Page 1

in

out

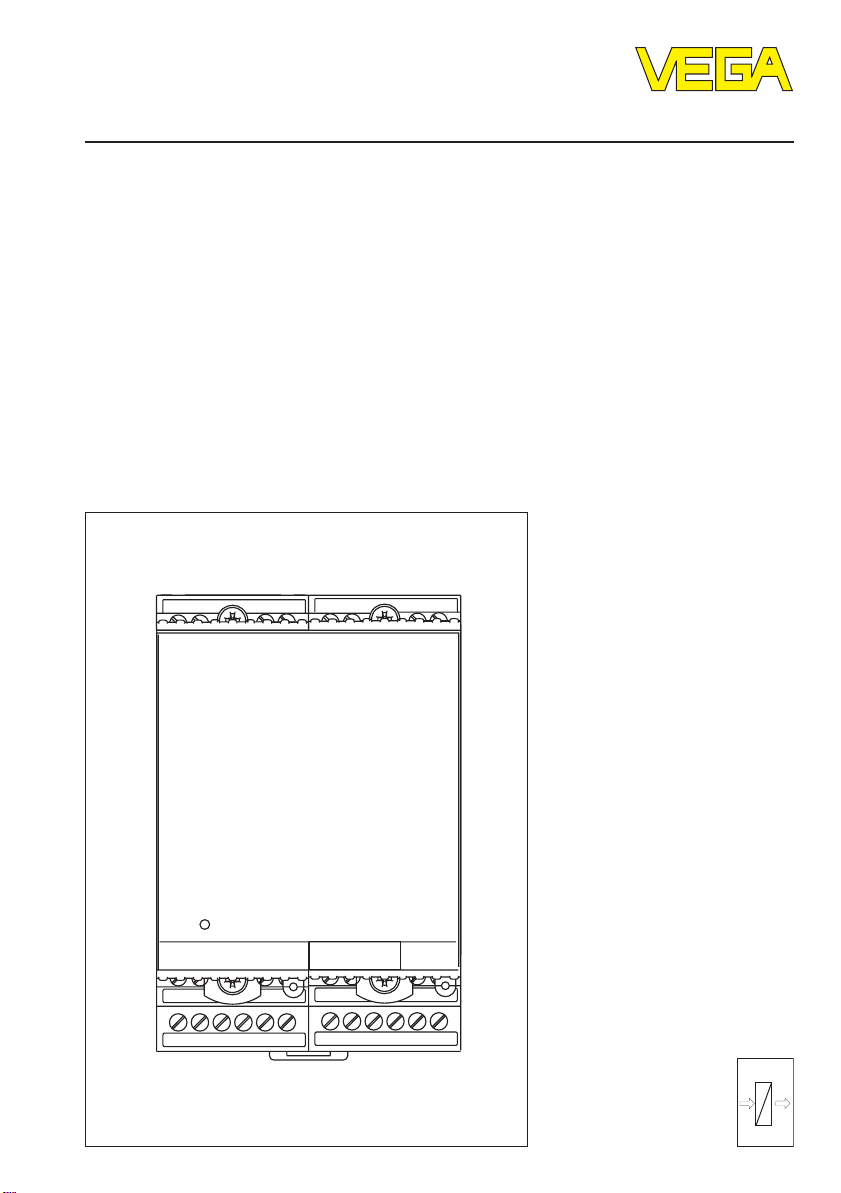

Operating Instructions

VEGASTAB 692 MD

Level and Pressure

12 34

56 78

on

VEGASTAB 692 MD

13 14 15

910 11

17 18 20 21 22

12

23 24 25 26 27 28

Ser. No.

12345678

16

out

in

Page 2

Safety information, Note Ex area

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGASTAB 692 MD

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the operating instructions and come with the Ex approved instruments.

Page 3

Contents

Contents

Safety i nformation ........................................................................ 2

Note Ex a rea ................................................................................ 2

1 Product description

1.1 Function and configuration ................................................ 4

1.2 Scope of delivery ............................................................... 4

1.3 Ex area ............................................................................... 4

1.4 Features ............................................................................. 4

1.5 Sensor choice .................................................................... 4

1.6 Technical dat a .................................................................... 5

1.7 Dimensions......................................................................... 6

2 Mounting and installation instructions ................................ 7

3 Electrical connection

3.1 Connection instructions ..................................................... 8

3.2 Connection diagram ........................................................... 9

3.4 Installation examples of HART® sensors ....................... 10

4 Setup

4.1 General information on HART® multidrop ........................... 11

4.2 Procedure......................................................................... 11

4.3 Address assignment with VVO ....................................... 12

5 Diagnosis

5.1 Maintenance ..................................................................... 14

5.2 Fault signal........................................................................ 14

5.3 Failure diagnostics ........................................................... 14

5.4 Repair ............................................................................... 14

VEGASTAB 692 MD 3

Page 4

1 Product description

Product description

1.1 Function and configuration

VEGASTAB 692 MD is a power supply unit

for connection of up to 15 VEGA sensors

(HART® two-wire sensors in Multidrop mode).

Function

VEGASTAB 692 MD provides a galvanically

separated supply circuit for up to 15 VEGA

sensors (HART® two-wire loop-powered in

Multidrop mode). The power supply for the

sensors is 17 … 25 V DC depending on the

number of connected sensors. VEGASTAB

692 MD delivers up to 60 mA constant current (15 sensors with 4 mA each) and is

open-circuit and short-circuit proof (current

limitation at approx. 200 mA). The instrument

has an RS 232 interface for communication

with the software Visual VEGA (VV) or VEGA

Visual Operating (VVO) via the

VEGACONNECT 3 interface adapter.

Configuration

VEGASTAB 692 MD is a module unit with

plug-in socket suitable for carrier rail mounting EN 50022.

1.2 Scope of delivery

1.3 Ex area

This power supply unit is not approved for

use in Ex areas.

It must neither be installed in hazardous

areas nor be used for power supply of sensors in these areas.

1.4 Features

- Power supply unit for up to 15 HART® sensors (two-wire loop-powered in Multidrop

mode).

- Digital transmission of measured values

(HART® protocol, Multidrop mode).

- Input voltage range 20 … 250 V AC,

20 … 72 V DC.

- Galvanically separated and overload,

short-circuit or open-circuit proof circuit.

- Integrated HART® resistance.

- RS 232 interface via VEGACONNECT 3 for

connection to a modem or PC.

- Communication with Visual VEGA (VV) and

VEGA Visual Operating (VVO).

1.5 Sensor choice

The following VEGA HART® sensors can be

connected to the unit:

- VEGASTAB 692 MD

- Plug-in socket

- Coded pins, bonding jumpers

- VEGACONNECT 3

- Operating instructions VEGASTAB 692 MD

- Operating instructions VEGACONNECT 3

- Operating instructions remote parameter

adjustment

4 VEGASTAB 692 MD

- VEGAPULS series 40 and VEGAPULS

series 50 radar sensors.

- VEGAFLEX series 50 sensors with guided

microwaves.

- VEGASON series 50 ultrasonic sensors

- Series D80 pressure transmitters and

VEGABAR 40

Make sure that only VEGA HART® sensors in

two-wire loop-powered version (in Multidrop

mode) are used.

It is not possible to connect sensors of other

manufacturers.

Page 5

Product description

1.6 Technical data

Power supply

Operating voltage/Power consumption U

Output or measured data input

Num ber 1 x 24 V output or digital measured data input

Type of measured data input active two-wire input, digital (HART® protocol),

Sensor type up to 15 VEGA two-wire loop-powered HART

Output voltage approx. 17 … 24 V DC

Output constant current max. 60 mA (15 sensors with 4 mA each)

Current limitation at approx. 200 mA, short-circuit proof

Connection cable 2-wire standard cable (screening is

max. cable length 1000 m

max. resistance per wire 15 Ohm

Serial interface (RS 232)

Num ber 1 x RS 232 via VEGACONNECT 3

Function communication via modem or PC for data

max. cable length 15 m

Interfac e paramete rs 9600 baud, no parity, 1 stop bit

Protocol VEGA specific

= 20 … 250 V AC, 50/60 Hz/approx. 12 VA

nom

= 20 … 72 V DC

for up to 15 sensors

sensors are powered by VEGASTAB 692 MD

sensors in Multidrop mode

(pressure transmitters, ultrasonic and radar

sensors, see chapter "1.5 Sensor choice")

recommended)

recording with Visual VEGA (VV) or

sensor adjustment with VEGA Visual Operating

(VVO)

®

Indicating elements

LED in front plate green: power supply and output voltage on

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +80°C

Electrical connection

Screw terminals max. 1.5 mm

2

RS 232 interface (VEGACONNECT 3) Sub-D 9-pole

Electrical protective measures

Instrument IP 30

Plug-in socket IP 20

Protection class II

Overvoltage category II

VEGASTAB 692 MD 5

Page 6

Product description

Electrical separating measures

Reliable separation acc. to

VDE 0106, part 1 between power supply and measured data input

- refe rence voltage 250 V

- insulation resistance 2.3 kV

Mechanical data

Seri es module unit with plug-in socket, coded pin, two

bonding jumpers

Mounting carrier rail mounting acc. to EN 50 022

Dimensions, not assembled W = 72 mm, H = 118.5 mm, D = 134 mm

Weight approx. 480 g

1.7 Dimensions

Carrier rail 35 x 7.5 or 35 x 15 acc.

to EN 50 022

126

54,5

12 34

on

VEGASTAB 692 MD

910 1112

17 18 20 21 22

56 78

13 14 15 16

23 24 25 26 27 28

72

Ser. No.

12345678

108

6 VEGASTAB 692 MD

Page 7

Mounting and installation instructions

6201828

5

0

9

0

0V

876

a

US

10V

9

8

3

C

3

2 Mounting and installation instructions

Mounting

Each series 600 instrument consists of a

plug-in socket for carrier rail mounting

EN 50 022 and a module unit.

The supply voltage can be connected to

terminals 17 and 18.

For neighbouring series 600 instruments it is

possible to continue connection L1 and N

directly via the supplied jumpers.

Note!

The jumpers must not be used with single

instruments or at the respective end of an

instrument row.

If this is not maintained, it is possible to come

in contact with the operating voltage or to

cause a short-circuit.

The power supply unit VEGASTAB 692 MD

must neither be installed in hazardous areas

nor used for power supply of sensors in

these areas.

Safe operation is only ensured if the operating instructions manual and the EC type

approval certificate are observed.

VEGASTAB 692 MD must not be opened.

Coding

To avoid interchanging the different instruments, the plug-in socket is provided with

pins and the instrument with corresponding

gaps (mechanical coding).

With VEGASTAB 692 MD, the supplied coded

pins must be plugged in acc. to the following

scheme.

Instrument

coding

VEGASTAB 692 MD right 3

Direct supply for supply

voltage via jumpers

left B

right B

1

EEx i

left

B

right

...1

1

252

VEGASTAB 692 MD 7

Page 8

3 Electrical connection

Electrical connection

3.1 Connection instructions

For electrical connection, you should always

observe the following instructions:

- The connection must be made according to

the appropriate national installation standards (e.g. in Germany acc. to the VDE

regulations).

- The wiring between VEGASTAB 692 MD

and the sensors can be standard two-wire

cable.

- If electromagnetic interference is expected,

the use of screened cable is recommended. The screening must be earthed at

one sensor end.

- The line resistances stated in the technical

data must not be exceeded.

- If overvoltages are expected, we recommend a sensor electronics module with

integrated overvoltage protection or the

installation of VEGA overvoltage arresters.

- When connecting more than one sensor

(max. 15), it is obligatory to connect (before complete connection) each sensor

individually to VEGASTAB 692 MD and to

assign a different address to each sensor

(1-15) via the software VVO (see chap. "4

Setup").

- Make sure when connecting

VEGACONNECT 3 to a modem that the

modem connection cable for

VEGACONNECT 3 (MODEM.KX) is used.

8 VEGASTAB 692 MD

Page 9

Electrical connection

3.2 Connection diagram

+

12 34

56 78

-

HART® sensors

on

VEGASTAB 692 MD

910 11

17 18 20 21 22

L+N

-

Supply voltage

13 14 15

12

23 24 25 26 27 28

Ser. No.

12345678

16

VEGACONNECT 3

RS 232 connection

(9-pole Sub-D

socket)

VVO

PC/Laptop

Modem connection cable:

MODEM.KX

Modem

VEGASTAB 692 MD 9

Page 10

Electrical connection

3.4 Installation examples of HART

®

sensors

Example 1

One common (two-wire) bus cable is used to

connect up to 15 sensors in series (right

down to the last sensor of the group) to

VEGASTAB 692 MD. The total cable length

can be up to 1000 m.

12 34

VEGASTAB 692 MD

910 11

17 18 20 21 22

Example 2

One common (two-wire) bus cable for up to

15 sensors is lead from VEGASTAB 692 MD

to the facility and from there radially to the

sensors. The branching point should be as

close as possible to the sensors. The cable

length to the farthest sensor can be up to

1000 m.

56 78

on

13 14 15

12

23 24 25 26 27 28

Ser. No.

12345678

16

56 78

12 34

on

VEGASTAB 692 MD

910 11

17 18 20 21 22

13 14 15

12

23 24 25 26 27 28

Ser. No.

12345678

16

10 VEGASTAB 692 MD

Page 11

Setup

4 Setup

4.1 General information on HART

multidrop

As a rule, a HART® sensor outputs a current

of 4...20 mA, proportional to the measured

value. Multidrop mode means that the sensor

always consumes a constant current of 4 mA.

The measured value is therefore no longer

transmitted by means of the strength of the

current, but exclusively through a digital

signal superimposed on the current. This

way, up to 15 HART® sensors can be operated on one two-wire cable. However, before

connecting several sensors, each individual

sensor must be switched to multidrop mode

and have its own address (1-15) assigned

by VVO.

Keep in mind that the software VVO supports

the multidrop mode of HART® sensors only in

version 2.60 and higher, and Visual VEGA

only in version 4.50 and higher.

®

4.2 Procedure

• Connect VEGASTAB 692 MD to power

supply.

• Connect VEGACONNECT 3 to VEGASTAB

692 MD and the serial interface of your PC.

• Connect the first HART® sensor and adjust

to multidrop and instrument address 1 via

the software VVO (see chapter "4.3 Address assignment with VVO").

• A HART® load resistance must not be connected as usual to the sensor cable, since

it is already integrated in VEGASTAB 692

MD

• Disconnect voltage from the first sensor

and mark address 1 outside on its housing.

• Connect the second sensor and set it to

multidrop with address 2 and mark it.

• Assign an address to all other sensors in

the same way and mark them.

• Connect all sensors to VEGASTAB 692 MD

and start the setup with VVO. Note that this

can last a few minutes depending on the

number of connected sensors.

• Check if all sensors are displayed in VVO.

• Carry out adjustment and parameter setting of the individual sensors or measurement loops.

• If all measurements work satisfactorily,

Visual VEGA can be installed for measured

value enquiry. If this is to be done by remote enquiry via modem (previously connected via a direct connection), the modem

connection cable for VEGACONNECT 3

(MODEM.KX) must be used. The connected modem is then automatically initialised with the correct interface parameters

by VEGACONNECT 3. The initialisation is

confirmed by the lighting of the AA-LED on

the modem.

Further information on modem operation

can be found in the operating instructions

manual

Remote parameter adjustmentRemote parameter adjustment

Remote parameter adjustment.

Remote parameter adjustmentRemote parameter adjustment

VEGASTAB 692 MD 11

Page 12

Setup

4.3 Address assignment with VV O

After having connected the first sensor, VVO

can be started. Choose the item

and confirm with

PassworPasswor

and

Passwor

PassworPasswor

as another password can be entered later on

if necessary under

User accessUser access

User access. Press

User accessUser access

After entering the password, the window

ModeMode

Mode appears. Choose the menu item

ModeMode

rect cable connectionrect cable connection

rect cable connection and confirm with

rect cable connectionrect cable connection

OKOK

OK. Now enter as

OKOK

d VEGAd VEGA

d VEGA. Your own name as well

d VEGAd VEGA

Configuration - Program -Configuration - Program -

Configuration - Program -

Configuration - Program -Configuration - Program -

OKOK

OK to continue.

OKOK

PlanningPlanning

Planning

PlanningPlanning

NameName

Name

NameName

Di-Di-

Di-

Di-DiOKOK

OK.

OKOK

VVOVVO

VVO

VVOVVO

After the configuration, the name of the sensor appears on the desktop. To adjust

HART® multidrop mode and assign an address, please choose the menu item

figuration - Measuring systemfiguration - Measuring system

figuration - Measuring system.

figuration - Measuring systemfiguration - Measuring system

Press the button

sensor to HART® multidrop mode.

Configure modeConfigure mode

Configure mode to set the

Configure modeConfigure mode

Con-Con-

Con-

Con-Con-

Choose

between 1 and 15. Make sure that each address is only assigned once. Confirm with

OK.OK.

OK.

OK.OK.

Now a call setup is automatically started and

the database of the connected sensor is

transferred to the PC.

12 VEGASTAB 692 MD

MultidropMultidrop

Multidrop and assign any address

MultidropMultidrop

Page 13

Setup

After having assigned an address to all sensors, connect all sensors to VEGASTAB 692

MD and start via

Services - Connection Services - Connection

Services - Connection or

Services - Connection Services - Connection

a further call setup. Proceed as previously

described in

systemsystem

system and check by means of the list box if

systemsystem

Configuration - MeasuringConfiguration - Measuring

Configuration - Measuring

Configuration - MeasuringConfiguration - Measuring

VVO has found all sensors. The first number

in the list box is the assigned multidrop address, the second is the serial number of the

corresponding sensor.

Now you can set up (adjustment, parameter

setting) each measurement loop with VVO as

described in the respective operating instructions manual of the sensor. Then, the

measured values can be read out with the

visualisation software VISUAL VEGA.

F8F8

F8

F8F8

VEGASTAB 692 MD 13

Page 14

5 Diagnosis

Diagnosis

5.1 Maintenance

The instrument is maintenance-free.

5.2 Fault signal

If the green power LED in the front plate does

not light, either supply voltage is not available

or VEGASTAB 692 MD is defective.

5.3 Failure diagnostics

- If VVO outputs the message "no connection

possible", there is no communication between the RS-232 interface of the PC and

VEGACONNECT 3. Possible reasons can

be: wrong connection cable or wrong serial

interface used (e.g. COM 1 set in VVO and

plugged into COM 2).

- If in VVO the message "no instrument available on VEGACONNECT" appears, then

there is no sensor connected, the polarity

is reversed or the connected sensors are

not set to multidrop and have therefore all

the same address 0 (see chapter "4

Setup").

- If individual sensors are not available in

VVO, they have the same multidrop address (see chapter "4 Setup").

- On all sensors, a supply voltage between

16 and 25 V must be available. If this is not

the case, either the cable is too long or the

cross-section too small or there is an interruption or short-circuit.

- If you have connected a modem, the modem connection cable for VEGACONNECT

3 (MODEM.KX) must be used. If further

problems occur, you can find additional

helpful information in the operating instructions manual

ment.ment.

ment.

ment.ment.

Remote parameter adjust-Remote parameter adjust-

Remote parameter adjust-

Remote parameter adjust-Remote parameter adjust-

5.4 Repair

For safety and warranty reasons, any internal

work on the instruments, apart from that

required in normal installation and connection,

must be carried out only by VEGA personnel.

In case of defect, please return the affected

instrument with a short description of the fault

to our repair department.

14 VEGASTAB 692 MD

Page 15

Notes

VEGASTAB 692 MD 15

Page 16

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (07836) 50-0

Fax (07836) 50-201

E-Mail info@de.vega.com

www.vega.com

ISO 9001

All statements concerning scope of delivery, application, practical

use and operating conditions of the sensors and processing systems correspond to the latest information at the time of printing.

Technical data to subject to alterations

24755-EN-020301

Loading...

Loading...