Page 1

M211861EN-A

User Guide

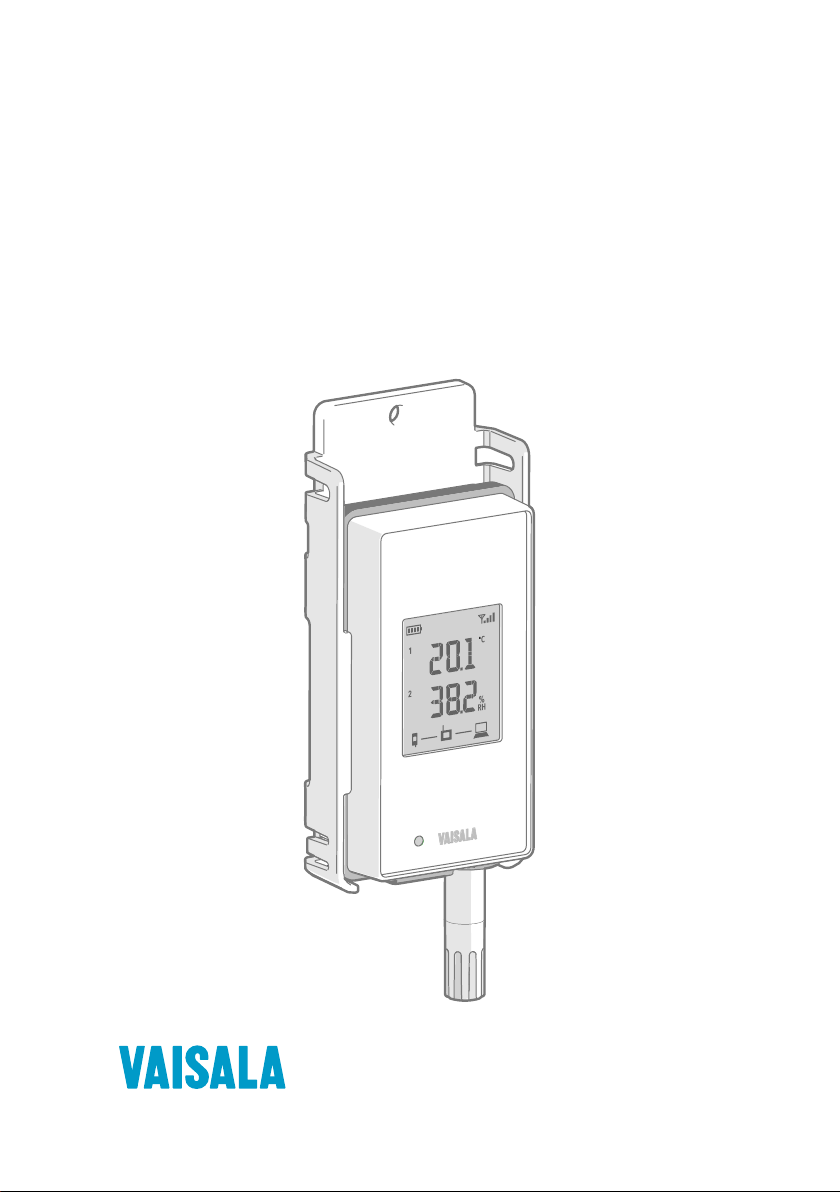

Vaisala VaiNet Wireless Humidity and

Temperature Data Logger

RFL100

Page 2

PUBLISHED BY

Vaisala Oyj

Street address: Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

Mailing address: P.O. Box 26, FI-00421 Helsinki, Finland

Phone: +358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala 2018

No part of this manual may be

reproduced, published or publicly

displayed in any form or by any

means, electronic or mechanical

(including photocopying), nor

may its contents be modified,

translated, adapted, sold or

disclosed to a third party without

prior written permission of the

copyright holder. Translated

manuals and translated portions

of multilingual documents are

based on the original English

versions. In ambiguous cases, the

English versions are applicable,

not the translations.

The contents of this manual are

subject to change without prior

notice.

Local rules and regulations may

vary and they shall take

precedence over the information

contained in this manual. Vaisala

makes no representations on this

manual’s compliance with the

local rules and regulations

applicable at any given time, and

hereby disclaims any and all

responsibilities related thereto.

This manual does not create any

legally binding obligations for

Vaisala towards customers or end

users. All legally binding

obligations and agreements are

included exclusively in the

applicable supply contract or the

General Conditions of Sale and

General Conditions of Service of

Vaisala.

This product contains software

developed by Vaisala or third

parties. Use of the software is

governed by license terms and

conditions included in the

applicable supply contract or, in

the absence of separate license

terms and conditions, by the

General License Conditions of

Vaisala Group.

This product may contain open

source software (OSS)

components. In the event this

product contains OSS

components, then such OSS is

governed by the terms and

conditions of the applicable OSS

licenses, and you are bound by

the terms and conditions of such

licenses in connection with your

use and distribution of the OSS in

this product. Applicable OSS

licenses are included in the

product itself or provided to you

on any other applicable media,

depending on each individual

product and the product items

delivered to you.

Page 3

Table of Contents

Table of Contents

1. About This Document................................................................................... 5

1.1 Version Information..........................................................................................5

1.2 Related Manuals................................................................................................5

1.3 Documentation Conventions...........................................................................5

1.4 Trademarks........................................................................................................ 6

2. Product Overview........................................................................................... 7

2.1 RFL100 Overview..............................................................................................7

2.2 RFL100 Parts..................................................................................................... 8

2.3 RFL100 Batteries.............................................................................................10

2.3.1 Battery Level Indicator............................................................................10

2.4 Alarm Indicators............................................................................................... 11

2.4.1 Alarm Examples........................................................................................12

2.5 Service Port......................................................................................................13

2.6 Delays in a VaiNet Network............................................................................13

2.7 Regulatory Compliance..................................................................................14

2.7.1 FCC Compliance Statement....................................................................14

2.7.2 ISED Compliance Statement...................................................................15

2.7.3 EU Declaration of Conformity.................................................................15

2.8 Safety................................................................................................................ 17

2.9 Symbols in RFL100 Product Markings.......................................................... 17

2.10 ESD Protection.................................................................................................18

3. Installation........................................................................................................19

3.1 Setting Up RFL100 Data Logger....................................................................19

3.2 Mounting RFL100...........................................................................................20

3.3 Connection Indicators....................................................................................22

3.3.1 Connection Examples............................................................................. 23

4. Operation......................................................................................................... 24

4.1 Remote Management.....................................................................................24

4.2 Releasing RFL100 from a viewLinc Monitoring System.............................25

4.3 Speeding Up Radio Scanning Temporarily..................................................26

5. Maintenance....................................................................................................28

5.1 Cleaning RFL100.............................................................................................28

5.2 Changing the Probe Filter............................................................................. 28

5.3 Disconnecting the Probe...............................................................................29

5.4 Connecting the Probe....................................................................................29

5.5 Calibration and Adjustment..........................................................................29

5.5.1 Field Checking Using a Reference Instrument.................................... 30

5.5.2 Calibration and Adjustment Using HM40............................................30

5.5.3 Calibration and Adjustment using MI70...............................................36

5.6 Changing RFL100 Batteries...........................................................................37

5.7 Changing RFL100 Clock Battery...................................................................38

5.8 Updating RFL100 Firmware.......................................................................... 38

1

Page 4

RFL100 User Guide M211861EN-A

6. Troubleshooting............................................................................................40

6.1 Problem Situations........................................................................................ 40

6.2 Error Codes...................................................................................................... 41

6.3 Verifying Operation of RFL100.....................................................................42

6.4 Downloading Data Using Service Port........................................................ 42

7. Technical Data............................................................................................... 44

7.1 RFL100 Technical Specification....................................................................44

7.2 Spare Parts and Accessories.........................................................................48

7.3 RFL100 Dimensions....................................................................................... 49

Technical Support...................................................................................................... 51

Warranty........................................................................................................................ 51

Recycling....................................................................................................................... 51

2

Page 5

List of Figures

Figure 1 Connecting RFL100 to the viewLinc Monitoring System........................ 7

Figure 2 Front and Display...............................................................................................8

Figure 3 Under the Silicone Plug.................................................................................... 8

Figure 4 Rear and Inside................................................................................................... 9

Figure 5 Mounting Bracket...............................................................................................9

Figure 6 Alarm Indicators on RFL100 Display............................................................ 11

Figure 7 RFL100 with High Alarm Active on Channel 1...........................................12

Figure 8 RFL100 with High-High Alarm Active on Channel 1................................12

Figure 9 RFL100 Mounting Methods...........................................................................20

Figure 10 RFL100 Remote Management using viewLinc Enterprise Server...... 24

Figure 11 RFL100 Properties in viewLinc.....................................................................25

Figure 12 RFL100 Data Logger Dimensions with Mounting Bracket...................49

Figure 13 RFL100 Data Logger Dimensions................................................................50

Figure 14 RFL100 Mounting Bracket Dimensions......................................................50

List of Figures

3

Page 6

RFL100 User Guide M211861EN-A

List of Tables

Table 1 Document Versions.............................................................................................5

Table 2 Related Manuals...................................................................................................5

Table 3 Battery Level Indicator.....................................................................................10

Table 4 Alarm Symbols.....................................................................................................11

Table 5 Specifications for a USB Power Supply........................................................13

Table 6 Symbols Used in RFL100 Product Markings...............................................17

Table 7 Symbols................................................................................................................22

Table 8 Connection States.............................................................................................22

Table 9 Troubleshooting Table.....................................................................................40

Table 10 RFL100 Error Codes.......................................................................................... 41

Table 11 Wireless............................................................................................................... 44

Table 12 Memory................................................................................................................44

Table 13 Operating Environment...................................................................................45

Table 14 General.................................................................................................................45

Table 15 Mechanical Specifications.............................................................................. 45

Table 16 HMP110/T Probe Measurement Performance........................................... 46

Table 17 HMP115/T Probe Measurement Performance............................................47

Table 18 RFL100 Spare Parts and Accessories..........................................................48

Table 19 HMP110/T Probe Spare Parts and Accessories......................................... 48

Table 20 HMP115/T Probe Spare Parts and Accessories..........................................49

4

Page 7

Chapter 1 – About This Document

1. About This Document

1.1 Version Information

This document provides instructions for installing, using, and maintaining the RFL100 Data

Logger.

Table 1 Document Versions

Document Code Date Description

M211861EN-A May 2018 First version.

1.2 Related Manuals

Table 2 Related Manuals

Document Code Name

M211822EN RFL100 Data Logger Quick Guide

M211821EN AP10 Access Point Quick Guide

M211860EN AP10 Access Point User Guide

M211820EN viewLinc Monitoring System Setup Guide

M211975EN viewLinc Enterprise Server User Guide

1.3 Documentation Conventions

WARNING!

follow instructions carefully at this point, there is a risk of injury or even death.

CAUTION!

follow instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

Warning alerts you to a serious hazard. If you do not read and

Caution warns you of a potential hazard. If you do not read and

5

Page 8

RFL100 User Guide M211861EN-A

Tip gives information for using the product more eciently.

Lists tools needed to perform the task.

Indicates that you need to take some notes during the task.

1.4 Trademarks

Vaisalaâ and HUMICAPâ are registered trademarks of Vaisala Oyj.

The LoRa™ name and associated logo are trademarks of Semtech Corporation or its

subsidiaries.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

6

Page 9

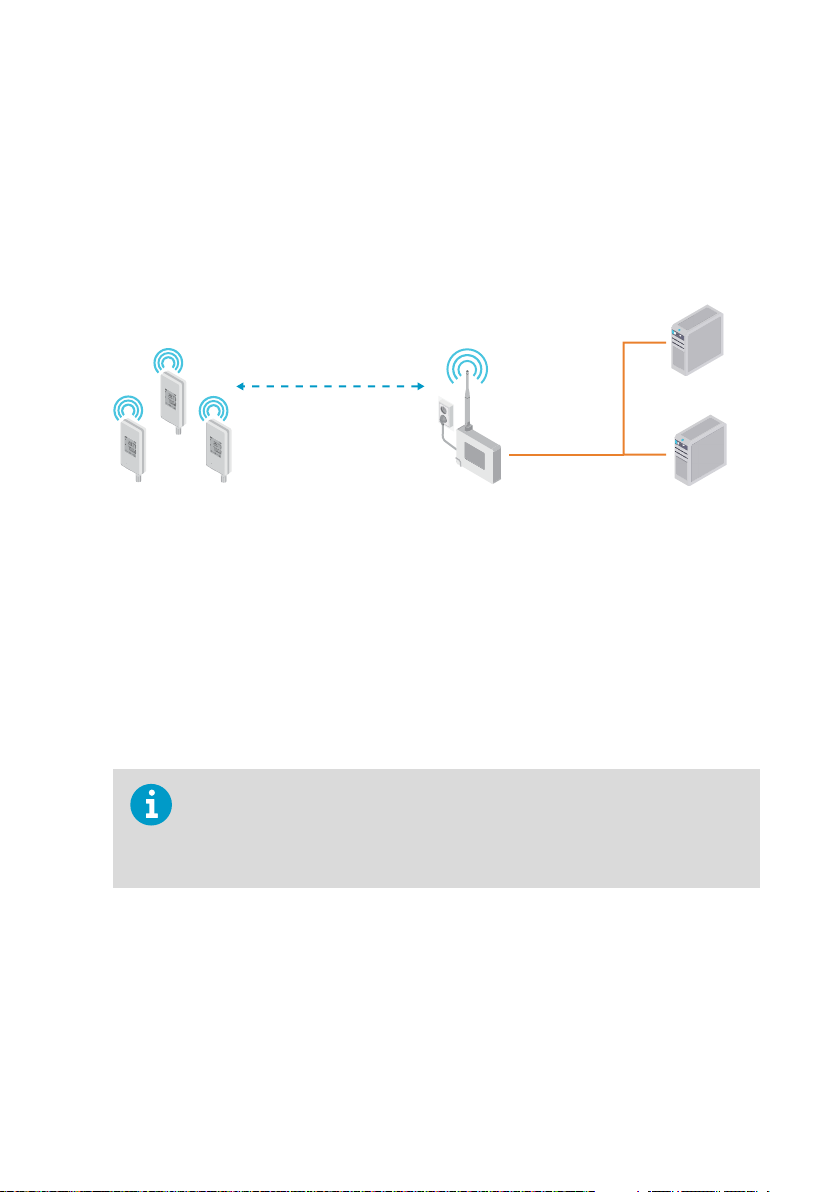

viewLinc

Enterprise Server

AP10

Access Point

RFL100

Data Loggers

VaiNet wireless

>100 m (328 ft) range

NTP Server

Wired

network

Chapter 2 – Product Overview

2. Product Overview

2.1 RFL100 Overview

Vaisala RFL100 Data Logger is a completely wireless, battery powered humidity and

temperature data logger. It is intended as a data collection point in a Vaisala viewLinc

Monitoring System.

Figure 1 Connecting RFL100 to the viewLinc Monitoring System

RFL100 requires a connection to a Vaisala AP10 Access Point. AP10 can connect up to 32

loggers to the viewLinc Monitoring System. In a typical indoor space, install the AP10 within

100 meters of the RFL100. In an open space without many interfering structures, the range

significantly higher.

may be

RFL100 is optimized for low power operation. It reads the probe once a minute, and transmits

measurement data to the access point every four minutes. Because the radio link is not

continuous, remote management actions and system joining status may take some time to be

updated on the display of the data logger.

Before you start installing RFL100 Data Loggers, install the viewLinc Enterprise

Server and at least one AP10 Access Point within range of the RFL100. This way

RFL100 can immediately discover your access point and join your system.

For more information on viewLinc Monitoring System installation, see viewLinc

Setup Guide.

7

Page 10

1

2

3

4

5

6

7

8

1

2

RFL100 User Guide M211861EN-A

2.2 RFL100 Parts

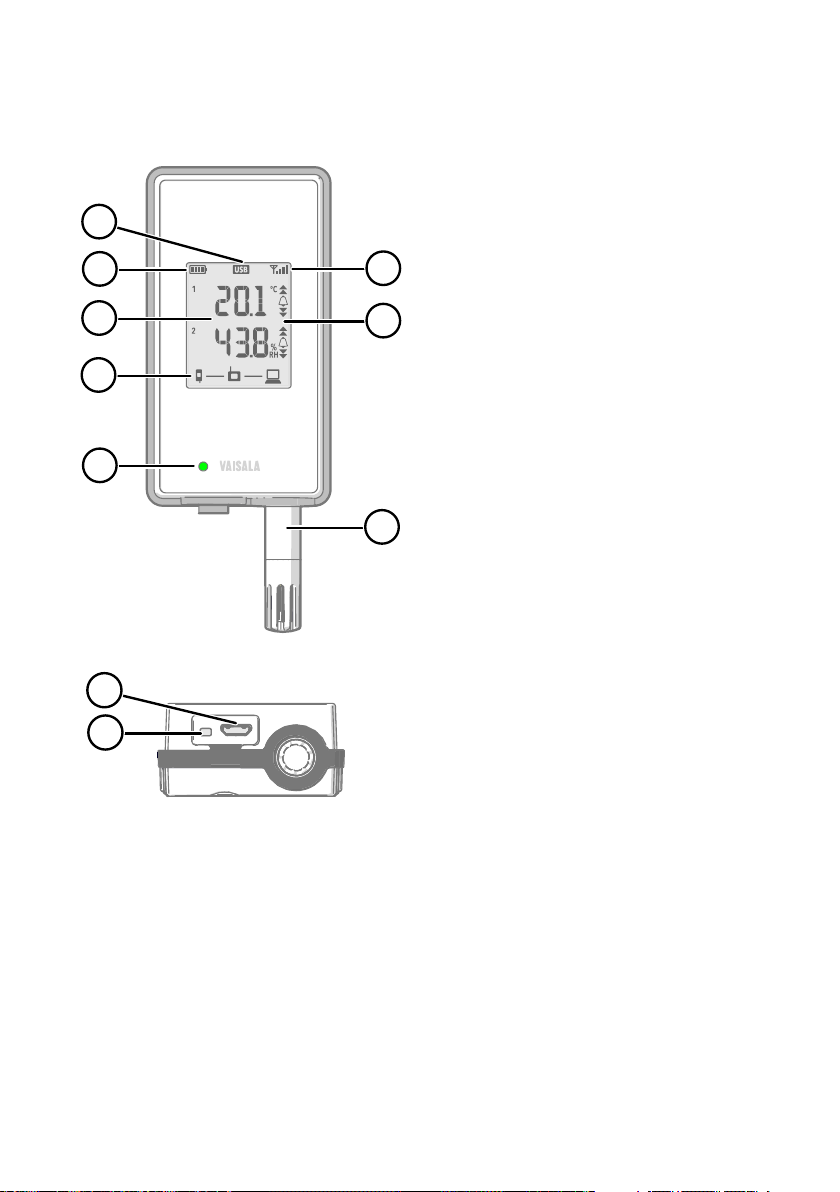

Figure 2 Front and Display

1 Service port connection indicator.

2 Battery level indicator.

3 Currently measured values.

4 Connection indicators.

5 Status LED. Blinks green for normal

operation, red for error or alarm.

6 Signal strength of access point

connection.

7 Alarm indicators. Alarms are

configured in viewLinc Enterprise

Server software.

8 Detachable probe or probe cable.

Figure 3 Under the Silicone Plug

1 Service port (Micro-USB).

2 Refresh button. Push to enable a faster

wireless scanning interval for one hour.

Also wakes up the display if it has

been turned o remotely, and shows

firmware version and currently

connected VaiNet channel.

8

Page 11

1

2

3

4

5

6

7

8

1

2

5

4

3

2

Chapter 2 – Product Overview

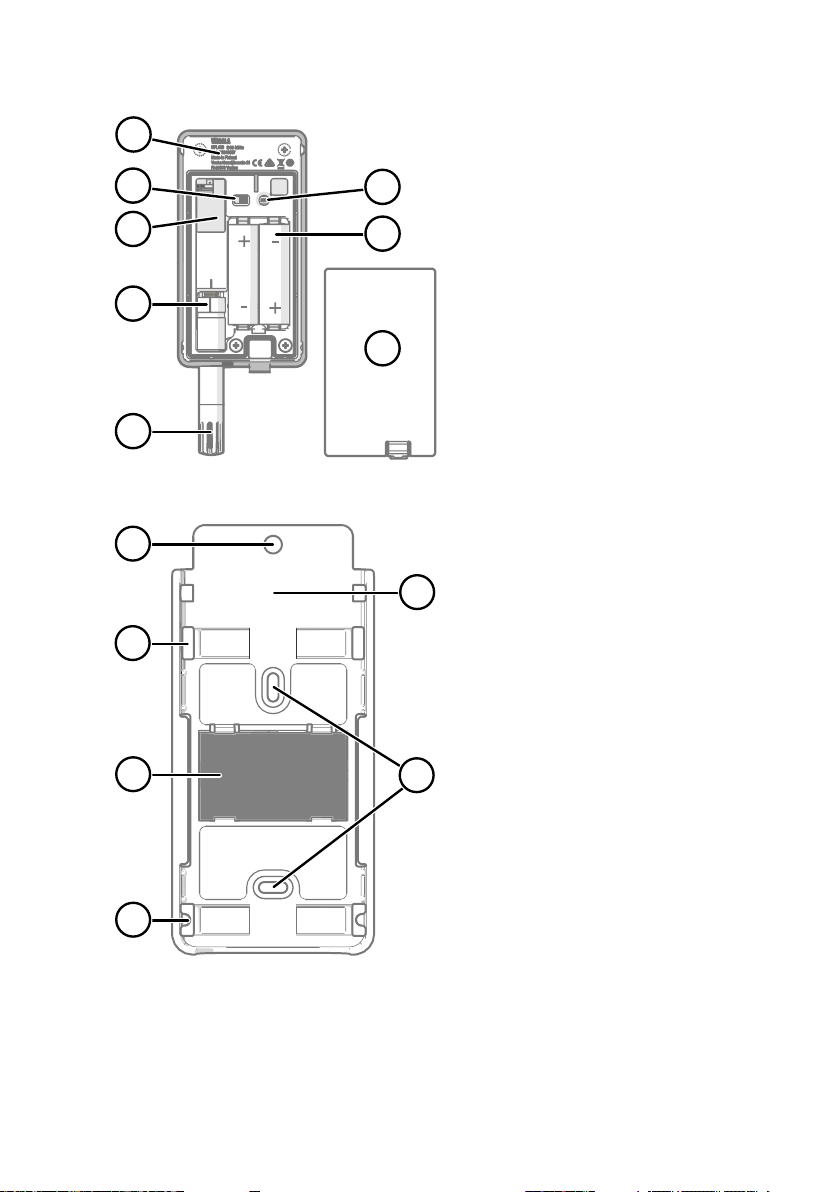

Figure 4 Rear and Inside

1 Type label.

2 On/o switch.

3 Clock battery.

4 Probe orientation mark. When

connecting the probe, line up the

markings on the probe and above the

connector before pushing the probe to

the connector.

5 Humidity and/or temperature sensors

under the filter.

6 Release button. Push to release

RFL100 from its current viewLinc

system, and allow it to connect to any

viewLinc system.

7 Main batteries. Use only non-

rechargeable, AA size, 1.5 V alkaline

(LR6) or lithium (FR6) batteries.

8 Battery cover.

Figure 5 Mounting Bracket

1 6 mm (0.23 inch) hole for hook

mounting.

2 Holes for mounting with zip ties.

3 Strong magnet (in magnetic mounting

bracket only). Handle with care.

4 Suitable area for attaching labels.

5 3.80 mm (0.15 inch) holes for screw

mounting.

9

Page 12

RFL100 User Guide M211861EN-A

2.3 RFL100 Batteries

Main Batteries

RFL100 Data Logger is powered by two AA size primary (non-chargeable) batteries with 1.5 V

nominal voltage. Operation of the data logger always requires that compatible batteries with

sucient voltage are in place. When replacing batteries, always use new batteries, not partially

discharged ones. Minimum battery voltage for operation is 2.15 V in series.

Compatible battery types are:

• 1.5 V alkaline batteries, designation IEC-LR6, ANSI 15A. Standard choice for most

applications.

• 1.5 V lithium batteries, designation IEC-FR14505 (FR6), ANSI 15-LF. Typically higher

capacity, better in cold temperatures.

Do not use batteries with a nominal voltage higher than 1.5 V.CAUTION!

Use of rechargeable batteries is not recommended. RFL100 will not charge

batteries even if the service port is connected to a power supply.

Clock Battery

RFL100 also has a separate 3 V lithium battery (type CR1/3N button cell) to keep the real-time

clock powered when the device is otherwise turned o. This battery is good for 10 years, and

should only be replaced if the data logger gives the low clock battery error.

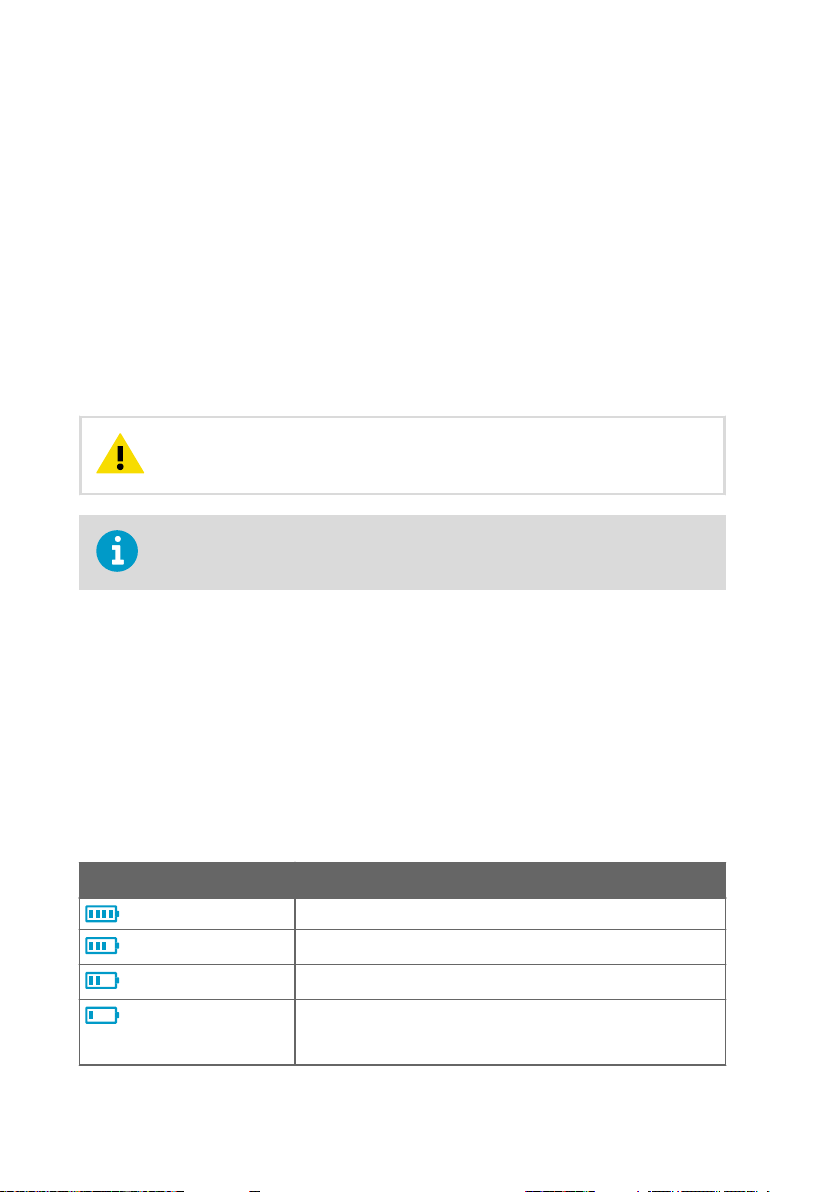

2.3.1 Battery Level Indicator

Battery level indicator displays an estimate of the capacity remaining in the main batteries of

the data logger. It is based on typical behavior of batteries in this application.

Table 3 Battery Level Indicator

Symbol on Display Description

Full batteries.

One quarter of battery capacity used.

Half of the battery capacity used.

Low battery alarm is activated by viewLinc at this level.

Remaining battery capacity is typically enough for 2 … 4 weeks of

normal operation. Replace the batteries.

10

Page 13

Symbol on Display Description

1

2

Battery voltage is too low to support radio communication. Data

logging continues locally for 2 … 4 weeks until device shuts down

completely. Replace batteries immediately.

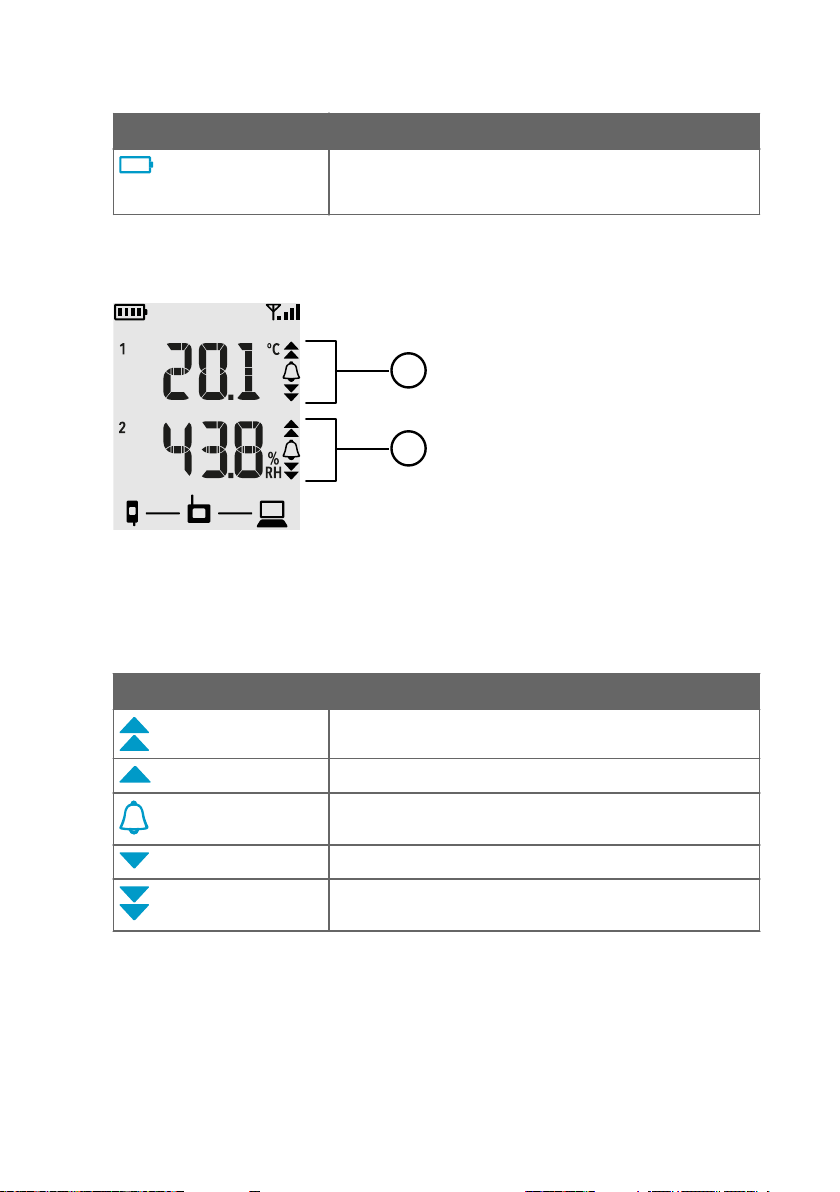

2.4 Alarm Indicators

Figure 6 Alarm Indicators on RFL100 Display

1 Alarm indicators for channel 1

2 Alarm indicators for channel 2

Chapter 2 – Product Overview

Table 4 Alarm Symbols

Symbol on Display Description

High-high threshold alarm active.

High threshold alarm active.

Alarm bell symbol that is always shown when any threshold

alarm is active on this channel.

Low threshold alarm active.

Low-low threshold alarm active.

RFL100 can show active threshold alarms on its local display. When a threshold alarm is active

on RFL100, the appropriate alarm indicators will be shown on the display. Additionally, the LED

flash red for high-high and low-low threshold alarms.

will

11

Page 14

RFL100 User Guide M211861EN-A

Threshold alarms cannot be configured locally on the RFL100 itself; they are configured using

viewLinc Enterprise Server software. When applying a threshold alarm template to a Location,

you can choose to show the alarms on the data logger that is linked to the location. To show

the alarms, enable the Send to device setting, and then enable Alarm on Device for each

threshold that you want to generate an alarm on the RFL100.

On the RFL100, only one set of thresholds can be active at a time for one channel. The latest

set that is pushed to the device replaces the previous one. The Send to device setting of any

previously sent threshold alarm is automatically set to No.

RFL100 does not implement the Alarm Delay and Alarm o margin settings of

viewLinc threshold alarms. Local alarm status on RFL100 changes as soon as the

measured values cross the thresholds.

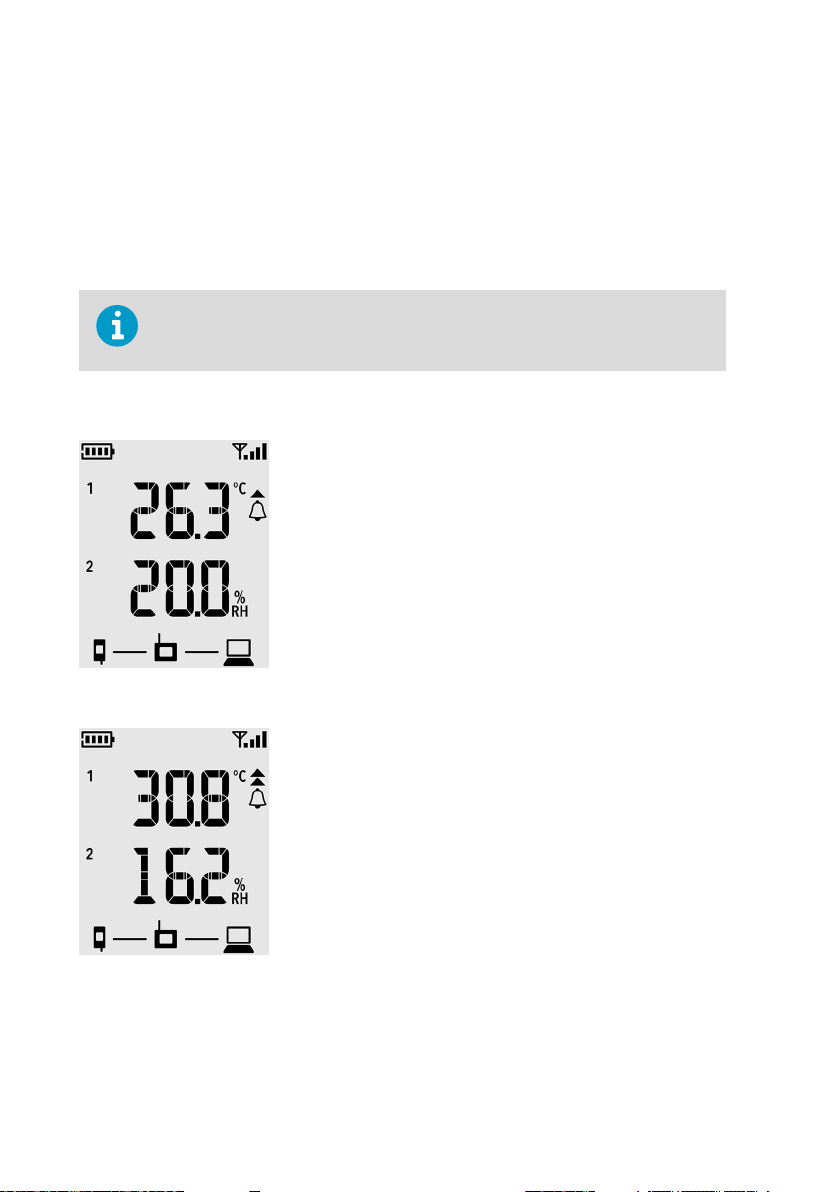

2.4.1 Alarm Examples

Figure 7 RFL100 with High Alarm Active on Channel 1

Figure 8 RFL100 with High-High Alarm Active on Channel 1

12

Page 15

Chapter 2 – Product Overview

2.5 Service Port

The service port of the data logger provides a local interface for performing service actions

that cannot be done over the air, such as updating the device firmware. The service actions are

based on file transfer using Media Transfer Protocol (MTP), so no special software is needed.

The service port connector is a standard micro-USB connector.

The service port can be used to supply operating power to the data logger. Use a power

supply that fulfills the requirements listed in Table 5 (page 13).

Table 5 Specifications for a USB Power Supply

Property Specification

Output voltage 5 VDC

Output current min. 100 mA

Output connector Micro-USB

Certifications and approvals • Certified to IEC 60950-1 or IEC 62368-1

Batteries with a sucient voltage must always be in place inside the data logger, even when

supplying external power through the service port.

• Approved for use in your country

CAUTION!

drained very slowly. As alkaline batteries may leak when left in place for a long

time, always use compatible 1.5 V lithium batteries instead of alkaline batteries

when using an external power supply.

When using an external power supply, the main batteries will be

2.6 Delays in a VaiNet Network

VaiNet protocol and VaiNet devices are designed for power-ecient operation. Some of the

design choices that enable long battery life also create significant delays that the users should

be aware of.

Intermittent Radio Connections

Radio connections between VaiNet access points and data loggers are not continuous. Access

points take turns communicating in a two-minute cycle, and connected data loggers send their

measurement data to their connected access point every four minutes. This introduces various

delays:

13

Page 16

RFL100 User Guide M211861EN-A

• Data loggers that are not currently connected (new devices or ones that have fallen out of

radio contact) have to scan for available access points for a complete cycle before they

can decide what is the optimal access point for them. This means that connection

attempts typically take at least a couple of minutes. Additionally, some joining scenarios

may take multiple attempts. For example, when filling a single access point up to its full

capacity of 32 data loggers, it may take an hour for the last data logger to successfully

connect to the access point.

• Access points request missing data and issue management commands to data loggers

within their communication window. Transferring a full month's worth of measurement

data from 32 data loggers using one access point takes several hours.

Data Logger Scanning Interval

Scanning for available access points consumes power. To prevent repeated scanning from

draining their batteries, RFL100 Data Loggers shut down their radio temporarily if they can

find no access points to join. They will resume scanning after a waiting interval that gets

progressively longer if they keep failing to find an access point. The maximum interval is 8

hours and 30 minutes.

This means that when access points become available after an outage, it may take several

hours for data loggers to discover them. This is why you should always keep your access points

powered up, and why you should start your network installation by installing the viewLinc

Enterprise Server and access points

You can manually wake up the radio of an RFL100 Data Logger by pressing its

Refresh button. The button is located next to the service port under the silicone

plug.

first.

2.7 Regulatory Compliance

2.7.1 FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference

at his own expense.

WARNING!

approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

14

Changes or modifications to this equipment not expressly

Page 17

Chapter 2 – Product Overview

WARNING!

subject to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This device complies with part 15 of the FCC Rules. Operation is

2.7.2 ISED Compliance Statement

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is

subject to the following two conditions:

1. This device may not cause interference; and

2. This device must accept any interference, including interference that may cause undesired

operation of the device.

This device has a PCB integrated inverted F-antenna with a gain of 1 dBi.

Le présent appareil est conforme aux CNR d’lndustrie Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes:

1. l’appareil ne doit pas produire de brouillage, et

2. l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d’en compromettre le fonctionnement.

Le présent appareil dispose d'une antenne F inversée intégrée à la carte avec un gain de 1 dBi.

2.7.3 EU Declaration of Conformity

BG: С настоящото Vaisala Oyj декларира, че този тип радиосъоръжение RFL100 е в

съответствие с Директива 2014/53/ЕС. Цялостният текст на ЕС декларацията за

съответствие може да се намери на следния интернет адрес: www.vaisala.com/

declarationofconformity

CS: Tímto Vaisala Oyj prohlašuje, že typ rádiového zařízení RFL100 je v souladu se směrnicí

2014/53/EU. Úplné znění EU prohlášení o shodě je k dispozici na této internetové adrese:

www.vaisala.com/declarationofconformity

DA: Hermed erklærer Vaisala Oyj , at radioudstyrstypen RFL100 er i overensstemmelse med

direktiv 2014/53/EU. EU-overensstemmelseserklæringens fulde tekst kan

internetadresse: www.vaisala.com/declarationofconformity

DE: Hiermit erklärt Vaisala Oyj , dass der Funkanlagentyp RFL100 der Richtlinie 2014/53/EU

entspricht. Der vollständige Text der EU-Konformitätserklärung ist unter der folgenden

Internetadresse verfügbar: www.vaisala.com/declarationofconformity

EL:Με την παρούσα ο/η Vaisala Oyj , δηλώνει ότι ο ραδιοεξοπλισμός RFL100 πληροί την

οδηγία 2014/53/ΕΕ. Το πλήρες κείμενο της δήλωσης συμμόρφωσης ΕΕ διατίθεται στην

ακόλουθη ιστοσελίδα στο διαδίκτυο: www.vaisala.com/declarationofconformity

EN: Hereby, Vaisala Oyj declares that the radio equipment type RFL100 is in compliance with

Directive 2014/53/EU. The full text of the EU declaration of conformity is available at the

following internet address: www.vaisala.com/declarationofconformity

findes på følgende

15

Page 18

RFL100 User Guide M211861EN-A

ES: Por la presente, Vaisala Oyj declara que el tipo de equipo radioeléctrico RFL100 es

conforme con la Directiva 2014/53/UE. El texto completo de la declaración UE de conformidad

está disponible en la dirección Internet siguiente: www.vaisala.com/declarationofconformity

ET: Käesolevaga deklareerib Vaisala Oyj , et käesolev raadioseadme tüüp RFL100 vastab

direktiivi 2014/53/EL nõuetele. ELi vastavusdeklaratsiooni täielik tekst on kättesaadav

järgmisel internetiaadressil: www.vaisala.com/declarationofconformity

FI: Vaisala Oyj vakuuttaa, että radiolaitetyyppi RFL100 on direktiivin 2014/53/EU mukainen.

EU-vaatimustenmukaisuusvakuutuksen täysimittainen teksti on saatavilla seuraavassa

internetosoitteessa: www.vaisala.com/declarationofconformity

FR: Le soussigné, Vaisala Oyj , déclare que l'équipement radioélectrique du type RFL100 est

conforme à la directive 2014/53/UE. Le texte complet de la déclaration UE de conformité est

disponible à l'adresse internet suivante: www.vaisala.com/declarationofconformity

HR: Vaisala Oyj ovime izjavljuje da je radijska oprema tipa RFL100 u skladu s Direktivom

2014/53/EU. Cjeloviti tekst EU izjave o sukladnosti dostupan je na sljedećoj internetskoj adresi:

www.vaisala.com/declarationofconformity

HU: Vaisala Oyj igazolja, hogy a RFL100 típusú rádióberendezés megfelel a 2014/53/EU

irányelvnek. Az EU-megfelelőségi nyilatkozat teljes szövege elérhető a következő internetes

címen: www.vaisala.com/declarationofconformity

IT: Il fabbricante, Vaisala Oyj , dichiara che il tipo di apparecchiatura radio RFL100 è conforme

alla direttiva 2014/53/UE. Il testo completo della dichiarazione di conformità UE è disponibile

al seguente indirizzo Internet: www.vaisala.com/declarationofconformity

LT: Aš, Vaisala Oyj , patvirtinu, kad radijo įrenginių tipas RFL100 atitinka Direktyvą 2014/53/ES.

Visas ES atitikties deklaracijos tekstas prieinamas šiuo interneto adresu: www.vaisala.com/

declarationofconformity

LV: Ar šo Vaisala Oyj deklarē, ka radioiekārta RFL100 atbilst Direktīvai 2014/53/ES. Pilns ES

atbilstības deklarācijas teksts ir pieejams šādā interneta vietnē: www.vaisala.com/

declarationofconformity

MT: B'dan, Vaisala Oyj , niddikjara li dan it-tip ta' tagħmir tar-radju RFL100 huwa konformi

mad-Direttiva 2014/53/UE. It-test kollu tad-dikjarazzjoni ta' konformità tal-UE huwa

disponibbli f'dan l-indirizz tal-Internet li ġej: www.vaisala.com/declarationofconformity

NL: Hierbij verklaar ik, Vaisala Oyj , dat het type radioapparatuur RFL100 conform is met

Richtlijn 2014/53/EU. De volledige tekst van de EU-conformiteitsverklaring kan worden

geraadpleegd op het volgende internetadres: www.vaisala.com/declarationofconformity

PL: Vaisala Oyj niniejszym oświadcza, że typ urządzenia radiowego RFL100 jest zgodny z

dyrektywą 2014/53/UE. Pełny tekst deklaracji zgodności UE jest dostępny pod następującym

adresem internetowym: www.vaisala.com/declarationofconformity

PT: O(a) abaixo assinado(a) Vaisala Oyj declara que o presente tipo de equipamento de rádio

RFL100 está em conformidade com a Diretiva 2014/53/UE. O texto integral da declaração de

conformidade está disponível no seguinte endereço de Internet: www.vaisala.com/

declarationofconformity

16

Page 19

Chapter 2 – Product Overview

RO: Prin prezenta, Vaisala Oyj declară că tipul de echipamente radio RFL100 este în

conformitate cu Directiva 2014/53/UE. Textul integral al declarației UE de conformitate este

disponibil la următoarea adresă internet: www.vaisala.com/declarationofconformity

SK: Vaisala Oyj týmto vyhlasuje, že rádiové zariadenie typu RFL100 je v súlade so smernicou

2014/53/EÚ. Úplné EÚ vyhlásenie o zhode je k dispozícii na tejto internetovej adrese:

www.vaisala.com/declarationofconformity

SL: Vaisala Oyj potrjuje, da je tip radijske opreme RFL100 skladen z Direktivo 2014/53/EU.

Celotno besedilo izjave EU o skladnosti je na voljo na naslednjem spletnem naslovu:

www.vaisala.com/declarationofconformity

SV: Härmed försäkrar Vaisala Oyj att denna typ av radioutrustning RFL100 överensstämmer

med direktiv 2014/53/EU. Den fullständiga texten till EU-försäkran om överensstämmelse

på följande webbadress: www.vaisala.com/declarationofconformity

2.8 Safety

finns

CAUTION!

strong magnet. Handle it with care and keep it away from devices that are

sensitive to magnetic fields (for example, pacemarkers, magnetic cards, and

mechanical watches.)

CAUTION!

distance must be maintained between the user and the device when the device

is operating.

ATTENTION

cm. Cette distance doit être maintenue entre l'utilisateur et l'appareil lorsque

l'appareil est en fonctionnement.

The optional magnetic mounting bracket of the RFL100 has a

This device requires a separation distance of at least 20 cm. This

Cet appareil nécessite une distance de séparation d'au moins 20

2.9 Symbols in RFL100 Product Markings

Table 6 Symbols Used in RFL100 Product Markings

Symbol Description

Meets the essential requirements of the applicable EC directives

Symbol of electrical and electronic equipment according to the WEEE

directive

17

Page 20

RFL100 User Guide M211861EN-A

Symbol Description

FCC mark

Environment Friendly Use Period of 10 years

Read user instructions

Read user instructions

Battery orientation symbol

Regulatory Compliance Mark (RCM)

2.10 ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to electronic circuits.

Vaisala products are adequately protected against ESD for their intended use. However, it is

possible to damage the product by delivering an electrostatic discharge when touching,

removing or inserting any objects inside the equipment housing.

Avoid touching component contacts or connectors when working with the device.

18

Page 21

1

2

3

Chapter 3 – Installation

3. Installation

3.1 Setting Up RFL100 Data Logger

1 Power switch.

2 Protection cap. Remove after

installation is complete.

3 Latch of the battery cover.

1. Open the battery cover of the data logger.

2. Move the power switch to the On position.

3. Close the battery cover of the data logger. Push the latch down until you hear a click. If

the cover does not close easily, push the probe (or the probe cable) in and try again.

4. Look at the display and verify that:

• Battery indicator shows full batteries

• Display shows measurement readings instead of dashes or error codes.

If measurement readings are not shown after a few seconds, check that the probe is

properly connected. It is possible to disconnect the probe by pulling on the probe with

the battery cover open. In that case the display will show error code ERR 202.

.

When you turn on the RFL100 it starts to scan for VaiNet access points that are in

installation mode. RFL100 will connect to the access point with the best signal

strength, and wait to be accepted by the administrator of the viewLinc Enterprise

Server.

19

Page 22

A B

DC

68 [2.65]

mm

[in]

RFL100 User Guide M211861EN-A

3.2 Mounting RFL100

Figure 9 RFL100 Mounting Methods

Mounting with screws. Screws and wall plugs are included with the data logger.

A

B Mounting with zip ties. Zip ties are included with the data logger.

C Magnetic mounting (with optional magnetic mounting bracket)

D Mounting with a hook (hook not included)

20

Page 23

Chapter 3 – Installation

1. Select a suitable mounting location. A good location is easily accessible, protected from

water and condensation, and remains within the operating temperature range of the

RFL100:

• +2 ... +60 °C (+35.6 ... +140 °F) with alkaline batteries

• -20 ... +60 °C (-4 ... +140 °F) with lithium batteries

Use the HMP110 probe to measure a wider range of conditions (operating

temperature range -40 ... +80 °C (-40 °F ... +176 °F)). HMP110 probe is always

connected using a connection cable, so you can leave the RFL100 data

logger in an environment that is suitable to its specification.

2. Attach the mounting bracket using one of the mounting methods shown in Figure 9

(page 20). Orient the bracket vertically so that the probe or probe cable points down

after installation. Do not attach the RFL100 without the mounting bracket.

CAUTION!

If you are mounting the data logger higher than 2 m (6 ft) or in

a location where it would pose a hazard if dropped, ensure the mounting

bracket is securely fixed with screws or zip ties.

3. Slide the logger into the mounting bracket with the probe or probe cable pointing

downward.

4. Peel o the protective film from the display and remove the yellow plug from the probe.

5. If the probe is attached with a cable, place the probe in the desired measurement location

and secure the cable.

6. Recommended: Apply location labels to the mounting bracket and the RFL100 Data

Logger according to your installation plan and company policy.

21

Page 24

RFL100 User Guide M211861EN-A

3.3 Connection Indicators

Table 7 Symbols

Symbol Description Symbol Description

Data logger Connection OK

Access point Connection currently

viewLinc Enterprise Server

Table 8 Connection States

Symbols on Display Description

Data logger is searching for an access point.

Data logger has failed to find an access point that is in installation

mode. viewLinc server icon is not shown, as the data logger has

not been accepted to a viewLinc system yet.

The data logger has failed to connect to an access point that

belongs to its own network.

Data logger is successfully connected to an access point, but

there is no connection between the access point and viewLinc

server. Data logger has not been accepted to a viewLinc system

yet.

Data logger is successfully connected to an access point, but

there is no connection between the access point and viewLinc

server. Data logger has been accepted to a viewLinc system.

Data logger is successfully connected to an access point, and

connection between the access point and viewLinc server is also

OK. The viewLinc symbol is flashing to indicate that the data

logger is waiting to be accepted to the viewLinc system as a new

device.

Data logger is successfully connected to an access point, and

connection between the access point and viewLinc server is also

OK. Data logger has been accepted to the viewLinc system.

unavailable

22

Page 25

3.3.1 Connection Examples

Chapter 3 – Installation

Looking for an access point to join: Line

between data logger and access point

symbols is blinking, and signal strength

indicator shows no bars.

Connected to an access point but

viewLinc Enterprise Server not

discovered yet: Signal strength indicator

shows the strength of the access

point connection.

Full connectivity: Data logger has

discovered a viewLinc Enterprise Server

and is connected to it through the access

point. You can now log in to the viewLinc

Enterprise Server and accept the device to

the system.

23

Page 26

RFL100 User Guide M211861EN-A

4. Operation

4.1 Remote Management

After a RFL100 Data Logger has been accepted to a viewLinc Monitoring System, it can be

remotely managed using viewLinc Enterprise Server software. Remote management

operations can be performed directly from the Sites Manager > Hosts and Devices tree.

Figure 10 RFL100 Remote Management using viewLinc Enterprise Server

24

Page 27

Chapter 4 – Operation

Figure 11 RFL100 Properties in viewLinc

Local alarms on the RFL100 are also managed remotely, but in a dierent way. See Alarm

Indicators (page 11).

viewLinc automatically issues calibration reminder notifications at 3 months and 1

month before to the due date, and again on the due date.

4.2 Releasing RFL100 from a viewLinc Monitoring System

• Pen or a small screwdriver

After RFL100 Data Logger has been accepted to a viewLinc Monitoring System by a viewLinc

Enterprise Server administrator, it will not connect to any other system unless

from its current system. Follow this procedure to release the data logger using its physical

Release button. Alternatively, you can release it remotely from viewLinc Enterprise Server

software.

first released

25

Page 28

RFL100 User Guide M211861EN-A

Measurement and data logging is not aected by the release procedure. Existing

data will remain unaected on the data logger. All remotely managed RFL100

settings will be reset to defaults: threshold alarm indicators will be cleared, and

display and LED will turn on if they have been remotely turned o.

1. Remove the data logger from the mounting bracket.

2. Open the battery cover of the data logger.

3. Press the Release button using a pen or a small screwdriver.

4. Verify from the display that the text NWK REL appears

icon that denotes the viewLinc Enterprise Server

After a delay of 4 … 6 minutes, the RFL100 will be ready to join any compatible viewLinc

Monitoring System. The connecting access point must be in installation mode.

5. Close the battery cover of the data logger. Push the latch down until you hear a click. If

the cover does not close easily, push the probe (or the probe cable) in and try again.

6. Insert the data logger back in the mounting bracket.

briefly, and that the connection

disappears.

4.3

Speeding Up Radio Scanning Temporarily

• Pen or a small screwdriver

RFL100 has a small button next to the service port: the Refresh button. Pressing this button

enables the following for one hour, after which the RFL100 returns to normal behavior:

• Display and LED are turned on if they have been turned

• RFL100 starts radio scanning immediately if it has been shut down to save power.

• Firmware version of the RFL100 is shown on the screen, alternating with measurement

results.

26

o remotely.

Page 29

Chapter 4 – Operation

• If RFL100 is connected to an access point:

• Signal strength indicator is updated faster, approximately every 30 seconds.

• Access point shows the currently connected VaiNet channel, alternating with

measurement results and firmware version.

1. Open the plug that covers the service port.

2. Push the small button next to the service port using a pen or a small screwdriver.

3. Verify from the display that the text INFO ON appears briefly.

4. Close the plug over the service port.

27

Page 30

RFL100 User Guide M211861EN-A

5. Maintenance

5.1 Cleaning RFL100

• Lint-free cloth

• Isopropyl alcohol (70%)

Do not spray anything directly on the RFL100, since that may deposit impurities

on the sensor.

1. Remove the data logger from the mounting bracket.

2. Moisten some lint-free cloth with isopropyl alcohol (70%).

3. Wipe the data logger and the mounting bracket.

4. Check the filter on the probe. If the filter becomes contaminated, it is very likely to aect

the humidity measurement since residue on the filter will retain some moisture. If the filter

is dirty, replace it with a new one. See Changing the Probe Filter (page 28).

5. Insert the data logger back in the mounting bracket.

5.2

Changing the Probe Filter

• New filter for the probe

Filter on the probe should be replaced when it is damaged or dirty. You can change the probe

filter without disconnecting the probe from the data logger.

CAUTION!

Handle the probe carefully.

1. Turn the filter counter-clockwise to loosen it.

2. Remove the filter from the probe. Be careful not to touch the sensors with the filter.

3. Install a new filter on the probe, and tighten it so it is finger-tight. Make sure the filter sits

straight and meets the thread properly.

28

The sensors are easily damaged when the filter is not in place.

Page 31

Chapter 5 – Maintenance

More Information

‣

Spare Parts and Accessories (page 48)

5.3 Disconnecting the Probe

1. To disconnect a fixed probe from RFL100 Data Logger:

a. Remove the data logger from the mounting bracket.

b. Open the battery cover of the data logger.

c. Grip the probe from above the

Pull the probe straight out of the data logger. Do not rotate the probe.

2. To disconnect a cabled probe from RFL100 Data Logger:

a. Loosen the locking ring of the connector at the end of the probe cable.

b. Pull the probe away from the connector.

5.4

Connecting the Probe

1. To connect a fixed probe to RFL100 Data Logger:

a. Open the battery cover of the data logger.

b. Align the orientation mark on the probe with the line above the probe connector.

Push the probe straight in all the way, do not rotate.

c. Close the battery cover of the data logger. Push the latch down until you hear a click.

If the cover does not close easily, push the probe in and try again.

2. To connect a cabled probe to RFL100 Data Logger:

a. Connect the probe to the connector at the end of the probe cable.

b. Tighten the locking ring of the connector.

filter and hold the data logger with the other hand.

5.5

Calibration and Adjustment

If you think the device is not measuring correctly, calibration and adjustment is

not the first thing to do. Check the following first:

• Make sure nothing is interfering with the measurement: heat sources,

temperature

• Check that there is no moisture on the probe. If the sensor has become wet,

wait for it to dry.

• Always wait for the measurement to stabilize.

dierences, or condensation.

29

Page 32

RFL100 User Guide M211861EN-A

Calibration means comparing the measurement output of the device to a known

reference, such as a known environment in a calibration chamber or the output of

a reference instrument. Correcting the reading of the device so that it measures

accurately is referred to as adjustment.

Sensors and measurement electronics used by the data logger are fully contained in the

replaceable probe. This allows the probe to be calibrated, adjusted, and replaced as needed.

The calibration frequency depends on the application and your compliance requirements.

Vaisala recommends having the probe calibrated and adjusted once a year by Vaisala

Calibration and Repair Services. See www.vaisala.com/calibration.

Generic procedures for on-site calibration and adjustment are provided in this guide:

• To verify the measurement accuracy of the probe without disconnecting it from the data

logger, compare its readings with a calibrated reference instrument. Doing this at the

installation location of the data logger is referred to as a

Using a Reference Instrument (page 30).

• To calibrate and adjust the probe using humidity and temperature references, connect the

probe to compatible Vaisala humidity and temperature meter. See Calibration and

Adjustment Using HM40 (page 30) and Calibration and Adjustment using MI70

(page 36).

field check. See Field Checking

5.5.1 Field Checking Using a Reference Instrument

You can perform a field check of the RFL100 using any humidity and temperature

measurement instrument with a display. Typically field checking is done with a recently

calibrated portable instrument.

1. Place the probe of the reference instrument (or the entire instrument) in the same

environment as the probe of the RFL100. The environment should be as stable as

possible.

2. Wait for 30 minutes for humidity and temperature to stabilize. Verify that measurements

are no longer changing at the end of the stabilization period.

3. Record the readings from both instruments.

5.5.2 Calibration and Adjustment Using HM40

• Vaisala HM40 Hand-Held Humidity and Temperature Meter

• Connection cable for HM40 Hand-Held Meter (Vaisala item HMT120Z300)

• Reference environments for the desired calibration points

• RFL100 data logger with the probe to be calibrated

30

Page 33

Chapter 5 – Maintenance

You can calibrate and adjust the probe of your RFL100 data logger in one or two points using

the HM40. For a 2-point calibration, you need two reference environments. For example, LiCl

and NaCl salt chambers provide 11% and 75% relative humidity references. Note that when

performing a 2-point RH calibration, the first point requires a < 50% RH humidity reference,

and the second point must be > 50% RH. The dierence between the two humidity references

must be at least 30% RH.

1. Disconnect the probe to be calibrated from the RFL100 Data Logger. See Disconnecting

the Probe (page 29).

2. Connect the probe to the HM40 hand-held meter using the connection cable.

3. Turn on the HM40 and check that the measurements from the probe are displayed on the

screen.

4. Press the Menu button and select the Calibration submenu.

5. Select the parameter to be calibrated at menu item [1] Quantity. You can calibrate

Temperature (T) or Relative Humidity (RH) measurement. All other humidity parameters

are calculated from RH and T, so they will also be adjusted.

31

Page 34

RFL100 User Guide M211861EN-A

6. Select the number of calibration points at menu item [2] Points.

7. Place the probe in the first reference environment (first calibration point). Wait 20 – 40

minutes for the reading to stabilize.

32

Page 35

Chapter 5 – Maintenance

8. Select menu item [3] Point 1 and press the Set button. The meter now shows the

currently measured value of the selected parameter. Set the reference value using the

arrow buttons and press the OK button.

The correction to the measurement at point 1 is now shown in the text for menu item [3]

Point 1. If you are only doing a 1-point calibration, skip to step 11.

9. Place the probe in the second reference environment (second calibration point). Wait 20 –

40 minutes for the reading to stabilize.

33

Page 36

RFL100 User Guide M211861EN-A

10. Select menu item [4] Point 2 and press the Set button. The meter now shows the

currently measured value of the selected parameter. Set the reference value using the

arrow buttons and press the OK button.

The correction to the measurement at point 2 is now shown in the text for the menu item

[4] Point 2.

34

Page 37

Chapter 5 – Maintenance

11. Select menu item [5] Note to edit the calibration info text that is stored in the probe. Edit

the text using the select button and arrow keys. When done, select the OK character in

the bottom right corner to save the changed text. To exit without saving, press the Cancel

button.

12. Select menu item [6] Apply to view the calibration result. Verify the applied corrections in

the confirmation screen and press the Apply button to apply the adjustment to the probe,

or Cancel to exit without applying the adjustment.

13. Disconnect the probe from the HM40.

14. Connect the probe to the RFL100 Data Logger. See Connecting the Probe (page 29).

35

Page 38

RFL100 User Guide M211861EN-A

5.5.3 Calibration and Adjustment using MI70

• Vaisala MI70 Measurement Indicator

• Connection cable for MI70 Measurement Indicator (Vaisala item 219980SP)

• Reference environments for the desired calibration points

• RFL100 data logger with the probe to be calibrated

Optional:

• MI70-compatible reference probe and connection cable

You can calibrate and adjust the probe of your RFL100 data logger in one or two points using

the MI70 indicator. For a 2-point calibration, you need two reference environments. For

example, LiCl and NaCl salt chambers provide 11% and 75% relative humidity references. Note

that when performing a 2-point RH calibration, the

reference, and the second point must be > 50% RH. The dierence between the two humidity

references must be at least 30% RH.

Using the MI70 indicator, you can also do the 1-point calibration so that you compare the

reading of the probe to any MI70-compatible Vaisala probe that provides the same

measurement parameter.

1. Disconnect the probe from the data logger. See Disconnecting the Probe (page 29).

2. Connect the probe to be calibrated to port I of the MI70 measurement indicator using the

connection cable.

3. If you want to calibrate by comparing to the reading of a reference probe, connect it to

port II of the MI70 indicator.

4. Turn on the MI70 indicator.

5. Start the adjustment sequence from Main menu > Functions > Adjustments. If you have

two probes connected, make sure to start the adjustment sequence for probe I.

notifies you that automatic power o is disabled during adjustment mode, select OK

6. MI70

to acknowledge.

7. Select RH or T parameter for adjustment and select OK. This procedure assumes you are

adjusting relative humidity, but the same principles apply for temperature adjustment.

8. Insert the probe to be calibrated in the reference environment. If you are calibrating

relative humidity using two reference environments, use the dry reference

a reference probe, insert that in the same environment. If you are comparing against the

reading of a reference probe, you can also use the ambient condition as the reference

environment, as long as its conditions are stable.

9. Wait for the measurement to stabilize. You can follow the stabilization from the GRAPH

display. Select ADJUST when the reading is stabilized in the reference.

first point requires a < 50% RH humidity

first. If you have

36

Page 39

Chapter 5 – Maintenance

10. To perform the adjustment using one reference environment (1-point adjustment),

perform these steps:

a. Select 1-point adjustment > SELECT > OK.

b. When the measurement is stable, select READY.

c. Give the reference RH value by using the arrow buttons and select OK.

d. To confirm the adjustment, select YES. If you select NO, you return to the adjustment

mode display and no changes are made.

e. Continue from step 13.

11. To perform the adjustment using two reference environments (two-point adjustment),

perform these steps:

a. Select 2-point adjustment > SELECT > OK.

b. When the measurement is stable, select READY.

c. Give the reference RH value by using the arrow buttons and select OK.

d. Insert the probe to be calibrated in the second reference environment.

e. When the measurement is stable, select READY.

f. Give the reference RH value by using the arrow buttons and select OK.

g. To

confirm the adjustment, select YES. If you select NO, you return to the adjustment

mode display and no changes are made.

h. Continue from step 13.

12. To perform the adjustment using a reference probe, perform these steps:

a. Select To same as RH[II].

b. To confirm the adjustment, select YES. If you select NO, you return to the adjustment

mode display and no changes are made.

13. Calibration and adjustment is now completed. Select BACK to exit the adjustment mode

and EXIT to return to the basic display.

14. Disconnect the calibrated probe from the MI70 indicator.

15. Reconnect the probe to the data logger. See Connecting the Probe (page 29).

5.6

Changing RFL100 Batteries

• 2 pcs of new AA size 1.5 V batteries: alkaline (type LR6) or lithium (type FR6)

1. Remove the data logger from the mounting bracket.

2. Open the battery cover of the data logger.

3. Move the power switch to the

O position.

37

Page 40

RFL100 User Guide M211861EN-A

4. Remove the old AA size batteries from the data logger.

5. Check the battery orientation markings on the data logger and insert the new batteries in

the correct orientation.

6. Move the power switch to the On position.

7. Close the battery cover of the data logger. Push the latch down until you hear a click. If

the cover does not close easily, push the probe (or the probe cable) in and try again.

8. Insert the data logger back in the mounting bracket.

5.7 Changing RFL100 Clock Battery

• New 3 V lithium battery (type CR1/3N button cell)

• Small flat-head screwdriver

1. Open the battery cover of the data logger.

2. Use a small flat-head screwdriver to lift the top part of the small plastic cover marked

Clock battery (CR1/3N), and slide the cover upward until it comes loose.

3. Use the small screwdriver to lift the old clock battery from the battery socket.

4. Take the new clock battery and verify the + and - markings of the battery itself and the

clock battery socket. Insert the new clock battery in the clock battery socket.

5. Replace the clock battery cover.

6. Close the battery cover of the data logger. Push the latch down until you hear a click. If

the cover does not close easily, push the probe (or the probe cable) in and try again.

5.8

Updating RFL100 Firmware

Required:

• Computer with a free USB port and an operating system that supports the

Media Transfer Protocol (MTP). For example, Windowsâ 7 and newer.

• USB connection cable (USB 2.0 Type A - Micro-B, Vaisala cable 244961). You

also can use a generic cable that has all pins connected (not just power).

• RFL100 firmware update file from Vaisala

CAUTION!

Before updating, verify from the viewLinc Enterprise Server that up-to-date data

from this device is available. You can also copy the data from the device; see

Downloading Data Using Service Port (page 42).

38

Updating RFL100 firmware erases the recorded data on the device.

Page 41

Chapter 5 – Maintenance

Updating the firmware will not aect the data logger's status in the Vaisala viewlinc

Monitoring System. If the device was accepted in the system before the update, it will remain

accepted.

1. Turn the RFL100 on. The currently installed firmware version is shown briefly during startup. If the firmware version you have downloaded is newer than the installed version,

continue with the update.

2. Open the plug that covers the service port and connect the USB cable between your

computer and the service port of the RFL100. After the computer detects the RFL100 and

installs the appropriate driver, it is available for

file transfer.

3. Copy the firmware update file supplied by Vaisala into the \Data\Update folder on the

RFL100. Select to overwrite the old file when prompted by your computer.

file is valid, RFL100 begins the update automatically. Do not unplug the cable or turn

If the

o the RFL100 during the update.

4. Monitor the update progress on the display of the RFL100. When the update is done, you

will see UPD OK message on the display.

5. Disconnect the USB cable and close the plug over the service port.

39

Page 42

RFL100 User Guide M211861EN-A

6. Troubleshooting

6.1 Problem Situations

Table 9 Troubleshooting Table

Problem Possible Cause Solution

Display shows one or more

error codes.

You are adding a new RFL100

Data Logger to the system but

it is not coming up as a New

Device in viewLinc.

Various causes. Check meaning of the error

RFL100 is not in range of an

AP10 that has installation

mode turned on, and capacity

to add more data loggers

(maximum 32 for each AP10).

RFL100 is connected to an

AP10 that is not connected to

viewLinc.

RFL100 has been previously

accepted to a dierent

viewLinc system.

RFL100 has joined an AP10 but

has not been accepted to the

viewLinc system. The AP10 is

no longer in range, but RFL100

cannot change to a dierent

access point as it is pending to

be accepted to the system.

code(s) and proceed

accordingly. See Error Codes

(page 41).

Turn on installation mode in an

AP10 that is within 100 m of the

data logger, and has capacity

to add more data loggers.

Verify the following:

• AP10 is connected to the

network and has an IP

address.

• AP10 is configured to

connect to the correct

viewLinc Enterprise Server.

• viewLinc connection of the

AP10 is OK.

Press the Release button of the

RFL100 and verify that the

message NWK REL appears on

screen. The RFL100 is now

ready to join any AP10 that is in

installation mode.

40

Page 43

Chapter 6 – Troubleshooting

Problem Possible Cause Solution

RFL100 turns o by itself. Display and LED of the RFL100

have been turned o remotely

using viewLinc Enterprise

Server. All other functions of

the data logger remain active.

Main batteries are empty. Replace the main batteries. See

You can change the setting

from the Hosts and Devices

tree in viewLinc Enterprise

Server.

If you are connecting the

RFL100 to a new viewLinc

Monitoring System and you

want the display and LED back

on again, press the Release

button of the RFL100 and

verify that the message NWK

REL appears on screen.

Changing RFL100 Batteries

(page 37).

6.2 Error Codes

Table 10 RFL100 Error Codes

Error Code Cause Recommended Action

Err 100 User parameter bank checksum failure. Turn the data logger o and on again. If

Err 101 Factory parameter bank checksum

failure.

Err 102 Real-time clock of the data logger has

lost accurate time.

Err 103 Main battery voltage is critically low.

Data logger has stopped radio

communication to conserve energy but

continues to record measurement data in

the local memory.

Err 104 Incorrect factory configuration

parameters.

Err 105 Real-time clock hardware error. Turn the data logger o and on again. If

Err 200 Real-time clock battery voltage is low. Replace the clock battery. See Changing

the error persists, contact Vaisala.

Turn the data logger o and on again. If

the error persists, contact Vaisala.

Restore the wireless connection to an

AP10 access point. RFL100 will

synchronize its clock with the time from

the access point.

Replace main batteries. See Changing

RFL100 Batteries (page 37).

Turn the data logger o and on again. If

the error persists, contact Vaisala.

the error persists, contact Vaisala.

RFL100 Clock Battery (page 38).

41

Page 44

RFL100 User Guide M211861EN-A

Error Code Cause Recommended Action

Err 202 Probe communication failure. Check that the probe is connected

Err 203 Probe error. Can be caused by probe

incompatibility, damage, or a wet

humidity sensor.

Err 204 Real-time clock temperature

compensation problem.

properly.

Inspect the probe and replace it if

necessary. If the error has been caused

by a wet humidity sensor, wait for it to

dry out.

1. If error 202 is also active, replace the

clock battery. See Changing RFL100

Clock Battery (page 38).

2. Turn the data logger o and on again.

3. If the error persists, contact Vaisala.

6.3 Verifying Operation of RFL100

1. Open the battery cover of the data logger.

2. Move the power switch to the On position.

3. Look at the display and verify that:

• Battery indicator shows full batteries .

• Display shows measurement readings instead of dashes or error codes.

If measurement readings are not shown after a few seconds, check that the probe is

properly connected. It is possible to disconnect the probe by pulling on the probe with

the battery cover open. In that case the display will show error code ERR 202.

4. Move the power switch to the

5. Close the battery cover of the data logger. Push the latch down until you hear a click. If

the cover does not close easily, push the probe (or the probe cable) in and try again.

O position.

6.4

Downloading Data Using Service Port

• Computer with a free USB port and an operating system that supports the

Media Transfer Protocol (MTP). For example, Windowsâ 7 and newer.

• USB connection cable (USB 2.0 Type A - Micro-B, Vaisala cable 244961). You

also can use a generic cable that has all pins connected (not just power).

1. Open the plug that covers the service port.

2. Connect the USB cable between your computer and the service port of the RFL100 Data

Logger. When the computer detects the RFL100, it is available for

3. Navigate to the \Data\Log folder on the RFL100.

42

file transfer.

Page 45

Chapter 6 – Troubleshooting

4. The folder contains the following files.

Filename Content

Log_1h.txt Measurement data from the past hour.

Log_24h.txt Measurement data from the past 24 hours.

Log_30d.txt Measurement data from the past 30 days.

5. Copy the files in the folder to retrieve the data.

6. Disconnect the USB cable and close the plug over the service port.

43

Page 46

RFL100 User Guide M211861EN-A

7. Technical Data

7.1 RFL100 Technical Specification

Table 11 Wireless

Property Specification

Networking standards Vaisala VaiNet

Modulation

Output power 14 dBm (25 mW)

Antenna Internal

Typical range (indoors) At least 100 m (328 ft)

Frequency bands 868 MHz (Europe)

Safety

Electrical safety EN/UL/IEC 61010-1

RF exposure KDB 447498 (United States)

EMC and Radio Standards

EMC compliance EN/IEC 61326-1, industrial environment

868 MHz model ETSI EN 300 220-2

915 MHz model FCC title 47 part 15.247 (FCC ID: 2AO39-

LoRa™ chirp spread spectrum modulation

915 MHz (North America, Australia, and New

Zealand)

RSS-102 Issue 5 (Canada)

EN 301 489-1

EN 301 489-3

RFL100A)

ICE RSS-247 (IC: 23830-RFL100A)

AS/NZS 4268

Table 12 Memory

Property Specification

Sample capacity 30 days (43200 samples per channel)

Memory type Non-volatile EEPROM

Memory mode Ring buer (FIFO)

44

Page 47

Chapter 7 – Technical Data

Property Specification

Sampling rate One sample / channel / minute

(nonchangeable)

Table 13 Operating Environment

Property Description/Value

Operating temperature +2 ... +60 °C (+35.6 ... +140 °F) with alkaline

batteries

-20 ... +60 °C (-4 ... +140 °F) with lithium

batteries

1)

1)

Storage temperature -40 ... +60 °C (-40 ... +140 °F)

Operating humidity 0 ... 100 %RH, non-condensing

1) For both alkaline and lithium, battery temperature operating specifications apply.

Table 14 General

Property Specification

Compatible probes HMP115, HMP115T

HMP110, HMP110T (cabled only)

Compatible viewLinc versions 5.0 and above

Batteries 2 × AA sized, 1.5 V (LR6 or FR6)

Clock battery CR 1/3N (3 V lithium button cell)

Operation time at 20 °C (without external power

18 months

supply)

Internal clock accuracy ±30 s/month

Synchronizes with Network Time Protocol (NTP)

server

Table 15 Mechanical Specifications

Property Specification

Housing color White

Mounting methods Screws, tie-wrap, hook, or magnetic mounting

bracket (optional accessory)

Probe interface 4-pin female M8 connector

Service port USB 2.0 with Micro-USB connector

45

Page 48

RFL100 User Guide M211861EN-A

Property Specification

IP Rating

RFL100 IP54

HMP110 IP65

HMP115 IP54

Dimensions (H × W × D)

Without mounting bracket 158 × 62 × 31 mm (6.22 × 2.4 × 1.22 in)

With mounting bracket 186 × 68 × 36.5 mm (7.32 × 2.68 × 1.44 in)

Weight

With batteries (2 pcs alkaline) and HMP115 probe 190 g (6.7 oz)

With batteries (2 pcs alkaline), HMP115 probe,

254 g (8.96 oz)

and magnetic mounting bracket

RFL100 Materials

Housing PC/ABS blend

Display window PMMA (acrylic)

Sealings TPE

HMP110 Probe Materials

Body Stainless steel (AISI 316)

Grid filter Chrome coated ABS plastic

HMP115 Probe Materials

Body PC/ABS blend

Grid filter PC (glass reinforced)

Sleeve PC/ABS blend

Table 16 HMP110/T Probe Measurement Performance

Property Description/Value

Relative Humidity

Measurement range 0 ... 100 %RH

Accuracy in Temperature Range 0 ... +40 °C (+32 ... +104 °F)

0 ... 90 %RH

90 ... 100 %RH

±1.5 %RH

±2.5 %RH

1)

Accuracy in Temperature Range -40 ... 0 °C, +40 ... +80 °C (-40 ... +32 °F, +104 ... +176 °F)

46

1)

Page 49

Chapter 7 – Technical Data

Property Description/Value

0 ... 90 %RH

90 ... 100 %RH

Factory Calibration Uncertainty at +20 °C (68 °F)

0 ... 90 %RH

90 ... 100 %RH

±3.0 %RH

±4.0 %RH

2)

±1.1 %RH

±1.8 %RH

Humidity sensor Vaisala HUMICAPâ 180R

Stability ±2 %RH over 2 years

Temperature

Measurement range -40 ... +80 °C (-40 °F ... +176 °F)

Accuracy over Temperature Range

at 0 ... +40 °C (+32 °F ... +104 °F)

at -40 ... 0 °C, +40 ... +80 °C (-40 ... +32 °F,

± 0.2 °C (0.36 °F)

± 0.4 °C (0.72 °F)

+104 ... +176 °F)

Factory calibration uncertainty

2)

± 0.2 °C (0.36 °F)

Temperature sensor Pt1000 RTD Class F0.1 IEC 60751

1) Includes non-linearity, hysteresis, and repeatability.

2) Small variations possible; see also calibration certificate.

Table 17 HMP115/T Probe Measurement Performance

Property Description/Value

Relative Humidity

Measurement range 0 ... 100 %RH

Accuracy in Temperature Range 0 ... +40 °C (+32 ... +104 °F)

0 ... 90 %RH

90 ... 100 %RH

±1.5 %RH

±2.5 %RH

1)

Accuracy in Temperature Range -40 ... 0 °C, +40 ... +60 °C (-40 ... +32 °F, +104 ... +140 °F)

0 ... 90 %RH

90 ... 100 %RH

Factory Calibration Uncertainty at +20 °C (68 °F)

0 ... 40 %RH

40 ... 75 %RH

±3.0 %RH

±4.0 %RH

2)

±0.6 %RH

±1.0 %RH

Humidity sensor Vaisala HUMICAPâ 180R

1)

47

Page 50

RFL100 User Guide M211861EN-A

Property Description/Value

Stability ±2 %RH over 2 years

Temperature

Measurement range -40 ... +60 °C (-40 °F ... +140 °F)

Accuracy over Temperature Range

at 0 ... +40 °C (+32 °F ... +104 °F)

at -40 ... 0 °C, +40 ... +60 °C (-40 ... +32 °F,

+104 ... +140 °F)

Factory calibration uncertainty

Temperature sensor Pt1000 RTD Class F0.1 IEC 60751

1) Includes non-linearity, hysteresis, and repeatability.

2) Small variations possible; see also calibration certificate.

2)

± 0.2 °C (0.36 °F)

± 0.4 °C (0.72 °F)

± 0.1 °C (0.18 °F)

7.2 Spare Parts and Accessories

Table 18 RFL100 Spare Parts and Accessories

Description Vaisala Item Code

Mounting bracket (5 pcs) DRW244769SP

Magnetic mounting bracket (5 pcs) ASM211527SP

Battery cover (5 pcs) DRW244766SP

Mounting kit 245679SP

Table 19 HMP110/T Probe Spare Parts and Accessories

Description Vaisala Item Code

Spare HMP110 probe HMP110 order form, code: Z00B0C1A0

Spare HMP110T probe HMP110 order form, code: Z0B01A0

Probe cable for RFL100, 3 m CBL210555-3MSP

Probe cable for RFL100, 10 m CBL210555-10MSP

Plastic grid filter DRW010522SP

Plastic grid with membrane filter DRW010525SP

Sintered stainless steel filter HM46670SP

PTFE filter DRW244938SP

48

Page 51

Description Vaisala Item Code

68 [2.68]

186 [7.32]

36.5 [1.44]

12 [0.47]

mm

[in]

Mounting nuts (2 pcs), hex M12 × 1 Pa 6.6 18350SP

Probe mounting clamps, heavy duty (10 pcs) 226067

Duct installation kit 215619

Table 20 HMP115/T Probe Spare Parts and Accessories

Description Vaisala Item Code

Spare HMP115 probe HMP115

Spare HMP115T probe HMP115T

Plastic grid filter DRW240185SP

Plastic grid with membrane filter ASM210856SP

PTFE filter 219452SP

7.3 RFL100 Dimensions

Chapter 7 – Technical Data

Figure 12 RFL100 Data Logger Dimensions with Mounting Bracket

49

Page 52

158 [6.22]

62 [2.4]

31 [1.22]

12 [0.47]

mm

[in]

68 [2.68]

146 [5.75]

68 [2.65]

Ø 6 [0.23]

Ø 3.80 [0.15]

Ø 3.80 [0.15]

mm

[in]

RFL100 User Guide M211861EN-A

Figure 13 RFL100 Data Logger Dimensions

Figure 14 RFL100 Mounting Bracket Dimensions

50

Page 53

Technical Support

Contact Vaisala technical support at helpdesk@vaisala.com. Provide at least the

following supporting information:

• Product name, model, and serial number

• Name and location of the installation site

• Name and contact information of a technical person who can provide further

information on the problem

For more information, see www.vaisala.com/support.

Warranty

For standard warranty terms and conditions, see www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of damage due to normal wear

and tear, exceptional operating conditions, negligent handling or installation, or unauthorized

modifications. Please see the applicable supply contract or Conditions of Sale for details of the

warranty for each product.

Recycling

Recycle all applicable material.

Follow the statutory regulations for disposing of the product and packaging.

51

Page 54

RFL100 User Guide M211861EN-A

52

Page 55

Page 56

www.vaisala.com

Loading...

Loading...