Page 1

M211897EN-B

User Guide

Vaisala CARBOCAP

(R)

Carbon Dioxide Probe

GMP252

Page 2

PUBLISHED BY

Vaisala Oyj

Street address: Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

Mailing address: P.O. Box 26, FI-00421 Helsinki, Finland

Phone: +358 9 8949 1

Fax: +358 9 8949 2227

Visit our Internet pages at www.vaisala.com.

© Vaisala 2016

No part of this manual may be reproduced,

published or publicly displayed in any form

or by any means, electronic or mechanical

(including photocopying), nor may its

contents be modified, translated, adapted,

sold or disclosed to a third party without

prior written permission of the copyright

holder. Translated manuals and translated

portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this manual are subject to

change without prior notice.

Local rules and regulations may vary and

they shall take precedence over the

information contained in this manual.

Vaisala makes no representations on this

manual’s compliance with the local rules

and regulations applicable at any given

time, and hereby disclaims any and all

responsibilities related thereto.

This manual does not create any legally

binding obligations for Vaisala towards

customers or end users. All legally binding

obligations and agreements are included

exclusively in the applicable supply

contract or the General Conditions of Sale

and General Conditions of Service of

Vaisala.

This product contains software developed

by Vaisala or third parties. Use of the

software is governed by license terms and

conditions included in the applicable

supply contract or, in the absence of

separate license terms and conditions, by

the General License Conditions of Vaisala

Group.

Page 3

Table of Contents

1. About This Document........................................................................................ 7

1.1. Documentation Conventions................................................................................ 7

1.2. Version Information............................................................................................... 7

1.3. Related Manuals..................................................................................................... 8

1.4. Trademarks............................................................................................................. 8

1.5. Patent Notice..........................................................................................................8

2. Product Overview................................................................................................9

2.1. Introduction to GMP252 .......................................................................................9

2.2. Basic Features and Options................................................................................10

2.3. Operating Principle of CO2 Measurement.......................................................... 11

2.4. Environmental Compensation.............................................................................12

2.4.1. Temperature Compensation......................................................................... 13

2.4.2. Pressure Compensation.................................................................................13

2.4.3. Background Gas Compensation...................................................................13

2.5. Probe Startup........................................................................................................14

2.6. Analog Output Overrange Behavior..................................................................14

2.6.1. Analog Output Overrange Example............................................................ 15

2.7. Safety.....................................................................................................................16

2.7.1. ESD Protection............................................................................................... 16

2.8. Regulatory Compliances......................................................................................16

3. Installation.............................................................................................................17

3.1. GMP252 Probe Dimensions................................................................................. 17

3.2. Recommended Installation..................................................................................17

3.3. Installation Accessories........................................................................................17

3.3.1. 243261SP Installation Flange........................................................................ 18

3.3.2. 243257SP Mounting Clips............................................................................. 19

3.4. Power Supply........................................................................................................19

3.5. Wiring................................................................................................................... 20

4. Vaisala Industrial Protocol..............................................................................21

4.1. Overview................................................................................................................ 21

4.2. Serial Interface Settings.......................................................................................21

4.3. Physical Interface..................................................................................................21

4.4. Connecting with a Computer............................................................................. 22

4.4.1. Installing the Driver for the USB Service Cable......................................... 23

4.5. Accessing Serial Commands from Modbus or Analog Mode......................... 23

4.6. Enabling Modbus Mode from Vaisala Industrial Protocol...............................24

4.7. Changing From Digital Output to Analog Output........................................... 25

4.8. Serial Commands.................................................................................................25

4.9. Device Information and Status...........................................................................28

4.10. Serial Line Output and Communication.............................................................31

4.11. Analog Output..................................................................................................... 39

4.12. Calibration and Adjustment...............................................................................44

4.13. Environmental Compensation Commands...................................................... 48

4.14. Other Commands................................................................................................ 55

5. Modbus...................................................................................................................57

1

Page 4

GMP252 User Guide M211897EN-B

6. Operating with MI70 Indicator.................................................................... 58

6.1. Overview of MI70 Support................................................................................. 58

6.2. Basic Display........................................................................................................ 58

6.3. Graphical Display.................................................................................................59

6.4. Main Menu............................................................................................................ 59

6.5. Connecting Probe to MI70 Indicator................................................................. 59

6.6. MI70 Indicator Parts............................................................................................60

6.7. Holding and Saving the Display........................................................................ 60

6.8. Recording Data.....................................................................................................61

6.9. Changing Environmental Compensation Settings with MI70 Indicator........62

6.10. Calibration and Adjustment with MI70 Indicator............................................ 63

6.10.1. 1-Point Adjustment with an MI70-Compatible Reference Probe............ 63

6.10.2. 1-Point Adjustment with a Reference Gas................................................. 64

7. Maintenance.........................................................................................................67

7.1. Cleaning................................................................................................................ 67

7.1.1. Chemical Tolerance....................................................................................... 67

7.2. Changing the Filter..............................................................................................68

7.3. Calibration and Adjustment............................................................................... 68

7.3.1. Calibration Setup.......................................................................................... 69

7.3.2.

Eect of Environmental Compensations...................................................69

7.3.3. Limits of Adjustment....................................................................................70

7.3.4. Adjustment Types.........................................................................................70

7.3.5. DRW244827SP Calibration Adapter............................................................71

8. Troubleshooting................................................................................................. 72

8.1. Problem Situations.............................................................................................. 72

8.2. Error Messages.....................................................................................................72

8.3. Analog Output Error State..................................................................................74

9. Technical Data.....................................................................................................75

9.1. GMP252

Specifications........................................................................................75

9.2. Spare Parts and Accessories.............................................................................. 78

9.3. GMP252 Probe Dimensions................................................................................ 78

9.4. 243261SP Mounting Flange Dimensions........................................................... 79

9.5. 243261SP Calibration Adapter Dimensions......................................................80

Appendix A:

Modbus Reference..........................................................................81

A.1. Function Codes..................................................................................................... 81

A.2. Modbus Registers................................................................................................. 81

A.2.1. Measurement Data......................................................................................... 81

A.2.2. Configuration Registers................................................................................82

A.2.3. Status Registers............................................................................................ 84

A.2.4. Device Identification Objects...................................................................... 84

A.3. Modbus Communication Examples...................................................................86

A.4. Filtering Factor.....................................................................................................88

Technical Support

........................................................................................................... 89

Warranty...........................................................................................................................89

Recycling..........................................................................................................................89

2

Page 5

List of Figures

Figure 1 GMP252 Probe Parts........................................................................................... 9

Figure 2 Probe Cuvette with Mirror and Sensor Chips...............................................11

Figure 3 CO2 Measurement in the Measurement Cuvette....................................... 12

Figure 4 Example of Analog Output Overrange Behavior ......................................15

Figure 5 GMP252 Dimensions.......................................................................................... 17

Figure 6 Probe with 243261SP Installation Flange..................................................... 18

Figure 7 Probe in 243257SP Mounting Clips................................................................19

Figure 8 Example of analog output overrange behavior........................................ 43

Figure 9 MI70 Basic Display.............................................................................................58

Figure 10 MI70 Indicator Parts......................................................................................... 60

Figure 11 CO2 Reading with Tcomp and Pcomp on MI70 Screen.......................... 62

Figure 12 Probe Compensation Settings on MI70 Screen.........................................62

Figure 13 Opening the Filter............................................................................................. 68

Figure 14 DRW244827SP Calibration Adapter with Probe Inserted.......................71

Figure 15 GMP252 Dimensions......................................................................................... 78

Figure 16 243261SP Mounting Flange Dimensions..................................................... 79

Figure 17 243261SP Mounting Flange Dimensions, Cross Section......................... 79

Figure 18 243261SP Calibration Adapter Dimensions................................................80

3

Page 6

GMP252 User Guide M211897EN-B

List of Tables

Table 1 Document Versions.............................................................................................. 7

Table 2 Related Documents.............................................................................................. 8

Table 3 Applicable Patents................................................................................................8

Table 4 Analog Output Overrange Clipping and Error Limits................................14

Table 5 M12 Male Connector...........................................................................................20

Table 6 Default Serial Interface Settings......................................................................21

Table 7 Basic Serial Commands.....................................................................................26

Table 8 Advanced Serial Commands............................................................................27

Table 9 ? Command.......................................................................................................... 28

Table 10 Errs Command.....................................................................................................28

Table 11 Help Command................................................................................................... 29

Table 12 Snum command.................................................................................................. 29

Table 13 System Command.............................................................................................. 30

Table 14 Time Command...................................................................................................30

Table 15 Vers Command....................................................................................................30

Table 16 Addr Command....................................................................................................31

Table 17 Close Command................................................................................................... 31

Table 18 Form Command................................................................................................... 31

Table 19 Output Parameters for Form Command...................................................... 33

Table 20 Modifiers for Form Command.........................................................................34

Table 21 Intv Command..................................................................................................... 35

Table 22 Open Command.................................................................................................. 35

Table 23 R Command..........................................................................................................36

Table 24 S Command..........................................................................................................36

Table 25 Sdelay Command............................................................................................... 36

Table 26 Send Command................................................................................................... 37

Table 27 Seri Command..................................................................................................... 37

Table 28 Smode Command............................................................................................... 38

Table 29 Amode Command.............................................................................................. 39

Table 30 Aover Command................................................................................................ 40

Table 31 Asel Command.................................................................................................... 43

Table 32 Adate Command................................................................................................ 44

Table 33 Atext Command..................................................................................................45

Table 34 Cdate Command.................................................................................................45

Table 35 Ctext Command..................................................................................................45

Table 36 CCO2 Command................................................................................................. 46

Table 37 Env Command.....................................................................................................49

Table 38 O2cmode Command...........................................................................................51

Table 39 Pcmode Command.............................................................................................52

Table 40 Rhcmode Command.......................................................................................... 53

Table 41 Tcmode Command.............................................................................................54

Table 42 Frestore Command.............................................................................................55

Table 43 Pass Command....................................................................................................55

Table 44 Reset Command................................................................................................. 56

Table 45 Default Modbus Serial Communication Settings....................................... 57

Table 46 Performance.........................................................................................................75

Table 47 Operating Environment.................................................................................... 76

Table 48 Inputs and Outputs.............................................................................................77

Table 49 Mechanics............................................................................................................. 77

Table 50 Supported Function Codes...............................................................................81

4

Page 7

Table 51 Modbus Measurement Data Registers (Read-Only)..................................81

Table 52 Modbus Configuration Data Registers (Writable).....................................82

Table 53 Modbus Status Registers (Read-Only).........................................................84

Table 54 Device Identification Objects.......................................................................... 84

5

Page 8

GMP252 User Guide M211897EN-B

6

Page 9

1. About This Document

1.1. Documentation Conventions

Chapter 1 – About This Document

DANGER!

carefully at this point, death will follow.

WARNING!

carefully at this point, there is a risk of injury or even death.

CAUTION!

carefully at this point, the product could be damaged or important data could be lost.

Note highlights important information on using the product.

Tip gives information for using the product more eciently.

alerts you to a fatal hazard. If you do not read and follow instructions

alerts you to a serious hazard. If you do not read and follow instructions

warns you of a potential hazard. If you do not read and follow instructions

1.2. Version Information

Table 1 Document Versions

Document Code Date Description

M211897EN-B August 2016 Modbus status register values and

descriptions updated.

M211897EN-A May 2016 First version.

7

Page 10

GMP252 User Guide M211897EN-B

1.3. Related Manuals

Table 2 Related Documents

Document Code Description

M211893EN

M211799EN

M211798EN

Vaisala CARBOCAP

GMP252 Quick Guide

Vaisala CARBOCAP

User Guide

Vaisala CARBOCAP

Quick Guide

(R)

Carbon Dioxide Probe

(R)

Carbon Dioxide Probe GMP251

(R)

Carbon Dioxide Probe GMP251

1.4. Trademarks

Vaisala

Windows

(R)

and CARBOCAP

(R)

is either a registered trademark or trademark of Microsoft Corporation in the

United States and other countries.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

(R)

are registered trademarks of Vaisala Oyj.

1.5. Patent Notice

This product is protected by the following patents and their corresponding national rights:

Table 3 Applicable Patents

Patent Issued By Patent Number

United States Patent and Trademark Oce US 5,827,438

US 6,177,673

European Patent Oce EP0776023

EP0922972

German Patent and Trade Mark Oce 69615635

Japan Patent Oce 4263285

Finnish Patent Oce 112005

105598

8

Page 11

1

2 3 4 5

Chapter 2 – Product Overview

2. Product Overview

2.1. Introduction to GMP252

GMP252 is designed for CO2 measurement in demanding applications that require reliable

and accurate performance. The measurement range is 0 ... 10 000 ppmCO2 (measurements

can be carried out in the 10 000 ... 30 000 ppmCO2 range with reduced accuracy).

The probe is based on Vaisala’s patented 2nd generation CARBOCAP

equipped with Vaisala's Microglow infrared light source. The probe is easy to install with a

plug-in/plug-out M12 connection.

GMP252 is able to compensate for temperature, pressure and background gas. For

temperature compensation purposes, the probe includes an internal temperature sensor

that allows measurement compensation according to ambient temperature. As dust and

most chemicals do not

background gas can be compensated for, GMP252 can provide accurate and stable

measurements in a wide range of applications.

aect the measurement, and the eect of temperature, pressure and

(R)

technology and

Figure 1 GMP252 Probe Parts

1 5-pin M12 connector. For pinout, see 3.5. Wiring (page 20).

2 Probe name and orientation mark for Vaisala transmitter installations (front) and laser-

printed type label (back).

3 Probe body. Contains the main component board.

4

Measurement cuvette with optics and CARBOCAP

5 Filter (sintered, PTFE)

CAUTION!

inside the probe body.

Do not attempt to open the probe body. There are no user serviceable parts

(R)

CO2 sensor.

9

Page 12

GMP252 User Guide M211897EN-B

2.2. Basic Features and Options

• CO2 measurement range 0 ... 10 000 ppmCO2.

• Measurement up to 30 000 ppmCO2 with reduced accuracy.

• Operating temperature range -40…+60 °C (-40...140 ºF).

(R)

• Vaisala CARBOCAP

• Measurement compensated for

The temperature compensation can be based on an integrated temperature sensor or

use a set temperature. Pressure and background gas parameters can be set to the

probe.

• Heating to avoid condensation on optical elements.

• Digital output with RS-485:

• Modbus RTU

• Vaisala Industrial Protocol

• Analog output:

• Current output (0 ... 20 mA or 4 ... 20 mA)

• Voltage output (0 ... 5 V or 0...10 V)

• Compatible with MI70 hand-held meter.

• Easy plug-in, plug-out.

CO2 sensor with excellent long-term stability.

eects of temperature, pressure, and background gas.

More Information

‣

GMP252

‣

Operating Principle of CO2 Measurement (page 11)

‣

Environmental Compensation (page 12)

‣

Modbus (page 57)

‣

Overview of MI70 Support (page 58)

Specifications (page 75)

10

Page 13

1

2

3

Chapter 2 – Product Overview

2.3. Operating Principle of CO

Measurement

The Vaisala CARBOCAP

probe is a silicon-based, nondispersive

infrared (NDIR) sensor for the measurement

of gaseous carbon dioxide in air-like gases.

Figure 2 Probe Cuvette with Mirror and Sensor

Chips

1 Mirror

2 Cuvette

3 Sensor chips under TO5 package

2

(R)

sensor used in the

The sensitivity to carbon dioxide is based on absorption of infrared light at a characteristic

wavelength. During measurement, infrared light is routed through the cuvette that contains

the gas to be measured. A mirror

that measures the light intensity at a wavelength determined by a Fabry–Pérot

interferometer (FPI) and a band pass

The carbon dioxide measurement consists of two steps: first, the FPI is electrically tuned so

that its pass band coincides with the characteristic absorption wavelength of carbon dioxide

and the signal is recorded. Second, the pass band is shifted to a wavelength where no

absorption occurs in order to get a reference signal. The ratio of these two signals, one at

the absorption wavelength and the other at the reference wavelength, gives the fraction of

light absorption from which the carbon dioxide concentration is calculated. Measuring the

reference signal compensates the possible

due to dirt on optical surfaces, making the sensor very stable over time.

TO5 packages with hermetic windows are used to protect the sensor chips from moisture

and contamination. A heater chip is utilized to prevent condensation in normal operation.

reflects the light from the cuvette to a thermopile detector

filter.

eects of sensor aging and signal attenuation

11

Page 14

1

2

3

4

6

7

5

GMP252 User Guide M211897EN-B

Figure 3 CO

Measurement Cuvette

1 Gold-plated mirror

2 Light absorbed by CO2 in the measured

gas

3 Hermetic window

4 Fabry-Perot interferometer

5 Light source (Microglow)

6 Hermetic window

7 Thermopile detector

Measurement in the

2

2.4. Environmental Compensation

When necessary, various environmental compensations can be applied to improve the CO

measurement accuracy of the probe.

The probe can compensate for the eects of the following parameters:

• Temperature

• Pressure

• Background gas oxygen (O2) content

• Background gas relative humidity (%RH)

The probe has an on-board temperature sensor that can be used to compensate for

temperature. Additionally, if the probe is integrated in a system that measures one or more

of the compensation parameters (T, P, RH, O2), they can be updated to the probe

continuously.

To apply an accurate relative humidity compensation, make sure that also the temperature

compensation and pressure compensation

environment.

configurations match the measurement

2

12

Page 15

Chapter 2 – Product Overview

Compensation parameters are configured on the order form when ordering the probe, and

can later be updated using Vaisala Industrial Protocol or Modbus protocol.

You can also turn o any of the compensations. In that case, the probe uses the default

compensation value that is mathematically neutral for the probe’s internal compensation

model.

2.4.1. Temperature Compensation

The probe can measure the approximate temperature of the CARBOCAP

compensation, or use a

fixed setpoint. The temperature measurement is accurate enough to

(R)

sensor for

be useful for compensation, and is recommended for use unless a dedicated temperature

measurement is available and can be regularly updated to the probe. If the measurement is

made in a constant temperature, this

fixed temperature setpoint can be set as the

compensation value.

If temperature compensation is turned o, the probe uses the default value of +25 °C

(+77 °F).

When the probe is installed through a

outside the measuring environment, it is possible that temperature conduction from the

probe body and cable outside the measurement environment aects the temperature

compensation and decreases measurement accuracy.

flange and part of the probe and the cable is left

2.4.2. Pressure Compensation

The probe does not have on-board pressure measurement. However, a pressure reading

from an external source can be used as a setpoint value for compensation using Vaisala

Industrial Protocol or Modbus.

If pressure compensation is turned o, the probe uses the default compensation value of

1013 hPa.

2.4.3. Background Gas Compensation

The probe does not have on-board oxygen or relative humidity measurement. However,

oxygen and relative humidity readings from an external source can be used as setpoint

values for compensation using Vaisala Industrial Protocol or Modbus. The default setpoint

values are as follows:

• Oxygen concentration: 0 %O2 or 21 %O

• Relative humidity: 0 %RH or 50 %RH

If background gas compensations are turned

In practice, when CO2 is measured at a ppm level, O2 and RH compensations have a very

eect on the accuracy of the measurement.

small

2

o, the probe uses the value 0 % for both.

13

Page 16

GMP252 User Guide M211897EN-B

2.5. Probe Startup

When powered on, the probe starts up within 12 seconds. Measurements from the outputs

(digital and analog) become available during this time but note that they will only reach

specified accuracy after a 2-minute warm-up period. For this reason, you should design your

system so that it does not rely on measurements from the probe during this time. When the

probe is in analog output mode, the probe remains in an error state during the start-up

phase until measurement output becomes available.

Specifically note that the CO2 reading will rise to the correct reading as the sensor’s

infrared emitter achieves operation temperature.

2.6. Analog Output Overrange Behavior

Analog output of the probe has a defined behavior when the values measured by the probe

are outside the scaled analog output range. At first, the output is clipped when the

measurement exceeds a set limit (the measurement continues, but the output does not

change from the clipped value).

When the measurement exceeds the second limit (error limit), the analog output switches to

the error state

defined for the output. The table below lists the clipping and error limits and

default error state outputs for the analog voltage and current outputs.

Table 4 Analog Output Overrange Clipping and Error Limits

Output voltage / current Clipping Limit Error Limit Default Error State Output

0 ... 5 V >5 % >10 % 0 V

0 ... 10 V >1 % >10 % 0 V

0 ... 20 mA >5 % >10 % 23 mA

4 ... 20 mA >5 % >10 % 2 mA

The same clipping and error limits are applied when the measured value drops back to the

scaled range: at

first the output returns to the clipped value from the error state, and then to

normal output.

Clipping and error state limits

the limits are 1 % and 10 %, and for 0 ... 5 V output the limits are 5 % and 10 %.

dier for 0 ... 10 V and 0 ... 5 V outputs. For 0 ... 10 V output

14

Page 17

More Information

Output

voltage (V)

Time

0.00

In error state at

>2200 ppm

(2000 ppm + 10%)

5.00

5.25

Clipped at

2100 ppm

(2000 ppm + 5%)

Regular

measurement

Output clipping limit

Error level

‣

Analog Output Error State (page 74)

2.6.1. Analog Output Overrange Example

Consider a probe with 0 ... 5 V output, scaled to 0 ... 2000 ppmCO2.

Chapter 2 – Product Overview

• When the measured CO

rises above 2000 ppmCO2, the output rises above 5 V.

2

• The output keeps rising until the measurement is 2100 ppmCO2, at which point the

probe outputs 5.25 V.

• If the CO2 level rises above 2100 ppmCO2, the output still remains at 5.25 V.

• If the CO2 level rises above 2200 ppmCO2, the output enters the error state, which is 0

V for the 0 ... 5 V output.

Figure 4 Example of Analog Output Overrange Behavior

This example uses output scaled to 0 ... 5 V and 0 ...2000 ppmCO2, error level set to 0 V,

clipping set to 5 % overrange, and error limit set to 10 % overrange. CO2 concentrations

(ppm) are indicated for the clipping point and error limit point.

This overrange and error behavior is

readings of the digital outputs.

You can change the analog output overrange behavior using the aover command.

specific to the analog output, and does not aect the

15

Page 18

GMP252 User Guide M211897EN-B

2.7. Safety

The probe delivered to you has been tested for safety and approved as shipped from the

factory. Note the following precautions:

WARNING!

been exposed to dangerous contamination, and is safe to handle without special

precautions.

CAUTION!

lead to malfunction.

CAUTION!

inside the probe body.

When returning a product for calibration or repair, make sure it has not

Do not modify the unit. Improper modification can damage the product or

Do not attempt to open the probe body. There are no user serviceable parts

2.7.1. ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to electronic circuits.

Vaisala products are adequately protected against ESD for their intended use. However, it is

possible to damage the product by delivering electrostatic discharges when touching an

exposed contact on the product.

To make sure you are not delivering high static voltages yourself, avoid touching the pins on

the M12 connector.

2.8. Regulatory Compliances

The probe is in conformity with the provisions of the following EU directives:

• RoHS Directive

• EMC Directive

Conformity is shown by compliance with the following standards:

• EN 50581: Technical documentation for the assessment of electrical and electronic

products with respect to the restriction of hazardous substances.

• EN 61326-1: Electrical equipment for measurement, control, and laboratory use – EMC

requirements – Generic environment.

• EN 55022: Information technology equipment – Radio disturbance characteristics –

Limits and methods of measurement.

16

Page 19

3. Installation

12 mm 76 mm 42 mm

130 mm, Ø 25 mm

3.1. GMP252 Probe Dimensions

The dimensions are given in millimeters (mm).

Chapter 3 – Installation

Figure 5 GMP252 Dimensions

3.2. Recommended Installation

The probe can be installed in an environment with an operating temperature range -40 ...

+60 °C (-40 ... +140 °F). Make sure the probe is in a location that represents the

measurement environment properly.

The 5-pin male M12 connector on the probe provides an easy plug-in/plug-out connection to

a compatible cable.

3.3. Installation Accessories

The probe can be installed through a surface using the optional

product code 243261SP, or attached for example to a wall with the optional clip accessory

(two-clip set, Vaisala product code 243257SP.

More Information

‣

Spare Parts and Accessories (page 78)

flange accessory (Vaisala

17

Page 20

1

2

3

GMP252 User Guide M211897EN-B

3.3.1. 243261SP Installation Flange

The optional flange accessory is used to install the probe body through a wall or other

surface.

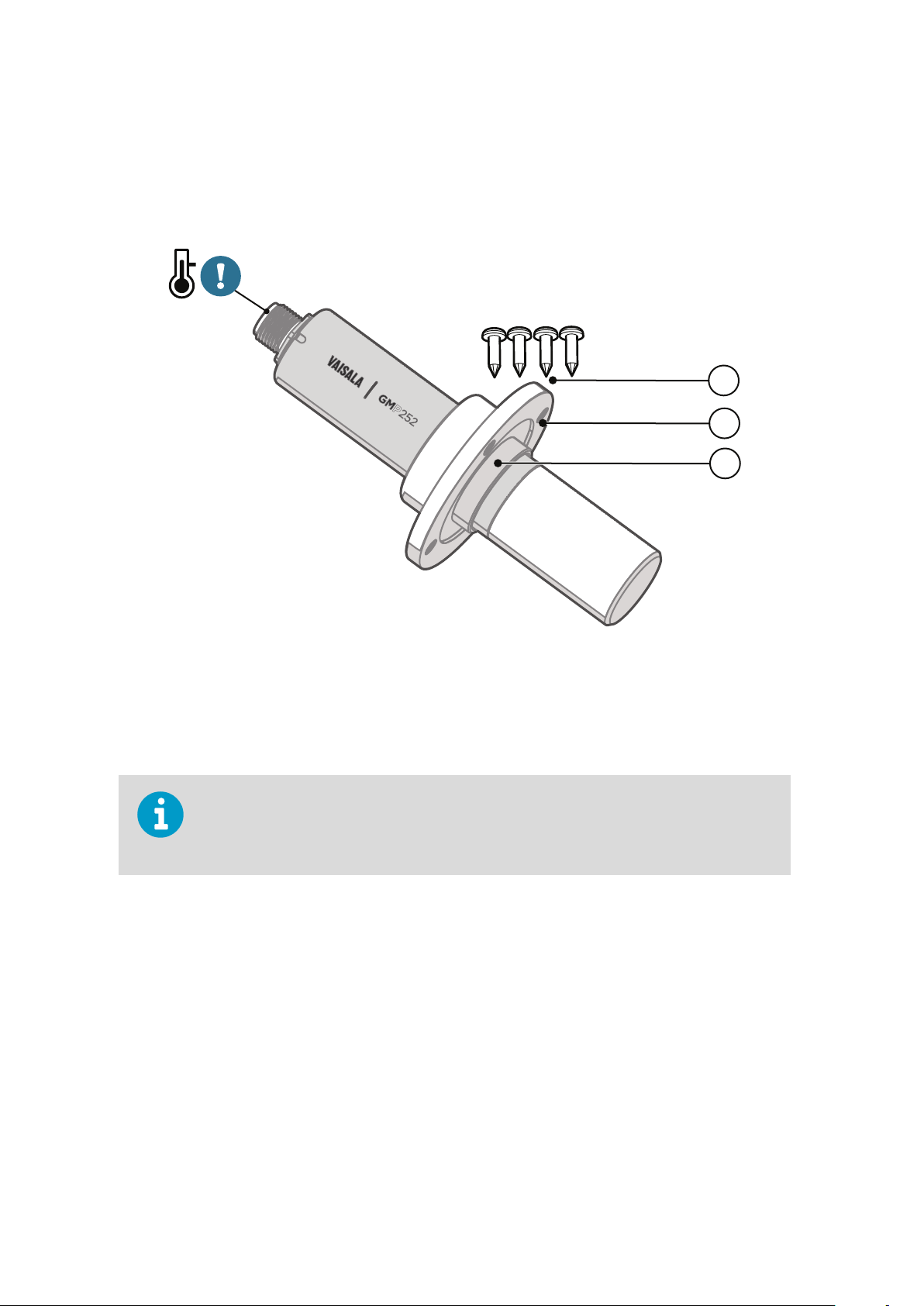

Figure 6 Probe with 243261SP Installation Flange

1 4 Phillips head screws (included)

2 Installation flange (diameter 60 mm) with four Ø 4.2 mm screw holes

3 Gasket ring

Leaving part of the probe body and the cable outside the measurement environment can

cause heat conduction that aects the temperature compensation and measurement

accuracy.

More Information

‣

243261SP Mounting Flange Dimensions (page 79)

18

Page 21

Ø 4.2 mm

Chapter 3 – Installation

3.3.2. 243257SP Mounting Clips

The optional mounting clips (set of two clips) are used to hold the probe in place for

example on a wall or other surface. Each clip base attaches to the installation surface with

one screw (screw hole Ø 4.2 mm).

Figure 7 Probe in 243257SP Mounting Clips

3.4. Power Supply

The supply voltage range of the probe is 12 ... 30 VDC with the digital output option. If the

analog output is used, the supply voltage range is 12 ... 30 VDC for voltage output and

20 ... 30 VDC for current output.

Typical power consumption is less than 0.4 W in continuous operation, and the maximum is

0.5 W.

19

Page 22

1

5

3

4

2

GMP252 User Guide M211897EN-B

3.5. Wiring

Table 5 M12 Male Connector

Pin# Function Note Cable 223263SP

Wire Colors

1 Power in • With digital output: 12 ... 30 VDC

• With voltage output: 12 ... 30 VDC

• With current output: 20 ... 30 VDC

Typical average power consumption <0.4 W, maximum

0.5 W.

2 RS-485-

or voltage

output

3 GND – Blue

4 RS-485 +

or current

output

5 Output control Connecting pin #5 to GND (pin #3) forces the probe to

Voltage:

0 ... 5 VDC or 0 ... 10 VDC (default analog output scaling)

Current:

0 … 20 mA or 4 ... 20 mA (default analog output scaling)

analog output mode. If an analog output configuration

has not been selected, default 0...10 VDC and 4...20 mA

scalings are used.

If pin #5 is not connected, the analog or digital output

selected when ordering or set later through

configuration is used.

Brown

White

Black

Gray

20

Note that the probe always remains in analog mode when pin #5 is connected to pin #3,

and cannot be switched to digital output in this wiring option.

Page 23

Chapter 4 – Vaisala Industrial Protocol

4. Vaisala Industrial Protocol

4.1. Overview

RS-485 line of the probe provides an implementation of the Vaisala Industrial Protocol that

can be used for service and configuration use, or for interfacing with the system to which

the probe is integrated. The protocol is a plaintext protocol suitable for use both by human

operators and automated systems.

4.2. Serial Interface Settings

Table 6 Default Serial Interface Settings

Property Description/Value

Bit rate 19200

Parity None

Data bits 8

Stop bit 1

Flow control None

4.3. Physical Interface

The physical interface is a non-isolated 2-wire interface. The data lines are RS-485 D- and

RS-485 D+. Ground is shared with power supply. The connector is a 5-pin male M12.

More Information

‣

Wiring (page 20)

21

Page 24

GMP252 User Guide M211897EN-B

4.4. Connecting with a Computer

• Vaisala USB service cable (order code 242659)

• Computer with:

• Windows operating system

• Terminal application (for example PuTTy, available from www.vaisala.com/

software)

• Free USB port

• Driver for Vaisala USB service cable installed (available on the cable installation

media and at www.vaisala.com/software)

The steps below describe how to connect to the probe using the PuTTY terminal application

for Windows and a USB computer connection cable. Connecting with a computer allows you

to

configure and troubleshoot your probe using serial line commands.

1. If you have not used the Vaisala USB cable before, install the driver before attempting

to use the cable.

2. Connect the USB serial interface cable between your computer and the M12 connector

of the probe.

3. Start the PuTTY application.

4. Select Connection > Serial & USB and check that the correct COM port is selected in

the Serial or USB line to connect to

field. If you are using the PuTTY terminal

application supplied by Vaisala, you can press the USB Finder button to open the

Vaisala USB Instrument Finder program.

5. Check that the other serial settings are correct for your connection, and change if

necessary. Flow control should be set to None unless you have a reason to change it.

22

Page 25

Chapter 4 – Vaisala Industrial Protocol

6. Select Terminal. Use the following settings:

• Local Echo

Select Force on. This setting ensures that your typing is shown on the session

window.

• Send line ends with line feeds (CR+LF)

Set to Selected. This setting ensures that all text lines remain visible on the

session window.

7. To open the connection window and start using the serial line, select Open.

If PuTTY is unable to open the serial port you selected, it shows you an error message

instead. If this happens, restart PuTTY and check the settings.

More Information

‣

Serial Interface Settings (page 21)

‣

Installing the Driver for the USB Service Cable (page 23)

4.4.1. Installing the Driver for the USB Service Cable

Before taking the USB service cable into use for the

USB driver on your computer (requires Windows). When installing the driver, you must

accept any security prompts that may appear.

1. Check that the USB service cable is not connected. Disconnect the cable if you have

already connected it.

2. Insert the media that came with the cable, or download the latest driver from

www.vaisala.com/software.

3. Run the USB driver installation program (setup.exe), and accept the installation

defaults. The installation of the driver may take several minutes.

4. After the driver has been installed, connect the USB service cable to a USB port on your

computer. Windows will detect the new device, and use the driver automatically.

5. The installation has reserved a COM port for the cable. Verify the port number, and the

status of the cable, using the Vaisala USB Instrument Finder program that has been

installed in the Windows Start menu. Windows will recognize each individual service

cable as a

port in the settings of your terminal program.

dierent device, and reserve a new COM port. Remember to use the correct

first time, you must install the provided

4.5. Accessing Serial Commands from Modbus or Analog Mode

1. Connect the USB cable to your PC and start the terminal application as instructed in

4.4. Connecting with a Computer (page 22).

23

Page 26

GMP252 User Guide M211897EN-B

2. Start a new terminal session using the default serial settings.

3. Keep the Enter key pressed down and connect the probe to the USB cable. When the

probe is powered on (connected to your PC with the USB cable), you must send five

carriage returns (Enter key presses) within 0.7 seconds to force the probe to serial

command mode. The probe model information appears in the terminal application

when the mode has been succesfully changed, and Vaisala Industrial Protocol

commands are available for use.

4. To test the connection, enter for example the ? command. If the mode change failed,

close the terminal application, disconnect the probe from the USB cable, and repeat

step 2 and step 3.

5. To keep the serial mode in use (forced serial mode access is temporary and switches

at reset), select a serial output option (stop/run/poll) with the smode command.

Note that the probe always remains in analog mode when pin #5 is connected to pin #3,

and cannot be switched to digital output in this wiring option.

More Information

‣

Serial Interface Settings (page 21)

‣

Enabling Modbus Mode from Vaisala Industrial Protocol (page 24)

4.6. Enabling Modbus Mode from Vaisala Industrial Protocol

If you need to switch from Vaisala Industrial Protocol to Modbus mode, you must

the following settings:

• Serial line operating mode

• Modbus address

• Serial line settings (bit rate, parity, stop and data bits)

configure

o

1. Connect the USB cable to your PC and start the terminal application as instructed in

4.4. Connecting with a Computer (page 22).

2. Set the serial mode to Modbus with the smode command:

smode modbus

24

Page 27

Chapter 4 – Vaisala Industrial Protocol

3. Set the Modbus address to 240 with the addr command:

addr 240

4. Set the serial line settings to 19200/N/8/2 with the seri command:

seri 19200 N 8 2

5. Power

configuration is available at the next restart.

More Information

‣

Accessing Serial Commands from Modbus or Analog Mode (page 23)

o (disconnect) the probe or reset with the reset command. The new

4.7. Changing From Digital Output to Analog Output

1. Set up a terminal connection as instructed in 4.4. Connecting with a Computer

(page 22).

2. Change the mode from digital to analog with the smode serial command: smode

analog.

3. Reset the probe (disconnect and reconnect the cable or use the reset serial command)

to power on in analog output mode.

More Information

‣

Accessing Serial Commands from Modbus or Analog Mode (page 23)

4.8. Serial Commands

The notation <cr> refers to the carriage return control character, which you can send in a

terminal application by pressing enter on your keyboard. Before entering commands, send a

<cr> to clear the command

You can enter the commands in uppercase or lowercase. In the command examples, the

keyboard input by the user is in bold type.

Table 7 (page 26) lists the basic serial commands that are available by default. To access

advanced serial commands (listed in Table 8 (page 27)), enter the command pass 1300.

buer.

25

Page 28

GMP252 User Guide M211897EN-B

Table 7 Basic Serial Commands

Command Description

Device information and status

?

??

errs

help

snum

system

time

vers

Serial line output and communication

close

form [modifier string]

intv [0 ... 255 s/min/h]

open [address]

Show probe information.

Show probe information (will respond in POLL mode).

Show currently active errors.

Show list of currently available serial commands.

Show probe serial number.

Show probe firmware information.

Show probe operation hours and uptime.

Show probe firmware version.

Close connection to probe (POLL mode)

Show or set output format.

Set continuous output interval for R command.

Open connection to probe in POLL mode.

r

s

sdelay [0 ... 255]

send

seri [baud data stop

parity]

smode [mode]

Environmental compensation

env

Adjustment information

adate

atext

Other commands

Start the continuous outputting.

Stop the continuous outputting.

Show or set serial line transmission delay in milliseconds.

Output a single measurement message.

Show or set the serial interface settings.

Show or set startup serial mode: RUN, STOP, or POLL.

Show or set environmental parameters.

Show CO2 factory adjustment date.

Show CO2 factory adjustment information.

26

Page 29

Command Description

Chapter 4 – Vaisala Industrial Protocol

reset

pass [1300]

Reset the probe.

Access advanced serial commands.

Table 8 Advanced Serial Commands

Command Description

Serial line output and communication

addr [0 … 254] Show or set probe address.

Analog output

amode

aover

asel

Calibration and adjustment

cco2

Show or set analog output mode (analog output limits and error level).

Show or set analog output overrange and clipping behavior.

Show or set analog output parameter and scaling.

Adjust CO2 measurement gain and oset.

cdate

ct

ctext

Environmental compensation

o2cmode

pcmode

rhcmode

tcmode

Other commands

frestore

Show or set calibration date.

Adjust temperature measurement oset.

Show or set calibration information.

Show or set oxygen compensation mode.

Show or set pressure compensation mode.

Show or set humidity compensation mode.

Show or set temperature compensation mode.

Restore probe to factory settings.

27

Page 30

GMP252 User Guide M211897EN-B

4.9. Device Information and Status

Table 9 ? Command

Syntax Description

?<cr>

??<cr>

Example:

?

Device : GMP25x

Copyright : Copyright (c) Vaisala Oyj 2016. All rights

reserved.

SW Name : GMP25x

SW version : 1.0.0

SNUM : GMP233_5_18

SSNUM : S1234567

CBNUM : c1234567

Calibrated : 20160504 @ Vaisala/R&D

Address : 0

Smode : STOP

Show listing of device information.

Show listing of device information even if device is in

poll mode and connection has not been opened

using the open command.

Table 10 Errs Command

Syntax Description

errs<cr>

Example (no active errors):

errs

NO CRITICAL ERRORS

NO ERRORS

NO WARNINGS

STATUS NORMAL

28

Show active error(s). For a list of possible errors and

their remedies, see 8.2. Error Messages (page 72).

Page 31

Table 11 Help Command

Syntax Description

Chapter 4 – Vaisala Industrial Protocol

help<cr>

Example (showing a list of the basic commands):

help

ADATE

ADDR

ATEXT

CLOSE

ENV

ERRS

FORM

HELP

INTV

PASS

RR

ESET

RX

SDELAY

SEND

SENDX

SERI

SMODE

SNUM

SYSTEM

UNIQID

TIME

VERS

Show list of currently available serial commands.

Table 12 Snum command

Syntax Description

snum<cr>

Example:

snum

SNUM : M0220028

Show serial number of the probe.

29

Page 32

GMP252 User Guide M211897EN-B

Table 13 System Command

Syntax Description

system<cr>

Show probe firmware information.

Example:

system

Device Name : GMP25x

SW Name : GMP25x

SW version : 1.0.0

Operating system : TSFOS1.0

Table 14 Time Command

Syntax Description

time<cr>

Example:

Show how long the probe has been in operation

since the last startup or reset.

The operation counter is in format hh:mm:ss.

time

Time : 01:41:24

Table 15 Vers Command

Syntax Description

vers<cr>

Example:

vers

SW version : 1.0.0

Show firmware version of the probe.

30

Page 33

4.10. Serial Line Output and Communication

Table 16 Addr Command

Syntax Description

Chapter 4 – Vaisala Industrial Protocol

addr<cr>

addr [aaa]<cr>

Example (shows 0 as current address, enter 5 as the new address):

addr

Address : 0

addr 5

Address : 5

Show current device address. Addresses are required

for POLL mode.

Set new device address. aaa = address, 0 ... 254

(default = 0)

Table 17 Close Command

Syntax Description

close<cr> Close the connection that was opened with the open

command.

Example:

close

line closed

Table 18 Form Command

Syntax Description

form<cr>

form /<cr>

Show the currently used measurement format.

Reset measurement format to default.

31

Page 34

GMP252 User Guide M211897EN-B

Syntax Description

form [sss]<cr>

Set a new measurement format.

sss = String consisting of modifiers and

abbreviations for measured parameters.

See Table 19 on the facing page and Table 20 on the

facing page.

Maximum length is 150 characters. Maximum length

may be shorter when text strings are used.

Example (show currently used measurement format (default format shown here)):

form

6.0 "CO2=" CO2 " " U3 #r #n

Output example (continuous output from RUN mode):

CO2= 452 ppm

Example (set output format as %CO

):

2

form 3.1 "CO2=" CO2% " " U4 #r #n

OK

Output example (continuous output from RUN mode):

CO2= 5.1 %CO2

CO2= 5.1 %CO2

CO2= 5.0 %CO2

...

32

Page 35

Syntax Description

Example (set output format as CO2 ppm with Modulus-65536 checksum):

form 6.0 "CO2=" CO2 " " U3 " " CS4 #r #n

OK

Output example (continuous output from RUN mode):

CO2= 3563 ppm 9F

CO2= 3562 ppm 9E

CO2= 3559 ppm A4

...

Chapter 4 – Vaisala Industrial Protocol

Example (set output format as CO

ppm, with start of text (ASCII character 002) and end of text (003) ASCII

2

codes, and without line feed and carriage return at the end):

form #002 6.0 "CO2=" CO2 " " U3 #003

OK

Output example (continuous output from RUN mode, ASCII codes not visible here):

CO2= 866 ppm CO2= 866 ppm CO2= 867 ppm CO2= 867 ppm

CO2= 867 ppm CO2= 868 ppm CO2= 868 ppm CO2= 869 ppm

...

Table 19 Output Parameters for Form Command

Output Parameter Abbreviation in Form Command

Carbon dioxide in ppm

Carbon dioxide in percent

Currently used temperature compensation value

Currently used pressure compensation value

co2

co2%

tcomp

pcomp

33

Page 36

GMP252 User Guide M211897EN-B

Output Parameter Abbreviation in Form Command

Currently used oxygen concentration compensation

o2comp

value

Currently used relative humidity compensation value

rhcomp

Table 20 Modifiers for Form Command

Modifier Description

x.y

#t

#r

#n

""

#xxx

addr

Length modifier (number of digits and decimal

places).

Tabulator.

Carriage-return.

Line feed.

String constant, length 1 ... 15 characters.

ASCII code value (decimal) of a special character; for

example, #027 for ESC.

Probe address (0 ... 254).

sn

time

ux

cs4

csx

Probe serial number.

Cumulative operating hours of the probe.

Name of the measurement unit using x number of

characters. For example, u3 shows the name of the

measurement unit with three characters.

Modulus-65536 checksum of message sent so far,

ASCII encoded hexadecimal notation.

NMEA xor-checksum of message sent so far, ASCII

encoded hexadecimal notation.

You can also use the backslash character \ instead of the hash character #.

34

Page 37

Table 21 Intv Command

Syntax Description

Chapter 4 – Vaisala Industrial Protocol

intv<cr>

intv [iii uuu]<cr>

Example:

intv 5 s

Output interval: 5 S

Table 22 Open Command

Show the output interval of the automatically

repeating measurement messages (r command and

run mode).

Set the output interval.

iii = interval, range 0 ... 255.

u = unit for interval setting:

• s = seconds

• min = minutes

• h = hours

If you set the interval to 0, the output messages are

output as quickly as they are generated, without

additional delay.

Syntax Description

open [aaa]<cr>

Open a connection to a device at the specified

address. Required when device is in poll mode.

aaa = address, range 0 ... 254.

Example (target probe in POLL mode, with address 52):

open 52

GMP25x: 52 Opened for operator commands

35

Page 38

GMP252 User Guide M211897EN-B

Table 23 R Command

Syntax Description

r<cr>

Start the continuous outputting of measurement

values as an ASCII text string to the serial line. The

probe keeps outputting measurement messages at

the interval that has been set with the intv

command until stopped with the s command.

Example:

r

CO2= 1024 ppm

CO2= 1024 ppm

CO2= 1028 ppm

CO2= 1026 ppm

CO2= 1028 ppm

...

Table 24 S Command

Syntax Description

s<cr>

Stop the continuous outputting that was started with

the r command.

Example:

...

CO2= 658 ppm

CO2= 654 ppm

CO2= 655 ppm

s

Table 25 Sdelay Command

Syntax Description

sdelay<cr>

sdelay [delay]<cr>

Show serial line transmission delay in milliseconds.

Set a new serial line transmission delay.

delay = Serial line delay, range 0 … 255

(milliseconds).

36

Page 39

Syntax Description

Example (set delay to 50 milliseconds):

sdelay 50

COM transmit delay : 50

Table 26 Send Command

Syntax Description

Chapter 4 – Vaisala Industrial Protocol

send<cr>

send [aaa]<cr>

Example:

send

CO2= 1422 ppm

Example (target probe in POLL mode, with address 52):

send 52

CO2= 458 ppm

Output a single measurement message.

Output a single measurement message from a device

in poll mode.

aaa = address of the probe, range range 0 ... 254

Table 27 Seri Command

Syntax Description

seri<cr>

Show current serial line settings.

37

Page 40

GMP252 User Guide M211897EN-B

Syntax Description

seri [b p d s]<cr>

Example (show current settings):

seri

Com1 Baud rate : 19200

Com1 Parity : N

Com1 Data bits : 8

Com1 Stop bits : 1

Set new serial line settings. The new settings will be

taken into use when the probe is reset or powered

up.

b = baud rate (9600, 19200, or 38400)

p = parity

• n = none

• e = even

• o = odd

d = data bits (7 or 8)

s = stop bits (1 or 2)

For Modbus, baud rate must be 9600 ... 38400 and

parity must be none.

Example (set serial line to 9600 baud, even, 7 data bits, and 1 stop bit, and reset the probe to take the new

settings in use):

seri 9600 e 7 1

OK

seri

Com1 Baud rate : 9600

Com1 Parity : E

Com1 Data bits : 7

Com1 Stop bits : 1

reset

GMP25x 1.0.0

Table 28 Smode Command

Syntax Description

smode<cr>

Show current start-up operating mode of the serial

line, and prompt to enter new mode.

38

Page 41

Syntax Description

Chapter 4 – Vaisala Industrial Protocol

smode [mode]<cr>

Example (set serial mode to "poll"):

Set serial line start-up operating mode. New mode is

taken into use when the device is reset or powered

up.

Available modes:

stop = No automatic output. All commands

available. Default mode.

run = Automatic output of measurement messages.

You can stop the output with the s command, and

recontinue with the r command.

poll = No automatic output. Will respond to

addressed send command and ?? command. You

can use other commands after opening a connection

using an addressed open command. Use with RS485 buses where multiple probes can share the same

line.

modbus = Serial line communication uses the

Modbus protocol. Serial line commands (Vaisala

Industrial Protocol) are not accessible in the Modbus

mode.

analog = Switches the probe from digital output to

analog output (active after probe reset). Serial line

commands are not accessible in the analog mode.

smode poll

Serial mode : POLL

4.11. Analog Output

Table 29 Amode Command

Syntax Description

amode [channel]<cr>

Show currently set analog output limits and error

level.

channel = Analog output channel

• 1 = voltage output (V)

• 2 = current output (mA)

39

Page 42

GMP252 User Guide M211897EN-B

Syntax Description

amode [channel lo_value hi_value

error_value]<cr>

Set new analog output limits and error output value.

channel = Analog output channel

• 1 = voltage output (V)

• 2 = current output (mA)

lo_value = Low limit of the channel.

hi_value = High limit of the channel.

error_value = Error value of the channel.

Example (show current configuration):

pass 1300

amode 1

Aout 1 range (V) : 0.00 ... 10.00 (error : 0.00)

amode 2

Aout 2 range (mA) : 4.00 ... 20.00 (error : 2.00)

Example (set channel 1 to 0 … 5 V, and error output to 0.0 V; set channel 2 to 0 ... 20 mA, and error output to

23 mA):

amode 1 0 5 0.0

Aout 1 range (V) : 0.00 ... 5.00 (error : 0.00)

amode 2 0 20 23

Aout 2 range (mA) : 0.00 ... 20.00 (error : 23.00)

Table 30 Aover Command

Syntax Description

aover [channel<cr>

Show the behavior of the analog output when the

measured value is outside the scaled output range.

channel = Analog output channel

• 1 = voltage output (V)

• 2 = current output (mA)

40

Page 43

Syntax Description

Chapter 4 – Vaisala Industrial Protocol

aover [channel clipping error_

limit]<cr>

Set the behavior of the analog output when the

measured value is outside the scaled output range.

channel = Analog output channel

• 1 = voltage output (V)

• 2 = current output (mA)

clipping = Output margin (%) at which the output

is clipped.

error_limit = Measurement value margin (%) at

which the output of the channel goes into the error

state. The current or voltage output of the error state

is

defined using the amode command.

Example (view currently set analog output overrange behavior on channel 1):

pass 1300

aover 1

Aout 1 clipping :5.00 %

Aout 1 error limit :10.00 %

41

Page 44

GMP252 User Guide M211897EN-B

Syntax Description

Example (for channel 1):

1. View currently set analog output scaling (asel command), limits and error level (amode command),

and overrange behavior (aover command):

pass 1300

asel 1

Aout 1 quantity : CO2(0 ... 2000)

amode 1

Aout 1 range (V) : 0.00 ... 5.00 (error : 0.00)

aover 1

Aout 1 clipping :1.00 %

Aout 1 error limit :5.00 %

2. Set analog output overrange clipping to 5 % and error limit to 10 %:

aover 1 5 10

Aout 1 clipping : 5.00 %

Aout 1 error limit : 10.00 %

The analog output now behaves like this:

• Clipping is now set to 5.00 %, meaning the voltage output is allowed to vary between 0 ... 5.25 V. The

analog channel will output the measurement for 0 ... 2100 ppmCO2, but range 0 ... 5 V remains scaled to

0 ... 2000 ppmCO2.

• Error limit is 10 %, which means the output will show the error state (0 V) when the measured CO

concentration is 10 % outside the scaled output range. With the settings above, this will happen if the

measured CO2 concentration is outside range 0 ... 2200 ppmCO2.

• The voltage output will never be above 5.25 V because of clipping: the voltage output is clipped when

the output reaches 5.25 V, and if the measured CO2 concentration keeps rising above 2200 ppmCO2,

the output jumps directly to the error state 0 V.

2

42

Page 45

Syntax Description

Output

voltage (V)

Time

0.00

In error state at

>2200 ppm

(2000 ppm + 10%)

5.00

5.25

Clipped at

2100 ppm

(2000 ppm + 5%)

Regular

measurement

Output clipping limit

Error level

Chapter 4 – Vaisala Industrial Protocol

Figure 8 Example of analog output overrange behavior

The example shown above uses output scaled to 0 ... 5 V and 0 ... 2000 ppmCO2, has error level set to 0 V,

clipping set to 5 % overrange, and error limit set to 10 % overrange. CO2 concentrations (ppm) are indicated

for the clipping point and error limit point

Table 31 Asel Command

Syntax Description

asel [channel]<cr>

asel [channel] [parameter lowlimit

highlimit]<cr>

Show the parameter and scaling of the analog

output in ppm.

channel = Analog output channel

• 1 = voltage output (V)

• 2 = current output (mA)

Set the parameter and scaling of the analog output.

channel = Analog output channel

parameter = Parameter that is output on analog

channel. The only parameter available is CO2 (in

ppm).

lowlimit = Lower limit of channel scaling in ppm.

Minimum value is -1000000 ppm (= - 100 %).

highlimit = High limit of channel scaling in ppm.

Maximum value is 1000000 ppm (= 100 %).

43

Page 46

GMP252 User Guide M211897EN-B

Syntax Description

Example (for channel 1, show the currently set analog output parameter and scaling):

pass 1300

asel 1

Aout 1 quantity : CO2(0 ... 10000 ppm)

Example (for channel 1, set scaling to 0 ... 4000 ppmCO2):

pass 1300

asel 1 co2 0 4000

Aout 1 quantity : CO2(0 ... 4000 ppm)

4.12. Calibration and Adjustment

CAUTION!

Calibration and Adjustment (page 68). Make sure that the environmental

compensation settings of the probe are properly set for your calibration environment;

see 2.4. Environmental Compensation (page 12).

Table 32 Adate Command

Syntax Description

adate<cr>

Example:

adate

Adjustment date : 20150420

Before using the calibration and adjustment commands, read through 7.3.

Show CO2 factory adjustment date.

44

Page 47

Chapter 4 – Vaisala Industrial Protocol

Table 33 Atext Command

Syntax Description

atext<cr> Show CO2 factory adjustment information.

Example:

atext

Adjusted at Vaisala/Helsinki

Table 34 Cdate Command

Syntax Description

cdate<cr>

cdate [yyyymmdd]<cr>

Example:

pass 1300

cdate

Calibration date : 20150220

Example (set a new calibration date to June 30, 2015):

cdate 20150630

Calibration date : 20150630

Show calibration date.

Set a new calibration date.

yyyymmdd = Year (yyyy), month (mm) and day (dd)

of calibration

Table 35 Ctext Command

Syntax Description

ctext<cr>

ctext [text]<cr>

Show calibration information text.

Set a new calibration information text to be shown

after the automatic text "Calibrated at".

45

Page 48

GMP252 User Guide M211897EN-B

Syntax Description

Example:

pass 1300

ctext

Calibrated at 500 ppm in lab

Example (set a new information text):

ctext 0/1000 by NN

Calibrated at 0/1000 ppm by NN

Table 36 CCO2 Command

Syntax Description

cco2<cr>

cco2 -lo [co2]<cr>

cco2 -hi [co2]<cr>

cco2 -save<cr>

cco2 -cancel<cr>

cco2 -reset<cr>

Show current user adjustment status.

Perform a 1-point (only either low or high

concentration) or 2-point (both low and high

concentrations) calibration and adjustment.

-lo = Adjustment at low concentration (under 1000

ppmCO2)

-hi = Adjustment at high concentration (over 2000

ppmCO2)

co2 = CO2 concentration reference in ppm

Save the currently entered adjustments.

Successfully saving the adjustment clears the

calibration date (cdate command) and calibration

text (ctext command) that have been stored in the

probe. Use those commands to enter a new

calibration date and text.

Cancel currently entered adjustments.

Clear user adjustments.

46

Page 49

Syntax Description

Example (show current user adjustment status; no adjustment done):

pass 1300

cco2

1.Ref. point low 0

1.Meas. point low 0

2.Ref. point high 3000

2.Meas. point high 3000

Gain : 1.0000

Offset : 0.0000

Example (perform a 1-point calibration):

1. Let the probe stabilize in the desired CO2 concentration (here: 500 ppmCO2).

2. Enter the calibration commands:

Chapter 4 – Vaisala Industrial Protocol

pass 1300

cco2 -lo 500

OK

cco2 -save

OK

3. Enter a new calibration date and information text:

cdate 20160325

Calibration date : 20160325

ctext 500 ppm in lab

Calibrated at 500 ppm in lab

47

Page 50

GMP252 User Guide M211897EN-B

Syntax Description

Example (perform 2-point calibration):

1. Let the probe stabilize in the desired low CO2 concentration (here: 200 ppmCO2).

2. Enter the calibration commands:

pass 1300

cco2 -lo 200

OK

cco2 -save

OK

3. Let the probe stabilize in the desired high CO2 concentration (here: 3000 ppmCO2).

4. Enter the calibration commands:

pass 1300

cco2 -hi 3000

OK

cco2 -save

OK

5. Enter a new calibration date and information text:

pass 1300

cdate 20160425

Calibration date : 20160425

ctext 200/3000 ppm

Calibrated at 200/3000 ppm

4.13. Environmental Compensation Commands

To apply an accurate relative humidity compensation, the temperature and pressure

compensation

rhcmode, tcmode and pcmode commands for instructions on enabling compensation

configuration, and env command for instructions on setting a compensation value.

48

configurations must also match your measurement environment. See the

Page 51

For more information on environmental compensation and the default (neutral)

compensation values used for disabled compensations, see 2.4. Environmental

Compensation (page 12)

Table 37 Env Command

Syntax Description

Chapter 4 – Vaisala Industrial Protocol

env<cr>

env [temp | pres | oxy | hum]

[value]<cr>

Show current compensation values.

Before using this command, you must enable

environmental compensation using the following

commands:

• o2cmode [on]

• pcmode [on]

• rhcmode [on]

• tcmode [on | measured]

Set new permanent compensation values and store

them in eeprom.

Eeprom:

• Non-volatile memory, values retained during

power o.

• Number of writes is limited to 30000 cycles by

memory implementation.

• Must only be used for writing permanent

values, to avoid wearing out the eeprom.

temp = Compensation temperature. Range -40 ...

+100 °C.

pres = Compensation pressure. Range 500 ... 1100

hPa.

oxy = Oxygen content of background gas. Range

0 ... 100 %.

hum = Relative humidity of background gas. Range

0 ... 100 %.

49

Page 52

GMP252 User Guide M211897EN-B

Syntax Description

env [xtemp | xpres | xoxy | xhum]

[value]<cr>

Set new compensation values and store them in

RAM.

RAM: n Volatile memory that loses the values when

probe is reset, and where values are loaded from

non-volatile memory at startup. n Must be used for

continuously updated values.

xtemp = Compensation temperature stored in RAM.

Range -40 ... 100 °C.

xpres = Compensation pressure stored in RAM.

Range 500 ... 1100 hPa.

xoxy = Oxygen content of background gas stored

in RAM. Range 0 ... 100 %.

xhum = Relative humidity of background gas stored

in RAM. Range 0 ... 100 %.

Note: If temperature

compensation is configured to

use an internally measured value

(tcmode is set to measured), it

will continuously update the

value in RAM, overriding any

temperature value that is written

to RAM with the ENV command.

Example (Show current compensation values; all compensations are enabled. Note that temperature

compensation is in "measured" mode, so the value in use is constantly changing):

env

In eeprom:

Temperature (C) : 8.00

Pressure (hPa) : 1013.00

Oxygen (%O2) : 21.00

Humidity (%RH) : 30.00

In use:

Temperature (C) : 4.90

Pressure (hPa) : 1013.00

Oxygen (%O2) : 19.70

Humidity (%RH) : 27.00

50

Page 53

Chapter 4 – Vaisala Industrial Protocol

Syntax Description

Example (set temperature compensation to setpoint mode, and change temperature setpoint value to

5.00 °C in RAM):

pass 1300

tcmode on

T COMP MODE : ON

env xtemp 5.00

In eeprom:

Temperature (C) : 8.00

Pressure (hPa) : 1013.00

Oxygen (%O2) : 21.00

Humidity (%RH) : 30.000

In use:

Temperature (C) : 5.00

Pressure (hPa) : 1013.00

Oxygen (%O2) : 21.00

Humidity (%RH) : 30.00

Table 38 O2cmode Command

Syntax Description

o2cmode<cr>

o2cmode [on | off]<cr>

Example (check oxygen compensation mode; oxygen compensation is disabled, a neutral value is used):

pass 1300

o2cmode

O2 COMP MODE : OFF

Check current oxygen compensation mode.

Possible modes:

• on = Compensation enabled using setpoint

value.

• off = Compensation disabled, default

(neutral) value used: see 2.4. Environmental

Compensation (page 12)

Change oxygen compensation mode (on or off).

51

Page 54

GMP252 User Guide M211897EN-B

Syntax Description

Example (enable oxygen compensation):

pass 1300

o2cmode on

O2 COMP MODE : ON

Table 39 Pcmode Command

Syntax Description

pcmode<cr> Check current pressure compensation mode.

Possible modes:

• on = Compensation enabled using setpoint

value.

• off = Compensation disabled, default

(neutral) value used: see 2.4. Environmental

Compensation (page 12).

pcmode [on | off]<cr>

Change pressure compensation mode (on or off).

Example (check pressure compensation mode; pressure compensation is enabled using a setpoint value):

pass 1300

pcmode

P COMP MODE : ON

52

Page 55

Table 40 Rhcmode Command

Syntax Description