Vaisala PDT101 Quick Start Guide

Vaisala Differential Pressure Transmitter

Performance

Measurement range (bidirectional)

±60 Pa, ±125 Pa,

Overpressure

Proof pressure

1.0 bar

Burst pressure

1.7 bar

Static pressure

1.7 bar

Pressure type

Differential, gauge,

vacuum and compound

Accuracy

(incl. non-linearity, hysteresis,

calibration settings)

0.4 % span

Long-term stability

≤0.5 % span/year

Response time (10...90 %)

250 ms

Warm-up time

15 s

Compensated temperature range

+2...+54 °C

(+35.6...+129.2 °F)

Temperature dependence

±(0.065 Pa + 0.054 % of reading) / °C

O + 0.03 % of reading) / °F

(reference 21 °C or 70 °F)

Mounting position error

(zero adjustable)

≤1 %/g (calibration in vertical

position is standard)

Adjustments (front accessible):

Zero (span low)

±5 % span

Span (span high)

±3 % span

Operating environment

Operating temperature

-18...+70 °C (-0.4...+158 °F)

Storage temperature

-40...+82 °C (-40...+179.6 °F)

Electromagnetic compatibility

EN61326-1, Basic immunity

test requirements

Note: If used in an electromagnetic field of 3 V/m, with narrow frequency area

max. 0.8% (with accuracy specified 0.4%).

Inputs and outputs

Process connection

1/4" barbed fittings

Output signal

2-wire

4...20 mA

3-wire

0...5 VDC

(user selectable 0...10 VDC)

Operating voltage

2-wire output 4...20 mA

12...36 VDC

3-wire output 0...5 VDC

11.5...36 VDC

or 24 VAC

3-wire output 0...10 VDC

14...36 VDC

or 24 VAC

Max. loop resistance for 4...20 mA

≤ (Supply voltage - 12V)/0.022 A

Supply current

max. 20 mA for 4...20 mA output signal

Optical process diagnostics

LED visual indicator

Electrical connection

Euro style pluggable terminal block accepts

12...26 AWG wire (0.13 up to 3.31 mm2)

Mechanics

Medium (measured gas)

Clean and dry air, non-conducting and

non-corrosive gases

Material

Process connection

Brass

Sensor element

Silicon, aluminum, glass

Case

NEMA type 1 fire-retardant ABS 1

(meets UL94-5VA)

Mounting

Threaded fastener for wall mounting

or DIN rail type EN50022

Housing classification

IP40

Weight

0.07 kg

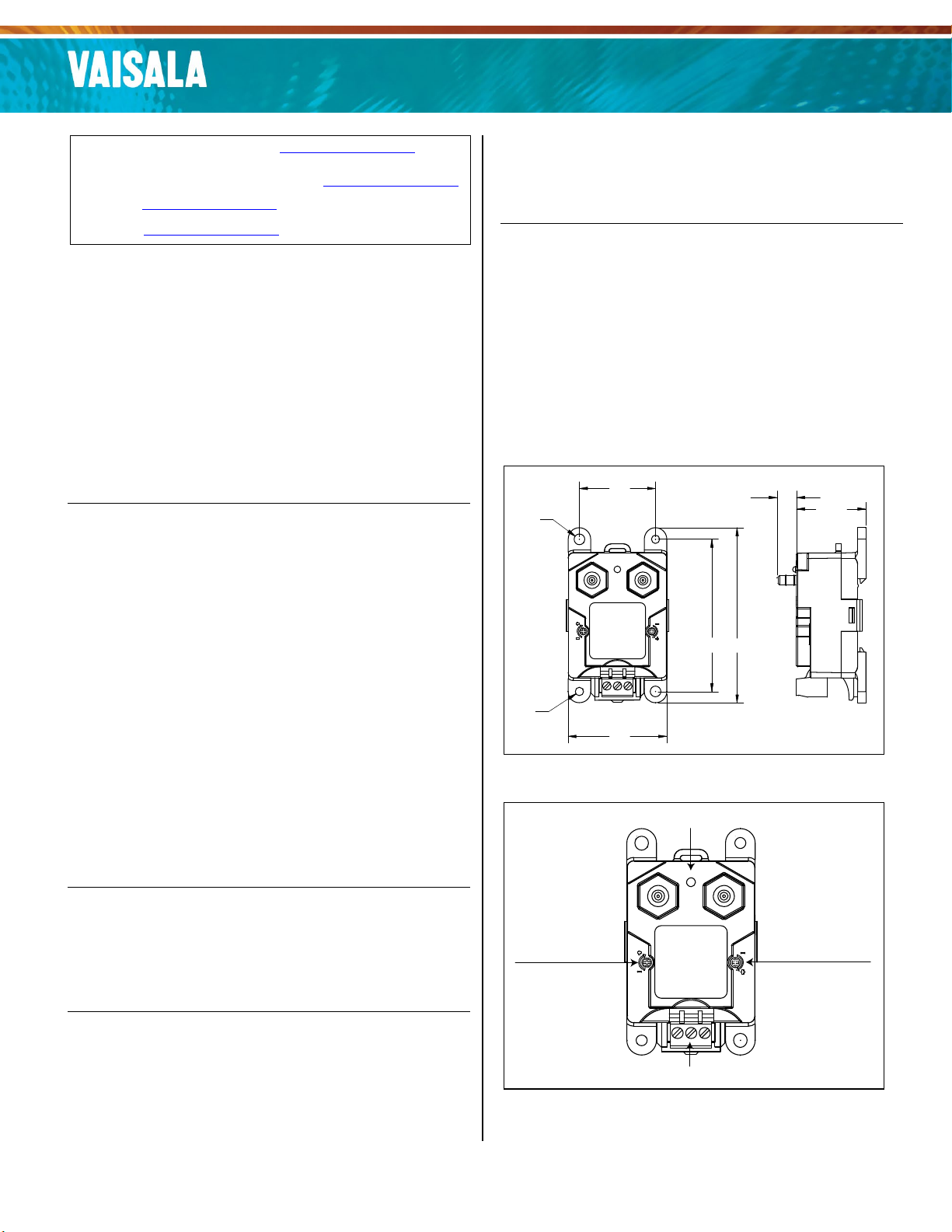

POWER

HI LO

SPAN

ZERO

ø

5

ø

4

37

48

74 84.6

9.4

33.6

POW ER

HI LO

SPAN

ZERO

Zero adjust

potentiometer

Span adjust

potentiometer

Power LED

Terminal block

Die deutschsprachige Version kann von www.vaisala.com/PDT101

heruntergeladen werden.

Vous pouvez télécharger la version française sur www.vaisala.com/PDT101.

日本語版は www.vaisala.com/PDT101 からダウンロードできます。

您可以访问 www.vaisala.com/PDT101 下载简体中文翻译。

WARNING - READ BEFORE INSTALLATION

Vaisala Differential Pressure Transmitter PDT101 is a high-performance

instrument designed primarily for use in life science and cleanroom

applications. PDT101 is not authorized for use as a critical component in life

support devices or systems. Consult Vaisala before installing if there are any

questions or concerns.

Overpressure: Pressure spikes in excess of the rated overpressure capability

of the transmitter may cause irreversible electrical and/or mechanical damage

to the transmitter.

Static electrical charges: To avoid damage to the transmitter the

operator/installer should follow proper ESD (electrostatic discharge)

protection procedures.

TECHNICAL SPECIFICATION

PDT101

MOUNTING

The transmitter can be mounted on an EN550022 rail or with M4 (#8) or

M5 (#10) screws using the mounting holes provided.

of 80 - 120 Mhz, it is possible that the current output of PDT101 can deviate

repeatability and zero/span

±(0.00015 inH

±0.25 inH2O, or ±0.5 inH2O

2

or

Figure 1 Dimensions (in mm)

Figure 2 PDT101 Transmitter

M211284EN-H ___________________________________________________________________________________ 1

Quick Guide _______________________________________________________________________________ PDT101

+

–

–

+

–

+

BCS

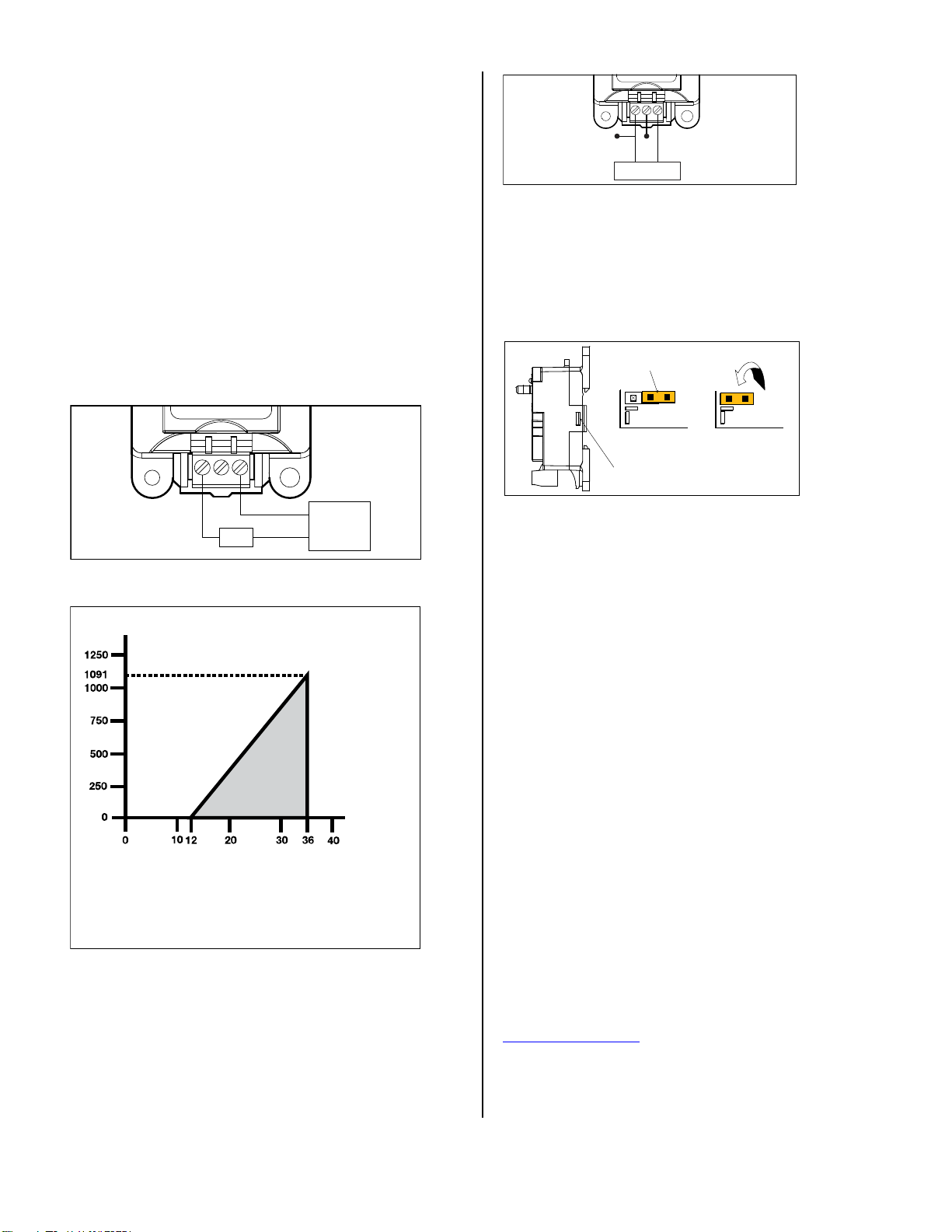

Power

Supply

Loop Resistance (Ω)

Supply

Voltage (V)

Vmin = 12V+ [.022A*(R L)]

*includes a 10% safety factor

RL = RS + RW

RL = Loop Resist ance (ohms)

RS = Sense Resistance (ohms)

RW = Wire Resistance (ohms)

Loop Supply Voltage (Vdc)

OPERATI NG

REGIO N

+

–

Output signal

Common (V-)

V

out Vin (V+, Supply)

Power Supply

Jumper (orange or red)

Housing tabs (2 pcs)

0...5 Vdc

0...10 Vdc

SETUP

Transmitters are calibrated in a vertical position at the factory. Mounting in a

horizontal position may cause a zero shift of as much as +/-1 % of span. To

check for zero shift, see section Calibration below.

ELECTRICAL WIRING

1. Remove the terminal block on the front of the transmitter.

2. Follow the terminal block label markings on the PDT101 to identify the

terminals, and connect the wires.

3. Firmly reinstall the terminal block plug to its mating connector.

Current Output Wiring (Black Terminal Block)

The left, negative (-), and right, positive (+) terminals are used, ignore the

center terminal which is not used. Connect the power supply positive lead to

the PDT101 positive terminal, connect the negative power supply lead to the

negative terminal of the BCS 4...20 mA input. Last, connect the (-) negative

terminal on the PDT101 to the (+) positive BCS input.

Use of a shielded cable, with the shield grounded, is required. Do not connect

the shield to the transmitter.

Figure 5 Voltage Output Wiring

The PDT101 voltage output model is supplied as standard with 0...5 VDC

output. You can convert the unit to 0...10 VDC output by moving a jumper

inside the transmitter. Access the jumper by simultaneously pushing both

housing tabs away from the housing. Change jumper (orange or red) to the left

as shown below, and carefully reattach the housing cover. When finished,

mark the checkbox on front label indicating that the unit now provides a 0...10

VDC output.

Figure 6 Voltage Output Jumper

Figure 3 Current Output Wiring

Figure 4 Load Limitations

Voltage Output Wiring (Green Terminal Block)

The left terminal is the common (supply and output negative), the right

terminal is the Vin (supply positive). The middle terminal is the Vout (output

signal).

Use of a shielded cable, with the shield grounded, is required. Do not connect

the shield to the transmitter. Maximum cable length for voltage output wiring

is 30 m (98.4 ft).

CALIBRATION

1. Pneumatically connect the transmitter’s pressure ports to each other.

The barbed pressure connections accept 1/4” O.D. 1/8” I.D. tubing.

2. Measure the analog output of the transmitter to establish the zero offset

reading in the as-installed position.

3. If the reading is not at the middle of the output range (for example, 12 mA

for 4 … 20 mA output), the zero point of the transmitter has shifted. To

remove the zero shift, adjust the transmitter as described below.

ADJUSTMENT

Note: You need a high accuracy pressure standard and high quality electrical

meter to adjust the PDT101.

1. Connect the pressure standard to the ports of the PDT101.

2. Bring the pressure to 0 % of the transmitter’s span.

3. Adjust the zero potentiometer (on the front, left side of the transmitter) so

that the analog output value is at the low end of its range. Use a 3/32” or

2.5 mm slotted or Phillips screwdriver to turn the potentiometer.

4. Now bring the pressure to 100 % of the transmitter’s span.

5. Adjust the span potentiometer (on the front, right side of the transmitter) so

that the analog output value is at the high end of its range.

REMOVAL FROM DIN RAIL

1. Unplug the wiring terminal block from the transmitter.

2. Insert a small slotted screwdriver into the black plastic clip extending

slightly below the transmitter case.

3. Raise the screwdriver handle up thereby forcing the spring clip down.

WARRANTY

For warranty information, visit our Internet pages at:

www.vaisala.com/warranty

DISPOSAL

Dispose of the unit according to local regulations. Do not dispose of with

regular household waste. Recycle all applicable material.

.

© Vaisala 2020. All rights reserved. ___________________________________________________________________ 2

Loading...

Loading...