Page 1

USER'S GUIDE

Vaisala HUMICAP® Moisture and

Temperature Transmitter Series for Oil

MMT310

M210474EN-C

Page 2

PUBLISHED BY

Vaisala Oyj

Street address: Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

Mailing address: P.O. Box 26, FI-00421 Helsinki, Finland

Phone: +358 9 8949 1

Fax: +358 9 8949 2227

Visit our Internet pages at www.vaisala.com.

© Vaisala 2014

No part of this manual may be reproduced, published or publicly displayed in any form

or by any means, electronic or mechanical (including photocopying), nor may its

contents be modified, translated, adapted, sold or disclosed to a third party without prior

written permission of the copyright holder. Translated manuals and translated portions

of multilingual documents are based on the original English versions. In ambiguous

cases, the English versions are applicable, not the translations.

The contents of this manual are subject to change without prior notice.

This manual does not create any legally binding obligations for Vaisala towards

customers or end users. All legally binding obligations and agreements are included

exclusively in the applicable supply contract or the General Conditions of Sale and

General Conditions of Service of Vaisala.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ............................................................................ 7

About This Manual ................................................................... 7

Contents of This Manual ....................................................... 7

Version Information ............................................................... 8

Related Manuals ................................................................... 8

Documentation Conventions ................................................. 8

Safety ......................................................................................... 9

ESD Protection ...................................................................... 9

Recycling ................................................................................ 10

Regulatory Compliances ....................................................... 10

Emissions ....................................................................... 10

Immunity ......................................................................... 10

Trademarks ............................................................................. 10

Software License .................................................................... 11

Warranty .................................................................................. 11

CHAPTER 2

PRODUCT OVERVIEW ................................................................................ 13

Introduction to MMT310 Series ............................................. 13

MMT310 Transmitter Parts ................................................. 15

Probe Options ..................................................................... 16

Filter Options ....................................................................... 16

CHAPTER 3

INSTALLATION ............................................................................................ 17

Mounting ................................................................................. 17

Selecting a Place for the Probe........................................... 17

Mounting the Transmitter /

Removing the Transmitter Unit ........................................... 18

Mounting the Transmitter with Optional Rain Shield ........... 19

Mounting the Rain Shield with

Larger Transmitter Mounting Plate...................................... 19

Mounting the MMT318 ........................................................ 20

Mounting for Pressurized Pipelines/Oils ............................. 20

Tightening the Clasp Nut ............................................... 21

Ball Valve Installation Kit for MMT318 ................................ 23

Sampling Cell for MMT318 .................................................. 25

Mounting the MMT317 ........................................................ 25

MMT317 Probe with Swagelok Connector

for Tight-place Installations ............................................ 26

Connections ............................................................................ 28

Cable Wiring ........................................................................ 28

Power Supply Requirements ................................................ 29

VAISALA _________________________________________________________________________ 3

Page 4

User's Guide _______________________________________________________________________

CHAPTER 4

OPERATION ................................................................................................. 31

Power Supply .......................................................................... 31

Transmitter Start-Up ............................................................... 31

Serial Line and Analog Communication Options ................ 32

RS-232 Serial Port Connection ........................................... 32

USB Connection .................................................................. 33

Installing the Driver for the USB Cable .......................... 33

Connection to an MI70 Hand-held Indicator ........................ 34

Terminal Program Settings .................................................... 35

Opening a Serial/USB Connection with PuTTY ............. 35

List of Serial Commands ....................................................... 36

Measurement Output .............................................................. 38

Starting the Continuous Reading Output............................. 38

Stopping the Continuous Reading Output ........................... 38

Set Continuous Output Interval for RUN Mode ................... 38

Output Reading Once .......................................................... 39

Set Serial Interface Mode .................................................... 39

Serial Line Settings .............................................................. 40

Set Transmitter Address for Use in POLL Mode ................. 40

Temporarily Open Transmitter from POLL Mode

to Receive Serial Commands .............................................. 41

Set Transmitter in POLL Mode ............................................ 41

Output Formatting .................................................................. 42

Set Serial Output Format ..................................................... 42

Set Time and Date ............................................................... 43

Add Time and Date to SEND and R Outputs ...................... 43

Select Metric or Nonmetric Output Units ............................. 44

Setting, Scaling and Testing the Analog Outputs ............... 44

Set Analog Outputs ............................................................. 44

Select Parameter for Analog Outputs .................................. 45

Scale Analog Outputs .......................................................... 46

Test Analog Outputs ............................................................ 46

Test Analog Outputs for Desired Readings ......................... 47

Set Error Outputs ................................................................. 47

Other Commands.................................................................... 48

Check Transmitter Settings ................................................. 48

Serial Bus Echo ................................................................... 49

All Devices in POLL Mode Send Their Addresses .............. 49

List Commands .................................................................... 49

Set Result Filtering .............................................................. 49

Reset Transmitter ................................................................ 50

Display Error Messages ...................................................... 50

CHAPTER 5

MAINTENANCE ............................................................................................ 51

Periodic Maintenance ............................................................. 51

Calibration Interval ............................................................... 51

Replacing Consumables ........................................................ 51

Changing the Filter .............................................................. 51

Changing the Sensor ........................................................... 52

Clean the Sensor Before Storing the Transmitter ............... 53

Technical Support .................................................................. 53

4 ____________________________________________________________________ M210474EN-C

Page 5

_________________________________________________________________________________

Product Returns ..................................................................... 53

CHAPTER 6

CALIBRATION AND ADJUSTMENT ........................................................... 55

Preparations Before the Calibration .................................... 56

Relative Humidity Calibration and Adjustment

(in Two Points) .................................................................... 56

Low End Adjustment ...................................................... 57

High End Adjustment ..................................................... 58

Temperature Calibration and Adjustment

(in One Point) ...................................................................... 59

Revert Factory Calibration .................................................. 60

View Current Offset and Gain Adjustment .......................... 60

Relative Humidity Calibration after Sensor Change............ 61

Set Calibration Information Text.......................................... 61

Set Calibration Date ............................................................ 61

Analog Output Calibration ................................................... 62

Adjustment Using an MI70 Indicator .................................... 62

Starting MI70 Adjustment .................................................... 62

Adjusting RH with MI70 ....................................................... 63

1-point RH Adjustment ................................................... 63

2-point RH Adjustment ................................................... 63

LiCl – NaCl Automatic Adjustment ................................. 64

Adjusting T with MI70 .......................................................... 65

1-point T adjustment ...................................................... 65

2-point T adjustment ...................................................... 65

Environment Settings .......................................................... 66

Last Adjustment Date .......................................................... 66

CHAPTER 7

TECHNICAL DATA ...................................................................................... 67

Specifications ......................................................................... 67

Spare Parts and Accessories ................................................ 69

Dimensions in mm (inches) .................................................. 70

Transmitter Enclosure and Mounting Plates ....................... 70

Rain Shield Dimensions ...................................................... 71

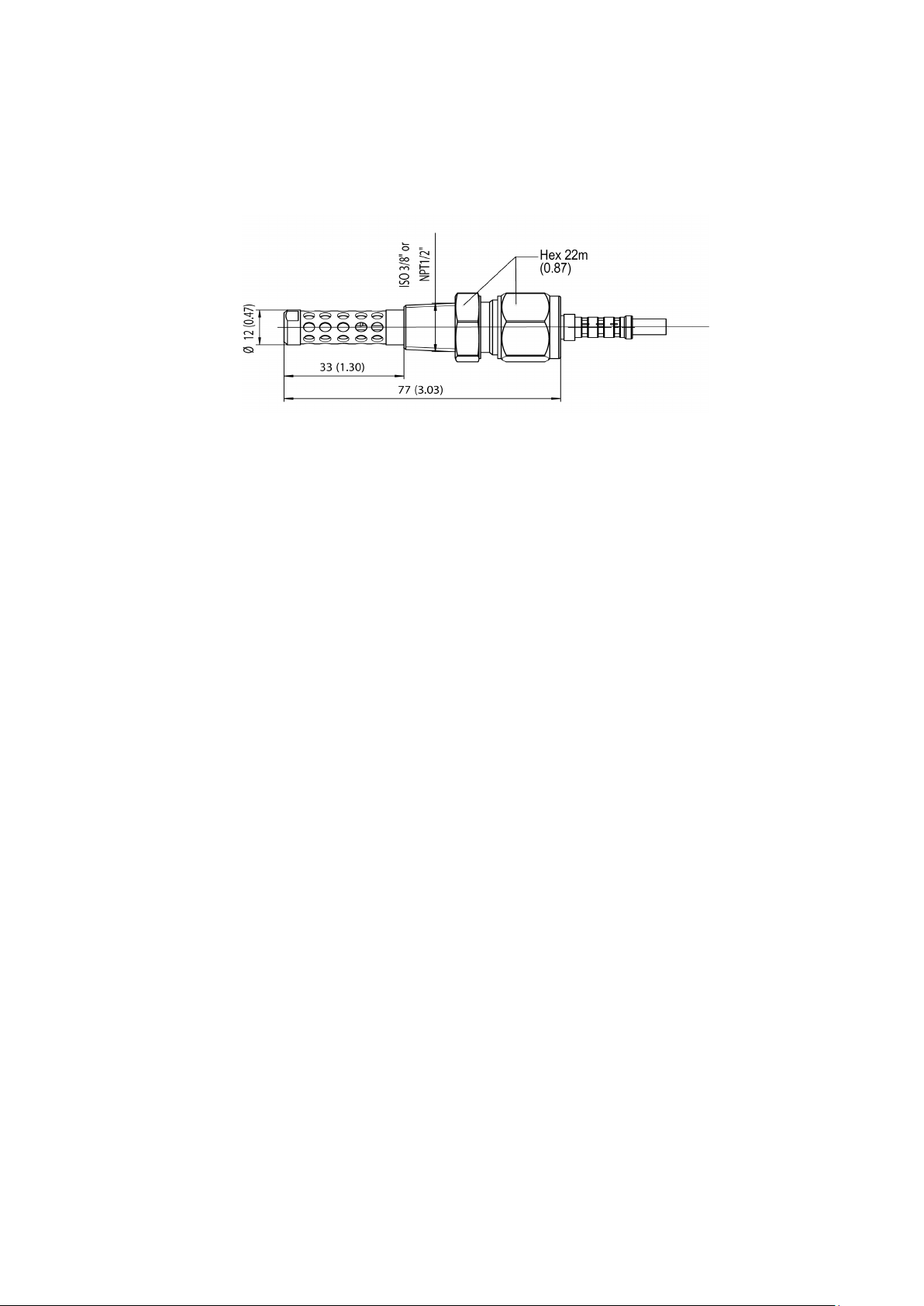

MMT318 Probe Dimensions ................................................ 72

Ball Valve Set Dimensions .................................................. 73

MMT317 Probe with Optional Swagelok Connector,

Dimensions .......................................................................... 74

APPENDIX A

APPLICATIONS ........................................................................................... 75

Transformer Oils .................................................................... 75

PPM Calculation for Transformer Oils ................................ 76

Calculation Model with Average Coefficients ...................... 77

Calculation Model with Oil Specific Coefficients ................. 77

PPM Calculation Setting ........................................................ 78

Calculation Setting (Calculation Model with Average

Coefficients) ........................................................................ 78

Changing the Calculation Coefficients

(Calculation Model with Oil Specific Coefficients) ............... 78

Technical Data ............................................................... 79

Paper Machine Application ................................................... 80

VAISALA _________________________________________________________________________ 5

Page 6

User's Guide _______________________________________________________________________

List of Figures

Figure 1 MMT310 Transmitter Parts ...................................................... 15

Figure 2 MMT310 Probes ....................................................................... 16

Figure 3 Mounting with Mounting Plates ................................................. 18

Figure 4 Rain Shield with Large Mounting Plate .................................... 19

Figure 5 MMT318 Probe ......................................................................... 20

Figure 6 Sealing of Fitting Body into Process ......................................... 21

Figure 7 Tightening the Clasp Nut .......................................................... 22

Figure 8 MMT318 Ball Valve Assembly Installation ............................... 23

Figure 9 Sampling Cell DMT242SC2 ...................................................... 25

Figure 10 MMT317 Probe with Swagelok Installation Kit ......................... 26

Figure 11 MMT317 Probe Installation to Pipeline with Swagelok

Installation Kit ........................................................................... 26

Figure 12 8-Pin Connector (Left) and

Screw Terminal Connector (Right) ........................................... 28

Figure 13 PuTTY Serial Line Configuration .............................................. 35

Figure 14 Changing the Sensor ................................................................ 52

Figure 15 Location of Adjustment Button .................................................. 56

Figure 16 Transmitter Enclosure and Mounting Plate Dimensions .......... 70

Figure 17 Rain Shield Dimensions (Back) ................................................ 71

Figure 18 Rain Shield Dimensions (Side and Outer) ................................ 71

Figure 19 MMT318 Probe Dimensions ..................................................... 72

Figure 20 Ball Valve Set Dimensions ....................................................... 73

Figure 21 MMT317 Probe with Swagelok Connector ............................... 74

Figure 22 The Water Solubility of Transformer Oils

Versus Temperature ................................................................. 76

Figure 23 Maximum Errors Caused by Deviation of Mineral Oils Using

Calculation Model with Average Coefficients ........................... 79

List of Tables

Table 1 Manual Revisions ....................................................................... 8

Table 2 Related Manuals ......................................................................... 8

Table 3 MMT310 Measurement and Calculation Quantities ................. 13

Table 4 MMT318 Pipe Dimensions ....................................................... 21

Table 5 Current Consumption by Output Type ...................................... 29

Table 6 Measurement Output ................................................................ 36

Table 7 Output Formatting ..................................................................... 36

Table 8 Calibration and Adjustment* ..................................................... 36

Table 9 Setting, Scaling and Testing Analog Outputs ........................... 37

Table 10 Other Commands ..................................................................... 37

Table 11 Modifiers ................................................................................... 42

Table 12 Analog Output Quantity Abbreviations ..................................... 42

Table 13 Analog Output Quantity Abbreviations ..................................... 45

Table 14 Water Activity ............................................................................ 67

Table 15 Temperature ............................................................................. 67

Table 16 Electrical Connections .............................................................. 68

Table 17 General ..................................................................................... 68

Table 18 Spare Parts and Accessories ................................................... 69

6 ____________________________________________________________________ M210474EN-C

Page 7

Chapter 1 _________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the manual and the MMT310.

About This Manual

This manual provides information for installing, operating, and

maintaining Vaisala HUMICAP® Moisture and Temperature Transmitter

Series for Oil MMT310 (MMT317 and MMT318).

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides general notes for the manual

and the MMT310.

- Chapter 2, Product Overview, introduces the features, advantages, and

the product nomenclature.

- Chapter 3, Installation, provides you with information that is intended

to help you install the MMT310.

- Chapter 4, Operation, contains information that is needed to operate

the MMT310.

- Chapter 5, Maintenance, provides information that is needed in basic

maintenance of the MMT310.

- Chapter 6, Calibration and adjustment, describes the calibration and

adjustment procedures.

- Chapter 7, Technical Data, provides the technical data of the

MMT310.

- Appendix A, Applications, describes typical applications where

MMT310 is used.

VAISALA _________________________________________________________________________ 7

Page 8

User's Guide _______________________________________________________________________

Manual Code

Description

M210474EN-C

March 2014. This manual. New software

template updated, quality improvement updates.

M210474EN-B

Previous version. MMT318 and MMT317 User's

dimension figure.

Manual Code

Manual Name

M210878EN

Vaisala HUMICAP® Hand-held Moisture Meter for

Oil MM70 User’s Guide

M210185EN

Vaisala Humidity calibrator HMK15 User’s Guide

Version Information

Table 1 Manual Revisions

functionality applicable from version 2.0.1 onward.

Voltage output added to analog output options, new

voltage parameters in the AMODE command.

Added information on rain shield, sampling cell,

MI70 hand-held indicator, and USB connection.

Transmitter plastic housing material changed to

PPS. Updated serial terminal instructions, list of

optional accessories and operating voltage and

power consumption specifications. Document

Guide. The manual has been updated with

MMT317 installation instructions and MMT317

WARNING

CAUTION

Related Manuals

Table 2 Related Manuals

Documentation Conventions

Throughout the manual, important safety considerations are highlighted

as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

NOTE

Note highlights important information on using the product.

8 ____________________________________________________________________ M210474EN-C

Page 9

Chapter 1 _________________________________________________________ General Information

Ground the product and verify outdoor installation grounding

periodically to minimize shock hazard.

Do not modify the unit. Improper modification can

or lead to malfunction.

Do not touch the sensor plate.

In pressurized processes it is essential to tighten the supporting nuts and

screws very carefully to prevent loosening of the probe by the action of

pressure.

Take care not to damage the probe body. A damaged body makes the

probe less tight and may prevent it from going through the clasp nut.

Safety

The Vaisala HUMICAP® Moisture and Temperature Transmitter Series

for Oil MMT310 is delivered to you tested for safety and approved as

shipped from the factory. Note the following precautions:

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

damage the product

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. It is possible to damage the product,

however, by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench.

- When an ESD workbench is not available, ground yourself to the

equipment chassis with a wrist strap and a resistive connection cord.

- If you are unable to take either of the above precautions, touch a

conductive part of the equipment chassis with your other hand before

touching ESD sensitive components.

- Always hold component boards by the edges and avoid touching the

component contacts.

VAISALA _________________________________________________________________________ 9

Page 10

User's Guide _______________________________________________________________________

Test

Complies with Standard

Radiated emissions

EN/IEC 55022 / CISPR16/22 Class B

Test

Complies with Standard

Electrostatic discharge

(ESD)

EN/IEC 61000-4-2

Radiated immunity

EN/IEC 61000-4-3

EFT burst (Electric fast

transients)

EN/IEC 61000-4-4

Surge

EN/IEC 61000-4-5

Conducted immunity

EN/IEC 61000-4-6

Recycling

Recycle all applicable material.

Dispose of the unit according to statutory regulations. Do not dispose of

with regular household refuse.

Regulatory Compliances

MMT310 complies with the following performance and environmental

test standards:

- EN 61326-1, Industrial environment.

Emissions

Immunity

Trademarks

HUMICAP® is a registered trademark of Vaisala.

Windows® is a registered trademark of Microsoft Corporation in the

United States and/or other countries.

10 ___________________________________________________________________ M210474EN-C

Page 11

Chapter 1 _________________________________________________________ General Information

Software License

This product contains software developed by Vaisala. Use of the software

is governed by license terms and conditions included in the applicable

supply contract or, in the absence of separate license terms and

conditions, by the General License Conditions of Vaisala Group.

Warranty

Visit our Internet pages for standard warranty terms and conditions:

www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of

damage due to normal wear and tear, exceptional operating conditions,

negligent handling or installation, or unauthorized modifications. Please

see the applicable supply contract or Conditions of Sale for details of the

warranty for each product.

VAISALA ________________________________________________________________________ 11

Page 12

User's Guide _______________________________________________________________________

This page intentionally left blank.

12 ___________________________________________________________________ M210474EN-C

Page 13

Chapter 2 ___________________________________________________________ Product Overview

Quantity

Abbreviation

Metric Unit

Non Metric Unit

Water activity

aw

aw

aw

Temperature

T

°C

°F

Parts per million

(for transformer oil only)

ppm

ppm

ppm

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the features, advantages, and the product

nomenclature.

Introduction to MMT310 Series

The Vaisala HUMICAP® Moisture and Temperature Transmitter Series

for Oil MMT310 is a small-size oil moisture and temperature transmitter

that powers up with 10 ... 35 VDC (mode-dependent power supply

requirements).

The MMT310 probe options are:

- MMT317 – small pressure-tight probe

- MMT318 – probe for pressurized pipelines

MMT310 supports the following output alternatives:

- Analog outputs 0/4 ... 20 mA and 0 … 5/10 V

(1 … 5 V available as scaled output: see section Setting, Scaling and

Testing the Analog Outputs on page 44).

- RS-232 serial line

- USB cable (optional accessory, order code 238607)

- MI70 handheld indicator connection (optional connection cable

DRW216050)

For a list of MMT310 optional accessories and spare parts, see section

Spare Parts and Accessories on page 69.

The transmitter measures and calculates the following quantities:

Table 3 MMT310 Measurement and Calculation Quantities

VAISALA ________________________________________________________________________ 13

Page 14

User's Guide _______________________________________________________________________

Vaisala HUMICAP moisture in oil transmitters MMT318 and MMT317

are designed for industrial applications. They measure water in oil in

terms of water activity (aw) which can be determined as follows: water

activity indicates the amount of oil in the scale of 0 - 1 aw. In this scale, 0

aw is an indication of completely water free oil and 1 aw an indication of

oil fully saturated with water. Water is present in free form. The water

activity is used for alarming at the point of > 0.9 aw where the risk for

free water is obvious.

The most advanced feature which distinguishes the measurement of

water activity (aw) from the traditional measurement of absolute water

content (in ppm) is that in the water activity measurement the saturation

point remains stable regardless of the oil type, aging of oil or additives

used. As water activity of the oil exceeds 0.9 aw, there is a risk for

segregation (especially if the temperature decreases).

The MMT318 and MMT317 transmitters can be used for continuous online measurements and can be calibrated against salt solutions, no

reference oils are needed.

Appendix A on page 75 presents application information when using the

MMT318 and MMT317 with transformer oil (output unit= ppm). General

information on paper machine use is also included in the Appendix.

14 ___________________________________________________________________ M210474EN-C

Page 15

Chapter 2 ___________________________________________________________ Product Overview

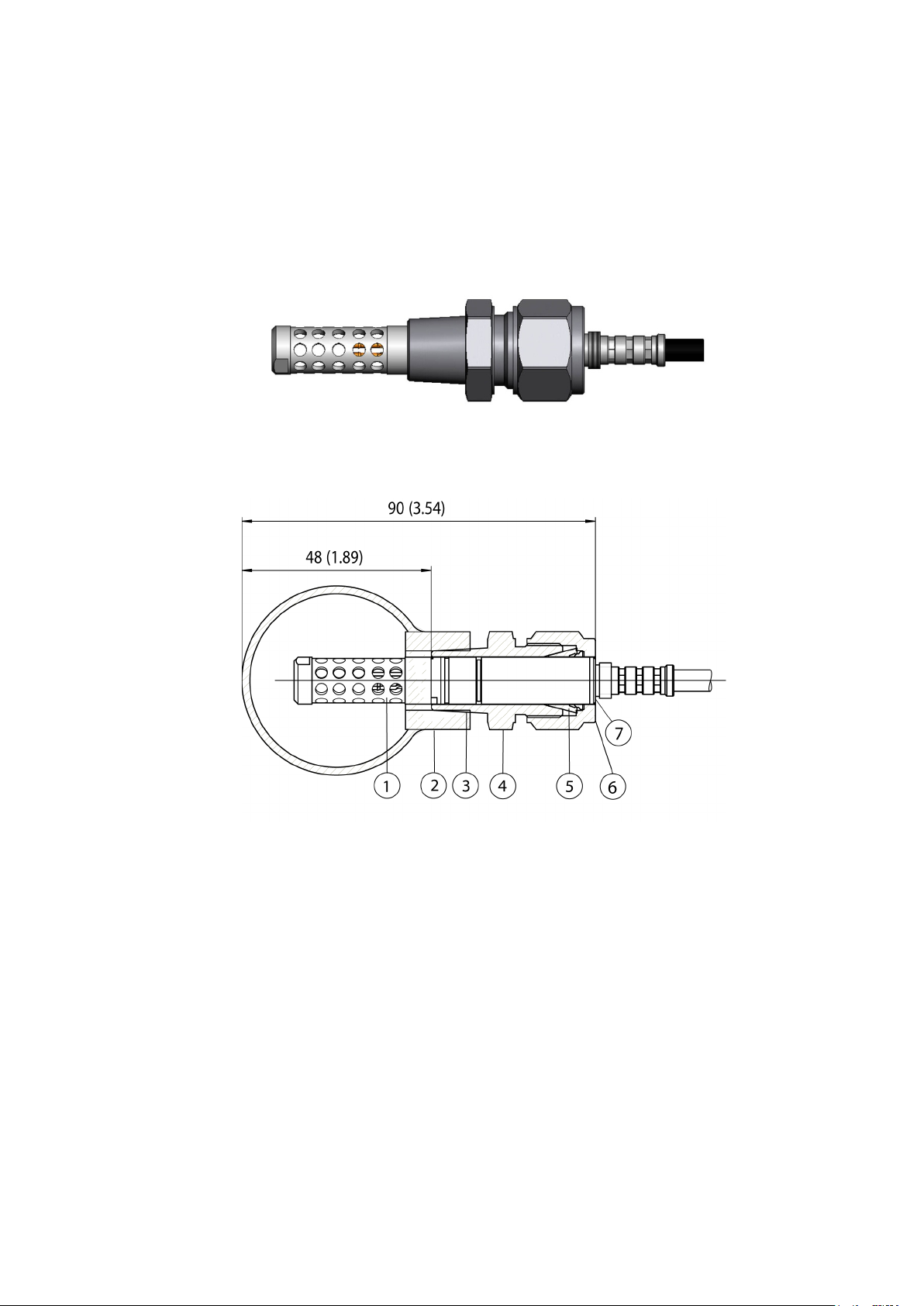

The following numbers refer to Figure 1 above:

1 = Transmitter unit

2 = Mounting plate (smaller mounting plate also available)

3 = Connector for signal output and power supply. Available with

female connector with 5 m cable or screw terminal connector.

4 = Probe

MMT310 Transmitter Parts

Figure 1 MMT310 Transmitter Parts

1403-179

VAISALA ________________________________________________________________________ 15

Page 16

User's Guide _______________________________________________________________________

The following numbers refer to Figure 2 above:

1 = MMT317 probe with optional Swagelok connector for tight-place

installations.

2 = MMT318 probe for pressurized pipelines with two adjustable

probe lengths and optional ball valve set.

Probe Options

1311-199

Figure 2 MMT310 Probes

For probe dimensions, see section MMT317 Probe with Optional

Swagelok Connector, Dimensions on page 74 and section MMT318

Probe Dimensions on page 72.

Filter Options

MMT310 filter options include stainless steel filters with 3.15 mm and

1.5 mm (for high flow velocity oil measurements) holes. The filters are

12 mm in diameter with a female thread. The filters recommended for a

probe type can be selected on the corresponding MMT310 order form.

For information on ordering accessories, see section Spare Parts and

Accessories on page 69.

16 ___________________________________________________________________ M210474EN-C

Page 17

Chapter 3 ________________________________________________________________ Installation

Avoid mounting the transmitter housing close to steam sources or

directly exposed to rain. To ensure an IP 6

mount the transmit

downwards.

Take care not to damage the pipe of the probe. If the pipe

the probe head is less tight and will not go through the clasp nut. Make

sure that the filter is tightly fastened to

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended to help you

install the MMT310.

Mounting

Selecting a Place for the Probe

Select a place which gives a true picture of the process. Oil should

circulate freely around the sensor; clear oil flow is recommended. Install

the probe directly into the circulation system and not into the oil reservoir

because of deposition.

It is recommended that the sensor head is installed directly in the process

through the ball valve assembly. When the ball valve assembly is used,

the pipe does not have to be emptied or shut down for installation or

removal of the probe. Install the sensor head transversely against the

direction of the process flow.

NOTE

6 class protection, always

ter housing with the cable bushings pointing

NOTE

protect the sensors.

is damaged,

VAISALA ________________________________________________________________________ 17

Page 18

User's Guide _______________________________________________________________________

The following letters and numbers refer to Figure 3:

A = Mounting with larger mounting plate (mount from flanges)

B = Mounting with smaller mounting plate (remove the transmitter

and mount using the holes in mounting plate base)

1 = Two Allen screws for fastening or removing the transmitter

module (Allen key provided)

2 = Four screw holes (Ø 4.5 mm) for wall mounting (screws not

provided)

3 = Two screw holes (Ø 6.0 mm) on the base of the plate for wall

mounting (screws not provided)

Mounting the Transmitter/Removing the Transmitter Unit

Select a place with stable conditions for mounting the transmitter. Do not

expose the transmitter to direct sunlight or rain. Always mount the

transmitter housing with the cable bushings pointing downwards.

NOTE

If the transmitter is mounted outdoors, cover it with a shelter (purchased by

customer). A rain shield designed for MMT310 is available as an optional

accessory. For information on ordering accessories, see section Spare Parts

and Accessories on page 69.

1. Mount the plate onto the wall with four/two screws

(Ø 4.5 mm/6.0 mm).

2. Place the transmitter onto the mounting plate and fasten it with two

Allen screws.

The transmitter module can be unfastened for calibration by releasing the

two Allen screws on the left side.

Figure 3 Mounting with Mounting Plates

18 ___________________________________________________________________ M210474EN-C

1403-181

Page 19

Chapter 3 ________________________________________________________________ Installation

It is recommended that

plug to transmitter during installation or service/calibration.

Vaisala does not recommend installing the transmitter outdoors with the

smaller

with flanges for outdoor installations.

The following numbers refer to Figure 4 above:

1 = Transmitter’s larger mounting plate: attaches to rain shield from

flanges with four Ø 4.5 mm screws (not provided).

2 = Rain shield: Four Ø 8.5 mm holes for (U-bolt) mounting. The

maximum diameter of the pole in U-bolt mounting is 60 mm.

3 = Rain shield: Four Ø 4.5 mm screw holes for mounting.

NOTE

NOTE

the supply is switched off before connecting the cable

Mounting the Transmitter with Optional Rain Shield

If you mount MMT310 outdoors, use a shelter to protect the transmitter.

An MMT310 rain shield is available from Vaisala as an optional

accessory (order code ASM211103).

mounting plate (without flanges). Use the larger mounting plate

Mounting the Rain Shield with Larger Transmitter Mounting Plate

1311-251

Figure 4 Rain Shield with Large Mounting Plate

VAISALA ________________________________________________________________________ 19

Page 20

User's Guide _______________________________________________________________________

The following numbers refer to Figure 5 above:

1 = Clasp nut; 24 mm hex nut

2 = Fitting body; 27 mm hex head

You can mount the rain shield and transmitter directly to a wall with

screws through both the mounting plate and the rain shield, or attach the

transmitter mounting plate to the rain shield and use for example U-bolt

mounting depending on the requirements of the installation site.

For rain shield measurements, see section Rain Shield Dimensions on

page 71.

Mounting the MMT318

NOTE

Do not unsolder and then again resolder the sensor head cable from and

to the printed board during installation; this procedure may alter the

humidity calibration of the transmitter.

Mounting for Pressurized Pipelines/Oils

Due to the sliding fit, MMT318 is easy to install into and remove from

the pressurized process. The probe is especially suitable for

measurements in pipelines.

Figure 5 MMT318 Probe

20 ___________________________________________________________________ M210474EN-C

0507-041

Page 21

Chapter 3 ________________________________________________________________ Installation

Type

Pipe Dimension

Adjustment Range

Standard

178 mm

120 mm

Optional

400 mm

340 mm

The following two fitting body options are available:

- Fitting Body ISO1/2 solid structure (DRW212076SP)

- Fitting Body NPT1/2 solid structure (NPTFITBODASP)

Table 4 MMT318 Pipe Dimensions

Use teflon tape or thread sealant to seal the connection between the

fitting body and the process/ball valve.

0507-025

Figure 6 Sealing of Fitting Body into Process

Tightening the Clasp Nut

1. Adjust the probe to a suitable depth according to the type of

installation.

2. Tighten the clasp nut first manually.

3. Mark the fitting screw and the clasp nut.

4. Tighten the nut a further 50 - 60º (ca. 1/6 turn) with a wrench. If

you have suitable torque wrench, tighten the nut to max 45 ± 5 Nm

(33 ± 4 ft-lbs).

VAISALA ________________________________________________________________________ 21

Page 22

User's Guide _______________________________________________________________________

The following numbers refer to Figure 7:

1 = Probe

2 = Clasp nut

3 = Fitting screw

4 = Pen (for marking)

NOTE

CAUTION

0505-276

Figure 7 Tightening the Clasp Nut

Take care not to overtighten the clasp nut to avoid difficulties when

opening it.

Take care not to damage the probe body. A damaged body makes the

probe less tight and may prevent it from going through the clasp nut.

CAUTION

In pressurized processes it is essential to tighten the supporting nuts and

screws very carefully to prevent loosening of the probe by the action of

pressure.

When the probe is used in a pressurized process the sensor head should

preferably be installed through a ball valve assembly. See section Ball

Valve Installation Kit for MMT318 for more information on the optional

ball valve installation kit.

22 ___________________________________________________________________ M210474EN-C

Page 23

Chapter 3 ________________________________________________________________ Installation

The following numbers refer to Figure 8 above:

1 = Manual press tool

2 = Handle of the ball valve

3 = Probe

4 = Process chamber or pipeline

5 = Groove on the probe indicates the upper adjustment limit

6 = Filter

7 = Ball of the ball valve

8 = Fitting screw

Ball Valve Installation Kit for MMT318

The optional ball valve installation kit (Vaisala order code:

BALLVALVE-1) is preferred when connecting the probe to a

pressurized process or pipeline. Use the ball valve set or a 1/2" ball valve

assembly with a ball hole of Ø14 mm or more.

If you install the sensor head (Ø 12 mm) in a process pipe, please note

that the nominal size of the pipe must be at least 1 inch (2.54 cm). Use a

manual press handle to press the sensor head into the pressurized (< 10

bar) process or pipeline.

0507-043

Figure 8 MMT318 Ball Valve Assembly Installation

VAISALA ________________________________________________________________________ 23

Page 24

User's Guide _______________________________________________________________________

The probe can be installed

assembly provided that the process pressure is less than 10 bars. This

way, the process does not have to be shut down when installing or

removing the probe. However, if the process is shut down before

removing the prob

When measuring temperature dependent quantities make sure that the

temperature at the measurement point is equal to that of the process,

otherwise the moisture reading may be incorrect.

NOTE

NOTE

in the process through the ball valve

e, the process pressure can be max. 20 bars.

Follow the steps below to install the MMT318 probe through a ball valve

assembly. After the installation, the probe should be sitting in the process

chamber or pipeline as shown in Figure 8 on page 23.

1. Shut down the process if the process pressure is more than 10 bars.

If the pressure is lower there is no need to shut down the process.

2. Close the ball valve.

3. Seal the threads on the fitting body; refer to Figure 6 Sealing of

Fitting Body into Process on page 21.

NOTE

4. Attach the fitting body to the ball valve and tighten it.

5. Slide the clasp nut of the probe toward the filter, as far as it will go.

6. Insert the probe to the fitting body, and manually tighten the clasp

nut to the fitting body.

7. Open the ball valve.

8. Push the probe through the ball valve assembly into the process. If

the pressure is high, use the pressing handle that is provided with

the probe. If you push the probe hard without using the handle, you

may damage the cable.

Note that the probe must be pushed to a depth where the filter is

completely inside the process flow.

9. Mark the fitting screw and the clasp nut.

10. Tighten the clasp nut with an open-end wrench a further 50 ... 60º

(ca. 1/6 turn). If you have a suitable torque wrench, tighten the nut

to max 45 ± 5 Nm (33 ± 4 ft-lbs). Refer to Figure 7 on page 22.

Take care not to tighten the clasp nut more than 60° to avoid difficulties

when opening it.

24 ___________________________________________________________________ M210474EN-C

Page 25

Chapter 3 ________________________________________________________________ Installation

The following numbers refer to Figure 9 above:

1 = Male pipe weld connector Swagelok 1/4"

2 = G1/2"

Do not unsolder and then again resolder the sensor head cable from and

to the printed board during installation; this procedure may alter the

calibration of the transmitter.

If you wish to remove the probe from the process, note that you have to

pull the probe out far enough. You cannot close the valve if the groove

on the probe body is not visible.

Sampling Cell for MMT318

It may be necessary to use a sampling cell if the MMT318 probe cannot

be installed directly into the process pipe, for example, if the pipe is too

small for the probe. Using a bypass sampling line may be feasible in

these cases. Sampling Cell with Swagelok Connectors (Vaisala order

code: DMT242SC2) is available as an optional accessory.

Figure 9 Sampling Cell DMT242SC2

Mounting the MMT317

The MMT317 uses a small pressure-tight probe and is ideal for tight

spaces with threaded connection. The small probe is installed using the

threaded fitting bodies as instructed in this section.

NOTE

0511-108

VAISALA ________________________________________________________________________ 25

Page 26

User's Guide _______________________________________________________________________

The following numbers refer to Figure 11 above:

1 = Probe

2 = Duct connector

3 = ISO3/8" or NPT1/2" thread

4 = Swagelok connector

5 = Ferrules

6 = Upper edge of the connector nut

7 = Upper edge of the probe

MMT317 Probe with Swagelok Connector for Tightplace Installations

The Swagelok installation kit for MMT317 includes a Swagelok

connector with ISO3/8" thread (Vaisala order code: SWG12ISO38) or

NPT1/2" thread (Vaisala order code: SWG12NPT12).

0509-144

Figure 10 MMT317 Probe with Swagelok Installation Kit

0509-150

Figure 11 MMT317 Probe Installation to Pipeline with Swagelok

Installation Kit

26 ___________________________________________________________________ M210474EN-C

Page 27

Chapter 3 ________________________________________________________________ Installation

Mount the MMT317 as follows:

1. Select the correct connector for the installation. The connector

options are:

a. R3/8" ISO (Swagelok code SS-12M0-1-6RTBT)

b. 1/2" NPT (Swagelok code SS-12M0-1-8BT)

Note that the connector inner diameters extend for Ø12 mm probe.

2. Check that the probe position is correct. Before the final tightening

check that the upper edge of the connector nut is in line with the

upper edge of the probe. Otherwise the sealing may not be gas

tight.

3. Ensure gas-tight sealing:

a. Turn the connector nut finger tight and draw a vertical mark

on the nut and the fitting body.

b. Be sure that the probe position follows step 2.

c. Tighten the connector nut with a wrench 1 and 1/4 turns

(360º +90º) with the help of marks you drew. The connector

now has a gas tight connection to the probe. Excess

tightening can damage the probe.

d. The connector can be disconnected and re-installed. In re-

installation first turn the connector nut finger tight and then

with wrench 1/4 turn (90º).

4. Use teflon tape or thread sealant to seal the connection between the

Swagelok connector and the process (see Figure 6 on page 21).

VAISALA ________________________________________________________________________ 27

Page 28

User's Guide _______________________________________________________________________

Pin

Wire

Serial Signal RS-232C

Analog Signal

1

White

Data out TX

- 2 Brown

-

Ch 1 - / Ch 2 -

3

Green

-

Ch 2 +

4

Yellow

-

Ch 1 +

5

Grey

Supply - / RS-232 GND

Supply -

6

Pink

Supply +

Supply +

7

Blue

Data in RX

- 8 Red

Not connected

Not connected

Connections

When the MMT310 leaves the factory, the measurement ranges, output

scaling and quantities have already been set according to the customer

order. The unit is calibrated at the factory and ready for use. The

transmitter is delivered with either a screw terminal connector or with a

detachable 5m cable with eight wires for serial port, analog outputs and

10 … 35 VDC power supply (requirements vary dependending on the

operating environment and output type). The wiring is described in this

section. For power supply requirements, see section Power Supply

Requirements on page 29.

Cable Wiring

Figure 12 8-Pin Connector (Left) and Screw Terminal

0507-044, 0507-045

Connector (Right)

28 ___________________________________________________________________ M210474EN-C

Page 29

Chapter 3 ________________________________________________________________ Installation

Output

Consumption

RS-232

12 mA

Uout 10 V (10kOhm)

Channel1 & Channel 2

12 mA

Iout 20mA (load 511Ohm)

Channel 1 & Channel 2

50 mA

M

connection to a computer

and USB connection cables, see section

page

Power Supply Requirements

The minimum supply voltage required by the MMT310 transmitter

depends on the output type and pressure:

- RS-232 output: 10 ... 35 VDC.

- Analog output: 15 ... 35 VDC.

- Pressures above 10 bara (145 psia): minimum 24 VDC.

Table 5 below lists the MMT310 current consumption according to

output type.

Table 5 Current Consumption by Output Type

NOTE

MT310 can also be powered by an MI70 indicator or a USB cable

69.

. For information on ordering the optional MI70

Spare Parts and Accessories on

VAISALA ________________________________________________________________________ 29

Page 30

User's Guide _______________________________________________________________________

This page intentionally left blank.

30 ___________________________________________________________________ M210474EN-C

Page 31

Chapter 4 _________________________________________________________________ Operation

CHAPTER 4

OPERATION

This chapter contains information that is needed to operate the MMT310.

Power Supply

Use a 10 … 35 VDC power supply (required minimum voltage varies

depending on the operating environment and output type). For

instructions on selecting the correct operating voltage, see section Power

Supply Requirements on page 29.

Transmitter Start-Up

When the transmitter is connected to a power supply, there is a delay of

three seconds as the transmitter starts up. After the start-up is complete,

the measurement data is available from the analog output and serial line.

If serial line output is used, note that the transmitter will behave

according to the configured serial mode:

- In STOP mode, the transmitter outputs the transmitter model and

software version. This is the default mode.

- In RUN mode a measurement output starts immediately.

- In POLL mode the transmitter does not output anything after

powerup.

For instructions on configuring the serial mode, see section Set Serial

Interface Mode on page 39.

VAISALA ________________________________________________________________________ 31

Page 32

User's Guide _______________________________________________________________________

Serial Line and Analog Communication Options

MMT310 measurement data can be accessed with the following serial or

analog options:

- RS-232 serial port connection to a computer

- Analog output (current or voltage)

For temporary access, you can also connect to the transmitter with the

following:

- USB connection to a computer using an optional USB cable (238607)

- Connection to a hand-held MI70 indicator using an optional MI70

calibration cable (DRW216050SP)

When using the MMT310 with a serial connection (RS-232 serial cable

or USB), you need a terminal program to operate the MMT310 command

line interface. For instructions on installing and using the PuTTY

terminal application for Windows (available from www.vaisala.com), see

section Terminal Program Settings on page 35.

For information on using the analog outputs, see section Setting, Scaling

and Testing the Analog Outputs on page 44.

RS-232 Serial Port Connection

When connecting the MMT310 to a computer with an RS-232 cable, use

the following data format settings (factory settings) in the terminal

program:

- 1 start bit

- 7 data bits

- 1 stop bit

- Even parity

- 4800 bits per second, programmable to 19200

- Full duplex

- Serial asynchronous

- Configured as Data Terminal Equipment (DTE)

Enter the communication parameters when using this terminal session for

the first time and save them for future use.

32 ___________________________________________________________________ M210474EN-C

Page 33

Chapter 4 _________________________________________________________________ Operation

Before starting to use the USB cable, you must install the USB cable

driver

USB Connection

MMT310 can be connected to a computer by using a USB cable (order

code 238607). The USB cable is an optional accessory: for more

information on ordering optional items, see section Spare Parts and

Accessories on page 69.

NOTE

(requires Windows).

Installing the Driver for the USB Cable

Complete the following steps to install the USB driver before taking the

USB cable into use:

1. Check that the USB cable is not connected. Disconnect the cable if

you have already connected it.

2. Insert the media that came with the cable, or download the driver

from www.vaisala.com.

3. Execute the USB driver installation program (setup.exe), and

accept the installation defaults. The installation of the driver may

take several minutes.

4. After the driver has been installed, connect the USB cable to a USB

port on your computer. Windows will detect the new device, and

use the driver automatically.

5. The installation has reserved a COM port for the cable. Verify the

port number, and the status of the cable, using the Vaisala USB

Device Finder program that has been installed in the Windows Start

menu.

Windows will recognize each individual cable as a different device, and

reserve a new COM port. Remember to use the correct port in the

settings of your terminal program.

VAISALA ________________________________________________________________________ 33

Page 34

User's Guide _______________________________________________________________________

Connection to an MI70 Hand-held Indicator

MMT310 can be connected to the hand-held MI70 indicator with the

MI70 connection cable (DRW216050SP). The MI70 connection cable is

an optional accessory: for more information on ordering optional items,

see section Spare Parts and Accessories on page 69.

When MMT310 is connected to the MI70 indicator, you can view

MMT310 readings and perform MMT310 adjustments using the MI70

indicator’s interface.

For instructions on performing MMT310 adjustments with the MI70

indicator, see section Adjustment Using an MI70 Indicator on page 62.

For general instructions on using the MI70 hand-held indicator to view

and log readings and further information on using MI70, see the

MI70/MM70 user documentation.

34 ___________________________________________________________________ M210474EN-C

Page 35

Chapter 4 _________________________________________________________________ Operation

Terminal Program Settings

The instructions in this section describe how to connect a computer to the

MMT310 using the PuTTY terminal application for Windows (available

for download at www.vaisala.com). Perform the necessary cabling and

configuration of the transmitter before following the instructions.

Opening a Serial/USB Connection with PuTTY

1. Power up the MMT310 and start the PuTTY application.

2. Select the Serial & USB settings category, and check that the

correct COM port is selected in the “Serial or USB line to connect

to” field. Change the port if necessary.

If you are using a Vaisala USB cable, you can check the port that it

uses by clicking the USB Finder... button. This opens the Vaisala

USB Instrument Finder program that has been installed along with

the USB drivers.

3. Check that the other serial/USB line settings are correct for your

connection, and change if necessary.

1311-113

Figure 13 PuTTY Serial Line Configuration

4. Click the Open button to open the connection window and start

using the serial connection command line interface.

If PuTTY is unable to open the serial port you selected, an error

message is displayed. If this happens, restart PuTTY and check the

settings.

VAISALA ________________________________________________________________________ 35

Page 36

User's Guide _______________________________________________________________________

Command

Description

R

Start continuous reading output

S

Stop continuous reading output

INTV [0 … 255 S/MIN/H]

Set continuous output interval for RUNmode

SEND [0 … 99]

Output reading once

SMODE [STOP/RUN/POLL]

Set serial interface mode

SERI [baud p d s]

Serial line settings (default: 4800 E 7 1)

baud: 300…19200

ADDR [0 … 99]

Set transmitter address for use in POLLmode

OPEN [0 … 99]

Temporarily open transmitter from POLL

mode to receive commands

CLOSE

Close the temporary connection (back to

POLL mode)

Command

Description

FORM

Set serial output format

TIME

Set time

DATE

Set date

FTIME [ON/OFF]

Add time to SEND and R outputs

FDATE [ON/OFF]

Add date to SEND and R outputs

UNIT

Select metric or nonmetric output units

Command

Description

CRH

Relative humidity calibration

CT

Temperature calibration

L

View the currently applied standard user

adjustment offset and gain

LI

Revert factory calibration

FCRH

Relative humidity calibration after sensor

change

CTEXT

Set calibration information text

CDATE

Set calibration date

ACAL

Analog output calibration

List of Serial Commands

All commands can be issued either in uppercase or lowercase. In the

command examples, the keyboard input by the user is in bold type.

The notation <cr> refers to pressing the carriage return (Enter) key on

your computer keyboard. Enter a <cr> to clear the command buffer

before starting to enter commands. In the following command tables, the

bold text in the brackets is the default setting.

Table 6 Measurement Output

Table 7 Output Formatting

Table 8 Calibration and Adjustment*

*These commands are presented in section Calibration and adjustment on

page 55.

36 ___________________________________________________________________ M210474EN-C

Page 37

Chapter 4 _________________________________________________________________ Operation

Command

Description

AMODE

Set analog outputs (0/4 ... 20 mA or

scaling)

ASEL

Select parameter for analog outputs

ASCL

Scale analog outputs

ITEST

Test analog outputs

AQTEST

Test analog outputs for desired readings

AERR

Change analog error output value

Command

Description

?

Check transmitter settings

??

Check transmitter settings in POLL mode

ECHO [ON/OFF]

Serial bus echo

FILT

Set result filtering

FIND

All devices in POLL mode send their

addresses

HELP

List commands

RESET

Reset transmitter

ERRS

List error messages

OIL [ON/OFF]

Enable/disable ppm output when

measuring moisture in oil.

Table 9 Setting, Scaling and Testing Analog Outputs

0 … 5/10 V, 1 … 5 V available through

Table 10 Other Commands

VAISALA ________________________________________________________________________ 37

Page 38

User's Guide _______________________________________________________________________

Where

Xxx

=

Output interval (0 ... 255)

yyy

=

Unit (s, min or h)

Measurement Output

Starting the Continuous Reading Output

Syntax: R <cr>

Starts output of measurements to the peripheral devices (RUN mode).

While the measurement output is active the only command that can be

given is S (stop).

The output mode can be changed with the FORM command.

Example:

>r

aw= 0.2000 aw T= 25.09 'C …

aw= 0.2000 aw T= 25.20 'C …

Stopping the Continuous Reading Output

Syntax: S <cr>

Stops the continuous output. <ESC> can also be used to stop the output.

Set Continuous Output Interval for RUN Mode

Syntax: INTV xxx yyy<cr>

Example:

>intv 1

Output interval: 1 S

>intv 1 min<cr>

Output interval: 1 MIN

>intv 1 h<cr>

Output interval: 1 H

38 ___________________________________________________________________ M210474EN-C

Page 39

Chapter 4 _________________________________________________________________ Operation

Where

aa = Address of the transmitter when more than one transmitter is

connected to a serial bus (0 ... 99).

Where

x = STOP/RUN/POLL

STOP

commands

RUN

POLL

addressed command

address>

commands

mode.

Output Reading Once

Syntax in STOP-mode: SEND<cr>

Syntax in POLL-mode: SEND aa<cr>

Example:

>send

aw= 0.2 aw T= -47.37 'C …

If the value is too long to fit to the allocated space or if there is an error

in outputting, the value is displayed with stars ‘*’.

For example,

aw=*.* aw T= 31.0 'C

The output mode can be changed with the FORM command.

Set Serial Interface Mode

Syntax: SMODE x<cr>

mode: Transmitter in standby for serial

mode: Transmitter outputs data continuously

mode: Transmitter only responds to

s. Use the OPEN <transmitter

command to temporarily enable serial

(as in STOP mode) when in POLL

VAISALA ________________________________________________________________________ 39

Page 40

User's Guide _______________________________________________________________________

Where

b = bauds (300, 600, 1200, 2400, 4800, 9600,19200)

p = parity (n = none, e = even, o = odd)

d = data bits (7 or 8)

s = stop bits (1 or 2)

Where

aa = Address (0 ... 99)

Example:

>smode run

Output mode : RUN

>r

02:08:01.03 aw= 0.2 aw T= -47.13 'C …

02:08:04.21 aw= 0.2 aw T= -47.16 'C …

<ESC>

>smode stop

Output mode : STOP

Serial Line Settings

Syntax: SERI b p d s<cr>

The settings can be changed one parameter at a time or all parameters at

once.

Example:

>seri o changing parity only

4800 o 7 1

>seri 600 n 8 1

600 n 8 1

changing all parameters

Set Transmitter Address for Use in POLL Mode

Syntax: ADDR aa<cr>

Example:

>addr

Address : 0

>addr 1

Address : 1

40 ___________________________________________________________________ M210474EN-C

Page 41

Chapter 4 _________________________________________________________________ Operation

Where

nn = Address of the transmitter (0 ... 99)

Temporarily Open Transmitter from POLL Mode to Receive Serial Commands

Syntax: OPEN nn<cr>

The OPEN command sets the bus temporarily in STOP mode so that the

SMODE command can be issued.

Example:

>open 4

Device: 4 line opened for operator commands

>

Set Transmitter in POLL Mode

Syntax: CLOSE<cr>

In STOP mode: the command OPEN has no effect, CLOSE sets the

transmitter temporarily in POLL mode.

In POLL mode: the command OPEN sets the transmitter temporarily in

STOP mode, command CLOSE returns the instrument to POLL mode.

Example:

Relative humidity calibration is performed at transmitter 2, which is in

POLL mode.

>open 2

Opens the line to transmitter 2.

>crh

Calibration started.

...

>close

Line closed.

VAISALA ________________________________________________________________________ 41

Page 42

User's Guide _______________________________________________________________________

Where

x = Formatter string

Modifier

Description

x.y

Length modifier (whole numbers and decimal places)

#t

Tabulator

#r

Carriage return

#n

Line-feed

""

String-constant

U5

Unit field and length (unit can be changed with the UNIT

command)

Quantity

Abbreviation

aw water activity

aw

T Temperature

T

ppm (for transformer oil only)

ppm

Output Formatting

Set Serial Output Format

Syntax: FORM x<cr>

The FORM command can be used to change the output format of the

SEND and R commands.

A formatter string consists of quantities and modifiers: use the modifiers

presented in Table 11 and quantities presented in Table 12 when

configuring the output format.

Use the FORM / command to return the default output form.

Table 11 Modifiers

Table 12 Analog Output Quantity Abbreviations

Example:

>form "aw="1.2 aw #r#n

aw=0.79

>form "aw="1.2 aw U3 #t "ppm="3.1 ppm " " U5 #t "T="3.1 T

U3 #r#n

aw=0.78 ppm= 53.4 ppm T= 27.3'C

>

>send

2000-01-01 20:56:27 N 0 aw=0.78 ppm= 53.2 ppm T=

27.2'C

>

42 ___________________________________________________________________ M210474EN-C

Page 43

Chapter 4 _________________________________________________________________ Operation

Time and date are cleared to 2000

Only about 1 % accuracy is obtained with the software clock.

Where

x = ON/OFF

Set Time and Date

Syntax: TIME<cr>

Syntax: DATE<cr>

Sets the time and date to the transmitter.

Example:

>time

Current time is 04:12:39

Enter new time (hh:mm:ss) ? 12:24:00

>date

Current date is 2000-01-01

Enter new date (yyyy-mm-dd) ? 2013-06-30

>

NOTE

NOTE

-01-01 00:00:00 at reset.

Add Time and Date to SEND and R Outputs

Syntax: FTIME x<cr>

Syntax: FDATE x<cr>

The command enables or disables output of time and date to the serial

line.

>send

aw= 0.2 aw T= 31.0 'C

>ftime on

Form. time : ON

>send

03:47:59 aw= 0.2 aw T= 31.0 'C

>fdate on

Form. date : ON

>send

2000-01-01 03:48:03 aw= 0.2 aw T= 31.0 'C

>

VAISALA ________________________________________________________________________ 43

Page 44

User's Guide _______________________________________________________________________

Where

x = M or N

M = metric units

N = nonmetric units

Quantity

Metric Unit

Non-Metric Unit

aw water activity

-

aw

T Temperature

°C

T

ppm (for

transformer oil only)

ppm

ppm

Where

ch1 and ch2

=

I0 = 0 ... 20 mA

I1 = 4 ... 20 mA

U1 = 0 … 5 V

U2 = 0 … 10 V*

Select Metric or Nonmetric Output Units

Syntax: UNIT x<cr>

Setting, Scaling and Testing the Analog Outputs

You can select for the two outputs

- current or voltage range (0...20 mA/4...20 mA, 0 … 5/10 V,1 … 5 V

available through scaling) and

- output parameter (aw/ ppm*/ T).

and scale the two outputs according to your needs.

*for transformer oil only

Set Analog Outputs

Syntax: AMODE ch1 ch2<cr>

*

*Voltage output applicable from software version 2.0.1 onward.

44 ___________________________________________________________________ M210474EN-C

Example:

>amode i1 u1

Ch1 output mode: 4...20mA

Ch2 output mode: 0...5V

>

Page 45

Chapter 4 _________________________________________________________________ Operation

1 … 5 V output can be selected when ordering the device. The 1 .. 5

output is based on the 0 … 5 V output mode, but has been adjusted to

1

output mode, 0 V is reserved for error output (

Where

xxx

=

Quantity of channel 1

yyy

=

Quantity of channel 2

Quantity

Abbreviation

aw water activity

-

T Temperature

°C

ppm (for

transformer oil only)

ppm

NOTE

… 5 V by scaling the valid range to 1 … 5. In the scaled 1 … 5 V

AERR set to 0).

If the output includes the reminder 'remember to set jumpers', ignore the

reminder.

Select Parameter for Analog Outputs

Syntax: ASEL xxx yyy<cr>

After entering the command, the low and high values of each channel are

displayed one row at a time and a new value can be entered. Enter a new

value and press <cr> to move to the next row, or press <cr> without

entering a value to keep the current setting.

Use abbreviations shown in Table 13 Analog Output Quantity

Abbreviations below.

Table 13 Analog Output Quantity Abbreviations

Examples:

>asel aw t

Ch1 aw lo : 0.00 ?

Ch1 aw hi : 1.00 ?

Ch2 T lo : -40.00 'C ?

Ch2 T hi : 60.00 'C ?

>asel t ppm

Ch1 T lo : -40.00 'C ?

Ch1 T hi : 60.00 'C ?

Ch2 ppm lo : 0.00 ppm ?

Ch2 ppm hi : 5000.00 ppm ?

>

VAISALA ________________________________________________________________________ 45

Page 46

User's Guide _______________________________________________________________________

Where

aa.aaa

=

Current/voltage value to be set for channel 1

bb.bbb

=

Current/voltage value to be set for channel 2

Scale Analog Outputs

Syntax: ASCL<cr>

Example:

>ascl

Ch1 T lo : -40.00 'C ? -20

Ch1 T hi : 60.00 'C ? 40

Ch2 ppm lo : 0.00 ppm ? 0

Ch2 ppm hi : 5000.00 ppm ? 3000

>ascl

Ch1 T lo : -20.00 'C ?

Ch1 T hi : 40.00 'C ?

Ch2 ppm lo : 0.00 ppm ?

Ch2 ppm hi : 3000.00 ppm ?

The ppm calculation is only used for transformer oils.

Test Analog Outputs

Syntax: ITEST aa.aaa bb.bbb<cr>

The operation of the analog outputs is tested by forcing the outputs to

given values. The values in the analog outputs can then be measured with

a current/voltage meter.

Example:

>itest 8.30 6.40

8.30000mA 2c30 6.40000mA 2278

>

The ITEST command output includes internal debugging values shown

in hexadecimal format (2c30 and 2278 in the example above).

The set values remain valid until you issue the ITEST command without

readings or reset the transmitter.

46 ___________________________________________________________________ M210474EN-C

Page 47

Chapter 4 _________________________________________________________________ Operation

Where

x = Output quantity (aw / T / ppm)

yyy.yyy

=

Value

The e

The error

faults such as a humidity sensor open circuit. When there is a severe

device malfunction

microprocessor ROM/RAM failure, the error output value is

necessarily shown.

Test Analog Outputs for Desired Readings

Syntax: AQTEST x yyy.yyy<cr>

Using the AQTEST command, you can test the analog output by forcing

the output to correspond to a chosen value.

For example:

>aqtest aw 0.5

CH1 aw : 0.5000 aw 10.000mA

CH2 T : 22.3 'C 7.568mA

>

The set values remain valid until you give the command AQTEST

without a value or RESET the transmitter.

NOTE

NOTE

Set Error Outputs

Syntax: AERR<cr>

The factory default state for analog outputs during error condition is

0 mA. Be careful when selecting the new error value: the error state of

the transmitter should not cause problems in process monitoring.

Example:

>aerr

Ch1 error out : 0.000mA ?

Ch2 error out : 0.000mA ?

rror output value must be within the output type’s valid range.

output value is shown only when there are minor electrical

, such as an analog output electronics failure or a

not

VAISALA ________________________________________________________________________ 47

Page 48

User's Guide _______________________________________________________________________

Other Commands

Check Transmitter Settings

Syntax: ?<cr>

Syntax: ??<cr>

Use the ? command to check the current transmitter configuration. The

?? command is similar but can also be used if the transmitter is in POLL

mode.

Example (factory default settings):

>?

MMT310 / 1.03

PRB serial nr : V1234567

Calibration : 2003-03-25

Cal. info : NU/HMK15

Output units : metric

Pressure : 1013.25 hPa

RS232 settings

Address : 2

Output interval: 1 MIN

Baud P D S : 4800 E 7 1

Serial mode : STOP

Analog outputs

Ch1 output mode: 0 ...20mA

Ch2 output mode: 4 ...20mA

Ch1 error out : 0.000mA

Ch2 error out : 0.000mA

Ch1 T lo : -40.00 'C

Ch1 T hi : 60.00 'C

Ch2 ppm lo : 0.00 ppm

Ch2 ppm hi : 5000.00 ppm

>

48 ___________________________________________________________________ M210474EN-C

Page 49

Chapter 4 _________________________________________________________________ Operation

Where

x = ON/OFF (default = ON)

Where

x = ON, OFF or EXT

ON = Short filter of about 15 s (

show

OFF = No filtering (default)

EXT = Extended filter of about 1 min (

will show the average value of the last 1 min measurement data)

Serial Bus Echo

Syntax: ECHO x<cr>

The command enables or disables echo of characters received over the

serial line.

All Devices in POLL Mode Send Their Addresses

Syntax: FIND<cr>

List Commands

Syntax: HELP<cr>

Set Result Filtering

Syntax: FILT xx<cr>

Enable or disable the filtering or select the extended filter to reduce noise

of the measurement.

the measurement output will

the average value of the last 15 s measurement data)

the measurement output

VAISALA ________________________________________________________________________ 49

Page 50

User's Guide _______________________________________________________________________

Reset Transmitter

Syntax: RESET<cr>

This command resets the device, resulting in a short start-up delay. The

serial interface mode (STOP, RUN or POLL) selected with the SMODE

command is taken into use at restart.

Display Error Messages

Syntax: ERRS<cr>

Display transmitter error messages. If there are no errors present,

a PASS will be returned.

Examples:

>errs

PASS

>

>errs

FAIL

Error: Temperature measurement malfunction

Error: Humidity sensor open circuit

>

In case of a constant error, please contact a Vaisala Service Center.

For information on contacting Vaisala Service Centers, see

www.vaisala.com/servicecenters.

50 ___________________________________________________________________ M210474EN-C

Page 51

Chapter 5 _______________________________________________________________ Maintenance

Be careful when changing the filter, since it is easy to break the sensor

when the filter is removed.

If the transmitter is installed

that the pressure of the chamber is equalized with the ambient pressure

prior to removing the transmitter. When the transmitter is removed for

maintenance, cap the hole with a capped nut. This way, the chamber ca

be pressurized although the transmitter is not in place.

Plugs are available from Vaisala for ISO threaded connections.

CHAPTER 5

MAINTENANCE

This chapter provides information that is needed in basic maintenance of

the MMT310.

Periodic Maintenance

Calibration Interval

MMT310 is fully calibrated and adjusted as shipped from factory.

Typical calibration interval is one year. In certain applications it may be

advisable to do more frequent checks. Calibration needs to be done

always when there is reason to believe that the device is not within the

accuracy specifications.

You can carry out calibration and adjustment by yourself, or contact

Vaisala technical support (see section Technical Support on page 53) for

information about calibration services. For more information on

calibration, see section Calibration and adjustment on page 55.

Replacing Consumables

Changing the Filter

Replace the filter if it is contaminated. New filters are available from

Vaisala; see section Spare Parts and Accessories on page 69

CAUTION

CAUTION

in a pressurized chamber, always make sure

n

VAISALA ________________________________________________________________________ 51

Page 52

User's Guide _______________________________________________________________________

When replacing the sensor, the new sensor must be of the same type as

the old sensor (HUMICAP180

sensors is availab

The following numbers refer to Figure 14 above:

1 = Pull out the sensor

2 = Plastic socket

When replacing the filter, wear clean gloves to avoid depositing dirt or

oil on the filter.

Replace the filter as follows:

1. Turn the filter counterclockwise until it is loose.

2. Pull the filter straight out carefully. Do not damage the sensor.

3. Take the new filter, and insert it to the filter thread.

4. Tighten the new filter to 5 Nm by turning it clockwise.

Changing the Sensor

NOTE

L2 for MMT310). Information on Vaisala

le online at www.vaisala.com/sensorinfo.

Changing the sensor should be considered corrective maintenance, and it

is not necessary in normal operation. If the accuracy of the transmitter

does not seem to be within specification, it is more likely that the

transmitter is in need of calibration and adjustment, and not sensor

replacement. Refer to section Calibration and adjustment on page 55.

1. Remove the filter from the probe. See the instructions in section

Changing the Filter on page 51.

2. Remove the damaged sensor and insert a new one. Handle the new

sensor by the plastic socket. DO NOT TOUCH THE SENSOR

PLATE.

3. Perform a calibration and adjustment as instructed in section

Relative Humidity Calibration after Sensor Change on page 61.

4. Attach a new filter on the probe. When using the stainless steel

filter, take care to tighten the filter properly (recommended force

5 Nm).

0508-079

Figure 14 Changing the Sensor

52 ___________________________________________________________________ M210474EN-C

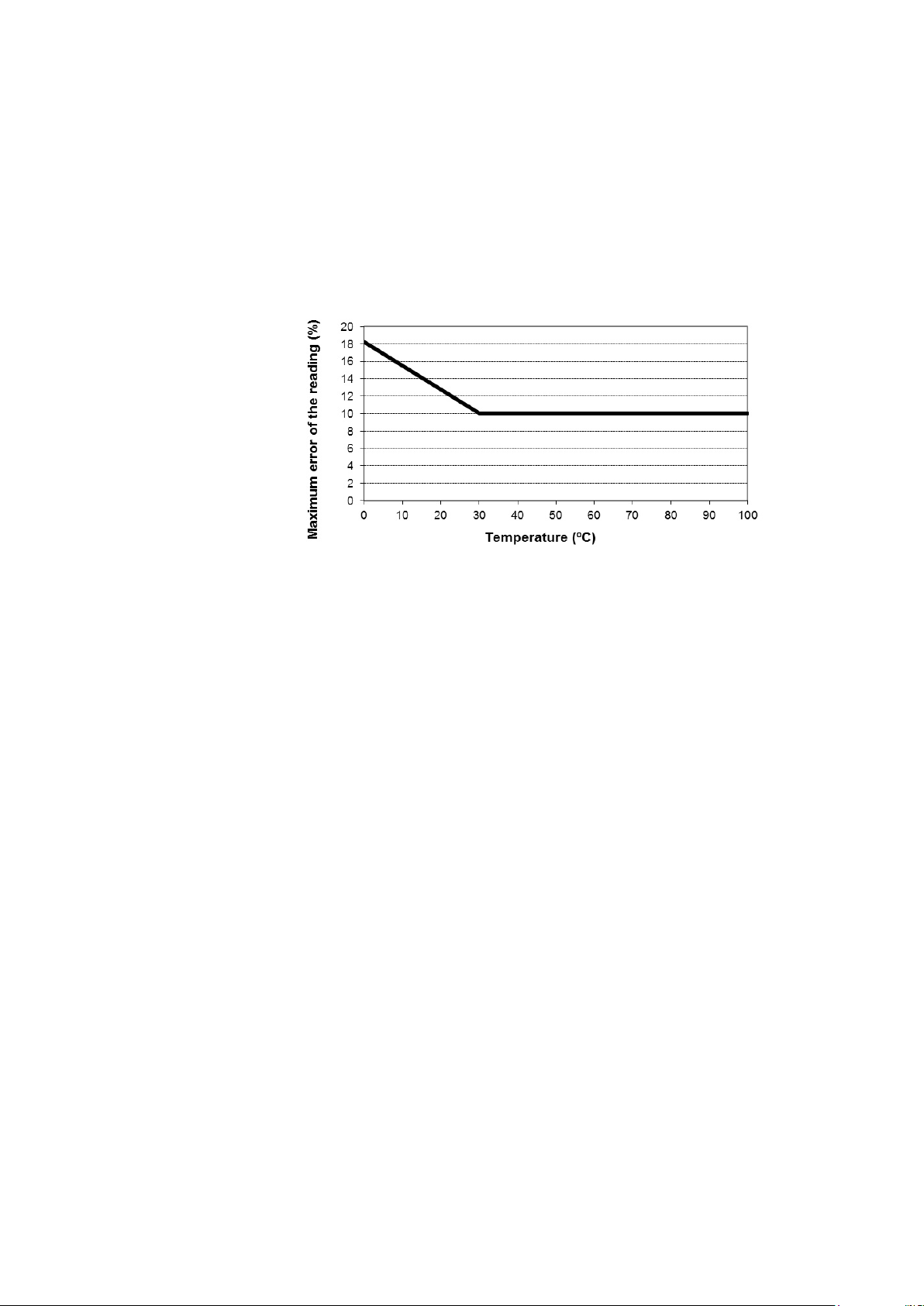

Page 53