VanDerLande High Capacity Diverter Maintenance instruction

Maintenance instruction

MAINTENANCE MANUAL HCD US

Markcode HCD

Document Nr |

A_DOC021709 |

Language |

EN |

Revision |

D |

© 2007 Vanderlande Industries b.v. All rights reserved. The information in this document is confidential and may be used only in accordance with the terms determined by Vanderlande Industries b.v. No part of this publication may be altered, reproduced, stored in a retrieval system, or transmitted, in any form or by any means without the prior permission of Vanderlande Industries b.v.

Always use last revision!

Maintenance instruction: maintenance manual HCD US

General information

|

Used symbols |

|

|

|

|

|

|

Ö |

Input |

|

$WARNING |

|

||

|

|

Õ |

Output |

|

|

Risk of personal injury |

|||

|

|

Special tools |

||

|

|

|

% |

|

|

$CAUTION |

|

||

|

|

+ |

Related documents |

|

|

|

|

||

Risk of damage to equipment

NOTE

Information that requires attention

Product identification

Nr |

Description |

|

|

N55301-000 HCD Left

N55301-017 HCD Right

Related documents

Document Nr |

Description |

A_DOC016452.EN |

Assembly manual High Capacity Diverter |

Special tools |

|

|

|

Item Nr |

Description |

|

|

A_DOC021709-EN-D |

22-09-2008 |

Page 2 of 26 |

Maintenance instruction: |

|

|

maintenance manual HCD US |

|

|

Table of contents |

|

|

Safety information.................................................................................................................... |

4 |

|

Exploded view.......................................................................................................................... |

5 |

|

Replacing spare parts for 1 HCD, Left and Right..................................................................... |

6 |

|

Replacing spare parts for 5 HCD, Left and Right..................................................................... |

8 |

|

Replacing spare parts for 10 HCD, Left or Right.................................................................... |

10 |

|

Replacing spare parts (HCD Left and Right).......................................................................... |

12 |

|

Preventive maintenance ........................................................................................................ |

13 |

|

Procedure |

Replace A1: Divert Blade.................................................................................. |

14 |

Procedure |

Replace B1/F1: V-belt pulleys .......................................................................... |

17 |

Procedure |

Replace P1/R1: Sealed spherical bearings ...................................................... |

19 |

Procedure |

Replace M1: V-belt Reaction Beam.................................................................. |

22 |

Procedure |

Replace Q1: Belt PHR2-90MF RT X BB-GP .................................................... |

23 |

Instruction Manual Supplier Dodge Bearings......................................................................... |

24 |

|

Troubleshooting ..................................................................................................................... |

25 |

|

Troubleshooting ..................................................................................................................... |

26 |

|

A_DOC021709-EN-D |

22-09-2008 |

Page 3 of 26 |

Maintenance instruction: maintenance manual HCD US

Safety information

The High Capacity Diverter (HCD) is designed to handle baggage and / or packages. Handling persons and / or creatures with the HCD is strictly prohibited.

No water or fluids may be used to clean the HCD.

In order to exclude any danger to the user or other persons and to avoid any damage, maintained and operated by appropriately trained personnel.

Work on electrical equipment may only be carried out by qualified electricians.

Installation contractor or mechanical engineer are always responsible for safety and must work according to the local safety codes and regulations.

$WARNING |

Prior to all installation, service and maintenance work, the plant's main |

disconnect switch must be switched off and locked out to prevent switching on again. |

|

|

|

$WARNING |

Adjusting the plant with the safety features disabled is dangerous. The danger |

area must |

area must be secured to prevent access by other persons. |

A_DOC021709-EN-D |

22-09-2008 |

Page 4 of 26 |

Maintenance instruction: maintenance manual HCD US

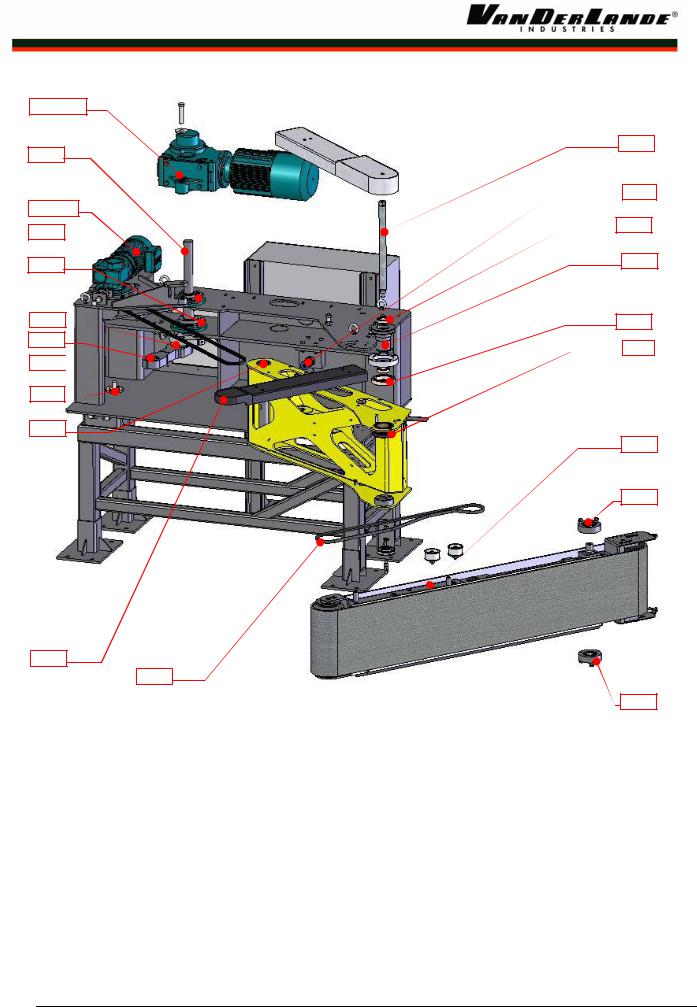

Exploded view

J1/L1

D1

H1/K1

U1

V1

R1

P1

M1

S1

G1

B1

N1

C1

W1

T1

E1

O1

F1

A1

Q1

Q1

A_DOC021709-EN-D |

22-09-2008 |

Page 5 of 26 |

Maintenance instruction: maintenance manual HCD US

Replacing spare parts for 1 HCD, Left and Right.

Pos |

QTY. |

QTY. |

Item Nr |

Description |

How to / |

Nr. |

HCD |

HCD |

|

|

Instruction See |

|

RH |

LH |

|

|

|

|

|

|

|

|

|

A1.2 |

|

|

N55301-007 |

Driving pulley assembly |

A_DOC021709 |

|

2 |

2 |

N04933-00005 |

Bearing type 6207-2RS1/2ZR-C3-35-ISO15-1981 (SKF) |

|

A1.3 |

|

|

N55301-008 |

Driven pulley assembly |

A_DOC021709 |

|

2 |

2 |

N04933-00005 |

Bearing type 6207-2RS1/2ZR-C3-35-ISO15-1981 (SKF) |

|

A1.4 |

2 |

2 |

N55301-010 |

Guiding rail with carrier HGH30CA E2(Hiwin) |

A_DOC021709 |

A1.5 |

1 |

1 |

N55301-636 |

Mounting block guiding rail |

A_DOC021709 |

A1.6 |

1 |

1 |

N55301-321 |

Modified Oil free bushing |

A_DOC021709 |

A1.7 |

1 |

1 |

N03805-80001 |

Hinge bush 55-30-94-89.5 (Meadler 68500800) |

A_DOC021709 |

A1.8 |

1 |

1 |

N55301-724 |

Belt PHR2-90MF RT X BB-GP (Siegling 908214), |

Page 22 |

|

|

|

|

VI N04404-00401 |

|

|

1 |

1 |

N04404-00403 |

Emergency belt, PHR2-90MF RT x BB-GP W=300 |

|

|

|

|

|

L+3517mm, Lacing and pin |

|

A1.9 |

1 |

1 |

N55301-689 |

Rubber sweep |

A_DOC021709 |

A1.10 |

1 |

1 |

N06520-00001 |

Oil free bushing type MPFZ30-40 (Misumi) |

A_DOC021709 |

D1 |

1 |

1 |

N55301-302 |

Welding assy crank mechanism |

Page 25 |

E1 |

|

|

N55301-020 |

Bearing assy divert blade |

Page 17-18 |

|

1 |

1 |

N04933-00003 |

Bearing type 6006-2RS1 C3 (SKF) |

|

|

1 |

1 |

N04933-00007 |

Bearing type 6013-2RS C3 (SKF) |

|

G1 |

2 |

2 |

N04935-04050 |

Bearing type MPBZ 40-50 (Misumi) |

A_DOC021709 |

H1 |

|

1 |

See specification |

Motor reducer V-belt Left |

Page 22 |

J1 |

|

1 |

N00704-67001 |

Motor reducer reaction beam Left (See doc. |

Page 19 |

|

|

|

|

a_doc020081 “HCD Motor Specification” |

|

K1 |

1 |

|

See specification |

Motor reducer V-belt Right |

Page 22 |

L1 |

1 |

|

N00704-67002 |

Motor reducer reaction beam Right (See doc. |

Page 19 |

|

|

|

|

a_doc020081 “HCD Motor Specification” |

|

M1 |

1 |

1 |

N04503-42282 |

V-belt type SPA REDPOWER II L= 2282 mm (supplier |

Page 15 |

|

|

|

|

Optibelt) |

|

N1 |

1 |

1 |

N04503-41807 |

V-belt type SPA REDPOWER II L= 1807 mm (supplier |

Page 22 |

|

|

|

|

Optibelt) |

|

O1 |

1 |

1 |

N04933-00007 |

Bearing type 6013-2RS C3 (SKF) |

Page 18 |

P1 |

1 |

1 |

N04933-00004 |

Sealed spherical roller bearing BS2-2206 C-2CS/VT |

Page 21 |

|

|

|

|

1898 (SKF) |

|

Q1 |

2 |

2 |

N04933-00004 |

Sealed spherical roller bearing BS2-2206 C-2CS/VT |

A_DOC021709 |

|

|

|

|

1898 (SKF) |

|

R1 |

1 |

1 |

N04933-00006 |

Sealed spherical roller bearing BS2-2207 C-2CS/VT |

Page 21 |

|

|

|

|

1898 (SKF) |

|

S1 |

1 |

1 |

N02006-00001 |

Oil free thrust washer type MPWZ 40 (Misumi) |

A_DOC021709 |

T1 |

2 |

2 |

N04933-00003 |

Bearing type 6006-2RS1 C3 (SKF) |

Page 18 |

U1 |

1 |

1 |

N04931-00112 |

Grip tight ball bearing range 209 FC-GT-112 (Dodge) |

Page 21 |

V1 |

1 |

1 |

N04931-00115 |

D-LOK ball bearing range 210 FC-DL-115 (Dodge) |

Page 21 |

A_DOC021709-EN-D |

22-09-2008 |

Page 6 of 26 |

Maintenance instruction: maintenance manual HCD US

W1 |

1 |

1 |

N03804-80001 |

Shock absorber OEMXT 1.5M x 2 (ENIDINE) |

A_DOC021709 |

|

2 |

2 |

N03804-60001 |

Enidine Lock Ring OEM 1.5, M42x1.5 |

A_DOC021709 |

W1 |

1 |

1 |

N03804-70001 |

Enidine Urethane Striker Cap No. UC 2940 |

A_DOC021709 |

Recommended Controls spare parts for 1 HCD

1 |

6 |

6 |

ATDR20 |

Type CC Fuses for Main Disconnect, 20A (Gould) |

|

2 |

1 |

1 |

800T-H2A |

Selector Switch (Allen Bradley) |

|

3 |

1 |

1 |

800T-B2D1 |

Push Button Black, 1NO (Allen Bradley) |

|

4 |

1 |

1 |

800T-QT24R |

Pilot Light Red (Allen Bradley) |

|

5 |

1 |

1 |

BW100-006 |

Braking Resistor (SEW) |

|

6 |

6 |

6 |

ATDR-1-1/4 |

Type CC Fuses for Vertibelt Motor, 1-1/4 A (Gould) |

|

7 |

1 |

1 |

1761-L32BBB |

MicroLogix Controller (Allen Bradley) |

|

8 |

1 |

1 |

700-HB33Z24 |

Relays 24 VDC Coil, 3 Pole (Allen Bradley) |

|

9 |

1 |

1 |

1606-XL240E-3 |

480 VAC – 24 VDC Power Supply (Allen Bradley) |

|

10 |

1 |

1 |

140M-C2E-B25 |

Motor Protector (Allen Bradley) |

|

11 |

1 |

1 |

100-M09NZ243 |

Contactor, 24VDC COIL, 9 AMPS (Allen Bradley) |

|

12 |

6 |

6 |

ATDR15 |

Type CC fuses for Diverter Arm Motor, 15 A (Gould) |

|

13 |

1 |

1 |

MC07B0022-5A3- |

VFD 2.2 KW, 480 VAC (SEW) |

|

|

4-00 |

|

|||

14 |

1 |

1 |

BMK-1-5 |

Brake Control System (SEW) |

|

15 |

1 |

1 |

700-HA33A1 |

Relays 120 VAC Coil, 3 Pole, 11 Pin Round (Allen |

|

|

Bradley) |

|

|||

16 |

1 |

1 |

100-C09DJ10 |

24V dc Motor Contactor (Allen Bradley) |

|

|

|

|

|

|

|

This list includes all controls spare part which are highly recommended by Vanderlande Industries for one single unit.

The scope of this list only covers components mounted at the HCD and inside the control box.

Control items mounted on the HCD unit like motors, sensors and wiring are assigned to the mechanical spare parts list.

A_DOC021709-EN-D |

22-09-2008 |

Page 7 of 26 |

Maintenance instruction: maintenance manual HCD US

Replacing spare parts for 5 HCD, Left and Right.

Pos |

QTY. |

QTY. |

Item Nr |

Description |

How to / |

|

Nr. |

HCD |

HCD |

|

|

Instruction See |

|

|

RH |

LH |

|

|

|

|

|

|

|

|

|

|

|

A1.1 |

1 |

1 |

N55301-006 |

Assembly Divert Blade Left |

Page 14-16 |

|

|

1 |

1 |

N55301-018 |

Assembly Divert Blade Right |

Page 14-16 |

|

A1.2 |

|

|

N55301-007 |

Driving pulley assembly |

A_DOC021709 |

|

|

2 |

2 |

N04933-00005 |

Bearing type 6207-2RS1/2ZR-C3-35-ISO15-1981 (SKF) |

|

|

A1.3 |

|

|

N55301-008 |

Driven pulley assembly |

A_DOC021709 |

|

|

2 |

2 |

N04933-00005 |

Bearing type 6207-2RS1/2ZR-C3-35-ISO15-1981 (SKF) |

|

|

A1.4 |

2 |

2 |

N55301-010 |

Guiding rail with carrier HGH30CA E2(Hiwin) |

A_DOC021709 |

|

A1.6 |

1 |

1 |

N55301-321 |

Modified Oil free bushing |

A_DOC021709 |

|

A1.8 |

1 |

1 |

N55301-724 |

Belt PHR2-90MF RT X BB-GP (Siegling 908214), |

Page 22 |

|

|

|

|

|

VI N04404-00401 |

|

|

|

2 |

2 |

N04404-00403 |

Emergency belt, PHR2-90MF RT x BB-GP W=300 |

|

|

|

|

|

|

L+3517mm, Lacing and pin |

|

|

A1.9 |

1 |

1 |

N55301-689 |

Rubber sweep |

A_DOC021709 |

|

A1.10 |

1 |

1 |

N06520-00001 |

Oil free bushing type MPFZ30-40 (Misumi) |

A_DOC021709 |

|

C1 |

|

|

N55301-003 |

Assy Central shaft Divert Blade |

Page 16 |

|

|

1 |

1 |

N55301-317 |

Shaft Divert Blade |

|

|

D1 |

1 |

1 |

N55301-302 |

Welding assy crank mechanism |

Page 25 |

|

E1 |

1 |

1 |

N55301-020 |

Bearing assy divert blade |

Page 17-18 |

|

G1 |

2 |

2 |

N04935-04050 |

Bearing type MPBZ 40-50 (Misumi) |

A_DOC021709 |

|

H1 |

|

1 |

See specification |

Motor reducer V-belt Left |

Page 22 |

|

J1 |

|

1 |

N00704-67001 |

Motor reducer reaction beam Left (See doc. |

Page 19 |

|

|

|

|

|

a_doc020081 “HCD Motor Specification” |

|

|

K1 |

1 |

|

See specification |

Motor reducer V-belt Right |

Page 22 |

|

L1 |

1 |

|

N00704-67002 |

Motor reducer reaction beam Right (See doc. |

Page 19 |

|

|

|

|

|

a_doc020081 “HCD Motor Specification” |

|

|

M1 |

2 |

2 |

N04503-42282 |

V-belt type SPA REDPOWER II L= 2282 mm (Optibelt) |

Page 15 |

|

N1 |

2 |

2 |

N04503-41807 |

V-belt type SPA REDPOWER II L= 1807 mm (Optibelt) |

Page 22 |

|

P1 |

1 |

1 |

N04933-00004 |

Sealed spherical roller bearing BS2-2206 C-2CS/VT |

Page 21 |

|

|

|

|

|

1898 (SKF) |

|

|

Q1 |

2 |

2 |

N04933-00004 |

Sealed spherical roller bearing BS2-2206 C-2CS/VT |

A_DOC021709 |

|

|

|

|

|

1898 (SKF) |

|

|

R1 |

1 |

1 |

N04933-00006 |

Sealed spherical roller bearing BS2-2207 C-2CS/VT |

Page 21 |

|

|

|

|

|

1898 (SKF) |

|

|

S1 |

1 |

1 |

N02006-00001 |

Oil free thrust washer type MPWZ 40 (Misumi) |

A_DOC021709 |

|

U1 |

1 |

1 |

N04931-00112 |

Grip tight ball bearing range 209 FC-GT-112 (Dodge) |

Page 21 |

|

V1 |

1 |

1 |

N04931-00115 |

D-LOK ball bearing range 210 FC-DL-115 (Dodge) |

Page 21 |

|

W1 |

1 |

1 |

N03804-80001 |

Shock absorber OEMXT 1.5M x 2 (ENIDINE) |

A_DOC021709 |

|

|

2 |

2 |

N03804-60001 |

Enidine Lock Ring OEM 1.5, M42x1.5 |

A_DOC021709 |

|

|

2 |

2 |

N03804-70001 |

Enidine Urethane Striker Cap No. UC 2940 |

A_DOC021709 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A_DOC021709-EN-D |

22-09-2008 |

Page 8 of 26 |

Loading...

Loading...