Page 1

M212022EN-D

User Guide

Vaisala Indigo compatible

humidity and temperature probes

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1

Page 2

PUBLISHED BY

Vaisala Oyj

Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

P.O. Box 26, FI-00421 Helsinki, Finland

+358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala Oyj 2020

No part of this document may be

reproduced, published or publicly

displayed in any form or by any means,

electronic or mechanical (including

photocopying), nor may its contents be

modified, translated, adapted, sold or

disclosed to a third party without prior

written permission of the copyright holder.

Translated documents and translated

portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this document are subject

to change without prior notice.

Local rules and regulations may vary and

they shall take precedence over the

information contained in this document.

Vaisala makes no representations on this

document’s compliance with the local

rules and regulations applicable at any

given time, and hereby disclaims any and

all responsibilities related thereto.

This document does not create any legally

binding obligations for Vaisala towards

customers or end users. All legally binding

obligations and agreements are included

exclusively in the applicable supply

contract or the General Conditions of Sale

and General Conditions of Service of

Vaisala.

This product contains software developed

by Vaisala or third parties. Use of the

software is governed by license terms and

conditions included in the applicable

supply contract or, in the absence of

separate license terms and conditions, by

the General License Conditions of Vaisala

Group.

Page 3

Table of contents

Table of contents

1. About this document.....................................................................................7

1.1 Version information.......................................................................................... 7

1.2 Related manuals................................................................................................7

1.3 Documentation conventions........................................................................... 8

1.4 Trademarks........................................................................................................ 8

2. Product overview............................................................................................ 9

2.1 Probe structure................................................................................................. 9

2.2 Basic features and options.............................................................................. 9

2.3 Output parameters......................................................................................... 10

2.4 Additional features with Indigo 200 series transmitters.............................11

2.5 Safety................................................................................................................. 11

2.6 ESD protection.................................................................................................12

2.7 Regulatory compliances................................................................................. 12

2.7.1 FCC Part 15 compliance statement.........................................................12

2.7.2 Canada ICES-003 compliance statement............................................. 13

3. Installation........................................................................................................14

3.1 HMP3 probe......................................................................................................15

3.2 HMP4 probe..................................................................................................... 16

3.3 HMP5 probe......................................................................................................17

3.4 HMP7 probe......................................................................................................18

3.5 HMP8 probe..................................................................................................... 19

3.5.1 Attaching ball valve kit to process........................................................20

3.6 HMP9 probe......................................................................................................21

3.6.1 Installing HMP9 through a cable gland.................................................22

3.7 MMP8 probe.................................................................................................... 23

3.8 TMP1 probe......................................................................................................24

3.9 Wiring...............................................................................................................25

4. Configuration with Insight software..................................................... 27

4.1 Vaisala Insight software.................................................................................27

4.2 Installing driver for the USB service cable...................................................27

4.3 Connecting to Insight software.................................................................... 28

4.4 Configuration options....................................................................................29

5. Using probe with Indigo transmitters................................................... 31

5.1 Indigo 200 series transmitter overview........................................................31

5.2 Attaching probe to Indigo 200 series transmitter..................................... 33

5.3 Wireless configuration interface overview..................................................34

5.4 Connecting to wireless configuration interface..........................................34

5.5 Logging in to wireless configuration interface........................................... 35

6. Maintenance....................................................................................................36

6.1 Cleaning the probe.........................................................................................36

6.1.1 Chemical tolerance................................................................................. 36

1

Page 4

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

6.2 Changing the probe filter.............................................................................. 37

6.3 Replacing the HUMICAPâ R2 sensor........................................................... 37

6.4 Calibration and adjustment...........................................................................39

6.4.1 Adjustment points and requirements.................................................. 40

6.4.2 Adjusting measurement with Insight software.................................... 41

6.4.3 Adjusting measurement with Indigo 200 transmitter........................42

7. Troubleshooting............................................................................................46

7.1 Problem situations......................................................................................... 46

7.2 Error messages...............................................................................................46

8. Technical data................................................................................................49

8.1 HMP3 specifications.......................................................................................49

8.2 HMP4 specifications.......................................................................................52

8.3 HMP5 specifications.......................................................................................55

8.4 HMP7 specifications....................................................................................... 58

8.5 HMP8 specifications........................................................................................ 61

8.6 HMP9 specifications.......................................................................................64

8.7 MMP8 specifications.......................................................................................67

8.8 TMP1 specifications........................................................................................ 70

8.9 Accessories and spare parts..........................................................................72

Appendix A:

Modbus reference...................................................................77

A.1 Default communication settings...................................................................77

A.2 Function codes................................................................................................77

A.3 Data encoding.................................................................................................77

A.3.1 32-bit floating point or integer format................................................. 78

A.3.2 16-bit integer format...............................................................................78

A.4 Modbus registers............................................................................................ 78

A.4.1 Measurement Data Registers.................................................................79

A.4.2 Configuration registers...........................................................................82

A.4.3 Device identification objects................................................................. 85

A.4.4 Status registers........................................................................................85

A.4.5 Test value registers..................................................................................87

A.4.6 Modbus communication examples.......................................................88

Online store....................................................................................................... 91

Warranty.............................................................................................................91

Technical support.............................................................................................91

Recycling............................................................................................................91

2

Page 5

List of figures

Figure 1 Probe parts......................................................................................................... 9

Figure 2 Example installation........................................................................................14

Figure 3 HMP3 probe dimensions................................................................................15

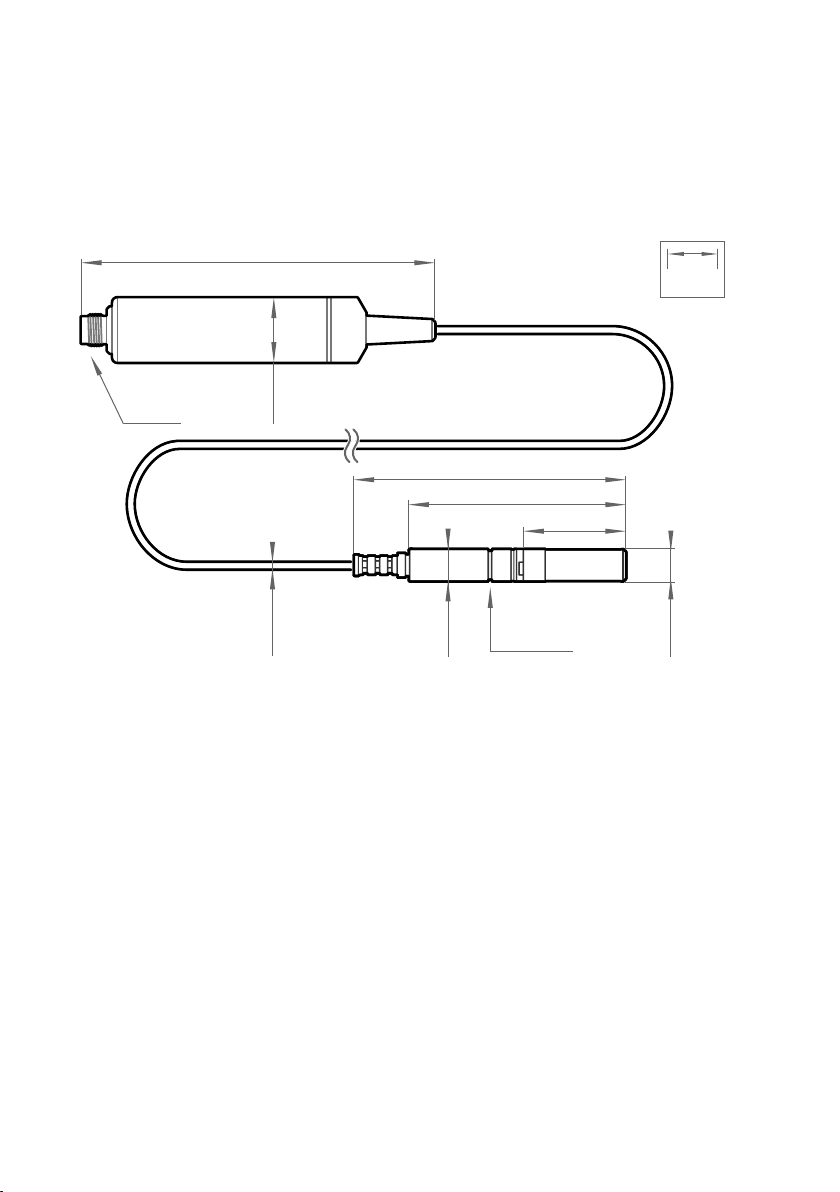

Figure 4 HMP4 probe dimensions................................................................................16

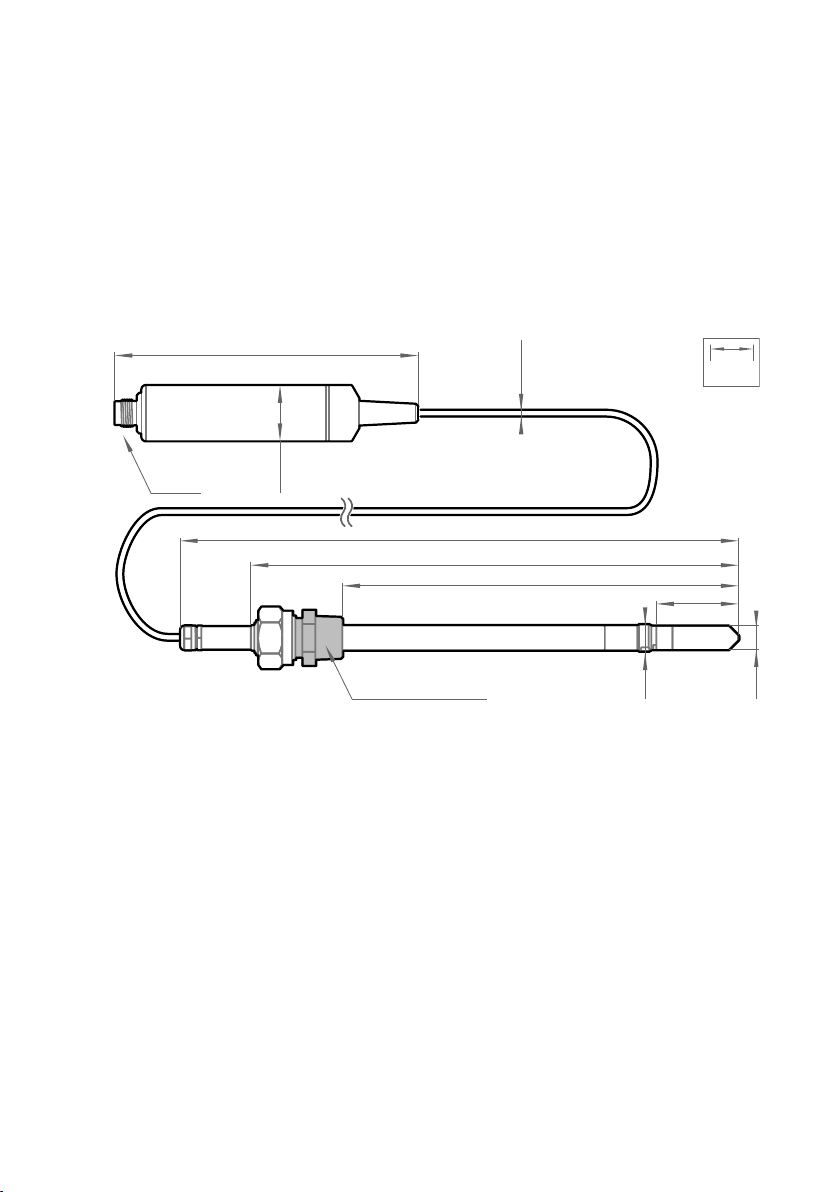

Figure 5 HMP5 probe dimensions................................................................................17

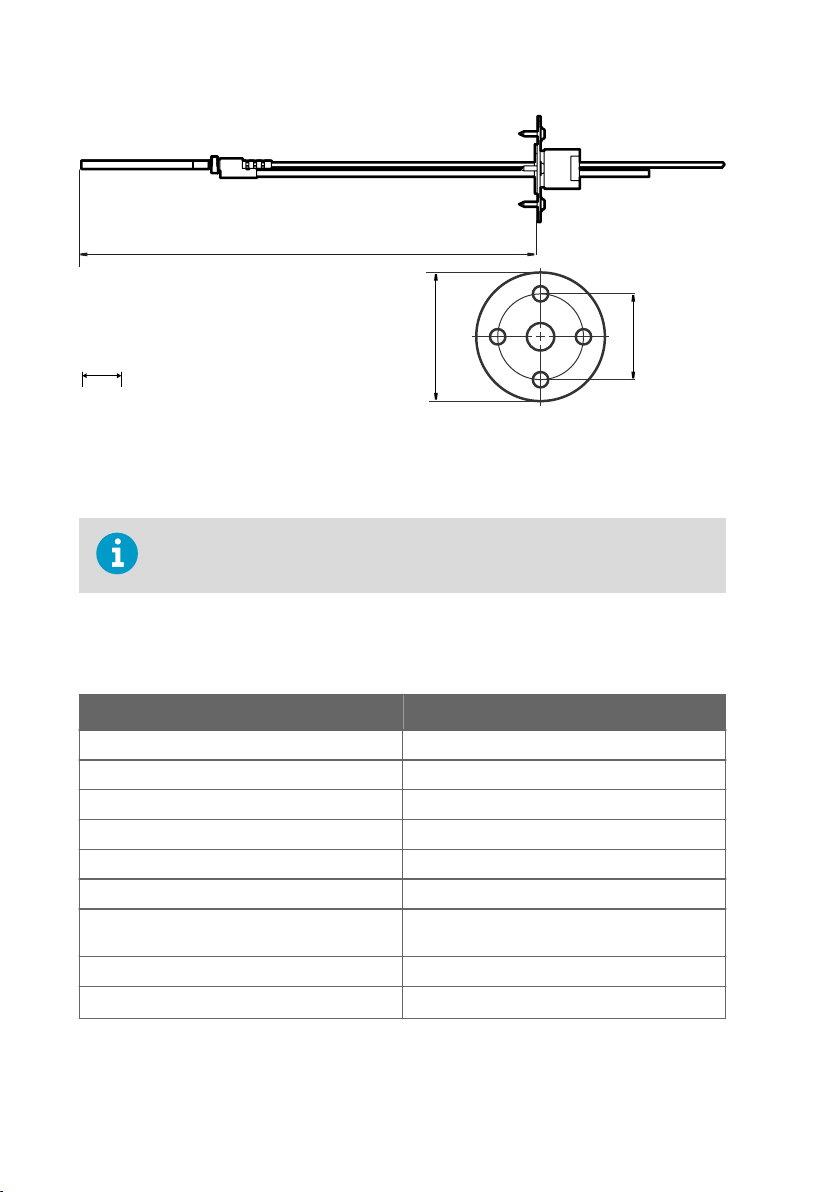

Figure 6 Optional mounting flange 210696 dimensions....................................... 17

Figure 7 HMP7 probe dimensions................................................................................18

Figure 8 HMP8 probe dimensions................................................................................19

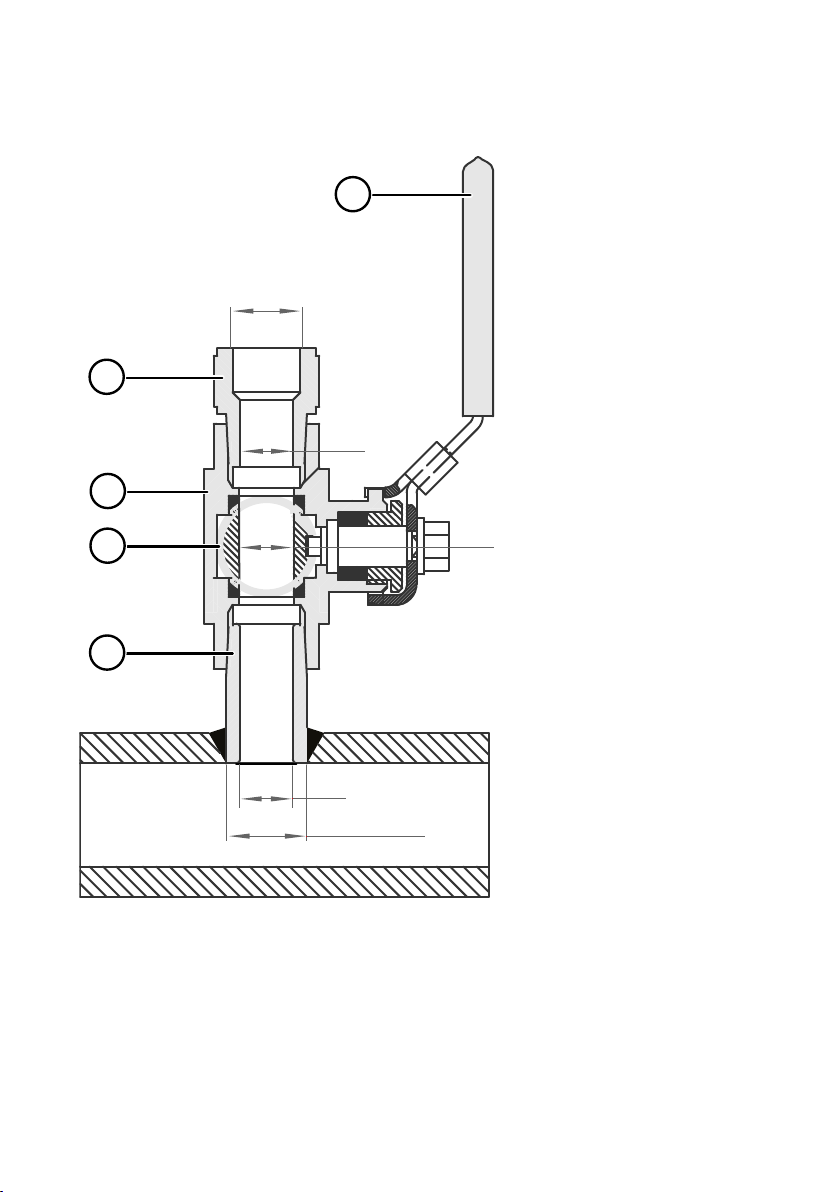

Figure 9 HMP9 probe dimensions................................................................................21

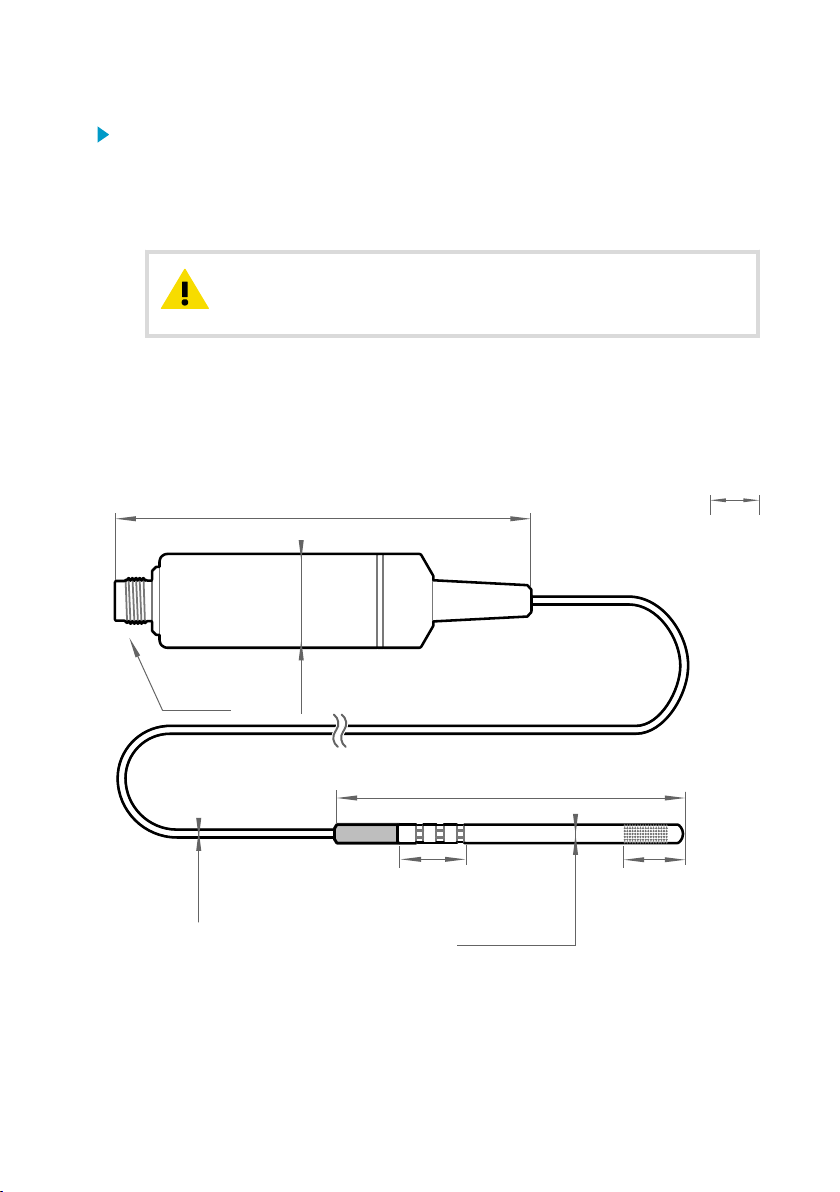

Figure 10 Installing HMP9 probe head through a cable gland..............................22

Figure 11 MMP8 dimensions...........................................................................................23

Figure 12 TMP1 probe dimensions................................................................................ 24

Figure 13 M12 5-pin A-coded male connector pinout............................................. 25

Figure 14 RS-485 wiring.................................................................................................. 25

Figure 15 Connecting probe to Insight........................................................................29

Figure 16 HMP5 in Insight software..............................................................................30

Figure 17 HMP7 attached to Indigo 200 series transmitter....................................31

Figure 18 HMP7 attached to Indigo 200 series transmitter with a cable...........32

Figure 19 Attaching the probe to Indigo 200 series transmitter......................... 33

Figure 20 Enabling and accessing wireless configuration interface

of Indigo 200................................................................................................... 34

Figure 21 Indigo login view.............................................................................................35

Figure 22 HMP3 probe head with filter removed......................................................38

Figure 23 Calibration page in the Indigo 200 wireless

configuration interface..................................................................................44

Figure 24 HMP3 humidity measurement accuracy as a function of

temperature.....................................................................................................50

Figure 25 HMP3 temperature measurement accuracy over full range............... 50

Figure 26 HMP3 probe dimensions...............................................................................52

Figure 27 HMP4 humidity measurement accuracy as a function of

temperature......................................................................................................53

Figure 28 HMP4 temperature measurement accuracy over full range............... 53

Figure 29 HMP4 probe dimensions...............................................................................55

Figure 30 HMP5 humidity measurement accuracy as a function of

temperature..................................................................................................... 56

Figure 31 HMP5 temperature measurement accuracy over full range............... 56

Figure 32 HMP5 probe dimensions...............................................................................58

Figure 33 HMP7 humidity measurement accuracy as function of

temperature......................................................................................................59

Figure 34 HMP7 temperature measurement accuracy over full range............... 59

Figure 35 HMP7 probe dimensions................................................................................61

Figure 36 HMP8 humidity measurement accuracy as a function of

temperature......................................................................................................62

Figure 37 HMP8 temperature measurement accuracy over full range............... 62

Figure 38 HMP8 probe dimensions.............................................................................. 64

List of figures

3

Page 6

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

Figure 39 Optional ball valve installation kit dimensions.......................................64

Figure 40 HMP9 probe dimensions...............................................................................67

Figure 41 Aw measurement accuracy..........................................................................68

Figure 42 MMP8 dimensions...........................................................................................69

Figure 43 TMP1 temperature measurement accuracy over full range.................70

Figure 44 TMP1 probe dimensions................................................................................. 71

Figure 45 Optional duct kit 215003 dimensions........................................................72

4

Page 7

List of tables

Table 1 Document versions (English)...........................................................................7

Table 2 Related Manuals...................................................................................................7

Table 3 Availability of output parameters.................................................................10

Table 4 Suitability of cleaning agents........................................................................ 36

Table 5 Troubleshooting table.....................................................................................46

Table 6 Measurement performance............................................................................49

Table 7 Operating environment.................................................................................. 50

Table 8 Inputs and outputs............................................................................................ 51

Table 9 Mechanical specifications................................................................................51

Table 10 Measurement performance............................................................................52

Table 11 Operating environment...................................................................................54

Table 12 Inputs and outputs........................................................................................... 54

Table 13 Mechanical specifications...............................................................................54

Table 14 Measurement performance............................................................................55

Table 15 Operating environment...................................................................................57

Table 16 Inputs and outputs............................................................................................57

Table 17 Mechanical specifications............................................................................... 57

Table 18 Measurement performance............................................................................58

Table 19 Operating environment.................................................................................. 60

Table 20 Inputs and outputs...........................................................................................60

Table 21 Mechanical specifications.............................................................................. 60

Table 22 Measurement performance.............................................................................61

Table 23 Operating environment...................................................................................63

Table 24 Inputs and outputs........................................................................................... 63

Table 25 Mechanical specifications...............................................................................63

Table 26 Measurement performance........................................................................... 64

Table 27 Operating environment...................................................................................65

Table 28 Inputs and outputs........................................................................................... 66

Table 29 Mechanical specifications...............................................................................66

Table 30 Measurement performance............................................................................67

Table 31 Operating environment...................................................................................68

Table 32 Inputs and outputs........................................................................................... 68

Table 33 Mechanical Specifications.............................................................................. 69

Table 34 Measurement performance............................................................................70

Table 35 Operating environment...................................................................................70

Table 36 Inputs and outputs............................................................................................ 71

Table 37 Mechanical specifications................................................................................71

Table 38 Connection cables.............................................................................................72

Table 39 Accessories......................................................................................................... 73

Table 40 Spare parts..........................................................................................................73

Table 41 Spare parts..........................................................................................................73

Table 42 Accessories......................................................................................................... 73

Table 43 Spare parts..........................................................................................................74

Table 44 Accessories......................................................................................................... 74

Table 45 Spare parts..........................................................................................................74

List of tables

5

Page 8

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

Table 46 Accessories......................................................................................................... 74

Table 47 Spare parts..........................................................................................................75

Table 48 Accessories......................................................................................................... 75

Table 49 Accessories......................................................................................................... 75

Table 50 Spare parts..........................................................................................................75

Table 51 Accessories......................................................................................................... 75

Table 52 Default Modbus serial communication settings....................................... 77

Table 53 Modbus function codes................................................................................... 77

Table 54 16-bit signed integer format details.............................................................78

Table 55 Floating point measurement data registers (read-only).......................79

Table 56 Integer measurement data registers (read-only)....................................80

Table 57 Modbus configuration data registers (writable)...................................... 82

Table 58 Device identification objects......................................................................... 85

Table 59 Modbus status data registers (read-only)................................................. 85

Table 60 Error codes in register 0203

.....................................................................86

hex

Table 61 Modbus test registers (read-only)............................................................... 87

6

Page 9

Chapter 1 – About this document

1. About this document

1.1 Version information

This document provides instructions for installing, using, and maintaining Vaisala HUMICAPâ

Humidity and Temperature Probes HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, Moisture in Oil

Probe MMP8, and Temperature Probe TMP1.

Table 1 Document versions (English)

Document code Date Description

M212022EN-D March 2020 Added content for HMP3 and MMP8 probe models.

M212022EN-C June 2019 Applicable from software version 1.0.9 onward. Added

M212022EN-B June 2018 Applicable from software version 1.0.6 onward. Updated

content for HMP9 probe model. Other added content:

• Output parameters (page 10)

• Adjusting measurement with Indigo 200 transmitter

(page 42)

• Problem situations (page 46)

• Error messages (page 46)

• Status registers (page 85)

Updated content:

• Updated technical specifications and dimension

drawings of probe models

• Updated presentation of Modbus register maps

• Corrected numbering of decimal registers in section

Measurement Data Registers (page 79)

instructions for connecting to Indigo transmitters.

Updated sections Measurement Data Registers (page 79)

and Configuration registers (page 82).

1.2 Related manuals

Table 2 Related Manuals

Document code Name

M211982EN HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, and TMP1 Quick Guide

7

Page 10

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

1.3 Documentation conventions

WARNING!

follow instructions carefully at this point, there is a risk of injury or even death.

CAUTION!

follow instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

Tip gives information for using the product more eciently.

Lists tools needed to perform the task.

Indicates that you need to take some notes during the task.

Warning alerts you to a serious hazard. If you do not read and

Caution warns you of a potential hazard. If you do not read and

1.4 Trademarks

Vaisalaâ and HUMICAPâ are registered trademarks of Vaisala Oyj.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

8

Page 11

1

2

3

4

5

6

7

8

Chapter 2 – Product overview

2. Product overview

HMP series probes are humidity and temperature measurement probes with a digital output

(Modbus protocol). The probes are designed for demanding humidity and temperature

measurement applications. The probes have a two-part structure, with measurement

electronics contained in the probe body and sensor(s) in the probe head. The probe body and

the probe head are connected by a cable. Length options for this connecting cable depend on

the probe model.

The probes are compatible with Vaisala Indigo transmitters. They can also be connected to

Vaisala Insight software for configuration, calibration, adjustment, diagnostics, and temporary

online monitoring.

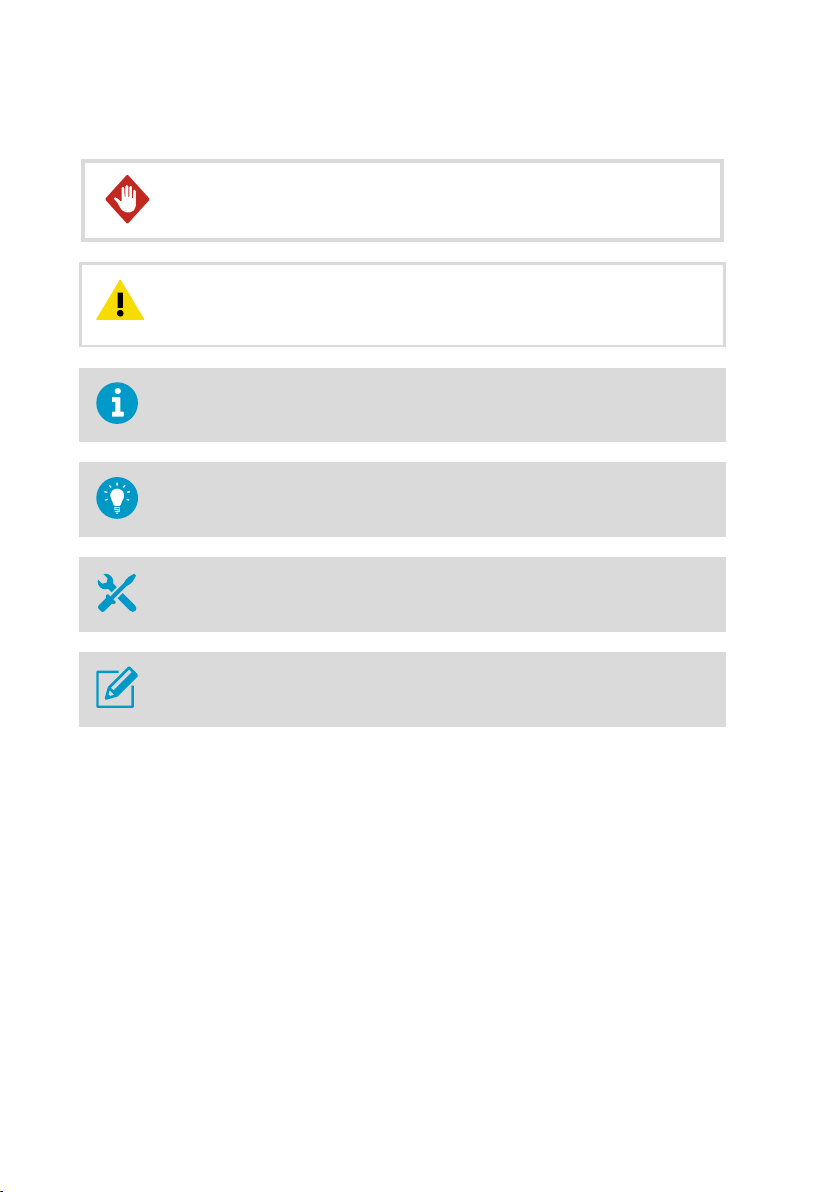

2.1 Probe structure

Figure 1 Probe parts

1 Protection cap (remove before use)

2 5-pin M12 connector

3 Probe body with type label

4 Status indicator:

Green Power on and probe online,

Red Error

O Power o or indicator

5 Probe cable (do not cut)

6 Probe head (HMP7 model shown)

7 Location of sensor(s) on the probe

head. Most probe models have a

removable filter over the sensors that

can be replaced if it gets dirty or

damaged. Note that HMP9 and TMP1

do not have a removable filter.

8 Protection cap (remove before use)

flashes when communicating

disabled

2.2 Basic features and options

• Comprehensive list of output parameters. For example: relative humidity, temperature,

dew point temperature, wet-bulb temperature, absolute humidity, mixing ratio, water

vapor pressure, enthalpy. See Output parameters (page 10).

• Sensor purge provides superior chemical resistance (HMP models only)

• Probe and sensor warming functions minimize condensation on probe (HMP models only)

9

Page 12

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

• Traceable calibration certificate:

• HMP and MMP models: 6 points for humidity, 1 point for temperature

• TMP1: 2 points for temperature

• Standalone Modbus RTU over RS-485

• Compatible with Indigo series of transmitters

• Can be connected to Vaisala Insight PC software for configuration, calibration,

diagnostics, and temporary online monitoring

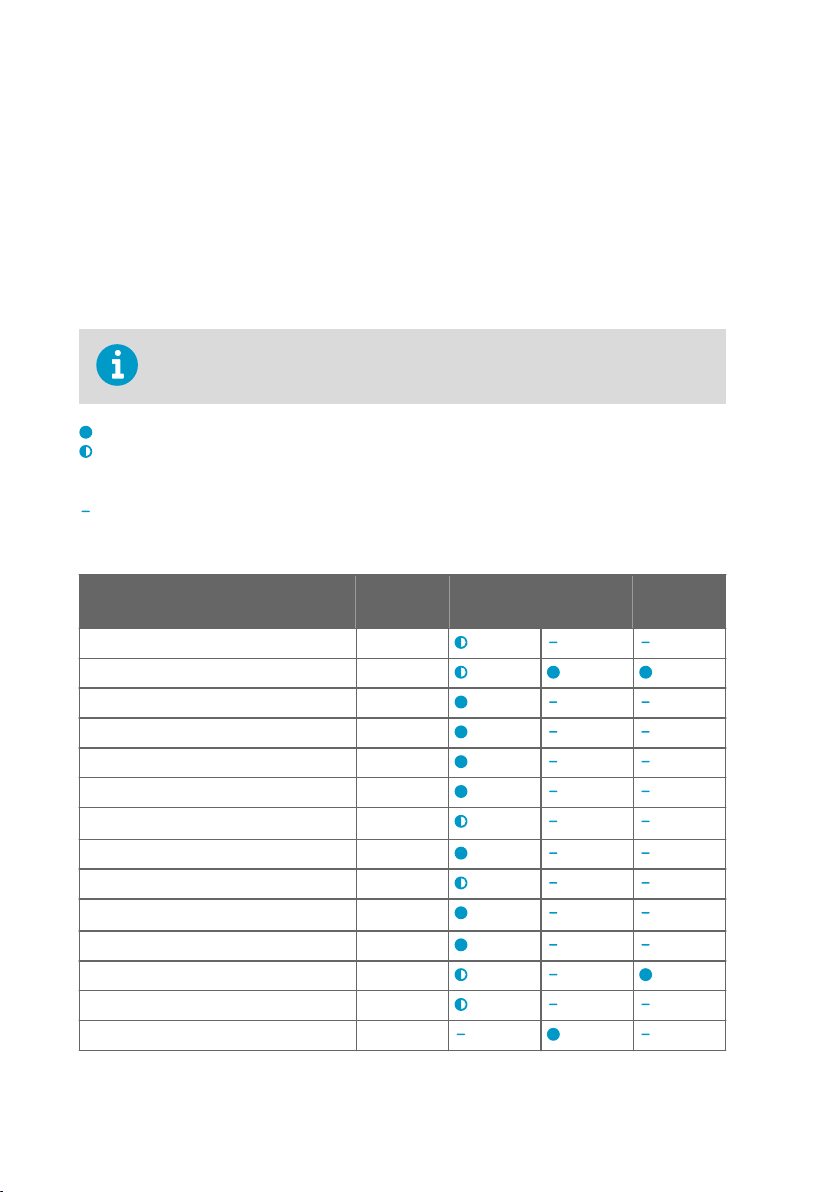

2.3 Output parameters

On HMP probe models, the values of all available output parameters are always

locked when chemical purge or extra heat functions are heating the sensor.

Output parameter is available

Output parameter is available but its value is locked during sensor warming or probe

heating (HMP7 only) unless temperature is written to register 0334

source

Output parameter is not available on this model

Table 3 Availability of output parameters

from an external

hex

Output parameter Output unit HMP3, 4, 5,

Relative humidity %RH

Temperature °C

Dew point temperature °C

Dew/frost point temperature °C

Dew/frost point temperature at 1 atm °C

Dew point temperature at 1 atm °C

Absolute humidity

Mixing ratio g/kg

Wet-bulb temperature °C

Water concentration ppm

Water vapor pressure hPa

Water vapor saturation pressure hPa

Enthalpy kJ/kg

Water activity -

10

g/m

3

v

7, 8, and 9

MMP8 TMP1

Page 13

Chapter 2 – Product overview

Output parameter Output unit HMP3, 4, 5,

Dew point temperature dierence °C

Absolute humidity at NTP

Water concentration in oil ppm

Relative saturation %RS

Water mass fraction ppm

g/m

3

v

w

7, 8, and 9

MMP8 TMP1

2.4 Additional features with Indigo 200 series transmitters

Connecting the probe to an Indigo transmitter provides a range of additional options for

outputs, measurement viewing, status monitoring, and configuration interface access.

Examples of additional features available with Indigo 200 series transmitters include:

• 3.5” TFT LCD color display or non-display model with LED indicator

• Digital output or 3 analog outputs (depending on the transmitter model)

• 2 configurable relays

• Wireless browser-based configuration interface for mobile devices and computers (IEEE

802.11 b/g/n WLAN)

The selection of available additional features (for example, output and connectivity options)

varies depending on the Indigo transmitter model. For more information on Indigo

transmitters, see www.vaisala.com/indigo.

2.5

Safety

WARNING!

has not been exposed to dangerous contamination, and is safe to handle

without special precautions.

CAUTION!

serviceable parts inside the probe body.

CAUTION!

deposit impurities on the probe head.

When returning a product for calibration or repair, make sure it

Do not attempt to open the probe body. There are no user

Do not touch the probe head with your bare hands. Touching will

11

Page 14

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

CAUTION!

functions such as chemical purge and probe heating are active.

Be aware that the probe head may become hot to touch when

2.6 ESD protection

Electrostatic discharge (ESD) can cause immediate or latent damage to electronic circuits.

Vaisala products are adequately protected against ESD for their intended use. However, it is

possible to damage the product by delivering an electrostatic discharge when touching,

removing or inserting any objects inside the equipment housing.

Avoid touching component contacts or connectors when working with the device.

2.7 Regulatory compliances

The probes are in conformity with the provisions of the following EU directives:

• RoHS Directive

• EMC Directive

Conformity is shown by compliance with the following standards:

• EN 50581: Technical documentation for the assessment of electrical and electronic

products with respect to the restriction of hazardous substances.

• EN 61326-1: Electrical equipment for measurement, control, and laboratory use – EMC

requirements – intended for use in industrial locations.

• EN 55032: Information technology equipment – Radio disturbance characteristics – Limits

and methods of measurement.

2.7.1 FCC Part 15 compliance statement

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that the interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by

turning the equipment o and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that of the receiver.

• Consult the dealer or an experienced radio/TV technician for help.

12

Page 15

Chapter 2 – Product overview

CAUTION!

by the party responsible for compliance could void the user's authority to

operate the equipment.

Changes or modifications to this equipment not expressly approved

2.7.2 Canada ICES-003 compliance statement

This Class B digital apparatus complies with Canadian ICES‑003.

Cet appareil numerique de la classe B est conforme a la norme NMB‑003 du Canada.

13

Page 16

1

2

3

4

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

3. Installation

When you choose the installation location for the probe, consider the following:

• Verify the operating environment specification of the probe model. The probe head

typically has a much wider operating temperature range than the probe body.

• If the temperature of the measured environment diers greatly from ambient

temperature, the entire probe head and preferably plenty of cable must be inside the

measured environment. This prevents measurement inaccuracy caused by heat

conduction along the cable.

• Probe mounting options are model-specific.

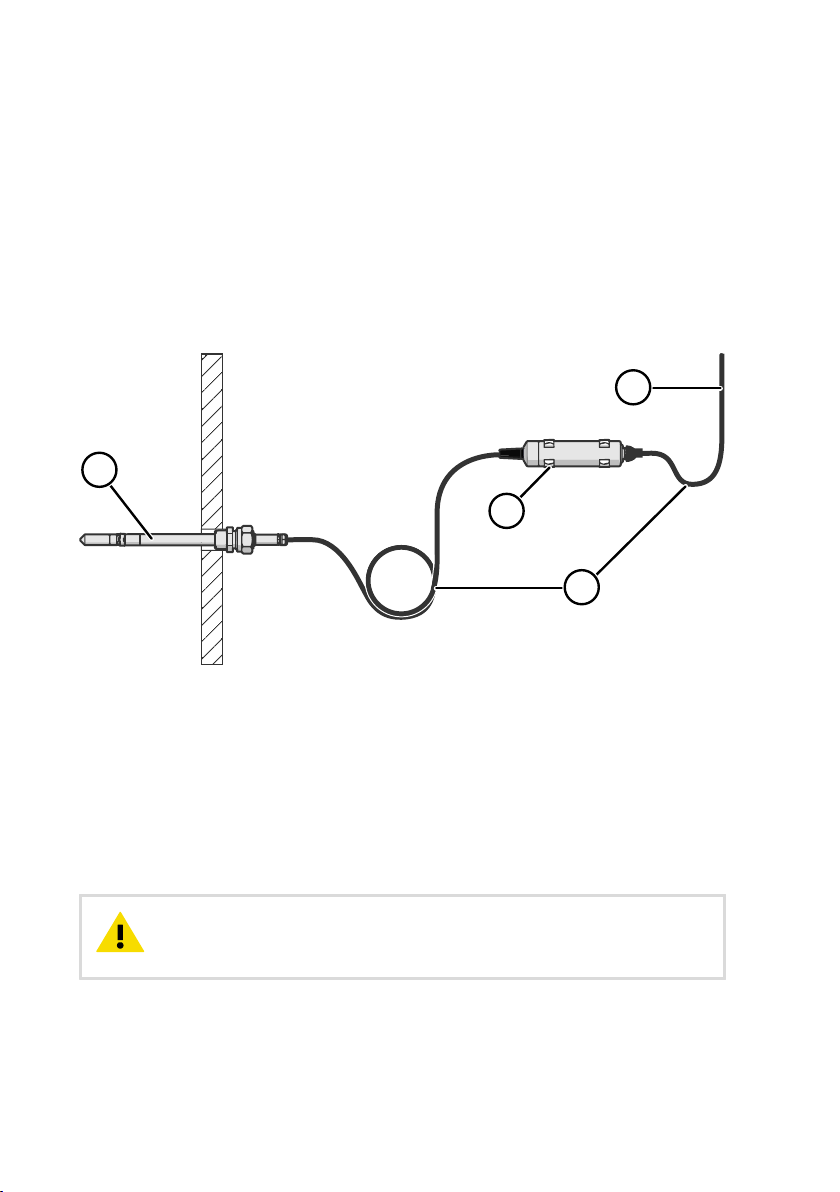

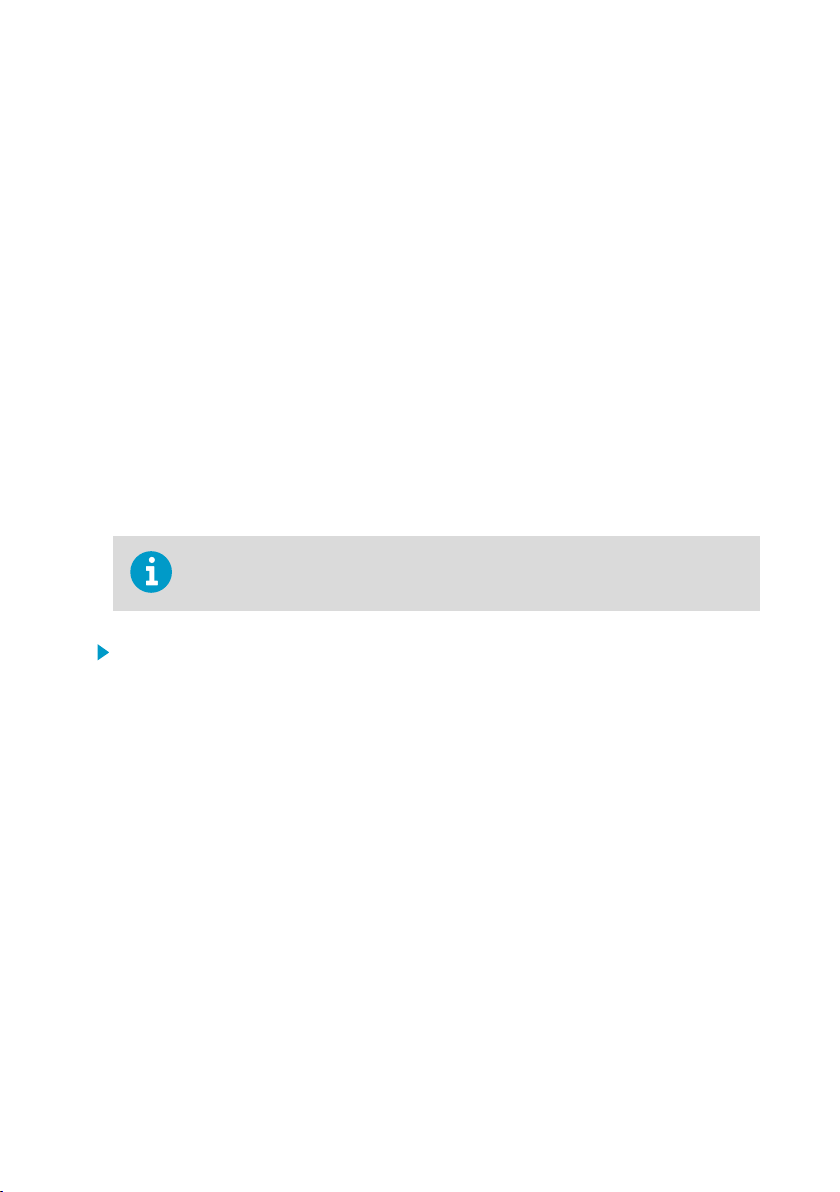

Figure 2 Example installation

Mount the probe head horizontally to prevent any water condensing on the probe head

1

from running to the sensors.

2 Let the cable hang loosely to prevent condensed water from running along the cable to

the probe body or probe head.

3 Attach the probe body to a wall or other surface using the two mounting clips (Vaisala

item 243257SP) supplied with the probe. Each clip attaches to the installation surface with

one screw (screw hole Ø 4.2 mm).

4 Cable to Modbus master or Indigo transmitter.

CAUTION!

vibration. Use other methods to secure the probe body if necessary. For

example, attach the probe body using a cable tie.

The supplied mounting clips are not designed to withstand strong

More information

‣

Default communication settings (page 77)

14

Page 17

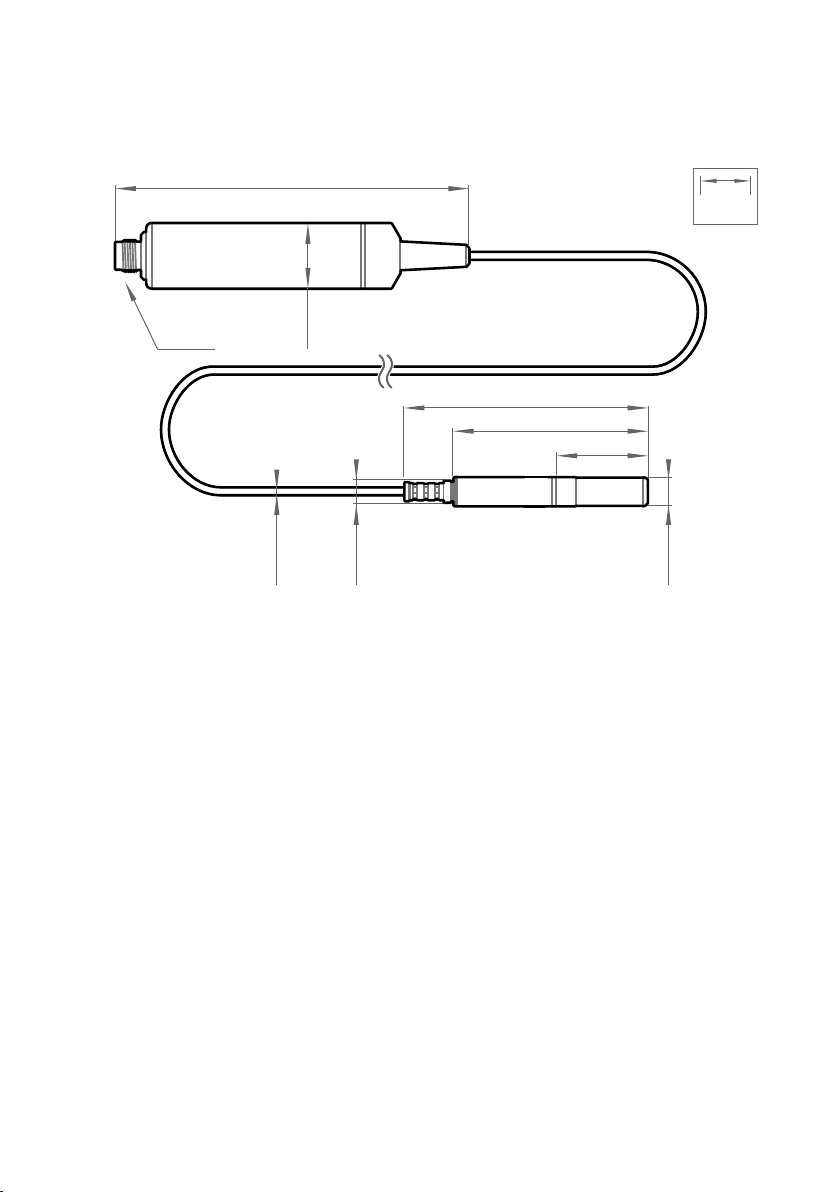

3.1 HMP3 probe

136 [5.35]

Probe cable 2 m [6.56 ft]

Ø 25

[0.98]

M12/5

98.5 [3.88]

78.5 [3.09]

37.5 [1.48]

Ø 5

[0.2]

Ø 12

[0.47]

M9x1

mm

[in]

Figure 3 HMP3 probe dimensions

Chapter 3 – Installation

Vaisala HUMICAPâ Humidity and Temperature Probe HMP3 is a general purpose probe

designed for various industrial processes. The probe structure allows for replacing the sensor

without tools, making it suitable for applications such as paint booths and other industrial

applications where periodic recalibration alone is not sucient for maintaining the probe

performance. Other suitable applications include, for example, industrial HVAC systems,

cleanrooms, and environmental chambers.

• Operating temperature for probe head −40 … +120 °C (−40 … +248 °F)

• Operating temperature for probe body −40 … +80 °C (−40 … +176 °F)

If purchased with a composite sensor instead of the field replaceable HUMICAPâ R2 sensor,

HMP3 can use the chemical purge feature. In environments with high concentrations of

chemicals and cleaning agents, the chemical purge option helps to maintain measurement

accuracy between calibration intervals.

15

Page 18

136 [5.35]

Probe cable 2 m [6.56 ft]

Ø 25

[0.98]

M12/5

183 [7.20]

120 [4.72]

41 [1.61]

Ø 5

[0.2]

Fitting body NPT1/2” or M22×1.5

with sealing ring Ø22×27×1.5 Cu

Ø 12

[0.47]

32 mm 27 mm

mm

[in]

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

3.2 HMP4 probe

Figure 4 HMP4 probe dimensions

Vaisala HUMICAPâ Humidity and Temperature Probe HMP4 is designed for high-pressure

applications such as compressed air systems in maritime, breathing air, and industrial

applications, where measurement performance and chemical tolerance are essential.

• Temperature measurement range −70 … +180 °C (−94 … +356 °F)

• Operating pressure 0 … 10 MPa (0 … 100 bar)

• Operating temperature for probe body −40 … +80 °C (−40 … +176 °F)

• M22×1.5 or NPT1/2” fitting body

Use a sealing ring (Ø22×27×1.5 Cu) with the M22×1.5 fitting. Replace the sealing

ring every time the probe is detached. Three sealing rings are supplied with the

fitting.

16

Page 19

3.3 HMP5 probe

136 [5.35]

Ø 25

[0.98]

M12/5

41 [1.61]

253 [9.96]

243 [9.57]

Ø 12

[0.47]

Ø 13.5

[0.53]

Probe cable

2 m [6.56 ft] or 10 m [32.8 ft]

Ø 5

[0.2]

mm

[in]

mm

[in]

75 [2.95]

50 [1.96] 19 [0.75]

Figure 5 HMP5 probe dimensions

Chapter 3 – Installation

Figure 6 Optional mounting flange 210696 dimensions

Vaisala HUMICAPâ Humidity and Temperature Probe HMP5 is designed for high-temperature

applications such as baking ovens, pasta dryers, and industrial drying kilns, where

measurement performance and chemical tolerance are essential.

• Temperature measurement range −70 … +180 °C (−94 … +356 °F)

17

Page 20

mm

[in]

136 [5.35]

Ø 25

[0.98]

M12/5

Ø 12

[0.47]

99.5 [3.92]

79.5 [3.13]

37.5 [1.48]

Groove for

lock ring

Ø 12

[0.47]

Ø 5

[0.2]

Probe cable

2 m [6.56 ft] or 10 m [32.8 ft]

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

• Operating temperature of probe body −40 … +80 °C (−40 … +176 °F)

• 250-mm (9.84 in) probe allows easy process installation through insulation

3.4 HMP7 probe

Figure 7 HMP7 probe dimensions

Vaisala HUMICAPâ Humidity and Temperature Probe HMP7 is designed for applications that

involve constant high humidity or rapid changes in humidity, such as drying and test

chambers, combustion air, and other humidifiers and meteorological measurements, where

measurement performance and chemical tolerance are essential.

Probe heating

HMP7 supports probe heating. Probe heating heats up not only the sensor, but the entire

probe head. When probe temperature is heated above dew point temperature, condensation

on the probe can be avoided while measuring the dew point temperature of the process.

• Temperature measurement range −70 … +180 °C (−94 … +356 °F)

• Operating temperature of probe body −40 … +80 °C (−40 … +176 °F)

• Probe heating and sensor warming functions minimize condensation on probe

• Vapor and pressure proof construction

18

Page 21

136 [5.35]

Probe cable 2 m [6.56 ft]

Ø 25

[0.98]

M12/5

Ø 12

[0.47]

41 [1.61]

Ø 13.5

[0.53]

Fitting body

ISO1/2” or NPT1/2”

Ø 5

[0.2]

mm

[in]

268 [10.55]

230 [9.06]

41 ... 185 [1.16 ... 7.28]

Chapter 3 – Installation

If probe heating is enabled, output parameters that are dependent on temperature

measurement (such as relative humidity) are locked whenever probe is heated unless the true

temperature of the measured environment is updated to the temperature compensation

register of the probe from another measurement instrument (for example, the TMP1 probe).

Output parameters such as dew point temperature that can be measured or calculated

without this external temperature information are available even without the temperature

input.

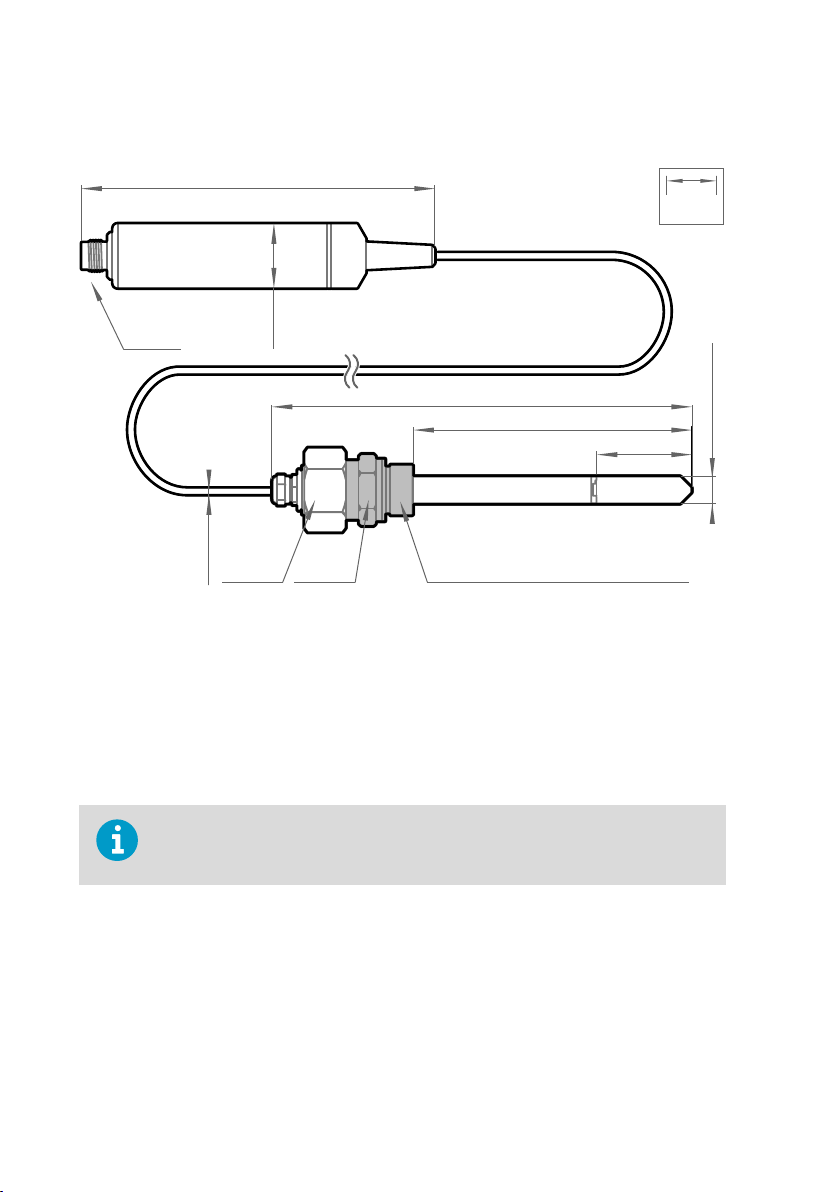

3.5 HMP8 probe

Figure 8 HMP8 probe dimensions

Vaisala HUMICAPâ Humidity and Temperature Probe HMP8 is designed for pressurized

applications in compressed air systems, refrigerant dryers, and other pressurized industrial

applications, where easy insertion and removal of the probe and adjustable installation depth

into the pipeline are needed.

• Temperature measurement range −70 … +180 °C (−94 … +356 °F)

• Operating temperature of probe body −40 … +80 °C (−40 … +176 °F)

• Operating pressure 0 … 4 MPa (0 … 40 bar)

• Probe installation depth can be freely adjusted and probe can be hot-swapped from

pressurized pipelines with an installation valve

• ISO1/2" or NPT1/2" fitting body

19

Page 22

G1/2

ISO 228/1

Ø21.5 (drilling)

Ø14

Ø14

Ø14

2

3

4

5

1

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

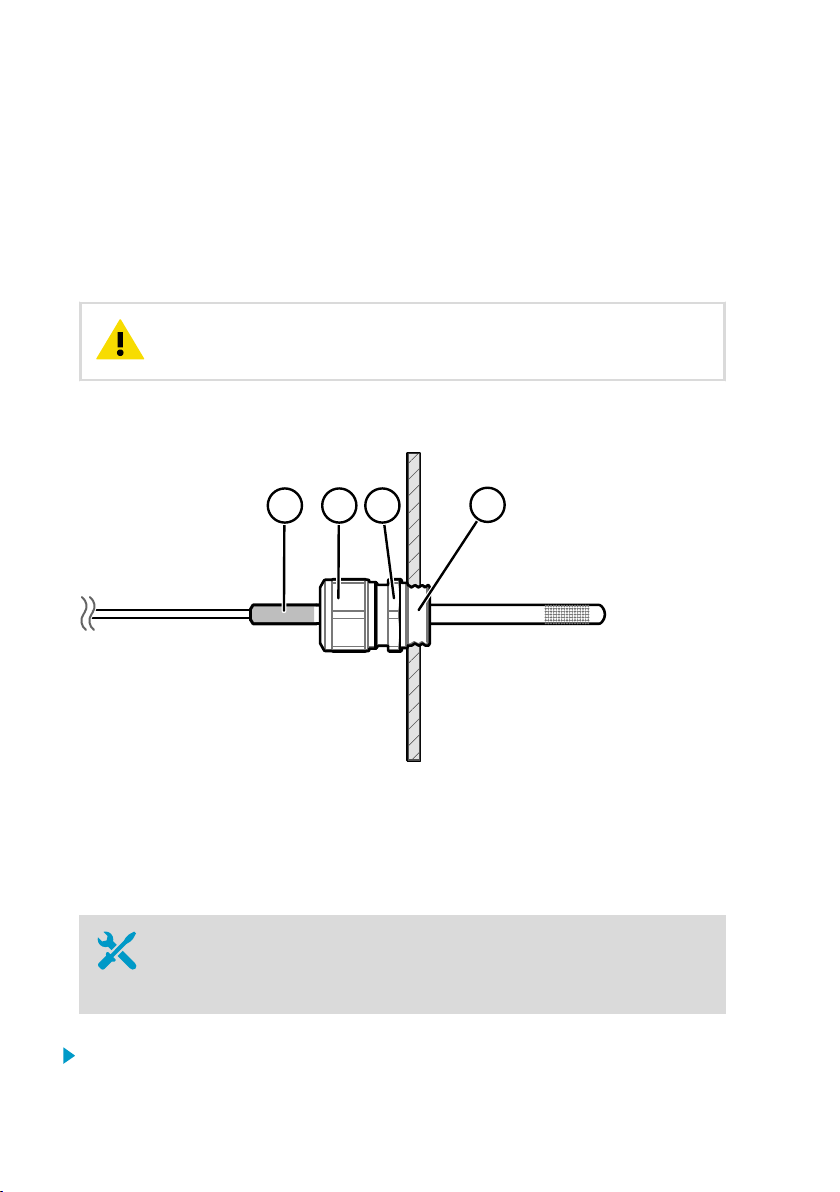

3.5.1 Attaching ball valve kit to process

1 Ball valve handle: must point to the same direction as the ball valve body when installing.

2 Extension nipple, threads G1/2 ISO228/1 and R1/2 ISO7/1.

3 Ball valve body. When tightening the assembly, turn only from the ball valve body.

4 Ball of the ball valve.

5 Welding joint, threads R1/2 ISO7/1.

20

Page 23

mm

[in]

112 [4.41]

Probe cable 2 m [6.56 ft]

Ø 25

[0.98]

M12/5

94 [3.70]

Ø 2.4

[0.094]

Ø 5 ±0.05

[0.20 ±0.002]

16 [0.63]

Attachment point

Chapter 3 – Installation

1. Attach the welding joint to the process pipe or chamber.

2. Apply a sealant (MEGA-PIPE EXTRA No. 7188 or LOCTITEâ No. 542 with activator No.

7649) on the threads of the welding joint and screw the bottom of the ball valve onto the

welding joint.

3. Tighten the ball valve assembly by turning from the ball valve body.

CAUTION!

can break the sealing. Tighten the ball valve assembly only from the ball

valve body.

4. If you need to cap the ball valve assembly before installing or after removing the probe,

attach a blanking nut to close the top of the valve.

3.6

HMP9 probe

Tightening the ball valve kit by turning the extension nipple

Figure 9 HMP9 probe dimensions

Vaisala HUMICAPâ Humidity and Temperature Probe HMP9 is designed for easy installation

into rapidly changing environments where fast response time, measurement performance, and

chemical tolerance are essential.

21

Page 24

1 2 3

4

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

The probe head can be mounted through thin metal walls using the included cable gland or

mounting grommet. Two grommets are included: small one for 6.5 mm diameter hole, and

large one for 12.5 mm diameter hole.

You can also attach the probe head directly using a zip tie. The probe head should be attached

from the point near the black plastic part.

• Temperature measurement range −40 … +120 °C (−40 … +248 °F)

• Operating temperature of probe body −40 … +60 °C (−40 … +140 °F)

• Integrated filter (non-replaceable)

CAUTION!

Avoid overtightening when installing the probe head through a cable gland.

Do not damage the probe head by bending, crushing, or striking it.

3.6.1 Installing HMP9 through a cable gland

Figure 10 Installing HMP9 probe head through a cable gland

Black plastic part of the HMP9 probe head

1

2 Nut for tightening the probe in place

3 Base of the cable gland

4 M10×1.5 threads of the cable gland

• M10×1.5 cable gland (included with HMP9 probe)

• Drill with 8.5 mm bit

• M10×1.5 threading tap

• 13 mm wrench

1. Drill a 8.5 mm diameter hole in the installation location.

22

Page 25

136 [5.35]

Probe cable 2 m [6.56 ft]

Ø 25

[0.98]

M12/5

Ø 5

[0.2]

mm

[in]

262 [10.32]

224 [8.82]

35 ... 179 [1.37 ... 7.05]

35 [1.37]

Ø 13.5

[0.53]

Fitting body

ISO1/2” or NPT1/2”

Ø 12

[0.47]

Chapter 3 – Installation

2. Use a threading tap to create a M10×1.5 thread in the hole.

3. Install the base of the cable gland in the hole and tighten with a 13 mm wrench.

4. Insert the seal of the cable gland in the base and place the nut of the cable gland over the

probe head.

5. Insert the probe head in the cable gland up to the black plastic part of the probe head.

Leave the black plastic part entirely outside the cable gland. Tighten the cable gland to

finger tightness.

6. Tighten the nut of the cable gland with a 13 mm wrench until the probe head stops

moving. Do not overtighten.

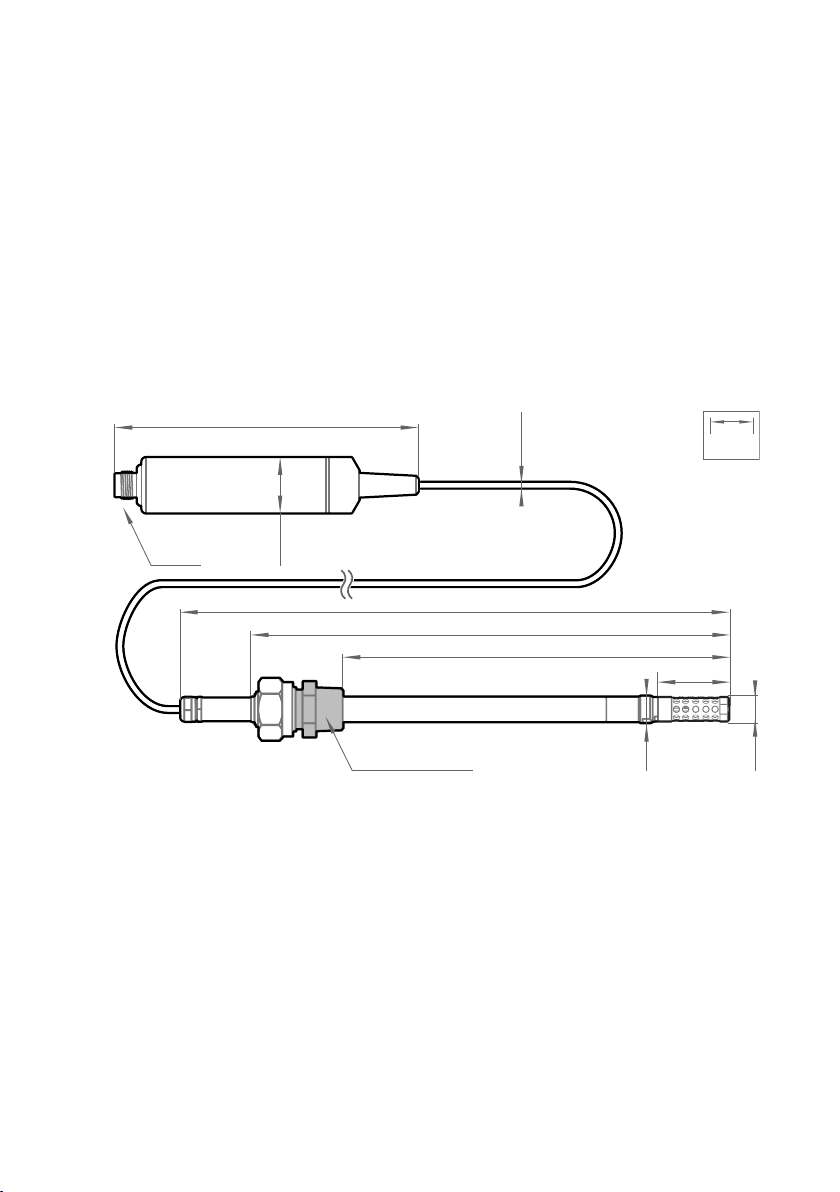

3.7 MMP8 probe

Figure 11 MMP8 dimensions

Vaisala HUMICAPâ Moisture in Oil Probe MMP8 enables fast and reliable measurement of

moisture in oil. It uses proven Vaisala HUMICAPâ sensor that was developed for demanding

dissolved moisture measurements in transformer and lubrication oils, hydraulic fluids, and

other liquids.

MMP8 measures dissolved moisture in oil in terms of the water activity (aw), relative saturation

(%RS), and temperature (T). Water activity or relative saturation indicate directly whether

there is a risk of free water formation. This data is relevant in lubrication oil applications where

detecting water ingress and preventing free water formation is crucial. The measurement is

independent of oil type and age.

23

Page 26

130 [5.12]

Ø 6

[0.24]

136 [5.35]

Ø 25

[0.98]

M12/5

Ø 3.2

[0.13]

mm

[in]

Probe cable

2 m [6.56 ft] or 10 m [32.8 ft]

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

MMP8 can also output ppm, the average mass concentration of water in oil. Vaisala has this

conversion readily available for specific oils, including mineral transformer oil. This allows

continuous measurement of ppm concentration in power transformer condition monitoring.

• Temperature measurement range −40 … +180 °C (−40 … +356 °F)

When installed with the ball valve kit, the MMP8 is ideal for installation into processes where

the probe needs to be installed or removed while the process is running. Probe installation

depth is adjustable. Pressure fitting options are ISO 1/2" and NPT 1/2". MMP8 is delivered with

a manual pressing handle that allows the probe to be pushed against process pressure.

For installation instructions of the ball valve see Attaching ball valve kit to process (page 20).

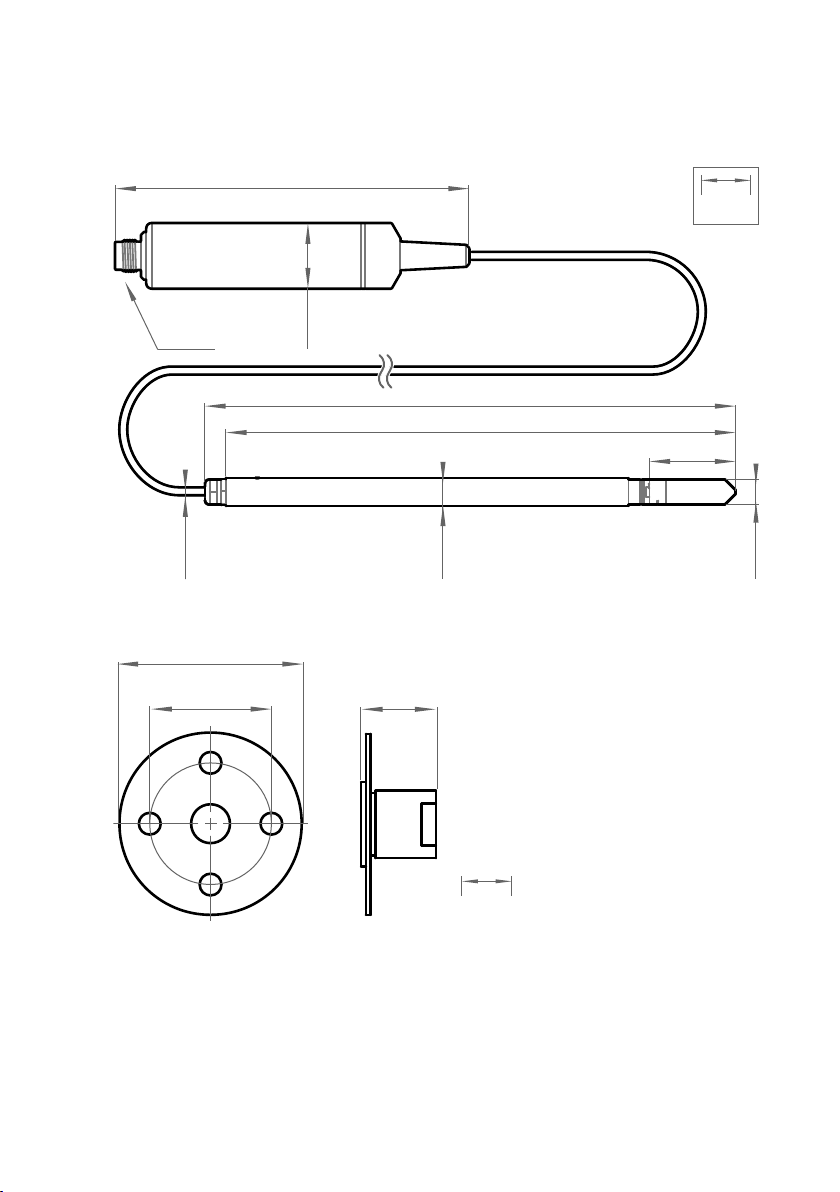

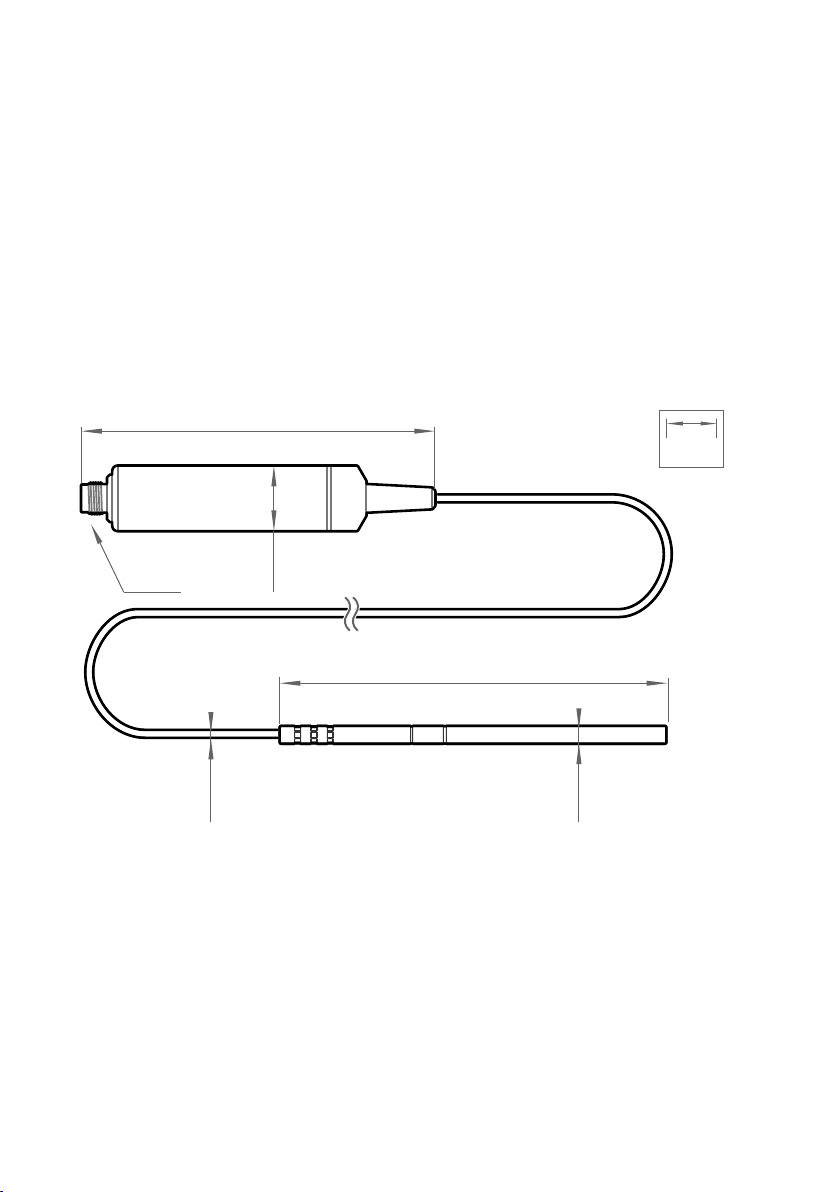

3.8 TMP1 probe

Figure 12 TMP1 probe dimensions

Vaisala Temperature Probe TMP1 is designed for demanding temperature measurements in

industrial applications such as pharmaceutical industry and calibration laboratories, where

accuracy and robustness are essential.

• Temperature measurement range −70 … +180 °C (−94 … +356 °F)

• Operating temperature of probe body −40 … +80 °C (−40 … +176 °F)

24

Page 27

1

534

2

RS-485 host

DC power supply

RS-485 +

RS-485 -

RS-485 common

+

-

Pin #1

Power supply

Pin #2

RS-485 -

Pin #3

Power GND

RS-485 common

Pin #4

RS-485 +

Pin #5

Probe

Chapter 3 – Installation

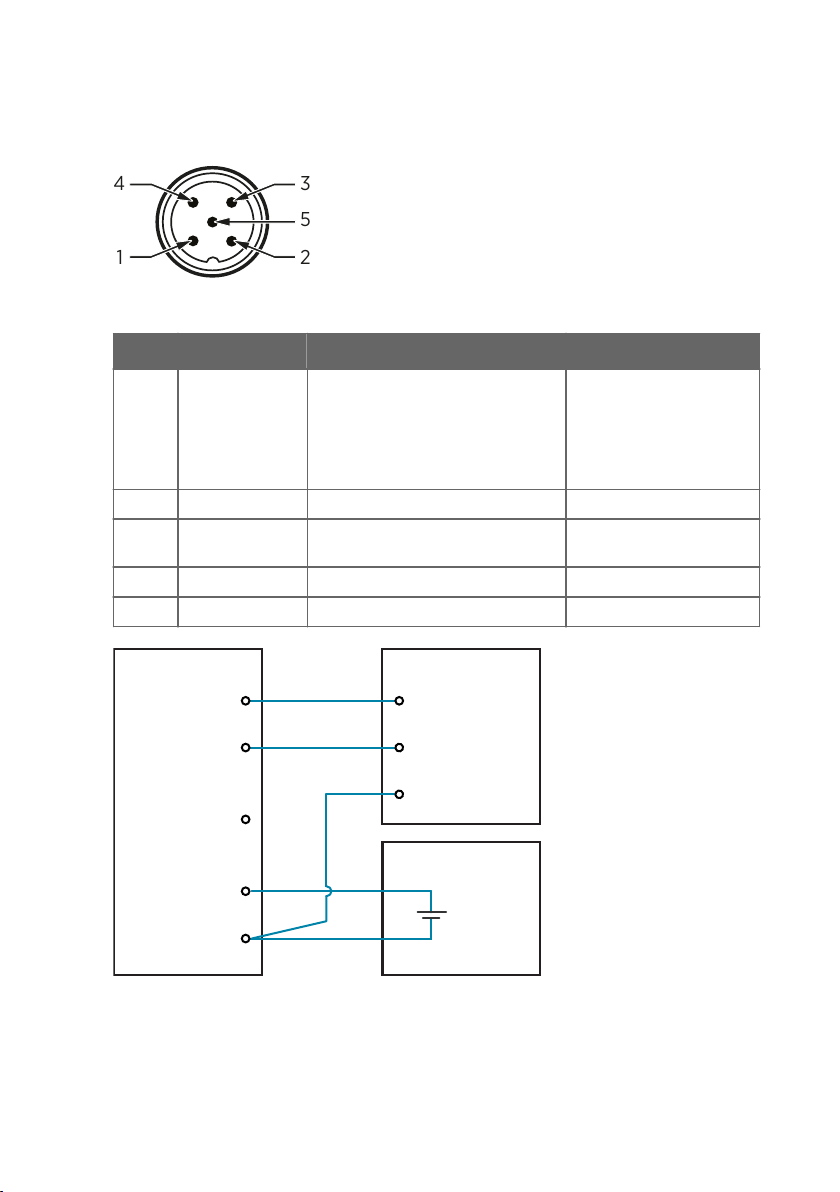

3.9 Wiring

Figure 13 M12 5-pin A-coded male connector pinout

Pin # Function Notes Wire colors in Vaisala cables

1 Power supply Operating voltage:

• HMP7: 18 ... 30 VDC

• Other models: 15 ... 30 VDC

Current consumption: 10 mA typical,

500 mA max.

2 RS-485 - White

3 Power GND and

Blue

RS-485 common

4 RS-485 + Black

5 Not connected Gray

Brown

Figure 14 RS-485 wiring

25

Page 28

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

Recommended maximum length of the RS-485 line is 30 m (98 ft).

26

Page 29

Chapter 4 – Configuration with Insight software

4. Configuration with Insight software

4.1 Vaisala Insight software

Vaisala Insight software is a configuration software for Indigo-compatible devices. With the

Insight software, you can:

• See probe information and status

• See real-time measurement

• Record data up to 48 hours and export in CSV format

• Calibrate and adjust the probe

• Configure probe features such as measurement filtering, chemical purge, heating, and

serial communication

Microsoft Windowsâ operating system and Vaisala USB cable (no. 242659) required.

Download Vaisala Insight software at www.vaisala.com/insight.

4.2

Installing driver for the USB service cable

Only Windowsâ operating systems are supported by the driver of the USB

service cable.

1. Connect the USB service cable to a USB port on your computer. Windowsâ detects the

new device and installs the appropriate driver.

2. Open Devices and Printers from the Windowsâ Start menu. Use search to find it if

necessary (search for "devices").

27

Page 30

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

3. Locate the cable in the list of devices:

• If the device is listed as Vaisala USB Device with a COM port number in brackets, the

cable is ready for use. Note the COM port number, you will need it later.

• If the device is listed as Vaisala USB Instrument Cable without a COM port number

listed, you must install the driver manually.

4. To install the driver manually:

a. Disconnect the USB service cable from the computer.

b. Download the Vaisala USB driver at http://www.vaisala.com/software (select the

appropriate USB Instrument Driver Setup for your cable).

c. Run the USB driver installation program Vaisala USB Device Driver

Setup.exe. Accept the installation defaults.

d. Go back to step 1 and verify that the driver installation works as expected.

4.3

Connecting to Insight software

• Computer with Microsoft Windowsâ operating system and Vaisala Insight

software installed

• USB connection cable (no. 242659)

CAUTION!

computer may not be able to supply enough power through its USB ports. Use

an externally powered USB hub that can supply >2 W for each port.

28

When connecting several devices at the same time, note that your

Page 31

Chapter 4 – Configuration with Insight software

Figure 15 Connecting probe to Insight

1. Open Insight software.

2. Connect the USB cable to a free USB port on the PC or USB hub.

3. Connect the probe to the USB cable.

4. Wait for Insight software to detect the probe.

4.4

Configuration options

Select > Configure Device to access configuration options in Insight software.

Available configuration options include all of the Modbus configuration registers (see

Configuration registers (page 82)) and several additional options. Insight software is the

recommended way to change the probe configuration.

You can restore the probe back to its default settings using the Factory Default

Settings > Restore Settings function. Doing this will also clear any user

adjustment and restore the latest factory calibration.

29

Page 32

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

Figure 16 HMP5 in Insight software

30

Page 33

1

2

3

4

5

6

Chapter 5 – Using probe with Indigo transmitters

5. Using probe with Indigo transmitters

5.1 Indigo 200 series transmitter overview

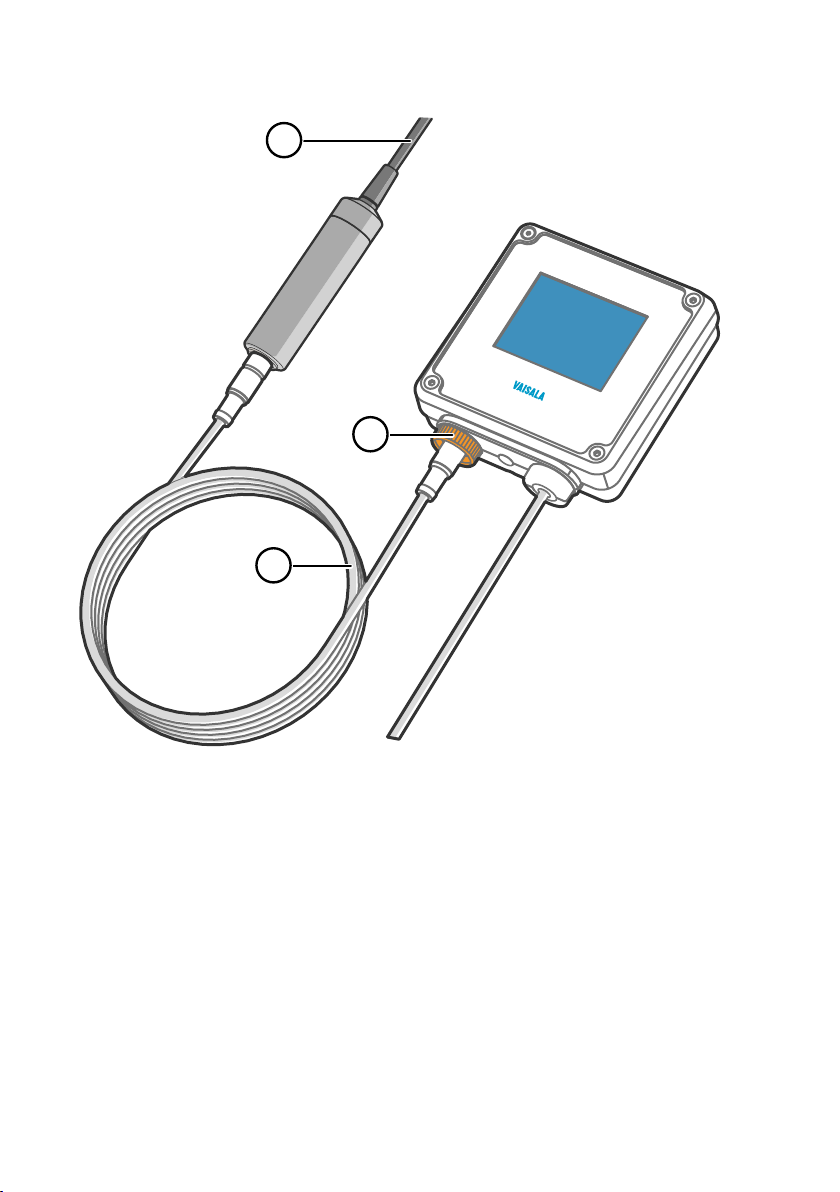

Figure 17 HMP7 attached to Indigo 200 series transmitter

3.5” TFT LCD color display: non-display option with LED available for certain models

1

2 Locking wheel: insert probe, hold in place, and turn the wheel counterclockwise

3 Cable to probe head

4 Wireless configuration interface (WLAN) activation button

5 Rubber lead-through with strain relief. Cable feedthrough option also at back of

transmitter.

6 Input/output cable

31

Page 34

1

2

3

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

Figure 18 HMP7 attached to Indigo 200 series transmitter with a cable

Cable to probe head

1

2 Locking wheel: insert cable, hold in place, and turn the wheel counterclockwise

3 Connection cable

The probe can be connected to Vaisala Indigo transmitters, either directly on the transmitter

from the probe's connector, or by using a cable between Indigo and the probe.

Indigo transmitters are host devices that extend the feature set of connected probes with a

range of additional options for outputs, configuration access, measurement viewing, and

status monitoring.

The selection of available additional features (for example, output and connectivity options)

varies depending on the Indigo transmitter model. Depending on the model, a display is

available as an optional selection or as a standard feature. In the non-display model, an LED

indicator is used for notifications.

32

Page 35

Chapter 5 – Using probe with Indigo transmitters

5.2 Attaching probe to Indigo 200 series transmitter

Figure 19 Attaching the probe to Indigo 200 series transmitter

1. Insert the probe or the connection cable into the transmitter's connector. Use of

connection cable is recommended for strain relief.

2. Turn the locking wheel of the transmitter to lock the probe or cable in place.

Do not turn the probe or the cable itself, as that will damage the connectors.

3. If you are using a connection cable, connect the probe to the cable.

4. When the transmitter recognizes the connected probe, it shows a notification message on

the display.

33

Page 36

19.75

%RH

RH

-3.50

°C

T

19.88

°C

T

WLAN is activated

Indigo 201

d/f

Select WLAN to connect to:

1. WLAN XYZ

3. WLAN ABC

2. Indigo_ID[xx]

1 2 3

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

5.3 Wireless configuration interface overview

The wireless configuration interface has two user levels:

• All users have view-only access (no configuration rights, not password protected).

• Personnel that carry out configuration tasks can log in with an administrative password

that allows changing the transmitter and probe settings.

To use the wireless configuration interface to modify the settings of your Indigo transmitter

and the connected probe, you must first enable the transmitter's wireless connection and then

connect to Indigo with your mobile device or computer. Most major browsers (for example,

Firefox, Chrome, Safari, and Internet Explorer) are supported: using the most recent version is

recommended.

5.4 Connecting to wireless configuration interface

Figure 20 Enabling and accessing wireless configuration interface of Indigo 200

Wireless connection activation button

1

2 Wireless connection indicator (WLAN symbol) on the Indigo display

3 Choose Indigo (Indigo_ID[xx]) from your wireless device's list of available connections

34

Page 37

Chapter 5 – Using probe with Indigo transmitters

5.5 Logging in to wireless configuration interface

Figure 21 Indigo login view

When you open Indigo's wireless configuration interface in your browser, you are prompted to

log in. There are 2 available user levels:

• User: view-only access available for all users. Does not require a password.

• Admin: password-protected access. To change settings, you must log in as admin.

To log in:

1. Enter the user name and password:

a. To log in as user (view-only access, no configuration rights), select User from the

User name dropdown. Leave the Password field empty.

b. To log in as admin (required for configuration), select Admin in the User name

dropdown and type the admin password (default: 12345) in the Password field.

2. Select Log in after entering the login credentials. The wireless configuration interface

opens in the Measurements view.

The user level (User or Admin) is shown in the upper right corner of all menu

views.

Select the user/admin icon in the upper right corner to change the user level.

35

Page 38

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

6. Maintenance

6.1 Cleaning the probe

Do not attempt to clean the sensors under the filter in any way.CAUTION!

Do not spray anything directly on the probe head, since that may deposit

impurities on the sensors.

You can clean the probe, probe body, and cable by wiping them with a soft, lint-free cloth

moistened with water or a suitable cleaning agent, such as isopropyl alcohol. Do not wipe the

filter: wiping the filter may block its pores and/or deposit residue on the filter. If the filter is

heavily contaminated, replace it.

When cleaning, follow these precautions:

• Avoid touching the filter. If you need to touch the filter, always wear clean gloves (cotton,

rubber or similar material). Keep the filter free of any grease or oil.

• Do not scrape the probe or the probe body.

• Do not immerse the probe or the probe body in liquid to clean them.

• Wipe cleaning agents o the probe, probe body, and the cable after cleaning.

After cleaning the probe, it is recommended to perform a chemical purge.

6.1.1 Chemical tolerance

Avoid exposing the probe to cleaning agents for unnecessarily long periods of

time.

Table 4 Suitability of cleaning agents

Cleaning Agent Suitability

Acetone Suitable

Chlorine disinfectants Suitable

Ethanol Suitable

Heptane Suitable

Isopropyl alcohol Suitable

36

Page 39

6.2 Changing the probe filter

• New compatible filter

• Clean lint-free gloves

Chapter 6 – Maintenance

CAUTION!

the probe head carefully.

HMP9 and TMP1 probe models do not have a removable filter.

1. Put on clean gloves before touching the filter.

2. Turn the filter counter-clockwise to loosen it.

3. Remove the filter from the probe head. Be careful not to touch the sensors with the filter.

4. Install a new filter on the probe head. Tighten the filter properly (recommended force

5 Nm).

6.3

Replacing the HUMICAP R2 sensor

• New HUMICAPâ R2 sensor

• New compatible filter

• Clean lint-free gloves

• 11.3 %RH and 75.5 %RH humidity references (using Vaisala HMK15 Humidity

Calibrator)

• Computer with Microsoft Windowsâ operating system and Vaisala Insight

software installed

• USB connection cable (no. 242659)

Sensors are easily damaged when the filter is not in place. Handle

Follow this procedure to replace a HUMICAPâ R2 humidity sensor it has been damaged, or

normal adjustment is not sucient to restore the humidity measurement accuracy. It is

recommended that you replace the filter at the same time. The procedure includes a special 2point adjustment of humidity measurement using Insight PC software. This adjustment must

be done every time after the HUMICAPâ R2 sensor has been replaced.

37

Page 40

2

1

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

CAUTION!

user. Other humidity sensor types available for HMP series probes are composite

sensors where the humidity sensor and temperature sensor are permanently

attached together. If you need to replace a composite sensor, contact a Vaisala

Service Center.

CAUTION!

the probe head carefully.

CAUTION!

entered in this procedure. If you need to revert the probe to factory settings

after replacing the sensor yourself, write down the values on the Adjustment

data page beforehand, and enter them again after applying the factory settings.

Only the HUMICAPâ R2 sensor is designed to be replaced by the

Sensors are easily damaged when the filter is not in place. Handle

Reverting the probe to factory settings clears the adjustment values

Figure 22 HMP3 probe head with filter removed

Pt100 temperature sensor

1

2 HUMICAPâ R2 humidity sensor

1. Put on clean gloves before touching the filter.

2. Turn the filter counter-clockwise to loosen it.

3. Remove the filter from the probe head. Be careful not to touch the sensors with the filter.

4. There are two sensors under the filter, the HUMICAPâ sensor and a temperature sensor.

Identify the HUMICAPâ sensor and make sure it is of the R2 type (temperature sensor not

attached to it).

38

Page 41

5. Pull out the old HUMICAPâ R2 sensor and insert the new one.

Chapter 6 – Maintenance

CAUTION!

sensor element in the middle of the sensor. Do not touch the temperature

sensor.

6. Open Insight software.

7. Select Settings > Advanced Mode.

8. Connect the probe to Insight. See Connecting to Insight software (page 28).

9. Select

10. Select Adjustment data.

11. Adjust the 11.3 %RH point (dry end):

12. Adjust the 75.5 %RH point (wet end):

13. Click outside the table to commit the adjustment.

14. Remove the probe head from the calibration reference and install a new filter. Tighten the

filter properly (recommended force 5 Nm).

15. Select the Calibration information tab and update the Calibration date and Calibration

text.

16. Select Close > Yes to exit the calibration mode.

> Calibrate > Yes to switch the probe to calibration mode.

a. Insert the probe head in the 11.3 %RH reference.

b. Wait for the measurement to stabilize fully.

c. Click table cell A1 under RH adjustment data and enter the value of the humidity

reference (11.3).

d. Click table cell B1 and enter the %RH measured by the probe.

a. Insert the probe head in the 75.5 %RH reference.

b. Wait for the measurement to stabilize fully.

c. Click table cell A2 and enter the value of the humidity reference (75.5).

d. Click table cell B2 and enter the %RH measured by the probe.

Handle the new sensor by the plastic frame. Do not touch the

6.4

Calibration and adjustment

The probe is fully calibrated and adjusted as shipped from the factory. To maintain the

accuracy of the measurement, calibrate and adjust the probe as needed. Typical calibration

interval is one year, but depending on the application it may be necessary to check the

accuracy more frequently.

When adjustment is necessary, you can have Vaisala calibrate and adjust the probe. To order

calibration services from Vaisala, visit store.vaisala.com. You can also do the adjustment

yourself using the Insight software.

39

Page 42

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

WARNING!

has not been exposed to dangerous contamination, and is safe to handle

without special precautions.

If you think the device is not measuring correctly, calibration and adjustment is

not the first thing to do. Check the following first:

• Make sure nothing is interfering with the measurement: heat sources,

temperature dierences, or condensation.

• Check that there is no moisture on the probe. If the sensor has become wet,

wait for it to dry.

• Always wait for the measurement to stabilize.

Calibration means comparing the measurement output of the device to a known

reference, such as a known environment in a calibration chamber or the output of

a reference instrument. Correcting the reading of the device so that it measures

accurately is referred to as adjustment.

When returning a product for calibration or repair, make sure it

6.4.1 Adjustment points and requirements

You can adjust the humidity measurement in 1 ... 5 points, and temperature measurement in 1 ...

2 points. Note the following:

• Humidity adjustment in more than two points is available when using Insight software in

Advanced Mode.

• If you are adjusting in more than one humidity point, make sure the first two points are at

least 10 %RH apart.

• The probe will reject adjustments that are too large, that is, greater than 10 %RH for

humidity and 0.5 °C for temperature. If the probe appears to need such a large correction,

perform a sensor purge and repeat the adjustment procedure. Make sure the

measurement has stabilized and the reference environment is reliable. If the required

adjustment is still too large, the probe needs to be serviced by Vaisala.

40

When adjustment of humidity measurement is necessary, Vaisala recommends

adjusting in two points, 11 %RH and 75 %RH. These humidities can be produced

using the Vaisala HMK15 Humidity Calibrator.

Adjustment of temperature measurement is typically not necessary.

Page 43

Chapter 6 – Maintenance

6.4.2 Adjusting measurement with Insight software

• Computer with Windows operating system and Vaisala Insight software

installed

• Vaisala USB cable 242659 for connecting the probe

• Reference environment(s) for producing the desired humidity and/or

temperature

This procedure can be used to adjust the probe's humidity or temperature measurement. If you

want to adjust both, repeat the procedure.

Because stabilization of temperature and humidity takes time, you should expect the

adjustment procedure to take at least 30 minutes for each adjustment point.

1. Connect the probe to Insight. See Connecting to Insight software (page 28).

2. If you intend to adjust humidity measurement, first select > Purge to perform a

chemical purge to condition the sensor. Wait a few minutes for purge to complete.

3. Select > Calibrate > Yes to switch the probe to calibration mode.

In calibration mode, the device will not use functions that may interfere with calibration

and adjustment.

4. Select the type of adjustment to perform: RH adjustment or T adjustment.

5. Define the needed adjustment for the first measurement point:

a. Insert the probe head in the reference environment for the first calibration point.

b. Wait for the measurement to stabilize fully.

c. Click the Reference value, point 1 text box and enter the reference value of the

calibration point. Press ENTER or click outside the text box when done.

d. The probe automatically enters the measured values for the calibration point.

6. If you want to adjust in more than one point, repeat step 5 for all desired calibration

points.

You can adjust humidity measurement in up to five points when Insight is set

to Advanced mode.

7. Select Activate adjustment > Yes to store the adjustment in the probe.

8. Check the message that appears at the top of the screen. If the message indicates that

the adjustment is activated successfully, your adjustment is stored in the probe.

9. Select the Calibration information tab and update the Calibration date and Calibration

text.

10. Select Close > Yes to exit the calibration mode.

41

Page 44

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

6.4.3 Adjusting measurement with Indigo 200 transmitter

• Indigo 200 transmitter

• Reference environment(s) for producing the desired humidity and/or

temperature (see Adjustment points and requirements (page 40) for more

information)

• Mobile device or computer with an internet browser and a Wi-Fi connection

• Connection cable for connecting the probe to Indigo 200 transmitter

(optional)

This procedure can be used to adjust the humidity or temperature measurement of an Indigocompatible HMP or TMP-series probe. Because stabilization of temperature and humidity takes

time, you should expect the adjustment procedure to take at least 30 minutes for each

adjustment point.

This procedure assumes the Indigo 200 transmitter is powered on and the probe

is connected to it. Refer to the user guide of your Indigo 200 transmitter model

for instructions on connecting probes. The user guide also provides more detailed

instructions for operating and troubleshooting the wireless connection.

1. Connect to the wireless configuration interface of the Indigo 200 transmitter:

a. Press the wireless connection activation button on the bottom of the transmitter.

b. Open the wireless connection menu in your mobile device or computer and select

Indigo_ID[xx] (transmitter-specific SSID) from the list of available connections.

c. If the wireless configuration interface does not launch automatically on your device,

start your browser application manually and navigate to address 192.168.1.1.

d. Log in to the interface:

• User name: Admin

• Password: 12345 (default)

42

Stay close to the transmitter for a strong wireless signal and the possibility to

read on-screen messages from the transmitter's display (display models

only). Starting with Indigo 200 firmware version 1.4.0, messages from the

probe are also shown through the wireless configuration interface.

Page 45

Chapter 6 – Maintenance

2. To adjust humidity measurement:

a. If your probe supports the chemical purge feature, wait for the start-up purge to

finish or start the purge manually from Calibration > Configuration > Purge.

Measurement will be frozen for the duration of the purge. Continue when the

measured values are changing again.

b. Select the Calibration tab and select Start calibration to start the calibration mode.

c. In the RH adjustment section of the page, select Restore factory adjustment to

remove any existing non-factory adjustments.

d. Insert the probe head in the reference environment for RH adjustment point 1 (dry

point, recommendation 0 … 35 %RH).

e. Wait for the RH and temperature measurements to stabilize fully. This may take more

than 30 minutes. Monitor the readings to see when the measurement has stabilized.

f. Enter the value of the first reference into the Reference value, point 1 field. Select

outside the text box when done. The probe automatically enters the measured values

for the calibration point.

g. If you want to adjust humidity measurement in two points, repeat steps

step 2.d … step 2.f for RH adjustment point 2 (wet point, recommendation

65 … 85 %RH).

h. Select Activate adjustment to store the adjustment in the probe.

When the adjustment is successful, the fields for reference and measured

values are cleared. The message %0 adjustment activated successfully.

appears on the local display (display models only).

If the adjustment fails, the fields are not cleared. A message on the

transmitter's display will indicate the reason. For example, if the humidity

adjustment would be over the maximum 10 %RH allowed by the probe,

the message Cumulative adjustment too large. appears on the local

display.

43

Page 46

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

Figure 23 Calibration page in the Indigo 200 wireless configuration interface

44

Page 47

Chapter 6 – Maintenance

3. To adjust temperature measurement:

a. If you did not adjust humidity measurement, select the Calibration tab and select

Start calibration to start the calibration mode.

b. In the T adjustment section of the page, select Restore factory adjustment to remove

any existing non-factory adjustments.

c. Insert the probe head in the reference environment for T adjustment point 1.

d. Wait for temperature measurement to stabilize fully. This may take more than 30

minutes. Monitor the reading to see when the measurement has stabilized.

e. Enter the value of the first reference into the Reference value, point 1 field. Select

outside the text box when done. The probe automatically enters the measured value

for the adjustment point.

f. If you want to adjust temperature measurement in two points, repeat steps

step 3.c … step 3.f for T adjustment point 2.

g. Select Activate adjustment to store the adjustment in the probe.

4. In the Calibration information section of the page, update the Calibration date and

Calibration text fields.

5. Select Stop calibration to end the calibration mode.

45

Page 48

HMP3, HMP4, HMP5, HMP7, HMP8, HMP9, MMP8, TMP1 User Guide M212022EN-D

7. Troubleshooting

7.1 Problem situations

Table 5 Troubleshooting table

Problem Possible cause Solution

Measurement output seems

incorrect

Probe status indicator LED is

red

Values of measurement

parameters stop changing for a

few minutes

Installation location is not

representative of actual

conditions you want to

measure

Heat conduction along probe

head and cable is interfering

with measurement accuracy

Probe is in need of adjustment Calibrate and adjust the probe.

Probe is in error state Connect the probe to Insight

Probe is performing a sensor

heating function such as

chemical purge or waiting for

the sensor to cool down

Verify the installation location

and relocate the probe if

necessary.

Follow the installation

recommendations for cases

when temperature of measured

environment diers greatly

from ambient. See Installation

(page 14).

See Calibration and adjustment

(page 39).

software or an Indigo

transmitter and read the error

message(s). See Vaisala Insight

software (page 27) and Error

messages (page 46).

Wait for the function to

complete and measurement

parameters to be available

again

7.2 Error messages

The error messages are categorized according to the severity of the status:

• Critical errors are fatal to the operation of the device. It may not be able to respond to

communication at all, and will not measure correctly.

• Errors prevent normal operation of the device. Depending on the problem, errors may

resolve themselves. For example, a completely wet humidity sensor may cause a humidity

measurement error.

• Warnings do not prevent normal operation but may indicate possible problems.

• Status indicates a known state of the unit.

46

Page 49

Chapter 7 – Troubleshooting

Error message Description Recommended action

Critical errors

Firmware checksum mismatch Firmware is corrupted Contact Vaisala technical

Factory default settings

corrupted

Parameter memory is

corrupted

support

Main configuration settings

corrupted

Additional configuration

settings corrupted

Device settings corrupted

Sensor coecients corrupted

Non-volatile memory read

Hardware fault

write failure

Errors

Temperature measurement

error

Humidity measurement error

Humidity sensor failure

Readings from sensors missing

or out of range

Inspect probe head and

sensors visually. If the probe is

completely wet, allow it to dry

out.

If the sensors are damaged or

missing and the error

message(s) stay active, contact

Vaisala to have the probe

repaired.