Page 1

OPERATING INSTRUCTIONS

for the

AUTO-OHM 100/200 Series 2

10-100/200 Amperes True DC

Digital Micro Ohm Meter

Vanguard Instruments Company, Inc.

TEL: (909) 923-9390 January 2009

FAX: (909) 923-9391 Rev. 3

1520 S. Hellman Ave.

Ontario, California 91761

Page 2

AUTO-OHM 100/200 Series 2 Operating Procedures

SAFETY SUMMARY

NOTICE

This manual applies to Models Auto-Ohm 100 Series 2, and Auto-Ohm 200 Series 2. The

operating procedures are virtually the same for all models. Any differences are clearly

described in the step-by-step procedures.

FOLLOW EXACT OPERATING PROCEDURES

Any deviation from the procedures described in this operator’s manual may create one or more

safety hazards, damage the Auto-Ohm, or cause errors in the test results; Vanguard Instruments

Co., Inc. assumes no liability for unsafe or improper use of the Auto-Ohm.

The following safety precautions must be observed during all phases of test set-up, test hookups,

testing, and test-lead disconnects.

SAFETY WARNINGS AND CAUTIONS

This device shall be used only by trained operators.

All circuit breakers under test shall be off line and fully isolated.

DO NOT MODIFY TEST EQUIPMENT

Because of the risk of introducing unknown hazards, do not install substitute parts or perform

any unauthorized modification to any Model Auto-Ohm Test unit. To ensure that all designed

safety features are maintained, it is recommended that repairs be performed only by Vanguard

Instruments Co. factory personnel or by an authorized repair service. Unauthorized modifications

can cause serious safety hazards and will nullify the manufacturer's warranty.

2 Rev 3, 2009

Page 3

AUTO-OHM 100/200 Series 2 Operating Procedures

Table of Contents

1.0 INTRODUCTION .............................................................................................................. 6

1.1 Applicability ......................................................................................................................... 6

1.2 General Description..............................................................................................................6

1.3 Functional Description.......................................................................................................... 6

1.4 Furnished Test Accessories................................................................................................... 6

1.5 Optional Accessories ............................................................................................................ 9

2.0 AUTO-OHM SPECIFICATIONS.................................................................................... 10

2.1 Auto-Ohm 100 Series 2 Specifications............................................................................... 10

2.2 Auto-Ohm 200 Series 2 Specifications............................................................................... 11

3.0 CONTROL AND DISPLAY............................................................................................12

3.1 Auto-Ohm 100 Series 2 Front Panel................................................................................... 12

3.2 Auto-Ohm 200 Series 2 Front Panel................................................................................... 14

4.0 OPERATING VOLTAGES.............................................................................................. 16

5.0 CABLE CONNECTION .................................................................................................. 16

6.0 OPERATING THE AUTO-OHM .................................................................................... 19

6.1 Step-by-Step Procedures..................................................................................................... 19

6.2 Precautions.......................................................................................................................... 19

6.3 Preparations......................................................................................................................... 19

6.4 Running a Normal Test Procedure...................................................................................... 20

6.5 Running an Automatic Test Procedure............................................................................... 23

6.6 Auto-Ohm Quick Test Procedure ....................................................................................... 25

6.7 Contrast Adjustment ........................................................................................................... 25

6.8 Auto-Ohm Calibration Check............................................................................................. 26

6.9 Display Previous Results .................................................................................................... 29

List of Tables

Table 1.0 Auto-Ohm 100 Series 2 Specifications............................................................. 10

Table 2.0 Auto-Ohm 200 Series 2 Specifications............................................................. 11

Table 3.0 Functional Description of Auto-Ohm 100 Series 2 Controls and Display ....... 13

Table 4.0 Functional Description of Auto-Ohm 200 Series 2 Controls and Display ....... 15

3 Rev 3, 2009

Page 4

AUTO-OHM 100/200 Series 2 Operating Procedures

Table of Figures

Figure 1.0 Combined Current and Sense Leads....................................................................... 7

Figure 2.0 Auto-Ohm 100/200 Sense Leads............................................................................7

Figure 3.0 Auto-Ohm 100/200 Hand Spikes............................................................................ 8

Figure 4.0 Auto-Ohm 100/200 Current Cable.......................................................................... 8

Figure 5.0 Auto-Ohm 100/200 C-Clamp Cable....................................................................... 9

Figure 6.0 Auto-Ohm 100 Series 2 Control-Panel Controls and Display.............................. 12

Figure 7.0 Auto-Ohm 200 Series 2 Control-Panel Controls and Display.............................. 14

Figure 8.0 AUTO-OHM 100/200 Connection Diagram 1 (Separate Leads)......................... 16

Figure 9.0 AUTO-OHM 100/200 Connection Diagram 2 (Combined Leads) ...................... 16

Figure 10.0 AUTO-OHM 100/200 Connection Diagram 3 (Separate Leads)......................... 17

Figure 11.0 AUTO-OHM 100/200 Connection Diagram 4 (Combined Leads)...................... 17

Figure 12.0 Step-by-Step Procedures for Auto-Ohm Operation.............................................. 18

Figure 13.0 Main Menu............................................................................................................ 19

Figure 14.0 Test Type Menu <NORMAL> ............................................................................. 20

Figure 15.0 Select 10A Menu................................................................................................... 20

Figure 16.0 Select Custom Current Menu................................................................................ 20

Figure 17.0 Custom Current Menu........................................................................................... 20

Figure 18.0 The BURN-IN TIME Menu.................................................................................. 21

Figure 19.0 The RAMP TIME Menu....................................................................................... 21

Figure 20.0 Test Current & Burn-In Time............................................................................... 21

Figure 21.0 Current Ramp Message......................................................................................... 21

Figure 22.0 The BURNING IN Menu...................................................................................... 22

Figure 23.0 Test Current & Resistance Readings .................................................................... 22

Figure 24.0 The REPEAT TEST Menu ................................................................................... 22

Figure 25.0 Cable Error Message............................................................................................. 22

Figure 26.0 Test Type Menu <AUTOMATIC>....................................................................... 23

Figure 27.0 Select 10A Menu................................................................................................... 23

Figure 28.0 Select Custom Current Menu................................................................................ 23

Figure 29.0 Custom Current Menu........................................................................................... 24

Figure 30.0 The Ramp Time Menu.......................................................................................... 24

Figure 31.0 Select 50 Amperes Menu...................................................................................... 24

Figure 32.0 Auto Test Mode Menu.......................................................................................... 24

Figure 33.0 Automatic Mode Test results................................................................................ 25

Figure 34.0 Quick Test Menu................................................................................................... 25

Figure 35.0 Select Adjust Contrast Menu................................................................................ 25

Figure 36.0 Contrast Menu....................................................................................................... 25

Figure 37.0 100A Cal Check.................................................................................................... 26

Figure 38.0 Attach Short Bar Prompt....................................................................................... 26

Figure 39.0 Calibration Connection (Separate Leads)............................................................. 26

Figure 40.0 Calibration Connection (Combined Leads).......................................................... 27

Figure 41.0 Current Ramp Message......................................................................................... 27

Figure 42.0 Current-Ramp Error Message............................................................................... 27

Figure 43.0 Current Ramp Circuit Pass Message..................................................................... 27

Figure 44.0 Zero Circuit Test Message.................................................................................... 28

Figure 45.0 Full-Scale Circuit Test Message........................................................................... 28

Figure 46.0 Measure Circuit Test Message.............................................................................. 28

4 Rev 3, 2009

Page 5

AUTO-OHM 100/200 Series 2 Operating Procedures

Figure 47.0 Cal Check Complete Message.............................................................................. 28

Figure 48.0 Previous Results Menu ......................................................................................... 29

Figure 49.0 Select Reading Menus........................................................................................... 29

Figure 50.0 Test Record Readout............................................................................................. 29

5 Rev 3, 2009

Page 6

AUTO-OHM 100/200 Series 2 Operating Procedures

1.0 INTRODUCTION

1.1 Applicability

This manual applies to the Model Auto-Ohm 100 Series 2 and Model Auto-Ohm 200 Series 2

(hereafter, Auto-Ohm), made by Vanguard Instruments Company.

1.2 General Description

The Auto-Ohm-100/200 Series 2 are the third generation micro-ohmmeters made by Vanguard

Instruments Company. The Auto-Ohm 100/200 features microprocessor-controlled measuring of

very low resistances ranging from 1 micro-ohm to 300 milli-ohms with high accuracy. The AutoOhm is field-portable, rugged, and easily operated by first-time users having a minimum of

training. It features one-knob control and an LCD alpha/numeric display of the resistance

measured. The one-knob control operation is logical and simple: Turning the knob scrolls

through a menu of possible options (which display in sequence) and pressing the knob activates

the selected function. As its name implies, the Auto-Ohm operation is automatic, requiring little

more from the user than connecting it to an unknown resistance and selecting the desired

functions and its options. The Auto-Ohm automatically stores the last 3 resistance measurements,

which can be displayed after testing.

1.3 Functional Description

The Auto-Ohm’s operation is based on the electrical relationships described by Ohm’s law:

R=V/I, where I is a known current and V is the dc voltage measured across the unknown

resistance (typically, a circuit breaker’s contacts). Since the current (user selected) through the

unknown resistance is known and the voltage across the unknown resistance is measured by a

precision voltmeter, the resistance read-out can be calculated using Ohm’s law.

The Auto-Ohm test voltage is supplied by a true 5Vdc power supply. The true DC test current is

selectable in 2-amp steps, from 10 to 100 amperes for the Auto-Ohm-100 and from 10 to 200

amperes for Auto-Ohm-200. The test current is automatically ramped up and down slowly. This

current ramp rate is programmable from 5 seconds to 30 seconds.

The voltmeter test leads run separately from the current-bearing test leads to the resistive load

thus eliminating any I•R voltage drop error in the current cables. These Auto-Ohm features make

very precise micro-ohm measurements possible without having to calculate compensations for

current lead resistance errors.

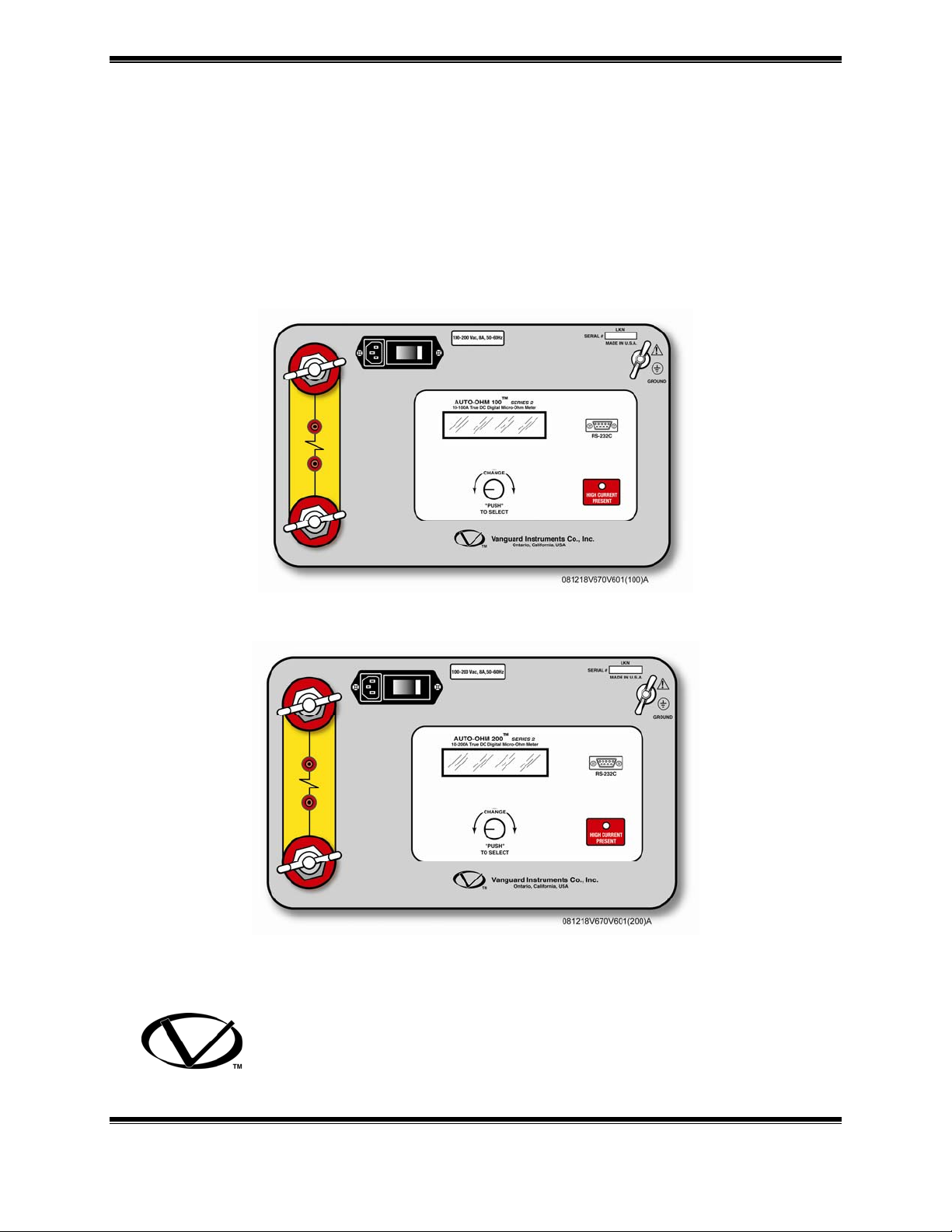

1.4 Furnished Test Accessories

The Auto-Ohm is supplied with two 30-foot test cables with heavy-duty alligator clamps. Both

the current (#1 AWG) and sense leads are combined into one cable (Figure 1.0). A Ground cable,

and power cord are also included with each Auto-Ohm.

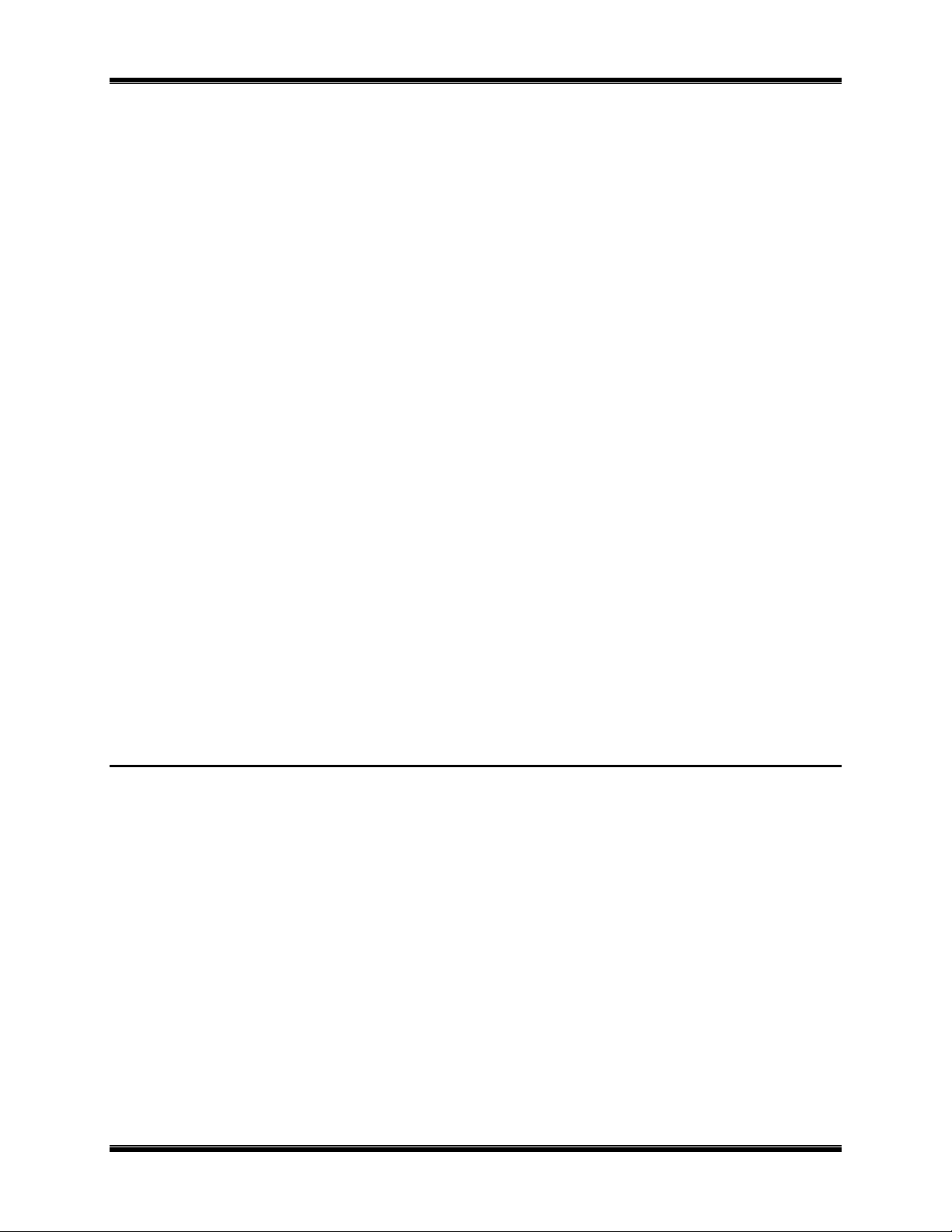

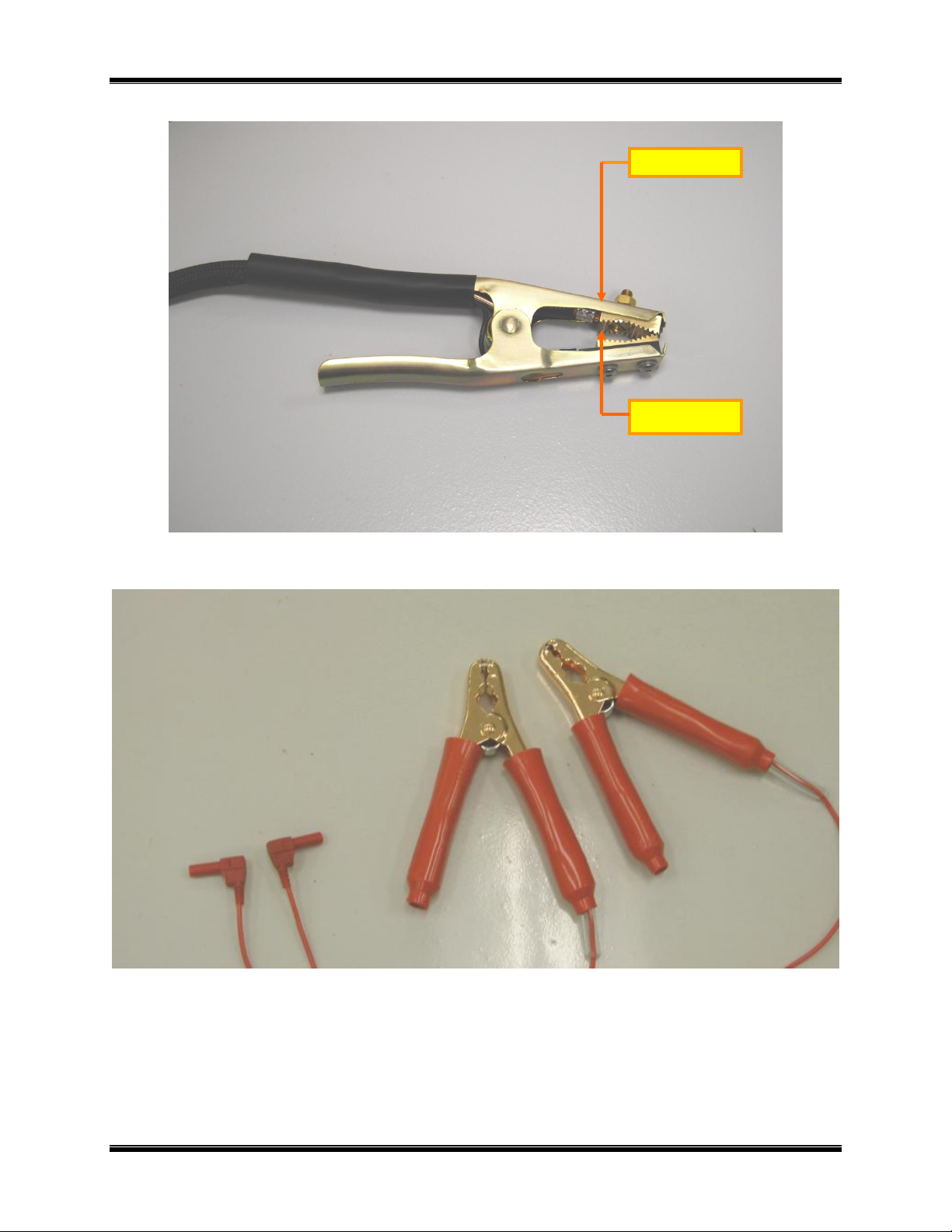

Users can select to have the current and sense leads separated as shown in Figure 2.0 and Figure

4.0. Optional hand spike sense leads are also available as shown in Figure 3.0.

6 Rev 3, 2009

Page 7

AUTO-OHM 100/200 Series 2 Operating Procedures

Current Jaw

Voltage Jaw

Figure 1.0 Combined Current and Sense Leads

Figure 2.0 Auto-Ohm 100/200 Sense Leads

7 Rev 3, 2009

Page 8

AUTO-OHM 100/200 Series 2 Operating Procedures

Figure 3.0 Auto-Ohm 100/200 Hand Spikes

Figure 4.0 Auto-Ohm 100/200 Current Cable

8 Rev 3, 2009

Page 9

AUTO-OHM 100/200 Series 2 Operating Procedures

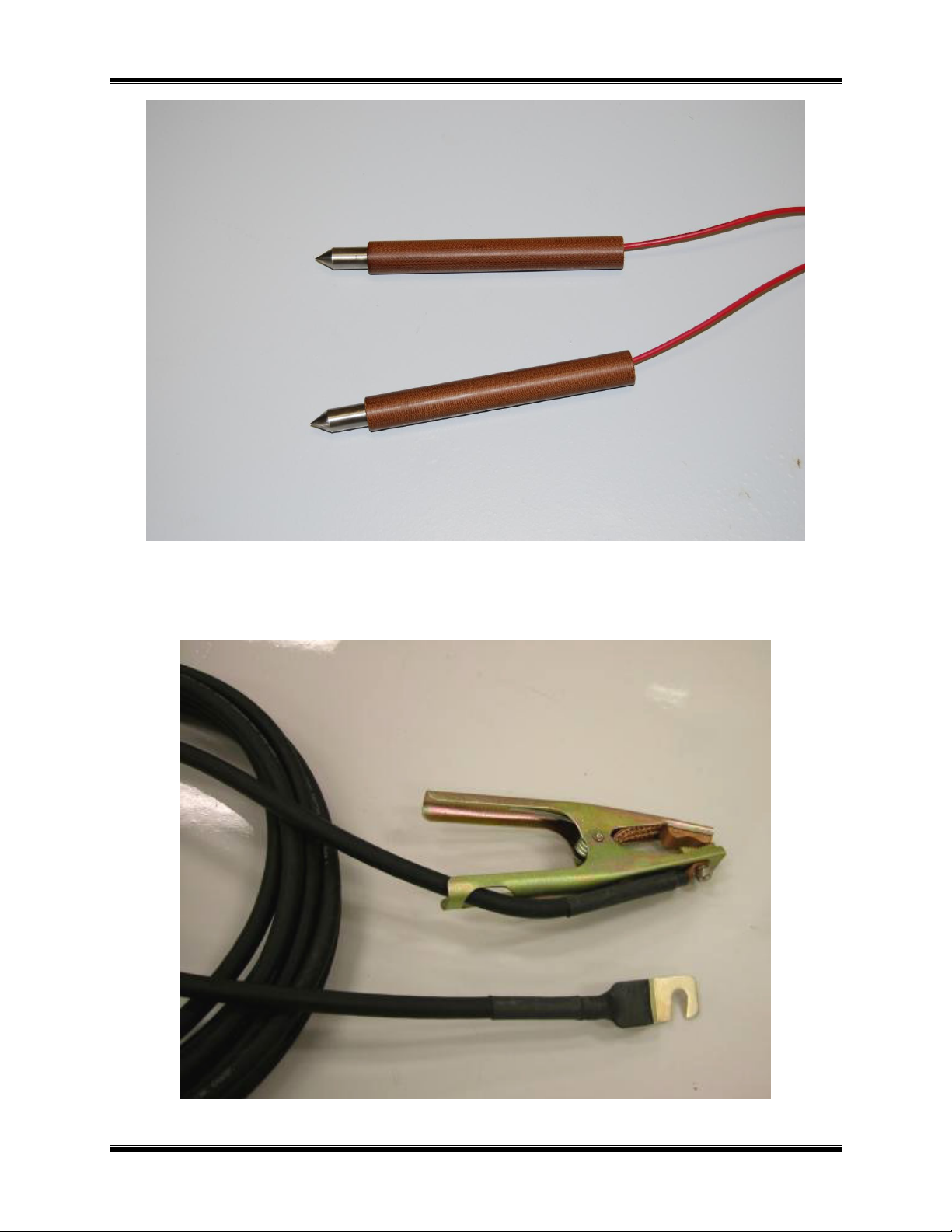

1.5 Optional Accessories

1. Heavy-duty welding-type C-clamps (Figure 5.0) are available as optional accessories.

These C-clamps allow test lead connections to a wide variety of bushing sizes, bus bars,

and conductors that require low-resistance test-lead contacts.

2. Light weight (#4 AWG) cables are also available upon request.

3. Custom cable lengths are available upon request.

4. An optional shipping case (which holds the Auto-Ohm and its cables) is also available.

Figure 5.0 Auto-Ohm 100/200 C-Clamp Cable

9 Rev 3, 2009

Page 10

AUTO-OHM 100/200 Series 2 Operating Procedures

2.0 AUTO-OHM SPECIFICATIONS

2.1 Auto-Ohm 100 Series 2 Specifications

Table 1.0 Auto-Ohm 100 Series 2 Specifications

MODEL...................... Auto-Ohm 100 Series 2

TYPE............................. Special-Purpose Test Equipment, Portable, Low Resistance-Ohmmeter

CONFIGURATION...... Third-generation (improved design, superseding original model)

SIZE (inches).............. 16.8 Wide by 12.6 High by 10.6 Deep (42.7 Cm x 32 Cm x 30.5 Cm)

WEIGHT........................ Less than 15 pounds (6.8 Kg)

OPERATING

VOLTAGE.................... 8 amps, 100-240 Vac, 50/60 Hz, with built in 10A circuit breaker

RESISTANCE

RANGE......................... 1 micro-ohm to 300 milli-ohms

TEST CURRENT

RANGE......................... 10 Amperes to 100 Amperes, Selectable in 2 ampere steps

DISPLAY...................... Backlit LCD, 2-lines high by 16 characters Wide

ACCURACY................. ± 1 % of Reading, ± 1 Count

UNIT PROTECTION... thermal-overload sensor and cutoff

INTERFACE................. RS-232C Connector Port for PC Interface

ENVIRONMENT.......... Operating: 0°C to 55°C; Storage: -40°C to 65°C

FURNISHED ITEMS... One power cord, one ground cable, two 30-ft. test lead cables.

WARRANTY................ One-Year Parts & Labor (Post-Warranty Service Contracts Available)

AUTO-OHM SPECIFICATIONS ARE SUBJECT TO UPGRADES AND MAY BE CHANGED WITHOUT PRIOR NOTICE.

10 Rev 3, 2009

Page 11

AUTO-OHM 100/200 Series 2 Operating Procedures

2.2 Auto-Ohm 200 Series 2 Specifications

Table 2.0 Auto-Ohm 200 Series 2 Specifications

MODEL...................... Auto-Ohm 200 Series 2

TYPE............................. Special-Purpose Test Equipment, Portable, Low Resistance-Ohmmeter

CONFIGURATION...... Third-generation (improved design, superseding original model)

SIZE (inches).............. 16.8 Wide by 12.6 High by 10.6 Deep (42.7 Cm x 32 Cm x 30.5 Cm)

WEIGHT........................ Less than 21 pounds (9.5 Kg)

OPERATING

VOLTAGE.................... 8 amps, 100-240 Vac, 50/60 Hz, with built in 10A circuit breaker

RESISTANCE

RANGE......................... 1 micro-ohm to 300 milli-ohms

TEST CURRENT

RANGE......................... 10 Amperes to 200 Amperes, Selectable in 2 ampere steps

DISPLAY...................... Backlit LCD, 2-lines high by 16 characters wide

ACCURACY................. ± 1 % of Reading, ± 1 Count

UNIT PROTECTION... thermal-overload sensor and cutoff

INTERFACE................. RS-232C Connector Port for PC Interface

ENVIRONMENT.......... Operating: 0°C to 55°C; Storage: -40°C to 65°C

FURNISHED ITEMS... One power cord, one ground cable, two 30-ft. test lead cables

WARRANTY................ One-Year Parts & Labor (Post-Warranty Service Contracts Available)

AUTO-OHM SPECIFICATIONS ARE SUBJECT TO UPGRADES AND MAY BE CHANGED WITHOUT PRIOR NOTICE.

11 Rev 3, 2009

Page 12

AUTO-OHM 100/200 Series 2 Operating Procedures

3.0 CONTROL AND DISPLAY

3.1 Auto-Ohm 100 Series 2 Front Panel

The Auto-Ohm 100 Series 2 controls and displays are shown in the control-panel illustration

below (Figure 6.0). Pointing leader lines reference each item with an index number. Each index

number is cross-referenced to a functional description in Table 3.0, which describes the function

and purpose of each item on the control panel. Although the purpose of these controls and the

display may seem obvious and intuitive, users should become familiar with them before

attempting to use the Auto-Ohm 100 Series 2. First-time users should also review and become

familiar with the Safety Summary on the front page.

Figure 6.0 Auto-Ohm 100 Series 2 Control-Panel Controls and Display

12 Rev 3, 2009

Page 13

AUTO-OHM 100/200 Series 2 Operating Procedures

Table 3.0 Functional Description of Auto-Ohm 100 Series 2 Controls and Display

Figure 6.0

Index #

1 & 8

2

3

4

5

Adjacent Panel Marking

(Wing Nut)

100-240 Vac, 8A, 50-60 Hz

no marking

GROUND

(Wing Nut)

RS-232C

Functional Description

Current lead connectors

Input power connector with third-wire safety

ground and built-in 10A circuit breaker.

LCD; 2-line by 16-character, back-lighted,

displays menus of selections, operator entries,

and test-measurement results.

Auto-Ohm-100 Series 2 ground stud. Connect

ground stud to substation ground using

provided cable.

RS-232C interface port, 9-pin connector,

female DB type. The data rate is set to 19,200

baud, 1 start bit, 8 data bits, and no parity bit.

PIN ................SIGNAL

2 Rx

3 Tx

5 Signal Gnd

This serial port is dedicated for factory

calibration and software update.

LED indicator, red, lights when high-testcurrent is going through the test leads.

One-knob control (all Auto-Ohm menus and

selections are controlled by this one control

knob). Turning this control knob scrolls

through different menu options (shown on

6

7

HIGH CURRENT

PRESENT

CHANGE

“PUSH”

TO SELECT

an LCD), which display. Pressing the knob

selects the displayed function, usually

producing a new menu of selectable options.

See Figure 12.0 for a summary of the step-bystep operating procedures.

9 & 10

(resistor symbol)

Voltage-sensing connector jacks (red).

13 Rev 3, 2009

Page 14

AUTO-OHM 100/200 Series 2 Operating Procedures

3.2 Auto-Ohm 200 Series 2 Front Panel

The Auto-Ohm 200 Series 2 controls and displays are shown in the control-panel illustration,

Figure 7.0. Pointing leader lines reference each item with an index number. Each index number

is cross-referenced to a functional description in Table 4.0, which describes the function and

purpose of each item on the control panel. Although the purpose of these controls and the display

may seem obvious and intuitive, users should become familiar with them before attempting to

use the Auto-Ohm 200 Series 2. First-time users should also review and become familiar with

the Safety Summary on the front page.

Figure 7.0 Auto-Ohm 200 Series 2 Control-Panel Controls and Display

14 Rev 3, 2009

Page 15

AUTO-OHM 100/200 Series 2 Operating Procedures

Table 4.0 Functional Description of Auto-Ohm 200 Series 2 Controls and Display

Figure 7.0

Index #

1 & 8

2

3

4

5

Adjacent Panel Marking

(Wing Nut)

100-240 Vac, 8A, 50-60 Hz

no marking

GROUND

(Wing Nut)

RS-232C

Functional Description

Current lead connectors

Input power connector with third-wire safety

ground and built-in 10A circuit breaker.

LCD; 2-line by 16-character; back-lighted;

displays menus of selections, operator entries,

and test-measurement results.

Auto-Ohm 200 Series 2 ground stud. Connect

ground stud to substation ground using

provided cable.

RS-232C interface port; 9-pin connector;

female DB type. The data rate is set to 19,200

baud, 1 start bit, 8 data bits, and no parity bit.

PIN ................SIGNAL

2 Rx

3 Tx

5 Signal Gnd

This serial port is dedicated for factory

calibration and software update.

LED indicator, red, lights when high-testcurrent is going through the test leads.

One-knob control (all Auto-Ohm menus and

selections are controlled by this one control

knob). Turning this control knob scrolls

through different menu options (shown on

6

7

HIGH CURRENT

PRESENT

CHANGE

“PUSH”

TO SELECT

an LCD), which display. Pressing the knob

selects the displayed function, usually

producing a new menu of selectable options.

See Figure 12.0 for a summary of the step-bystep operating procedures.

9 & 10

(resistor symbol)

Voltage-sensing connector jacks (red).

15 Rev 3, 2009

Page 16

AUTO-OHM 100/200 Series 2 Operating Procedures

4.0 OPERATING VOLTAGES

The Auto-Ohm operates on voltages between 100-240Vac, 50/60Hz.

5.0 CABLE CONNECTION

The Auto-Ohm is supplied with 30-foot test cables with heavy-duty alligator clamps. Both the

current (#1 AWG) and sense leads are combined into one cable (Figure 1.0). A typical cable

connection for the Auto-Ohm to a device under test (using the combined test leads) is shown in

Figure 9.0 and Figure 11.0. Figure 8.0 and Figure 10.0 which illustrate the connection using

separate current and sense leads.

To protect the Auto-Ohm against static discharge in the substation, always connect the unit’s

ground stud to the substation ground. It is also highly recommended to ground one side of the

circuit breaker bushing during test to eliminate any static discharge to the Auto-Ohm.

NOTE

The sense input is not polarity sensitive. The sense cables may be

connected to either input without affecting circuit operation.

Figure 8.0 AUTO-OHM 100/200 Connection Diagram 1 (Separate Leads)

Figure 9.0 AUTO-OHM 100/200 Connection Diagram 2 (Combined Leads)

16 Rev 3, 2009

Page 17

AUTO-OHM 100/200 Series 2 Operating Procedures

Figure 10.0 AUTO-OHM 100/200 Connection Diagram 3 (Separate Leads)

Figure 11.0 AUTO-OHM 100/200 Connection Diagram 4 (Combined Leads)

17 Rev 3, 2009

Page 18

AUTO-OHM 100/200 Series 2 Operating Procedures

Figure 12.0 Step-by- Step Procedures for Auto-Ohm Operation

18 Rev 3, 2009

Page 19

AUTO-OHM 100/200 Series 2 Operating Procedures

6.0 OPERATING THE AUTO-OHM

The Auto-Ohm is operated with one dual-function control knob. The operator turns the control

knob to scroll through different menu selections on the display. When the desired option appears,

it is selected by pressing the control knob like a pushbutton. Review Figure 12.0 before

proceeding with the step-by-step procedures that follow.

6.1 Step-by-Step Procedures

The following sections present step-by-step procedures for the operation of the Auto-Ohm 100

and Auto-Ohm 200 Series 2.

6.2 Precautions

Do not measure the resistance of inductive devices. This can generate unsafe high-voltage spikes

(created by a collapsing magnetic field) if the test current is interrupted by detaching a test lead

during a test. Do not touch or disconnect any test lead that is connected to a device under test

while current is being conducted. Failure to heed this warning can result injury to the user

and/or damage to the Auto-Ohm. The Auto-Ohm measures low, non-inductive resistances

(e.g., breaker contacts and bus-bar junctions). If the resistance of an inductive device needs to be

measured, then the use of an instrument designed for that purpose is recommended (such as the

WRM made by the Vanguard Instruments Company).

6.3 Preparations

a. Ground Auto-Ohm to Substation ground.

b. Plug the Auto-Ohm power cable into a power outlet.

c. Connect current-cable lugs and voltage-sensing cable plugs to control-panel (Figure 6.0 and

Figure 7.0).

d. Attach current test-cable clamps to opposite terminals of the resistive load being tested (Figure

8.0 to Figure 11.0).

e. If separate cables are used, attach voltage-sensing clamps to the terminals of the resistive load.

Sensing voltage clamps should be inside the current clamps.

f. To turn on Auto-Ohm power, press the rocker switch to ON.

NOTE

All Auto-Ohm operations begin at the MAIN MENU, which appears after the initial

boot-up (after configuration and software revision data display briefly.) The Main

Menu display is shown below.

MAIN MENU

<RUN TEST>

Figure 13.0 Main Menu

g. The main menu displays a list of four options, which appear in sequence as the control knob is

turned. The four options of the MAIN MENU list are RUN TEST, ADJ CONTRAST, 100A

CAL. CHECK, and PREVIOUS RESULTS.

19 Rev 3, 2009

Page 20

AUTO-OHM 100/200 Series 2 Operating Procedures

h. When the option of choice appears in the MAIN MENU, press (or “Push”) the control knob

to enter the selection and start that sequence. The step-by-step operating procedures to follow

describe each of the selected options in the order listed above.

6.4 Running a Normal Test Procedure

To run a test, turn the control knob until RUN TEST appears on the display, then press the

control knob to begin the procedures for running a test.

The TEST TYPE menu allows the user to select NORMAL Test or AUTOMATIC Test mode.

NORMAL test mode allows the user to select test current, ramp time, and burn-in time. Press

the control knob when the Auto-Ohm displays <NORMAL> under the TEST TYPE menu.

Figure 14.0 Test Type Menu <NORMAL>

The SELECT TEST CUR (current) menu will now appear on the Auto-Ohm’s display.

Figure 15.0 Select 10A Menu

a. This screen prompts the user to select the desired test current. Test current options are 10, 25,

50, and 100 Amp (for Auto-Ohm 100) or 10, 25, 50, 100, and 200 Amp (for Auto-Ohm 200),

CUSTOM, and ABORT TEST. Select the desired test current option by turning the control knob

until the proper current level displays, then press the knob to enter that choice (in which case go

to step d). If a smaller increment of current is desired, select CUSTOM (Figure 16.0) and press

the control knob and go to the next step.

Figure 16.0 Select Custom Current Menu

b. This menu allows the user to select any test current from 10 to 100 amperes (200 amperes for

Auto-Ohm 200) in 2 amperes steps.

SELECT TEST CUR

Figure 17.0 Custom Current Menu

TEST TYPE

<NORMAL>

SELECT TEST CUR

<10 AMPS>

<CUSTOM>

SET CURRENT:

50 AMPS

20 Rev 3, 2009

Page 21

AUTO-OHM 100/200 Series 2 Operating Procedures

c. Custom current is defaulted to 50 amperes for the Auto-Ohm 100 (100A for Auto-Ohm 200)

in this menu. Turning the control knob clockwise or counter-clockwise will increment or

decrement the current reading on the display. Turn the control knob until the desired current is

displayed, then press the control knob to enter the desired current. The display will now show the

BURN IN TIME menu (Figure 18.0).

NOTE

Selecting ABORT TEST causes the display to return to

the Main Menu without making any selections.

BURN IN TIME

<5 SEC>

Figure 18.0 The BURN-IN TIME Menu

d. This menu selects the amount of time the burn-in current will be run through the test load

before its resistance is measured. Burn-in time range is from 5 to 60 seconds (in 5-second steps).

The default burn-in time is set for 5 seconds. Turn the control knob until the desired burn-in time

appears in the display, then press the control knob to enter that time. Go to the next step.

RAMP TIME:

< 5 SEC>

Figure 19.0 The RAMP TIME Menu

e. The display above shows the ramp time. The ramp time range is 5 to 30 seconds. Turn the

control knob until the desired ramp time appears in the display, then press the control knob to

select that time. Go to the next step.

50 AMPS 5 SEC

“PRESS” TO RUN

Figure 20.0 Test Current & Burn-In Time

f. The display above shows the current and time that have been selected. If these are the intended

current and time, press the control knob to accept the selections and begin the burn-in and

measurement sequence. Go to the next step. Turning the knob in either direction will return the

display to the MAIN MENU.

CUR RAMP: 20%

Figure 21.0 Current Ramp Message

21 Rev 3, 2009

Page 22

AUTO-OHM 100/200 Series 2 Operating Procedures

g. The display above shows the current ramp percentage of the test-level current. The Auto-Ohm

will ramp the test current from 0 (zero) amperes to the selected test current level in the selected

ramp time. The test current is automatically ramped up and down. This current ramp rate is

programmable from 5 seconds to 30 seconds. When the current reaches 100%, the next display

(shown in Figure 22.0) appears automatically. This display shows the resistance reading and the

remaining burn-time of the test.

BURNING IN: 02

120.1 MICRO-OHM

Remaining burnin time

Figure 22.0 The BURNING IN Menu

I=100 AMPS

120 MICRO-OHM

Test Current

Final Resistance

Reading

Figure 23.0 Test Current & Resistance Readings

h. The Auto-Ohm then ramps the test current back to zero. Figure 23.0 shows the final resistance

measurement and the test current at which the resistance was measured. After the result is

examined, press or turn the control knob for the REPEAT TEST menu.

REPEAT TEST?

<YES>

Figure 24.0 The REPEAT TEST Menu

i. To repeat the test, press then release the control knob. The Auto-Ohm repeats the test using the

same test current, ramp time, and burn-in time settings.

To exit this test mode, turn the control knob to select <NO>. Press the control knob to return to

the MAIN MENU.

From the Main Menu another test can be run. If all tests have been completed, turn off power to

the Auto-Ohm, disconnect test leads and power cable, and stow them. This completes the

procedure for performing the NORMAL test procedure.

NOTE

A CABLE ERROR message will be displayed on the Auto-Ohm LCD if the current

cables or sense cables are not connected as shown in Figure 8.0 to Figure 11.0.

CABLE ERROR!

Figure 25.0 Cable Error Message

22 Rev 3, 2009

Page 23

AUTO-OHM 100/200 Series 2 Operating Procedures

6.5 Running an Automatic Test Procedure

The TEST TYPE menu allows the user to select the Normal or Automatic test mode. In the

Automatic test mode the user selects the test current and ramp time. The measurement cycle is

initiated when the sense leads are connected to the device under test. This feature is handy when

the user wants to take resistance readings of multiple points.

To use the Automatic Test Mode the user must connect the current cables outside the two points

where the measurement is to be made. The Auto-Ohm is then placed in the Automatic Test

mode. The test will start as soon as the sense cables are connected to the two points of interest.

The Auto-Ohm test current will ramp from zero to the selected test current. After a five second

burn-in time, the Auto-Ohm current is ramped back to zero. The resistance reading is then

displayed on the LCD. To start a new test, disconnect, then reconnect the sense leads between

the same or two new points of interest.

NOTE

• Current cables should be connected across the resistive load to establish the

current path. Removing and reconnecting one or both sense cables starts a new test.

• Hand spikes (see Figure 3.0) are designed specifically for this application.

To select the Automatic mode, turn the control knob in the TEST TYPE menu until

<AUTOMATIC> menu is displayed (Figure 26.0). Press the control knob to select the

Automatic test mode.

Figure 26.0 Test Type Menu <AUTOMATIC>

The SELECT TEST CUR (current) menu will now appear on the Auto-Ohm’s display.

Figure 27.0 Select 10A Menu

a. This screen prompts the user to select the desired test current. Test current options are: 10, 25,

50, 100 Amp (for Auto-Ohm 100) or 10, 25, 50, 100, 200 Amp (for Auto-Ohm 200), CUSTOM,

and ABORT TEST. Select the desired test current option by turning the control knob until the

proper current level displays, then press the knob to enter that choice (in which case, go to step

d). If a smaller increment of current is desired, select <CUSTOM> (Figure 28.0), press the

control knob and go to the next step.

Figure 28.0 Select Custom Current Menu

SELECT TEST CUR

TEST TYPE

<AUTOMATIC>

SELECT TEST CUR

<10 AMPS>

<CUSTOM>

23 Rev 3, 2009

Page 24

AUTO-OHM 100/200 Series 2 Operating Procedures

b. This menu allows the user to select any test current from 10 to 100 amperes (or 200 amperes

for Auto-Ohm 200) in 2 amperes steps.

SET CURRENT:

50 AMPS

Figure 29.0 Custom Current Menu

c. Custom current is defaulted to 50AMPS for the Auto-Ohm 100 (100A for Auto-Ohm 200) in

this menu. Turning the control knob clockwise or counter-clockwise will increment or decrement

the current reading on the display. Turn the control knob until the desired current is displayed,

then press the control knob to enter the desired current. The RAMP TIME menu (Figure 30.0)

will appear.

RAMP TIME:

<5 SEC>

Figure 30.0 The Ramp Time Menu

d. The display above shows the Ramp Time. The Ramp Time range is 5 to 30 seconds. Turn the

control knob until the desired ramp time appears in the display, then press the control knob to

select that time. Go to the next step.

50 AMPS AUTO

“PRESS” TO RUN

Figure 31.0 Select 50 Amperes Menu

e. The display above (Figure 31.0) shows the selected test current. Press the control knob to start

the AUTO TEST mode (Figure 32.0).

AUTO TEST MODE

Figure 32.0 Auto Test Mode Menu

f. The Auto-ohm is ready to start testing when the Auto Test Mode menu shown above is

displayed. To start testing, connect the sense leads across the device under test. The test current

is gradually ramped up and down with a 5 second burn-in test time. Test results will be displayed

as shown in Figure 33.0 below.

24 Rev 3, 2009

Page 25

AUTO-OHM 100/200 Series 2 Operating Procedures

I=10 AMPS

101.0 MICRO-OHM

Figure 33.0 Automatic Mode Test results

g. To initiate another test, disconnect and reconnect the sense leads to the device under test. To

terminate the Automatic Test Mode, press the Auto-Ohm control knob.

NOTE

The user should allow two seconds between disconnecting and reconnecting to the test

leads to initiate a new test.

6.6 Auto-Ohm Quick Test Procedure

The Auto-Ohm Quick Test mode is a preset test that runs a test at 100 Amps for 5 seconds. To

start a quick test, go to the RUN TEST option in the MAIN MENU. Press and hold the control

knob for 2 seconds. A short beep will be heard at which point the knob must be quickly released.

The Auto-Ohm will beep twice to acknowledge the quick test command has been accepted. Press

then release the control knob again to initiate the test. The Auto-Ohm will run a 100A test with a

5-second burn in time (Figure 34.0). The displayed test result will resemble Figure 33.0.

100 AMPS 5 SEC

“PRESS” TO RUN

Figure 34.0 Quick Test Menu

6.7 Contrast Adjustment

The purpose of this procedure is to adjust the darkness level of the alpha-numeric characters

shown in the LCD display, in order to produce the best readability for the ambient light in the

testing area. To adjust the contrast, turn the control knob to select the ADJ. CONTRAST option

from the MAIN MENU as shown in Figure 35.0.

MAIN MENU

<ADJ. CONTRAST>

Figure 35.0 Select Adjust Contrast Menu

a. Press the control knob to select ADJ. CONTRAST mode. The following menu (Figure 36.0)

will be shown.

ADJUST CONTRAST

“PRESS”= DONE

Figure 36.0 Contrast Menu

25 Rev 3, 2009

Page 26

AUTO-OHM 100/200 Series 2 Operating Procedures

b. Turn the control knob until the contrast is suitable. Press the control knob to set the contrast.

The display will return to the MAIN MENU. The contrast setting will be recalled each time the

Auto-Ohm is turned on and remain until it is changed again using this procedure.

6.8 Auto-Ohm Calibration Check

The purpose of the Calibration Check is to verify that the Auto-Ohm is operating within

acceptable specifications by running a functional check on the Auto-Ohm electronics.

To run a Calibration Check, turn the control knob to select the 100A CAL CHECK option from

the MAIN MENU (see Figure 37.0).

MAIN MENU

<100A CAL CHECK>

Figure 37.0 100A Cal Check

a. Press the control knob to begin the calibration check. The following display will appear.

ATTACH SHORT BAR

<START CAL CHK>

Figure 38.0 Attach Short Bar Prompt

b. Attach the test leads to a piece of aluminum or copper bar (several inches apart, the spacing is

not critical, since this is a functional check). See Figure 39.0 and Figure 40.0 below for a

connection illustration. Press the control knob to start the test.

Figure 39.0 Calibration Connection (Separate Leads)

26 Rev 3, 2009

Page 27

AUTO-OHM 100/200 Series 2 Operating Procedures

Figure 40.0 Calibration Connection (Combined Leads)

c. During the calibration check the display below (Figure 41.0) shows the current ramping status.

When the test current ramps to 100 %, this display is automatically replaced with the test result

display of Figure 42.0 or Figure 43.0.

Figure 41.0 Current Ramp Message

Figure 42.0 Current-Ramp Error Message

d. If the current did not ramp properly (test failed) the CUR RAMP ERROR display above

(Figure 42.0) will appear. Press the control knob to abort the test (restart the CAL CHECK

when the problem is corrected).

Figure 43.0 Current Ramp Circuit Pass Message

e. The above status display indicates that the current ramped properly. The status displays of

Figure 44.0 through Figure 46.0 show for about 3 seconds each as each test is performed and

passed. If any test fails, the status display will stop at the failed function and indicate “FAIL” on

CUR RAMP: 20%

CUR RAMP ERROR!

CHECK CABLES

CURRENT RAMP CKT

“PASS”

27 Rev 3, 2009

Page 28

AUTO-OHM 100/200 Series 2 Operating Procedures

the display. The Auto-Ohm will continue to beep until the control knob is pressed. Once the

problem has been fixed, the CAL CHECK can be rerun.

Figure 44.0 Zero Circuit Test Message

f. The Auto-Ohm checks the ZERO circuit. The “PASS” message is displayed as shown above

in Figure 44.0.

Figure 45.0 Full-Scale Circuit Test Message

g. The full scale range check (FSCL CKT CHECK) is performed next. The “PASS” message is

displayed as shown above in Figure 45.0.

h. The measure circuit test (MEASURE CKT CHECK) is performed next. The “PASS”

message displays as shown below in Figure 46.0.

Figure 46.0 Measure Circuit Test Message

i. If all of the calibration functions pass, the Auto-Ohm calibration complete m essage appears as

shown in Figure 47.0.

Figure 47.0 Cal Check Complete Message

This completes the Calibration Check procedure. Press the control knob to return to the MAIN

MENU.

ZERO CKT CHECK

“PASS”

FSCL CKT CHECK

“PASS”

MEASURE CKT CHECK

“PASS”

CAL CHECK DONE!

PRESS KEY……....

28 Rev 3, 2009

Page 29

AUTO-OHM 100/200 Series 2 Operating Procedures

6.9 Display Previous Results

The purpose of this procedure is to let an operator view the last 3 readings stored in the AutoOhm. To view previous results, turn the control knob to select the PREV RESULTS option

from the MAIN MENU, as shown in Figure 48.0.

Figure 48.0 Previous Results Menu

a. Press the control knob to select this option. The user now can select any of the last three

readings to be displayed. To select the reading, turn the control knob to one of the menus.

Figure 49.0 Select Reading Menus

b. When one of the prompts above displays, press the control knob to display its reading. The

test results will be displayed as shown in Figure 50.0 below.

Figure 50.0 Test Record Readout

c. The above display shows the recorded test resistance (120.2 Micro-ohms) and the test current

level (100 amps) at which it was measured. When the displayed record of resistance is reviewed

and noted, press the control knob to return to the MAIN MENU. This ends the PREVIOUS

RESULTS procedure.

MAIN MENU

<PREV RESULTS>

PREVIOUS RESULTS

<LAST TEST>

PREVIOUS RESULTS

<SECOND TO LAST>

PREVIOUS RESULTS

<THIRD TO LAST>

I= 100AMPS

120.2 MICRO-OHM

NOTE

To display previous test results, the Auto-Ohm must contain tests performed since it was last

(most recently) powered on. When the Auto-Ohm is powered off, it loses all test information.

This concludes the operating procedures for all of the Auto-Ohm functions.

29 Rev 3, 2009

Page 30

AUTO-OHM 100/200 Series 2 Operating Procedures

APPENDIX A

Auto-Ohm Troubleshooting Guide

Item Symptom Possible Problem Solution

1 Reading is

incorrect.

1. Poor connection at

the test clamps.

1. Check connections to

ensure teeth of voltagesensing and current clamps

are firmly in contact with

the device under test.

2 “Cable Error”

Message.

1. No test current

going through the

device under test.

2. Sensing cables

problem.

1. Check current cable

Connection to the device

under test.

2. Check sensing cable

connection.

3. Run Calibration Test.

30 Rev 3, 2009

Page 31

AUTO-OHM 100/200 Series 2 Operating Procedures

1520 S. Hellman Ave., Ontario, CA 91761, USA

Phone 909-923-9390 Fax 909-923-9391

Web site: http//www.vanguard-instruments.com

Copyright 2009 by Vanguard Instruments Company, Inc.

Auto-Ohm 100/200 Series 2 HPN Jan 2009

31 Rev 3, 2009

Loading...

Loading...