Page 1

r

USER'S GUIDE

Vaisala SPECTRACAP®

Oxygen Transmitte

OMT355

M210735EN-D

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2008

No part of this manual may be reproduced in any form or by any means,

electronic or mechanical (including photocopying), nor may its contents

be communicated to a third party without prior written permission of the

copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding

obligations for Vaisala towards the customer or end user. All legally

binding commitments and agreements are included exclusively in the

applicable supply contract or Conditions of Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

General Safety Considerations . . . . . . . . . . . . . . . . . . . . .11

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Product Related Safety Precautions . . . . . . . . . . . . . . . . . .12

ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Regulatory Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

CHAPTER 2

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Introduction to Vaisala SPECTRACAP® Oxygen

Transmitter OMT355 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Oxygen Measurement Range . . . . . . . . . . . . . . . . . . . . . . . .17

OMT355 for In-Line and Sampling Cell Mounting . . . . . . .18

Ambient Gas Measurement Version of OMT355 . . . . . . . .20

CHAPTER 3

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Measurement Principle and Sensor Technology . . . . . . . .21

Construction of OMT355 Probe . . . . . . . . . . . . . . . . . . . . . .23

Eye Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

CHAPTER 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Selecting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Chemical Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

OMT355 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Temperature Conditions of Installation Location . . . . . . . .27

Powerful Light Sources Near the Oxygen Measurement

Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Maximum Allowed Installation Angle . . . . . . . . . . . . . . . . .28

Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Process Conditions in Regard to Mounting Options . . . . .29

Flange Mounted for In-Line Process Gas Measurement . .31

VAISALA________________________________________________________________________ 1

Page 4

________________________________________________________________________________

Suitable Process Flanges . . . . . . . . . . . . . . . . . . . . . . 31

Filter Recommendation . . . . . . . . . . . . . . . . . . . . . . . . 31

Mounting with Flange Adapter . . . . . . . . . . . . . . . . . . . 32

Mounting with Sampling Cell . . . . . . . . . . . . . . . . . . . . . . .34

Filter Recommendation . . . . . . . . . . . . . . . . . . . . . . . . 34

Mounting with Wall Mounting Bracket . . . . . . . . . . . . . 36

Tubing Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation Instructions for Swagelok Tube Fittings 36

Sampling Cell Instructions . . . . . . . . . . . . . . . . . . . . . . 37

Mounting OMT355 for Ambient Gas Measurement . . . . . .39

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Signal and Power Supply Wiring . . . . . . . . . . . . . . . . . . . .41

Connecting OMT355 with Optional 8-Pin Connector. . 44

CHAPTER 5

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Device Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Keypad, Display and LEDs . . . . . . . . . . . . . . . . . . . . . . . .45

Service Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Installing the Driver for the USB Cable . . . . . . . . . . . . 46

Customer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Local Interface (Keypad and Display) . . . . . . . . . . . . . . . . .48

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Display Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Error Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Service Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Customer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

General Instructions for Using Functions . . . . . . . . . . . . . .52

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Serial Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

List of Serial Commands . . . . . . . . . . . . . . . . . . . . . . . . . .57

Outputting Measurement Results . . . . . . . . . . . . . . . . . . . .58

Start Continuous Output Command (R) . . . . . . . . . . . . . . .58

Stop Continuous Output Command (S) . . . . . . . . . . . . . . .59

Show/Set Continuous Output Interval Command (INTV) . .59

Send Measurement Results Command (SEND) . . . . . . . .59

Show/Set Serial Communications Mode Command

(SMODE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Show/Set Serial Communications Mode for Line 2

Command (SMODE2) . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Show/Set Serial Communications Settings Command

(SERI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

2 _______________________________________________________________________________

Page 5

________________________________________________________________________________

Show/Set Serial Communication Settings for Line 2

Command (SERI2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Show Serial Line 1 Status Command (SCI1) . . . . . . . . . . .63

Show Serial Line 2 Status Command (SCI2) . . . . . . . . . . .63

Show Measurement Status Command (MEA) . . . . . . . . . .64

Oxygen Statistics Display Function . . . . . . . . . . . . . . . . . .64

Temperature Statistics Display Function . . . . . . . . . . . . . .65

Formatting Measurement Results . . . . . . . . . . . . . . . . . . . .65

Set Output Format Command (FORM) . . . . . . . . . . . . . . .65

Show/Set Date Command (DATE) . . . . . . . . . . . . . . . . . .67

Show/Set Time Command (TIME) . . . . . . . . . . . . . . . . . . .68

Networking Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Show/Set Device Address Command (ADDR) . . . . . . . . .69

Open Communications Line Command (OPEN) . . . . . . . .69

Close Serial Line in Poll Mode Command (CLOSE) . . . . .70

Set Echoing Mode Command (ECHO) . . . . . . . . . . . . . . .70

Accessing Service Level Commands . . . . . . . . . . . . . . . . .71

Issue Password Command (PASS) . . . . . . . . . . . . . . . . . .71

Issue Password Function (Pas) . . . . . . . . . . . . . . . . . . . . .72

Analog Output Calibration . . . . . . . . . . . . . . . . . . . . . . . . . .73

Calibrate Analog Output Command (ICAL) . . . . . . . . . . . .73

Analog Output Scaling and Settings . . . . . . . . . . . . . . . . . .73

Scale Analog Output Function (Ascl) . . . . . . . . . . . . . . . . .73

Show/Set Output Parameters Command (OUT_PARAMS) 75

Analog Output Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Set Test Current to Analog Output Command (ITEST) . . .75

Test Analog Output Function (Aou) . . . . . . . . . . . . . . . . . .76

Relay Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Show/Set Relay Operating Mode Command

(RELAY_MODE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Show/Set Relay Trigger Points Command (RSEL) . . . . . .78

Test Alarm Relay Function (Ala) . . . . . . . . . . . . . . . . . . . .78

Device Information and Other General Commands . . . . . .79

Show Information about the Device Command (?) . . . . . .79

Show Information about the Device Overriding POLL

Mode Command (??) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Show Measuring Parameters Command (CALCS) . . . . . .80

Show Calibration Information (CINFO) . . . . . . . . . . . . . . .80

Show Display Board Status Command (DB) . . . . . . . . . . .81

List Commands Command (HELP) . . . . . . . . . . . . . . . . . .81

Show Laser Temperature Controller Status Command

(LTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Show Output Status Command (OUT) . . . . . . . . . . . . . . .82

Show All Modifiable Parameter Values (PARAM) . . . . . . .83

Measure Signal Level Command (SIL) . . . . . . . . . . . . . . .84

Signal Level Display Function (Sil) . . . . . . . . . . . . . . . . . .84

Show Statistical Information Command (STATS) . . . . . . .85

Show Status of Subfunctions Command (STATUS) . . . . .85

Show Product Name and Software Version Command

(VERS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

VAISALA________________________________________________________________________ 3

Page 6

________________________________________________________________________________

Memory Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Save Parameters Command (SAVE) . . . . . . . . . . . . . . . . .86

Resetting the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Reset Command (RESET) . . . . . . . . . . . . . . . . . . . . . . . . .87

Reset Function (Off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

CHAPTER 6

SETTING ENVIRONMENTAL PARAMETERS . . . . . . . . . . . . . . . . . . . . . .89

Environmental Parameter Compensations . . . . . . . . . . . . .89

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Operating Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Show/Set Pressure for Compensation Command

(PRES). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Set Pressure for Compensation Command (XPRES) . 93

Set (Average) Process Pressure Function (App). . . . . 93

Background Gas Effects . . . . . . . . . . . . . . . . . . . . . . . . . .94

General Information About Background Gas Effects. . 94

Water Content of Background Gas . . . . . . . . . . . . . . . 95

Set Water Content for Compensation Command (H2O) 97

Set (Average) Water Content Function (H2O). . . . . . . 98

CO2 Concentration of Background Gas. . . . . . . . . . . . 98

Set Carbon Dioxide Content for Compensation

Command (CO2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Set (Average) Carbon Dioxide Content Function (CO2) 99

Setting Several/All Environmental Parameters with

Single Command (ENV) . . . . . . . . . . . . . . . . . . . . . . . . . .100

CHAPTER 7

CALIBRATION AND ADJUSTMENT (IN-LINE AND SAMPLING CELL

VERSIONS OF OMT355) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Hardware Arrangements for Calibration and

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Gas Feed Setup for Calibration and Adjustment . . . . . . .102

Using Ambient Air . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Using Bottled Gas and Calibration Chamber. . . . . . . 103

Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Calibration or Adjustment in Process. . . . . . . . . . . . . 103

Connections and Systems . . . . . . . . . . . . . . . . . . 104

Preparations for Adjustment . . . . . . . . . . . . . . . . . 104

Connecting the Gas . . . . . . . . . . . . . . . . . . . . . . . 104

Adjusting Gas Flow. . . . . . . . . . . . . . . . . . . . . . . . 105

Information on Calibration Gases. . . . . . . . . . . . . . . . 106

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Using Ambient Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Using Calibration Gases . . . . . . . . . . . . . . . . . . . . . . . . .108

Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Lock Outputs for Calibration Command (ADJUST) . . . . .108

Calibration Check Function (Cal.C) . . . . . . . . . . . . . . . . .109

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

4 _______________________________________________________________________________

Page 7

________________________________________________________________________________

Possible Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

One-Point Adjustment Using Serial Line . . . . . . . . . . . . .110

Make One-Point Adjustment Command (COXY1). . . 110

One-Point Adjustment Procedure Using Serial Line . 111

One-Point Adjustment Using Local Interface . . . . . . . . . .113

One-Point Adjustment Function (CAL1). . . . . . . . . . . 113

One-Point Adjustment Procedure Using Local

Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Two-Point Adjustment Using Serial Line . . . . . . . . . . . . .115

Make Two-Point Adjustment Command (COXY2). . . 115

Two-Point Adjustment Procedure Using Serial Line . 116

Two-Point Adjustment Using Local Interface . . . . . . . . . .119

Two-Point Adjustment Function (CAL2). . . . . . . . . . . 119

Two-Point Adjustment Procedure Using Local

Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Restoring Factory Calibration . . . . . . . . . . . . . . . . . . . . .121

Restore Factory Calibration Command

(FCRESTORE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Restore Factory Calibration Function (Fac). . . . . . . . 121

CHAPTER 8

CALIBRATION AND ADJUSTMENT (AMBIENT GAS MEASUREMENT

VERSION OF OMT355) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Hardware Arrangements for Calibration and

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Gas Feed Setup for Calibration and Adjustment . . . . . . .125

Using Ambient Air . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Using Bottled Calibration Adjustment Gas. . . . . . . . . 125

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Using Ambient Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Using Calibration Gas . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Information on Calibration Gases . . . . . . . . . . . . . . . . . .129

Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Lock Outputs for Calibration Command (ADJUST) . . . . .129

Calibration Check Function (Cal.C) . . . . . . . . . . . . . . . . .130

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Possible Adjustments for Ambient Measurement Version 131

One-Point Adjustment Using Serial Line . . . . . . . . . . . . .132

One-Point Adjustment Command (COXY1). . . . . . . . 132

One-Point Adjustment Procedure Using Serial Line . 133

One-Point Adjustment Using Local Interface . . . . . . . . . .135

One-Point Adjustment Function (CAL1). . . . . . . . . . . 135

One-Point Adjustment Procedure Using Local

Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Restoring Factory Calibration . . . . . . . . . . . . . . . . . . . . .136

Restore Factory Calibration Command

(FCRESTORE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Restore Factory Calibration Function (Fac). . . . . . . . 137

VAISALA________________________________________________________________________ 5

Page 8

________________________________________________________________________________

CHAPTER 9

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Field Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Cleaning the Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Using Solvents to Clean the Optics . . . . . . . . . . . . . . 140

Cleaning the Mirror. . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Cleaning the Lens . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Replacing Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . .142

OMT355 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Filter Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Cleaning and Changing the Stainless Steel Mesh

Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Changing the PTFE Filter. . . . . . . . . . . . . . . . . . . . . . 143

Spare Parts and Accessories . . . . . . . . . . . . . . . . . . . . . .144

CHAPTER 10

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Operation Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Error Detection During Operation . . . . . . . . . . . . . . . . . . .146

Error Control and Error Categories . . . . . . . . . . . . . . . . .147

Fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Nonfatal Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Emergency Shutdown State . . . . . . . . . . . . . . . . . . . 149

Show Error Control Status (ERR) . . . . . . . . . . . . . . . . . .149

Show Error Log (ERRL) . . . . . . . . . . . . . . . . . . . . . . . . . .150

Show Detected Errors (ERRS) . . . . . . . . . . . . . . . . . . . . .150

Show Error Table (ERRT) . . . . . . . . . . . . . . . . . . . . . . . .150

Error Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Error Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Return Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Vaisala Service Centers . . . . . . . . . . . . . . . . . . . . . . . . . . .153

CHAPTER 11

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

APPENDIX A

FLANGE PREPARATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . .159

APPENDIX B

HUMIDITY CONVERSION TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

6 _______________________________________________________________________________

Page 9

________________________________________________________________________________

List of Figures

Figure 1 Flange Mounted Vaisala SPECTRACAP® Oxygen

Transmitter OMT355 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 2 OMT355 with Sampling Cell. . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 3 OMT355 for Ambient Gas Measurement. . . . . . . . . . . . . . . . .20

Figure 4 O2 Absorption Spectrum Around the 760 nm Near Infrared

Region . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Figure 5 Adjacent O2 Absorption Lines and Laser Emission Peak . . . .22

Figure 6 Schematic of Probe Design . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 7 OMT355 Laser Eye Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 8 OMT355 Dimensions in mm. . . . . . . . . . . . . . . . . . . . . . . . . . .26

Figure 9 Installation Angle Limitations in High Humidities . . . . . . . . . . .29

Figure 10 OMT355 Transmitter with Flange Adapter. . . . . . . . . . . . . . . .31

Figure 11 Dimensions, OMT 355 Flange Mounted . . . . . . . . . . . . . . . . .33

Figure 12 OMT355 Transmitter with Sampling Cell. . . . . . . . . . . . . . . . .34

Figure 13 Sample Gas Treatment System. . . . . . . . . . . . . . . . . . . . . . . .35

Figure 14 Swagelok Tube Fitting Instructions . . . . . . . . . . . . . . . . . . . . .37

Figure 15 Detaching Sampling Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Figure 16 Dimensions, OMT355 with Sampling Cell . . . . . . . . . . . . . . . .38

Figure 17 OMT355 for Ambient Gas Measurement with Wall Mounting

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Figure 18 OMT355 Wall Mounted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 19 Dimensions and Drilling Holes, Wall Mounting Bracket (Right)

and Flange Adapter (Left) . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 20 Connections/Local Interface Layout. . . . . . . . . . . . . . . . . . . . .42

Figure 21 Optional 8-Pin Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 22 OMT355 Display Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Figure 23 Effect of Process Pressure Compensation . . . . . . . . . . . . . . .91

Figure 24 Attaching OMT355 Probe into Calibration Chamber . . . . . . .103

Figure 25 Flow Rate vs. Pressure, Back Pressure Valve Swagelok

SS-CHSM2-KZ-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Figure 26 Oxygen Readings in Relative Humidity . . . . . . . . . . . . . . . . .108

Figure 27 Attaching OMT355 Probe into Sample Cell . . . . . . . . . . . . . .126

Figure 28 Oxygen Readings in Alternating Humidity . . . . . . . . . . . . . . .127

Figure 29 Calibration Gas O2 Concentration Readings for Ambient

Gas Measurement Version of OMT355 . . . . . . . . . . . . . . . . .128

Figure 30 Location of Mirror in Oxygen Measurement Probe . . . . . . . .140

Figure 31 Location of Lens in Oxygen Measurement Probe . . . . . . . . .141

Figure 32 Stainless Steel Mesh and PTFE Filters . . . . . . . . . . . . . . . . .142

VAISALA________________________________________________________________________ 7

Page 10

________________________________________________________________________________

8 _______________________________________________________________________________

Page 11

________________________________________________________________________________

List of Tables

Table 1 Chemical tolerance of sealing materials . . . . . . . . . . . . . . . . . . .26

Table 2 Process Conditions and Mounting Options . . . . . . . . . . . . . . . . .30

Table 3 8-Pin Connector Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Table 4 Meaning of the Command Line Elements . . . . . . . . . . . . . . . . . .56

Table 5 OMT355 Default Serial Communication Settings. . . . . . . . . . . . .56

Table 6 List of Serial Commands without Password. . . . . . . . . . . . . . . . .57

Table 7 List of Additional Serial Commands with Password Given. . . . . .57

Table 8 Format String Abbreviations and Quantities . . . . . . . . . . . . . . . .66

Table 9 Format String Modifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Table 10 Conversion Table from T and RH to Absolute Humidity and the

Effect of Humidity on Transmitter Reading . . . . . . . . . . . . . . . . .96

Table 11 Available Spare Parts and Accessories. . . . . . . . . . . . . . . . . . . .144

Table 12 Actions When Fatal Error Has Been Detected. . . . . . . . . . . . . . .147

Table 13 Actions When Nonfatal Error Has Been Detected . . . . . . . . . . . .148

Table 14 Actions When Warning Has Been Detected . . . . . . . . . . . . . . . .148

Table 15 Emergency Shutdown Actions. . . . . . . . . . . . . . . . . . . . . . . . . . .149

Table 16 Error Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Table 17 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Table 18 Background Gas Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Table 19 Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Table 20 Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Table 21 Approvals and Fulfilled Standards . . . . . . . . . . . . . . . . . . . . . . . .157

Table 22 Dimensions and Mechanics. . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Table 23 Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

VAISALA________________________________________________________________________ 9

Page 12

________________________________________________________________________________

10 ______________________________________________________________________________

Page 13

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

About This Manual

WARNING

CAUTION

This manual provides information for installing, operating, and

maintaining Vaisala SPECTRACAP® Oxygen Transmitter OMT355.

General Safety Considerations

Throughout the manual, important safety considerations are highlighted

as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

NOTE

VAISALA_______________________________________________________________________ 11

Note highlights important information on using the product.

Page 14

User's Guide ______________________________________________________________________

Feedback

Vaisala Customer Documentation Team welcomes your comments and

suggestions on the quality and usefulness of this publication. If you find

errors or have other suggestions for improvement, please indicate the

chapter, section, and page number. You can send comments to us by email: manuals@vaisala.com.

Product Related Safety Precautions

The Vaisala SPECTRACAP® Oxygen Transmitter OMT355 delivered

to you has been tested for safety and approved as shipped from the

factory. The wetted components of the transmitter are oxygen

compatible, and have been cleaned at the factory to ensure that they can

be safely placed in 100% oxygen. Only oxygen compatible lubricant

(Krytox 240 AC) has been used in the assembly.

WARNING

CAUTION

CAUTION

Note the following precautions:

Ground the product, and verify outdoor installation grounding

periodically to minimize shock hazard.

Do not modify the unit. Improper modification can damage the

product or lead to malfunction.

The OMT355 is a Class 1 laser product.

Normal handling and operation of the device is eye-safe, because laser

radiation is collimated and maintained inside the probe, as is

schematically shown in Figure 7 on page 24. No laser radiation is

emitted outside the probe. Avoid placing reflective surfaces (tools,

etc.) directly into the probe when the transmitter is in operation, since

this might cause reflection of laser radiation outside the probe.

12 __________________________________________________________________ M210735EN-D

Page 15

Chapter 1 ________________________________________________________ General Information

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations.

Do not dispose of with regular household refuse.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. However, it is possible to damage the

product by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench. When this is not possible, ground

yourself with a wrist strap and a resistive connection cord to the

equipment chassis before touching the boards. When neither of the

above is possible, at least touch a conductive part of the equipment

chassis with your other hand before touching the boards.

- Always hold the boards by the edges and avoid touching the

component contacts.

Recycling

VAISALA_______________________________________________________________________ 13

Page 16

User's Guide ______________________________________________________________________

Regulatory Compliances

The OMT355 is classified as Class 1 laser device in accordance with

IEC 60825-1.

Trademarks

SPECTRACAP® is a registered trademark of Vaisala. Kalrez® and

®

Krytox

are registered trademarks of DuPont.

License Agreement

All rights to any software are held by Vaisala or third parties. The

customer is allowed to use the software only to the extent that is

provided by the applicable supply contract or Software License

Agreement.

14 __________________________________________________________________ M210735EN-D

Page 17

Chapter 1 ________________________________________________________ General Information

Warranty

Vaisala hereby represents and warrants all Products

manufactured by Vaisala and sold hereunder to be free

from defects in workmanship or material during a

period of twelve (12) months from the date of delivery

save for products for which a special warranty is given.

If any Product proves however to be defective in

workmanship or material within the period herein

provided Vaisala undertakes to the exclusion of any

other remedy to repair or at its own option replace the

defective Product or part thereof free of charge and

otherwise on the same conditions as for the original

Product or part without extension to original warranty

time. Defective parts replaced in accordance with this

clause shall be placed at the disposal of Vaisala.

Vaisala also warrants the quality of all repair and

service works performed by its employees to products

sold by it. In case the repair or service works should

appear inadequate or faulty and should this cause

malfunction or nonfunction of the product to which the

service was performed Vaisala shall at its free option

either repair or have repaired or replace the product in

question. The working hours used by employees of

Vaisala for such repair or replacement shall be free of

charge to the client. This service warranty shall be

valid for a period of six (6) months from the date the

service measures were completed.

This warranty does not however apply when the defect

has been caused through

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use of

the Product or negligence or error in storing,

maintaining or in handling the Product or any

equipment thereof;

c) wrong installation or assembly or failure to se rv ice

the Product or otherwise follow Vaisala's service

instructions including any repairs or installation or

assembly or service made by unauthorized personnel

not approved by Vaisala or replacements with parts not

manufactured or supplied by Vaisala;

d) modifications or changes of the Product as well as

any adding to it without Vaisala's prior authorization;

e) other factors depending on the Customer or a third

party.

Notwithstanding the aforesaid Vaisala's liability under

this clause shall not apply to any defects arising out of

materials, designs or instructions provided by the

Customer.

This warranty is however subject to following

conditions:

a) A substantiated written claim as to any alleged

defects shall have been received by Vaisala within

thirty (30) days after the defect or fault became known

or occurred, and

b) The allegedly defective Product or part shall, should

Vaisala so require, be sent to the works of Vaisala or to

such other place as Vaisala may indicate in writing,

freight and insurance prepaid and properly packed and

labelled, unless Vaisala agrees to inspect and repair the

Product or replace it on site.

This warranty is expressly in lieu of and excludes all

other conditions, warranties and liabilities, express or

implied, whether under law, statute or otherwise,

including without limitation any implied warranties of

merchantability or fitness for a particular purpose and

all other obligations and liabilities of Vaisala or its

representatives with respect to any defect or deficiency

applicable to or resulting directly or indirectly from the

Products supplied hereunder, which obligations and

liabilities are hereby expressly cancelled and waived.

Vaisala's liability shall under no circumstances exceed

the invoice price of any Product for which a warranty

claim is made, nor shall Vaisala in any circumstances

be liable for lost profits or other consequential loss

whether direct or indirect or for special damages.

VAISALA_______________________________________________________________________ 15

Page 18

User's Guide ______________________________________________________________________

16 __________________________________________________________________ M210735EN-D

Page 19

Chapter 2 __________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

Introduction to Vaisala SPECTRACAP® Oxygen Transmitter OMT355

The following sections provide a short overview of Vaisala

SPECTRACAP® Oxygen Transmitter OMT355 and describes the three

different versions of the product.

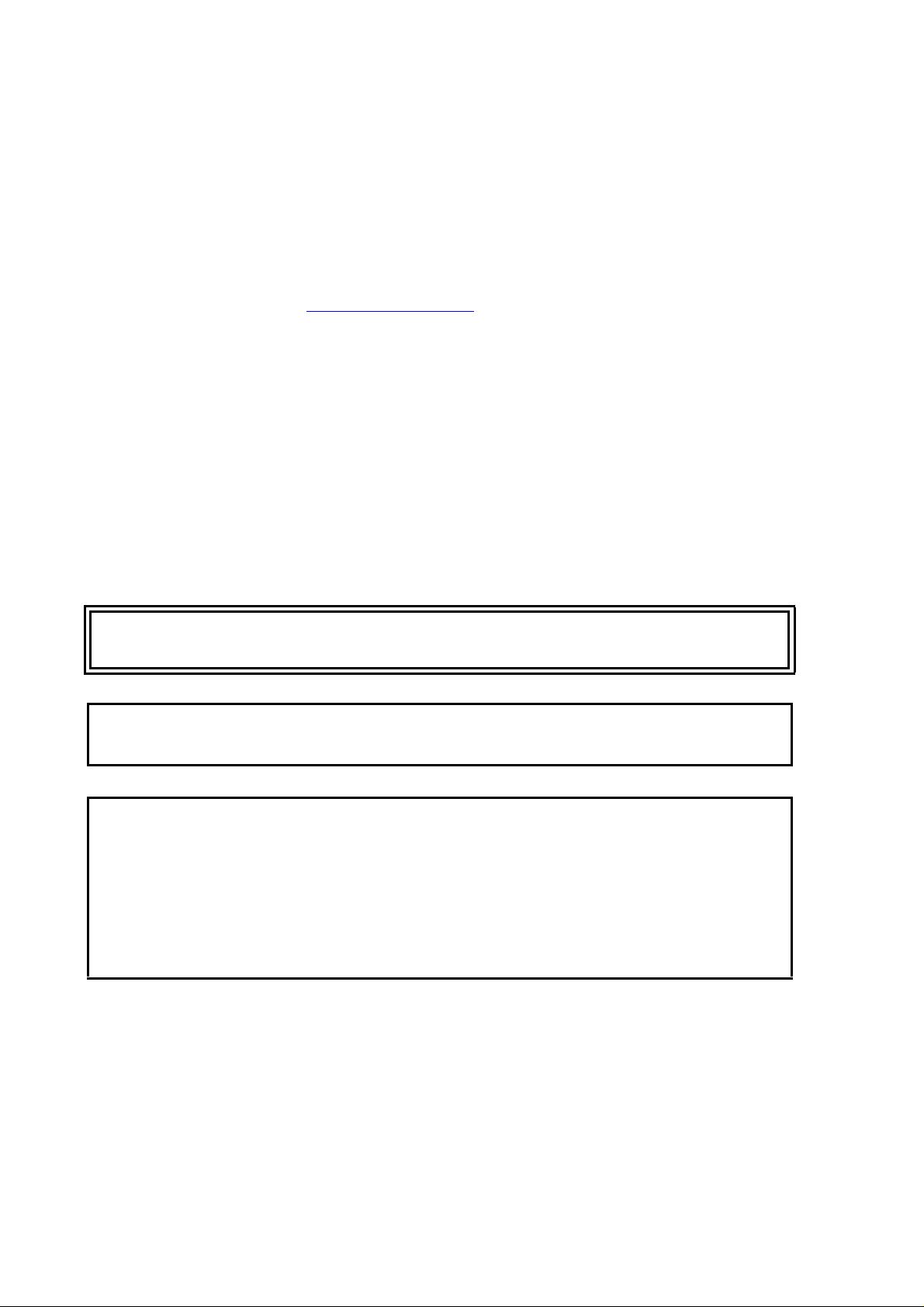

Vaisala SPECTRACAP® Oxygen Transmitter OMT355 is an optical

device for measuring oxygen concentration in gases. The instrument

consists of a measurement probe attached to an electronics enclosure.

Typical applications of OMT355 include inert gas generators,

fermentation and composting process monitoring, flue gas monitoring,

inert gas blanketing as well as oxygen deficiency monitoring in

demanding environments.

Oxygen Measurement Range

Vaisala SPECTRACAP® Oxygen Transmitter OMT355 is available

with a measurement range of either 0 ... 25 %O2 or 0 ... 100 %O2. Great

care has been taken to ensure that the devices for measurement of O2

concentrations up to 100 %O2 are manufactured and shipped according

to such cleanliness criteria that the they are compatible with 100 %O

The wetted parts of these devices are cleaned to the necessary standards

.

2

VAISALA_______________________________________________________________________ 17

Page 20

User's Guide ______________________________________________________________________

and the lubrication materials used in the sealings do not react with

oxygen.

WARNING

Beware of high concentrations of O2: they are highly oxidant/

oxidizing. High O2 concentrations strongly promote combustion and

may react violently with combustible substances.

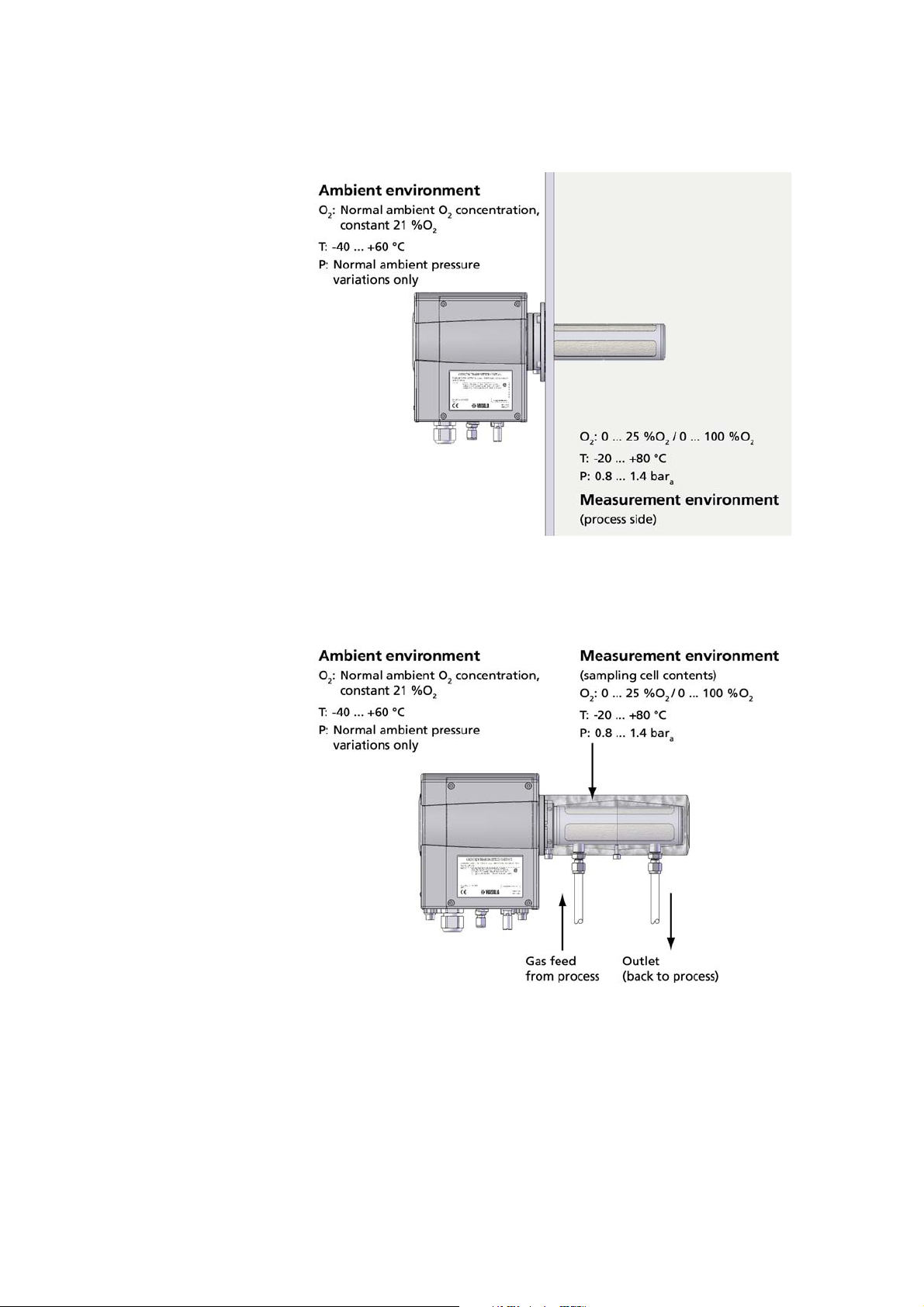

OMT355 for In-Line and Sampling Cell Mounting

In processes with moderate temperatures (up to 80 °C) and limited

pressures (0.8 ... 1.4 bara), OMT355 can be installed directly into the

process (in-line mounting) using a mounting flange, whereas in

processes with high temperatures (> 80 °C), high pressures (> 1.4 bara)

or extremely difficult mechanical conditions (viscous liquids or slurries,

adhesive materials) an extractive measurement can be made by feeding

a sample of gas into an optional sampling cell.

In in-line and sampling cell configurations the OMT355 transmitter

measures process and sampled O2 concentrations of 0 ... 25 %O2 or

0 ... 100 %O2, depending on the choice of measurement range (see

Oxygen Measurement Range on page 17). With these configurations, it

is assumed that the transmitter housing is mounted in an environment

that has only normal pressure variations and O2 concentration of normal

ambient air, approximately 21 %O2. The environmental conditions of

the electronics housing affect the O2 measurement, because O2

absorption of normal surrounding air inside the enclosure is used for

realizing certain internal functions of the measurement.

Figure 1 and Figure 2 contain the main specifications for the

measurement environment and mounting the OMT355.

18 __________________________________________________________________ M210735EN-D

Page 21

Chapter 2 __________________________________________________________ Product Overview

0605-001

Figure 1 Flange Mounted Vaisala SPECTRACAP® Oxygen

Transmitter OMT355

0605-002

Figure 2 OMT355 with Sampling Cell

VAISALA_______________________________________________________________________ 19

Page 22

User's Guide ______________________________________________________________________

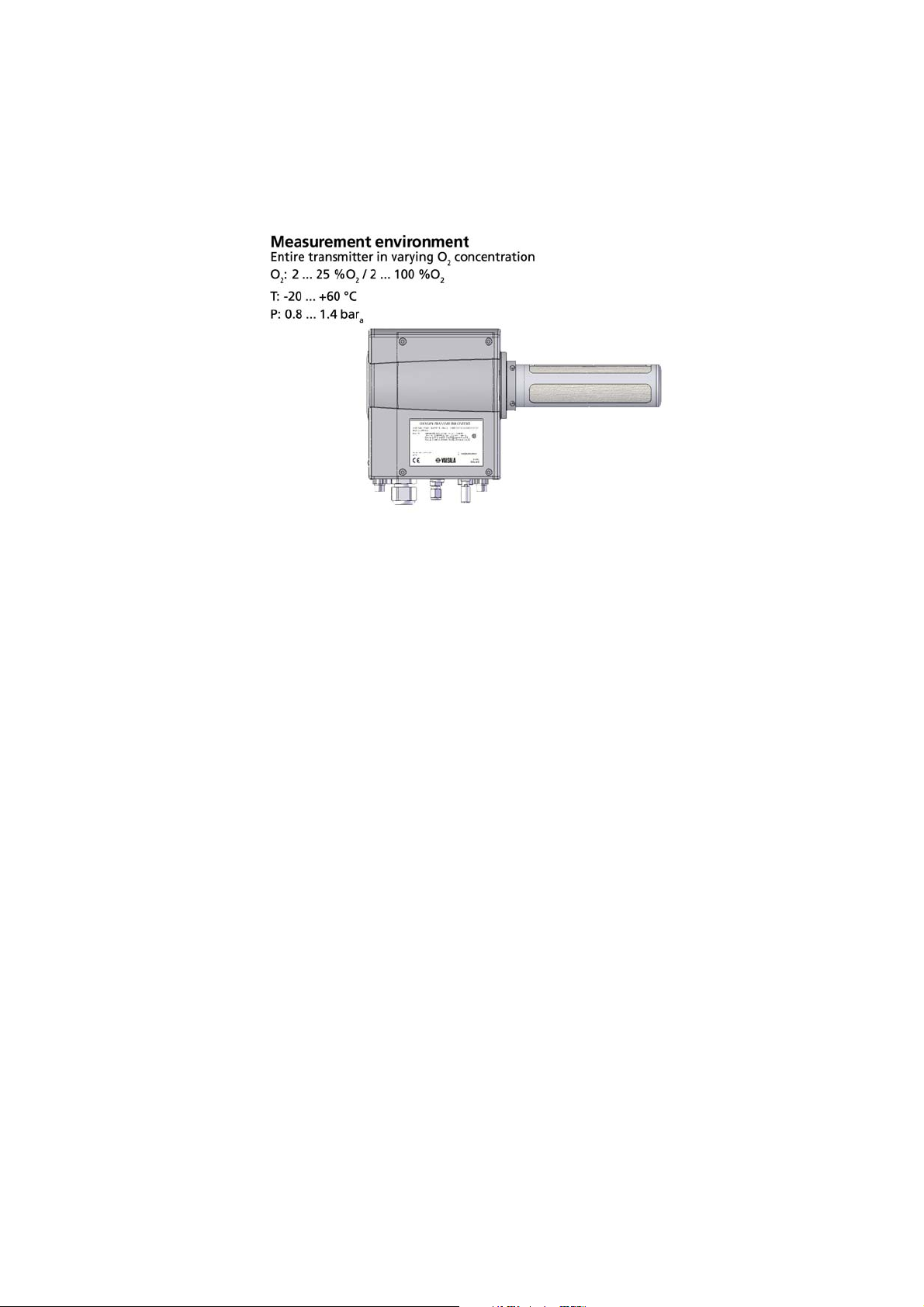

Ambient Gas Measurement Version of OMT355

0605-003

Figure 3 OMT355 for Ambient Gas Measurement

Ambient oxygen concentration measurement, for example in oxygen

deficiency monitoring, requires a special version of OMT355. Please

observe that sections of this User's Guide covering the version for

ambient gas measurement are applicable only to customers who have

ordered this specific version of the transmitter.

With the ambient environment configuration it is assumed that the

entire transmitter (both measurement probe and transmitter housing)

is installed in an environment of changing O2 concentration. See Figure

3 on page 20 for an installation environment example.

The ambient environment configuration of OMT355 measures ambient

oxygen concentrations of 2 ... 25 %O2, that is, the main difference

between this version in comparison with the other two is that the

measurement range does not go all the way down to zero percent O2.

There are also differences in operating temperature ranges between

these configurations, see Figures 1-3 and Table 19 on page 156.

To facilitate easy installation on walls, OMT355 for ambient gas

measurement is available with a wall mounting kit.

20 __________________________________________________________________ M210735EN-D

Page 23

Chapter 3 ______________________________________________________ Functional Description

CHAPTER 3

FUNCTIONAL DESCRIPTION

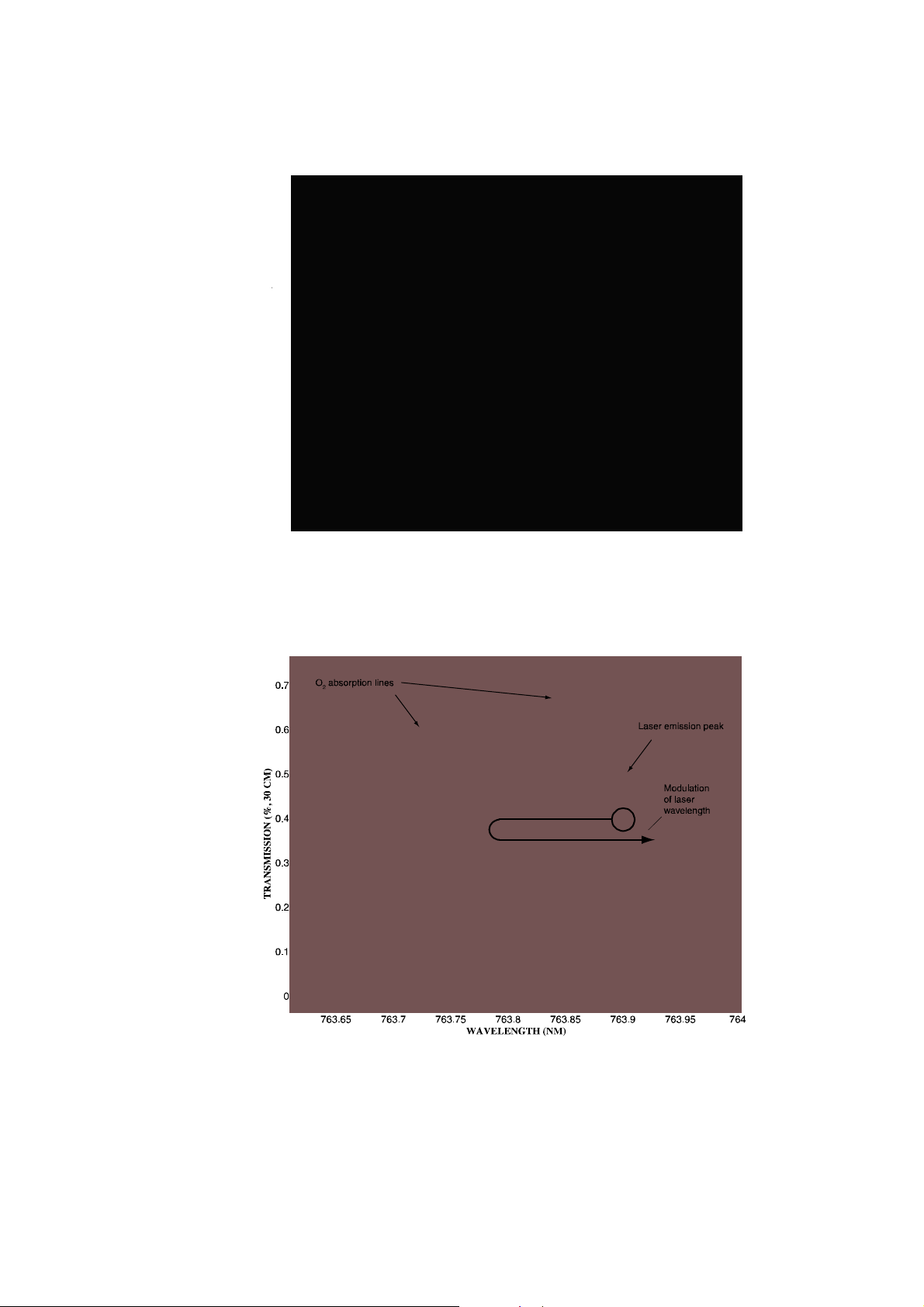

Measurement Principle and Sensor Technology

The operation of the SPECTRACAP® sensor used in OMT355 is based

on Tunable Diode Laser Absorption Spectroscopy (TDLAS) method. In

this technology the gas concentration is sensed by measuring the

attenuation of a beam of laser light from a tunable diode laser source in

the sample gas. For oxygen sensing the laser wavelength is selected to

match with one of the characteristic absorption lines of oxygen in the

wavelength range of around 760 nm (0.76 μm), in the near infrared

(NIR) region of the electromagnetic spectrum. In the measurement the

diode laser wavelength is continuously modulated to scan across one of

the oxygen absorption lines to generate a periodic signal from a

photodetector, the amplitude of which is proportional to the amount of

oxygen on the path of the laser beam. Figure 4 on page 22 illustrates the

oxygen absorption spectrum and Figure 5 on page 22 the modulation of

the laser wavelength.

VAISALA_______________________________________________________________________ 21

Page 24

User's Guide ______________________________________________________________________

759 760 761 762 763 764 765 766 767

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

WAVELENGTH (NM)

TRANSMISSION (%, 30 CM)

0512-049

Figure 4 O2 Absorption Spectrum Around the 760 nm Near

Infrared Region

0511-034

Figure 5 Adjacent O2 Absorption Lines and Laser Emission

Peak

22 __________________________________________________________________ M210735EN-D

Page 25

Chapter 3 ______________________________________________________ Functional Description

Characteristic of the SPECTRACAP® sensor is its inherently good

stability which is obtained due to the continuous reference measurement

built in the measurement algorithm. Furthermore the technology is fast

since no chemical reactions or gas diffusion in sensor materials are

involved - in practice the response time is dictated only by the gas

exchange into the sensor volume and the signal processing time of the

electronics. Furthermore, since the absorption lines of gases are very

narrow and unique by nature, there is no direct cross sensitivity to other

gases in the measurement.

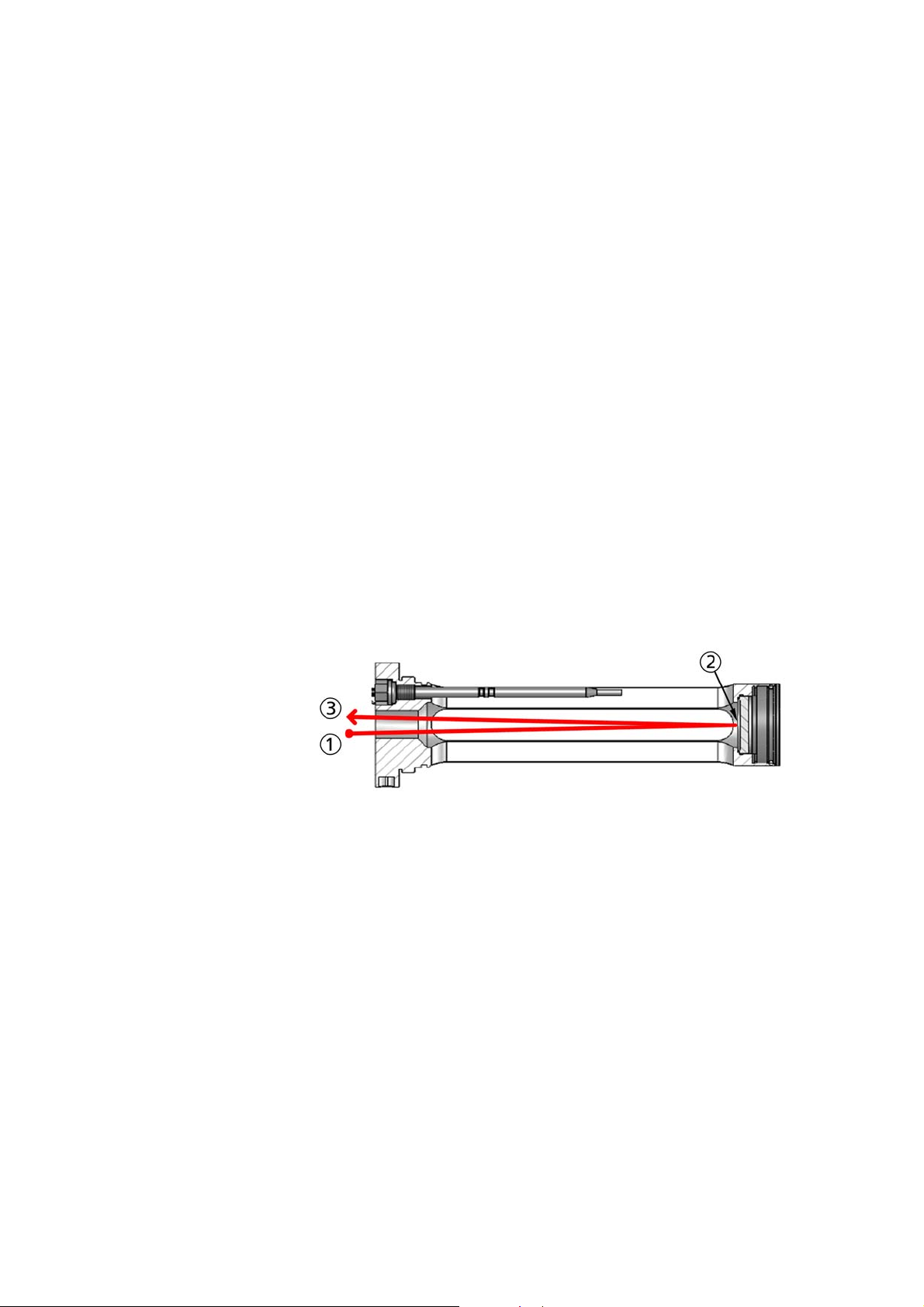

Construction of OMT355 Probe

In OMT355 the SPECTRACAP® sensor has been built into a compact

and robust probe for direct insertion into the measurement location. In

the probe the diode laser light source and the photodetector measuring

the light have been placed behind a protective window, and the light is

directed onto the photodetector using a focusing mirror at the far end of

the probe. Figure 6 on page 23 illustrates the probe design and how the

beam of light goes once back and forth inside the probe.

0511-035

Figure 6 Schematic of Probe Design

The following numbers refer to Figure 6 on page 23:

1 = Light source

2=Mirror

3 = Light detector

The probe is constructed from AISI 316 stainless steel for good

resistance to aggressive chemicals and demanding environments. Other

sample wetted materials are the thin film coating of the optical surfaces

(MgF2 on the lens, SiN on the mirror), and the choice of O-ring

VAISALA_______________________________________________________________________ 23

Page 26

User's Guide ______________________________________________________________________

material. The probe design incorporates also a Pt1000 temperature

sensor in a stainless steel enclosure for making an on-line temperature

compensation to the measurement, and two heating resistors used to

heat the protective window and the focusing mirror to prevent

condensation on the optical surfaces. The probe is also equipped with a

stainless steel mesh filter (additional porous PTFE filter available as an

option) to prevent dust or particles from entering inside the probe. If this

should nevertheless happen the algorithm used with the

SPECTRACAP® sensor has been designed to minimize the effects of

light obstruction, and even to issue a maintenance warning signal

informing of excessive light loss in the sensor well before the

measurement quality is affected.

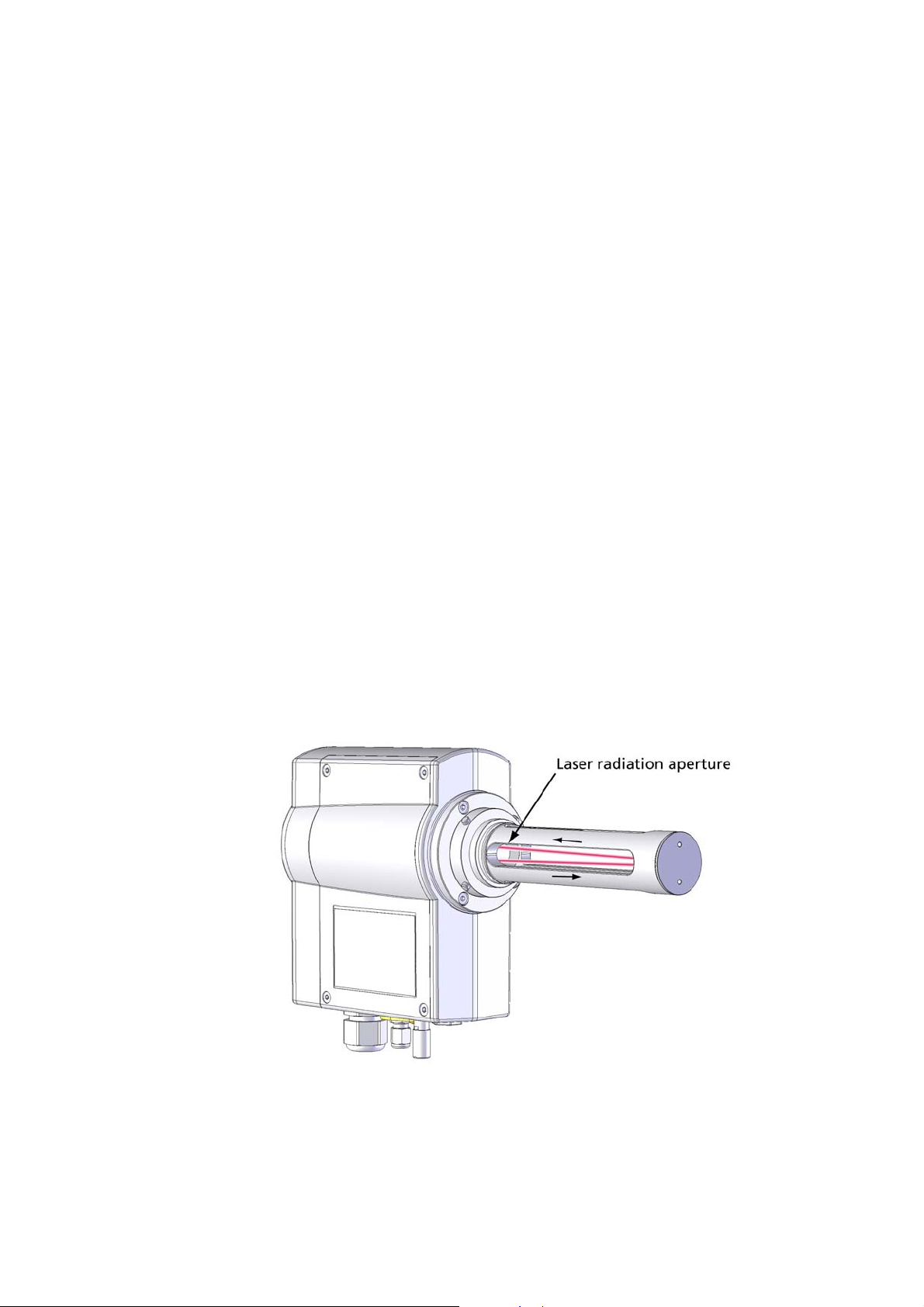

Eye Safety

The OMT355 is eye-safe. Laser radiation in OMT355 is emitted

through the laser radiation aperture, as shown in Figure 7 on page 24.

No laser radiation is emitted outside the probe, and in normal conditions

it is not possible to look straight into the laser radiation aperture and

place the eye in the path of the laser beam. Therefore normal handling

and operation of OMT355 is eye-safe. Avoid placing reflective surfaces

(tools, etc.) directly into the probe when the transmitter is in operation,

since this might cause reflection of laser radiation outside the probe.

0611-007

Figure 7 OMT355 Laser Eye Safety

24 __________________________________________________________________ M210735EN-D

Page 27

Chapter 4 _______________________________________________________________ Installation

CHAPTER 4

INSTALLATION

Selecting Location

The main advantage of OMT355 is its low sensitivity to sample gas

conditions, meaning that the requirements for costly and complicated

sample conditioning systems are minimal. In many applications

OMT355 can be installed directly into the process using a mounting

flange. There is no need for sampling and sample conditioning

equipment. This type of setup also provides a real-time measurement

with no sampling or sample switching delays.

Chemical Tolerance

The OMT355 transmitter contains several O-ring sealings. Two

material options are available for the sealings:

- EPDM (ethylene propylene polymers)

-Kalrez® Spectrum 6375 (perfluoroelastomer with a fluorinated

backbone)

EPDM is the default material, and suitable for a variety of applications.

Kalrez sealings may be used if aggressive solvents or chemicals are

present. Note that Kalrez is not suitable for temperatures below

VAISALA_______________________________________________________________________ 25

Page 28

User's Guide ______________________________________________________________________

-20 °C (-4 °F). Refer to the table below for chemical tolerance of the

materials with common solvents.

Table 1 Chemical tolerance of sealing materials

Chemical EPDM Kalrez

Acetone Excellent Excellent

Benzene Not recommended Excellent

Butanol Good Excellent

Dietyl ether Not recommended Excellent

Ethanol Excellent Excellent

Ethyl acetate Good Excellent

Isopropanol Excellent Excellent

Methanol Excellent Excellent

Toluene Not recommended Excellent

Xylene Not recommended Excellent

NOTE

If the Kalrez sealings are required, it should be specified when the

transmitter is ordered. Changing the sealings later is work intensive,

and can only be done at Vaisala.

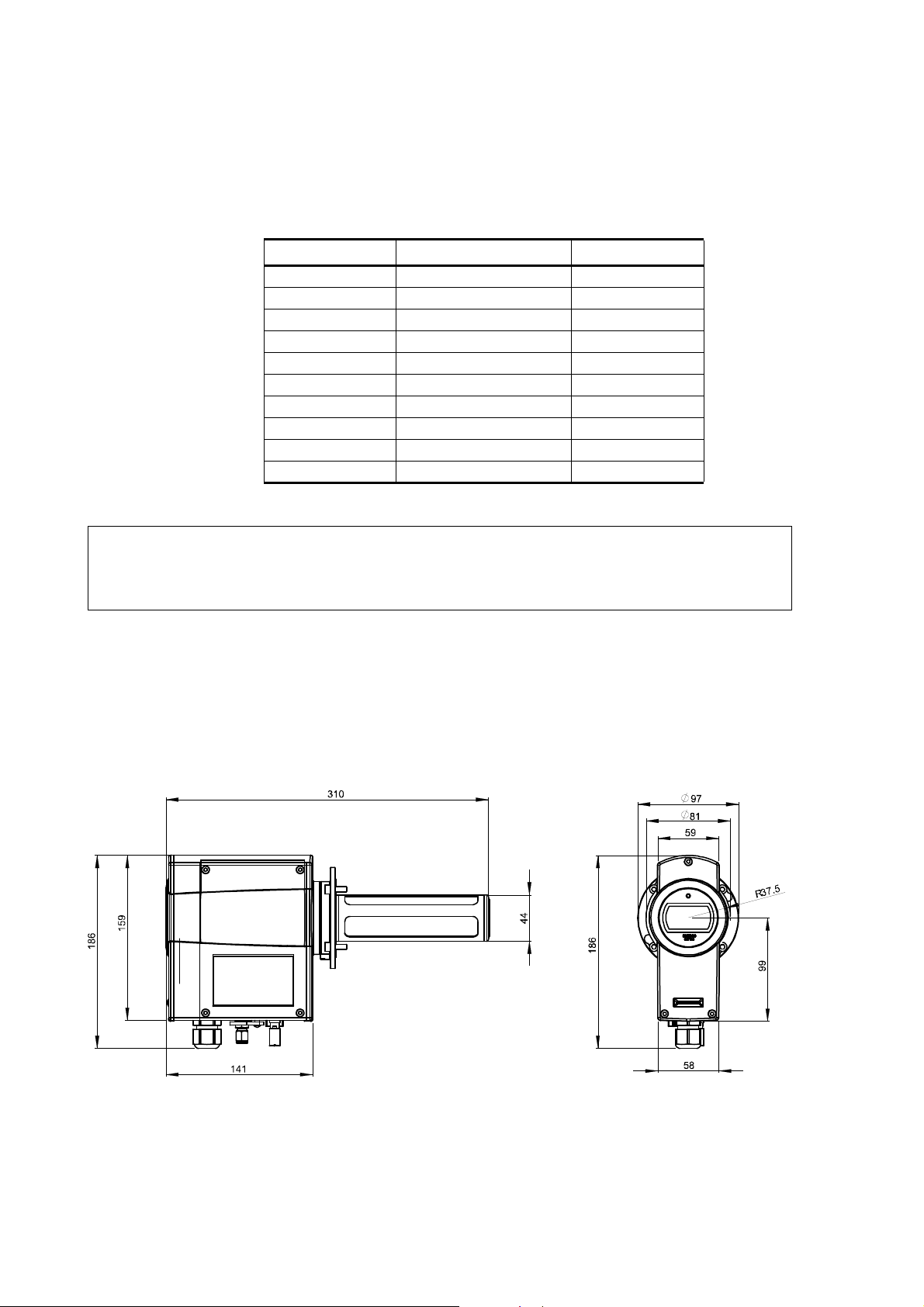

OMT355 Dimensions

In Figure 8 on page 26, all the important dimensions of the Vaisala

SPECTRACAP® Oxygen Transmitter OMT355 are given in mm.

0705-192

Figure 8 OMT355 Dimensions in mm

26 __________________________________________________________________ M210735EN-D

Page 29

Chapter 4 _______________________________________________________________ Installation

Temperature Conditions of Installation Location

The probe design of OMT355 incorporates a temperature sensor for

making an on-line temperature compensation to the oxygen

measurement. Therefore finding a suitable site for OMT355 is

important for getting representative temperature measurements.

In spite of the low sensitivity to sample gas conditions when installing

OMT355 directly into the process, it is still important to take into

account the differences between the process gas temperature and the

ambient temperature. In this type of installation, the integrated

temperature probe of OMT355 is located inside the process while the

transmitter electronics enclosure remains outside the process. For

operating temperature range of the transmitter, see Table 19 on page

156.

The temperature probe and transmitter enclosure are in contact with

each other via some heat transferring components. Thus, ambient

temperature affects the reading of the temperature probe. This causes

measurement error, because the temperature reading used in the

compensations will be slightly different compared to the actual process

gas temperature.

A location in which the ambient temperature of the transmitter

enclosure is as close to the process temperature as possible minimizes

this effect and vice versa - the smaller the temperature gradient from the

process to the ambient is, the smaller the error will be. Please see Table

17 on page 155 for measurement specifications.

Powerful Light Sources Near the Oxygen Measurement Probe

It is not recommended to install the transmitter in locations where there

is an exceptionally powerful light source in close proximity to the

measurement probe (this only concerns the probe, the transmitter

housing is not affected by light sources).

A powerful light source can interfere with the operation of the light

detector. The interfering effect of a light source depends on the filter

used on the measurement probe and how badly the light is shining into

the measurement probe. The interfering effect is at its worst if no filter

VAISALA_______________________________________________________________________ 27

Page 30

User's Guide ______________________________________________________________________

is used and the light (for example, sun) is shining directly to the probe

lens or mirror.

Even the stainless steel mesh filter attenuates some ambient light.

Usually it is enough to suppress for example normal indoor or

laboratory universal lighting. More attenuation and better protection

from the effects of exceptionally powerful light sources is provided by

the PTFE filter, which should be used for example outdoors in direct

sunlight.

Maximum Allowed Installation Angle

To prevent liquid from entering the optical path, the drain slots of the

sensor need to be below the optical components' cavities. This limits

installation in high-humidity processes.

For installation in locations of high relative humidity, see Figure 9 on

page 29 for installation angle limitations. If process gas is dry (the

process temperature is much higher than the dewpoint temperature of

the gas) so that there is no risk for condensation, the probe can be tilted

quite freely. However, vertical installation of the measurement probe is

not recommended when using the sampling cell. With a vertically

installed probe and sampling cell, it is possible to encounter some flowdependency when measuring high O2 concentrations.

28 __________________________________________________________________ M210735EN-D

Page 31

Chapter 4 _______________________________________________________________ Installation

0511-038

Figure 9 Installation Angle Limitations in High Humidities

The following letters refer to Figure 9 on page 29:

A = In high humidities, installation with probe pointing upwards

absolutely prohibited

B = In high humidities, installation allowed only with probe

horizontal or at a maximum downward angle of 45°

Mounting Options

Process Conditions in Regard to Mounting Options

The basic version of OMT355 has the following mounting options:

1. Flange mounted for in-line process gas measurement

2. Sampling cell mounted; either

- with direct feed from the process, or

- with sample gas treatment system.

The different mounting options have certain limitations regarding

process conditions. These are listed in Table 2 on page 30.

VAISALA_______________________________________________________________________ 29

Page 32

User's Guide ______________________________________________________________________

Also available is a version of OMT355 specifically designed for

ambient gas measurement, see Mounting OMT355 for Ambient Gas

Measurement on page 39 for its installation.

Table 2 Process Conditions and Mounting Options

Flange Mounted (InLine)

Gas velocity (flow rate) no limitations no limitations no limitations

Gas velocity where in-

line adjustment is

possible

Process pressure 0.8 ... 1.4 bar

Dirt in gas SS mesh filter: only few

Process temperature

(probe)

Ambient temperature

(transmitter)

1. After treatment of gas sample the measurement conditions inside the sampling cell must conform to the

specifications of the device, that is they need to be the same as in the above table column "Sampling

Cell, Direct Feed from Process".

0 ... 20 m/s no limitations if 3-way

a

large dirt or dust

particles

PTFE filter: dust, water

droplets

-20...+80°C -20...+80°C

-40...+60°C -40...+60°C -40...+60°C

Sampling Cell

Mounted, Direct Feed

from Process

valve is installed

0.8 ... 1.4 b ar

SS mesh filter: only few

large dirt or dust

particles

PTFE filter: dust, water

droplets

a

Sampling Cell

Mounted, Sample Gas

Treatment System

(Filter, Regulator etc.)

no limitations if 3-way

valve is installed

no limitations

no limitations

no limitations

no limitations

1

1

1

1

CAUTION

Filter clogging must be checked periodically. If the filter is clogged, it

must be changed. For more information, see Filter Change on page

142.

30 __________________________________________________________________ M210735EN-D

Page 33

Chapter 4 _______________________________________________________________ Installation

Flange Mounted for In-Line Process Gas Measurement

Mounting OMT355 with a flange is intended for in-line process gas

measurement.

0511-037

Figure 10 OMT355 Transmitter with Flange Adapter

Suitable Process Flanges

The maximum diameter of the OMT355 flange adapter is ø 97 mm. It

has been chosen to suit the center of a DIN 2572/B flange (mounted

with M16 hex bolts). The smallest possible ANSI flange is ANSI 150

2.5" (mounted with 3/4" hex bolts).

The flange can of course be larger than the minimum requirements

given above. See Appendix A, Flange Preparation Instructions, on page

159.

Filter Recommendation

At a minimum, use of the stainless steel mesh filter is recommended.

The stainless steel mesh provides protection against coarse dirt such as

large specks of dust. If a short response time is not of great importance,

VAISALA_______________________________________________________________________ 31

Page 34

User's Guide ______________________________________________________________________

use of the PTFE filter in addition to the stainless steel mesh filter is

advised.

The PTFE filter is placed under the stainless steel mesh filter and it is

effective at preventing liquid water, dust and other contaminants from

entering the optics. The PTFE filter is also effective at attenuating

exceptionally powerful ambient and thereby reducing any effects that

powerful ambient light has on the oxygen measurement. However, the

PTFE filter is still permeable to gases and vapors.

In applications where a very short response time is desired, all filters

can be removed. However, when the filters are removed, the optics are

openly exposed to contamination and cleaning of the optics may be

necessary more often, see Cleaning the Optics on page 139. Removal of

filters is not recommended if there is a risk of getting water or dirt on

the optics. Before removing the filters, see also section Powerful Light

Sources Near the Oxygen Measurement Probe on page 27.

Mounting with Flange Adapter

The smallest DIN flange suited for the flange adapter of OMT355 is

DIN 2572/B flange (mounted with M16 hex bolts). See Suitable Process

Flanges on page 31 for more information on process flanges. The flange

adapter is installed at the factory and is held in place by one screw at the

bottom of the adapter.

To mount OMT355 using the flange adapter:

1. Prepare four threaded screw holes in the process flange for

attaching the flange adapter. See Figure 19 on page 41 for flange

adapter dimensions and drilling instructions.

2. Screw the four provided M5 flange adapter fixing screws about

half-way in to the threaded holes you have prepared. The flange

mounting installation accessories include a flange adapter gasket;

check that it sits snugly in its slot in the flange adapter. The gasket

between the flange adapter and process flange provides a gas-tight

installation.

3. Slide the transmitter through the process flange. Notice you have

to tilt the transmitter slightly clockwise in order for the screws to

fit through the larger slots of the flange adapter. Tilt the transmitter

back to the left to set it in the right position for tightening the

screws.

4. Finish the installation by tightening the screws.

32 __________________________________________________________________ M210735EN-D

Page 35

Chapter 4 _______________________________________________________________ Installation

Notice that while it is possible to detach the transmitter from the process

by removing the screw holding the flange adapter in place, reinstallation

of the transmitter in this case is cumbersome. Therefore this procedure

is not recommended.

0511-039

Figure 11 Dimensions, OMT 355 Flange Mounted

The following number refers to Figure 11 on page 33:

1 = Max. screw size M5

VAISALA_______________________________________________________________________ 33

Page 36

User's Guide ______________________________________________________________________

Mounting with Sampling Cell

For processes with high temperatures, elevated pressure or extremely

difficult mechanical conditions the sampling cell option of OMT355

can be used. Due to the robustness of the SPECTRACAP® sensor and

its low sensitivity to gas flow and pressure variations a very simple

sampling system can be used.

0511-040

Figure 12 OMT355 Transmitter with Sampling Cell

The following numbers refer to Figure 12 on page 34:

1 = Swagelok connectors for ø 6 mm gas tubes or 1/8" NPT thread

2 = Drain slot

3 = Max. screw size M6

4 = Wall mounting bracket

Filter Recommendation

At a minimum, use of the stainless steel mesh filter is recommended

with the sampling cell option. The PTFE filter is recommended if the

gas contains moisture or dirt with fine particle size.

If the process gas is very dirty and humid, the sample gas should be

filtered and dried before it is pumped to the sampling cell. A

hydrophobic dust filter before the inlet of the sampling cell is needed in

34 __________________________________________________________________ M210735EN-D

Page 37

Chapter 4 _______________________________________________________________ Installation

order to prevent particles and water from the surroundings from

contaminating the optics. The dust filter needs to be changed often

enough to provide an adequate flow.

In humid environments it is important to avoid water condensation

inside the sampling cell. This can be avoided by drying the sample gas.

The most common method of drying the sample gas is cooling and

reheating it. A simple system may consist for example of a cooling coil

and a water trap which are either cooled or located in a cool

environment, followed by a reheating system. The idea is to get the

moisture in the sample to condense on the walls of the copper tube, trap

this water and then lower the relative humidity by reheating the sample.

If the temperature inside the sampling cell is significantly higher than

the surroundings, the cooling coil and the water trap can simply be

located outside the sampling cell. For reheating, the heat generated by a

pumping system may sometimes be adequate, meaning that no

additional heater is needed. A simplified diagram of a sample gas

treatment system for removing dirt and moisture is illustrated in Figure

13 on page 35.

0511-041

Figure 13 Sample Gas Treatment System

The following numbers refer to Figure 13 on page 35:

1=Gas in

2 = Hydrophobic filter

3 = Stainless steel (AISI316) tube coil

4 = Water trap

5 = Sample pump

6 = Oxygen sensor

VAISALA_______________________________________________________________________ 35

Page 38

User's Guide ______________________________________________________________________

Mounting with Wall Mounting Bracket

The transmitter is mounted with the wall mounting bracket as follows:

1. The wall mounting bracket has four ø 6.5 mm holes for wall

attachment with screws or bolts; see Figure 19 on page 41 for wall

mounting bracket dimensions. Attach the wall mounting bracket to

the desired location using an attachment method appropriate for the

building material of the wall (for example, anchor bolts for a

concrete wall).

2. Attach the transmitter to the wall mounting bracket using the four

M6 screws provided. For easier installation, you can pre-fix the

two outer screws to the threads at the bottom of the transmitter as

the outer screw holes of the wall mounting bracket are slotted. This

way it is easier to attach the two inner screws as you place the

transmitter on the wall mounting bracket. Finish the installation by

tightening all four screws.

Tubing Instructions

The sampling cell of OMT355 has Swagelok connectors for ø 6 mm gas

tubes or 1/8" NPT thread. Use of stainless steel tubing is recommended.

Instructions for installing the Swagelok tube fittings are provided

below.

Provide adequate support for the tubing, for example by attaching the

tubing to the wall. The weight of the tubing must not exert torque on the

sampling cell as this could damage the transmitter or cause the wall

mounting bracket to come out of the wall.

The incoming gas should be fed through the connector closer to the

transmitter side of the sampling cell. This setup should provide better

gas exhange at the sensor end of the sampling cell volume and shorten

response time.

Installation Instructions for Swagelok Tube Fittings

1. Insert the tubing into the Swagelok tube fitting. Tubing should rest

firmly on the shoulder of the fitting. The nut should be finger tight.

See Figure 14 on page 37.

2. Mark the nut at the 6 o'clock position.

36 __________________________________________________________________ M210735EN-D

Page 39

Chapter 4 _______________________________________________________________ Installation

3. Hold the fitting body with a backup wrench and tighten the nut 1¼

turns. Watch the marking and make one complete turn and

continue to 9 o'clock position.

0511-042

Figure 14 Swagelok Tube Fitting Instructions

Sampling Cell Instructions

OMT355 with the sampling cell mounting option is delivered with the

sampling cell installed at the factory and ready for wall mounting.

However, to check and replace the filters, it is necessary to remove and

reinstall the sampling cell. The sampling cell is removed and reinstalled

as follows:

1. The sampling cell is held in place by a bayonet type fitting. A screw

at the bottom of the sampling cell is used to prevent accidental

opening. Open the screw and detach the sampling cell: first turn the

sampling cell and then pull it clear from the transmitter, see Figure

15 on page 38.

2. To reinstall, simply reverse the procedure. There is a sealing

between the sampling cell and transmitter housing. Check that it is

in its place when reinstalling the sampling cell. The Swagelok

connectors for the sample gas are to face directly downwards.

VAISALA_______________________________________________________________________ 37

Page 40

User's Guide ______________________________________________________________________

0604-066

Figure 15 Detaching Sampling Cell

There is a drain slot in the middle of the sampling cell for draining any

condensation that might have gathered inside the sampling cell. The slot

is plugged with a screw and a small O-ring sealing. If the process

conditions are such that a lot of condensation is to be expected inside

the sampling cell, it is recommended that you install a valve in the drain

slot for draining the condensed water from the sampling cell.

0511-043

Figure 16 Dimensions, OMT355 with Sampling Cell

38 __________________________________________________________________ M210735EN-D

Page 41

Chapter 4 _______________________________________________________________ Installation

Mounting OMT355 for Ambient Gas Measurement

This version of OMT355 is intended specifically for ambient gas

measurement. It can be easily mounted on a wall using the wall

mounting bracket.

0511-044

Figure 17 OMT355 for Ambient Gas Measurement with Wall

Mounting Setup

Mounting Instructions

The transmitter is mounted with the wall mounting bracket as follows:

1. The wall mounting bracket has four ø 6.5 mm holes for wall

attachment with screws or bolts; see Figure 19 on page 41 for wall

mounting bracket dimensions. Attach the wall mounting bracket to

the desired location using an attachment method appropriate for the

building material of the wall (for example, anchor bolts for a

concrete wall).

2. Attach the transmitter to the wall mounting bracket using the four

M6 screws provided. For easier installation, you can pre-fix the

two outer screws to the threads at the bottom of the transmitter as

VAISALA_______________________________________________________________________ 39

Page 42

User's Guide ______________________________________________________________________

the outer screw holes of the wall mounting bracket are slotted. This

way it is easier to attach the two inner screws as you place the

transmitter on the wall mounting bracket. Finish the installation by

tightening all four screws.

0511-045

Figure 18 OMT355 Wall Mounted

The following numbers refer to Figure 18 on page 40:

1 = M20 × 1.5 cable gland for power and signal wires

2 = Calibration gas inlet with ø 6 mm Swagelok connector

(optional)

3 = External grounding connector

4 = Stainless steel mesh filter

5 = Max. screw size M6

40 __________________________________________________________________ M210735EN-D

Page 43

Chapter 4 _______________________________________________________________ Installation

Connections

CAUTION

0511-046

Figure 19 Dimensions and Drilling Holes, Wall Mounting

Bracket (Right) and Flange Adapter (Left)

The following numbers refer to Figure 19 on page 41:

1 = ø 6.5 mm, four pieces

2 = Max. screw size M5

Signal and Power Supply Wiring

Before making any electrical connections, always make sure that the

power supply wires are unpowered.

VAISALA_______________________________________________________________________ 41

Page 44

User's Guide ______________________________________________________________________

0511-047

Figure 20 Connections/Local Interface Layout

The following numbers refer to Figure 20 on page 42:

1 = Cable bushing (conduit fitting or connector)

2 = Calibration gas inlet (optional)

3 = Grounding terminal

4 = LED

5 = Power ON/OFF switch

6 = Service Interface (RS232C)

7 = Local Interface keypad push buttons

8 = Supply voltage terminals

9 = Current output terminals

10 = RS-485 terminals

11 = Relay contact terminal

12 = RS-485 line termination jumper

42 __________________________________________________________________ M210735EN-D

Page 45

Chapter 4 _______________________________________________________________ Installation

1. Open the transmitter back cover. Make sure that the Power ON/

OFF switch is in the OFF position.

2. Slide in the cable through the bushing in the bottom of the

transmitter. To avoid damage, the cable must be unpowered.

3. Connect the supply voltage between the terminals Uin (24V) and

(0).

4. Current output is available between the terminals Iout (+) and (-).

Current output can be tested by connecting an ammeter between

the test points ITEST+ and ITEST- when output is loaded.

5. Two wire RS-485 is available between the terminals RS 485 (A)

and (B). Line termination can be enabled by changing the

RS485 Termination jumper position to EN.

6. Floating relay contact is available between the two Alarm

terminals. Additional information is given in sections Test Alarm

Relay Function (Ala) on page 78 and Show/Set Relay Operating

Mode Command (RELAY_MODE) on page 77.

7. Turn on the supply voltage from the power supply. Turn on the

transmitter with the Power ON/OFF switch.

8. The transmitter starts performing the self test. The text "PASS" is

displayed when the self-test is completed. It takes a short while

after the self-test before the device is ready for measurement and

starts displaying oxygen readings. A green LED lights up after the

transmitter has found the absorption line and a valid measurement

can be made.

9. When the self test has successfully been completed, close the

transmitter back cover. The transmitter is now ready for use.

VAISALA_______________________________________________________________________ 43

Page 46

User's Guide ______________________________________________________________________

Connecting OMT355 with Optional 8-Pin Connector

If you have purchased your OMT355 with the optional 8-pin connector,

please refer to Figure 21 on page 44 and Table 3 on page 44 for

information on the connector terminals.

0511-048

Figure 21 Optional 8-Pin Connector

Table 3 8-Pin Connector Terminals

Terminal Color Connector #

24 V PINK 6

0 V GREY 5

Iout+ YEL 4

Iout- BRN 2

RS-485 A WHT 1

RS-485 B BLU 7

Alarm RED 8

Alarm GRN 3

44 __________________________________________________________________ M210735EN-D

Page 47

Chapter 5 ________________________________________________________________ Operation

CHAPTER 5

OPERATION

This chapter contains a description of the device interfaces and the

software commands.

Read the instructions through carefully before making any adjustments

or parameter changes. Vaisala accepts no responsibility for parameter

or settings changes nor adjustments made by the user. When you require

technical support or assistance, please contact Vaisala Technical

Support (see Technical Support on page 152).

Device Interfaces

Power Supply

Supply voltage is 11 ... 36 VDC. The transmitter cannot be used with

AC voltage. Note that the power supply interface is galvanically

isolated from other electronics.

Keypad, Display and LEDs

OMT355 transmitter has a seven segment display and four push buttons

inside its housing. The local display shows the oxygen reading, but

through the user interface you can gain access to basic functions such as

calibration and adjustment, analog output scaling and so on.

VAISALA_______________________________________________________________________ 45

Page 48

User's Guide ______________________________________________________________________

During operation the operating stage of the transmitter is also indicated

by LEDs. Continuously lit green LED indicates normal operation, for

other LED indications, refer to section Operation Errors on page 145.

The keypad push buttons are indicated as Up, Dn, Back and Ent:

Up - up key

Dn - down key

Back - back key

Ent - enter key

See Figure 20 on page 42 and Figure 22 on page 48 for keypad and

display layout.

Service Interface

The transmitter has an RS232C serial port for service functions. You

can access all adjustable parameters with a PC terminal program

through the Service Interface. The transmitter can be connected to a PC

by using either a Serial interface cable (Vaisala order code: 19446ZZ)

or a USB-RJ45 Serial interface cable (Vaisala order code: 219685). If

you need to reconfigure device alarm level(s), Customer Interface or

other settings, the Service Interface provides a wider range of options

than the keypad and display functions.

Installing the Driver for the USB Cable

Before taking the USB cable into use, you must install the provided

USB driver on your PC. When installing the driver, you must

acknowledge any security prompts that may appear. The driver is

compatible with Windows 2000, Windows XP, Windows Server 2003,

and Windows Vista.

1. Check that the USB cable is not connected. Disconnect the cable if

you have already connected it.

2. Insert the media that came with the cable, or download the driver

from www.vaisala.com.

3. Execute the USB driver installation program (setup.exe), and

accept the installation defaults. The installation of the driver may

take several minutes.

46 __________________________________________________________________ M210735EN-D

Page 49

Chapter 5 ________________________________________________________________ Operation

4. After the driver has been installed, connect the USB cable to a USB

port on your PC. Windows will detect the new device, and use the

driver automatically.

5. The installation has reserved a COM port for the cable. Verify the

port number, and the status of the cable, using the Vaisala USB

Instrument Finder program that has been installed in the

Windows Start menu. The reserved ports are also visible in the

Ports section of the Windows Device Manager.

Remember to use the correct port in the settings of your terminal