Page 1

Total solder points: 775

Difficulty level:

beginner 1o 2o 3o 4o 5þ advanced

Multifunctional clock display

Features :

R 6 x 36mm high digits.

R Time, date & temperature indication, selectable with toggle option.

R 1 sec. resolution chronometer with lap function.

R Count down function to a specific date.

R Scoreboard function (two players or teams, count up to 199).

R Random generator from 00 to 99.

R 2 digit dice.

R Hour chime option.

R Counter display.

R Relay output for temperature control or time alarm.

R US or Europe display option: time, date, degrees Celsius or Fahrenheit.

R Wireless remote control for all functions (wired remote possible).

R Optional enclosure type B8009.

R Optional extra remote type K6706A, K6706B or K6706G.

K8009

Specifications :

— Fixed 433.92 MHz transmitter frequency, as required by law.

— Key chain remote control included.

— Temperature indication from -20 to +70 ºC (resolution 1º).

— Temperature indication from 0 to +150 ºF (resolution 2º).

— Memory backup option: 9V battery or rechargeable battery T331

— Relay output: 1A / 24V max.

— Supply: 12VDC/300mA power supply (adapter type PS1203).

— Dimensions : 252 x 80mm (without enclosure).

Modifications reserved

ILLUSTRATED ASSEMBLY MANUAL H8009IP-3

Page 2

Assembly hints

0.000

1. Assembly (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project

successful. Read them carefully.

1.1 Make sure you have the right tools:

• A good quality soldering iron (25-40W) with a

small tip.

• Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to

the tip, to give it a wet look. This is called ‘thinning’ and will protect the tip,

and enables you to make good connections. When solder

rolls off the tip, it needs cleaning.

• Thin raisin-core solder. Do not use any flux or grease.

• A diagonal cutter to trim excess wires. To avoid injury when cutting

excess leads, hold the lead so they cannot fly towards the eyes.

• Needle nose pliers, for bending leads, or to hold components in place.

• Small blade and phillips screwdrivers. A basic range

is fine.

For some projects, a basic multi-meter is required, or might

be handy

1.2 Assembly Hints :

⇒ Make sure the skill level matches your experience, to avoid disappointments.

⇒ Follow the instructions carefully. Read and understand the entire step before

you perform each operation.

⇒ Perform the assembly in the correct order as stated in this manual

⇒ Position all parts on the PCB (Printed Circuit Board) as shown on the draw-

ings.

⇒ Values on the circuit diagram are subject to changes.

⇒ Values in this assembly guide are correct*

⇒ Use the check-boxes to mark your progress.

⇒ Please read the included information on safety and customer service

* Typographical inaccuracies excluded. Always look for possible last minute

manual updates, indicated as ‘NOTE’ on a separate leaflet.

2

Page 3

Assembly hints

1.3 Soldering Hints :

1- Mount the component against the PCB surface

and carefully solder the leads

2- Make sure the solder joints are cone-shaped

and shiny

3- Trim excess leads as close as possible to the solder joint

AXIAL COMPONENTS ARE TAPED IN

THE CORRECT MOUNTING SEQUENCE !

REMOVE THEM FROM THE TAPE ONE AT A

TIME !

the essential requirements and all other relevant stipulations of directive 1999/5/

Velleman hereby certifies that the device K8009 meets

EG and 1995/5/EC.

For the complete conformity declaration check out :

http://www.velleman.be/downloads/doC/CE_K8009.pdf

3

Page 4

Color code table

5%

4K7= ( 4 - 7 - 2 - B )

1%

4K7= ( 4 - 7 - 0 - 1 - 1 )

COLOR= 2… 5

C

O

D

KODE

KLEUR

CODIFI-

CATION

DES

CODE

COLOUR

FARB

KODE

KODE

FARGE-

KODE

FARVE-

E

COU-

LEURS

4

FÄRG

VÄRI

CODIGO

CODIGO

I P E SF S DK N D GB F NL

CODICE

C

SCHEMA

KOODI

S

DE

COLORE

DE

CORES

COLORE

O

D E

Oranssi Orange Orange Orange Orange Orange Orange Oranje 3

Rojo Punainen Röd Rød Rød Rot Red Rouge Rood 2

jado

nado

Laranja Naran-

ciato

0 Nero Preto Negro Musta Svart Sort Sort Schwarz Black Noir Zwart 0

1 Marrone Castanho Marrón Ruskea Brun Brun Brun Braun Brown Brun Bruin 1

2 Rosso Encar-

3 Aran-

4 Giallo Amarelo Amarillo Keltainen Gul Gul Gul Gelb Yellow Jaune Geel 4

5 Verde Verde Verde Vihreä Grön Grøn Grønn Grün Green Vert Groen 5

6 Blu Azul Azul Sininen Blå Blå Blå Blau Blue Bleu Blauw 6

7 Viola Violeta Morado Purppura Lila Violet Violet Violet Purple Violet Paars 7

8 Grigio Cinzento Gris Harmaa Grå Grå Grå Grau Grey Gris Grijs 8

9 Bianco Branco Blanco Valkoinen Vit Hvid Hvidt Weiss White Blanc Wit 9

A Argento Prateado Plata Hopea Silver Sølv Sølv Silber Silver Argent Zilver A

B Oro Dourado Oro Kulta Guld Guld Guldl Gold Gold Or Goud B

Page 5

Construction

IMPORTANT

First the remote control PCB is assembled, P6706A:

The remote control can be build for wireless remote operation or for “wired” remote

operation (no need for battery in the transmitter). In case of a wired remote, only a few

components are mounted, see further.

Before mounting the components on the PCB, first check that the PCB fits in the

housing. Watch the small notch next to LD1. Should it not fit, then grind the edges of

the PCB carefully.

Mount only the components marked with “#” if wired remote is wanted.

1. Jumperwire

q J1 #

5. Push buttons

2. Diodes (Check the polarity)

CATHODE

D...

q D1 : BAT85 #

q D2 : BAT85 #

3. 1/4W Resistors

R...

q SW1 : KRS0611 #

q SW2 : KRS0611 #

6. IC socket

(Watch the position of the notch)

1

IC...

q IC1 : 18p #

q R4 : 33K (3 - 3 - 3 - B)

q R5 : 100K (1 - 0 - 4 - B) #

7. Capacitors

C...

4. SAW resonator

(Watch the position of the notch)

X...

q C1 : 100pF (101)

q C2 : 1pF small type !

q C3 : 56pF

q C4 : 4,7pF (4p7, 4.7)

q C5 : 56pF

q C6 : 470pF (471) #

q X1 : SAW433

5

Page 6

Construction

18mm

8. Transistor

q T1 : MPSH10

Check the minimum height ! :

7mm

9. 1/4W Resistors

(check the color code)

R...

q R1 : 33K (3 - 3 - 3)

q R2 : 47 (4 - 7 - 0)

q R3 : 220 (2 - 2 - 1)

11. Coil

5mm

A simple air core coil has to be made

as shown in the diagram using the

jumper lead supplied

q L1: 1 turn

12. Battery contacts

Check for good attachment of the

solder to the contacts.

Mount them as straight as possible!

10. LED (check the polarity)

COLOR= 2...5

q LD1 : 3mm (2)

CATHODE

Mount at the indicated height :

6

LD...

11mm

13. IC

(Watch the position of the notch !)

1

PIN 1

IC...

q IC1 : UM3758 #

Page 7

Construction

14. Create your code

Your own individual code can be set for a transmitter/clock combination. There is

a row of nine code pads that are the closest to IC1, only one code connection is

used. The code can be set by linking the code pad to a neighbouring "-" pad or "+"

pad by using a jumper lead. JC1 and JC2 are located on the main PCB P8009.

There are 3 different combinations possible:

1. JC1 and JC2 are not mounted on the main PCB, then do not mount code

jumpers on the transmitter.

2. JC1 is mounted on the main PCB, Mount a jumper like in the drawing:

3. JC2 is mounted on the main PCB, Mount a jumper like in the drawing:

In case of a “wired” remote, continue the assembly.

In case of a wireless remote, the transmitter PCB can be placed in his enclosure.

Fit a new 12V battery type V23GA or GP23A. Check the polarity which is shown

in the enclosure.

REMARK: If the buttons do not “click”, please check the position of the PCB. It

is also possible that the first time, you have to press firmly the button cap before

they work properly.

15. Sticker

Affix the supplied sticker to the housing.

Velleman

433,92 MHz

SRFCE

7

Page 8

Construction

Assembly of the main PCB P8009 :

1. Jumperwires

q J1

q J2

q J3

q J4

q J5

q J6

q J7

q J8

q J9

q J10

q J11

q J12

q J13

q J14

q J15

q J16

q J17

q J18

q J19

q J20

q J21

q J22

q J23

q J24

q J25

q J26

q J27

q J28

q J29

q J30

q J31

q J32

q J33

q J34

q J35

q J36

q J37

q J38

q J39

q J40

q J41

q J42

q J43

q J44

q J45

q J46

q J47

2. Diodes (Check the polarity)

CATHODE

D...

q D1 : 1N4007

q D2 : 1N4148

q D3 : 1N4148

q D4 : BAT85

q D5 : BAT85

q D6 : 1N4148

q D7 : 1N4148

q D8 : 1N4148

q D9 : 1N4148

3. Zener diode (Check the polarity)

CATHODE

ZD...

q ZD1 : 6V2

q ZD2 : 3V3

q ZD3 : 4V7

q ZD4 : 4V3

q ZD5 : 5V1

q ZD6 : 9V1

8

Page 9

Construction

4. 1/4W Resistors

R...

q R1 : 100K (1 - 0 - 4)

q R2 : 270 (2 - 7 - 1)

q R3 : 270 (2 - 7 - 1)

q R4 : 4K7 (4 - 7 - 2)

q R5 : 270 (2 - 7 - 1)

q R6 : 5K6 (5 - 6 - 2)

q R7 : 2K7 (2 - 7 - 2)

q R8 : 2K2 (2 - 2 - 2)

q R9 : 10K (1 - 0 - 3)

q R10 : 100K (1 - 0 - 4)

q R11 : 10K (1 - 0 - 3)

q R12 : 4K7 (4 - 7 - 2)

q R13 : 10K (1 - 0 - 3)

q R14 : 100K (1 - 0 - 4)

q R15 : 47K (4 - 7 - 3)

q R16 : 2K2 (2 - 2 - 2)

q R17 : 150 (1 - 5 - 1)

q R18 : 100K (1 - 0 - 4)

q R19 : 4K7 (4 - 7 - 2)

q R20 : 10K (1 - 0 - 3)

q R21 : 270 (2 - 7 - 1)

q R22 : 100K (1 - 0 - 4)

q R23 : 100K (1 - 0 - 4)

q R24 : 270 (2 - 7 - 1)

q R25 : 270 (2 - 7 - 1)

q R26 : 100K (1 - 0 - 4)

q R27 : 100K (1 - 0 - 4)

q R28 : 100K (1 - 0 - 4)

q R29 : 100K (1 - 0 - 4)

q R30 : 100K (1 - 0 - 4)

q R31 : 100K (1 - 0 - 4)

q R32 : 4K7 (4 - 7 - 2)

q R33 : 10K (1 - 0 - 3)

q R34 : 270 (2 - 7 - 1)

q R35 : 270 (2 - 7 - 1)

q R36 : 100K (1 - 0 - 4)

q R37 : 4K7 (4 - 7 - 2)

q R38 : 10K (1 - 0 - 3)

q R39 : 100K (1 - 0 - 4)

q R40 : 100K (1 - 0 - 4)

q R41 : 100K (1 - 0 - 4)

q R42 : 10K (1 - 0 - 3)

q R43 : 10K (1 - 0 - 3)

q R44: 10K (1 - 0 - 3)

q R45 : 10K (1 - 0 - 3)

q R46 : 10K (1 - 0 - 3)

q R47 : 4K7 (4 - 7 - 2)

q R48 : 100K (1 - 0 - 4)

q R49 : 560 (5 - 6 - 1)

q R50 : 100K (1 - 0 - 4)

q R51 : 2K2 (2 - 2 - 2)

q R52 : 4K7 (4 - 7 - 2)

q R53 : 2K2 (2 - 2 - 2)

q R54 : 2K2 (2 - 2 - 2)

q R55 : 1K (1 - 0 - 2)

q R56 : 1K (1 - 0 - 2)

q R57 : 6M8 (6 - 8 - 5)

q R58 : 6K8 (6 - 8 - 2)

q R59 : 18K (1 - 8 - 3)

q R60 : 270 (2 - 7 - 1)

q R61 : 33K (3 - 3 - 3)

q R62 : 18K (1 - 8 - 3)

q R63 : 10K (1 - 0 - 3)

q R64 : 10K (1 - 0 - 3)

q R65 : 5K6 (5 - 6 - 2)

q R66 : 2K7 (2 - 7 - 2)

q R67 : 100K/1% (1 - 0 - 0 - 3)

q R68 : 270K/1% (2 - 7 - 0 - 3)

5. Axial coil

L2

q L1 : 1µH (1 - 0 - B)

9

Page 10

Construction

6. IC socket

(Watch the position of the notch)

q IC1 : 8p

q IC2 : 18p

q IC3 : 18p

1

IC...

q IC4 : 18p

q IC5 : 16p

q IC6 : 8p

7. Capacitors

C...

q C1 : 470pF (471)

q C2 : 470pF (471)

q C3 : 100nF (104, µ1)

q C4 : 100nF (104, µ1)

q C5 : 100nF (104, µ1)

q C6 : 2pF (2.2, 2p2)

q C7 : 12pF

q C8 : 330pF (331)

q C9 : 330pF (331)

q C10 : 22pF

q C11 : 330pF (331)

q C12 : 1pF

q C13 : 2pF

q C14 : 82pF

q C15 : 330pF (331)

q C16 : 100nF (104, µ1)

9. Transistors

q T1 : BC547C

q T2 : BC547C

q T3 : BC547C

q T4 : BC547C

q T5 : BC547C

q T6 : BC547C

q T7 : BC547C

q T8 : BC547C

q T9 : BC547C

q T10 : BC547C

q T11 : BC547C

q T12 : BC547C

q T13 : BC547C

q T14 : BC547C

q T15 : BC547C

q T16 : BC547C

q T17 : BC557

q T18 : BC557

q T19 : BC557

q T20 : BC557

q T21 : BC557

q T22 : BC557

q T23 : BC557

q T24 : BF199

10. Voltage regulator

8. Quartz crystal

X...

q X1 : 4.194304

Fix the quartz crystal by means of a

jumpwire.

10

VR...

q VR1 : 78L05

Page 11

Construction

C...

11. Trim capacitors

q CV1 :Trim 22p (Green)

CV...

q CV2 : TRIM 5p5

12. Electrolytic capacitors

q C17 : 1µF

q C18 : 100µF / 16V

q C19 : 1µF

q C20 : 10µF

q C21 : 1µF

q C22 : 470µF / 25V

13. Buzzer (check the polarity)

BUZ...

+

q BUZ1 : SV4 / 12-S

14. Relay

RY...

q RY1 : VR3D121C

A selection is possible for a normal

closed contact output, or a normal open

contact output :

For normal closed, mount jumper JNC:

For normal open, mount jumper JNO:

15. PCB pin. Mount only if you

have access to a frequency

counter.

q GND

q Testpin for time calibration 15.625ms

(64Hz)

This testpin can be used to calibrate the

clock (see chapt. 22) by means of a

counter.

Adjust CV1 for a period measurement of

15.625ms or 64Hz frequency.

11

Page 12

Conctruction

16. Temperature sensor

q SENS: LM335

Make the connections longer when using an enclosure like our optional enclosure

type B8009 (use blank jumpwires)

SENS...

12

Page 13

Construction

17. LED mounting

To mount all the LED’s at the same hight, we are going to use some spacers.

Mount the spacers on the PCB:

15mm M3 BOLT

10mm SPACER

COMPONENT SIDE UP

M3 NUT

Mount about five LED’s, then turn over the PCB and solder ONE connection of each

LED. Now correct the position of the LED’s and solder the other connection of each

LED.

Continue mounting all the LED’s as above.

It is important that when our optional enclosure B8009 is used, that the

maximum hight is respected !

q LD1… LD132: 3mm LED.

Now the spacers can be removed.

13

Page 14

Construction

18. Resistor trimmer

RV...

q RV1 : 500E (470)

19. Connectors

SK...

+

SW

-

q SK1 : DJ005

SK...

q SK2 : BATCON

q SK3 : SCREW02

If a 9V block battery is used for the

memory backup, then the following

snap can be connected:

RED

BLACK

Check the polarity !

20. IC’s

(Watch the position of the notch !)

1

PIN 1

IC...

q IC1 : CA3160

q IC2 : VK8009 (PIC16C715)

q IC3 : UM3758

q IC4 : UM3758

q IC5 : CD4017

q IC6 : LM258

14

Page 15

Connection

21. Connecting the wired remote control

Only three wires are used to connect the transmitter with the display.

q Connect one wire between the + from the display and the + of the transmitter

(connection next to R5)

q Connect one wire between the - from the display and the - of the transmitter

(connection next to C5)

q Connect one wire between C on the display and the connection at R1 on the

transmitter (see drawing).

P8009

SK4

C

C

P6706

-

-

C

R1

+

+

Before mounting the transmitter PCB in the enclosure, make a small slot in the

bottom enclosure to pass the wires.

CUT OUT

Now the transmitter can be placed in his enclosure.

G REMARK: If the buttons do not “click”, please check the position of the PCB.

It is also possible that the first time, you have to press firmly the button cap

before they work properly.

15

Page 16

Test & adjustment

22. Test and adjustment

First we will test if the display works properly:

• Connect a 12VDC / 300mA adapter (check the polarity and the connector

type) to the display. The display should indicate the time 00:00:00

(HH:MM:SS) and the (HH) should blink.

Next step is adjusting the displays- receiver to the transmitter. (skip this

step if a wired transmitter is used).

2

>Remote control button code.

1

• Hold the transmitter about one meter (one yard) away from the display.

• Press button 1 on the transmitter, the LED on the transmitter should blink

rapidly.

• Now adjust the trimmer capacitor CV2 (RECEIVER ADJUST) on the display

using the supplied plastic tuning screwdriver, until the receiver LED (REC),

blinks at the same rate as the transmitter.

• If a maximum range between transmitter - display is wanted, then it is advisable to repeat the above adjustment with the transmitter at about 10m (10

yard).

• If the adjustment is OK, then the HH of the display should increase each time

button 1 is pressed.

Next step is to calibrate the temperature indication :

G Remark : Hold the display away from large metal objects.

• Disconnect the power supply from the display.

• Reconnect the power supply to the display.

• Put a known good thermometer next to the display temperature sensor.

• Press repeatedly button 2 on the transmitter until the display shows dAtE

blinking.

• Now press button 1 until rEGIOn is blinking.

• Next press button 2, Eu will blink. Use button 1 to choose between Eu

(Europe) or uS (USA) display format for time, date and temperature.

• Confirm your choice by pressing button 2.

• Now press the left button until dEGrEE is displayed and confirm with but-

ton 2.

• Now adjust the trim potentiometer RV1 (TEMP. CALIBRATION) until the displayed temperature corresponds with the “reference” thermometer.

G Repeat the above adjustment after the display is warmed up for a few hours.

16

Page 17

Test & adjustment

Next step is to calibrate the clock time base

The processor has an internal oscillator that is used to run the clock.

By means of CV1(TIME CALIBRATION), it is possible to adjust the oscillator

frequency if the clock does not run correctly.

1. Start by setting the trim capacitor in his center (50% overlap) position:

50%

2. should the clock run too fast, then turn the capacitor more in the maximum

(100% overlap) direction:

100%

3. should the clock run too slow, then turn the capacitor more in the minim um

(no overlap) direction:

0%

17

Page 18

Mounting

23. Mounting the display into the optional enclosure B8009

• Remove the display window and the side panels from the enclosure.

• Slide the PCB into the lower slot of the enclosure.

• At the left hand side two holes must be made in the small cover, one for the

power supply plug*, and one for the temperature sensor.

* Alternatively a hole can be made at the back of the enclosure to pass the

power supply plug.

• Mount the two side panels.

• At the right hand side there is space for a battery, a 9V battery or a 3.6V re-

chargeable battery type T331 can be used. Connect the battery to the appropriate connector.

After connecting the power supply plug, the display window can be mounted.

G REMARK : It is important that the temperature sensor body is outside the

enclosure otherwise the temperature readout will be faulty.

G Keep the display out of direct sunlight.

See the user manual for further instructions.

18

Page 19

PCB

&

DIAGRAMS

19

Page 20

PCB

24. Transmitter PCB

20

Page 21

Display PCB

SK2

-

3V6

+

OUT

SK3

C

RY1

JNO

COIL2

NO

JNC

T8

R41

BUZ1

T7

R40

J45

R43

R42

J44

R44

R45

J43

C19

D7

C20

D8

IC5

P8009'2

1

J36

+ RED

9V BATTERY

BLACK -

T23

ZD2

D6

J25

J24

D5

R31

D4

VELLEMAN

15.625ms

GND

TESTPIN FOR TIME CALIBRATION

J18

D3

C21

R17

D2

C4

C3

R16

R15

VR1

D1

C22

+

SW

-

SK1

-

J2

+

12VDC/200mA

C

NC

111

89

90

91

66

67

68

45

46

47

22

23

24

R10

LD1

2

3

COIL1

LD132

110

112

R39

R18

J8

16

R1

J42

92

104

J35

69

48

60

J17

25

37

J7

J1

PCB

SK4

C18

C16

C17

D9

R54

OUT

113

T22

R46

125

T6

93

R38

T21

T5

R36

70

R33

81

T4

49

R20

T19

T3

ZD1

R11

T2

4

R9

T1

C

+

ZD6

-

R58

C13

R63

R57

1

ZD5

ZD4

R56

R55

IC6

J46

114

115

116

128

129

126

130

127

R47

122

J41

J40

123

95

94

J37

107

108

109

J38

105

106

101

R37

102

J34

LD87

J31

J30

72

71

84

J26

85

T20

86

82

J27

83

J22

78

R32

J23

79

51

50

63

52

J19

64

65

J20

61

62

57

58

R19

LD43

26

J13

J12

28

27

J9

29

40

41

T18

42

38

J10

39

J5

R12

34

J6

35

7

5

6

J3

19

T17

20

17

21

R4

18

R3

13

14

R2

R60

J39

J28

J21

J11

J4

R66

R61

J47

119

120

124

98

99

100

LD88

J32

55

56

LD44

36

11

12

C15

R65

L1

C14

C12

C11

c

b

T24

R62

e

R59

C10

RECEIVER ADJUST

CV2

R53

REC

R52

LD131

R51

118

ZD3

JC2

-

1

121

IC4

1

97

IC3

103

74

80

R35

R34

53

54

59

R21

J15

30

9

10

15

JC1

+

R50

C9

ADDRESS SELECTION: MOUNT JC1 OR JC2 OR LEFT OPEN

R49

R48

C8

J33

X1

C7

C6

CV1

1

75

76

77

31

32

1

33

R5

R26

R22

T9

SENS

R25

R24

R23

R27

R68

R6

R28

R8

R14

R13

J29

IC2

C2

C1

R67

TIME CALIBRATION

C5

R29

R30

T16

T15

T14

T13

T12

T11

T10

J16

IC1

R7

TEMP. CALIBRATION

RV1

R64

117

96

73

J14

8

21

Page 22

Diagrams

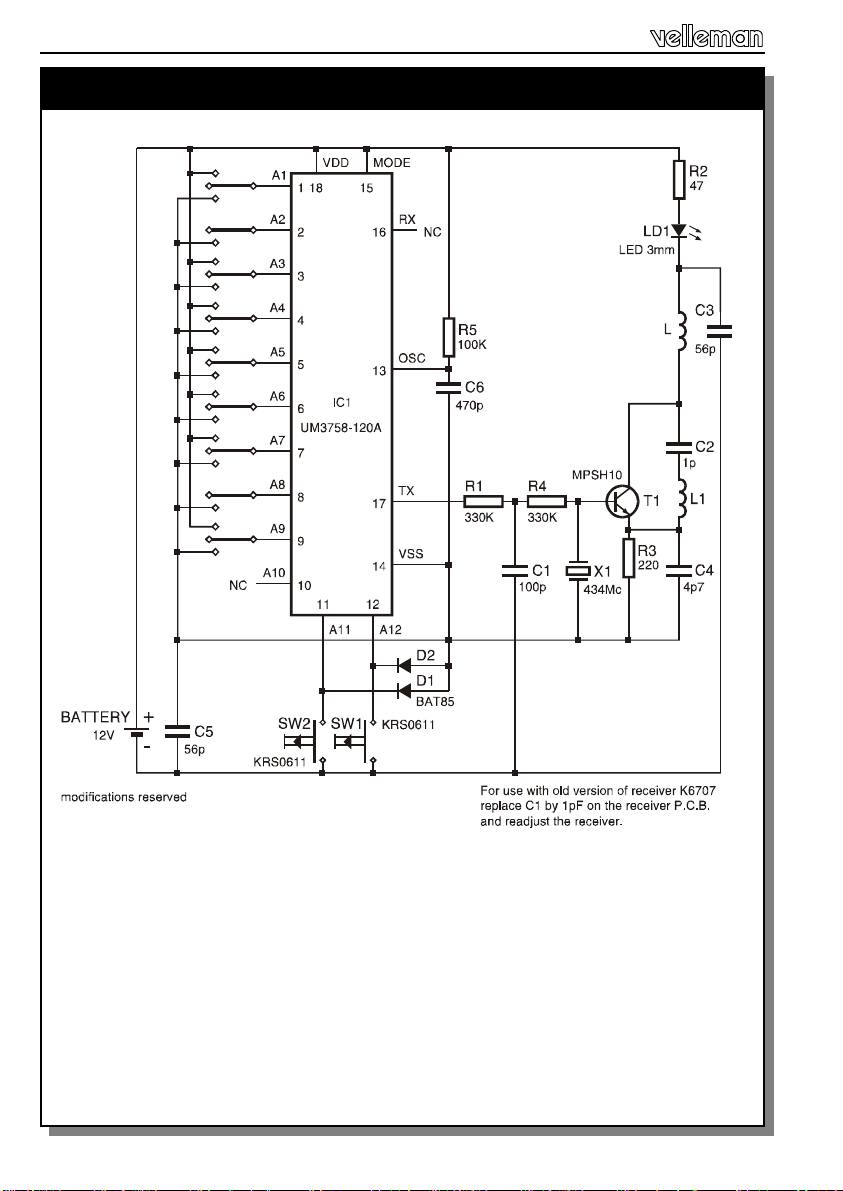

25. Transmitter diagram

22

Page 23

Display diagram

NONCC

SK3

VR3D121C

RELAY OUTPUT

T8

BC547C

RY1

+VL

BUZ1

SV4-12S

+VL

R42

D8

1N4148

+VL

+RED

E2

9V BATTERY

BC557

T23

+V

D3

1N4148

O

VR1

I

UA78L05

R15

47K

+VL

D1

1N4007

+

SW

SK1

12VDC/200mA INPUT

R54

T7

10K

-BLACK

ZD2

3V3

D4

C21

C4

C3

R16

R17

C22

-

2K2

BC547C

2K2

270

100K

C19

1N4148

BAT85

1u

100n

100n

470u

DJ-005

D9

OUT

CLL30331

R40

1u

R9

D6

BAT85

D5

D2

+VR

R41

100K

1N4148

R43

10K

C20

10u

+VL

LD132

1N4148

D7

T19

+VL

R20

10K

R19

BC557

T18

+VL

R11

10K

R12

4K7

BC557

T17

10K

R4

4K7

T2

T1

BC547C

BC547C

R10

100K

R1

100K

DO3

DO6

DO7

6

7

5

DO9

IC5

11

14

16

VDD

C5

CLK

R45

10K

100n

R49

560

RA1

18

VDD

14

4

MCLR

-SK2

+SK2

3V6

E1

1N4148

6V2

ZD1

C16

100n

2p

A1

C13

6M8

R57

C18

2

100u

C17

ZD6

9V1

R58

+VR

R62

270

R60

L2

R59

18K

C14

82p

CD4017

+VR

1

1u

6K8

18K

C10

4K7

R18

DO2

R63

3

R33

BC557

T3

4

1/2 LM258

C15

330p

CV2

5p

22p

R61

100K

+SK4

10K

+VL

BC557

T20

10K

R32

4K7

T4

BC547C

BC547C

R31

100K

15.625ms

DO1

2

15

RST

R44

10K

RA0

17

-SK4

cSK4

7

8

+VR

R64

10K

5

+VR

1K

R55

R56

+VR

RECEIVER ADJUST

C12

L1

1uH

1p

T24

BF199

330p

C11

33K

R65

5K6

BC557

T22

+VL

R46

10K

LD110

CLL30331

LD111

R47

4K7

CLL30331

T21

R38

10K

R37

GND

DO0

R53

2K2

4

A2

6

1K

R66

BC557

4K7

T5

R36

DO5

1

3

9

DO8

NC

NC

REC

LD131

1/2 LM258

ZD5

5V1

A1,A2 = IC6 (LM258/RV4558)

ZD4

4V3

2K7

LD112

LD89

CLL30331

LD90

CLL30331

LD91

LD66

CLL30331

LD67

CLL30331

LD68

LD45

CLL30331

LD46

CLL30331

LD47

LD22

CLL30331

LD23

CLL30331

LD24

LD1

CLL30331

LD2

T6

CLL30331

BC547C

BC547C

LD3

100K

R39

100K

DO4

6

10

VSS

8

13

12

CE

CO

NC

JC1

RED 3mm

A1

VDD

18

16

Rx IN

A1

VDD

18

ADDRESS SELECTION: MOUNT JC1 OR JC2 OR LEFT OPEN

16

Rx IN

2K2

R51

ZD3

4V7

4K7

R52

CLL30331

CLL30331

CLL30331

CLL30331

CLL30331

CLL30331

1

1

Diagrams

LD113

LD116

LD119

LD122

LD125

CLL30331

CLL30331

CLL30331

LD114

LD117

CLL30331

CLL30331

LD115

LD118

CLL30331

CLL30331

LD92

LD95

CLL30331

CLL30331

LD93

LD96

CLL30331

CLL30331

LD94

LD97

CLL30331

CLL30331

LD69

LD72

CLL30331

CLL30331

LD70

LD73

CLL30331

CLL30331

LD71

LD74

CLL30331

CLL30331

LD48

LD51

CLL30331

CLL30331

LD49

LD52

CLL30331

CLL30331

LD50

LD53

CLL30331

CLL30331

LD25

LD28

CLL30331

CLL30331

LD26

LD29

CLL30331

CLL30331

LD27

LD30

CLL30331

CLL30331

LD4

LD7

CLL30331

CLL30331

LD5

LD8

CLL30331

CLL30331

LD6

LD9

CLL30331

CLL30331

a

b

c

R5

PIC16C71

A6

543

13

C9

543

13

330p

C8

560

R23

RB3

6

IC4

330p

6

IC3

T10

BC547C

100K

9

A7

UM3758-120A

A7

7

UM3758-120A

R34

NC

NCNCNCNCNCNCNC

A8

A9

A10

987

NC

NCNCNCNCNCNCNC

A8

A9

A10

9

8

10

R2

560

T9

BC547C

R14

100K

RB6

12

IC2

JC2

NC

A4

A3

A5

A2

2

OSC

R50

100K

NC

A3

A4A6A5

A2

2

OSC

R48

100K

CLL30331

LD120

LD123

CLL30331

CLL30331

LD121

LD124

CLL30331

CLL30331

LD98

LD101

CLL30331

CLL30331

LD99

LD102

CLL30331

CLL30331

LD100

LD103

CLL30331

CLL30331

LD75

LD78

CLL30331

CLL30331

LD76

LD79

CLL30331

CLL30331

LD77

LD80

CLL30331

CLL30331

LD54

LD57

CLL30331

CLL30331

LD55

LD58

CLL30331

CLL30331

LD56

LD59

CLL30331

CLL30331

LD31

LD34

CLL30331

CLL30331

LD32

LD35

CLL30331

CLL30331

LD33

LD36

CLL30331

CLL30331

LD10

LD13

CLL30331

CLL30331

LD11

LD14

CLL30331

CLL30331

LD12

LD15

CLL30331

CLL30331

d

e

R25

560

560

T15

BC547C

R30

100K

RB0

6

1

RA2

OUT

A12

A11

12NC10

11

17

NC

A11

OUT

A12

12

11

17

R35

T14

BC547C

R28

100K

RB4

10

3

RA4

MODE

15

14

R8

2K2

VSS

+V

R7

2K7

+V

MODE

15

14

VSS

CLL30331

LD126

CLL30331

LD104

CLL30331

LD105

CLL30331

LD81

CLL30331

LD82

CLL30331

LD60

CLL30331

LD61

CLL30331

LD37

CLL30331

LD38

CLL30331

LD16

CLL30331

LD17

CLL30331

560

T16

BC547C

R29

100K

RB7

13

2

AN3

C1

470p

5

IC1

+V

7

3

2

LM335

SENS

500

RV1

TEMP. CALIBRATION

LD127

LD106

LD83

LD62

LD39

LD18

6

CLL30331

CLL30331

CLL30331

CLL30331

CLL30331

CLL30331

C2

4

R67

R6

470p

CA3160

100K

5K6

LD128

CLL30331

LD129

CLL30331

LD130

CLL30331

LD107

LD88

CLL30331

CLL30331

LD108

CLL30331

LD109

CLL30331

LD84

LD87

CLL30331

LD85

CLL30331

CLL30331

LD86

CLL30331

LD63

LD44

CLL30331

LD64

CLL30331

CLL30331

LD65

CLL30331

LD40

LD43

CLL30331

LD41

CLL30331

CLL30331

LD42

CLL30331

LD19

CLL30331

LD20

CLL30331

LD21

CLL30331

f

g

dp

R21

R3

560

560

T11

R22

RB2

8

R68

BC547C

100K

R24

560

T12

T13

BC547C

BC547C

R26

100K

R27

100K

RB1

RB5

7

11

VSS

5

16

15

OSC1

OSC2

C7

X1

4.194304MHz

12p

C6

2p

22p

CV1

R13

10K

270K

TIME CALIBRATION

23

Page 24

VELLEMAN COMPONENTS NV

Legen Heirweg 33

9890 Gavere

Belgium Europe

Info & support: www.velleman.be

Modifications and typographical errors reserved

© Velleman Components NV

H8009IP - 2002 - ED3

Loading...

Loading...