Page 1

V

OPERATING INSTRUCTIONS

for the

CT-6500 Series 2

Digital Circuit Breaker Analyzer

anguard Instruments Company

TEL: (909) 923-9390 May 2008

FAX: (909) 923-9391 Rev 2

1520 South Hellman Avenue

Ontario, California 91761, USA

Page 2

CT-6500 Series 2 Operating Instructions

SAFETY WARNINGS AND CAUTIONS

Only trained operators shall use the device. All circuit breakers under test shall be off line and

fully isolated.

DO NOT SERVICE OR TEST ALONE

Do not perform test procedures or service unless another person is also present who is

capable of rendering aid and resuscitation.

DO NOT MODIFY TEST EQUIPMENT

Due to the added risk of introducing additional or unknown hazards, do not install substitute

parts or perform any unauthorized modifications to any CT-6500 test unit. To ensure that all

designed safety features are maintained, it is recommended that repairs be performed only by

Vanguard Instruments Company’s factory personnel or by an authorized repair and service

center. Unauthorized modifications can cause serious safety hazards and will nullify the

manufacturer's warranty.

FOLLOW EXACT OPERATING PROCEDURES

Any deviation from the procedures described in the operator’s manual may create one or more

safety hazards, damage the CT-6500, the test circuit breaker or cause errors in the test

results. Vanguard Instruments Company, Incorporated assumes no liability for unsafe or

improper use of the CT-6500.

WARRANTY

The CT-6500’s warranty is only valid to the original purchaser to be free from defects in

material and workmanship for a period of one year. The warranty does not apply to normal

wear or damage from misuse, abuse, improper storage, installation, accident, unauthorized

repair or alterations.

I

Page 3

CT-6500 Series 2 Operating Instructions

Table of Contents

1.0 Introduction ............................................................................................................................. 7

2.0 CT-6500 Description ............................................................................................................... 8

2.1 Contact Timing Channels ............................................................................................ 8

2.2 Analog Voltage Monitoring Channel ............................................................................ 8

2.3 Digital Voltage Monitoring Channel ............................................................................. 8

2.4 Trip/Close Current Monitoring ..................................................................................... 8

2.5 Travel Transducer Input Channels .............................................................................. 8

2.6 Breaker Initiate Capability ........................................................................................... 8

2.7 Built-in Thermal Printer ............................................................................................... 9

2.8 Computer Interface Capabilities .................................................................................. 9

2.9 Timing Records Storage Capabilities .......................................................................... 9

2.10 Diagnostic Capabilities .............................................................................................. 9

2.11 CT-6500 Display and Control Switches .................................................................... 9

3.0 Test Result Tabulation ............................................................................................................ 9

3.1 Timing Test Measurement Results ............................................................................. 9

3.2 Mechanical Measurement Results ............................................................................ 10

3.3 Analog Voltage Input Results .................................................................................... 10

3.4 Digital Voltage Input Results ..................................................................................... 10

3.5 Initiate Current Results.............................................................................................. 10

3.6 Slow-Close Test Results ........................................................................................... 11

4.0 Test Result Graphics ............................................................................................................ 11

4.1 Thermal Printer Graphic Printout .............................................................................. 11

5.0 CT-6500 Controls and Display .............................................................................................. 12

6.0 CT-6500 Analyzer Specifications .......................................................................................... 15

7.0 CT-6500 Special Features .................................................................................................... 17

7.1 CT-6500 Supplied Cables ......................................................................................... 17

7.2 CT-6500 Operating Voltages .................................................................................... 18

7.3 CT-6500 Main Power Switch & Circuit Breaker ........................................................ 18

7.4 Initiate Circuit Protection Fuses ................................................................................ 18

7.5 CT-6500 Printer and Printer Paper ........................................................................... 19

7.6 Replacing CT-6500 Thermal Paper .......................................................................... 19

7.7 CT-6500 Printer Paper Control ................................................................................. 19

7.8 CT-6500 LCD Contrast Control ................................................................................. 19

8.0 Test Hook-up Connections ................................................................................................... 20

8.1 Contact Cable Hookup .............................................................................................. 20

8.2 Initiate Cable Hookup ................................................................................................ 22

8.3 Analog Voltage Monitor Hookup ............................................................................... 23

8.4 Digital Voltage Monitor Hookup ................................................................................. 23

8.5 External Trigger Input ................................................................................................ 24

8.6 Digital Transducer Connection .................................................................................. 25

9.0 Operating Procedures ........................................................................................................... 26

9.1 Timing a Circuit Breaker ............................................................................................ 27

9.1.1 Timing an OPEN Operation (With No Insertion Resistors) .................................... 28

9.1.2 Timing an OPEN Operation with Insertion Resistors ............................................. 29

9.1.3 Timing CLOSE-OPEN Operation Using Contact Channel #1 ................................ 30

9.1.4 Timing OPEN-CLOSE-OPEN Operation ................................................................ 32

II

Page 4

CT-6500 Series 2 Operating Instructions

9.2 Printing Tabulated Timing Results Using the Thermal Printer .................................. 33

9.2.1 Tabulated Results Interpretation ............................................................................ 35

9.3 Get Graphic Timing Results Using the Thermal Printer ............................................ 36

9.4 Save Timing Test Records in the EEPROM ............................................................. 41

9.5 Printing Timing Test Record Directory Stored in the EEPROM ................................ 42

9.6 Recalling a Timing Test Record ................................................................................ 44

9.7 Deleting a Timing Test Record .................................................................................. 45

9.8 Test Record Description............................................................................................ 46

9.9 Computer Interface ................................................................................................... 48

9.10 Breaker Travel Analysis .......................................................................................... 49

9.10.1 Breaker Stroke ..................................................................................................... 49

9.10.2 Breaker Over-Travel Distance .............................................................................. 49

9.10.3 Breaker Bounce-Back Distance ........................................................................... 49

9.10.4 Contact Wipe........................................................................................................ 49

9.10.5 Breaker Velocity ................................................................................................... 49

9.10.6 Analysis Point Selections ..................................................................................... 49

9.10.7 Analysis Point No.1 (AP1) .................................................................................... 50

9.10.8 Analysis Point No. 2 (AP2) ................................................................................... 50

9.10.9 Set-Up Open Analysis Points ............................................................................... 52

9.11 Select English or Metric Measurement Unit. ........................................................... 54

9.12 Digital Rotary Transducer Selection ........................................................................ 54

9.13 Slow-Close Test ...................................................................................................... 55

9.14 Transducer Self-Test............................................................................................... 57

9.15 Check Cable Hookup .............................................................................................. 58

9.16 Set CT-6500 Time and Date ................................................................................... 59

9.17 Automatic Print Setting ............................................................................................ 60

9.18 Selecting 50 Hz or 60 Hz for Contact Time Reading .............................................. 61

9.19 CT-6500 Channel Configuration ............................................................................. 63

9.20 Print Test Record Data ............................................................................................ 64

9.21 Transducer Encoder Filter Setting .......................................................................... 65

9.22 Contact Filter Setting............................................................................................... 66

9.23 Running CT-6500s in Tandem ................................................................................ 68

10.0 CT-6500 Trouble Shooting Guide ....................................................................................... 69

III

Page 5

CT-6500 Series 2 Operating Instructions

List of Figures

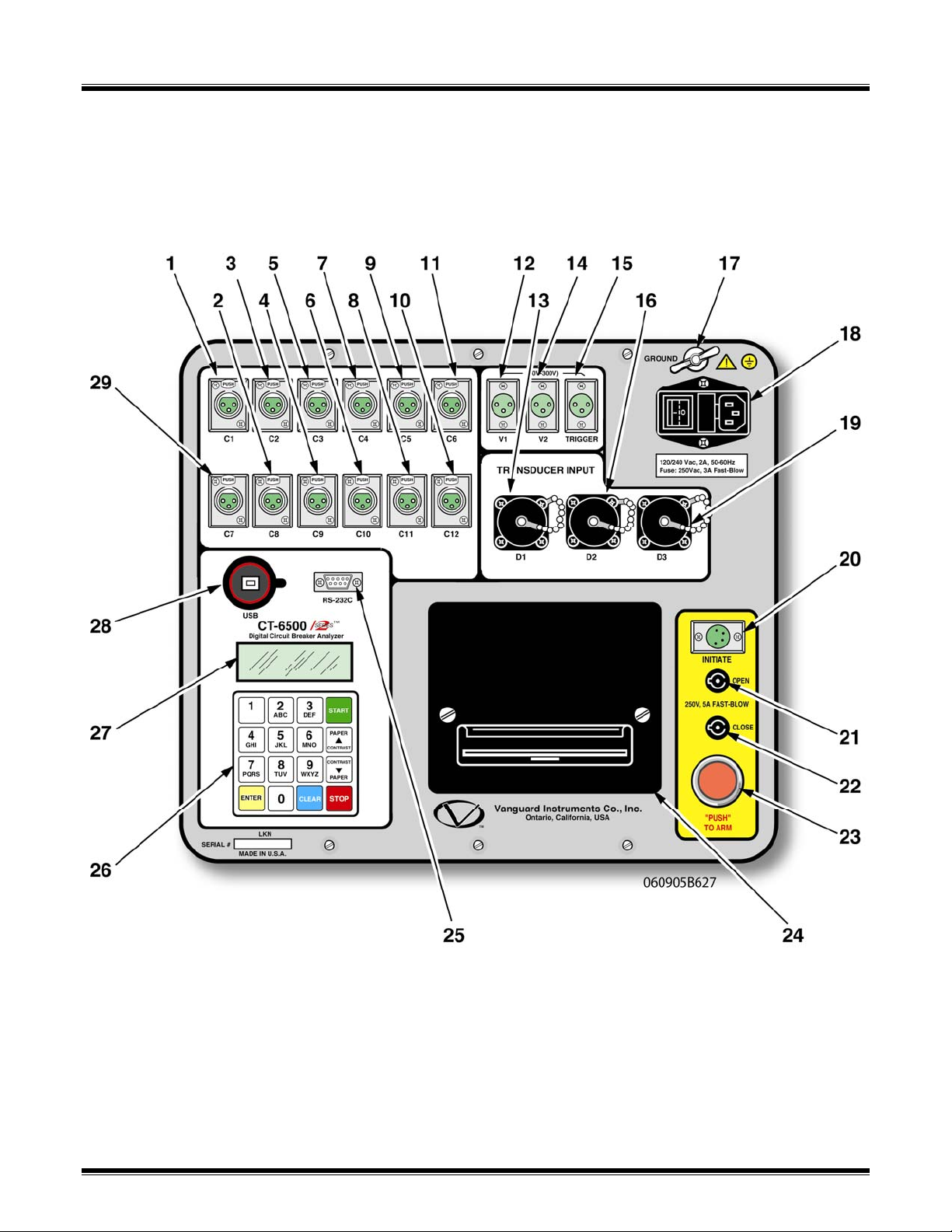

Figure 1.0 CT-6500 Control Panel .......................................................................................... 12

Figure 2.0 CT-6500 Operating Voltage Setting ....................................................................... 18

Figure 3.0 Contact Cable Connection ..................................................................................... 20

Figure 4.0 Series Contact Cable Connection .......................................................................... 21

Figure 5.0 DC Trip and DC Close, Initiate Circuit Cable Hook-Up .......................................... 22

Figure 6.0 DC Trip and AC Close, Initiate Circuit Cable Hook-Up .......................................... 22

Figure 7.0 Voltage Monitoring Cable Hook-Up ....................................................................... 23

Figure 8.0 External Trigger Cable Hook-Up ............................................................................ 24

Figure 9.0 Transducer Connection ......................................................................................... 25

Figure 10.0 CT-6500 Operating Steps .................................................................................... 26

Figure 11.0 Typical Tabulated Printout of an Open Operation From the Thermal Printer ....... 34

Figure 12.0 Typical Graphic Result Printed on Thermal Printer .............................................. 37

Figure 13.0 Expansion Graph From 0 to 300ms Printed on Thermal Printer .......................... 38

Figure 14.0 Graphical Interpretation of an Open Timing Shot ................................................ 39

Figure 15.0 Graphical Interpretation of a Close Timing Shot .................................................. 39

Figure 16.0 Graphical Interpretations of an Open-Close and a Close-Open Timing Shot ...... 40

Figure 17.0 Printout of the Timing Shot Directory From the Thermal Printer .......................... 43

Figure 18.0 Typical Slow-Close Test Report .......................................................................... 56

Figure 19.0 Typical 50 Hz Tabulated Report .......................................................................... 62

Figure 20.0 Typical 60 Hz Tabulated Report .......................................................................... 62

Figure 21.0 CT-6500 Timing Data ........................................................................................... 64

Figure 22.0 Contact Filter Setting Illustration .......................................................................... 67

IV

Page 6

CT-6500 Series 2 Operating Instructions

List of Tables

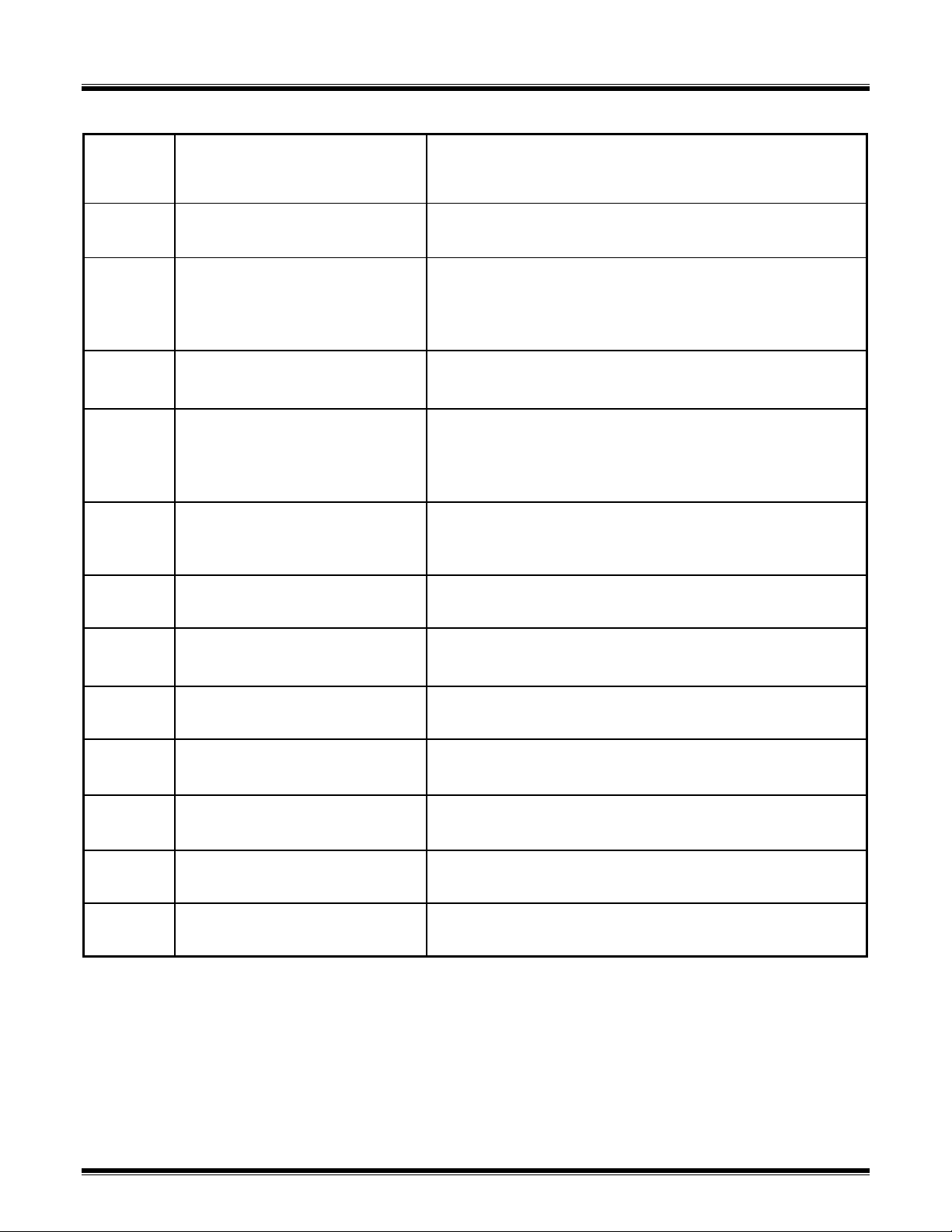

Table 1.0 CT-6500 Controls and Displays .............................................................................. 13

Table 2.0 CT-6500 Cable set .................................................................................................. 17

Table 3.0 Open Operation With No Insertion Resistors .......................................................... 28

Table 4.0 Open Operation With Insertion Resistor ................................................................. 29

Table 5.0 Close-Open Operation Using Contact Channel #1 ................................................. 31

Table 6.0 Open-Close-Open Operation Using Delay .............................................................. 32

Table 7.0 Printing Tabulated Results ...................................................................................... 33

Table 8.0 Plot Timing Chart .................................................................................................... 36

Table 9.0 Save Timing Test Record In EEPROM ................................................................... 41

Table 10.0 Print Timing Test Record Directory ....................................................................... 42

Table 11.0 Recalling a Timing Test Record ............................................................................ 44

Table 12.0 Deleting a Timing Record ..................................................................................... 45

Table 13.0 Entering Test Record Identification Header .......................................................... 46

Table 14.0 RS-232C Connector Pin Definition ....................................................................... 48

Table 15.0 Setting Up "OPEN" Analysis Points Using Distance ............................................. 52

Table 16.0 Select English or Metric Procedure ....................................................................... 54

Table 17.0 Select Rotary Transducer ..................................................................................... 54

Table 18.0 Performing a Slow-Close Test .............................................................................. 55

Table 19.0 Performing a Transducer Self Test ....................................................................... 57

Table 20.0 Checking the Cable Hookup ................................................................................. 58

Table 21.0 Set CT-6500 Time and Date ................................................................................. 59

Table 22.0 Automatic Print Setting ......................................................................................... 60

Table 23.0 Selecting 50Hz or 60 Hz for Contact Time Reading .............................................. 61

Table 24.0 Channel Configuration .......................................................................................... 63

Table 25.0 Print Test Record Data ......................................................................................... 64

Table 26.0 Set Transducer Filter ............................................................................................ 65

Table 27.0 Set Contact Filter .................................................................................................. 66

V

Page 7

CT-6500 Series 2 Operating Instructions

Appendix

APPENDIX A ITE Circuit Breaker model 14.4K Timing Chart ................................................... 71

APPENDIX B CLOSE-OPEN Timing Chart for ITE Circuit Breaker Model 14.4K ..................... 72

APPENDIX C CLOSE-OPEN Tabulated Report for ITE Circuit Breaker Model 14.4K .............. 73

APPENDIX D OPEN-CLOSE Timing Chart for ITE Circuit Breaker Model 14.4K ..................... 74

APPENDIX E OPEN-CLOSE Tabulated Report for ITE Circuit Breaker Model 14.4K .............. 75

APPENDIX F SIEMENS TCP Breaker Velocity Calculation ...................................................... 76

APPENDIX G SIEMENS SPS2 Breaker Velocity Calculation ................................................... 77

APPENDIX H CT-6500 SIEMENS SPS2 Test Plan .................................................................. 78

APPENDIX I CT-6500 Transducer Illustration ........................................................................... 79

VI

Page 8

CT-6500 Series 2 Operating Instructions

1.0 Introduction

The CT-6500 is the fifth generation microprocessor-based, digital time travel circuit breaker

analyzer developed by Vanguard Instruments Co. The CT-6500 can fully analyze a utility circuit

breaker’s performance by measuring: the contact time, stroke, velocity, over-travel, bounce-back

and contact wipe.

The circuit breaker contact motion analysis includes: Open, Close, Open-Close, Close-Open

and Open-Close-Open operations. A timing window of one second, ten second or twenty second

can be selected. The ten and twenty second windows allow timing of long timing events such as

circuit switcher contact activities.

The conventional Time-Travel test mode allows the user to fully analyze the circuit breaker

contact time and contact travel information. Additional circuit breaker information such as:

Operating-coil current reading, breaker DC coil power supply voltage reading are also

available.

The CT-6500 is available with the following configurations:

CT-6500-3:

- Three Contact-Input channels

- Three Digital Travel Transducer Input channels

- One Analog Voltage Monitor Input channel

- One Digital Voltage Monitor Input channel

- One Trip/Close Current Monitor channel

CT-6500-6:

- Six Contact-Input channels

- Three Digital Travel Transducer Input channels

- One Analog Voltage Monitor Input channel

- One Digital Voltage Monitor Input channel

- One Trip/Close Current Monitor channel

CT-6500-12:

- Twelve Contact-Input channels

- Three Digital Travel Transducer Input channels

- One Analog Voltage Monitor Input channel

- One Digital Voltage Monitor Input channel

- One Trip/Close Current Monitor channel

There are two different modes of operation for the CT-6500 which are Stand Alone Mode and

Computer Control Mode. The manual will focus on the Stand Alone Mode. The Computer Control

Mode is covered under the Circuit Breaker Analyzer Software Series 2 manual.

7

Page 9

CT-6500 Series 2 Operating Instructions

2.0 CT-6500 Description

2.1 Contact Timing Channels

A breaker's interruption of contacts are timed with the dry-contact input channels. Each contact

channel can detect the main contacts and the insertion resistor contact times in milliseconds and

cycles.

The CT-6500 applies a test voltage of 35Vdc to each of the contact channels thus allowing an

analog to digital converter (A/D) to determine if a close, an open or an insertion resistor was the

state of the contact. The CT-6500 records into the memory 20,000 readings from the A/Ds and

the transducer position counters. The contact time, circuit breaker stroke and velocity is then

derived from the data that was stored in the memory.

NOTE

The CT-6500 can detect insertion resistors ranging from 10 to 7,000 Ohms.

Resistances over 7,000 Ohms are detected as an open contact.

2.2 Analog Voltage Monitoring Channel

One analog voltage, input channel, “V1” is dedicated to monitoring the breaker's DC power

supply or coil voltages from 0 to 255Vdc or peak Vac.

NOTE

Maximum input voltage is 300Vdc or peak Vac. Recording voltage readings are from 0

to 255Vdc.

2.3 Digital Voltage Monitoring Channel

One digital voltage, input channel, “V2” monitors the status voltage as “ON” or “OFF.” Voltages

from 30 to 255Vdc are considered as “ON” status. Voltages less than 30Vdc are considered as

“OFF” status.

2.4 Trip/Close Current Monitoring

A built-in, hall-effect, current sensor measures the trip and close coil current levels and

duration. The coil current waveform can be graphically plotted onto a printout. The coil current

reading is also printed in the tabulated report. The CT-6500 initiate circuit is capable of carrying

up to 30 amperes. Maximum coil current reading is 20 amperes.

2.5 Travel Transducer Input Channels

Each CT-6500 has three digital transducer input channels. The CT-6500 uses up-down

counters to sense the breaker’s transducer reading. The CT-6500 travel transducer employs

optical encoders to send quadrature signals to the CT-6500’s counters. With the use of digital

transducers and counters, the need to set up or calibrate the transducers is eliminated.

The CT-6500 will interface with a linear, a rotary and other special transducers developed by

Vanguard Instruments Company. Please refer to Appendix I for more details.

2.6 Breaker Initiate Capability

A built-in, solid-state, initiate device allows the user to operate the circuit breaker from the CT-

6500. Operational modes include: Open, Close, Open-Close, Close-Open and Open-CloseOpen. The multiple operations of: Open-Close, Close-Open and Open-Close-Open can be

initiated with a programmable delay time or by sensing the breaker's contact state.

The solid-state switching implemented in the initiate circuitry allows the CT-6500 to switch a

8

Page 10

CT-6500 Series 2 Operating Instructions

breaker's AC or DC control circuit. . The CT-6500 initiate circuit is capable of carrying up to 30

amperes. Separate 5 Ampere, fast-blow fuses protect each trip and close circuits. An interlock

“ARM” switch action is required by the operator to operate the initiate circuit.

2.7 Built-in Thermal Printer

The breaker's contact analysis results can be printed in both tabular and graphical formats by

a built-in, 4.5 inch wide, thermal printer. Refer to paragraph 7.5 for ordering thermal paper.

2.8 Computer Interface Capabilities

Built-in, RS-232C and USB ports allow the CT-6500 to be interfaced with an IBM-compatible

personal computer. A Windows XP Circuit Breaker Analyzer software is supplied with each CT-

6500. The software allows the user to:

- Control CT-6500 from a personal computer.

- Retrieve timing records stored in the CT-6500.

- Transfer circuit breaker test plans to CT-6500.

- Recall timing records from a hard drive for reanalysis at an office PC.

2.9 Timing Records Storage Capabilities

The CT-6500 uses Electrically Erasable Programmable Read-Only-Memory (EEPROM) to

store timing-shot data. Unlike other media, EEPROMs are immune to temperature, shock and

humidity. Stored shots can be recalled to reanalyze the test data, to reprint test reports or to

transfer data to a personal computer for record keeping. Up to 100 timing records can be stored

in the EEPROMs. The number of test records stored in the EEPROMs may vary depending upon

the size of the records.

2.10 Diagnostic Capabilities

The CT-6500 is designed with self-diagnostic capability to check the integrity of the electronics.

Self testing of the contact cable hook-up and transducers permits the user to examine the CT6500‘s components whenever verification is required.

2.11 CT-6500 Display and Control Switches

An alphanumeric keypad enables the users to operate the CT-6500 and to enter the breaker’s

nameplate data such as: the substation name, breaker model and other descriptions. A 4-line by

20-character LCD readout displays user messages and menus. The LCD is back-lighted to allow

messages to be viewed in low light conditions.

3.0 Test Result Tabulation

3.1 Timing Test Measurement Results

In the Time Travel Mode, each CT-6500 contact channel provides the following test results:

- Contact Close time

- Contact Open time

- Insertion Resistor Contact Open and Close times

- Contact Bounce time

- Resistor On time

- Contact Spread time

9

Page 11

CT-6500 Series 2 Operating Instructions

NOTE

The CT-6500 can detect insertion resistors ranging from 10 to 7,000 Ohms.

Resistances over 7,000 Ohms are detected as an open contact.

3.2 Mechanical Measurement Results

In the Time Travel Mode, the digital transducer channels provide the following test results:

- CB contact stroke

- CB contact over travel

- CB Contact bounce back

- CB Contact wipe

- CB Contact velocity

Breaker contact speed calculations are based upon a contact's travel distance over a period of

time, which is defined by the manufacturer's specifications.

NOTE

When the resistor type transducer channel is used, the test results are shown as

transducer channel 1.

CB contact mechanical measurement can be shown in “English” or “Metric” units.

3.3 Analog Voltage Input Results

The analog voltage, input channel, “V1” measures the breaker's DC control voltage during an

operation. Printed voltage readings include nominal voltage (when the supply voltage has no

load) and minimum voltage (when the supply voltage is under load or when a coil is energized).

The “V1” connection allows the user to monitor the DC power supply’s voltage fluctuations during

a breaker operation. This feature is effective in detecting breaker power supply problems, which

normally can not be seen by using a voltmeter.

NOTE

Printed voltage readings can range from 0 to 255Vdc.

3.4 Digital Voltage Input Results

The digital voltage, input channel, “V2” monitors the voltage status as “ON” or “OFF”

conditions and graphs the result. A voltage level above 30Vdc is considered as the “ON” state.

The input channel is dedicated to monitor the breaker’s auxiliary switch action during a breaker

operation.

NOTE

The input voltage ranges from 0 to 300Vdc or peak ac.

3.5 Initiate Current Results

The CT-6500 not only plots the trip or close current waveforms, but also prints the steady-state

current readings of the trip and close coils during an operation. A typical circuit breaker timing

report is shown in Figure 11.0.

10

Page 12

CT-6500 Series 2 Operating Instructions

3.6 Slow-Close Test Results

A Slow-Close test determines the contact touch distance and penetration by using the travel

transducer and dry contact channels. See section 9.13 for Slow-Close test Procedure.

4.0 Test Result Graphics

4.1 Thermal Printer Graphic Printout

A 4.5 inch wide, built-in, thermal printer can output graphic waveforms of the contact channels,

travel curves and actuator-coil currents. Using the Zoom Graphics Mode, the user can enlarge

the graphical outputs by specifying the timing zone. Typical graphical results are shown in

Figures 12.0 and 13.0.

11

Page 13

CT-6500 Series 2 Operating Instructions

5.0 CT-6500 Controls and Display

Before using the CT-6500, users should become familiar with all of the controls and display

indications. The keypad and display are used to operate the CT-6500. Figure 1.0 represents the

control panel and the numbered lines pointing to each control and indicator refer to Table 1.0,

which describes the function of each control and indicator.

Figure 1.0 CT-6500 Control Panel

12

Page 14

CT-6500 Series 2 Operating Instructions

Table 1.0 CT-6500 Controls and Displays

Fig. 1.0

Index

no.

1-11 &

31

12

13, 16,

19

14

15

17

PANEL MARKING FUNCTIONAL DESCRIPTION

CONTACT INPUT

Female connectors for the contact channels.

(C1–C12)

0-300V

V1

D1, D2, D3

TRANSDUCER INPUT

0-300V

V2

0-300V

TRIGGER

GROUND

3-pin connector. V1 voltage input channel is dedicated to

monitor circuit breaker DC power supply or coil voltages.

Voltage sensing range is from 0-255 volts, dc or peak

ac.

16-pin connectors. Digital travel transducer input

channels.

3-pin connector. V2 voltage input channel is dedicated to

detect voltage on/off status (present or absent) of an A/B

switch. Voltage input ranges from 0-300 volts, dc or

peak ac.

3-pin connector. Triggers voltage input for external

trigger application. Voltage levels ranging from 30 to 300

V, dc or peak ac.

Safety, ground terminal. 5/16-18 thread stud, with wing

nut.

18

20

21

22

23

24

120/240Vac, 2A, 50-60Hz

Fuse: 250V 3A, Fast Blow

INITIATE

OPEN

250V, 5A FAST-BLOW

CLOSE

250V, 5A FAST-BLOW

“PUSH” TO ARM

(Printer; No panel marking)

3-wire power plug. 3 Ampere, AC fuses. The ON/OFF

switch is a 2-pole rocker.

4-pin connector used for the switching circuit for

operating the circuit breaker under test.

Open circuit fuse: 5 Ampere, 250V, Fast-Blow.

Close circuit fuse: 5 Ampere, 250V, Fast-Blow.

Spring-loaded, pushbutton switch. Press and hold to

complete the Trip or Close circuits for breaker tests.

Thermal printer. Microprocessor controlled printer that

uses specially treated, 4.5 inch wide paper.

13

Page 15

CT-6500 Series 2 Operating Instructions

Table 1.0 CT-6500 Controls and Displays (Continued)

Fig. 1.0

Index no.

25

26

27

28

PANEL MARKING FUNCTIONAL DESCRIPTION

RS-232C

1-9, 0, ENTER, START,

STOP, CLEAR,

↑ PAPER LCD,

RS-232C serial computer interface port.

16 button keypad. The keys are momentary-contact,

pushbutton switches. Allows users to make menu

selections, enter alphanumeric data, adjust the LCD

contrast and reposition the printer paper.

↓ PAPER LCD

(Display; no panel marking)

4-line by 20-character, backlit LCD. Displays menus,

options, prompts and test result data.

USB

Computer interface, USB Port.

14

Page 16

CT-6500 Series 2 Operating Instructions

6.0 CT-6500 Analyzer Specifications

PHYSICAL SPECIFICATIONS 16” W by 11”H by 14”D (40.6 cm x 29.9 cm x 35.6 cm)

Weight: 25lbs (11.3Kg).

INPUT POWER 8 Amperes, 90-120Vac or 200-240Vac (selectable), 50/60 Hz.

DRY-CONTACT INPUT 3 or 6 or 12 contact channels. All contact inputs are grounded until testing

is started. Each contact detects main and insertion resistor contacts.

TIMING WINDOW Selectable between: 1, 10, or 20 second.

TIMING RESOLUTION ±50 microseconds at 1 second duration.

±0.5 millisecond at 10 second duration.

±1.0 millisecond at 20 second duration.

TIMING ACCURACY 0.05% of reading, ±50 micro-seconds at 1-second duration.

CONTACT DETECTION RANGE CLOSED: less than 20 Ohms.

RANGE OPEN: greater than 10,000 Ohms.

RESISTOR DETECTION RANGE Ranges from 50 to 5,000 Ohms.

EXTERNAL TRIGGER INPUT Open/Close: 30 to 300Vdc, peak Vac.

VOLTAGE SENSING INPUTS V1: analog input, 0-255V dc or peak ac. Sensitivity: ±1V;

V2: voltage detector (present/absent).Input: 30-300V, dc or peak ac.

BREAKER OPERATION Open, Close, Open-Close, Close-Open, and Open-Close-Open.

BREAKER INITIATE CAPACITY 30A/250V ac/dc max (100A inrush).

INITIATE CURRENT READING One, Non-contact, hall-effect sensor ranging from 0-20 Amperes, DC to 5 kHz.

RANGE

TRAVEL TRANSDUCER 3 travel-transducer channels. Linear motion from 0.0 to 30.0 inches (±0.01) inch.

INPUT Rotary ranges from 0 to 360

BREAKER SLOW-CLOSE Measures “Slow-Close” the contact point distance (hard copy printout).

TEST

DISPLAY Back-lit LCD screen, 4-lines by 20-characters, sunlight viewable.

PRINTOUT Both graphic contact-travel waveforms & tabulated results are printed on 4.5 inch

thermal paper.

STORAGE CAPABILITIES Store up to 100 timing records.

COMPUTER INTERFACE RS-232C Port, USB Port.

PC SOFTWARE (included) Furnished Circuit Breaker Analyzer PC software. Windows XP and Windows Vista

compatible. Th e analysis softw are can be installed on an IBM-compatible computer

for graphical display, numerical reports and database utility for office use.

SAFETY Designed to meet UL 61010A-1 Certification and CAN/CSA C22.2 No 1010.1-92.

o

(± 0.36º).

15

Page 17

CT-6500 Series 2 Operating Instructions

ENVIROMENT Operating: -10°C to 50°C (+15°F to +122°F).

Storage: -30°C to 70°C (-22°F to +158°F).

OPTIONS Hard shipping case for CT-6500.

Hard shipping case for Travel Transducers.

WARRANTY One year warranty on parts and labor.

16

Page 18

7.0 CT-6500 Special Features

7.1 CT-6500 Supplied Cables

ITEM DESCRIPTION QTY

1 GND Cable 1

2 Power Cord 1

3 Contact Cable 3 or 6 or 12

4 Contact Extension Cable 3 or 6 or 12

5 Transducer cable 1

6 Voltage & Trigger Leads 3

7 Voltage & Trigger Extension cables 3

8 Initiate Lead 1

9 Initiate Extension Cable 1

10 USB Cable 1

11 RS-232C Cable 1

CT-6500 Series 2 Operating Instructions

Table 2.0 CT-6500 Cable set

17

Page 19

CT-6500 Series 2 Operating Instructions

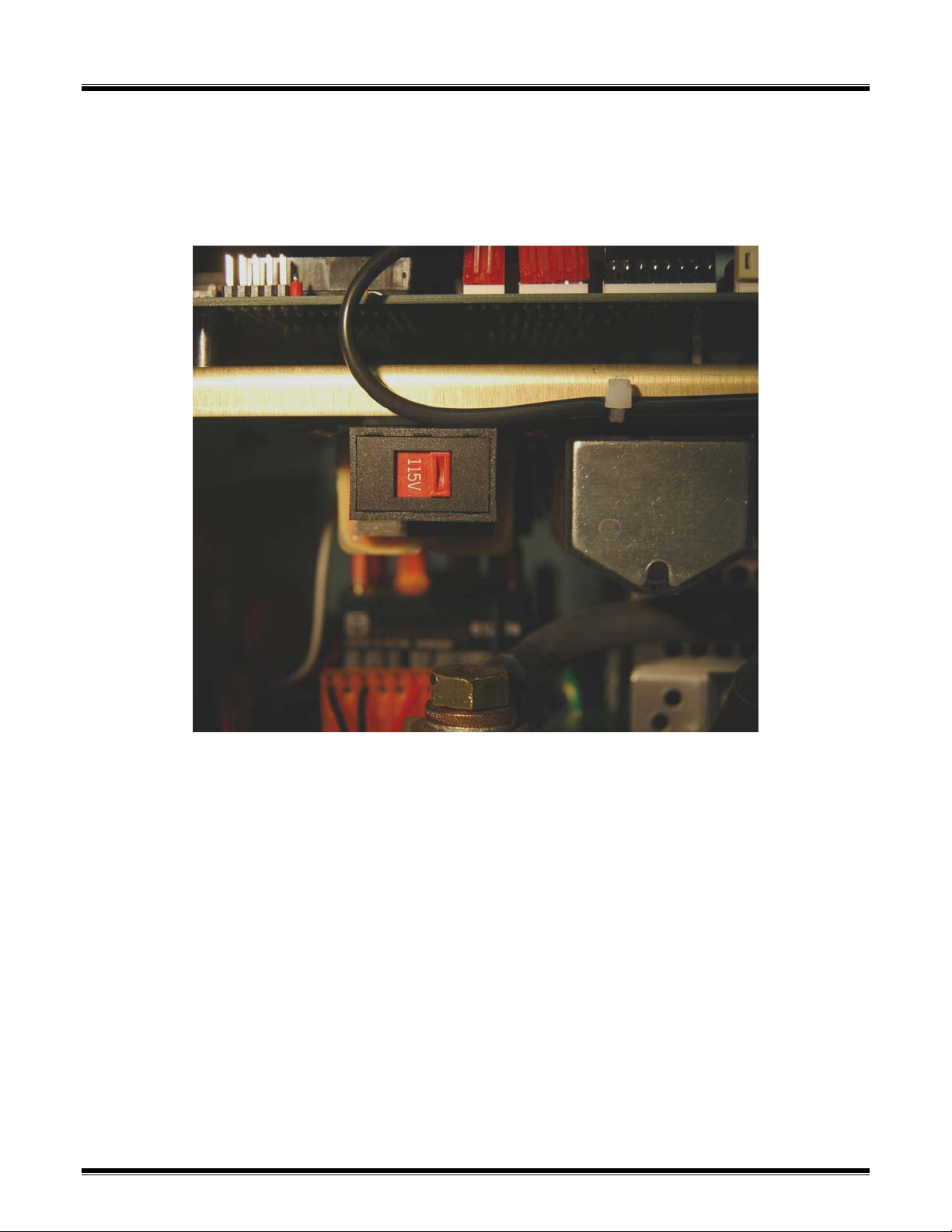

7.2 CT-6500 Operating Voltages

The CT-6500 operating voltage is selectable between 110-120Vac, 50/60 Hz or 220-240Vac,

50/60 Hz. Operating voltage is set by the voltage selection switch as shown in Figure 2.0.

To change the voltage setting, remove the CT-6500 from the case, locate the voltage setting

switch and set the new operating voltage.

Figure 2.0 CT-6500 Operating Voltage Setting

7.3 CT-6500 Main Power Switch & Circuit Breaker

The CT-6500 uses an AC input module that contains the AC receptacle, power switch and

fuse holder. A 3AG, 250Vac, 3 ampere, fast-blow type fuse is recommend.

7.4 Initiate Circuit Protection Fuses

The OPEN and CLOSE initiate circuits are protected by 5 Ampere fuses (3AG, 250Vac, fastblow types).

18

Page 20

CT-6500 Series 2 Operating Instructions

7.5 CT-6500 Printer and Printer Paper

The built-in, thermal printer uses 4.5 inch wide, thermal paper for printing test results. To

maintain the highest, quality printing and to avoid paper jamming, it is highly recommended

that the thermal paper be supplied by the factory. Additional paper can be ordered from either

of the two sources listed below:

Vanguard Instruments Co, Inc.

1520 S. Hellman Ave.

Ontario, CA 91761

Tel: 909-923-9390

Fax: 909-923-9391

Part Number: TP-4 Paper

BG Instrument Co.

13607 E. Trent Avenue

Spokane, WA 99216

Tel: 509-893-9881

Fax: 509-893-9803

Part Number: TP-4 paper

7.6 Replacing CT-6500 Thermal Paper

The roll of thermal paper resides inside a pocket underneath the printer cover. To replace

the paper, follow the steps below:

- Remove the printer cover.

- Remove the leftover thermal paper roll from the paper holder.

- Unroll the new thermal paper.

- Feed the thermal paper into the slot between the paper pocket and the rubber

roller. The printer will automatically pull the paper under the thermal head.

7.7 CT-6500 Printer Paper Control

To advance the paper from the printer, press and release the “↑ PAPER LCD” button. To

retract the thermal paper from the printer, press and release the “↓ PAPER LCD” button.

7.8 CT-6500 LCD Contrast Control

To darken the LCD screen, press and hold the “↑ PAPER LCD” button to decrease the

contrast of the LCD screen, press and hold the “↓ PAPER LCD” until the desired contrast is

reached.

- Place the paper roll into the paper holder.

- Lift the thermal head and align the thermal paper if necessary.

- Replace the printer cover back.

NOTE

The paper should feed from the bottom of the roll.

The thermal paper will show a colored stripe in the margin to indicate that the roll

is about to run out of paper.

19

Page 21

CT-6500 Series 2 Operating Instructions

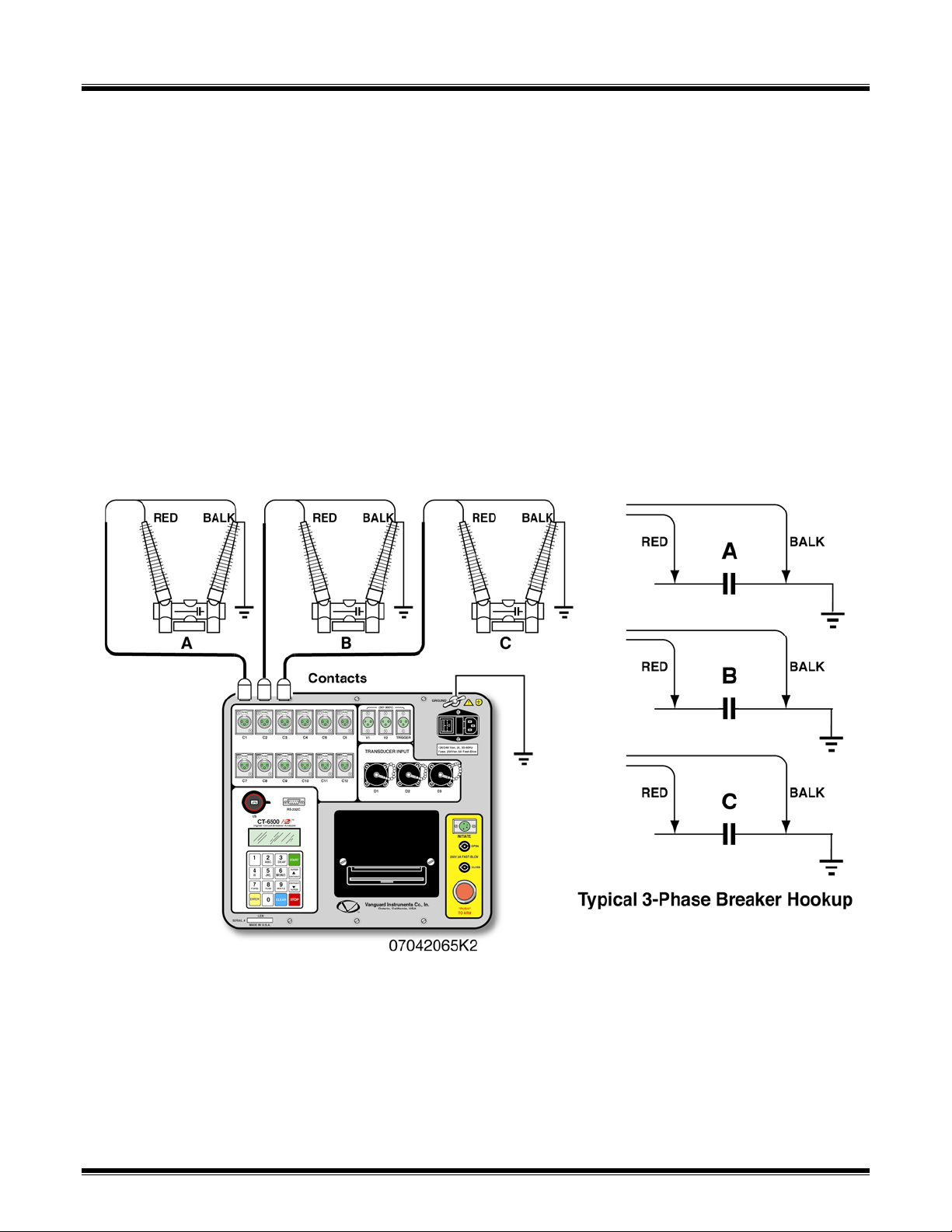

8.0 Test Hook-up Connections

8.1 Contact Cable Hookup

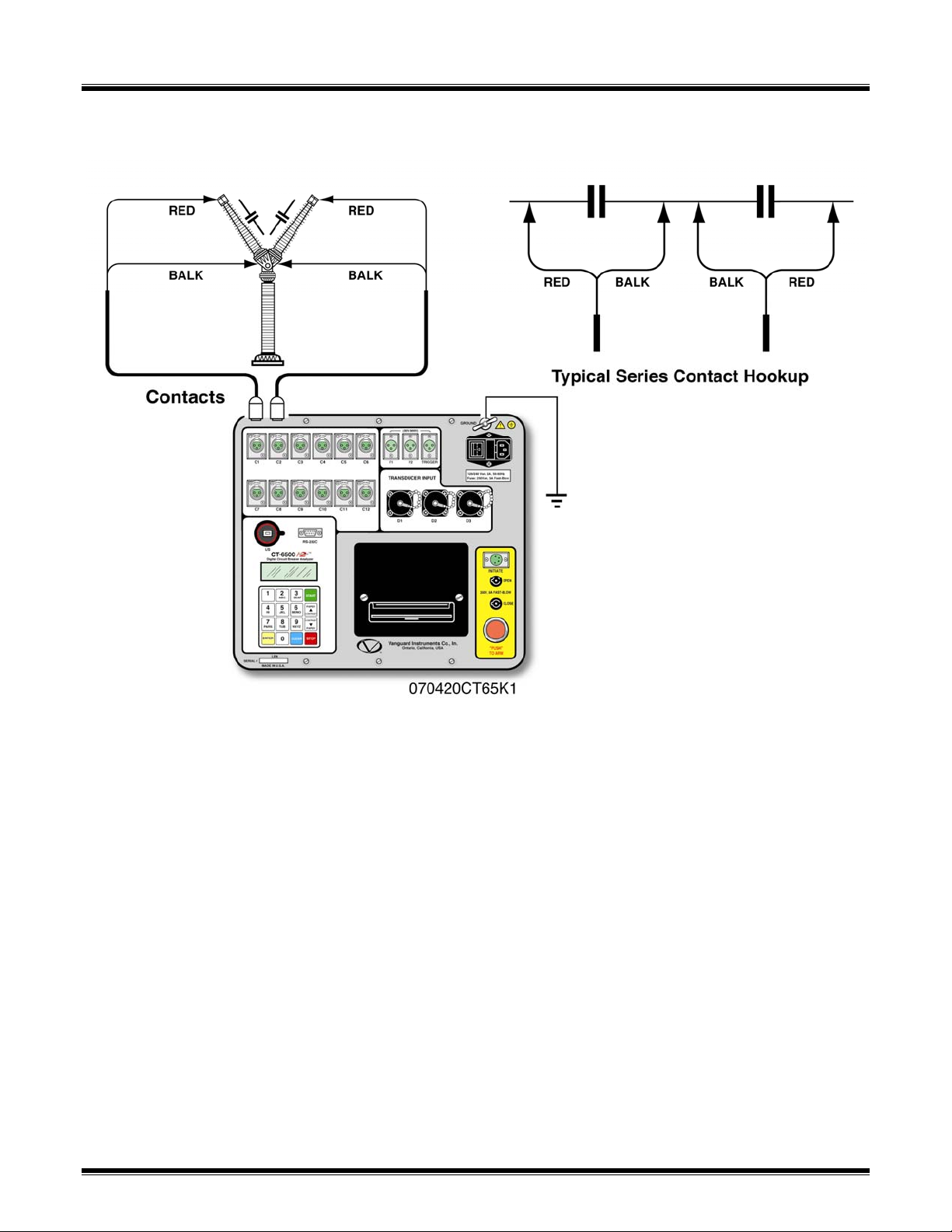

A typical, contact cable connection to a circuit breaker is shown in Figure 3.0. Red and black

clips are connected across the circuit breaker contact phase A, B and C.

A typical circuit breaker with series contacts is shown in Figure 4.0. In the below example,

the circuit breaker has 2 contacts in series per phase. Contact timing channel 1 and 2 are

used in the illustration.

NOTE

It is advisable to ground one side of the contacts for most testing purposes. If a breaker

is floating or ungrounded, ensure that the contact channel inputs are protected against

static discharge.

Figure 3.0 Contact Cable Connection

20

Page 22

CT-6500 Series 2 Operating Instructions

Figure 4.0 Series Contact Cable Connection

21

Page 23

CT-6500 Series 2 Operating Instructions

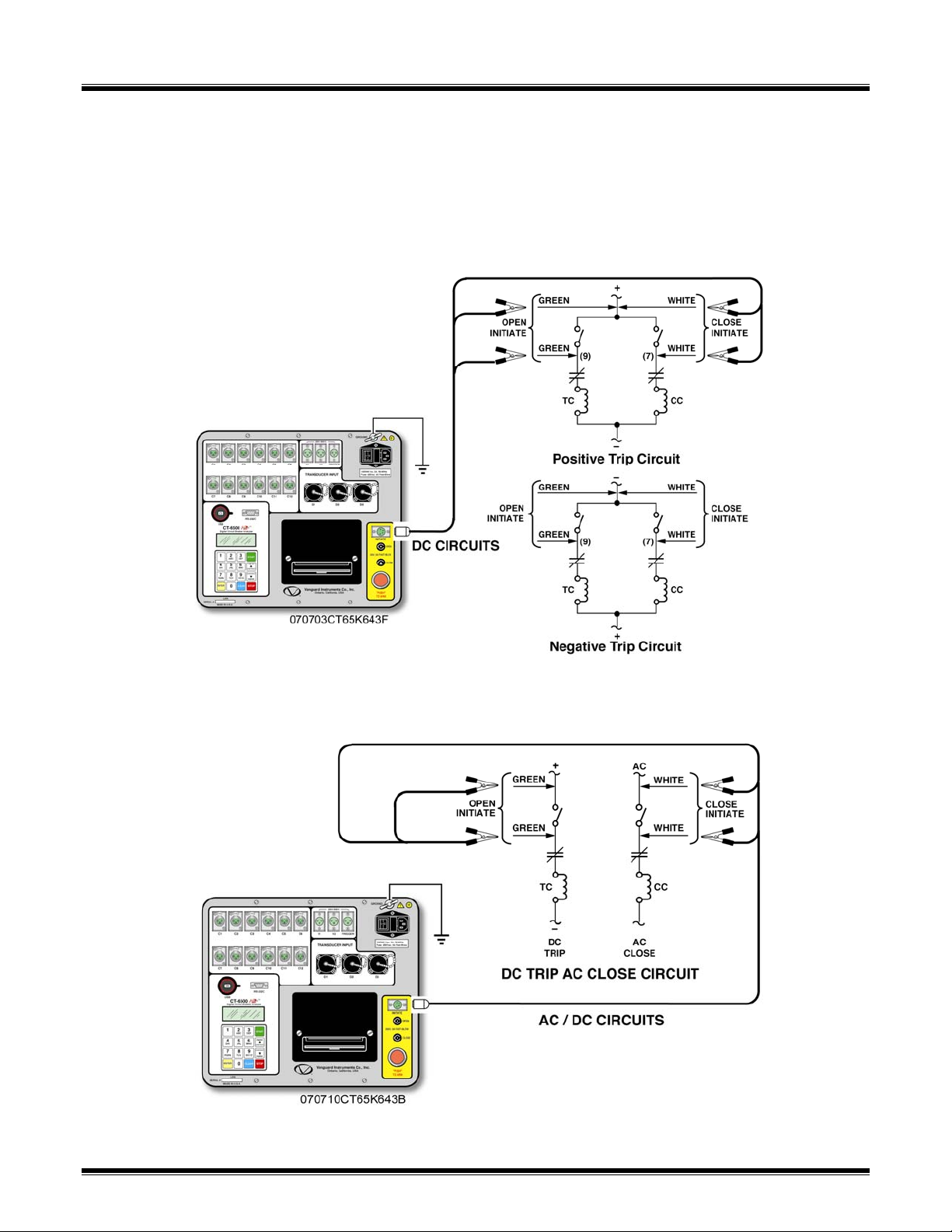

8.2 Initiate Cable Hookup

The CT-6500 will trip or close breakers through a solid-state device, which will operate on any

AC or DC control voltage ranging from 10 to 300 Volts. Both the trip and close circuits are

protected by 5 Ampere fuses.

A typical DC trip and DC close, control circuit test hookup is shown in Figure 5.0.

A typical DC trip and AC close, control circuit test hookup is shown in Figure 6.0.

Figure 5.0 DC Trip and DC Close, Initiate Circuit Cable Hook-Up

Figure 6.0 DC Trip and AC Close, Initiate Circuit Cable Hook-Up

22

Page 24

CT-6500 Series 2 Operating Instructions

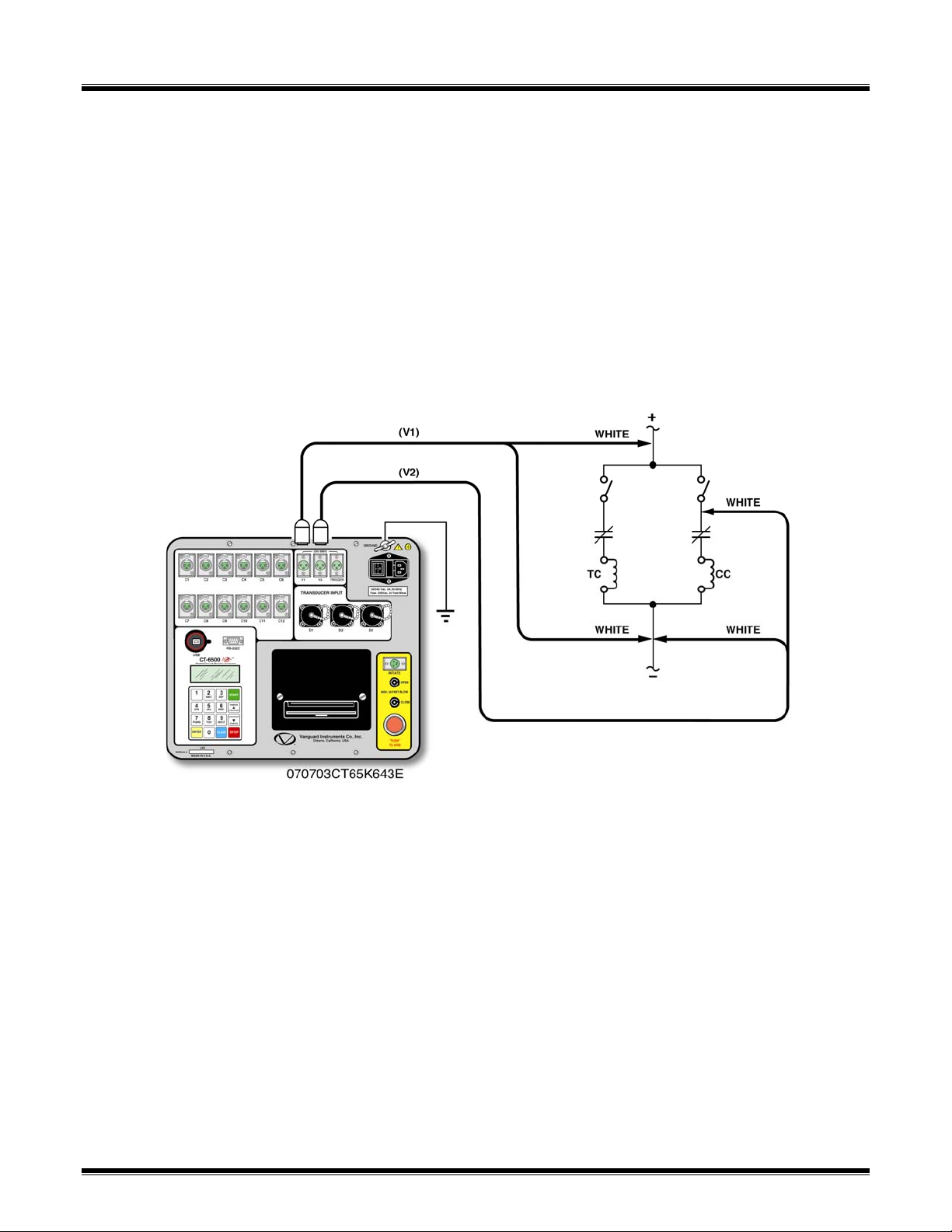

8.3 Analog Voltage Monitor Hookup

The analog voltage input, “V1” permits the user to monitor a breaker's DC control voltage

during an operation. The analog voltage input will record the nominal DC voltage at no load and

the minimum DC voltage while the Trip or Close coil is energized.

The nominal and minimal voltage readings will be printed on a tabulated report. Analog

waveforms will also be plotted in a graphical format. Thus, the user is able to see the breaker's

DC control voltage "dip" under load conditions. Problems, such as a poor connection or an

excessive voltage drop, during the circuit breaker operation can be easily detected.

A typical voltage monitoring hook up scheme is shown on Figure 7.0.

NOTE

The maximum voltage that can be recorded is 255 Vdc.

Figure 7.0 Voltage Monitoring Cable Hook-Up

8.4 Digital Voltage Monitor Hookup

The digital, voltage input channel, “V2” permits the user to monitor the voltage status as “ON”

or “OFF” states. The voltage “ON” or “OFF” states will be plotted on the graphical report. A typical

hook up is shown in Figure 7.0.

23

Page 25

CT-6500 Series 2 Operating Instructions

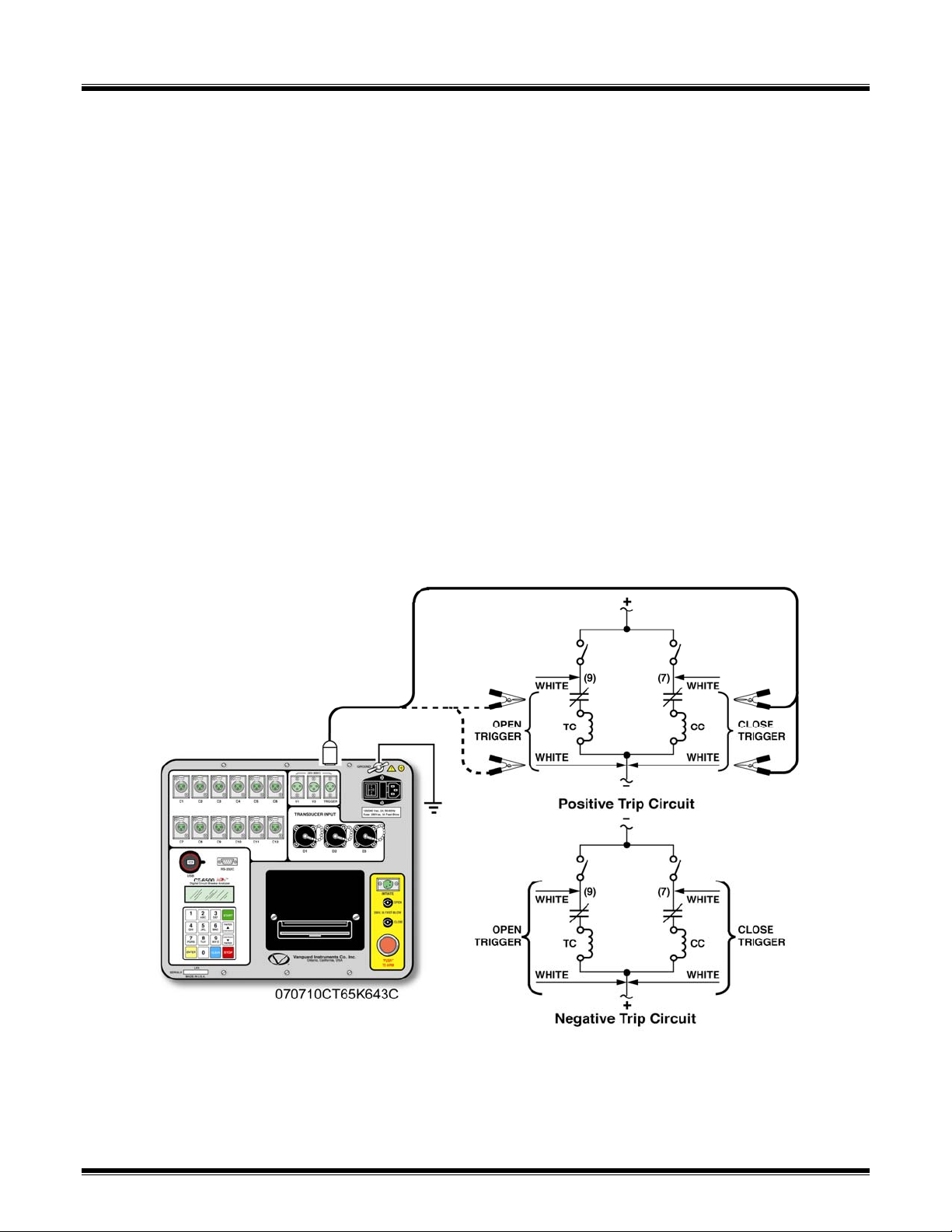

8.5 External Trigger Input

The External Trigger Mode enables the user to start recording data when the CT-6500 senses

a voltage. A typical application for the External Trigger Mode is to time a circuit breaker in a close

operation and to start timing only when the close coil is energized, thus bypassing the 52X relay

delay time.

Since the 52X relay carries the close coil current, the user will need to connect the CT-6500’s

initiate cable to the close terminal shown in Figure 5.0. The CT-6500 will energize the 52X relay

to start the close operation, which will then start the timing when the CT-6500 senses the voltage

across the closing coil. See Figure 8.0 for a typical test hookup. Another application for external

trigger is to start timing the breaker when the user trips or closes the breaker remotely.

NOTE

Minimum trigger voltage is set for 30 Vac/dc. Maximum, continuous voltage is limited to

300 Vac/dc. Different trigger voltages can be set at the factory, based upon specific

requests.

The CT-6500 will start looking for the external trigger voltage when the message,

“AWAITING TRIGGER…” is shown on the LCD screen. The external trigger voltage

needs to be sensed by the CT-6500 within 15 seconds after the initiate sequence has

begun. The CT-6500 will return to the main menu if no voltage is sensed.

Figure 8.0 External Trigger Cable Hook-Up

24

Page 26

CT-6500 Series 2 Operating Instructions

8.6 Digital Transducer Connection

A typical transducer connection is shown on Figure 9.0. See Appendix I for more transducer

connections.

Figure 9.0 Transducer Connection

25

Page 27

CT-6500 Series 2 Operating Instructions

9.0 Operating Procedures

The main steps to time a circuit breaker are listed in Figure 10.0.

.

To reduce the possibility of damaging the CT-6500 contact channels due to static

discharge in high voltage substations, it is recommend to ground one side of the

breaker’s bushings.

Always connect the CT-6500 ground stud to the substation ground before

connecting any cables to the unit.

HOOKUP CT-6500

1. GROUND THE CT-6500 (See NOTE)

2. CONNECT CT-6500 CABLES TO BREAKER

3. INSTALL TRANSDUCER WITH CABLE

APPLY POWER

1. TURN THE CT-6500 ON

2. PERFORM SELF TESTS: HOOK-UP TEST,

CABLE TEST, IF NECESSARY

TIME BREAKER

1. SELECT THE CT-6500 TEST

2. OPERATE THE BREAKER

GET RESULTS

1. READ OR PRINT THE TABULATED RESULTS

2. PRINT THE GRAPHICAL RESULTS

3. SAVE THE TIMING SHOT

Figure 10.0 CT-6500 Operating Steps

NOTE

26

Page 28

CT-6500 Series 2 Operating Instructions

9.1 Timing a Circuit Breaker

The CT-6500 will initiate the breaker operation and do a timing test on the following

operations:

- OPEN

- CLOSE

- OPEN-CLOSE

- CLOSE-OPEN

- OPEN-CLOSE-OPEN

NOTE

1. The CT-6500 can start the OPEN-CLOSE operations without a delay or by using a

programmable delay between the OPEN and CLOSE commands.

2. The CLOSE-OPEN operation can be started by the CT-6500, using several options.

- Contact #1 Close

The CT-6500 can initiate a CLOSE command and then an OPEN command after

detecting the breaker’s contact was closed. The CT-6500 detects that the

breaker’s contact was closed through contact channel #1. The selection is

recommended for the CLOSE-OPEN operation since it truly represents when the

circuit breaker closed and then opened.

- Set DELAY

The CT-6500 can initiate a CLOSE command and then an OPEN command after

a programmable delay that can be set in milliseconds.

- No DELAY

The CT-6500 can initiate a CLOSE command and then an OPEN command

without any delay. Since the circuit breaker is in the open state, the circuit

breaker’s 52B contact allows the close coil to be energized, which can start the

close command. When the circuit breaker is making the transition from an open

state to a closed state, the 52A contact will close allowing the breaker to initiate

the open command.

3. The OPEN-CLOSE-OPEN operation can be initiated by the CT-6500, by using a

programmable delay between each of the operations, where the delays can be set

between the OPEN to CLOSE and between the CLOSE to OPEN commands.

27

Page 29

CT-6500 Series 2 Operating Instructions

9.1.1 Timing an OPEN Operation (With No Insertion Resistors)

The following example shows the steps for performing an Open Test on a circuit breaker.

Table 3.0 Open Operation With No Insertion Resistors

STEP OPERATION ACTION DISPLAY

1 READY TIMER FOR BREAKER OPERATION.. PRESS #1 KEY. INSERTION RESISTOR?

1.NO

2.YES

2 SELECT NO INSERTION RESISTOR. PRESS #1 KEY. TIMING WINDOWS:

1.WINDOW = 1 SEC

2.WINDOW = 10 SEC

3. WINDOW = 20 SEC

3 SELECT 1-SECOND TIMING WINDOW. PRESS #1 KEY. TRIGGER MODE:

1. INTERNAL TRIGGER

2. EXTERNAL TRIGGER

4 SELECT INTERNAL TRIGGER. PRESS #1 KEY. TIMING MODE:

1. OPEN 2. CLOSE

3. O-C 4. C-O

5. O-C-O

5 SELECT OPEN OPERATION. PRESS #1 KEY. OPEN TIMING

Hold "ARM" Switch,

Then "START".

"STOP" to ABORT

6 INITIATE OPEN COMMAND. HOLD THE "ARM"

SWITCH AND

PRESS THE "START"

KEY.

7 OBSERVE BREAKER OPERATED.

ANALYZER IS READY TO OUTPUT RESULTS.

NONE. 1.RUN TEST 06/12/07

TEST IN PROGRESS

Hold "ARM" Until

Test complete.

(Up to 25 seconds)

2.GET RSLT 19:20:01

3.SET-UP

4.DIAGNOSTIC

Go to section 9.2 to print a test report.

NOTE

One-second timing windows are used for breaker timing. The 10 and 20 second

timing windows are used for long timing events (i.e. timing circuit-switchers).

The user can set the CT-6500 to print tabulated and graphical reports

automatically after it completes a test. See Paragraph 9.17 for the automatic print

setting.

28

Page 30

CT-6500 Series 2 Operating Instructions

9.1.2 Timing an OPEN Operation with Insertion Resistors

The CT-6500 can time breakers with insertion resistors. The insertion resistor can

range from 10 to 7,000 Ohms. Any insertion resistor more than 7,000 Ohms is detected as

an open circuit. The timing results will show the main contact time and the insertion

resistor contact time. Graphic reports will show the main contact and the resistor contact

activities on each of the channels.

Table 4.0 Open Operation With Insertion Resistor

STEP OPERATION ACTION DISPLAY

1 READY TIMER FOR BREAKER OPERATION. PRESS #1 KEY. INSERTION RESISTOR?

1.NO

2.YES

2 SELECT INSERTION RESISTOR. PRESS #2 KEY. RESISTOR VALUE:

1.LESS THAN 1000 OHM

2.1000 to 2000 OHM

3.MORE THAN 2000 OHM

3 SELECT LESS THAN 1000 OHM RESISTOR

RANGE.

4 SELECT 1-SECOND WINDOW. PRESS #1 KEY. TRIGGER MODE:

5 SELECT INTERNAL TRIGGER. PRESS #1 KEY. TIMING MODE:

6 SELECT OPEN OPERATION. PRESS #1 KEY. OPEN TIMING

7 INITIATE OPEN COMMAND. HOLD THE "ARM"

8 ANALYZER IS READY TO OUTPUT RESULTS.

PRESS #1 KEY. TIMING WINDOWS:

1.WINDOW = 1 SEC

2.WINDOW = 10 SEC

3.WINDOW = 20 SEC

1. Internal Trigger

2. External Trigger

1. OPEN 2. CLOSE

3. O-C 4. C-O

5. O-C-O

Hold "ARM" Switch,

Then "START".

"STOP" to ABORT

TEST IN PROGRESS

SWITCH AND

PRESS THE "START"

KEY.

NONE. 1.RUN TEST 06/12/07

Hold "ARM" Until

Test complete.

(Up to 25 seconds)

2.GET RSLT 19:20:01

3.SET-UP

4.DIAGNOSTIC

Go to section 9.2 to print a test report.

29

Page 31

CT-6500 Series 2 Operating Instructions

NOTE

One-second timing windows are used for breaker timing. The 10 and 20 second

timing windows are used for slower timing events (i.e. timing circuit-switchers).

The user can set the CT-6500 to print tabulated and graphical reports

automatically after it completes a test. See Paragraph 9.17 for the automatic print

setting.

9.1.3 Timing CLOSE-OPEN Operation Using Contact Channel #1

The CLOSE-OPEN operation of the breaker simulates a condition where a breaker is

closed on a fault. There are 3 choices for the user to setup the CLOSE-OPEN operation:

1. Contact #1 CLOSE

The CT-6500 will initiate a CLOSE operation. The Open operation is then

initiated after contact channel # 1 is closed.

2. Set DELAY

The user can set a delay from 10 to 500 ms between a CLOSE command

to the OPEN command. The CT-6500 will initiate the CLOSE operation and

start the delay counter. The OPEN operation will be initiated when the delay

time completes.

3. No DELAY

Both the CLOSE and OPEN commands are initiated by the CT-6500

simultaneously. The OPEN coil is energized when the Open auxiliary switch

makes.

NOTE

The CLOSE-OPEN command option “Contact #1 CLOSE” closely simulates the

breaker closing on a fault condition in the field.

30

Page 32

CT-6500 Series 2 Operating Instructions

Table 5.0 Close-Open Operation Using Contact Channel #1

STEP OPERATION ACTION DISPLAY

1 READY TIMER FOR BREAKER OPERATION. PRESS #1 KEY. INSERTION RESISTOR?

1.NO

2.YES

2 SELECT NO INSERTION RESISTOR. PRESS #1 KEY. TIMING WINDOWS:

1.WINDOW = 1 SEC

2.WINDOW = 10 SEC

3.WINDOW = 20 SEC

3 SELECT 1-SECOND WINDOW. PRESS #1 KEY. TRIGGER MO DE:

1.INTERNAL TRIGGER

2.EXTERNAL TRIGGER

4 SELECT INTERNAL TRIGGER. PRESS #1 KEY. TIMING MODE:

1. OPEN 2. CLOSE

3. O-C 4. C-O

5. O-C-O

5 SELECT CLOSE-OPEN OPERATION. PRESS #4 KEY. C-O Second Trigger:

1. Contact #1 CLOSE

2. Set DELAY

3. No DELAY

6 SELECT CONTACT #1 CLOSE. PRESS #1 KEY. CLOSE-OPEN TIMING

Hold "ARM" Switch

Then "START"

"STOP" to ABORT

7 INITIATE OPEN COMMAND. HOLD THE "ARM"

SWITCH AND

PRESS THE "START"

KEY.

8 ANALYZER IS READY TO OUTPUT RESULTS. NONE. 1.RUN TEST 06/12/07

TEST IN PROGRESS

Hold "ARM" Until

Test complete.

(Up to 25 seconds)

2.GET RSLT 19:20:01

3.SET-UP

4.DIAGNOSTIC

NOTE

1. Users can program a delay from 10 to 500 ms between the CLOSE and

OPEN commands. When a delay is used in the operation, it may not

represent a true breaker operating condition.

2. Users can also program in no delay for the operation in which case, the

CLOSE and OPEN commands are initiated at the same time by the CT-

6500.

31

Page 33

CT-6500 Series 2 Operating Instructions

9.1.4 Timing OPEN-CLOSE-OPEN Operation

The OPEN-CLOSE-OPEN operation requires the user to enter two time-delays

between the circuit breaker operations. The time delays are in millisecond intervals.

The first delay is from the first OPEN command to the CLOSE command. The second

delay is from the CLOSE command to the second OPEN command. Refer to Table 6.0

for setting up the OPEN-CLOSE-OPEN operation.

Table 6.0 Open-Close-Open Operation Using Delay

STEP OPERATION ACTION DISPLAY

1 READY TIMER FOR BREAKER OPERATION. PRESS #1 KEY. INSERTION RESISTOR?

1.NO

2.YES

2 SELECT NO INSERTION RESISTOR. PRESS #1 KEY. TIMING WINDOWS:

1.WINDOW = 1 SEC

2.WINDOW = 10 SEC

3.WINDOW = 20 SEC

3 SELECT 1-SECOND WINDOW. PRESS #1 KEY. TRIGGER MO DE:

1.INTERNAL TRIGGER

2.EXTERNAL TRIGGER

4 SELECT INTERNAL TRIGGER. PRESS #1 KEY. TIMING MODE:

1. OPEN 2. CLOSE

3. O-C 4. C-O

5. O-C-O

5 SELECT OPEN-CLOSE-OPEN OPERATION. PRESS #5 KEY. O-C Delay in mS:

(10 – 350)

mSec

ENTER when done

6 SELECT DELAY BETWEEN OPEN-CLOSE

OPERATION.

7 SELECT DELAY BETWEEN CLOSE-OPEN

OPERATION.

8 INITIATE O-C-O COMMAND. HOLD THE "ARM"

9 ANALYZER IS READY TO OUTPUT RESULTS. NONE. 1.RUN TEST 06/12/07

ENTER DELAY USING

0-9 KEYS, PRESS THE

“ENTER” KEY TO

CONFIRM.

ENTER DELAY USING

0-9 KEYS, PRESS THE

“ENTER” KEY TO

CONFIRM.

SWITCH AND

PRESS THE "START"

KEY.

C-O Delay in mS:

(10 – 350)

mSec

ENTER when done

OPEN-CLOSE-OPEN TIMING

Hold "ARM" Switch,

Then "START".

"STOP" to ABORT

TEST IN PROGRESS

Hold "ARM" Until

Test complete.

(Up to 25 seconds)

2.GET RSLT 19:20:01

3.SET-UP

4.DIAGNOSTIC

32

Page 34

CT-6500 Series 2 Operating Instructions

9.2 Printing Tabulated Timing Results Using the Thermal Printer

The circuit breaker timing results can be printed on the thermal printer by using the steps listed

in Table 7.0.

A typical circuit breaker timing result printed on thermal printer is shown in Figure 11.0.

Table 7.0 Printing Tabulated Results

STEP OPERATION ACTION DISPLAY

1 GET TIMING RESULTS. PRESS #2 KEY. 1.PRINT TEST RESULTS

2.PLOT FULL CHART

3.PLOT EXPANSION

4.PLOT 0-200 MS

2 PRINT TABULATED RESULTS. PRESS #1 KEY. SELECT PRINTER

1.THERMAL PRINTER

2.DISPLAY RESULTS

3 OUTPUT TABULATED RESULTS ON

THERMAL PRINTER.

PRESS #1 KEY. BUSY PRINTING

33

Page 35

CT-6500 Series 2 Operating Instructions

1

2

3

4

12

9

5

6

7

8

9

10

11

13

14

17

16

15

Figure 11.0 Typical Tabulated Printout of an Open Operation From the Thermal Printer

34

Page 36

CT-6500 Series 2 Operating Instructions

9.2.1 Tabulated Results Interpretation

1. Timing Record is time and date stamped by the CT-6500.

2. Timing record header information (Company, Substation name, Circuit, etc) is also saved

with test record.

3. Timing test type (OPEN, CLOSE, O-C, C-O, O-C-O) is identified. A CLOSE timing shot is

shown in Figure12.0.

4. Contact channel #1 time is shown in both milliseconds and cycles. From Figure 12.0,

contact channel #1 time was 184.85 ms or 11.09 cycles.

5. Contact channel #1 bounce duration was 19.80 ms.

6. Contact channel #1 wipe was measured as 0.93 inches.

7. The slowest contact and fastest contact differential time is shown as contact delta, 1.15 ms.

8. Breaker contact stroke was measured as 7.08inches.

9. Contact velocity calculation was 8.18 feet per second.

10. Contact over-travel distance was measured as 0.33 inches.

11. Contact bounce-back distance was measured 0.24 inches.

12. Contact velocity calculation was from the two analysis points:

Analysis point # 1 was 1.00 inch from the fully closed position.

Analysis point # 2 was 2.00 inches from the fully closed position.

13. The DC power supply was monitored during the test. The nominal voltage was 55 Volts

and the minimum voltage was 50 Volts.

14. Initiate current was 6.2 Amperes.

15. Timing shot duration was one second.

16. Trigger mode was internal therefore the timing window starts at the same time when the

CT-6500 energized the circuit breaker.

17. There was no insertion resistor in the test, thus no insertion resistor time was measured.

35

Page 37

CT-6500 Series 2 Operating Instructions

9.3 Get Graphic Timing Results Using the Thermal Printer

Selecting the “PLOT FULL CHART” command will plot the timing chart as follows:

- Timing chart from 0 to 1000 ms with one second window and 50 ms time markers.

- Timing chart from 0 to 10 seconds with 10 second window and 500 ms time markers.

- Timing chart from 0 to 20 seconds with 20 second window and one second time markers.

Table 8.0 Plot Timing Chart

STEP OPERATION ACTION DISPLAY

1 GET TIMING RESULTS. PRESS #2 KEY. 1.PRINT TEST RESULTS

2.PLOT FULL CHART

3.PLOT EXPANSION

4.PLOT 0-200 MS

2 PLOT FULL CHART. PRESS #2 KEY. SELECT PRINTER

1.INTERNAL THERMAL

2.EXTERNAL INK JET

3 SELECT THERMAL PRINTER. PRESS #1 KEY. PLEASE WAIT

PLOTTING GRAPH

4 RETURN TO MAIN MENU AFTER

PRINT CHART.

1. Plot Expansion, which is Selection #3, in Step 1, allows the user to expand the graphic

results in 100 ms increments.

2. Selecting “PLOT 0-200 MS” will automatically plot the timing chart from 0 to 200

milliseconds in the expansion mode with 10 ms timing markers.

3. Typical graphic results are shown in Figure 12.0 and 13.0.

4. Graphical result interpretations are shown in Figures 14.0, 15.0 and 16.0.

NO ACTION. 1.RUN TEST 06/12/07

2.GET RSLT 19:20:01

3.SET-UP

4.DIAGNOSTIC

NOTE

36

Page 38

CT-6500 Series 2 Operating Instructions

Contact Trace

Travel Trace

Initiate Current Trace

Analog Voltage Channel V1

Figure 12.0 Typical Graphic Result Printed on Thermal Printer

37

Page 39

CT-6500 Series 2 Operating Instructions

y

y

sis Point #1

Anal

sis Point #2

Anal

Figure 13.0 Expansion Graph From 0 to 300ms Printed on Thermal Printer

NOTE

Analysis point # 1 and point #2 are shown on chart.

38

Page 40

CT-6500 Series 2 Operating Instructions

Figure 14.0 Graphical Interpretation of an Open Timing Shot

Figure 15.0 Graphical Interpretation of a Close Timing Shot

39

Page 41

CT-6500 Series 2 Operating Instructions

Figure 16.0 Graphical Interpretations of an Open-Close and a Close-Open Timing Shot

40

Page 42

CT-6500 Series 2 Operating Instructions

9.4 Save Timing Test Records in the EEPROM

Use the steps in Table 9.0 to save a timing test record in the FLASH EEPROM.

Table 9.0 Save Timing Test Record In EEPROM

STEP OPERATION ACTION DISPLAY

1 SELECT SETUP MENU. PRESS #3 KEY. 1.ANALYSIS POINTS

2.MEASUREMENT UNITS

3.SAVE / RESTORE

4.NEXT PAGE

2 SELECT SAVE MENU. PRESS #3 KEY. 1.SAVE SHOT

2.RECALL SHOT

3.SHOT DIRECTORY

4.ERASE SHOT

3 SELECT SAVE SHOT. PRESS #1 KEY. SAVE SHOT # 002

TEST: CLOSE

DATE: 05/23/07 12:36

"ENTER" TO PROCEED

4 CONFIRM SAVING SHOT. PRESS THE

"ENTER" KEY.

5 OBSERVE SHOT BEING SAVED. NONE. SHOT SAVE

6 RETURN TO MAIN MENU. PRESS ANY KEY.

SAVE IN PROCESS

PLEASE WAIT

1.RUN TEST 06/10/07

2.GET RESULTS 20:10:01

3.SETUP

4.DIAGNOSTIC

NOTE

Timing test record storage capability varies, depending upon the size of the records.

The CT-6500 will assign an identification number for each of the records stored in

the EEPROM.

Shot ID #2 was assigned in the example above.

41

Page 43

CT-6500 Series 2 Operating Instructions

9.5 Printing Timing Test Record Directory Stored in the EEPROM

The user can obtain a timing-record directory that was stored in the CT-6500’s FLASH

EEPROM by using the steps in Table 10.0.

Table 10.0 Print Timing Test Record Directory

STEP OPERATION ACTION DISPLAY

1 SELECT SETUP MENU. PRESS #3 KEY. 1.ANALYSIS POINT

2.MEASUREMENT UNITS

3.SAVE / RESTORE

4.NEXT PAGE

2 SELECT SAVE/RESTORE MENU.

3 SELECT SHORT DIRECTORY.

4 SELECT SHORT DIRECTORY. PRESS #1 KEY. PRINTING ABBREVIATED

5 RETURN TO MAIN MENU. NO ACTION.

PRESS #3 KEY. 1.SAVE SHOT

2.RESTORE SHOT

3.SHOT DIRECTORY

4.ERASE SHOT

PRESS # 3 KEY. 1.SHORT DIRECTORY

2.FULL DIRECTORY

"STOP" TO QUIT

DIRECTORY

“STOP” TO QUIT

1.RUN TEST 06/10/07

2.GET RESULTS 20:10:01

3.SETUP

4.DIAGNOSTIC

NOTE

1. If the "Short Directory" was selected, the CT-6500 will print out the shot

identifications of the last ten timing shots stored in the EEPROM.

2. If the "Full Directory" was selected, the CT-6500 will print out the shot

identifications of all the timing shots stored in the EEPROM.

3. A typical shot directory printout is shown on in Figure 17.0.

42

Page 44

CT-6500 Series 2 Operating Instructions

Figure 17.0 Printout of the Timing Shot Directory From the Thermal Printer

43

Page 45

CT-6500 Series 2 Operating Instructions

9.6 Recalling a Timing Test Record

The following steps in Table 11.0 are used to recall a timing test record stored in the EEPROM

to the working memory. Once a test record is recalled, the user can get a printout of the test

results from the thermal printer.

Table 11.0 Recalling a Timing Test Record

STEP OPERATION ACTION DISPLAY

1 SELECT SETUP MENU. PRESS #3 KEY. 1.ANALYSIS POINT

2.MEASUREMENT UNITS

3.SAVE / RESTORE

4.NEXT PAGE

2 SELECT SAVE/RESTORE SHOT. PRESS # 3 KEY. 1.SAVE SHOT

2.RESTORE SHOT

3.SHOT DIRECTORY

4.ERASE SHOT

3 SELECT RESTORE SHOT. PRESS #2 KEY. ENTER SHOT NUMBER

4 ENTER SHOT NUMBER “1” TO BE

RESTORED.

5 CONFIRM SHOT TO BE RESTORED. PRESS THE

6 CONFIRM TEST RESTORED. NONE. RESTORE COMPLETE

7 RETURN TO MAIN MENU. PRESS ANY KEY.

PRESS KEYS 0-9

FOR SHOT ID THEN

PRESS THE

"ENTER" KEY.

"ENTER" KEY.

TO BE RESTORED

XXXX

"ENTER" TO CONFIRM

ENTER SHOT NUMBER

TO BE RESTORED

0001

"ENTER" TO CONFIRM

RESTORING SHOT # 0001

TEST: OPEN

DATE: 06\12\07 09:12

"ENTER" TO CONFIRM

1.RUN TEST 06/10/07

2.GET RESULTS 20:10:01

3.SETUP

4.DIAGNOSTIC

44

Page 46

CT-6500 Series 2 Operating Instructions

9.7 Deleting a Timing Test Record

Users can delete a specific timing test record or all of the timing test records from the CT6500’s EEPROM by using the steps in Table 12.0.

Table 12.0 Deleting a Timing Record

STEP OPERATION ACTION DISPLAY

1 SELECT SET UP MENU. PRESS # 3 KEY. 1.ANALYSIS POINTS

2.MEASUREMENT UNITS

3.SAVE / RESTORE

4.NEXT PAGE

2 SELECT SAVE / RESTORE MENU. PRESS # 3 KEY. 1.SAVE SHOT

2.RESTORE SHOT

3.SHOT DIRECTORY

4.ERASE SHOT

3 SELECT ERASE SHOT. PRESS # 4 KEY. 1.ERASE SHOT

2.ERASE ALL SHOTS!

4 SELECT ERASE SHOT. PRESS # 1 KEY. ENTER SHOT NUMBER

TO BE ERASED

XXXX

"ENTER" TO CONFIRM

5 ENTER SHOT NUMBER “1” TO BE

ERASED.

6 CONFIRM TO ERASE SHOT. PRESS THE

7 WAIT FOR SHOT BEING ERASED. NO ACTION. ERASE COMPLETE

8 RETURN TO MAIN MENU. PRESS ANY KEY.

PRESS KEYS 0-9 TO

SELECT SHOT

NUMBER, PRESS

THE "ENTER" KEY

TO CONFIRM.

"ENTER" KEY.

ERASE SHOT # 0001

TEST: OPEN

DATE: 03\12\07 09:12

"ENTER" TO CONFIRM

ERASE IN PROCESS

PLEASE WAIT

1.RUN TEST 06/10/07

2.GET RESULTS 20:10:01

3.SETUP

4.DIAGNOSTIC

45

Page 47

CT-6500 Series 2 Operating Instructions

9.8 Test Record Description

The CT-6500 has the capability for users to enter the breaker and other identification

information. The data usually consists of the name of the company, station, circuit and

manufacturer. Other information could be the breaker's model, serial number and the operator's

name. The identification data will print out in the header section of the tabulated report.

If the user saves the timing shot, the identification data will also be saved with the timing shot,

along with the time and date.

The user can input letters of the alphabet by utilizing the alphanumeric keys. To select the

letter "A," the user will need to press key numbered “2,” twice. To select the letter "C," the user

will need to press the key numbered “2,” four times and so on.

To move the cursor forward, press the “UP ARROW” key. To move the cursor backwards, use

the “DOWN ARROW” key. Use the “CLEAR” key to enter a space.

Table 13.0 Entering Test Record Identification Header

STEP OPERATION ACTION DISPLAY

1 SELECT SET UP MENU.

2 SELECT NEXT PAGE.

3 SELECT SHOT DESCRIPTION.

4 ENTER COMPANY NAME.

5 ENTER STATION NAME. PRESS KEYS 0-9 AND

6 ENTER CIRCUIT NAME. PRESS KEYS 0-9 AND

PRESS #3 KEY. 1.ANALYSIS POINTS

PRESS # 4 KEY. 1.SHOT DESCRIPTION

PRESS # 1 KEY. COMPANY:

PRESS KEYS 0-9 AND

PRESS "ENTER" KEY.

PRESS "ENTER" KEY.

PRESS "ENTER" KEY.

2.MEASUREMENT UNIT

3.SAVE / RESTORE

4.NEXT PAGE

2.NUMBER OF CHANNELS

3.SET DATE & TIME

4.SET PRINT MODE

XXXXXX

↑/↓ TO POSITION

"ENTER" TO ACCEPT

STATION

XXXXXX

↑/↓ TO POSITION

"ENTER" TO ACCEPT

CIRCUIT

XXXXXX

↑/↓ TO POSITION

"ENTER" TO ACCEPT

MANUFACTURER

XXXXXX

↑/↓ TO POSITION

"ENTER" TO ACCEPT

7 ENTER MANUFACTURER NAME. PRESS KEYS 0-9 AND

PRESS "ENTER" KEY.

46

BREAKER

XXXXXX

↑/↓ TO POSITION

"ENTER" TO ACCEPT

Page 48

CT-6500 Series 2 Operating Instructions

Table 13.0 Entering Test Record Identification Header (Continued)

STEP OPERATION ACTION DISPLAY

8 ENTER BREAKER MODEL. PRESS KEYS 0-9 AND

PRESS "ENTER" KEY.

9 ENTER SERIAL NUMBER. PRESS KEYS 0-9 AND

PRESS "ENTER" KEY.

10 RETURN TO MAIN MENU. NO ACTION.

SERIAL

XXXX

↑/↓ TO POSITION

"ENTER" TO ACCEPT

OPERATOR

XXXX

↑/↓ TO POSITION

"ENTER" TO ACCEPT

1.RUN TEST 06/10/07

2.GET RESULTS 20:10:01

3.SETUP

4.DIAGNOSTIC

47

Page 49

CT-6500 Series 2 Operating Instructions

9.9 Computer Interface

Each CT-6500 has one RS-232C and one USB port, where the Circuit Breaker Analyzer

Software Series 2 package provided with each CT-6500, enables an IBM-compatible personal

computer to communicate with the unit. The software operating under Windows XP environments

allows the user to transfer timing records stored in the EEPROM into the computer. From the

user's computer, the user can now reanalyze the breaker’s timing shots and then print the timing

reports through an office printer. Since timing shots are stored in the office computer, users can

create a database of a breaker's timing history.

This PC program allows the user to generate and transfer circuit breaker test plans to the CT6500 EEPROM. Up to 99 circuit breaker test plans can be stored in the CT-6500 EEPROM.

Using the PC program, the user can control the CT-6500 to time circuit breakers.

Note

1. There is no requirement to place the CT-6500 under computer control to access the RS232C or USB port.

2. An interconnect cable must be run between the CT-6500’s RS-232C port or USB port

to the user’s PC.

3. The CT-6500's RS-232 connector pin layout is shown in the table below.

Table 14.0 RS-232C Connector Pin Definition

Pin No. Signal Name

2 Tx

3 Rx

5 Gnd

48

Page 50

CT-6500 Series 2 Operating Instructions

9.10 Breaker Travel Analysis

The CT-6500’s travel analysis includes the breaker’s stroke, over-travel, bounce-back, contactwipe distances and contact velocity calculations.

9.10.1 Breaker Stroke

The CT-6500 uses a digital transducer to measure a breaker's contact stroke, over-travel and

bounce-back. The digital transducer output is 200 counts per linear inch of travel, therefore the

resolution is accurate to about 1/200 inch. The output resolution is ±0.01 inch on the test result

report.

Unlike slide-wire transducers, the CT-6500’s digital transducer needs no calibration or setup.

A user verifies the transducer’s functionality by selecting a diagnostic test for the transducer,

which is further explained in Paragraph 9.14.

9.10.2 Breaker Over-Travel Distance

Over-travel is the distance the contact moves beyond the resting position. Over-travel is

typically found in the close operation. (See Appendix A for more details).

9.10.3 Breaker Bounce-Back Distance

Bounce-back is the distance the breaker contact moves before the resting position after the

over- travel. Again, bounce-back is typically found in the close operation. (See appendix A for

more details).

9.10.4 Contact Wipe

Contact wipe is the distance measured from the close position to the contacts touching or

parting positions. In the close operation, contact wipe is measured from the contacts touching

position to the final close position.

In the open operation, the contact wipe is measured from the close position to the contact

break or parting position.

NOTE

Contact wipe is measured during an operation. The measurement may not be as

accurate as the measurement done using the Slow-Close Mode. It is recommended

that the user use the Slow-Close Test to verify the contact wipe measurement, if

required. Please refer to Paragraph 9.13 for further information on the Slow-Close

Mode.

9.10.5 Breaker Velocity

When used with a travel transducer, the CT-6500 can calculate the breaker contact velocity

through the arc zone. Users will need to program the calculation points or analysis points on the

travel curve for the unit to calculate the contact velocity. Analysis point selections and setup are

discussed in the following paragraphs.

9.10.6 Analysis Point Selections

Analysis points are used to calculate the average contact speed through the contact's arc

zone. The analysis points are usually specified by the breaker’s manufacturers. The analysis

points can be programmed into the CT-6500 by the user. The CT-6500 will store the two setup

points for calculating velocity one set each for the open and another set for the close operations.

These setups remain in the CT-6500’s memory until it is changed by the user.

49

Page 51

CT-6500 Series 2 Operating Instructions

9.10.7 Analysis Point No.1 (AP1)

Three selections are available to the user for setting analysis point No. 1:

1. PERCENTAGE OF STRK

2. DISTANCE FROM CLOSE

3. CONTACT #1

a. Percentage of Stroke

Percentage of stroke is the distance based upon the percentage of the total breaker’s stroke

distance. The distance is always measured from the starting point at the fully closed position

of the breaker contacts.

b. Distance From Close

Distance from Close range is selectable from 00.0 inch to 99.99 inches or from 0.0

centimeter to 99.90 centimeters. Again, the distance is referenced from the contact's

closed position. See Appendix A for more detail.

c. Contact Point #1

Contact point is the distance from the contact's closed position to the point where it is in

transition from the close-to-open or the open-to-close position. Contact channel #1 will be

used for the selection.

9.10.8 Analysis Point No. 2 (AP2)

There are three selections for analysis point 2:

1. PERCENTAGE OF STRK

2. DISTANCE FROM CLOSE

3. CONTACT +/- TIME

a. See Paragraph 9.10.7.a for “PERCENTAGE OF STROKE” description.

b. See Paragraph 9.10.7.b for “DISTANCE FROM CLOSE” description.

c. “CONTACT +/- TIME”, is available for both OPEN and CLOSE operation under analysis

point #2 only. For “CONTACT + TIME”, the user enters the millisecond time after the

contact channel #1 made the transition from OPEN to CLOSE or CLOSE to OPEN to define

the Analysis Point No. 2.

For “CONTACT – TIME”, the user enters the millisecond time before the contact channel #1

makes the transition from OPEN to CLOSE or CLOSE to OPEN to define the Analysis Point

No. 2.

See appendix A for more detail.

50

Page 52

CT-6500 Series 2 Operating Instructions

NOTES

1. Average velocity through the arc zone is calculated by using the following

formula:

V

= Distance ÷ Time

avg

2. The breaker contact velocity can be recalculated based upon the data stored

inside the memory after any new analysis points were selected. The user does not

need to operate the breaker again to acquire new contact velocity data after

changing the analysis points because the new velocity is then calculated from the

travel data stored in memory from the last operation.

3. For complex velocity calculations, the user can create a test plan using the CT6500 Breaker Analysis Software from a PC. The test plan then can be downloaded

to the CT-6500. The complex breaker velocity calculation can now be executed

easily by recalling the test plan before running the timing test.

51

Page 53

CT-6500 Series 2 Operating Instructions

9.10.9 Set-Up Open Analysis Points

The following procedure allows the user to set the analysis points to calculate velocity of the circuit

breaker in the open operation. The open analysis point #1 is 1.00 inch from the fully closed

position of the circuit breaker. The open analysis point #2 is 2.00 inches from the fully closed

position.

Table 15.0 Setting Up "OPEN" Analysis Points Using Distance

STEP OPERATION ACTION DISPLAY

1 SELECT SET UP MENU.

2 SELECT ANALYSIS POINT.

3 SELECT OPEN TIMING.

4 SELECT DISTANCE FROM CLOSE. PRESS # 2 KEY. OPEN ANALYSIS PT 1

5 ENTER 1 INCH. PRESS KEYS 0-9 TO

6 CONFIRM ENTRY. PRESS THE "ENTER"

PRESS # 3 KEY. 1.A NALYSIS POINT

2.MEASUREMENT UNITS

3.SAVE / RESTORE

4.NEXT PAGE

PRESS # 1 KEY. 1.OPEN TIMING

2.CLOSE TIMING

3.PRINT SETTING

4.TEST PLAN

PRESS # 1 KEY. OPEN ANALYSIS PT 1

1.PERCENT OF STROKE

2.DISTANCE FROM CLOSE

3.CONTACT #1

DISTANCE FROM CLOSE

VALUE: XX.XX in

"ENTER" TO CONFIRM

OPEN ANALYSIS PT 1

SET 1.00. USE THE

“ENTER” KEY TO

CONFIRM.

KEY.

DISTANCE FROM CLOSE

VALUE: 01.00 in

"ENTER" TO CONFIRM

OPEN ANALYSIS PT 2

1.PERCENTAGE OF STROKE

2.DISTANCE FROM CLOSE

3.CONTACT +/- TIME

7 SELECT DISTANCE FROM CLOSE. PRESS # 2 KEY. OPEN ANALYSIS PT 2

DISTANCE FROM CLOSE

VALUE: XX.XX in

"ENTER" TO CONFIRM

8 ENTER 2 INCHES. PRESS KEYS 0-9 TO

SET 2.00 INCHES.

9 RETURN TO MAIN MENU. PRESS THE "ENTER"

KEY.

OPEN ANALYSIS PT 2

DISTANCE FROM CLOSE

VALUE: 02.00 in

"ENTER" TO CONFIRM

1.RUN TEST 06/10/07

2.GET RESULTS 20:10:01

3.SETUP

4.DIAGNOSTIC

52

Page 54

CT-6500 Series 2 Operating Instructions

NOTES

1. If an entry is not correct, re-enter the digits until the screen shows the desired

numbers, then press the “ENTER” key.

2. Analysis Point #1 is 1.00 inch from the fully closed position.

3. Analysis Point #2 is 2.00 inches from the fully closed position.

53

Page 55

CT-6500 Series 2 Operating Instructions

9.11 Select English or Metric Measurement Unit.

The CT-6500 supports and displays both English and Metric calculations from the breaker's

travel parameters such as the stroke, velocity and other parameters. The user can switch from

one system to the other by following the steps in Table 16.0.

Table 16.0 Select English or Metric Procedure

STEP OPERATION ACTION DISPLAY

1 SELECT SET UP MENU.

2 MEASUREMENT UNITS.

3 SELECT METRIC UNIT

PRESS # 3 KEY. 1.ANALYSIS POINT

2.MEASUREMENT UNITS

3.SAVE / RESTORE

4.NEXT PAGE

PRESS # 2 KEY. SELECT UNITS

1.ENGLISH

2.METRIC

3.ROT ENC 4.RES ENC

PRESS # 2 KEY.

1.RUN TEST 06/10/07

2.GET RESULTS 20:10:01

3.SETUP

4.DIAGNOSTIC

9.12 Digital Rotary Transducer Selection