Page 1

USER'S GUIDE

Vaisala Barometric Pressure Transfer

Standard

PTB330TS

M210983EN-A

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FI-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2009

No part of this manual may be reproduced in any form or by any means,

electronic or mechanical (including photocopying), nor may its contents

be communicated to a third party without prior written permission of the

copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding

obligations for Vaisala towards the customer or end user. All legally

binding commitments and agreements are included exclusively in the

applicable supply contract or Conditions of Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Contents of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Version Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

General Safety Considerations . . . . . . . . . . . . . . . . . . . . .10

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Product Related Safety Precautions . . . . . . . . . . . . . . . . . .11

ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

CHAPTER 2

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Introduction to PTB330TS . . . . . . . . . . . . . . . . . . . . . . . . . .15

Basic Features and Options . . . . . . . . . . . . . . . . . . . . . . .18

Pressure Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Pressure Measurement Principle . . . . . . . . . . . . . . . . . . . .20

Humidity and Temperature Measurement (Option) . . . . . .21

Additional Temperature Probe (Option) . . . . . . . . . . . . . . .21

Chemical Purge (Option) . . . . . . . . . . . . . . . . . . . . . . . . . .22

CHAPTER 3

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Basic Use of the MI70 Indicator . . . . . . . . . . . . . . . . . . . . . .24

Menus and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Preparations for Measurement . . . . . . . . . . . . . . . . . . . . . .29

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Using AA Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pressure Input Connectors . . . . . . . . . . . . . . . . . . . . . . . .30

MI70 Indicator Settings . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Measuring Barometric Pressure . . . . . . . . . . . . . . . . . . . . .32

Measuring Humidity and Temperature (Option) . . . . . . . . .33

Graphic History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

VAISALA________________________________________________________________________ 1

Page 4

________________________________________________________________________________

Recording Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Saving Individual Data Points . . . . . . . . . . . . . . . . . . . . . .38

Viewing and Deleting Recorded Files . . . . . . . . . . . . . . . .38

Alarm Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

MI70 Link Interface Software for Data Handling . . . . . . . . .40

CHAPTER 4

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Changing the MI70 Battery Pack . . . . . . . . . . . . . . . . . . . . .41

Changing the HMP155 Probe Filter . . . . . . . . . . . . . . . . . . .42

Changing the Sensor in the HMP155 . . . . . . . . . . . . . . . . . .44

Calibration and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . .44

Calibration and Adjustment of PTB330 . . . . . . . . . . . . . . . .45

Opening and Closing the Adjustment Mode . . . . . . . . . . . .46

1-Point Adjustment (LCP1) . . . . . . . . . . . . . . . . . . . . . . . .47

Multipoint Adjustment (MPCP1) . . . . . . . . . . . . . . . . . . . . .48

Entering Adjustment Information . . . . . . . . . . . . . . . . . . . .50

Calibration and Adjustment of HMP155 . . . . . . . . . . . . . . .50

Calibrating and Adjusting Relative Humidity . . . . . . . . . . .51

Calibrating and Adjusting Temperature . . . . . . . . . . . . . . .53

CHAPTER 5

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Return Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Vaisala Service Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

CHAPTER 6

SERIAL LINE COMMUNICATION WITH PTB330 BAROMETER . . . . . . .61

Connecting to the Serial Line . . . . . . . . . . . . . . . . . . . . . . . .61

Service Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . .62

Installing the Driver for the USB Cable . . . . . . . . . . . . 63

User Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

List of PTB330 Serial Commands . . . . . . . . . . . . . . . . . . . .66

Measurement Commands . . . . . . . . . . . . . . . . . . . . . . . . . . .68

INTV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

SEND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Measurement Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

AVRG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

DPMAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

TQFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

HHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

HQFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

HQNH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

2 _______________________________________________________________________________

Page 5

________________________________________________________________________________

Formatting Measurement Output . . . . . . . . . . . . . . . . . . . .71

FORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

User Port Serial Settings . . . . . . . . . . . . . . . . . . . . . . . . . . .74

SERI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

SMODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

ECHO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Other Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

ERRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

VERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

CHAPTER 7

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Mechanics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . .85

VAISALA________________________________________________________________________ 3

Page 6

________________________________________________________________________________

4 _______________________________________________________________________________

Page 7

________________________________________________________________________________

List of Figures

Figure 1 The PTB330TS with Case Open . . . . . . . . . . . . . . . . . . . . . . .17

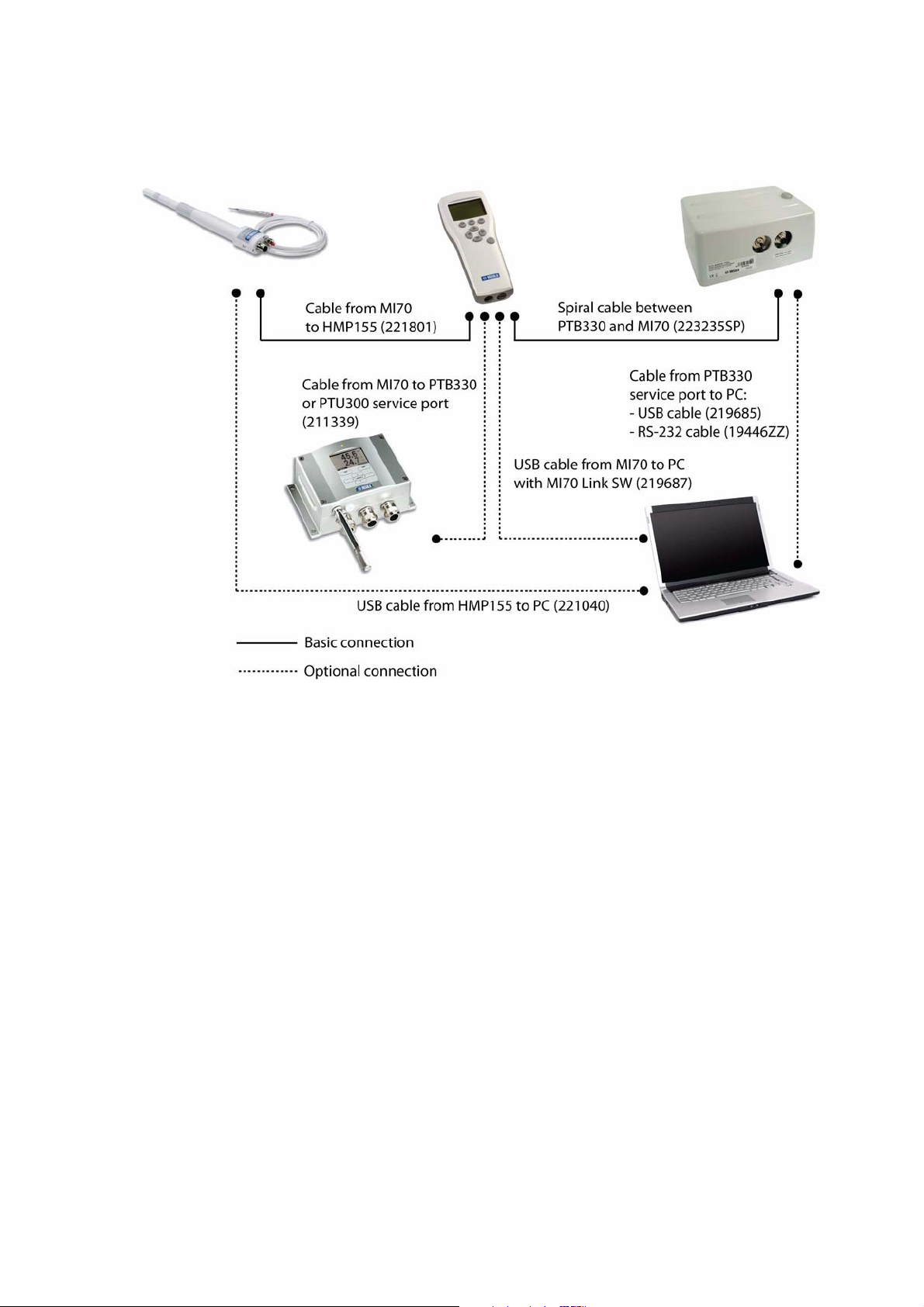

Figure 2 Typical Connections and Cables . . . . . . . . . . . . . . . . . . . . . . .19

Figure 3 PTB330 Barometer in Tabletop Casing . . . . . . . . . . . . . . . . . .20

Figure 4 HMP155 Probe with Additional T-probe. . . . . . . . . . . . . . . . . .22

Figure 5 Transport Case Pressure Release Valve. . . . . . . . . . . . . . . . .23

Figure 6 Transport Case With Shoulder Strap. . . . . . . . . . . . . . . . . . . .24

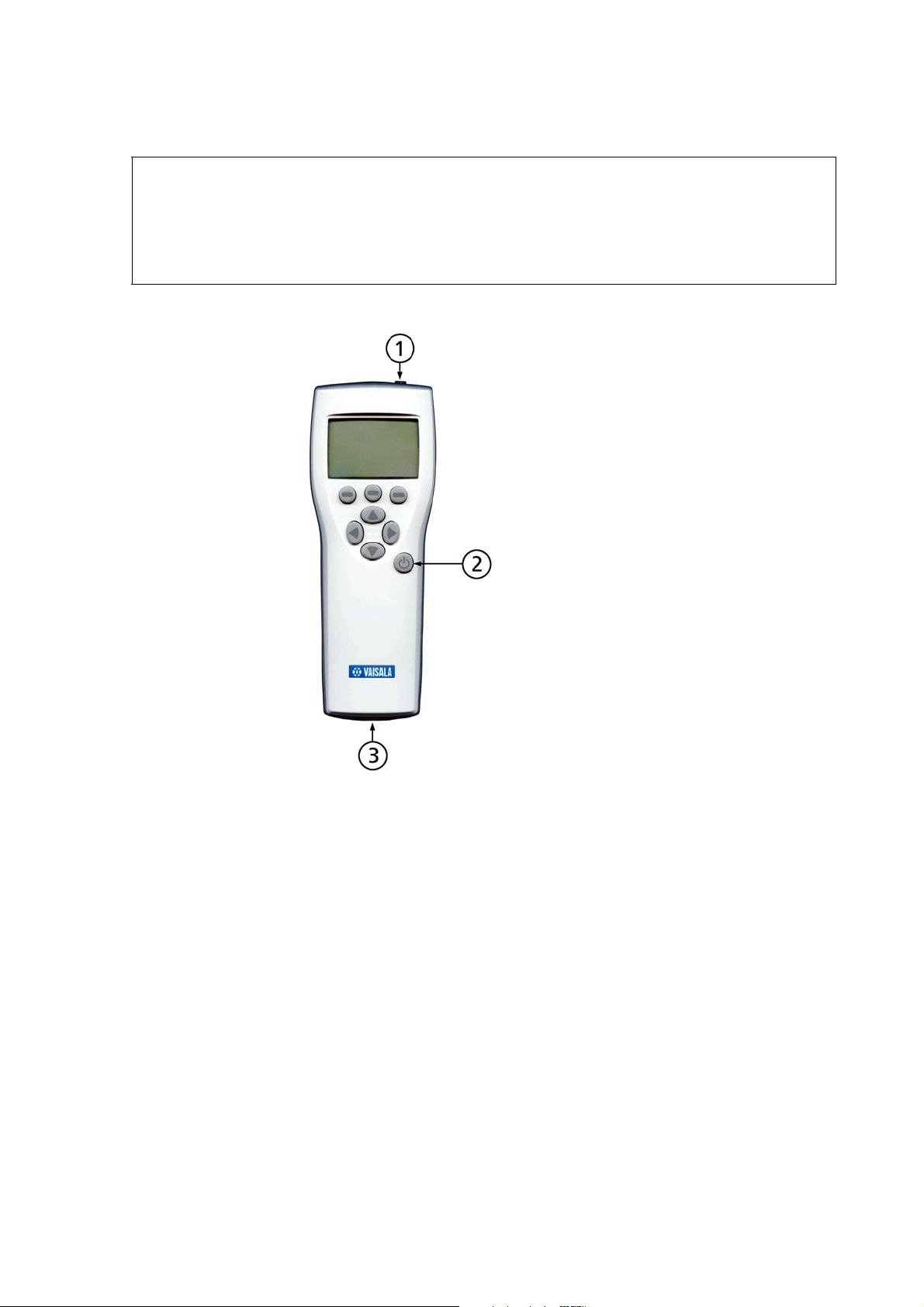

Figure 7 MI70 Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 8 MI70 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Figure 9 MI70 Basic View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 10 Installing the Clip for AA Batteries . . . . . . . . . . . . . . . . . . . . . .30

Figure 11 Pressure Input Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 12 Ready for Pressure Measurement. . . . . . . . . . . . . . . . . . . . . .33

Figure 13 PTB330 and HMP155 Connected . . . . . . . . . . . . . . . . . . . . . .35

Figure 14 Graphic History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Figure 15 Recording in Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Figure 16 List of Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Figure 17 Alarm Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Figure 18 Changing the MI70 Battery Pack . . . . . . . . . . . . . . . . . . . . . . .42

Figure 19 HMP155 Sensor and Filter Structure. . . . . . . . . . . . . . . . . . . .43

Figure 20 PTB330 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 21 Inside of Open Barometer . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Figure 22 HMP155 Adjustment Buttons. . . . . . . . . . . . . . . . . . . . . . . . . .51

Figure 23 Starting Adjustment Mode for HMP155 . . . . . . . . . . . . . . . . . .52

Figure 24 Select Quantity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Figure 25 Service Port on the PTB330 Motherboard. . . . . . . . . . . . . . . .63

Figure 26 Wiring of the M12 (8-Pin) Connector . . . . . . . . . . . . . . . . . . . .65

Figure 27 Female M12 Connector with Screw Terminals . . . . . . . . . . . .66

Figure 28 Accuracy Over Temperature Range . . . . . . . . . . . . . . . . . . . .83

VAISALA________________________________________________________________________ 5

Page 8

________________________________________________________________________________

6 _______________________________________________________________________________

Page 9

________________________________________________________________________________

List of Tables

Table 1 Manual Revisions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Table 2 Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

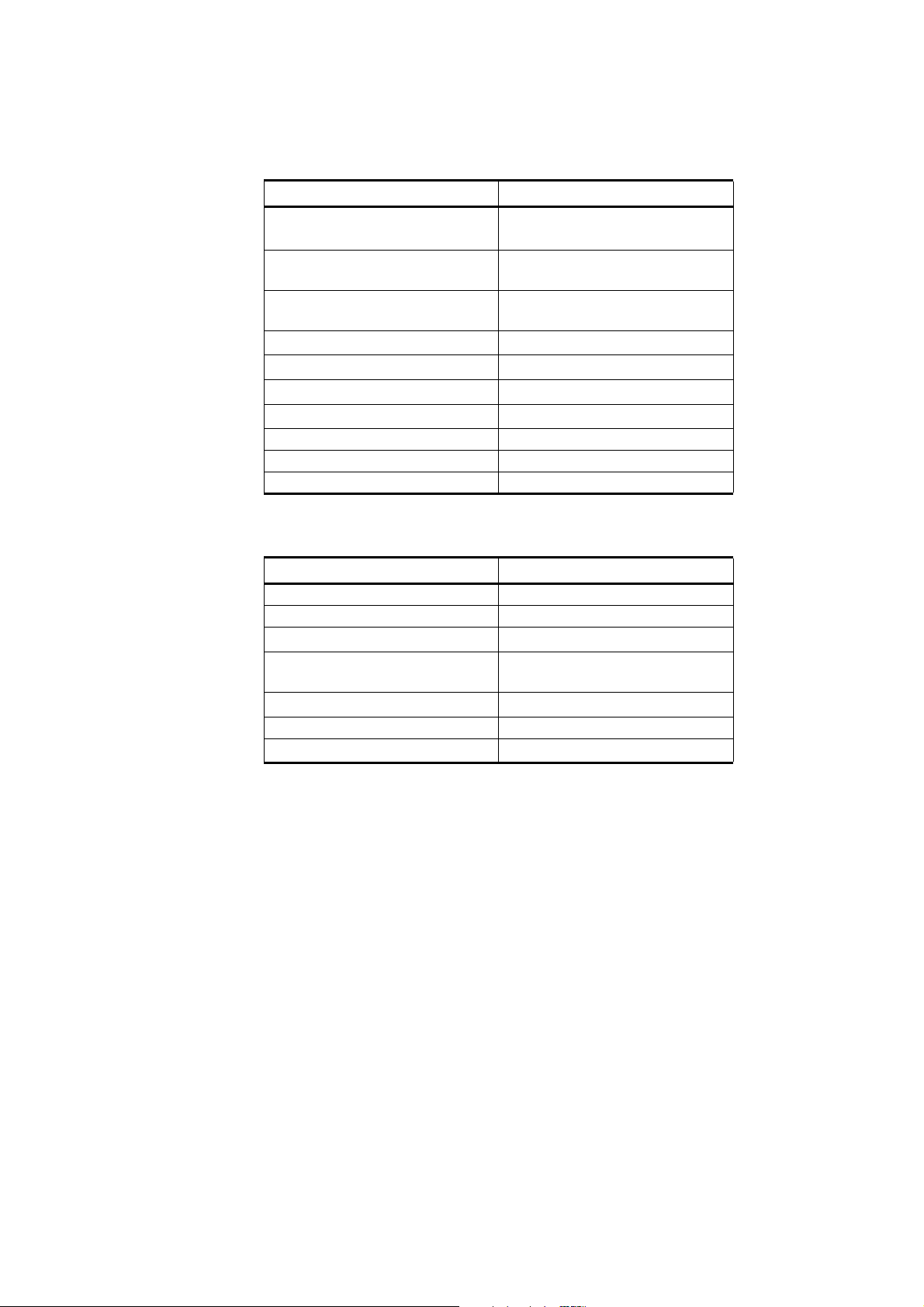

Table 3 Quantities Measured by PTB330TS. . . . . . . . . . . . . . . . . . . . . . .16

Table 4 Quantities Available With Optional HMP155 . . . . . . . . . . . . . . . .16

Table 5 Menu Structure of the MI70 Indicator. . . . . . . . . . . . . . . . . . . . . .28

Table 6 Maximum Recording Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 7 Adjustment and Calibration Com ma nds for Module P1. . . . . . . .46

Table 8 Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Table 9 Serial Communication Settings for the Service Port . . . . . . . . . .62

Table 10 Default Serial Communication Settings for the User Port . . . . . .64

Table 11 M12 Connector Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . .65

Table 12 The modifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Table 13 Output Quantities and Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Table 14 Selection of Output Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Table 15 Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

VAISALA________________________________________________________________________ 7

Page 10

________________________________________________________________________________

8 _______________________________________________________________________________

Page 11

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the manual and the PTB330TS.

About This Manual

This manual provides information for installing, operating, and

maintaining Vaisala BAROCAP® Digital Barometer PTB330.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information: This chapter provides general

notes for the manual and the PTB330TS.

- Chapter 2, Product Overview: This chapter introduces the features,

advantages, and the product nomenclature of PTB330TS.

- Chapter 3, Operation: This chapter contains information that is

needed to operate the PTB330TS.

- Chapter 4, Maintenance: This chapter contains information that is

needed maintenance of the PTB330TS.

- Chapter 5, Troubleshooting: This chapter contains instructions for

diagnosing problems with the PTB330TS.

VAISALA________________________________________________________________________ 9

Page 12

User's Guide ______________________________________________________________________

- Chapter 6, Serial Line Communication With PTB330 Barometer:

This chapter contains instructions for serial line use of the PTB330

barometer.

- Chapter 7, Technical Data: This chapter provides the technical data

of the PTB330TS.

Version Information

Table 1 Manual Revisions

Manual Code Description

M210983EN-A March 2009 - First version

Related Manuals

The manuals listed below contain additional information about the

PTB330 barometer and the HMP155 humidity and temperature probe,

including the calculation formulas used by the products. You can

download the manuals from www.vaisala.com.

WARNING

CAUTION

Table 2 Related Manuals

Manual Code Description

M210855EN PTB330 User’s Guide

M210912EN HMP155 User’s Guide

General Safety Considerations

Throughout the manual, important safety considerations are highlighted

as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

NOTE

10 ___________________________________________________________________M210983EN-A

Note highlights important information on using the product.

Page 13

Chapter 1 ________________________________________________________ General Information

Feedback

Vaisala Customer Documentation Team welcomes your comments and

suggestions on the quality and usefulness of this publication. If you find

errors or have other suggestions for improvement, please indicate the

chapter, section, and page number. You can send comments to us by email: manuals@vaisala.com

Product Related Safety Precautions

The product delivered to you has been tested for safety and approved as

shipped from the factory. Note the following precautions:

CAUTION

Do not modify the unit. Improper modification can damage the

product or lead to malfunction.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. However, it is possible to damage the

product by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench. When this is not possible, ground

yourself to the equipment chassis before touching the boards.

Ground yourself with a wrist strap and a resistive connection cord.

When neither of the above is possible, touch a conductive part of

the equipment chassis with your other hand before touching the

boards.

- Always hold the boards by the edges and avoid touching the

component contacts.

VAISALA_______________________________________________________________________ 11

Page 14

User's Guide ______________________________________________________________________

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations.

Do not dispose of with regular household refuse.

Regulatory Compliance

PTB330TS is in conformity with the following EU directives:

- EMC Directive (2004/108/EC)

Complies with the EMC product family standard

EN61326-1, Electrical equipment for measurement control and

laboratory use - Basic immunity test requirements.

- Low Voltage Directive (2006/95/EC)

- ROHS Directive (2002/95/EC)

Recycling

Trademarks

HUMICAP® and BAROCAP® are registered trademarks of Vaisala.

Microsoft®, Windows®, Windows 2000®, Windows XP®, Windows

Server 2003®, and Windows Vista® are are registered trademarks of

Microsoft Corporation in the United States and/or other countries.

License Agreement

All rights to any software are held by Vaisala or third parties. The

customer is allowed to use the software only to the extent that is

provided by the applicable supply contract or Software License

Agreement.

12 ___________________________________________________________________M210983EN-A

Page 15

Chapter 1 ________________________________________________________ General Information

Warranty

Vaisala hereby represents and warrants all Products

manufactured by Vaisala and sold hereunder to be free

from defects in workmanship or material during a

period of twelve (12) months from the date of delivery

save for products for which a special warranty is given.

If any Product proves however to be defective in

workmanship or material within the period herein

provided Vaisala undertakes to the exclusion of any

other remedy to repair or at its own option replace the

defective Product or part thereof free of charge and

otherwise on the same conditions as for the original

Product or part without extension to original warranty

time. Defective parts replaced in accordance with this

clause shall be placed at the disposal of Vaisala.

Vaisala also warrants the quality of all repair and

service works performed by its employees to products

sold by it. In case the repair or service works should

appear inadequate or faulty and should this cause

malfunction or nonfunction of the product to which the

service was performed Vaisala shall at its free option

either repair or have repaired or replace the product in

question. The working hours used by employees of

Vaisala for such repair or replacement shall be free of

charge to the client. This service warranty shall be

valid for a period of six (6) months from the date the

service measures were completed.

This warranty does not however apply when the defect

has been caused through

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use of

the Product or negligence or error in storing,

maintaining or in handling the Product or any

equipment thereof;

c) wrong installation or assembly or failure to se rv ice

the Product or otherwise follow Vaisala's service

instructions including any repairs or installation or

assembly or service made by unauthorized personnel

not approved by Vaisala or replacements with parts not

manufactured or supplied by Vaisala;

d) modifications or changes of the Product as well as

any adding to it without Vaisala's prior authorization;

e) other factors depending on the Customer or a third

party.

Notwithstanding the aforesaid Vaisala's liability under

this clause shall not apply to any defects arising out of

materials, designs or instructions provided by the

Customer.

This warranty is however subject to following

conditions:

a) A substantiated written claim as to any alleged

defects shall have been received by Vaisala within

thirty (30) days after the defect or fault became known

or occurred, and

b) The allegedly defective Product or part shall, should

Vaisala so require, be sent to the works of Vaisala or to

such other place as Vaisala may indicate in writing,

freight and insurance prepaid and properly packed and

labelled, unless Vaisala agrees to inspect and repair the

Product or replace it on site.

This warranty is expressly in lieu of and excludes all

other conditions, warranties and liabilities, express or

implied, whether under law, statute or otherwise,

including without limitation any implied warranties of

merchantability or fitness for a particular purpose and

all other obligations and liabilities of Vaisala or its

representatives with respect to any defect or deficiency

applicable to or resulting directly or indirectly from the

Products supplied hereunder, which obligations and

liabilities are hereby expressly cancelled and waived.

Vaisala's liability shall under no circumstances exceed

the invoice price of any Product for which a warranty

claim is made, nor shall Vaisala in any circumstances

be liable for lost profits or other consequential loss

whether direct or indirect or for special damages.

VAISALA_______________________________________________________________________ 13

Page 16

User's Guide ______________________________________________________________________

14 ___________________________________________________________________M210983EN-A

Page 17

Chapter 2 __________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the features, advantages, and the product

nomenclature of PTB330TS.

Introduction to PTB330TS

Barometric Pressure Transfer Standard PTB330TS combines a PTB330

digital barometer with a handheld MI70 indicator into a portable unit

that can be used as a transfer standard. Optional HMP155 probe is

available for accurate humidity and temperature measurement. The

PTB330TS is suitable for reference measurements in industrial and

meteorological areas.

The PTB330TS is housed in a durable and weatherproof transport case

that can be easily carried and shipped. The components of the

PTB330TS are placed in a foam interior, with accessories and user’s

guide placed in the lid organizer. The case includes a shoulder strap.

The quantities measured and calculated by PTB330TS are presented in

Table 3 on page 16. Quantities available using the optional HMP155

probe are presented in Table 4 on page 16.

VAISALA_______________________________________________________________________ 15

Page 18

User's Guide ______________________________________________________________________

Table 3 Quantities Measured by PTB330TS

Quantity Abbreviation

Pressure (measures average

pressure from P

, P2, and P3)

1

Pressure from barometer

P

P

, P2, and P

1

3

module 1 or 2 or 3

Temperature of barometer

TP1, TP2, and TP

3

module 1 or 2 or 3

Pressure trend and tendency P

Pressure difference (P1 -P2) deltaP

Pressure difference (P1 -P3) deltaP

Pressure difference (P2-P3) deltaP

3h

12

13

23

QNH pressure QNH

QFE pressure QFE

Height Corrected Pressure HCP

Table 4 Quantities Available With Optional HMP155

Quantity Abbreviation

Relative Humidity RH

Temperature T

Additional T- probe temperature T

Dewpoint / Frostpoint

a

T

d/f

temperature

Dewpoint temperature T

d

Mixing ratio x

Wetbulb temperature T

w

16 ___________________________________________________________________M210983EN-A

Page 19

Chapter 2 __________________________________________________________ Product Overview

0910-031

Figure 1 The PTB330TS with Case Open

where

1 = HMP155 humidity and temperature probe (option)

2 = P TB330 barometer in tabletop case, with room for CDs under

the case

3 = Shoulder strap and documentation

4 = Cables and pressure tubing

5 = Spiral cable and additional T-probe (option)

6 = MI70 indicator

7 = AC adapter and accessories (e.g. quick connector and M12

connector)

VAISALA_______________________________________________________________________ 17

Page 20

User's Guide ______________________________________________________________________

Basic Features and Options

- PTB330 digital barometer for accurate pressure measurement

- 1 ... 3 barometer modules

- barbed fitting for pressure input installed, quick connector

supplied

- calculated output quantities, QFE and QNH, available

- handheld MI70 indicator with a user friendly, multilingual display

- service port for MI70 Link Interface Software or PC

- weatherproof transport case

Available options:

- ISO/IEC 17025 Accredited calibration for PTB330

- HMP155 humidity and temperature probe

- HMP155 options: additional temperature probe, manually

controlled chemical purge feature

- MI70 Link software and USB or RS232 cable for downloading

measurement data to a PC

- USB service cable for connecting to the service port on the

PTB330 barometer

18 ___________________________________________________________________M210983EN-A

Page 21

Chapter 2 __________________________________________________________ Product Overview

0901-017

Figure 2 Typical Connections and Cables

Pressure Measurement

The PTB330TS uses a PTB330 series digital barometer that is housed

in a tabletop casing. The barometer does not come with its own display

and keypad; instead, it is designed to be operated using the handheld

MI70 indicator. The MI70 indicator also provides the operation power

for the barometer.

The pressure port, and the M12 connector for the MI70 indicator, are

placed on the side of the casing for easy access. The top of the casing

has a holder for the MI70 indicator for tabletop use. To access the

service port, the barometer can be opened without removing it from the

tabletop casing.

VAISALA_______________________________________________________________________ 19

Page 22

User's Guide ______________________________________________________________________

0810-032

Figure 3 PTB330 Barometer in Tabletop Casing

Numbers refer to Figure 3 on page 20:

1 = MI70 holder

2 = M12 connector for MI70 connection

3 = Pressure port

Pressure Measurement Principle

PTB330 uses a BAROCAP® silicon capacitive absolute pressure sensor

developed by Vaisala for barometric pressure measurement

applications. The BAROCAP® sensor has excellent hysteresis and

repeatability characteristics, low temperature dependence and a very

®

good long-term stability. The ruggedness of the BAROCAP

outstanding and the sensor is resistant to mechanical and thermal

shocks.

The measurement principle of the PTB330 is based on an advanced RC

oscillator and reference capacitors against which the capacitive pressure

sensor is continuously measured. The microprocessor of the barometer

performs compensation for pressure linearity and temperature

dependence.

sensor is

PTB330 can be ordered with 1 ... 3 barometer modules. The use of more

than one module provides increased accuracy and fault tolerance.

20 ___________________________________________________________________M210983EN-A

Page 23

Chapter 2 __________________________________________________________ Product Overview

Humidity and Temperature Measurement (Option)

An optional HMP155 humidity and temperature probe is available for

the PTB330TS. HMP155 provides reliable humidity and temperature

measurement in a wide range of applications. Humidity measurement is

based on the capacitive thin film polymer sensor HUMICAP®180R.

Temperature measurement is based on resistive platinum sensors

(Pt100). Both the humidity and temperature sensors are located at the

tip of the probe, protected by a sintered Teflon filter.

The MI70 indicator is used as the display, and the MI70 indicator also

provides the operation power for the probe. The PTB330 and HMP155

can be connected to the MI70 indicator simultaneously. The HMP155

version that is offered for the PTB330TS has RS-485 digital output.

Additional Temperature Probe (Option)

The HMP155 can be ordered with an additional temperature probe. The

T-probe is attached to the HMP155 with a two meter cable.

When the HMP155 is equipped with the additional T-probe, it

calculates the relative humidity value based on the dewpoint (Td) value

obtained from the humidity probe and the Ta value obtained from the Tprobe. This means that when you measure relative humidity (RH),

mixing ratio (x) or wetbulb temperature (Tw) using HMP155 with Tprobe, it is important to make sure that the humidity probe and the T-

probe are placed in the same conditions in order to get accurate

readings.

VAISALA_______________________________________________________________________ 21

Page 24

User's Guide ______________________________________________________________________

0910-033

Figure 4 HMP155 Probe with Additional T-probe

Chemical Purge (Option)

Chemicals in the measured gas may interfere with the humidity sensor

of the HMP155. The sensor polymer absorbs the interfering chemical,

gradually reducing its ability to absorb water molecules. Consequently

the sensor gain decreases.

The chemical purge function heats humidity sensor to a temperature of

approximately +180 °C for several minutes, which evaporates the

interfering chemical and any moisture on the sensor. The purge function

starts with heating stage, continues with settling and when the

temperature of the sensor has decreased, the probe returns to normal

mode. The entire cycle takes about eight minutes. For the duration of the

purge, the output from the HMP155 is locked to the last measured

values.

If your HMP155 is equipped with the chemical purge function, perform

it always before RH calibration (see section Calibration and Adjustment

of HMP155 on page 50) or when there is a reason to believe that a

sensor has become exposed to an interfering chemical. The purge can

be activated from the Functions menu of the MI70 indicator. Make sure

that the temperature of the sensor has come down to normal temperature

before starting a calibration.

If the chemical purge function is enabled, and the HMP155 is left

continuously powered, it will perform the chemical purge at a very long

interval of approximately 22.7 days (automatic purge). This interval can

be changed using serial line; see the HMP155 User’s Guide.

22 ___________________________________________________________________M210983EN-A

Page 25

Chapter 3 ________________________________________________________________ Operation

CHAPTER 3

OPERATION

This chapter contains information that is needed to operate the

PTB330TS.

Transport

Before transporting the PTB330TS, make sure that all instruments are

securely placed in the foam interior. The inside of the case should be

clean and dry. If water has entered the case due to operation in the field,

let it dry before closing.

The transport case has an air pressure release valve below the handle.

Close the valve for maximum protection during for transport, and open

it before attempting to open the case. The valve is closed when the

indicator in the valve is red, and open when it is green. Refer to Figure

5 on page 23. It may take some minutes for pressure to equalize after

opening the valve.

0801-001

Figure 5 Transport Case Pressure Release Valve

VAISALA_______________________________________________________________________ 23

Page 26

User's Guide ______________________________________________________________________

A shoulder strap is included with the transport case. The attachment

holes for the shoulder strap are located on the handle; see Figure 6 on

page 24. The other two holes on the case can be used to lock the case

with a padlock (not supplied).

0902-009

Figure 6 Transport Case With Shoulder Strap

where

1 = Holes for shoulder strap clips

2 = Padlock holes for locking the case (lock not included)

Basic Use of the MI70 Indicator

The MI70 indicator is used as the display and keypad in the PTB330TS.

Connections to the PTB330 barometer and the HMP155 probe are

through the two connection ports at the bottom of the indicator. The

MI70 indicator has a rechargeable battery, which provides the operation

power to the PTB330 and the HMP155.

24 ___________________________________________________________________M210983EN-A

Page 27

Chapter 3 ________________________________________________________________ Operation

NOTE

The MI70 indicator is also used in other Vaisala products, such as the

Vaisala HUMICAP Hand-Held Humidity and Temperature Meter

HM70. Because of this, the MI70 indicator has some software features

and accessories that are not relevant for the PTB330TS, and are not

described in this manual.

0704-035

Figure 7 MI70 Indicator

Numbers refer to Figure 7 on page 25:

1 = Recharger connection

2 = Power button

3 = Connection ports (2) for cables

VAISALA_______________________________________________________________________ 25

Page 28

User's Guide ______________________________________________________________________

0704-034

Figure 8 MI70 Keypad

Numbers refer to Figure 8 on page 26:

1 = Shortcut buttons: press to activate the function shown above

the button

2 = Arrow buttons: for navigating the menus, and zooming the

view when in graph mode. To open the main menu while in

basic view, press any arrow key, followed by the middle

shortcut button.

3 = Power button: press until the indicator turns on/off. If data

recording is underway , it will continue in the background even

if the indicator is turned off.

26 ___________________________________________________________________M210983EN-A

Page 29

Chapter 3 ________________________________________________________________ Operation

0810-073

Figure 9 MI70 Basic View

Numbers refer to Figure 9 on page 27:

1 = Selected quantities (1 ... 3), measurement value and unit.

Also shows the MI70 port (I or II) that is connected to the

instrument that measures the quantity.

2 = Battery indicator (showing full battery)

3 = Alarm indicator, shown when the alarm function is enabled.

4 = Indicator for serial connection, shown when the MI70 is

connected to a PC

5 = Indicator for chemical purge, shown when purge is active

6 = Environment settings (showing pressure compensation setting

for RH measurement)

7 = Shortcut button Graphic switches the display to graph mode

8 = Shortcut button Hold/Sa freezes the display, and allows you

to save the data point to memory

9 = Shortcut button Record takes you to the Recording/Viewing

menu

You can change the default shortcuts of the shortcut buttons; see section

MI70 Indicator Settings on page 31.

VAISALA_______________________________________________________________________ 27

Page 30

User's Guide ______________________________________________________________________

Menus and Functions

The table below shows the menu structure of the MI70 Indicator. The

functions available under some entries, such as the Environment menu,

depend on the connected devices.

Table 5 Menu Structure of the MI70 Indicator

Main Menu First level submenu Functions in the submenu

Display Quantities and units Select measured quantities and units.

Rounding Turn the rounding of measured values ON/OFF

Hold/Save display Hold and save current readings

Graphic history Show history graphs

Functions Alarm Configure the alarm functio n of the M I70 indi cat or

Analog output Configure the analog output function of the MI70 indicator

Chemical purge Start the chemical purge function

Calibrate transmitters Start the calibration function for compatible transmitters

Recording/

Viewing

Environment (Available settings

Settings User interface Configure user interface settings of the MI70 indicator

Record data Start and stop data recording

View recorded data View recorded files

Memory status Show memory usage

Clear data memory Clear all recorded files

Set environment settings for measurement compensation.

depend on connected

devices)

Date and time Set date, date format, time, and clock type (12h or 24h)

Measurement settings Set measurement settings; available settings depend on

Device information View device information

Factory settings Revert the MI70 indicator to factory settings

When HMP155 is connected, pressure compensation for

RH measurement can be set.

connected devices. When PTB330 is connected, you can

set measurement settings for HCP, QFE and QNH

quantities, measurement averanging filter, and pressure

stability.

Note: the pressure stability setting (P stab) controls the

"OK" indication on the display of the PTB330 barome ter . It is

not used in the PTB330TS, so you can ignore the "P stab"

setting.

28 ___________________________________________________________________M210983EN-A

Page 31

Chapter 3 ________________________________________________________________ Operation

Preparations for Measurement

Charging

When the MI70 indicator is turned on, the battery level symbol in the

top left corner of the display indicates the current status of the battery.

It is best to prepare for measurement by having a fully charged battery.

To charge the MI70 indicator, plug in the recharger to the base of the

indicator, and connect the other end to a wall socket. The battery symbol

is animated when charging is in progress.

- It is not recommended to use MI70 during the first recharging.

After the first charge cycle is complete, you can use the MI70 while

recharging.

- The duration of recharging depends on the charge level of the

battery pack. 4 hours is a typical recharging time. The

recommended first charging time is 6 hours.

NOTE

- When the battery symbol animation stops, the battery is fully

recharged. Disconnect the recharger.

If the indicator will not turn on at all, it is likely that the battery is empty.

If the battery will not charge at all, or the operation time is very short

even after a full charge, see section Changing the MI70 Battery Pack on

page 41.

Using AA Batteries

You can use regular AA batteries (IEC LR6) instead of the rechargeable

battery pack to power the MI70 indicator. To use AA batteries, you

must remove the rechargeable battery pack, and install a small metallic

clip on the bottom end of the battery compartment. The clip is provided

in a small plastic bag, along with a black plastic plug that you can use

to cover an unused port on the MI70 indicator.

The battery clip is not designed to be installed and removed repeatedly.

Install it only if you intend to power the MI70 indicator with AA

batteries exclusively, and not use the rechargeable battery pack.

VAISALA_______________________________________________________________________ 29

Page 32

User's Guide ______________________________________________________________________

0901-001

Figure 10 Installing the Clip for AA Batteries

1. Open the back cover of the MI70 indicator and remove the

rechargeable battery pack. See section Changing the MI70 Battery

Pack on page 41 for instructions.

NOTE

2. Position the metallic clip as shown in Figure 10 on page 30, and

push down on it to snap it into place. Note that you have to push

quite hard.

3. Insert four AA batteries. The correct orientation of the batteries is

imprinted on the bottom of the battery compartment.

4. Close the back cover, and power on the MI70 indicator to check

that the clip and batteries are installed properly.

If you connect the charger when the MI70 indicator is equipped with

AA batteries, it will run on the power from the charger. The MI70 will

not charge AA batteries, only the rechargeable battery pack.

Pressure Input Connectors

The PTB330 barometer is equipped with a 1/8" barbed fitting for the

pressure input. To measure the pressure from a specific source, connect

the pressure source to this connector using a suitable tube.

You can also attach a 1/8" quick connector as an alternative connector.

The quick connector is included with every PTB330TS. To remove the

barbed fitting, use a 9mm wrench. Unless your wrench is suitably slim,

30 ___________________________________________________________________M210983EN-A

Page 33

Chapter 3 ________________________________________________________________ Operation

you may have to remove the PTB330 barometer from the tabletop case

to change the connector.

0812-016

Figure 11 Pressure Input Connectors

MI70 Indicator Settings

Before starting to use the PTB330TS, go through the user interface

settings of the MI70 indicator:

1. Turn on the MI70 indicator.

2. Open the Settings menu.

3. Select User Interface.

4. Set the interface options as desired. Use the arrow up and down

buttons to move the selection, and the shortcut buttons to change

the setting.

- Language: Changes the language of the user interface. Note

that some menu entries and messages may still be in English

only.

- Auto power off: The indicator can power off automatically

after 15 or 60 minutes of inactivity. The default is 15 minutes.

You can also disable the auto power off.

- Program shortcut keys: If you wish to change the shortcut

button functions that are shown in the basic view, select this

option and follow the instructions. You can, for example,

replace the Hold/Sa button with the Chemical purge.

VAISALA_______________________________________________________________________ 31

Page 34

User's Guide ______________________________________________________________________

- Key click: Turn on/off the click sound when indicator buttons

are pressed.

- Backlight on key press: Turn on/off the automatic display

backlight activation when buttons are pressed.

5. Return to the Settings menu using the left arrow button, and select

Date and Time.

6. Set the Date, Time, and Desired date format using the options.

You can also select a 12-hour clock.

NOTE

If you have accidentally selected an unfamiliar language and cannot

read the menu anymore, you can navigate to the language selection by

pressing the following button sequence (from the basic view):

Right, middle shortcut key, up, right, right, middle shortcut key.

Measuring Barometric Pressure

1. Check that the MI70 indicator is connected to the PTB330, and

turn it on. Set the correct time, date, and environmental settings if

prompted.

You can keep the PTB330 in the transport case if you wish; it does

not affect the pressure measurement.

2. If the quantities or units that appear on the MI70 indicator are not

the ones you want to measure, change them from the Display

menu:

a. Open the menu by pressing an arrow button, followed by

OPEN.

b. Select the Display menu and press the right arrow button.

c. Select Quantities and units and press the right arrow again.

d. To select a quantity, move on the quantity you want by using

the arrow buttons, and press SELECT. You can select up to

three quantities.

You can change the measurement unit by pressing UNIT, and

hide a selected quantity by pressing HIDE.

e. After completing your selection, press EXIT to return to the

basic display. You may be prompted to check the environment

32 ___________________________________________________________________M210983EN-A

Page 35

Chapter 3 ________________________________________________________________ Operation

settings upon exiting; select YES if you want to check the

settings, or NO to exit.

3. Attach the MI70 indicator to the top of the tabletop casing, and wait

for the reading to stabilize.

0812-017

Figure 12 Ready for Pressure Measurement

Measuring Humidity and Temperature (Option)

1. Place the HMP155 probe in the desired measurement location:

- Make sure the probe sits securely and will not fall when

operating the MI70 indicator.

- The probe should be out of direct sunlight and not near any

heat sources.

- If you are measuring relative humidity (RH), mixing ratio (x)

or wetbulb temperature (Tw) and your HMP155 has the

additional temperature probe (T-probe), it is important to

make sure that the humidity probe and the T-probe are placed

in the same conditions in order to get meaningful and accurate

humidity readings. The two probes need to be installed so that

the humidity probe does not heat the T-probe, but is close

enough for the probes to share the same environment

conditions.

VAISALA_______________________________________________________________________ 33

Page 36

User's Guide ______________________________________________________________________

2. Check that the MI70 indicator is connected to the HMP155, and

turn it on. Set the correct time, date, and environmental settings

(pressure compensation) if prompted.

3. If the measured quantities or units that appear on the MI70

indicator are not the ones you want, change them from the Display

menu:

a. Open the menu by pressing an arrow button, followed by

OPEN.

b. Select the Display menu and press the right arrow button.

c. Select Quantities and units and press the right arrow again.

d. To select a quantity, move on the quantity you want by using

the arrow buttons, and press SELECT. You can select up to

three quantities.

You can change the measurement unit by pressing UNIT, and

hide a selected quantity by pressing HIDE.

NOTE

e. After completing your selection, press EXIT to return to the

basic display. You may be prompted to check the environment

settings upon exiting; select YES if you want to check the

settings, or NO to exit.

4. If your HMP155 has the chemical purge option, you can manually

start the chemical purge which will dry out the sensor from the

Functions menu.

When the HMP155 starts the purge, it will stop updating the

measurement values to the MI70 indicator for approximately eight

minutes. The measurements will be unchanging until the purge is

done. While the purge is ongoing, an indicator is displayed next to

the battery indicator.

5. Wait for the reading to stabilize; this may take up to 20 minutes.

Make sure that the Stevenson Screen is closed if you are using one.

Beware of temperature differences when measuring humidity. It is

essential that temperature of the probe and measuring environment is

the same. Even a small difference in temperature between the

environment and the probe causes an error. Temperature differences

may also cause water to condense on the sensor surface.

34 ___________________________________________________________________M210983EN-A

Page 37

Chapter 3 ________________________________________________________________ Operation

0903-021

Figure 13 PTB330 and HMP155 Connected

Graphic History

Graphic history shows you the measurements from the last hour in a

form of curve. To see longer graphs, use the data recording function to

save the data and then view it as a graph. See section Recording Data on

page 36.

To open the graphic history, press the Graphic shortcut button when

the MI70 indicator is in the basic display. You can also open the

graphical display using the Graphic history menu item in the Display

menu.

The curve for the quantity that is uppermost in the basic display is

shown first. You can show the curve for the next quantity by pressing

the Next shortcut button, or show up to three curves at the same time by

pressing the All button. The All selection is shown after browsing

through the curves of the available quantities. To get the statistical info

on the graph area (minimum, maximum and mean values), press Info.

VAISALA_______________________________________________________________________ 35

Page 38

User's Guide ______________________________________________________________________

0812-020

Figure 14 Graphic History

Recording Data

You can record measurement data into the memory of the MI70

indicator, and view it later on the display. You can also use the MI70

Link program to transfer and view the data on a PC.

To start the data recording:

1. Open the Recording/Viewing menu. You can get to this menu

directly from the basic view by pressing the Record shortcut

button.

2. Select Memory status and press Show to check the currently

available space for recordings. Press OK to exit from the memory

status view.

3. Select Record data.

4. Check the currently selected recording Interval, and press Set to

adjust it. The MI70 indicator will record the values of the currently

selected quantities at this interval (for example, one minute).

5. Check the recording Duration, and press Set to adjust it. If you

select Memory full, the recording will continue until memory is

full. Table 6 on page 37 presents the maximum recording times for

each interval with one, two and three recorded quantities.

6. Select Start/Stop recording, and press the Start button to star t the

recording. If you chose "Memory full" as the duration, you see the

maximum recording time on the display. You can also delete files

in order to empty the memory. Press Start again to accept

maximum recording time.

The recording indicator will appear in the basic view when a

recording is ongoing.

36 ___________________________________________________________________M210983EN-A

Page 39

Chapter 3 ________________________________________________________________ Operation

0812-021

Figure 15 Recording in Progress

The recording will continue until the selected duration has elapsed, until

the MI70 indicator runs out of power, or until you manually stop the

recording using the Start/Stop recording option.

You can switch the MI70 indicator off during recording to save battery.

Display message tells you that recording continues undisturbed even

when power is off. If the indicator is switched off during recording, a

progress bar is shown on the display every 10 seconds (all the time, if a

charger is connected). This bar shows the amount of recorded data.

CAUTION

Do not disconnect any cables when the data recording is on, even if the

indicator is off. This may cause loss of recorded data.

Table 6 Maximum Recording Times

Recording

interval

1 s 45 min 22 min 15 min

5 s 3 h 1 13 min 75 min

15 s 11 h 5 h 3 h

30 s 22 h 11 h 7 h

1 min 45 h 22 h 15 h

5 min 9 days 4 days 3 days

15 min 28 days 14 days 9 days

30 min 56 days 28 days 18 days

1 h 113 days 56 days 37 days

3 h 339 days 169 days 112 days

12 h 1359 days 678 days 451 days

Maximum recording time (memory full)

1 quantity 2 quantities 3 quantities

VAISALA_______________________________________________________________________ 37

Page 40

User's Guide ______________________________________________________________________

Saving Individual Data Points

You can save the currently displayed readings in memory using the

Hold/Save function. When in the basic display, press the Hold/Sa

shortcut button to freeze the currently shown readings., and press Save

to save the data point in memory.

The data points are are saved as individual files, and identified by the

saving date and time. The files remain in memory even if the indicator

is turned off.

Viewing and Deleting Recorded Files

To view the recorded files and data points:

1. Open the Recording/Viewing menu. You can get to this menu

directly from the basic view by presssing the Record shortcut

button.

2. Select View recorded data. A list of data files will be shown,

unless the memory is empty.

0811-015

Figure 16 List of Data Files

3. Select a file using the up and down arrow buttons, and view the file

using the right arrow.

To delete a file, select it and press the Delete button. To delete all

files, open the Recording/Viewing menu and select Clear data

memory.

Press the Info button to view details of the recording, including:

- Recording start time

- Recorded quantities

38 ___________________________________________________________________M210983EN-A

Page 41

Chapter 3 ________________________________________________________________ Operation

- Number of recorded data points

- Recording interval

Alarm Function

The MI70 indicator can produce an alarm when a measured quantity is

outside the allowed range. The range is controlled by setting the lower

and upper limits. When the alarm is active, the indicator will show an

alarm message, play a beeping sound, and blink the display backlight.

The alarm can only be set for one quantity at a time. Set the alarm as

follows:

1. Open the Functions menu.

2. Select Alarm.

3. Select the measured Quantity for the alarm. Only quantities that

are currently measured can be selected.

NOTE

4. Set two limit values for the alarm using the Limit options.

5. Check the Alarm on/off checkbox to enable the alarm. After you

enable the alarm and exit the menu, the alarm symbol will appear

on the display, and flash briefly.

0812-019

Figure 17 Alarm Menu

The alarm will automatically turn off if you change the measurement

configuration (change the measured quantities, or connect/disconnect

devices). If you use the alarm function, always check the alarm

settings after changes.

VAISALA_______________________________________________________________________ 39

Page 42

User's Guide ______________________________________________________________________

MI70 Link Interface Software for Data Handling

Recorded data can be transferred from the MI70 indicator to a PC by

using MI70 Link Interface Software. You can examine the recorded

data easily in Windows environment and transfer it further to a

spreadsheet program (such as Microsoft Excel) or virtually to any

Windows program in numeric or graphical format. The MI70 Link

program also allows you to monitor the readings directly with a PC

(real-time window function).

The MI70 Link program and the connection cables are available from

Vaisala. See list of accessories in section Options and Accessories on

page 85.

Connect the PTB330TS to the MI70 Link as follows:

1. Connect the connection cable between your PC and one of the

probe ports on the MI70 indicator. If you are using the USB

connection cable, you must install the included driver software

before using the cable.

2. Connect the PTB330 barometer or the HMP155 probe to the other

probe port on the MI70 indicator.

3. Turn on the MI70 indicator.

4. Start the MI70 Link program. The program detects the connection

type automatically, so there is usually no reason to select a COM

port manually.

40 ___________________________________________________________________M210983EN-A

Page 43

Chapter 4 ______________________________________________________________ Maintenance

CHAPTER 4

MAINTENANCE

This chapter contains information that is needed in maintenance of the

PTB330TS.

Cleaning

You can clean the transport case and the barometer enclosure with a

soft, lint-free cloth moistened with mild detergent.

Changing the MI70 Battery Pack

The battery pack of your MI70 indicator can be replaced if necessary.

New battery packs can be ordered from Vaisala; see Options and

Accessories on page 85. Change the battery pack as follows:

1. Turn off the MI70 indicator.

2. Open the screw on the back plate, and lift the plate from the narrow

end to remove it.

3. Note the orientation of the black battery pack connector. Detach

connector by pulling up carefully from the wires, and remove the

old battery pack.

4. Connect the black connector of the new battery pack. Ensure that

the white wires are on the right edge of the connector as shown in

Figure 18 on page 42.

VAISALA_______________________________________________________________________ 41

Page 44

User's Guide ______________________________________________________________________

Do not push the connector with conducting material, for example

with a metallic screwdriver.

0811-094

Figure 18 Changing the MI70 Battery Pack

5. Position the battery pack in inside the case, replace the back plate,

and tighten the screw.

6. Charge the battery pack before use. Refer to section Charging on

page 29.

Changing the HMP155 Probe Filter

New filters for the HMP155 probe can be ordered from Vaisala; see

Options and Accessories on page 85. Change the filter as follows:

1. Remove the filter from the probe by turning it counter-clockwise.

When pulling out the filter, be sure not to damage the sensor. Refer

to Figure 19 on page 43.

2. After removing the filter, check the O-ring and replace it if

necessary.

3. Install a new filter on the probe.

42 ___________________________________________________________________M210983EN-A

Page 45

Chapter 4 ______________________________________________________________ Maintenance

0802-159

Figure 19 HMP155 Sensor and Filter Structure

where

1 = Filter

2=O-ring

3=

HUMICAP® sensor

4 = Pt100 temperature sensor

VAISALA_______________________________________________________________________ 43

Page 46

User's Guide ______________________________________________________________________

Changing the Sensor in the HMP155

If your HMP155 uses the HUMICAP® 180R sensor, you can change it

yourself without sending in the probe for service. After changing the

sensor, you must calibrate the new sensor using serial line.

For instructions on how to change the sensor and calibrate it, refer to the

HMP155 User’s Guide. It is available for download from

www.vaisala.com.

CAUTION

HUMICAP® 180RC sensors cannot be changed by the user.

Calibration and Adjustment

The PTB330 and HMP155 are fully calibrated and adjusted as shipped

from factory. Calibration must be done always when there is reason to

believe that the device is not within the accuracy specifications.When

defining the calibration interval the long term specifications and the

requirements of the customer must be taken into consideration. Contact

Vaisala Service Centers for details. It is recommended that calibration

and adjustment should be carried out by Vaisala. See Vaisala Service

Centers on page 59.

Users can calibrate the PTB330 barometer using serial port commands.

Using the service port is recommended; see section Connecting to the

Serial Line on page 61. The calibration and adjustment procedure, as

well as the calibration commands, are described in section Calibration

and Adjustment of PTB330 on page 45.

The HMP155 can be adjusted using the MI70 indicator, or through the

serial port. This document explains the adjustment using the MI70

indicator. For instructions on using the serial port, refer to the HMP155

User’s Guide.

44 ___________________________________________________________________M210983EN-A

Page 47

Chapter 4 ______________________________________________________________ Maintenance

Calibration and Adjustment of PTB330

In PTB330, the raw measured pressure value of each barometer module

is first corrected using the corresponding multipoint adjustment values.

The additional linear adjustment (if enabled) is applied to the corrected

values. This allows the user to fine-tune the pressure reading using the

linear adjustment without performing a complete readjustment for the

barometer module, see Figure 20 on page 45.

NOTE

0708-053

Figure 20 PTB330 Adjustments

To measure new adjustment values and perform the actual adjustment,

first disable the corresponding adjustment on each barometer module

you are going to adjust (see the procedure above). If you are going to

perform a multipoint adjustment, disable also the linear adjustments. If

you are going to do only a linear adjustment, leave the multipoint

adjustments untouched.

After disabling the previous adjustments, calibrate the PTB330 against

your pressure reference. Make a note of the pressure reading of each

PTB330 barometer module separately (quantities P

, P2, and P3). Then

1

use the display/keypad to enter and activate the new multipoint/linear

adjustment factors.

Making adjustments is possible only after adjustments have been

unlocked. To unlock the adjustment menu, press the ADJ button on the

motherboard of the transmitter.

The user can select a simple offset or a two-point offset and gain

adjustment and use the LCP command for adjustment of the barometer

module. The MPCP command is used for the more sophisticated

multipoint correction capability at up to eight pressure levels. Check

first what linear corrections the transmitter is currently using before

VAISALA_______________________________________________________________________ 45

Page 48

User's Guide ______________________________________________________________________

attempting to readjust the barometer module. As the previous linear

corrections will disappear when new linear corrections are input, the

user has to take into account the previous linear corrections when

deciding about the new ones.

NOTE

Entering new linear or multipoint corrections will always cancel the

previous corrections. It is advisable to write down the previous linear

and multipoint corrections so that they will not be lost by mistake.

Table 7 Adjustment and Calibration Commands for Module

P1

Command Function

LCP1 ON/OFF Enables/Disables the linear

corrections

LCP1 Enter linear corrections

MPCP1 ON/OFF Enables/Disables the multipoint

corrections

MPCP1 Enters multipoint corrections

CDATE Shows or sets the calibration date

CTEXT Shows or sets the calibration info

text.

Opening and Closing the Adjustment Mode

The adjustment mode has to be available before you can proceed with

the adjustment and calibration. The adjustment button with indicator

LED is located in the upper corner on the left-hand side of the

motherboard. See the position of the adjustment button in Figure 21 on

page 47.

1. Open the barometer cover.

2. Press the ADJ button. The adjustment mode is now available. The

red indicator LED is on.

3. Press the ADJ button again to end the adjustment mode. The red

indicator LED is off.

46 ___________________________________________________________________M210983EN-A

Page 49

Chapter 4 ______________________________________________________________ Maintenance

0705-091

Figure 21 Inside of Open Barometer

Numbers refer to Figure 21 on page 47:

1 = Adjustment button with indicator LED

2 = Power supply module (not included in PTB330TS)

3 = Power supply mode selections (do not change)

4 = Service port (RS-232)

5 = Module 1/Module 3 connectors

6 = User port (wired to the M12 connector)

7 = Module 2/Module 4 connectors

1-Point Adjustment (LCP1)

The LCP1 command performs linear correction for barometer

module/module P1. Use the command LCP1

- to activate or deactivate the linear adjustment function

- to enter new linear offset and offset/gain pressure corrections to the

transmitter

- to edit existing linear offset and offset/gain pressure corrections.

VAISALA_______________________________________________________________________ 47

Page 50

User's Guide ______________________________________________________________________

Key in the linear corrections for each barometer module separately.

Feeding ON or OFF as a parameter enables or disables the linear

correction. A single question mark shows the reading and reference

information stored and the state of the linear correction. Each barometer

module has its own adjustment commands. If there are three barometer

modules installed, the commands LCP1, LCP2, and LCP3 will be

available. First deactivate the previous corrections by using the LCP1

OFF command.

LCP1 [x/y] [z]

where

x=ON

y=OFF

z=?

NOTE

Example

>lcp1

1. Reading ? 980.2

1. Reference ? 980.0

2. Reading ? 1100.1

2. Reference ? 1100.0

>

The new linear corrections will always cancel the previous corrections

as well as the valid date of calibration of the transmitter.

Multipoint Adjustment (MPCP1)

Use the MPCP1 command

- to perform multipoint correction for barometer module/module P1

- to activate or deactivate the multipoint adjustment function

- to enter new linear offset and offset/gain pressure corrections to the

transmitter

- to edit existing linear offset and offset/gain pressure corrections.

48 ___________________________________________________________________M210983EN-A

Page 51

Chapter 4 ______________________________________________________________ Maintenance

The command operates like LCP1, but can take up to eight reading/

reference pairs. If there are three pressure barometer modules installed,

the commands MCP1, MCP2, and MCP3 will be available. First

deactivate the previous corrections by using the MPCP1 OFF

command. Precalibration of the transmitter then gives the required

corrections. When entering new multipoint corrections, always start at

the low-pressure end and then go up the pressure range. Key in the

multipoint corrections for each barometer module separately.

NOTE

The new multipoint corrections will always cancel the previous

corrections as well as the valid date of calibration of the transmitter.

MPCP1 [x/y] [z]

where

x=ON

y=OFF

z=?

Example:

>mpcp1

1. Reading ? 980.1

1. Reference ? 980.0

2. Reading ? 999.8

2. Reference ? 1000.0

3. Reading ? 1020.2

3. Reference ? 1020.0

.

.

.

8. Reading ? 1100.1

8. Reference ? 1100.0

>

VAISALA_______________________________________________________________________ 49

Page 52

User's Guide ______________________________________________________________________

Entering Adjustment Information

Adjustment information and date are a part of the device information

that is shown using the ? command. Use the CTEXT and CDATE

commands to enter updated adjustment information.

CTEXT

Use the CTEXT command to enter text to the adjustment information

field.

Example:

>ctext Vaisala/MSL

Calibration text : Vaisala/MSL

>

CDATE

Use the CDATE command to enter date to adjustment information field.

Set the adjustment date in format YYYY-MM-DD.

>cdate 2006-06-12

Calibration date : 2006-06-12

>

Calibration and Adjustment of HMP155

The procedures below provide a simple way to check and adjust the

HMP155 using the MI70 indicator. You can perform a 1-point or

2-point adjustment on relative humidity and temperature.

The humidity quantity to be adjusted is always RH. The temperature

quantity that you can adjust using the MI70 indicator depends on your

hardware options, since the HMP155 can have two temperature sensors:

- If you do not have the additional temperature probe, the quantity

you can calibrate and adjust is T. It is measured on the HMP155

probe, next to the HUMICAP® sensor.

- If you have the additional temperature probe, the quantity is T

.

a

It is measured by the separate temperature probe that is attached to

the HMP155.

50 ___________________________________________________________________M210983EN-A

Page 53

Chapter 4 ______________________________________________________________ Maintenance

Calibrating and Adjusting Relative Humidity

1. Check that the MI70 indicator is connected to the HMP155, and

turn it on. Set the correct time, date, and environmental settings

(pressure compensation) if prompted.

2. Start the chemical purge from the Functions menu, if available.

After the chemical purge is complete, allow sufficient time for the

probe to reach ambient temperature before continuing.

3. Uncover the adjustment buttons on the HMP155 probe by

removing the protective cover and removing the calibration seal.

Refer to Figure 22 on page 51.

0801-076

Figure 22 HMP155 Adjustment Buttons

where

1 = Protective cover

2 = Down button

3 = ADJ button

4 = Up button

5 = Protective plug

VAISALA_______________________________________________________________________ 51

Page 54

User's Guide ______________________________________________________________________

4. Activate the adjustment mode by holding down the ADJ button on

the probe until the message below appears on the MI70 display.

0811-086

Figure 23 Starting Adjustment Mode for HMP155

5. Press OK to move on to the adjustment and select RH as the

quantity you want to adjust.

0811-087

Figure 24 Select Quantity

6. Check the environment settings if prompted.

7. Insert the probe into a known reference environment. You can, for

example, use the HMK15 humidity calibrator.

If you have the additional temperature probe, it is not necessary to

place it into the reference environment. The HMP155 turns off the

additional temperature probe during RH adjustment, and uses

internal temperature measurement instead. When you exit the

adjustment mode or start calibrating temperature, the HMP155

takes the temperature probe into use again.

8. Wait for the reading to stabilize, and compare the reading with the

reference. If the reading is not within the stated accuracy of the

HMP155, continue this procedure to adjust the measurement. If the

reading is accurate, exit the adjustment mode by pressing the Back

button, then the Exit button.

9. Press the Adjust button and select 1-point or 2-point calibration. If

a Cannot adjust message is displayed, press OK and try again.

10. Follow the instructions given on the display to finish the

adjustment.

52 ___________________________________________________________________M210983EN-A

Page 55

Chapter 4 ______________________________________________________________ Maintenance

Calibrating and Adjusting Temperature

NOTE

If your HMP155 has the additional temperature probe, you cannot

calibrate the temperature sensor on the HMP155 probe using the MI70

indicator. However, you can do so using the CT command on the serial

line. Additional calibration and adjustment methods are provided in

the HMP155 User’s Guide, which is available for download from

www.vaisala.com.

1. Check that the MI70 indicator is connected to the HMP155, and

turn it on. Set the correct time, date, and environmental settings

(pressure compensation) if prompted.

2. Uncover the adjustment buttons on the HMP155 probe by

removing the protective cover and removing the calibration seal.

Refer to Figure 22 on page 51.

3. Activate the adjustment mode by holding down the ADJ button on

the probe.

4. Press OK to move on to the adjustment and select T or Ta as the

quantity you want to adjust. Only one of them is shown; if you can

select T, it means you do not have the additional temperature

probe.

5. Insert the probe into a known reference environment:

- If you are calibrating and adjusting T, insert the HMP155

probe in the environment.

- If you are calibrating and adjusting Ta, insert the additional

temperature probe in the environment, and ignore the main

HMP155 probe.

6. Wait for the reading to stabilize, and compare the reading with the