Page 1

®

USER'S GUIDE

Vaisala HUMICAP

Temperature Transmitters

Humidity and

HMD60U/Y

U301EN11

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2006

No part of this manual may be reproduced in any form or by any means, electronic or

mechanical (including photocopying), nor may its contents be communicated to a third

party without prior written permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or Conditions of

Sale.

Page 3

HMD60U/Y Transmitters

U301en-1.1 Operating Manual

Contents

1. PRODUCT DESCRIPTION ...................................................................................................1

2. TO BE NOTED WHEN M EASURING HUMIDITY ..................................................................2

3. INSTALLATION....................................................................................................................3

3.1 Selecting the place of installation ..........................................................................3

3.2 Mounting..................................................................................................................3

3.3 Grounding................................................................................................................4

3.4 Electrical connections.............................................................................................5

3.5 Electronics ...............................................................................................................6

4. CALIBRATION .....................................................................................................................7

4.1 One-point humidity calibration...............................................................................7

4.2 Two-point humidity calibration...............................................................................7

4.2.1 Two-point humidity calibration procedure ...................................................7

4.3 Calibration table......................................................................................................8

5. MAINTENANCE....................................................................................................................8

5.1 Replacing the HUMICAP

6. TECHNICAL DATA...............................................................................................................9

6.1 Relative humidity.....................................................................................................9

6.2 Temperature (Y model only) ...................................................................................9

6.3 General...................................................................................................................10

6.4 Electromagnetic compatibility..............................................................................11

6.4.1 Emissions................................................................................................11

6.4.2 Immunity .................................................................................................11

GUARANTEE .....................................................................................................................1 1

180 sensor and the filter ..............................................8

1997-07-31 i

Page 4

HMD60U/Y Transmitters

Operating Manual U301en-1.1

This page intentionally left blank.

ii 1997-07-31

Page 5

HMD60U/Y Transmitters

U301en-1.1 Operating Manual

1. PRODUCT DESCRIPTION

The HMD60 transmitters are duct mounted two-wire transmitters for the

measurement of humidity (HMD60U) and for the measurement of humidity

and temperature (HMD60Y).

The HMD60U/Y transmitters are easy to install and maintain: the electronics

can be disconnected without dismantling the installation. One point calibration

is easily performed with the HMI41 indicator and the calibration cable

19116ZZ.

Both transmitter types incorporate the HUMICAP®180 humidity sensor which

uses an operating principle based on changes in the capacitance of a thin

polymer film as it absorbs water molecules. The HMD60Y transmitters

measure temperature with the reliable Pt 1000 sensor.

1997-07-31 1

Page 6

HMD60U/Y Transmitters

Operating Manual U301en-1.1

2. TO BE NOTED WHEN MEASURING HUMIDITY

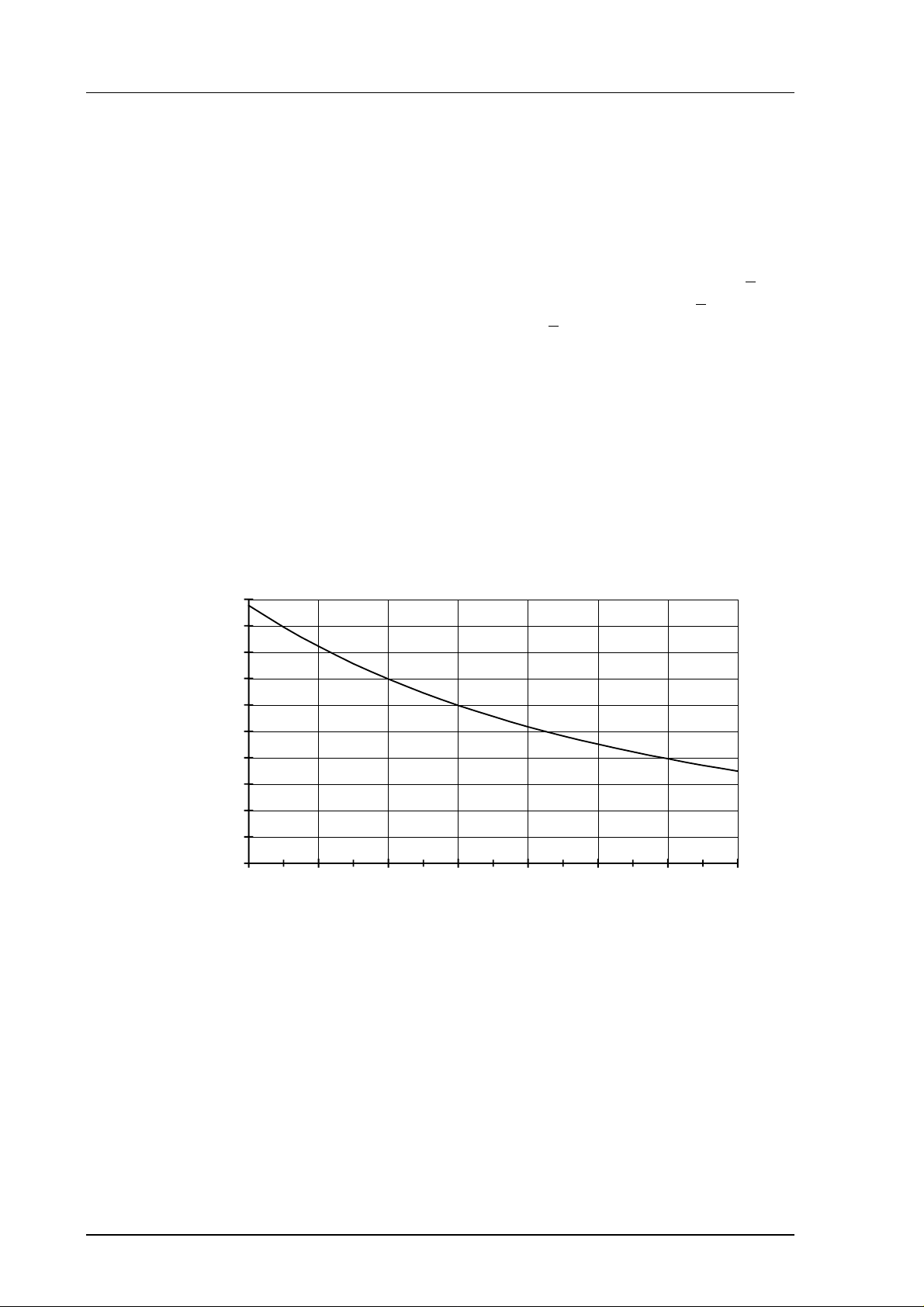

In the measurement of humidity and especially in calibration, it is essential

that the temperature equilibrium is reached. Even a slight difference in the

temperature between the measured object and the sensor causes an error. For

example, at +20 °C (+ 68 °F) and 50 %RH, a temperature difference of +1 °C

between the measured object and the sensor causes an error of +3 %RH. If

relative humidity is 90 %RH, the error is about +5.4 %RH.

The error is at its greatest when the temperature of the sensor differs from that

of the surroundings and the humidity is high. A few degrees’ difference in

temperature may cause water to condense on sensor surface. Efficient

ventilation accelerates evaporation whereas in an unventilated space, it may

take hours. The HUMICAP180 sensor returns to its normal functioning as

soon as water has evaporated. Any contaminated water condensing on the

sensor may shorten its life span and change the calibration.

10

9

8

7

6

5

4

dRH (%RH)

3

2

1

0

-40-200 20406080100

Temperature (°C)

Figure 2.1 Measurement error at 100 %RH when the temperature

difference between th e ambient and the sensor i s 1 °C

2 1997-07-31

Page 7

HMD60U/Y Transmitters

U301en-1.1 Operating Manual

3. INSTALLATION

3.1 Selecting the place of installation

Select a place that gives a true picture of the environment or process and is as

clean as possible. Air should circulate freely around the sensor. A rapid air

flow is recommended as it ensures the same temperature for the ambient air

and the sensor head.

Install the transmitter in a place where no cold or hot spot can develop. If the

sensor head is installed in a duct or channel where the temperature is different

from the ambient temperature, insulate the point of entry. An uninsulated

installation might lead to condensation on the sensor head and even if no

condensation occurs, the resultant air flow may change the temperature near

the sensor head and distort the readings.

3.2 Mounting

Mount the transmitter with two screws. Place the drilling template on the duct

surface and drill the holes as indicated. Remember to drill an additional hole

for calibration purposes.

250 (9.84)62 (2.44)

Ø 12

(0.47)

100 (3.94)

100 (3.94)

Mounting hole 82 (3.23)>>>

Mounting hole 82 (3.23)>>>

Figure 3 Dimensions of the HMD60U/Y (in mm)

1997-07-31 3

Page 8

HMD60U/Y Transmitters

Operating Manual U301en-1.1

3.3 Grounding

Open the lid and mount the cable bushing set 18941HM. Do the grounding

according to Figure 3.3. When connecting the signal cable to the transmitter

housing, fold the cable braid between the brass disk in order to achieve the

best possible EMC performance. Do not leave the bare shield of the

connected wires so that it can shortci rcuit the el ectronics!

flexible wires 0.5 mm²

(AWG 20), stranded wires

recommended

3

140

165

braid

brass

disks

rubber

ring

nut

cable

25

D = Ø 7...10mm

(If the cable diameter is less

than 7mm, use a shrinking

tube or an adhesive tape)

shielding tube

braid

brass disks

Figure 3.3 Signal cable grounding with bushing 18941HM

4 1997-07-31

Page 9

HMD60U/Y Transmitters

U301en-1.1 Operating Manual

3.4 Electrical connections

Connect the signal cables to a removeable 5-pole screw connector. Make

connections according to Figure 3.4. RH test and T test connectors are used

with the HMI41 indicator and calibration cable 19116ZZ.

RH

TEST

RH GAIN

12345

-RH +T+RH -T

+

or

mA

mA

T GAIN

RH OFFSET

T OFFSET

Figure 3.4 Electrical connections

T

TEST

-

+

-

or

mA mA

1997-07-31 5

Page 10

HMD60U/Y Transmitters

Operating Manual U301en-1.1

3.5 Electronics

SCREWS

LID

SCREW TERMINAL

10528HM

TO REMOVE THE SENSOR HEAD:

1. Open the lid

2. Disconnect the screw terminal

3. Open the screws (2 pcs)

4. Pull out carefully

TO REINSTALL THE SENSOR HEAD:

1. Push in the sensor head

2. Fasten the screws

3. Connect the screw terminal

4. Close the lid

18941HM

GLANDS

SPARE PART SENSOR

HUMICAP180

MEMBRANE FILTER

part no. 17039HM

STAINLESS STEEL SINTERED FILTER

part no. HM46670

Figure 3.5 Electronics (can be disconnected ), accessories, spare parts

6 1997-07-31

Page 11

HMD60U/Y Transmitters

U301en-1.1 Operating Manual

4. CALIBRATION

4.1 One-point humidity calibration

The accuracy is recommended to be checked at least once a year; the interval

depends on the operating conditions and the required accuracy of the

measurement. The transmitter calibration can be conveniently checked with

the HMI41 indicator equipped with an appropriate probe and optional

calibration cable. If adjustment is needed, use the one-point calibration

potentiometer. If you prefer to calibrate the HMD60U/Y transmitters against

saturated salt solutions, use LiCl (11 %RH) and NaCl (75 %RH) solutions.

4.2 Two-point humidity calibration

The calibration can also be done with salt calibrators, or the instrument can be

sent to Vaisala or a Vaisala representativ e.

4.2.1 Two-point humidity calibration procedure

• Leave the calibrator and the transmitter for at least 30 minutes in the

same space so that their temperatures have time to equalize.

• Place the probe into the calibration hole of the LiCl bottle in the

humidity calibrator.

• Wait for 10 minutes.

• Use the RH offset potentiometer (see Figure 3.4) to adjust the output

signal to the value given in the calibration table (Chapter 4.3).

• Place the probe into the calibration hole of the NaCl bottle in the

calibrator.

• Wait for 10 minutes.

• Check that the reading corresponds within the desired accuracy to the

reading given in the calibration table. If not, adjust the reading with

the RH gain potentiometer (see Figure 3.4).

• Check again the reading at the first point and adjust if necessary.

1997-07-31 7

Page 12

HMD60U/Y Transmitters

Operating Manual U301en-1.1

4.3 Calibration table

Temperature °C 15 20 25 30 35

°F 59 68 77 86 95

LiCl %RH *) 11.3 11.3 11.3 11.3

4...20 mA mA 5.81 5.81 5.81 5.81

0...20 mA mA 2.26 2.26 2.26 2.26

0...1 V V 0.113 0.113 0.113 0.113

0...5 V V 0.565 0.565 0.565 0.565

0...10 V V 1.13 1.13 1.13 1.13

NaCl %RH 75.6 75.5 75.3 75.1 74.9

4...20 mA mA 16.10 16.08 16.05 16.02 15.98

0...20 mA mA 15.12 15.10 15.06 15.02 14.98

0...1 V V 0.756 0.755 0.753 0.751 0.749

0...5 V V 3.780 3.775 3.765 3.755 3.745

0...10 V V 7.56 7.55 7.53 7.51 7.49

*) LiCl solution must not be used or stored in temperatures below +18 °C (+64 °F) ;

otherwise the equilibrium humidity of the salt solution changes permanently

Table 1 Greenspan’s calibration table with output values accordin g to

the chosen scale

5. MAINTENANCE

5.1 Replacing the HUMICAP180 sensor and the filter

Remove the damaged sensor and insert a new one. Handle the sensor by the

plastic socket. DO NOT TOUCH THE SENSOR PLATE. Recalibrate the

transmitter.

Replace a dirty filter (membrane or sintered) to ensure a maximum lifetime

and a fast response for the sensor. Do not try to clean the filter.

8 1997-07-31

Page 13

HMD60U/Y Transmitters

U301en-1.1 Operating Manual

6. TECHNICAL DATA

6.1 Relative humidity

Measurement range 0...100 %RH

Accuracy at +20 °C:

%RH

3

2

1

0

10 4020 605030 8070

0 90 100

-1

-2

-3

Temperature dependence:

%RH

2.0

1.5

1.0

0.5

0

-20 200

-0.5

-1.0

-1.5

-2.0

%RH

8040 60 °C10-10 30 50 70

Humidity sensor HUMICAP180

Response time (90%) at 20 °C in still air 15 s with membrane filter

6.2 Temperature (Y model only)

Measurement range -20...+80 °C

Accuracy:

°C

0.8

0.6

0.4

0.2

0

-10

-0.2

-0.4

-0.6

-0.8

0-20 10 20 30 40 50 60 70 80 °C

Linearity better than 0.1 °C

Temperature sensor Pt 1000 IEC 751 class B

1997-07-31 9

Page 14

HMD60U/Y Transmitters

Operating Manual U301en-1.1

6.3 General

Supply voltage 10...35 VDC (RL= 0Ω)

20...35 VDC (RL=500Ω)

Output signal 4...20 mA

Operating temperature range:

electronics -5...+55 °C

sensor head -40...+80 °C

Storage temperature range -40...+80 °C

Housing:

sensor head stainless steel

electronics housing cast aluminium

Cable lead-through:

bushing for 7...10 mm (PG9) cable

(housing IP65 / NEMA 4),

part no. 18941HM

or armoured cable glands part no. 10528HM

Sensor protection:

standard membrane filter

(part no. 17039HM)

option stainless steel sintered filter

(part no. HM46670)

Connections screw terminals 0.5...1.5 mm

2

10 1997-07-31

Page 15

HMD60U/Y Transmitters

U301en-1.1 Operating Manual

6.4 Electromagnetic compatibility

The emission and immunity tests have been performed according to standards

EN50081-1 and EN50082-1.

6.4.1 Emissions

Test Setup according to Performance

Radiated interference EN55022 class B

6.4.2 Immunity

Test Setup according to Performance

Electrostatic discharge IEC 801-2:1991 criteria B

Electrical fast transients IEC 801-4:1988 criteria B

RF-radiated fields IEC 801-3:1984 criteria A

*GSM-field immunity ENV50204:1995 criteria A

(*additional test)

GUARANTEE

Vaisala issues a guarantee for the material and

workmanship of this product under normal operating

conditions for one year from the date of delivery.

Exceptional operating conditions, damage due to

careless handling or misapplication will void the

guarantee.

1997-07-31 11

Page 16

Page 17

Page 18

www.vaisala.com

Loading...

Loading...