Page 1

USER'S GUIDE

Vaisala HUMICAP® Moisture and

Temperature Transmitter for Oil

MMT162

M210934EN-C

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FI-00421 Helsinki

Finland

Visit our Internet pages at www.vaisala.com

© Vaisala 2013

No part of this manual may be reproduced, published or publicly displayed in any form

or by any means, electronic or mechanical (including photocopying), nor may its

contents be modified, translated, adapted, sold or disclosed to a third party without prior

written permission of the copyright holder. Translated manuals and translated portions

of multilingual documents are based on the original English versions. In ambiguous

cases, the English versions are applicable, not the translations.

The contents of this manual are subject to change without prior notice.

This manual does not create any legally binding obligations for Vaisala towards

customers or end users. All legally binding obligations and agreements are included

exclusively in the applicable supply contract or the General Conditions of Sale and

General Conditions of Service of Vaisala.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ............................................................................ 5

About This Manual ................................................................... 5

Contents of This Manual ....................................................... 5

Version Information ............................................................... 6

Related Manuals ................................................................... 6

Documentation Conventions ................................................. 6

Safety ......................................................................................... 7

Recycling .................................................................................. 7

Regulatory Compliances ......................................................... 7

Trademarks ............................................................................... 8

License Agreement .................................................................. 8

Warranty .................................................................................... 8

CHAPTER 2

PRODUCT OVERVIEW .................................................................................. 9

Introduction to MMT162 ........................................................... 9

Basic Features and Options .................................................. 10

Transmitter Structure ............................................................. 11

Typical Applications .............................................................. 12

Method Used for Measuring Moisture in Oil ........................ 12

Lubrication Oil ..................................................................... 12

Transformer Oil ................................................................... 13

CHAPTER 3

INSTALLATION ............................................................................................ 15

Installing the Transmitter ...................................................... 15

Wiring ...................................................................................... 17

Connection Cables .............................................................. 18

Power Supply Requirements ............................................... 19

CHAPTER 4

OPERATION ................................................................................................. 21

Getting Started ....................................................................... 21

Analog Output Operation Modes .......................................... 21

Normal Operation Mode and Malfunction Alarm ................. 21

Limit Alarm .......................................................................... 22

Serial Communication ........................................................... 22

Connecting to Serial Interface ............................................. 22

Installing the Driver for the USB Cable ............................... 23

Terminal Program Settings ................................................. 24

List of Serial Commands ....................................................... 26

Device Information and Status ............................................. 27

Show Device Information .................................................... 27

VAISALA ________________________________________________________________________ 1

Page 4

User's Guide ______________________________________________________________________

Show Firmware Version ...................................................... 27

Configuring Serial Line Operation ........................................ 28

Set Serial Line Settings ....................................................... 28

Set Serial Line Response Time ........................................... 29

Set Transmitter Address ...................................................... 29

Format Measurement Output .............................................. 30

Select Unit ........................................................................... 32

Set Serial Interface Mode .................................................... 33

Configuring Measurement Parameters ................................ 33

Select Analog Output Parameter and Scaling ..................... 33

Set Analog Output Mode (mA/V) ......................................... 34

Calibrate Analog Output ...................................................... 34

Set Malfunction Alarm Output for Analog Channels ............ 35

Set Alarm Limits and LED Indication for Analog Outputs.... 35

Set Voltage for LED Alarm .................................................. 36

Extend Analog Output Range .............................................. 36

Serial Line Output Commands .............................................. 37

Start Measurement Output .................................................. 37

Stop Measurement Output .................................................. 37

Set Output Interval............................................................... 38

Output Reading Once .......................................................... 38

Troubleshooting Commands ................................................. 39

Display the Currently Active Errors ..................................... 39

Test Analog Outputs ............................................................ 39

Other Commands ................................................................... 40

Opening the Transmitter in POLL Mode ............................. 40

Closing the Connection to a Transmitter in POLL Mode ..... 40

Display Command List ........................................................ 41

Reset Transmitter ................................................................ 42

Restore Factory Settings ..................................................... 42

ppm Conversion ..................................................................... 43

MMT162 ppm Conversion for Transformer Oils .................. 43

Conversion Model with Average Coefficients ...................... 43

Conversion Model with Oil-specific Coefficients ................. 44

Setting Oil Coefficients Using Serial Line ............................ 44

OIL .................................................................................. 44

Determination of Oil-Specific Coefficients ........................... 45

CHAPTER 5

MAINTENANCE ............................................................................................ 47

Cleaning ................................................................................... 47

Changing the Filter ................................................................. 48

Changing the Sensor ............................................................. 48

Error States ............................................................................. 48

Unknown Serial Settings ....................................................... 49

Technical Support .................................................................. 50

Product Returns...................................................................... 50

CHAPTER 6

CALIBRATION AND ADJUSTMENT ........................................................... 51

MM70 in Checking and Adjusting ......................................... 52

One-Point Relative Humidity Adjustment ............................ 52

Using Serial Line ................................................................. 52

2 ___________________________________________________________________ M210934EN-C

Page 5

________________________________________________________________________________

CRH ............................................................................... 52

Using MI70 .......................................................................... 53

One-Point Temperature Adjustment .................................... 56

Using Serial Line ................................................................. 56

Using MI70 .......................................................................... 57

Analog Output Adjustment.................................................... 58

CHAPTER 7

TECHNICAL DATA ...................................................................................... 59

Measured Parameters ............................................................ 59

Operating Environment ......................................................... 60

Inputs and Outputs ................................................................ 60

Mechanics ............................................................................... 60

Spare Parts and Accessories ................................................ 61

Dimensions in mm (inches) .................................................. 62

VAISALA ________________________________________________________________________ 3

Page 6

User's Guide ______________________________________________________________________

List of Figures

Figure 1 Moisture and Temperature Transmitter for Oil MMT162 .......... 11

Figure 2 Water Solubility of Transformer Oils versus Temperature ....... 14

Figure 3 Removing the Transportation Protection Cap .......................... 15

Figure 4 Installing the Transmitter .......................................................... 16

Figure 5 Connecting the Cable ............................................................... 16

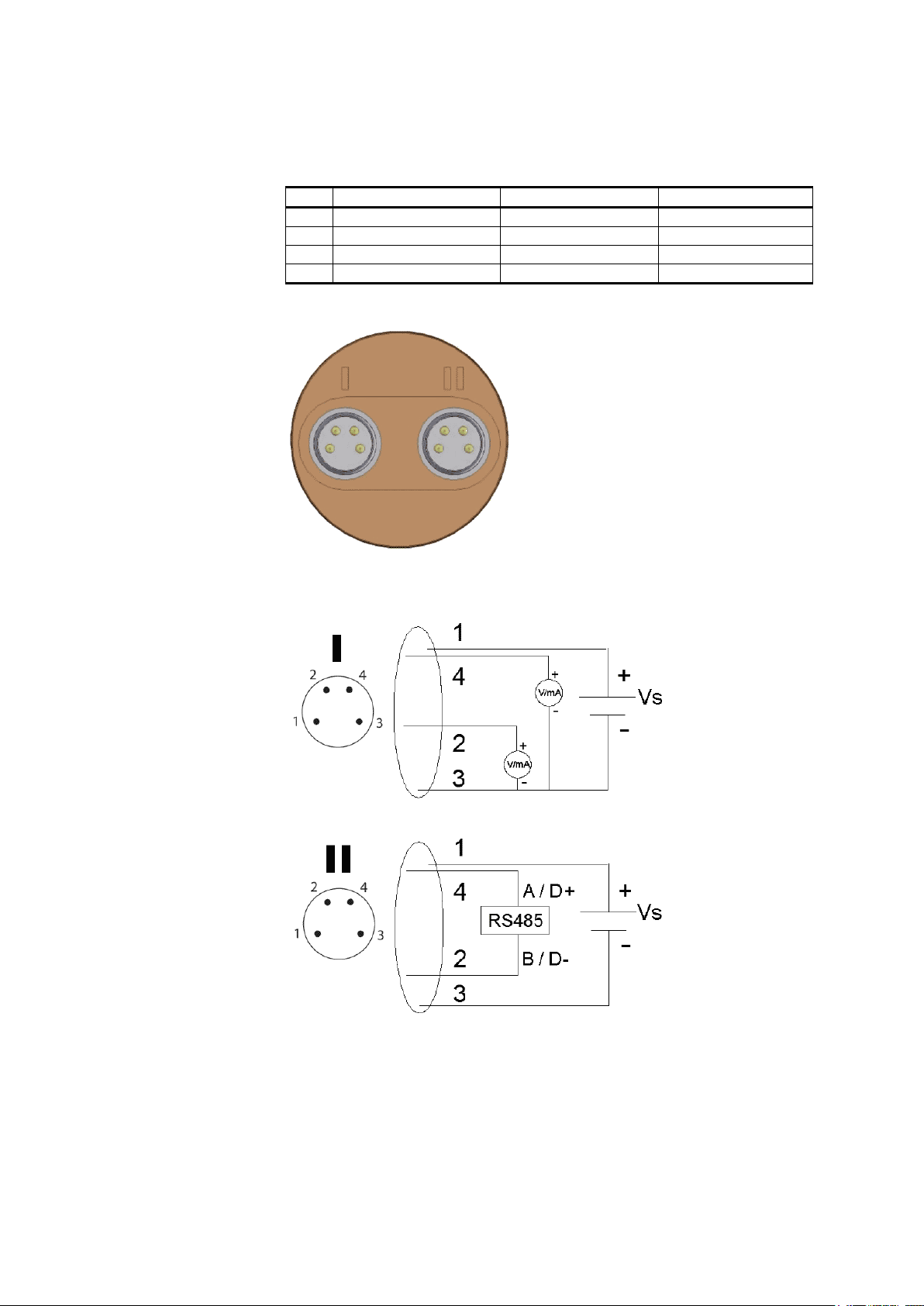

Figure 6 Connectors I and II ................................................................... 17

Figure 7 Connector Pinout ...................................................................... 17

Figure 8 Cable with Threaded Connector ............................................... 18

Figure 9 Cable with 90° Angle Threaded Connector .............................. 18

Figure 10 LED Cable ................................................................................ 19

Figure 11 USB Serial Interface Cable ....................................................... 19

Figure 12 PuTTY Terminal Application ..................................................... 25

Figure 13 Metal Housing Transmitter Dimensions ................................... 62

Figure 14 Plastic Housing Transmitter Dimensions .................................. 63

List of Tables

Table 1 Manual Revisions ....................................................................... 6

Table 2 Related Manuals ......................................................................... 6

Table 3 Parameters Measured and Calculated by MMT162 ................... 9

Table 4 Default Serial Interface Settings ............................................... 23

Table 5 Serial Line Commands ............................................................. 26

Table 6 FORM Command Modifiers ...................................................... 31

Table 7 Symbols Used in FORM Checksum Equations ........................ 32

Table 8 Analog Output Modes ............................................................... 34

Table 9 Error Messages ........................................................................ 49

4 ___________________________________________________________________ M210934EN-C

Page 7

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the manual and the product.

About This Manual

This manual provides information for installing, operating, and

maintaining Vaisala HUMICAP® Moisture and Temperature Transmitter

for Oil MMT162.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides general notes for the manual

and the product.

- Chapter 2, Product Overview, introduces the features, advantages, and

the product nomenclature

- Chapter 3, Installation, provides you with information that is intended

to help you install the product.

- Chapter 4, Operation, provides information that is needed in basic

maintenance of the product.

- Chapter 5, Maintenance, provides information that is needed in basic

maintenance of the product.

- Chapter 6, Calibration and Adjustment, provides information that is

needed in calibration and adjustment of the product.

- Chapter 7, Technical data, provides the technical data of the product.

VAISALA ________________________________________________________________________ 5

Page 8

User's Guide ______________________________________________________________________

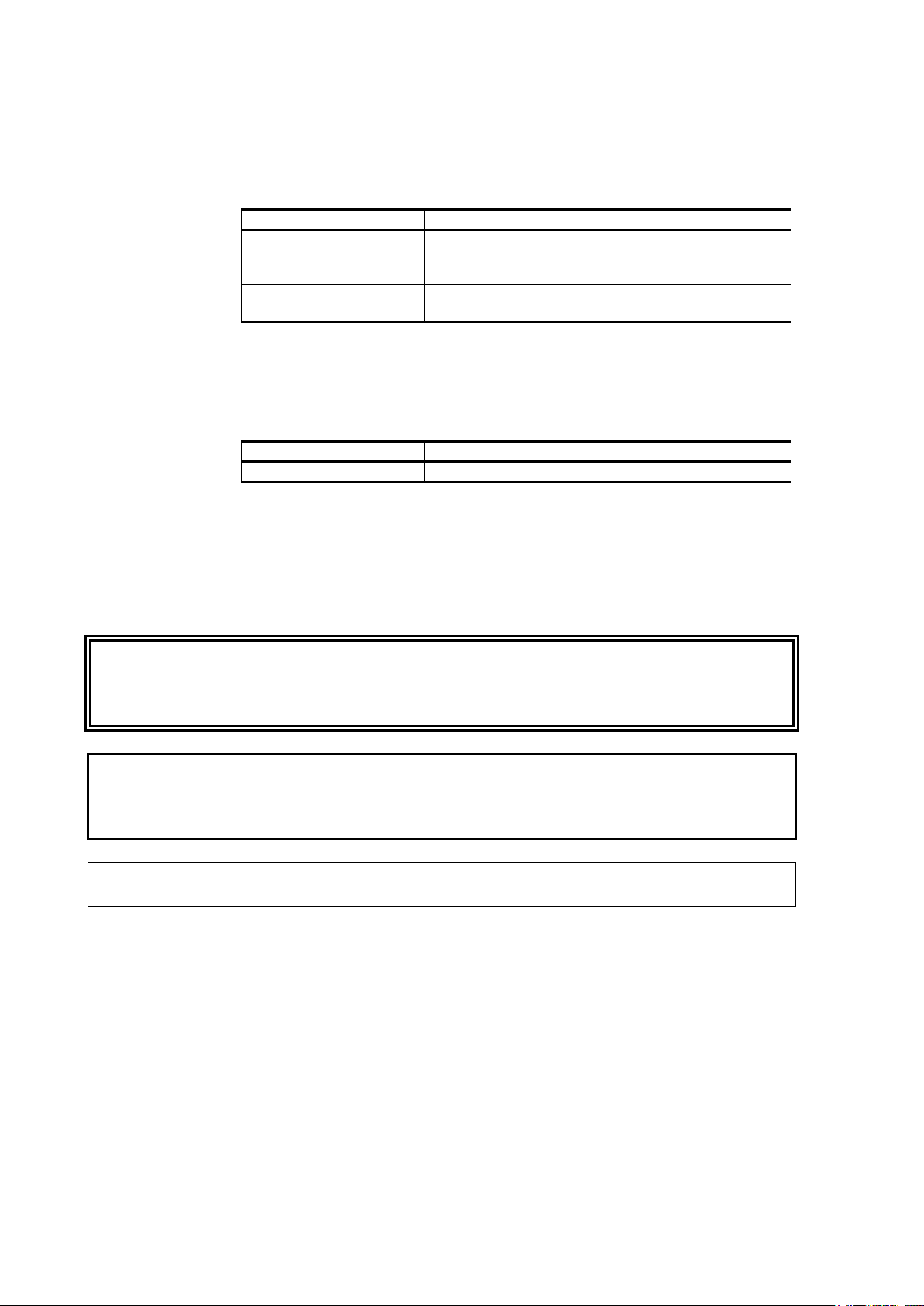

Manual Code

Description

M210934EN-C

April 2013. This manual. Updated descriptions of

Updated list of spare parts and accessories.

M210934EN-B

March 2009. Previous version. Updated cable

specification.

Manual Code

Manual Name

M210935EN

MMT162 Quick Reference Guide

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important

Version Information

Table 1 Manual Revisions

connection cables and serial line commands.

Related Manuals

Table 2 Related Manuals

Documentation Conventions

WARNING

CAUTION

NOTE

Throughout the manual, important safety considerations are highlighted

as follows:

a risk of injury or even

information on using the product.

6 ___________________________________________________________________ M210934EN-C

Page 9

Chapter 1 ________________________________________________________ General Information

Ground the

periodically to minimize shock hazard.

Do not modify the unit. Improper modification can damage the product

or lead to malfunction.

Recycle all applicable material.

Dispose of

not dispose of with regular household refuse.

Safety

The Vaisala HUMICAP® Moisture and Temperature Transmitter for Oil

MMT162 delivered to you has been tested for safety and approved as

shipped from the factory. Note the following precautions:

WARNING

CAUTION

Recycling

product, and verify outdoor installation grounding

batteries and the unit according to statutory regulations. Do

Regulatory Compliances

Vaisala HUMICAP® Moisture and Temperature Transmitter for Oil

MMT162 is in conformity with the following EU directive:

- EMC-Directive

Conformity is shown by compliance with the following standards:

- EN 61326-1: Electrical equipment for measurement, control and

laboratory use - EMC requirements - Industrial environment.

- EN 55022 Class B: Information technology equipment – Radio

disturbance characteristics – Limits and methods of measurement.

VAISALA ________________________________________________________________________ 7

Page 10

User's Guide ______________________________________________________________________

Trademarks

HUMICAP® is a registered trademark of Vaisala Oyj.

Windows® is a registered trademark of Microsoft Corporation in the

United States and/or other countries.

License Agreement

All rights to any software are held by Vaisala or third parties. The

customer is allowed to use the software only to the extent that is provided

by the applicable supply contract or Software License Agreement.

Warranty

Visit our Internet pages for standard warranty terms and conditions:

www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of

damage due to normal wear and tear, exceptional operating conditions,

negligent handling or installation, or unauthorized modifications. Please

see the applicable supply contract or Conditions of Sale for details of the

warranty for each product.

8 ___________________________________________________________________ M210934EN-C

Page 11

Chapter 2 __________________________________________________________ Product Overview

Parameter

Abbreviation

Metric Unit

Non Metric Unit

Water activity

Aw

Temperature

T

°C

°F

Mass concentration of

water in oil

ppm

ppm is

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the features, advantages, and the product

nomenclature of Moisture and Temperature Transmitter for Oil

MMT162.

Introduction to MMT162

The MMT162 transmitter is a microprocessor based instrument for the

measurement of moisture in terms of water activity, for example in the

lubrication of circulation systems or in transformer oil. The probe

incorporates a capacitive thin film sensor. The operation of the sensor is

based on changes in its capacitance as the thin polymer film absorbs

water molecules.

NOTE

The MMT162 transmitter is available with either metal or plastic

housing. The transmitter can be configured in many ways: two analog

output signals can be scaled, the measurement ranges can be changed

within certain limits and there are two mechanical connection options,

ISO and NPT 1/2. The MMT162 probe is supplied with a three or five

meter connection cable.

The MMT162 also provides for accurate temperature measurement. It is

an easy-to-install on-line probe which can be calibrated against, for

example, traceable salt solutions.

Table 3 Parameters Measured and Calculated by MMT162

only applicable to transformer oil.

Vaisala HUMICAP® Moisture and Temperature Transmitter for Oil

MMT162 provides reliable moisture measurement in wide range of

applications. Analog outputs can be chosen between current and voltage

signals. Alternatively, digital output RS-485 comes as standard.

VAISALA ________________________________________________________________________ 9

Page 12

User's Guide ______________________________________________________________________

Basic Features and Options

- Two analog outputs

- Digital output: RS-485

- USB connectivity for service connections via the optional

USB M8 cable

- Different cable lengths available

- Available with two different thread options: ISO G1/2" and NPT 1/2"

- Low maintenance requirements due to excellent long term stability

- LED cable option that enables a visual alarm function

- Field calibration possible with MM70

- Two filter types available: stainless steel grid filter and high flow

stainless steel grid filter (> 1 m/s)

10 __________________________________________________________________ M210934EN-C

Page 13

Chapter 2 __________________________________________________________ Product Overview

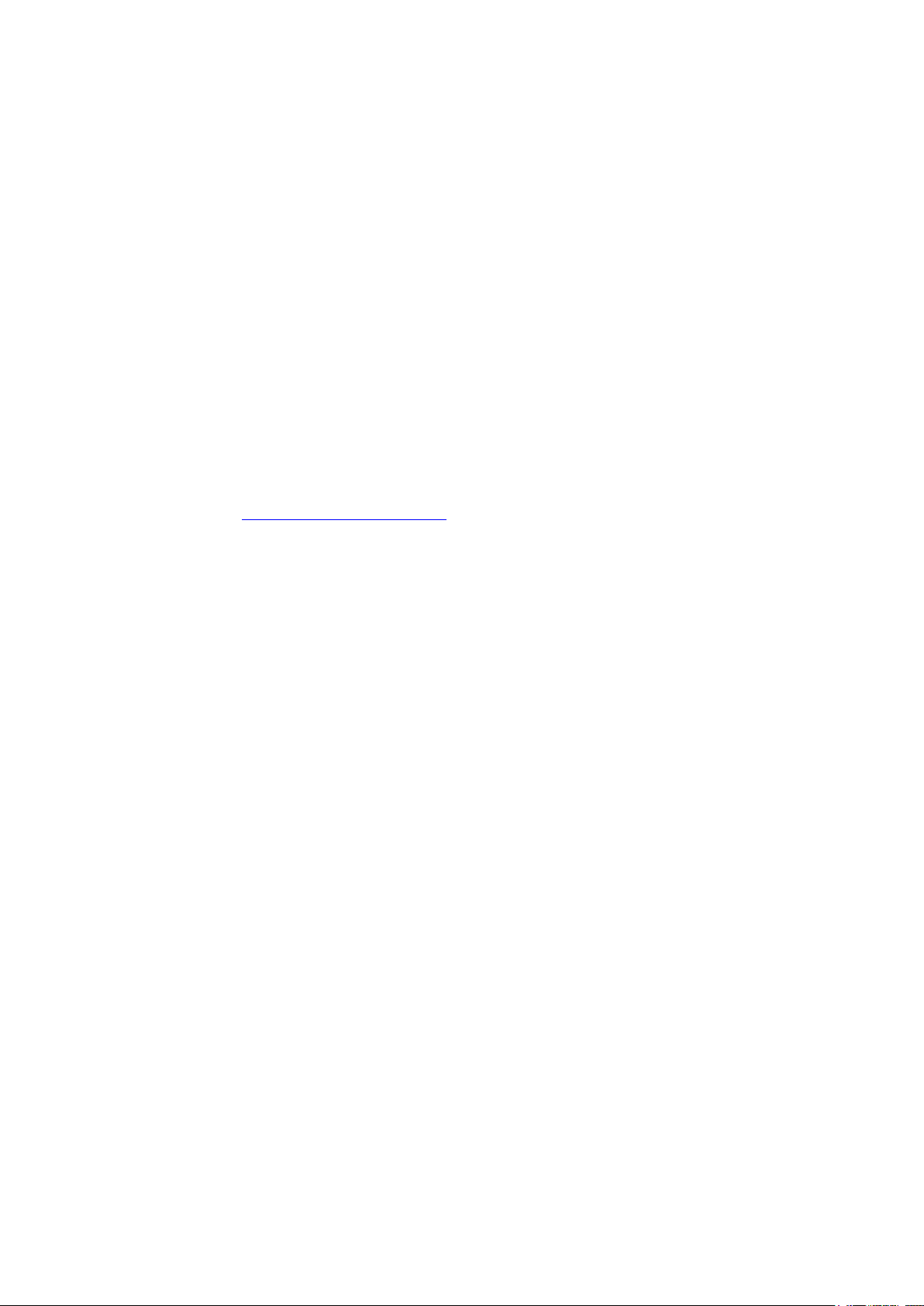

where

1 = 4-pin M8 connector I: analog output channels and operating

power

2 = 4-pin M8 connector II (shown with protective cap):

digital output (RS-485) and operating power

3 = 30 mm nut

4 = HUMICAP® sensor protected with stainless steel grid filter

5 = Connection thread: ISO G1/2" or NPT 1/2"

Transmitter Structure

The structure of the MMT162 is shown in Figure 1 on page 11. The

transmitter body does not have user serviceable parts inside, and is not

designed to be opened. Opening the transmitter will void the warranty.

When the transmitter is delivered, the filter is protected by a yellow

transport protection cap. Remove the transport protection cap before

installing the transmitter.

0805-007

Figure 1 Moisture and Temperature Transmitter for Oil

MMT162

VAISALA _______________________________________________________________________ 11

Page 14

User's Guide ______________________________________________________________________

To avoid self

errors, make sure there is some flow in the application

Typical Applications

Method Used for Measuring Moisture in Oil

The MMT162 transmitter measures water in oil in terms of water activity

(aw) which can be determined as follows: water activity indicates the

amount of water on the scale of 0 - 1 aw. In this scale, 0 aw is an

indication of completely water free oil and 1 aw an indication of oil fully

saturated with water. Water is present in free form.

The most important feature which distinguishes the measurement of

water activity (aw) from the traditional measurement of absolute water

content (in ppm) is that the saturation point remains stable regardless of

the oil type or the aging of oil, additives used etc. As water activity

exceeds 0.9 aw in any system, there is a risk for segregation (especially if

the temperature decreases).

NOTE

The water activity is used for alarming at the point of >0.9 aw that the

risk for free water in the system is obvious. The most important

advantages of this system are the fact that water activity is immune to the

aging of oil and to additives, and that the MMT162 transmitter can be

used for continuous on-line measurements. In addition, the MMT162 can

be calibrated against salt solutions and no reference oils are needed.

-heating of the probe and consequential measurement

process.

Lubrication Oil

In many industrial plants, like paper mills, hydro power plants and offshore wind turbines, there is a certain amount of free moisture constantly

present. This means that there is a high risk of the free moisture

becoming into contact with the machine bearings. The most common

reasons for the entrance of water are inadequate sealing of the housing or

moisture absorption from ambient air. Accidental leakages from oil

coolers and other equipment can also cause damage.

Free water in lubrication oil prevents oil from forming a uniform layer on

the metal surfaces and thus deteriorating its lubrication properties. This

can cause, for example, spot heating, cavitation, corrosion and micro

pitting. Free water also ruins additives like AW (antiwear) and EP

(extreme pressure). Note that bearings should never be exposed to oils

that have high water content; this is also important during standstill

because the risk for corrosion increases as the oil temperature decreases.

12 __________________________________________________________________ M210934EN-C

Page 15

Chapter 2 __________________________________________________________ Product Overview

It is essential to monitor the water content and to keep it on a suitable

level, meaning below saturation.

When measuring the water content of oil, it is best to measure the water

activity before an oil reservoir and from a pressure line flow. This way

the performance of dehumidifiers can be kept under control to ensure that

no free water reaches the bearings.

Transformer Oil

The determination of moisture in oil is an essential part of a

comprehensive transformer maintenance program. Aging and

deterioration increase the capacity of oil to absorb water. The primary

interest in transformers is to measure the water not in oil but in the

cellulosic insulation around the transformer windings. Heating and

cooling have a considerable effect on moisture levels in oil. While

temperature rises, the paper insulation of transformers tends to loose

moisture which is absorbed by the oil surrounding it. Saturation level is

thus a true indicator of moisture present. The MMT162 method provides

for a reliable detection of the aging of oil and possible leakages.

Oil immersed transformers rely on the oil for cooling, protection from

corrosion and as an important component of their insulation. Excessive

moisture content in oil causes accelerated ageing of the insulation

materials and reduces their dielectric strength. In extreme cases this can

result in arcing and short circuits within the windings. Accurate moisture

measurements can also warn about leaks in the oil system, as water is

absorbed from the surrounding air.

Heating and cooling of a transformer affect moisture levels in oil. This is

due to the fact that the water solubility of oil is temperature dependent. In

general, water solubility increases as temperature rises; see Figure 2 on

page 14 below. Changes in temperature also have an effect on water

desorption of the paper insulation around the transformer windings.

Desorption of water from the insulation increases as temperature rises

and the surrounded oil absorbs desorbed water. Moisture level in oil is

thus a true indicator of moisture present in the paper insulation.

In addition, it must be noted that capacity of oil to absorb water depends

both on the chemical structure of the oil and the additives.

VAISALA _______________________________________________________________________ 13

Page 16

User's Guide ______________________________________________________________________

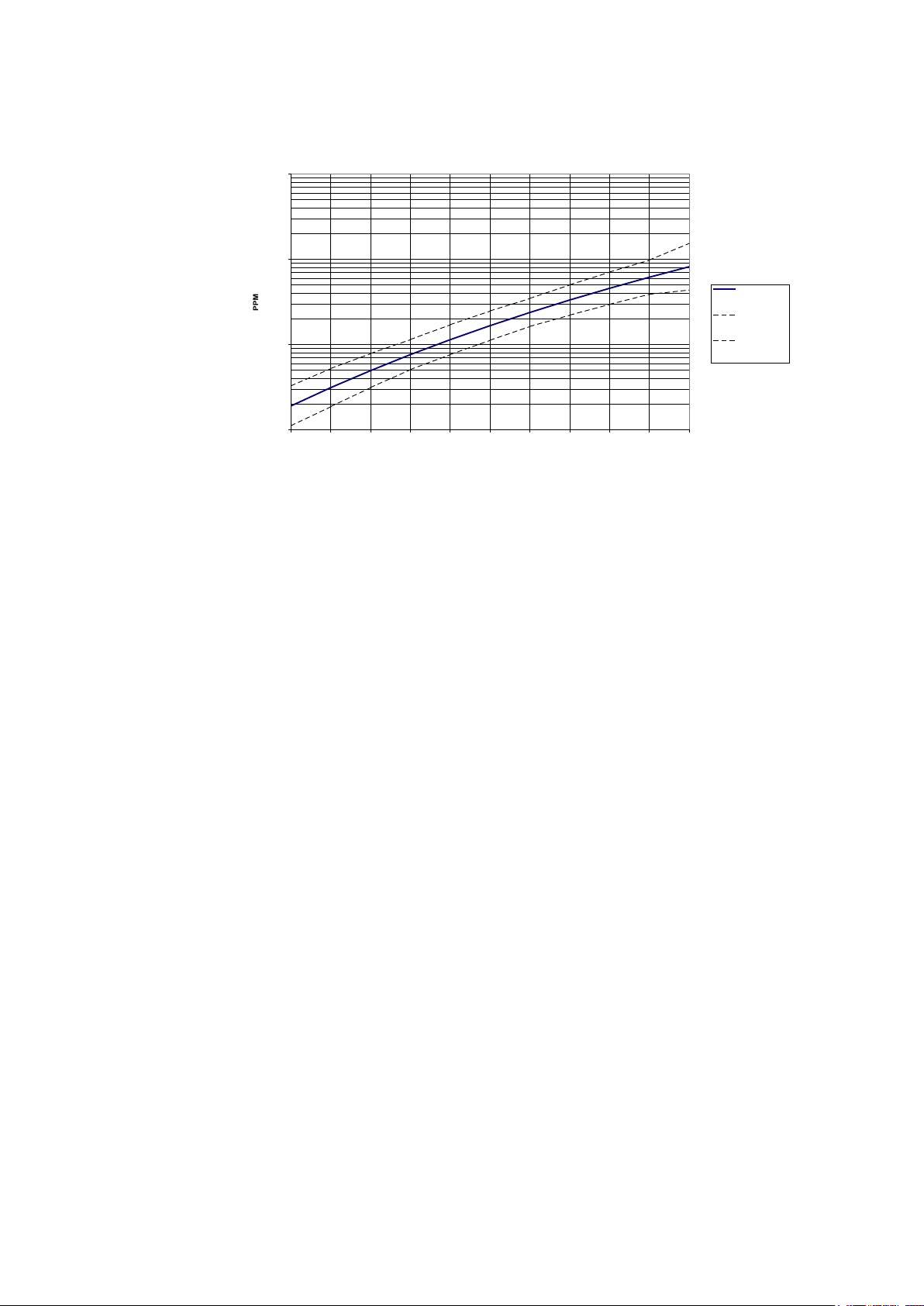

WATER SOLUBILITY IN MINERAL TRANSFORMER OIL

10

100

1000

10000

0 10 20 30 40 50 60 70 80 90 100

Temperature (°C)

average water

solubility

range of

variation due to

oil type

range of

variation due to

oil type

0510-029

Figure 2 Water Solubility of Transformer Oils versus

Temperature

The margins show the range of variation of water solubility found in

mineral oils.

14 __________________________________________________________________ M210934EN-C

Page 17

Chapter 3 _______________________________________________________________ Installation

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended to help you

install the product.

Installing the Transmitter

After selecting a suitable measurement location, follow the procedure

below to install the transmitter:

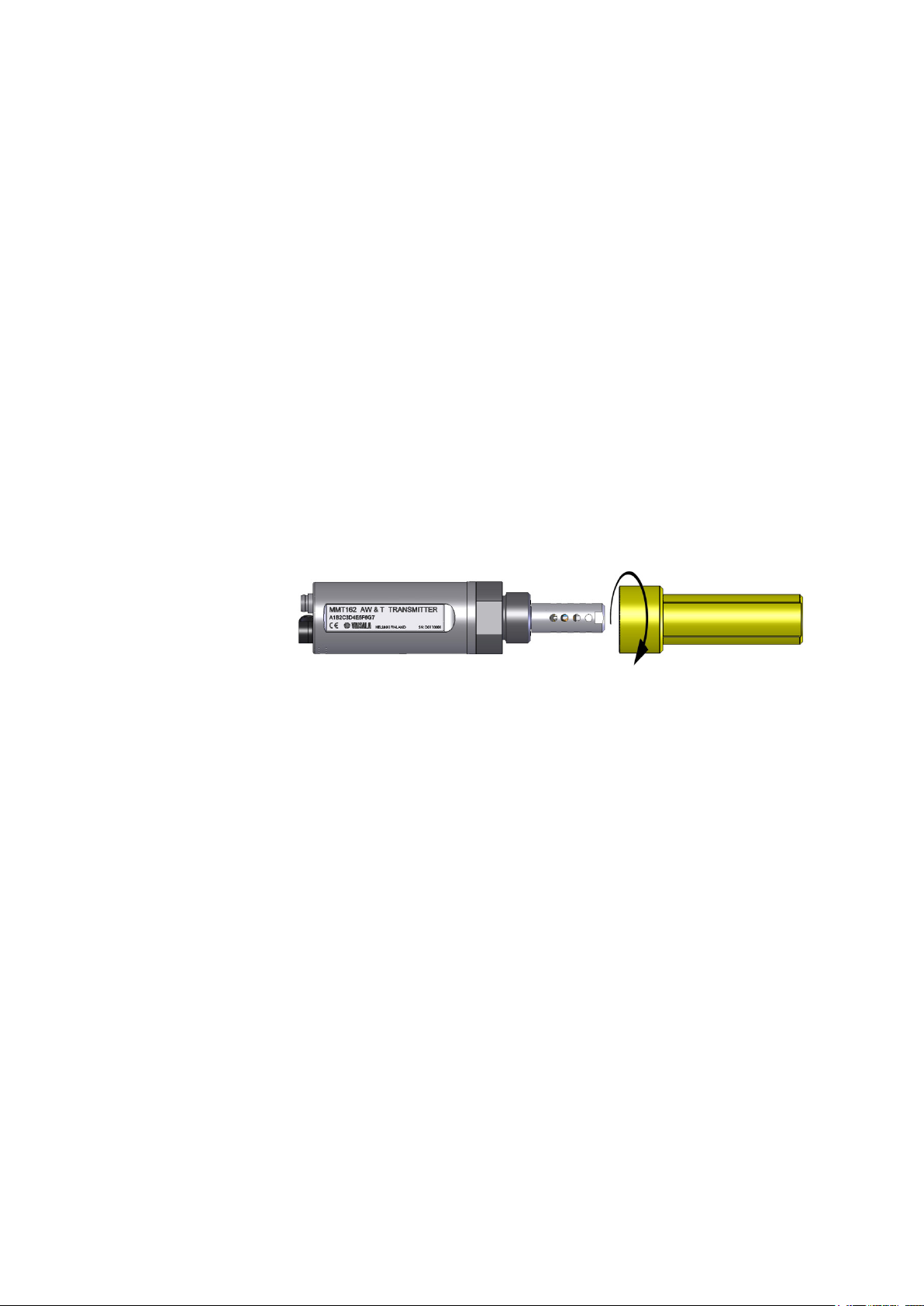

1. Remove the yellow transport protection cap from the transmitter.

0805-005

Figure 3 Removing the Transportation Protection Cap

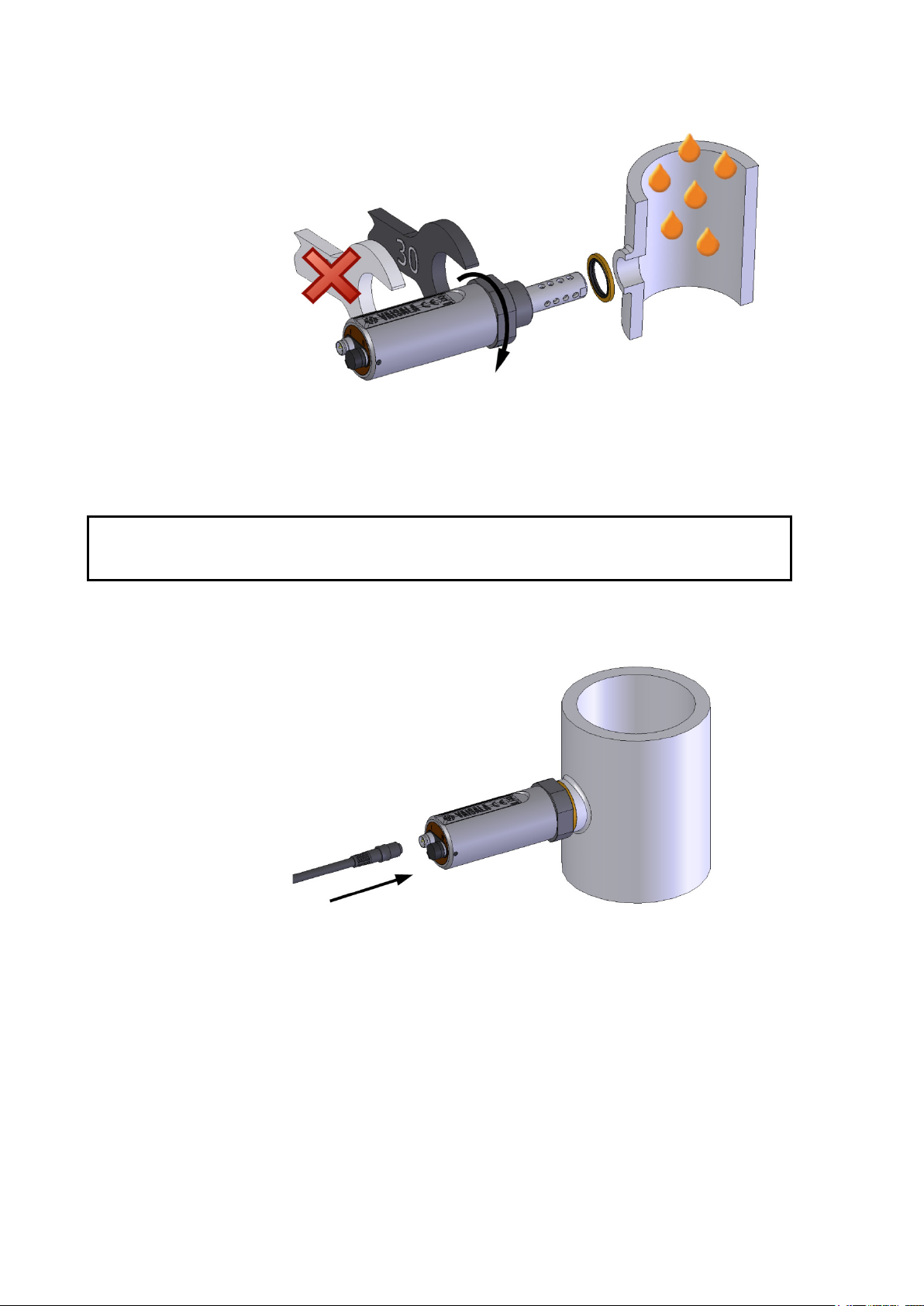

2. Prepare the sealing of the connection:

- If the transmitter has a parallel ISO G1/2" thread, place the

sealing ring at the base of the thread. Always use a new

sealing ring; do not re-use a previously installed one.

- If the transmitter has an NPT 1/2" thread, do not use the

sealing ring. Instead, apply PTFE tape or suitable paste

sealant to the thread. Follow the application instructions of

the sealant.

3. Make sure that the threads on the mounting point are of the correct

type, and fasten the transmitter to the measurement point. Use your

hands to turn the probe until it feels tight. Do not use force at this

point, and check that the sealing ring

(if used) remains centered.

VAISALA _______________________________________________________________________ 15

Page 18

User's Guide ______________________________________________________________________

Only tighten the probe from the 30

other points in the probe body.

CAUTION

0805-006

Figure 4 Installing the Transmitter

4. Use a 30 mm wrench to tighten the connection to 25 Nm, as shown

in Figure 4 above. If you do not have a 30 mm wrench, use a

1 3/16” wrench or an adjustable wrench instead.

mm nut. Do NOT apply force to

5. Connect the wires of the connection cable.

6. Plug in the cable to the transmitter. Be sure to use the correct

7. Cover the unused connector on the transmitter with the rubber plug

16 __________________________________________________________________ M210934EN-C

0710-130

Figure 5 Connecting the Cable

connector; refer to section Wiring on page 17.

that is attached to the transmitter.

Page 19

Chapter 3 _______________________________________________________________ Installation

Pin I II

Wire Color

1

Vcc

Vcc

Brown

2

Analog output 1

RS-485 B / D-

White

3

GND

GND

Blue

4

Analog output 2 / LED

RS-485 A / D+

Black

Wiring

0707-035

Figure 6 Connectors I and II

VAISALA _______________________________________________________________________ 17

1210-005

Figure 7 Connector Pinout

Page 20

User's Guide ______________________________________________________________________

Connection Cables

The following connection cable options are available for MMT162:

- Shielded cables with M8 female straight threaded connector

- Cables with M8 female 90° angle threaded connector

- LED cable

- USB serial interface cable

The figures below show the different cable options that are available.

For order codes, see section Spare Parts and Accessories on page 61.

1210-063

Figure 8 Cable with Threaded Connector

1211-024

Figure 9 Cable with 90° Angle Threaded Connector

18 __________________________________________________________________ M210934EN-C

Page 21

Chapter 3 _______________________________________________________________ Installation

1211-025

Figure 10 LED Cable

1210-062

Figure 11 USB Serial Interface Cable

Power Supply Requirements

The MMT162 transmitters are designed to operate with a supply voltage

of 14 … 24 VDC.

The power supply should maintain the voltage for all load conditions.

Current consumption during normal measurement is 20 mA + load

current. For more specific information, see chapter Technical data on

page 59.

VAISALA _______________________________________________________________________ 19

Page 22

User's Guide ______________________________________________________________________

This page intentionally left blank.

20 __________________________________________________________________ M210934EN-C

Page 23

Chapter 4 ________________________________________________________________ Operation

The malfunction alarm

is malfunctioning, the analog outputs are set to the levels specified with

the

being controlled.

CHAPTER 4

OPERATION

This chapter contains information that is needed to operate this product.

Getting Started

MMT162 is ready to be used once it has been connected to a power

source.

Analog Output Operation Modes

The MMT162 has two analog output channels. These channels can

function in two different modes, which can be set individually for both

channels:

1. Normal operation mode

2. Limit alarm mode

When the transmitter is ordered from Vaisala, the modes are configured

as specified in the order form. You can change the operation settings

after delivery by using serial commands and the USB cable accessory.

Normal Operation Mode and Malfunction Alarm

In the normal operation mode, a channel outputs voltage or current that

corresponds to the reading of the selected parameter.

If the transmitter is malfunctioning, the channel output is set to a predefined level. This level can be changed using the AERR command; see

page 35.

NOTE

AERR command, unless the malfunction prevents the outputs from

VAISALA _______________________________________________________________________ 21

overrides the limit alarm mode. If the transmitter

Page 24

User's Guide ______________________________________________________________________

Limit Alarm

The limit alarm is activated when the measured parameter goes below the

low limit, or above the high limit. The alarm levels and limits are

configurable using the ALARM command (see page 35). By default, the

alarm levels are set as follows:

- For current output, an active alarm is indicated by the current being

at the maximum of the scale (20 mA).

- For voltage output, an active alarm is indicated by the voltage being

at the maximum of the selected scale. For example, if the voltage

output scale is 0 … 5 V, an output of 5 V indicates the alarm is active.

- For LED alarm, an active alarm is indicated by a lit LED. When the

alarm status is low, the LED is not lit. If the transmitter is

malfunctioning or it cannot measure for some reason, this causes the

LED to blink at 0.5 Hz frequency.

LED alarm indicator is integrated to a LED cable (Vaisala item

MP300LEDCBL) that can be ordered and used instead of a regular

connection cable.

Serial Communication

Connecting to Serial Interface

The MMT162 can be connected to a PC using the RS-485 line,

for example using the USB serial connection cable (Vaisala item

219690). The cable also provides operation power to the transmitter from

the USB port. It is OK to connect the USB serial connection cable even if

the transmitter is already supplied with operation power from another

cable.

To connect to serial interface:

1. If you have not used the MMT162 USB serial connection cable

before, install the driver that came with the cable. Refer to section

Installing the Driver for the USB Cable on page 23 for detailed

instructions.

2. Connect the USB serial connection cable between your PC and the

RS-485 port of the MMT162 (port II).

3. Open the terminal program (for example, PuTTY in Microsoft

Windows®).

4. Set the serial settings of the terminal program, and open the

connection. See the following table.

22 __________________________________________________________________ M210934EN-C

Page 25

Chapter 4 ________________________________________________________________ Operation

Property

Description / Value

Baud rate

19200

Parity

none

Data bits

8

Stop bits

1

Table 4 Default Serial Interface Settings

Installing the Driver for the USB Cable

Before taking the USB cable into use, you must install the provided USB

driver on your PC.

1. Check that the USB cable is not connected. Disconnect the cable if

you have already connected it.

2. Insert the media that came with the cable, or download the driver

from www.vaisala.com.

3. Execute the USB driver installation program and accept the

installation defaults. The installation of the driver may take several

minutes.

4. After the driver has been installed, connect the USB cable to a USB

port on your PC. Windows will detect the new device, and use the

driver automatically.

5. The installation has reserved a COM port for the cable. Verify the

port number, and the status of the cable, using the Vaisala USB

Instrument Finder program that has been installed in the

Windows Start menu.

Windows will recognize each individual cable as a different device, and

reserve a new COM port. Remember to use the correct port in the

settings of your terminal program.

There is no reason to uninstall the driver for normal use. However, if you

wish to remove the driver files and all Vaisala USB cable devices, you

can do so by uninstalling the entry for Vaisala USB Instrument Driver

from the Programs and Features menu in the Windows Control Panel.

In Windows XP and earlier Windows versions the menu is called Add or

Remove Programs.

VAISALA _______________________________________________________________________ 23

Page 26

User's Guide ______________________________________________________________________

Terminal Program Settings

The default settings of the MMT162 serial interface are presented in

Table 4 on page 23. If the settings of your MMT162 have been changed

and you do not know what they are, refer to section Unknown Serial

Settings on page 49.

The steps below describe how to connect to the MMT162 using the

PuTTY terminal application for Windows (available for download at

www.vaisala.com) and a USB serial interface cable:

1. Connect the USB serial interface cable between your PC and the

RS-485 port of the MMT162 (port II).

2. Start the PuTTY application.

3. Select the Serial settings category, and check that the correct COM

port is selected in the Serial line to connect to field.

Note: You can check which port the USB cable is using with the

Vaisala USB Instrument Finder program that has been installed

in the Windows Start menu.

4. Check that the other serial settings are correct for your connection,

and change if necessary. Flow control should be set to None unless

you have a reason to change it.

5. Click the Open button to open the connection window and start

using the serial line.

Note: If PuTTY is unable to open the serial port you selected, it

will show you an error message instead. If this happens, restart

PuTTY and check the settings.

6. You may need to set the Local echo setting to Force on in the

Terminal category to see what you are typing on the serial line. To

access the configuration screen while a session is running, click the

right mouse button over the session window, and select Change

Settings... from the pop-up menu.

24 __________________________________________________________________ M210934EN-C

Page 27

Chapter 4 ________________________________________________________________ Operation

Figure 12 PuTTY Terminal Application

0807-004

VAISALA _______________________________________________________________________ 25

Page 28

User's Guide ______________________________________________________________________

Command

Description

?

Output information about the device

??

Output information about the device in

POLL mode

ACAL

Analog output calibration

ADDR [0 ... 255]

Set the transmitter address (for POLL

mode)

AERR

Change the analog error output values

ALARM

Set analog output limit alarm modes

AMODE

Set analog output modes

AOVER [ON/OFF]

Allow analog outputs to exceed their range

10%

ASEL

Select the parameters for the analog

outputs

ATEST

Set and display current output values

CLOSE

Close the temporary connection (Back to

POLL mode)

CRH

Relative humidity calibration

CT

Temperature calibration

ERRS

List present transmitter errors

FORM

Set the output format of SEND and R

commands

FRESTORE

Restore factory settings

HELP

List the most common commands

INTV [0 ... 255 S/MIN/H]

Set the continuous output interval

(for RUN mode)

LED

Set voltage for LED alarm

OIL

Display oil parameters

OILI

Set new oil parameters

OPEN [0 ... 255]

Open a temporary connection to a POLL

mode device

R

Start the continuous outputting

RESET

Reset the transmitter

S

Stop the continuous outputting

SDELAY

View or set user port (RS-485) answer

minimum delay

SEND [0 ... 255]

Output the reading once

SERI [baud p d s]

User Port settings (Default: 4800 E 7 1)

baud: 300 ... 115200

SMODE

[STOP/RUN/POLL]

Set the serial interface mode

UNIT [M/N]

Select the metric or non-metric output units

VERS

Display the software version information

List of Serial Commands

All commands can be issued either in uppercase or lowercase. In the

command examples, the keyboard input by the user is in bold type.

The notation <cr> refers to pressing the carriage return (Enter) key on

your computer keyboard. Enter a <cr> to clear the command buffer

before starting to enter commands.

Table 5 Serial Line Commands

26 __________________________________________________________________ M210934EN-C

Page 29

Chapter 4 ________________________________________________________________ Operation

Device Information and Status

Show Device Information

The ? command outputs a listing of device information. If you wish to

display the listing for all devices on the current serial line, issue the

command ??.

?<cr>

??<cr>

Example:

?

MMT162 0.92

Serial number : G0000002

Batch number : D0720012

Module number : ????????

Sensor number : C6010000

Sensor model : Humicap L2

Cal. date : YYYYMMDD

Cal. info : NONE

Time : 00:21:19

Serial mode : STOP

Baud P D S : 4800 E 7 1

Output interval: 2 S

Serial delay : 0

Address : 0

Pressure : 1.0132 bar

Filter : 0.800

Ch1 output : 0 ... 20 mA

Ch2 output : 0 ... 20 mA

Ch0 error out : 0.000 mA

Ch1 error out : 0.000 mA

Ch0 aw lo : 0.00

Ch0 aw hi : 1.00

Ch1 T lo : -20.00 'C

Ch1 T hi : 80.00 'C

Show Firmware Version

Use the VERS command to display software version information.

Example:

vers

MMT162 1.02

VAISALA _______________________________________________________________________ 27

Page 30

User's Guide ______________________________________________________________________

where

b = Bit rate (110, 150, 300, 600, 1200, 2400, 4800, 9600,19200,

38400)

p = Parity (n = none, e = even, o = odd)

d = Data bits (7 or 8)

s = Stop bits (1 or 2)

Configuring Serial Line Operation

Set Serial Line Settings

Use the serial line command SERI [b p d s] to set communication

settings for the user port.

SERI [b p d s]<cr>

Example:

seri 600 n 8 1

600 N 8 1

You need to reset the transmitter to activate the new communication

settings set with the SERI command.

The settings can be changed one parameter at a time or all parameters at

once:

seri o changing parity only

4800 O 7 1

seri 600 n 8 1

600 N 8 1

changing all parameters

You can use the SERI command to change/view the user port settings

even if you are currently connected to the service port.

28 __________________________________________________________________ M210934EN-C

Page 31

Chapter 4 ________________________________________________________________ Operation

where

delay

=

Serial line delay, range 0 ... 255. Multiply the value by four

to get milliseconds (for example, delay value of

40 millisecond delay).

where

aaa

=

address (0 ... 255) (default = 0)

Set Serial Line Response Time

With the SDELAY command you can set delay (response time) of the

serial line, or view the currently set delay value.

SDELAY [delay]<cr>

10 equals

Example:

sdelay

Serial delay : 0 ? 10

sdelay

Serial delay : 10 ?

Set Transmitter Address

Addresses are required only for POLL mode (see Set Serial Interface

Mode on page 33). Use the ADDR command to input the RS-485

transmitter address.

ADDR [aaa]<cr>

Example (configure transmitter to address 99):

addr

Address : 2 ? 99

VAISALA _______________________________________________________________________ 29

Page 32

User's Guide ______________________________________________________________________

where

x = Formatter string

Format Measurement Output

Use the serial line command FORM to change the format or select

certain parameters for the output commands SEND and R.

FORM [x]<cr>

Formatter string consists of parameters and modifiers. The MMT162

measures the following parameters:

- water activity (aw)

- temperature (T) (metric unit: ºC, non metric unit:ºF)

- ppm for transformer oil only (H2O)

When selecting the parameter, use its abbreviation (for example, aw).

The modifiers are presented in Table 6 on page 31.

Example (configure transmitter to output water activity and temperature):

form "aw=" 6.4 aw #t "t=" 6.2 t #r#n

OK

send

aw= 0.2644 t= 25.50

Example (configure transmitter to output ppm only):

form "Oil ppm= " h2o " " u3 #r#n

OK

send

Oil ppm= 16.6 ppm

Example (configure transmitter to default output format):

form /

OK

send

aw= 0.087 T= 24.0 'C

30 __________________________________________________________________ M210934EN-C

Page 33

Chapter 4 ________________________________________________________________ Operation

Modifier

Description

/

Restores the default output message (depends on the

device configuration). Used alone.

x.y

Length modifier (number of digits and decimal places).

parameter

Abbreviation of a measured parameter, for example aw.

* characters if measured value is not available.

U1…U7

Unit symbol in the specified number of characters

(truncated or space filled as necessary).

“xxx”

String constant (free text).

#a

\a

Audible bell character <0x07>.

#b

\b

Backspace character <0x08>

#f

\f

Form feed character <0x0C>.

#n

\n

Line feed character <0x0A>.

#r

\r

Carriage return character <0x0D>.

#t

\t

Horizontal tabulator character <0x09>.

#v

\v

Vertical tabulator character <0x0B>.

#\

\\

Backslash character.

#0…#255

\0…\255

Data byte with the specified decimal value.

ADDR

Device address (left-filled with spaces).

CS2

Modulus-256 checksum of message sent so far,

hexadecimal format.

CS4

Modulus-65536 checksum of message sent so far,

hexadecimal format.

CSX

NMEA XOR checksum of message sent so far, hexadecimal

format

ERR

Currently active transmitter errors in a four bit field.

bit4 = Internal error (Program flash check sum error)

SN

Device serial number.

TIME

Time since transmitter startup in format hh:mm:ss.

Table 6 FORM Command Modifiers

Outputs the measured value of the parameter, or

0 = no error, 1 = error.

bit1 = Temperature measurement (T meas error)

bit2 = Not used

bit3 = Humidity measurement (F meas error)

VAISALA _______________________________________________________________________ 31

Page 34

User's Guide ______________________________________________________________________

1

=

∑

=

=

n

i

i

bcs

1

2

256mod

2

=

65536mod

1

4

∑

=

=

n

i

i

bcs

3

=

24630'

2463'

'''

i

21

===

≠≠=

⊕⊕⊕=

ii

iiii

nx

borbifb

bandbifbb

bbbcs

Symbol

Description

cs2

Value of CS2 checksum in the output message.

cs4

Value of CS4 checksum in the output message.

csx

Value of CSX checksum in the output message.

bi

Value of the byte at position i (1-based) in the output message.

n

Number of bytes in the output message before the CS2, CS4,

or CSX field (including earlier checksum fields, if any).

⊕

Bit-wise exclusive-or operator.

36

Byte value of ASCII $ character.

42

Byte value of ASCII * character.

where

x

=

M or N

where

M = Metric units

N = Non-metric units

Checksums are calculated as described in the equations below.

Table 7 Symbols Used in FORM Checksum Equations

Select Unit

Use the UNIT command to select metric or non-metric output units.

UNIT [x]<cr>

32 __________________________________________________________________ M210934EN-C

Page 35

Chapter 4 ________________________________________________________________ Operation

where

xxxx

=

STOP, RUN or POLL

In STOP mode:

measurements output only by command SEND, all

commands can be used

In RUN mode:

outputting automatically, only command S can be

used to stop.

In POLL mode:

measurements output only with command SEND

[addr].

where

xxx

=

Parameter of channel 1

yyy

=

Parameter of channel 2

Set Serial Interface Mode

Use the SMODE command to set the default serial interface mode.

SMODE [xxxx]<cr>

When several transmitters are connected to the same line, each

transmitter must be entered an own address in the initial configuration,

and POLL mode must be used.

Configuring Measurement Parameters

Select Analog Output Parameter and Scaling

Select and scale the parameters for the analog outputs with the ASEL

command. Note that the optional parameters can be selected only if they

have been selected when ordering the device.

ASEL [xxx yyy]<cr>

Always enter all the parameters for all outputs. The MMT162 measures

the following parameters:

- water activity (aw)

- temperature (T) (metric unit: ºC, non metric unit: ºF)

- ppm for transformer oil only (H2O)

Example:

asel

Ch0 aw lo : 0.00 ?

Ch0 aw hi : 1.00 ?

Ch1 T lo : -20.00 'C ?

Ch1 T hi : 80.00 'C ?

VAISALA _______________________________________________________________________ 33

Page 36

User's Guide ______________________________________________________________________

Parameter

Output mode

1

0 … 20 mA

2

4 … 20 mA

4

0 … 5 V

5

0 … 10 V

6

LED alarm

7

Current alarm

8

Voltage alarm

where

channel

=

Analog output channel to be adjusted, 1 or 2.

Set Analog Output Mode (mA/V)

The AMODE command can be used to change the analog output mode

of channels 1 and 2. When used without parameters it displays the

current settings and with parameters new settings can be set. The

available parameters are listed in Table 8 below.

Table 8 Analog Output Modes

Example:

amode 1 2

Ch1 output : 0 ... 20 mA

Ch2 output : 4 ... 20 mA

Calibrate Analog Output

Use the ACAL command to adjust analog output channels.

ACAL [channel]<cr>

After entering the ACAL command, use a calibrated current/voltage

meter to measure the output, and enter the values.

Example:

acal 1

Ch1 U1 ( V ) ? 1.001

Ch1 U2 ( V ) ? 9.011

acal 2

Ch2 U1 ( V ) ? 0.0988

Ch2 U2 ( V ) ? 0.8997

34 __________________________________________________________________ M210934EN-C

Page 37

Chapter 4 ________________________________________________________________ Operation

The error output value must be within a valid range of the output mode.

The error output value is displayed only when

faults such as a humidity sensor damage. When there is a severe device

malfunction, the error output value is not necessarily shown.

Set Malfunction Alarm Output for Analog Channels

Use the AERR command to set the analog output levels that are output in

case of a device malfunction. The default output level is 0.

AERR<cr>

Example:

aerr

Ch1 error out : 10.000V ? 0

Ch2 error out : 1.000V ? 0

NOTE

NOTE

there are minor electrical

Set Alarm Limits and LED Indication for Analog Outputs

Use the ALARM command to set the analog output alarm limits and

parameters. For an explanation of the alarm limits, see section Limit

Alarm on page 22.

ALARM<cr>

Before setting the alarm limits, verify the currently set analog output

modes using the AMODE command.

The following example shows that a high limit alarm has been enabled

for channel 2. If the measured value rises above the limit ( 0.90 aw), an

error is reported. If you are using a LED cable, the LED lights up to

indicate an error state.

Example:

alarm ?

Channel 1:

Low Limit : OFF

High Limit : OFF

Aerr : ON

Quantity : T

Limit Lo : 15.00

Limit Hi : 30.00

VAISALA _______________________________________________________________________ 35

Page 38

User's Guide ______________________________________________________________________

Hysteresis : 0.50

Level Lo : 0.20

Level Hi : 0.80

Channel 2:

Low Limit : OFF

High Limit : ON

Aerr : OFF

Quantity : aw

Limit Lo : 0.10

Limit Hi : 0.90

Hysteresis : 0.01

Level Lo : 0.20

Level Hi : 0.80

Set Voltage for LED Alarm

With the LED command, you can set a different voltage level for each

channel.

LED<cr>

Example:

led ?

Ch 1 Led Voltage : 2.80 V

Ch 2 Led Voltage : 2.80 V

Extend Analog Output Range

Use the AOVER command to allow the analog output channels to

exceed their specified range by 10 %. The scaling of the parameter

remains as before; the extra range is used for additional measurement

range in the wet end.

AOVER [ON/OFF]<cr>

Example:

aover on

: ON

36 __________________________________________________________________ M210934EN-C

Page 39

Chapter 4 ________________________________________________________________ Operation

Serial Line Output Commands

Start Measurement Output

Use the R command to start the continuous outputting of measurement

values as an ASCII text string to the serial line. The format of the

measurement message is set with the FORM command.

R<cr>

Example:

r

aw= 0.261 T= 23.8 'C H2O= 15 ppm

You can change the format of the output with the following commands:

- Outputting interval can be changed with the INTV command.

- Output message format can be changed with the FORM command.

Stop Measurement Output

Use the S command to end the RUN mode. After this command all other

commands can be used. You can also press the Esc button or reset the

transmitter to stop the outputting.

S<cr>

Since the interface is half-duplex, you must enter the command when the

transmitter is not outputting. Give the command again if the transmitter

continues to output measurement messages.

See SMODE command on page 33 to change the default (power-up)

operation mode.

VAISALA _______________________________________________________________________ 37

Page 40

User's Guide ______________________________________________________________________

where

n = time interval = 0 ... 255

xxx

=

time unit = "S", "MIN", or "H"

where

aaa = Transmitter address (0 ... 255). Must be specified if the

transmitter is in POLL mode, and a line has not been opened

using the OPEN command.

Set Output Interval

Use the INTV command to set or display the output interval.

INTV [n xxx]<cr>

Example:

intv 1 min

Output interval: 1 MIN

The shortest output interval (with n = 0) is approximately one second due

to the internal measurement cycle.

Output Reading Once

Use the SEND command to output the reading once in STOP mode.

The output format depends on which parameters the transmitter can

output.

SEND [aaa]<cr>

Example:

send

T= 25.2 'C aw= 0.299 H2O= 19 ppm RS= 29.9 %

38 __________________________________________________________________ M210934EN-C

Page 41

Chapter 4 ________________________________________________________________ Operation

where

xxx

=

Channel 1 output value (V or mA)

yyy

=

Channel 2 output value (V or mA)

Troubleshooting Commands

Display the Currently Active Errors

Use the ERRS command to display the currently active transmitter error

states. Possible errors and their causes are listed in Table 9 on page 49.

ERRS<cr>

Example:

errs

No errors

Test Analog Outputs

The operation of the analog outputs can be tested with the ATEST

command by forcing the output to a given value which can then be

measured with calibrated multimeter. The command uses the currently

selected analog output types for the channels (voltage or current) so you

do not have to specify the unit.

Before testing, you can verify the currently set analog output modes

using the AMODE command. After testing the output, give the ATEST

command again to exit the test mode.

ATEST [xxx yyy]<cr>

The output shows the test values of the analog channels, and diagnostic

information that may be useful to Vaisala Service if there is a problem

with the analog outputs.

Example:

atest 1 15

1.00 2660

15.00 19425

atest

0.00 79

0.00 20110

VAISALA _______________________________________________________________________ 39

Page 42

User's Guide ______________________________________________________________________

where

aaa = address (0 ... 255)

Other Commands

Opening the Transmitter in POLL Mode

Use the OPEN command to connect to a transmitter that is in POLL

mode.

OPEN [aaa]<cr>

Example:

open 0

MMT162 0 line opened for operator commands

Closing the Connection to a Transmitter in POLL Mode

The CLOSE command closes the connection to the transmitter.

CLOSE<cr>

Example:

close

line closed

40 __________________________________________________________________ M210934EN-C

Page 43

Chapter 4 ________________________________________________________________ Operation

Display Command List

Use the HELP command to list the available commands.

HELP<cr>

Example:

help

?

??

ACAL

ADDR

ADJD

AERR

ALARM

AMODE

AOVER

ASEL

ATEST

CDATE

CLOSE

CRH

CT

CTEXT

ERRS

FILT

FORM

FRESTORE

HELP

INTV

L

LED

OIL

OILI

OPEN

PCOMP

PRES

R

RESET

SDELAY

SEND

SERI

SMODE

UNIT

VAISALA _______________________________________________________________________ 41

Page 44

User's Guide ______________________________________________________________________

Reset Transmitter

When the RESET command is given, the transmitter will restart as if it

had just been powered on. All transmitter settings are retained. The serial

line mode of the transmitter will be set to the mode that was set using the

SMODE command.

RESET<cr>

Restore Factory Settings

Use the FRESTORE command to restore the factory settings to the

transmitter. All user settings will be lost.

FRESTORE<cr>

42 __________________________________________________________________ M210934EN-C

Page 45

Chapter 4 ________________________________________________________________ Operation

where

aw = water activity

A,B

=

coefficients (average/oil-specific)

T = temperature (ºC)

ppm Conversion

MMT162 ppm Conversion for Transformer Oils

Traditionally, moisture in transformer oil is measured by using ppm

units. The ppm output shows the average mass concentration of water in

oil.

The moisture and temperature transmitter MMT162 has an option for

ppm-output provided that this has been notified when placing the order

for the transmitter. Vaisala has this conversion readily available for

mineral transformer oils.

Conversion Model with Average Coefficients

The conversion model of the MMT162 is based on the average water

solubility behaviour of transformer oils. The ppm-output is calculated as

follows:

ppm = aw×10

Generally, measurements with MMT162 give accuracy better than 10 %

of the reading. If additional accuracy is needed, refer to section

Conversion Model with Oil-specific Coefficients below.

(A/(T+273.16)+B)

VAISALA _______________________________________________________________________ 43

Page 46

User's Guide ______________________________________________________________________

Conversion model with oil

silicone based oils.

where

Oil [0]

corresponds to parameter A

Oil [1]

corresponds to parameter B

Oil [2]

Corresponds to parameter C

Conversion Model with Oil-specific Coefficients

For additional accuracy, oil-specific conversion model can be used both

for mineral and silicon based oils. An oil sample has to be sent to Vaisala

for modelling. As a result, the specific coefficients (A and B) for the

transformer oil are determined by Vaisala. For additional information,

please contact Vaisala.

The determined coefficients of the transformer oil can be programmed to

the MMT162 by Vaisala or by a user according to the instructions

presented in this chapter.

NOTE

-specific coefficients is always needed for

Setting Oil Coefficients Using Serial Line

If the ppm conversion and oil-specific coefficients have been

programmed at Vaisala, you do not have to set the conversion coefficients.

If you have defined the coefficients or separately received from Vaisala

the oil-specific coefficients A and B, related to your own oil type, the

coefficients can be set to the software of MMT162 by using serial line.

OIL

Use the serial line command OIL to display oil-specific parameters for

ppm conversion. With OILI command you can set new oil parameters.

Example:

44 __________________________________________________________________ M210934EN-C

oil

Oil[0] : -1.66269994E+03

Oil[1] : 7.36940002E+00

Oil[2] : 0.00000000E+00

Page 47

Chapter 4 ________________________________________________________________ Operation

The sample has to be sealed very carefully

will

If the oil sample is very dry and the temperatures are close to each

other, it may cause inaccuracy to the calculation model. In order

get the best possible performance it is recommended to use oil

conditions that represent real conditions in application.

Recommended values for sample are aw approx. 0.5 at 20 °C.

Determination of Oil-Specific Coefficients

The equation of the ppm calculation is:

ppm = aw×10

With the following procedure the coefficients A and B can be defined for

the equation:

LOG(PPM

Equipment needed:

- Apparatus for determining water content ( for example, coulometric

titrator and e.g. magnetic stirrer.)

- Oil test station:

Procedure:

1. Define the water content of the oil sample with the titration. Use

the oil moisture level that is close to real conditions in the process.

(B+A/T)

)= B + A/T

sat

- a temperature test chamber.

- a suitable container (for example, a conical 1 L flask) sealed

by PTFE stopper with an inlet for a moisture probe.

- a MMT162 transmitter by Vaisala.

- a magnetic stirrer.

NOTE

NOTE

2. Measure the water activity of this sample with MMT162 at two

temperatures that differ at least 20 °C.

. Contact with ambient air

change the water content.

to

VAISALA _______________________________________________________________________ 45

Page 48

User's Guide ______________________________________________________________________

[ ] [ ]

( ) ( )

1/1-2/1

1(-2(

TT

TPPM

LOGTPPMLOG

A

satsat

))

=

[ ]

)(

A/T1 - 1TPPMLOGB

sat

=

T (°C)

aw

ppm

24.1

0.478

213/0.478 = 445.6067

57.6

0.188

213/0.188 = 1132.979

3. Define the correlation between aw, T and PPM (w/w) from the

measured values. Calculate A and B according to the following

example.

Example (measured water content 213 ppm):

saturation

A = (LOG(1132.98)-LOG(445.607))/(1/(57.6+273.16)1/(24.1+273.16)) = -1189.4581

B= LOG(445.607)-(-1189.4581)/(24.1 + 273.16) = 6.6503583

Assumptions:

The isoterm of water activity versus water concentration is linear and the

solubility curve has the form of the given equation.

46 __________________________________________________________________ M210934EN-C

Page 49

Chapter 5 ______________________________________________________________ Maintenance

Do not immerse the sensor in any polar solvents, for example ketones

or alcohols.

CHAPTER 5

MAINTENANCE

This chapter provides information that is needed in basic maintenance of

the product.

Cleaning

Clean the transmitter enclosure with a soft. lint-free cloth moistened with

mild detergent.

Clean the sensor before storing the MMT162 probe and before

calibration. For cleaning the the probe you need instrument air and

heptane (C7H16) liquid. If heptane is not available, you can also use diesel

oil or petrol. Dry with instrument air to prevent oxidation of the oil on the

sensor. The oxidation of the oil on the sensor can cause extended

response times or drifting.

NOTE

1. Blow the probe head (with filter) with instrument air to remove the

remains of oil.

2. Immerse the probe head into heptane liquid and rinse out the oil

(for one minute maximum).

3. Dry the probe head with instrument air. In case you are going to

calibrate the probe, remove the filter and dry the sensor with

instrument air. Check that the sensor looks clean.

VAISALA _______________________________________________________________________ 47

Page 50

User's Guide ______________________________________________________________________

Changing the Filter

1. Remove the filter from the probe.

2. Install a new filter on the probe. When using the stainless steel

filter (for oil and fuel cell), take care to tighten the filter properly

(recommended force 130 Ncm).

New filters can be ordered from Vaisala, see section Spare Parts and

Accessories on page 61.

Changing the Sensor

If you need to change the sensor on your MMT162, send it to Vaisala

where the sensor will be changed for you.

Error States

MMT162 has the following states that indicate a problem with the probe:

- Analog 4 - 20 mA current output at 0 mA

- Analog voltage output at 0 V

- Serial line outputs asterisk characters (*** **)

The asterisk characters on the serial line may also appear during the startup procedure.

You can also check the error message via the serial interface by using the

ERRS command. In case of constant error, please contact Vaisala; see

section Technical Support on page 50.

48 __________________________________________________________________ M210934EN-C

Page 51

Chapter 5 ______________________________________________________________ Maintenance

Error Message

Action

Voltage error

Internal error or invalid supply voltage.

T meas error

Internal error, can be caused by

damage to the temperature sensor.

F meas error

Internal error, can be caused by

damage to the HUMICAP® sensor.

Voltage too low error

Supplied operating voltage is too low

for reliable operation.

Voltage too low for mA output

Supplied operating voltage is too low

current output.

Voltage is too low for V output

Supplied operating voltage is too low

voltage output.

Program flash check sum error

Internal error

Parameter check sum error

Internal error

INFOA check sum error

Internal error

SCOEFS check sum error

Internal error

CURRENT check sum error

Internal error

Table 9 Error Messages

for reliable operation of the analog

for reliable operation of the analog

Unknown Serial Settings

If you are not sure what the current serial settings of your transmitter are,

follow the steps below to connect to the transmitter. This procedure

assumes you have the USB service cable available.

For more information on the USB service cable and the PuTTY terminal

application, see section Serial Communication on page 22.

1. Connect the USB service cable to your PC, but do not connect it to

the transmitter yet.

2. Start a terminal application and open a terminal session using the

default serial settings of 19200 8 N 1.

3. Plug the USB service cable into the transmitter, and quickly send at

least one hash character # to the serial line:

#

4. The normal startup of the transmitter is now interrupted, and the

transmitter is available for commands with the default serial

settings. You can now check the transmitter’s information by

issuing the ? command:

?

The transmitter’s currently stored serial settings are visible on the

line marked Baud P D S.

VAISALA _______________________________________________________________________ 49

Page 52

User's Guide ______________________________________________________________________

Technical Support

For technical questions, contact the Vaisala technical support by e-mail at

helpdesk@vaisala.com. Provide at least the following supporting

information:

- Name and model of the product in question

- Serial number of the product

- Name and location of the installation site

- Name and contact information of a technically competent person who

can provide further information on the problem.

Product Returns

If the product must be returned for service, see www.vaisala.com/returns.

For contact information of Vaisala Service Centers, see

www.vaisala.com/servicecenters.

50 __________________________________________________________________ M210934EN-C

Page 53

Chapter 6 ___________________________________________________ Calibration and Adjustment

NOTE

It is important to clean the sensor before calibration as the oily

condition.

CHAPTER 6

CALIBRATION AND ADJUSTMENT

This chapter provides information that is needed in calibration and

adjustment of the product.

The MMT162 is fully calibrated and adjusted as shipped from factory.

The calibration interval depends on the application. It is recommended

that calibration is done always when there is a reason to believe that the

device is not within the accuracy specifications.

You can calibrate the MMT162 yourself or send it to Vaisala for

calibration. Calibration and adjustment is usually carried out through

serial line. One-point calibrations and adjustments can also be done by

using an MI70 indicator and Vaisala humidity calibrator HMK15.

Before the calibration, the used sensor needs to be cleaned with

instrument air to blow out existing oil or gently first flush with hepthane

(C7H16) and dry with instrument air to decrease response time, see

section Cleaning on page 47.

sensor can contaminate the salt bath and change the reference

Vaisala HUMICAP® hand-held moisture and temperature in oil meter

MM70 can also be used for calibration.

VAISALA _______________________________________________________________________ 51

Page 54

User's Guide ______________________________________________________________________

Make sure that both probes are stabilized to same conditions so that

the temperature readings are the same.

MM70 in Checking and Adjusting

MMT162 can be checked and adjusted by using the MM70. In the field

you can check and adjust the probe's reading against the calibrated

reference probe of the MM70.

To check the MMT162 transmitter with MM70:

1. Connect the MMT162 to the MM70 indicator with the appropriate

connection cable (Vaisala item 219980).

2. Turn on the MM70.

3. Prepare the probe for adjustment by opening the adjustment menu

on the MM70 (Menu → Functions → Adjustments)

NOTE

4. Press the OK key to start adjustment.

One-Point Relative Humidity Adjustment

Note that the humidity reference must be at least 50% RH. The MMT162

must be unpowered during stabilization which can take 30 minutes or

more.

Using Serial Line

To adjust the relative humidity:

1. Remove the filter from the probe and insert the probe into a

measurement hole of the dry end reference chamber (for example,

NaCl: 75 % RH in the humidity calibrator HMK15). Use the

adapter fitting.

2. Wait at least 30 minutes for the sensor to stabilize.

3. Connect the MMT162 to a PC, see section Serial Communication

on page 22. Then open a terminal program.

4. Enter the CRH command and press ENTER.

CRH

5. Type C and press ENTER a few times to check if the reading has

stabilized.

52 __________________________________________________________________ M210934EN-C

Page 55

Chapter 6 ___________________________________________________ Calibration and Adjustment

6. When the reading is stable, give the reference humidity after the

question mark and press ENTER.

crh

RH : 25.21 Ref1 ?

RH : 25.22 Ref1 ?

RH : 25.22 Ref1 ? 30.1

Press any key when ready ...

RH : 25.19 Ref2 ?

OK

7. OK indicates that the adjustment has succeeded and the new

calibration coefficients are calculated and stored.

8. Take the probe out of the reference conditions and replace the

filter.

Using MI70

To adjust the relative humidity:

1. Connect MI70 to MMT162.

2. Turn MI70 on.

3. On the MI70, go to Menu → Functions → Adjustments.

VAISALA _______________________________________________________________________ 53

Page 56

User's Guide ______________________________________________________________________

4. Follow the instructions given on the display.

5. Select RH from the list and press Select.

6. When adjusting relative humidity, you need to check the

environment settings before making the adjustment.

54 __________________________________________________________________ M210934EN-C

Page 57

Chapter 6 ___________________________________________________ Calibration and Adjustment

7. In adjustment mode, enter the correct reference value and then exit

by pressing Back.

VAISALA _______________________________________________________________________ 55

Page 58

User's Guide ______________________________________________________________________

One-Point Temperature Adjustment

The MMT162 must be unpowered during stabilization which can take 30

minutes or more.

Using Serial Line