Varec 8315 User Manual

8315 Tank Gate Interface

The 8315 scans up to 50 L&J tank gauges or

transmitters (on a single channel) via L&J

Technologies® Tankway protocol

Installation and Operations Manual

DVR Firmware Version: LJGT1_11

IOM035GVAE1313

Automation Solutions for oil & gas, defense and aviation applications

8315 TGI

Copyright

All rights reserved. Printed in the United States of America.

Except as permitted under the United States Copyright Act of 1976, no part of this publication

may be reproduced, stored in a retrieval system or transmitted in any form or by any means electronic, mechanical, photocopying, recording, or otherwise - without the prior written

permission of the Publisher:

Varec, Inc.

5834 Peachtree Corners East

Norcross (Atlanta), Georgia 30092

Phone: (770) 447-9202

Fax: (770) 662-8939

Trademarks Acknowledged

Varec, Inc. recognizes all other trademarks. Trademarks of other products mentioned in this

manual are held by the companies producing them.

FuelsManager® and Varec® are registered trademarks of Varec, Inc.

Acrobat Reader® is a registered trademark of Adobe Systems Incorporated.

MODBUS® is a registered trademark of Modicon, Inc.

All other product and service names mentioned are the trademarks of their respective

companies.

Disclaimer of Warranties

The contract between the Seller and the Buyer states the entire obligation of the Seller. The

contents of this instruction manual shall not become part of or modify any prior or existing

agreement, commitment, or relationship between the Seller and Buyer. There are no express or

implied warranties set out in this instruction manual. The only warranties that apply are those

in the existing contract between the Seller and Buyer.

The 8300 TGI has not been tested by Varec under all possible operational conditions, and Varec

may not have all the data relative to your application. The information in this instruction manual

is not all inclusive and does not and cannot take into account all unique situations.

Consequently, the user should review this product literature in view of his or her application. If

you have any further questions, please contact Varec for assistance.

Limitations of Seller's Liability

In the event that a court holds that this instruction manual created some new warranties, Seller's

liability shall be limited to repair or replacement under the standard warranty clause. In no case

shall the Seller's liability exceed that stated as Limitations of Remedy in the contract between

the Seller and Buyer.

Use of parts that are not manufactured or supplied by Varec voids any warranty and relieves

Varec of any obligation to service the product under warranty. Varec recommends the use of

only Varec manufactured or supplied parts to maintain or service the 8300 TGI.

Varec, Inc. i

Tank Gate Interface

Terms of Use

The information provided in this document is provided "as is" without warranty of any kind.

Varec, Inc. disclaim all warranties, either express or implied, including the warranties of

merchantability and fitness for a particular purpose. In no event shall Varec, Inc. or its suppliers

be liable for any damages whatsoever including direct, indirect, incidental, consequential, loss

of business profits or special damages, even if Varec, Inc. or its suppliers have been advised of

the possibility of such damages.

This manual is solely intended to describe product installation and functions and should not be

used for any other purpose. It is subject to change without prior notice. This manual was

prepared with the highest degree of care. However, should you find any errors or have any

questions, contact one of our service offices or your local sales agent.

ii Installation and Operations Manual

8315 TGI

Safety Precaution Definitions

Caution! Damage to equipment may result if this precaution is disregarded.

Warning! Direct injury to personnel or damage to equipment which can cause injury to

personnel may result if this precaution is not followed.

Safety Precautions

Read this manual carefully and make sure you understand its contents before using this product.

Follow all instructions and safety guidelines presented in this manual when using this product.

If the user does not follow these instructions properly, Varec cannot guarantee the safety of the

system.

Note Comply with all applicable regulations, codes, and standards. For safety precautions,

the user should refer to the appropriate industry or military standards.

Caution! Electrical Hazard! Read and understand static and lightning electrical protection

and grounding described in API 2003. Make certain that the installation, operation, and

maintenance conforms with the practice set forth therein.

Warning! Striking the product with a metal object could cause a spark to occur. When

removing or replacing the product in flammable or hazardous liquid storage areas, take

necessary measures to protect it from impact.

Warning! Sparks or static charge could cause fire or explosion! Mechanical connections,

worker activity and worker clothing may accumulate electrostatic charges. Care should be

used in flammable environments to avoid the hazard.

Varec, Inc. iii

Tank Gate Interface

iv Installation and Operations Manual

Contents

1Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.1 System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.2 Software Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.3 Host Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.4 Modbus Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.5 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.6 Power consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.7 Surge protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.8 Operating temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.9 Humidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.10 Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.11 Mechanical Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Hardware Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Motherboard Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.2 Switches and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.3 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 8215 L&J Tankway Communications Interface Module . . . . . . . . . 15

3.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.1 ID DIP Switch (SW1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.2 LED Indicators (D1-D6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.3 External Power Connector (+48V) (J2). . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.4 Surge/Shield Ground Connector (J4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.5 Field Wiring terminal block (J3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Software Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Software Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.1 Real-Time / Multitasking Executive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.2 Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.3 Automatic Fault Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.4 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.5 Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Varec, Inc. v

Contents

4.1.6 Data Scanning Task. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.7 Database Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.8 System Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.9 Tank Gate Interface Software Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Database Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.1 Point Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.2 Parameter Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 Gathering Point Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.1 Standard Request-Response Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.2 Change of State Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.3 Change of State-Related Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.4 Modbus Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.5 Fixed Modbus Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.6 GWBLK method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4 Common Software Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4.1 Clock (CLK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4.2 Communications (COM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4.3 Floating Point Register (FPREG). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.4 Emulator (EMU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.5 EMU Gateway (EMUGW). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.6 Gateway Block (GWBLK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4.7 Integer Register (IREG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4.8 Modbus Gateway (MODGW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4.9 Scaler Point (SCALER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.10 System Information (SYS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5 L&J Tankway Software Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1 L&J MCG1000 Tank Gauge (LJ1000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.1 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.2 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2 L&J MCG1200 Tank Gauge (LJ1200) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.1 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.2 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.3 L&J MCG1500 Tank Gauge (LJ1500) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.1 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.2 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.4 L&J MCG2000 Tank Gauge (LJ2000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.4.1 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.4.2 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.5 L&J Scanner (LJSCAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.5.1 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.5.2 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

vi Installation and Operations Manual

Tank Gate Interface

6 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.1 General Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Installation Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3.1 Mounting the Tank Gate Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3.2 Select the Unit Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3.3 Wiring Up Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3.4 Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.3.5 Installing Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7 Using ViewRTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.2 System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.3 Installing ViewRTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.4 Executing ViewRTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.4.1 ViewRTU window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.5 The ViewRTU Menu Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.5.1 The File Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.5.2 The Point Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.5.3 The Config Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.5.4 The Communications Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.5.5 The Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.5.6 The Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.6 Using ViewRTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.6.2 Configuring Single Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.6.3 To modify a Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.6.4 Configuring Multiple Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.6.5 Creating and Editing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.2 Troubleshooting the Tank Gate Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.2.1 LED Displays under normal conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.2.2 LED Displays under Abnormal Conditions . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.3 Using the Tank Gate Interface Push-buttons. . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.4 Performing a Hard Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

A Appendix - Order Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Varec, Inc. vii

Contents

viii Installation and Operations Manual

8315 TGI Overview

1Overview

The 8300 series Tank Gate Interface acts as a tank gauge interface for data acquisition and host

gateway for tank farm, pipeline or refinery applications. Options are available for interfacing to

nearly any brand of tank gauge equipment or technologies, making it possible to integrate float

and tape transmitters, HTG, servo, magnetostrictive and radar gauges.

Each 8300 series Tank Gate Interface unit has a built-in motherboard and specific

communications module based on the local field protocol or tank gauging instrumentation

requirements. The motherboard contains a serial data link to enable communication to a host

PC, PLC, or DCS.

Note! Each intelligent module is identified by a 82xx designation that matches the product designation, for example, the 8303 TGI contains a 8203 communications module.

Each module contains its own processor for fast and reliable field data scanning. Compatibility

of every module also makes configuration of the internal database simple and straightforward.

1.1 Versions

The 8300 series Tank Gate Interface is available in a number of versions that can interface to a

variety of field devices and intelligent instrumentation via interface modules listed below:

1.2 Features

• 8303-2 Dual RS-485 (MODBUS) Communications Tank Gate Interface

• 8303-6 Dual RS-485 (GSI ASCII) Communications Interface Module

• 8310 Varec Mark/Space (Varec 1800, 1900, 4000) Tank Gate Interface

• 8311-1 Current Loop (Whessoe Bus) Tank Gate Interface

• 8311-2 Current Loop (GPE) Tank Gate Interface

• 8312 Saab (TRL/2) Tank Gate Interface

• 8314 Enraf (811, 802/812, 854, 873) Tank Gate Interface

• 8315 L&J Tankway (MCG 1000, MCG 1500, MCG 2000) Tank Gate Interface

• 8316 LON (Prime Measurement 3500 ATG) Tank Gate Interface

• 8317 Dual RS-232 Veeder Root (TLS 350) Tank Gate Interface

• Inputs are reported to Host Computer by Exception or Scanned Poll

• Built-in Software Function Library

• Surge Protection Conforming to ANSI/IEEE C37.90a-1974

• Host Communication via RS-232, RS-485, radio, modem or fiber optic link

• Industry Standard Protocol: Modbus

• Quick-Disconnect I/O Terminations

• Modular Construction for Optimum Expandability

• Non-Volatile Database

Varec, Inc. 1

Overview Tank Gate Interface

1.3 Applications

The 8300 series Tank Gate Interface is ideally suited for Tank Farm, Terminal, Pipeline and

Refinery applications. It is an effective solution used in SCADA applications.

• Level, temperature, pressure, flow, local indication, and alarms

1.4 Specifications

1.4.1 System Design

• 16-bit processor with optional intelligent communication modules

• Intelligent field device communications

• 128K bytes Non-Volatile Database Memory

• Serial RS-232

• Visual indication - 4 LEDs on main board indicate power and status

1.4.2 Software Functionality

• Tank gauge scanning - Data acquisition of measured values from connected tank gauges/

transmitters

• Service & diagnostics*

• Gauge diagnostics

• Read level, temperature and status data from gauge/transmitter

1.4.3 Host Communication

• Host comm. ports - 2

• Comm. type:

• COM 0: RS-232C

• COM 1: RS-232C or RS485

• Baud Rate - selectable baud rate depending on equipment parameters

• Protocol - Modbus™ RTU protocol

• Mode - RTU mode, master and slave

• Media access - Master/Slave

1.4.4 Modbus Functionality

• Modbus™ commands - 3, 4, 5, 6, 15, 16

• Modbus™ mapping - Configurable

1.4.5 Power Supply

• Supply 100...240 Vac, 50/60 Hz

1.4.6 Power consumption

• 50 VA max (500 mA)

2 Installation and Operations Manual

8315 TGI Overview

1.4.7 Surge protection

• Gas Discharge Tubes (GDTs) and clamping diodes on all field inputs, power supply inputs

and communications channels

1.4.8 Operating temperature

• -40...+185 °F (-40...+85 °C)

1.4.9 Humidity

• 5...95% (non-condensing)

1.4.10 Storage temperature

• -40...+212 °F (-40...100 °C)

1.4.11 Mechanical Construction

• Dimensions (HxDxW) - 2.5" (64 mm) x 8.6" (220 mm) x 5.2" (133 mm)

• Material - Aluminum Powder coated

*Gauge/transmitter Dependent

Varec, Inc. 3

Overview Tank Gate Interface

4 Installation and Operations Manual

8315 TGI Hardware

2 Hardware

The Tank Gate Interface consists of an enclosure, motherboard, single tank gauge interface

module and connectors.

2.1 Hardware Block Diagram

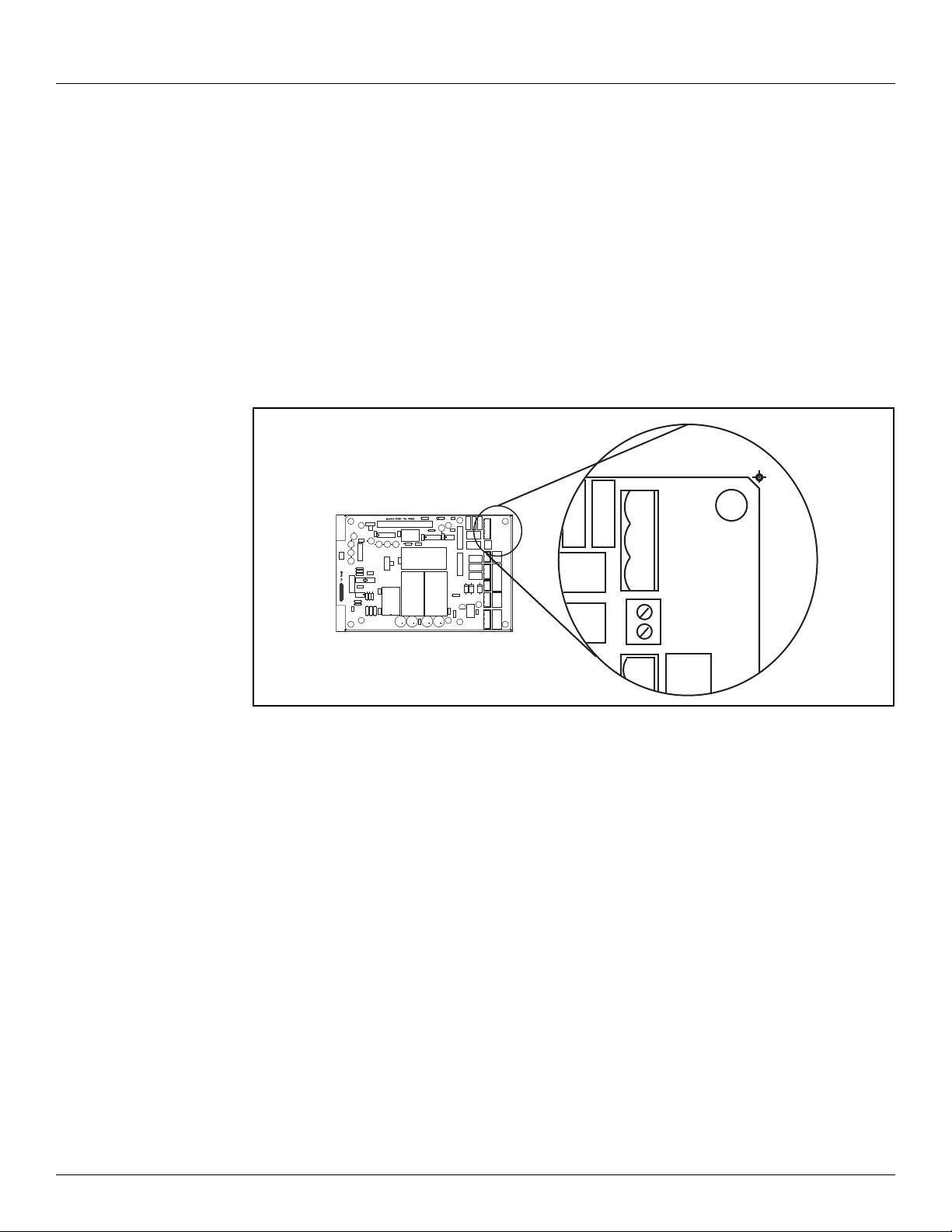

A Tank Gate Interface hardware functional block diagram is shown below. This diagram shows

the relationship between major subsystems and components in the Tank Gate Interface.

The heart of the Tank Gate Interface is an Intel 80C188EB microprocessor operating at 18.432

MHz. Designed specifically for real-time embedded applications, the µP includes timer/

counters, an interrupt controller, and chip-select circuitry. It also includes 2 serial channels that

are designated as COM0 and COM1.

2.2 Motherboard Description

The motherboard description is broken into three sections. Each section identifies the location

of the components on the motherboard. When necessary, a brief description of the component

is provided. These sections are listed below:

• Power Supply

• Switches and Indicators

• Communications

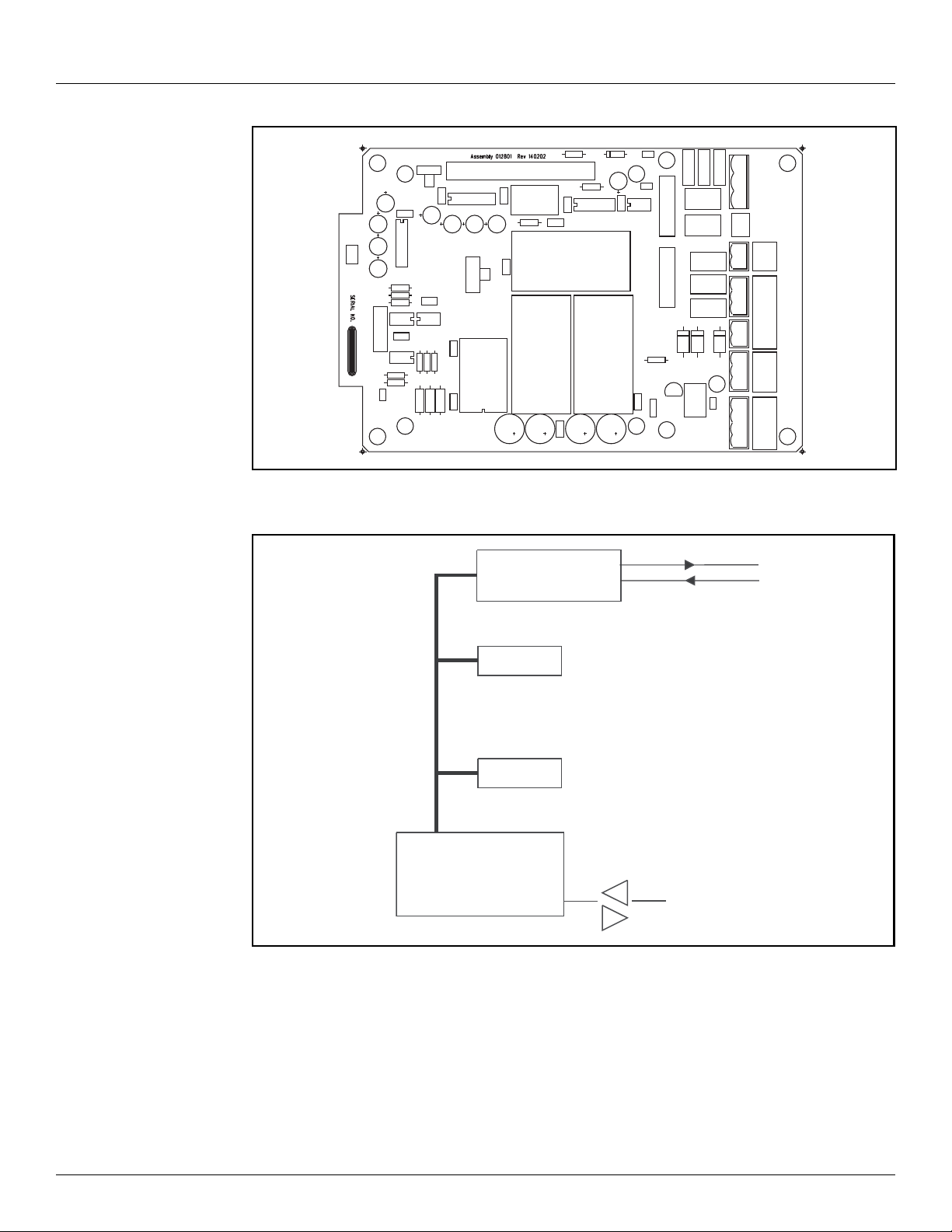

Figure 2-1: Tank Gate Interface Hardware Components

Varec, Inc. 5

Hardware Tank Gate Interface

COM 0

RS-232

128 K

256 k

uP

Serial 0

Serial 1

PROM

Tank Gauge

Interface Circuitry

NOVRAM

HARDWARE HANDSHAKING

A

B

RESET

RS232

COM1

RS485

Figure 2-2: The Tank Gate Interface Motherboard

VFIELD=48V

VFIELD=24V

EARTH

NEUTRAL

LINE

SURGE GND

+

-

A/TXD

B/RXD

GND

RTS

CTS

TXD

RXD

GND

+15V

+5V

GND

-15V

VFIELD

COM1

COM 0 AUX POWER

Figure 2-3: Tank Gate Interface Functional Block Diagram

6 Installation and Operations Manual

8315 TGI Hardware

EARTH

NEUTRAL

LINE

SURGE GND

+

VFIELD

EARTH

NEUTRAL

LINE

SURGE GND

A/TXD

B/RXD

GND

RTS

CTS

TXD

RXD

GND

+15V

+5V

GND

-15V

+

-

VFIELD

COM1

COM 0

AUX POWER

VFIELD=48V

VFIELD=24V

RESET

RS232

RS485

COM1

HARDWARE HANDSHAKING

A

B

2.2.1 Power Supply

• Unit AC Power terminal block (J2)

• Surge Protection terminal block (J4)

• Field Power terminal block (J3)

• Auxiliary DC Power Output terminal block (J8)

• AC Power fuses (500 mA - 250V 5x20 mm) (F1, F2)

• Field Voltage Selection Jumper (W3)

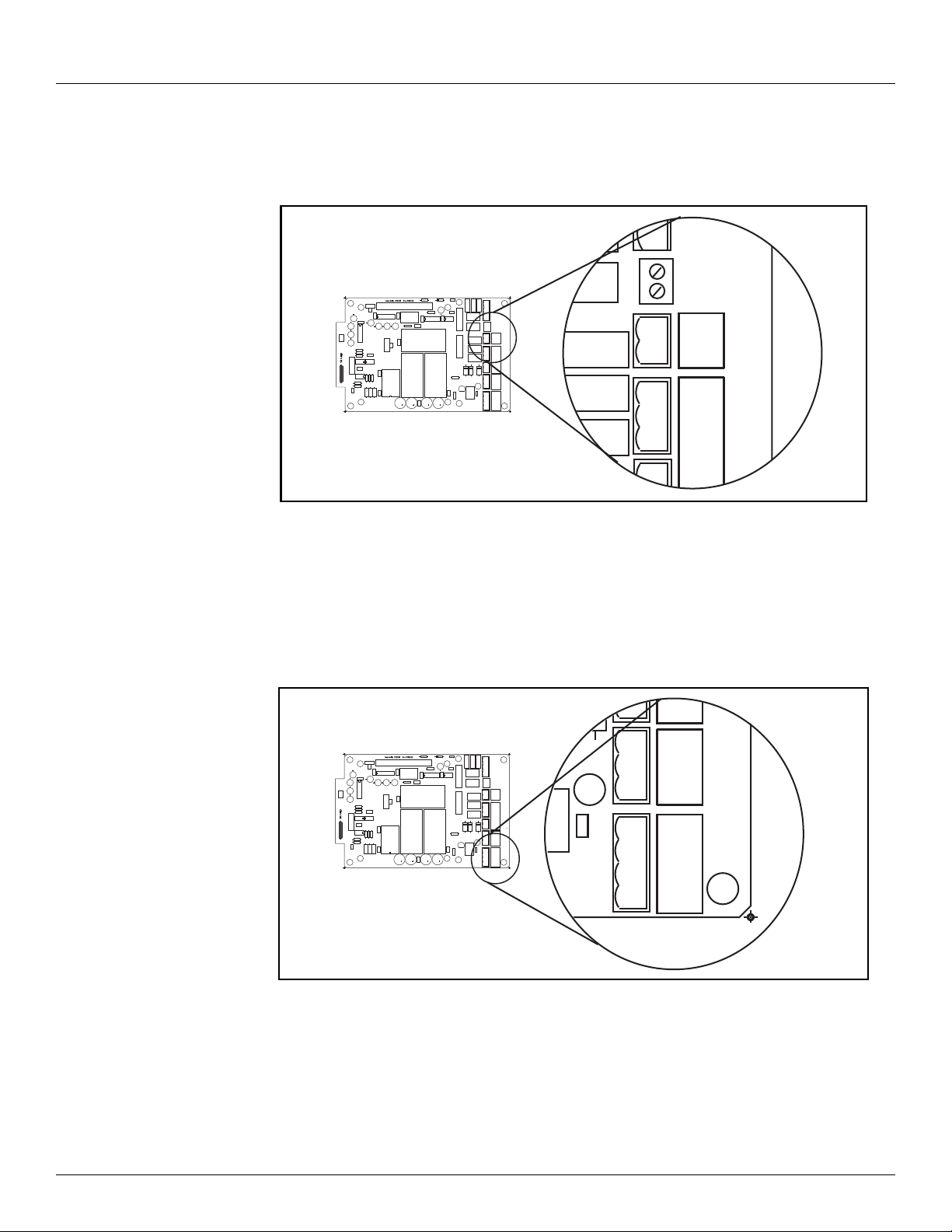

2.2.1.1 Unit AC Input Power terminal block (J2)

The Unit AC power terminal block is used to provide AC power to the Tank Gate Interface. The

power requirements for the Tank Gate Interface are 100-240 VAC, 50/60 Hz. The AC Input

Power terminal block is shown in the figure below.

J2

HARDWARE HANDSHAKING

RESET

RS232

COM1

RS485

EARTH

NEUTRAL

LINE

SURGE GND

VFIELD

A/TXD

B/RXD

COM1

GND

RTS

CTS

TXD

COM 0

RXD

GND

AUX POWER

VFIELD=48V

+15V

VFIELD=24V

+5V

GND

-15V

J4

Figure 2-4: AC Input Terminal Block

2.2.1.2 Surge Protection (Surge Gnd) terminal block (J4)

The Surge Gnd terminal block is used to connect the surge protection components (gas tubes,

MOVs) to earth ground. Ensure there is a low impedance path (< 1ohm) to earth ground (a

ground rod or grounding system).

Varec, Inc. 7

Hardware Tank Gate Interface

LINE

SURGE GND

A/TXD

B/RXD

GND

+

-

VFIELD

COM1

J3

J4

EARTH

NEUTRAL

LINE

SURGE GND

A/TXD

B/RXD

GND

RTS

CTS

TXD

RXD

GND

+15V

+5V

GND

-15V

+

-

VFIELD

COM1

COM 0 AUX POWER

VFIELD=48V

VFIELD=24V

RESET

RS232

RS485

COM1

HARDWARE HANDSHAKING

A

B

CTS

TXD

RXD

GND

+15V

+5V

GND

-15V

COM 0 AUX POWER

J8

J7

2.2.1.3 Field Power (VFIELD) terminal block (J3)

The Field Power terminal block, referred to as VFIELD, is used to provide power for field

instruments. The output is configurable using jumpers (Jumper W3, discussed below).

Figure 2-5: Field Power Terminal Block

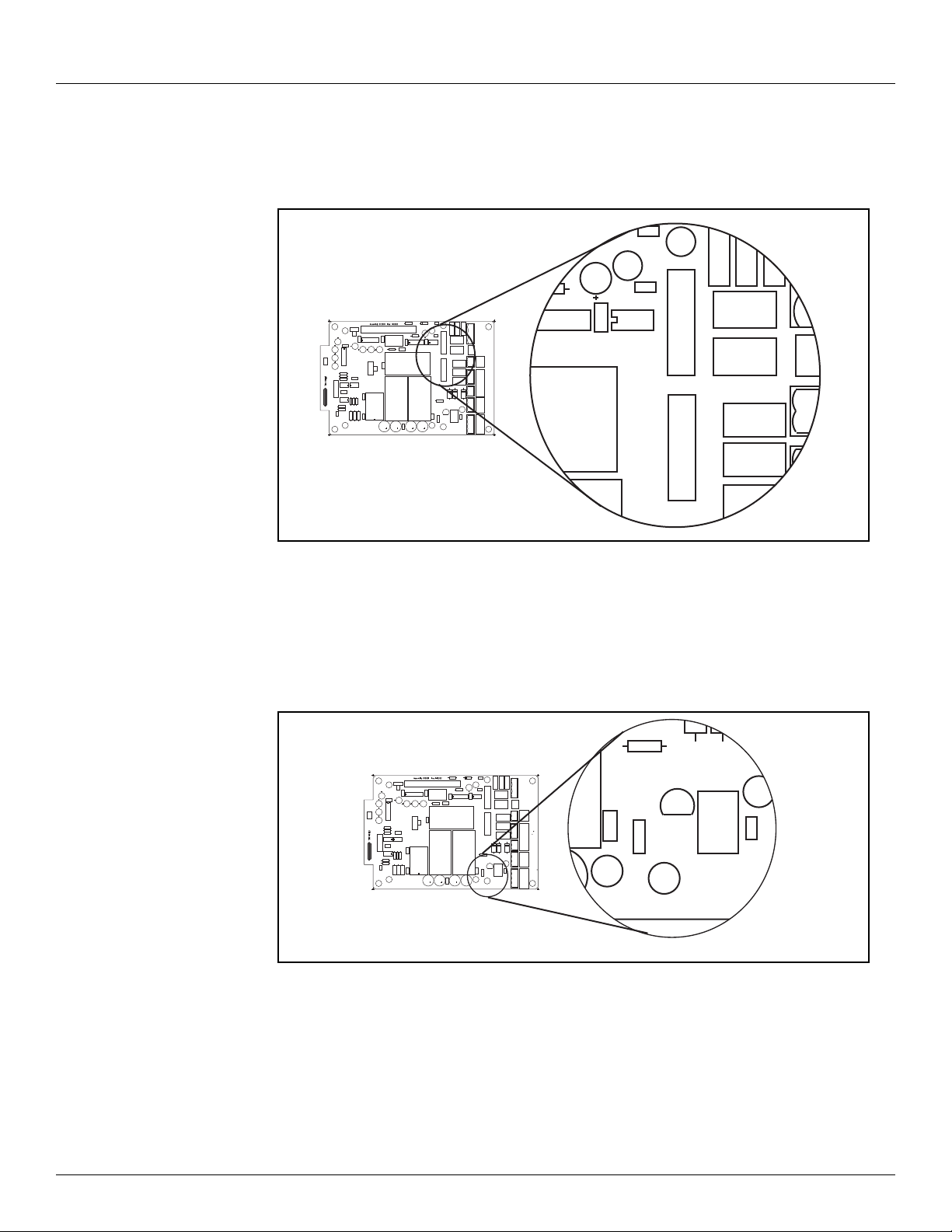

2.2.1.4 Auxiliary DC Output Power terminal block (J8)

The Auxiliary power terminal block is used when external equipment must be powered from the

Tank Gate Interface’s internal power supply. The triple output power supply provides +5, +15

and -15 Volts. These are rated 210 mA, 50 mA, and 5 mA, respectively. The DC Power terminal

block is shown below.

T

HARDWARE HANDSHAKING

A

B

RESET

RS232

COM1

RS485

8 Installation and Operations Manual

Figure 2-6: DC Input Voltage Terminal Block

EARTH

NEUTRAL

LINE

SURGE GND

VFIELD

+

-

A/TXD

B/RXD

COM1

GND

RTS

CTS

TXD

COM 0 AUX POWER

RXD

GND

VFIELD=48V

+15V

VFIELD=24V

+5V

GND

-15V

8315 TGI Hardware

VFIELD=48V

VFIELD=24V

J8

J7

2.2.1.5 AC Power Fuses (F1,F2)

The AC Power Fuses provide protection for the AC input power. The two fuses, F1 and F2, are

rated at 500 mA, 250 V.

F1

HARDWARE HANDSHAKING

A

B

RESET

RS232

COM1

RS485

EARTH

NEUTRAL

LINE

SURGE GND

VFIELD

+

-

A/TXD

B/RXD

COM1

GND

RTS

CTS

TXD

COM 0 AUX POWER

RXD

GND

VFIELD=48V

+15V

VFIELD=24V

+5V

GND

-15V

F2

Figure 2-7: AC Power Fuse

2.2.1.6 Field Voltage Selection Jumper (W3)

The Field Voltage Selection Jumper W3 determines the voltage available at the VFIELD terminals

(J3). The Field Voltage can be configured for +24 VDC or +48VDC. At +24VDC, there is 230 mA

of field power available. At +48VDC, there is 230 mA of field power available.

HARDWARE HANDSHAKING

A

B

RESET

RS232

COM1

RS485

EARTH

NEUTRAL

LINE

SURGE GND

VFIELD

+

-

A/TXD

B/RXD

COM1

GND

RTS

CTS

TXD

COM 0 AUX POWER

RXD

GND

VFIELD=48V

+15V

VFIELD=24V

+5V

GND

-15V

W3

Figure 2-8: Selection Jumper W3

2.2.2 Switches and Indicators

2.2.2.1 Reset push-button (SW3)

Varec, Inc. 9

The RESET Switch is used to re-initialize the system hardware by causing it to go to a known

starting state. This switch may be pressed at any time; however, it will do the following:

Hardware Tank Gate Interface

RESET

• Re initialize System Hardware

• Clear Scratch Memory

• Verify Database and Re initialize if Invalid

• Reset All Timers

• Enable Communications

HARDWARE HANDSHAKING

A

B

RESET

RS232

COM1

RS485

EARTH

NEUTRAL

LINE

SURGE GND

VFIELD

+

-

A/TXD

B/RXD

COM1

GND

RTS

CTS

TXD

COM 0 AUX POWER

RXD

GND

VFIELD=48V

+15V

VFIELD=24V

+5V

GND

-15V

SW3

Figure 2-9: Switches SW3 on the Tank Gate Interface Motherboard

2.2.2.2 Hard Reset

A special form of Reset is available for occasions when the battery backed-up data base must

be re-initialized. This type of reset, the Hard Reset, can be performed before a database is

downloaded from a host PC.

Caution! The Hard Reset should be used as a last resort if the Tank Gate Interface is not

functioning. A Hard reset clears the installed database. For the Hard Reset procedure, refer

to the Troubleshooting and Maintenance chapter.

2.2.3 Communications

The Communications installation requires connection of the appropriate communication cable

to one of two connectors. The available options include RS-232 and RS-485 communications.

• COM0 (RS-232) (J7)

• COM1 (RS-232 or RS-485) (J5)

• COM1 Transmit Control (RS-232) (J6)

• COM1 Hardware Handshaking Switch (SW1)

• COM1 RS-232/RS-485 Selection Switch (SW2)

• COM1 RS-485 Terminating Resistor Jumper (W2)

Note COM1 is not available on the 8315 Tank Gate Interface

10 Installation and Operations Manual

8315 TGI Hardware

A/TXD

B/RXD

GND

RTS

CTS

TXD

RXD

GND

+15V

+

-

VFIELD

COM1

COM 0 AUX POW

J7

J5

J6

EARTH

NEUTRAL

LINE

SURGE GND

A/TXD

B/RXD

GND

RTS

CTS

TXD

RXD

GND

+15V

+5V

GND

-15V

+

-

VFIELD

COM1

COM 0 AUX POWER

VFIELD=48V

VFIELD=24V

RESET

RS232

RS485

COM1

HARDWARE HANDSHAKING

A

B

EARTH

NEUTRAL

LINE

SURGE GND

A/TXD

B/RXD

GND

RTS

CTS

TXD

RXD

GND

+15V

+5V

GND

-15V

+

-

VFIELD

COM1

COM 0 AUX POWER

VFIELD=48V

VFIELD=24V

RESET

RS232

RS485

COM1

HARDWARE HANDSHAKING

A

B

CTS

TXD

RXD

GND

+15V

+5V

GND

-15V

COM 0 AUX POWER

J8

J7

Figure 2-10: COM1 J5 Terminal Block

2.2.3.1 COM0 (J7)

COM0 is an RS-232 port for use in diagnostic testing/local programming or communications to

a host system. The protocol defaults to Tank Gate Interface Slave at the 9600 baud, 8 data bits,

and no parity (for use with ViewRTU or FuelsManager).

Varec, Inc. 11

Figure 2-11: COM0 J7 Terminal Block

2.2.3.2 COM1 (RS-232/RS-485) (J5)

Note COM1 is not available on the 8315 Tank Gate Interface

RS-232 is one of the two types of high-speed serial communications channels available to

interface to Host systems using several different protocols. RS-232 will operate at distances up

to 100 feet, while RS-485 allows multidrop communications at distances up to 4000 feet. RS232 can be used for flexibility in configuring other types of communications links. Other

variations of RS-232 communications interfaces include radio, modem and fiber optic

interfaces.

Hardware Tank Gate Interface

EARTH

NEUTRAL

LINE

SURGE GND

A/TXD

B/RXD

GND

RTS

CTS

TXD

RXD

GND

+15V

+5V

GND

-15V

+

-

VFIELD

COM1

COM 0 AUX POWER

VFIELD=48V

VFIELD=24V

RESET

RS232

RS485

COM1

HARDWARE HANDSHAKING

A

B

RS232

RS485

COM1

SW2

HARDWARE HANDSHAKING

A

B

The choice of RS-232 or RS-485 is determined by the COM RS-232/RS-485 Selection Switch

SW2.

2.2.3.3 COM1 RS232/RS-485 Selection Switch (SW2)

Note COM1 is not available on the 8315 Tank Gate Interface

Switch SW2 determines whether RS-232 or RS485 is used. Note that the Hardware Handshaking

Switch SW1 affects the operation of COM1.

Figure 2-12: COM1 SW2 Switch

2.2.3.4 COM1 Hardware Handshaking Switch (SW1)

Note COM1 is not available on the 8315 Tank Gate Interface

For RS-232, there are two different settings. One setting is used if hardware handshaking (RTS/

CTS) is required. The other setting eliminates the need for hardware handshaking. Set the

Hardware Handshaking Switch to the ‘A’ position to use RTS/CTS when a modem or signal

converter is involved and requires RTS/CTS to operate. The RTS and CTS signals will be available

on terminal block J6. If the connection is direct using RS-232, jumper RTS to CTS by setting SW1

to the ‘B’ position.

HARDWARE HANDSHAKING

A

B

RESET

RS232

COM1

RS485

EARTH

NEUTRAL

LINE

SURGE GND

VFIELD

+

-

A/TXD

B/RXD

COM1

GND

RTS

CTS

TXD

COM 0 AUX POWER

RXD

GND

VFIELD=48V

+15V

VFIELD=24V

+5V

GND

-15V

SW1

12 Installation and Operations Manual

Figure 2-13: COM1 SW1 Switch

8315 TGI Hardware

For RS-485, set the Hardware Handshaking Switch SW1 to the ‘A’ position. Refer to the following

table:.

Comm.

Physical

Layer

RS-232 No A UP (towards the

RS-232 Yes B UP (towards the

RS-485 Yes A DOWN (towards

Hardware

Handshake

SW1

Setting

SW2

Setting

RS-232 side)

RS-232 side)

the RS-485

side)

Notes

Use with a PC. Signals at terminal block J5 will

be RS-232

Use to communicate to systems that require

Request To Send (RTS) in order to transmit

(Modems, Radios, etc.)

RTS and CTS signals will be available at

terminal block J6

Always SW1 set to the A position when using

RS-485..

Table 2-1: Tank Gate Interface Communications Cable

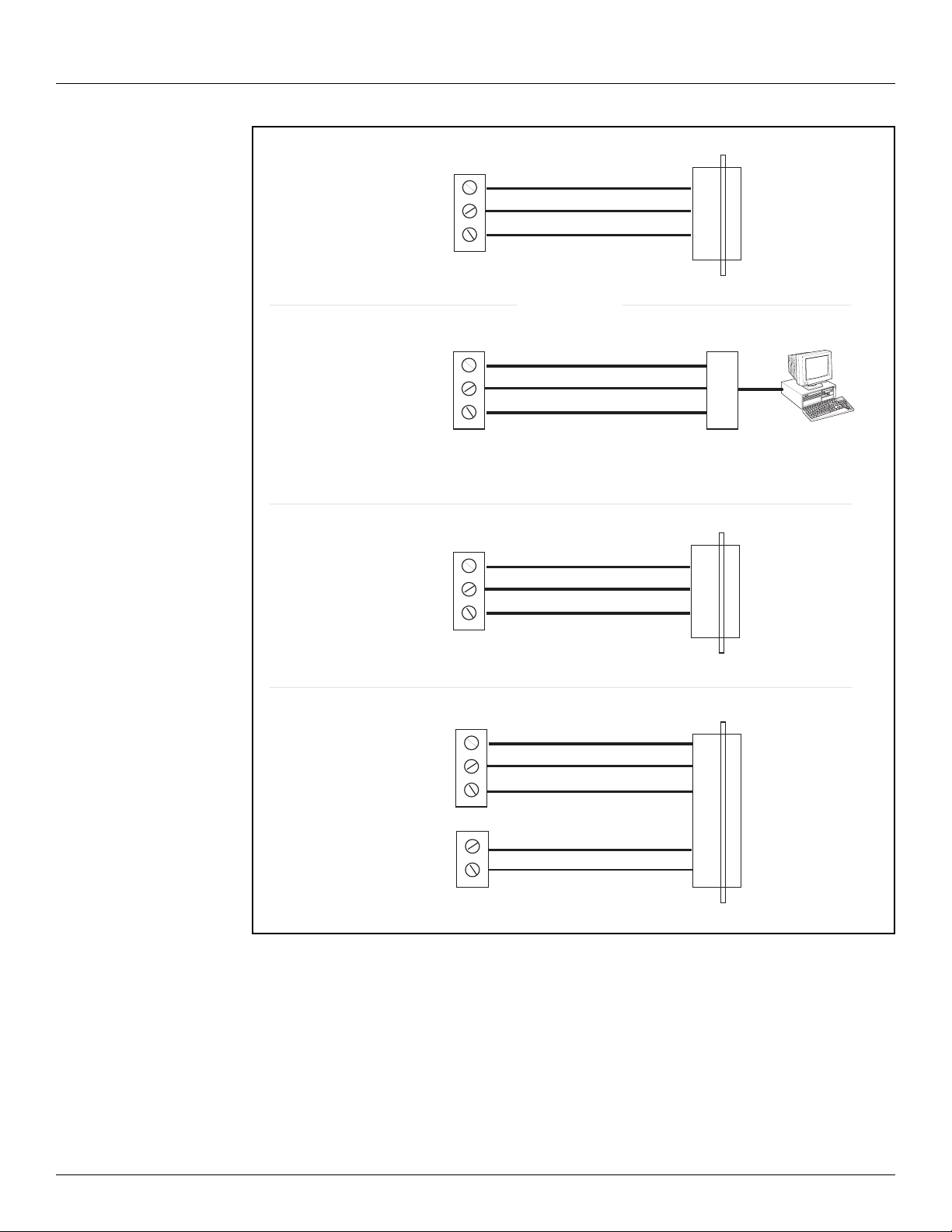

The layout for the RS-232 cable between the PC and the Tank Gate Interface is shown in the

following illustrations.

Varec, Inc. 13

TANK GATE

J7

PC

COM0

(RS-232)

TXD

RXD

GND

2

3

5

DB9 Female

Pin Signal

2

3

5

RXD

TXD

GND

NOTE! Signals on RS485 / RS232 converter may have different designations.

Refer to OFM manual for the converter for more information.

A

B

GND

TANK GATE

R5485 / R5238

Converter

J6

PC

A

B

GND

COM1

(RS485)

TANK GATE

J6

PC

COM1

without RTS / CTS

(RS-232)

TXD

RXD

GND

2

3

5

DB9 Female

Pin Signal

2

3

5

RXD

TXD

GND

TANK GATE

J6

DCE

COM1

with RTS / CTS

(RS-232)

TXD

RXD

GND

3

2

5

DB9 Male

Pin Signal

2

3

5

RXD

TXD

GND

8

7

RTS

CTS

J7

78RTS

CTS

Hardware Tank Gate Interface

14 Installation and Operations Manual

Figure 2-14: COM1 Cable without RTS/CTS

Note COM1 is not available on the 8315 Tank Gate Interface.

8315 TGI 8215 L&J Tankway Communications Interface Module

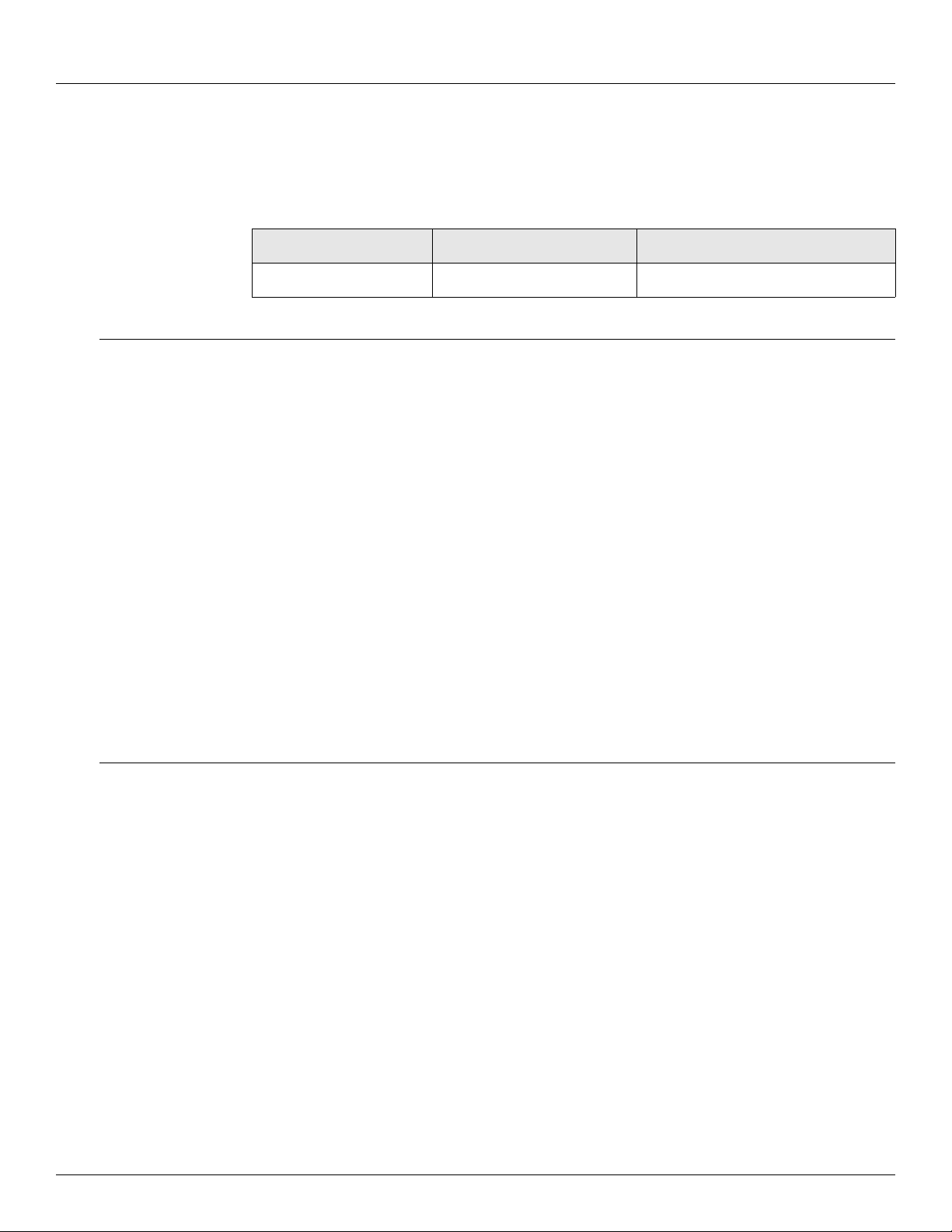

3 8215 L&J Tankway Communications Interface Module

This communications interface module is the processing card that mounts on the TankGate

Interface (TGI) motherboard. The firmware installed on this card determines which protocol is

provided.

Firmware Version Protocol Software Blocks

LJGT1_11 L&J Tankway See section 5 on page 41

3.1 Features

• Supports up to 50 tanks

• Communicates using L&J Tankway protocol

• Interfaces to L&J Tankway compatible Tank Gauge transmitters

• ANSI/IEEE surge protection

The 8315 Tank Gate Interface uses L&J Tankway to communicate. There are a number of

transmitters that are compatible, including:

3.2 Description

• L&J MCG 1000

• L&J MCG 1200

• L&J MCG 1500

• L&J MCG 2000

Note The 8315 Tank Gate Interface uses the 8215 communications module.

The 8215 communications module requires an external +48VDC power supply. It is also

possible to use the +48VDC power supply of the TankGate to power the tank gauge

transmitters, if there are fewer than 15 devices.

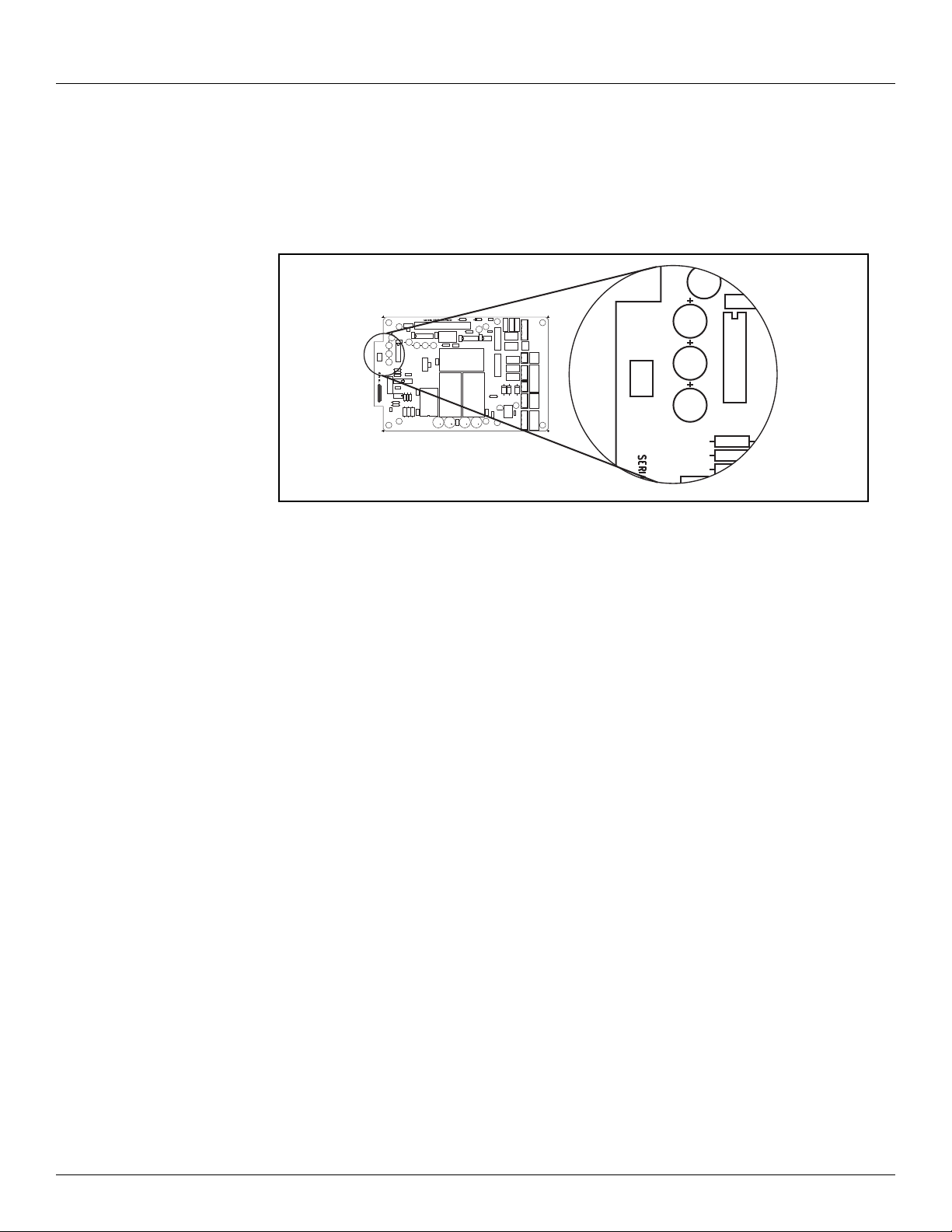

The components of the 8215 are illustrated in the following figure. This section explains how

to connect field wiring and to configure jumper settings.

• Unit ID DIP Switch (SW 1)

• LED Indicators (D1 - D5, D14)

• +48V Line fuse (1A 250V TR5) (F1)

• External Power Connector (+48V) (J2)

• Surge/Shield ground connector (J4)

• Field Wiring termination block (J3)

Varec, Inc. 15

8215 L&J Tankway Communications Interface Module Tank Gate Interface

Field wiring

terminal block (J3)

LED indicators (D1 – D6)

Surge/Shield

ground connector (J4)

External Power Connector

(+48 - 65 VDC) (J2)

+48-65 VDC power fuse

(1 A 250V TR5) (F1)

ID DIP Switch (SW1)

Transmit Line Fuse

(63 mA 250V TR5) (F2)

Firmware

Address 1 Shown

CLOSED

OPEN

1234

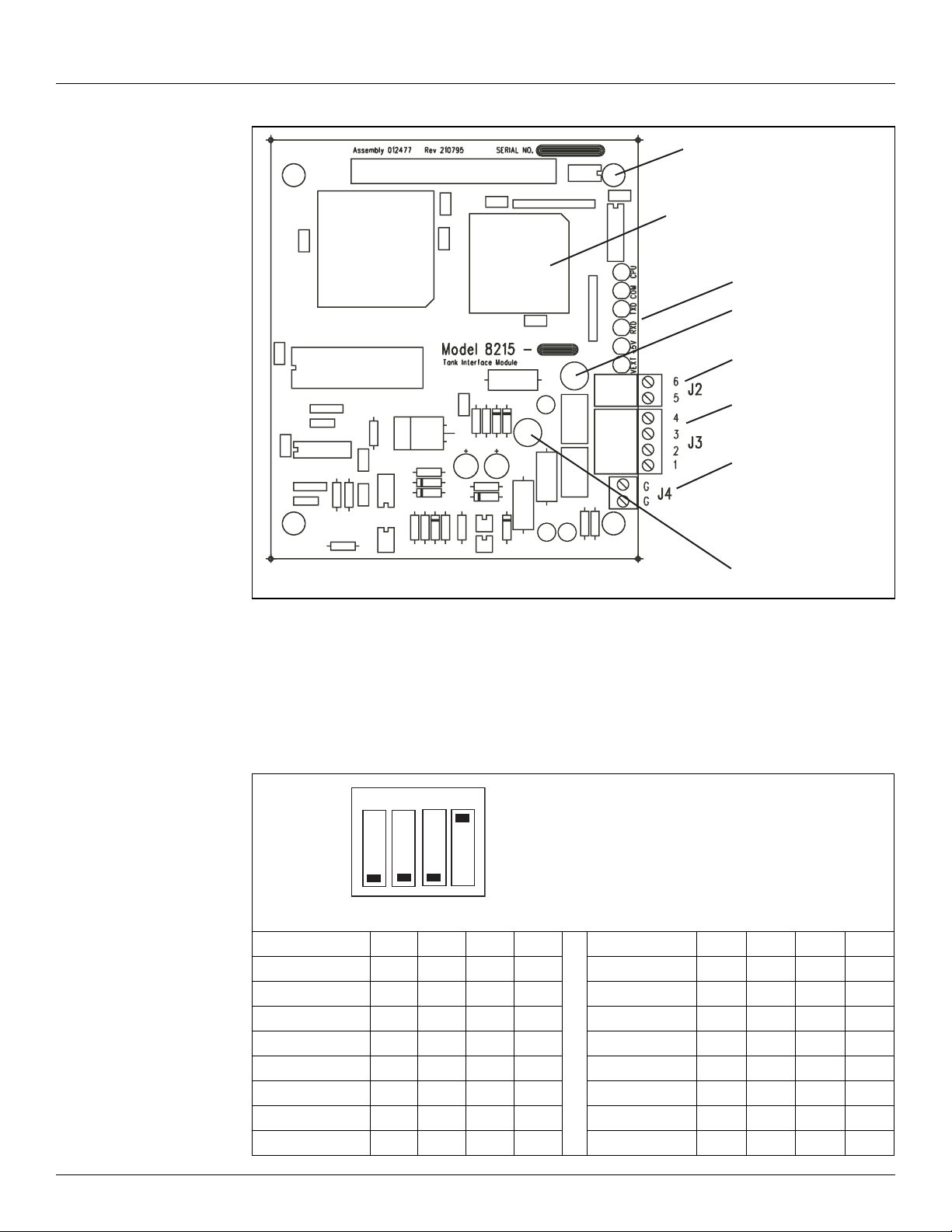

3.2.1 ID DIP Switch (SW1)

Figure 3-1: L&J Tankway Tank Gate Interface Module

The dip switch is used for setting the ID number (1-14). The ID is a binary number representing

the address of the 8317 TGI.

Table 3-1: ID DIP Switch settings

Binary 8 4 2 1 Binary 8 4 2 1

Switch # 1 2 3 4 Switch # 1 2 3 4

Address 1 o o o c Address 8 c o o o

Address 2 o o c o Address 9 c o o c

Address 3 o o c c Address 10 c o c o

Address 4 o c o o Address 11 c o c c

Address 5 o c o c Address 12 c c o o

Address 6 o c c o Address 13 c c o c

Address 7 o c c c Address 14 c c c o

16 Installation and Operations Manual

8315 TGI 8215 L&J Tankway Communications Interface Module

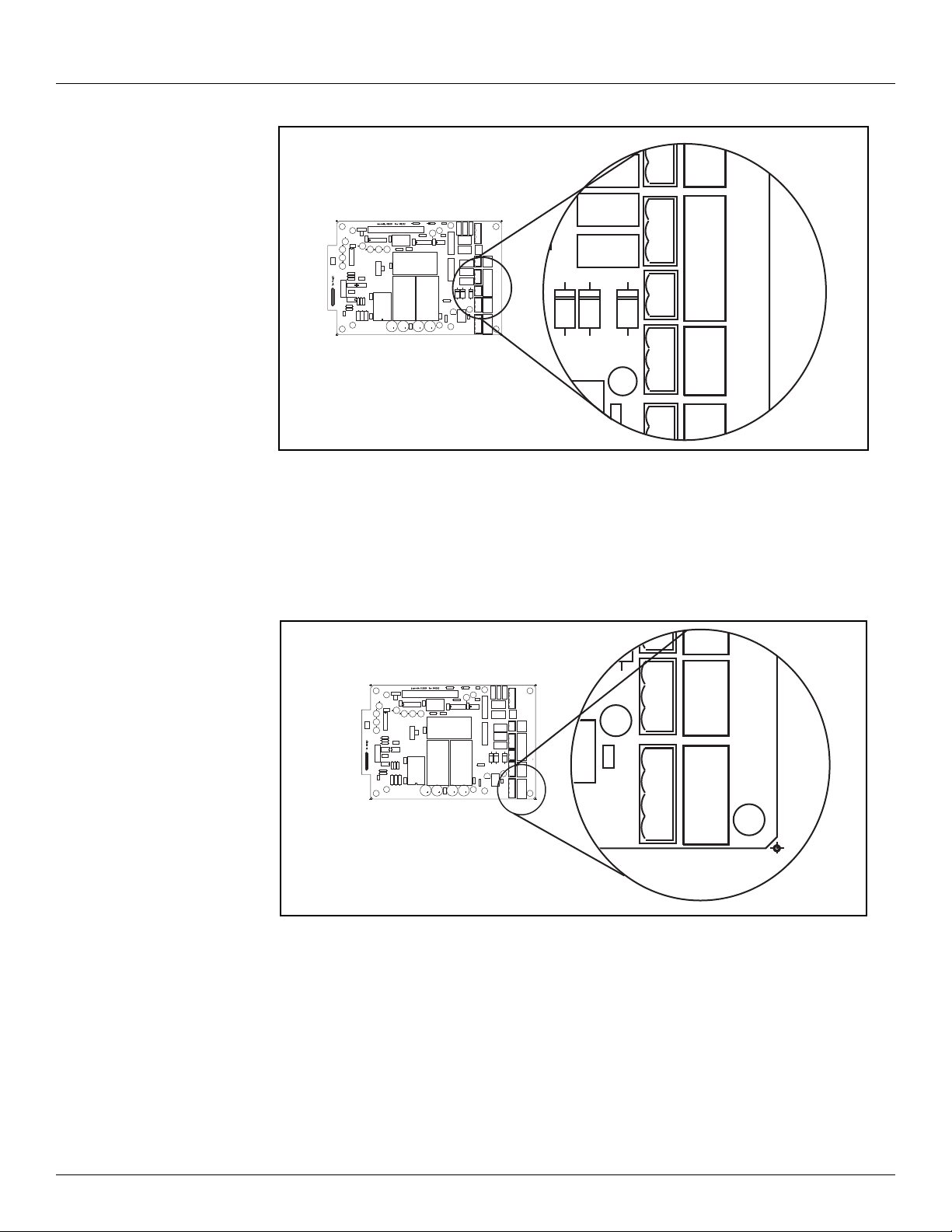

3.2.2 LED Indicators (D1-D6)

The LED displays indicate the status of the Model 8315’s CPU and

communications. The indicators are identified in the following figure.

• CPU: CPU activity

• COM: Communication between the TankGate and the host computer

• TXD: Transmitting data to tank gauge

• RXD: Receiving data from tank gauge

• +5V: Indicates interface module power

• +VEXT: Indicates external power

Figure 3-2: LED Indicators

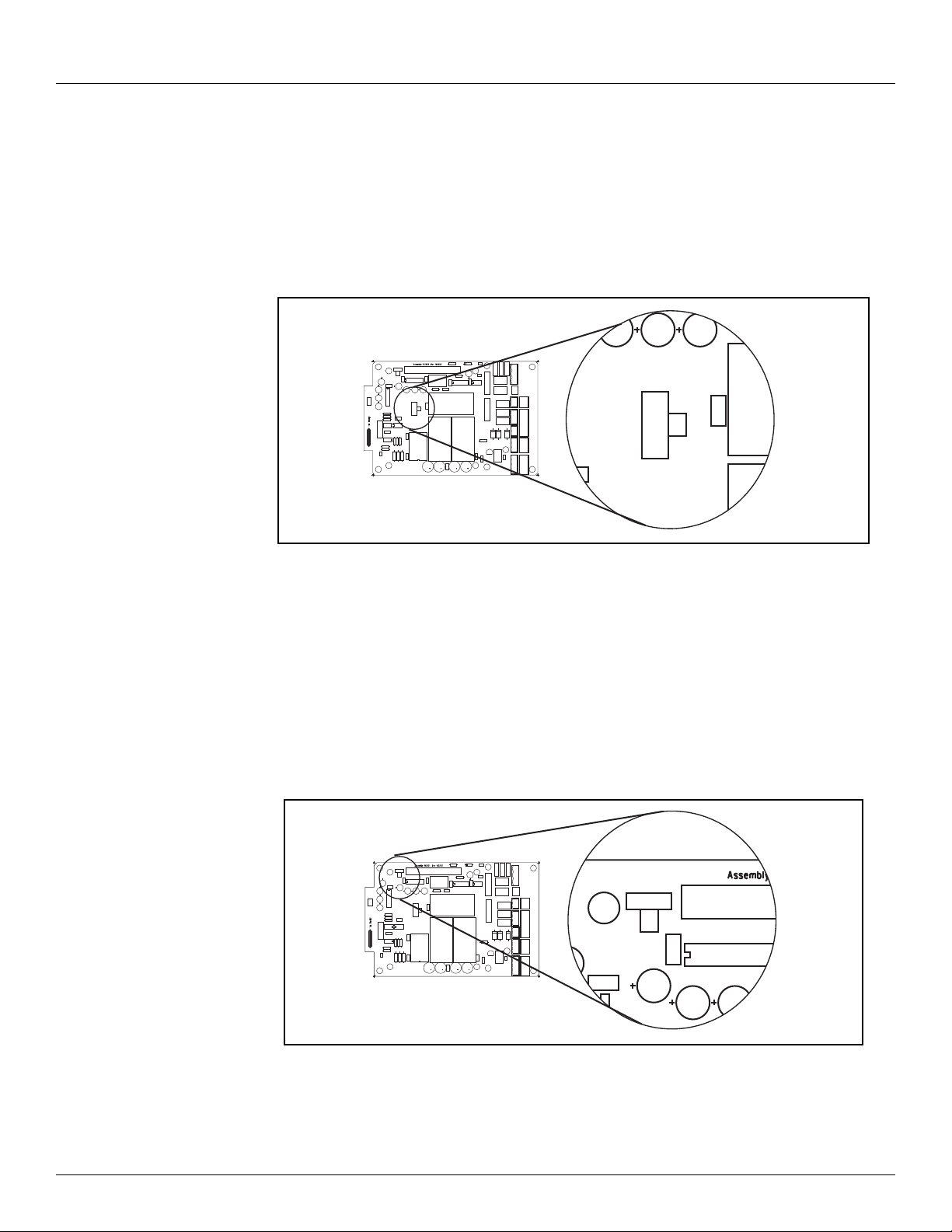

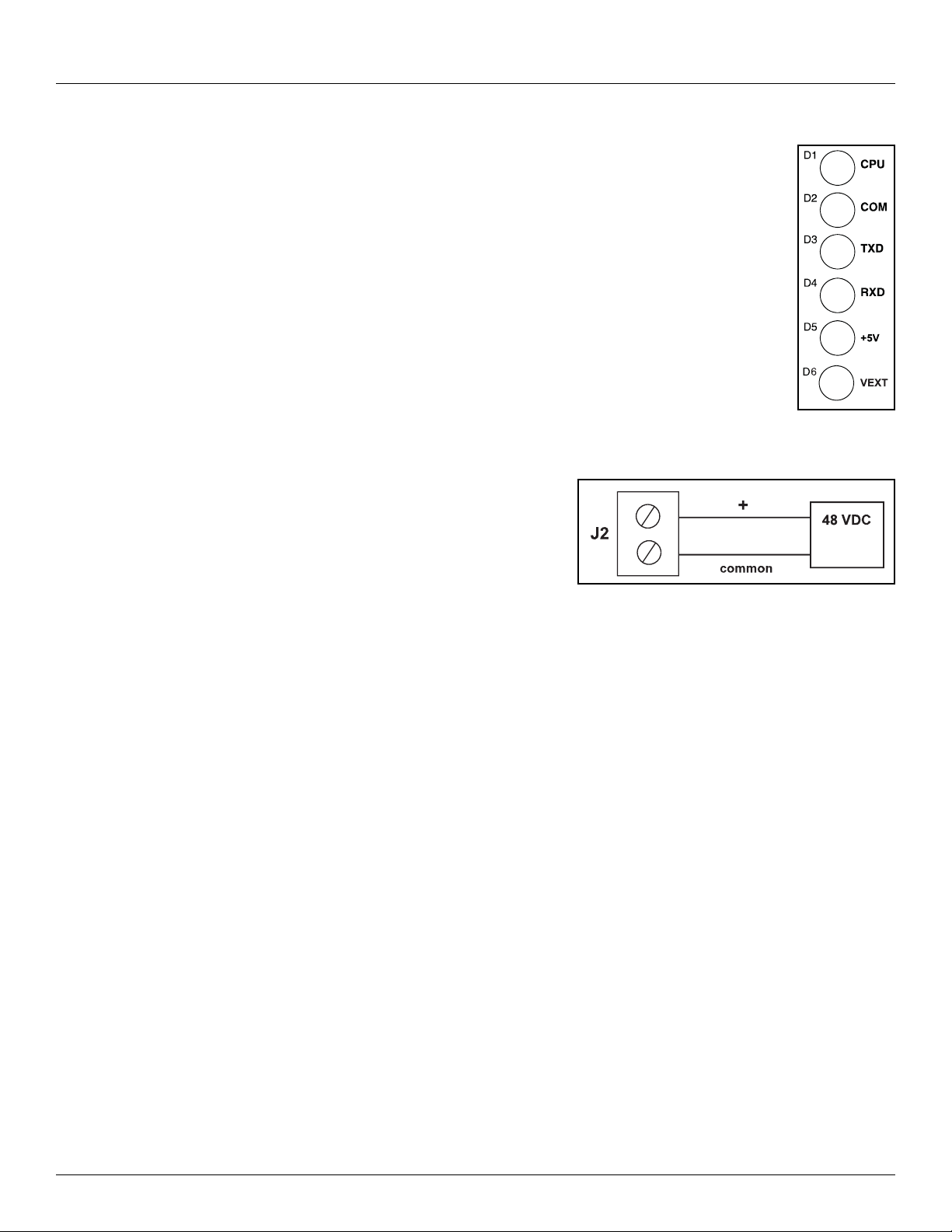

3.2.3 External Power Connector (+48V) (J2)

Connect the +48 VDC External Power as shown

below:

Figure 3-3: External Power Connector

3.2.4 Surge/Shield Ground Connector (J4)

Connecting the Surge/Shield ground connector

Caution! This ground connection is important for system safety.

• Connect a 14 AWG copper wire between the ground terminal (J4) and a good earth ground.

Perform this step before connecting ANY other wires.

• Verify that the resistance in this connection does not exceed 1 ohm.

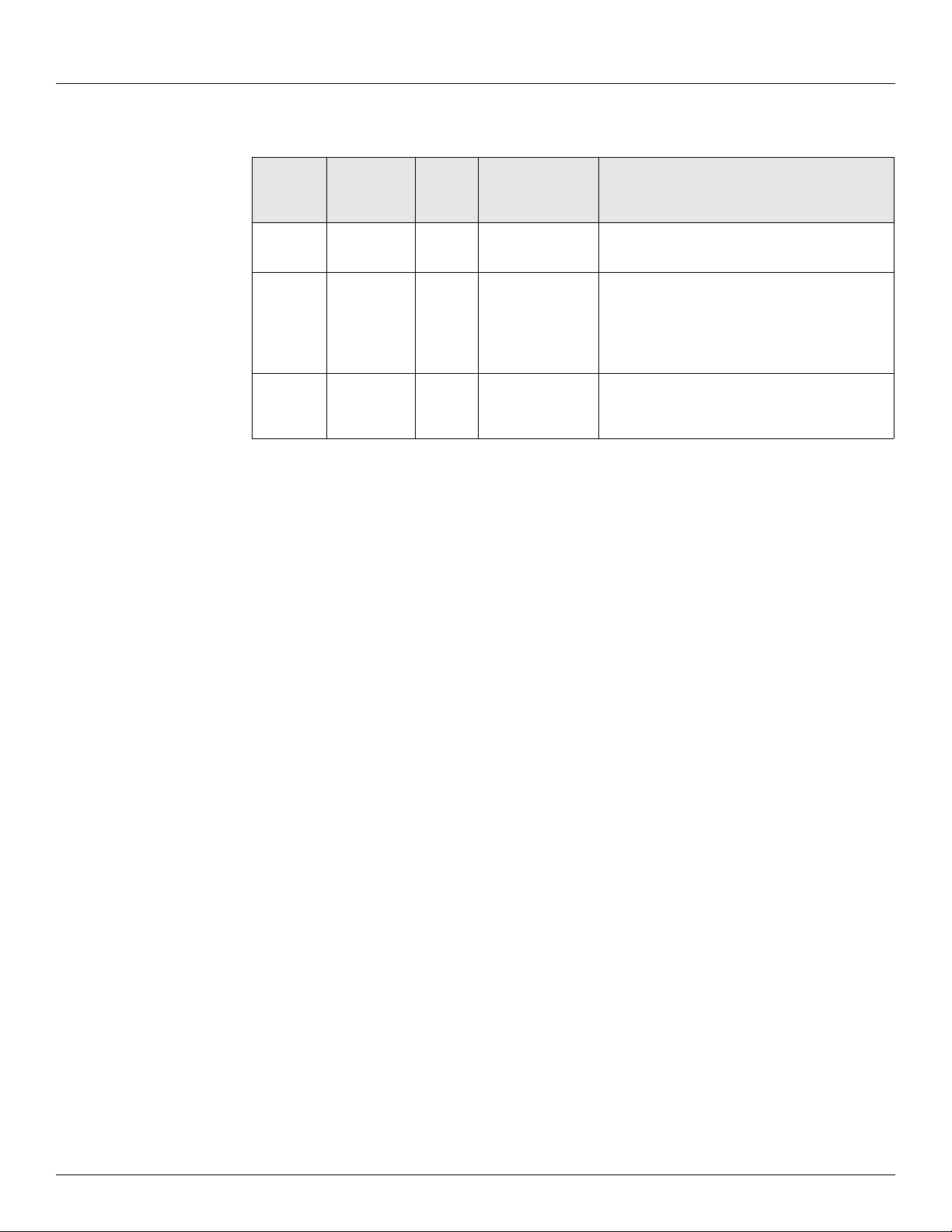

3.2.5 Field Wiring terminal block (J3)

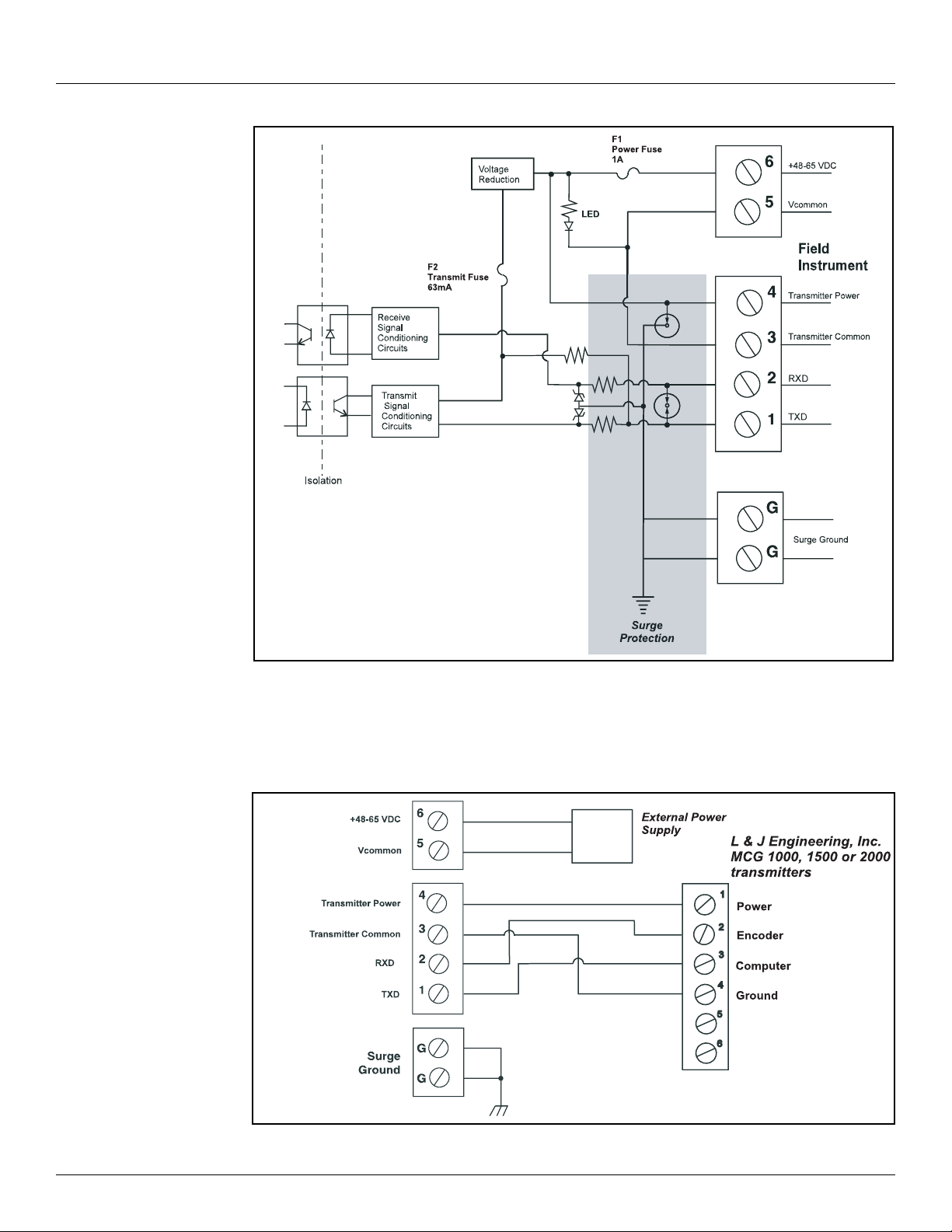

A schematic illustrating the terminal connections of the Model 8315 is shown below:

Varec, Inc. 17

8215 L&J Tankway Communications Interface Module Tank Gate Interface

Figure 3-4: Input Circuit

3.2.5.1 Connect the field wiring

Connect the wiring following the diagram below.

Figure 3-5: Application

18 Installation and Operations Manual

8315 TGI Software Description

4 Software Description

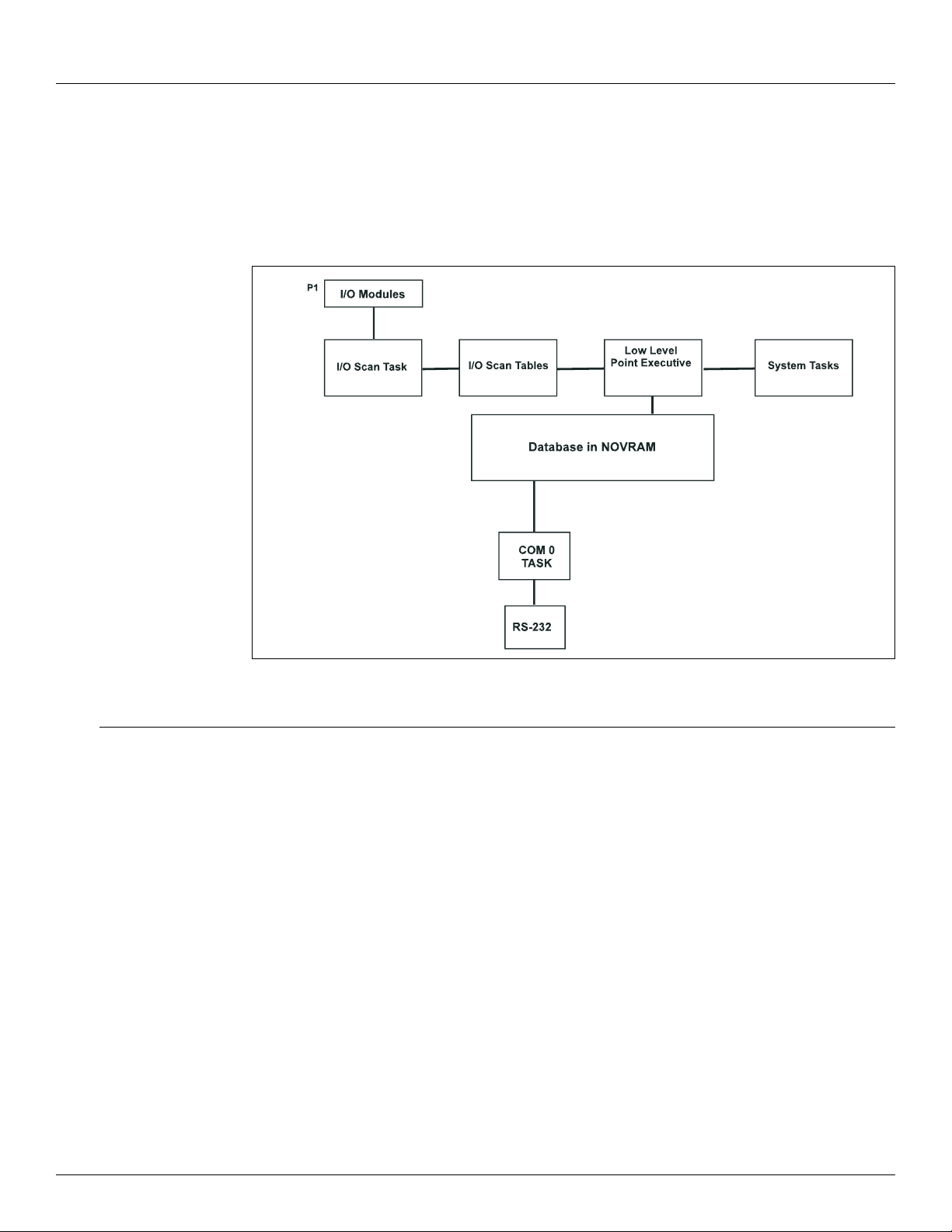

The Tank Gate Interface software platform is based on a real-time, multi-tasking operating

system. The software consists of I/O scanning functions for data acquisition, a database/

database manager and communication functions for data transfer.

Note COM1 is not available on the 8315 Tank Gate Interface.

Figure 4-1: Software Block Diagram

4.1 Software Features

4.1.1 Real-Time / Multitasking Executive

The operation of the Tank Gate Interface is based on a highly reliable, field-proven real-time

multitasking executive. It provides task switching based on real-time events and interrupts,

message passing and task priorities. Its capabilities also include timed suspension of tasks,

queue handlers and interrupt processing tasks.

4.1.2 Real-Time Clock

Integral to the real-time executive is the system’s real-time clock. All timed events of the Tank

Gate Interface are coordinated by this clock. In addition to the real-time executive interaction,

all field data scanning is coordinated by the real-time clock.

4.1.3 Automatic Fault Recovery

The Tank Gate Interface has a watchdog timer that is periodically strobed by the microprocessor.

Should the processor suffer a lapse due to hardware or software failure, the watchdog timer will

time out and the Tank Gate Interface will then be reset and normal operation will resume.

Varec, Inc. 19

Software Description Tank Gate Interface

4.1.4 Communications

There are two communications tasks - one for each of the communication channels. COM ports

0 and1 are used to interface to external devices or host systems. Refer to the Hardware Chapter

for the location of these ports.

Note COM1 is not available on the 8315 Tank Gate Interface.

COM0 and COM1

COM 0 and 1 can be configured for communications to Host systems using a variety of

protocols. For COM 0 and 1 the communication interfaces include the following:

• RS-485 for use in multi-drop configurations or long cable runs (or both)

• RS-232 for flexibility in configuring other types of communications links such as radio and

fiber optic interfaces

• RTS/CTS lines are available for hardware handshaking.

4.1.5 Protocols

The Tank Gate Interface is fully compatible with FuelsManager® software. It is also compatible

with a variety of other Host systems including through Modbus protocol.

• RS-485 for use in multi-drop configurations or long cable runs (or both), with an RS232-

to-RS485 converter.

• RS-232 for flexibility in configuring other types of communications links such as radio and

fiber optic interfaces.

The default communication settings for the COM ports are as follows:

COM Port Protocol Baud Rate Data Bits Parity Stop Bits

COM0 RTU Slave or Modbus

- Auto-sensing

COM1 Modbus 9600 8 N 0

9600 8 N 0

Note COM1 is not available on the 8315 Tank Gate Interface.

4.1.6 Data Scanning Task

The Data Scanning Task is dedicated to the scanning of field input data from tank gauges. The

input data is stored in arrays that are subsequently accessed by the Point Executive.

4.1.7 Database Manager

The Database Manager is a collection of programs and data. The Database Manager allows the

Tank Gate Interface system executive to access data from the database in an organized and

program-independent manner. It resides in non-volatile RAM.

The Database Manager also contains a Database Dictionary. This dictionary describes how the

database is organized and also provides information describing how data should be presented

to the operator.

After power-up or system reset, a CRC verification of each point in the database is performed.

If the CRC does not have a match for the point, then it is disabled and a flag is set indicating

that the point is invalid.

20 Installation and Operations Manual

Loading...

Loading...