Page 1

USER'S GUIDE

Vaisala CARBOCAP® Carbon Dioxide,

Temperature, and Humidity Transmitters

GMW90 Series

M211659EN-B

Page 2

PUBLISHED BY

Street address: Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

Mailing address: P.O. Box 26, FI-00421 Helsinki, Finland

Phone: +358 9 8949 1

Fax: +358 9 8949 2227

Visit our Internet pages at www.vaisala.com.

© Vaisala 2014

No part of this manual may be reproduced, published or publicly displayed in any form

or by any means, electronic or mechanical (including photocopying), nor may its

contents be modified, translated, adapted, sold or disclosed to a third party without prior

written permission of the copyright holder. Translated manuals and translated portions

of multilingual documents are based on the original English versions. In ambiguous

cases, the English versions are applicable, not the translations.

The contents of this manual are subject to change without prior notice.

This manual does not create any legally binding obligations for Vaisala towards

customers or end users. All legally binding obligations and agreements are included

exclusively in the applicable supply contract or the General Conditions of Sale and

General Conditions of Service of Vaisala.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ............................................................................ 7

About This Manual ................................................................... 7

Contents of This Manual ....................................................... 7

Version Information ............................................................... 8

Related Manuals ................................................................... 8

Documentation Conventions ................................................. 8

Safety ......................................................................................... 9

ESD Protection ...................................................................... 9

Recycling ................................................................................ 10

Regulatory Compliances ....................................................... 10

Patent Notice .......................................................................... 10

Trademarks ............................................................................. 11

Software License .................................................................... 11

Warranty .................................................................................. 11

CHAPTER 2

PRODUCT OVERVIEW ................................................................................ 12

Introduction to GMW90 Series .............................................. 12

GMW90 Series Transmitters ................................................. 13

Output Parameters Explained ............................................... 14

Transmitter parts .................................................................... 15

Decorative Cover Option ....................................................... 18

CHAPTER 3

INSTALLATION ............................................................................................ 19

Configuration Before Installation ......................................... 19

Configuration of Analog Output Models .............................. 19

DIP Switches of Analog Output Models ......................... 20

Changing Between DIP and Custom Configuration ....... 21

Configuration of Digital Output Models ............................... 21

DIP Switches of Digital Output Models .......................... 22

Addressing with BACnet Protocol .................................. 23

Addressing with Modbus Protocol .................................. 23

Selecting Location ................................................................. 24

Installing the Mounting Base ................................................ 25

Wiring ...................................................................................... 25

Wiring GMW93R/RA ........................................................... 27

Wiring GMW93 .................................................................... 27

Wiring GMW94R ................................................................. 28

Wiring GMW94 .................................................................... 28

Wiring GMW95 .................................................................... 29

Connecting Several Transmitters on Same

RS-485 Line ................................................................... 29

VAISALA _________________________________________________________________________ 1

Page 4

User's Guide _______________________________________________________________________

Connecting a Common AC Power Supply to Several

Transmitters ......................................................................... 30

CHAPTER 4

OPERATION ................................................................................................. 31

Display ..................................................................................... 31

Startup Screens ................................................................... 31

Measurement Screen .......................................................... 32

Indicators on the Display ..................................................... 33

Service Port ............................................................................. 33

Connecting With an MI70 Indicator ..................................... 33

Connecting With a Computer .............................................. 34

Installing the Driver for the USB Service Cable ............. 34

Terminal Application Settings ......................................... 35

List of Serial Commands ....................................................... 37

Transmitter Information ......................................................... 38

Show Transmitter Information ............................................. 38

Show Transmitter Firmware Version ................................... 38

Show Transmitter Serial Number ........................................ 38

Show Transmitter Status ..................................................... 39

Show Measured Parameters ............................................... 41

Show Command Help.......................................................... 41

Show Command List ........................................................... 42

Measurement Settings ........................................................... 42

Set Environmental Parameters ........................................... 42

Select Units ......................................................................... 43

Analog Output Settings ......................................................... 43

Set Analog Output Mode ..................................................... 43

Set Analog Output Scaling .................................................. 44

Set Output Clipping and Error Limit ..................................... 45

Display Settings ...................................................................... 47

Select Parameters to Display .............................................. 47

Serial Line Output Commands .............................................. 48

Start Measurement Output .................................................. 48

Stop Measurement Output .................................................. 48

Output a Reading Once ....................................................... 48

Set Output Interval ............................................................... 49

Set Output Format ............................................................... 50

Serial Line Settings ................................................................ 52

Set Remote Echo ................................................................ 52

Set Serial Line Turnaround Delay ....................................... 52

Calibration and Adjustment Commands .............................. 53

Adjust CO2 Measurement .................................................... 53

Show Current CO2 Adjustment ....................................... 53

1-point Adjustment of CO2 Measurement ...................... 54

2-point Adjustment of CO2 Measurement ...................... 54

Clear User Adjustment of CO2 Measurement ................ 55

Adjust Humidity Measurement ............................................ 55

Show Current RH Adjustment ........................................ 55

1-point Adjustment of RH Measurement ........................ 56

2-point Adjustment of RH Measurement ........................ 56

Clear User Adjustment of RH Measurement .................. 57

Adjust Temperature Measurement ...................................... 57

Show Current T Adjustment ........................................... 57

1-point Adjustment of T Measurement ........................... 57

2 ____________________________________________________________________ M211659EN-B

Page 5

_________________________________________________________________________________

Clear User Adjustment of T Measurement .................... 58

Enter Calibration and Adjustment Information .................... 58

Testing Commands ................................................................ 59

Test Analog Outputs ........................................................... 59

Other Commands ................................................................... 60

Enable Advanced Serial Commands .................................. 60

Reset Transmitter ................................................................ 60

Set BACnet Parameters ...................................................... 61

Set CO2 Indicator LED Parameters ..................................... 62

CHAPTER 5

MAINTENANCE ........................................................................................... 63

Cleaning .................................................................................. 63

Calibration and Adjustment .................................................. 63

Adjustment Methods ........................................................... 63

Notes for CO2 Adjustment ................................................... 64

Using Calibration Gas vs. Ambient Gas......................... 64

Effect of Temperature on CO2 Measurement ................ 64

Effect of Pressure on CO2 Measurement ....................... 65

Notes for T Adjustment ....................................................... 65

Notes for RH Adjustment .................................................... 65

Adjustment Using Display and Trimmers ............................ 66

Adjustment Using a Hand-Held Meter ................................ 67

Adjustment Using a Computer ............................................ 68

Repair Maintenance ............................................................... 69

Replacing the GM10 Module ............................................... 70

Replacing the HTM10 Module ............................................. 71

CHAPTER 6

TROUBLESHOOTING ................................................................................. 72

Problem Situations ................................................................. 72

Error Messages ...................................................................... 73

Viewing Error Messages on Serial Line .............................. 74

View Currently Active Errors .......................................... 74

View Error Table ............................................................ 74

Error State ............................................................................... 75

Reverting to Factory Settings ............................................... 76

Reverting to Factory Settings Using DIP Switches ............. 76

Reverting to Factory Settings Using Service Port ............... 77

Technical Support .................................................................. 78

Product Returns ..................................................................... 78

CHAPTER 7

TECHNICAL DATA ...................................................................................... 79

Specifications ......................................................................... 79

Spare Parts and Accessories ................................................ 81

Dimensions in mm ................................................................. 82

APPENDIX A

BACNET REFERENCE ................................................................................ 83

VAISALA _________________________________________________________________________ 3

Page 6

User's Guide _______________________________________________________________________

BACnet Protocol Implementation Conformance

Statement ................................................................................ 83

Transmitter Models and Objects ........................................... 85

Device Object .......................................................................... 86

Carbon Dioxide Object ........................................................... 88

Temperature Object ................................................................ 89

Relative Humidity Object ....................................................... 90

Calculated Humidity Objects ................................................. 91

Operation Pressure Object .................................................... 92

Operation Altitude Object ...................................................... 93

BIBBs Supported .................................................................... 94

Application Services Supported ........................................... 95

APPENDIX B

MODBUS REFERENCE ............................................................................... 96

4 ____________________________________________________________________ M211659EN-B

Page 7

_________________________________________________________________________________

List of Figures

Figure 1 GMW90 with Visible Display and Indicator LEDs .................... 12

Figure 2 Transmitter Parts - Outside ...................................................... 15

Figure 3 Opening the Transmitter........................................................... 16

Figure 4 Transmitter Parts – Inside ........................................................ 17

Figure 5 Decorative Cover ...................................................................... 18

Figure 6 DIP Switch Settings of Analog Output Models ......................... 20

Figure 7 DIP Switch Settings of Digital Output Models .......................... 22

Figure 8 Example of Transmitter Addressing ......................................... 23

Figure 9 Selecting Transmitter Location ................................................. 24

Figure 10 Installing the Mounting Base .................................................... 25

Figure 11 Wiring from Behind (Recommended) ....................................... 26

Figure 12 Wiring from Above .................................................................... 26

Figure 13 Wiring GMW93R/RA ................................................................ 27

Figure 14 Alternate Wiring for GMW93R/RA ............................................ 27

Figure 15 Wiring GMW93 ......................................................................... 27

Figure 16 Wiring GMW94R ...................................................................... 28

Figure 17 Wiring GMW94 ......................................................................... 28

Figure 18 Wiring GMW95 ......................................................................... 29

Figure 19 Several Transmitters on Same RS-485 Line............................ 29

Figure 20 Connecting a Common AC Power Supply ............................... 30

Figure 21 GMW95R Startup Screens ....................................................... 31

Figure 22 Measurement Screen – Normal Operation .............................. 32

Figure 23 Measurement Screen – Problem With Humidity Measurement32

Figure 24 PuTTY Terminal Application..................................................... 36

Figure 25 Effect of Pressure on CO2 Reading ......................................... 65

Figure 26 Trimmer Centering Screen ....................................................... 66

Figure 27 Adjustment Screen ................................................................... 66

Figure 28 Disconnecting the GM10 Module ............................................. 70

Figure 29 Replacing the HTM10 Module .................................................. 71

Figure 30 DIP Switch Factory Reset (GMW93/94) ................................... 76

Figure 31 DIP Switch Factory Reset (GMW95) ........................................ 76

Figure 32 GMW90 Series Dimensions ..................................................... 82

Figure 33 Dimensions of the Mounting Base ........................................... 82

VAISALA _________________________________________________________________________ 5

Page 8

User's Guide _______________________________________________________________________

List of Tables

Table 1 Manual Revisions ....................................................................... 8

Table 2 Related Manuals ......................................................................... 8

Table 3 Applicable Patents .................................................................... 10

Table 4 GMW90 Series Transmitters .................................................... 13

Table 5 Parameters Supported by GMW90 Series ............................... 14

Table 6 Serial Interface Settings ........................................................... 35

Table 7 Basic Serial Commands ........................................................... 37

Table 8 Advanced Serial Commands .................................................... 37

Table 9 FORM Command Parameters .................................................. 51

Table 10 FORM Command Modifiers ...................................................... 51

Table 11 Troubleshooting Table .............................................................. 72

Table 12 Error Messages ........................................................................ 73

Table 13 Performance ............................................................................. 79

Table 14 Operating Environment ............................................................. 80

Table 15 Inputs and Outputs ................................................................... 80

Table 16 Mechanics ................................................................................. 80

Table 17 GMW90 Series Spare Parts and Accessories .......................... 81

Table 18 Device Object Properties .......................................................... 86

Table 19 Carbon Dioxide Object Properties ............................................ 88

Table 20 Status Flags .............................................................................. 88

Table 21 Reliability .................................................................................. 88

Table 22 Event State ............................................................................... 88

Table 23 Temperature Object Properties ................................................ 89

Table 24 Status Flags .............................................................................. 89

Table 25 Reliability .................................................................................. 89

Table 26 Event State ............................................................................... 89

Table 27 Relative Humidity Object Properties ......................................... 90

Table 28 Status Flags .............................................................................. 90

Table 29 Reliability .................................................................................. 90

Table 30 Event State ............................................................................... 90

Table 31 Calculated Humidity Objects .................................................... 91

Table 32 Calculated Humidity Object Properties ..................................... 91

Table 33 Status Flags .............................................................................. 91

Table 34 Reliability .................................................................................. 92

Table 35 Event State ............................................................................... 92

Table 36 Operation Pressure Object Properties ..................................... 92

Table 37 Status Flags .............................................................................. 92

Table 38 Operation Altitude Object Parameters ...................................... 93

Table 39 Status Flags .............................................................................. 93

Table 40 BACnet Smart Sensor BIBBs Support...................................... 94

Table 41 BACnet Standard Application Services Support ...................... 95

Table 42 Modbus Functions Supported by GMW90 ............................... 96

Table 43 GMW90 Modbus Measurement Data Registers ....................... 96

Table 44 GMW90 Modbus Status Registers (Read-only) ....................... 97

Table 45 GMW90 Modbus Error Code Bits ............................................. 97

Table 46 GMW90 Modbus Configuration Parameter Registers .............. 97

Table 47 GMW90 Modbus Device Identification ..................................... 98

Table 48 GMW90 Modbus Exception Responses ................................... 98

6 ____________________________________________________________________ M211659EN-B

Page 9

Chapter 1 _________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the manual and the products that

are covered.

About This Manual

This manual provides information for installing, operating, and

maintaining GMW90 series transmitters. All transmitter models in the

series are covered, which means that some information in the manual is

model-specific.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides general notes for the manual

and the products that are covered.

- Chapter 2, Product Overview, introduces the GMW90 series

transmitters.

- Chapter 3, Installation, provides you with information that is intended

to help you install the GMW90 series transmitters.

- Chapter 4, Operation, contains information that is needed to operate

the GMW90 series transmitters.

- Chapter 5, Maintenance, provides information that is needed in basic

maintenance of the GMW90 series.

- Chapter 6, Troubleshooting, describes possible problems, their

probable causes and remedies, and provides contact information for

technical support.

- Chapter 7, Technical Data, provides the technical data of the GMW90

series transmitters.

- Appendix A, BACnet Reference,describes the BACnet protocol

implementation of the GMW90 series digital transmitters.

- Appendix B, Modbus Reference, describes the Modbus protocol

implementation of the GMW90 series digital transmitters.

VAISALA _________________________________________________________________________ 7

Page 10

User's Guide _______________________________________________________________________

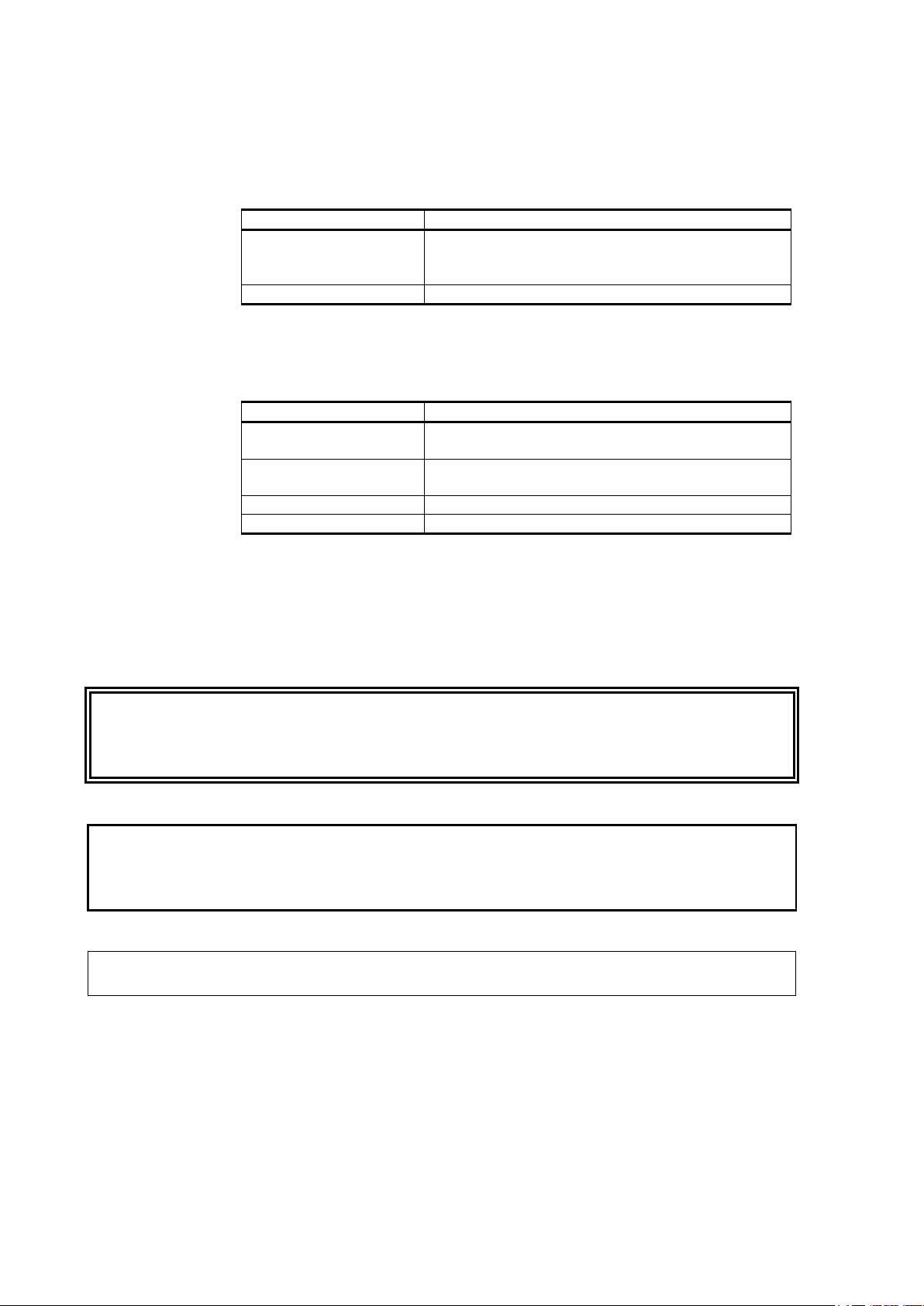

Manual Code

Description

M211659EN-B

April 2014. This manual. Added transmitter models

appendix.

M211659EN-A

November 2013. First version.

Manual Code

Manual Name

M211511EN

HMW90 and GMW90 Series Quick Guide for

Digital Output models

M211398EN

HMW90 and GMW90 Series Quick Guide for

Analog Output models

M211476EN

Decorative Cover Quick Guide

M211606EN

Decorative Cover Printable Insert

Version Information

Table 1 Manual Revisions

with analog outputs. Updated BACnet reference

Related Manuals

Table 2 Related Manuals

WARNING

CAUTION

NOTE

Documentation Conventions

Throughout the manual, important safety considerations are highlighted

as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

8 ____________________________________________________________________ M211659EN-B

Page 11

Chapter 1 _________________________________________________________ General Information

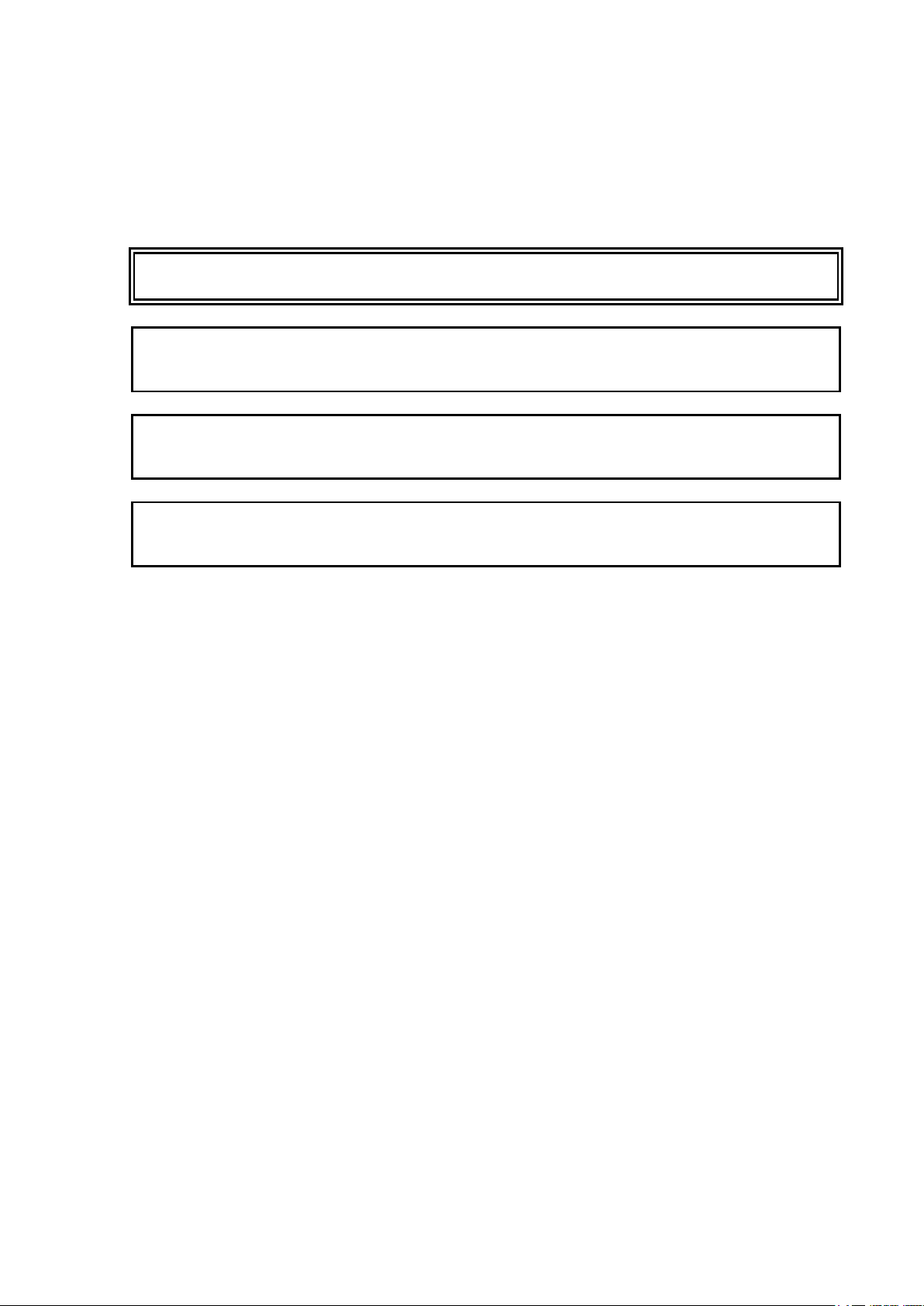

Connect only de

If you connect more than one transmitter to a single 24 VAC transformer,

always connect the phase (~) to the +Vs connector in each transmitter.

The trimmers only turn 135 degrees each way, less than half a rotation.

Do not force the trimmer past the stopping po

Do not modify the unit. Improper modification can damage the product

or lead to malfunction.

Safety

The transmitter delivered to you has been tested and approved as shipped

from the factory. Note the following precautions:

WARNING

CAUTION

CAUTION

CAUTION

-energized wires.

int.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. It is possible to damage the product,

however, by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- When installing the transmitter, do not touch exposed contacts on the

component board.

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench.

- Always hold component boards by the edges and avoid touching the

component contacts.

VAISALA _________________________________________________________________________ 9

Page 12

User's Guide _______________________________________________________________________

Patent Issued By

Patent Number

United States Patent and Trademark Office

US 5,827,438

US 6,177,673

European Patent Office

EP0776023

EP0922972

German Patent and Trade Mark Office

69615635

Japan Patent Office

4263285

Finnish Patent Office

112005

105598

Recycling

Recycle all applicable material.

Dispose of the unit according to statutory regulations.

Do not dispose of with regular household refuse.

Regulatory Compliances

GMW90 series transmitters comply with the following performance and

environmental test standards:

- EMC Directive

Conformity is shown by compliance with the following standards:

- EN 61326-1: Electrical equipment for measurement, control, and

laboratory use – EMC requirements – for use in industrial locations.

- EN 550022: Information technology equipment – Radio disturbance

characteristics – Limits and methods of measurement.

Patent Notice

GMW90 series are protected by the following patents and their

corresponding national rights:

Table 3 Applicable Patents

10 ___________________________________________________________________ M211659EN-B

Page 13

Chapter 1 _________________________________________________________ General Information

Trademarks

CARBOCAP® is a registered trademark of Vaisala Oyj.

All other trademarks are the property of their respective owners.

Software License

This product contains software developed by Vaisala. Use of the software

is governed by license terms and conditions included in the applicable

supply contract or, in the absence of separate license terms and

conditions, by the General License Conditions of Vaisala Group.

Warranty

Visit our Internet pages for standard warranty terms and conditions:

www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of

damage due to normal wear and tear, exceptional operating conditions,

negligent handling or installation, or unauthorized modifications. Please

see the applicable supply contract or Conditions of Sale for details of the

warranty for each product.

VAISALA ________________________________________________________________________ 11

Page 14

User's Guide _______________________________________________________________________

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the GMW90 series transmitters.

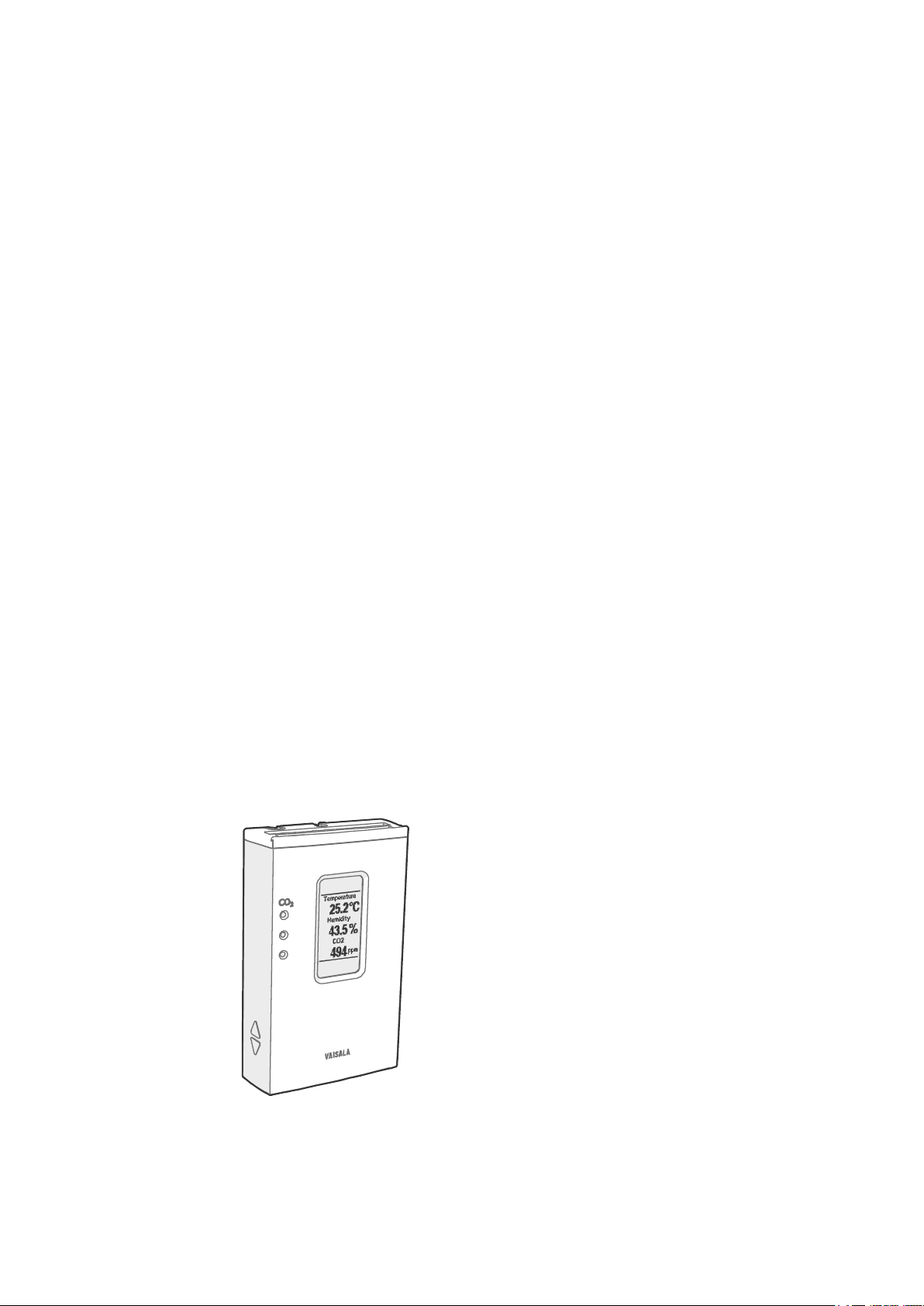

Introduction to GMW90 Series

GMW90 series transmitters are wall-mount transmitters for building

automation applications. All GMW90 series transmitters measure carbon

dioxide (CO2) and temperature (T), and some models also include

humidity measurement. The CO2 measurement is based on a new

generation CARBOCAP® sensor, which uses a novel, silicon-based

microchip emitter instead of an incandescent light bulb.

All transmitter models in the series share the following common features:

- Detachable mounting base for easy installation and wiring.

- Display (visible or hidden behind the cover).

- Sliding cover for accessing maintenance functions.

- Adjustment trimmers.

- DIP switches for most common configuration tasks.

- RS-485 line for temporary service use with hand-held MI70 indicator

or PC.

1310-036

Figure 1 GMW90 with Visible Display and Indicator LEDs

12 ___________________________________________________________________ M211659EN-B

Page 15

Chapter 2 ___________________________________________________________ Product Overview

Model

Measurement

Output

Display

Visible

CO2 LEDs

GMW93

CO2, temperature

2 x analog

(0 ... 5/10V)

No

No

GMW93D

CO2, temperature

2 x analog

(0 ... 5/10V)

Yes

No

GMW93R

CO2, humidity,

temperature

3 x analog

(0 ... 5/10V)

No

No

GMW93RD

CO2, humidity,

temperature

3 x analog

(0 ... 5/10V)

Yes

No

GMW93RA

CO2, humidity,

temperature

3 x analog

(0 ... 5/10V)

Yes

Yes

GMW94

CO2, temperature

2 x analog

(0/4 ... 20 mA)

No

No

GMW94D

CO2, temperature

2 x analog

(0/4 ... 20 mA)

Yes

No

GMW94R

CO2, humidity,

temperature

3 x analog

(0/4 ... 20 mA)

No

No

GMW94RD

CO2, humidity,

temperature

3 x analog

(0/4 ... 20 mA)

Yes

No

GMW95

CO2, temperature

Digital

(Modbus/BACnet)

No

No

GMW95D

CO2, temperature

Digital

(Modbus/BACnet)

Yes

No

GMW95R

CO2, humidity,

temperature

Digital

(Modbus/BACnet)

No

No

GMW95RD

CO2, humidity,

temperature

Digital

(Modbus/BACnet)

Yes

No

GMW90*

CO2, temperature

Configurable

(digital or analog)

Optional

Optional

GMW90R*

CO2, humidity,

temperature

Configurable

(digital or analog)

Optional

Optional

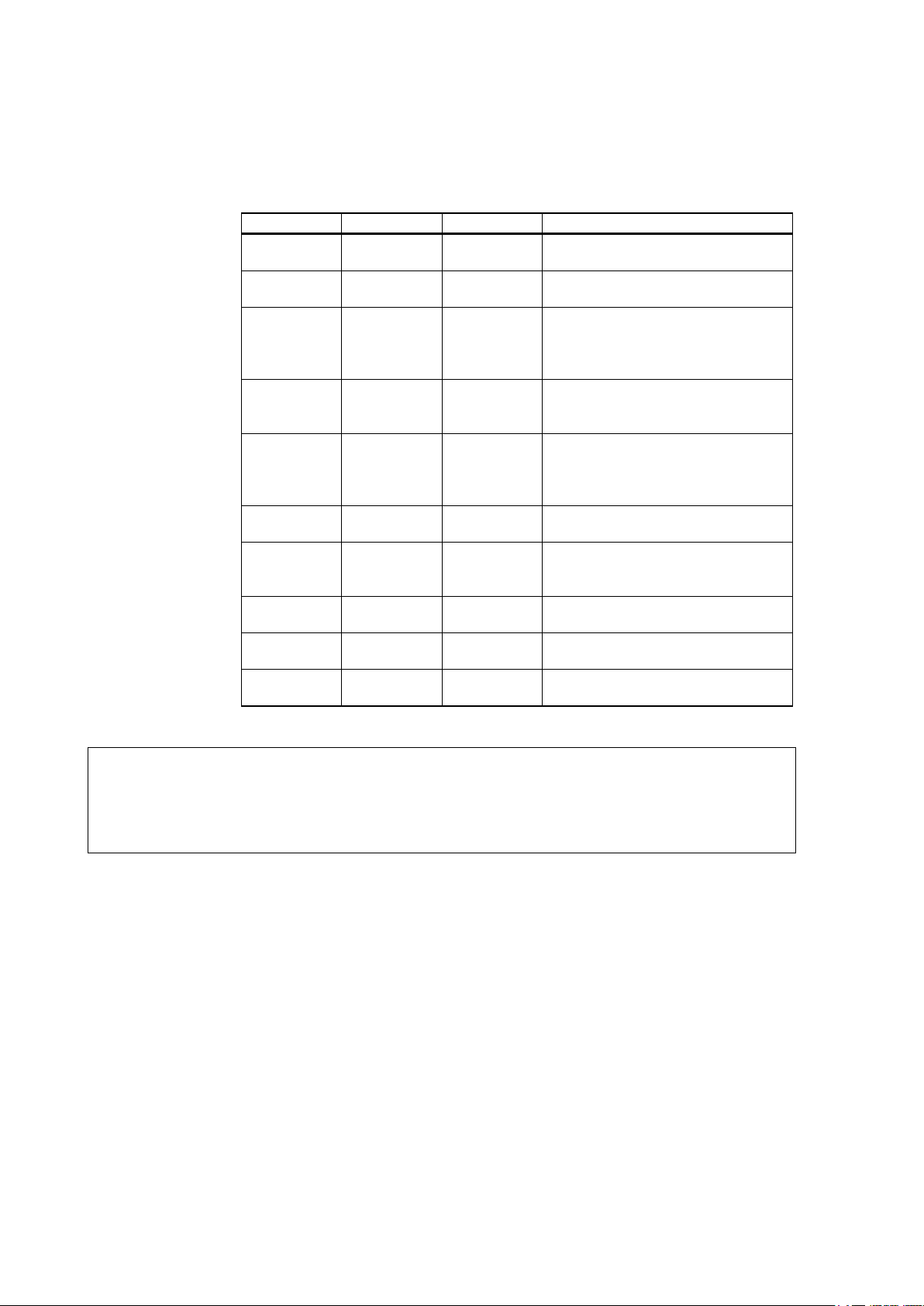

GMW90 Series Transmitters

Table 4 below lists the most important differences between the GMW90

series transmitter models. For technical specifications, see Chapter 7,

Technical Data, on page 79.

Table 4 GMW90 Series Transmitters

* Factory configurable model. See order form for details.

VAISALA ________________________________________________________________________ 13

Page 16

User's Guide _______________________________________________________________________

Parameter

Symbol

Unit(s)

Description

Carbon

dioxide

CO2

ppm

Concentration of carbon dioxide

gas (CO2).

Temperature

T

°C

°F

Temperature in Celsius or

Fahrenheit scale.

Relative

RH % Ratio of the partial pressure of

at the current temperature.

Dewpoint

Td

°C

Temperature at which the water

water at the current pressure.

Dewpoint

Tdf

°C

Same as Td, except when the

instead of dewpoint.

Dewpoint

depression

dTd

°C

°F

Difference between ambient

temperature and dewpoint (Tdf).

Wet bulb

Tw

°C

The minimum temperature that

cooling in the current conditions.

Absolute

humidity

a

g/m3

gr/ft3

Quantity of water in a cubic meter

(or cubic foot) of air.

Mixing ratio

x

g/kg

gr/lb

Ratio of water vapor mass per

kilogram (or pound) of dry air.

Enthalpy

h

kJ/kg

btu/lb

Sum of the internal energy of a

thermodynamic system.

Output Parameters Explained

Table 5 Parameters Supported by GMW90 Series

NOTE

humidity

temperature

°F

°F

°F

water vapor in the air to the

saturation vapor pressure of air

vapor in the air will condense into

dewpoint is below 0 °C, the

transmitter outputs frostpoint (Tf)

can be reached by evaporative

All of these parameters are visible and selectable using the service port

(serial line and MI70 indicator use) even if your transmitter model does

not have a humidity sensor. However, the transmitter will not show any

measurement results for parameters that it cannot measure or calculate.

14 ___________________________________________________________________ M211659EN-B

Page 17

Chapter 2 ___________________________________________________________ Product Overview

1 = Locking screw for mounting base.

Not included, M3×6 recommended.

2 = Inlet for CO2 calibration gas.

Use a 3 mm inner diameter silicone tube and 0.4 l/min flow.

3 = Adjustment trimmers.

4 = Service port.

5 = Window for display (only in models where the display is visible)

6 = Locking screw for slide. Not included, M3×6 recommended.

7 = Display.

8 = CO2 level indicator LEDs. Enabled on models with LED option.

Default settings:

blinking at > 5000 ppm CO2.

9 = Type label.

10 = Holes for indicator LEDs (only in models with LED option).

11 = Grip for slide.

7

9

8

11

10

1

3

4

2

5

6

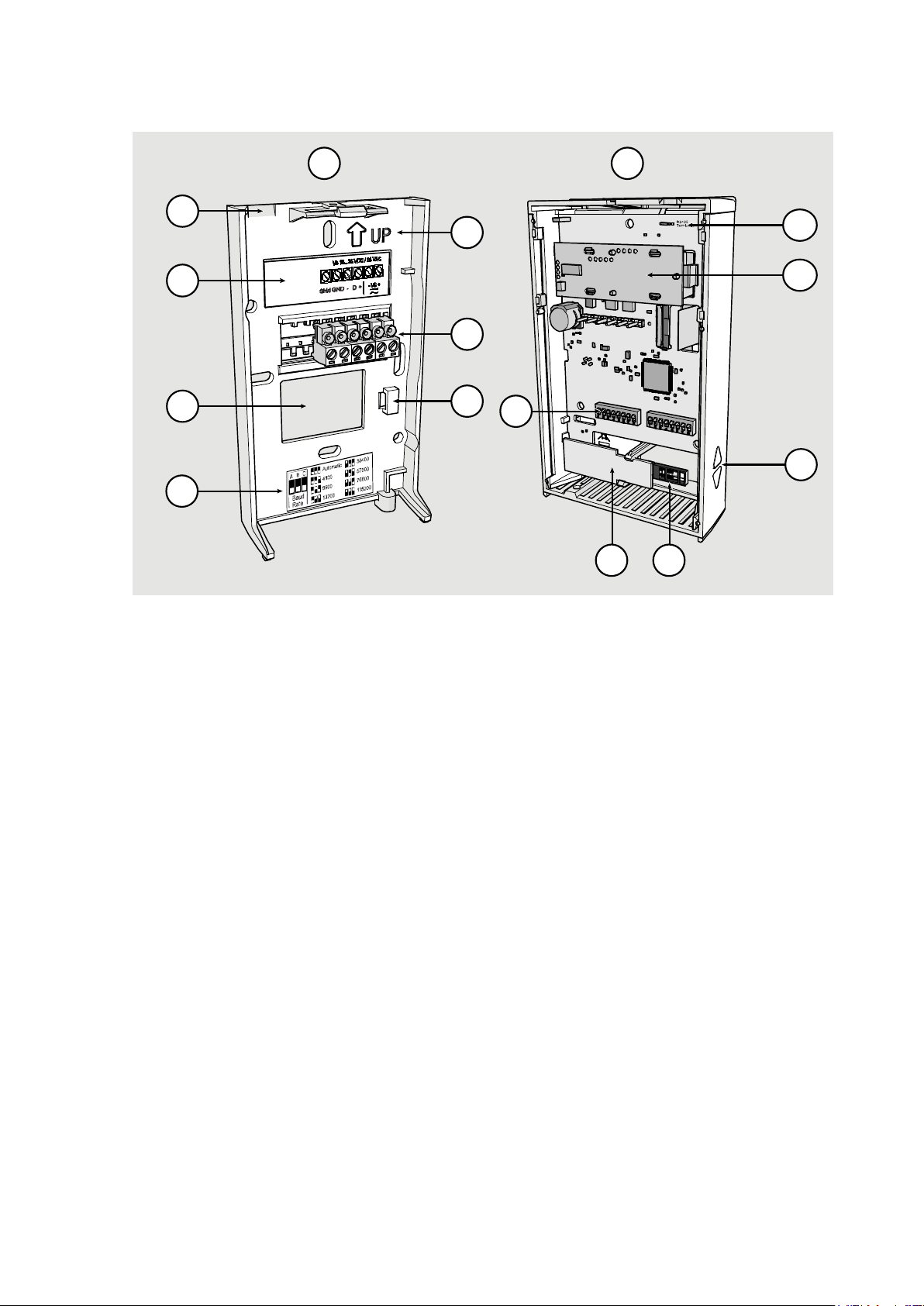

Transmitter parts

1310-038

Figure 2 Transmitter Parts - Outside

VAISALA ________________________________________________________________________ 15

- Green LED (bottom): lit between 0 ... 800 ppm CO2.

- Yellow LED (middle): lit between 800 ... 1200 ppm CO2.

- Red LED (top): lit between 1200 ... 5000 ppm CO2,

Page 18

User's Guide _______________________________________________________________________

1 = Push tab down with a screwdriver to open the transmitter.

1

CAUTION

1201-005

Figure 3 Opening the Transmitter

To open, use a screwdriver to push down the tab that holds the

transmitter cover and mounting base together. Pull the mounting base

away from the cover, starting from the top.

To close, connect the bottom of the transmitter first, and tilt the top

forward to close the tab. Do not push on the display. Closing the

transmitter starts it up if power is supplied to the screw terminals.

When opening or closing the transmitter, avoid damaging the transmitter

electronics with the two plastic supports on the mounting base.

16 ___________________________________________________________________ M211659EN-B

Page 19

Chapter 2 ___________________________________________________________ Product Overview

1 = Mounting base.

2 = Opening for cable (wiring from top).

3 = Terminal label.

4 = Opening for cable (wiring from behind, recommended).

5 = Label for RS-485 baud rate DIP switch settings.

Included only on digital models.

6 = Orientation arrow – should point up after the mounting base has

been installed.

7 = Screw terminals.

8 = Place for zip tie (for cable strain relief)

9 = Transmitter body.

10

=

RS-485 termination jumper (connects a 120 Ω resistor).

Included only on digital models.

11 = GM10 module (measures CO2).

12 = DIP switches for common configuration options. Digital models

have an extra DIP switch bank for transmitter address.

13 = Grip for slide.

14 = TM10 module (measures temperature only) or

HTM10 module (measures humidity and temperature).

15 = HUMICAP® sensor (on models with humidity measurement).

2

3

4

6

8

7

14 15

1

9

13

10

11

5

12

1310-039

Figure 4 Transmitter Parts – Inside

VAISALA ________________________________________________________________________ 17

Page 20

User's Guide _______________________________________________________________________

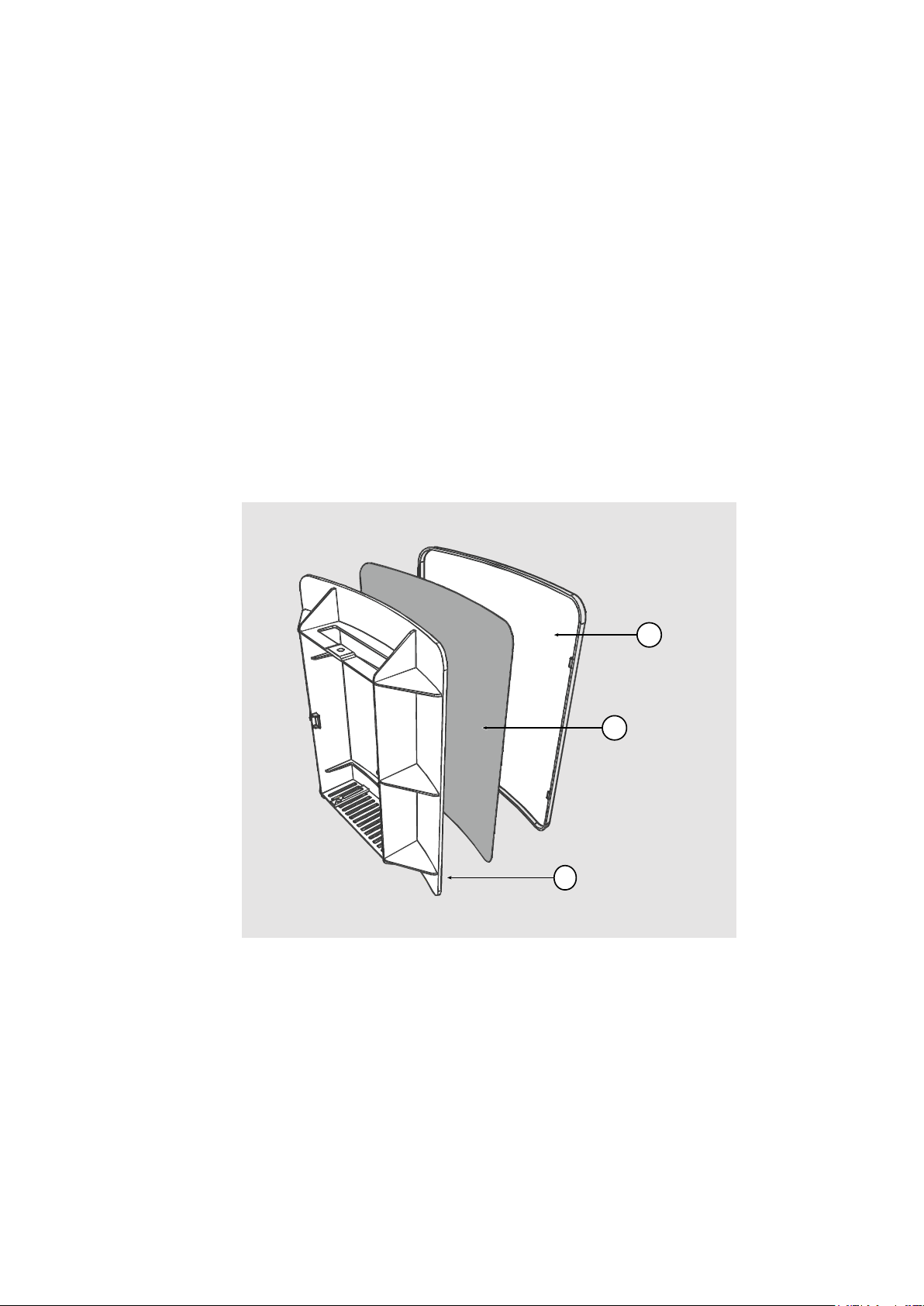

1 = Decorative cover lid. If you intend to paint the cover, paint the

outer surface of this

unpainted.

2 = Space for wallpaper or printed insert. The decorative cover is

delivered with a quick guide that can be used as a stencil for

cutting the required shape.

3 = Decorative cover base part.

1

2

3

Decorative Cover Option

The decorative cover is an installation accessory for HMW90 and

GMW90 series transmitters that can be used to hide the transmitter from

view. The cover material is transparent polycarbonate, but the idea is to

customize it to match the wall the transmitter is on. There are two easy

ways to change the cover’s appearance:

- Paint the cover to the same color as the wall.

- Insert a piece of wallpaper under the lid.

You can also use the cover as a holder for printed material, for example

an informational sign.

You must remove the sliding cover of the transmitter to install the

decorative cover. Installation instructions are included with the cover.

Figure 5 Decorative Cover

part, and leave the other part entirely

18 ___________________________________________________________________ M211659EN-B

1310-042

Page 21

Chapter 3 ________________________________________________________________ Installation

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended to help you

install the GMW90 series transmitters.

Configuration Before Installation

If you need to change the settings of the transmitter, it is best to do this

before it has been installed. Available configuration options are different

for analog output models (such as GMW93) and digital output models

(for example, GMW95).

Configuration of Analog Output Models

You can configure analog output models of GMW90 series transmitters

in two ways:

- Using the DIP switches on the component board. See section DIP

Switches of Analog Output Models on page 20.

- Configuring the settings in software through the service port. See

connection instructions and serial line commands in Chapter 4,

Operation, on page 31.

These two configuration methods are mutually exclusive. If the DIP

switch configuration is used, software settings have no effect on settings

that are controlled by the DIP switches. Additionally, standard analog

output settings and display configuration are always set in the DIP

configuration mode. DIP switch number 8 is the master switch that

controls which configuration method is used.

VAISALA ________________________________________________________________________ 19

Page 22

User's Guide _______________________________________________________________________

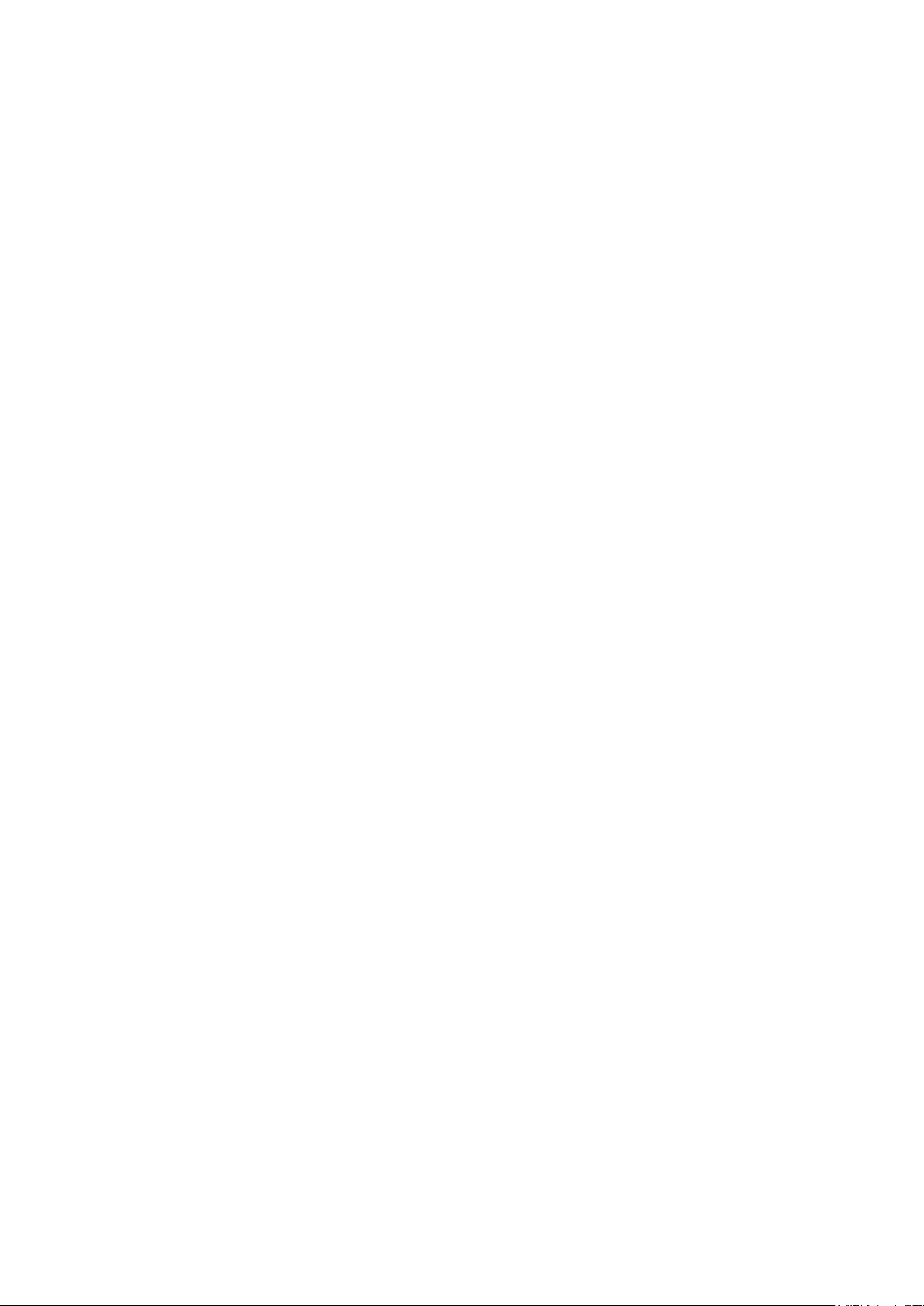

DIP

Position

Setting

1

Non-metric

Non-metric units (°F).

Metric

Metric units (°C).

2

Td

Td (dewpoint) as humidity parameter on display and

to -20 ... +55 °C.

RH

RH (relative humidity) as humidity parameter on display

0 ... 100 %RH.

3

0...5V or

0...20 mA

Set analog output channels to 0 ... 5 V (voltage output) or

0 ... 20 mA (current output)

0...10V or

4...20 mA

Set analog output channels to 0 ... 10 V (voltage output)

or 4 ... 20 mA (current output)

4

Not used

5 Not used

6 Not used

7 Not used

8 Custom

Configuration through service port only.

DIP

Configuration by DIP switches only.

Resets display analog outputs to standard settings.

Non-Metric

Td

0...20mA

Custom

Metric

RH

4..20mA

DIP

1

2 3 4

5 6

7

8

Non-Metric

Td

Custom

Metric

RH

DIP

1

2 3 4

5 6

7

8

GMW93 GMW94

0...5V

0...10V

DIP Switches of Analog Output Models

1402-027

Figure 6 DIP Switch Settings of Analog Output Models

NOTE

analog output. Sets analog output scaling

and analog output. Sets analog output scaling to

If DIP switch 8 is set to Custom, the transmitter ignores all other DIP

switch settings. In custom mode the transmitter uses settings that are

configured in software using the service port. Before changing the

position of this switch, see section Changing Between DIP and Custom

Configuration on page 21.

20 ___________________________________________________________________ M211659EN-B

Page 23

Chapter 3 ________________________________________________________________ Installation

Changing Between DIP and Custom Configuration

If you change the position of DIP switch 8, note the following:

When changing from DIP to Custom: The DIP settings that were used

when the power was last on are carried over to the custom settings at next

power up.

When changing from Custom to DIP: Current custom settings are

overwritten by the settings from the DIP switches at next power up.

Display layout and analog outputs are set to default settings:

- Channel 1 output parameter CO2, scaling 0 ... 2000 ppm.

- Channel 2 output parameter T, scaling -5 ... +55 °C.

- Channel 3 output parameter RH, scaling 0 ... 100 %RH (if humidity

measurement is present on the transmitter).

If you have a factory customized transmitter, this may lead to a situation

where the wiring label on the mounting base does not reflect the outputs

of the transmitter. To return the transmitter to its factory customized

settings, follow the instructions in section Reverting to Factory Settings

on page 76.

Configuration of Digital Output Models

Digital output models of the GMW90 series have the following

configuration interfaces:

- DIP switches on the component board control operating protocol,

serial line settings, and transmitter MAC address. For instructions, see

DIP Switches of Digital Output Models on page 22.

- You can set a jumper for RS-485 line termination on the component

board (120 Ω resistor). For location of the jumper, see Figure 4 on

page 17.

- Other settings are configured in software. You can change most

configuration settings through the service port. For connection

instructions and serial line commands, see Chapter 4, Operation, on

page 31.

- Some configuration actions can be done using the BACnet and

Modbus protocols. See the following appendices for protocol

implementation details:

- Appendix A, BACnet Reference, on page 83.

- Appendix B, Modbus Reference, on page 96.

VAISALA ________________________________________________________________________ 21

Page 24

User's Guide _______________________________________________________________________

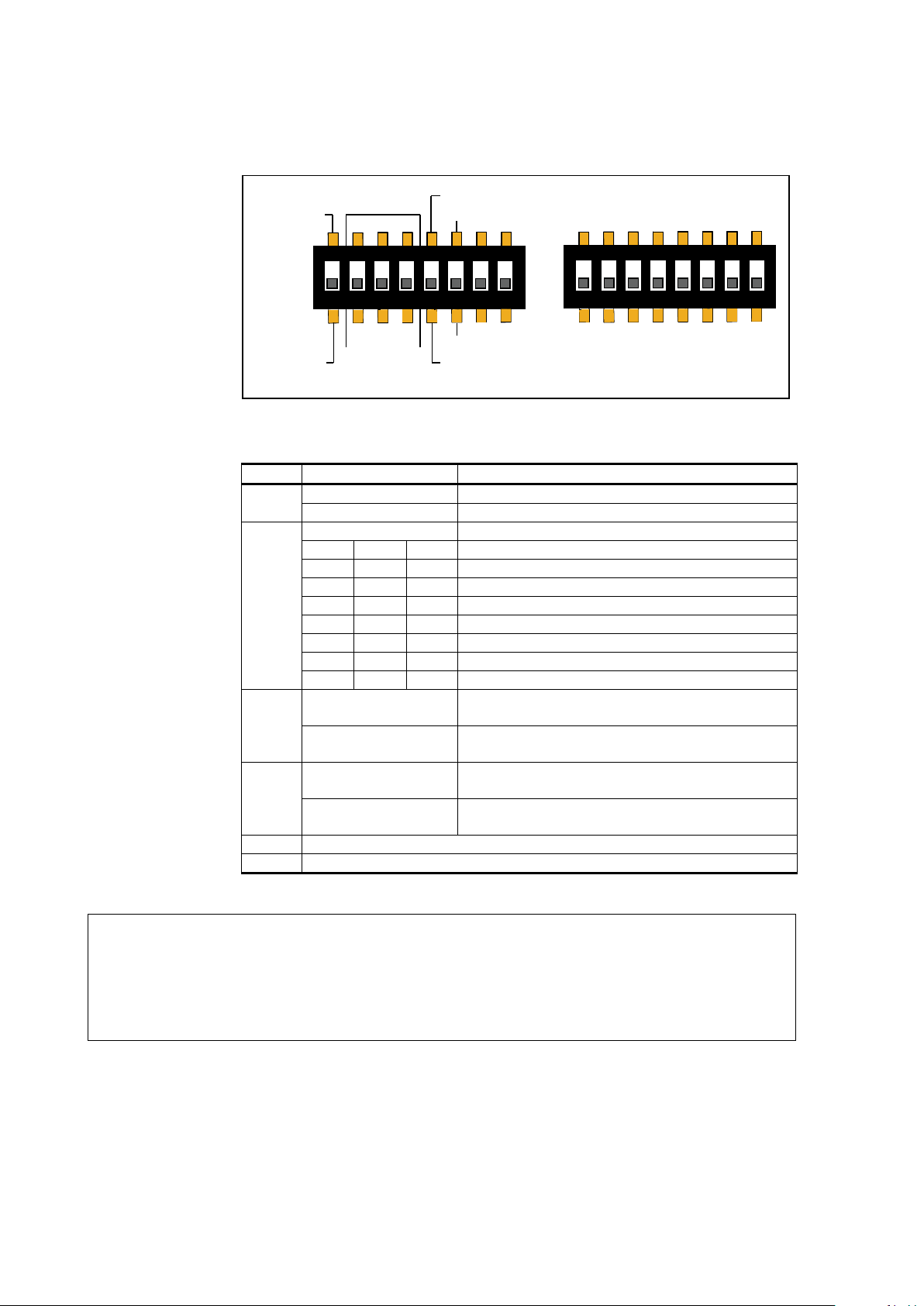

DIP

Position

Setting

1

Modbus

Modbus protocol in use.

BACnet

BACnet protocol in use.

2 ... 4

A B C

Serial line baud rate.

Off

Off

Off

Automatic (default).

Off

Off

On

4800 (not available with BACnet protocol)

Off

On

Off

9600

Off

On

On

19200

On

Off

Off

38400

On

Off

On

57600

On

On

Off

76800

On

On

On

115200

5

Parity Even

Select 8 data bits, parity even, one stop bit

(8E1) for Modbus protocol.

Parity None

Select 8 data bits, parity none, and two stop bits

(8N2) for Modbus protocol.

6

Non-Metric

Use non-metric units on display and service

port. No effect on Modbus and BACnet.

Metric

Use metric units on display and service port.

No effect on Modbus and BACnet.

7

Not used

8

Not used

1

ON

2 3 4

5 6

7

8

Modbus

BACnet

Parity Even

A B C

Parity None

Baud

Rate

1

2 3 4

5 6

7

8

128 64 32 16 8 4 2 1

Address

(Binary Weighting)

ON

Metric

Non-Metric

DIP Switches of Digital Output Models

1209-016

Figure 7 DIP Switch Settings of Digital Output Models

NOTE

If the serial line baud rate is set to Automatic, the transmitter attempts to

determine the baud rate of the traffic in the RS-485 network. The

transmitter cycles through all baud rate choices, listening for 10 seconds

at each rate. When it detects valid RS-485 traffic, it remains at the

detected baud rate until it is reset or power cycled.

22 ___________________________________________________________________ M211659EN-B

Page 25

Chapter 3 ________________________________________________________________ Installation

1

2 3 4

5 6

7

8

128 64 32 16 8 4 2 1

ON

Binary: 10100001

Decimal: 161

(128 + 32 + 1)

=

Dip switches marked Address (Binary Weighting) set the MAC address

of the GMW90 series digital transmitter. The address is encoded in eight

bit binary form, with each numbered switch representing a single bit. For

example:

1209-009

Figure 8 Example of Transmitter Addressing

Addressing with BACnet Protocol

BACnet MS/TP MAC address range is 0 … 255. The transmitter is a

BACnet MS/TP master if address is below 128. Otherwise the transmitter

is a slave.

Addressing with Modbus Protocol

Transmitter is always a Modbus slave. MAC address range for Modbus

slaves is 1 … 247.

VAISALA ________________________________________________________________________ 23

Page 26

User's Guide _______________________________________________________________________

Selecting Location

The conditions at the location should represent well the area of interest.

Do not install the transmitter on the ceiling. Avoid placing the transmitter

near heat and moisture sources, close to the discharge of the supply air

ducts, and in direct sunlight.

NOTE

1111-070

Figure 9 Selecting Transmitter Location

Use the mounting holes to attach the mounting base securely. Use at least

two screws (not included, max screw diameter 4 mm). Remember to

leave sufficient clearance below the transmitter to operate the slide. For

mounting dimensions, see section Dimensions in mm on page 82.

When bringing a cable through the wall, note that the hole may also

supply air from outside the room into the transmitter. This may affect the

measurement readings. For example, fresh concrete binds CO2 and may

cause low readings, especially in new buildings. Seal the cable opening if

necessary.

24 ___________________________________________________________________ M211659EN-B

Page 27

Chapter 3 ________________________________________________________________ Installation

Connect only de

Installing the Mounting Base

Use the mounting holes to attach the mounting base securely. Use at least

two screws (not included). The arrow on the mounting base must point

straight up after installation. Proper orientation is important: air must

flow through the vents on the bottom and top.

Wiring

WARNING

1310-043

Figure 10 Installing the Mounting Base

Connect the wiring to the screw terminals on the mounting base. The

supply voltage and terminal assignments are model-specific. Max wire

size 2 mm2 (AWG14).

You can bring the cable to the housing from above or from

behind (recommended). If you are wiring a GMW90 series transmitter

from above, note that the GM10 module takes up significant space inside

the transmitter. To make sure there is enough space to close the

transmitter, use a < Ø 5 mm cable, and route it from the left side of the

mounting base. See Figure 12 on page 26.

After completing the wiring, connect the transmitter body over the

mounting base. Note that mounting bases are model-specific.

-energized wires.

VAISALA ________________________________________________________________________ 25

Page 28

User's Guide _______________________________________________________________________

1310-044

Figure 11 Wiring from Behind (Recommended)

1310-045

Figure 12 Wiring from Above

26 ___________________________________________________________________ M211659EN-B

Page 29

Chapter 3 ________________________________________________________________ Installation

T+

GND -VsCO2+ +Vs

Power supply

18 ... 35 VDC

or 24 VAC ±20%

V

RL = 10 kΩ min.

V

RH+

V

T+

GND -Vs

CO

2

+ +Vs

Power supply

18 ... 35 VDC

or 24 VAC ±20%

RL = 10 kΩ min.

V

RH+

V

V

T+

GND -VsCO2+ +Vs

Power supply

18 ... 35 VDC

or 24 VAC ±20%

V

R

L

= 10 kΩ min.

V

Wiring GMW93R/RA

Recommended wiring for long cables:

1402-032

Figure 13 Wiring GMW93R/RA

-Vs terminal is internally connected to GND terminal, so you can also

use the -Vs terminal as common ground. Maximum cable resistance is

2.5 Ω (24V supply, 0 ... 10 V output):

1402-031

Figure 14 Alternate Wiring for GMW93R/RA

Wiring GMW93

VAISALA ________________________________________________________________________ 27

GMW93 is wired in the same way as GMW93R/RA, except for the

humidity output that is not present:

1402-030

Figure 15 Wiring GMW93

Page 30

User's Guide _______________________________________________________________________

T+GND -VsCO

2

+ +Vs

Power supply

18 ... 35 VDC

or 24 VAC ±20%

RH+

R

L

= 0 ... 600 Ω

mA

mA

mA

T+GND -VsCO

2

+ +Vs

Power supply

18 ... 35 VDC

or 24 VAC ±20%

RL = 0 ... 600 Ω

mA

mA

Wiring GMW94R

-Vs terminal is internally connected to GND terminal.

1402-034

Figure 16 Wiring GMW94R

Wiring GMW94

GMW94 is wired in the same way as GMW94R, except for the humidity

output that is not present:

1402-033

28 ___________________________________________________________________ M211659EN-B

Figure 17 Wiring GMW94

Page 31

Chapter 3 ________________________________________________________________ Installation

D- -VsD+ +Vs

+

-

Power supply

18 ... 35 VDC

or 24 VAC ±

20

%

RS

-485

S

h

ld

GN

D

Transmit

te

r

D-

-Vs

D+

+Vs

Shld

GND

B

uil

din

g con

tro

lle

r Tr

ansm

itt

er Transmi

tt

er

Power

su

ppl

y

D-

D+

+Vs

-Vs

GN

D

SHIEL

D

RS-485:

BACne

t or

MO

DBU

S

master

Connect shield on

contro

ller side

Set RS-485

termination j

umper

D-

-Vs

D+

+V

s

Shld

GND

D-

-V

s

D+

+Vs

Sh

ld

G

ND

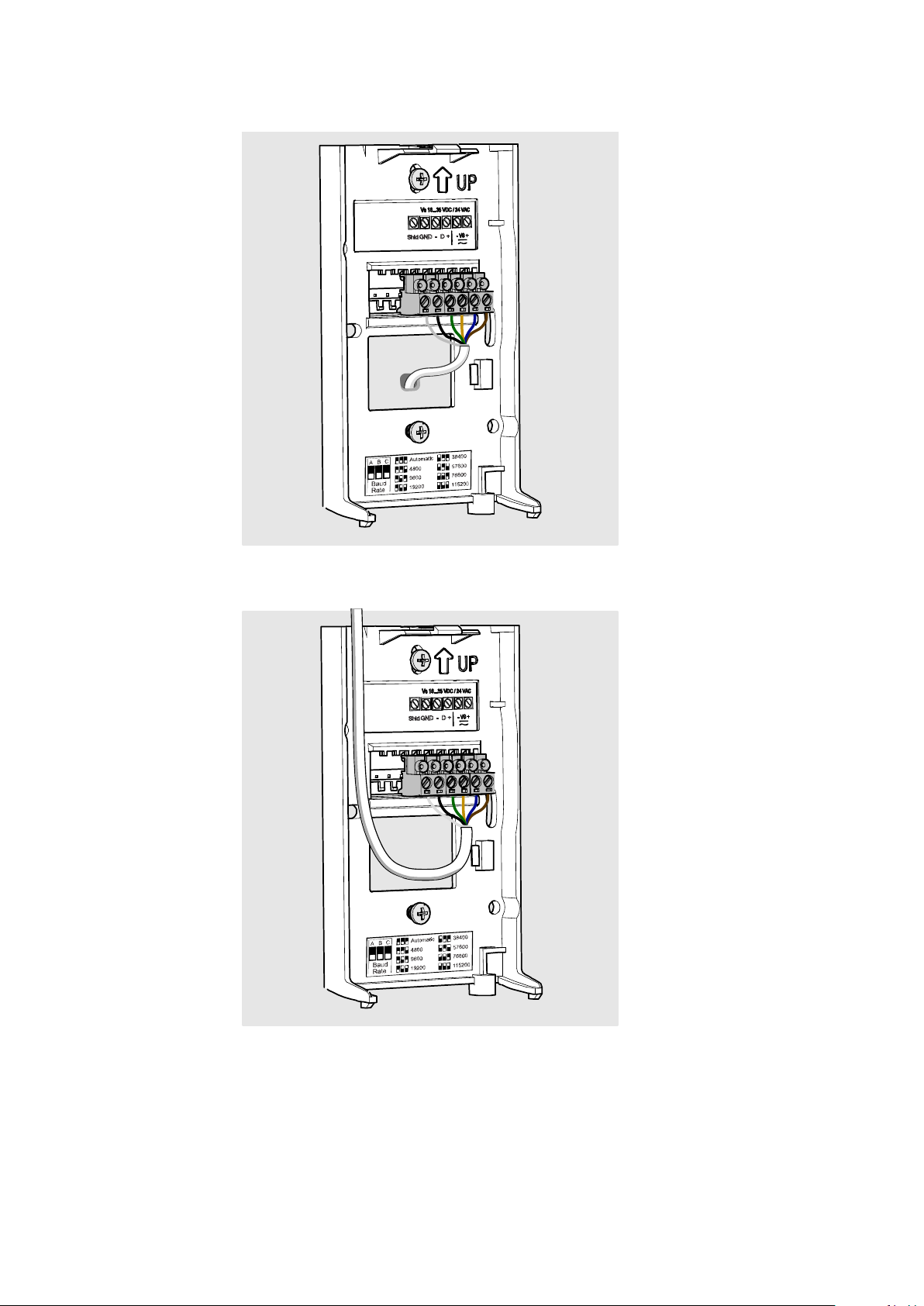

Wiring GMW95

The RS-485 line of the transmitter is isolated from the power supply. A

separate ground reference terminal (GND) is provided for the RS-485

connection.

If you are using a shielded cable, you can use the Shld terminal to hold

the exposed part of the shield. Note that the Shld terminal is floating

(not electrically connected).

1209-014

Figure 18 Wiring GMW95

Connecting Several Transmitters on Same RS-485

Line

Set the RS-485 termination jumper to “ON” on the transmitter that is at

the end of the line. This terminates the line with a 120 Ω resistor. For

location of the jumper, see Figure 4 on page 17.

Connect the cable shield to ground on the building controller side.

VAISALA ________________________________________________________________________ 29

Figure 19 Several Transmitters on Same RS-485 Line

1209-015

Page 32

User's Guide _______________________________________________________________________

+Vs OUT

-Vs

+Vs OUT

-Vs GND

Shared

common

line

GMW90

GMW90

CONTROLLER

24 VAC

Supply

voltage

Supply

voltage

Signal

output

Signal

output

GND

Connecting a Common AC Power Supply to Several Transmitters

If you are connecting a common 24 VAC power supply to several

transmitters, make sure to connect the same terminal to +Vs and –Vs on

all transmitters. This will avoid a short-circuit through the shared

common line at the controller; see Figure 20 below.

1310-046

Figure 20 Connecting a Common AC Power Supply

30 ___________________________________________________________________ M211659EN-B

Page 33

Chapter 4 _________________________________________________________________ Operation

CHAPTER 4

OPERATION

This chapter contains information that is needed to operate the GMW90

series transmitters.

Display

Startup Screens

When the transmitter is powered on, it displays a sequence of

information screens. The screens are shown for a few seconds each.

The first screen identifies the transmitter and the connected measurement

modules, and shows if the transmitter is operating normally (status OK)

or if there is an error (status ERROR).

The following screens show configuration information that is relevant to

the outputs of the transmitter. Transmitters with digital output show

information on the selected communication protocol (BACnet or

Modbus). Transmitters with analog output show the analog output mode

and scaling.

The last screen shows the currently configured pressure compensation

setting.

1310-049, 1310-047

Figure 21 GMW95R Startup Screens

After the startup screens the transmitter shows the measurement screen. It

shows the measured parameters and currently active indicators.

VAISALA ________________________________________________________________________ 31

Page 34

User's Guide _______________________________________________________________________

Measurement Screen

Measurement screen shows the measured parameters and currently active

indicators.

1310-040

Figure 22 Measurement Screen – Normal Operation

If there is a problem with measurement, affected readings are replaced

with stars. The alarm indicator and an error message will also appear on

the screen.

1310-041

Figure 23 Measurement Screen – Problem With Humidity

Measurement

32 ___________________________________________________________________ M211659EN-B

Page 35

Chapter 4 _________________________________________________________________ Operation

Indicator

Position on Screen

Meaning

Top right

Communication arrows. Shown only on

transmitter is transmitting to the RS-485 line.

Top left

MI70 connection indicator. Is shown when an

port.

Bottom left

Alert indicator and error text. Is shown if an

Error Messages on page 73.

The s

transmitter

supply (not grounded) to the service port. If you connect a device that is

grounded to a different potential

will affect the

even affect the transmitter’s functionality or cause damage to the

transmitter.

Indicators on the Display

Service Port

You can connect to the service port on the GMW90 series transmitters

using a computer or an MI70 indicator. The MI70 indicator is the handheld display device that is included with, for example, the Vaisala

CARBOCAP® Hand-Held Carbon Dioxide Meter GM70.

CAUTION

models with digital output. Down arrow is

shown when transmitter detects valid traffic

on the RS-458 line. Up arrow is shown when

MI70 Indicator is connected to the service

error is active. The error message is

written after the indicator. See section

ervice port is not galvanically isolated from the rest of the

electronics. Connect only equipment with a floating power

than the transmitter’s power supply, you

accuracy of the transmitter’s analog outputs. You may

Connecting With an MI70 Indicator

When connecting using an MI70 indicator, use the connection cable for

GM70 hand-held meter (Vaisala order code 219980). The following

functionality is available when using the MI70:

- Standard MI70 functions such as viewing, logging, and graphs of

measurement results.

- Calibration and adjustment fuctions for the transmitter. For more

information, see section Adjustment Using a Hand-Held Meter on

page 67.

- Setting of the pressure compensation value for carbon dioxide and

humidity measurement (Environment menu in the MI70).

VAISALA ________________________________________________________________________ 33

Page 36

User's Guide _______________________________________________________________________

Connecting With a Computer

Connecting with a computer allows you to configure and troubleshoot

your transmitter using serial line commands. For a list of commands, see

section List of Serial Commands on page 37.

When connecting using a computer, use the Vaisala USB cable

(Vaisala order code 219690) and a suitable terminal application:

- If you have not used the Vaisala USB cable before, install the driver

before attempting to use the cable. Refer to section Installing the

Driver for the USB Service Cable on page 34 for detailed instructions.

- For more information on using a terminal application, see section

Terminal Application Settings on page 35.

Installing the Driver for the USB Service Cable

Before taking the USB service cable into use, you must install the

provided USB driver on your computer (requires Windows).

When installing the driver, you must acknowledge any security prompts

that may appear.

1. Check that the USB service cable is not connected. Disconnect the

cable if you have already connected it.

2. Insert the media that came with the cable, or download the latest

driver from www.vaisala.com.

3. Execute the USB driver installation program (setup.exe), and

accept the installation defaults. The installation of the driver may

take several minutes.

4. After the driver has been installed, connect the USB service cable

to a USB port on your computer. Windows will detect the new

device, and use the driver automatically.

5. The installation has reserved a COM port for the cable. Verify the

port number, and the status of the cable, using the Vaisala USB

Instrument Finder program that has been installed in the

Windows Start menu.

Windows will recognize each individual cable as a different device, and

reserve a new COM port. Remember to use the correct port in the

settings of your terminal program.

34 ___________________________________________________________________ M211659EN-B

Page 37

Chapter 4 _________________________________________________________________ Operation

Property

Description / Value

Baud rate

19200

Parity

None

Data bits

8

Stop bits

1

Flow control

None

If PuTTY is unable to open the serial port you selected, it will show you

an error message instead. If this happens, restart PuTTY and check the

settings.

Terminal Application Settings

The serial interface settings of the service port are presented in Table 6

below. The settings are fixed, and cannot be changed by the user.

Table 6 Serial Interface Settings

The steps below describe how to connect to the transmitter using the

PuTTY terminal application for Windows (available for download at

www.vaisala.com) and a USB serial interface cable:

1. Connect the USB serial interface cable between your computer and

the service port of the transmitter.

2. Start the PuTTY application.

NOTE

3. Select the Serial settings category, and check that the correct COM

port is selected in the Serial line to connect to field.

Note: You can check which port the USB cable is using with the

Vaisala USB Instrument Finder program that has been installed

in the Windows Start menu.

4. Check that the other serial settings are correct for your connection,

and change if necessary. Flow control should be set to None unless

you have a reason to change it.

5. Click the Open button to open the connection window and start

using the serial line.

6. You may need to adjust the Local echo setting in the Terminal

category to see what you are typing on the serial line. You must

enable either local echo (on the terminal side) or remote echo (on

the transmitter side, adjustable using the ECHO command).

To access the configuration screen while a session is running, click

the right mouse button over the session window, and select Change

Settings... from the pop-up menu.

VAISALA ________________________________________________________________________ 35

Page 38

User's Guide _______________________________________________________________________

0807-004

Figure 24 PuTTY Terminal Application

36 ___________________________________________________________________ M211659EN-B

Page 39

Chapter 4 _________________________________________________________________ Operation

Command

Description

?

Show transmitter information.

CALCS

Show all measured and calculated parameters.

ECHO

Show or set remote echo mode.

ENV

Show or set environmental parameters.

ERRT

Show error table.

ERRS

Show currently active errors.

FORM [modifier string]

Show or set output format.

HELP

Show list of currently available serial commands.

INTV [0 ... 9999 s/min/h]

Set continuous output interval for R command.

PASS [9000]

Access advanced serial commands.

R

Start the continuous outputting.

RESET

Reset the transmitter.

S

Stop the continuous outputting.

SDELAY [0 ... 255]

Show or set serial line turnaround delay in

milliseconds.

SEND

Output measurement message once.

SNUM

Show transmitter serial number.

STATUS

Show transmitter status.

UNIT [m/n]

Select metric or non-metric units.

VERS

Show transmitter firmware version.

Command

Description

AMODE

Show or set analog output mode.

AOVER

Show or set analog output overrange and clipping

behavior.

ASEL

Show or set analog output parameter.

ATEST

Test analog putput.

BACNET

Show or set BACnet parameters.

CCO2

Calibrate and adjust CO2 measurement.

CDATE

Show or set calibration date.

CRH

Calibrate and adjust RH measurement.

CT

Calibrate and adjust T measurement.

CTEXT

Show or set calibration information.

DSEL

Select parameters to display on screen.

FRESTORE

Restore transmitter to factory settings.

TRAF

Show or set CO2 indicator LED parameters.

List of Serial Commands

All commands can be issued either in uppercase or lowercase. In the

command examples, the keyboard input by the user is in bold type.

The notation <cr> refers to pressing the carriage return (Enter) key on

your computer keyboard. Enter a <cr> to clear the command buffer

before starting to enter commands.

Some commands, such as CRH, are not available if the required feature

is not present on the transmitter, or the command is not relevant.

Table 7 Basic Serial Commands

Table 8 Advanced Serial Commands

VAISALA ________________________________________________________________________ 37

Page 40

User's Guide _______________________________________________________________________

Transmitter Information

Show Transmitter Information

The ? command outputs a listing of device information.

?<cr>

Example:

>?

Device : GMW95R

SW version : 1.1.28.5849

SNUM : H2930002

HTM10 module information

Software version : 0.11.1

SNUM : H2950107

GM10 module information

Software version : 1.1.0

SNUM : J04C030105

Show Transmitter Firmware Version

Use the VERS command to show the transmitter model and firmware

version.

VERS<cr>

Example:

>vers

GMW95R / 1.1.28

Show Transmitter Serial Number

Use the SNUM command to show the transmitter serial number.

SNUM<cr>

Example:

>snum

Serial number : H2930002

38 ___________________________________________________________________ M211659EN-B

Page 41

Chapter 4 _________________________________________________________________ Operation

where

Function

=

Optional switch to display a more detailed status for

BACnet or Modbus protocol

models with digital output).

are -bacnet and –modbus.

Show Transmitter Status

Use the STATUS command to view detailed information on transmitter

model and configuration.

STATUS [function]<cr>

(available on transmitter

Available switches

Example (display detailed BACnet status):

>status –bacnet

* BACnet module (BACNET) *

BACnet protocol : active

MAC : 0 (00h)

Device Instance : 6 (00000006h)

Name : GMW95R_ H2930002

Location : Location

Description : Description

MAX_MASTER : 127 (7Fh)

Node type : Master

Baud setting : Auto

Current baudrate : 19200 8N1

Baudrate locked : No

Baud detection interval: 10 s

DCC : Communication enabled

Valid frames : 0

Invalid frames : 0

Unwanted frames : 0

Lost tokens : 0

Failed TX : 0

VAISALA ________________________________________________________________________ 39

Page 42

User's Guide _______________________________________________________________________

Example (display full status):

>status

Device Name : GMW95R

Copyright : Copyright Vaisala Oyj 2013

SW Name : XM90

SW Model : XM9x

SW version : 1.1.28.5849

Serial number : H2930002

Address : 0

SUB FUNCTIONS

* Serial Port (COM1) *

Mode : STOP

* Error Manager (ERR) *

Status : NORMAL

Active errors : 0

* MCI communication (MCI) *

Status : NORMAL

* Measurement module (HTM10) *

Status : NORMAL

Factory date : 20130720

* Measurement module (GM10) *

Status : NORMAL

Calibration : 20130819

* BACnet module (BACNET) *

BACnet protocol : active

MAC : 0 (00h)

Device Instance : 6 (00000006h)

Name : GMW95R_ H2930002

Location : Location

Description : Description

MAX_MASTER : 127 (7Fh)

Node type : Master

Baud setting : Auto

* MODBUS module (MODBUS) *

MODBUS protocol : inactive

40 ___________________________________________________________________ M211659EN-B

Page 43

Chapter 4 _________________________________________________________________ Operation

CALCS

transmitter model does not measure h

Show Measured Parameters

Use the CALCS command to list the measurement parameters that are

supported by the GMW90 series transmitters. CO2, RH and T are

measured directly by the transmitter, the rest are calculated based on the

measured values.

CALCS<cr>

Example:

>calcs

RH - Relative Humidity

T - Temperature

Tdf - Dew/Frost point temperature

Td - Dew point temperature

Tw - Wetbulb temperature

h - Enthalpy

x - Mixing ratio

a - Absolute humidity

dTd - Dew/frostpoint depression

CO2 - Filtered CO2

NOTE

command also lists all humidity parameters, even if your

umidity.

Show Command Help

To see a short description of an individual command, issue the command

with a question mark as a parameter.

Example:

>calcs ?

Display measured quantities

VAISALA ________________________________________________________________________ 41

Page 44

User's Guide _______________________________________________________________________

where

pressure

=

Ambient pressure in hPa.

Show Command List

Use the HELP command to list the currently available serial commands.

If the PASS command has not been used, only the basic serial commands

are available.

HELP<cr>

Example (basic serial commands from a transmitter model with analog

outputs, advanced commands are not enabled):

>help

?

CALCS

ECHO

ENV

ERRT

ERRS

FORM

HELP

INTV

PASS

R

RESET

SDELAY

SEND

SNUM

STATUS

UNIT

VERS

Measurement Settings

Set Environmental Parameters

Use the ENV command to set environmental parameters that affect the

measurement. For GMW90 series transmitters you can set the ambient

pressure value that is used for pressure compensation of CO2

measurement and calculated humidity parameters.

ENV [pressure]<cr>

Example:

>env 1013.3

Pressure (hPa) : 1013.3

42 ___________________________________________________________________ M211659EN-B

Page 45

Chapter 4 _________________________________________________________________ Operation

Where

x = Selects the unit type to output:

m = metric units, for example, Celsius

n = non-metric units, for example, Fahrenheit

If you want to change analog output settings, you must set the

transmitter’s configuration DIP switch 8 to position

switch is set to

Commands for configuring analog outputs are not available on digital

output models (for example, GMW95).

where

channel

=

Analog output channel, 1 ... 3.

lo_value

=

Low limit of the channel.

hi_value

=

High limit of the channel.

error_value

=

Error value of the channel.

Select Units

Use the UNIT command to select metric or non-metric output units.

Only affects data shown on the display and service port, has no effect on

the analog and digital outputs. This command is not available on the

digital output models (for example, GMW95).

UNIT [x]<cr>

Example:

>unit m

Unit : Metric

Analog Output Settings

NOTE

DIP, the settings are view-only.

NOTE

Set Analog Output Mode

Use the AMODE command to set the analog output mode and error

level. Note that you cannot change between analog output types, for

example, from voltage to current output.

AMODE [channel lo_value hi_value error_value]<cr>

Custom. If the

VAISALA ________________________________________________________________________ 43

Page 46

User's Guide _______________________________________________________________________

where

channel

=

Analog output channel, 1 ... 3.

parameter

=

Parameter that is output on the channel.

dTd dew/frostpoint depression

lo_value

=

Low limit of the scaling, in the units of the selected

parameter.

hi_value

=

High limit of the scaling in the units of the selected

parameter.

Example (show current configuration):

>pass 9000

>amode

Aout 1 range (mA) : 4.00 ... 20.00 (error: 3.60)

Aout 2 range (mA) : 4.00 ... 20.00 (error: 3.60)

Aout 3 range (mA) : 4.00 ... 20.00 (error: 3.60)

Example (set channel 1 to 0 ... 20 mA output, with error level at 21 mA):

>amode 1 0 20 21

Aout 1 range (mA) : 0.00 ... 20.00 (error: 21.00)

>

Set Analog Output Scaling

Use the ASEL command to select the output parameter and scaling for

analog output channels.

ASEL [channel parameter lo_value hi_value]<cr>

Example (set channel 1 to output dewpoint, in the range -10 ... 20 °C):

>pass 9000

>asel 1 TD -10 20

Aout 1 quantity : Td (-10.00 ... 20.00 'C)

Available parameters are:

CO2 carbon dioxide

RH relative humidity

T temperature

Tdf dew/frostpoint temperature

Td dewpoint temperature

Tw wetbulb temperature

h enthalpy

x mixing ratio

a absolute humidity

44 ___________________________________________________________________ M211659EN-B

Page 47

Chapter 4 _________________________________________________________________ Operation

where

channel

=

Analog output channel, 1 ... 3.

clip%

=

Output margin (%) at which the output is clipped.

Range 0 ... 20, default is 0.

valid%

=

Output margin (%) at which the output of the channel

goes into

humidity and temperature, 0 for carbon dioxide

The error state is defined using the

see section Set Analog Output Mode on page 43.

These settings have no effect on the measurements shown on the display.

The dis

outside the scaled output range, as long as the measurement is still

functioning.

Set Output Clipping and Error Limit

Use the AOVER command to define the behavior of the analog outputs

when the measured value is outside the scaled output range.

AOVER [channel clip% valid%]<cr>

the error state. Range 0 ... 20. Default is 5 for

.

AMODE command,

NOTE

play will always show the currently measured values, even

For example, first check the analog output settings using ASEL,

AMODE, and AOVER commands:

>pass 9000