Page 1

M211972EN-B

User Guide

Vaisala PEROXCAPâ Hydrogen Peroxide,

Humidity and Temperature Probe

HPP272

Page 2

PUBLISHED BY

Vaisala Oyj

Street address: Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

Mailing address: P.O. Box 26, FI-00421 Helsinki, Finland

Phone: +358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala 2017

No part of this manual may be

reproduced, published or publicly

displayed in any form or by any

means, electronic or mechanical

(including photocopying), nor

may its contents be modified,

translated, adapted, sold or

disclosed to a third party without

prior written permission of the

copyright holder. Translated

manuals and translated portions

of multilingual documents are

based on the original English

versions. In ambiguous cases, the

English versions are applicable,

not the translations.

The contents of this manual are

subject to change without prior

notice.

Local rules and regulations may

vary and they shall take

precedence over the information

contained in this manual. Vaisala

makes no representations on this

manual’s compliance with the

local rules and regulations

applicable at any given time, and

hereby disclaims any and all

responsibilities related thereto.

This manual does not create any

legally binding obligations for

Vaisala towards customers or end

users. All legally binding

obligations and agreements are

included exclusively in the

applicable supply contract or the

General Conditions of Sale and

General Conditions of Service of

Vaisala.

This product contains software

developed by Vaisala or third

parties. Use of the software is

governed by license terms and

conditions included in the

applicable supply contract or, in

the absence of separate license

terms and conditions, by the

General License Conditions of

Vaisala Group.

Page 3

Table of Contents

Table of Contents

1. About This Document................................................................................... 5

1.1 Version Information..........................................................................................5

1.2 Related Manuals................................................................................................5

1.3 Documentation Conventions...........................................................................5

1.4 Trademarks........................................................................................................ 6

1.5 Patent Notice.....................................................................................................6

2. Product Overview........................................................................................... 7

2.1 Introduction to HPP272....................................................................................7

2.2 Basic Features and Options.............................................................................8

2.3 Safety..................................................................................................................8

2.4 ESD Protection.................................................................................................. 9

2.5 Measured Parameters.......................................................................................9

2.5.1 Understanding Relative Humidity and Relative Saturation................ 10

2.6 Probe Filter........................................................................................................11

2.7 Chemical Purge.................................................................................................11

2.8 Environmental Compensation for Pressure..................................................12

2.9 Measurement Filtering Factor........................................................................12

2.10 Connectivity to Vaisala Insight Software......................................................12

2.11 Additional Features with Indigo Transmitters..............................................13

3. H2O2 Measurement....................................................................................... 14

3.1 Operating Principle of H2O2 Measurement.................................................. 14

3.2 Typical Applications........................................................................................16

3.3 Condensation Monitoring...............................................................................18

4. Installation.......................................................................................................20

4.1 Wiring...............................................................................................................22

4.2 Power Supply.................................................................................................. 23

4.3 Setting Probe in Analog or Digital Mode.....................................................23

5. Operation......................................................................................................... 25

5.1 Probe Start-Up................................................................................................25

5.2 Behavior at Exposure to H2O2.......................................................................25

5.3 H2O2 Concentration Reading When Not Exposed to H2O2.......................25

5.4 Modbus............................................................................................................ 26

5.5 Operation in Analog Mode............................................................................26

5.5.1 Analog Output Overrange Behavior.....................................................26

5.5.2 Triggering Purge in Analog Mode......................................................... 27

6. Vaisala Insight Software............................................................................ 28

6.1 Connecting to Insight Software....................................................................28

1

Page 4

HPP272 User Guide M211972EN-B

7. Using Probe with Indigo Transmitters................................................. 29

7.1 Indigo Overview............................................................................................. 29

7.1.1 Wireless Configuration Interface Overview.........................................30

7.2 Attaching Probes.............................................................................................31

7.3 Connecting to Wireless Configuration Interface........................................ 32

7.4 Logging in to Wireless Configuration Interface..........................................33

8. Maintenance....................................................................................................34

8.1 Cleaning the Probe.........................................................................................34

8.1.1 Chemical Tolerance................................................................................. 34

8.2 Calibration and Adjustment.......................................................................... 35

9. Troubleshooting............................................................................................ 36

9.1 Problems and Their Possible Solutions........................................................36

9.2 Analog Output Error State............................................................................40

10. Technical Data................................................................................................. 41

10.1 Dimensions...................................................................................................... 43

10.2 Accessories.....................................................................................................44

Appendix A:

Modbus Reference........................................................................45

A.1 Default Communication Settings................................................................. 45

A.2 Function Codes...............................................................................................45

A.3 Data Encoding................................................................................................45

A.3.1 32-Bit Floating Point or Integer Format...............................................45

A.3.2 16-Bit Integer Format............................................................................. 46

A.4 Modbus Registers...........................................................................................46

A.4.1 Measurement Data Registers.................................................................47

A.4.2 Configuration Registers......................................................................... 48

A.4.3 Status Registers...................................................................................... 54

A.4.4 Device Identification Objects.................................................................56

A.4.5 Test Value Registers................................................................................ 57

A.5 Modbus Communication Examples..............................................................58

Warranty........................................................................................................................ 61

Technical Support...................................................................................................... 61

Recycling....................................................................................................................... 61

2

Page 5

List of Figures

Figure 1 HPP272 Probe Parts...........................................................................................7

Figure 2 Eect of H2O and H2O2 on relative saturation (RS) and

relative humidity (RH).....................................................................................10

Figure 3 Operating principle of PEROXCAP measurement................................... 15

Figure 4 Example behavior of H2O2 concentration, relative

saturation (RS), and relative humidity (RH) in a

vaporized H2O2 bio-decontamination cycle (non-

condensing conditions)...................................................................................17

Figure 5 Example: RS behavior in dierent temperatures when

H2O2 concentration (500 ppm) and H2O concentration

(8850 ppm) are constant............................................................................... 18

Figure 6 Decontaminated space with dierent temperatures and

RS levels (H2O2 and H2O concentration evenly distributed)................19

Figure 7 Probe M12/5 Pins..............................................................................................22

Figure 8 Wiring Example for Connecting HPP272 to a PLC in

Analog Mode..................................................................................................... 23

Figure 9 Pins on the M12 male connector.................................................................. 24

Figure 10 Connecting Probe to Insight.........................................................................28

Figure 11 Attaching Probes to Indigo............................................................................31

Figure 12 Enabling and Accessing Indigo's Wireless Configuration

Interface..............................................................................................................32

Figure 13 Indigo Login View............................................................................................33

Figure 14 HPP272 Dimensions........................................................................................ 43

List of Figures

3

Page 6

HPP272 User Guide M211972EN-B

List of Tables

Table 1 Document Versions..............................................................................................5

Table 2 Related Manuals....................................................................................................5

Table 3 Applicable Patents or Applications.................................................................6

Table 4 Available Parameters...........................................................................................9

Table 5 Measurement Performance..............................................................................41

Table 6 Inputs and Outputs............................................................................................42

Table 7 Mechanical Specifications............................................................................... 43

Table 8 Operating Environment....................................................................................43

Table 9 Spare Parts and Accessories.......................................................................... 44

Table 10 Default Modbus Serial Communication Settings...................................... 45

Table 11 Modbus Function Codes.................................................................................. 45

Table 12 16-bit Signed Integer Format Details........................................................... 46

Table 13 Modbus Measurement Data Registers (Read-Only).................................47

Table 14 Modbus Configuration Data Registers (Writable)....................................49

Table 15 Modbus Status Registers (Read-Only)........................................................ 54

Table 16 Error Codes in Register 0201

Table 17 Error Codes in Register 0203

Table 18 Device Identification Objects......................................................................... 56

Table 19 Test Value Registers...........................................................................................57

(32-bit)..................................................... 55

hex

(32-bit).................................................... 56

hex

4

Page 7

Chapter 1 – About This Document

1. About This Document

1.1 Version Information

This document provides instructions for installing, using, and maintaining Vaisala PEROXCAPâ

Hydrogen Peroxide, Humidity and Temperature Probe HPP272.

Table 1 Document Versions

Document

Code

M211972EN-B December 2017 This document. Added description and Modbus registers for

M211972EN-A September 2017 First version.

Date Description

pressure compensation, removed restriction not to perform a

purge during H2O2 exposure, clarified operating system

requirements for Vaisala Insight software, clarified Indigo

200 transmitter compatibility with HPP272.

1.2 Related Manuals

Table 2 Related Manuals

Document Code Name

M211887EN Hydrogen Peroxide, Humidity and Temperature Probe HPP270 Series Quick

M211877EN Indigo 201 Analog Output Transmitter User Guide

Guide

1.3 Documentation Conventions

WARNING!

follow instructions carefully at this point, there is a risk of injury or even death.

Warning alerts you to a serious hazard. If you do not read and

CAUTION!

follow instructions carefully at this point, the product could be damaged or

important data could be lost.

Caution warns you of a potential hazard. If you do not read and

5

Page 8

HPP272 User Guide M211972EN-B

Note highlights important information on using the product.

Tip gives information for using the product more eciently.

Lists tools needed to perform the task.

Indicates that you need to take some notes during the task.

1.4 Trademarks

Vaisalaâ, HUMICAPâ, and PEROXCAPâ are registered trademarks of Vaisala Oyj.

Indigo™ is a trademark of Vaisala Oyj.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

1.5

Patent Notice

This product is protected by the following patents and patent applications and their

corresponding national rights:

Table 3 Applicable Patents or Applications

Issuing Oce Publication Number

European Patent Oce EP 3004868

State Intellectual Property Oce of the P.R.C. CN 105229463A

United States Patent and Trademark Oce US 20160084811

6

Page 9

21 543

6

Chapter 2 – Product Overview

2. Product Overview

2.1 Introduction to HPP272

Vaisala PEROXCAPâ Hydrogen Peroxide, Humidity and Temperature Probe HPP270 series is

designed for demanding hydrogen peroxide bio-decontamination processes. The probes are

suitable for a variety of applications such as isolator, material transfer hatch, and room biodecontamination.

Hydrogen Peroxide, Humidity and Temperature Probe HPP272 provides measurement for

vaporized H2O2 concentration, relative saturation, relative humidity, and temperature.

The H2O2 measurement is based on comparing the readings of two composite humidity

sensors to determine the vapor concentration of H2O2. The probes are easy to install with a

plug-in/plug-out M12/5 connection. The digital and analog output options include an RS-485

interface for Modbus communication and two current output channels.

The probe is not intended for safety level measurement.

The probe is not intended to be used in vacuum applications.

CAUTION!

always be powered on. When powered on, the PEROXCAP sensor is heated,

which permits using the probe in condensing H2O2 conditions, maintains

measurement performance, and lengthens the probe's lifetime. When the probe

is powered o, exposure to H2O2 condensation can break the PEROXCAP sensor

within a day, and the sensor will not recover.

When there is H2O2 in the probe's environment, the probe must

Figure 1 HPP272 Probe Parts

1 Yellow transport cap. Remove this cap

before using the probe.

2 Filter covering the sensor. The filter is

an essential part of the measurement

technology: do not remove the filter.

Filters are available as spare parts.

3 PEROXCAP sensor under the filter.

4 H2O2 and humidity probe.

5 Temperature probe.

6 5-pin M12 connector.

7

Page 10

HPP272 User Guide M211972EN-B

More Information

‣

Dimensions (page 43)

‣

Operating Principle of H2O2 Measurement (page 14)

‣

Installation (page 20)

‣

Wiring (page 22)

2.2 Basic Features and Options

• Vaisala PEROXCAPâ H2O2 measurement technology with excellent long-term stability.

• Vaporized H2O2 measurement range 0 ... 2000 ppm.

• Relative saturation (RS) measurement range 0 ... 100 %RS.

• Relative humidity (RH) measurement range 0 … 100 %RH.

• Temperature (T) measurement range +5 ... +70 °C.

• Robust design allowing the probe to be installed directly in the process environment.

When powered on, the probe withstands H2O2 and H2O condensation. The probe also

withstands nitrogen gas.

• Protective

• Sensor heating to avoid condensation on the sensors.

• Chemical purge for optimized performance and lifetime.

• Pressure compensation for H2O2 concentration (ppm), H2O concentration (ppm), and

relative saturation (%RS) measurement.

• Digital output: RS-485 interface for Modbus communication.

• Analog output: 2 x 4 ... 20 mA (default).

• Easy plug-in, plug-out.

• Can be used as a stand-alone probe or with Vaisala Indigo 200 series transmitters.

• Can be connected to Vaisala Insight software for

temporary online monitoring.

filter over the sensors designed to withstand high air flow rates and turbulence.

configuration, diagnostics, and

More Information

‣

Technical Data (page 41)

2.3

Safety

WARNING!

to minimize shock hazard.

WARNING!

has not been exposed to dangerous contamination, and is safe to handle

without special precautions.

8

Ground the product and verify installation grounding periodically

When returning a product for calibration or repair, make sure it

Page 11

Chapter 2 – Product Overview

CAUTION!

Do not attempt to open the probe body. There are no user

serviceable parts inside the probe body.

2.4 ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to electronic circuits.

Vaisala products are adequately protected against ESD for their intended use. However, it is

possible to damage the product by delivering an electrostatic discharge when touching,

removing or inserting any objects inside the equipment housing.

Avoid touching component contacts or connectors when working with the device.

2.5 Measured Parameters

Table 4 Available Parameters

Parameter Unit

Vaporized hydrogen peroxide concentration by

volume

Relative saturation (RS) (H2O + H2O2) %RS

Relative humidity (RH) (H2O) %RH

Temperature °C

Absolute hydrogen peroxide

Absolute humidity (H2O)

Water concentration by volume ppm

Water vapor pressure hPa

Water vapor saturation pressure hPa

ppm

mg/m

g/m

3

3

The probe provides both digital and analog outputs.

• In digital output mode, the probe outputs all the measurement parameters.

• In analog output mode, the probe outputs the readings of two measurement parameters

(one parameter in each analog output channel). These measurement parameters are

chosen at the time of ordering the probe, and you can change them using Insight

software and via Modbus. The probe is also compatible with Vaisala Indigo transmitters,

which provide the option of three analog output channels.

9

Page 12

%RH%RS

00

100100

H2O

H2O

2

%RS %RH

0 0

100

100

H2O

1 2

HPP272 User Guide M211972EN-B

More Information

‣

Understanding Relative Humidity and Relative Saturation (page 10)

‣

Measurement Data Registers (page 47)

‣

Configuration Registers (page 48)

‣

Connectivity to Vaisala Insight Software (page 12)

‣

Setting Probe in Analog or Digital Mode (page 23)

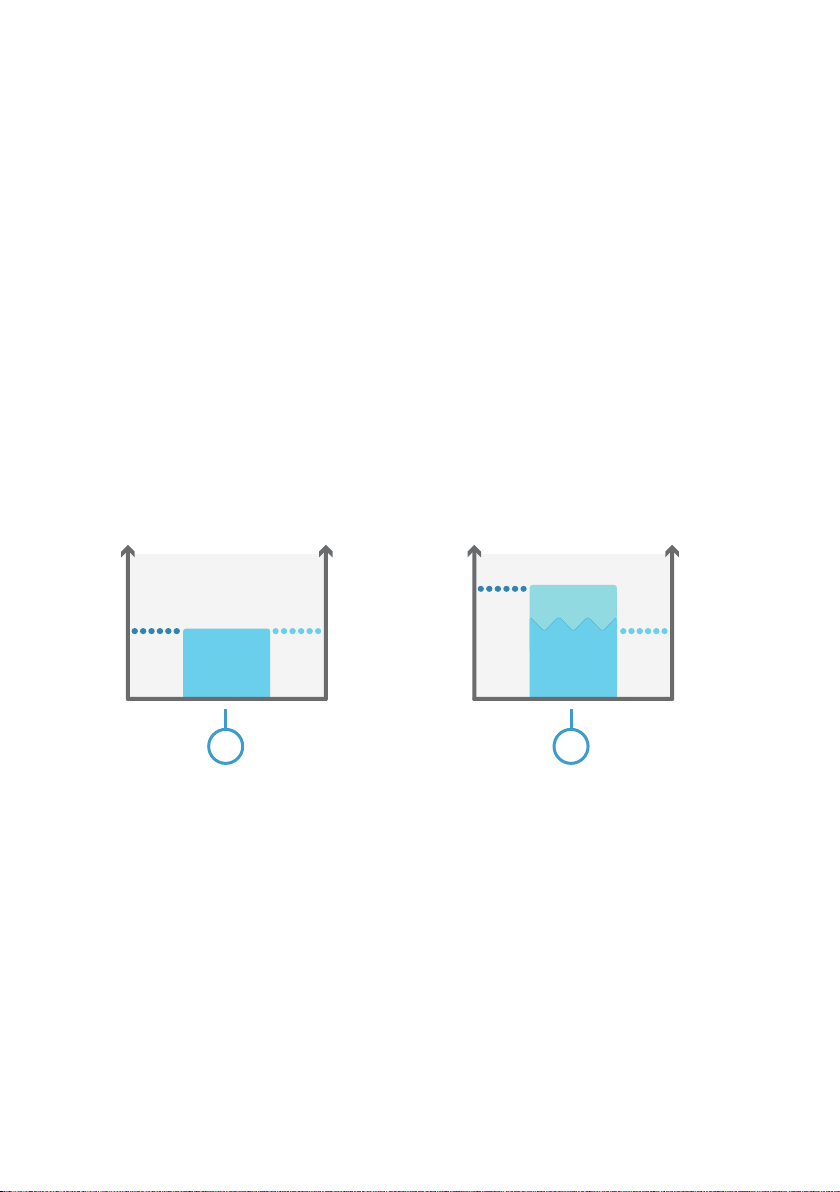

2.5.1 Understanding Relative Humidity and Relative Saturation

Water and hydrogen peroxide have a very similar molecular structure, and they both aect the

humidity of the air in which they are present. HPP272 measurement makes a

between the humidity caused by both H2O2 vapor and water vapor, and the humidity caused

only by water vapor:

• Relative saturation is a parameter that indicates the humidity of the air caused by both

H2O2 vapor and water vapor. When relative saturation reaches 100 %RS, the vapor

mixture starts to condense.

• Relative humidity is a parameter that indicates the humidity of the air caused only by

water vapor.

dierence

Figure 2 Eect of H2O and H2O2 on relative saturation (RS) and relative humidity (RH)

Space without H2O2 vapor. When H2O2 vapor is not present, relative saturation equals

1

relative humidity.

2 Same space with H2O2 vapor introduced. Relative saturation is higher than relative

humidity.

During H2O2 bio-decontamination processes, it is often important to monitor the possibility of

condensation. For this purpose, it is not enough to know the level of relative humidity (RH),

because RH only indicates the humidity caused by water vapor. The possibility of

condensation is

aected by the combined humidity of H2O2 vapor and water vapor, which is

why you need to monitor relative saturation (RS).

10

Page 13

Chapter 2 – Product Overview

2.6 Probe Filter

The white filter on the probe covers the PEROXCAP sensor. The filter is made of porous PTFE

that allows ambient air to reach the PEROXCAP sensor while protecting the sensor in strong or

turbulent air flow.

CAUTION!

broken, dirty, or removed altogether, measurement does not work as intended.

• Do not touch the

use clean gloves (rubber, cotton or similar material).

• Keep the

• Do not touch any parts under the filter. Touching parts under the filter may

damage the sensors.

More Information

‣

Problems and Their Possible Solutions (page 36)

2.7

Chemical Purge

Chemical purge is a 4-minute process where the sensors are heated to remove possible

contamination. The purge is essential for the long-term performance and accuracy of the

probe in demanding H2O2 environments. During the purge, only temperature measurement is

available.

The purge is automatically performed:

• At probe start-up.

• At intervals (default 24 hours,

software, Modbus, or Indigo 200 transmitters). Purge is postponed by 30 minutes if H2O

is present or RH is not steady.

Purge is recommended at least every 24 hours of powered-on time, even if the probe has not

been continuously exposed to H2O2.

Optional: if needed, you can also trigger a purge manually with Modbus (in digital mode) or

pin #5 on the M12 connector (in analog mode).

The filter is an essential part of the measurement. If the filter is

filter with bare hands. If you need to touch the filter, always

filter free of any grease or oil.

configurable between 1 hour ... 1 week using Vaisala Insight

2

More Information

‣

Triggering Purge in Analog Mode (page 27)

‣

Operation in Analog Mode (page 26)

11

Page 14

HPP272 User Guide M211972EN-B

2.8 Environmental Compensation for Pressure

When necessary, you can apply pressure compensation to improve the measurement accuracy

of the probe (probe software v.1.1.0 and later). The probe does not have on-board pressure

measurement, but a pressure reading from an external source can be used as a setpoint value

for compensation.

You can configure the pressure compensation parameters using Vaisala Insight software,

Modbus configuration registers, or an Indigo 200 transmitter.

By default, the pressure compensation is turned o. When the compensation is o, the probe

uses the default compensation value (1013.25 hPa).

Pressure compensation

• H2O2 concentration (ppm)

• H2O concentration (ppm)

• Relative saturation (%RS)

More Information

‣

Vaisala Insight Software (page 28)

‣

Configuration Registers (page 48)

2.9

Measurement Filtering Factor

You can set a filtering factor that aects the speed at which the latest H2O2 and RS

measurements are integrated into the output of the probe. This allows averaging the output if

the measuring environment produces occasional exceptionally high or low readings.

filtering factor can be set either with Modbus configuration register 0308

The

Insight software, or an Indigo 200 transmitter.

By default, the

directly in the output, without any filtering. To apply filtering, enter a lower filtering factor to

include previous measurements in the calculation of measurement output. For example,

changing the

measurement (90%) and the previous measurement output (10%).

filtering factor to 0.9 results in an output that is a combination of the latest

aects the following parameters:

, Vaisala

hex

filtering factor is set to 1.0, which means the latest measurement is shown

More Information

‣

Configuration Registers (page 48)

2.10

Connectivity to Vaisala Insight Software

The probe can be connected to Vaisala Insight software using a Vaisala USB cable (no.

242659). With the Insight software, you can:

• See device information and status.

12

Page 15

Chapter 2 – Product Overview

• See real-time measurement.

• Configure serial communication settings, purge settings, filtering factor, and analog

output parameters and scaling.

More Information

‣

Connecting to Insight Software (page 28)

2.11 Additional Features with Indigo Transmitters

The probes are compatible with Vaisala Indigo 200 transmitters starting from Indigo

transmitter serial number N4650357 (Indigo 200 transmitter software version 1.3.2 or higher).

Connecting the probe to an Indigo transmitter provides a range of additional options for

outputs, measurement viewing, status monitoring, and

Examples of additional features available with Indigo transmitters include:

• 3.5” TFT LCD color display or non-display model with LED indicator

• Digital output or 3 analog outputs (depending on the transmitter model)

• 2 configurable relays

• Wireless browser-based configuration interface for mobile devices and computers (IEEE

802.11 b/g/n WLAN)

The selection of available additional features (for example, output and connectivity options)

varies depending on the Indigo transmitter model. For more information on Indigo

transmitters, see www.vaisala.com/indigo.

More Information

‣

Indigo Overview (page 29)

configuration interface access.

13

Page 16

HPP272 User Guide M211972EN-B

3. H2O2 Measurement

3.1 Operating Principle of H2O2 Measurement

CAUTION!

always be powered on. When powered on, the PEROXCAP sensor is heated,

which permits using the probe in condensing H2O2 conditions, maintains

measurement performance, and lengthens the probe's lifetime. When the probe

is powered o, exposure to H2O2 condensation can break the PEROXCAP sensor

within a day, and the sensor will not recover.

PEROXCAPâ sensor technology works using measurements from two Vaisala HUMICAPâ

sensors. HUMICAP sensors guarantee quality and reliability, with their reputation for

repeatability, accuracy, excellent long-term stability, and negligible hysteresis – even in the

most demanding high-concentration H2O2 applications in atmospheric pressure.

HUMICAP sensor is a

polymer film is deposited between two electrodes. The film absorbs or releases vapor

according to humidity changes in the environment. As the humidity changes, the dielectric

properties of the polymer

instrument’s electronics measure the capacitance of the sensor and convert it into a humidity

reading.

PEROXCAP measurement uses two composite HUMICAP sensors, one with a catalytic layer

and one without. The catalytic layer catalyzes H2O2 from the vapor mixture. Therefore, the

HUMICAP sensor with this layer only senses water vapor, providing a measurement of partial

water pressure, i.e. relative humidity (RH). The sensor without the catalytic layer senses both

hydrogen peroxide vapor and water vapor in the air mixture. The

readings from these two sensors indicates the vapor concentration of H2O2.

When there is H2O2 in the probe's environment, the probe must

thin-film polymer sensor consisting of a substrate on which a thin

film change, and so does the capacitance of the sensor. The

dierence between the

14

Page 17

H20

2

H20

2H20

0

2

2H20

2

H20

2

1

3

2

3

A B

Chapter 3 – H2O2 Measurement

Figure 3 Operating principle of PEROXCAP measurement

HUMICAP sensor with a catalytic layer (under the probe filter). This sensor only senses

A

water vapor.

B HUMICAP sensor without a catalytic layer (under the probe filter). This sensor senses the

air mixture with both hydrogen peroxide vapor and water vapor.

1 Catalytic layer over the thin film polymer. This layer catalyzes hydrogen peroxide into

water and oxygen and prevents it from entering the sensing polymer.

2 Thin film polymer between two electrodes.

3 Alumina substrate.

In addition to measuring vaporized H2O2 concentration, HPP272 provides measurement for

relative saturation, relative humidity, and temperature. Relative humidity (RH) is a parameter

that indicates the humidity value derived from water vapor only, whereas relative saturation

(RS) indicates the humidity percentage derived from water vapor and H2O2 vapor together.

When relative saturation reaches 100 %RS, the vapor mixture starts to condense.

15

Page 18

HPP272 User Guide M211972EN-B

3.2 Typical Applications

The probe is not intended for safety level measurement.

The probe is not intended to be used in vacuum applications.

Vaporized hydrogen peroxide is used for bio-decontamination in several applications from

healthcare and pharmaceutics to food and beverage industry. Vaporized hydrogen peroxide is

an easy-to-use and eective bio-decontaminating agent that destroys the full spectrum of

biological contaminants including micro-organisms such as bacterial spores, mycobacteria,

and non-enveloped, non-lipid viruses. Bio-decontamination with vaporized hydrogen peroxide

is a low-temperature, environmentally friendly process that leaves no real residues, only water

vapor and oxygen. One of the

validated.

Common vaporized H2O2 bio-decontamination applications include isolators, transfer hatches,

closed Restricted Access Barrier Systems, and room bio-decontamination (for example, in

hospital environments, cleanrooms, decontamination tents, aircrafts, ships, and shipping

containers).

The bio-decontamination process typically has the following phases:

1. Optional dehumidification, where relative humidity is decreased to a desired level, for

example, by warming the space.

2. Conditioning, where vaporized H2O2 mixture is introduced into the space to be biodecontaminated.

3. Decontamination, where H2O2 concentration is maintained at a desired level for a certain

time.

4. Aeration, where H2O2 is removed from the bio-decontaminated space.

benefits also is that the bio-decontamination process can be

16

Page 19

100%

0%

More

Less

Cycle Phase

Aeration

Decontamination

Conditioning

Dehumidification

CONDENSATION POINT

RELATIVE

SATURATION (RS)

RELATIVE HUMIDITY (RH)

VAPORIZED HYDROGEN

PEROXIDE CONCENTRATION

Humidity

H2O

2

Concentration

Chapter 3 – H2O2 Measurement

Figure 4 Example behavior of H2O2 concentration, relative saturation (RS), and relative humidity

(RH) in a vaporized H2O2 bio-decontamination cycle (non-condensing conditions)

In the non-condensing bio-decontamination cycle example shown in Figure 4 (page 17):

• In the dehumidification phase, RH (and RS) decreases.

• When the conditioning phase starts, H2O2 concentration rises rapidly. There is also a rapid

increase in RS, which indicates the humidity caused by both H2O2 vapor and water vapor.

Because the generated H2O2 vapor is typically mixed with water vapor, RH also starts to

rise.

• In the decontamination phase, H2O2 concentration is steady. However, RS level rises slowly

close to 100 %RS, i.e. condensation point, due to rising RH level.

• In the aeration phase, H2O2 concentration, RS, and RH all decrease. When H2O

2

concentration is zero, RS equals RH.

The way your bio-decontamination process is designed

measure in dierent phases.

Depending on your bio-decontamination process, you may also want to either create or avoid

condensation during the conditioning and decontamination phases. In these phases, the air in

the bio-decontaminated space always contains both water and H2O2 vapor, which both

the possibility of condensation. To monitor and control whether and when condensation

forms, it is useful to know the combined humidity level of water vapor and H2O2 vapor: relative

aects which parameters you want to

saturation (RS). When relative saturation reaches 100 %RS, the vapor mixture starts to

condense.

aect

17

Page 20

Temperature

Relative saturation

21 21.5 22 22.5

100

95

85

90

H2O2 = 500 ppm

H2O = 8850 ppm

HPP272 User Guide M211972EN-B

For condensation monitoring, choosing the right measurement location is very important. If

the bio-decontaminated space has surfaces with a lower temperature than where RS is

measured, condensation may start to form on those surfaces even before RS reaches 100 %RS

in the exact measurement location. To monitor the possibility of condensation, consider

installing the probe close to a surface where you suspect condensation may form.

More Information

‣

Understanding Relative Humidity and Relative Saturation (page 10)

‣

Installation (page 20)

3.3 Condensation Monitoring

H2O+H2O2 vapor mixture starts to condense when relative saturation (RS) reaches 100 %RS.

RS level is strongly aected by temperature: decreasing the temperature increases RS. If there

are temperature

that space even if the H2O+H2O2 vapor is evenly distributed.

dierences in the bio-decontaminated space, RS varies in dierent parts of

Figure 5 Example: RS behavior in dierent temperatures when H2O2 concentration (500 ppm) and

H2O concentration (8850 ppm) are constant

For condensation monitoring, this means that even if you measure < 100 %RS in one point, RS

may be 100 %RS in another, cooler point. The following

can vary in a decontaminated space according to temperature dierences.

18

figure shows an example of how RS

Page 21

3

1

2

T= 21.5 ˚C

RS= 94.5 %RS

T= 22 ˚C

RS= 89.5 %RS

T= 21 ˚C

RS= 100 %RS

Chapter 3 – H2O2 Measurement

Figure 6 Decontaminated space with dierent temperatures and RS levels (H2O2 and H2O

concentration evenly distributed)

1 Center of the decontaminated space. The center is warmer than the wall and the window,

and the RS level is lower.

2 Wall of the decontaminated space. Because the wall is 0.5 °C cooler than the center of the

space, RS level is higher than in the center.

3 Window of the decontaminated space. The window is 1 °C cooler than the center of the

space, and RS = 100 %RS. Condensation starts to form on the window surface.

Condensation forms typically on surfaces, and first on surfaces that are cooler than the

surrounding air, such as:

To monitor the possibility of condensation by measuring RS, it is recommended to measure as

close as possible to places where condensation might occur.

• Walls

• Windows

• Supplies that have just been brought in the decontaminated space

19

Page 22

HPP272 User Guide M211972EN-B

4. Installation

Accurate RH and RS measurement requires both humidity and temperature data from the

same environment. Install the H2O2 and humidity probe and the temperature probe in the

same measurement environment and temperature, approximately 6 ... 10 cm apart from each

other. Do not install the temperature probe directly above the H2O2 and humidity probe, as

moderate heat rising up from the H2O2 and humidity probe body may aect the ambient

temperature around the temperature probe.

When you choose the installation location for the probe, consider the following:

• Choose a location that represents the environment and process you want to measure.

Some factors may make a location unrepresentative of the process:

• Heat sources

• Materials that absorb H2O2, such as several plastics, rubbers and sealing materials

• Limited air

• The probes withstand bio-decontamination process conditions. For signal cables, you

must verify their suitability in the installation environment.

• The probes withstand high air flow rates.

• For condensation monitoring with relative saturation, consider installing the probe close

to a surface where condensation may form (typically, on cooler surfaces in the biodecontaminated space).

• The probe is intended for use in atmospheric pressure. Do not install the probe in a

vacuum.

When there is H2O2 in the probe's environment, the probe must always be powered on. When

powered on, the PEROXCAP sensor is heated, which permits using the probe in condensing

H2O2 conditions, maintains measurement performance, and lengthens the probe's lifetime.

flow

20

CAUTION!

broken, dirty, or removed altogether, measurement does not work as intended.

• Do not touch the

use clean gloves (rubber, cotton or similar material).

• Keep the

• Do not touch any parts under the filter. Touching parts under the filter may

damage the sensors.

The filter is an essential part of the measurement. If the filter is

filter with bare hands. If you need to touch the filter, always

filter free of any grease or oil.

Page 23

6 ... 10 cm

≤ 6 mm

Ø 40 mm

Ø 8 mm

1

2

4 cm

(recommended)

6 ... 10 cm

Chapter 4 – Installation

Example: Installation Through a Wall

A through-wall installation is

recommended especially in very harsh

processes.

Seal the lead-throughs on the metal body

of the probes.

The figure shows an example installation

using Vaisala spare part glands

(HPP272MOUNTINGSET1).

1 Nut for tightening the probe in place

2 Nut for mounting the gland

Example: Installation Entirely in Process Environment

Mount the H2O2 and humidity probe from

the probe body.

Mount the temperature probe from the

metal body. Note that the temperature

sensor is at the tip of the temperature

probe.

Let the signal cable hang loosely so that it

makes a bend. This prevents condensing

water from running to the probe along the

cable. Do not hang the probe by the signal

cable.

Make sure the signal cable you

use is suitable for your biodecontamination process.

21

Page 24

1

5

3

4

2

HPP272 User Guide M211972EN-B

4.1 Wiring

Figure 7 Probe M12/5 Pins

Pin # Function Notes Wire

1 Power supply With digital output: 15 ... 30 VDC

With analog output: 15 ... 25 VDC

When using analog outputs, it is recommended to

use a low supply voltage to minimize self-heating

and maximize measurement performance.

2 RS-485- or analog

output 2

3 Power and signal GND Blue

4 RS-485+ or analog

output 1

5 Output control and purge

trigger in analog mode

1) Wire colors apply to the following cables: 223263SP, 26719SP, 26720SP, 216546SP,

244669SP

2) The ordered parameters and scaling are shown in the calibration certificate delivered with

the probe.

Current output: 4 … 20 mA (default).

Current output: 4…20 mA (default)

Floating = RS-485

Grounded = Analog outputs

If you want to be able to trigger a purge manually in

the analog mode, do not connect pin #5

permanently to ground, but instead, use a relay or

similar to control the pin.

2)

2)

Color

1)

Brown

White

Black

Grey

22

Page 25

PLC

DC power

supply

IN+ Current input

IN-

IN+ Current input

IN-

Relay/switch

control

+

-

Pin #1

(Power supply)

Pin #2

(Analog output 2)

Pin #3

(Power and signal

GND)

Pin #4

(Analog output 1 )

Pin #5

(Output control

and purge trigger

in analog mode)

HPP270 series

probe

Figure 8 Wiring Example for Connecting HPP272 to a PLC in Analog Mode

More Information

‣

Accessories (page 44)

‣

Triggering Purge in Analog Mode (page 27)

4.2

Power Supply

Chapter 4 – Installation

Operating voltage range of the probe:

Maximum current consumption at 25 °C:

4.3

The probe has two output modes: digital mode (RS-485 using Modbus) and analog mode

(current output).

Both the digital output and analog output use the same pins in the M12 male connector (pins

#2 and #4), but only one of the output modes can be active at the same time. You select which

output mode is active with the output control pin #5.

• With digital output: 15 ... 30 VDC

• With analog output: 15 ... 25 VDC

• With digital output: 15 mA

• With analog output: 50 mA

• During purge: 200 mA

Setting Probe in Analog or Digital Mode

23

Page 26

1

5

3

4

2

HPP272 User Guide M211972EN-B

Figure 9 Pins on the M12 male connector

1. If the probe is powered on, power o the probe.

2. Select the output mode with pin #5:

a. To set the probe in analog mode, connect pin #5 to ground.

b. To set the probe in digital mode, leave pin #5

3. Power on the probe. The probe checks the state of pin #5 (grounded or floating) and goes

in the selected output mode.

floating.

24

Page 27

Chapter 5 – Operation

5. Operation

5.1 Probe Start-Up

When powered on, the probe starts up within 2 seconds and the digital/analog outputs are

activated. The probe performs a start-up purge, which takes approximately 4 minutes. During

the purge, hydrogen peroxide, relative humidity, and relative saturation measurements are not

available. If the probe is in analog mode, analog outputs are in the error state (default: 3.6 mA)

during the purge.

Measurements from the outputs (digital and analog) will reach

minute warm-up period. For this reason, you should design your system so that it does not rely

on measurements from the probe during this time.

More Information

‣

Behavior at Exposure to H2O2 (page 25)

5.2

Behavior at Exposure to H2O

specified accuracy after a 8½-

2

CAUTION!

always be powered on. When powered on, the PEROXCAP sensor is heated,

which permits using the probe in condensing H2O2 conditions, maintains

measurement performance, and lengthens the probe's lifetime. When the probe

is powered o, exposure to H2O2 condensation can break the PEROXCAP sensor

within a day, and the sensor will not recover.

When the bio-decontamination process starts and the probe is exposed to H2O2, the probe's

H2O2 concentration reading changes to > 0 ppm after approximately 20 ... 30 seconds. This

time is included in the response time of the probe.

5.3

H2O2 Concentration Reading When Not

Exposed to H2O

The PEROXCAP sensor consists of two humidity sensors that have a minor dierence in

behavior when the humidity level changes. Because of this

reading may vary slightly (typically 0 … 3 ppm) when the probe is not exposed to H2O2. This

variation is normal and does not require any actions. If needed, you can hide the variation by

setting a low clipping limit with the Vaisala Insight software, Modbus

030C

, or an Indigo 200 transmitter. For example, if you set the low clipping limit to 3 ppm,

hex

any reading < 3 ppm is clipped to show 0 ppm.

When there is H2O2 in the probe's environment, the probe must

2

dierence, the H2O2 concentration

configuration register

25

Page 28

HPP272 User Guide M211972EN-B

More Information

‣

Vaisala Insight Software (page 28)

‣

Configuration Registers (page 48)

5.4 Modbus

The probe can be accessed using the Modbus serial communication protocol. The supported

Modbus variant is Modbus RTU (Serial Modbus) over RS-485 interface.

More Information

‣

Modbus Reference (page 45)

‣

Setting Probe in Analog or Digital Mode (page 23)

5.5

Operation in Analog Mode

In analog output mode, the probe outputs the readings of two measurement parameters (one

parameter in each analog output channel). These measurement parameters are chosen at the

time of ordering the probe, and you can change them using Insight software and via Modbus.

You can check the chosen parameters in the calibration

The default output range for both channels is 4 ... 20 mA.

When using analog outputs, it is recommended to use a low supply voltage to minimize selfheating and maximize measurement performance. The operating voltage range with analog

output is 15 ... 25 V.

When the probe performs the chemical purge, the analog outputs have a defined behavior:

• During start-up purge, analog output is in the error state (default: 3.6 mA).

• During interval purge and manually triggered purge, output is frozen to show the last

measured value before the purge began.

certificate delivered with the probe.

More Information

‣

Setting Probe in Analog or Digital Mode (page 23)

‣

Analog Output Error State (page 40)

‣

Configuration Registers (page 48)

‣

Chemical Purge (page 11)

5.5.1 Analog Output Overrange Behavior

If the values measured by the probe are outside the scaled analog output range, the analog

output goes in the error state. The default error state is 3.6 mA.

26

Page 29

Chapter 5 – Operation

More Information

‣

Analog Output Error State (page 40)

5.5.2 Triggering Purge in Analog Mode

In the analog mode, pin #5 in the probe's M12 male connector is connected to ground.

Additionally, pin #5 is used to trigger a purge in analog mode. To be able to trigger a purge, do

not connect pin #5 to ground permanently, but instead, use a relay or similar to control the pin.

For a wiring example, see Figure 8 (page 23).

1. To trigger the purge, disconnect pin #5 from ground for a minimum of 50 ms, and then

reconnect the pin to ground.

Do not leave pin #5 floating for a long time. If the probe is reset while pin #5

is floating, the probe will go into digital mode instead of analog mode.

The probe starts performing the purge. The duration of the purge is approximately 4 minutes.

During the purge, hydrogen peroxide, relative saturation, and relative humidity measurements

are not available.

27

Page 30

HPP272 User Guide M211972EN-B

6. Vaisala Insight Software

Vaisala Insight software is a configuration software for Indigo-compatible probes. The

supported operating systems are Windows 7 (64-bit), Windows 8.1 (64-bit), and Windows 10

(64-bit).

With the Insight software, you can:

• See device information and status.

• See real-time measurement.

Configure serial communication settings, purge settings, filtering factor, and analog

•

output parameters and scaling.

• Calibrate and adjust the device.

Download Vaisala Insight software at www.vaisala.com/insight.

The probe can be connected to Vaisala Insight software using a Vaisala USB cable (no.

242659).

6.1

Connecting to Insight Software

• Computer with Insight software installed

• USB connection cable (no. 242659)

Figure 10 Connecting Probe to Insight

1. Open the Vaisala Insight software.

2. Connect the USB cable to a free USB port on the PC.

3. Connect the probe to the USB cable.

4. Wait for the Insight software to recognize and identify the probe.

28

Page 31

1

5

4

2

3

Chapter 7 – Using Probe with Indigo Transmitters

7. Using Probe with Indigo Transmitters

7.1 Indigo Overview

1 3.5” TFT LCD color display: non-display option with LED available for certain models.

2 Cable locking wheel: insert cable, hold in place, and turn the wheel counterclockwise.

3 Wireless configuration interface (WLAN) activation button.

4 Rubber lead-through with strain relief. Cable feedthrough option also at back of

transmitter.

5 Input/output cable.

The probe can be connected to Vaisala Indigo transmitters by using a cable.

29

Page 32

HPP272 User Guide M211972EN-B

Indigo transmitters are host devices that extend the feature set of connected probes with a

range of additional options for outputs, configuration access, measurement viewing, and

status monitoring.

The selection of available additional features (for example, output and connectivity options)

varies depending on the Indigo transmitter model. Depending on the model, a display is

available as an optional selection or as a standard feature. In the non-display model, an LED

indicator is used for notifications.

7.1.1 Wireless Configuration Interface Overview

The wireless configuration interface has two user levels:

• All users have view-only access (no configuration rights, not password protected).

• Personnel that carry out configuration tasks can log in with an administrative password

that allows changing the transmitter and probe settings.

To use the wireless configuration interface to modify the settings of your Indigo transmitter

and the connected probe, you must

connect to Indigo with your mobile device or computer. Most major browsers (for example,

Firefox, Chrome, Safari, and Internet Explorer) are supported: using the most recent version is

recommended.

first enable the transmitter's wireless connection and then

30

Page 33

7.2 Attaching Probes

Chapter 7 – Using Probe with Indigo Transmitters

Figure 11 Attaching Probes to Indigo

1. Connect the cable to the probe.

2. Insert the other end of the cable in Indigo's cable connector and lock it in place by turning

the locking wheel counterclockwise. Do not turn the cable connector when attaching the

cable, only the locking wheel on the transmitter.

3. When Indigo recognizes the connected probe, it shows a

display.

notification message on the

31

Page 34

435

ppm

HO

74.2

%RS

RS (HO+HO)

32.4

°C

T

WLAN is activated

Indigo 201

2

1

Select WLAN to connect to:

2. Indigo_IDxx

3

HPP272 User Guide M211972EN-B

7.3 Connecting to Wireless Configuration

Interface

Figure 12 Enabling and Accessing Indigo's Wireless Configuration Interface

1 Wireless connection activation button

2 Wireless connection indicator (WLAN symbol) on the Indigo display

3 Choose Indigo (Indigo_ID[xx]) from your wireless device's list of available connections

To connect to the wireless configuration interface:

1. Press the wireless connection activation button on the bottom of the transmitter.

2. When the wireless configuration interface becomes available, the Indigo display shows a

connection notification. In the Indigo models with an LED indicator, the LED blinks green

when the connection is active.

3. Open the wireless connection menu in your mobile device or computer and select

Indigo_ID[xx] (transmitter-specific SSID) from the list of available connections.

4. Depending on your device, the wireless

automatically in your browser after you connect to Indigo, or you may need to start your

browser application manually.

5. When you open the Indigo interface in your browser, you are prompted to log in.

configuration interface either launches

Only one device can be connected to the wireless configuration interface at a

time.

32

Page 35

Chapter 7 – Using Probe with Indigo Transmitters

7.4 Logging in to Wireless Configuration Interface

Figure 13 Indigo Login View

When you open Indigo's wireless configuration interface in your browser, you are prompted to

log in. There are 2 available user levels:

• User: view-only access available for all users. Does not require a password.

• Admin: password-protected access. To change settings, you must log in as admin.

To log in:

1. Enter the user name and password:

a. To log in as user (view-only access, no

User name dropdown. Leave the Password field empty.

b. To log in as admin (required for

dropdown and type the admin password (default: 12345) in the Password field.

2. Select Log in after entering the login credentials. The wireless configuration interface

opens in the Measurements view.

The user level (User or Admin) is shown in the upper right corner of all menu

views.

Select the user/admin icon in the upper right corner to change the user level.

configuration rights), select User from the

configuration), select Admin in the User name

33

Page 36

HPP272 User Guide M211972EN-B

8. Maintenance

8.1 Cleaning the Probe

Do not remove the filter.CAUTION!

Do not attempt to clean the sensors under the filter in any way.CAUTION!

Avoid exposing the probe to cleaning agents for unnecessarily long periods of

time.

You can clean the H2O2 and humidity probe body and temperature probe body and cable by

wiping them with a soft, lint-free cloth moistened with water or mild cleaning agent, such as

isopropanol. Do not wipe the filter: wiping the filter may block its pores and/or deposit residue

on the filter. If the filter is heavily contaminated, replace it.

When cleaning, follow these precautions:

• Avoid touching the filter. If you need to touch the filter, always wear clean gloves (cotton,

rubber, or similar material). Keep the

• Do not scrape the probe body.

• Do not immerse the probe in liquid to clean it.

• Wipe cleaning agents

If needed, you can spray the probe surfaces with water.

After cleaning the probe, it is recommended to perform a chemical purge.

o the probe after cleaning.

filter free of any grease or oil.

8.1.1 Chemical Tolerance

Avoid exposing the probe to chemicals for unnecessarily long periods of time. Do

not immerse the probe in a chemical, and wipe chemicals o the probe after

exposure.

You can use mild cleaning agents, such as isopropanol, to wipe the probe body. Avoid

exposing the

The probe does not withstand DMSO (dimethyl sulfoxide C2H6OS).

After exposing the probe to chemicals, it is recommended to perform a chemical purge.

34

filter to chemicals.

Page 37

Chapter 8 – Maintenance

More Information

‣

Chemical Purge (page 11)

‣

Triggering Purge in Analog Mode (page 27)

8.2 Calibration and Adjustment

The probe is fully calibrated and adjusted as shipped from the factory. A typical calibration

interval is 1 year, depending on how frequently and long your probe is exposed to vaporized

H2O2.

Calibration and adjustment is performed by Vaisala. For contact information, visit

www.vaisala.com/calibration.

35

Page 38

HPP272 User Guide M211972EN-B

9. Troubleshooting

9.1 Problems and Their Possible Solutions

If you have a problem with using the probe, check the following tables before contacting

Vaisala. If the problem you have is not listed in the tables, or if the proposed solution does not

fix the problem, contact Vaisala technical support.

You can check the probe diagnostics and status with the Insight software and Modbus status

registers (see Status Registers (page 54)).

Problem: Response time is slower than specified.

Possible Cause: Solution:

The filter is blocked. Change the filter.

Be careful not to touch the sensors when the filter is o the

probe.

The probe has fallen and the

filter has hit the floor.

The probe has been exposed to

unsuitable chemicals (for

example, DMSO).

The measurement filtering

factor is configured to be too

slow.

The ambient temperature has

changed quickly, which may

result in a slower change in RH

reading.

Remove the filter and visually check the sensors.

• If the sensors are bent, broken, or disconnected, contact

Vaisala technical support.

• If the sensors are intact, change the filter. The filter is made of

porous material, and if the filter hits the floor, the filter material

may get pressed and become less permeable. This reduces the

rate at which air

the measurement.

Be careful not to touch the sensors when the

probe.

Change the filter and perform a chemical purge.

Be careful not to touch the sensors when the filter is o the

probe.

Use the Vaisala Insight software, Modbus configuration register

030A

, or an Indigo 200 transmitter to disable the filtering

hex

factor (set filtering factor to "1"), and check the measurement

again. See:

• Measurement Filtering Factor (page 12)

• Vaisala Insight Software (page 28)

•

Configuration Registers (page 48)

No actions required.

flows in and out of the filter, directly aecting

filter is o the

36

Page 39

Chapter 9 – Troubleshooting

Problem: H2O2 or humidity reading does not change during regular use for less than 5 minutes.

Possible Cause: Solution:

Purge is being performed

No actions required.

(duration of the purge is 4

minutes).

Problem: H2O2 or humidity reading does not change during regular use for more than 5 minutes.

Possible Cause: Solution:

In analog mode: The scaling of

the output is unsuitable,

Check and change the analog output scaling with Insight

software (see Vaisala Insight Software (page 28)).

preventing the change from

showing.

In analog mode: The error level

is configured within the

measurement output level, and

the probe is in error state.

Problem: Measurement reading appears incorrect.

Check the probe diagnostics with the Insight software (see

Vaisala Insight Software (page 28)).

Consider changing the analog output error level to be outside the

measurement scale.

Possible Cause: Solution:

The temperature probe is

installed near a heat source or

Change the location of temperature probe. See Installation

(page 20) for recommended installation locations.

too close to the H2O2 and

humidity probe.

The filter is wet. Remove the filter, pour out any water, and let the filter dry.

Depending on air humidity and temperature, drying the filter in

ambient air can take from a few hours to a day. Alternatively, you

can dry the removed filter with nitrogen gas or dry pressurized

air. When the filter is dry, reinstall the filter.

Be careful not to touch the sensors when the filter is o the

probe.

Perform a chemical purge.

The filter is blocked or dirty. Change the filter.

Be careful not to touch the sensors when the filter is o the

probe.

Condensation has formed on

the sensor when the probe was

powered o.

When the probe is powered o, exposure to H2O2 condensation

can break the PEROXCAP sensor within a day, and the sensor will

not recover. When the probe is powered on, the heated sensor

withstands condensing H2O2 conditions.

A sensor damaged with H2O2 condensation during power-o

time cannot be repaired.

37

Page 40

HPP272 User Guide M211972EN-B

Problem: Measurement reading appears incorrect.

The filter is not installed on the

probe.

The yellow transport cap is still

on the probe.

Do not use the probe without the filter. Install the filter on the

probe.

Remove the yellow transport cap when measuring with the

probe.

The filter is broken. Do not use the probe if the filter is broken. Remove the filter and

visually check the sensors:

• If the sensors are bent, broken, or disconnected, contact

Vaisala technical support.

• If the sensors are intact, change the filter.

Be careful not to touch the sensors when the filter is o the

probe.

In analog mode: Maximum load

has been exceeded.

Check the analog output load, and reduce it to the specified

maximum load or less. See Table 6 (page 42) for the permitted

maximum load.

Ambient pressure is not normal

atmospheric pressure.

Problem: The filter is wet.

Check the ambient pressure. See Table 8 (page 43) for the

permitted operating pressure.

Possible Cause: Solution:

Sprayed water has entered the

filter when cleaning the probe.

Remove the filter, pour out any water, and let the filter dry.

Depending on air humidity and temperature, drying the filter in

ambient air can take from a few hours to a day. Alternatively, you

can dry the removed filter with nitrogen gas or dry pressurized

air. When the filter is dry, reinstall the filter.

Be careful not to touch the sensors when the filter is o the

probe.

Perform a chemical purge.

Problem: The filter is broken.

Possible Cause: Solution:

The probe has fallen or an

object has hit the filter.

Do not use the probe if the filter is broken. Remove the filter and

visually check the sensors:

• If the sensors are bent, broken, or disconnected, contact

Vaisala technical support.

• If the sensors are intact, change the filter.

Be careful not to touch the sensors when the filter is o the

probe.

38

Page 41

Chapter 9 – Troubleshooting

Problem: H2O2 concentration reading shows > 0 ppm even though the probe is not exposed to H2O2.

Possible Cause: Solution:

Normal variation due to a slight

No actions required.

dierence in behavior between

the two humidity sensors.

If the reading remains > 0 ppm

for 2 ... 10 hours, H2O

2

concentration has drifted.

The intelligent measurement algorithm can correct errors of

< 30 ppm by itself when the probe is not exposed to H2O2. Keep

the probe powered on for a few hours in a stable temperature

and RH, not exposed to H2O2.

Problem: The probe does not power on, or there is no communication from the probe after power-on.

Possible Cause: Solution:

Power input to the probe is o. Turn on the power input to the probe.

Probe wiring is incorrect. Check the probe wiring and correct it if needed. See Wiring

(page 22).

The probe cable is not properly

Check the cable connection and correct it if needed.

connected.

The operating voltage is

incorrect.

In digital mode: The

communication settings (for

example the device address)

are incorrect either in the probe

Check the operating voltage and correct if needed. See Table 6

(page 42) for the correct voltage.

Check the communication settings. You can check the probe's

communication settings with the Insight software. See

• Vaisala Insight Software (page 28)

or in the system where the

probe is connected.

Problem: In analog mode, there is no output signal (signal level is 0 mA).

Possible Cause: Solution:

Pin #5 was floating at start-up

Check pin #5. See Wiring (page 22).

or reset, which means the

probe is in digital mode.

Analog outputs are configured

to be o.

Check the analog output mode with the Insight software or

Modbus configuration registers 0700

and 0800

hex

hex

. See:

• Vaisala Insight Software (page 28)

• Configuration Registers (page 48)

Probe wiring is incorrect. Check the probe wiring and correct it if needed. See Wiring

(page 22).

The operating voltage is

incorrect.

Check the operating voltage and correct if needed. See Table 6

(page 42) for the correct voltage.

39

Page 42

HPP272 User Guide M211972EN-B

Problem: In analog mode, there is no output signal (signal level is 0 mA).

The probe cable is not properly

connected.

Power input to the probe is o. Turn on the power input.

The analog output error level is

configured to be 0 mA, and the

probe is performing start-up

purge or is in error state.

Problem: At start-up in analog mode, the probe remains in the error state for over 5 minutes.

Possible Cause: Solution:

The analog output scaling is

unsuitable. For example, the

scale 0 ... 5 %RH is too narrow

compared to the full

measurement scale of RH.

There is a probe or sensor error. Check the probe diagnostics with the Insight software (see

Problem: In analog mode, start-up purge is not performed.

Possible Cause: Solution:

The probe is in digital mode at

start-up (pin #5 is floating).

Check the cable connection and correct it if needed.

Wait for 5 minutes for the possible start-up purge to finish. If the

output remains 0 mA after 5 minutes, check the probe

diagnostics with the Insight software (see Vaisala Insight

Software (page 28)).

Check the analog output scaling with the Insight software and

correct the scaling if needed (see Vaisala Insight Software

(page 28)).

Vaisala Insight Software (page 28)).

Check pin #5. See Wiring (page 22).

9.2 Analog Output Error State

The probe sets the analog output channel into a defined error level instead of the measured

result in three situations:

• Probe is performing start-up purge (duration 4 minutes).

• Probe detects a measurement malfunction. This means an actual measurement problem,

such as sensor damage, or unsuitable environmental conditions.

• Measured value(s) are outside the scaled output range.

The default error level for the analog outputs is 3.6 mA. You can change the error level (range

0 ... 25 mA) with the Insight software and via Modbus (registers 0706

More Information

‣

Configuration Registers (page 48)

40

and 0806

hex

hex

).

Page 43

Chapter 10 – Technical Data

10. Technical Data

Table 5 Measurement Performance

Property Description/Value

Hydrogen Peroxide

Sensor PEROXCAPâ

Measurement range 0 ... 2000 ppm

Measurement temperature range +5 ... +50 °C (+41 ... +122 °F)

Repeatability at +25 °C (+77 °F), 500 ppm H2O

2

Accuracy (including non-linearity, hysteresis, and

repeatability) at +25 °C (77 °F), 10 ... 2000 ppm H2O

Factory calibration uncertainty, at +25 °C (+77 °F), 500

ppm H2O2

1)

Response time at +23 °C (+73 °F), still air:

T

63

T

90

Relative Saturation

Measurement range 0 ... 100 %RS

Measurement temperature range +5 ... +50 °C (+41 ... +122 °F)

Repeatability at +25 °C (+77 °F), 500 ppm H2O

2

Accuracy (including non-linearity, hysteresis, and repeatability) at +25 °C (+77 °F):

at 0 ppm H2O

at 500 ppm H2O

Factory calibration uncertainty, at +25 °C (+77 °F), 500

ppm H2O2

2

2

1)

Relative Humidity

Measurement range 0 ... 100 %RH

Measurement temperature range +5 ... +70 °C (+41 ... +158 °F)

Accuracy (including non-linearity, hysteresis, and repeatability):

at 0 ppm H2O2, 0 ... 60 %RH, +25 °C (77 °F) ±1 %RH

at 0 ppm H2O2, 0 ... 95 %RH, over temperature range ±2 %RH

at 500 ppm H2O2, 0 ... 95 %RH, +25 °C (77 °F) ±2 %RH

±20 ppm

±10 ppm or 5 % of reading (whichever

is greater)

2

±10 ppm

120 s

200 s

±0.5 %RS

±2 %RS

±6 %RS

±2 %RS

41

Page 44

HPP272 User Guide M211972EN-B

Property Description/Value

Factory calibration uncertainty, at +25 °C (77 °F), 0 ppm H2O2:

1)

at 0 … 40 %RH ±0.6 %RH

at 40 … 95 %RH ±1 %RH

Temperature

Sensor Pt-1000 RTD Class F0.1

Accuracy over temperature range ±0.2 °C (±0.36 °F)

Other Parameters

Absolute H2O2, absolute H2O, H2O ppm by volume, saturation vapor pressure

1) Defined as ±2 standard deviation limits. See also calibration certificate.

Table 6 Inputs and Outputs

Property Description/Value

Operating voltage With digital output: 15 ... 30 VDC

With analog output: 15 ... 25 VDC (use lowest available

operating voltage to minimize heating)

Current Consumption at +25 °C (+77 °F)

In digital mode Max. 15 mA

In analog mode Max. 50 mA

During purge Max. 200 mA

Digital Output

Interface RS-485, not isolated, no line termination

Bit rate 9600, 19200 (default), 38400, 57600, or 115200 bps

Parity None (default), even, odd

Data bits 8

Stop bits 1, 2 (default)

Communication protocol Modbus RTU v.1.02

Analog Output

Outputs 2 × 4 ... 20 mA 3-wire current outputs

Max. load 500 Ω

42

Page 45

118.3

44

Ø=18.5

69.8, Ø=4.8

38.5

Ø=30

400

22

Ø=16/18.5

mm

Chapter 10 – Technical Data

Table 7 Mechanical Specifications

Property Description/Value

Weight 130 g

IP rating IP65

Connector M12/5 male

Materials

Probe body AISI316L stainless steel

Filter cap Porous PTFE

Temperature probe AISI316L stainless steel

Temperature probe cable PTFE

Table 8 Operating Environment

Property Description/Value

Operating temperature +0 ... +70 °C (+32 ... +158 °F)

Storage temperature -20 ... +70 °C (-4 ... +158 °F)

Ambient pressure Normal atmospheric pressure

EMC compliance EN61326-1, Controlled Environment

10.1 Dimensions

Figure 14 HPP272 Dimensions

43

Page 46

HPP272 User Guide M211972EN-B

10.2 Accessories

Table 9 Spare Parts and Accessories

Name Order Code

USB cable for PC connection 242659

Probe cable with open wires (1.5 m) 223263SP

Probe cable with open wires (3 m) 26719SP

Probe cable with open wires (5 m) 26720SP

Probe cable with open wires (10 m) 216546SP

Probe cable with open wires and 90° plug (0.6 m) 244669SP

Filter DRW246363SP

Gland set for through-wall installation, HPP272 HPP272MOUNTINGSET1

Transmitters

Indigo 200 series See www.vaisala.com/indigo

Connection cable to Indigo (1 m) INDIGOCABLE1M

Connection cable to Indigo (3 m) INDIGOCABLE3M

Connection cable to Indigo (5 m) INDIGOCABLE5M

Connection cable to Indigo (10 m) INDIGOCABLE10M

44

Page 47

Appendix A – Modbus Reference

Appendix A. Modbus Reference

A.1 Default Communication Settings

Table 10 Default Modbus Serial Communication Settings

Description Default Value

Serial bit rate 19200

Parity N

Number of data bits 8

Number of stop bits 2

Modbus device address 240

A.2 Function Codes

Table 11 Modbus Function Codes

Function Code

(Decimal)

03 03

16 10

43 / 14 2B

Function Code

(Hexadecimal)

hex

hex

/ 0E

hex

hex

Name Notes

Read Holding

Registers

Write Multiple

Registers

Read Device

Identification

Class 0

Class 0

A.3 Data Encoding

In the data registers, the numeric values are available in one or two formats with separate

register addresses: 32-bit IEEE

A.3.1 32-Bit Floating Point or Integer Format

Least-significant 16 bits of floating point or integer numbers are placed at the smaller Modbus

address as specified in Open Modbus TCP Specification, Release 1.0. This is also known as

"little-endian" or "Modicon" word order. Floating point values are represented in standard IEEE

floating point format.

32-bit

floating point format and/or 16-bit signed integer format.

45

Page 48

HPP272 User Guide M211972EN-B

Despite the specification, some Modbus masters may expect "big-endian" word

order (most-significant word first). In such case, you must select "word-swapped"

floating point format in your Modbus master for the Modbus registers of the

device.

A "quiet NaN" value is returned for unavailable values. A quiet NaN is, for example,

7FC00000

; however, the master should understand any NaN value.

hex

A complete 32-bit floating point or integer value should be read and written in a

single Modbus transaction.

A.3.2 16-Bit Integer Format