Page 1

M212305EN-A

User Guide

Intrinsically Safe Humidity and Temperature

Transmitter Series

HMT370EX

Page 2

PUBLISHED BY

Vaisala Oyj

Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

P.O. Box 26, FI-00421 Helsinki, Finland

+358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala 2021

No part of this document may be

reproduced, published or publicly

displayed in any form or by any means,

electronic or mechanical (including

photocopying), nor may its contents be

modified, translated, adapted, sold or

disclosed to a third party without prior

written permission of the copyright holder.

Translated documents and translated

portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this document are subject

to change without prior notice.

Local rules and regulations may vary and

they shall take precedence over the

information contained in this document.

Vaisala makes no representations on this

document’s compliance with the local

rules and regulations applicable at any

given time, and hereby disclaims any and

all responsibilities related thereto.

This document does not create any legally

binding obligations for Vaisala towards

customers or end users. All legally binding

obligations and agreements are included

exclusively in the applicable supply

contract or the General Conditions of Sale

and General Conditions of Service of

Vaisala.

This product contains software developed

by Vaisala or third parties. Use of the

software is governed by license terms and

conditions included in the applicable

supply contract or, in the absence of

separate license terms and conditions, by

the General License Conditions of Vaisala

Group.

Page 3

Table of contents

Table of contents

1. About this document.....................................................................................7

1.1 Version information.......................................................................................... 7

1.2 Related manuals................................................................................................7

1.3 Documentation conventions............................................................................7

1.4 Trademarks........................................................................................................ 7

2. Product overview............................................................................................ 9

2.1 Introduction to HMT370EX series...................................................................9

2.2 Basic features and options.............................................................................. 9

2.3 Hazardous area safety......................................................................................9

2.4 Available measurement parameters.............................................................10

2.5 Display options................................................................................................. 11

2.5.1 LED states in transmitter with no display..............................................12

2.6 Connectivity to Vaisala Insight software...................................................... 12

2.7 Transmitter parts............................................................................................. 13

2.7.1 Cable gland and conduit options........................................................... 14

2.8 Using HTM370EX Series transmitters in hazardous locations...................16

2.8.1 Guidelines for safe use in hazardous conditions.................................. 17

3. Probe options..................................................................................................21

3.1 HMT370EX probe options overview..............................................................21

3.1.1 HMT370EX probe accessories............................................................... 22

3.2 HMP371 fixed probe........................................................................................23

3.3 HMP373 probe for confined spaces..............................................................23

3.4 HMP374 probe for high pressure applications............................................25

3.5 HMP375 probe for high temperature applications.....................................26

3.6 HMP377 probe for high humidity applications........................................... 27

3.7 HMP378 probe for pressurized pipelines.....................................................28

3.7.1 Attaching ball valve kit to process........................................................30

3.7.2 HMP378F probe option for measuring oil moisture and

temperature.............................................................................................. 31

3.7.3 HMP378H probe option for measuring fuel moisture and

temperature.............................................................................................. 31

4. Installation....................................................................................................... 33

4.1 HMT370EX installation overview..................................................................33

4.1.1 Installation preparations........................................................................ 34

4.1.2 Probe installation overview....................................................................35

4.1.3 HMT370EX transmitter dimensions...................................................... 35

4.2 Mounting......................................................................................................... 36

4.3 Attaching cable glands and conduit fittings............................................... 37

4.4 Wiring.............................................................................................................. 38

4.4.1 Wiring with galvanic isolators...............................................................40

4.4.2 Wiring with Zener barriers......................................................................41

4.5 Finalizing installation: closing transmitter and attaching grounding...... 42

4.6 Optional: testing analog output level with a multimeter..........................43

1

Page 4

HMT370EX User Guide M212305EN-A

5. HMT370 local display interface..............................................................46

5.1 Local display overview.................................................................................. 46

5.1.1 Local display PIN code........................................................................... 48

5.1.2 Light and dark display themes..............................................................49

5.1.3 Sleep mode..............................................................................................49

5.2 HMT370EX display main menu.....................................................................50

5.3 Settings menu.................................................................................................50

5.3.1 Display menu............................................................................................ 51

5.3.2 Analog outputs menu ............................................................................52

5.3.3 Measurement settings menu..................................................................52

5.4 Calibration menu............................................................................................ 53

5.5 Status menu.................................................................................................... 53

5.6 Maintenance menu......................................................................................... 54

6. Operating with Insight PC software......................................................55

6.1 Vaisala Insight PC software...........................................................................55

6.1.1 Basic and Advanced user modes.......................................................... 55

6.2 Connecting to Insight PC software...............................................................55

6.2.1 Installing driver for the USB service cable........................................... 57

6.3 Insight main view with transmitter...............................................................59

6.4 Insight main view with probe.......................................................................60

7. Analog output configuration....................................................................61

7.1 Analog output configuration overview.........................................................61

7.2 Configuring analog outputs with Insight.....................................................62

7.3 Configuring analog outputs with local display interface...........................62

7.4 Analog output level test................................................................................ 63

7.4.1 Testing analog output level with local display interface....................63

7.4.2 Testing analog output level with Insight..............................................64

8. Environmental compensation and measurement settings..........66

8.1 Environmental compensation and measurement settings overview...... 66

8.2 Configuring pressure compensation............................................................67

8.3 Configuring filtering factor............................................................................68

8.4 Configuring calculation coecients............................................................ 69

8.4.1 HMP378F calculation model with average oil coecients................ 69

8.4.2 HMP378F calculation model with oil-specific coecients................ 70

9. Calibration and adjustment.......................................................................71

9.1 Calibration and adjustment overview...........................................................71

9.2 Adjusting measurements with Insight......................................................... 72

9.3 Adjusting measurements with HMT370EX local display interface...........72

9.4 Analog output adjustment overview........................................................... 74

9.4.1 Adjusting analog output level with Insight..........................................76

9.4.2 Adjusting analog output level with local display interface................ 77

2

Page 5

Table of contents

10. Maintenance....................................................................................................78

10.1 Overview..........................................................................................................78

10.1.1 Technical support....................................................................................78

10.2 Cleaning...........................................................................................................78

10.3 Changing probe filter.....................................................................................78

11. Troubleshooting............................................................................................80

11.1 Problems and their possible solutions........................................................ 80

11.2 Error messages................................................................................................ 81

11.3 Restoring factory default settings................................................................82

12. Technical data................................................................................................84

12.1 Specifications..................................................................................................84

12.2 HMP371 specifications....................................................................................88

12.3 HMP373 specifications...................................................................................88

12.4 HMP374 specifications...................................................................................89

12.5 HMP375 specifications.................................................................................. 90

12.6 HMP377 specifications....................................................................................91

12.7 HMP378 specifications...................................................................................92

12.8 Spare parts and accessories..........................................................................93

12.9 Recycling instructions....................................................................................94

Maintenance and calibration services........................................................99

Warranty............................................................................................................99

Technical support............................................................................................99

Recycling...........................................................................................................99

3

Page 6

HMT370EX User Guide M212305EN-A

List of figures

Figure 1 HMT370EX transmitter display options......................................................11

Figure 2 HMT370EX transmitter external parts....................................................... 13

Figure 3 HMT370EX transmitter internal parts........................................................14

Figure 4 Default plugs in HMT370EX lead-throughs..............................................15

Figure 5 HMT370EX parts overview............................................................................17

Figure 6 Location of test points and service port................................................... 19

Figure 7 HMT370EX probe options.............................................................................21

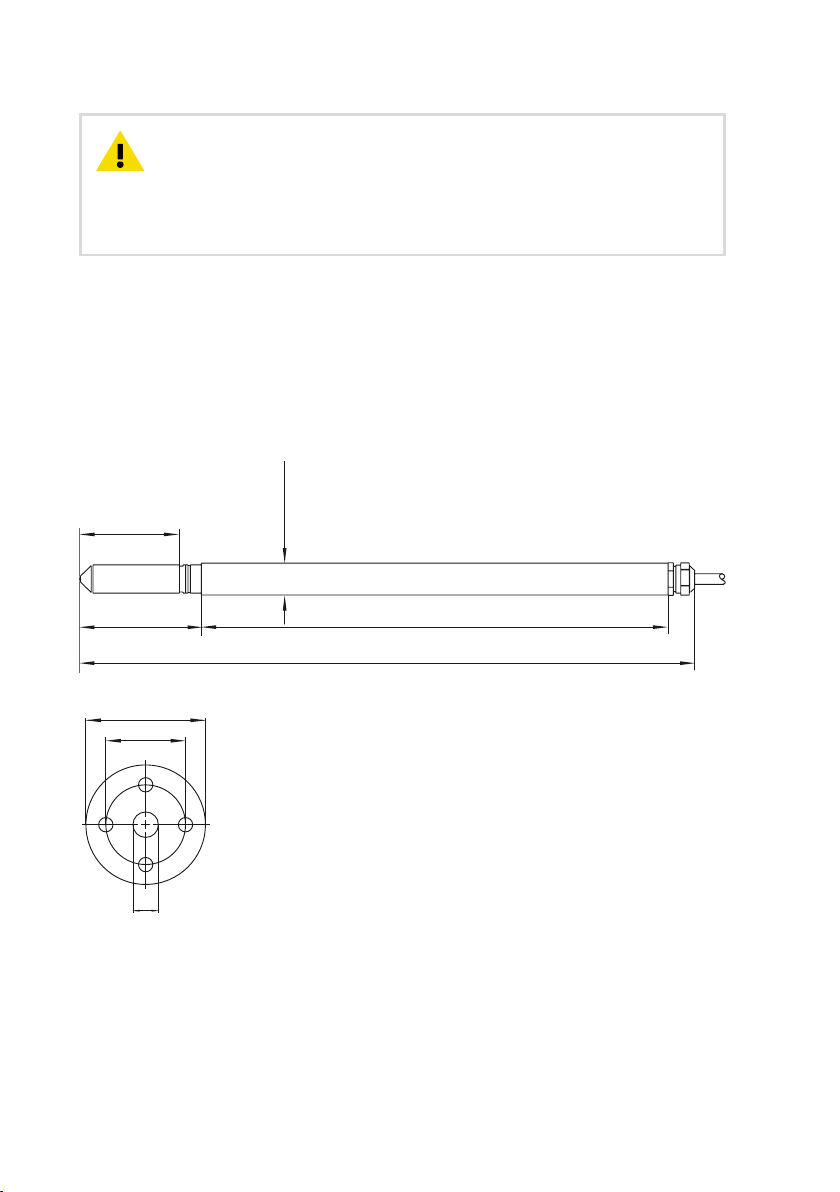

Figure 8 Dimensions in mm (inches)..........................................................................23

Figure 9 Dimensions in mm (inches)..........................................................................23

Figure 10 Left: Installation kit for duct mounting. Right:

Installation flange. Aluminum or stainless steel.....................................24

Figure 11 Dimensions in mm (inches)..........................................................................25

Figure 12 HMP375 probe and stainless steel installation flange.

Dimensions in mm (inches)..........................................................................26

Figure 13 Dimensions in mm (inches)..........................................................................27

Figure 14 Dimensions in mm (inches)..........................................................................29

Figure 15 Example wall installation with HMP373 probe........................................33

Figure 16 Duct installation example with HMP373 probe and duct

installation kit...................................................................................................35

Figure 17 HMT370EX transmitter dimensions...........................................................35

Figure 18 Mounting HMT370EX directly through the transmitter body............ 36

Figure 19 Wiring example using one cable................................................................ 39

Figure 20 Wiring diagram with galvanic isolators................................................... 40

Figure 21 Wiring diagram with Zener barriers...........................................................41

Figure 22 Multimeter test point overview.................................................................. 44

Figure 23 HMT370EX local display examples: measurement graph

view and main menu screen........................................................................46

Figure 24 HMT370EX display interface buttons....................................................... 46

Figure 25 2 parameter view example...........................................................................47

Figure 26 Graph view example.......................................................................................47

Figure 27 Parameter list view example....................................................................... 48

Figure 28 Display PIN code button presses............................................................... 48

Figure 29 Dark (left) and light (right) display theme examples...........................49

Figure 30 Transmitter display in sleep mode.............................................................49

Figure 31 HMT370EX display interface main menu.................................................50

Figure 32 Settings menu................................................................................................. 50

Figure 33 Display menu.....................................................................................................51

Figure 34 Analog output settings................................................................................. 52

Figure 35 Calibration menu.............................................................................................53

Figure 36 Status menu......................................................................................................53

Figure 37 Maintenance menu.........................................................................................54

Figure 38 Connecting to Insight: probe body and transmitter

service port locations.................................................................................... 56

Figure 39 Insight main menu and settings: transmitter view................................59

Figure 40 Insight main menu and settings: probe view..........................................60

4

Page 7

Figure 41 Analog output configuration options in Insight PC software..............61

Figure 42 Multimeter test point overview...................................................................63

Figure 43 Filtering factor configuration in Insight PC software............................68

Figure 44 Insight PC software calibration view example.........................................71

Figure 45 Local display calibration menu.................................................................... 71

Figure 46 Analog output level adjustment in Insight PC software...................... 76

Figure 47 Humidity measurement accuracy as function of temperature.......... 85

Figure 48 Temperature measurement accuracy over full range........................... 85

Figure 49 Aw measurement accuracy..........................................................................86

Figure 50 HMT370EX transmitter dimensions...........................................................88

Figure 51 Dimensions in mm (inches)..........................................................................88

Figure 52 Dimensions in mm (inches)......................................................................... 89

Figure 53 Dimensions in mm (inches)......................................................................... 90

Figure 54 HMP375 probe and stainless steel installation flange.

Dimensions in mm (inches).......................................................................... 91

Figure 55 Dimensions in mm (inches)..........................................................................92

Figure 56 Dimensions in mm (inches)..........................................................................93

Figure 57 Recyclable and non-recyclable parts in transmitters

with no display................................................................................................ 95

Figure 58 Recyclable and non-recyclable parts in transmitters

with no display after disposing of electronics and probe...................95

Figure 59 Recyclable and non-recyclable parts in transmitters with display...95

Figure 60 Recyclable and non-recyclable parts in transmitters

with display after disposing of electrical and electronic waste.........95

List of figures

5

Page 8

HMT370EX User Guide M212305EN-A

List of tables

Table 1 Document versions (English)...........................................................................7

Table 2 Related manuals...................................................................................................7

Table 3 Available measurement parameters for HMP371, HMP373,

HMP374, HMP375, HMP377, and HMP378................................................... 10

Table 4 Available measurement parameters for HMP378F and HMP378H.......10

Table 5 LED status indicator states..............................................................................12

Table 6 Cable lead-through accessories.....................................................................15

Table 7 HMT370EX series hazardous area classifications..................................... 16

Table 8 Allowed ambient temperature ranges......................................................... 18

Table 9 Intrinsically safe input parameters................................................................19

Table 10 HMT370EX probe accessories.......................................................................22

Table 11 HMP371 for wall mounting.............................................................................. 23

Table 12 HMP373 for confined spaces..........................................................................24

Table 13 HMP374 for high pressure...............................................................................25

Table 14 HMP375 for high temperature.......................................................................27

Table 15 HMP377 for high humidities........................................................................... 27

Table 16 HMP378 for pressurized pipelines................................................................29

Table 17 HMP378F measurement parameters............................................................31

Table 18 HMP378H measurement parameters...........................................................32

Table 19 Measurement performance............................................................................84

Table 20 HUMICAPâ L2 measurement performance...............................................85

Table 21 Operating environment...................................................................................86

Table 22 Compliance.........................................................................................................86

Table 23 Inputs and outputs............................................................................................87

Table 24 Mechanical specifications............................................................................... 87

Table 25 HMP371 for wall mounting..............................................................................88

Table 26 HMP373 for confined spaces..........................................................................88

Table 27 HMP374 for high pressure...............................................................................89

Table 28 HMP375 for high temperature.......................................................................90

Table 29 HMP377 for high humidities............................................................................91

Table 30 HMP378 for pressurized pipelines................................................................92

Table 31 Accessory availability.......................................................................................93

6

Page 9

Chapter 1 – About this document

1. About this document

1.1 Version information

Table 1 Document versions (English)

Document code Date Description

M212305EN-A March 2021 This manual. First version of the document.

1.2 Related manuals

Table 2 Related manuals

Document code Description

M212306EN HMT370EX Multilingual Installation and Safety Guide (languages:

1.3 Documentation conventions

English, German, French, Dutch, Spanish, Portuguese, Italian,

Hungarian, Czech, Polish, Finnish, Estonian, Swedish, Norwegian,

Danish)

WARNING!

follow instructions carefully at this point, there is a risk of injury or even death.

CAUTION!

follow instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

Warning alerts you to a serious hazard. If you do not read and

Caution warns you of a potential hazard. If you do not read and

1.4 Trademarks

Vaisalaâ and HUMICAPâ are registered trademarks of Vaisala Oyj.

7

Page 10

HMT370EX User Guide M212305EN-A

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

8

Page 11

Chapter 2 – Product overview

2. Product overview

2.1 Introduction to HMT370EX series

Vaisala HUMICAP® Humidity and Temperature Transmitter Series HMT370EX is the ideal

solution for measuring humidity in hazardous areas. Intrinsically safe and robust, HMT370EX

operates safely and reliably even in the most hazardous areas, such as Zone 0. The nextgeneration HMT370EX transmitter can be used as a replacement for the long-running HMT360

transmitter series in all HMT360 applications.

HMT370EX can be installed directly in explosive areas. It can withstand continuous exposure to

potentially explosive environments that contain flammable gases or dust, and requires no

additional protective enclosures for operation in either gas or dust environments.

HMT370EX oers several probe options for dierent applications. Thanks to the detachable

probe module, probes can be easily replaced and removed for calibration outside the

hazardous area without removing the entire transmitter.

The transmitter has 2 analog current output channels (4 – 20 mA) for connection via safety

barriers. For easy-to-use access to configuration, diagnostics, and calibration and adjustment

functionalities, the probe and transmitter body can be connected to Vaisala Insight PC

software for configuration either together as one unit or separately.

2.2

Basic features and options

• Available measurement parameters: relative humidity (RH) and temperature (T)

• For a list of calculated measurement parameters, see Available measurement

parameters (page 10).

• Ex classification: IECEx and ATEX certified for use in Zone 0 and Zone 20 environments:

for full Ex classifications, see Table 7 (page 16).

• 2 analog outputs (4 – 20 mA, scalable, isolated)

• Display options: graphical LCD display or non-display model

• Power supply input: 12 – 28 V

• Compatible with Vaisala Insight PC software

2.3

Hazardous area safety

CAUTION!

reviewing the safety information in Using HTM370EX Series transmitters in

hazardous locations (page 16).

Do not install or use HMT370EX in a hazardous area before

9

Page 12

HMT370EX User Guide M212305EN-A

2.4 Available measurement parameters

Table 3 (page 10) lists the available HMT370EX measurement parameter options and their

abbreviations and units for the standard probe options HMP371, HMP373, HMP374, HMP375,

HMP377, and HMP378.

Table 3 Available measurement parameters for HMP371, HMP373, HMP374, HMP375, HMP377, and

HMP378

Parameter Abbreviation Unit

Relative humidity RH %RH

Temperature T °C (°F)

Dew point temperature T

Dew point / frost point

temperature

d

T

d/f

Absolute humidity a

Mixing ratio x g/kg (gr/lb)

Wet-bulb temperature T

w

Water concentration H2O ppm

Water vapor pressure pw hPa (psi)

Water vapor saturation

pws hPa (psi)

pressure

Enthalpy h kJ/kg (Btu/lb)

Dew point temperature

ΔT °C (°F)

dierence

Absolute humidity at NTP aNTP

Water mass fraction H2O

w

°C (°F)

°C (°F)

g/m3 (gr/ft3)

°C (°F)

v

g/m3 (gr/ft3)

ppm

w

Table 4 (page 10) lists the measurement parameter options available for the oil and fuel

probe variants HMP378F and HMP378H.

Table 4 Available measurement parameters for HMP378F and HMP378H

Parameter Abbreviation Unit

Available for both HMP378F and HMP378H

Temperature T °C (°F)

Relative saturation RS %RS

Water activity a

w

10

Page 13

2

1

Chapter 2 – Product overview

Parameter Abbreviation Unit

Only available for HMP378F

Water concentration in oil H2O (oil) ppm

Only available for HMP378H

Water concentration in fuel H2O (fuel) ppm

Saturation temperature T

s

w

w

°C (°F)

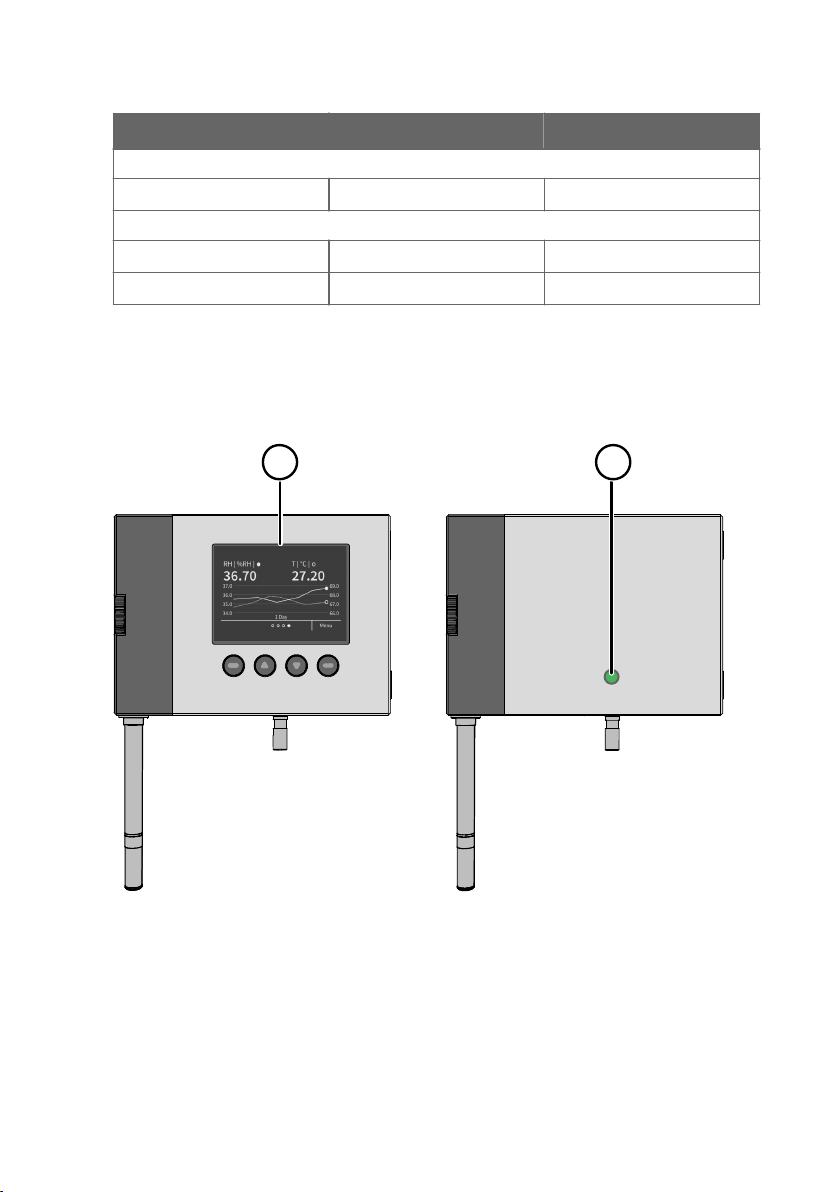

2.5 Display options

The HMT370EX transmitter can be ordered either with a graphical LCD display, or alternatively

without a display. The display options are shown in Figure 1 (page 11).

Figure 1 HMT370EX transmitter display options

Transmitter with display: LCD display with 4-button interface

1

2 Transmitter without display: LED status indicator

11

Page 14

HMT370EX User Guide M212305EN-A

In the display model, probe and transmitter configuration can be carried out either using the

4-button interface of the display, or by connecting the probe or transmitter to Vaisala Insight

PC software. In the model without display, all configuration must be carried out with Vaisala

Insight PC software.

For information on Vaisala Insight PC software, see Vaisala Insight PC software (page 55).

For information on the display interface, see Local display overview (page 46).

2.5.1 LED states in transmitter with no display

In the transmitter model with no display, the status LED indicator on the front of the

transmitter provides a visual indication of the transmitter's status. If the transmitter LED status

indicates that notifications or error messages exist, connect to Vaisala Insight PC software to

view status information and carry out any required configuration.

For instructions on connecting to Insight, see Connecting to Insight PC software (page 55).

For an overview of the Insight software, see Vaisala Insight PC software (page 55).

Table 5 LED status indicator states

LED color Meaning

Not lit Power o.

Green, fast blinking Starting up.

Green, not blinking Power on, normal measurement.

Green, slow blinking Notification or warning, normal measurement. Connect to Insight

Red Error. Connect to Insight to view status information and

Red and blinking Critical error. Connect to Insight to view status information and

to view status information and configure.

configure.

configure.

2.6 Connectivity to Vaisala Insight software

The HMT370EX transmitter and HMT370EX series probes can be connected to Vaisala Insight

software either together as one unit or separately with a Vaisala USB cable (see Spare parts

and accessories (page 93)). With the Insight software, you can:

• Calibrate and adjust the measurement.

• Test and adjust the analog outputs.

• Configure analog output parameter selection, scaling, error, and clipping settings.

• Configure environmental compensations, measurement settings, and local display

settings.

• View real-time measurements and device and status information.

12

Page 15

1 2

3

10

7

54

9

8

6

Chapter 2 – Product overview

More information

‣

Connecting to Insight PC software (page 55)

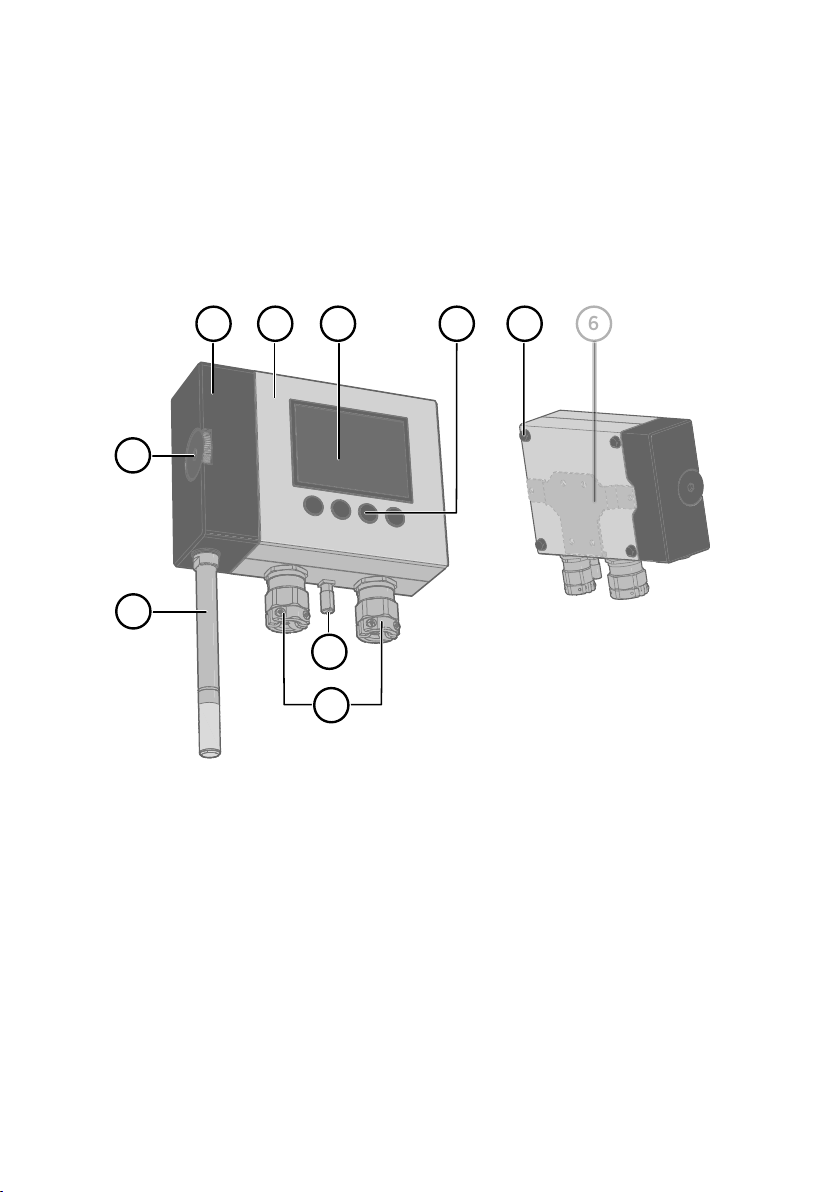

2.7 Transmitter parts

The external parts of the transmitter are shown in Figure 2 (page 13), and the internal parts of

the transmitter are shown in Figure 3 (page 14).

Figure 2 HMT370EX transmitter external parts

Detachable probe body

1

2 Transmitter body (for internal parts, see Figure 3 (page 14))

3 Graphical LCD display (see Display options (page 11))

4 Display interface buttons (see Local display overview (page 46))

5 Wall pads (4 pcs)

6 Retrofit mounting plate for replacing HMT360 installations (optional)

7 Probe body locking wheel

8 Probe head (for information on dierent probe options, see HMT370EX probe options

overview (page 21))

9 Grounding terminal

10 Lead-throughs for wiring (for lead-through accessory options, see Cable gland and

conduit options (page 14))

13

Page 16

2

mA

Test Points

CH1

CH2

mA

V

V

2a

2b

3 4

1

5

HMT370EX User Guide M212305EN-A

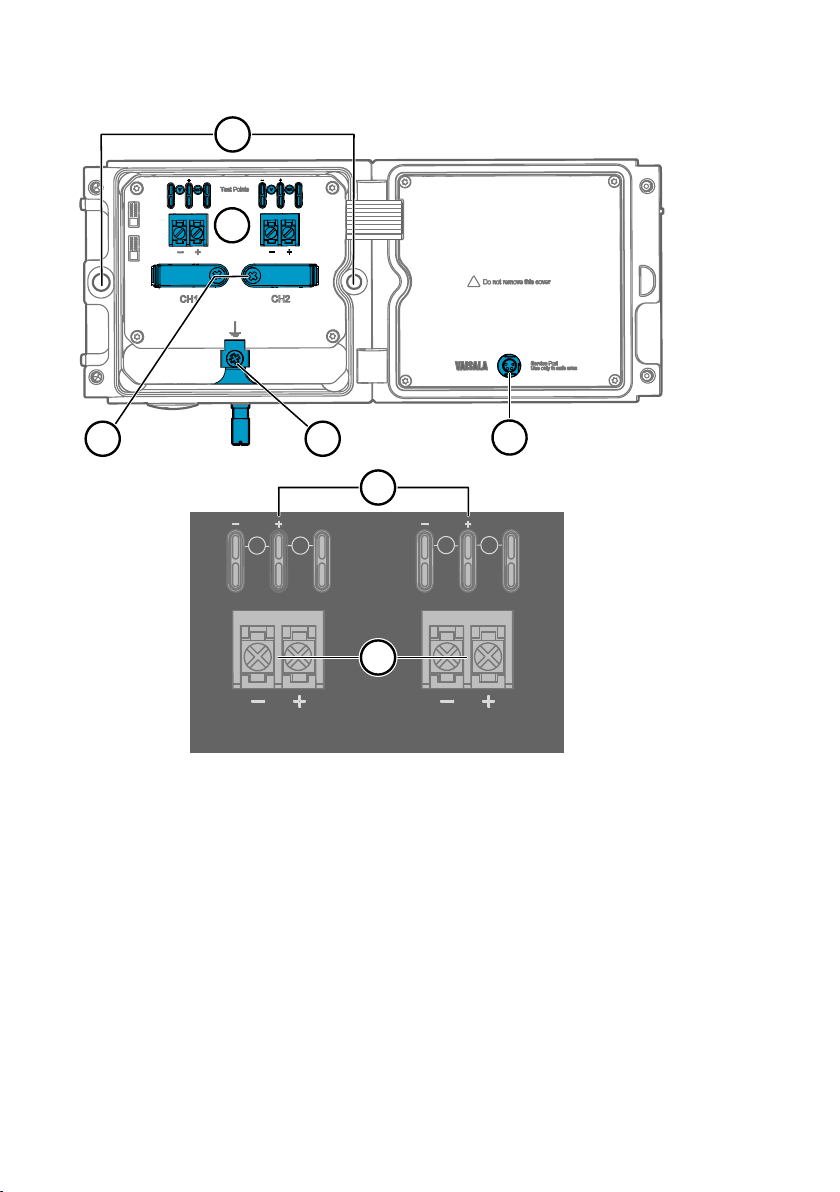

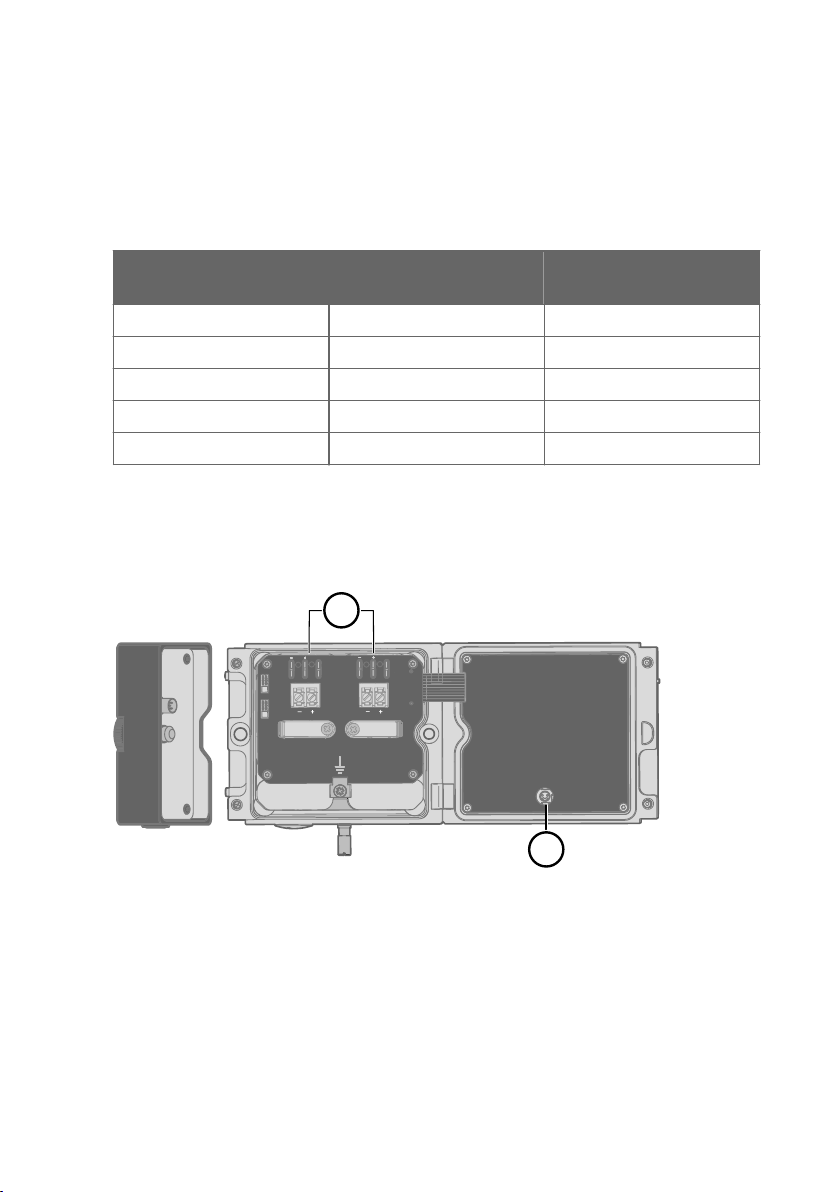

Figure 3 HMT370EX transmitter internal parts

Holes for mounting screws

1

2 Screw terminals and output test points: see 2a and 2b

2a Analog output channel 1 and 2 multimeter test points for current and voltage

2b Screw terminals for wiring analog output channels 1 and 2

3 Cable fastening clamps

4 Transmitter grounding terminal

5 Transmitter service port (M8, requires Vaisala USB cable accessory)

2.7.1 Cable gland and conduit options

The HMT370EX transmitter body has two M20x1.5 lead-throughs that can be fitted with cable

glands, conduit fittings, and plugs, as required by your application. By default, the transmitter

comes delivered with 2 dierent plug types on the transmitter lead-throughs as shown in

Figure 4 (page 15).

14

Page 17

1

2

Chapter 2 – Product overview

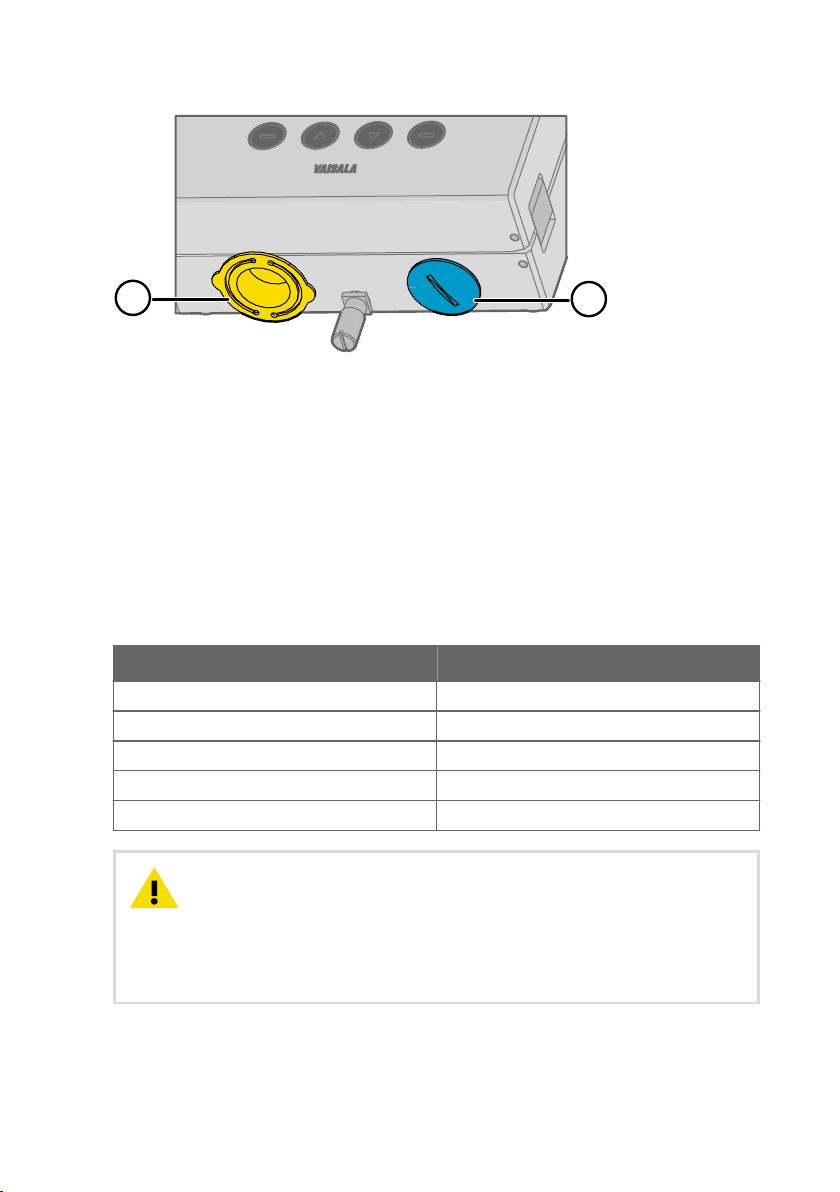

Figure 4 Default plugs in HMT370EX lead-throughs

1 Removable plastic transport cover: must be replaced (fold sides of transport cover

together and pull out)

2 Metal sealing plug: can be used in final installation

The plastic transport cover (1) must always be replaced with an Ex compliant cable gland,

conduit, or seal when wiring HTM370EX. The metal sealing plug (2) can be left in place and

used in the final installation, if the right-hand lead-through is not used.

Cable glands, conduits, and plugs are available from Vaisala as accessories (listed in Table 6

(page 15)).

Table 6 Cable lead-through accessories

Accessory Vaisala item code

Cable gland M20 x 1.5 for Ø 5 … 11 mm cable 265207SP

Cable gland M20 x 1.5 for Ø 10 … 14 mm cable 265208SP

Conduit fitting M16 265243SP

Conduit fitting NPT1/2" 265240SP

Dummy plug (Ex, 2 pcs) 254931SP

CAUTION!

If you use lead-through accessories not ordered from Vaisala, note

the following requirements:

• The cable glands and cables used for wiring the device must not impair the Ex

protection.

• Unused lead-throughs must be sealed using Ex compliant plugs.

• The glands and plugs must be water and dust tight (minimum IP rating: IP54).

15

Page 18

HMT370EX User Guide M212305EN-A

2.8 Using HTM370EX Series transmitters in hazardous locations

WARNING!

Protected installation using galvanic isolators or Zener barriers is

mandatory in a hazardous environment.

In hazardous environments, always connect the transmitters via galvanic isolators or Zener

barriers. A galvanic isolator or Zener barrier must also be used when the transmitter and probe

body are in a safe area, but the probe head is installed in a hazardous environment. For wiring

information, see the galvanic isolator and Zener barrier wiring diagrams included in this

document.

HMT370EX does not include a galvanic isolator or a Zener barrier. They can be ordered as

optional accessories from Vaisala.

WARNING!

HMT370EX series transmitters have been designed for use in

hazardous locations as specified by the product classification. The personnel

installing, using, or maintaining HMT370EX transmitters are responsible for

determining the appropriate protection concept for the specific application

HMT370EX is used in, and that the hazardous area classification of the device

meets the requirements of the application.

WARNING!

If the equipment is used in a manner not specified by Vaisala, the

protection provided by the equipment may be impaired.

HMT370EX series transmitters are certified for use in hazardous areas as defined by the

following classifications:

Table 7 HMT370EX series hazardous area classifications

Certification HMT370EX classification

IECEx 1) / ATEX

1) International certification

2) EU certification

16

2)

II 1 G Ex ia IIC T4 Ga

II 1 D Ex ia IIIC T

-40 °C ≤ T

≤ +60 °C

amb

200

85 °C Da

Page 19

HMT370EX

1 2 31a

M20x1.5 M20x1.5

Chapter 2 – Product overview

CAUTION!

transmitters must have the required competencies for working in the hazardous

location, as defined by the applicable standards.

For information on the standards that apply to using HMT370EX based on the classification of

the device, see HMT370EX certification documentation and the declarations of conformity

related to HMT370EX at www.vaisala.com/declarationofconformity.

The personnel installing, operating, and maintaining HMT370EX

2.8.1 Guidelines for safe use in hazardous conditions

HMT370EX Series parts overview

Figure 5 HMT370EX parts overview

HMT370EX Series transmitters consist of 3 main parts: the transmitter body, a detachable

probe body, and a probe head attached to the probe body, either directly or using a cable.

Figure 5 (page 17) shows the main parts.

Probe heads (for variant descriptions, see HMT370EX User Guide)

1

1a Probe head filters

2 Probe body

3 Transmitter body

17

Page 20

HMT370EX User Guide M212305EN-A

The dierent probe head variants are designed for a range of applications, and have their own

specifications. Ensure that the transmitter body, probe body, and probe head are each placed

in an environment that matches the specification of the part. For allowed ambient temperature

ranges, see Table 8 (page 18).

Table 8 Allowed ambient temperature ranges

Equipment part Allowed ambient temperature range

Transmitter body -40 °C … +60 °C (-40 … +140 °F)

Probe body -40 °C … +60 °C (-40 … +140 °F)

Probe heads HMP374, HMP375, HMP377, and

HMP378

Probe head HMP371 Temperature class T4:

Probe head HMP373 Temperature class T4:

Temperature class T4:

-70 °C … +120 °C (-94 … +248 °F)

Temperature class T3:

-70 °C … +180 °C (-94 … +356 °F)

-40 °C … +60 °C (-40 … +140 °F)

Rubber cable version:

-40 °C … +80 °C (-40 … +176 °F)

FEP cable version:

-40 °C … +120 °C (-40 … +248 °F)

2.8.1.1 Specific conditions of use

CAUTION!

With the installation of the equipment in Zone 0 Group II area it has

to be ensured that sparks due to impact or friction do not occur.

Wiring requirements

• The cable glands and cables used for wiring the device must not impair the Ex protection.

• Unused lead-throughs must be sealed using Ex compliant plugs.

• Select a strain relief option that suits the application (either use cable glands that include

strain relief or install separate clamps: see IEC 60079-14).

CAUTION!

Connect only de-energized wires. Never switch on the power supply

input before completing the wiring and closing the transmitter body.

18

Page 21

mA

V

mA

V

CH1

CH2

A

Service Port

Use only in safe area

!

Do not remove this cover

1

2

Test Points

Chapter 2 – Product overview

Intrinsic safety

The overvoltage category of HMT370EX transmitters is I (non-mains equipment), and ambient

pollution degree is 4, as specified in IEC 60664-1. For intrinsically safe input parameters, see

Table 9 (page 19) .

Table 9 Intrinsically safe input parameters

Parameter Value Associated apparatus entity

parameters

U

i

I

i

P

i

C

i

L

i

28 VDC Uo ≤ U

100 mA Io ≤ I

700 mW Po ≤ P

i

i

i

12.1 nF Co ≥ Ci + C

16 µH Lo ≥ Li+ L

cable

cable

Using analog output test points

There are test points for measuring the voltages and currents of the analog outputs, located

above each screw terminal block as shown in Figure 6 (page 19). Accessing the test points on

the component board requires opening the transmitter enclosure.

Figure 6 Location of test points and service port

Multimeter test points for analog output channels 1 and 2

1

2 Service port for PC connection

19

Page 22

HMT370EX User Guide M212305EN-A

CAUTION!

The transmitter body enclosure must not be opened in an explosion

hazardous area, unless a safe work permit has been issued in accordance with

the standard IEC 60079-14. Either remove the transmitter from the hazardous

area before opening the enclosure, or ensure that an IEC 60079-14 compliant

safe work procedure has been implemented in the hazardous area.

Use an intrinsically safe multimeter that won't cause the intrinsically safe input parameters

listed in Table 9 (page 19) to be exceeded when it is connected in series (current

measurement) or parallel (voltage measurement) to the associated apparatus.

Using the service port

The service port (see Figure 6 (page 19)) must only be used in a safe area. Either remove the

transmitter from the hazardous area or ensure that a safe work procedure has been

implemented in the hazardous area. Only use the Vaisala accessory PC connection cable with

the service port.

Maintenance

The probe (includes probe body and head) can be detached and replaced by the user. The

probe head filter (see Figure 5 (page 17)) is also user-replaceable. For other maintenance

requirements, contact Vaisala.

CAUTION!

The probe can be detached and changed when HMT370EX is

powered. Any other live maintenance, including changing the probe head filter,

is not allowed.

The content in this chapter is maintained in the following separately tracked document:

Document ID: M212506EN Revision: A (25 Feb 2021)

20

Page 23

1 2 3 4 5 6

Chapter 3 – Probe options

3. Probe options

3.1 HMT370EX probe options overview

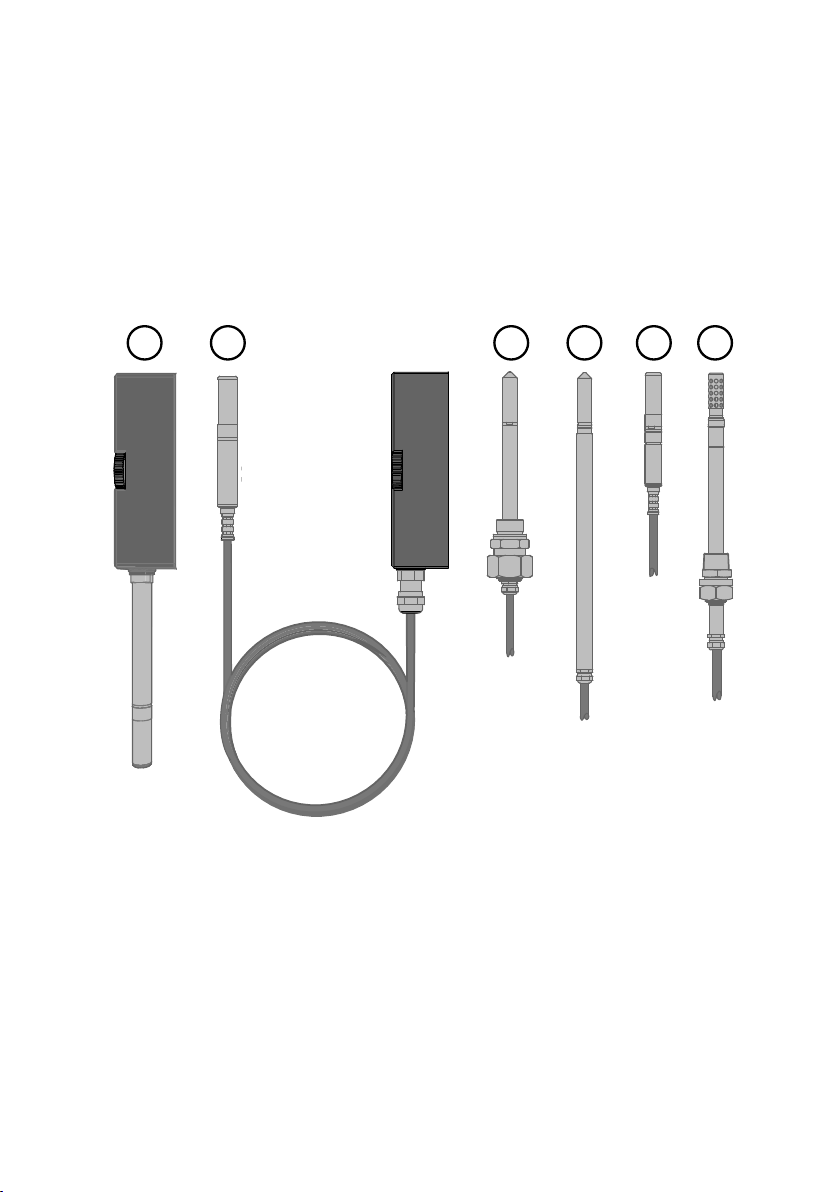

Figure 7 (page 21) shows the dierent probe options available for HMT370EX series

transmitters. The HMP371 fixed probe option uses a probe head that attaches directly to the

probe body. In the other probe options (HMP373, HMP374, HMP375, HMP377, and HMP378),

the probe head is attached to the probe body with a cable.

Figure 7 HMT370EX probe options

HMP371 fixed probe (page 23)

1

2 HMP373 probe for confined spaces (page 23)

3 HMP374 probe for high pressure applications (page 25)

4 HMP377 probe for high humidity applications (page 27)

5 HMP375 probe for high temperature applications (page 26)

6 HMP378 probe for pressurized pipelines (page 28)

6a HMP378 variant: HMP378F probe option for measuring oil moisture and temperature

(page 31)

6b HMP378 variant: HMP378H probe option for measuring fuel moisture and temperature

(page 31)

21

Page 24

HMT370EX User Guide M212305EN-A

More information

‣

Probe installation overview (page 35)

3.1.1 HMT370EX probe accessories

Table 10 (page 22) lists the available accessories for each probe option.

Table 10 HMT370EX probe accessories

Accessory Vaisala item code Models

M12 Indigo USB Adapter cable

accessory for connecting HMT370EX

probes to Insight

Ball valve ISO 1/2 with welding joint

• Pressure range at +20 °C (+68 °F)

0 … 20 bar (0 … 290 psia) (during

installation max. 10 bar (145 psia)

Duct installation kit 210697 HMP373, HMP377

Mounting flange 210696 HMP375

Cable gland M20 x 1.5 with split seal HMP247CG HMP373, HMP375, HMP377

Fitting body M22 x 1.5 17223SP HMP374

Fitting body NPT1/2 17225SP HMP374

Fitting body ISO1/2 solid structure DRW212076SP HMP378

Fitting body NPT1/2 solid structure 212810SP HMP378

Swagelok fitting for 12 mm probe, 1/2"

NPT thread

Swagelok fitting for 12 mm probe, 3/8"

ISO thread

Swagelok fitting for 12 mm probe, 1/2"

ISO thread

Thread adapter ISO 1/2" to NPT 1/2" 210662SP All models

Manual press HM36854SP HMP378/F/H

USB2 All models

BALLVALVE-1 HMP378

SWG12NPT12 HMP377

SWG12ISO38 HMP377

SWG12ISO12 HMP377

22

Page 25

[1.61]

ø12 [0.47]

86 (3.39)

55.5 [2.19]

53 [2.09]

127 [5]

41

ø 12 (0.47)

37.5 (1.48)

98.5 (3.88)

Chapter 3 – Probe options

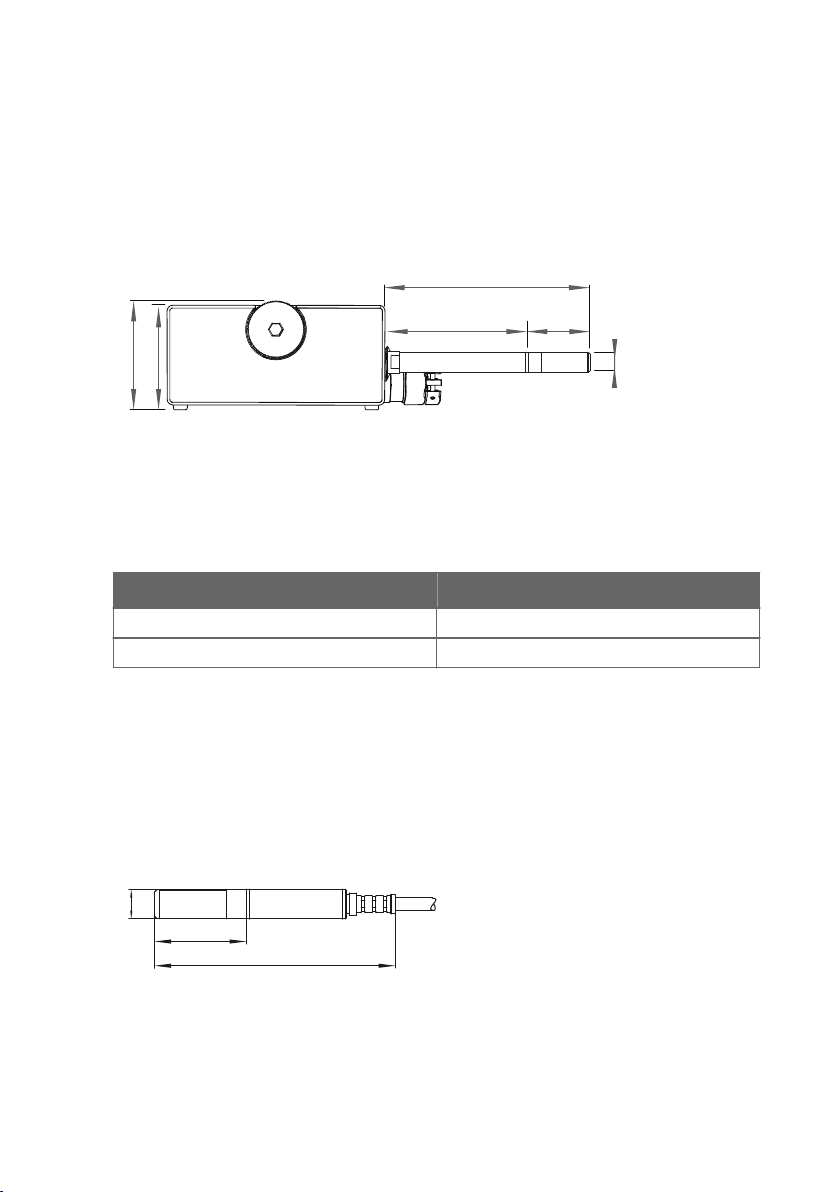

3.2 HMP371 fixed probe

Dimensions

The HMP371 fixed probe option has a probe head that attaches directly on the probe body,

making it suitable for wall mounting applications.

Figure 8 Dimensions in mm (inches)

Specifications

Table 11 HMP371 for wall mounting

Property Description/value

Temperature range -40 … +60 °C (-40 … +140 °F)

Probe diameter 12 mm (0.47 in)

3.3 HMP373 probe for confined spaces

Dimensions

HMP373 is a small size (ø = 12 mm) general-purpose probe that is suitable for installation into

confined spaces such as ducts and channels using the duct installation kit available from

Vaisala (item code 210697: see Figure 10 (page 24)).

Figure 9 Dimensions in mm (inches)

23

Page 26

Ø12 (0.47)

adjustable

duct wall

flange

drilling 16...22

50 (1.97)

75 (2.96)

(0.63...0.87)

HMT370EX User Guide M212305EN-A

Specifications

The HMP373 probe option has 2 operating temperature range options depending on the cable

selected for the probe. The rubber cable option has a temperature range of -40 … +80 °C

(-40 … +176 °F). With the Teflon cable option, the temperature range is -40 … +120 °C

(-40 … +248 °F).

Table 12 HMP373 for confined spaces

Property Description/value

Temperature range with teflon cable -40 … +120 °C (-40 … +248 °F)

Temperature range with rubber cable -40 … +80 °C (-40 … +176 °F)

Probe cable length 2, 5 or 10 meters (6 ft 7 in, 16 ft 5 in, 32 ft 10 in)

Probe diameter 12 mm (0.47 in)

Installation

Duct installation kit 210697

Cable gland M20x1.5 with splitting seal HMP247CG

Swagelok for 12mm probe, 1/2" NPT thread SWG12NPT12

Duct installation kit 210697

Figure 10 Left: Installation kit for duct mounting. Right: Installation flange. Aluminum or stainless

steel.

24

Page 27

M22×1.5 or

NPT 1/2"

120 (4.72)

170 (6.69)

41 (1.61)

ø12 (0.47)

Chapter 3 – Probe options

3.4 HMP374 probe for high pressure applications

Dimensions

The HMP374 probe option is designed for measurement in pressurized spaces or vacuum

chambers.

Figure 11 Dimensions in mm (inches)

Specifications

Table 13 HMP374 for high pressure

Property Description/value

Temperature range -70 … +180 °C (-94 … +356 °F)

Pressure range 0 … 10 MPa

Probe cable length 2, 5 or 10 meters (6 ft 7 in, 16 ft 5 in, 32 ft 10 in)

Probe diameter 12 mm (0.47 in)

Fitting body M22x1.5 17223

Fitting body NPT1/2 17225

CAUTION!

carefully when installing to prevent the loosening of the probe by the action of

pressure.

In pressurized processes it is essential to tighten the probe very

25

Page 28

41 (1.6)

51 (2.0)

ø13.5 (0.53)

192 (7.56)

253 (9.96)

drilling 16...22 (0.63...0.87)

50 (1.97)

75 (2.96)

HMT370EX User Guide M212305EN-A

CAUTION!

from normal atmospheric pressure, you must enter the pressure value of the

process as an environmental compensation in order to receive accurate

measurement results. For information on entering environmental compensations

with the transmitter display interface or Vaisala Insight PC software, see

Environmental compensation and measurement settings overview (page 66).

When HMP374 is installed in a process with a pressure diering

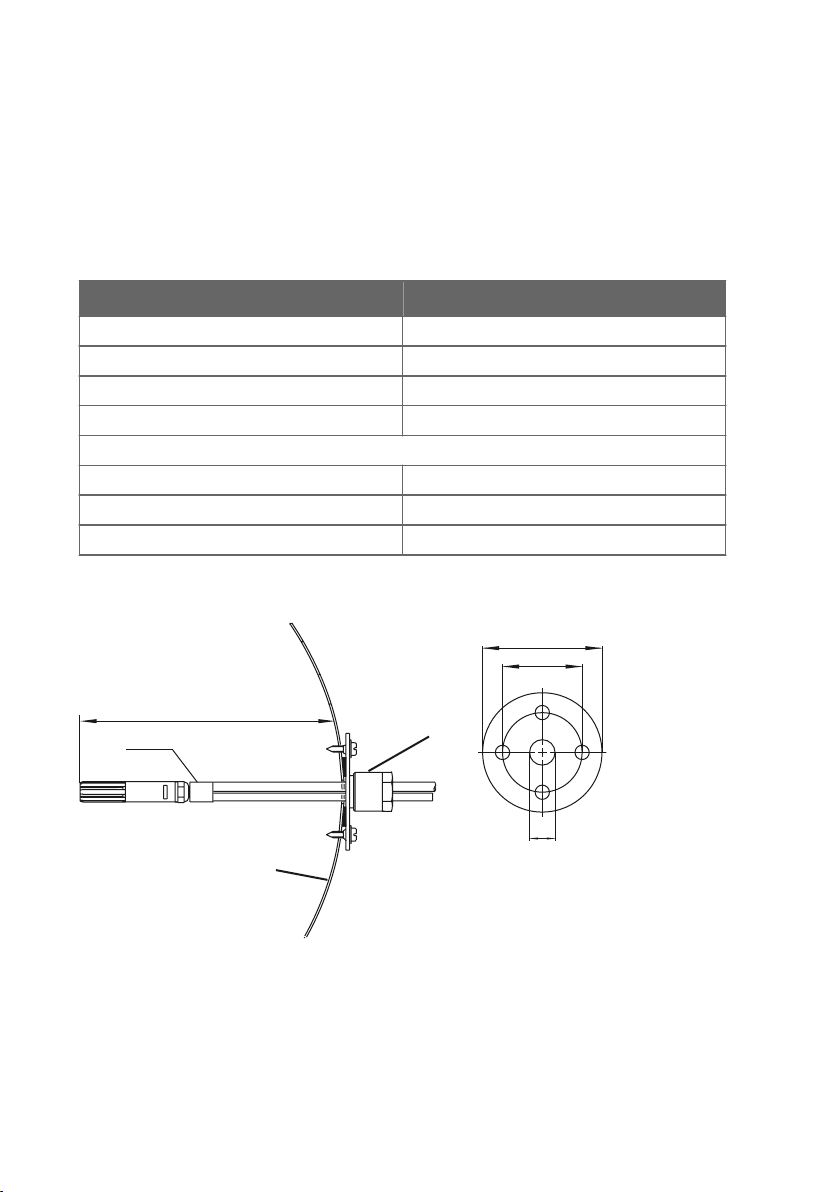

3.5 HMP375 probe for high temperature applications

The HMP375 probe option is designed for measurement in high temperature environments.

Dimensions

Figure 12 HMP375 probe and stainless steel installation flange. Dimensions in mm (inches).

26

Page 29

ø 12 (0.47)

37.5 (1.48)

79.5 (3.13)

99.5 (3.92)

M9×1

Chapter 3 – Probe options

Specifications

Table 14 HMP375 for high temperature

Property Description/value

Temperature range -70 … +180 °C (-94 … +356 °F)

Probe cable length 2, 5 or 10 meters (6 ft 7 in, 16 ft 5 in, 32 ft 10 in)

Probe diameter 13.5 mm (0.53 in)

Installation

Mounting flange 210696

Cable gland M20x1.5 with splitting seal HMP247CG

3.6 HMP377 probe for high humidity applications

The HMP377 probe option is constructed to be installed in environments with high humidities.

The same duct installation kit that is used with HMP373 can be used with HMP377: see Figure

10 (page 24).

Dimensions

Figure 13 Dimensions in mm (inches)

Specifications

Table 15 HMP377 for high humidities

Property Description/value

Temperature range -70 … +180 °C (-94 … +356 °F)

Probe cable length 2, 5 or 10 meters (6 ft 7 in, 16 ft 5 in, 32 ft 10 in)

Probe diameter 12 mm (0.47 in)

27

Page 30

HMT370EX User Guide M212305EN-A

Property Description/value

Installation

Duct installation kit 210697

Cable gland M20x1.5 with splitting seal HMP247CG

Swagelok for 12 mm probe, 3/8" ISO thread SWG12ISO38

Swagelok for 12 mm probe, 1/2" NPT thread SWG12NPT12

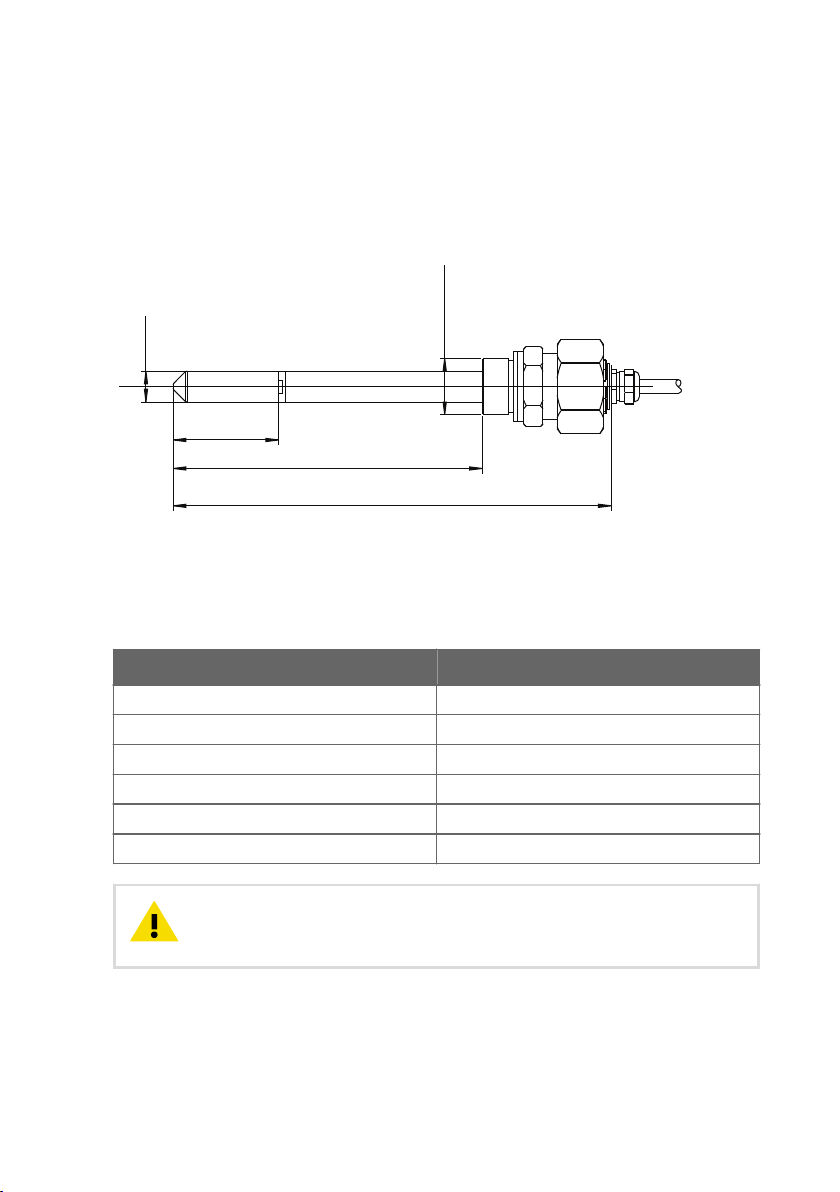

3.7 HMP378 probe for pressurized pipelines

The HMP378 probe option is especially suitable for measurements inside pipelines. Due to its

sliding fit (available probe lengths: 226 mm and 448 mm (8.90 in/17.6 in)), HMP378 is easy to

install into and remove from a pressurized process. A ball valve kit (Vaisala item code:

BALLVALVE-1) is available for connecting the probe to a pressurized process or pipeline: see

Attaching ball valve kit to process (page 30).

HMP378F and HMP378H probe variants for measuring oil and

fuel moisture

The HMP378F and HMP378H probe options are variants of the standard HMP378, designed for

measurements in oil (HMP378F) and fuel (HMP378H). They provide a specialized selection of

measurement parameters (see Table 4 (page 10)) intended specifically for oil and fuel

measurements. With HMP378F, oil-specific calculation coecients can be configured into use

to customize the measurement for a specific oil type: see Configuring calculation coecients

(page 69).

For more information on HMP378F, see HMP378F probe option for measuring oil moisture and

temperature (page 31).

For more information on HMP378H, see HMP378H probe option for measuring fuel moisture

and temperature (page 31).

28

Page 31

R1/2”ISO7/1 or NPT1/2”

Ø 13.5 (0.53)

35 (1.37)

Ø 12 (0.47)

14 (0.55)

35 - 157/379 (1.37 - 6.2/14.9) (user adjustable)

188/410 (7.40/16.1)

226/448 (8.90/17.6)

Length for standard/optional probes

Chapter 3 – Probe options

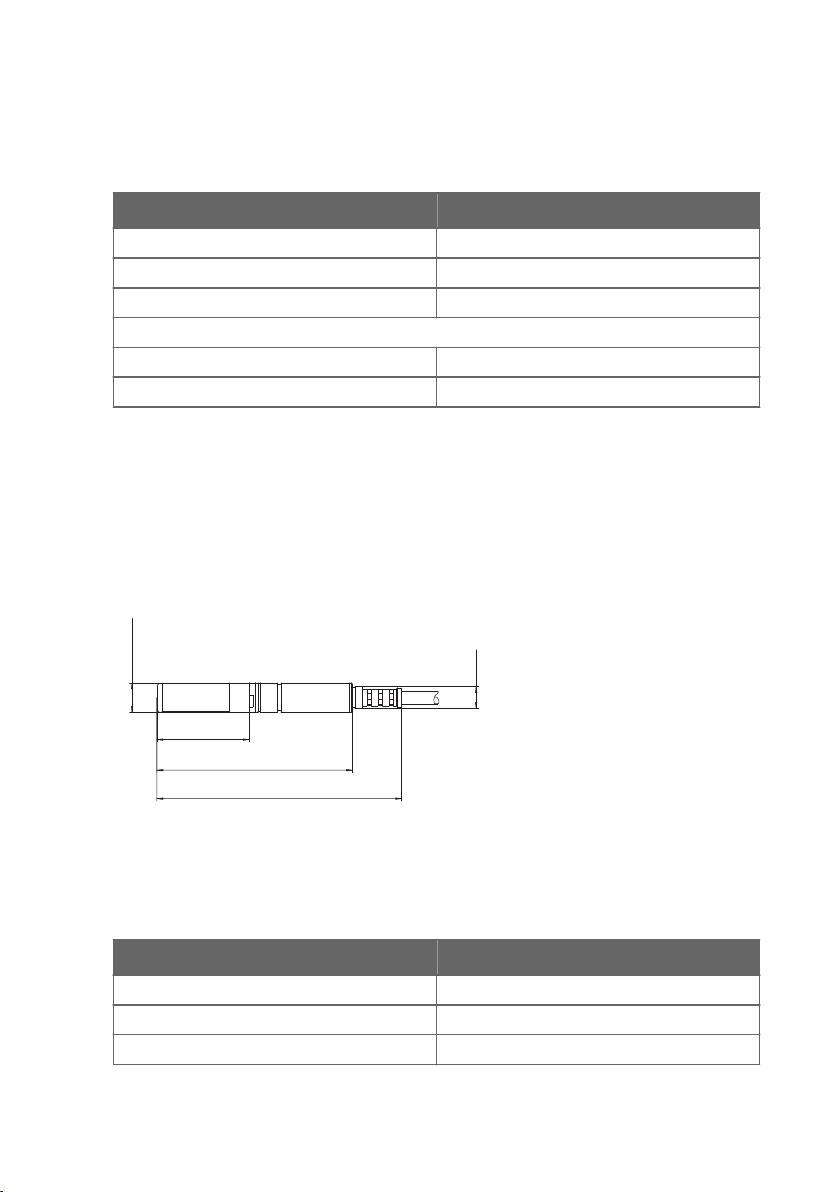

Dimensions

Figure 14 Dimensions in mm (inches)

Specifications

Table 16 HMP378 for pressurized pipelines

Property Description/value

Temperature range -70 … +180 °C (-94 … +356 °F)

Pressure range 0 … 4 MPa

Probe cable length 2, 5 or 10 meters (6 ft 7 in, 16 ft 5 in, 32 ft 10 in)

Probe diameter 13.5 mm/12 mm (0.53 in/0.47 in)

Available probe lengths 226 mm/448 mm (8.90 in/17.6 in)

Installation

Fitting body ISO1/2 solid structure DRW212076SP

Fitting body NPT1/2 solid structure NPTFITBODASP

Ball valve ISO 1/2 with welding joint BALLVALVE-1

29

Page 32

G1/2

ISO 228/1

Ø21.5 (drilling)

Ø14

Ø14

Ø14

2

3

4

5

1

HMT370EX User Guide M212305EN-A

3.7.1 Attaching ball valve kit to process

1 Ball valve handle: must point to the same direction as the ball valve body when installing.

2 Extension nipple, threads G1/2 ISO228/1 and R1/2 ISO7/1.

3 Ball valve body. When tightening the assembly, turn only from the ball valve body.

4 Ball of the ball valve.

5 Welding joint, threads R1/2 ISO7/1.

30

Page 33

Chapter 3 – Probe options

1. Attach the welding joint to the process pipe or chamber.

2. Apply a sealant (MEGA-PIPE EXTRA No. 7188 or LOCTITEâ No. 542 with activator No.

7649) on the threads of the welding joint and screw the bottom of the ball valve onto the

welding joint.

3. Tighten the ball valve assembly by turning from the ball valve body.

CAUTION!

Tightening the ball valve kit by turning the extension nipple

can break the sealing. Tighten the ball valve assembly only from the ball

valve body.

4. If you need to cap the ball valve assembly before installing or after removing the probe,

attach a blanking nut to close the top of the valve.

3.7.2 HMP378F probe option for measuring oil moisture and temperature

The HMP378F probe option is a variant of the standard HMP378, designed for measurements

in oil. The mechanics of the probe are the same as in the standard HMP378 probe option (see

HMP378 probe for pressurized pipelines (page 28)).

HMP378F uses the HUMICAPâ L2 sensor designed specifically for oil and fuel measurements.

For L2 sensor specifications, see Table 20 (page 85).

If required, oil-specific calculation coecients can be configured into use to customize

HMP378F measurements. For instructions, see Configuring calculation coecients (page 69).

The following measurement parameters are available for HMP378F:

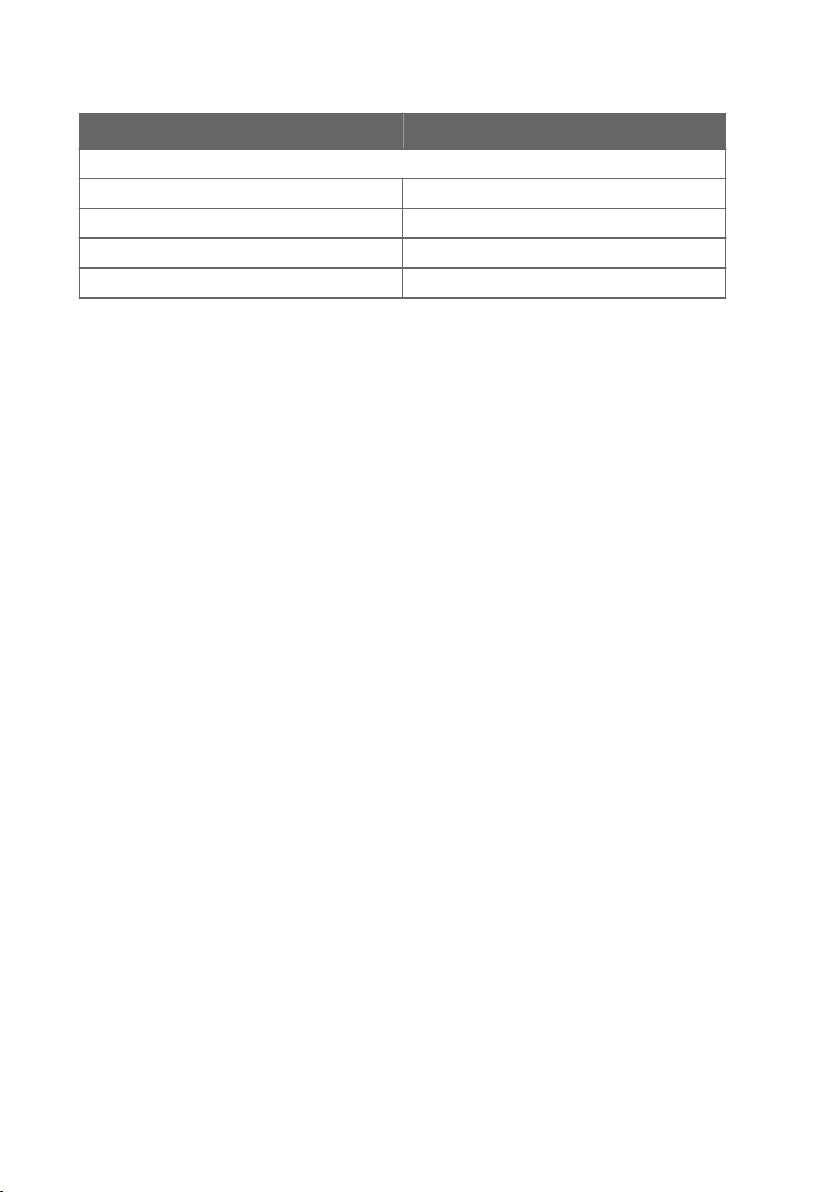

Table 17 HMP378F measurement parameters

Parameter Abbreviation Unit

Temperature T °C (°F)

Relative saturation RS %RS

Water activity a

Water concentration in oil H2O (oil) ppm

w

w

3.7.3 HMP378H probe option for measuring fuel moisture and temperature

The HMP378H probe option is a variant of the standard HMP378, designed for measurements

in fuel. The mechanics of the probe are the same as in the standard HMP378 probe option (see

HMP378 probe for pressurized pipelines (page 28)).

31

Page 34

HMT370EX User Guide M212305EN-A

HMP378H uses the HUMICAPâ L2 sensor designed specifically for oil and fuel measurements.

For HUMICAP L2 sensor specifications, see Table 20 (page 85).

The following measurement parameters are available for HMP378H:

Table 18 HMP378H measurement parameters

Parameter Abbreviation Unit

Temperature T °C (°F)

Relative saturation RS %RS

Water activity a

w

Water concentration in fuel H2O (fuel) ppm

Saturation temperature T

s

w

°C (°F)

32

Page 35

A

Chapter 4 – Installation

4. Installation

4.1 HMT370EX installation overview

Figure 15 (page 33) shows an example HMT370EX installation using the HMP373 probe with

the probe head mounted with a bracket, and with both lead-throughs fitted with cable glands.

Figure 15 Example wall installation with HMP373 probe

CAUTION!

requirements in this installation overview and the hazardous area safety section

Guidelines for safe use in hazardous conditions (page 17).

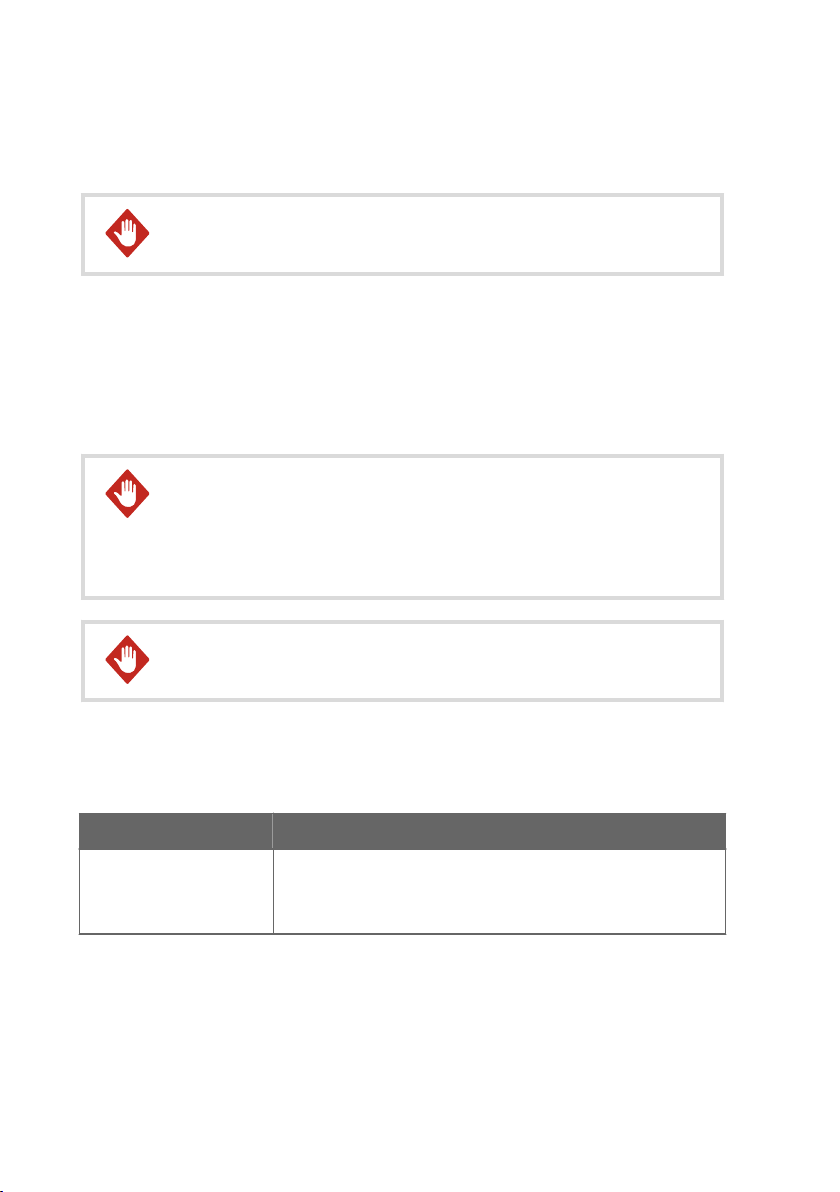

WARNING!

ensure that an IEC 60079-14 compliant safe work procedure has been

implemented in the hazardous area.

Before starting the installation, review the equipment and safety

The installation must be carried out in a safe area, or you must

33

Page 36

HMT370EX User Guide M212305EN-A

WARNING!

be opened in a hazardous area. The probe can be detached and changed

when HMT370EX is powered. Any other live maintenance, including changing

the probe head filter, is not allowed.

• Screws for mounting the transmitter:

• Installation directly through the transmitter body: 2 pcs Ø 5.5 mm screws

• Installation with optional mounting plate: 4 pcs Ø 5.5 mm screws and 2 pcs

• Crosshead screwdriver for transmitter cover captive screws and wiring screw

terminals

• Flathead screwdriver for the grounding terminal

• Cable glands, conduits, and plugs as required in your application, and suitable

tools for attaching and tightening them

• Wire-cutting pliers

Optional:

• Crimping tool and wire ferrules

• Allen key (5 mm) for probe body locking wheel

• Ex-compliant multimeter for testing analog outputs

When HMT370EX is powered, the transmitter enclosure must not

M6 Allen screws

4.1.1 Installation preparations

Before starting the installation, check the following:

• Make sure that your installation site suits the Ex classification of the transmitter: see Table

7 (page 16).

• Review the hazardous area information in Guidelines for safe use in hazardous conditions

(page 17) for further information on Ex safety requirements related to HMT370EX and

specific conditions of use.

• When selecting the cable glands and plugs for your application, review the information in

Cable gland and conduit options (page 14).

• Review the wiring diagrams included in this document for information on wiring using

either a galvanic isolator or a Zener barrier.

• Wiring with galvanic isolators (page 40)

• Wiring with Zener barriers (page 41)

34

WARNING!

mandatory in a hazardous environment.

CAUTION!

(CH1) must always be wired. The transmitter receives power through the

Channel 1 screw terminals, and does not power on if only Channel 2 (CH2) is

wired.

Protected installation using galvanic isolators or Zener barriers is

When planning the wiring of your application, note that Channel 1

Page 37

A

mm

[in]

160 [6.3]

35.5

[1.4]

124.5 [4.9]

115 [4.53]

59 [2.3]

56.5 [2.2]

141 [5.5]

115 [4.53]

141 [5.5]

Chapter 4 – Installation

4.1.2 Probe installation overview

Figure 16 Duct installation example with HMP373 probe and duct installation kit

HMT370EX transmitters can be used with 6 dierent probe options that are designed for a

variety of applications. The installation options vary from wall mounting (fixed HMP371 probe

option) to, for example, duct installations (as shown in the HMP373 example in Figure 16

(page 35)) and ball valve installations (HMP378 probe option for pressurized pipelines).

The dierent probe options have varying operating environment specifications, installation

methods, and installation accessories depending on their intended applications. For more

information on each option, see HMT370EX probe options overview (page 21). Also review the

safety information related to allowed ambient temperature ranges for probes before

installation: see Table 8 (page 18).

4.1.3 HMT370EX transmitter dimensions

Figure 17 HMT370EX transmitter dimensions

35

Page 38

2 ×

Ø 5 mm

[0.2 in]

HMT370EX User Guide M212305EN-A

4.2 Mounting

Figure 18 Mounting HMT370EX directly through the transmitter body

Select a surface (for example, a wall) for installing the transmitter. You can mount the

transmitter directly to the installation surface with 2 screws, or use an optional mounting plate

that attaches to the back of the transmitter.

1. Detach the probe body from the transmitter body, loosen the captive screws on the

transmitter cover, and open the cover.

36

Page 39

M6

4 ×Ø 5.5 mm

M6

Chapter 4 – Installation

2. Mount the transmitter body on the installation surface either directly through the

transmitter body, or using the optional HMT360 retrofit mounting plate:

a. Installation without mounting plate: attach the transmitter body directly to the

installation surface with 2 Ø 5.5 mm screws as shown in Figure 18 (page 36). The lefthand screw hole has extra vertical space for adjusting the position of the transmitter

after you have attached the right-hand screw.

b. Installation with mounting plate: attach the mounting plate to the installation surface

with 4 Ø 5.5 mm screws, and then attach the transmitter to the mounting plate with 2

M6 Allen screws.

4.3 Attaching cable glands and conduit fittings

The HMT370EX transmitter body has 2 lead-throughs (M20x1.5) for wiring. The combination of

cable glands, conduit fittings, and plugs used in the lead-throughs is application-specific, and

must be determined by the customer. For information on lead-through accessories available

from Vaisala and lead-through accessory requirements, see Cable gland and conduit options

(page 14).

CAUTION!

the following requirements:

• The cable glands and cables used for wiring the device must not impair the Ex

protection.

• Unused lead-throughs must be sealed using Ex compliant plugs.

• The glands and plugs must be water and dust tight.

If you use lead-through accessories not ordered from Vaisala, note

37

Page 40

M20×1.5

M20×1.5

HMT370EX User Guide M212305EN-A

1. Install the application-specific lead-through accessories and lead the wiring cables

through them into the transmitter body: an example is shown below.

4.4 Wiring

38

WARNING!

mandatory in a hazardous environment.

Galvanic isolators and Zener barriers are available from Vaisala as accessories. See

Spare parts and accessories (page 93).

CAUTION!

minimum voltage in all conditions, measured at the transmitter screw terminals.

If the supply voltage is less than 12 V DC, the analog output current can be

erroneous.

It is recommended to use ferrules on the stripped wires to help ensure a secure

connection with the screw terminals.

Protected installation using galvanic isolators or Zener barriers is

Ensure that the transmitter is powered correctly. 12 V DC is the

Page 41

4 – 20 mA

−

+

−

+

CH 1

4 – 20 mA

CH 2

12 – 28 V

Chapter 4 – Installation

Figure 19 Wiring example using one cable

1. Prepare the cabling wires as required in your application (cabling either through 1 or 2

lead-throughs).

a. Strip the cable wires: it is recommended to attach ferrules to the contact ends of the

wires.

b. Open the cable gland and insert a suitable length of the cable inside the transmitter

through the cable gland.

c. Tighten the cable gland: refer to the instructions of the glands used in your

application for maximum tightness.

d. If your installation does not require using both lead-throughs, plug the unused lead-

through with an Ex compliant seal.

2. Connect the screw terminal wiring as required in your application. For protected

installation wiring diagrams, see Wiring with galvanic isolators (page 40) and Wiring

with Zener barriers (page 41).

a. Open the cable fastening clamps below the screw terminals and lead the cables to the

terminals through the clamps.

b. Connect the wires to the screw terminals: for an example, see Figure 19 (page 39).

Note that Channel 1 (CH1) must always be wired. The transmitter receives

power through the CH1 screw terminals, and does not power on if only

Channel 2 (CH2) is wired.

c. Adjust the length of the wires and close the cable fastening clamps so that they hold

the cables in place.

39

Page 42

mA

Test Points

mA

V

V

HAZARDOUS AREA

External

grounding

terminal

SAFE AREA

4 ... 20

mA

+

-

+

-

4 ... 20

mA

+

-

+

-

L

L

+

-

L

L

+

-

Intrinsically

safe certified

galvanic isolators

Controller

DC power supply

+

-

If the controller

uses voltage input,

use a shunt resistor:

+

-

4 ... 20 mA

Controller

U = I*RI

RI

+

-

+

-

HMT370EX User Guide M212305EN-A

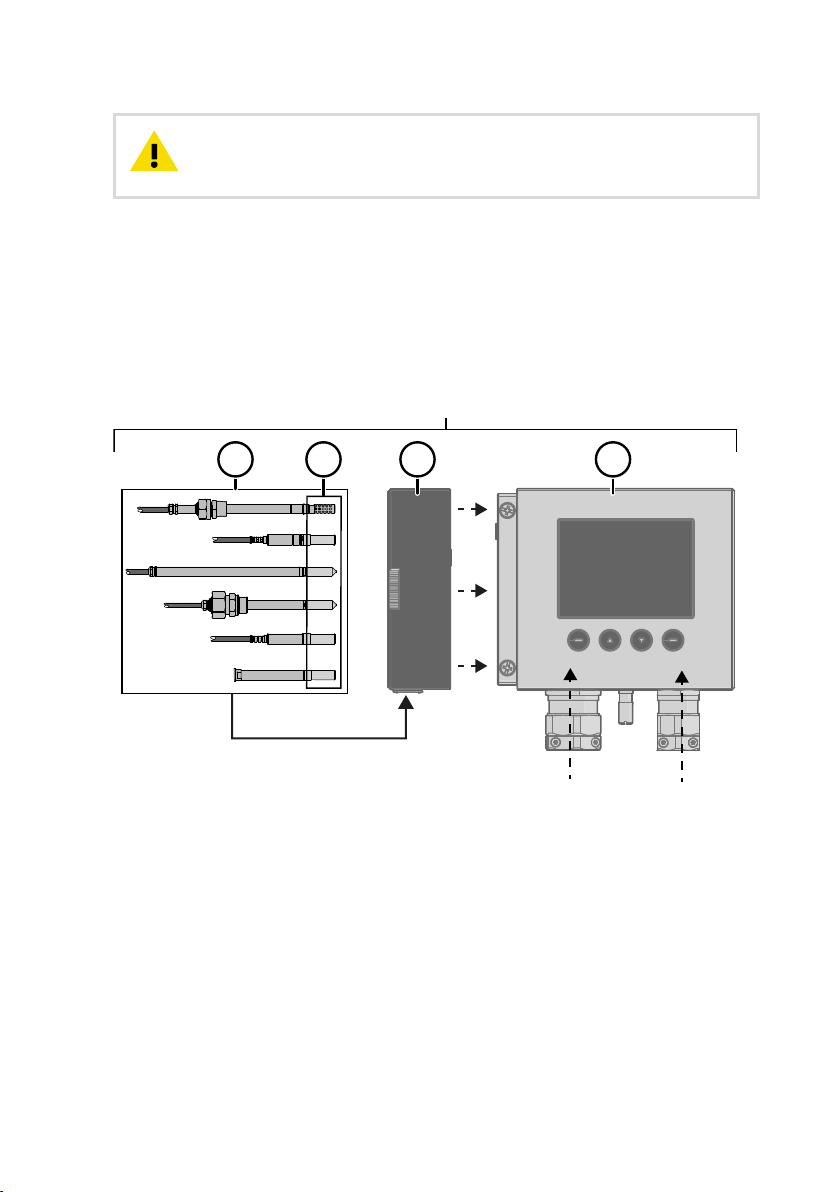

4.4.1 Wiring with galvanic isolators

Figure 20 Wiring diagram with galvanic isolators

40

Page 43

4.4.2 Wiring with Zener barriers

mA

Test Points

mA

V

V

HAZARDOUS AREA SAFE AREA

4 ... 20

mA

+-+

-

4 ... 20

mA

Intrinsically

safe certified

Zener barriers

Controller

DC power supply

+

-

+

-

If the controller

uses voltage input,

use a shunt resistor:

+

-

4 ... 20 mA

Controller

U = I*RI

RI

+-+

-

4 ... 20

mA

+

-

External

grounding

terminal

Chapter 4 – Installation

Figure 21 Wiring diagram with Zener barriers

41

Page 44

3.5 Nm

HMT370EX User Guide M212305EN-A

4.5 Finalizing installation: closing transmitter and attaching grounding

1. Close the transmitter body cover and tighten the captive screws. Tighten the screws to

approximately 3.5 Nm: ensure that there is no gap between the covers.

Ensure that the cover has been tightened suciently so that there is no gap

between the covers in the area highlighted in the illustration.

2. Attach the probe body to the transmitter.

42

It is sucient to tighten the probe body to finger tightness with the locking

wheel. To prevent detaching the probe body without tools, you can tighten

the locking wheel further with an Allen key (5 mm).

Page 45

4 mm2

Chapter 4 – Installation

3. Connect the grounding terminal on the bottom of the transmitter to the grounding

element of the installation site with a 4 mm2 grounding wire.

4. After grounding the transmitter, switch on the power supply input.

4.6

Optional: testing analog output level with a

multimeter

CAUTION!

hazardous area, unless a safe work permit has been issued in accordance with

the standard IEC 60079-14. Either remove the transmitter from the hazardous

area before opening the enclosure, or ensure that an IEC 60079-14 compliant

safe work procedure has been implemented in the hazardous area.

Always use an Ex compliant multimeter. The output parameters of the multimeter

must be compatible with the input parameters of the transmitter.

The transmitter body enclosure must not be opened in an explosion

43

Page 46

mA

Test Points

CH1

CH2

mA

V

V

20.0 mA

HMT370EX User Guide M212305EN-A

Figure 22 Multimeter test point overview

If you you want to verify the output level of the analog output channels, test the connection as

follows:

1. Detach the probe body and open the transmitter cover.

2. Connect a multimeter to the mA testing points located above the output screw terminals

on the transmitter component board.

3. Start the output test mode either by using the transmitter display interface, or, if using a

transmitter without a display, by connecting the transmitter to Insight PC software.

a. For instructions on using the output test mode with Insight PC software, see Testing

analog output level with Insight (page 64).

b. To start the output test mode with the display interface, open the Settings > Analog

outputs > Test outputs menu.

c. Select an output level to force the output to (4, 12, or 20 mA) and select Start. Verify

the output with the multimeter.

4. After verifying the output, remove the multimeter, close the transmitter cover, and

reattach the probe body.

44

Page 47

Chapter 4 – Installation

5. If the output is incorrect and requires adjustment, see Analog output adjustment overview

(page 74).

CAUTION!

The service port (see Figure 3 (page 14)) must only be used in

a safe area. Either remove the transmitter from the hazardous area or

ensure that a safe work procedure has been implemented in the hazardous

area. Only use the Vaisala accessory PC connection cable with the service

port.

45

Page 48

A

1 2

3 4

HMT370EX User Guide M212305EN-A

5. HMT370 local display interface

5.1 Local display overview

Figure 23 HMT370EX local display examples: measurement graph view and main menu screen

The display version of the HMT370EX transmitter has graphical LCD display with a 4-button

interface. The local display can be used to view measurement information, configure settings,

and calibrate and adjust measurements and outputs.

Using local display interface buttons

The display interface has 4 buttons for operating the display menus.

Figure 24 HMT370EX display interface buttons

Back: press to move back in the menu tree or cancel a selection.

1

2 Up: move up in the menu tree or increase a value.

3 Down: move down in the menu tree or decrease a value.

4 Select: press to open a menu or confirm a selection.

46

Page 49

Chapter 5 – HMT370 local display interface

Press and hold Back to return directly to the main menu.

Press and hold the Up or Down button to increase or decrease a value faster.

Measurement information views

The home view of the display has several options for showing the measurement information of

the connected probe. You can switch between the dierent views (for example, numerical

parameters or graph view) using the Up and Down buttons. The parameter display settings

can be configured in the Settings > Display menu.

Figure 25 2 parameter view example

Figure 26 Graph view example

47

Page 50

UP

SELECT

BACK

BACK

HMT370EX User Guide M212305EN-A

Figure 27 Parameter list view example

Configuration options

You can configure the following settings with the local display:

• Analog output settings (parameters, scaling, fault indication, output test and adjustment)

• Measurement settings (environmental compensation and filtering factor)

• Display settings (displayed parameters, units, graph visualization options, general display

settings such as timeout and PIN code)

In addition to configuration, you can also calibrate and adjust the measurement of the

connected probe with dierent references (1-point or 2-point adjustment), view device and

measurement status information, and reset the transmitter back to factory settings.

5.1.1 Local display PIN code

You can enable a (non-configurable) PIN code in the Settings > Display menu to prevent using

the display menus without entering the code.

The PIN code is the following 4 button presses: Up > Select > Back > Back

Figure 28 Display PIN code button presses

48

Page 51

Chapter 5 – HMT370 local display interface

5.1.2 Light and dark display themes

Figure 29 Dark (left) and light (right) display theme examples

You can select either a Light or Dark display theme to match the lighting conditions of your

environment.

The Light theme has a light background and dark text and graphics, and the Dark theme has a

dark background and light text and graphics.

5.1.3 Sleep mode

Figure 30 Transmitter display in sleep mode

You can define a timeout after which the display goes to sleep mode when not used with the

Settings > Display > Timeout selection (1, 5, 15, 30, 60 minutes or disabled). Pressing any

button returns the display back to normal operation from the sleep mode.

49

Page 52

HMT370EX User Guide M212305EN-A

5.2 HMT370EX display main menu

Figure 31 HMT370EX display interface main

menu

The first view of the display interface menu contains 4 submenus for dierent configuration

options. See the following sections for more information on each submenu:

• Settings menu (page 50)

• Calibration menu (page 53)

• Status menu (page 53)

• Maintenance menu (page 54)

5.3

Settings menu

Figure 32 Settings menu

The Settings menu contains the following configuration options:

Display

Analog outputs Analog output 1 and 2 parameter selection, scaling, error output

Measurement

settings

50

Selections for which parameters are displayed, display interface

language, graph settings, display PIN code protection, timeout (sleep

mode), and theme.

selection, and output test mode.

Environmental compensation and filtering factor configuration.

Page 53

Chapter 5 – HMT370 local display interface

5.3.1 Display menu

Figure 33 Display menu

In the Display menu, you can select which parameters are shown on the display, change the

local display interface language, and configure graph, unit, display timeout, menu access PIN

code, and color theme options.

Displayed

parameters

Language Set the local display interface language. The available options are English,

Graph Set the measurement parameters shown as graphs and the time period

Units Set the display interface to show units either as metric or non-metric.

Menu PIN

code

Timeout Define the time after which the screen enters power saving mode (sleep

Theme Set the display interface to use either a Light or Dark color theme.

Select which measurement parameters are shown on the display. Up to 4

parameters can be shown simultaneously.

German, French, Japanese, and Chinese.

visualized in the graph.

Enable or disable using the fixed PIN code to restrict access to configuration

menus.

mode) if not used.

If you have selected a wrong language and need to change the display language,

see the instructions in Problems and their possible solutions (page 80). You can

also change the display language by connecting the transmitter to the Insight PC

software.

51

Page 54

HMT370EX User Guide M212305EN-A

5.3.2 Analog outputs menu

Figure 34 Analog output settings

In the Analog outputs menu, you can select the measurement parameters that are sent on

analog output channels 1 and 2, select the output scaling and error indication level, and test

the accuracy of the outputs.

Output 1 Select which measurement is sent on analog output channel 1 and how the

Output 2 The same configuration options as for Output 1.

Test outputs You can force the analog output to a fixed value (options: 4, 12, and 20 mA)

For more information on analog output configuration using the local display or Vaisala Insight

PC software, see Analog output configuration overview (page 61).

measurement value is scaled on the 4 – 20 mA output range. You can also set

the current level that is output to indicate an error state (either 3.6 mA or 21

mA).

and read the fixed output to verify that the transmitter outputs are working

correctly.

5.3.3 Measurement settings menu

In the Measurement settings menu, you can set environmental compensations and configure

the filtering factor.

CAUTION!

accurately measure calculated parameters that require pressure data. By default,

the pressure compensation value is set as 1013.25 hPa.

Pressure Enter the pressure of the current measurement environment (in hPa).

Filtering on/o Enable or disable measurement output filtering using the default

Extended filtering

on/o