Page 1

M212243EN-A

User Guide

HMD60 Series Humidity and Temperature

Transmitters for Ducts in HVAC

HMD65

Page 2

PUBLISHED BY

Vaisala Oyj

Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

P.O. Box 26, FI-00421 Helsinki, Finland

+358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala Oyj 2019

No part of this document may be

reproduced, published or publicly

displayed in any form or by any means,

electronic or mechanical (including

photocopying), nor may its contents be

modified, translated, adapted, sold or

disclosed to a third party without prior

written permission of the copyright holder.

Translated documents and translated

portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this document are subject

to change without prior notice.

Local rules and regulations may vary and

they shall take precedence over the

information contained in this document.

Vaisala makes no representations on this

document’s compliance with the local

rules and regulations applicable at any

given time, and hereby disclaims any and

all responsibilities related thereto.

This document does not create any legally

binding obligations for Vaisala towards

customers or end users. All legally binding

obligations and agreements are included

exclusively in the applicable supply

contract or the General Conditions of Sale

and General Conditions of Service of

Vaisala.

This product contains software developed

by Vaisala or third parties. Use of the

software is governed by license terms and

conditions included in the applicable

supply contract or, in the absence of

separate license terms and conditions, by

the General License Conditions of Vaisala

Group.

Page 3

Table of Contents

Table of Contents

1. About This Document................................................................................... 3

1.1 Version Information..........................................................................................3

1.2 Related Manuals................................................................................................3

1.3 Documentation Conventions...........................................................................3

1.4 Trademarks........................................................................................................ 4

2. Product Overview........................................................................................... 5

2.1 Introduction to HMD60 Series.........................................................................5

2.2 HMD65 Basic Features and Options...............................................................5

2.3 Available Parameters and Default Scaling.....................................................5

2.4 Connectivity to Vaisala Insight Software....................................................... 6

2.5 Transmitter Parts...............................................................................................7

2.5.1 Cable Gland and Conduit Options...........................................................8

2.5.2 Filter Options..............................................................................................8

2.5.3 Transmitter Board......................................................................................9

2.5.4 Trimmers................................................................................................... 10

2.5.5 DIP Switch Humidity Output Selection...................................................11

2.6 Filtering Factor.................................................................................................12

2.7 Environmental Compensation........................................................................12

3. Installation........................................................................................................ 13

3.1 Transmitter Dimensions..................................................................................13

3.2 Duct Mounting Overview................................................................................14

3.3 Installing into Duct.......................................................................................... 15

3.4 Wiring............................................................................................................... 16

4. Operating with Insight PC Software......................................................18

4.1 Vaisala Insight Software................................................................................. 18

4.2 Connecting to Insight Software.....................................................................18

4.3 Insight Main View............................................................................................ 19

4.3.1 Basic and Advanced User Modes..........................................................20

4.4 Configuring Analog Outputs with Insight...................................................20

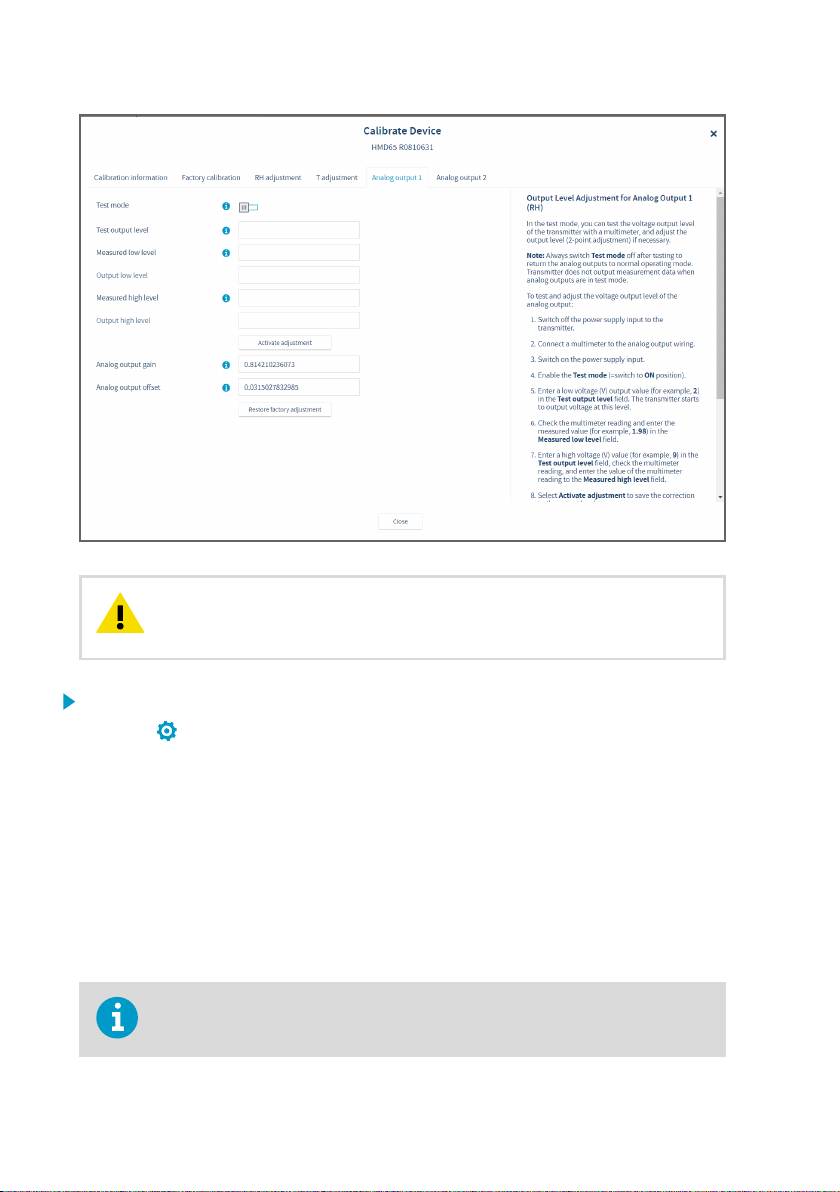

4.4.1 Testing and Adjusting Analog Output Voltage (V) Level....................21

4.5 Configuring Minimum and Maximum RH and T Errors with Insight.........22

4.6 Changing Pressure Compensation Settings with Insight..........................24

4.7 Setting Filtering Factor with Insight............................................................ 25

5. Modbus and BACnet Communication..................................................26

5.1 Modbus and BACnet Overview.....................................................................26

5.2 Modbus and BACnet Configuration with Insight........................................ 27

5.2.1 Configuring Modbus Response Delay with Insight.............................28

5.2.2 Configuring BACnet with Insight...........................................................28

6. Operating with MI70 Indicator............................................................... 30

6.1 Overview of MI70 Support............................................................................30

6.1.1 MI70 Indicator Parts............................................................................... 30

1

Page 4

HMD65 User Guide M212243EN-A

6.2 Connecting HMD60 to MI70 Indicator.......................................................... 31

6.3 Basic Display................................................................................................... 32

6.4 Graphical Display............................................................................................32

6.5 Main Menu....................................................................................................... 32

6.6 Holding and Saving the Display....................................................................33

6.7 Recording Data............................................................................................... 33

7. Calibration and Adjustment.....................................................................34

7.1 Calibration and Adjustment Overview........................................................ 34

7.2 Calibration and Adjustment Using Trimmers.............................................. 34

7.2.1 1-Point Adjustment Using Trimmers and Reference Calibrator.........35

7.2.2 Adjusting Output Using Trimmers and Reference

Transmitter (1-point adjustment).......................................................... 35

7.2.3 Resetting Trimmers Back to Zero..........................................................36

7.3 Calibration and Adjustment with Insight PC Software.............................. 37

7.3.1 2-Point Adjustment with Insight and Reference Calibrator...............38

7.3.2 1-Point Adjustment with Insight and Reference Transmitter............. 38

7.4 Calibration and Adjustment with MI70 Hand-Held Indicator...................40

7.4.1 1-Point Adjustment Using Reference Environment............................40

8. Maintenance....................................................................................................43

8.1 Cleaning........................................................................................................... 43

9. Technical Data............................................................................................... 44

9.1 Specifications................................................................................................. 44

9.2 Spare Parts and Accessories.........................................................................46

9.3 Transmitter Dimensions.................................................................................47

Appendix A:

Modbus Registers.................................................................. 48

A.1 Measurement Data Registers........................................................................48

A.2 Status Registers...............................................................................................51

A.3 Configuration Registers.................................................................................53

A.4 Communication Test Registers.....................................................................53

Appendix B:

BACnet Reference..................................................................54

B.1 BACnet Protocol Implementation Conformance Statement ................... 56

B.2 Device Object..................................................................................................59

B.3 Relative Humidity Object.............................................................................. 62

B.4 Temperature Object.......................................................................................64

B.5 Calculated Humidity Objects........................................................................ 67

B.6 Operation Pressure Object............................................................................69

B.7 BIBBs Supported............................................................................................ 70

B.8 Application Services Supported....................................................................71

Warranty............................................................................................................ 75

Technical Support............................................................................................ 75

Recycling........................................................................................................... 75

2

Page 5

Chapter 1 – About This Document

1. About This Document

1.1 Version Information

Table 1 Document versions

Document Code Date Description

M212243EN-A April 2019 This manual. First version of the document.

1.2 Related Manuals

Table 2 Related Manuals

Document Code Description

M212264EN HMD65 Multilingual Quick Guide

M212016EN HMD62 and TMD62 User Guide

M212049EN HMD62 and TMD62 Multilingual Quick Guide

1.3 Documentation Conventions

WARNING!

instructions carefully at this point, there is a risk of injury or even death.

CAUTION!

instructions carefully at this point, the product could be damaged or important

data could be lost.

Note highlights important information on using the product.

Tip gives information for using the product more eciently.

alerts you to a serious hazard. If you do not read and follow

warns you of a potential hazard. If you do not read and follow

3

Page 6

HMD65 User Guide M212243EN-A

1.4 Trademarks

Vaisalaâ and HUMICAPâ are registered trademarks of Vaisala Oyj.

Windowsâ is either a registered trademark or trademark of Microsoft Corporation in the

United States and other countries.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

4

Page 7

Chapter 2 – Product Overview

2. Product Overview

2.1 Introduction to HMD60 Series

The duct mounted HMD60 HUMICAPâ Humidity and Temperature Transmitters are designed

for monitoring humidity and temperature in demanding HVAC and light industrial applications.

HMD60 series transmitters provide stable, reliable, and highly accurate (up to ±1.5 %RH and

±0.1 °C (0.18 °F)) measurements, and are resistant to chemicals and dust.

HMD60 series transmitter options include the HMD62 and TMD62 analog output transmitters

with loop powered 4 … 20 mA current output, and the analog and digital output transmitter

HMD65 with analog voltage output (0 … 10 V) and digital Modbus RTU and Bacnet output

(RS-485).

Thanks to easy access to electronics also when the transmitter is installed to a duct,

configuration and adjustment can be carried out quickly and conveniently. Available

configuration and adjustment interface options range from physical trimmers and DIP switches

on the transmitter's circuit board to Modbus, BACnet, and Vaisala Insight PC software for

Windowsâ.

2.2

HMD65 Basic Features and Options

• Humidity and temperature measurement:

• available humidity parameters: RH, Td, Tdf, A, X, Tw, H

• T measurement in °C or °F

• Analog output: 2 analog 0 … 10 V output channels for humidity and temperature

measurements

• Digital output (RS-485): Modbus RTU and BACnet MS/TP

• Power supply input: 15 … 35 VDC / 16 … 24 VAC

• Configuration and adjustment options:

• RH and T measurement field adjustment with trimmers

• Humidity output parameter selection and Modbus/BACnet serial setting configuration

with DIP switches

• Configuration and adjustment with Vaisala Insight PC software

• Configuration with Modbus and BACnet

• Field adjustment with MI70 hand-held indicator

2.3

Available Parameters and Default Scaling

HMD65 Measurement Parameters and Default Analog Output

Scaling

Table 3 (page 6) shows the available output parameters and the default analog output

scaling of the parameters for HMD65.

5

Page 8

HMD65 User Guide M212243EN-A

Table 3 HMD65 Measurement Parameters and Default Scaling

Parameter Default Scaling for 1 … 10 V Output Range

Relative humidity (RH) 0 … 100 %RH

Temperature (T) -20 ... +80 °C (-4 ... +176 °F)

Dew point temperature (Td) -40 ... +80 °C (-40 ... +176 °F)

Dew point/frost point

temperature (Tdf)

Absolute humidity (A)

Mixing ratio (X) 0 … 600 g/kg (0 … 4200 gr/lb)

Wet-bulb temperature (Tw) -40 ... +80 °C (-40 ... +176 °F)

Enthalpy (H) -40 … 1600 kJ/kg (-9.5 ... 695.6 Btu/lb)

-40 ... +80 °C (-40 ... +176 °F)

0 … 300 g/m3 (0 … 131.1 gr/ft3)

Changing Measurement Parameter Scaling

If your application requires an analog output scaling that diers from the defaults shown in

Table 3 (page 6), you can configure the scaling by connecting the transmitter to Vaisala Insight

PC software (requires Vaisala USB cable 219690).

2.4

Connectivity to Vaisala Insight Software

The transmitter can be connected to Vaisala Insight software using a Vaisala USB cable (order

code 219690). With the Insight software, you can:

• See device information and status.

• See real-time measurement.

• Configure output parameters and scaling.

• Configure serial communication settings.

More Information

‣

Connecting to Insight Software (page 18)

6

Page 9

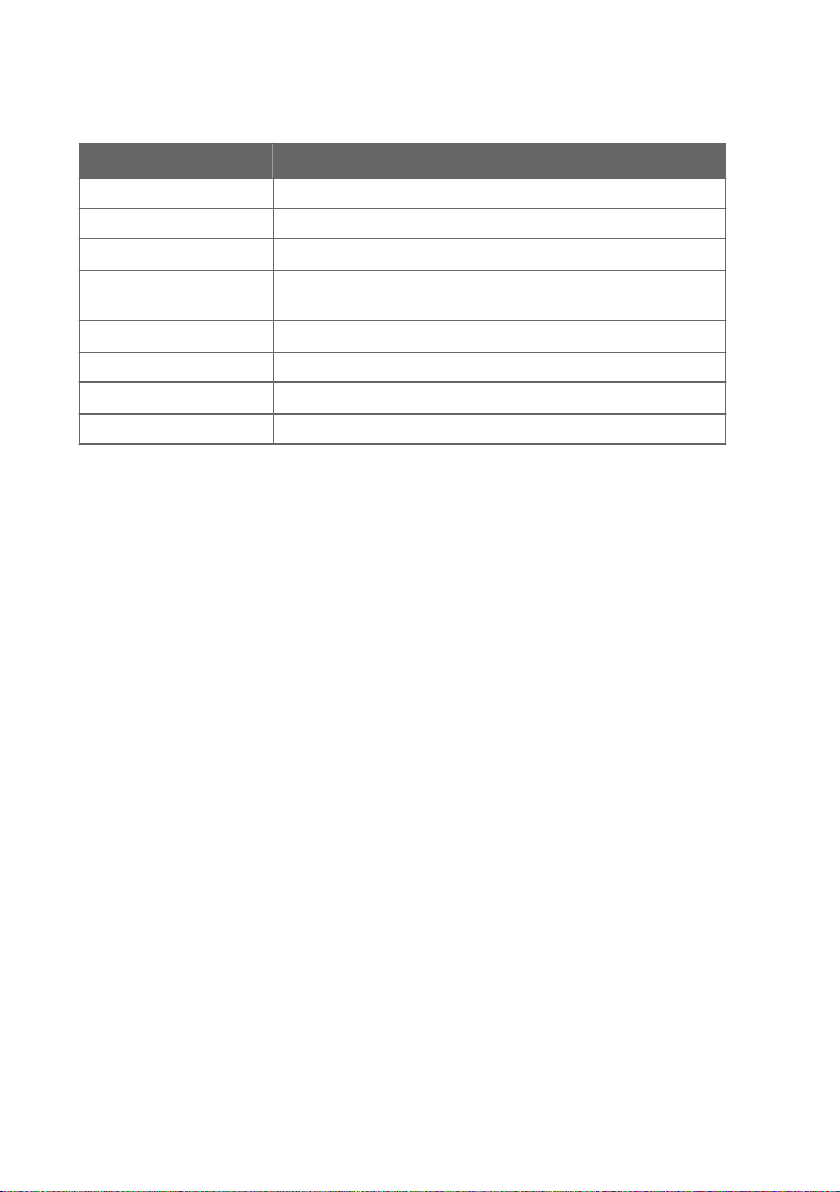

2.5 Transmitter Parts

1

2

3

4

5

6

7

8

9

Chapter 2 – Product Overview

Figure 1 HMD65 Transmitter Parts Overview

Captive screw (2 pcs, cross-head) for attaching the lid of the transmitter.

1

2 Screw (2 pcs) for mounting the transmitter on the installation surface.

3 Transmitter lid. Open the captive screws of the lid to access input and output electronics.

4 Transmitter base. Contains the input and output connectors on the transmitter board: see

Transmitter Board (page 9).

5 Cable gland (M16 x 1.5 lead-through) for leading wires into the transmitter.

6 Alternative lead-through (M20 x 1.5) for wiring.

7 Probe body. Long (shown) and short probe options available: see Transmitter Dimensions

(page 13).

8 Probe filter (default option: AISI 316L stainless steel).

9 HUMICAPâ sensor inside the probe filter.

Do not touch the sensor element.CAUTION!

7

Page 10

1

2

1 2

HMD65 User Guide M212243EN-A

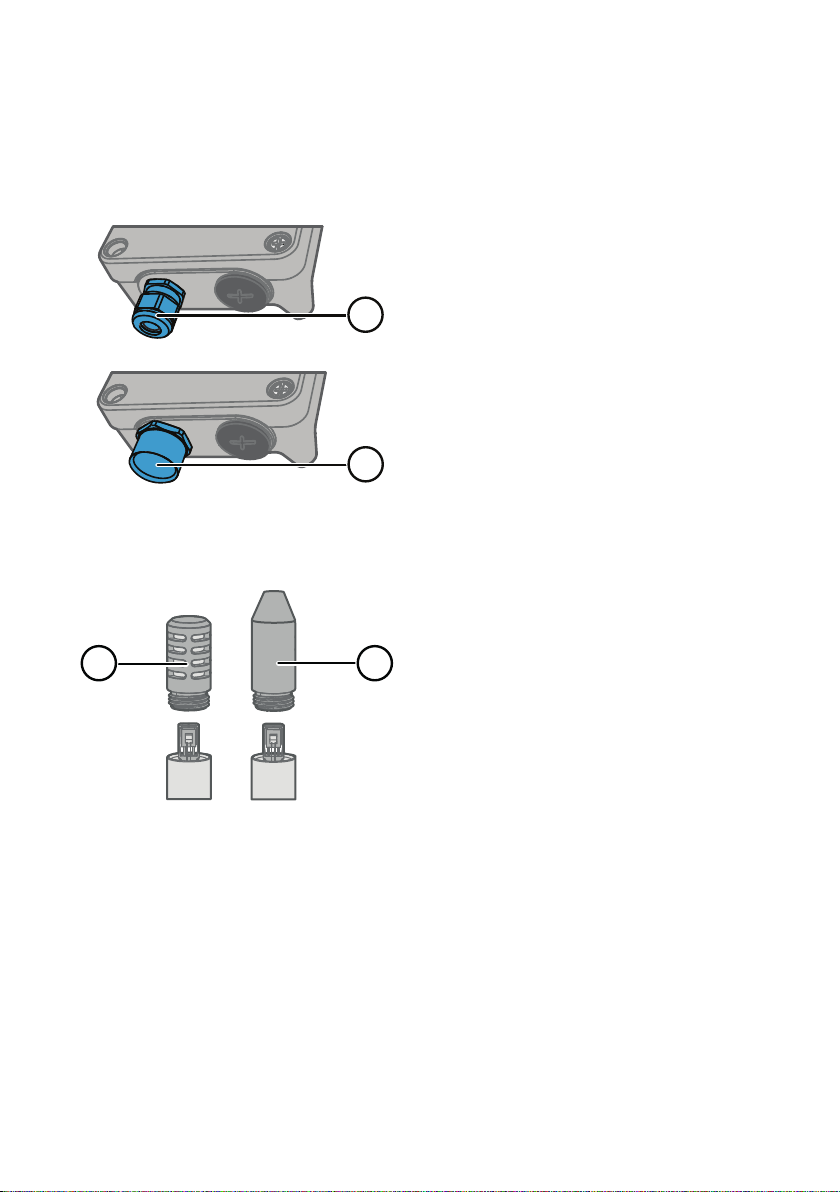

2.5.1 Cable Gland and Conduit Options

HMD60 has 2 lead-throughs (M16x1.5 and M20x1.5) that can be used with a variety of cable

gland and conduit options. Figure 2 (page 8) shows the cable gland and conduit options

available from Vaisala.

Figure 2 HMD60 Cable Gland and Conduit

Options

1 Cable Gland and O-ring M16 x 1.5

(Vaisala order code: 254280SP). This is

the default option delivered with

HMD60.

2 Conduit fitting and O-ring (M16x1.5 /

NPT1/2") (Vaisala order code:

210675SP).

2.5.2 Filter Options

Figure 3 (page 8) shows the filter options available for HMD60.

Figure 3 HMD60 Filter Options

Metal Grid with PTFE Membrane (Vaisala order code ASM212652SP). This is the default

1

option delivered with HMD60.

2 Sintered Filter (Vaisala order code HM46670SP).

8

Page 11

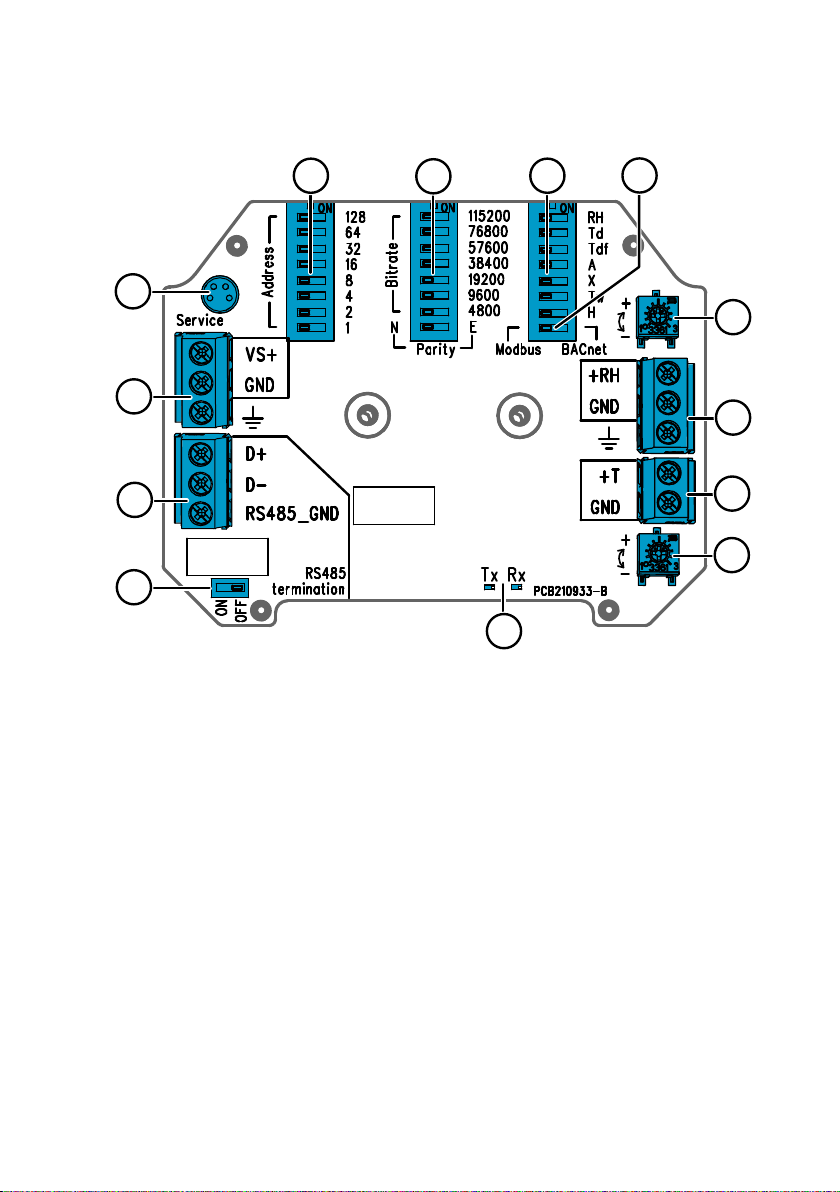

2.5.3 Transmitter Board

4

5

6

7

8

3

2

1

9

10

11

12

13

Chapter 2 – Product Overview

Figure 4 HMD65 Transmitter Board: Service Port, DIP switches, Trimmers, and Screw Terminals

RS-485 termination (120 Ω resistor) ON/OFF switch.

1

2 RS-485 (Modbus/BACnet) screw terminals.

3 Power supply input (15 … 35 VDC or 16 … 24 VAC) screw terminals.

4 Service port for MI70 hand-held indicator and Insight PC software cable connection.

5 DIP switches for setting the HMD65 Modbus RTU or BACnet MS/TP MAC address.

6 DIP switches for selecting Modbus/BACnet communication bit rate and parity (Modbus

7 DIP switches for humidity output parameter selection.

8 DIP switch for selecting either Modbus or BACnet mode.

9 Trimmer for humidity measurement adjustment.

10 Screw terminals for humidity measurement output.

11 Screw terminals for temperature measurement output.

12 Trimmer for temperature measurement adjustment.

13 Indicator LEDs: flash when there is RS-485 transmit (TX) or receive (RX) activity.

More Information

‣

‣

only).

Wiring (page 16)

Modbus and BACnet Overview (page 26)

9

Page 12

1

±0 %RH

−1 %RH

−2 %RH

−3 %RH

−4 %RH

−5 %RH

+1 %RH

+2 %RH

+3 %RH

+4 %RH

+5 %RH

±0 °C

−0.06 °C

−0.12 °C

−0.18 °C

−0.24 °C

−0.3 °C

+0.06 °C

+0.12 °C

+0.18 °C

+0.24 °C

+0.3 °C

RH: −5 %RH ... +5 %RH T: −0.3 °C ... +0.3 °C

RH T

HMD65 User Guide M212243EN-A

2.5.4 Trimmers

Figure 5 Component Board Adjustment

Trimmer

1 Use a Phillips head screwdriver (PH0)

to rotate the RH or T adjustment

trimmer. To increase the measurement

output value, rotate the trimmer

clockwise. To decrease, rotate

counterclockwise.

Note that there is a slight delay before

the measurement output changes

after rotating the trimmer.

You can adjust the transmitter's RH or T measurement output with the trimmers on the

component board. During trimmer adjustment, the output of the transmitter is corrected using

the trimmers until the output matches the known value of a reference.

Figure 6 RH and T Trimmer Adjustment Ranges (Indicative)

You can only calibrate the relative humidity measurement (RH) and temperature

measurement (T). Other parameters (available for HMD62) are calculated

internally based on RH and T. Check that the output selection DIP switch is set to

RH when making adjustments with the physical trimmer; when using the Insight

PC software, set all DIP switches to the OFF position.

CAUTION!

restore the factory settings, always return the physical trimmer to the middle

position before starting. When you make an adjustment with Insight, the

10

position in which the trimmer is at that point is set as the ±0 point.

If you use the Insight PC software to adjust the measurement or to

Page 13

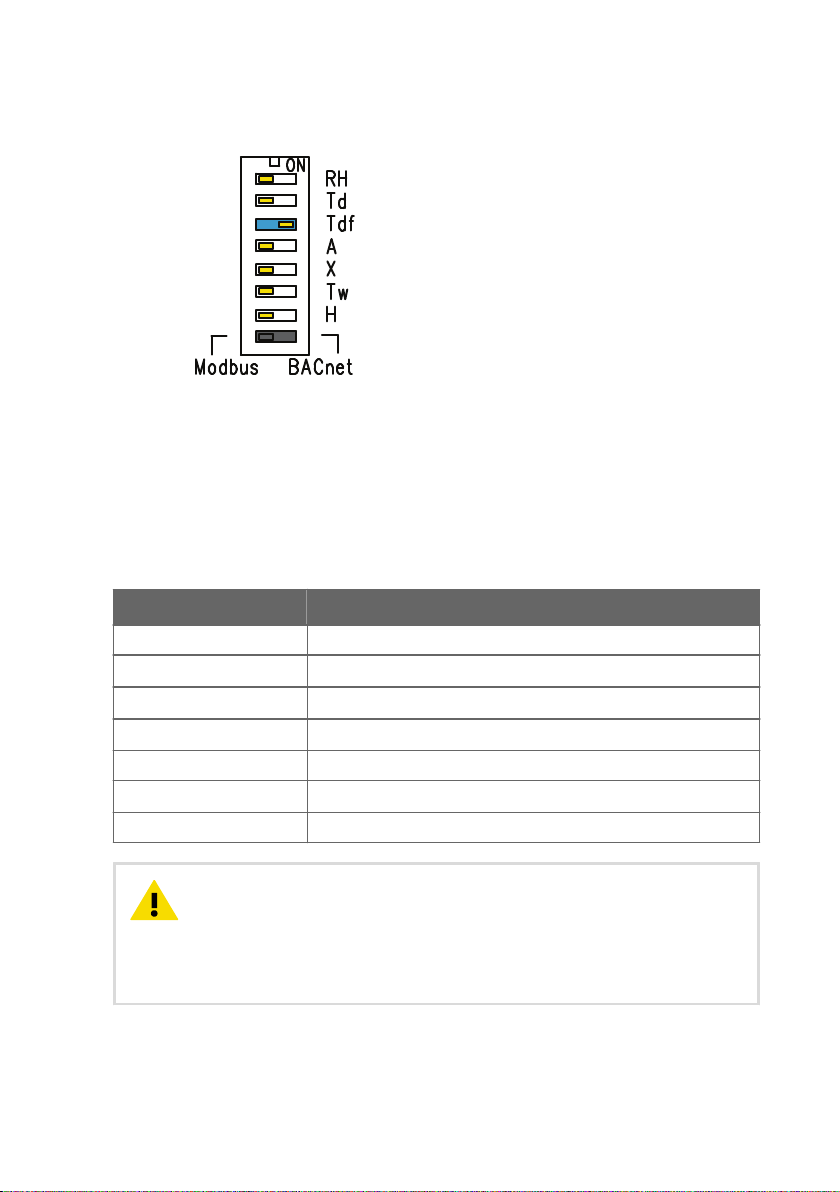

2.5.5 DIP Switch Humidity Output Selection

Chapter 2 – Product Overview

Figure 7 HMD65 DIP Switch Example: T

Output Selected

df

RH Relative humidity

Td Dew point temperature

Tdf Dew point/frost point temperature

A Absolute humidity

X Mixing ratio

Tw Wet-bulb temperature

H Enthalpy

You can change the humidity parameter that is output on the RH channel of HMD65 with the

DIP switches on the component board. Select the parameter you want the transmitter to

output by sliding the parameter's DIP switch to the right (ON). In the example in Figure 7

(page 11), the selected output parameter is dew point/frost point temperature (Tdf). Keep the

other DIP switches in the OFF position (left).

The selected parameter uses the default scaling shown in Table 4 (page 11).

Table 4 HMD65 Default Parameter Scaling

Parameter Default Scaling for 0 … 10 V Output Range

RH 0 … 100 %RH

T

d

T

df

A

X 0 … 600 g/kg (0 … 4200 gr/lb)

T

w

H -40 … 1600 kJ/kg (-9.5 ... 695.6 Btu/lb)

-40 ... +80 °C (-40 ... +176 °F)

-40 ... +80 °C (-40 ... +176 °F)

0 … 300 g/m3 (0 … 131.1 gr/ft3)

-40 ... +80 °C (-40 ... +176 °F)

CAUTION!

Note that the humidity output parameter selected with the DIP

switches on the transmitter component board will be used instead of the

parameter selected with Insight. When using Insight to configure the output, set

all humidity parameter selection DIP switches on the transmitter component

board to the OFF position (left) to ensure they do not cause a conflict with the

Insight settings.

11

Page 14

HMD65 User Guide M212243EN-A

If you use Insight to set both analog output channels to output T measurement,

the humidity parameter DIP switches do not have an eect on the output.

2.6 Filtering Factor

If the measuring environment produces occasional exceptionally high or low readings that

need to be averaged out in the output, you can apply a filtering factor to the RH or T output

(filtering factor range: 0.001 … 1.000). The filtering factor defines the speed at which the latest

measurement is integrated into the transmitter's output. By default, the filtering factor is set to

0.500, which means that the displayed output is a 50%+50% combination of the previous

measurement and the most recent measurement. To show the latest measurement directly in

the output, set the filtering factor to 1.000 (no filtering).

The following formula is used when calculating the output:

output = [(new (unfiltered) measurement × filtering factor) + (previous output × (1.0 - filtering

factor))]

The filtering factor can be configured with the Insight PC software.

More Information

‣

Setting Filtering Factor with Insight (page 25)

2.7

Environmental Compensation

By default, the pressure value used in HMD65 measurement calculation is 1013.2 hPa. If the

pressure of your measurement environment diers from this, you can configure the

transmitter's pressure compensation value with the Insight PC software.

More Information

‣

Changing Pressure Compensation Settings with Insight (page 24)

12

Page 15

3. Installation

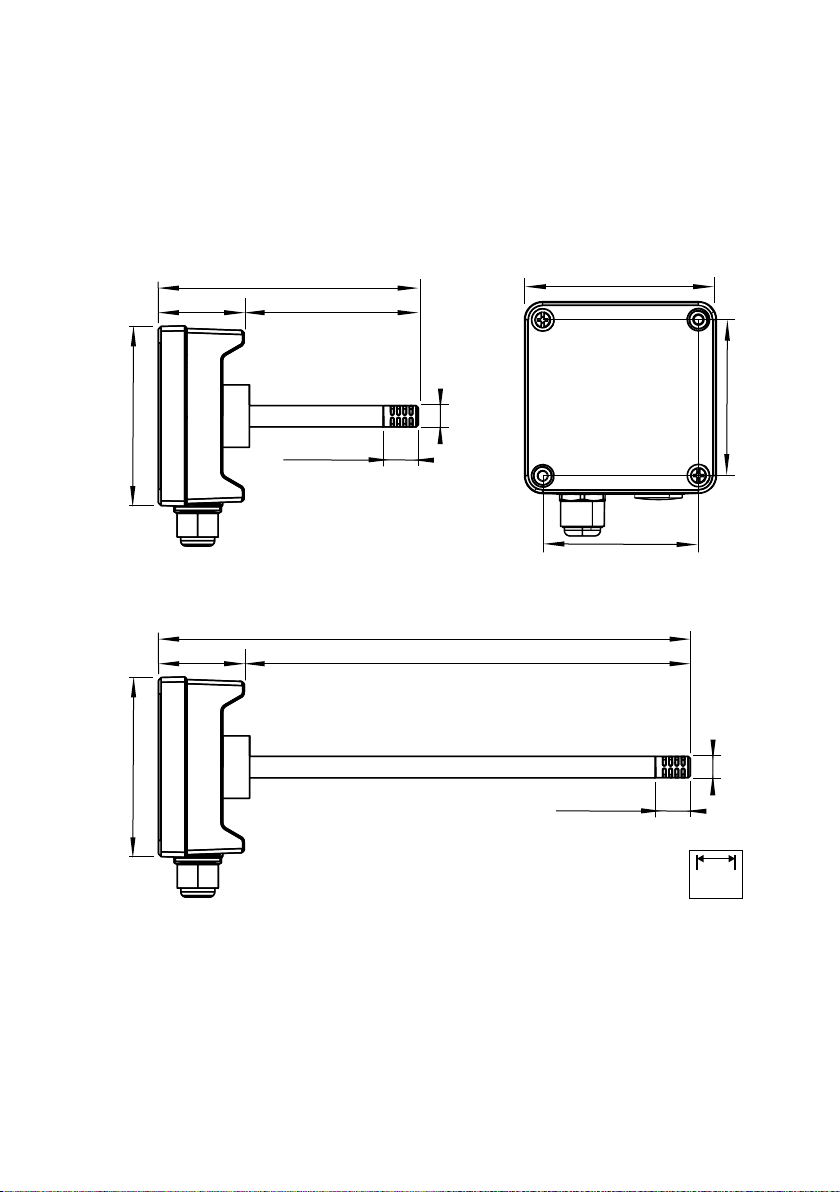

299 [11.77]

49 [1.92]

250 [9.84]

101 [3.97]

mm

[in]

101 [3.97]

82[3.23]

82 [3.23]

Ø 12 [0.47]

19.5 [0.77]

149 [5.87]

49 [1.92]

100 [3.94]

101 [3.97]

Ø 12 [0.47]

19.5 [0.77]

3.1 Transmitter Dimensions

The dimensions are given in millimeters and [inches].

Chapter 3 – Installation

Figure 8 Dimensions with Long and Short Probe

13

Page 16

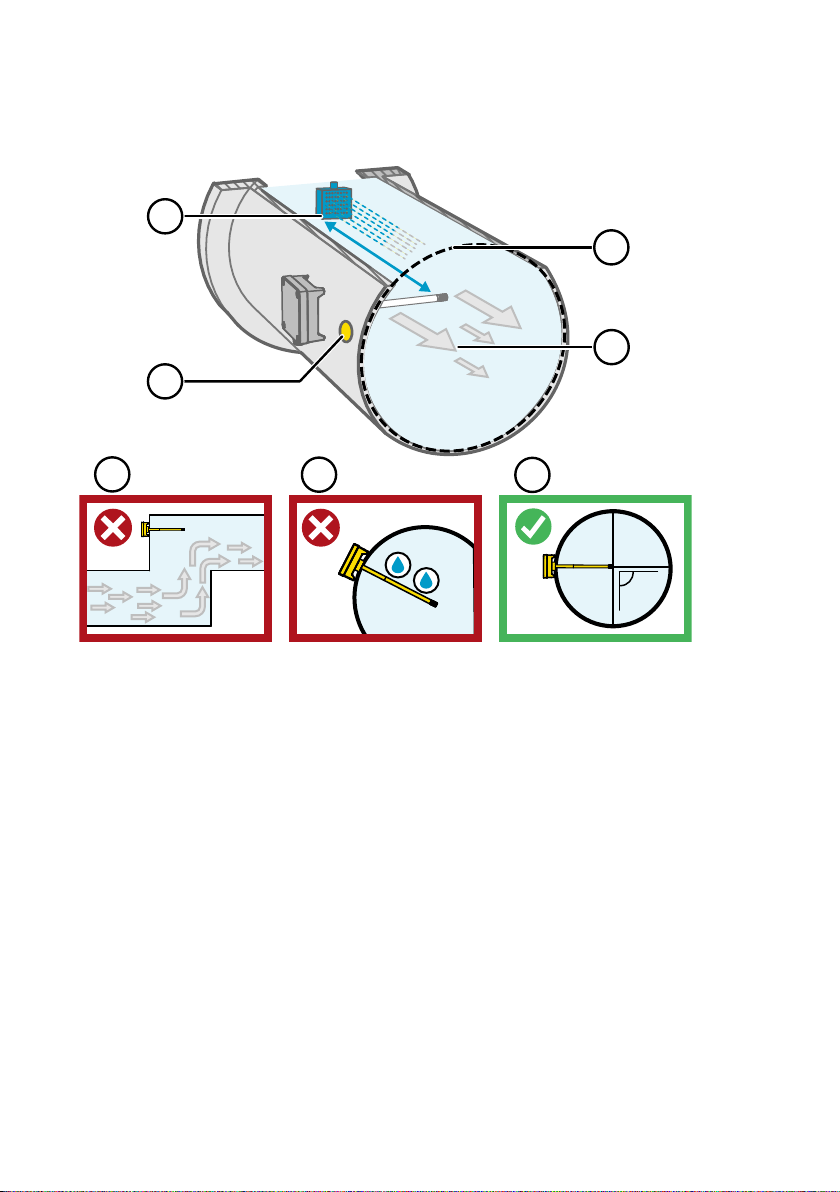

90°

1

4

3

2

5

6

7

HMD65 User Guide M212243EN-A

3.2 Duct Mounting Overview

Figure 9 Duct Installation Overview

Make sure there is a minimum clearance of 5 m (16.5 ft) between the probe body and any

1

possible humidifier. Avoid installing in a location where condensation can fall on the

sensor inside the duct.

2 When installing the transmitter, drill a second hole approximately 30 cm (12 in) from the

installation hole, towards the direction of the air flow, and plug it with a removable seal.

This second hole is intended for later use in reference measurement with another device

when calibrating or adjusting the transmitter.

3 Check that the duct diameter is suitable for the probe body (see Transmitter Dimensions

(page 13)). Ideally, the sensor (probe head) should be installed in the middle of the duct.

4 Maximum air flow speed: 50 m/s (with sintered filter).

5 Avoid installing the transmitter in dead legs. Supersaturation can occur in areas where

there is no air flow.

6 Do not install the probe in a downward angle. Condensation can travel to the sensor along

the probe body if the probe points down.

7 Install the probe in a 90° angle so that the sensor is placed as close to the middle of the

duct as possible.

14

Page 17

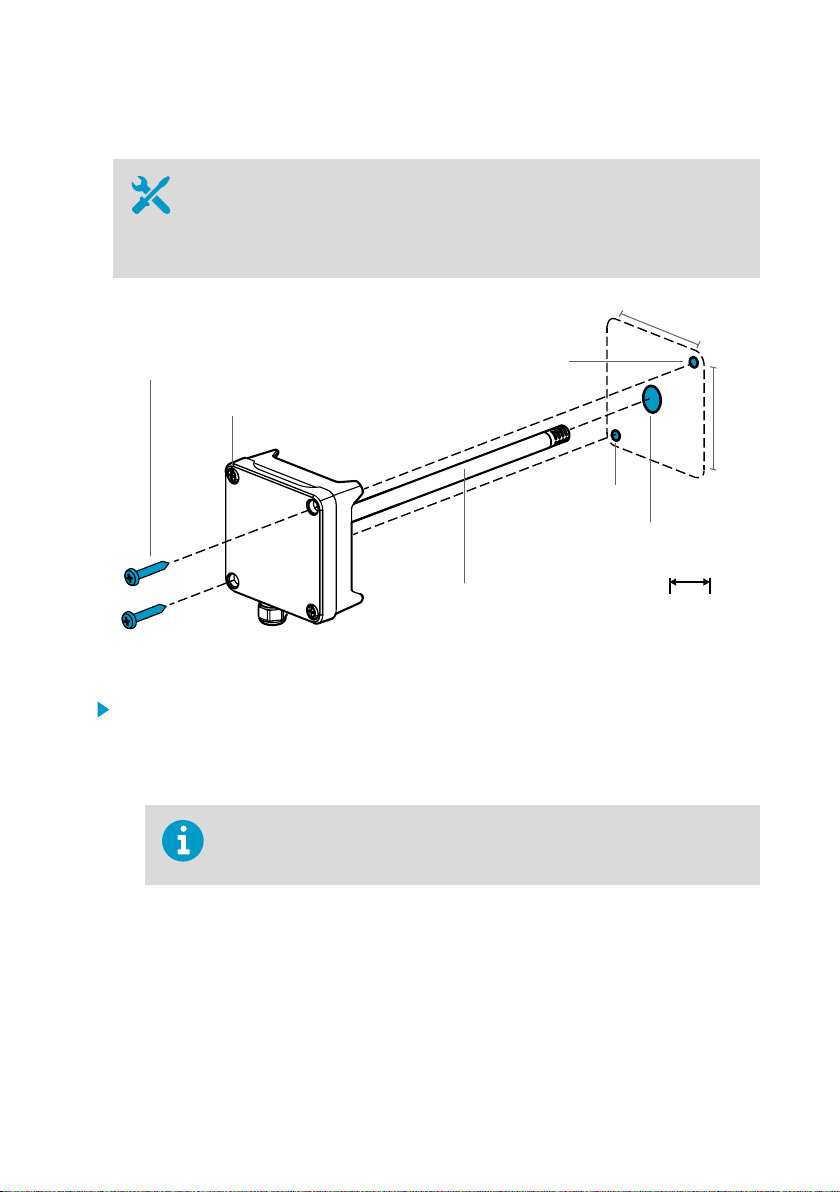

3.3 Installing into Duct

2 x Ø 3.5 [0.14]

Ø 13 ... 15 [0.51 ... 0.59]

Ø 12 [0.47]

82 [3.23]

82 [3.23]

mm

[in]

Ø 3.5 [0.14]

Ø 3.5 [0.14]

3.1 ... 3.4 Nm [2.3 ... 2.5 ft-lbs]

• Medium size crosshead screwdriver for mounting screws and lid screws.

• Small slotted screwdriver for screw terminals.

• Drill with 3.5 mm (0.14 in) and 13 … 15 mm (0.51 … 0.59 in) bits for making the

installation holes.

• Tools for cutting and stripping wires.

Chapter 3 – Installation

Figure 10 Drilling and Mounting Screws

1. Select an installation location for the transmitter on the duct surface and drill a

Ø 13 … 15 mm (0.51 … 0.59 in) hole for inserting the probe.

2. Push the probe through the hole on the duct until the transmitter body meets the duct.

3. Attach the transmitter body to the duct with 2 Ø 3.5 mm (0.14 in) screws.

Check that the insulation ring sits tightly over the installation hole. If the duct

has a negative pressure, external air can be drawn into the duct and aect

the measurement if the installation hole is not sealed tightly.

4. Optional: Drill a second hole for reference measurements approximately 30 cm (12 in)

from the transmitter installation hole. See Figure 9 (page 14).

5. Open the 2 captive screws on the transmitter body and remove the lid.

6. Attach the input/output wiring to the screw terminals on the transmitter component

board. See Wiring (page 16). Tighten cable glands firmly after wiring.

7. Check that the DIP switches and trimmers are in the correct position. See Transmitter

Board (page 9) for more information on DIP switches and trimmers.

15

Page 18

0 ... 10 V ANALOG OUTPUT WIRING

DIGITAL (RS-485) COMMUNICATION WIRING

CONTROLLER

RS-485 +

RS-485 -

RSGND

HMD65

HMD65

+

-

V

V

POWER SUPPLY

(16 ... 24 VAC)

15 ...35 VDC

1)

1)

1) HMD65 GROUNDING SCREW TERMINALS ARE INTERNALLY

CONNECTED TO HMD65 CHASSIS GROUNDING.

CONNECT GROUNDING AS APPLICABLE

TO INSTALLATION SITE WIRING IMPLEMENTATION.

1)

CONTROLLER

+

-

POWER SUPPLY

(16 ... 24 VAC)

15 ...35 VDC

ANALOG INPUT

ANALOG INPUT GROUND

ANALOG INPUT

ANALOG INPUT GROUND

HMD65 User Guide M212243EN-A

8. Close the transmitter lid and switch on the transmitter's power supply input.

3.4 Wiring

Figure 11 HMD65 Wiring Diagrams (Analog and Digital Output Options)

16

Page 19

Chapter 3 – Installation

• Screw terminal wire size: 0.5 ... 2.5 mm

2

• Flat head screwdriver: 0.6×3.5 mm

Make sure that you prepare or connect only de-energized wires.WARNING!

CAUTION!

Do not connect any wires to unused terminals (for example, if you

are using only analog outputs, do not connect wires to the RS-485 terminals).

Connecting unnecessary wires can increase the power consumption and cause

heating.

17

Page 20

HMD65 User Guide M212243EN-A

4. Operating with Insight PC Software

4.1 Vaisala Insight Software

Vaisala Insight software is a configuration software for Vaisala Indigo-compatible probes and

transmitters. The supported operating systems are Windows 7 (64-bit), Windows 8.1 (64-bit),

and Windows 10 (64-bit).

To ensure support for your HMD60 series transmitter, download the latest version

of Insight at www.vaisala.com/insight.

With the Insight software, you can:

• See real-time measurements, device information and status.

• Configure outputs and scaling.

• Calibrate and adjust the device.

HMD60 can be connected to Insight using a Vaisala USB cable (order code 219690).

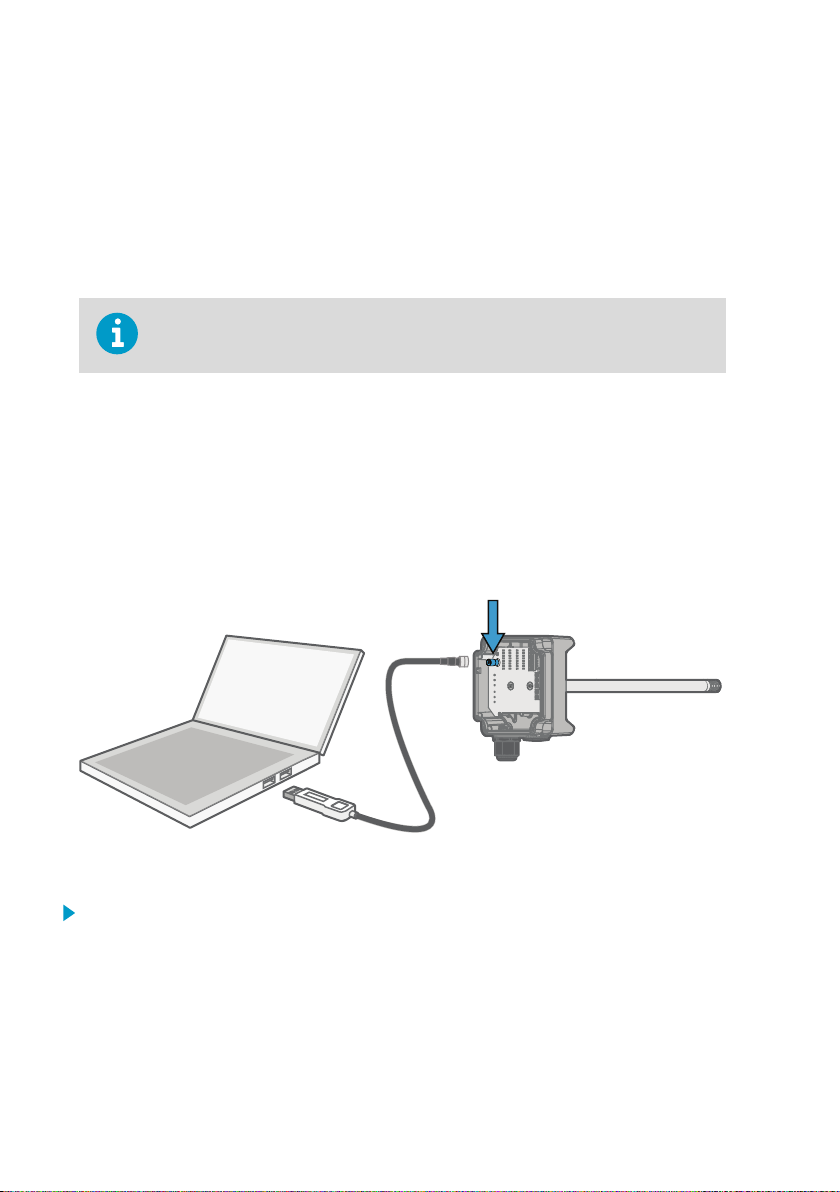

4.2

Connecting to Insight Software

Figure 12 Connecting Transmitter to Insight

1. Open the Insight software.

2. Connect the USB cable to a free USB port on the PC.

3. Connect the USB cable to the service port of the transmitter.

4. Wait for Insight software to detect the transmitter.

18

Page 21

Chapter 4 – Operating with Insight PC Software

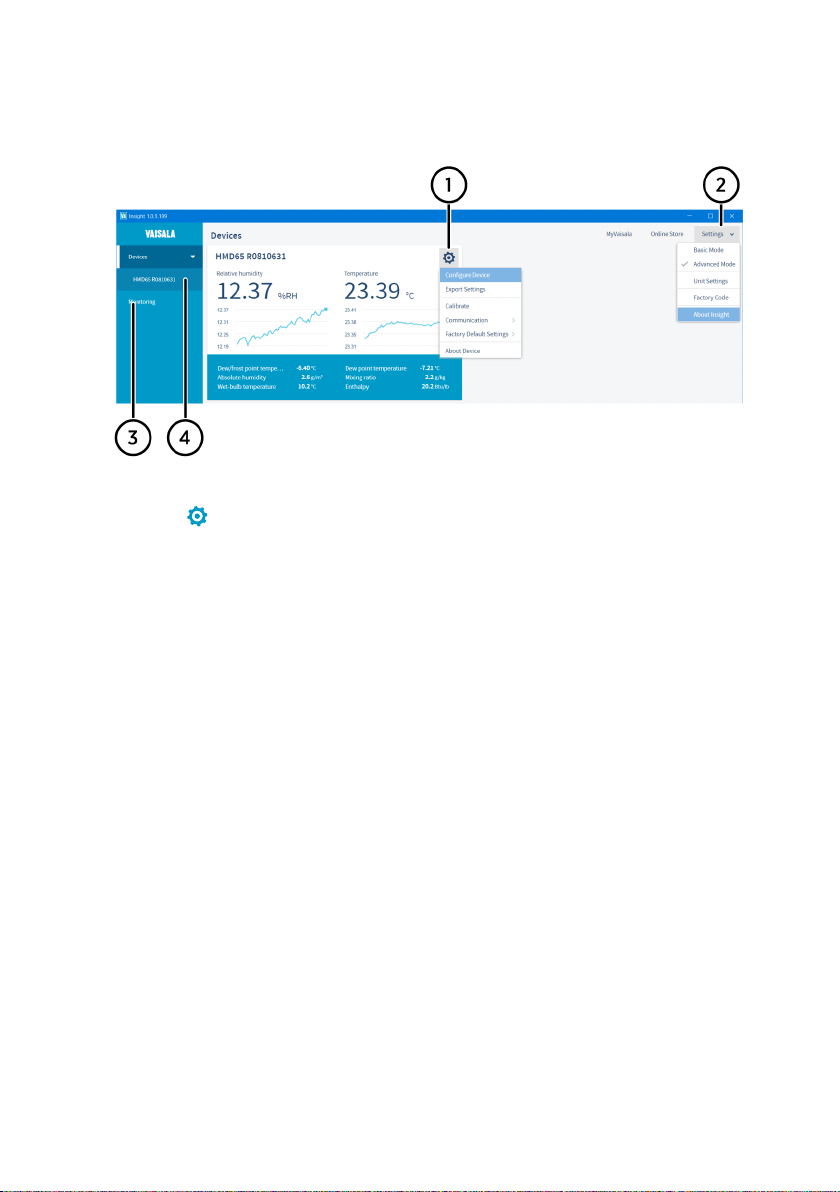

4.3 Insight Main View

Figure 13 Insight Main Menu and Settings

1 Select to access Insight main menu.

• Configure Device: environmental compensation settings, analog output 1 and 2

settings, Modbus and BACnet configuration, filtering factor, error limits and

general settings.

• Export Settings: creates a text file export of the device settings.

• Calibrate: options for calibrating and adjusting RH and T output, testing and

adjusting voltage (V) output levels, and restoring factory adjustments.

• Communication: contains a quick access selection for restarting the device.

• Factory Default Settings: restores the transmitter back to default settings, clears

any user adjustments and restores the latest factory calibration.

• About Device: general device information such as serial number and software

2 Select Settings to switch between the Basic Mode and Advanced Mode user modes,

3 Monitoring provides options for monitoring and recording selected parameters, and

4 Device information menu with the following tabs:

version.

change the units of parameters (metric/non-metric), enter a factory code to access

restricted functionalities, or view information about the Insight software.

exporting the monitoring data as a CSV (comma-separated values) file.

• Measurements: measurement graph view with parameter drop-down selection.

• Calibration Information: read-only information about the latest stored calibration.

• Diagnostics: troubleshooting and administrative information about the device

status. Also includes an option to export the device error log as a text file. When

contacting Vaisala support, it is recommended to include an up-to-date export of

the error log with the support request.

19

Page 22

HMD65 User Guide M212243EN-A

4.3.1 Basic and Advanced User Modes

You can switch between the Basic Mode and Advanced Mode user modes with the selections

in the Settings menu.

Certain functionalities are only available in Advanced Mode. The options enabled by switching

to Advanced Mode are often intended for administrative users: set the user mode according to

the requirements of the personnel that use the device.

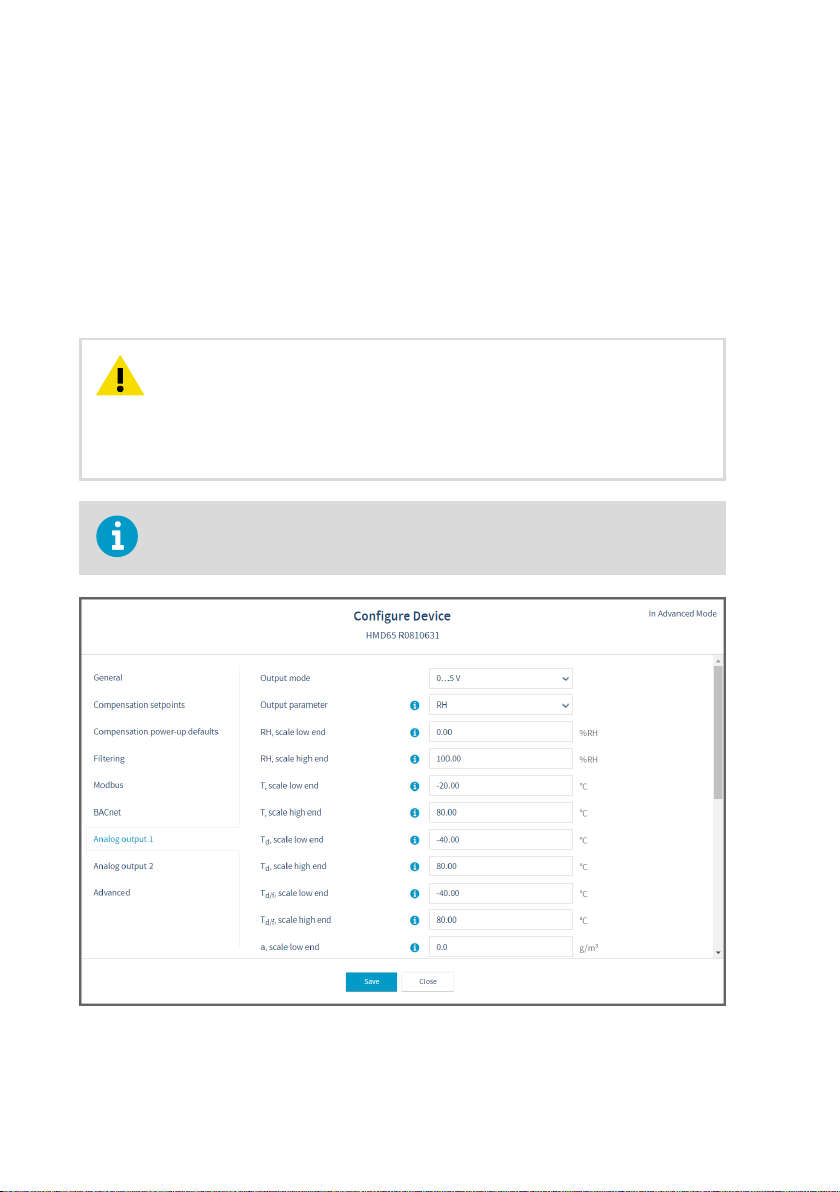

4.4 Configuring Analog Outputs with Insight

CAUTION!

switches on the transmitter component board will be used instead of the

parameter selected with Insight. When using Insight to configure the output, set

all humidity parameter selection DIP switches on the transmitter component

board to the OFF position (left) to ensure they do not cause a conflict with the

Insight settings.

If you use Insight to set both analog output channels to output T measurement,

the humidity parameter DIP switches do not have an eect on the output.

Note that the humidity output parameter selected with the DIP

Figure 14 Analog Output Configuration Options in Insight

20

Page 23

Chapter 4 – Operating with Insight PC Software

To configure analog output with Insight:

1. Check that the output parameter selection DIP switches on the transmitter component

board are switched to the OFF position.

2. Connect to Insight and select > Configure Device > Analog Output 1[2].

3. Select the output mode (either 0 … 10 V, 0 … 5 V, 1 … 5 V, or O).

4. Select the output parameter.

The default analog output setup for HMD65 is 1 channel for RH and 1 channel

for T. Using Insight, you can set any RH and T output combination for the 2

channels (RH+RH, T+T, or RH+T).

5. Enter the lower and upper limits of the output scale for your selected parameter.

6. Set the error output value and the output clipping and error limits.

7. Select Save to store the configuration and exit the menu with Close when done.

4.4.1 Testing and Adjusting Analog Output Voltage (V) Level

• Computer with Windows operating system and Vaisala Insight software

installed

• Vaisala USB cable 219690 for connecting the probe to Insight

• Multimeter for checking the analog output voltage reading

Note that configuring these settings requires using Insight in Advanced Mode.

You can test the voltage (V) output level of the transmitter with a multimeter, and adjust the

output level (2-point adjustment) if necessary.

21

Page 24

HMD65 User Guide M212243EN-A

CAUTION!

outputs to normal operating mode. The transmitter does not output

measurement data when the analog outputs are in test mode.

1. Switch to Advanced Mode in the Settings menu.

2. Select > Calibrate > Yes to switch the probe to calibration mode.

3. Select the analog output you want to test (Analog Output 1[2]).

4. Follow the instructions in the Insight interface to carry out required output tests and

adjustments.

4.5

Configuring Minimum and Maximum RH and T

Always switch Test mode o after testing to return the analog

Errors with Insight

You can define the minimum and maximum limit that the RH or T measurement output can

reach before the output moves to error state.

Note that configuring these settings requires using Insight in Advanced Mode.

22

Page 25

Chapter 4 – Operating with Insight PC Software

Figure 15 Minimum/Maximum Allowed Measurement Value Before Error

To define the minimum/maximum error limits:

1. Switch to Advanced Mode in the Settings menu.

2. Select

> Configure Device > Advanced.

3. Enter the values for minimum and maximum RH and T as applicable, select Save and exit

the menu with Close.

More Information

‣

Basic and Advanced User Modes (page 20)

23

Page 26

HMD65 User Guide M212243EN-A

4.6 Changing Pressure Compensation Settings with Insight

Figure 16 Pressure Compensation Settings

By default, the pressure value used when calculating HMD65 measurements is 1013.2 hPa.

To change the pressure compensation setting:

1. Select

2. To change the volatile compensation value (resets back to power-up default at device

restart), select Compensation setpoints, enter a value, and select Save.

3. To change the default compensation value that stays in use also after device restart, select

Compensation power-up defaults, enter a value, and select Save.

4. Select Close to exit the menu after you have saved the compensations.

More Information

‣

Environmental Compensation (page 12)

24

> Configure Device.

Page 27

Chapter 4 – Operating with Insight PC Software

4.7 Setting Filtering Factor with Insight

Figure 17 Filtering Factor Configuration View

1 Enable filtering by moving the slider to the right (ON)

To set a filtering factor for the transmitter's measurement output:

1. Select > Configure Device > Filtering.

2. Enable filtering with the ON/OFF selections (slide right to enable, left to disable).

3. Enter a filtering factor below 1.000 to apply filtering to the output (range: 0.001 … 1.000).

Examples of the eect of filtering on output:

• Filtering factor 1.000 = No filtering, the latest measurement is output

directly without integrating previous measurements.

• Filtering factor 0.500 = The reading output integrates 50% of the

previous measurement with the latest measurement.

• Filtering factor 0.100 = The reading output integrates 90% of the

previous measurement with the latest measurement.

4. Select Save when done and exit with Close.

More Information

‣

Filtering Factor (page 12)

25

Page 28

3

2

1

7

4 5 6

HMD65 User Guide M212243EN-A

5. Modbus and BACnet Communication

5.1 Modbus and BACnet Overview

HMD65 can be accessed with the Modbus and BACnet protocols over the RS-485 interface.

The protocol selection and communication settings for either protocol are entered with the

DIP switches on the HMD65 component board (see Figure 18 (page 26)).

Figure 18 Modbus and BACnet DIP Switches and Screw Terminals on HMD65 Component Board

1

2 Screw terminals for RS-485 (Modbus/BACnet) communication

3 Screw terminals for power supply input wiring (15 … 35 VDC / 16 … 24 VAC)

4 DIP switches for setting the device MAC address: see Figure 19 (page 27)

5 DIP switches for setting the communication bitrate (4800 … 115200 bps) and parity (N/E)

6 DIP switch for selecting either Modbus RTU or BACnet MS/TP mode

7 LED indicators for RS-485 transmit/receive activity

DIP switch for setting RS-485 termination (120 Ω resistor) ON/OFF

Modbus

The Modbus variant used in HMD65 is Modbus RTU. For a list of the Modbus registers available

in HMD65, see Modbus Registers (page 48).

26

Page 29

Chapter 5 – Modbus and BACnet Communication

BACnet

The BACnet variant used in HMD65 is BACnet MS/TP. For a description of the HMD65 BACnet

implementation, see BACnet Reference (page 54).

Setting Device MAC Address with DIP Switches

Figure 19 MAC Address DIP Switch Example

DIP

switches 32,

8, and 1 set

to ON

The MAC address is

encoded in eight bit binary

form, with each numbered

switch representing a single

bit. This example shows

address 41 selected: DIP

switches 32, 8, and 1

(decimal: 41, binary:

00101001) are set to ON.

Modbus and BACnet MAC Address Ranges

The BACnet MS/TP MAC address range for the transmitter is 0 … 127 (master mode only).

The Modbus RTU MAC address range for the transmitter is 1 … 247.

Configuring an address above the range maximum results in the address defaulting back to

the maximum address (127 or 247). Addresses below the range minimum default to the

minimum address (0 or 1).

Bit Rate and Parity Options

• The bit rate 4800 is used only for Modbus RTU (use 9600 and above for BACnet MS/TP).

• If the bit rate DIP switches are all set to OFF (left), the following defaults are used:

• Modbus RTU: 19200

• BACnet MS/TP: 38400

• The parity selection (N/E) only has an eect on Modbus RTU communication.

5.2

Modbus and BACnet Configuration with

Insight

Modbus and BACnet communication settings are configured with the DIP switches on the

HMD65 component board (see Figure 18 (page 26)). In addition to the communication settings

available through the DIP switches, you can configure certain Modbus and BACnet settings

with Vaisala Insight PC software (requires Vaisala USB cable 219690).

For instructions on connecting HMD65 to Insight, see Connecting to Insight Software

(page 18).

27

Page 30

HMD65 User Guide M212243EN-A

5.2.1 Configuring Modbus Response Delay with Insight

Figure 20 Modbus Response Delay Setting in Insight

To configure Modbus response delay with Insight:

1. Connect to Insight and select > Configure Device > Modbus.

2. Enter the Response delay value in milliseconds: see the instructions in the Insight

interface for allowed ranges and additional information.

3. Select Save to store the setting.

5.2.2 Configuring BACnet with Insight

Figure 21 BACnet Device Information, MS/TP Master Address Poll Limit, and Remote Management

Password Settings in Insight

28

Page 31

Chapter 5 – Modbus and BACnet Communication

You can configure the following BACnet settings with Vaisala PC Insight software:

• Max_Master (highest address polled for MS/TP master)

• Device object identifier (BACnet ID of the device)

• Device object name (max. 40-character name for the device)

• Device location (max. 40-character location info for the device)

• Firmware revision (read-only version information)

• Remote management password (max. 20-character password for remote management,

default 1234)

To configure BACnet settings with Insight:

1. Connect to Insight and select > Configure Device > BACnet.

2. Enter the values for BACnet settings as necessary: see the instructions in the Insight

interface for allowed ranges and additional information.

3. Select Save to store the settings.

29

Page 32

6

5

4

3

2

1

HMD65 User Guide M212243EN-A

6. Operating with MI70 Indicator

6.1 Overview of MI70 Support

The MI70 hand-held indicator is a convenient service tool for viewing the measurement

readings and performing calibration and adjustment. MI70 is used as the display and

configuration tool in, for example, the HM70 Hand-Held Humidity and Temperature Meter, and

is also compatible with various Vaisala probes and transmitters.

You can use the MI70 indicator for the following tasks with HMD60:

• Measurement viewing and logging

• Calibration and 1-point adjustment (see Calibration and Adjustment with MI70 Hand-Held

Indicator (page 40))

• Viewing information about the transmitter (serial number, SW version, last adjustment

date)

To connect HMD60 to an MI70 indicator, you need the optional MI70 connection

cable (Vaisala order code 219980SP).

6.1.1 MI70 Indicator Parts

Figure 22 MI70 Indicator Parts

1 Charger socket

2 Function key shortcut buttons . The

functions change according to what

you are doing with the indicator.

3 Arrow buttons:

30

Move up in a menu

Move down in a menu

4 Power On/O button

5 Battery compartment at the back of

6 Two ports (labeled I and II) for

Enter a sub-menu

Return to previous menu level

the indicator

connecting probes and instruments.

Page 33

Chapter 6 – Operating with MI70 Indicator

To open menus, press an arrow button and then press the shortcut buttons. To activate a

function shown above the shortcut button, press the shortcut button. To navigate in the

menus, press arrow buttons.

6.2 Connecting HMD60 to MI70 Indicator

• MI70 connection cable (Vaisala order code 219980SP).

• Medium size crosshead screwdriver for opening the lid screws.

Figure 23 Connecting HMD60 to MI70 Indicator with Cable 219980SP

1. Open the 2 captive screws on the transmitter body and remove the lid.

2. If the MI70 indicator is on, turn it o.

3. Connect the MI70 connection cable 219980SP to HMD60 service port and either of the

MI70 connector ports.

4. Turn on the MI70 indicator (time and date are requested at first startup). MI70 detects

HMD60 and proceeds to show the measurement screen. MI70 will start to show valid

measurement results from HMD60 after a few seconds.

31

Page 34

HMD65 User Guide M212243EN-A

6.3 Basic Display

1 Measured parameter and compensations (up to three items on display simultaneously).

You can change the shown items in Main menu > Display > Quantities and units.

2 Battery indicator. Shows current status (charge) of the battery.

3 Function key Graphic shows the readings as a curve.

4 Function key Hold/Save freezes the display and you can save the reading in the MI70

memory.

5 Function key Record is a quick access to the Recording/Viewing menu.

Figure 24 MI70 Basic Display

You can change the default function key shortcuts (Graphic, Hold/Save, Record) to other

menus or functions in Main menu > Settings > User interface > Program shortcut keys.

6.4 Graphical Display

The graphical display shows you the measurements as a curve (the curve of the uppermost

quantity shown in the basic display). From the curve you can examine the data trend and

history of the last minutes.

To open the graphical display, select Graphic in the basic display or select Main menu >

Display > Graphic history > Show.

To get the statistical info on the graph area (minimum, maximum, and average values), press

Info.

To get the curve of the other selected quantities, press Next. To get the curves of all the

quantities, press Next until the text All appears, and then select All.

To zoom in and out, press the up/down arrow keys.

To move back and forward in the timeline, use the left/right arrow keys.

6.5

Main Menu

In the main menu, you can configure the MI70 settings and basic display options, view

information about the probe, access recordings and clear the memory, set alarms, start

adjustments, and use the analog output option of the MI70 indicator.

To open the main menu and navigate in the menus:

1. Go to the basic display.

2. Press any arrow key, then select

indicator returns to the basic display).

3. Move in the menus using the buttons.

4. Select an item with the

32

Open (must be pressed within 5 seconds or the

button.

Page 35

Chapter 6 – Operating with MI70 Indicator

5. To return to the previous level, press .

6. To return to normal operation, press Exit.

6.6 Holding and Saving the Display

With the Hold/Save function, you can freeze a certain display reading. This reading can be

saved in the MI70 memory and it will be available even after MI70 is disconnected from the

transmitter.

1. In the basic display, select Hold/Save. Alternatively, select Main menu > Display > Hold/

Save display > Hold.

2. Press Save.

3. To view the saved display, go to basic display and select Record > View recorded data.

Alternatively, select Main menu > Recording/Viewing > View recorded data.

A list of saved displays and data recordings appears. The icons on the left of the date and

time indicate whether the file is a saved display or a longer recording of data:

4. Select the saved display based on date and time by pressing the right arrow key.

Saved display

Data recording

6.7

Recording Data

With MI70, you can record transmitter measurement data over a certain period at chosen

intervals. These recordings are saved in MI70 memory and are available even after MI70 is

disconnected from the transmitter. To start recording, select the Record function key in the

basic display, or navigate to the recording menu: Main menu > Recording/Viewing > Record

data.

33

Page 36

±0 %RH

−1 %RH

−2 %RH

−3 %RH

−4 %RH

−5 %RH

+1 %RH

+2 %RH

+3 %RH

+4 %RH

+5 %RH

±0 °C

−0.06 °C

−0.12 °C

−0.18 °C

−0.24 °C

−0.3 °C

+0.06 °C

+0.12 °C

+0.18 °C

+0.24 °C

+0.3 °C

RH: −5 %RH ... +5 %RH T: −0.3 °C ... +0.3 °C

RH T

HMD65 User Guide M212243EN-A

7. Calibration and Adjustment

7.1 Calibration and Adjustment Overview

You can calibrate or adjust the transmitter's measurement output using one of the following

options:

• 1-point adjustment with the RH and T trimmers on the HMD60 component board

(adjustment range: -5%RH … +5 %RH and -0.3 °C … +0.3 °C (-0.54 °F … +0.54 °F).

• 1-point or 2-point adjustment by connecting the transmitter to Vaisala Insight PC software

(requires USB cable 219690).

• 1-point adjustment by connecting the transmitter to an MI70 hand-held indicator (requires

MI70 connection cable 219980SP).

7.2 Calibration and Adjustment Using Trimmers

HMD60 transmitters have 2 separate trimmers for RH and T measurement output adjustment

mounted on the component board. The trimmers allow for easy 1-point adjustment of the

measurement output against a reference with a known value.

The transmitters are shipped with the trimmers centered. Turning the trimmer counterclockwise decreases the measurement output value, and turning clockwise increases the value.

Figure 25 (page 34) shows the trimmer adjustment ranges for RH and T (-5 %RH … +5 %RH

and -0.3 °C … +0.3 °C (-0.54 °F … +0.54 °F).

Figure 25 RH and T Adjustment Trimmer Ranges (Indicative)

The trimmers will only turn 135 degrees each way, less than half a rotation. Do not

force the trimmer past the stopping point.

34

Page 37

Chapter 7 – Calibration and Adjustment

CAUTION!

restore the factory settings, always return the physical trimmer to the middle

position before starting. When you make an adjustment with Insight, the

position in which the trimmer is at that point is set as the ±0 point.

If you use the Insight PC software to adjust the measurement or to

7.2.1 1-Point Adjustment Using Trimmers and Reference Calibrator

• Reference environment(s) for producing the desired humidity and/or

temperature (for example, Vaisala HMK15 Humidity Calibrator).

• A multimeter for checking the analog output reading (connect in series to

measure the current output).

• Small Phillips head screwdriver for turning the trimmers.

To adjust the output:

1. Prepare the reference (for example, a humidity calibrator). Use a reference that matches

your normal measurement environment as closely as possible.

2. Connect the multimeter to the analog output (connect in series to measure the current

output).

3. Insert the probe head in the reference environment.

4. Wait for the reference measurement to stabilize fully. This may take more than 30

minutes. Monitor the readings to see when the measurement has stabilized.

5. When the measurement has stabilized, adjust the output with the trimmers until it

matches the known value of the reference.

Note that there is a small delay before the output value updates after you

turn the trimmer.

7.2.2 Adjusting Output Using Trimmers and Reference Transmitter (1-point adjustment)

• A recently calibrated reference device (for example, a second HMD60

transmitter).

• A multimeter for checking the analog output reading (connect in series to

measure the current output).

• Small Phillips head screwdriver for turning the trimmers.

35

Page 38

HMD65 User Guide M212243EN-A

It is assumed that a hole was drilled for the reference instrument during

installation, the transmitter is powered, and you can view the measurement

output value.

To adjust the output:

1. Insert the reference transmitter into the measurement environment next to the

transmitter that you are adjusting. The reference transmitter should be inserted

approximately 30 cm (12 in) from the HMD60 probe's installation hole, towards the

direction of the air flow. See Figure 9 (page 14).

2. Connect a multimeter to the analog output of the reference transmitter (connect in series

to measure the current output).

3. Wait for the measurement to stabilize fully. This may take more than 30 minutes. Monitor

the readings to see when the measurement has stabilized.

4. When the measurement has stabilized, adjust the output of your transmitter with the

trimmers until it matches the output of the reference transmitter.

Note that there is a small delay before the output value updates after turning

the trimmer.

5. When done, plug the installation hole of the reference transmitter.

7.2.3 Resetting Trimmers Back to Zero

• Computer with Windows operating system and Vaisala Insight software

installed

• Vaisala USB cable 219690 for connecting the probe

• Small Phillips head screwdriver for turning the trimmer(s)

If you need to reset a trimmer back to zero (±0 point), use the Insight PC software to restore

factory adjustments for the parameter the trimmer adjusts (RH or T).

1. Turn the trimmer(s) back to the middle position (±0 point)

2. Connect the transmitter to Insight. See Connecting to Insight Software (page 18).

3. Select

4. Select the parameter you want to reset (RH adjustment or T adjustment).

5. Select Restore factory adjustment and confirm by selecting Yes.

6. Reset each parameter (RH or T) separately as needed with the trimmer turned back to the

middle position (±0 point). The trimmer adjustment now starts from the ±0 point of the

default trimmer adjustment range (see Calibration and Adjustment Using Trimmers

(page 34)).

36

> Calibrate > Yes to switch the probe to calibration mode.

Page 39

Chapter 7 – Calibration and Adjustment

7.3 Calibration and Adjustment with Insight PC Software

Figure 26 Insight Calibration View

You can use the Insight PC software to calibrate and adjust the RH or T measurement in 1 or 2

points. Either a reference environment (such as a humidity calibrator) or a reference

instrument (for example, a second HMD60 transmitter) can be used when adjusting.

CAUTION!

or to restore the factory settings, always return the physical adjustment

trimmer(s) on the transmitter component board to the middle position before

starting. When you make an adjustment with Insight, the position in which the

adjustment trimmer is at that point is set as the ±0 point.

More Information

‣

Connecting to Insight Software (page 18)

When you use the Insight PC software to adjust the measurement

37

Page 40

HMD65 User Guide M212243EN-A

7.3.1 2-Point Adjustment with Insight and Reference Calibrator

• Computer with Windows operating system and Vaisala Insight software

installed

• Vaisala USB cable 219690 for connecting the probe

• Reference environment(s) for producing the desired humidity and/or

temperature

This procedure can be used to adjust the humidity (RH) or temperature (T) measurement of

the transmitter. If you want to adjust both RH and T , repeat the procedure for each parameter.

Because stabilization of temperature and humidity takes time, you should expect the

adjustment procedure to take at least 30 minutes for each adjustment point.

1. Prepare the reference environment (for example, Vaisala HMK15 Humidity Calibrator).

2. Connect the transmitter to Insight. See Connecting to Insight Software (page 18).

3. Select > Calibrate > Yes to switch the probe to calibration mode.

In calibration mode, the device will not use functions that may interfere with calibration

and adjustment.

4. Select the type of adjustment to perform: RH adjustment or T adjustment.

5. Define the needed adjustment for the first measurement point:

a. Insert the probe head in the reference environment for the first calibration point.

b. Wait for the measurement to stabilize fully.

c. Click the Reference value, point 1 text box and enter the reference value of the

calibration point. Press ENTER or click outside the text box when done.

d. Insight automatically enters the measured values for the calibration point.

6. Repeat step 5 for the second calibration point.

7. Select Activate adjustment > Yes to store the adjustment in the transmitter.

8. Check the message that appears at the top of the screen. If the message indicates that

the adjustment is activated successfully, your adjustment is stored.

9. Select the Calibration information tab and update the Calibration date and Calibration

text.

10. Select Close > Yes to exit the calibration mode.

7.3.2 1-Point Adjustment with Insight and Reference Transmitter

• Computer with Windows operating system and Vaisala Insight software

installed

• Vaisala USB cable 219690 for connecting the probe

• A recently calibrated reference transmitter (for example, another HMD60

transmitter) and the required equipment for powering the reference device

and viewing its measurements

38

Page 41

Chapter 7 – Calibration and Adjustment

This procedure can be used to adjust the humidity (RH) or temperature (T) measurement of

the transmitter. If you want to adjust both RH and T , repeat the procedure for each parameter.

It is assumed that a hole was drilled for the reference instrument during

installation, the reference instrument is powered, and you can view the

measurement output value.

1. Insert the reference transmitter into the measurement environment next to the

transmitter that you are adjusting. The reference transmitter should be inserted

approximately 30 cm (12 in) from the HMD60 probe's installation hole, towards the

direction of the air flow. See Figure 9 (page 14).

2. Monitor the measurement of the reference instrument and wait until the measurement has

stablized fully.

If you are using a second HMD60 transmitter as the reference device, you can

connect both transmitters to Insight simultaneously and view the

measurement of the reference device from Insight while making the

adjustment.

3. Connect the transmitter you are adjusting to Insight. See Connecting to Insight Software

(page 18).

4. Select > Calibrate > Yes to switch the transmitter to calibration mode.

In calibration mode, the transmitter will not use functions that may interfere with

calibration and adjustment.

5. Select the type of adjustment to perform: RH adjustment or T adjustment.

6. Define the needed adjustment for the first measurement point:

a. Read the measurement of the reference transmitter (make sure the measurement has

stabilized fully).

b. Click the Reference value, point 1 text box and enter the reference value of the

calibration point. Press ENTER or click outside the text box when done.

c. Insight automatically enters the measured values for the calibration point.

7. Select Activate adjustment > Yes to store the adjustment in the transmitter.

8. Check the message that appears at the top of the screen. If the message indicates that

the adjustment is activated successfully, your adjustment is stored.

9. Select the Calibration information tab and update the Calibration date and Calibration

text.

10. Select Close > Yes to exit the calibration mode.

11. When done, plug the installation hole of the reference transmitter.

39

Page 42

HMD65 User Guide M212243EN-A

7.4 Calibration and Adjustment with MI70 HandHeld Indicator

You can use the MI70 hand-held indicator to make a 1-point adjustment to temperature (T) or

relative humidity (RH). To connect the transmitter to MI70, you need the optional MI70

connection cable (Vaisala order code 219980SP). For instructions on connecting the

transmitter to MI70 and general information about using MI70, see Overview of MI70 Support

(page 30).

Before adjusting the measurement with MI70, turn the adjustment trimmer(s) on

the transmitter component board back to the ±0 position. When you adjust the

measurement with MI70, the position in which the trimmer is at that moment

becomes the new ±0 point.

More Information

‣

Connecting HMD60 to MI70 Indicator (page 31)

7.4.1 1-Point Adjustment Using Reference Environment

• A humidity or temperature reference (for example, Vaisala HMK15 Humidity

Calibrator) to create the reference condition used in the adjustment.

• MI70 hand-held indicator and MI70 connection cable 219980SP

This example describes an RH adjustment with a humidity calibrator. The same

steps can be applied to temperature calibration with a temperature reference.

1. Prepare the humidity reference for the adjustment point you are using (for example, 11

%RH).

2. Connect the transmitter to MI70 indicator with the MI70 connection cable 219980SP.

3. Turn on the MI70 indicator.

4. Insert the probe head into the reference environment.

5. Start the adjustment sequence from Main menu > Functions > Adjustments.

40

Page 43

Chapter 7 – Calibration and Adjustment

6. MI70 notifies you that automatic power o is disabled during adjustment mode, press OK

to acknowledge.

7. Select the RH parameter when prompted.

8. The adjustment mode is now active, and you can see the measured RH reading on the

screen. To proceed with the adjustment, press Adjust.

9. Select 1-point adjustment.

10. You are now in the 1-point adjustment screen. Wait until the measurement has stabilized

fully in the reference environment, and then press Ready.

11. Enter the known value of the RH reference with the arrow buttons (for example, 11 %RH)

and press OK.

41

Page 44

HMD65 User Guide M212243EN-A

12. You will be prompted if you really want to adjust. Select Yes.

13. If the adjustment is successful, MI70 will show the text Adjustment Done, after which you

will return to the adjustment mode. At this point you can press Back and Exit to leave the

adjustment mode. The adjustment is now completed. If the adjustment cannot be applied,

MI70 will show the text Cannot adjust, possibly followed by a text stating the reason. A

possible reason for an adjustment failure is attempting to apply a very large correction to

the reading.

42

Page 45

Chapter 8 – Maintenance

8. Maintenance

8.1 Cleaning

You can clean the transmitter and probe body by wiping with a moist cloth. Standard cleaning

agents can be used.

CAUTION!

cleaning chemicals that can damage the coating.

When cleaning, follow these precautions:

• Do not immerse the transmitter or probe in liquid to clean it.

• Take care not to damage the PTFE membrane inside the metal grid filter (ASM212652SP)

when cleaning. Do not use a pressure washer to clean the filter, and avoid pulling, tearing

or puncturing the membrane.

• When changing the filter, you can use clean instrument air to gently blow any loose dirt

and filter material from the sensor. Do not attempt to clean the optical surfaces in any

other manner.

Note that the transmitter body is powder coated. Do not use

43

Page 46

HMD65 User Guide M212243EN-A

9. Technical Data

9.1 Specifications

Table 5 Relative Humidity Measurement Performance

Property Specification

Humidity sensor Vaisala HUMICAPâ R2

Measurement range 0 ... 100 %RH

Stability ±0.5 %RH/year in typical HVAC applications

Accuracy at 0 … +40 °C (+32 … +104 °F) (Incl. Non-linearity, Hysteresis, and Repeatability)

0 ... 90 %RH ±1.5 %RH

90 ... 100 %RH ±2.5 %RH

Accuracy at +40 … +80 °C (+104 … +176 °F) and -40 ... 0 °C (-40 ... +32 °F) (Incl. Non-linearity,

Hysteresis, and Repeatability)

0 … 90 %RH ±2.5 %RH

90 … 100 %RH ±3.5 %RH

Factory calibration uncertainty ±1.0 %RH

Start-up and Response Time

Start-up time at +20 °C (+68 °F) 8 s

Response time (T63) at +20 °C (+68 °F) 15 s

Calculated Humidity Parameters (Default Analog Output Scale)

Dew point -40 ... +80 °C (-40 ... +176 °F)

Dew point / frost point -40 ... +80 °C (-40 ... +176 °F)

Absolute humidity

Wet bulb temperature -40 ... +80 °C (-40 ... +176 °F)

Enthalpy -40 … 1600 kJ/kg (-9.5 ... 695.6 Btu/lb)

Mixing ratio 0 … 600 g/kg (0 … 4200 gr/lb)

0 … 300 g/m3 (0 … 131.1 gr/ft3)

Table 6 Temperature Measurement Performance

Property Specification

Temperature sensor Pt1000 RTD Class F 0.1 IEC 60751

Measurement range -40 ... +80 °C (-40 ... +176 °F)

44

Page 47

Chapter 9 – Technical Data

Property Specification

Default analog output scale -20 … +80 °C (-4 … +176 °F)

Accuracy at +20 °C (+68 °F) ±0.1 °C (0.18 °F)

Temperature dependence ±0.005 °C/°C

Factory calibration uncertainty ±0.1 °C (0.18 °F)

Response time (T63) with free convection 8 min

Table 7 Analog Output Performance

Property Specification

Accuracy at +20 °C (68 °F) ±5 mV

Temperature dependence ±0.2 mV/°C

Table 8 Operating Environment

Property Specification

Operating temperature, electronics -40 ... +60 °C (-40 ... +140 °F)

Operating temperature, probe -40 ... +80 °C (-40 ... +176 °F)

Storage temperature range -40 ... +80 °C (-40 ... +176 °F)

Maximum flow speed 50 m/s with sintered filter

Electromagnetic compatibility EN61326-1, Industrial Environment

Table 9 Inputs and Outputs

Property Specification

Power supply input 15 … 35 VDC

16 … 24 VAC

Power consumption 1.0 W (typical, for both AC and DC)

Analog output 1 × RH output 0 … 10 V, 1 × T output 0 … 10 V 1

(load resistance: 10 kΩ min.)

Digital output (RS-485) Isolated, supports Modbus RTU and BACnet

MS/TP protocols

BACnet MS/TP Address range: 0 … 127 (master mode only)

Modbus RTU Address range: 1 … 247

45

Page 48

HMD65 User Guide M212243EN-A

Property Specification

Service port M8 4-pin male connector:

• MI70 handheld indicator (requires cable

219980SP)

• Vaisala Insight PC software 2 (requires USB

cable 219690)

Screw terminal wire size

1) Vaisala Insight software for Windowsâ available at www.vaisala.com/insight.

Table 10 Mechanical Specification

Property Specification

Housing material Cast aluminium

Probe material Stainless steel

IP rating IP66 (NEMA 4X)

Weight 511 g (18 oz)

0.5 ... 2.5 mm

2

9.2 Spare Parts and Accessories

Information on spare parts, accessories, and calibration products is available

online at www.vaisala.com and store.vaisala.com.

Table 11 Spare Parts and Accessories

Spare Part / Accessory Vaisala Order Code

USB cable for PC operation (Vaisala Insight

software)

Connection cable for HM70 (MI70) handheld

meter

Membrane filter ASM212652SP

Sintered filter HM46670SP

Conduit fitting and O-ring (M16×1.5 / NPT1/2") 210675SP

Cable Gland and O-ring (M16x1.5): default option

delivered with HMD60

46

219690

219980SP

254280SP

Page 49

9.3 Transmitter Dimensions

299 [11.77]

49 [1.92]

250 [9.84]

101 [3.97]

mm

[in]

101 [3.97]

82[3.23]

82 [3.23]

Ø 12 [0.47]

19.5 [0.77]

149 [5.87]

49 [1.92]

100 [3.94]

101 [3.97]

Ø 12 [0.47]

19.5 [0.77]

The dimensions are given in millimeters and [inches].

Chapter 9 – Technical Data

Figure 27 Dimensions with Long and Short Probe

47

Page 50

HMD65 User Guide M212243EN-A

Appendix A. Modbus Registers

The Modbus registers available for HMD65 include measurement output registers in metric and

non-metric units, pressure compensation setpoint configuration, status registers, and

communication test registers.

The Modbus communication settings are configured using the DIP switches on HMD65

component board: see Modbus and BACnet Overview (page 26).

CAUTION!

Registers are numbered in decimal, starting from one. Register

addresses in actual Modbus messages (Modbus Protocol Data Unit (PDU)) start

from zero.

Please check the reference documentation of your Modbus host (PLC) for the

notation of Modbus register addresses.

16-bit integers have a maximum value of +32767. Certain measurement

parameters can exceed this value when x100 scaling is used (see measurement

registers 0100

hex

… 0107

and 0180

hex

hex

… 0187

hex

recommended to use 32-bit float values.

A.1 Measurement Data Registers

Table 12 Modbus Measurement Data Registers (Read-Only)

Register

Number

(Decimal)

Floating Point Values (Metric)

1 0000

3 0002

5 0004

7 0006

Address

(Hexadecimal)

hex

0001

hex

hex

0003

hex

hex

0005

hex

hex

0007

hex

Register Description Data Format Unit

Relative humidity 32-bit float %RH

Temperature 32-bit float °C

Dew point temperature 32-bit float °C

Dew/frost point

temperature

). Whenever possible, it is

32-bit float °C

48

Page 51

Appendix A – Modbus Registers

Register

Number

Address

(Hexadecimal)

(Decimal)

Floating Point Values (Metric)

9 0008

11 000A

13 000C

15 000E

0009

000B

000D

000F

hex

hex

hex

hex

hex

hex

hex

hex

Floating Point Values (Non-metric)

129 0080

131 0082

133 0084

135 0086

137 0088

139 008A

141 008C

143 008E

0081

0083

0085

0087

0089

008B

008D

008F

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

Register Description Data Format Unit

Absolute humidity 32-bit float

g/m

Mixing ratio 32-bit float g/kg

Wet-bulb temperature 32-bit float °C

Enthalpy 32-bit float kJ/kg

Relative humidity 32-bit float %RH

Temperature 32-bit float °F

Dew point temperature 32-bit float °F

Dew/frost point

32-bit float °F

temperature

Absolute humidity 32-bit float

gr/ft

Mixing ratio 32-bit float gr/lb

Wet-bulb temperature 32-bit float °F

Enthalpy 32-bit float Btu/lb

3

3

49

Page 52

HMD65 User Guide M212243EN-A

Integer Values (x100, Metric)

257 0100

258 0101

259 0102

260 0103

261 0104

262 0105

263 0106

264 0107

Integer Values (x100, Non-metric)

385 0180

386 0181

387 0182

388 0183

389 0184

390 0185

391 0186

1)

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

Relative humidity 16-bit signed

integer

Temperature 16-bit signed

integer

Dew point temperature 16-bit signed

integer

Dew/frost point

temperature

16-bit signed

integer

Absolute humidity 16-bit signed

integer

Mixing ratio 16-bit signed

integer

Wet-bulb temperature 16-bit signed

integer

Enthalpy 16-bit signed

integer

1)

Relative humidity 16-bit signed

integer

Temperature 16-bit signed

integer

Dew point temperature 16-bit signed

integer

Dew/frost point

temperature

16-bit signed

integer

Absolute humidity 16-bit signed

integer

Mixing ratio 16-bit signed

integer

Wet-bulb temperature 16-bit signed

integer

%RH

°C

°C

°C

g/m

g/kg

°C

kJ/kg

%RH

°F

°F

°F

gr/ft

gr/lb

°F

3

3

50

Page 53

Appendix A – Modbus Registers

Integer Values (x100, Non-metric)

392 0187

hex

1)

Enthalpy 16-bit signed

integer

Btu/lb

1) NOTE: 16-bit integers have a maximum value of +32767. Certain measurement parameters

(for example, mixing ratio and enthalpy) can exceed this value in x100 scaling. In such cases,

the value of the parameter is cut o at +32767, and measurements above this value are not

reported. Verify that the measurement ranges in your application are suitable for the 16-bit

integer format with x100 scaling; whenever possible, it is recommended to use 32-bit float

values.

A.2 Status Registers

Table 13 Modbus Status Data Registers (Read-Only)

Register

Number

(Decima

l)

513 0200

514 0201

516 0203

Address

(Hexade

cimal)

hex

hex

0202

hex

hex

0204

hex

Register Description Data Format Bitmask

Device status 16-bit signed integer 0000

0001

maintenance needed.

0002

recover automatically

0004

0008

0010

active

Error code 32-bit signed

integer

0201

hex

Table 14 (page 52)

0202

Table 15 (page 52)

Security hash 32-bit signed

integer

Security hash changes on any

change to device settings/

adjustments.

:Status OK

hex

: Critical error,

hex

: Error, device may

hex

: Warning

hex

: Notification

hex

: Calibration mode

hex

(status code low): see

(status code high): see

hex

51

Page 54

HMD65 User Guide M212243EN-A

Register

Number

(Decima

Address

(Hexade

cimal)

Register Description Data Format Bitmask

l)

518 0205

519 0206

RH measurement

hex

status

T measurement

hex

status

16-bit signed integer 0000

0002

16-bit signed integer

0004

0008

0020

0040

0080

0100

: Status OK

hex

: Reading is not reliable

hex

: Under range

hex

: Over range

hex

: Value locked

hex

: Calibration expired

hex

: Sensor failure

hex

: Measurement not

hex

ready

Table 14 Error Codes in Register 0201

(Status Code Low)

hex

Bitmask Error Message Severity

0000

0001

0004

0008

0010

0040

0400

8000

hex

hex

hex

hex

hex

hex

hex

hex

Status OK

T sensor measurement failure Error

RH sensor measurement failure Error

Reference capacitance failure Error

Ambient temperature too high Error

Device settings corrupted Critical

Factory settings corrupted Critical

Calibration has expired Warning

Table 15 Error Codes in Register 0202

(Status Code High)

hex

Bitmask Error Message Severity

0000

0001

hex

hex

Status OK

Calibration is about to expire Info

52

Page 55

A.3 Configuration Registers

Table 16 Modbus Configuration Data Registers (Writable)

Appendix A – Modbus Registers

Register

Number

(Decimal)

769 0300

Address

(Hexadecimal)

hex

0301

hex

Register Description Data Format Unit

Pressure compensation

32-bit float Unit: hPA

setpoint

A.4 Communication Test Registers

Table 17 Modbus Communication Test Registers (Read-only)

Register

Number

(Decimal)

7937 1F00

7938 1F01

7940 1F03

Address