Page 1

Supple

mentary instructions

Bypass 72

Bypass

with VEGAFLEX level sensor

tube

Document ID:

33545

uided Microwave

G

Page 2

0 %

100 %

E

D

C

B

A

1

2

4

5

3

6

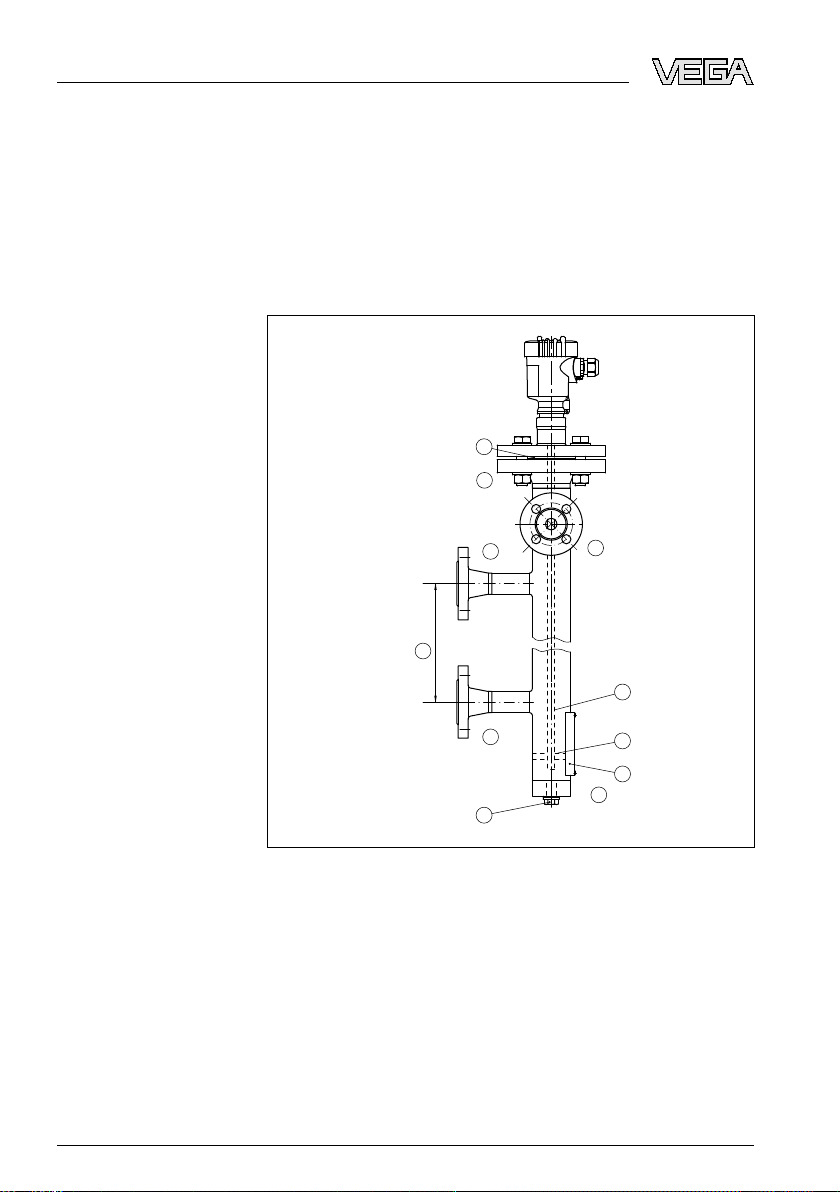

1 P roduc

t description

Features and fittings of

the bypass tube

1 Produc

t description

Bypass 72 is a complete level measuring system in a bypass tube,

complete with VEGAFLEX sensor.

Bypass 72 with VEGAFLEX sensor is immediately ready for operation

and requires no adjustment.

Depending on the process pressure or process temperature,

VEGAFLEX 61 and VEGAFLEX 66 sensors can be used in

combination with the bypass tube.

tube with VEGAFLEX

Fig. 1: Bypass

1 Dimensions tube center to tube center, 300 … 3000 mm (11.8 … 118 in)

2 Seal - measuring instrument flange

3 Electrode rod

4 Spacer

5 Type label

6 Closure rinsing connection, e.g. blind stopper

A Measuring instrument flange

B Connection flange, top

C Connection flange, bottom

D Rinsing air connection

E Ventilation connection - optional

2 Bypass 72 • with VEGAFLEX level

33545-EN-081216

sensor

Page 3

2 M

ounting

Operating instructions

Seals

2 Moun

Take note of the attached mounting instructions and the operating

instructions manual of the corresponding VEGAFLEX level sensor.

The seals for the connection flanges and ventilation fitting (optional)

must be provided by the customer.

The seal on the measuring instrument flange (A) and the rinsing

connection (D) are already mounted ex works.

Before use, check if the seal material is resistant against the medium,

the process pressure and the process temperature.

The max. permissible pressure of the sensor is specified in the

operating instructions manual of the sensor in chapter "Technical data"

or on the type label of the sensor.

ting

33545-EN-081216

Bypass 72 • with VEGAFLEX level

sensor 3

Page 4

3 Suppl

ement

3 Supp

lement

3.1 Technical data

General data

Take note of the information in the operating instructions manual of the installed VEGAFLEX level

sensor

Material 316L corresponds to 1.4404 or 1.4435

Materials

- Bypass tube 316L

- Spacer ≤ 250 °C PEEK

- Spacer > 250 °C (optional) 302 (1.4310)

- Seal - Measuring instrument flange

(standard)

- Seal - Measuring instrument flange

(higher pressure stages)

- Seal - Measuring instrument flange

(high temperature/high pressure)

Diameter ø 60.3 mm (2.37 in)

Wall thickness

- Standard version 2 mm (0.079 in)

- High pressure version 3.91 mm (0.154 in)

Volume - bypass tube See following diagram

Klingersil C-4500

Convex B45A graphite laminate

RTJ seal rings

4 Bypass 72 • with VEGAFLEX level

33545-EN-081216

sensor

Page 5

1

2

B

A

4

(1,056)

3

(0,793)

2

(0,528)

1

(0,264)

5

(1,321)

6

(1,585)

7

(1,849)

8

(2,113)

2500 (98

7

/

16

")

3000 (118

1

/

8

")

2000 (78

3

/

4

")

1500 (59

1

/

16

")

500

(19

5

/

8

")

1000 (39

3

/

8

")

0%

100%

0

3 Sup

plement

Fig. 2: Volume

of the bypass tube

1 Tube length in mm (in)

2 Volume in L (US.liq.gal)

A Standard version

B High pressure version

Process temperature see process fitting - connection flange (B,C)

Process pressure see process fitting - connection flange (B,C)

Process fitting - Measuring instrument flange (A)

DN 50 PN 40, Form C, DIN 2501

Flange 2" 300 lb RF, ANSI B16.5

Process fitting - connection flange top/bottom (B, C)

Process pressure in bar (psig) depending on the process temperature

Process temperature 150 °C (302 °F)

Flanges Process pressure Seal Wall thickness

Flange DN 20 PN 40, Form C,

DIN 2501

Flange DN 25 PN 40, Form C,

DIN 2501

Flange DN 50 PN 40, Form C,

DIN 2501

33545-EN-081216

Bypass 72 • with VEGAFLEX level

12 bar (174 psig)/31 bar (450 psig) Klingersil 2 mm (0.079 in)

12 bar (174 psig)/31 bar (450 psig) Klingersil 2 mm (0.079 in)

12 bar (174 psig)/31 bar (450 psig) Klingersil 2 mm (0.079 in)

sensor 5

Page 6

3 Suppl

ement

Flanges Process

Flange 1" 150 lb RF, ANSI B16.5 12 bar (174 psig) Klingersil 2 mm (0.079 in)

Flange 1" 300 lb RF, ANSI B16.5 12 bar (174 psig)/31 bar (450 psig) Klingersil 2 mm (0.079 in)

Flange 2" 150 lb RF, ANSI B16.5 12 bar (174 psig) Klingersil 2 mm (0.079 in)

Flange 2" 300 lb RF, ANSI B16.5 12 bar (174 psig)/31 bar (450 psig) Klingersil 2 mm (0.079 in)

Flange 2" 1500 lb RF, ANSI B16.5 128 bar (1856 psig) RTJ seal ring 3.91 mm (0.154 in)

Flange 2" 1500 lb RJF, ANSI B16.5 128 bar (1856 psig) RTJ seal ring 3.91 mm (0.154 in)

pressure Seal Wall thickness

Process temperature 250 °C (482 °F)

Flanges Process pressure Seal Wall thickness

Flange DN 20 PN 40, Form C,

DIN 2501

Flange DN 25 PN 40, Form C,

DIN 2501

Flange DN 50 PN 40, Form C,

DIN 2501

Flange 1" 150 lb RF, ANSI B16.5 10.5 bar (152 psig) Klingersil 2 mm (0.079 in)

Flange 1" 300 lb RF, ANSI B16.5 10.5 bar (152 psig)/27 bar

Flange 2" 150 lb RF, ANSI B16.5 10.5 bar (152 psig) Klingersil 2 mm (0.079 in)

Flange 2" 300 lb RF, ANSI B16.5 10.5 bar (152 psig)/27 bar

Flange 2" 1500 lb RF, ANSI B16.5 111 bar (1610 psig) RTJ seal ring 3.91 mm (0.154 in)

Flange 2" 1500 lb RJF, ANSI B16.5 111 bar (1610 psig) RTJ seal ring 3.91 mm (0.154 in)

10.5 bar (152 psig)/27 bar

(391 psig)

10.5 bar (152 psig)/27 bar

(391 psig)

10.5 bar (152 psig)/27 bar

(391 psig)

(391 psig)

(391 psig)

Klingersil 2 mm (0.079 in)

Klingersil 2 mm (0.079 in)

Klingersil 2 mm (0.079 in)

Klingersil 2 mm (0.079 in)

Klingersil 2 mm (0.079 in)

Process temperature 400 °C (752 °F)

Flanges Process pressure Seal Wall thickness

Flange DN 20 PN 40, Form C,

DIN 2501

Flange DN 25 PN 40, Form C,

DIN 2501

Flange DN 50 PN 40, Form C,

DIN 2501

Flange 1" 150 lb RF, ANSI B16.5 6.5 bar (94 psig) graphite 2 mm (0.079 in)

Flange 1" 300 lb RF, ANSI B16.5 6.5 bar (94 psig)/24 bar (348 psig) graphite 2 mm (0.079 in)

Flange 2" 150 lb RF, ANSI B16.5 6.5 bar (94 psig) graphite 2 mm (0.079 in)

Flange 2" 300 lb RF, ANSI B16.5 6.5 bar (94 psig)/24 bar (348 psig) graphite 2 mm (0.079 in)

6 Bypass 72 • with VEGAFLEX level

6.5 bar (94 psig)/24 bar (348 psig) graphite 2 mm (0.079 in)

6.5 bar (94 psig)/24 bar (348 psig) graphite 2 mm (0.079 in)

6.5 bar (94 psig)/24 bar (348 psig) graphite 2 mm (0.079 in)

33545-EN-081216

sensor

Page 7

3 Sup

plement

Flanges Process

Flange 2" 1500 lb RF, ANSI B16.5 95 bar (1378 psig) RTJ seal ring 3.91 mm (0.154 in)

Flange 2" 1500 lb RJF, ANSI B16.5 95 bar (1378 psig) RTJ seal ring 3.91 mm (0.154 in)

pressure Seal Wall thickness

Process fitting - Rinsing air connection (D)

Thread G½

½ NPT

Process fitting - Ventilation fitting (E) (optional)

Flange DN 15 PN 40

Flange ½" 1500 lb RF, ANSI B16.5

33545-EN-081216

Bypass 72 • with VEGAFLEX level

sensor 7

Page 8

115 mm

(4.53")

0 %

100 %

ø 60,3 mm

(2.37")

140 mm

(5.51")

150 mm (5.91")

250 mm (9.84")

100 mm

(3.94")

E

D

C

B

A

1

2

4

5

3

6

3 Suppl

3.2 D

ement

imensions

Fig. 3: Bypass

1 Dimensions tube center to tube center, 300 … 3000 mm (11.8 … 118 in)

2 Seal - measuring instrument flange

3 Electrode rod

4 Spacer

5 Type label

6 Closure rinsing connection, e.g. blind stopper

A Measuring instrument flange

B Connection flange, top

C Connection flange, bottom

D Rinsing air connection

8 Bypass 72 • with VEGAFLEX level

tube with VEGAFLEX

33545-EN-081216

sensor

Page 9

3 Sup

plement

E Ventilation

connection - optional

33545-EN-081216

Bypass 72 • with VEGAFLEX level

sensor 9

Page 10

3 Suppl

ement

10 Bypass 72 • with VEGAFLEX level

33545-EN-081216

sensor

Page 11

3 Sup

plement

33545-EN-081216

Bypass 72 • with VEGAFLEX level

sensor 11

Page 12

VEGA Grieshaber KG

ISO 9001

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info@de.vega.com

www.vega.com

Printing date:

statements concerning scope of delivery, application,

All

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

© VEGA Grieshaber KG, Schiltach/Germany 2008

Subject to change without prior notice 33545-EN-081216

Loading...

Loading...