Page 1

M211737EN-H

User Guide

Vaisala Moisture, Hydrogen and Temperature

Transmitter for Transformer Oil

MHT410

Page 2

PUBLISHED BY

Vaisala Oyj

Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

P.O. Box 26, FI-00421 Helsinki, Finland

+358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala 2021

No part of this document may be

reproduced, published or publicly

displayed in any form or by any means,

electronic or mechanical (including

photocopying), nor may its contents be

modified, translated, adapted, sold or

disclosed to a third party without prior

written permission of the copyright holder.

Translated documents and translated

portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this document are subject

to change without prior notice.

Local rules and regulations may vary and

they shall take precedence over the

information contained in this document.

Vaisala makes no representations on this

document’s compliance with the local

rules and regulations applicable at any

given time, and hereby disclaims any and

all responsibilities related thereto.

This document does not create any legally

binding obligations for Vaisala towards

customers or end users. All legally binding

obligations and agreements are included

exclusively in the applicable supply

contract or the General Conditions of Sale

and General Conditions of Service of

Vaisala.

This product contains software developed

by Vaisala or third parties. Use of the

software is governed by license terms and

conditions included in the applicable

supply contract or, in the absence of

separate license terms and conditions, by

the General License Conditions of Vaisala

Group.

Page 3

Table of contents

Table of contents

1. Safety................................................................................................................... 7

1.1 ESD protection.................................................................................................. 8

2. About this document.....................................................................................9

2.1 Documentation conventions..........................................................................10

2.2 Regulatory statements................................................................................... 10

2.2.1 FCC Part 15 compliance statement........................................................10

2.3 Trademarks........................................................................................................11

3. Product overview...........................................................................................12

3.1 Main features....................................................................................................12

3.2 Product parts and package contents............................................................13

3.3 Measurement parameters and units..............................................................15

3.4 Oil types............................................................................................................16

3.4.1 Oil type information in order code.........................................................16

3.4.2 Oil-specific coecients for ppmw moisture measurement................ 16

3.5 Data logging.....................................................................................................17

3.6 Status LEDs...................................................................................................... 17

4. Installation........................................................................................................ 19

4.1 Planning the installation................................................................................. 19

4.1.1 Recommended installation locations...................................................20

4.2 Mechanical installation....................................................................................21

4.3 Electrical installation......................................................................................28

4.4 Loop-powered display.................................................................................... 31

4.4.1 Wiring the loop-powered display..........................................................32

4.5 Checklist after installation............................................................................. 33

4.6 Oil fittings check after installation............................................................... 34

4.7 Removing the transmitter............................................................................. 34

4.8 Re-installing the transmitter in new location..............................................35

5. Analog output................................................................................................ 37

5.1 Analog output overrange behavior..............................................................37

6. Modbus............................................................................................................. 39

6.1 Overview of Modbus protocol support........................................................39

7. Vaisala Industrial Protocol........................................................................40

7.1 Connecting to MHT410 via service port........................................................41

7.1.1 Installing driver for the USB service cable............................................ 41

7.1.2 Connecting USB service cable...............................................................42

7.1.3 Configuring terminal application settings........................................... 42

7.2 Serial commands summary.......................................................................... 44

7.3 Device information and status commands................................................. 46

1

Page 4

MHT410 User Guide M211737EN-H

7.4 Serial line output and communication commands.....................................52

7.4.1 Measurement output commands.......................................................... 52

7.4.2 Measurement output format commands.............................................56

7.4.3 Serial line communication commands..................................................59

7.5 Analog output commands............................................................................ 63

7.6 Calibration and adjustment commands.......................................................67

7.7 Other commands............................................................................................68

8. DNP3 protocol.................................................................................................71

8.1 Taking DNP3 protocol into use...................................................................... 71

9. Vaisala MI70 Handheld Indicator........................................................... 73

9.1 MI70 indicator overview................................................................................ 73

9.1.1 MI70 indicator parts................................................................................73

9.1.2 Basic display.............................................................................................74

9.1.3 Graphical display..................................................................................... 74

9.1.4 Main menu................................................................................................ 75

9.2 Installing and recharging MI70 batteries..................................................... 75

9.3 Connecting MI70 to service port.................................................................. 76

9.4 Holding and saving the display.....................................................................76

9.5 Recording data................................................................................................77

9.5.1 Starting and stopping the recording.....................................................77

9.5.2 Viewing recorded data........................................................................... 78

9.5.3 Clearing data memory............................................................................78

9.6 Comparing readings with MM70 probe.......................................................78

9.7 Changing the rechargeable battery pack....................................................79

10. Vaisala Indigo520 Transmitter................................................................. 81

10.1 Taking Indigo520 Modbus settings into use in MHT410.............................81

10.2 Cabling and cable gland................................................................................ 82

10.3 Indigo520 and MHT410 wiring diagram......................................................83

10.4 MHT410 status messages shown in Indigo520...........................................84

10.5 Settings in Indigo520.....................................................................................84

11. Calibration and adjustment......................................................................85

11.1 H2 calibration and adjustment......................................................................85

11.1.1 Taking DGA sample and saving current H2 reading............................85

11.1.2 Entering DGA H2 reading to transmitter.............................................. 87

11.1.3 Clearing H2 calibration and adjustment............................................... 88

11.2 RS & T calibration and adjustment...............................................................89

12. Troubleshooting............................................................................................. 91

12.1 Error states.......................................................................................................91

12.2 Changing bleed screw................................................................................... 92

13. Technical data................................................................................................ 93

13.1 MHT410 specifications................................................................................... 93

13.2 Spare parts and accessories..........................................................................97

2

Page 5

Table of contents

13.3 Dimensions...................................................................................................... 98

13.4 Wiring diagrams.............................................................................................99

13.5 Recycling.........................................................................................................101

Appendix A: Operating principle..............................................................104

A.1 Method used for measuring moisture in oil...............................................105

A.2 Transformer oil..............................................................................................105

Appendix B: Modbus reference.................................................................107

B.1 Default Modbus communication settings..................................................107

B.2 Function codes..............................................................................................107

B.3 Data encoding............................................................................................... 107

B.3.1 32-bit floating point or 32-bit integer format....................................108

B.3.2 16-bit integer format.............................................................................108

B.4 Register map.................................................................................................108

B.5 Modbus registers.......................................................................................... 109

B.5.1 Measurement data registers................................................................ 109

B.5.2 Status registers........................................................................................ 111

B.6 Device identification objects........................................................................ 112

B.7 Exception responses......................................................................................112

Appendix C:

Moisture ppmw calculation for transformer oils.............113

C.1 Calculation model with average coecients..............................................113

C.2 Calculation model with oil-specific coecients.........................................113

Maintenance and calibration services........................................................115

Technical support........................................................................................... 115

Warranty........................................................................................................... 115

3

Page 6

MHT410 User Guide M211737EN-H

List of figures

Figure 1 MHT410 order code example (first digit 1 = mineral oil)........................ 16

Figure 2 Recommended installation locations.........................................................20

Figure 3 Loop-powered display 242003....................................................................32

Figure 4 Analog output overrange behavior............................................................ 38

Figure 5 Analog output overrange behavior............................................................64

Figure 6 MI70 indicator parts........................................................................................ 73

Figure 7 MI70 basic display............................................................................................74

Figure 8 Example of MI70 display with MHT410 in port I and

MM70 probe in port II. Shown parameters: aw (I), aw (II), Δ aw........ 79

Figure 9 Wiring between Indigo520 and MHT410 screw terminals....................83

Figure 10 MHT410 transmitter dimensions..................................................................98

Figure 11 Wiring Option 1: Wiring with four power supplies.

Separate loop-powering and galvanic isolation for

analog outputs. In transmitters ordered with Vaisala

cable CBL210392-5M, the cable is pre-wired according

to this option.....................................................................................................99

Figure 12 Wiring Option 2: Wiring with two power supplies.

Common loop-powering and galvanic isolation for

analog outputs............................................................................................... 100

Figure 13 Wiring Option 3: Wiring with one power supply. Non-

isolated configuration for analog outputs sharing

transmitter power supply............................................................................ 100

Figure 14 Wiring Option 4: Wiring with one power supply.

Alternative wiring to option 3, providing reduced

current loop area for analog outputs........................................................ 101

Figure 15 Materials for recycling...................................................................................102

Figure 16 Measuring hydrogen and moisture in oil with MHT410....................... 104

Figure 17 Water solubility of transformer oils versus temperature.

The margins show the range of variation of water

solubility found in mineral oils....................................................................106

4

Page 7

List of tables

Table 1 Document versions (English)...........................................................................9

Table 2 Related manuals.................................................................................................. 9

Table 3 Analog output values in dierent transmitter statuses..........................37

Table 4 Default serial interface settings....................................................................40

Table 5 Service port serial interface settings...........................................................43

Table 6 Serial commands.............................................................................................. 44

Table 7 ? command.........................................................................................................46

Table 8 alarm command................................................................................................ 47

Table 9 errlog command............................................................................................... 48

Table 10 errs command....................................................................................................49

Table 11 help command...................................................................................................50

Table 12 system command............................................................................................. 50

Table 13 time command....................................................................................................51

Table 14 vers command.................................................................................................... 51

Table 15 intv command.................................................................................................... 52

Table 16 log command..................................................................................................... 52

Table 17 r command..........................................................................................................55

Table 18 send command.................................................................................................. 55

Table 19 form command.................................................................................................. 56

Table 20 Output parameters for form command...................................................... 57

Table 21 Modifiers for form command.........................................................................58

Table 22 unit command....................................................................................................59

Table 23 addr command.................................................................................................. 59

Table 24 close command.................................................................................................60

Table 25 open command................................................................................................. 60

Table 26 sdelay command.............................................................................................. 60

Table 27 seri command..................................................................................................... 61

Table 28 smode command.............................................................................................. 62

Table 29 aerr command................................................................................................... 63

Table 30 aover command.................................................................................................63

Table 31 asel command................................................................................................... 64

Table 32 atest command..................................................................................................66

Table 33 cdate command.................................................................................................67

Table 34 ctext command..................................................................................................67

Table 35 h2 da and h2 db commands.......................................................................... 68

Table 36 h2 x command................................................................................................... 68

Table 37 dnp3 addr command....................................................................................... 68

Table 38 filt command...................................................................................................... 69

Table 39 frestore command............................................................................................69

Table 40 reset command..................................................................................................70

Table 41 oil command...................................................................................................... 70

Table 42 h2 is command.................................................................................................. 70

Table 43 Default communication settings....................................................................71

Table 44 MHT410 communication settings for Indigo520.......................................81

Table 45 MHT410 status messages shown in Indigo520.........................................84

List of tables

5

Page 8

MHT410 User Guide M211737EN-H

Table 46 Possible error messages via Vaisala Industrial Protocol.........................91

Table 47 MHT410 measurement performance...........................................................93

Table 48 MHT410 operating environment...................................................................94

Table 49 MHT410 inputs and outputs...........................................................................94

Table 50 MHT410 mechanical specifications.............................................................. 95

Table 51 MHT410 compliance.........................................................................................96

Table 52 Display with relays (external option).......................................................... 96

Table 53 MHT410 spare parts and accessories.......................................................... 97

Table 54 Vaisala cable CBL210392-5M wire colors (when pre-wired)................99

Table 55 Materials for recycling....................................................................................103

Table 56 Optimal sensor positions.............................................................................. 104

Table 57 Default Modbus RTU communication settings....................................... 107

Table 58 Supported Modbus function codes............................................................107

Table 59 Interpretation of 16-bit signed integer values.........................................108

Table 60 Modbus register blocks................................................................................. 109

Table 61 Modbus measurement data registers (read-only).................................109

Table 62 Modbus status registers (read-only)............................................................111

Table 63 Modbus device status bits.............................................................................. 111

Table 64 Device identification objects.........................................................................112

Table 65 Modbus exception responses........................................................................112

6

Page 9

Chapter 1 – Safety

1. Safety

Vaisala Moisture, Hydrogen and Temperature Transmitter MHT410 for Transformer Oil delivered

to you has been tested for safety and approved as shipped from the factory. Note the

following precautions:

CAUTION!

before installing the product.

WARNING!

to minimize shock hazard.

DANGER!

Pay attention to transmitter installation depth and possible energized parts

inside the power transformer to minimize electric shock hazard and equipment

damage.

CAUTION!

documentation. Improper modification or use may lead to safety hazards,

equipment damage, failure to perform according to specification, or decreased

equipment lifetime.

CAUTION!

installed. The probe body goes through the valve into the oil flow, and trying to

close the valve will damage the probe body and/or the valve.

If you must close the ball valve while the transmitter is on the valve, first open

the small tightening nut and pull the probe body out as far as possible. Then

close the valve.

Read the Quick Guide (including installation instructions) carefully

Ground the product and verify installation grounding periodically

Severe risk of death and of damage to transformer:

Do not modify the unit or use it in ways not described in the

Do not try to close the ball valve when the transmitter is fully

CAUTION!

step on the transmitter when the transmitter is installed.

CAUTION!

installation site.

To avoid damage to the installation valve of the transformer, do not

Follow the safety regulations related to the application and

7

Page 10

MHT410 User Guide M211737EN-H

1.1 ESD protection

Electrostatic Discharge (ESD) can damage electronic circuits. Vaisala products are adequately

protected against ESD for their intended use. However, it is possible to damage the product by

delivering electrostatic discharges when touching, removing, or inserting any objects in the

equipment housing.

To avoid delivering high static voltages to the product:

• Handle ESD‑sensitive components on a properly grounded and protected ESD workbench

or by grounding yourself to the equipment chassis with a wrist strap and a resistive

connection cord.

• If you are unable to take either precaution, touch a conductive part of the equipment

chassis with your other hand before touching ESD‑sensitive components.

• Hold component boards by the edges and avoid touching component contacts.

8

Page 11

Chapter 2 – About this document

2. About this document

Table 1 Document versions (English)

Document code Date Description

M211737EN-H March 2021 This document.

New chapters:

• Vaisala Indigo520 Transmitter (page 81)

• Clearing H2 calibration and adjustment (page 88)

Updated content:

• Added silicone oil to the list of supported oils

• Serial commands summary (page 44)

• Calibration and adjustment commands (page 67)

• Error states (page 91)

• MHT410

• Status registers (page 111)

M211737EN-G November 2018 Previous version. Added natural and synthetic ester oil

support information and instructions on checking the oil

type set at the factory from the product label. Added

instructions on

calculation coecients. Clarified the information on the

temperature range for accurate measurement in hydrogen

and temperature accuracy specifications and added

sensor head temperature tolerance specification. Added

instructions on using a safety pin with a warning label to

lock the valve handle in open position after installation.

M211737EN-F May 2018 Updated installation instructions regarding PTFE tape and

installation depth. Added DNP3 protocol information.

Added clarification about using the RS-485 line of the

screw terminals with Modbus or Vaisala Industrial Protocol.

Added maximum power consumption specification.

Added new parameter options for analog outputs: daily,

weekly, and monthly ROC and 24-hour average for H2 and

H2O. Added

change (ROC) readings. Changed unit "ppm" to "ppmv"

for H2 and to "ppmw" for H2O.

specifications (page 93)

configuring oil-specific moisture in oil

clarification about the calculation of rate of

Table 2 Related manuals

Document code Description

M211736EN Vaisala MHT410 Quick Guide

M212287EN Vaisala Indigo520 User Guide

M211784EN Loop-Powered Display 242003 for MHT410 Technical Note

9

Page 12

MHT410 User Guide M211737EN-H

2.1 Documentation conventions

WARNING!

follow instructions carefully at this point, there is a risk of injury or even death.

CAUTION!

follow instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

Tip gives information for using the product more eciently.

Lists tools needed to perform the task.

Indicates that you need to take some notes during the task.

Warning alerts you to a serious hazard. If you do not read and

Caution warns you of a potential hazard. If you do not read and

2.2 Regulatory statements

2.2.1 FCC Part 15 compliance statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference

at his own expense.

10

Page 13

Chapter 2 – About this document

CAUTION!

by the party responsible for compliance could void the user's authority to

operate the equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

Changes or modifications to this equipment not expressly approved

2.3 Trademarks

HUMICAPâ is a registered trademark of Vaisala Oyj.

Modbusâ is a registered trademark of Schneider Automation Inc.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

11

Page 14

MHT410 User Guide M211737EN-H

3. Product overview

Vaisala Moisture, Hydrogen and Temperature Transmitter MHT410 for Transformer Oil is

designed for online monitoring of insulating oil in power transformers. The transmitter

provides an accurate real-time measurement result of moisture, hydrogen and temperature

measured in oil, enabling reliable conclusions on the transformer's condition without delay.

The transmitter provides digital and analog outputs of all the measured parameters.

3.1 Main features

• Reliable online measurement of transformer oil for the following parameters:

• Moisture: relative saturation (%RS), water activity, and water content (ppmw)

• Hydrogen concentration (ppmv in oil)

• Temperature (°C and °F)

• Compatible with mineral oils, natural ester oils, synthetic ester oils, and silicone oils

• No need to take oil samples for measurement

• Installable and retro-fittable on a ball valve (ball valve thread: female 1.5" NPT)

• Low maintenance requirements due to excellent long term stability

• Outputs

• Digital: Modbus, DNP3, and Vaisala industrial protocol over RS-485

• Analog: three channels with scalable current output

• Status indication LEDs in the front panel

• Built-in data logging

• USB connectivity for service connections using an optional USB M8 cable

• Display options:

• Loop-powered display for continuous use

• MI70 handheld meter for temporary use

• Compatible with Vaisala Indigo500 series transmitters

More information

‣

Oil types (page 16)

‣

Status LEDs (page 17)

‣

Data logging (page 17)

‣

Connecting to MHT410 via service port (page 41)

‣

Loop-powered display (page 31)

‣

Vaisala MI70 Handheld Indicator (page 73)

‣

Technical data (page 93)

12

Page 15

59876

123

4

10

Chapter 3 – Product overview

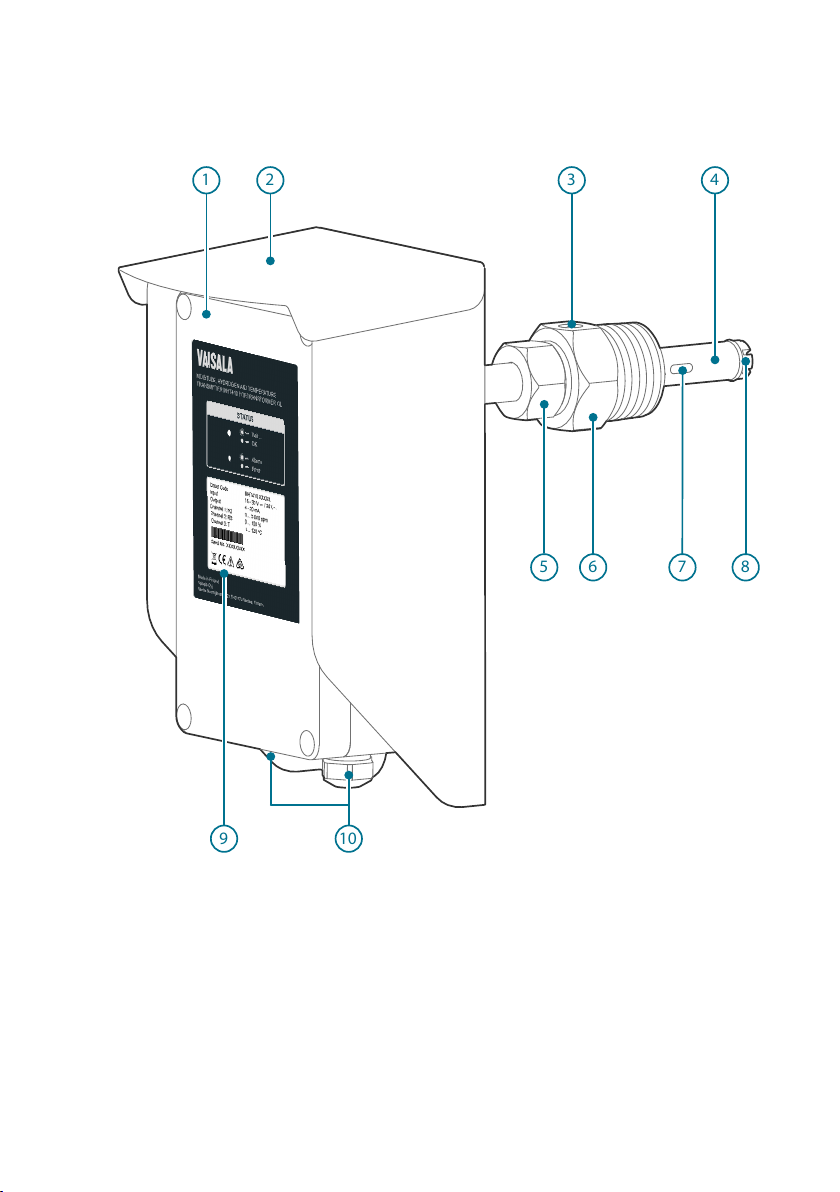

3.2 Product parts and package contents

13

Page 16

5 mm

3 mm

111413

12

+

MHT410 User Guide M211737EN-H

No. Item

1 = Electronics housing.

The front cover is additionally connected to the housing with a grounding wire.

2 = Weather shield

3 = Bleed screw

4 = Probe body

5 = Small tightening nut, used to adjust and fix the depth of the transmitter in the valve.

You can move the tightening nut and the mounting nut along the probe body.

6 = Mounting nut, used to fasten the transmitter in the ball valve.

You can move the tightening nut and the mounting nut along the probe body.

7 = Hydrogen sensor

8 = Moisture and temperature sensors under the filter

9 = Product label

10 = Lead-throughs (2 pcs) with a minimum of one cable gland (size M20x1.5) or conduit

Installation Kit:

11 = PTFE tape roll

12 = Allen keys (3 mm and 5 mm)

13 = Extra bleed screw and sealing ring

14 = Extra terminal blocks (4 x 4 screw terminals)

fitting.

Unused lead-throughs are plugged.

More information

‣

Dimensions (page 98)

14

Page 17

Chapter 3 – Product overview

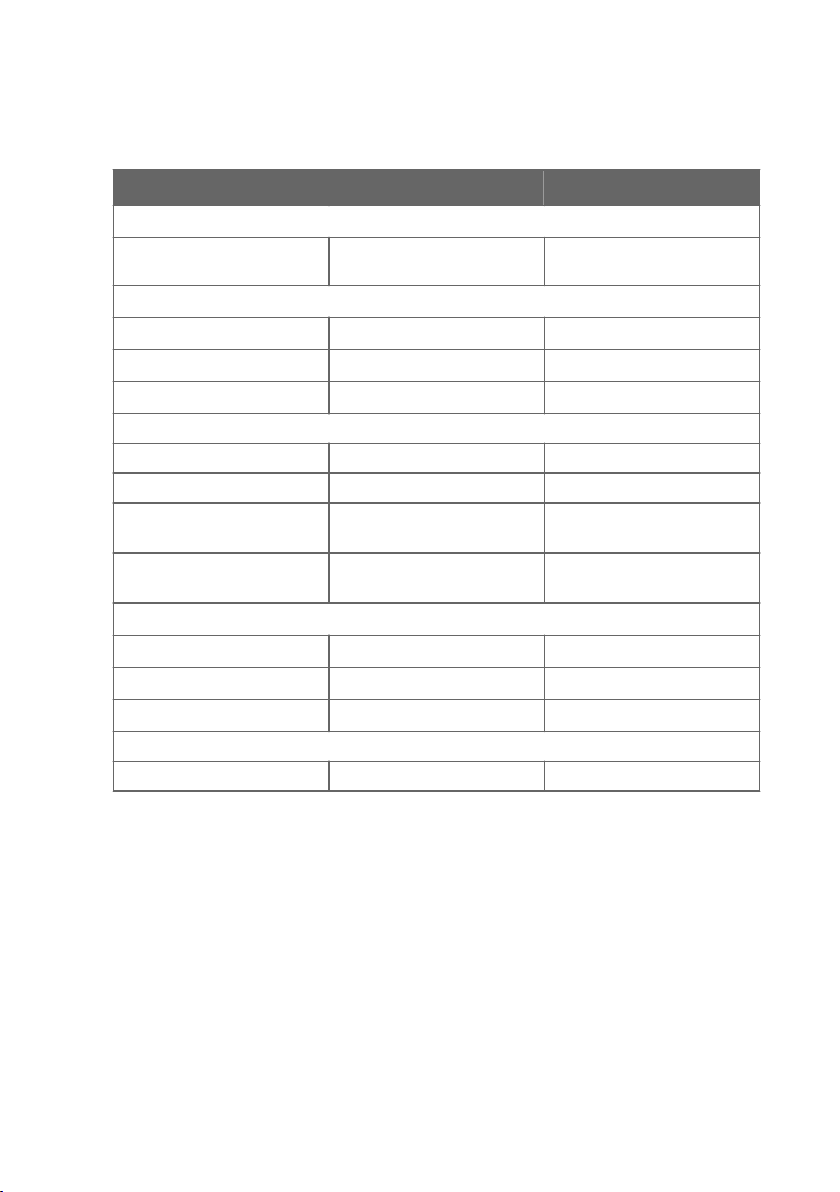

3.3 Measurement parameters and units

Parameter Abbreviation Unit

H2 concentration in oil

• 1 h average

• 24 h average

Rate of change of H2 concentration

In a day Daily ROC ppmv/day

In a week Weekly ROC ppmv/week

In a month Monthly ROC ppmv/month

Moisture in oil

Relative saturation RS %RS

Water activity aw (=RS/100) (no unit)

H2O concentration in oil

(current)

H2O concentration in oil (24 h

average)

Rate of change of H2O concentration in oil

In a day Daily ROC ppmw/day

In a week Weekly ROC ppmw/week

In a month Monthly ROC ppmw/month

Temperature

Oil temperature T °C or °F

H2 ppm

H2O ppm

H2O ppm

v

w

w

The rate of change (ROC) for H2 and for H2O shows the dierence in ppm between the latest

24-hour average and the 24-hour average 1 day ago (daily ROC), 7 days ago (weekly ROC), or

30 days ago (monthly ROC). ROC readings are updated every 12 hours.

After starting up or resetting the transmitter, ROC readings are available as follows:

• Daily ROC: after 2 days

• Weekly ROC: after 8 days

• Monthly ROC: after 31 days

Before the ROC readings are available, the ROC measurement registers in digital outputs

contain a "NaN" value, and the ROC analog outputs are set to 3.0 mA (= measurement not

ready).

15

Page 18

MHT410 1 B E G 0

1

MHT410 User Guide M211737EN-H

3.4 Oil types

MHT410 is compatible with the following oil types:

• Mineral oils

• Natural ester oils

• Synthetic ester oils

• Silicone oil

CAUTION!

for the unit at the factory. Using the transmitter with a dierent oil type requires

sending the unit to Vaisala for reconfiguration.

The oil type that MHT410 measures (mineral oils, natural ester oils, synthetic ester oils, or

silicone oil) is selected when ordering the transmitter. For instructions on checking the oil type

set at the factory from the product label, see Oil type information in order code (page 16).

Never use MHT410 with any other oil type than the one configured

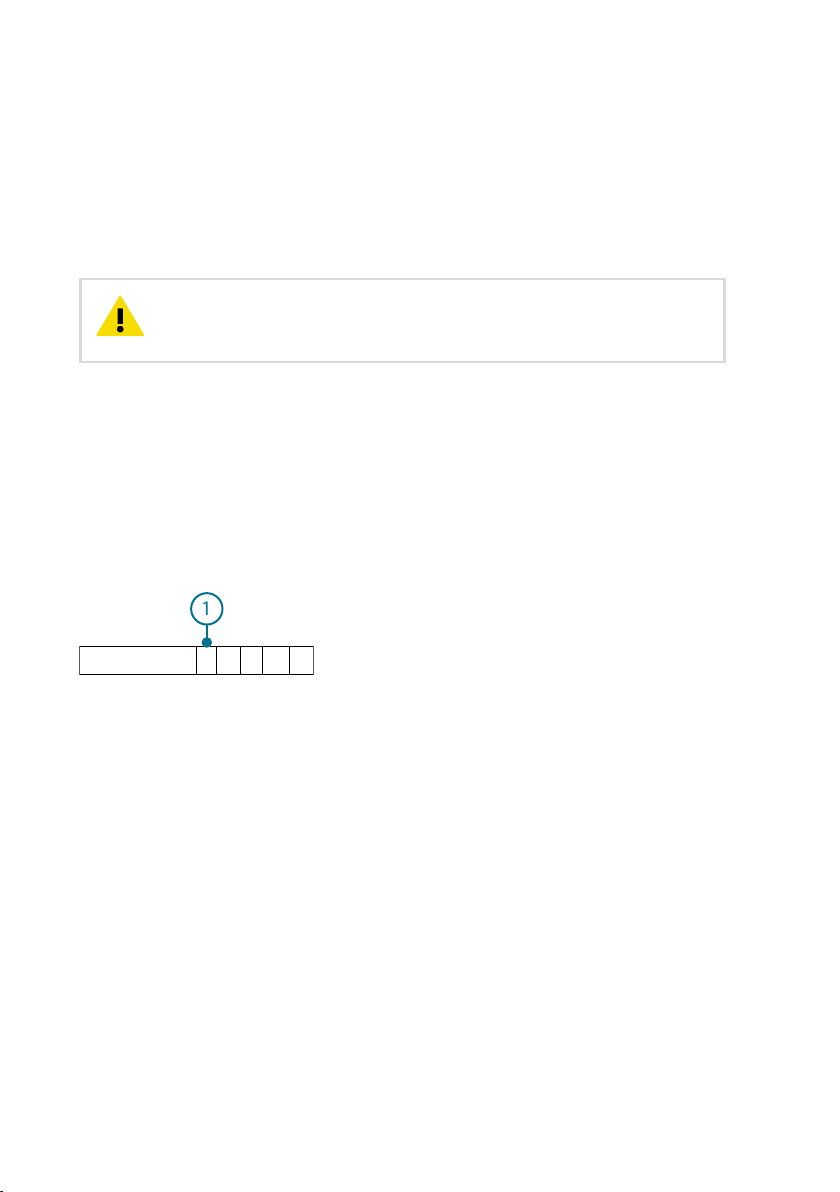

3.4.1 Oil type information in order code

MHT410 has been configured for a specific oil type based on the selection made when

ordering the transmitter, and must not be used with other oil types. The oil type configuration

set at the factory can be checked from the first digit (1, 2, 3, or 4) of the order code in the

MHT410 product label.

Figure 1 MHT410 order code example (first digit 1 = mineral oil)

First digit of the order code. The oil type configuration is shown in the first digit as 1, 2, 3,

1

or 4:

• 1 = Mineral oils (shown)

• 2 = Natural ester oils

• 3 = Synthetic ester oils

• 4 = Silicone oils

3.4.2 Oil-specific coecients for ppmw moisture measurement

MHT410 can be ordered with ppmw moisture output (average mass concentration of water in

oil). The calculation model that MHT410 uses for ppmw measurement is based on the average

water solubility behavior of transformer oils (see Calculation model with average coecients

(page 113)). If additional accuracy is required, you can configure oil-specific coecients into

MHT410 using Vaisala Industrial Protocol serial commands (see Table 41 (page 70)), or contact

Vaisala about setting the coecients.

16

Page 19

Chapter 3 – Product overview

More information

‣

Moisture ppmw calculation for transformer oils (page 113)

‣

Other commands (page 68)

3.5 Data logging

The transmitter automatically saves the measurement readings and other events in a log every

12 hours (configurable interval). The log can contain approximately 32000 entries.

The following events are logged:

• Hydrogen (ppmv) reading as 1 h average or 24 h average

• Moisture in oil (%RS and ppmw) and temperature (°C) readings as instant values or 24 h

averages

• Power outages

• Short power outages that don't turn o transmitter power (flagged "UPS")

• Long power outages that turn o transmitter power (flagged first as "UPS" and then

as "Reset")

• Manual resets (flagged as "Reset")

• Uptime and total operating time

• Occasions of exceeding hydrogen alarm level (optional)

To view the log and change the logging settings, use Vaisala Industrial Protocol.

You can save the log as a file from PuTTY by configuring the following settings in

PuTTY before opening the connection:

In the Session > Logging view:

• Session logging: Select "Printable output".

• Log file name: Type a name for the log file (use the file extension .txt) and

browse to the save location.

To prevent the log from getting very long, consider saving and then clearing the

log every few years.

More information

‣

Vaisala Industrial Protocol (page 40)

‣

Measurement output commands (page 52)

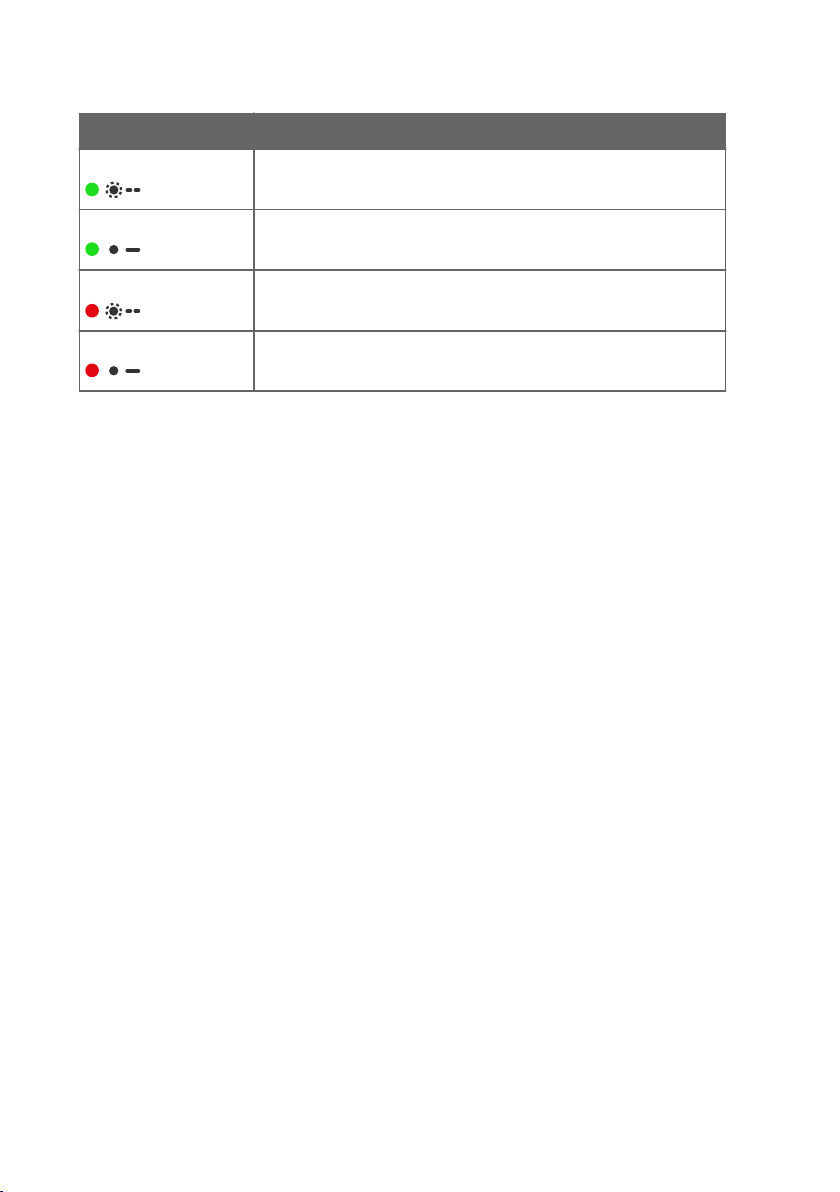

3.6

Status LEDs

When the transmitter is ON, one of the LEDs is always illuminated (solid or blinking). If no LED

is illuminated, the transmitter is OFF.

17

Page 20

Wait...

OK

Alarm

Error

MHT410 User Guide M211737EN-H

LED color and text Description

Green, blinking:

Transmitter is preparing H2 measurement after start-up or reset.

Green, solid:

Red, blinking:

Red, solid:

Transmitter is measuring.

H2 concentration is above the alarm limit.

Transmitter is in error state.

18

Page 21

4. Installation

Before you install the transmitter:

• Go through the check list in section Planning the installation (page 19).

• Read this whole guide carefully.

Chapter 4 – Installation

CAUTION!

configured for MHT410. See Oil type information in order code (page 16).

The installation instructions in this section are the same as in the MHT410 Quick

Guide.

Make sure the oil type of the transformer matches the oil type

4.1 Planning the installation

• Choose the installation location on the transformer (see Recommended installation

locations (page 20)).

CAUTION!

from the valve specifications. The correct thread of the valve is female 1.5"

NPT. Do not install the transmitter in a valve with a dierent thread. For

example, the R thread is incorrect. If you use a dierent thread than female

1.5" NPT, your equipment may be damaged and the connection is not leak

tight. If you are not sure which thread your installation valve has, verify the

thread with a 1.5" NPT thread gauge.

• Make sure the oil type of the transformer matches the one configured for MHT410

(mineral oil, natural ester oil, synthetic ester oil, or silicone oil).

• Make sure you have all the required tools for installing the transmitter. The required tools

are presented in the installation instructions.

• Choose the output signals: analog and/or digital.

• Choose the electrical wiring option. If the transmitter was ordered with the Vaisala cable

CBL210392-5M, the cable is already pre-connected to the transmitter according to Wiring

Option 1.

Make sure the installation valve and threads are appropriate

More information

‣

Wiring diagrams (page 99)

19

Page 22

MHT410 User Guide M211737EN-H

4.1.1 Recommended installation locations

The probe must always be installed in a valve. The correct thread of the valve is female 1.5"

NPT. Do not install the transmitter in a valve with a dierent thread. For example, the R thread

is incorrect. If you use a dierent thread than female 1.5" NPT, your equipment may be

damaged and the connection is not leak tight.

Figure 2 Recommended installation locations

Recommendation

Recommended:

Straight section in the

radiator’s outlet pipe.

20

Description

This is the best location for the transmitter.

The oil is measured in flow, which makes the oil sample

representative and instant. This is essential especially for correct

oil moisture measurement.

Compared to the radiator inlet pipe, oil in the outlet pipe is

cooled, preventing unnecessary heating of the sensors and the

transmitter.

Page 23

Recommendation Description

Possible alternative:

Wall of the oil tank, high

enough from the bottom to

enable proper oil movement.

An instrumentation valve is recommended. This is a typical valve

that is meant for oil analysis.

Moisture response time is moderate depending on the oil volume

and transmitter installation.

DANGER!

damage to transformer:

Pay attention to transmitter installation depth

and possible energized parts inside the power

transformer to minimize electric shock hazard

and equipment damage.

The moisture response can be poor due to static oil flow. There is

also a risk of separated water (leading to wrong results) and oil

Not recommended:

Drain valve of the oil tank.

sludge (risk of sensor contamination and clogged filters).

4.2 Mechanical installation

Chapter 4 – Installation

Severe risk of death and of

CAUTION!

Before you install the transmitter:

• Make sure there is no negative pressure in the transformer. If there is negative

pressure when you open the bleed screw during installation, air will flow into

the transformer oil tank.

• Do not open the ball valve on the transformer until you are instructed to do so

in this guide.

• Make sure the bleed screw on the mounting nut is closed.

• 2 wrenches (50 mm and 36 mm)

• Allen key (3 mm, provided)

• PTFE tape (provided)

• Gloves

• Bucket and cloth

21

Page 24

MHT410 User Guide M211737EN-H

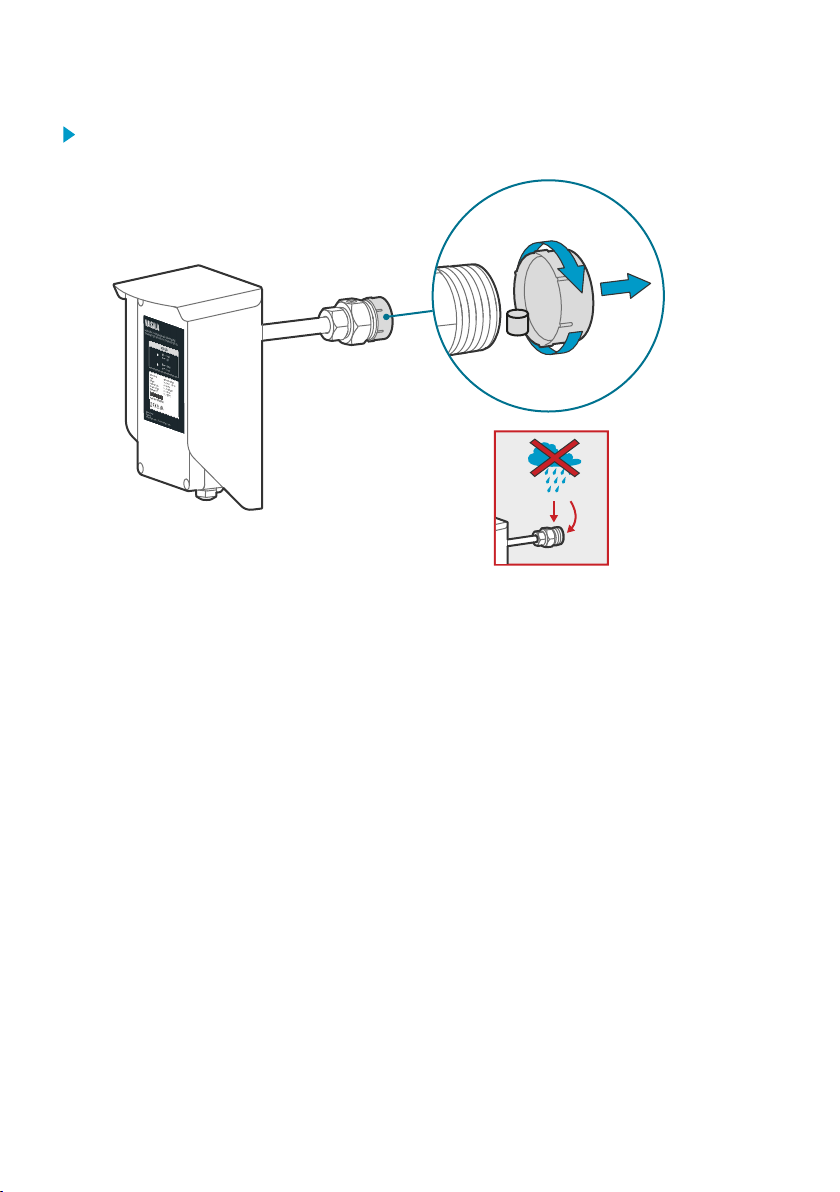

1. Remove the protective cap with sorbent packet from the mounting nut.

In case of rain, do not let any water fall on the filter.

22

Page 25

PTFE

Chapter 4 – Installation

2. Apply PTFE tape tightly on the mounting nut threads.

a. Before you start, clean the threads with a cloth.

b. To make sure you wrap the tape in the correct direction, hold the transmitter so that

the product label is facing you and the mounting nut points away from you.

c. Start wrapping counter-clockwise from the second thread on the tip of the mounting

nut.

d. Wrap each round very tightly about half way on top of the previous round so that the

tape overlaps. Stretch the tape for optimal tightness. Apply a couple of rounds of

tape.

23

Page 26

OPEN

max. 3 × 360°

MHT410 User Guide M211737EN-H

3. Make sure the bleed screw is closed. Fasten the mounting nut on the ball valve to finger-

tightness with your hand. Leave the bleed screw directly on top of the nut.

If you cannot position the bleed screw on top of the mounting nut by tightening just with

your hand, you can use a wrench (50 mm) to turn the mounting nut a maximum of a ½

turn.

CAUTION!

fastened it on the valve, you must remove the transmitter from the valve,

remove the PTFE tape, and start again from step 2 with new PTFE tape.

4. With a 3 mm Allen key, loosen the bleed screw. Place a bucket under the mounting nut.

If you need to loosen the mounting nut after you have

24

Page 27

CLOSE

SLOW

Chapter 4 – Installation

5. Start opening the valve very carefully to let air out through the bleed screw.

CAUTION!

If you open the valve too quickly, the air inside the mounting

nut will flow into the transformer instead.

When oil flows out, close the bleed screw. Clean the area with a cloth and open the ball

valve fully.

6. Continue tightening the mounting nut with a wrench. Be very careful not to over-tighten

the connection. Approximately 5 ... 8 mm of the mounting nut threads remain outside the

valve.

If the connection leaks after you have tightened the mounting nut, check the

thread type of the installation valve.

• If the valve thread is other than female 1.5" NPT (incorrect), do not

install the transmitter in that valve.

• If the valve thread is female 1.5" NPT (correct), close the valve, open

the mounting nut and remove the transmitter, remove old PTFE tape

and apply a thicker layer of new PTFE tape. Then continue from

step 3.

25

Page 28

180 ... 190 mm

200 mm

MHT410 User Guide M211737EN-H

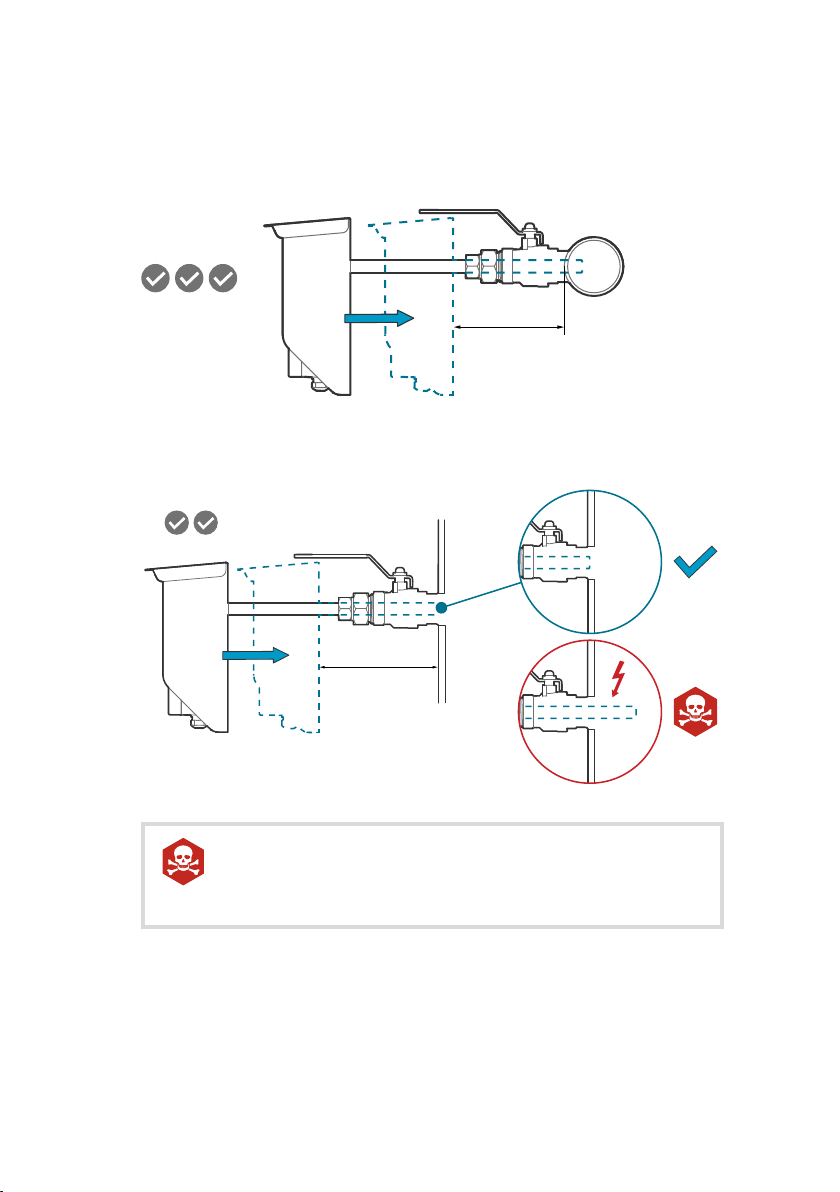

7. Push the probe to the correct depth. The correct depth depends on where the installation

valve is located: radiator pipe or transformer wall.

• Valve in radiator pipe: Install the probe so that the back of the weather shield is

180 ... 190 mm from the pipe surface.

• Valve in transformer wall: Install the probe so that the back of the weather shield is

200 mm from the transformer wall.

DANGER!

Severe risk of death and of damage to transformer:

Pay attention to transmitter installation depth and possible energized

parts inside the power transformer to minimize electric shock hazard

and equipment damage.

When the probe is in the correct depth, turn the transmitter 90 degrees two to three

times to remove any air bubbles from the sensor area.

26

Page 29

DO NOT CLOSE VALVE

WHEN TRANSMITTER

IS INSTALLED!

HOW TO CLOSE VALVE:

1

2

3

DO NOT CLOSE VALVE

WHEN TRANSMITTER

IS INSTALLED!

HOW TO CLOSE VALVE:

1

2

3

PULL INSTRUMENT OUT

BEFORE CLOSING VALVE

Chapter 4 – Installation

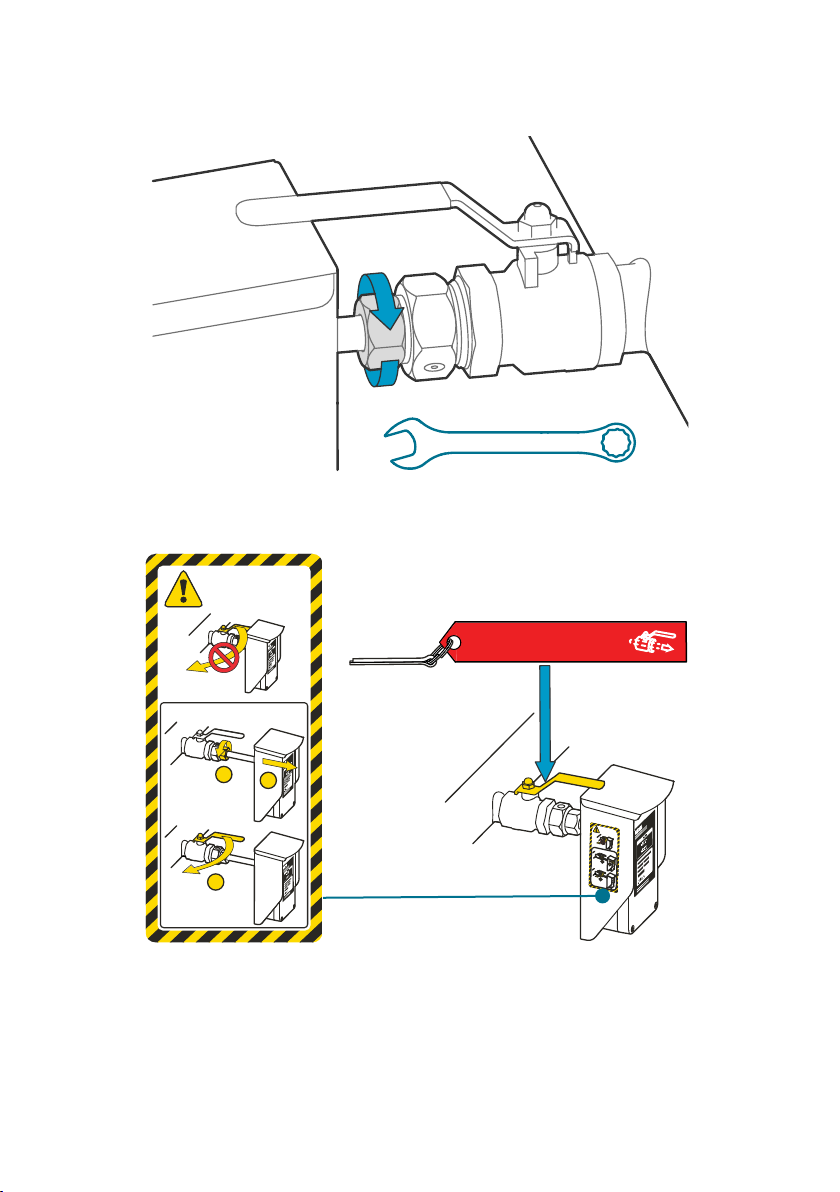

8. Tighten the small tightening nut with a wrench until the probe is securely fastened.

9. Press the caution sticker on the MHT410 weather shield or other visible location nearby,

and lock the handle of the valve in the open position with the safety pin.

More information

‣

Dimensions (page 98)

27

Page 30

+

CH2

– CH2

+

CH1

– CH1

SHLD

SHLD

RS

GND

D –

D

+

+

Vs

– Vs

3 4 5 6 7 8

9

10 11 12 13 14 15 16

RS-485

NALOG OUTPUTS

SERVICE

PORT

19200 b/s, 8, n, 1

POWER

SERIAL COMMANDS

Device information ?

List of errors ERRS

List of commands HELP

Modbus default

address: 240

RS-485

TERMINATION

ON

OFF

See manual for further

commands.

www.vaisala.com/MHT410

MHT410 User Guide M211737EN-H

4.3 Electrical installation

When connecting MHT410 to the Indigo520 transmitter, see also Indigo520 and

MHT410 wiring diagram (page 83).

If MHT410 was ordered with the Vaisala cable CBL210392-5M, the cable is already

pre-connected to MHT410 according to Wiring Option 1.

If cable is not pre-wired:

• Allen key (5 mm, provided)

• 2 medium wrenches (24 mm)

• Flat head screwdriver (2.5 mm)

• Wire-cutting pliers

• Suitable cable. You can order the following cables from Vaisala:

• 5 m shielded PUR cable (order code: CBL210392-5MSP)

• 10 m shielded PUR cable (order code: CBL210392-10MSP)

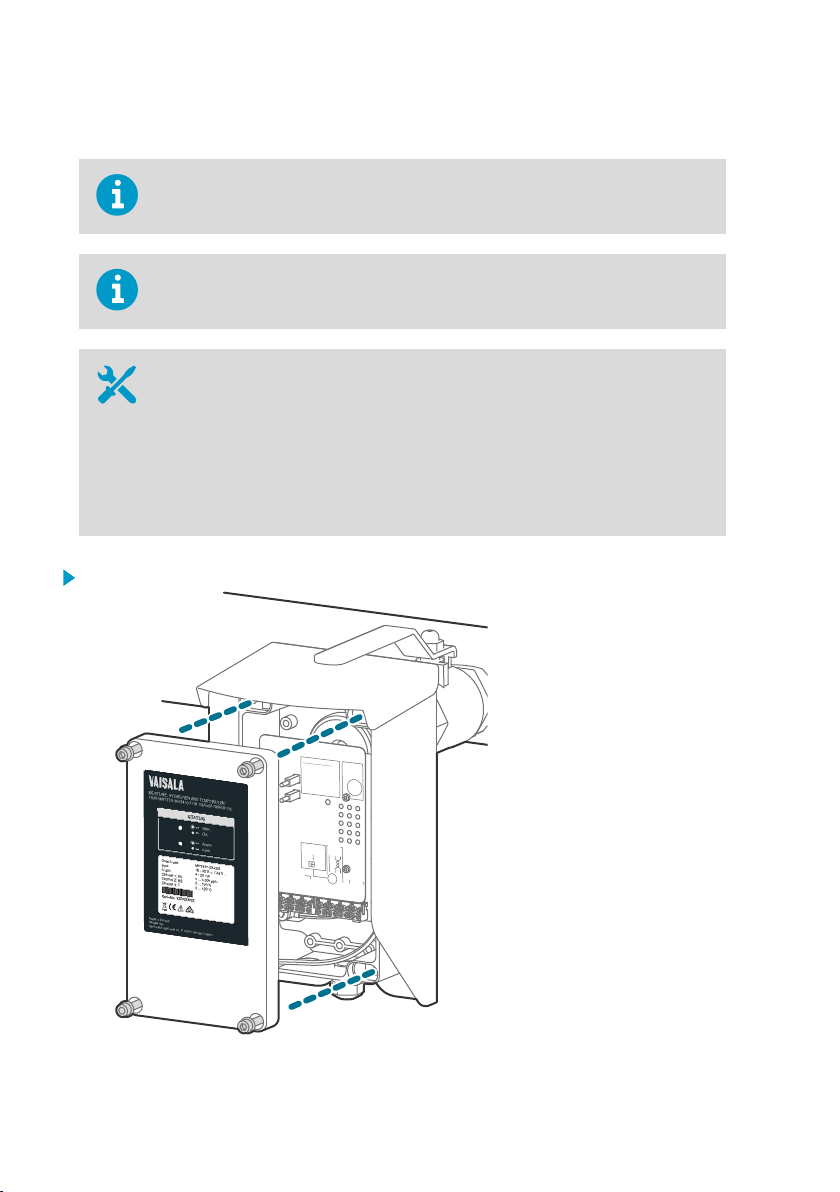

1. Open the electronics housing with a 5 mm Allen key to access the screw terminals.

28

Page 31

Chapter 4 – Installation

2. Hold the upper nut of the cable gland in place with a wrench (24 mm), and loosen the

sealing nut of the gland with another wrench (24 mm).

3. Lead the cable through the sealing nut and the rubber seal. Turn the shield over the edge

of the rubber seal.

29

Page 32

+

CH3

– CH3

+

CH2

– CH2

+

CH1

– CH1

SHLD

SHLD

RS

GND

D –

D

+

+

Vs

– Vs

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

RS-485

ANALOG OUTPUTS

POWER

Modbus default

address: 240

RS-485

TERMINATION

ON

OFF

MHT410 User Guide M211737EN-H

4. Lead the cable through the cable gland. Push the rubber seal back in place with the

shield. Cut o any excess shield. Tighten the sealing nut with wrench (24 mm).

5. Pull the screw terminal blocks (2 pcs) o from the circuit board.

6. Connect the wiring to the detachable screw terminals according to your chosen wiring

option. Note that wiring for digital output (RS-485) is the same in all wiring options.

30

Page 33

Chapter 4 – Installation

7. When you are finished with the wiring, plug the screw terminals back in and close the

electronics housing.

More information

‣

Wiring diagrams (page 99)

‣

Wiring diagrams (page 99)

4.4 Loop-powered display

The analog outputs of the transmitter can be connected to an external loop-powered LED

display (order code 242003). The display is a pre-configured Nokeval 302 display intended for

Vaisala MHT410 hydrogen channel measurements.

The display also includes two alarm relays to trigger an external hydrogen warning and alarm.

This display can be configured for other parameters (moisture/temperature in oil). If needed,

you can install up to three displays, each showing a dierent parameter.

The default display settings are presented in the Vaisala Technical Note inside the display

package. If needed, configure the display functions and scaling according to the

manufacturer's instructions delivered with the display. Manufacturer’s documentation is also

available from www.nokeval.com.

31

Page 34

MHT410 User Guide M211737EN-H

Figure 3 Loop-powered display 242003

The loop resistance of the display must be included in the loop resistance

calculation for the complete current loop. For the loop resistance of the display,

refer to the manufacturer’s documentation.

More information

‣

Wiring the loop-powered display (page 32)

4.4.1 Wiring the loop-powered display

If one of the cable lead-throughs on your transmitter is plugged and you want to

use that lead-through for the Nokeval display cable, you can order a cable gland

from Vaisala.

32

Page 35

1 2 3 4 5 6 7 8

+CH3

-CH3

+CH2

-CH2

+CH1

-CH1

SHLD

SHLD

1

2

3

Nokeval Display

mA-

mA+

7 6 5 4

A1(hi) A2(hihi)

4...20 mA

R

= 0...500

Ω

15...30 V DC,

L

power supply

for analog channel

and display

Chapter 4 – Installation

1. Connect the loop-powered display to the transmitter as shown in the following wiring

diagram. In the diagram, the display is connected to analog output Channel 1 according to

Wiring Option 1.

All the Wiring Options (1, 2, 3, and 4) have the same principle for connecting the

display:

• Wire from port 1 of the display connects to the minus port of the transmitter's

analog output channel (for example, to "-CH1").

• Wire from port 2 of the display connects to where the minus port wire of the

analog output channel would have connected without the display.

More information

‣

Spare parts and accessories (page 97)

‣

Wiring diagrams (page 99)

4.5

Checklist after installation

After the installation, check the following indicators to make sure the installation was

successful:

• No oil is leaking from the transformer and the transmitter.

If the connection leaks after you have tightened the mounting nut, the probable reason is

that the PTFE tape was applied incorrectly or the valve thread is other than female 1.5"

NPT.

33

Page 36

MHT410 User Guide M211737EN-H

• The H2 level LED indicator settles to a solid green. Note that it can take up to 30 minutes

for the H2 level measurement to settle after start-up or reset.

• Solid green indicates that the H2 level is below alarm limit.

• Blinking red indicates that the H2 level is above alarm limit (by default, the alarm is

o).

• After the initial stabilization period (approx. 24 h power on), the reading is correct.

4.6 Oil fittings check after installation

After the first month of continuous use, all oil fittings should be checked for leaks.

An annual check thereafter is recommended.

4.7 Removing the transmitter

To disconnect wiring:

• Allen key (5 mm, provided)

• 2 medium wrenches (24 mm)

• Flat head screwdriver (2.5 mm)

To remove transmitter:

• Large wrench (50 mm)

• Medium wrench (36 mm)

• Gloves

• Bucket and cloth

CAUTION!

installed. The probe body goes through the valve into the oil flow, and trying to

close the valve will damage the probe body and/or the valve.

1. If needed, disconnect the wiring:

a. Open the front cover and disconnect the wires from the detachable screw terminals.

b. Hold the upper nut of the cable gland in place with a wrench (24 mm), and loosen the

sealing nut of the gland with another wrench (24 mm).

c. Pull the cable out of the cable gland.

d. Re-attach the cable gland in its place.

2. Put a bucket under the ball valve to catch any oil falling from the valve.

34

Do not try to close the ball valve when the transmitter is fully

Page 37

Chapter 4 – Installation

3. Loosen the small tightening nut with a wrench.

To keep the larger mounting nut from opening, hold it in place with a wrench

as you are opening the smaller tightening nut.

4. Pull the transmitter outward so that the probe body is out of the ball valve.

5. Close the ball valve.

6. Open the mounting nut with a wrench and pull the transmitter out. Use the cloth to clean

up any spills.

Always make sure the bleed screw is closed before you turn the mounting

nut with a wrench.

4.8 Re-installing the transmitter in new location

If you re-install the transmitter in a new location, you must initialize the transmitter after the

re-installation by connecting to the service port and giving the initialization command using

Vaisala Industrial Protocol.

1. Remove the transmitter. See Removing the transmitter (page 34).

2. Install the transmitter in the new location as instructed in Installation (page 19) and its

subsections.

3. Connect to the transmitter via the service port and start communication using Vaisala

Industrial Protocol.

a. Connect to the service port (Connecting to MHT410 via service port (page 41)).

b. If needed, install the USB driver (Installing driver for the USB service cable

(page 41)).

c. Connect the USB cable (Connecting USB service cable (page 42)).

d. Configure the terminal application settings (Configuring terminal application settings

(page 42)).

4. Start the initialization sequence by issuing the command h2. The transmitter starts

outputting H2 measurement data.

> h2

Start hydrogen measurement module command line operation, quit by pressing

+

15832291.00 33.5719 50.06586 209.87 8413520 8410294 106 0.0 0 28.7938 0

15832292.00 33.5852 50.06617 209.82 8413484 8410254 106 0.0 0 28.7938 0

...

35

Page 38

MHT410 User Guide M211737EN-H

5. Stop the output by pressing the Esc key:

...

15832292.00 33.5852 50.06617 209.82 8413484 8410254 106 0.0 0 28.7938 0

<"Esc key">

H2scan:

6. Give the initialization command is, and when asked to erase the data log, confirm by

pressing the y key.

H2scan: is

Clearing old data:

...wait...Erase the Data Log (Y/N)? y

Clearing log

; SSN=B13.21L.10306TN1X, FW=3.85F , MDN=104400-FF02-P1, DF=0xB4B4s, L

TimeSec PcbTemp SnsrTemp HCurrent Res1Adc AdjRes1 H2Res.ppm

H2.ppm H2_DG.ppm OilTemp H2_G.ppm H2_SldAv Messages

7. Start the H2 measurement output again by pressing the v key.

v

15832363.00 31.9850 30.88629 0.00 8087342 8087342 641 - - - - - htr_off

wait

15832364.00 31.9565 30.84680 0.00 8086663 8086663 582 - - - - - htr_off

wait

...

8. Finish the initialization sequence by pressing the + key.

...

15832364.00 31.9565 30.84680 0.00 8086663 8086663 582 - - - - - htr_off

wait

<"+ key">

Quit hydrogen measurement module command line operation

9. Close the PuTTY terminal application.

10. Disconnect from the service port and close the transmitter cover.

36

Page 39

Chapter 5 – Analog output

5. Analog output

There are three analog output channels available for H2, moisture in oil, and temperature using

4 ... 20 mA current outputs.

The parameter for each output is configured at the factory according to order. If needed, you

can change the parameters using the asel command via Vaisala Industrial Protocol.

Table 3 Analog output values in dierent transmitter statuses

Transmitter status Analog output value

Normal 4 ... 20mA

Error 3.5 mA (default)

Measurement not ready 3.0 mA

More information

‣

Analog output commands (page 63)

5.1

Analog output overrange behavior

If the measured hydrogen, moisture and temperature levels go below or above their scaled

range, the analog output is clipped at the low (4 mA) or high (20 mA) end of the output range.

This means the analog output will not indicate measurement readings that are outside the

scaled ranges.

If needed, you can allow the analog outputs to extend 10 % of the range over 20 mA using the

aover command via Vaisala Industrial Protocol. With this extension, the allowed range for

analog outputs is 4 ... 21.6 mA. The aover command does not aect the scaling of the outputs.

You can also change the scaling of the outputs for each channel using the asel command via

Vaisala Industrial Protocol.

37

Page 40

20 mA

21.6 mA

4 mA

Low end

of scale

High end

of scale

High end

of scale

+10 %

of scale

Analog output

Analog output extended at high end of range

CURRENT

OUTPUT

MEASURED

VALUE

MHT410 User Guide M211737EN-H

Figure 4 Analog output overrange behavior

More information

‣

Analog output commands (page 63)

38

Page 41

Chapter 6 – Modbus

6. Modbus

6.1 Overview of Modbus protocol support

MHT410 can be accessed using the Modbus serial communication protocol on the RS-485 line

of the screw terminals. The supported Modbus variant is Modbus RTU (Serial Modbus).

The supported Modbus functions and registers are described in Modbus reference (page 107).

By default, the RS-485 line of the screw terminals is in Modbus mode. The pre-configured

default communication settings are presented in the following table.

Description Default value

Serial bit rate 19200

Parity None

Number of data bits 8 (read-only)

Number of stop bits 1

Modbus device address 240

You can change the serial line communication settings using Vaisala Industrial Protocol.

The minimum time between requests from Modbus is 1 second.

More information

‣

Modbus reference (page 107)

‣

Serial line communication commands (page 59)

‣

Vaisala Industrial Protocol (page 40)

39

Page 42

MHT410 User Guide M211737EN-H

7. Vaisala Industrial Protocol

The transmitter provides an implementation of the Vaisala Industrial Protocol that can be used

for service and configuration use, or for interfacing with the system to which the transmitter is

integrated. The protocol is a plaintext protocol suitable for use both by human operators and

automated systems.

You can access the Vaisala Industrial Protocol in two ways:

• For temporary connection with a computer, use the service port. See Connecting to

MHT410 via service port (page 41).

• For permanent connection, use the RS-485 line of the screw terminals.

The RS-485 line of the screw terminals is in Modbus mode by default. To use

Vaisala Industrial Protocol on the RS-485 line, you must first change the

communication mode for that line:

1. Connect to the service port (see Connecting to MHT410 via service port

(page 41)).

2. Change the mode using the smode command (see Table 28 (page 62)).

You can use Vaisala Industrial Protocol via the RS-485 line of the screw terminals

and the service port at the same time.

However, the transmitter responds to the commands one at a time from either

line, which may result in delayed responses if a command is entered from one line

while another command is in progress on the other line.

Table 4 Default serial interface settings

Property Description/Value

Baud rate 19200

Parity None

Number of data bits 8

Number of stop bits 1

Flow control None

More information

‣

Serial commands summary (page 44)

40

Page 43

Chapter 7 – Vaisala Industrial Protocol

7.1 Connecting to MHT410 via service port

• Vaisala USB service cable (item code 219690)

• Computer with:

• Windows operating system

• Free USB port

• Terminal application (for example, PuTTY, available from www.vaisala.com)

• Driver for Vaisala USB service cable installed (available on the cable

installation media and from www.vaisala.com/software)

You can connect to the MHT410 transmitter via Vaisala Industrial Protocol on a computer using

the service port located under the transmitter cover.

If you have not used the Vaisala USB service cable before, install the driver before attempting

to use the cable.

7.1.1 Installing driver for the USB service cable

Only Windowsâ operating systems are supported by the driver of the USB

service cable.

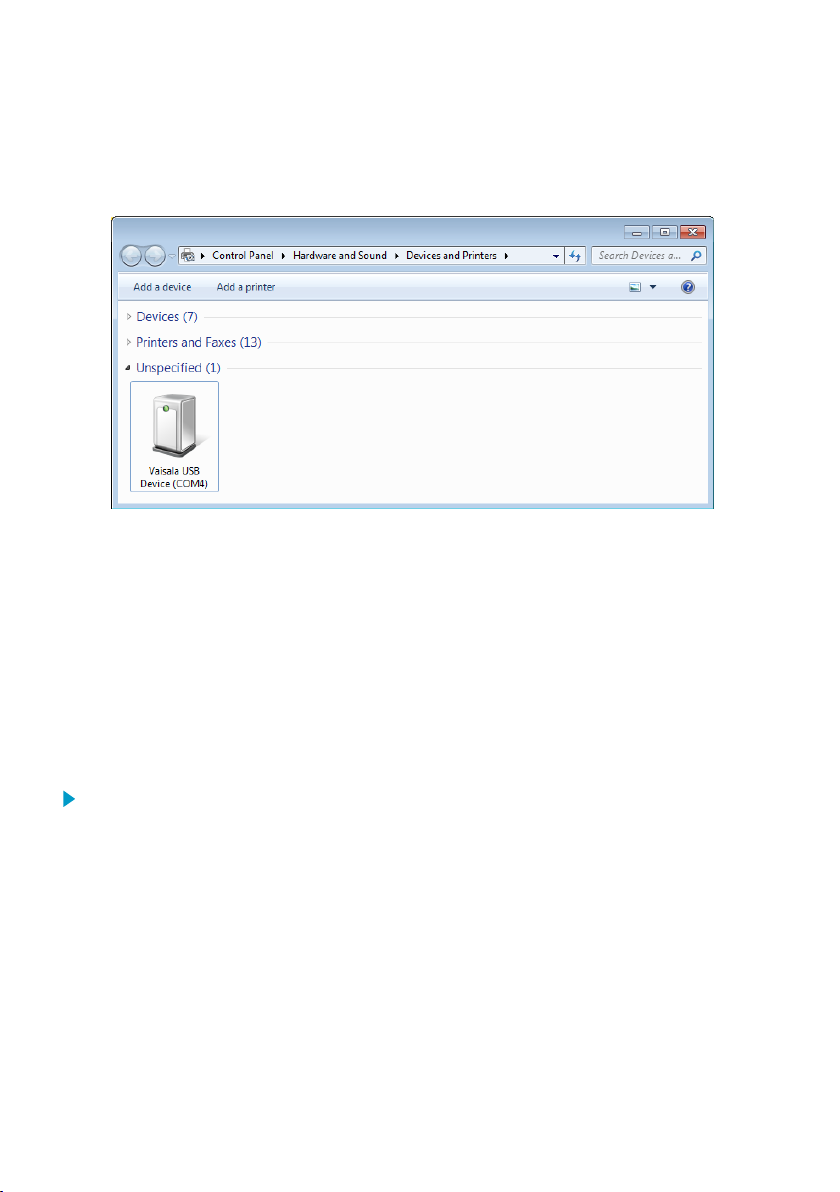

1. Connect the USB service cable to a USB port on your computer. Windowsâ detects the

new device and installs the appropriate driver.

2. Open Devices and Printers from the Windowsâ Start menu. Use search to find it if

necessary (search for "devices").

41

Page 44

MHT410 User Guide M211737EN-H

3. Locate the cable in the list of devices:

• If the device is listed as Vaisala USB Device with a COM port number in brackets, the

cable is ready for use. Note the COM port number, you will need it later.

• If the device is listed as Vaisala USB Instrument Cable without a COM port number

listed, you must install the driver manually.

4. To install the driver manually:

a. Disconnect the USB service cable from the computer.

b. Download the Vaisala USB driver at http://www.vaisala.com/software (select the

appropriate USB Instrument Driver Setup for your cable).

c. Run the USB driver installation program Vaisala USB Device Driver

Setup.exe. Accept the installation defaults.

d. Go back to step 1 and verify that the driver installation works as expected.

7.1.2 Connecting USB service cable

To connect the USB service cable to the service port:

1. Make sure the USB service cable is connected to your computer.

2. Open the 4 hex screws on the cover of the transmitter using a 5-mm Allen key, and open

the cover.

3. Connect the USB service cable to the service port connector on the transmitter circuit

board.

4. Configure the terminal application settings.

7.1.3 Configuring terminal application settings

The steps below describe how to connect to the transmitter using the PuTTY terminal

application for Windows (available for download at www.vaisala.com) and a USB service cable:

42

Page 45

Chapter 7 – Vaisala Industrial Protocol

1. Make sure the USB service cable is connected to your PC and the service port of the

transmitter.

2. Start the PuTTY application.

3. Select Connection > Serial & USB and check that the correct COM port is selected in the

Serial or USB line to connect to field. If you are using the PuTTY terminal application

supplied by Vaisala, you can select USB Finder... to open the Vaisala USB Instrument

Finder program.

4. Check that the other serial settings are correct, and change if necessary.

Table 5 Service port serial interface settings

Property Value

Baud rate 19200

Parity None

Data bits 8

Stop bits 1

Flow control None

5. Select Terminal. Use the following settings:

• Local Echo: "Force on". This setting ensures that your typing is shown on the session

window.

• Send line ends with line feeds (CR+LF): Selected. This setting ensures that all text

lines remain visible on the session window.

43

Page 46

MHT410 User Guide M211737EN-H

6. Select Open to open the connection window and start using the serial line.

If PuTTY is unable to open the serial port you selected, it will show you an

error message instead. If this happens, restart PuTTY and check the settings.

7.2 Serial commands summary

The notation <cr> refers to the carriage return control character, which you can send in a

terminal application by pressing Enter on your keyboard. Before entering commands, send a

<cr> to clear the command buer.

You can enter the commands in uppercase or lowercase. In the command examples, the

keyboard input by the user is in bold type.

Table 6 Serial commands

Command Description More

Device information and status:

?

??

alarm

errlog

errs

help

system

time

vers

Serial line output and communication:

addr

Show device information. Table 7

Show device information (will respond in poll mode).

Show or set H2 alarm level. Table 8

Show error log records. Table 9

Show active errors. Table 10

Show list of serial commands. Table 11

Show firmware information. Table 12

Show transmitter uptime (time since last reset). Table 13

Show the software version information. Table 14

Show or set device address used in Modbus communication and

in Vaisala Industrial Protocol when the device is in POLL mode.

information

(page 46)

(page 47)

(page 48)

(page 49)

(page 50)

(page 50)

(page 51)

(page 51)

Table 23

(page 59)

44

Page 47

Chapter 7 – Vaisala Industrial Protocol

Command Description More

close

Close connection to device in POLL mode.

This command cannot be used via the Service Port.

form

Set output format of measurement messages. Table 19

information

Table 24

(page 60)

(page 56)

intv

Set measurement output interval. Table 15

(page 52)

log

Show measurement log records and configure logging settings. Table 16

(page 52)

open

r

Open connection to device in POLL mode.

This command cannot be used via the Service Port.

Table 25

(page 60)

Start continuous output of measurement messages. Table 17

(page 55)

sdelay

Show or set serial line transmission delay. Table 26

(page 60)

send

Output one measurement message. Table 18

(page 55)

seri

Set serial line settings for the RS-485 line of the screw terminals.

Default is 19200 N 8 1.

Table 27

(page 61)

This command does not aect the service port settings.

smode

Set serial line operation mode for the RS-485 line of the screw

terminals.

Table 28

(page 62)

This command does not aect the service port settings. The

service port is always in stop mode.

unit

Set temperature unit to metric (°C) or non-metric (°F). Table 22

(page 59)

Analog output:

aerr

Show or set error level for analog output. Table 29

(page 63)

aover

Enable or disable analog output 10 % over range. Table 30

(page 63)

asel

Show or set analog output parameters and scaling. Table 31

(page 64)

atest

Test analog outputs by forcing them to a given value. Table 32

(page 66)

Calibration and adjustment:

cdate

Show or set adjustment date. Table 33

(page 67)

45

Page 48

MHT410 User Guide M211737EN-H

Command Description More

ctext

h2 da

h2 db

h2 x

Other commands:

dnp3 addr

filt

frestore

oil

reset

h2 is

Show or set adjustment information text. Table 34

Start or continue hydrogen calibration and adjustment sequence. Table 35

Clear hydrogen calibration and adjustment data. Table 36

Change the data link address of the transmitter in DNP3

communication.

Show or set measurement filtering. Table 38

Restore factory settings. Clears all user settings, factory

calibration remains.

Show or set oil-specific coecients for moisture ppm

calculation.

Reset the device. Table 40

Initialize the device after it has been re-installed in a new location. Table 42

w

information

(page 67)

(page 68)

(page 68)

Table 37

(page 68)

(page 69)

Table 39

(page 69)

Table 41

(page 70)

(page 70)

(page 70)

7.3 Device information and status commands

Table 7 ? command

Syntax Description

?<cr> Show listing of device information.

??<cr> Show listing of device information when device is in poll mode

46

and connection has not been opened using the open command.

Page 49

Syntax Description

Example:

?

MHT410 / 0.1.20

Serial number : L2110001

Batch number : L1940010

Sensor number : L102

Sensor model : Humicap L2

Order code : MHT410 1CXEO

Cal. date : 20150414

Cal. info : Vaisala

Uptime : 0000d 04:04:41

Total time : 0000d 04:04:41

Serial mode : STOP

Baud P D S : 19200 N 8 1

Output interval : 1 S

Serial delay : 25

Address : 0

Filter : 1.000

Ch1 output : 4 ... 20 mA

Ch2 output : 4 ... 20 mA

Ch3 output : 4 ... 20 mA

Ch1 RS lo : 0.00 %

Ch1 RS hi : 100.00 %

Ch2 T lo : -40.00 'C

Ch2 T hi : 100.00 'C

Ch3 H2 lo : 0.00 ppm

Ch3 H2 hi : 5000.00 ppm

Chapter 7 – Vaisala Industrial Protocol

Table 8 alarm command

Syntax Description

alarm<cr> Check the status and setpoint (ppmv) of the hydrogen alarm.

The alarm is activated when the 1-hour average for hydrogen

exceeds the setpoint.

alarm [on | off]

[setpoint]<cr>

Set the hydrogen alarm status.

on = Alarm indication is on.

o = Alarm indication is o.

setpoint = Hydrogen level above which the alarm is activated.

Example (check the hydrogen alarm status, alarm is o):

alarm

Alarm display : OFF ?

Setpoint (ppm) : 300 ?

47

Page 50

MHT410 User Guide M211737EN-H

Syntax Description

Example (enable the hydrogen alarm and set the alarm limit to 200 ppmv hydrogen):

alarm on 200

Alarm display : ON

Setpoint (ppm) : 200

Table 9 errlog command

Syntax Description

errlog print<cr>

Show the error log with max. 25 last log entries.

The error log stores the error status each time the status

changes.

You can save the error log as a file from PuTTY

by configuring the following settings in PuTTY

before opening the connection:

In the Session > Logging window:

• Session logging: Select "Printable output".

• Log file name: Type a name for the log file (use

extension .txt) and browse for the location

where to save the file.

errlog print [n]

[i]<cr>

errlog save<cr>

errlog clear<cr>

48

Show the error log with a chosen number of entries.

n = Number of entries to show (max. 9999).

i = Optional: Index number of the first shown entry. If this

parameter is not used, the list will show the last n number of

entries.

Save the current error status for troubleshooting purposes.

Remove all entries from the error log.

Clearing the error log may make

troubleshooting more dicult later if a problem

occurs.

Page 51

Chapter 7 – Vaisala Industrial Protocol

Syntax Description

Example (show error log):

errlog print

index RecNum Reset Days Time ERRS H2err Y(T) Y(RH) fm_cnt

1 1 1 0 00:00:00 8 0 1.0947 4.7467 0

2 2 2 0 00:37:29 8 0 1.0984 0.5565 6

3 3 2 0 00:37:14 8 0 1.1004 2.4597 0

4 4 2 0 00:38:46 8 0 1.1027 0.5147 7

5 5 2 0 01:10:02 8 0 1.1146 2.5202 0

6 6 2 0 01:15:57 8 0 1.1156 0.5876 6

7 7 3 0 00:36:21 8 0 1.1160 -3.9274 1

Example (show the last 5 entries):

errlog print 5

index RecNum Reset Days Time ERRS H2err Y(T) Y(RH) fm_cnt

27 27 19 0 04:59:27 8 0 1.1160 -3.9274 1

28 28 19 0 05:11:40 0 0 1.1167 0.5479 6

29 29 19 0 05:18:53 8 0 0.7497 0.3019 6

30 30 19 0 05:21:12 0 0 0.2000 -0.1030 6

31 31 19 0 05:22:36 8 0 1.1187 0.5538 7

Example (save the current error status):

errlog save

New value stored.

Example (remove all entries from the error log):

errlog clear

Erase all Error Log data? (Y/N) y

Erasing...

Error Log cleared.

Table 10 errs command

Syntax Description

errs<cr>

Show currently active errors.

The possible errors and their remedies are listed in Table 46

(page 91).

49

Page 52

MHT410 User Guide M211737EN-H

Syntax Description

Example (no errors active):

errs

No errors

Example (active error):

errs

0008 H2 module communication error

H2scan message: wait

Table 11 help command

Syntax Description

help<cr>

Show a list of available commands.

Example:

help

Stop mode commands:

ADDR AERR ALARM AOVER ASEL ATEST CDATE CLOSE

CTEXT DNP3 ERRLOG ERRS FILT FORM FRESTORE H2

HELP INTV LOG R RESET SDELAY SEND SERI

SMODE SYSTEM TIME UNIT VERS ?

Poll mode commands:

OPEN SEND ??

Table 12 system command

Syntax Description

system<cr>

Show firmware information.

Example:

system

Device Name : MHT410

Copyright : Copyright (c) Vaisala Oyj 2015. All rights reserved.

SW Name : MHP410

SW date : 2015-05-05

SW version : 1.0.0

OS version : TSF 1.0

50

Page 53

Table 13 time command

Syntax Description

time [mode]<cr>

Show transmitter uptime (time since last reset). Default output:

hh:mm:ss.

mode = alternative output option (optional)

• 1 = include days (dddd hh:mm:ss)

• 2 = include decimals of seconds (hh:mm:ss.sss)