Assembly instruction

ASSEMBLY MANUAL HIGH CAPACITY DIVERTER

Markcode

HCD

Document Nr A_DOC016452

Language EN

Revision F

© 2007 Vanderlande Industries b.v. All rights reserved. The information in this document is confidential and may be used only in accordance with the terms determined by Vanderlande Industries b.v. No

part of this publication may be altered, reproduced, stored in a retrieval system, or transmitted, in any form or by any means without the prior permission of Vanderlande Industries b.v.

Always use last revision!

Assembly instruction:

Assembly manual High Capacity Diverter

General information

Used symbols

$WARN

R isk of personal injury

ING

$CAUTION

Risk of damage to equipment

NOTE

Information that requires attention

Product identification

Nr Description

Related documents

Document Nr Description

-

Special tools

Ö

Õ

%

+

Input

Output

Special tools

Related documents

Item Nr Description

N55301-313 (1x) Hoisting tool small

N55301-320 (1x) Hoisting tool large

A_DOC016452-EN-F 23-12-2008 Page 2 of 32

Assembly instruction:

Assembly manual High Capacity Diverter

Table of contents

Safety information....................................................................................................................4

Procedure Assembly Divert Blade (N55301-006 left / N55301-018 right)............................5

Procedure Assembly Reaction Beam (N55301-002 left / N55301-016 right) .....................13

Procedure Assembly HCD (N55301-000 left / N55301-017 right)...................................... 16

A_DOC016452-EN-F 23-12-2008 Page 3 of 32

Assembly instruction:

Assembly manual High Capacity Diverter

Safety information

The High Capacity Divert (HCD) is designed to handle baggage and / or packages. Handling persons or creatures with the HCD is strictly prohibited.

Installation contractor or installation engineers are responsible for safety and should work according the local safety requirements/regulations.

$WARNING Before test running, check if the HCD is fixed well.

$WARNING Before test running be sure that nobody is present in the surrounding area of the HCD!

$WARNING When glue or other chemical liquid is used, read the prescriptions of the supplier. Use protecting

clothes, gloves and safety glasses.

A_DOC016452-EN-F 23-12-2008 Page 4 of 32

Assembly instruction:

Assembly manual High Capacity Diverter

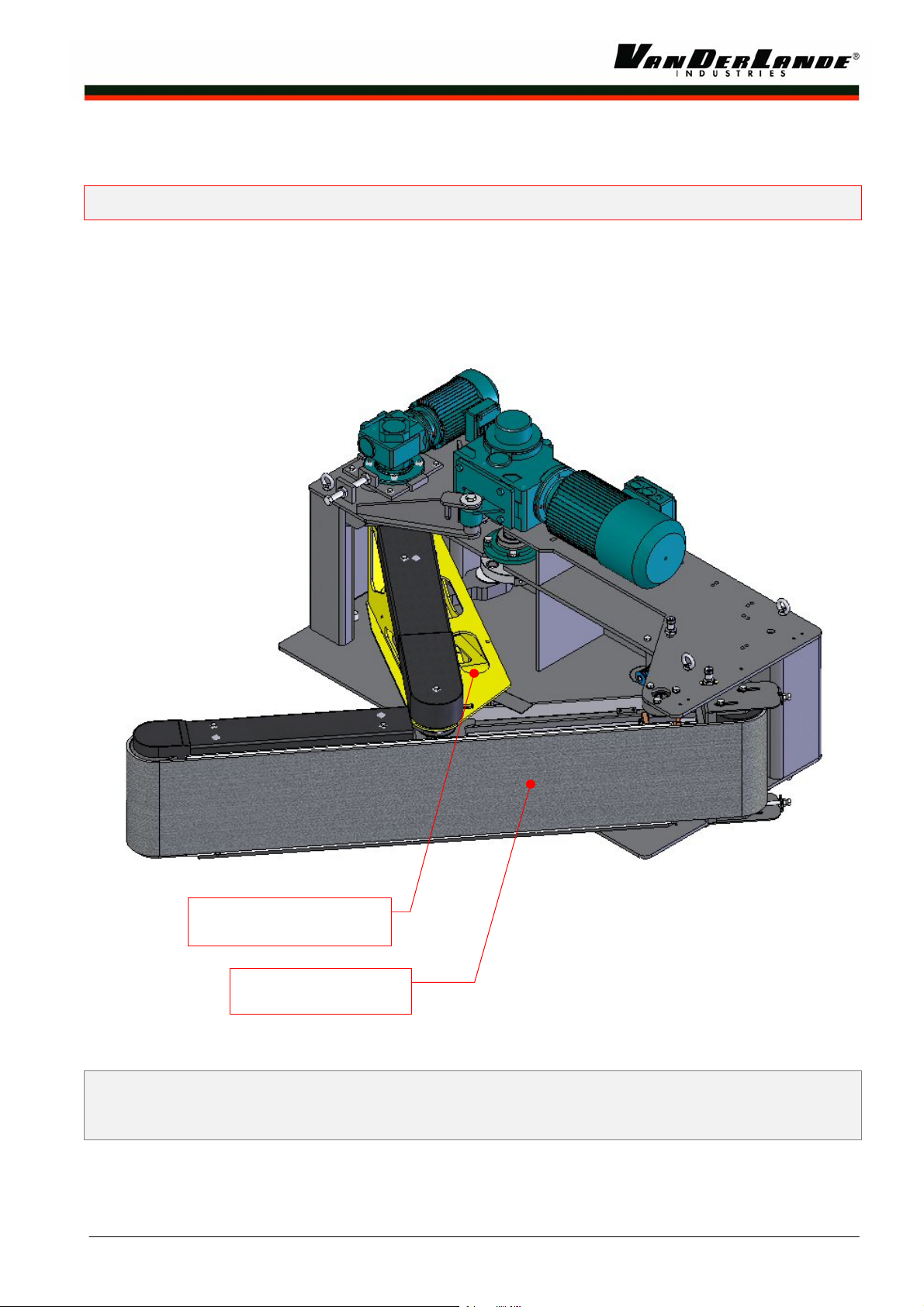

Procedure Assembly Divert Blade (N55301-006 left / N55301-018

right)

$WARN HeaING vy part!

High Capacity Diverter

NOTE

All treaded connections should be secured with Loctite nr. 243 !

NOTE

A_DOC016452-EN-F 23-12-2008 Page 5 of 32

All non-preserving interfaces of parts must be preserved with rust protection lubricant to prevent rust.

Reaction Beam

Divert Blade

Assembly instruction:

Assembly manual High Capacity Diverter

Figure 1 Divert Blade Left (N55301-006)

Figure 2 Divert Blade Right (N55301-018)

A_DOC016452-EN-F 23-12-2008 Page 6 of 32

Assembly instruction:

Assembly manual High Capacity Diverter

¾ Divert Blade Left / Right (left is drawn)

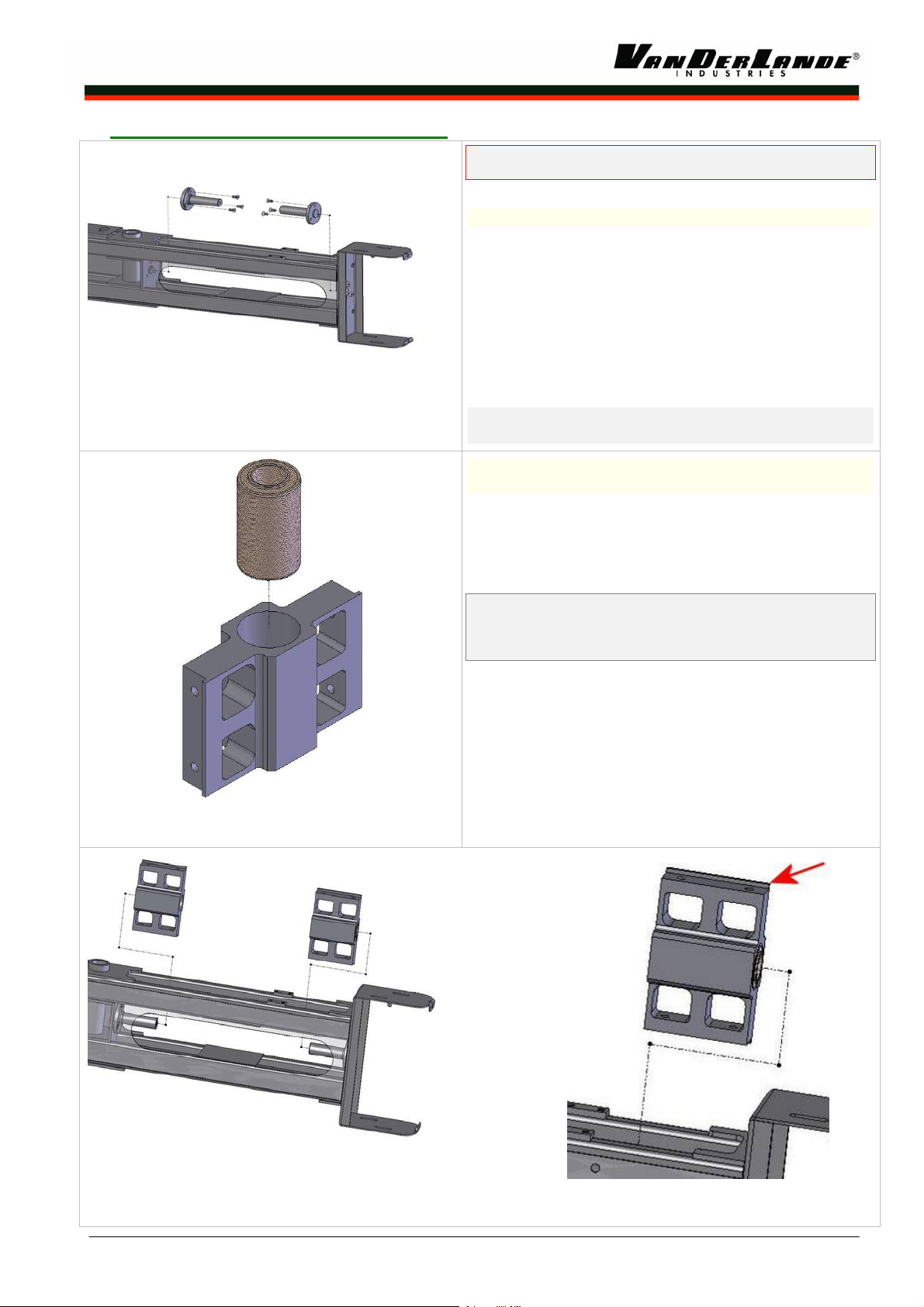

Figure 3 Axle torque bush

$WARNING N55301-305 / 314 are heavy parts !

Step 1 Mounting the axle torque bush.

1-305 (1x) Divert Blade Frame left execution Ö N5530

or

ight execution Ö N55301-314 (1x) Divert Blade Frame r

Ö N55301-637 (2x) Shaft Flexible Bush

002412-01025 (6x) Hex. socket countersunk head screw

Ö

M10x25

% N55301-313 (1x) Hoisting tool small

% N55301-320 (1x) Hoisting tool large

Step 2 Mounting the torque bushings and the block

guiding rails.

Ö N55301-636 (2x) Mounting block guiding rail

Ö N03805-80001 (2x) Hinge bush 55-30-94-89.5

(supplier Meadler 68500800)

Figure 4 Assemble mounting block guiding rail

NOTE

Make sure that the edge (see red arrow) on the

mounting block is mounted on the back side

of the divert blade frame

Figure 5 Torque bushing and mounting block guide rail

A_DOC016452-EN-F 23-12-2008 Page 7 of 32

Assembly instruction:

Assembly manual High Capacity Diverter

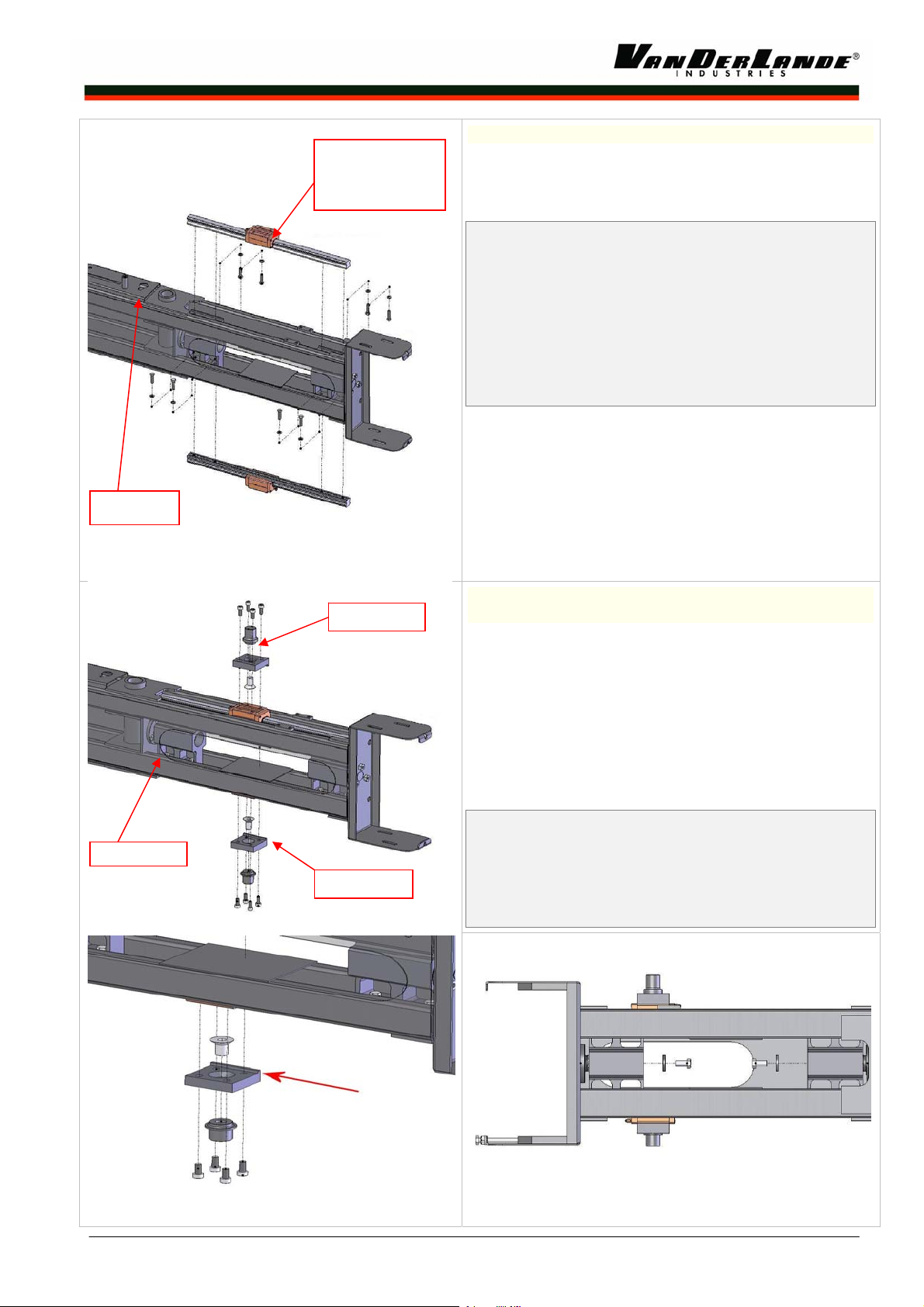

Impact side

Figure 6 Guide rail

Mount lubrication

tank on this side

Top and Bottom

Step 3 Mounting the guide rail.

Ö N55301-010 (2x) Guiding Rail HGR30T with carrier

HGH30CA E2 (supplier Hiwin)

Ö 002311-08030 (8x) Hex. head bolt M8x30

Ö 002764-00008 (8x) Spring lock washer M8

NOTE

If carrier (N04936-00030) and rail (N04936-00600)

delivered separated, first mount the carrier and rail

according supplier's information by using the

special delivered black plastic strip.

NOTE

tank on the "backside" (ETU) of the Divert Blade

NOTE

Make sure that the mounting blocks are in a straight

and a parallel position to each other.

ation For maintenance purposes mount the lubric

N55301-639

N55301-638

Step 4 Mounting the top and bottom shaft linear

guiding system

Ö N55301-635 (2x) Plate shaft

Ö N55301-638 (1x) Shaft bottom

Ö N55301-639 (1x) Shaft top

Ö 002412-01630 (2x) Hex. socket countersunk head screw

M16x30

Ö 002419-08020 (8x) Hex. socket head cap screw M8x20

Ö N55301-667 (2x) Washer

Ö 002311-12025 (2x) Hex. head bolt M12x25

NOTE

Make sure that the edge (see red arrow) on the

shaft plate is mounted on the back side of the

divert blade frame

NOTE

a torque of 93Nm (85LbFt)

ush must be tightened with The bolts for the hinge b

Figure 8 Bolts Hinge Bush

Figure 7 Top- and bottom shaft

A_DOC016452-EN-F 23-12-2008 Page 8 of 32

Assembly instruction:

Assembly manual High Capacity Diverter

N55301-321

Impact side

Figure 9 Slide bearings turn point.

Step 5 Mounting the slide bearings turn point Divert

Blade

Ö N06520-00001 (1x) Oil free bushing.

Ö N55301-321 (N06520-00001), machined part

NOTE

Make sure that both bearings are in line and have

the right tolerances (see checklist).

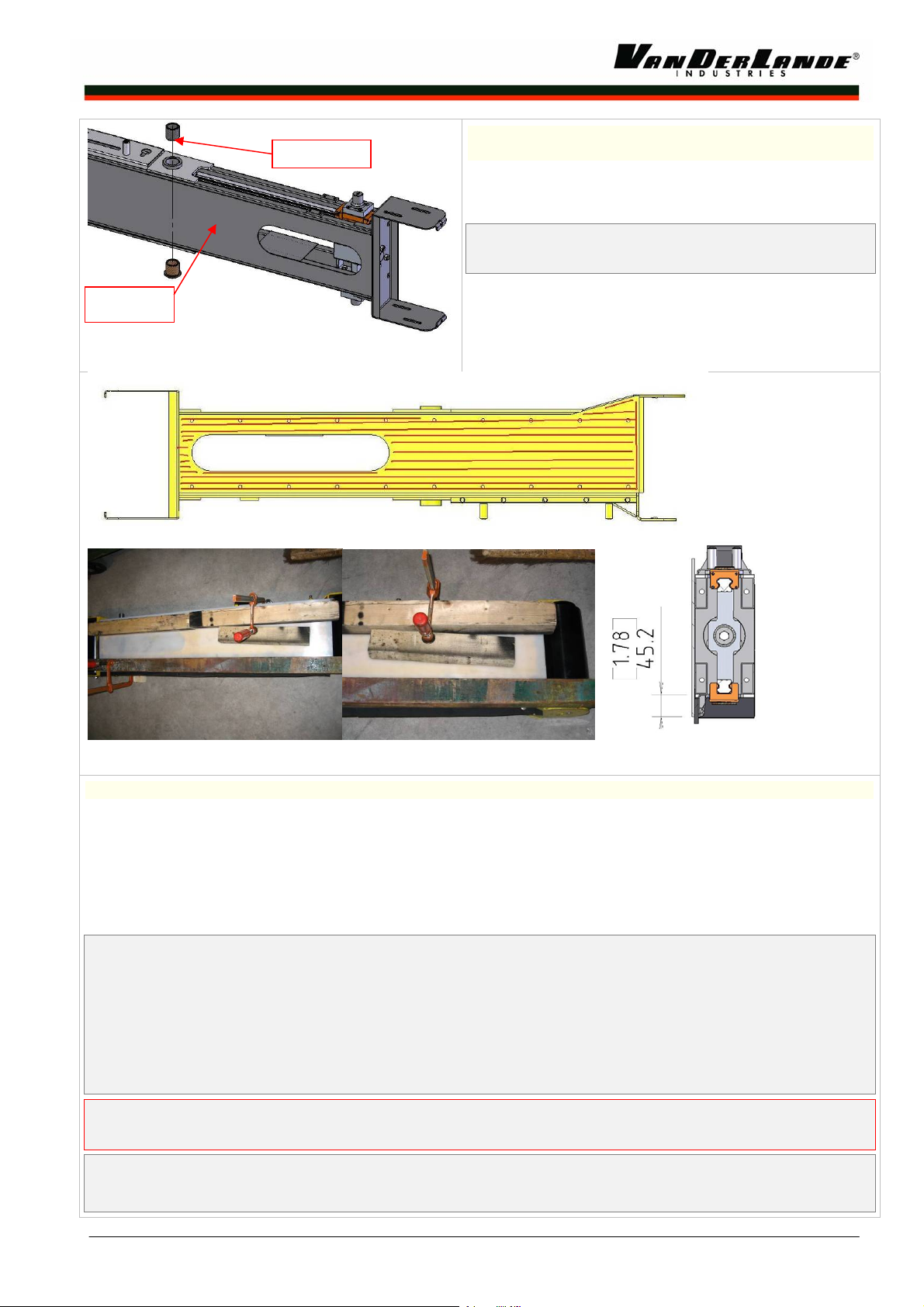

Figure 10 Impact plate

Step 6 Glue the impact plate

Ö N55301-668 (1x) Impact plate left execution

Ö or

Ö N55301-522 (1x) Impact plate right execution

Ö N07232-07063 Loctite 7063, Surface cleaner

Ö N07232-00770 Loctite 770, Primer

Ö N07232-00435 Loctite 435, Adhesive fast glue

NOTE

1) Clean both surfaces of the divert plate and the impact plate once with Lo ctite 7063 cleaner

2) Make both the divert blade and the Impact plate surfaces rough with sand paper

3) Clean both surfaces twice (divert blade and Impact plate) with Lo ctite 7063 cleaner

4) Spread out Loctite 770 primer on the total Impact plate surface, using a clean tissue might be an option

5) Spread out Loctite 435 on the front plate of the divert plate (see red lines, Figure 10), handling time more than 24h

6) Now the Impact plate can be placed on the divert blade,

$W ntacts the divert blade the glue already have 40% adhesive strength, do ARNING when the Impact plate co

not try to move the Impact plate after contact

7) Fasten the Impact plate by using wooden beams an d use 12-14 clamps (see Figure 10), or by using a fixture tool

8) After 1/2 hour the clamps and the wooden beams may be removed, the glue process is finished, now there is 80%

adhesive strength.

A_DOC016452-EN-F 23-12-2008 Page 9 of 32

Assembly instruction:

Assembly manual High Capacity Diverter

Step 7 Mounting the Rubber sweep

Ö N55301-689 (1x) Rubber sweep

Ö N55301-561 (2x) Bracket rubber sweep only for HCD Right

Ö N55301-548 (2x) Bracket rubber sweep only for HCD Left

Ö 002412-00825 (12x) Hex. socket countersunk head screw M8x25

Ö 002371-56008 (12x) Nut He x Lock Nyloc M8

A_DOC016452-EN-F 23-12-2008 Page 10 of 32

Loading...

Loading...