Page 1

HMD60U/Y

HMD60U/Y-M210276en-A Operating Manual

HUMIDITY TRANSMITTER HMD60U

HUMIDITY AND TEMPERATURE TRANSMITTER HMD60Y

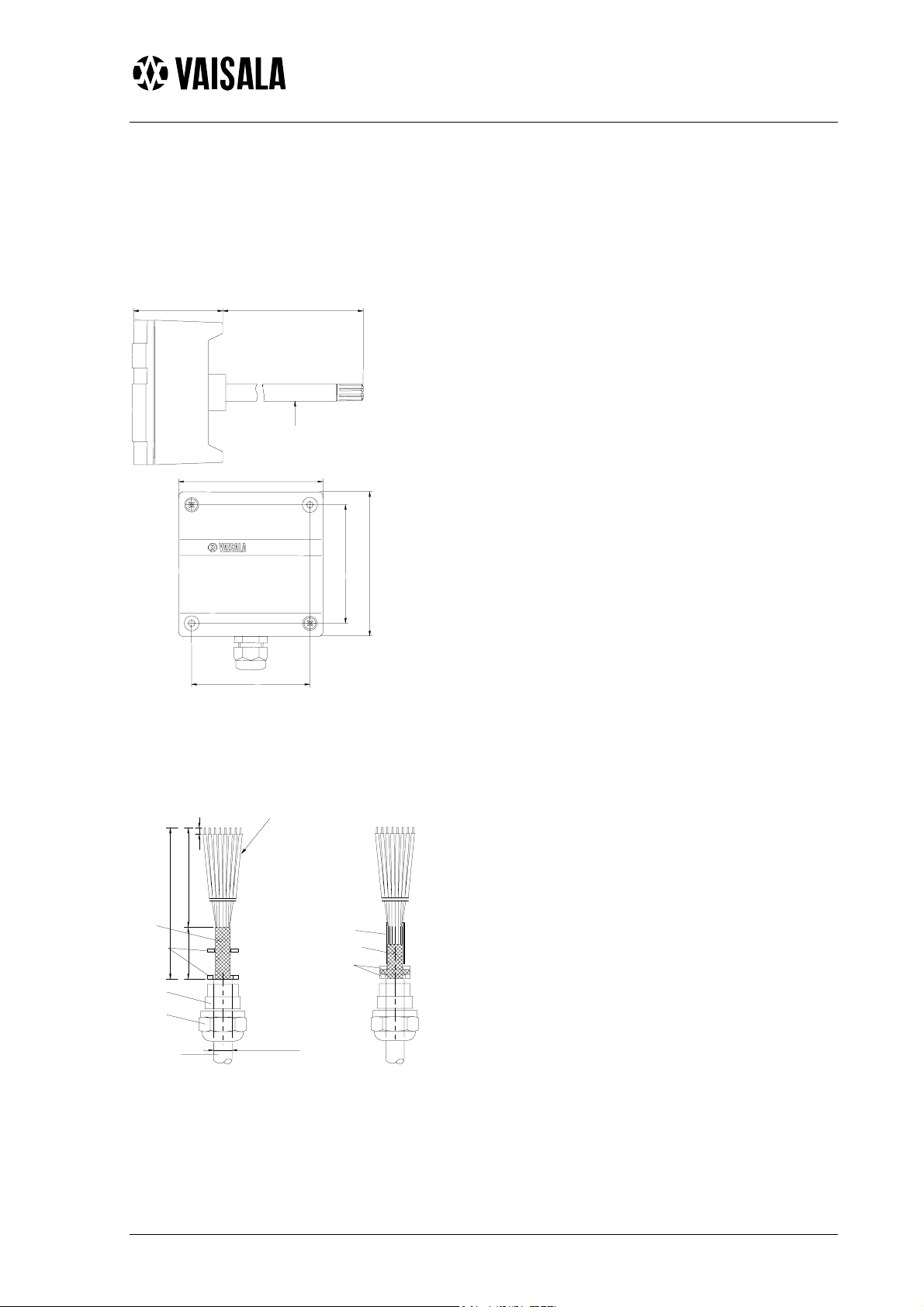

MOUNTING

250 (9.84)62 (2.44)

Ø 12

(0.47)

100 (3.94)

100 (3.94)

Mounting hole 82 (3.23)>>>

Mounting hole 82 (3.23)>>>

Figure 1 Dimensions of the HMD60U/Y

The HMD60U/Y humidity and

temperature transmitters are two-wire

transmitters. They are duct mounted, and

the electronics can be disconnected

without dismantling the installation.

Mount the transmitter with two screws.

Place the drilling template on the duct

surface and drill the holes as indicated.

Remember to drill an additional hole for

calibration purposes. The calibration can

be conveniently performed on site with

the HMI41 or HM70 portable indicator

equipped with an appropriate probe and

optional calibration cable.

GROUNDING

flexible wires 0.5 mm²

(AWG 20), stranded wires

recommended

3

140

165

braid

rubber

ring

brass

disks

nut

cable

25

(If the cable diameter is less

than 7mm, use a shrinking

tube or an adhesive tape)

shielding tube

braid

brass disks

D = Ø 7...10mm

Figure 2 Signal cable grounding with

bushing 18941HM

Open the lid and mount the cable

bushing set 18941HM. Do the grounding

according to Figure 2. When connecting

the signal cable to the transmitter housing,

fold the cable braid between the brass disk

in order to achieve the best EMC performance. Do not leave the bare shield of

the connected wires so that it can

shortcircuit the electronics!

2003-01-22 1

Page 2

HMD60U/Y

Operating Manual HMD60U/Y-M210276en-A

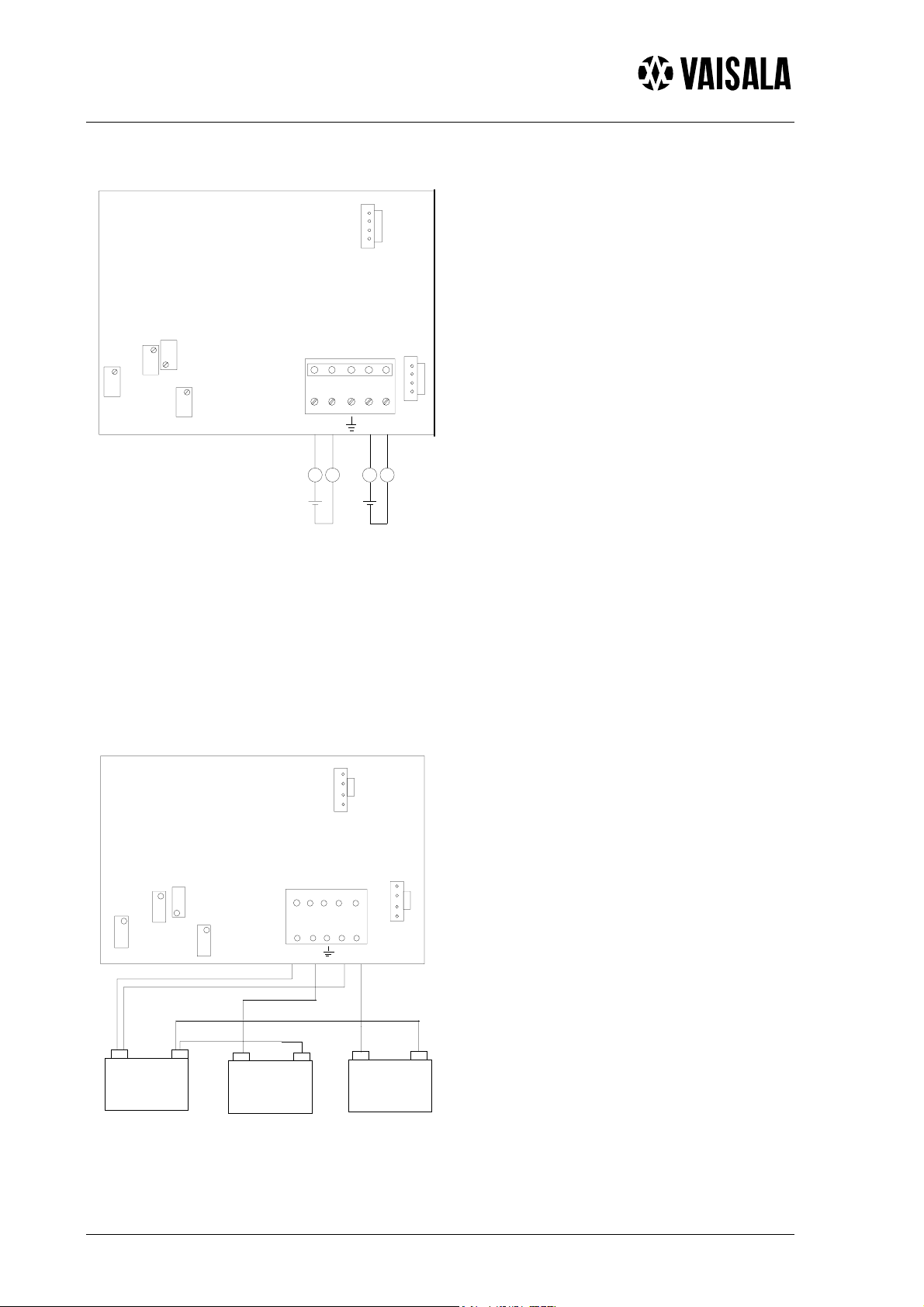

ELECTRICAL CONNECTIONS

RH

TEST

Figure 3a. Electrical

connections.

RH GAIN

RH OFFSET

12 345

T

TEST

T GAIN

T OFFSET

-RH +T+RH -T

+

or

mA

mA

-

+

-

or

mA mA

Signal cables are connected to a removeable 5-pole screw connector. Make the

connections according to Figure 3a above. RH test and T test connectors are used with the

HMI41 or HM70 indicator equipped with an appropriate probe and optional calibration

cable.

Figure 3b shows the same connections in alternative way.

RH TEST

Figure 3b. Electrical

connections.

RH GAIN

RH OFFSET

1 2 3 4 5

T TEST

T OFFSET

+

RH

-

T GAIN

+

POWER SUPPLY

10...35 VDC

------------

+

RH

CHART RECORDER

AMMETER

OR CONTROLL ER

RH+T-T

------------

+

TEMPERATURE

CHART RECORDER

AMMETER

OR CONTROLLER

------------

2 2003-01-22

Page 3

HMD60U/Y

HMD60U/Y-M210276en-A Operating Manual

ELECTRONICS

SCREWS

SPARE PART SENSOR

HUMICAP180

MEMBRANE FILTER

part no. 17039HM

LID

SCREW TERMINAL

10528HM

TO REMOVE THE SENSOR HEAD:

1. Open the lid

2. Disconnect the screw terminal

3. Open the screws (2 pcs)

4. Pull out carefully

TO REINSTALL THE SENSOR HEAD:

1. Push in the sensor head

2. Fasten the screws

3. Connect the screw terminal

4. Close the lid

18941HM

GLANDS

STAINLESS STEEL SINTERED FILTER

part no. HM46670

Electronics (can be disconnected), accessories, spare parts

ONE-POINT RH-CALIBRATION

REPLACEMENT OF THE HUMICAP SENSOR AND THE FILTER

The accuracy is recommended to be

checked at least once a year; the interval

depends on the operating conditions and

the required accuracy of the

measurement. The transmitter calibration

can be conveniently checked with the

HMI41 or HM70 indicator equipped with

Remove the damaged sensor and insert a

new one. Recalibrate the transmitter.

Replace a dirty filter (membrane or

sintered) to ensure a maximum lifetime

and a fast response for the sensor. Do not

attempt to clean the filter.

an appropriate probe and optional

calibration cable. If adjustment is

needed, use the one-point calibration

potentiometer. If you prefer to calibrate

the HMD60U/Y transmitters against

saturated salt solutions, use LiCl (11

%RH) and NaCl (75 %RH) solutions.

2003-01-22 3

Page 4

HMD60U/Y

Operating Manual HMD60U/Y-M210276en-A

TECHNICAL DATA

Relative humidity

Measurement range 0...100 %RH

Output signal

Accuracy at +20 °C

%RH

3

2

1

0

10 4020 605030 8070

0 90 100

-1

-2

-3

Temperature dependence

%RH

2.0

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

-2.0

-20 200

8040 60 ° C10-10 30 50 70

Humidity sensor HUMICAP180

Response time (90%)

at 20 °C in still air 15 s with membrane

filter

Temperature (Y model only)

Measurement range -20...+80 °C

Accuracy

°C

0.8

0.6

0.4

0.2

0

-10

-0.2

-0.4

-0.6

-0.8

0-20 10 20 30 40 50 60 70 80 °C

%RH

Sensor protection:

standard membrane filter

(part no. DRW010525)

option stainless steel sintered

filter

(part no. HM46670)

Connections screw terminals

0.5...1.5 mm

2

Electromagnetic compatibility

The emission and immunity tests have been performed

according to standard EN 61326-1:1997 + Am 1:1998,

Electrical equipment for measurement, control and

laboratory use- EMC requirements; Light

environment.

Emissions:

Test Setup according to Performance

Radiated

interference CISPR16 class B

Immunity:

Test Setup according to

Electrostatic

discharge EN/IEC 61000-4-2

Electrical fast

transients EN/IEC 61000-4-4

RF-radiated

fields EN/IEC 61000-4-3

*GSM-field

immunity ENV50204:1995 criteria A

Linearity better than 0.1 °C

(*additional test)

Temperature sensor Pt 1000 IEC 751 class B

General

Supply voltage 10...35 VDC (RL= 0Ω)

20...35 VDC (RL=500Ω)

Output signal 4...20 mA

Operating temperature range:

electronics -5...+55 °C

sensor head -40...+80 °C

Storage temperature range -40...+80 °C

Housing:

sensor head stainless steel

electronics housing cast aluminium

Cable lead-through:

bushing for 7...10 mm (PG9)

cable (housing IP65 /

NEMA 4),

part no. 18941HM

or armoured cable glands part no. 10528HM

4 2003-01-22

GUARANTEE

Vaisala issues a guarantee for the material and

workmanship of this product under normal operating

conditions for one year from the date of delivery.

Exceptional operating conditions, damage due to

careless handling or misapplication will void the

guarantee.

Loading...

Loading...