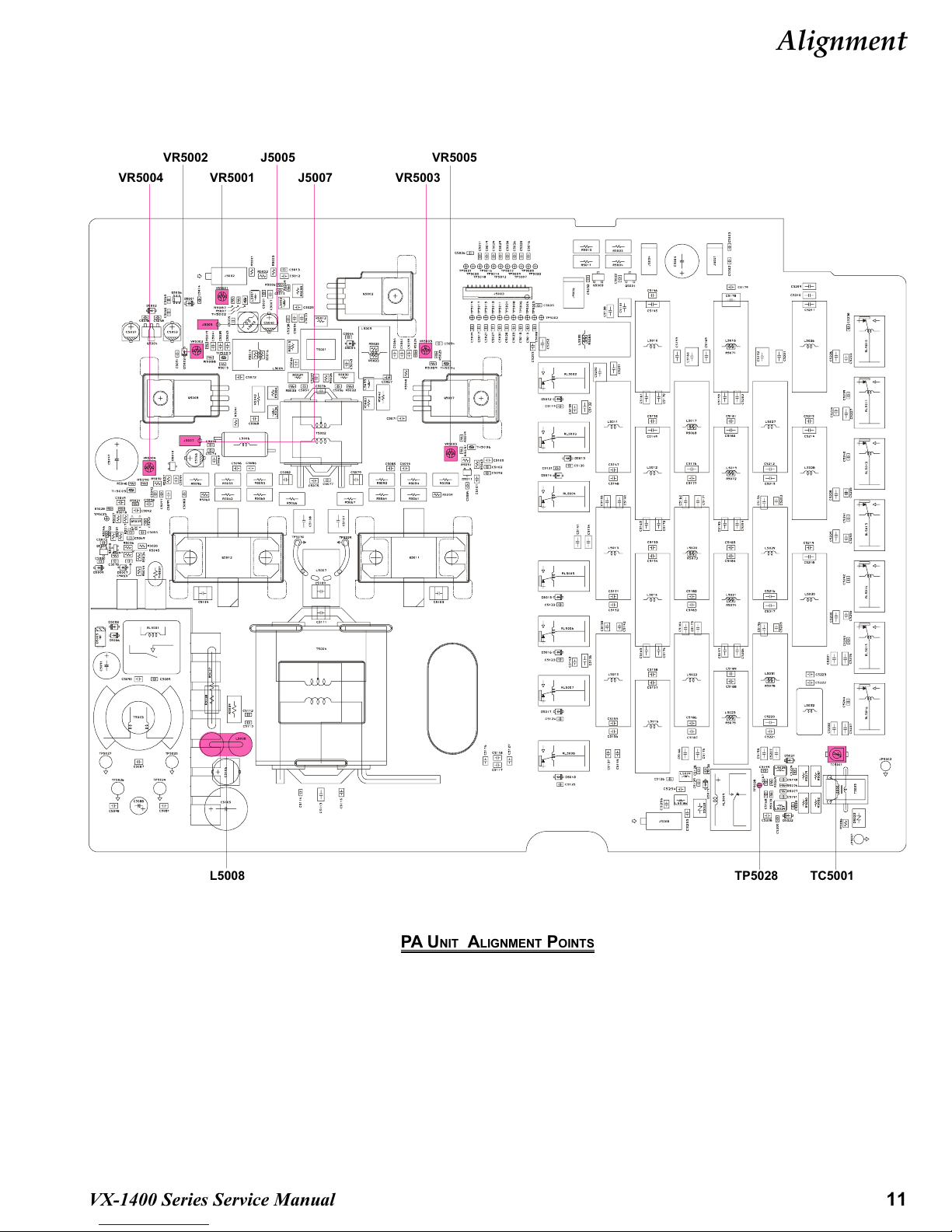

Alignment

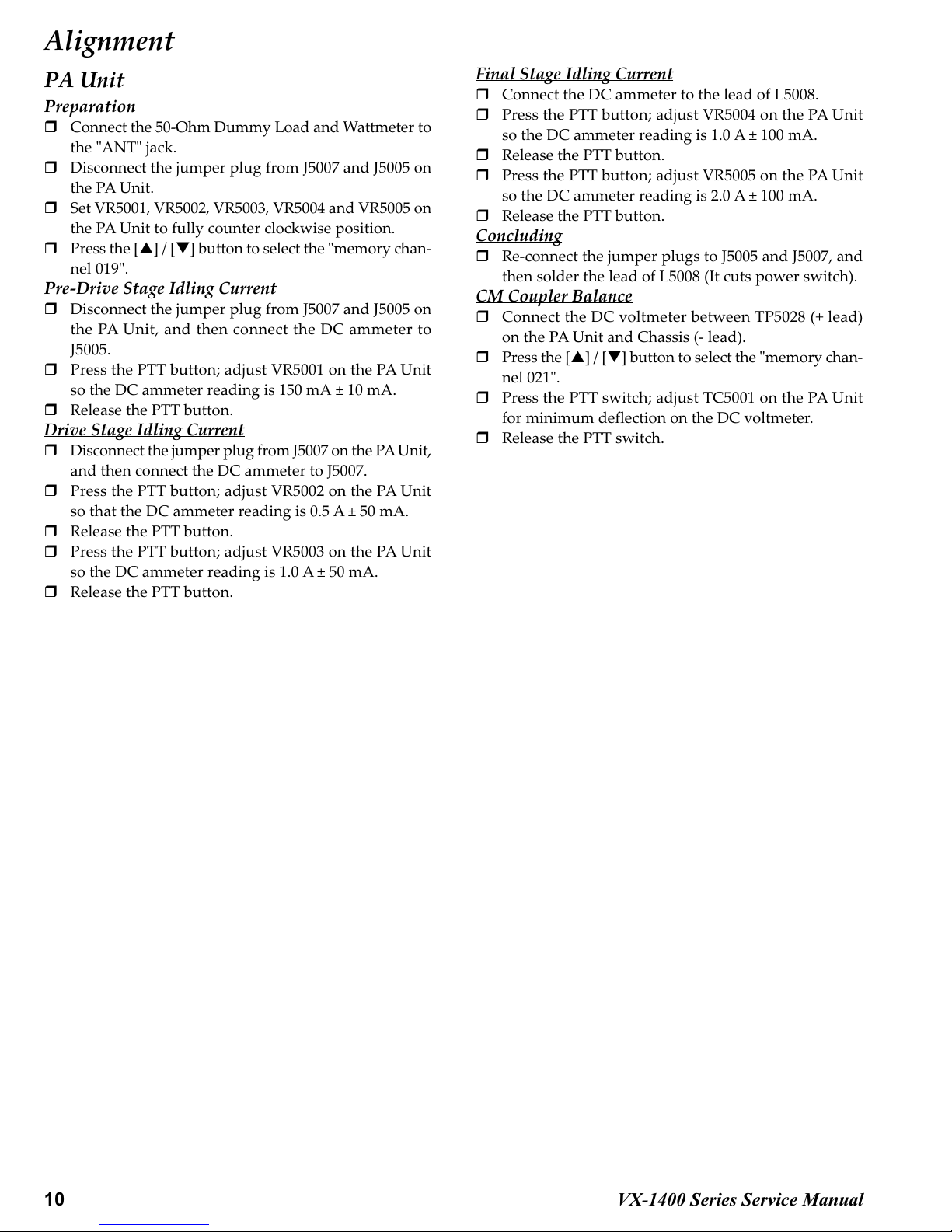

PA Unit

Preparation

Connect the 50-Ohm Dummy Load and Wattmeter to

the "ANT" jack.

Disconnect the jumper plug from J5007 and J5005 on

the PA Unit.

Set VR5001, VR5002, VR5003, VR5004 and VR5005 on

the PA Unit to fully counter clockwise position.

Press the [] / [] button to select the "memory chan-

nel 019".

Pre-Drive Stage Idling Current

Disconnect the jumper plug from J5007 and J5005 on

the PA Unit, and then connect the DC ammeter to

J5005.

Press the PTT button; adjust VR5001 on the PA Unit

so the DC ammeter reading is 150 mA ± 10 mA.

Release the PTT button.

Drive Stage Idling Current

Disconnect the jumper plug from J5007 on the PA Unit,

and then connect the DC ammeter to J5007.

Press the PTT button; adjust VR5002 on the PA Unit

so that the DC ammeter reading is 0.5 A ± 50 mA.

Release the PTT button.

Press the PTT button; adjust VR5003 on the PA Unit

so the DC ammeter reading is 1.0 A ± 50 mA.

Release the PTT button.

Final Stage Idling Current

Connect the DC ammeter to the lead of L5008.

Press the PTT button; adjust VR5004 on the PA Unit

so the DC ammeter reading is 1.0 A ± 100 mA.

Release the PTT button.

Press the PTT button; adjust VR5005 on the PA Unit

so the DC ammeter reading is 2.0 A ± 100 mA.

Release the PTT button.

Concluding

Re-connect the jumper plugs to J5005 and J5007, and

then solder the lead of L5008 (It cuts power switch).

CM Coupler Balance

Connect the DC voltmeter between TP5028 (+ lead)

on the PA Unit and Chassis (- lead).

Press the [] / [] button to select the "memory chan-

nel 021".

Press the PTT switch; adjust TC5001 on the PA Unit

for minimum deflection on the DC voltmeter.

Release the PTT switch.

10 VX-1400 Series Service Manual

Alignment

VR5004

VR5002

VR5001

J5005

J5007

VR5005

VR5003

L5008

PA U NIT ALIGNMENT POINTS

TP5028

TC5001

11VX-1400 Series Service Manual

Alignment

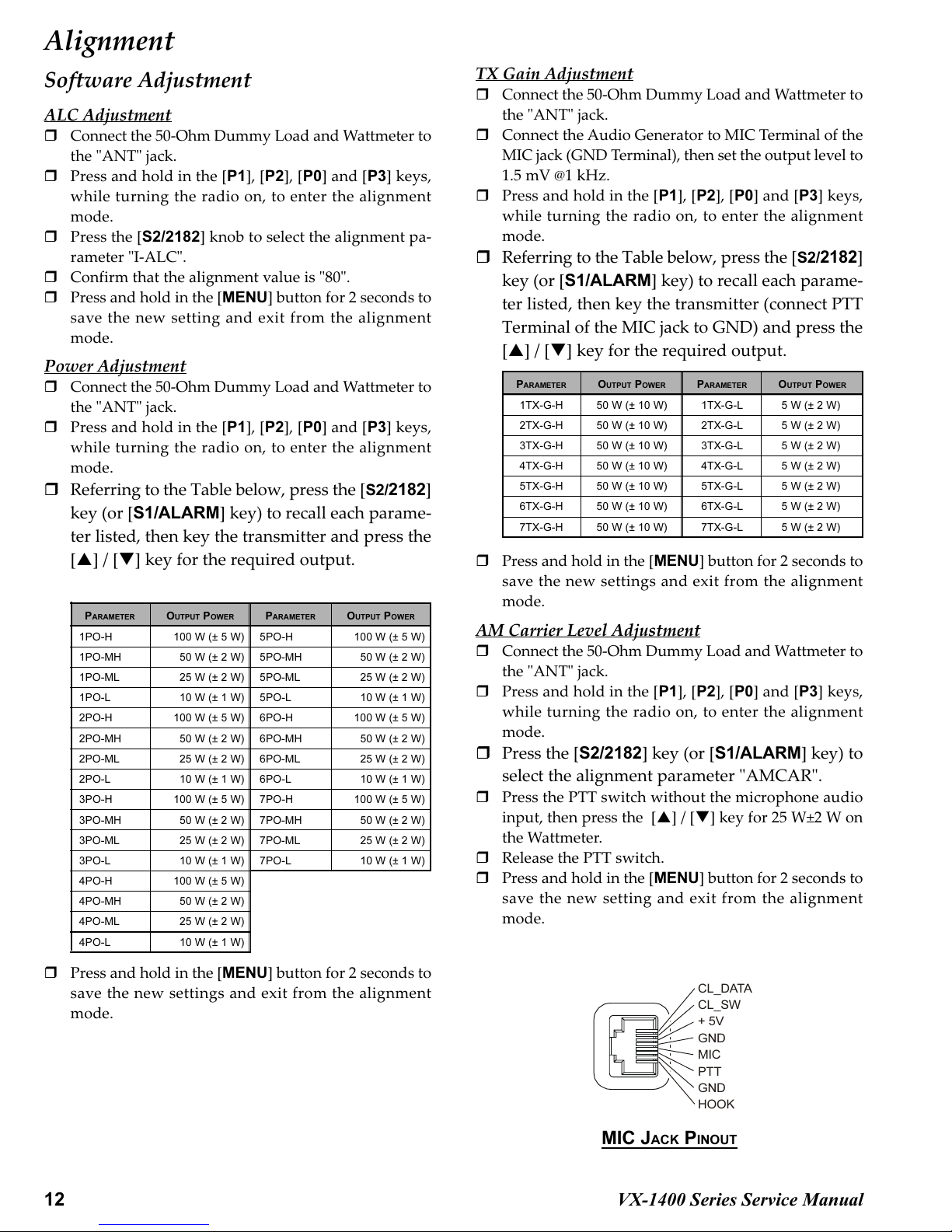

Software Adjustment

ALC Adjustment

Connect the 50-Ohm Dummy Load and Wattmeter to

the "ANT" jack.

Press and hold in the [P1], [P2], [P0] and [P3] keys,

while turning the radio on, to enter the alignment

mode.

Press the [S2/2182] knob to select the alignment pa-

rameter "I-ALC".

Confirm that the alignment value is "80".

Press and hold in the [MENU] button for 2 seconds to

save the new setting and exit from the alignment

mode.

Power Adjustment

Connect the 50-Ohm Dummy Load and Wattmeter to

the "ANT" jack.

Press and hold in the [P1], [P2], [P0] and [P3] keys,

while turning the radio on, to enter the alignment

mode.

Referring to the Table below, press the [S2/2182]

key (or [S1/ALARM] key) to recall each parame-

ter listed, then key the transmitter and press the

[] / [] key for the required output.

PARAMETER

1PO-H

1PO-MH

1PO-ML

1PO-L

2PO-H

2PO-MH

2PO-ML

2PO-L

3PO-H

3PO-MH

3PO-ML

3PO-L

4PO-H

4PO-MH

4PO-ML

4PO-L

OUTPUT POWER

100 W (± 5 W)

50 W (± 2 W)

25 W (± 2 W)

10 W (± 1 W)

100 W (± 5 W)

50 W (± 2 W)

25 W (± 2 W)

10 W (± 1 W)

100 W (± 5 W)

50 W (± 2 W)

25 W (± 2 W)

10 W (± 1 W)

100 W (± 5 W)

50 W (± 2 W)

25 W (± 2 W)

10 W (± 1 W)

PARAMETER

5PO-H

5PO-MH

5PO-ML

5PO-L

6PO-H

6PO-MH

6PO-ML

6PO-L

7PO-H

7PO-MH

7PO-ML

7PO-L

OUTPUT POWER

100 W (± 5 W)

50 W (± 2 W)

25 W (± 2 W)

10 W (± 1 W)

100 W (± 5 W)

50 W (± 2 W)

25 W (± 2 W)

10 W (± 1 W)

100 W (± 5 W)

50 W (± 2 W)

25 W (± 2 W)

10 W (± 1 W)

TX Gain Adjustment

Connect the 50-Ohm Dummy Load and Wattmeter to

the "ANT" jack.

Connect the Audio Generator to MIC Terminal of the

MIC jack (GND Terminal), then set the output level to

1.5 mV @1 kHz.

Press and hold in the [P1], [P2], [P0] and [P3] keys,

while turning the radio on, to enter the alignment

mode.

Referring to the Table below, press the [S2/2182]

key (or [S1/ALARM] key) to recall each parame-

ter listed, then key the transmitter (connect PTT

Terminal of the MIC jack to GND) and press the

[] / [] key for the required output.

PARAMETER

1TX-G-H

2TX-G-H

3TX-G-H

4TX-G-H

5TX-G-H

6TX-G-H

7TX-G-H

Press and hold in the [MENU] button for 2 seconds to

save the new settings and exit from the alignment

mode.

OUTPUT POWER

50 W (± 10 W)

50 W (± 10 W)

50 W (± 10 W)

50 W (± 10 W)

50 W (± 10 W)

50 W (± 10 W)

50 W (± 10 W)

PARAMETER

1TX-G-L

2TX-G-L

3TX-G-L

4TX-G-L

5TX-G-L

6TX-G-L

7TX-G-L

OUTPUT POWER

5 W (± 2 W)

5 W (± 2 W)

5 W (± 2 W)

5 W (± 2 W)

5 W (± 2 W)

5 W (± 2 W)

5 W (± 2 W)

AM Carrier Level Adjustment

Connect the 50-Ohm Dummy Load and Wattmeter to

the "ANT" jack.

Press and hold in the [P1], [P2], [P0] and [P3] keys,

while turning the radio on, to enter the alignment

mode.

Press the [S2/2182] key (or [S1/ALARM] key) to

select the alignment parameter "AMCAR".

Press the PTT switch without the microphone audio

input, then press the [] / [] key for 25 W±2 W on

the Wattmeter.

Release the PTT switch.

Press and hold in the [MENU] button for 2 seconds to

save the new setting and exit from the alignment

mode.

Press and hold in the [MENU] button for 2 seconds to

save the new settings and exit from the alignment

mode.

CL_DATA

CL_SW

+ 5V

GND

MIC

PTT

GND

HOOK

MIC JACK PINOUT

12 VX-1400 Series Service Manual

Reverse ALC Adjustment

Connect the 150-Ohm Dummy Load to the "ANT" jack.

Press and hold in the [P1], [P2], [P0] and [P3] keys,

while turning the radio on, to enter the alignment

mode.

Press the [S2/2182] key (or [S1/ALARM] key) to se-

lect the alignment parameter "1R-ALC".

Press the PTT switch, then press the [] / [] key for

50 W on the PO meter of the VX-1400.

Release the PTT switch.

RPress the [S2/2182] key (or [S1/ALARM] key) to se-

lect the alignment parameter "2R-ALC".

Press the PTT switch, then press the [] / [] key for

50 W on the PO meter of the VX-1400.

Release the PTT switch.

Press the [S2/2182] key (or [S1/ALARM] key) to se-

lect the alignment parameter "3R-ALC".

Press the PTT switch, then press the [] / [] key for

50 W on the PO meter of the VX-1400.

Release the PTT switch.

Press and hold in the [MENU] button for 2 seconds to

save the new settings and exit from the alignment

mode.

Alignment

13VX-1400 Series Service Manual

Alignment

Note

14 VX-1400 Series Service Manual

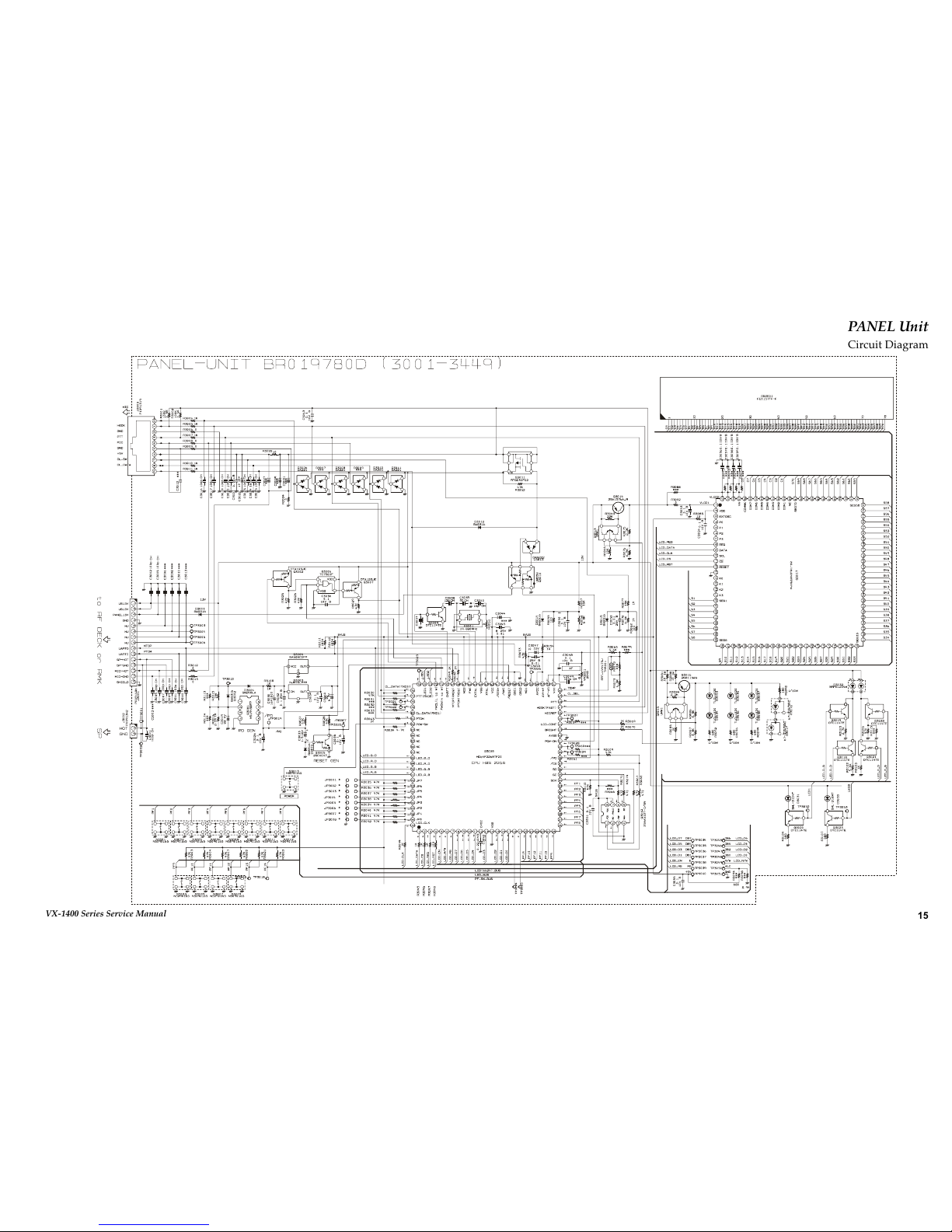

PANEL Unit

15

VX-1400 Series Service Manual

Circuit Diagram

16

PANEL Unit

VX-1400 Series Service Manual

Note

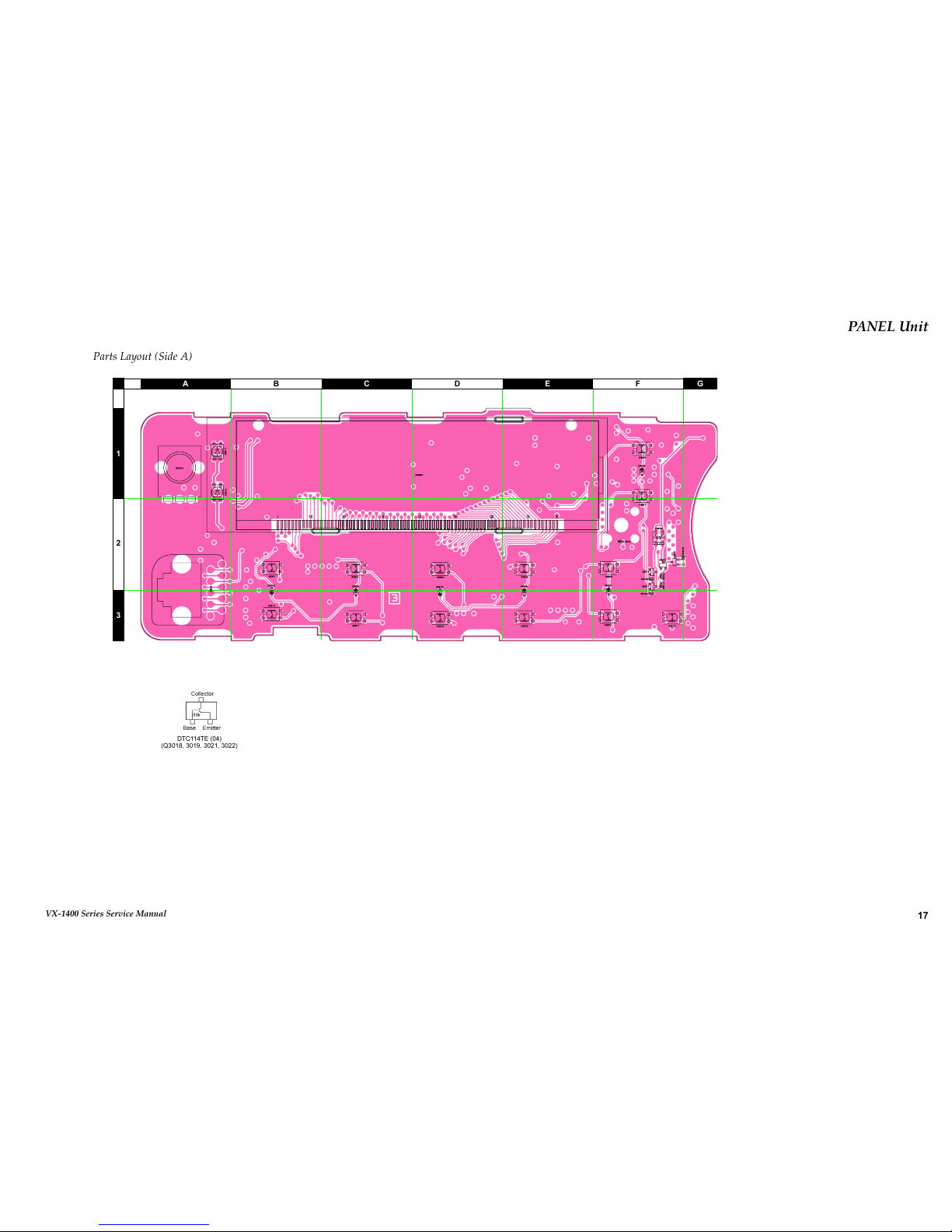

PANEL Unit

17

VX-1400 Series Service Manual

Parts Layout (Side A)

A B

C D E

1

2

3

F G

DTC114TE (04)

(Q3018, 3019, 3021, 3022)

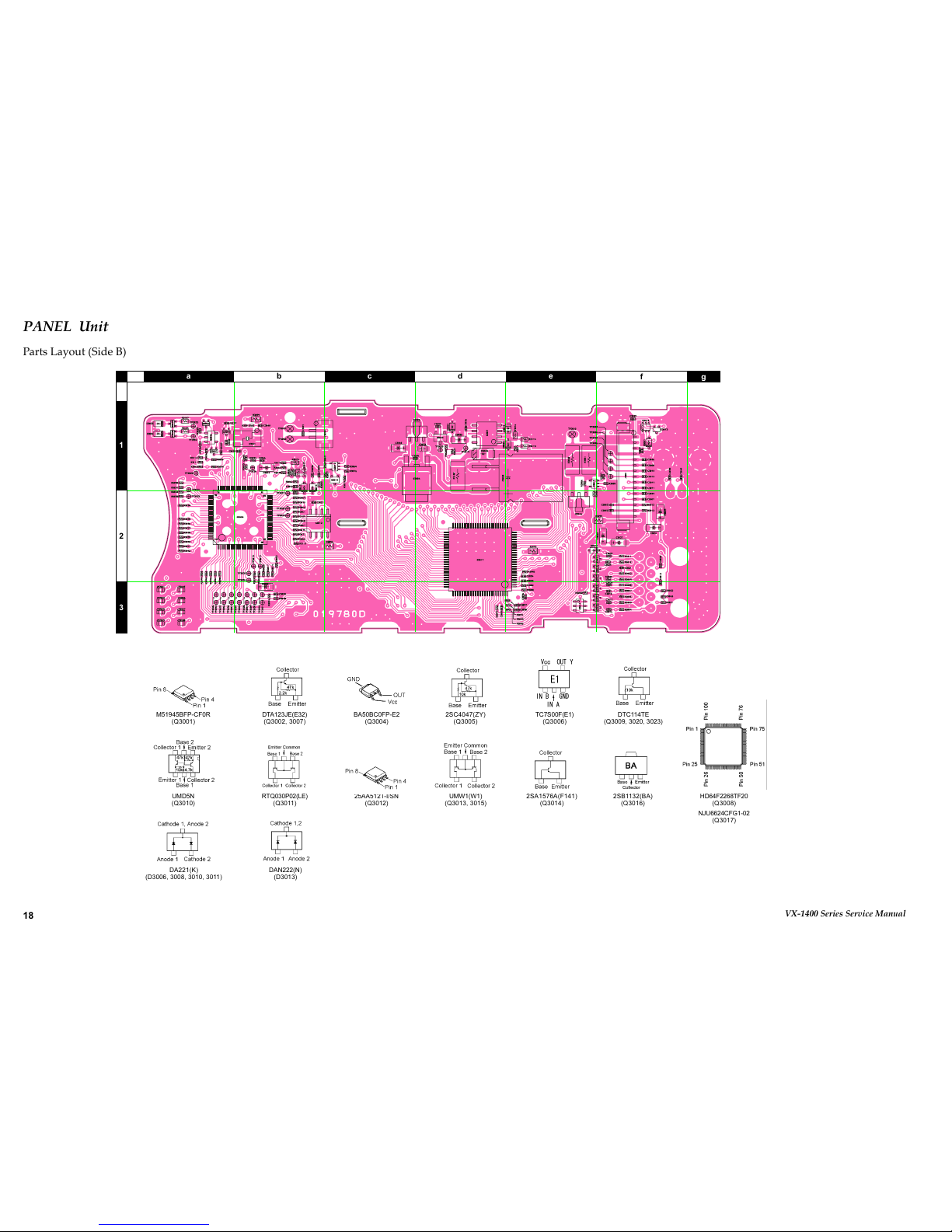

18

PANEL Unit

VX-1400 Series Service Manual

Parts Layout (Side B)

a b c d e

1

2

3

f g

25AA512T-I/SN

(Q3012)

2SA1576A(F141)

(Q3014)

2SB1132(BA)

(Q3016)

2SC4047(ZY)

(Q3005)

DAN222(N)

(D3013)

HD64F2268TF20

(Q3008)

NJU6624CFG1-02

(Q3017)

M51945BFP-CF0R

(Q3001)

BA50BC0FP-E2

(Q3004)

DA221(K)

(D3006, 3008, 3010, 3011)

DTA123JE(E32)

(Q3002, 3007)

DTC114TE

(Q3009, 3020, 3023)

UMW1(W1)

(Q3013, 3015)

UMD5N

(Q3010)

TC7S00F(E1)

(Q3006)

RTQ030P02(LE)

(Q3011)

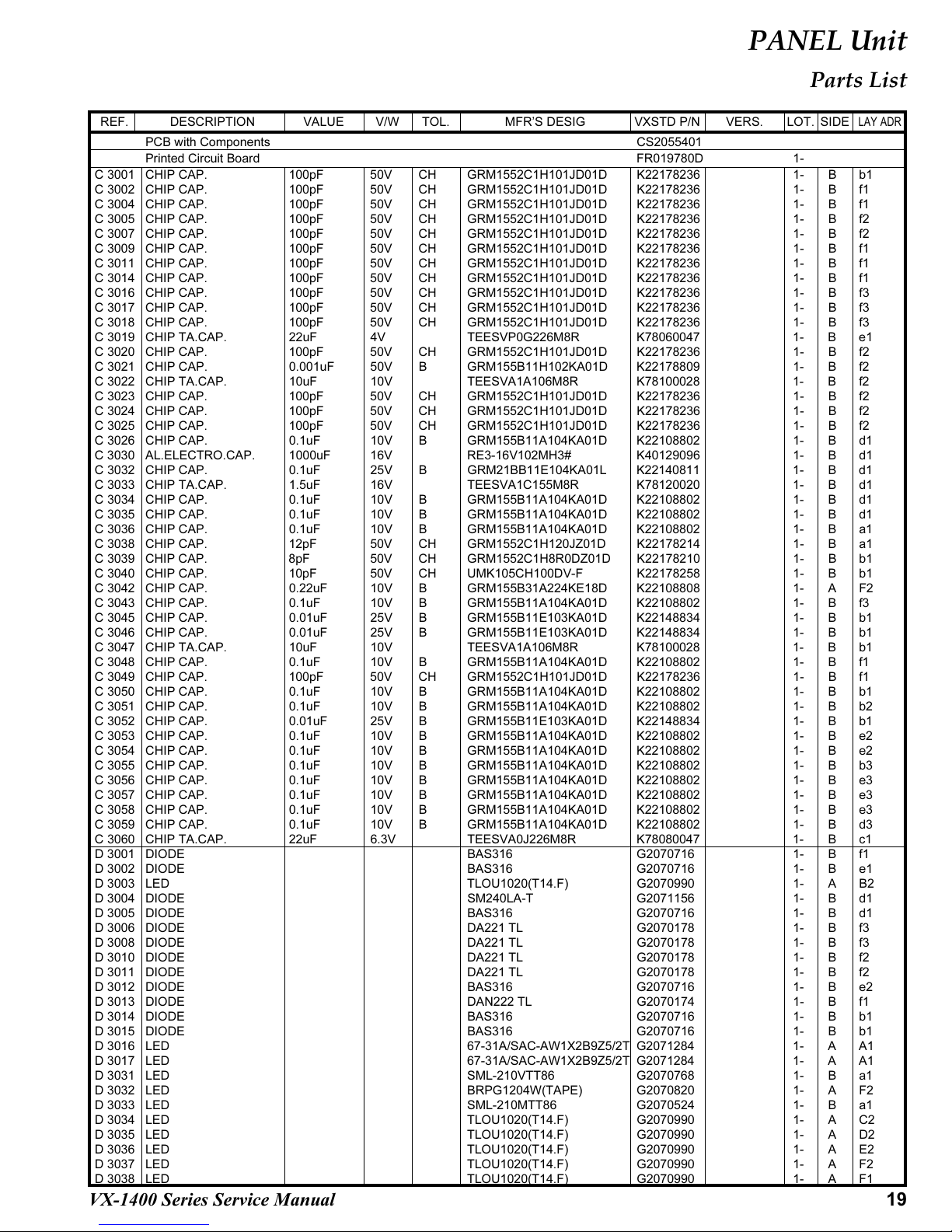

PANEL Unit

Parts List

DESCRIPTION VALUE V/W TOL. VXSTD P/NMFR’S DESIG VERS.REF. LOT. SIDE

PCB with Components CS2055401

Printed Circuit Board FR019780D 1-

C 3001 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B b1

C 3002 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f1

C 3004 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f1

C 3005 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f2

C 3007 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f2

C 3009 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f1

C 3011 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f1

C 3014 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f1

C 3016 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f3

C 3017 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f3

C 3018 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f3

C 3019 CHIP TA.CAP. 22uF 4V TEESVP0G226M8R K78060047 1- B e1

C 3020 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f2

C 3021 CHIP CAP. 0.001uF 50V B GRM155B11H102KA01D K22178809 1- B f2

C 3022 CHIP TA.CAP. 10uF 10V TEESVA1A106M8R K78100028 1- B f2

C 3023 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f2

C 3024 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f2

C 3025 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f2

C 3026 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B d1

C 3030 AL.ELECTRO.CAP. 1000uF 16V RE3-16V102MH3# K40129096 1- B d1

C 3032 CHIP CAP. 0.1uF 25V B GRM21BB11E104KA01L K22140811 1- B d1

C 3033 CHIP TA.CAP. 1.5uF 16V TEESVA1C155M8R K78120020 1- B d1

C 3034 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B d1

C 3035 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B d1

C 3036 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B a1

C 3038 CHIP CAP. 12pF 50V CH GRM1552C1H120JZ01D K22178214 1- B a1

C 3039 CHIP CAP. 8pF 50V CH GRM1552C1H8R0DZ01D K22178210 1- B b1

C 3040 CHIP CAP. 10pF 50V CH UMK105CH100DV-F K22178258 1- B b1

C 3042 CHIP CAP. 0.22uF 10V B GRM155B31A224KE18D K22108808 1- A F2

C 3043 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B f3

C 3045 CHIP CAP. 0.01uF 25V B GRM155B11E103KA01D K22148834 1- B b1

C 3046 CHIP CAP. 0.01uF 25V B GRM155B11E103KA01D K22148834 1- B b1

C 3047 CHIP TA.CAP. 10uF 10V TEESVA1A106M8R K78100028 1- B b1

C 3048 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B f1

C 3049 CHIP CAP. 100pF 50V CH GRM1552C1H101JD01D K22178236 1- B f1

C 3050 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B b1

C 3051 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B b2

C 3052 CHIP CAP. 0.01uF 25V B GRM155B11E103KA01D K22148834 1- B b1

C 3053 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B e2

C 3054 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B e2

C 3055 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B b3

C 3056 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B e3

C 3057 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B e3

C 3058 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B e3

C 3059 CHIP CAP. 0.1uF 10V B GRM155B11A104KA01D K22108802 1- B d3

C 3060 CHIP TA.CAP. 22uF 6.3V TEESVA0J226M8R K78080047 1- B c1

D 3001 DIODE BAS316 G2070716 1- B f1

D 3002 DIODE BAS316 G2070716 1- B e1

D 3003 LED TLOU1020(T14.F) G2070990 1- A B2

D 3004 DIODE SM240LA-T G2071156 1- B d1

D 3005 DIODE BAS316 G2070716 1- B d1

D 3006 DIODE DA221 TL G2070178 1- B f3

D 3008 DIODE DA221 TL G2070178 1- B f3

D 3010 DIODE DA221 TL G2070178 1- B f2

D 3011 DIODE DA221 TL G2070178 1- B f2

D 3012 DIODE BAS316 G2070716 1- B e2

D 3013 DIODE DAN222 TL G2070174 1- B f1

D 3014 DIODE BAS316 G2070716 1- B b1

D 3015 DIODE BAS316 G2070716 1- B b1

D 3016 LED 67-31A/SAC-AW1X2B9Z5/2T G2071284 1- A A1

D 3017 LED 67-31A/SAC-AW1X2B9Z5/2T G2071284 1- A A1

D 3031 LED SML-210VTT86 G2070768 1- B a1

D 3032 LED BRPG1204W(TAPE) G2070820 1- A F2

D 3033 LED SML-210MTT86 G2070524 1- B a1

D 3034 LED TLOU1020(T14.F) G2070990 1- A C2

D 3035 LED TLOU1020(T14.F) G2070990 1- A D2

D 3036 LED TLOU1020(T14.F) G2070990 1- A E2

D 3037 LED TLOU1020(T14.F) G2070990 1- A F2

D 3038 LED TLOU1020(T14.F) G2070990 1- A F1

LAY ADR

19VX-1400 Series Service Manual

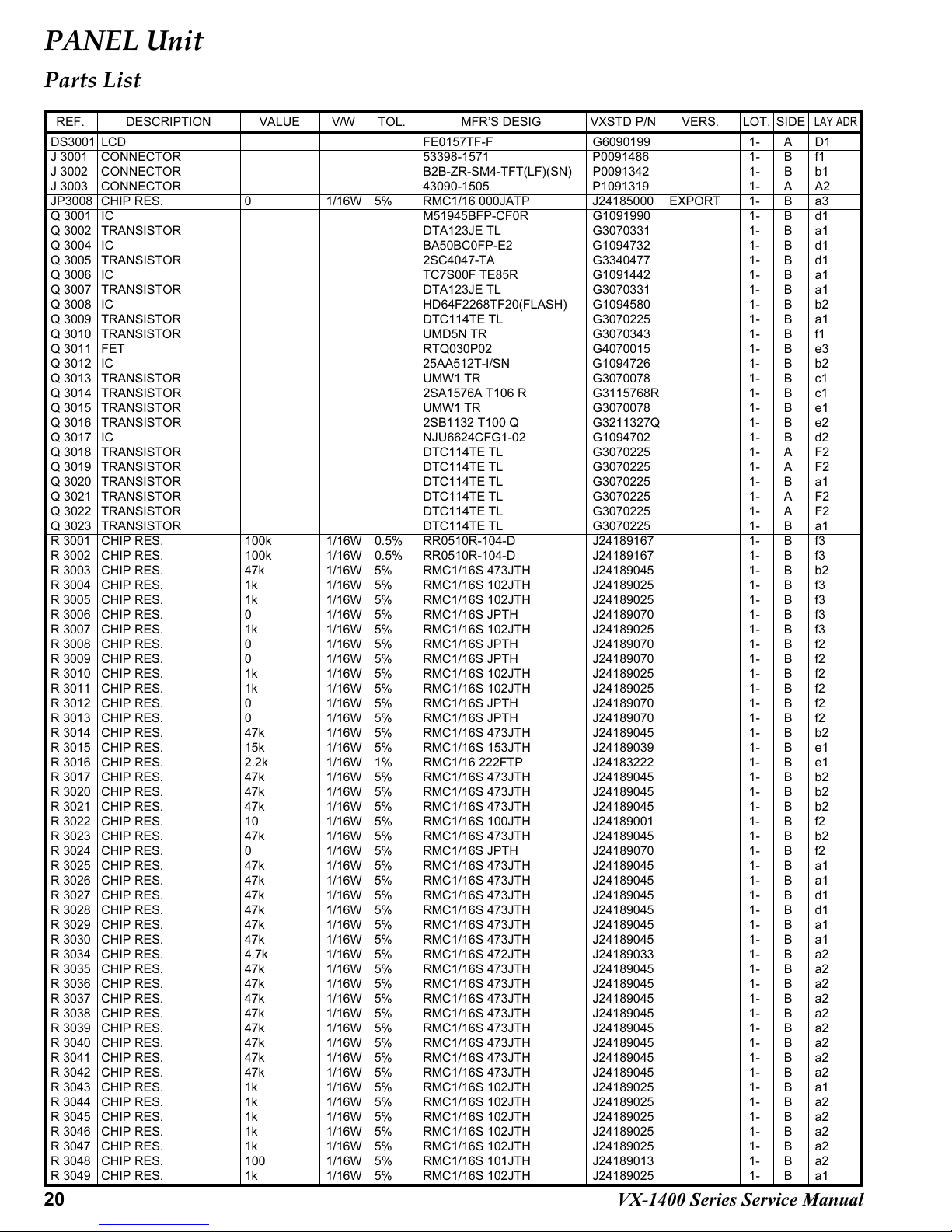

PANEL Unit

Parts List

DESCRIPTION VALUE V/W TOL. VXSTD P/NMFR’S DESIG VERS.REF. LOT. SIDE

DS3001 LCD FE0157TF-F G6090199 1- A D1

J 3001 CONNECTOR 53398-1571 P0091486 1- B f1

J 3002 CONNECTOR B2B-ZR-SM4-TFT(LF)(SN) P0091342 1- B b1

J 3003 CONNECTOR 43090-1505 P1091319 1- A A2

JP3008 CHIP RES. 0 1/16W 5% RMC1/16 000JATP J24185000 EXPORT 1- B a3

Q 3001 IC M51945BFP-CF0R G1091990 1- B d1

Q 3002 TRANSISTOR DTA123JE TL G3070331 1- B a1

Q 3004 IC BA50BC0FP-E2 G1094732 1- B d1

Q 3005 TRANSISTOR 2SC4047-TA G3340477 1- B d1

Q 3006 IC TC7S00F TE85R G1091442 1- B a1

Q 3007 TRANSISTOR DTA123JE TL G3070331 1- B a1

Q 3008 IC HD64F2268TF20(FLASH) G1094580 1- B b2

Q 3009 TRANSISTOR DTC114TE TL G3070225 1- B a1

Q 3010 TRANSISTOR UMD5N TR G3070343 1- B f1

Q 3011 FET RTQ030P02 G4070015 1- B e3

Q 3012 IC 25AA512T-I/SN G1094726 1- B b2

Q 3013 TRANSISTOR UMW1 TR G3070078 1- B c1

Q 3014 TRANSISTOR 2SA1576A T106 R G3115768R 1- B c1

Q 3015 TRANSISTOR UMW1 TR G3070078 1- B e1

Q 3016 TRANSISTOR 2SB1132 T100 Q G3211327Q 1- B e2

Q 3017 IC NJU6624CFG1-02 G1094702 1- B d2

Q 3018 TRANSISTOR DTC114TE TL G3070225 1- A F2

Q 3019 TRANSISTOR DTC114TE TL G3070225 1- A F2

Q 3020 TRANSISTOR DTC114TE TL G3070225 1- B a1

Q 3021 TRANSISTOR DTC114TE TL G3070225 1- A F2

Q 3022 TRANSISTOR DTC114TE TL G3070225 1- A F2

Q 3023 TRANSISTOR DTC114TE TL G3070225 1- B a1

R 3001 CHIP RES. 100k 1/16W 0.5% RR0510R-104-D J24189167 1- B f3

R 3002 CHIP RES. 100k 1/16W 0.5% RR0510R-104-D J24189167 1- B f3

R 3003 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B b2

R 3004 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B f3

R 3005 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B f3

R 3006 CHIP RES. 0 1/16W 5% RMC1/16S JPTH J24189070 1- B f3

R 3007 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B f3

R 3008 CHIP RES. 0 1/16W 5% RMC1/16S JPTH J24189070 1- B f2

R 3009 CHIP RES. 0 1/16W 5% RMC1/16S JPTH J24189070 1- B f2

R 3010 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B f2

R 3011 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B f2

R 3012 CHIP RES. 0 1/16W 5% RMC1/16S JPTH J24189070 1- B f2

R 3013 CHIP RES. 0 1/16W 5% RMC1/16S JPTH J24189070 1- B f2

R 3014 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B b2

R 3015 CHIP RES. 15k 1/16W 5% RMC1/16S 153JTH J24189039 1- B e1

R 3016 CHIP RES. 2.2k 1/16W 1% RMC1/16 222FTP J24183222 1- B e1

R 3017 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B b2

R 3020 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B b2

R 3021 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B b2

R 3022 CHIP RES. 10 1/16W 5% RMC1/16S 100JTH J24189001 1- B f2

R 3023 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B b2

R 3024 CHIP RES. 0 1/16W 5% RMC1/16S JPTH J24189070 1- B f2

R 3025 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a1

R 3026 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a1

R 3027 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B d1

R 3028 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B d1

R 3029 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a1

R 3030 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a1

R 3034 CHIP RES. 4.7k 1/16W 5% RMC1/16S 472JTH J24189033 1- B a2

R 3035 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a2

R 3036 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a2

R 3037 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a2

R 3038 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a2

R 3039 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a2

R 3040 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a2

R 3041 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a2

R 3042 CHIP RES. 47k 1/16W 5% RMC1/16S 473JTH J24189045 1- B a2

R 3043 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B a1

R 3044 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B a2

R 3045 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B a2

R 3046 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B a2

R 3047 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B a2

R 3048 CHIP RES. 100 1/16W 5% RMC1/16S 101JTH J24189013 1- B a2

R 3049 CHIP RES. 1k 1/16W 5% RMC1/16S 102JTH J24189025 1- B a1

20 VX-1400 Series Service Manual

LAY ADR

Loading...

Loading...