Page 1

HMI38 HUMIDITY DATA

PROCESSOR AND

HMP35/36/37E PROBES

Operating Manual

U063en-2.1

June 1998

Vaisala 1998

Page 2

© Vaisala Oyj 1998

No part of this document may be reproduced in any form or by any

means, electronic or mechanical (including photocopying), nor may

its contents be communicated to a third party without a prior written

notice of the copyright holder.

The instruction manuals may be changed without prior notice.

Yleisjäljennös 06/1998

Page 3

HMI38

U063en-2.1 Operating Manual

Contents

1. PRODUCT DESCRIPTION..........................................................................................1

2. TO BE NOTED WHEN M EASURING HUMIDITY ........................................................2

3. TAKING THE HMI38 INTO USE..................................................................................3

4. COMMISSIONING .......................................................................................................4

4.1. Initializing the probe locations......................................................................4

4.2. Connecting the analogue outputs.................................................................4

4.3. Connecting the RS 232C or RS 485 serial bus .............................................5

4.4. Summary of the factory settings ...................................................................6

5. COMMANDS...............................................................................................................7

5.1. Display/keypad commands............................................................................7

5.1.1. Display mode....................................................................................7

5.1.2. Command m ode ...............................................................................7

5.1.3. Selecting and scaling the analogue outputs ......................................8

5.1.4. Setting the serial line parameters......................................................9

5.1.5. Setting the output mode..................................................................11

5.1.6. Others ............................................................................................12

5.2. Serial commands .........................................................................................16

5.2.1. Analogue output commands............................................................16

5.2.2. Output via the serial bus .................................................................18

5.2.3. Operating the HMI38 via the serial bus ...........................................20

6. DATA LOGGING.......................................................................................................22

6.1. Logging using display/keypad commands.................................................23

6.1.1. Start/stop data logging in the

6.1.2. Start/stop data logging in the

CONTINUOUS mode.............................23

CATCH mode ......................................24

6.1.3. Outputting the logged data to the serial line ....................................25

6.1.4. Outputting the logged data to the display ........................................26

6.2. Logging using serial line commands (

CONTINUOUS mode) .........................27

6.2.1. Data logging ...................................................................................27

7. CALIBRATION..........................................................................................................30

7.1. Humidity calibration.....................................................................................30

7.1.1. Calibration procedure......................................................................30

7.2. Temperature calibration ..............................................................................31

7.2.1. With display/keypad comm ands:.....................................................31

7.2.2. With serial line c om m ands..............................................................32

7.3. Calibrating the analogue outputs................................................................32

8. USING THE HMI38 AS A FIELD CALIBRATOR ........................................................ 33

8.1. HMD/W60/70 and HM P140 series transmitters ........................................... 33

8.1.1. Calibrating transmitters with voltage outputs ...................................34

8.1.2. Calibrating transmitters with current outputs ...................................36

8.2. HMP230 series transmitters ........................................................................37

8.2.1. One point calibration.......................................................................38

i

Page 4

HMI38

Operating Manual U063en-2.1

8.2.2. Two point calibration.......................................................................39

8.3. HMD/W 20/30 and HM P130Y series transmit ters ........................................40

9. MAINTENANCE........................................................................................................42

9.1. Reference measurements............................................................................42

9.2. Self-diagnostics........................................................................................... 42

9.3. Adjusting the contrast of the display..........................................................43

10. TECHNICAL DATA...................................................................................................43

10.1. Relative humidity.........................................................................................43

10.2. Temperature.................................................................................................43

10.3. Calculated quantities...................................................................................43

10.4. Data logging.................................................................................................44

10.5. Analogue outputs.........................................................................................44

10.6. Serial interface.............................................................................................44

10.7. Electronics ...................................................................................................44

10.8. Mechanics ....................................................................................................45

10.9. Electromagnetic compatibility ....................................................................46

10.9.1. Emissions.......................................................................................46

10.9.2. Immunity.........................................................................................46

11. ACCESSORIES AND SPARE PARTS.......................................................................46

APPENDIX 1: SERIAL COMMANDS ..........................................................................47

APPENDIX 2: ERROR MESSAGES............................................................................69

APPENDIX 3: HMP35E PROBE..................................................................................75

APPENDIX 4: HMP36E PROBE..................................................................................81

APPENDIX 5: HMP37E PROBE..................................................................................87

WARRANTY.....................................................................................................................93

This manual is valid for programme version 2.01.

ii

Page 5

HMI38

U063en-2.1 Operating Manual

1. PRODUCT DESCRIPTION

The microprocessor based HMI38 Humidity Data Processor is a light, portable

instrument with an optional carrying case and built-in rechargeable battery

which make it suitable for spot checking measurements or for use as a transfer

standard.

The HMI38 is used together with Vaisala’s HMP35E, HMP36E or HMP37E

humidity and temperature probes to measure relative humidity and temperature quickly and accurately. Two probes can be connected to each HMI38. The

HMI38 also calculates dewpoint, mixing ratio, absolute humidity and wet bulb

temperature from the relative humidity and temperature it has measured.

The HMI38 has two analogue outputs (0...1V or 0...5 V) which can be selected

and scaled freely. The HMI38 also has an RS 232C and an RS 485 interface.

The HMI38 Humidity Data Processor is used through the menu-based display.

The user can choose between metric and non-metric units. Output modes are

flexible: measured or calculated quantities can be displayed or they can be

transferred to a computer or peripheral device using either RS 232C or RS 485

serial bus. Because the HMI38 units are addressable, there can be several units

on the same RS 485 line.

The HMI38 can be used as a one point field calibrator for HMP140 series and

HMD/W60/70 transmitters with standard or customized settings, as well as for

calibrating their predecessors HMD/W20/30 and HMP130Y series. It can also

be used as a one or two point calibrator for HMP230 series transmitters. The

transmitters are calibrated using an appropriate reference cable between the

HMI38 and the calibrated transmitter.

The HMI38 can also be used as a data logger. In continuous data logging, the

user selects the interval and the starting time of logging; the HMI38 can store

up to 254 readings from both probes in CONTINUOUS mode. In addition, the

HMI38 can also be used for manual data logging. The CATCH mode enables

the user to store readings manually at any given moment. In this mode, the

HMI38 can store 127 readings from both probes. The HMI38 stores the

measured relative humidity and temperature values. When the stored data is

transferred to a computer or a peripheral through the serial bus, it calculates

the other four quantities from them.

The HMI38 is powered with DC voltage, but with an AC adapter it can be

powered from the mains. HMI38 has a built-in battery and a charger.

1

Page 6

HMI38

Operating Manual U063en-2.1

2. TO BE NOTED WHEN MEASURING HUMIDITY

It is essential in the measurement of humidity and especially in calibration that

temperature equilibrium is reached. Even a small difference in temperature

between the measured object and the sensor causes an error. If the t emperature

is +20 °C (+68 °F) and the relative humidity 50 %RH, a difference of ±1 °C

between the measured object and the sensor causes an error of ±3 %RH. When

the humidity is 90 %RH, the corresponding error is ±5.4 %RH.

The error is at its greatest when the sensor is colder or warmer than the surroundings and the humidity is high. A temperature difference of a few degrees

can cause water to condense on the sensor surface. In an unventilated space

evaporation may take hours; good ventilation accelerates evaporation. The

HUMICAP® sensor starts to function normally as soon as the water has evapo-

rated. If the condensed water is contaminated, the life span of the sensor may

shorten and calibration may change.

10

9

8

7

6

5

4

dRH (%RH)

3

2

1

0

-40 -20 0 20 40 60 80 100

Temperature (°C)

Figure 2.1 Measurement error at 100 % RH when the dif feren ce

between the ambient and sensor temperature i s 1 °C

2

Page 7

HMI38

U063en-2.1 Operating Manual

3. TAKING THE HMI38 INTO USE

Please, note that when you take the HMI38 into use for the first time, both

probe locations have the factory setting for the probe type HMP35E. If this is

not the case, the HMI38 displays error message(s) after power up (see

appendix 3). Error messages can be cleared by pressing ENT button several

times. Should this happen, you must initialize the probe locations. During

initialization, the HMI38 gets information on which probe locations have

probes connected to them. Initializing is described in Chapter 4.1.

If you use the instrument as a data logger, you must enter the correct date and

time; see Chapter 6.

In order to enable the HMI38 to calculate the mixing ratio and wet bulb

temperature accurately, enter the ambient air pressure through the keypad or

serial bus. This setting is described in Chapter 5.

The HMI38 has a rechargeable battery which has not been charged in the

factory. Charge the battery overnight. You can use the instrument instantly

when you connect it to the mains for charging. To maximize the battery

lifetime, completely discharge and recharge the battery about once a month.

You can discharge the battery by leaving the HMI38 on without an AC adapter

until the low battery voltage switches the HMI38 automatically off.

3

Page 8

HMI38

T

T

Operating Manual U063en-2.1

4. COMMISSIONING

4.1. Initializing the probe locations

You can use either keypad or serial bus commands for the initialization of the

probe locations. If you use serial commands, see Appendix 1.

If the probe type setting in the HMI38 memory is not correct, some error

messages may appear on the display after power up (see Appendix 3). You can

clear these messages by pressing ENT button one or several times. When the

humidity and temperature readings appear on the display, press CL key to

enter the command mode. The first display is the main menu:

Use arrow keys to select Init which starts to blink, and then press ENT. The

following appears with the indication of PROBE 1 blinking (in this example,

HMP35E):

Use arrow keys to select the correct type for PROBE 1 (HMP35E, HMP36E,

HMP37E, HMP35BM, HMP36BM) and press ENT. If there is no probe in

location 1, select none and press ENT. Use arrow keys to select also the type

for PROBE 2 and press ENT. The HMI38 returns to the display mode showing

the current readings.

4.2. Connecting the analogue outputs

Figure 4.1 shows the connections to the analogue output connector. See

Chapter 5.1.3 and Chapter 5.1.3.2 for selecting the quantities and for scaling

the analogue outputs.

ANALOGUE OUTPUT

0-1V/0-5V

1

2

3

4

5

6

7

8

9

AGND

CH1 OU

NC

CH2 OU

AGND

NC

NC

NC

NC

D9S

Figure 4.1 Cable connections to the analogu e outpu t connector

4

Page 9

HMI38

-

U063en-2.1 Operating Manual

4.3. Connecting the RS 232C or RS 485 serial bus

Figure 4.2 shows the pin configuration of the serial line connector and the

RS 232C serial line connection of the HMI38 to a peripheral device.

DO NOT CONNECT

RS 232 C RXD

RS 232 C TXD

NC

GND

NC

NC

RS 485 HI

RS 485 LO

HMI38

SER I/O

D9P

COMPUTER (IBM AT)

1

2

3

4

5

6

7

8

9

SER I/O

2

3

4

5

6

7

8

9

1

D9S

RXD

TXD

DTR

GND

DSR

RTS

CTS

RI

DCD

DO NOT CONNECT

RS 232 C RXD

RS 232 C TXD

RS 485 HI

RS 485 LO

NC

GND

NC

NC

HMI38

SER I/O

D9P

SERIAL PRINTER

(RS 232 PANASONIC KX

1

2

3

4

5

6

7

8

9

SER I/O

2

3

4

5

6

7

8

20

22

D25P

TXD

RXD

NC

NC

DSR

GND

DCD

DTR

NC

Figure 4.2 Wiring between the HMI38 and a PC or a serial line

printer using RS 232C serial line.

Connect the serial bus between the PC and the HMI38 and switch the PC on.

Use a terminal emulation programme (e.g. Procomm Plus, Datastorm or

Windows terminal) when using a PC. The following chapter lists the factory

settings for data transfer.

NOTE

When changing the serial bus settings, switch the

instrument off and on again or give the serial line

command RESET to activate the new settings.

Refer to the manuals of the PC and the terminal emulation programme when

giving serial settings.

5

Page 10

HMI38

Operating Manual U063en-2.1

4.4. Summary of the factory settings

The factory settings of the HMI38 are the following:

• probe initializations:

-probe 1 HMP35E

-probe 2 HMP35E

• auto power-off off

• output units metric

• pressure 1013.25 hPa (= mbar)

• analogue outputs:

-channel 1 RH1: 0...100 %RH 0...1 V

-channel 2 T1: -40...160 °C 0...1 V

• serial line:

-bauds, parity, data, stop 4800, even, 7, 1

-duplexity FDX

• address 0

• serial mode stop

• echo on

• output interval 0 s

• measurement integration time16

• filter off

6

Page 11

HMI38

U063en-2.1 Operating Manual

5. COMMANDS

The HMI38 incorporates a microprocessor which allows the configuration to

be set according to the user’s needs. This is done through commands, either

utilizing the menus on the front panel display or giving commands through the

serial interface. The commands can be used e.g. to choose the displayed

quantities, to select and scale the analogue outputs, to calibrate the

temperature channels as well as the analogue outputs and to set the serial

interface.

5.1. Display/keypad commands

5.1.1. Display mode

In the display mode the HMI38 outputs measured and calculated quantities on

the display. You can scroll the first line with button s and the second line

with button t. After reset the instrument shows first the programme type and

version and then goes on to the display mode.

You can scroll different quantities with arrow switches. Acknowledge each

selection by pressing ENT; this way, they appear on the display even after

power off. The display also shows error messages and alarms if they occur.

5.1.2. Command mode

Press the CL key to enter the command mode. The first display is the main

menu:

You can scroll the commands with the arrow keys. The currently active

command blinks; select the desired command with the ENT key. When a menu

is on the display, either the first command or the currently valid setting blinks.

The CL key takes the HMI38 back to the display mode.

7

Page 12

HMI38

Operating Manual U063en-2.1

5.1.3. Selecting and scaling the analogue outputs

5.1.3.1. Selecting the output

• Select Mode in the main menu and Analog outputs in the Mode menu:

• Select Mode 1V / 5V. The current settings for channel 1 are displayed:

• If the settings are correct, press ENT.

• If you need to change the settings, press CL:

− the lower limit starts blinking

− acknowledge the lower limit with ENT or change it with the nu-

meric keys, then press ENT

− the upper limit starts blinking

− acknowledge the upper limit with ENT or change it with the nu-

meric keys, then press ENT

• When channel 1 has been set, the programme goes on to channel 2;

the procedure is the same as with channel 1.

NOTE

The hardware has two basic voltage ranges: 0...1 V and

0...5 V. When scaling analogue outputs, please note that

the relative accuracy of the output may become too low

if only a very small part of either range is used to output

a quantity with a wide measurement range.

5.1.3.2. Selecting and scaling the analogue output quantities

• Select Mode in the main menu and Analog outputs in the Mode menu:

• Select Scale. The quantity and scaling for channel 1 are displayed:

8

Page 13

HMI38

U063en-2.1 Operating Manual

• If the settings are correct, press ENT.

• If you need to change the settings, press CL:

− the quantity (RHn, Tn, Tdn, xn, an, Twn; n = 1 or 2) starts blink-

ing; change it with the arrow keys and acknowledged with the ENT

key

− the lower limit starts blinking

− acknowledge the lower limit with ENT or give a new value using

the numeric keypad and press ENT

− the upper limit starts blinking

− acknowledge the upper limit with ENT or give a new value using

the numeric keypad and press ENT

• After channel 1 has been set the settings of channel 2 appear on the

display; follow the procedure described above for channel 1.

5.1.4. Setting the serial line parameters

5.1.4.1. Turning the serial interface echo ON/OFF

• Select More in the main menu, More in the More menu and Echo in

the second More menu.

• Use the arrow keys to select the right alternative and press ENT.

5.1.4.2. Serial bus settings

• Select Seri in the main menu; the currently valid serial int erface set-

tings are displayed:

• If the settings are correct, press ENT; the programme returns to the

display mode.

• If you need to change the settings, press CL:

9

Page 14

HMI38

Operating Manual U063en-2.1

• Select the parameter to be changed with the arrow keys and ENT key.

− Selecting baud rate:

− Selecting parity:

− Selecting data bits:

− Selecting stop bits:

− Full duplex/half duplex:

NOTE

The serial bus settings become effective only after

power off/on or the serial line command RESET.

5.1.4.3. Setting the instrument address

Address is used when more than one instrument is connected to one serial bus;

this enables communication with one instrument at a time.

10

• Select More in the Main menu and then Addr in the More menu; the

following appears on the display:

• Change the address by entering a new value and pressing ENT.

• Pressing ENT returns the programme to the More menu.

Page 15

HMI38

U063en-2.1 Operating Manual

• Pressing CL returns the programme to display mode and leaves the

address unchanged.

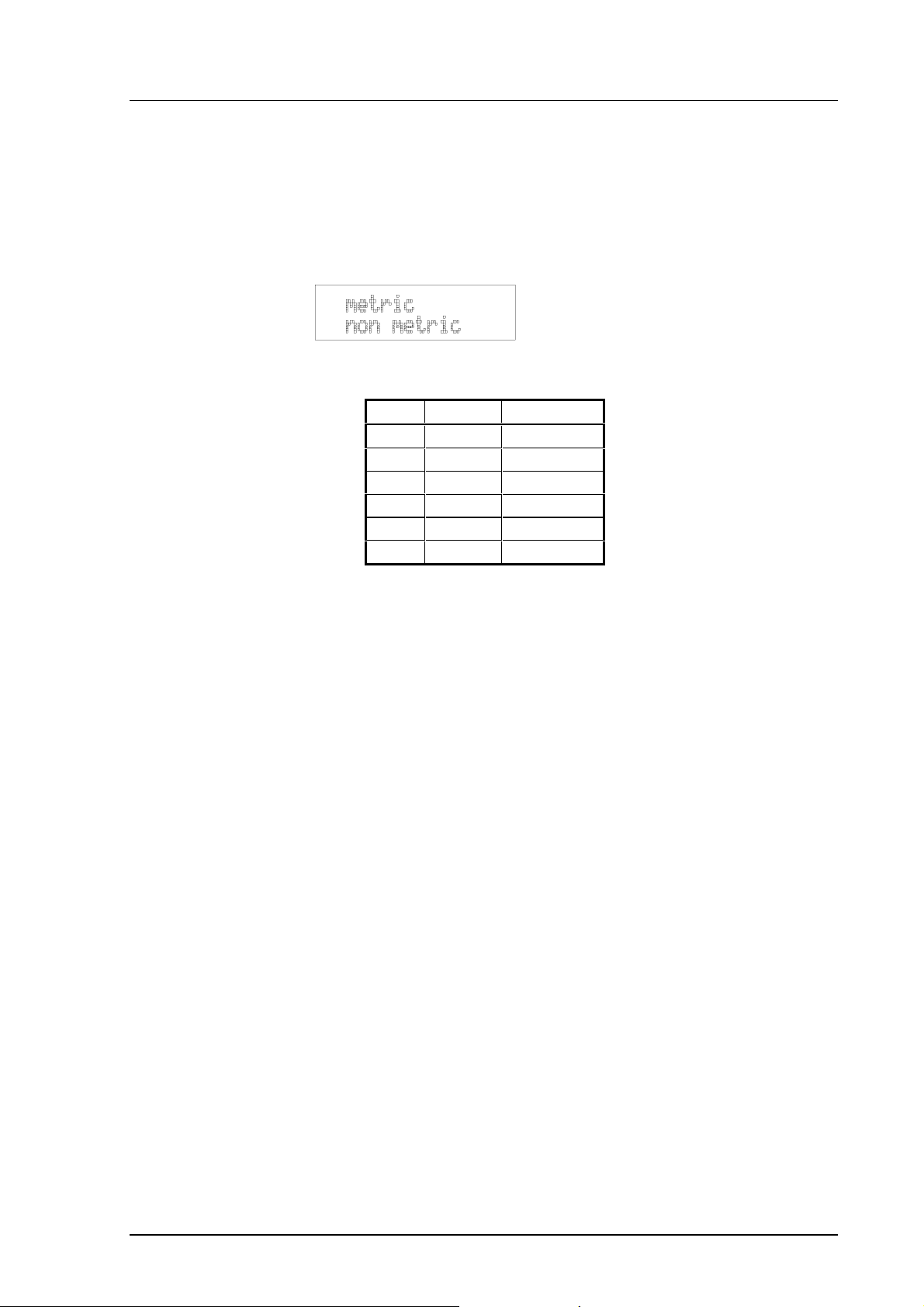

5.1.4.4. Selecting the output units

• Select More in the Main menu and Unit in the More menu:

• Use the arrow keys to select the right alternative and press ENT.

metric non-metric

RH %RH %RH

T °C °F

Td °C °F

ag/m3gr/ft

3

x g/kg gr/lb

Tw °C °F

5.1.5. Setting the output mode

The output modes only affect output through the serial interface: the instrument accepts all display/keypad commands irrespective of which serial output

mode it is in. The HMI38 has three serial output modes: RUN, STOP and

POLL.

In the RUN mode the instrument outputs measurements automatically through

the serial interface to a PC or a peripheral. The only command that can be

given through the serial interface is S (stop), which ends the RUN mode.

In the STOP mode serial commands are given to the instrument. Measurements can be output only by giving command SEND.

The POLL mode is used when more than one instrument is connected to the

same serial bus; a single instrument can be addressed and communicated with.

When the connection to one instrument is opened in the POLL mode, this

instrument goes into STOP mode and can then accept commands normally.

Closing the connection returns the instrument to POLL mode. In POLL mode

the instrument outputs measurements only when requested (command SEND

aa). If the user has forgotten the address of the instrument, it can be checked

using display/keypad commands.

11

Page 16

HMI38

Operating Manual U063en-2.1

5.1.5.1. Setting the serial interface operation mode

• Select Mode in the main menu; the following appears on the display:

• Select Serial:

• The currently valid setting blinks. Select the desired mode with the ar-

row keys and press ENT. After this the programme returns to the

previous Menu.

• If you select the Run mode, the currently valid output interval appears

on the display (with number and unit blinking):

If required, change the output interval setting as follows:

• press CL

• the number starts blinking

• if you need to change the interval, enter the new interval; otherwise

press ENT

• the unit (seconds, minutes or hours) starts blinking

• if necessary, change the unit with the arrow keys and acknowledge it

with ENT

• after this the programme returns to the previous menu

5.1.6. Others

5.1.6.1. Setting the measurement integration time

Lengthening of the measurement integration time filters out any stray changes

in the output: the instrument calculates the average of the number of

measurement cycles defined by the user.

12

• Select More in the main menu, More in the More menu and Mtim in

the second More menu:

Page 17

HMI38

U063en-2.1 Operating Manual

• Pressing ENT returns the programme to the previous menu without

changing the integration time.

• If you need to change the integration time, enter the new time

(4...255) and press ENT.

5.1.6.2. Setting the measurement integration filter

If the integration filter is set on, the output reading is an average of four last

measurements.

• Select More in the main menu, More in the More menu and Filt in the

second More menu:

• Choose the correct alternative (Filter on/off) with arrow keys and

press ENT.

5.1.6.3. Setting the pressure for mixing ratio and wet bulb

temperature calculations

The atmospheric pressure has an effect on mixing ratio and on wet bulb temperature. To achieve accurate calculations, the instrument needs to take the

ambient pressure into account.

• Select More in the main menu:

• Select Pres:

• Pressing ENT returns the programme to the previous menu without

changing the pressure reading.

• If you need to change the pressure, enter the new value and press

ENT.

13

Page 18

HMI38

Operating Manual U063en-2.1

5.1.6.4. Setting the date

• Select More in the main menu; select Date in the More menu:

• If the date is correct, acknowledge it by pressing ENT; this takes the

programme back to the More menu.

• If you need to change the date, press CL. Enter the new date in the

order the digits blink (year-month-day) and press ENT. Press ENT

again to return to the previous menu. If there is no need to change the

date, press CL.

5.1.6.5. Setting the time

• Select More in the main menu; select Time in the More menu:

• If the time is correct, acknowledge it by pressing ENT; this takes the

programme back to the More menu.

• If you need to change the time, press CL. Enter the new time in the

order the numbers blink and press ENT. Press ENT again to return to

the previous menu. If there is no need to change the time, press CL.

NOTE

As the HMI38 does not have a real-time clock with a

backup battery, the date and time settings do not stay in

the memory during power-off.

5.1.6.6. Setting the automatic shutdown

14

You can set the HMI38 to switch the power off automatically if no button is

pressed for a certain time.

• Select More in the main menu; select More in the first More menu

and then again in the second More menu:

• Press ENT and select the correct alternative (on/off) for the power-off

mode with the arrow keys, then press ENT.

Page 19

HMI38

U063en-2.1 Operating Manual

• If you choose On, the current power-off time appears. If required,

change the time setting as follows:

• press CL

• the number starts blinking

• if you need to change the time, enter the new time; otherwise press

ENT

• the unit (seconds, minutes or hours) starts blinking

• if required, change the unit with the arrow keys and acknowledge it

with ENT

• after this the programme returns to Main menu

NOTE

Auto power-off is not operational during data logging

and calibration procedures.

15

Page 20

HMI38

Operating Manual U063en-2.1

5.2. Serial commands

Appendix 1 contains more detailed descriptions of the serial commands. The

following chapters include only the most commonly used command

sequences.

You can interrupt any serial command while giving it by pressing ESC. In the

commands <cr> means carriage return.

5.2.1. Analogue output commands

5.2.1.1. Setting the analogue outputs

AMODE a.aaa b.bbb c.ccc d.ddd <cr>

a.aaa = l ower voltage limit of channel 1

b.bbb = upper voltage limit of channel 1

c.ccc = l ower voltage limit of channel 2

d.ddd = upper voltage limit of channel 2

Sets the voltage scale of the analogue outputs on channels 1 and 2 (anything

between 0...5 V).

NOTE

The hardware has two basic voltage ranges: 0...1 V and

0...5 V. When scaling analogue outputs, please note that

the relative accuracy of the output may become too low

if only a very small part of either range is used to output

a quantity with a wide measurement range.

Examples: Voltage output on channel 1 is set to 0...1 V and that on channel 2

is set to 2...5 V:

>AMODE 0 1 2 5 <cr>

Ch1 0.000 ... 1.000 V

Ch2 2.000 ... 5.000 V

The current settings are checked by entering AMODE without parameters

>AMODE <cr>

Ch1 0.000 ... 1.000 V

Ch2 2.000 ... 5.000 V

16

Page 21

HMI38

U063en-2.1 Operating Manual

5.2.1.2. Selecting and scaling the analogue output quantities

ASEL xxx yyy <cr>

xxx = quantity of channel 1 (RHn, Tn, Tdn, An, Xn or Twn)

yyy = quantity of channel 2 (RHn, Tn, Tdn, An, Xn or Twn)

(n = 1 or 2)

Examples: Relative humidity of probe 1 is output on channel 1 and tempera-

ture of probe 2 on channel 2; the temperature range is scaled to be

0...100 °C:

>ASEL RH1 T2 <cr>

Ch1 ( RH1 ) lo 0.000 %RH ? <cr>

Ch1 ( RH1 ) hi 100.000 %RH ? <cr>

Ch2 ( T2 ) lo -40.000 ’C ? 0 <cr>

Ch2 ( T2 ) hi 160.000 ’C ? 100 <cr>

>

After entering ASEL without parameters the instrument outputs its

current settings

>ASEL <cr>

Ch1 ( RH1 ) lo 0.000 %RH ? <cr>

Ch1 ( RH1 ) hi 100.000 %RH ? <cr>

Ch2 ( T2 ) lo 0.000 ’C ? <cr>

Ch2 ( T2 ) hi 100.000 ’C ? <cr>

>

5.2.1.3. Scaling the analogue outputs

ASCL <cr>

Scales the outputs selected on channels 1 and 2 (almost the same as ASEL but

for scaling only).

Example: Scaling relative humidity on the range of 0...100 %RH and tem-

perature -40...+160 °C

>ASCL <cr>

Ch1 ( RH1 ) lo 20.000 %RH ? 0 <cr>

Ch1 ( RH1 ) hi 90.000 %RH ? 100 <cr>

Ch2 ( T2 ) lo 0.000 ’C ? -40 <cr>

Ch2 ( T2 ) hi 100.000 ’C ? 160 <cr>

>

17

Page 22

HMI38

Operating Manual U063en-2.1

5.2.2. Output via the serial bus

5.2.2.1. Starting the measurement output

R <cr>

Starts the measurement outputting of to peripheral devices (RUN mode); the

only command that can be used is S (stop).

The output format can be changed with command FORM (see appendix 1).

5.2.2.2. Stopping the measurement output

S<cr>

Ends the RUN mode; after this command all other commands can be used.

5.2.2.3. Outputting the reading once

SEND <cr>

in STOP mode or

SEND aa <cr>

in POLL mode

aa = address of the transmitter when more than one instrument is

connected to a serial bus (0...99)

The output format can be changed with command FORM (see appendix 1).

5.2.2.4. Setting the output interval for the RUN state

INTV xxx yyy <cr>

xxx = output interval (0...255)

yyy = unit (s, min or h)

18

Sets the output interval for RUN mode and command R. If the interval is set to

zero (s, min or h), the output interval will be determined by the frequency of

measurements only.

Example: Changing output interval to 10 minutes

>INTV 10 min <cr>

Output intrv. : 10 min

Page 23

HMI38

U063en-2.1 Operating Manual

5.2.2.5. Serial bus settings

SERI b p d s x <cr>

b = bauds (300, 600, 1200, 2400, 4800, 9600)

p = parity (n = none, e = even, o = odd)

d = data bits (7 or 8)

s = stop bits (1 or 2)

x = duplex (H = half, F = full)

Examples: Giving new settings

>SERI O H <cr> changing parity and duplex only

4800 O 7 1 HDX

>SERI 600 N 8 2 F <cr>

600 N 8 2 FDX

changing all parameters

NOTE

New settings are effective only after switching the instrument off/on or after the serial command RESET has

been given.

If half-duplex setting is used with RS 485 bus, it will automatically turn the

echo off. Even then the ECHO command can indicate that echo is on.

5.2.2.6. Selecting the output units

UNIT x <cr>

x = m(etric units)

n(on-metric units)

metric non-metric

RH %RH %RH

T °C °F

Td °C °F

ag/m3gr/ft

x g/kg gr/lb

Tw °C °F

3

19

Page 24

HMI38

Operating Manual U063en-2.1

5.2.2.7. Setting the address

ADDR aa <cr>

aa = address (0...99)

Example: The HMI38 is given address 99

>ADDR <cr>

Address : 0 ? 99 <cr>

5.2.2.8. Resetting the HMI38

RESET <cr>

5.2.3. Operating the HMI38 via the serial bus

Setting the serial interface mode

SMODE xxxx<cr>

xxxx = STOP, RUN or POLL

In STOP mode: measurements output only by command, all

commands can be used

In RUN mode: outputting automatically, only command S can be

used

In POLL mode: measurements output only with command SEND.

When in POLL mode, the output mode is changed as follows:

OPEN aa <cr>

SMODE xxxx<cr>

20

aa = address of the transmitter

xxxx = STOP, RUN or POLL

The OPEN command sets the bus temporarily in STOP mode so that the

SMODE command can be given.

Example:

>SMODE STOP <cr> setting STOP mode

Serial mode : STOP

Page 25

HMI38

U063en-2.1 Operating Manual

5.2.3.1. OPEN & CLOSE

OPEN nn <cr>

nn = address of the transmitter (0...99)

CLOSE <cr>

In STOP mode: OPEN has no effect, CLOSE sets the serial bus

temporarily to the POLL mode

In POLL mode: OPEN sets the serial bus temporarily to STOP

mode; CLOSE sets the bus back to POLL mode

The temporary mode changes are not stored in the memory of the transmitter;

after reset the bus is in its original mode.

When more than one instrument is connected to the same serial bus, the POLL

mode enables communication with an individual instrument.

Example: Transmitter 2 is temperature calibrated (currently in POLL mode)

>OPEN 2 <cr> this line is not visible on the screen

HMI 2 line opened for operator commands

>CT <cr>

...

>CLOSE <cr>

line closed

calibration procedure

21

Page 26

HMI38

Operating Manual U063en-2.1

6. DATA LOGGING

The HMI38 has two data logging modes: the CONTINUOUS mode, i.e. automatic

logging which can store up to 254 readings from both probes and the CATCH

mode, i.e. manual logging with which the user can store up to 127 readings

from both probes. The user can choose the logging interval and starting time

of the logging when using the CONTINUOUS mode, and in the CATCH mode he

can store readings at any given moment by pushing the button ENT. The

HMI38 stores the measured relative humidity and temperature values and

when the stored data is transferred to a computer or peripheral through the

serial bus, it calculates the other four quantities – dewpoint temperature,

mixing ratio, absolute humidity and wet bulb temperature – from them.

NOTE

The CATCH mode is available only in units that have the

software version 2.01 or more. You can easily check the

version by reading the sticker on back of the device

(SV2 indicates software version 2.01 or more).

Activate logging with either display/keypad or serial line commands. The

logged data is output to serial line. In outputting the values for mixing ratio

and wet bulb temperature, the currently valid pressure setting is used.

NOTE 1

To save battery, the analogue outputs cannot be used

when data logging is on.

NOTE 2

When the HMI38 is powered from the battery and the

logging memory becomes full, the instrument automatically turns itself off.

22

Page 27

HMI38

U063en-2.1 Operating Manual

6.1. Logging using display/keypad commands

6.1.1. Start/stop data logging in the CONTINUOUS mode

NOTE

The HMI38 has no battery operated real-time clock.

Give current date and time settings manually after

power-on (see Chapter 5.1.6.5); this way, correct time

and date indications are stored with each reading.

To start data logging:

• Select Logg in the main menu. The LOGG menu is displayed:

• Select Start and in the START menu, select Continuous:

• The current delay (time before logging starts) and interval (time

between sequential data storings) settings appear on the display with

the current delay blinking:

• Press ENT to acknowledge the current delay time setting. To change

the setting press CL. Enter the new time and press ENT, then choose

the correct time unit (s, min, h) with the arrow keys and press ENT.

Acknowledge or change the time interval the same way.

After you have set the time interval, the data logging starts and the logging

status appears on the display. The HMI38 displays the logging status and

measurements alternately:

23

Page 28

HMI38

Operating Manual U063en-2.1

NOTE

If the HMI38 has not output previous logging data, text

Logged data is not transferred appears on the display.

A new logging starts only after the old data has been

transferred. To enable new logging, give command

Print-Display or Print-Serial interface.

To stop data logging:

• Press CL, select Logg in the main menu and then Stop in the LOGG

menu. Data logging ends.

The current status of the logging can be checked by selecting Status in the

LOGG menu.

6.1.2. Start/stop data logging in the CATCH mode

NOTE

The HMI38 has no battery operated real-time clock.

Give current date and time settings manually after

power-on (see Chapter 5.1.6.5); this way, correct time

and date indications are stored with each reading.

To start data logging in the CATCH mode:

• Select Logg in the main menu. The LOGG menu is displayed:

• Select Start in the LOGG menu and then Catch:

24

• The measurement readings appear on the display alternately with the

following display:

Page 29

HMI38

U063en-2.1 Operating Manual

• You can now store readings at any given moment by pressing ENT

while the readings are on the display. The text DATA STORED appears

to inform you that the readings as well as the time of measurement

were correctly stored in the HMI38 memory:

• Press ENT to return to the display showing the measurement

readings.

• Note that to save battery life, you can turn the HMI38 off while not

storing readings and then turn it on again to continue. However, in

this case remember to enter the correct date and time each time you

turn the instrument on as it does not have a real-time clock. You can

store max. 127 readings from both probes. To stop data logging,

select Logg in the main menu and then Stop in the LOGG menu. Data

logging ends.

6.1.3. Outputting the logged data to the serial line

• Select Logg in the main menu and Print in the LOGG menu. Select

Serial interface:

The following appears:

The HMI38 outputs the logged data to the serial line:

> Data logging is ended

Delay to start : 0 s

Interval : 10 min

First data stored: 1994-10-18 13:45:55

Number of loggings : 1

18.1 23.5 -2.1 3.0 3.2 11.3

15.7 23.0 -4.4 3.2 2.7 10.6

The factory format for the data output is:

RH1 T1 Td1 a1 x1 Tw1

RH2 T2 Td2 a2 x2 Tw2

25

Page 30

HMI38

Operating Manual U063en-2.1

You can change the format with serial line command LFORM and pause the

output by pressing CL. If you wish to continue, press ENT; if you wish to stop

the outputting completely, press CL:

The HMI38 stores the logged data in the memory until a new data logging

starts.

6.1.4. Outputting the logged data to the display

• Select Logg in the main menu and Print in the LOGG menu. Select

Display:

• The first logging point stored appears on the display, e.g.:

• The first number from the left on the first line (in this example, 1)

indicates which logging point is currently being observed. The

second number from the left on the first line (in this example, 69)

tells you how many logging points are stored in the HMI38 memory.

Other numbers indicate the time and date of the measurement.

• Press ENT and the readings of the first logging point appear on the

second line of the display, e.g.:

• The abbreviation of the measurement quantity and the number of the

probe appear on the left of the second line. If you wish to see the

readings of other measurement quantities or the readings of the

second probe (if connected), you can scroll them with buttons s or

t, for example:

26

• Press the button CL to move on to the following logging point. When

the readings are not on the display, you can select any logging point

for observation with buttons s or t.

• You can stop outputting the data by pressing twice the button CL.

The HMI38 stores the logged data in the memory until a new data logging

starts.

Page 31

HMI38

U063en-2.1 Operating Manual

6.2. Logging using serial line commands (CONTINUOUS mode)

See Appendix 1 for a description of the format of the serial line commands.

6.2.1. Data logging

LOG xxx aa bbb cc ddd <cr>

xxx = functional mode: ON, OFF or P(rint)

aa = logging start delay

bbb = delay unit (h, min, s)

cc = logging interval

ddd = interval unit (h, min, s)

Examples:

• start logging and continue with intervals of 10 minutes:

>log on 10 min <cr>

Data logging is ON

Delay to start : 0 s

Interval : 10 min

First data stored: 0000-00-00 00:00:00

Number of loggings : 0

• start logging after five hours and continue with intervals of 30 minutes:

>log on 5 h 30 min <cr>

Waiting for the start of logging

Delay to start : 5 h

Interval : 30 min

First data stored: ????-??-?? ??:??:??

Number of loggings : 0

• end logging:

>log off <cr>

Data logging is ended

Delay to start : 0 s

Interval : 10 min

First data stored: 1994-10-18 13:45:55

Number of loggings : 1

• output the logged data (defined by LFORM command):

>log p <cr>

Data logging is ended

Delay to start : 0 s

Interval : 10 min

First data stored: 1994-10-18 13:45:55

Number of loggings : 1

18.1 23.5 -2.1 3.0 3.2 11.3

15.7 23.0 -4.4 3.2 2.7 10.6

27

Page 32

HMI38

Operating Manual U063en-2.1

6.2.1.1. Setting the output format of the logged data

LFORM zzz...zzz <cr>

or

LFORM <cr>

xxx...xxx

? zzz...zzz <cr>

xxx...xxx = old format (blank = factory format)

zzz...zzz = new format

• Select output variables by variable name and the number of the measuring

probe:

RHn = relative humidity

Tn = temperature

Tdn = dewpoint temperature

An = absolute humidity

Xn = mixing ratio

TWn = wet bulb temperature

where n is the number of the probe (1 or 2)

• Give any other text you wish to appear in the output between inverted

commas (").

• Give the number format in front of the output variable as:

<full digits>.<decimal digits>, for example: 3.2 or 2.1 etc. (max. 9.9).

• Give the unit as:

Un where n specifi es the number of characters (m ax. 5), e.g. U3.

• other parameters are:

28

\n or #n line feed <lf>

\r or #r carriage return <cr>

\t or #t horizontal tabulation <ht> or <tab>

\nnn or #nnn ASCII-code nnn

TIME current time (HH:MM:SS)

DATE current date (YYYY-MM-DD)

Page 33

HMI38

U063en-2.1 Operating Manual

• If the input line is too short, continue the command parameter entry in the

following line as:

& <cr>.

Some examples:

command: >LFORM "rh1: " 3.2 RH1 " %RH" \r \n<cr>

output: rh1: 29.62 %RH<cr><lf>

command: >LFORM "RH: " 2.2 RH1 U1 \r \n<cr>

output: RH: 29.62%<cr><lf>

command: >LFORM date " " time #t RH1 #t T1 #r

#n<cr>

output: 1994-09-29 10:02:15 <tab> 29.6 <tab> 24.3

<cr><lf>

command: >LFORM "rh: " 2.2 RH2 " " U3 & <cr>

" t: " 2.2 T2 " " U2 #r #n<cr>

(line continued)

output: rh: 29.62 %RH t: 25.35 ’C <cr><lf>

The factory format can be recovered with command:

>LFORM * <cr>

Please, note that you can use the LFORM command for changing the format of

the output of logged data only; otherwise it is functionally similar to the

FORM command.

29

Page 34

HMI38

Operating Manual U063en-2.1

7. CALIBRATION

As the HMI38 indicators and their probes have been fully calibrated at the factory, there should be no immediate need for a recalibration. Calibrate them

only if you have a reason to believe that the adjustments have changed. The

adjustments of the temperature measurement channels and analogue output

channels are particularly stable and in normal circumstances, need not be

recalibrated. Perform humidity calibration for the probes at least once a year.

7.1. Humidity calibration

Perform the humidity calibration of the probes by adjusting the calibration potentiometers in the probe bodies (see Appendices 4, 5 or 6). Perform a twopoint calibration with the HMK15 or HMK13B calibrator or send the probe to

Vaisala. We recommend recalibration at least once a year. Please, note also

that the probe needs recalibration every time the HUMICAP® humidity sensor

is changed.

7.1.1. Calibration procedure

• Leave the calibrator, the HMI38 and the probe for at least 4 hours in

the same space so that their temperatures have time to equalize.

Remove the filter cap on the probe.

• Insert the probe into a measurement hole of t he LiCl chamber in the

calibrator.

• Wait at least 10 minutes, check the humidity reading from the HMI38

and adjust the reading to the correct value using the DRY

potentiometer in the probe body.

• Insert the probe into a measurement hole of the NaCl chamber i n the

calibrator.

• Wait at least 10 minutes and adjust the humidity reading using the

WET potentiometer.

Table 7.1 Greenspan’s calibration table

Temperature °C 15 20 25 30 35

°F 59 68 77 86 95

LiCl %RH * 11.3 11.3 11.3 11.3

NaCl %RH 75.6 75.5 75.3 75.1 74.9

*) If the LiCl solution is used or stored at temperatures below +18 °C

(+64 °F), the equilibrium humidity of the salt solution changes

permanently.

30

•

As the DRY and WET adjustments may affect each other, check again

the humidity reading in the LiCl chamber (wait for 10 minutes after

inserting the probe into the measurement hole). If the reading is not

Page 35

HMI38

U063en-2.1 Operating Manual

correct, repeat the adjustments in both LiCl and NaCL chambers unt il

the calibration is correct.

7.2. Temperature calibration

Temperature calibration should be done against an accurate temperature reference. It can be done by using either the serial bus or the display/keypad commands.

7.2.1. With display/keypad commands:

• Leave the reference instrument, the HMI38 and the probe in the same

space for at least 4 hours so that their temperatures have time to

equalize. Remove the filter before calibration.

• Select Cali in the main menu and select the probe:

• Select either one-point or two-point calibration:

• After the temperature of the instrument has stabilized, check the first

point reading against the reference instrument. Acknowledge the

reading by pressing ENT or give the correct reading and press ENT:

• In case of a two-point calibration, change the temperature and allow

enough time for temperature stabilization. Then check the transmitter

against the reference, give the correct reading and press ENT.

NOTE

If you change the factory temperature calibration, the

correction data stored in the HMI38 refers to the probe

location of the calibrated probe. If you change the probe

in this location, revert the measurement channel to its

factory settings (see serial command LI in Appendix 1)

or perform the calibration again with the new probe.

31

Page 36

HMI38

Operating Manual U063en-2.1

7.2.2. With serial line commands

CT n <cr>

n = probe (1 or 2)

With this command, you can calibrate the instrument against an accurate reference, such as a Pt 100 simulator.

Examples: two-point calibration for probe 1:

>CT 1 <cr>

T1 : 0.9 Ref1 ? 0 <cr>

Press any key when ready ...

T1 : 119.8 Ref2 ? 120 <cr>

>

one-point offset correction for probe 2 (<cr> is given after Ref2):

>CT 2 <cr>

T2 : 25.9 Ref1 ? 26 <cr>

Press any key when ready ...

T2 : 25.9 Ref2 ? <cr>

>

If you know the corrections at two points, you can also give the command directly as:

CT n aa.aa bb.bb cc.cc dd.dd <cr>

where: n = probe location (1 or 2)

aa.aa = first point

bb.bb = first point correction

cc.cc = second point

dd.dd= second point correction

Example: if you know the necessary corrections, perform the calibrations of

the previous examples as follows:

>CT 1 0.9 -0.9 119.8 0.2 <cr>

>CT 2 25.9 0.1 <cr>

You can monitor the progress of the sensor temperature stabilization by entering * <cr> at Ref1 or Ref2:

>CT 1 <cr>

T1 : 0.80 Ref1 ? * <cr>

T1 : 0.40 Ref1 ? 0.00 <cr>

Press any key when ready ...

T1 : 56.20 Ref2 ? 55.0 <cr>

>

7.3. Calibrating the analogue outputs

32

You can perform the calibration with an accurate voltage meter using serial

line command ACAL and make a test with command UTEST (see Appendix

1). Please, note that you should perform this calibration only if there is strong

reason to believe that the adjustments of the analogue outputs have changed.

Page 37

HMI38

U063en-2.1 Operating Manual

8. USING THE HMI38 AS A FIELD CALIBRATOR

You can also use the HMI38 as a field calibrator for HMD/W60/70 and

HMP140 series and their predecessors HMD/W20/30 and HMP130Y series, as

well as for the HMP230 series transmitters. Perform calibration by connecting

an appropriate reference connection cable between the HMI38 and the

transmitter to be calibrated (see chapter 11).

NOTE

The calibration of the HMD/W60/70 and HMP140

series is available only in units that have the software

version 2.01 or more. You can easily check the version

by reading the sticker on back of the device (SV2

indicates software version 2.01 or more).

8.1. HMD/W60/70 and HMP140 series transmitters

Use probe 1 as a reference measurement probe. Connect the D-connector of

the reference connection cable to the connector of probe 2 in the HMI38.

Connect the other connector of the cable to the test connector in the

transmitter to be calibrated (refer to the transmitter manual for details). The

connectors fit in one direction only.

NOTE

When you calibrate a transmitter with current output,

terminate the output loop.

Make sure that the sensors of the transmitter and the reference probe are close

to each other. If you are calibrating a duct type transmitter, push the probe

through the support piece into the ready-made hole in the duct.

When the power of the HMI38 is off, press and hold down the NUMBER 2

button. Press the ON/OFF button and release it; keep the NUMBER 2 button

still pressed. The following appears on the display:

Release the NUMBER 2 button and the following appears on the display:

33

Page 38

HMI38

Operating Manual U063en-2.1

Select RH scale with buttons s or t and press ENT when the text RH scale

is blinking. The following appears with the lower limit of the RH scale

(0.00) blinking:

The default scale is 0.00 - 100.00 %RH. Acknowledge the lower limit with

button ENT or enter the new value and press ENT. The upper limit (100.00)

starts to blink. Acknowledge it with button ENT or enter the new value and

press ENT. The display returns to show the following:

If you are calibrating a transmitter with current outputs, please, refer to

Chapter 8.1.2.

8.1.1. Calibrating transmitters with voltage outputs

If voltage outputs are used, select Voltage with buttons s or t and press

ENT when the text Voltage is blinking. The following text appears on the

display:

Select Range with with buttons s or t and press ENT when the text Range

is blinking. A text similar to the following appears on the display:

The lower limit (e.g. 0.00) is blinking. Acknowledge it with button ENT or

change it by entering the new value and pressing then ENT. The upper limit

(e.g. 1.00) starts to blink. Acknowledge it with button ENT or change it by

entering the new value and pressing then ENT.

The display returns to show the following:

34

Select Jumper selection with with buttons s or t and press ENT when the

text Jumper selection is blinking. A text similar to the following appears on

the display:

Page 39

HMI38

U063en-2.1 Operating Manual

The voltage range and the jumper selection are normally the same, but if the

transmitter has customized ranges, these selections may differ from one

another. Select the range according to the transmitter with buttons s or t

and press ENT. You can return to voltage range and jumper selections by

pressing the button CL. If you wish to return to the normal display mode, turn

the HMI38 OFF and then ON again.

When you have acknowledged the jumper selection with ENT, the display

changes to show a text similar to the following:

Numbers on the first line indicate the relative humidity measured by the

transmitter, and numbers on the second line indicate the RH measured by the

HMI38 reference probe. If you wish, you can now adjust the transmitter:

• Wait until the readings have stabilized and adjust the calibration

potentiometers until the readings on the first and the second line are

the same. It is recommended to use the offset potentiometer if the RH

is <65 %RH and the gain potentiometer if the RH is >65 %RH.

• After having completed the calibration, turn the HMI38 off

(disconnect the cable).

If you press the ENT button in the first RH calibration mode, you will go on to

the second RH calibration mode which is an alternative for the first one. A

text similar to the following is displayed:

Numbers on the first line indicate how much the RH measured by the

transmitter differs from that measured by the HMI38 reference probe.

Numbers on the second line indicate the relative humidity measured by the

reference probe. If you wish, you can now adjust the transmitter:

• Wait until the readings have stabilized and adjust the calibration

potentiometers until the numbers on the first line are at zero. It is

recommended to use the offset potentiometer if the RH is <65 %RH

and the gain potentiometer if the RH is >65 %RH.

• After having completed the calibration, turn the HMI38 off

(disconnect the cable).

35

Page 40

HMI38

Operating Manual U063en-2.1

8.1.2. Calibrating transmitters with current outputs

If current outputs are used, select Current with buttons s or t and press

ENT when the text Current is blinking. A text similar to the following appears

on the display:

Select the current range used with buttons s or t and press ENT. The

display changes to show a text similar to the following:

Numbers on the first line indicate the relative humidity measured by the

transmitter, and numbers on the second line indicate the RH measured by the

HMI38 reference probe. If you wish, you can now adjust the transmitter:

• Wait until the readings have stabilized and adjust the calibration

potentiometers until the readings on the first and the second line are

the same. It is recommended to use the offset potentiometer if the RH

is <65 %RH and the gain potentiometer if the RH is >65 %RH.

• After having completed the calibration, turn the HMI38 off

(disconnect the cable).

If you press the ENT button in the first RH calibration mode, you will go on to

the second RH calibration mode which is an alternative for the first one. A

text similar to the following is displayed:

Numbers on the first line indicate how much the RH measured by the

transmitter differs from that measured by the HMI38 reference probe.

Numbers on the second line indicate the relative humidity measured by the

reference probe. If you wish, you can now adjust the transmitter:

36

• Wait until the readings have stabilized and adjust the calibration

potentiometers until the numbers on the first line are at zero. It is

recommended to use the offset potentiometer if the RH is <65 %RH

and the gain potentiometer if the RH is >65 %RH.

• After having completed the calibration, turn the HMI38 off

(disconnect the cable).

Page 41

HMI38

U063en-2.1 Operating Manual

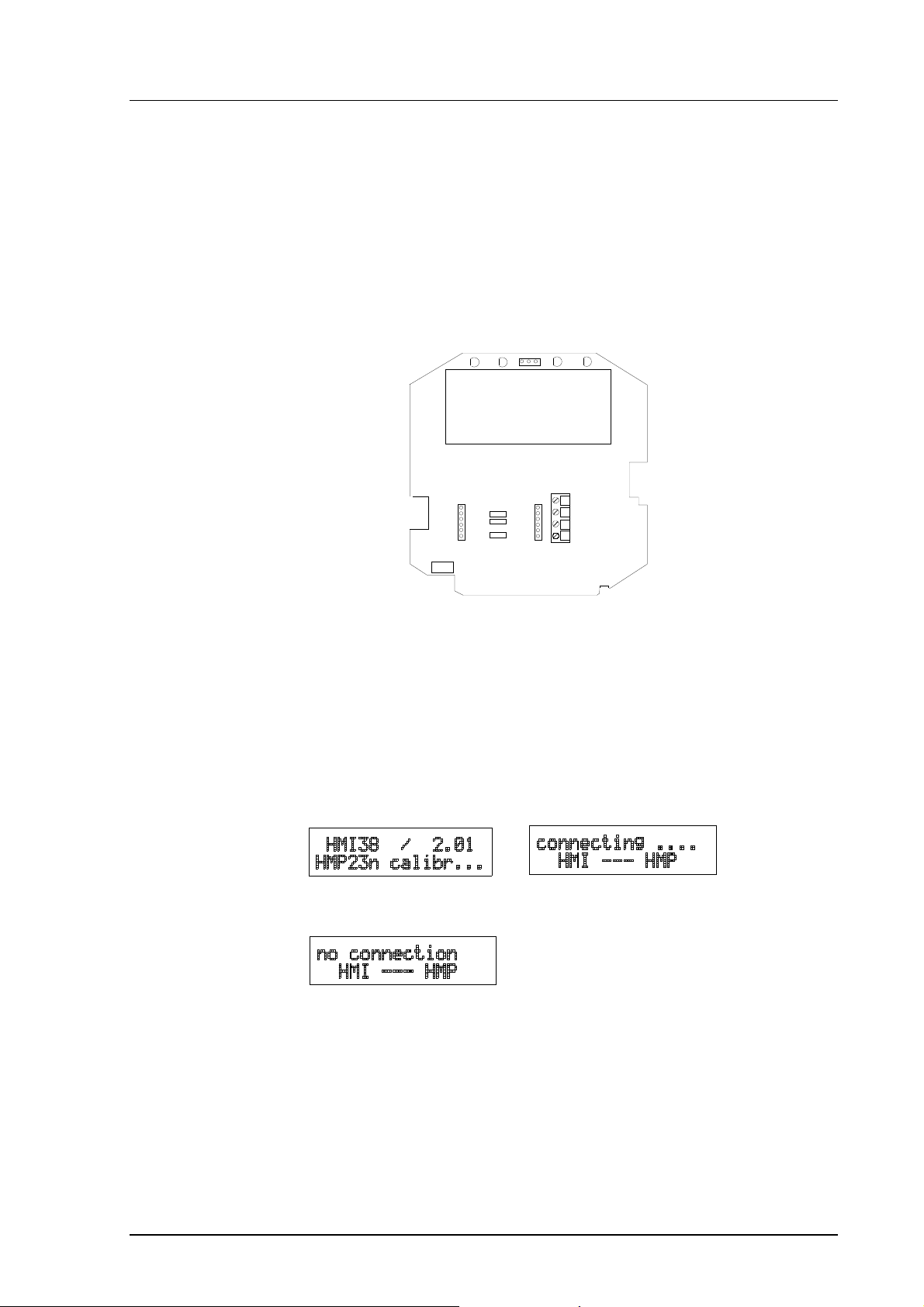

8.2. HMP230 series transmitters

Use probe 1 as a reference measurement probe. Open the cover of the

HMP230 to be calibrated. Connect the D-connector of the reference

connection cable to the serial I/O connector of the HMI38 and the other

connector of the cable to the connector X5 of the HMP230 (see Figure 8.1).

This connector is also the other mounting connector for RS 485/422 serial port

module and current loop module; if a module is mounted, it must first be

removed.

RX GND TX

X17

X6

RX +

R2

R3

X5

R4

RX TX +

TX -

SERIAL PORT

X4

Figure 8.1 Connector X5 on the main board of the HMP230

Make sure that the sensors of the transmitter and the reference probe are close

to each other.

When the power of the HMI38 is off, press and hold down the NUMBER 0

button. Press and release the ON/OFF button; keep the NUMBER 0 button still

pressed. When the programme type and version appear on the display, release

the NUMBER 0 button. The following appears on the display:

If the connection fails, the following text appears:

Should this happen, check that the HMP230 is powered and that the reference

cable is properly connected.

NOTE

The HMP230 must not be in the POLL mode and the

serial line settings must be 4800, e, 7, 1 (factory settings, which can be restored using the factory settings

jumper; see the HMP230 Operating Manual).

37

Page 42

HMI38

Operating Manual U063en-2.1

When connection has been formed, select either one or two point calibration

with the arrow keys and press ENT:

NOTE

If the programme version of the HMP230 is 1.06 or

earlier (version is printed on the CPU hybrid), start the

HMI38 as described above without connecting the

reference connection cable. After the text ’no

connection’ appears on the screen, connect the cable.

This procedure is necessary for avoiding a possible

overflow in the serial line buffer of the HMP230.

8.2.1. One point calibration

• Select either offset or gain calibration using arrow keys and press

ENT. If the reference humidity is above 50 %RH, gain calibration is

preferred. If the reference humidity is below 50 %RH, the HMP230

accepts only offset calibration .

• The humidity readings of the HMP230 and the reference probe appear

on the display:

• Wait until the readings have been stabilized and press ENT:

The correction factor is now stored to the memory of the HMP230 and the

new readings of both the transmitter and the reference appear again on the

display. In case of any drift in either of the readings, repeat the calibration by

pressing the ENT button again. End the calibration procedure by pressing the

CL button twice. This brings the following text on the display:

38

You have now completed the calibration; switch off the HMI38.

Page 43

HMI38

U063en-2.1 Operating Manual

If the calibration fails (e.g. after an attempt of gain calibration below

50 %RH), an error message appears and no correction factor is stored into the

HMP230:

8.2.2. Two point calibration

The HMI38 displays:

• Select two-point calibration using arrow keys and press ENT. The

readings at the first humidity point appear on the display, e.g.:

• Wait until the readings have stabilized and press ENT. The instrument

stores the correction at the first point and readings at the second

humidity point appear:

• Wait again until the readings have stabilized and press ENT. The

instrument stores the correction at the second point. End the

calibration procedure by pressing the CL button twice. This brings the

following text on the display:

• Switch off the HMI38.

If the calibration fails, an error message appears on the display and no correction factors are stored to the HMP230.

Two point calibration fails e.g. if the reference humidities at the first and the

second point differ less than 50 %RH of each other.

39

Page 44

HMI38

Operating Manual U063en-2.1

8.2.2.1. Two point calibration with reference salts

You can also give the reference humidities of the two point calibration

manually (using the HMI38 as a display only). Insert the probe of the HMP230

into the low humidity bath. Follow the procedure of the two point calibration.

• When the humidities at the first calibration point appear on the

display, press CL:

• Enter the reference humidity with numeric keys and press ENT.

• Insert the probe into the high humidity bath and repeat the procedure.

The correction factors are now stored to the HMP230. End the

calibration procedure by pressing the CL button twice. Switch off the

HMI38.

8.3. HMD/W 20/30 and HMP130Y series transmitters

Use probe 1 as a reference measurement probe. Connect the D-connector of

the reference connection cable to the connector of probe 2 in the HMI38.

Connect the other connector of the cable to the test connector in the

transmitter to be calibrated (refer to the transmitter manual for details). The

connectors fit in one direction only.

NOTE

When you calibrate a transmitter with current output,

terminate the output loop.

Make sure that the sensors of the transmitter and the reference probe are close

to each other. If you are calibrating a duct type transmitter, push the probe

through the support piece into the ready-made hole in the duct.

When the power of the HMI38 is off, press and hold down the NUMBER 1

button. Press the ON/OFF button and release it; keep the NUMBER 1 button

still pressed. When the programme type and version appear on the display,

release also the NUMBER 1 button. The following appears on the display:

40

The humidity readings of the transmitter and the reference probe appear on the

display:

Page 45

HMI38

U063en-2.1 Operating Manual

You can change the display to show the difference between the transmitter and

reference reading by pressing ENT; the reference reading appears on the

second line:

You can change the display mode between these two modes by pressing the

ENT button. You can make adjustments adjustment in all display modes. The

potentiometer used for adjusting the transmitter varies depending on the

transmitter type and the humidity level in which you perform the calibration

(see the transmitter manual).

HMW20/30 UB/YB (wall mount transmitters):

• use the "DRY" or one-point calibration trimmer potentiometer (see

the sticker inside the transmitter cover)

HMD20/30 UB/YB (duct mount transmitters):

• if the reference humidity is below 65 %RH use the "DRY" trimmer

potentiometer

• if the reference humidity is above 65 %RH use the "WET" trimmer

potentiometer

HMP130Y series:

• if the reference humidity is below 65 %RH use the trimmer potenti-

ometer R5 (offset)

• if the reference humidity is above 65 %RH use the trimmer potenti-

ometer R18

Wait until the readings stabilize and adjust the transmitter reading to correspond to the reference reading or adjust the difference reading to zero. Turn

the power of the HMI38 off and on again to return to normal operation.

41

Page 46

HMI38

Operating Manual U063en-2.1

9. MAINTENANCE

9.1. Reference measurements

Reference measurements help to verify whether the instrument readings are

within specifications. This way the user can check if the probe or the indicator

needs calibration or service.

The reference meter should preferably use the same technology as the instrument to be checked, i.e. equipment with capacitive sensors should be checked

with instruments using capacitive sensors. This minimizes the risk of errors

caused by different measurement techniques.

Whatever technique is used, make sure that the reference instrument and the

instrument to be checked are at the same temperature in order to avoid errors

caused by temperature differences. The reference measurements are most

accurate when made in laboratories where the conditions are stable. Make the

reference measurement as close to the sensor to be checked as possible and

read the readings simultaneously, when possible.

9.2. Self-diagnostics

The HMI38 goes through a self-diagnostics procedure when the power is

switched on. If the procedure does not reveal any errors or faults, the instrument the normal operation. If the procedure finds errors or faults, check first

that the probes are connected, the initialization of the probes is correct and the

humidity and temperature sensors are not damaged. If errors still appear,

follow the troubleshooting instructions in Appendix 3 to find out whether the

fault is in a probe or the HMI38. Send the faulty instrument to Vaisala or a

Vaisala representative for repairs.

If any errors occur during operation, the error messages appear on the LCD

display if the instrument displays measurements; if the menus are in use, error

messages do not appear. During operation, however, the error messages will

not output automatically through the serial interface. If there is any reason to

doubt that there is something wrong with the instrument, use command ERRS:

If there are no error messages, only a prompt is displayed:

>ERRS <cr>

>

When errors have occurred, the instrument outputs the error code (see Appendix 3 for all error messages):

ERRS <cr>

42

>ERRS <cr>

E40 f ( all ) out of range

>

Page 47

HMI38

U063en-2.1 Operating Manual

9.3. Adjusting the contrast of the display

Adjust the contrast of the display with the trimmer R9 "CONTRAST". Release

the six screws at the bottom of the HMI38 and remove the top cover of the

indicator body. The trimmer is located at the front end of the main board.

10. TECHNICAL DATA

10.1. Relative humidity

Measuring range 0...100 %RH

Accuracy (at +20°C) 0.1 %RH (for overall system ac-

curacy see probe specifications in

Appendix 4, 5 or 6)

Resolution 0.1 %RH

Temperature dependence over the

entire operating temperature range ±0.2 %RH

10.2. Temperature

Measuring range -40...+120 °C (depending on the

Accuracy (error caused by HMI38 at ±0.1°C

+20°C)

Resolution 0.1°C

Typical temperature dependence of

electronics 0.004 °C/°C

10.3. Calculated quantities

Widest ranges dewpoint temperature -40...+100 °C

(depending on the mixing ratio 0...500 g/kg dry air

probe used) absolute humidity 0...600 g/m

wet bulb temperature 0...+100 °C

probe used, see Appendices 4, 5

and 6)

3

Accuracies of the calculated quantities depend on the accuracies of the measured quantities; see Appendices 4, 5 or 6 for more details.

43

Page 48

HMI38

Operating Manual U063en-2.1

10.4. Data logging

Storage capacity:

continuous mode 254 measurements per probe

catch mode 127 measurements per probe

Logging interval from 10 s to 99 h

10.5. Analogue outputs

Two analogue outputs

ranges 0...1 V and 0...5 V (freely adjust-

able between 0...5 V)

Typical accuracy of analogue output

at +20 °C ±0.05 % full scale

Typical temperature dependence of

analogue output 0.005 %/°C full scale

10.6. Serial interface

Serial port types RS 232C and RS 485

(only one usable at a time)

Communication parameters

bauds 300, 600, 1200, 2400, 4800, 9600

data bits 7 or 8

stop bits 1 or 2

parity even, odd or none

mode full or half duplex

Connector D-type female D9S

Data format ASCII characters

10.7. Electronics

Display 2 x 16 character alphanumeric

character height 3.85 mm (0.15")

high-contrast, wide view angle

LCD

44

Keyboard 4 x 4 tactile membrane switches

Probes (max. 2) HMP35E, HMP36E or HMP37E

(with some modifications also

HMP35B or HMP36B - type

changes into BM)

Page 49

HMI38

U063en-2.1 Operating Manual

Rechargeable battery pack 8 NiCd 1.2 V cells, standard ’AA’

cell size

Battery operating time in

continuous use 8 hours

data-logging mode 24 hours

charging time 6 hours

Supply voltage 12 VDC (11...16 VDC), 0.2 A

Power consumption during charge 3 W maximum

Recommended external load for

0...1 V voltage output >2 kΩ (to ground)

Recommended external load for

0...5 V voltage output >10 kΩ (to ground)

Operating temperature (electronics) 0...+50 °C

Storage temperature range -20...+70 °C

Operating humidity range 95 %RH maximum, non-

Storage humidity range 90 %RH maximum

10.8. Mechanics

Housing material ABS plastic

Housing dimensions (h x w x l) 90 x 200 x 295 mm

condensing

NOTE

The operating humidity range is higher than the storage

humidity range because the air in a warm instrument

has a lower relative humidity than the ambient air.

Accessories optional carrying case

Weight 1090 g

45

Page 50

HMI38

Operating Manual U063en-2.1

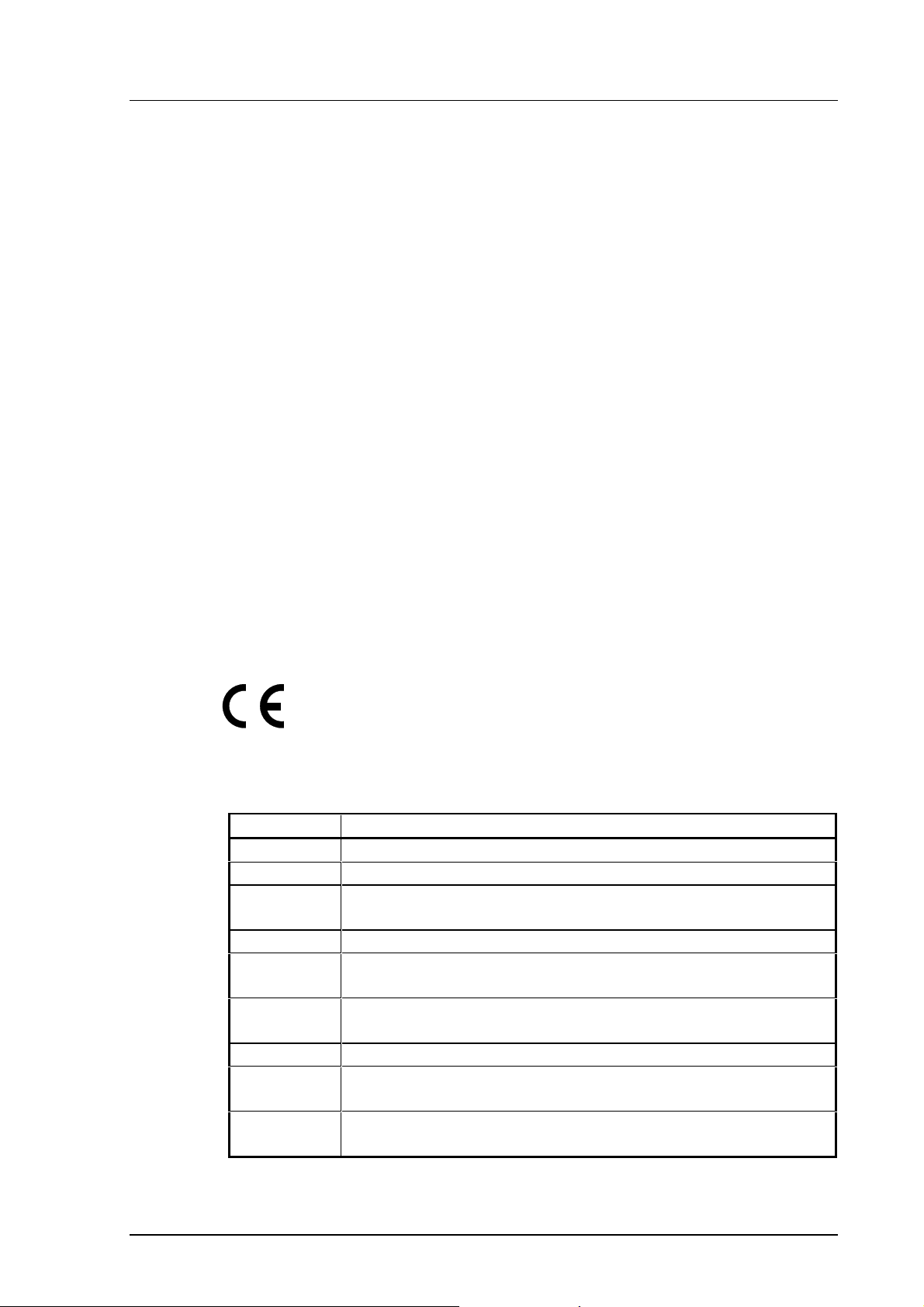

10.9. Electromagnetic compatibility

10.9.1. Emissions

Test: Setup according to:

Radiated interference EN55022 (class B)

10.9.2. Immunity

Test: Setup according to: Performance:

Electrostatic discharge EN61000-4-3:1995 criteria B

Electrical fast transients IEC 801-4:1988 criteria B

RF-radiated fields IEC 801-3:1984 criteria A

* GSM field immunity ENV50204:1995 criteria A

* (additional test)

Vibration IEC 68-2-6 Fc (0.15 mm/10...500 Hz/2 g/20 sweep cycles)

11. ACCESSORIES AND SPARE PARTS

Order code Description

18326 Carrying case

17371 AC adapter for 230 VAC with EURO plug

18100ZZ Connection cable for the calibration of HMD/W20/30 and

HMP130Y series transmitters

18200ZZ Connection cable for the calibration of HMP230 transmitters

18300ZZ Connection cable for the calibration of HMD/W60/70 and

HMP140 series transmitters

0606 Rechargeable 1.2 V NiCd battery

must be ordered in batches of 8 pcs

HMP35E Humidity and temperature probe for general measurement

HMP36E Humidity and temperature probe for measurement of granu-

lates and concrete

HMP37E Humidity and temperature probe for tight or remote places or

high temperatures (5 m cable)

46

Loading...

Loading...