Page 1

Quick setup guide

Submersible pressure transmitter with

metal measuring cell

VEGABAR 87

Probus PA

Document ID: 46328

Page 2

Contents

Contents

1 For your safety ......................................................................................................................... 3

1.1 Authorised personnel ....................................................................................................... 3

1.2 Appropriate use ................................................................................................................ 3

1.3 Warning about incorrect use ............................................................................................. 3

1.4 General safety instructions ............................................................................................... 3

1.5 EU conformity ................................................................................................................... 3

1.6 NAMUR recommendations .............................................................................................. 4

1.7 Environmental instructions ............................................................................................... 4

2 Product description ................................................................................................................. 5

2.1 Conguration .................................................................................................................... 5

3 Mounting ................................................................................................................................... 6

3.1 General instructions for use of the instrument .................................................................. 6

3.2 Ventilation and pressure compensation ............................................................................ 6

4 Connecting to the bus system ................................................................................................ 8

4.1 Connecting ....................................................................................................................... 8

4.2 Single chamber housing ................................................................................................... 9

4.3 Double chamber housing ................................................................................................. 9

5 Set up with the display and adjustment module ................................................................ 11

5.1 Insert display and adjustment module ............................................................................ 11

5.2 Parameter adjustment - Quick setup .............................................................................. 12

5.3 Parameter adjustment - Extended adjustment................................................................ 14

5.4 Menu overview ............................................................................................................... 15

6 Set up with smartphone/tablet, PC/notebook via Bluetooth ............................................. 18

6.1 Preparations ................................................................................................................... 18

6.2 Connecting ..................................................................................................................... 19

6.3 Sensor parameter adjustment ........................................................................................ 19

7 Supplement ............................................................................................................................ 21

7.1 Technical data ................................................................................................................ 21

Information:

This quick setup guide enables quick setup and commissioning of

your instrument.

You can nd supplementary information in the corresponding, more

detailed Operating Instructions Manual as well as the Safety Manual

that comes with instruments with SIL qualication. These manuals are

available on our homepage.

Operating instructions VEGABAR 87 - Probus PA: DocumentID 45047

Editing status of the quick setup guide: 2021-03-31

2

VEGABAR 87 • Probus PA

46328-EN-210430

Page 3

1 For your safety

1 For your safety

1.1 Authorised personnel

All operations described in this documentation must be carried out

only by trained, qualied personnel authorised by the plant operator.

During work on and with the device, the required personal protective

equipment must always be worn.

1.2 Appropriate use

Model VEGABAR 87 is a pressure transmitter for level and gauge

measurement.

You can nd detailed information about the area of application in

chapter " Product description".

Operational reliability is ensured only if the instrument is properly

used according to the specications in the operating instructions

manual as well as possible supplementary instructions.

1.3 Warning about incorrect use

Inappropriate or incorrect use of this product can give rise to applica-

tion-specic hazards, e.g. vessel overll through incorrect mounting

or adjustment. Damage to property and persons or environmental

contamination can result. Also, the protective characteristics of the

instrument can be impaired.

1.4 General safety instructions

This is a state-of-the-art instrument complying with all prevailing

regulations and directives. The instrument must only be operated in a

technically awless and reliable condition. The operator is responsible for the trouble-free operation of the instrument. When measuring

aggressive or corrosive media that can cause a dangerous situation

if the instrument malfunctions, the operator has to implement suitable

measures to make sure the instrument is functioning properly.

The safety instructions in this operating instructions manual, the na-

tional installation standards as well as the valid safety regulations and

accident prevention rules must be observed by the user.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbitrary conversions or modications are explicitly forbidden. For safety

reasons, only the accessory specied by the manufacturer must be

used.

To avoid any danger, the safety approval markings and safety tips on

the device must also be observed.

46328-EN-210430

VEGABAR 87 • Probus PA

1.5 EU conformity

The device fulls the legal requirements of the applicable EU directives. By axing the CE marking, we conrm the conformity of the

instrument with these directives.

3

Page 4

1 For your safety

The EU conformity declaration can be found on our homepage.

1.6 NAMUR recommendations

NAMUR is the automation technology user association in the process

industry in Germany. The published NAMUR recommendations are

accepted as the standard in eld instrumentation.

The device fulls the requirements of the following NAMUR recom-

mendations:

NE 21 – Electromagnetic compatibility of equipment

•

NE 53 – Compatibility of eld devices and display/adjustment

•

components

NE 107 – Self-monitoring and diagnosis of eld devices

•

For further information see www.namur.de.

1.7 Environmental instructions

Protection of the environment is one of our most important duties.

That is why we have introduced an environment management system

with the goal of continuously improving company environmental pro-

tection. The environment management system is certied according

to DIN EN ISO 14001.

Please help us full this obligation by observing the environmental

instructions in this manual:

Chapter "Packaging, transport and storage"

•

Chapter "Disposal"

•

46328-EN-210430

4

VEGABAR 87 • Probus PA

Page 5

Type label

2 Product description

2 Product description

2.1 Conguration

The type label contains the most important data for identication and

use of the instrument:

1

2

7

3

Fig. 1: Layout of the type label (example)

1 Product code

2 Field for approvals

3 Technical data

4 Serial number of the instrument

5 QR code

6 Symbol of the device protection class

7 ID numbers, instrument documentation

6

5

4

Serial number - Instrument search

46328-EN-210430

VEGABAR 87 • Probus PA

The type label contains the serial number of the instrument. With it

you can nd the following instrument data on our homepage:

Product code (HTML)

•

Delivery date (HTML)

•

Order-specic instrument features (HTML)

•

Operating instructions and quick setup guide at the time of ship-

•

ment (PDF)

Order-specic sensor data for an electronics exchange (XML)

•

Test certicate (PDF) - optional

•

Move to "www.vega.com" and enter in the search eld the serial

number of your instrument.

Alternatively, you can access the data via your smartphone:

Download the VEGA Tools app from the "Apple App Store" or the

•

"Google Play Store"

Scan the DataMatrix code on the type label of the instrument or

•

Enter the serial number manually in the app

•

5

Page 6

3 Mounting

Protection against moisture

Filter element - Position

3 Mounting

3.1 General instructions for use of the instrument

Protect your instrument against moisture ingress through the following

measures:

Use a suitable connection cable (see chapter "Connecting to

•

power supply")

Tighten the cable gland or plug connector

•

Lead the connection cable downward in front of the cable entry or

•

plug connector

This applies mainly to outdoor installations, in areas where high

humidity is expected (e.g. through cleaning processes) and on cooled

or heated vessels.

Note:

Make sure that during installation or maintenance no moisture or dirt

can get inside the instrument.

To maintain the housing protection, make sure that the housing lid is

closed during operation and locked, if necessary.

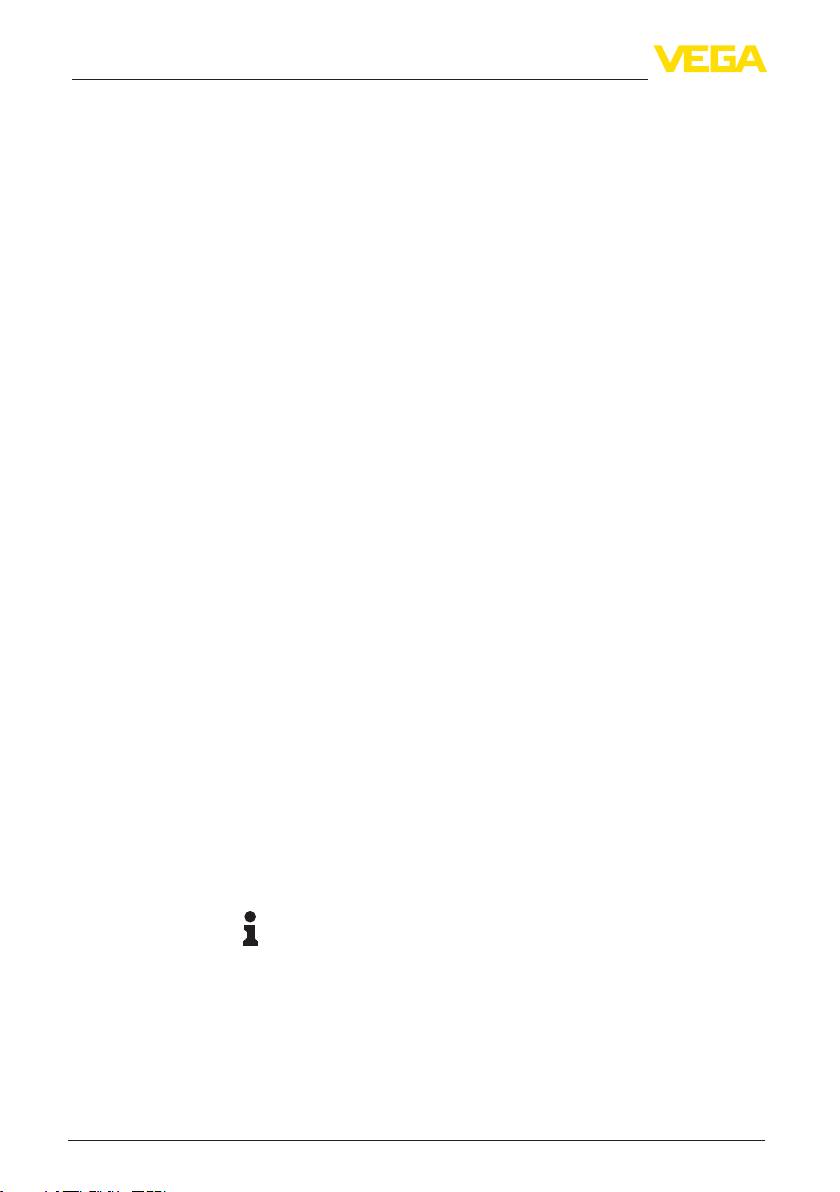

3.2 Ventilation and pressure compensation

6

6 6

1 2 3

6

4

Fig. 2: Position of the lter element

1 Plastic, stainless steel single chamber (precision casting)

2 Aluminium - single chamber

3 Stainless steel single chamber (electropolished)

4 Plastic double chamber

5 Aluminium, stainless steel double chamber housing (precision casting)

6 Filter element

With the following instruments a blind plug is installed instead of the

lter element:

6

6

5

46328-EN-210430

VEGABAR 87 • Probus PA

Page 7

3 Mounting

Instruments in protection IP66/IP68 (1 bar) - ventilation via capillar-

•

ies in non-detachable cable

Instruments with absolute pressure

•

46328-EN-210430

VEGABAR 87 • Probus PA

7

Page 8

4 Connecting to the bus system

Connection technology

4 Connecting to the bus system

4.1 Connecting

The voltage supply and signal output are connected via the springloaded terminals in the housing.

Connection to the display and adjustment module or to the interface

adapter is carried out via contact pins in the housing.

Information:

The terminal block is pluggable and can be removed from the

electronics. To do this, lift the terminal block with a small screwdriver

and pull it out. When reinserting the terminal block, you should hear it

snap in.

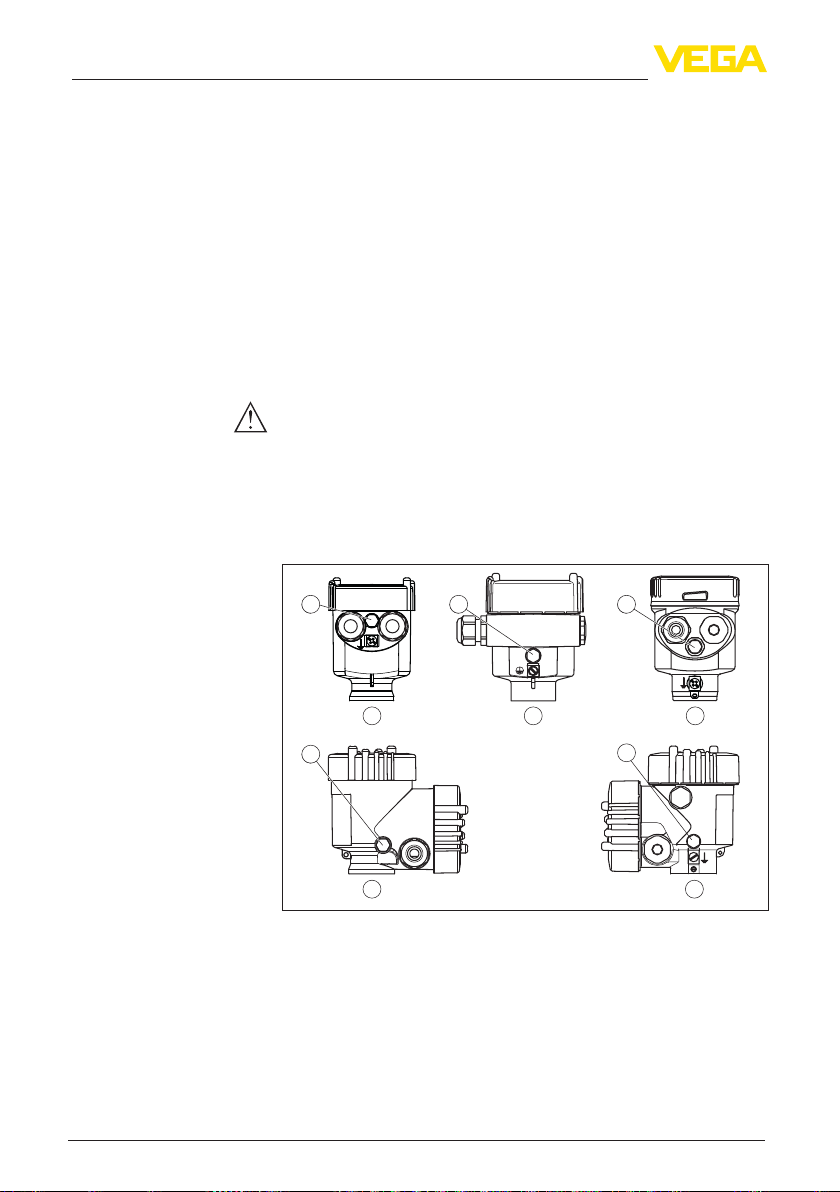

Connection procedure

Proceed as follows:

1. Unscrew the housing lid

2. If a display and adjustment module is installed, remove it by turn-

ing it slightly to the left

3. Loosen compression nut of the cable gland and remove blind

plug

4. Remove approx. 10 cm (4 in) of the cable mantle, strip approx.

1 cm (0.4 in) of insulation from the ends of the individual wires

5. Insert the cable into the sensor through the cable entry

1 2

Fig. 3: Connection steps 5 and 6

1 Single chamber housing

2 Double chamber housing

6. Insert the wire ends into the terminals according to the wiring plan

Note:

Solid cores as well as exible cores with wire end sleeves are inserted directly into the terminal openings. In case of exible cores without

end sleeves, press the terminal from above with a small screwdriver,

the terminal opening is then free. When the screwdriver is released,

the terminal closes again.

7. Check the hold of the wires in the terminals by lightly pulling on

them

8. Connect the shielding to the internal ground terminal, connect the

external ground terminal to potential equalisation

46328-EN-210430

8

VEGABAR 87 • Probus PA

Page 9

2

2

Electronics and connection compartment

4 Connecting to the bus system

9. Tighten the compression nut of the cable entry gland. The seal

ring must completely encircle the cable

10. Reinsert the display and adjustment module, if one was installed

11. Screw the housing lid back on

The electrical connection is nished.

4.2 Single chamber housing

The following illustration applies to the non-Ex, Ex-ia and Ex-d version.

3

00

0

1

1

9

9

2

2

1

8

8

3

1

0

Bus

+

( )

1

1

Fig. 4: Electronics and connection compartment - single chamber housing

1 Voltage supply, signal output

2 For display and adjustment module or interface adapter

3 Selection switch for instrument address

4 For external display and adjustment unit

5 Ground terminal for connection of the cable screening

3

7

7

4

4

6

6

5

5

(-)

2

5

678

4

5

Electronics compartment

46328-EN-210430

VEGABAR 87 • Probus PA

4.3 Double chamber housing

The following illustrations apply to the non-Ex as well as to the Ex-ia

version.

3

00

0

1

1

9

9

2

2

1

8

8

3

1

0

Bus

( )

+

1

Fig. 5: Electronics compartment - double chamber housing

1 Internal connection to the connection compartment

2 Contact pins for the display and adjustment module or interface adapter

3 Selection switch for bus address

3

7

7

4

4

6

6

5

5

(-)

2

5

678

11

9

Page 10

4 Connecting to the bus system

2

Connection compartment

Bus

( )

+

(-)

1

2

5

678

1

Fig. 6: Connection compartment - double chamber housing

1 Voltage supply, signal output

2 For display and adjustment module or interface adapter

3 For external display and adjustment unit

4 Ground terminal for connection of the cable screening

3

4

10

46328-EN-210430

VEGABAR 87 • Probus PA

Page 11

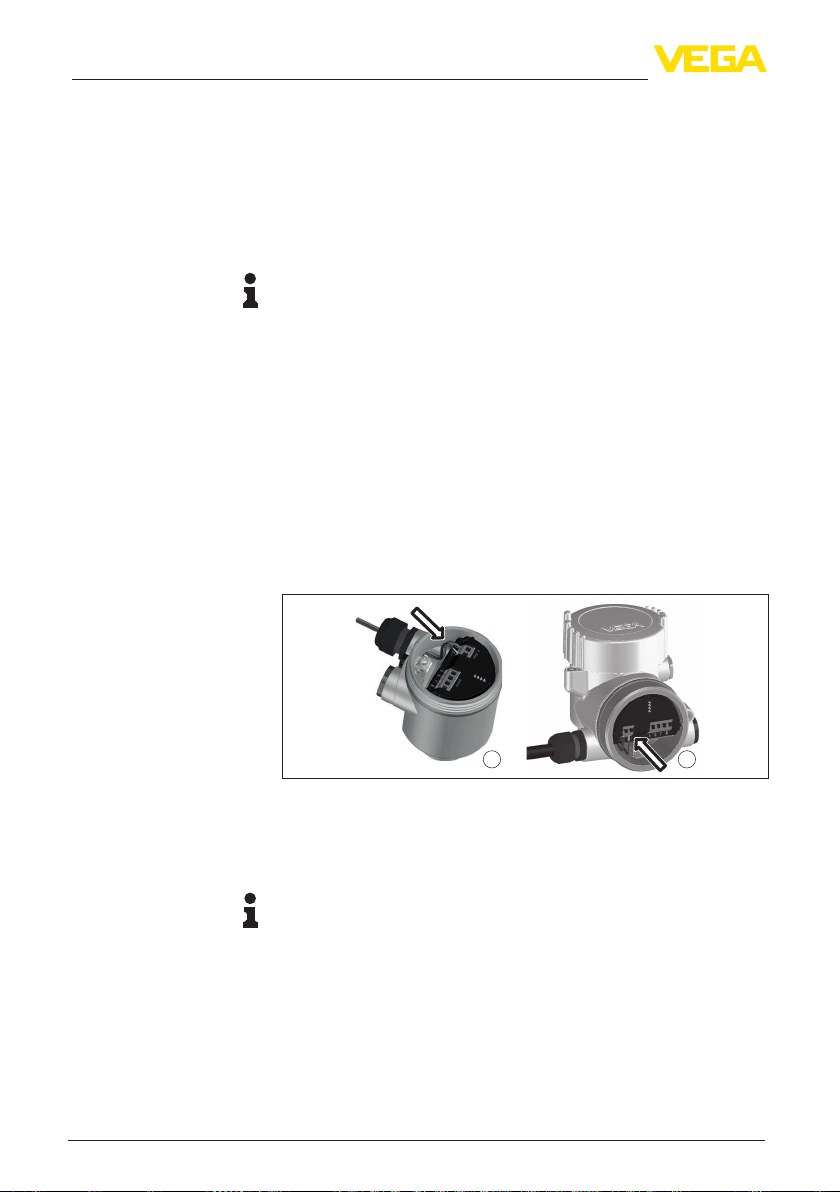

5 Set up with the display and adjustment module

5 Set up with the display and adjustment

module

5.1 Insert display and adjustment module

The display and adjustment module can be inserted into the sensor

and removed again at any time. You can choose any one of four dierent positions - each displaced by 90°. It is not necessary to interrupt

the power supply.

Proceed as follows:

1. Unscrew the housing lid

2. Place the display and adjustment module on the electronics in the

desired position and turn it to the right until it snaps in.

3. Screw housing lid with inspection window tightly back on

Disassembly is carried out in reverse order.

The display and adjustment module is powered by the sensor, an ad-

ditional connection is not necessary.

46328-EN-210430

VEGABAR 87 • Probus PA

Fig. 7: Installing the display and adjustment module in the electronics compartment of the single chamber housing

11

Page 12

5 Set up with the display and adjustment module

Fig. 8: Installing the display and adjustment module in the double chamber

housing

1 In the electronics compartment

2 In the connection compartment

Note:

If you intend to retrot the instrument with a display and adjustment

module for continuous measured value indication, a higher lid with an

inspection glass is required.

5.2 Parameter adjustment - Quick setup

To quickly and easily adapt the sensor to the application, select the

menu item " Quick setup" in the start graphic on the display and

adjustment module.

1 2

Quick setup - Presettings

12

Carry out the following steps in the below sequence.

You can nd " Extended adjustment" in the next sub-chapter.

Sensor address

In the rst menu item you have to enter a sensor address. The selection switches on the electronics module are preset to sensor address

126. This means that the sensor address can be changed via the

display and adjustment module.

46328-EN-210430

Measurement loop name

In this menu item you assign a suitable measurement loop name.

Permitted are names with a maximum of 19 characters.

VEGABAR 87 • Probus PA

Page 13

5 Set up with the display and adjustment module

Application

In this menu item, you activate/deactivate the Secondary sensor for

the electronic dierential pressure and select the application. The ap-

plication comprises process pressure and level measurement.

Units

In this menu item you determine the adjustment and temperature

units of the instrument. Depending on the selected application in the

menu item " Application", dierent adjustment units are available.

Quick setup - Process

pressure measurement

Quick setup - Level measurement

Position correction

In this menu item you compensate the inuence of the installation

position of the instrument (oset) on the measured value.

Zero adjustment

In this menu item you carry out the zero adjustment for the process

pressure.

Enter the corresponding pressure value for 0 %.

Span adjustment

In this menu item you carry out the span adjustment for the process

pressure

Enter the corresponding pressure value for 100 %.

Position correction

In this menu item you compensate the inuence of the installation

position of the instrument (oset) on the measured value.

Max. adjustment

In this menu item you carry out the max. adjustment for level

Enter the percentage value and the corresponding value for the max.

level.

Min. adjustment

In this menu item you carry out the min. adjustment for level

Enter the percentage value and the corresponding value for the min.

level.

46328-EN-210430

VEGABAR 87 • Probus PA

The quick setup is nished.

13

Page 14

5 Set up with the display and adjustment module

Parameterization example

VEGABAR 87 always measures pressure independently of the pro-

cess variable selected in the menu item " Application". To output the

selected process variable correctly, an allocation of the output signal

to 0 % and 100 % must be carried out (adjustment).

During adjustment, the pressure is entered e.g. for the level with full

and empty vessel, see following example:

100%

2

")

2 m

(78.74

0%

1

Fig. 9: Parameter adjustment example Min./max. adjustment, level measurement

1 Min. level = 0 % corresponds to 0.0 mbar

2 Max. level = 100 % corresponds to 196.2 mbar

If these values are not known, an adjustment with lling levels of e.g.

10 % and 90 % is also possible. By means of these settings, the real

lling height is then calculated.

The real product level during the adjustment is not important, because

the min./max. adjustment is always carried out without changing the

product level. These settings can be made ahead of time without the

instrument having to be installed.

Main menu

14

5.3 Parameter adjustment - Extended adjustment

For technically demanding measuring points, you can carry out

extended settings in "Extended adjustment".

46328-EN-210430

The main menu is divided into ve sections with the following functions:

VEGABAR 87 • Probus PA

Page 15

5 Set up with the display and adjustment module

Setup: Settings, for example, to measurement loop name, application, units, position correction, adjustment, AI FB 1 Channel - scaling

- damping

Display: Settings, e.g., for language, measured value display, lighting

Diagnosis: Information, e.g. on instrument status, pointer, measure-

ment reliability, AI FB 1 simulation

Additional adjustments: PIN, date/time, reset, copy function

Info: Instrument name, hardware and software version, date of manu-

facture, sensor features

To ensure optimum adjustment of the measurement, the individual

submenu items in the main menu "Setup" should be selected one

after the other and provided with the correct parameters. The menu

items are described in the following.

5.4 Menu overview

The following tables show the adjustment menu of the instrument.

Depending on the instrument version or application, all menu items

may not be available or some may be dierently assigned.

Setup

Menu item Parameter Default value

Sensor address 126

Measurement loop name 19 alphanumeric characters/special

characters

Application Level, process pressure Level

Secondary Device for electronic dierential pressure 1)

Units Adjustment unit (m, bar, Pa, psi … user-

dened)

Temperature unit (°C, °F) °C

Position correction 0.00 bar

Adjustment Zero/Min. adjustment 0.00 bar

Span/Max. adjustment Nominal measuring range in bar

Linearisation Linear, cylindrical tank, … user-dened Linear

Sensor

Deactivated

mbar (with nominal measuring range

≤ 400 mbar)

bar (with nominal measuring ranges

≥ 1 bar)

0.00 %

100.00 %

46328-EN-210430

VEGABAR 87 • Probus PA

1)

Parameter only active if the instrument is connected to the Secondary sensor

15

Page 16

5 Set up with the display and adjustment module

Menu item Parameter Default value

AI FB 1 Channel Primary Value

Scaling format Pressure

Scaling 0 % corresponds to 0 bar

100 % corresponds to measuring range

nal value

Damping PV FTime 1 s

Lock adjustment Blocked, released Released

Display

Menu item Default value

Menu language Selected language

Displayed value 1 Signal output in %

Displayed value 2 Ceramic measuring cell: Measuring cell temperature in °C

Metallic measuring cell: Electronics temperature in °C

Display format Number of positions after the decimal point, automatically

Backlight Switched on

Diagnostics

Menu item Parameter Default value

Device status -

Peak value indicator Pressure Current pressure measured value

Pointer function temp. Temperature Actual measuring cell and electronic tem-

Simulation Pressure, percent, signal output,

linearized percent, measuring cell temperature, electronics temperature

perature

Process pressure

Additional adjustments

Menu item Parameter Default value

Date/Time Actual date/Actual time

Reset Delivery status, basic settings

Copy instrument settings Read from sensor, write into sensor

Scaling Scaling size Volume in l

Scaling format 0 % corresponds to 0 l

100 % corresponds to 0 l

Special parameters Service-Login No reset

16

VEGABAR 87 • Probus PA

46328-EN-210430

Page 17

5 Set up with the display and adjustment module

Info

Menu item Parameter

Device name VEGABAR 87

Instrument version Hardware and software version

Factory calibration date Date

Probus Ident Number Identication number of the instrument on a Probus system

Sensor characteristics Order-specic characteristics

46328-EN-210430

VEGABAR 87 • Probus PA

17

Page 18

6 Set up with smartphone/tablet, PC/notebook via Bluetooth

6 Set up with smartphone/tablet, PC/

notebook via Bluetooth

6.1 Preparations

Activate Bluetooth

Make sure that the Bluetooth function of the display and adjustment

module is activated. For this, the switch on the bottom side must be

set to " On".

1

Fig. 10: Activate Bluetooth

1 Switch

On = Bluetooth active

O = Bluetooth not active

On

O

Change sensor PIN

18

The security concept of Bluetooth operation absolutely requires that

the default setting of the sensor PIN be changed. This prevents unauthorized access to the sensor.

The default setting of the sensor PIN is " 0000". First of all you have

to change the sensor PIN in the adjustment menu of the sensor, e.g.

to " 1111":

1. Go to setup via the extended operation

2. Lock operation by changing sensor PIN

46328-EN-210430

3. Enable operation by entering the sensor PIN once more

VEGABAR 87 • Probus PA

Page 19

Preparations

6 Set up with smartphone/tablet, PC/notebook via Bluetooth

After entering the changed sensor PIN once again, sensor operation is enabled again. For access (authentication) with Bluetooth, the

changed PIN is still eective.

Information:

Bluetooth communication functions only if the actual sensor PIN differs from the default setting " 0000".

6.2 Connecting

Smartphone/Tablet

Start the adjustment app and select the function "Setup". The smartphone/tablet searches automatically for Bluetooth-capable instruments in the area.

PC/Notebook

Start PACTware and the VEGA project assistant. Select the device

search via Bluetooth and start the search function. The device auto-

matically searches for Bluetooth-capable devices in the vicinity.

Connecting

Authenticate

46328-EN-210430

VEGABAR 87 • Probus PA

The message " Instrument search running" is displayed. All devices

found are listed in the operating window. The search is automatically

continued continuously.

Select in the device list the requested device. The message " Con-

necting" is displayed.

For the rst connection, the operating device and the sensor must

authenticate each other. After successful authentication, the next con-

nection functions without authentication.

For authentication, enter in the next menu window the 4-digit sensor

PIN.

6.3 Sensor parameter adjustment

The sensor parameterization is carried out via the adjustment app on

the smartphone/tablet or the DTM on the PC/notebook.

19

Page 20

6 Set up with smartphone/tablet, PC/notebook via Bluetooth

App view

Fig. 11: Example of an app view - Setup sensor adjustment

20

46328-EN-210430

VEGABAR 87 • Probus PA

Page 21

7 Supplement

7 Supplement

7.1 Technical data

Note for approved instruments

The technical data in the respective safety instructions which are included in delivery are valid for

approved instruments (e.g. with Ex approval). These data can dier from the data listed herein, for

example regarding the process conditions or the voltage supply.

All approval documents can be downloaded from our homepage.

Electromechanical data - version IP66/IP67 and IP66/IP68 (0.2 bar)

2)

Options of the cable entry

Ʋ Cable entry M20 x 1.5; ½ NPT

Ʋ Cable gland M20 x 1.5, ½ NPT (cable ø see below table)

Ʋ Blind plug M20 x 1.5; ½ NPT

Ʋ Closing cap ½ NPT

Material cable gland/Seal insert Cable diameter

5 … 9 mm 6 … 12 mm 7 … 12 mm 10 … 14 mm

PA/NBR ● ● – ●

Brass, nickel-plated/NBR ● ● – –

Stainless steel/NBR – – ● –

Wire cross-section (spring-loaded terminals)

Ʋ Massive wire, stranded wire 0.2 … 2.5 mm² (AWG 24 … 14)

Ʋ Stranded wire with end sleeve 0.2 … 1.5 mm² (AWG 24 … 16)

Voltage supply

Operating voltage U

B

Operating voltage UB with lighting

9 … 32 V DC

13.5 … 32 V DC

switched on

Number of sensors per DP/PA segment

32

coupler, max.

2)

IP66/IP68 (0.2 bar), only with absolute pressure.

46328-EN-210430

VEGABAR 87 • Probus PA

21

Page 22

Notes

22

46328-EN-210430

VEGABAR 87 • Probus PA

Page 23

Notes

46328-EN-210430

VEGABAR 87 • Probus PA

23

Page 24

Printing date:

All statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the information

available at the time of printing.

Subject to change without prior notice

© VEGA Grieshaber KG, Schiltach/Germany 2021

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

E-mail: info.de@vega.com

www.vega.com

46328-EN-210430

Loading...

Loading...