Page 1

USER'S GUIDE

Vaisala CARBOCAP® Carbon Dioxide Probe

GMP231

M211501EN-C

Page 2

PUBLISHED BY

Vaisala Oyj

Street address: Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

Mailing address: P.O. Box 26, FI-00421 Helsinki, Finland

Phone: +358 9 8949 1

Fax: +358 9 8949 2227

Visit our Internet pages at www.vaisala.com.

© Vaisala 2014

No part of this manual may be reproduced, published or publicly displayed in any form

or by any means, electronic or mechanical (including photocopying), nor may its

contents be modified, translated, adapted, sold or disclosed to a third party without prior

written permission of the copyright holder. Translated manuals and translated portions

of multilingual documents are based on the original English versions. In ambiguous

cases, the English versions are applicable, not the translations.

The contents of this manual are subject to change without prior notice.

This manual does not create any legally binding obligations for Vaisala towards

customers or end users. All legally binding obligations and agreements are included

exclusively in the applicable supply contract or the General Conditions of Sale and

General Conditions of Service of Vaisala.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ............................................................................ 7

About This Manual ................................................................... 7

Contents of This Manual ....................................................... 7

Version Information ............................................................... 8

Related Manuals ................................................................... 8

Documentation Conventions ................................................. 8

Safety ......................................................................................... 9

ESD Protection ...................................................................... 9

Recycling .................................................................................. 9

Regulatory Compliances ....................................................... 10

Patent Notice .......................................................................... 10

Trademarks ............................................................................. 10

Software License .................................................................... 10

Warranty .................................................................................. 11

CHAPTER 2

PRODUCT OVERVIEW ................................................................................ 12

Introduction to GMP231 ......................................................... 12

Basic Features and Options .................................................. 13

GMP231 Parts ......................................................................... 14

Operating Principle of CO2 Measurement ............................ 15

Environmental Compensation .............................................. 17

Pressure Compensation ...................................................... 17

Temperature Compensation ............................................... 17

Background Gas Compensations ....................................... 18

Probe Startup .......................................................................... 18

Analog Output Overrange Behavior ..................................... 19

CHAPTER 3

INSTALLATION ............................................................................................ 20

Thermal Management ............................................................ 20

Avoiding Condensation ......................................................... 21

Probe Installation Depth ........................................................ 21

Dimensions ............................................................................. 22

Recommended Installation ................................................... 23

Wiring ...................................................................................... 24

Power Supply .......................................................................... 24

CHAPTER 4

VAISALA INDUSTRIAL PROTOCOL .......................................................... 25

Overview ................................................................................. 25

VAISALA _________________________________________________________________________ 1

Page 4

User's Guide _______________________________________________________________________

Physical Interface ................................................................... 25

Connecting with a Computer ................................................. 26

Installing the Driver for the USB Service Cable ............. 26

Terminal Application Settings ......................................... 27

Serial Commands ................................................................... 28

Showing Device Information ................................................. 29

Show Probe Information ...................................................... 29

Show Serial Number ............................................................ 30

Show Firmware Version ...................................................... 30

Show Firmware Information ................................................ 30

Show Probe Uptime ............................................................. 30

Show Command List ........................................................... 31

Serial Line Output Commands .............................................. 31

Start Measurement Output .................................................. 31

Stop Measurement Output .................................................. 32

Set Output Interval ............................................................... 32

Output a Reading Once ....................................................... 32

Set Measurement Output Format ........................................ 33

FORM Command Examples .......................................... 34

Changing Measurement Settings .......................................... 35

Set Compensation Modes ................................................... 35

Change Compensation Setpoint Values ............................. 36

Set Measurement to Standby Mode .................................... 37

Configuring Serial Line Operatio n ........................................ 38

Set Serial Line Operating Mode .......................................... 38

Set Serial Line Settings ....................................................... 39

Set Probe Address .............................................................. 39

Set Serial Line Response Time ........................................... 40

Set Serial Line Echo ....................................................... 40

Calibration Commands .......................................................... 41

Adjust CO2 Measurement .................................................... 41

Set Calibration Date ............................................................ 42

Set Calibration Info Text ...................................................... 43

Adjust Temperature Measurement ...................................... 43

Adjust Pressure Measurement ............................................ 44

Configuring Analog Output ................................................... 45

Set Analog Output Scaling .................................................. 45

Set Analog Output Mode ..................................................... 45

Set Analog Output Clipping and Error Limit ........................ 46

Test Analog Output .............................................................. 47

Other Commands.................................................................... 47

Enable Advanced Commands ............................................. 47

Connecting to Probe in POLL Mode .................................... 48

Closing the Connection to a Probe in POLL Mode ............. 48

Show Active Errors .............................................................. 48

Reset Probe ......................................................................... 49

Restore Factory Settings ..................................................... 49

CHAPTER 5

I2C INTERFACE ............................................................................................ 50

Overview .................................................................................. 50

Physical Interface ................................................................ 50

Communication Param eters ................................................ 51

Addressing ........................................................................... 51

2 ____________________________________________________________________ M211501EN-C

Page 5

_________________________________________________________________________________

Communication Flow ............................................................. 52

GMP231 State Machine ...................................................... 53

Examples of Communication Flow ...................................... 54

Timing .................................................................................. 56

Status Byte .......................................................................... 56

Checksum ........................................................................... 56

Status Word......................................................................... 57

Commands .............................................................................. 58

Get_Interface_Version ........................................................ 58

Get_Parameter .................................................................... 59

Example: Read CO2 Measurement Result .................... 60

Set_Parameter .................................................................... 61

Example: Set Compensation Temperature ......................... 62

Get_Parameter_Info ............................................................ 63

Adjust .................................................................................. 64

Adjusting Measurement......................................................... 65

One Point Adjustment ......................................................... 65

Two Point Adjustment ......................................................... 66

Data Registers ........................................................................ 66

Data Formats....................................................................... 66

Register Table ..................................................................... 67

CHAPTER 6

MAINTENANCE ........................................................................................... 70

Cleaning .................................................................................. 70

Chemical Tolerance ............................................................ 70

Changing the Filter ................................................................. 71

Changing the Silicone Plug ................................................... 72

Calibration and Adjustment .................................................. 73

Calibration Setup ................................................................. 73

Using Ambient Air as Reference .................................... 74

Using a Calibration Gas as Reference........................... 74

Effect of Environmental Compensations ............................. 74

Limits of Adjustment ............................................................ 75

Adjustment Types ............................................................... 75

I2C Interface ................................................................... 76

Vaisala Industrial Protocol ............................................. 76

MI70 Hand-Held Indicator .............................................. 76

CHAPTER 7

OPERATING WITH MI70 INDICATOR ........................................................ 77

Overview of MI70 Support ..................................................... 77

Connecting GMP231 to MI70 Indicator ................................. 77

Changing Environmental Compensation Settings with MI70

Indicator .................................................................................. 78

Calibration and Adjustment with MI70 Indicator ................. 79

1-Point Adjustment with an MI70-Compatible Reference

Probe ................................................................................... 79

1-Point Adjustment with a Reference Gas .......................... 81

CHAPTER 8

TROUBLESHOOTING ................................................................................. 83

Problem Situations ................................................................. 83

VAISALA _________________________________________________________________________ 3

Page 6

User's Guide _______________________________________________________________________

Analog Output Error State ..................................................... 84

Technical Support .................................................................. 84

Product Returns...................................................................... 84

CHAPTER 9

TECHNICAL DATA ...................................................................................... 85

Specifications ......................................................................... 85

Spare Parts and Accessories ................................................ 87

4 ____________________________________________________________________ M211501EN-C

Page 7

_________________________________________________________________________________

List of Figures

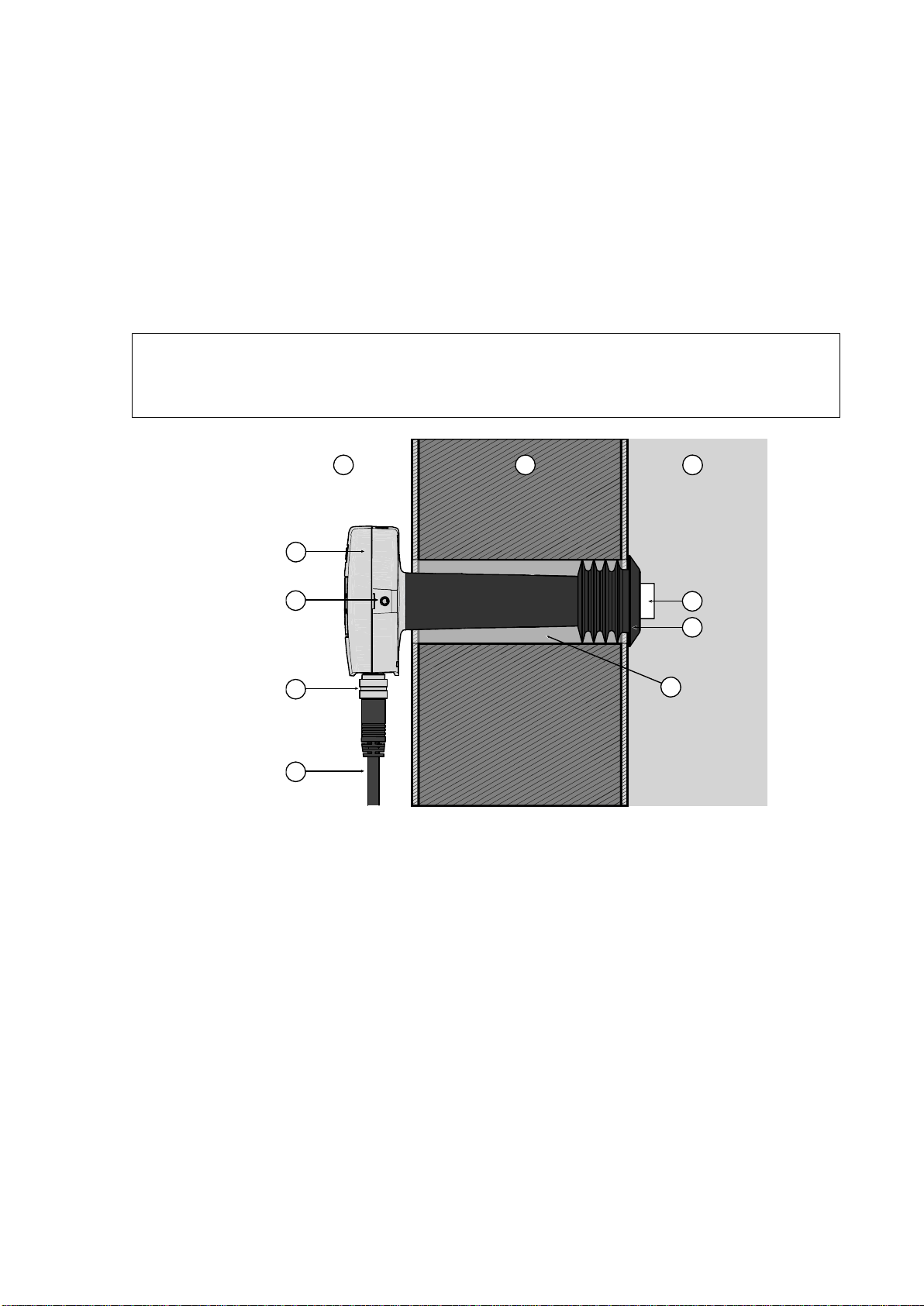

Figure 1 GMP231 Installed Through a Chamber Wall (Example) .......... 12

Figure 2 GMP231 Parts .......................................................................... 14

Figure 3 CARBOCAP® Sensor of the GMP231 ...................................... 15

Figure 4 CO2 Measurement Inside the Incubator ................................... 16

Figure 5 Probe Installation Depth ........................................................... 21

Figure 6 Probe Dimensions without Silico ne Plu g .................................. 22

Figure 7 Probe Dimensions with Silicone Plug ....................................... 22

Figure 8 Electronics Housing Dimensions .............................................. 22

Figure 9 Attachment Bracket Dimensions .............................................. 22

Figure 10 Recommended Installation ....................................................... 23

Figure 11 PuTTY Terminal Application..................................................... 27

Figure 12 Hardware Schematic ................................................................ 50

Figure 13 GMP231 State Machine ........................................................... 54

Figure 14 Get_Parameter with ACK ......................................................... 54

Figure 15 Set_Parameter with ACK ......................................................... 55

Figure 16 Get_Parameter with NACK ...................................................... 55

Figure 17 Get_Parameter with Alarm ....................................................... 55

Figure 18 Changing the Filter ................................................................... 71

Figure 19 Changing the Silicone Plug ...................................................... 72

Figure 20 Inserting the Calibration Adapter over the Filter ...................... 73

Figure 21 CO2 Reading on MI70 Screen .................................................. 77

Figure 22 CO2 Reading with Tcomp and Pcomp on MI70 Screen ........... 78

Figure 23 GMP231 Compensation Settings on MI70 Screen .................. 78

Figure 24 Functions Menu ........................................................................ 79

Figure 25 Comparing Readings in MI70 Adjustment Mode ..................... 80

Figure 26 Selecting the Adjustment Mode ............................................... 80

Figure 27 Functions Menu ........................................................................ 81

Figure 28 MI70 Adjustment Mode ............................................................ 81

Figure 29 Selecting the Adjustment Mode ............................................... 82

Figure 30 Entering the Reference CO2 Concentration ............................. 82

VAISALA _________________________________________________________________________ 5

Page 8

User's Guide _______________________________________________________________________

List of Tables

Table 1 Manual Revisions ....................................................................... 8

Table 2 Related Manuals ......................................................................... 8

Table 3 Applicable Patents .................................................................... 10

Table 4 GMP231 Connector Pinout ....................................................... 24

Table 5 Cable DRW240977 ................................................................... 24

Table 6 Default Serial Interface Settings ............................................... 25

Table 7 Basic Serial Commands ........................................................... 28

Table 8 Advanced Serial Commands .................................................... 29

Table 9 FORM Command Parameters .................................................. 33

Table 10 FORM Command Modifiers ...................................................... 33

Table 11 Selection of Output Modes ....................................................... 38

Table 12 GMP231 I2C Address ............................................................... 51

Table 13 GMP231 Device Address ......................................................... 51

Table 14 Invoke Message in GMP231 I2C Interface ............................... 52

Table 15 Response Message in GMP231 I2C Interface .......................... 53

Table 16 Timing ....................................................................................... 56

Table 17 Status Byte ............................................................................... 56

Table 18 Status Word Content ................................................................ 57

Table 19 Get_Interface_Version Invoke Message .................................. 58

Table 20 Get_Interface_Version Response Message ............................. 58

Table 21 Get_Parameter Invoke Message .............................................. 59

Table 22 Get_Parameter Response Message ........................................ 59

Table 23 Get_Parameter Invoke Message Example ............................... 60

Table 24 Get_Parameter Response Mes s age Example ......................... 60

Table 25 Set_Parameter Invoke Message .............................................. 61

Table 26 Set_Parameter Response Message......................................... 61

Table 27 Set_Parameter Return Codes .................................................. 61

Table 28 Example Set_Parameter Invoke Message ............................... 62

Table 29 Example Set_Parameter Response Message ......................... 62

Table 30 Get_Parameter_Info Invoke Message ...................................... 63

Table 31 Get_Parameter_Info Response Message ................................ 63

Table 32 Parameter Data Types ............................................................. 63

Table 33 Parameter Persistence ............................................................. 63

Table 34 Adjust Invoke Message ............................................................ 64

Table 35 Adjust Response Message ....................................................... 64

Table 36 Adjustment Subcommands ....................................................... 64

Table 37 Adjustment Parameters ............................................................ 64

Table 38 Adjustment Return Codes ........................................................ 65

Table 39 Data Formats ............................................................................ 66

Table 40 GMP231 Register Table ........................................................... 67

Table 41 Possible Problem Situations and Their Remedies ................... 83

Table 42 Performance ............................................................................. 85

Table 43 Operating Environm ent ............................................................. 86

Table 44 Inputs and Outputs ................................................................... 86

Table 45 Mechanics ................................................................................. 86

Table 46 Spare Parts and Accessories for GMP231 ............................... 87

6 ____________________________________________________________________ M211501EN-C

Page 9

Chapter 1 _________________________________________________________ General Information

CHAPTER 1

GENERAL INFORM ATION

This chapter provides general notes for the manual and the GMP231

probe.

About This Manual

This manual provides information for installing, operating, and

maintaining the Vaisala CARBOCAP® Carbon Dioxide Probe GMP231.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Informati on, provides general notes for the manual

and the GMP231 probe.

- Chapter 2, Product Overview, introduces the GMP231 probe and its

features.

- Chapter 3, Installation, provides you with information that is intended

to help you install the GMP231.

- Chapter 4, Vaisala Industrial Protocol, describes the Vaisala Industrial

Protocol implementation of the GMP231.

- Chapter 5, I2C Interface, describes the I2C interface implementation

of the GMP231.

- Chapter 6, Maintenance, provides information that is needed in the

basic maintenance of the GMP231.

- Chapter 8, Troubleshooting, describes possible problems, their

probable causes and remedies, and provides contact information for

technical support.

- Chapter 9, Technical Data, provides the technical data of the

GMP231.

VAISALA _________________________________________________________________________ 7

Page 10

User's Guide _______________________________________________________________________

Manual Code

Description

M211501EN-C

May 2014. This manual. Updated description for

Setpoint Values on page 36.

M211501EN-B

Previous version. Applicable from software version

and adjustment. Updated technical specification.

M211501EN-A

September 2013. First version.

Manual Code

Manual Name

M211603EN

GMP231 Quick Guide

Version Information

Table 1 Manual Revisions

ENV command in section Change Compensation

1.1.0 onward. Added instructions for operation with

the MI70 hand-held indicator. Updated description

2

C interface and Vaisala Industrial Prot oc ol.

of I

Updated description of envir onmental

compensations. Updated instructions for calibration

Related Manuals

Table 2 Related Manuals

WARNING

CAUTION

NOTE

Documentation Conventions

Throughout the manual, important safety considerations are highlighted

as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

8 ____________________________________________________________________ M211501EN-C

Page 11

Chapter 1 _________________________________________________________ General Information

When returning a product for calibration or repair, make sure it has not

been exposed to dangerous contamination, and is safe to handle without

special precautions.

Do not modify the unit. Improper modification can damage the

or lead to malfunction.

Do not open the

inside.

Recycle all applicable material.

Dispose of the unit according to statutory regulations. Do not dispose of

with regular household refuse.

Safety

The GMP231 probe delivered to you has been tested for safety and

approved as shipped from the factory. Note the following precautions:

WARNING

CAUTION

CAUTION

Recycling

product

probe housing. There are no user serviceable parts

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. It is possible to damage the product,

however, by delivering an electrostatic discharge when touching an

exposed contact on the product.

To make sure you are not delivering high static voltages yourself, avoid

touching the pins on the M12 connector.

VAISALA _________________________________________________________________________ 9

Page 12

User's Guide _______________________________________________________________________

Patent Issued By

Patent Number

United States Patent and Trademark Office

US 5,827,438

US 6,177,673

European Patent Office

EP0776023

EP0922972

German Patent and Trade Mark Office

69615635

Japan Patent Office

4263285

Finnish Patent Office

112005

105598

Regulatory Compliances

GMP231 is in conformity with the provisions of the following

EU directives:

- EMC-Directive

- RoHS-Directive

Conformity is shown by compliance with the following standards:

- EN 61326-1: Electrical equipment for measurement, control, and

laboratory use – EMC requirements – Generic environment.

- EN 550022: Information technology equipment – Radio disturbance

characteristics – Limits and methods of measurement.

Patent Notic e

GMP231 is protected by the following patents and their corresponding

national rights:

Table 3 Applicable Patents

Trademarks

CARBOCAP® is a registered trademark of Vaisala Oyj.

All other trademarks are the property of their respective owners.

Software License

This product contains software developed by Vaisala. Use of the software

is governed by license terms and conditions included in the applicable

supply contract or, in the absence of separate license terms and

conditions, by the General License Conditions of Vaisala Group.

10 ___________________________________________________________________ M211501EN-C

Page 13

Chapter 1 _________________________________________________________ General Information

Warranty

Visit our Internet pages for standard warranty terms and conditions:

www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of

damage due to normal wear and tear, exceptional operating conditions,

negligent handling or installation, or unauthorized modifications. Please

see the applicable supply contract or Conditions of Sale for details of the

warranty for each product.

VAISALA ________________________________________________________________________ 11

Page 14

User's Guide _______________________________________________________________________

CHAPTER 2

PRODUCT OVERVIE W

This chapter introduces the GMP231 probe and its features.

Introduction to GMP231

The Vaisala CARBOCAP® Carbon Dioxide Probe GMP231 is designed

for incubator manufacturers requiring accurate and reliable carbon

dioxide measurements and sterilization durability at high temperatures.

The GMP231 probe is based on Vaisala’s patented CARBOCAP®

technology and a new type of infra-red light source. The probe can

remain in place during high-temperature sterilization cycles that heat the

chamber interior to 180 °C. Special design of the probe enables easy

installation through the incubator wall and ensures that the sensor optics

and electronics are separated and thermally insulated.

Sensor performance is optimized at 5 %CO2 measurement. GMP231 also

has an internal pressure sensor, which allows compensation of the

measurement according to ambient pressure. Since dust and most

chemicals do not affect the measurement, and the effect of water vapor

can be compensated for, GMP231 is accurate and stable at CO2 incubator

conditions.

1403-144

Figure 1 GMP231 Installed Through a Chamber Wall (Example)

12 ___________________________________________________________________ M211501EN-C

Page 15

Chapter 2 ___________________________________________________________ Product Overview

Basic Features and Options

- CO2 measurement range 0 ... 20 %CO2.

- Temperature durability in standby mode up to 195 °C (383 °F). See

section Thermal Management on page 20.

- Vaisala CARBOCAP® CO2 sensor with excellent long-term stability.

See sections Operating Principle of CO2 Measurement on page 15 and

Specifications on page 85.

- Measurement compensated for effects of pressure, temperature, and

background gas. Pressure compensation based on integrated pressure

sensor. See section Environmental Compensation on page 17.

- Heating to avoid condensation on optical elements.

- Analog output: one current output channel (0 ... 20 mA or 4 ... 20 mA).

- Digital output:

- I2C.

- RS-485 (non-isolated) with Vaisala Industrial Protocol.

VAISALA ________________________________________________________________________ 13

Page 16

User's Guide _______________________________________________________________________

1 = Electronics housing. Contains the main component board,

including the digital pressure sensor.

2 = Holes for M4 screws on both sides of the housing.

Maximum

BN 10649 M4.

3 = Type label on housing cover (not shown).

4 = 8-pin M12 connector. For pinout, see Table 4 on page 24.

5 = Probe body.

6 = Measurement cuvette with optics and CARBOCAP® CO2 sensor.

7 = PTFE filter.

8 = Silicone plug for sealing the lead-through.

Recommended accessory, suitable for ⌀ 44 mm lead-throughs.

3

2

4

1

5

6

7

8

GMP231 Parts

CAUTION

1403-153

Figure 2 GMP231 Parts

screw depth 8 mm. Two screws included, type

Do not open the electronics housing; there are no user serviceable parts

inside. All wiring is done through the M12 connector (4).

14 ___________________________________________________________________ M211501EN-C

Page 17

Chapter 2 ___________________________________________________________ Product Overview

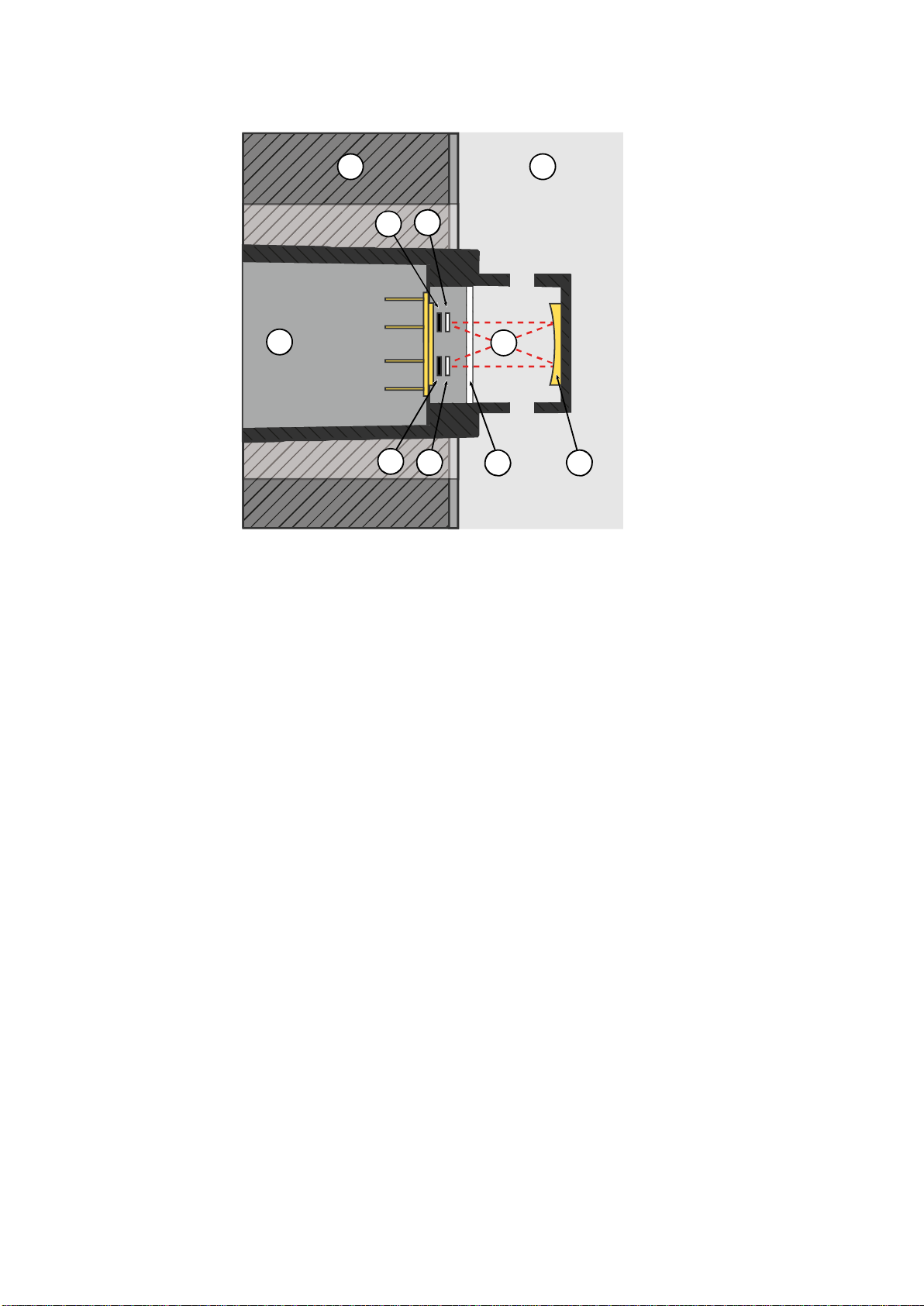

1 = Cuvette.

2 = Mirror.

3 = Window.

4 = Sensor chips.

2

3

4

1

Operating Principle of CO2 Measurement

The Vaisala CARBOCAP® sensor that is used in the GMP231 is a siliconbased, non-dispersive infrared (NDIR) sensor for the measurement of

gaseous carbon dioxide. It is especially designed to tolerate high

temperatures in standby mode, up to 195 °C (383 °F). This allows it to be

used in applications that utilize high temperature for heat sterilization. The

operating temperature range of the sensor is 0 … +70 °C (+32 ... +158 °F).

1403-160

Figure 3 CARBOCAP® Sensor of the GMP231

The sensitivity to carbon dioxide is based on absorption of infrared light

at a characteristic wavelength. The light is emitted by a novel, siliconbased microchip emitter into the cuvette which contains the gas to be

measured. After reflection from the mirror, the light intensity is measured

with a thermopile chip at a wavelength chosen by a micromechanical

Fabry–Pérot interferometer (FPI) and a band pass filter. A hermetically

sealed sapphire window is used to protect the sensor chips from moisture

and contamination. A heater chip is utilized to prevent condensation in

normal operation.

The carbon dioxide measurement consists of two steps: First, the FPI is

electrically tuned so that its pass band coincides with the characteristic

absorption wavelength of carbon dioxide and the signal is recorded.

Second, the pass band is shifted to a wavelength where no absorption

occurs in order to get a reference signal. The ratio of these two signals,

one at the absorption wavelength and the other at the reference

wavelength, gives the fraction of light absorption from which the carbon

dioxide concentration is calculated. The reference signal compensates the

possible effects of sensor aging and signal attenuation due to dirt on

optical surfaces, making the sensor very stable over time.

VAISALA ________________________________________________________________________ 15

Page 18

User's Guide _______________________________________________________________________

1 = Chamber wall.

2 = Chamber interior.

3 = Light source.

4 = Band pass filter.

5 = Ambient air (400 ... 1000 ppm CO2).

6 = Light absorbed by CO2 in the incubator gas.

7 = Thermopile detector.

8 = Fabry-Perot interferometer.

9 = Sapphire window. Separates the sensor’s active components

from the measured environment.

10 = Gold-plated mirror.

1

2

3 4

5

6

7

8

9 10

1403-161

Figure 4 CO2 Measurement Inside the Incubator

16 ___________________________________________________________________ M211501EN-C

Page 19

Chapter 2 ___________________________________________________________ Product Overview

Environmental Compensation

GMP231 improves the CO2 measurement accuracy by applying various

environmental compensations. GMP231 compensates for the effects of:

- Pressure

- Temperature

- Background gas oxygen (O2) content

- Background gas relative humidity (%RH)

Compensation parameters are configured on the order form when

ordering the probe, and can later be updated using serial commands,

MI70 Indicator, or I2C protocol. If the probe is integrated in a system that

measures one or more of the compensation parameters, they can be

updated to the probe continuously.

You can also turn off any of the compensations. In that case, GMP231

uses the default compensation value that is mathematically neutral for the

probe’s internal compensation model.

For the effect of the compensations on measurement accuracy, refer to

Table 42 on page 85.

Pressure Compensation

There is a pressure sensor on the component board of the GMP231 that

provides a live measurement of ambient pressure. GMP231 can

compensate the CO2 measurement based on this pressure reading, or it

can use a fixed setpoint. Using the GMP231’s own sensor is

recommended for most applications.

If pressure compensation is turned off, GMP231 uses the default

compensation value of 1013.2 hPa.

Temperature Compensation

GMP231 can measure the approximate temperature of the CARBOCAP®

sensor for compensation, or use a fixed setpoint. The temperature

measurement is accurate enough to be useful for compensation, and is

recommended for use unless a dedicated temperature measurement is

available and can be regularly updated to the GMP231.

If temperature compensation is turned off, GMP231 uses the default

value of +37 °C (+98.6 °F).

VAISALA ________________________________________________________________________ 17

Page 20

User's Guide _______________________________________________________________________

Background Gas Com p e nsations

Compensation for background gas parameters are based on setpoint

values only, as GMP231 has no internal measurement for oxygen

concentration or humidity. The default setpoint values are as follows:

- Oxygen concentration: 19.7 %O2.

- Relative humidity: 93 %RH.

If background gas compensations are turned off, GMP231 uses the value

0% for both.

Probe Startup

When powered on, GMP231 starts up within 10 seconds. Measurements

from the outputs (digital and analog) become available during this time

but note that they will only reach specified accuracy after a one minute

warm-up period. For this reason, you should design the incubator’s

control system so that it does not rely on measurements from GMP231

during this time.

NOTE

Specifically note that the CO2 reading will rise to the correct reading as

the sensor’s infrared emitter achieves operation temperature.

18 ___________________________________________________________________ M211501EN-C

Page 21

Chapter 2 ___________________________________________________________ Product Overview

This overrange and error state behavior is specific to the analog output,

and

Analog Output Overrange Behavior

Analog output of the GMP231 has a defined behavior when the values

measured by the probe are outside the scaled analog output range:

- Output is allowed to go 10% over the scaled range.

- Output is set to error state when measured value is more than 10%

outside the scaled range. See section Analog Output Error State on

page 84.

- Output resumes normal function when measured value returns to

within 10% of the selected range.

For example, consider a GMP231 with 0 ... 20 mA analog output, scaled

to 0 ... 10 %CO2.

- When measured CO2 rises above 10 %CO2, the output rises above

20 mA.

- The output keeps rising until the measurement is 11 %CO2, at which

point the probe outputs 22 mA.

NOTE

- If the CO2 level rises above 11 %CO2, the output enters the error

state, which is 23 mA for the 0 ... 20 mA output.

does not affect the readings provided by the digital outputs.

You can change the analog output overrange behavior using the AOVER

command. See section Set Analog Output Clipping and Error Limit on

page 46.

VAISALA ________________________________________________________________________ 19

Page 22

User's Guide _______________________________________________________________________

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended to help you

install the GMP231.

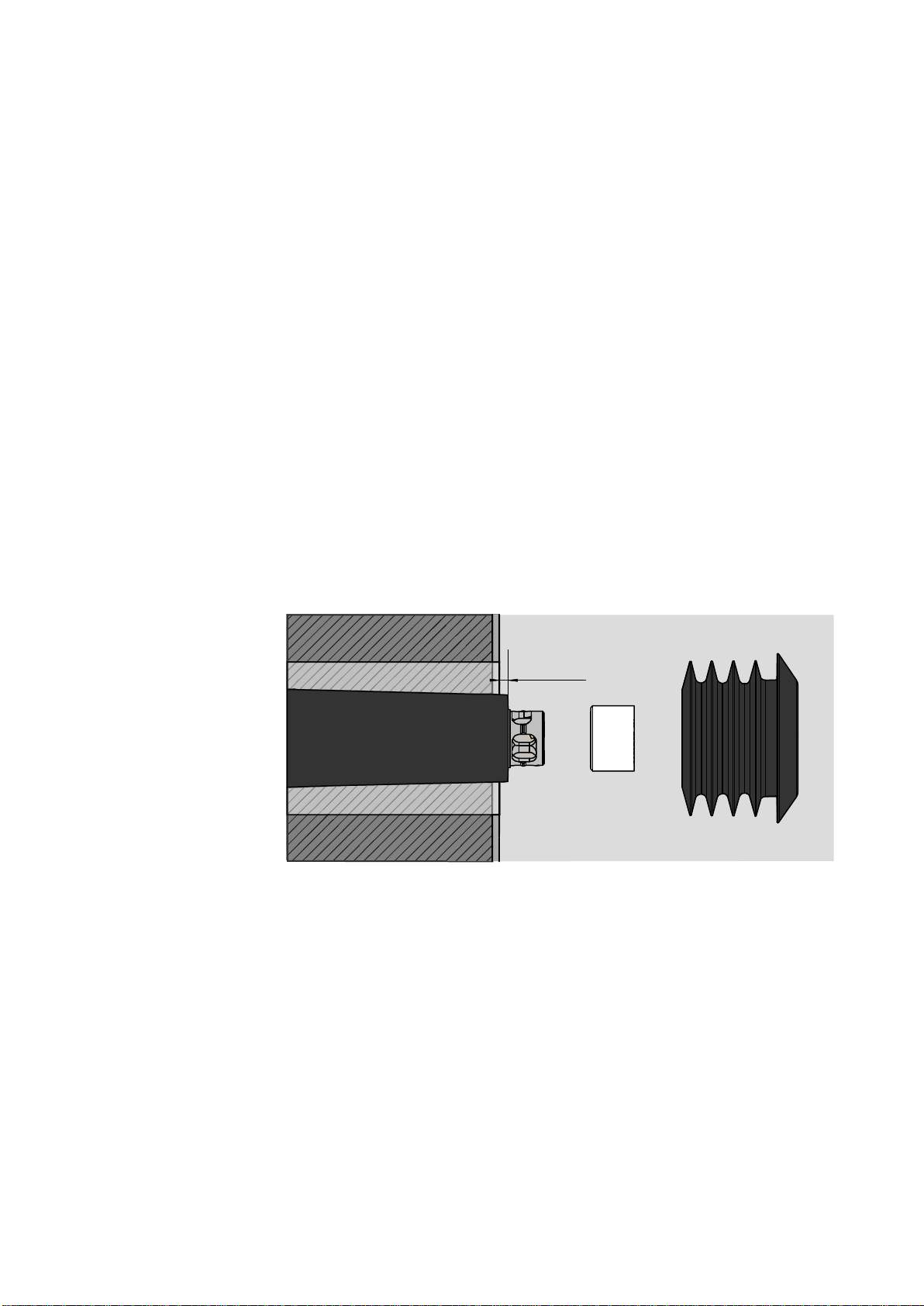

Thermal Management

GMP231 is designed to remain installed during typical heat sterilization

cycles that raise the chamber temperature to 180 °C (356 °F). Since

180 °C is the target temperature for sterilization, it is likely that there will

be hotspots inside the chamber that are above this temperature. Avoid

installing the GMP231 near such hotspots, for example near heating

elements. Do not expose the GMP231 to temperatures higher than 195 °C

/ 383 °F.

The following considerations are most important for achieving the

specified heat durability and measurement stability:

- Only the sensor and its filter should be exposed to heat. The filter

must be completely in the heated chamber. The probe body must

remain inside the unheated chamber wall so that only the end of the

probe body extends exactly 2.5 mm into the chamber.

- During the sterilization cycle, you must set the GMP231 to

standby mode (turns off the CO2 measurement), or power off the

probe completely. The GMP231 will automatically stop its

measurement cycle if it detects a high temperature, but it is best if the

incubator’s control system set the GMP231 to standby mode when the

sterilization cycle is started.

- The installation tube must be sealed from the chamber side to limit

heat conduction, and to prevent CO2 in the chamber from entering the

probe. Vaisala recommends a 44 mm diameter installation tube

together with Vaisala’s silicone plug.

- If the chamber wall contains heating elements, or has a construction

where hot air is circulated inside the wall, design the installation tube

so that excessive heat is not conducted to the GMP231.

20 ___________________________________________________________________ M211501EN-C

Page 23

Chapter 3 ________________________________________________________________ Installation

2.5 mm

Avoiding Condensation

The sensor head of the GMP231 is heated during normal operation,

which prevents condensation from forming inside the filter and on the

optical surfaces. The heating is not on when GMP231 is in standby mode

or unpowered. For this reason, keep the probe powered and operating

when the incubator is in use and humidity inside the chamber is high.

Correct installation depth of the probe is also important for preventing

condensation from running to the sensor along the chamber wall.

See below.

Probe Installation Depth

GMP231 must be installed so that only the sensor element and the filter

are inside the chamber. If the probe is longer the installation tube, the

extra length should extend to the outside of the chamber.

The installation depth must be 2.5 mm. This installation depth provides

the specified heat durability of the probe, and allows the silicone plug to

seal the Ø44 mm installation tube properly.

1403-154

Figure 5 Probe Installation Depth

VAISALA ________________________________________________________________________ 21

Page 24

User's Guide _______________________________________________________________________

163

118.5

Screw BN 10649 M4 x 8 mm

(for 1 mm thick sheet metal

attachment)

1121

Ø 30.2

1.3°

Ø 19

Ø 24.8

Position only the filter

inside the heated chamber

163

118.5

Screw BN 10649 M4 x 8 mm

(for 1 mm thick sheet metal

attachment)

1121

Ø 30.2

Ø 19

2.5

Incubator’s inner wall

1.3°

Position only the filter

inside the heated chamber

Recommended diameter

for installation tube 44 mm

M12

54.4

87

Reserve space for M12 cable

40

4 × Ø3.5

52

Dimensions

1403-108

Figure 6 Probe Dimensions without Silicone Plug

1403-110

Figure 7 Probe Dimensions with Silicone Plug

1403-112

Figure 8 Electronics Housing Dimensions

22 ___________________________________________________________________ M211501EN-C

1403-109

Figure 9 Attachment Bracket Dimensions

Page 25

Chapter 3 ________________________________________________________________ Installation

The probe and electronics housi

chamber. The electronics housing should be in a ventilated space that is

open to ambient air.

1 = Ambient air.

2 = Chamber wall.

3 = Chamber interior.

4 = GMP231 Electronics housing.

5 = M4 screw holes on both sides of the probe housing.

6 = 8-pin M12 connector. For pinout, see section Wiring on page 24.

7 = Cable.

8 = CARBOCAP® sensor under PTFE filter. The filter must be inside

the chamber completely.

9 = Silicone plug. Insert the plug over the probe from inside the

chamber.

10 = Ø 44 mm installation tube through the chamber wall.

The diameter is important for proper sealing by the silicone plug.

4

1

2

3

5

6

7

9

8

10

Recommended Installation

GMP231 is designed to be installed through a chamber wall, and attached

to the chamber chassis using an attachment bracket and the two screw

holes on the side of the probe. As the installation depth of the probe

inside the chamber is critical (see section Probe Installation Depth on

page 21), the mounting method must allow the probe to be positioned

exactly.

NOTE

ng must remain outside the heated

1403-123

Figure 10 Recommended Installation

VAISALA ________________________________________________________________________ 23

Page 26

User's Guide _______________________________________________________________________

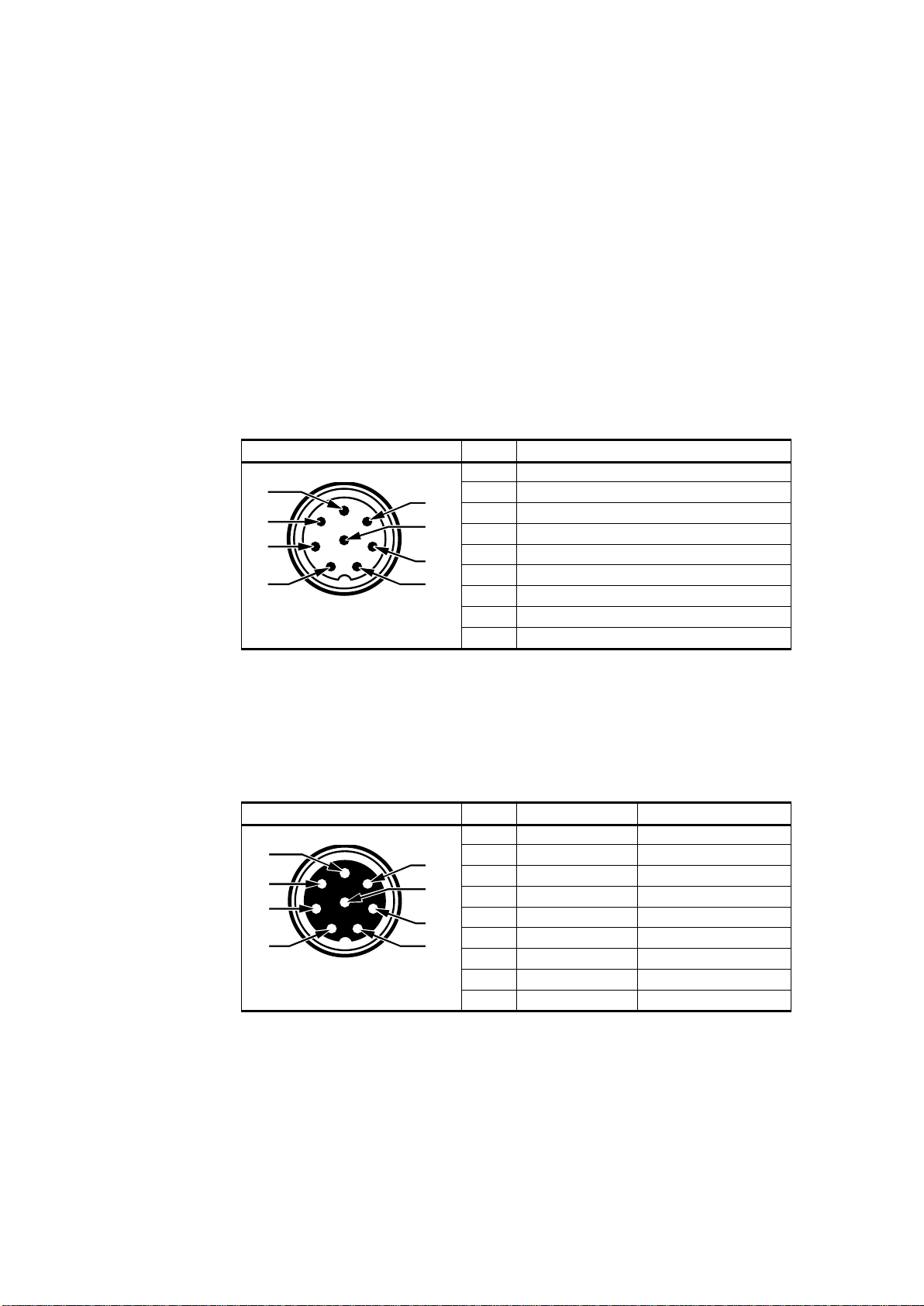

Male 8-pin M12

Pin #

Function

1

I2C SDA

2

RS-485 D-

3

I2C SCL

4

Analog output +

5

Standby

6

RS-485 D+

7

Power supply +

8

Ground

-

Shield

Female 8-pin M12

Pin #

Function

Wire Color

1

I2C SDA

White

2

RS-485 D-

Brown

3

I2C SCL

Green

4

Analog output +

Yellow

5

Standby

Gray

6

RS-485 D+

Pink

7

Power supply +

Blue

8

Ground

Red

-

Shield

Black

1

5

6

7

3

4

8

2

1

6

8

7

3

4

5

2

Wiring

GMP231 provides several outputs you can use. Connect the output pins

you need, and the power supply and ground pins. Use a shielded cable,

and connect the shield to the chassis of the GMP231’s M12 connector,

and to ground on the other side.

Ground pin 5 to put the probe in standby mode (stops CO2 measurement).

The probe resumes normal measurement operation when pin 5 is no

longer grounded, unless its internal measurement shows the temperature

is too high.

Table 4 GMP231 Connector Pinout

Vaisala’s standard connection cable for the GMP231 (order code

DRW240977) is a 90 cm long cable with female 8-pin M12 connector on

one end, and open ended wires on the other. It supports all outputs from

the GMP231, and connects the cable shield to the connector chassis.

Table 5 Cable DRW240977

Power Supply

24 ___________________________________________________________________ M211501EN-C

The supply voltage range of the GMP231 is 11 ... 30 VDC.

If the analog output is used, the supply voltage range is 20 ... 30 VDC.

The maximum power consumption is 1 W.

Page 27

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

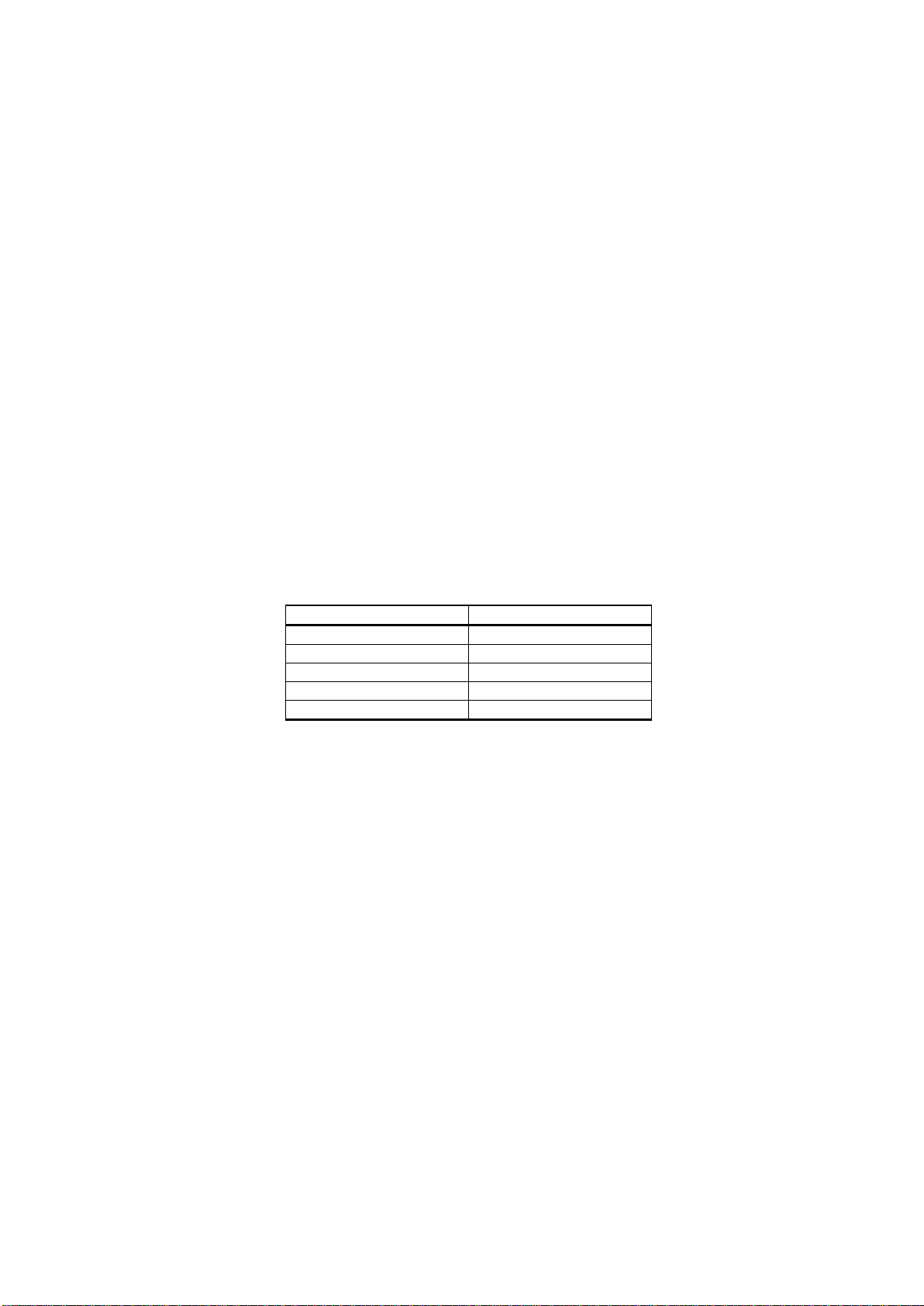

Property

Description / Value

Baud rate

19200

Parity

None

Data bits

8

Stop bits

1

Flow control

None

CHAPTER 4

VAISALA INDUSTRI AL PROTOCOL

This chapter describes the Vaisala Industrial Protocol implementation of

the GMP231.

Overview

RS-485 line of the GMP231 provides an implementation of the Vaisala

Industrial Protocol that can be used for service and configuration use, or

for interfacing with the incubator’s control system. The protocol is a

plaintext protocol suitable for use both by human operators and

automated systems.

Table 6 Default Serial Interface Settings

Physical Interface

The physical interface is a non-isolated 3-wire interface. The data lines

are RS-485 D- and RS-485 D+. Ground is shared with power supply.

The connector is an 8-pin male M12. For connector pinout and wiring

information, see section Wiring on page 24.

VAISALA ________________________________________________________________________ 25

Page 28

User's Guide _______________________________________________________________________

Connecting with a Computer

Connecting with a computer allows you to configure and troubleshoot

your probe using serial line commands. For a list of commands, see

section Serial Commands on page 28.

When connecting using a computer, use the Vaisala USB cable (Vaisala

order code 221040) and a suitable terminal application:

- If you have not used the Vaisala USB cable before, install the driver

before attempting to use the cable. Refer to section Installing the

Driver for the USB Service Cable below for detailed instructions.

- For more information on using a terminal application, see section

Terminal Application Settings on page 27.

Installing the Driver f or t he USB Servic e Cable

Before taking the USB service cable into use for the first time, you must

install the provided USB driver on your computer (requires Windows).

When installing the driver, you must accept any security prompts that

may appear.

1. Check that the USB service cable is not connected. Disconnect the

cable if you have already connected it.

2. Insert the media that came with the cable, or download the latest

driver from www.vaisala.com.

3. Run the USB driver installation program (setup.exe), and accept

the installation defaults. The installation of the driver may take

several minutes.

4. After the driver has been installed, connect the USB service cable

to a USB port on your computer. Windows will detect the new

device, and use the driver automatically.

5. The installation has reserved a COM port for the cable. Verify the

port number, and the status of the cable, using the Vaisala USB

Instrument Finder program that has been installed in the

Windows Start menu.

Windows will recognize each individual service cable as a different

device, and reserve a new COM port. Remember to use the correct port

in the settings of your terminal program.

26 ___________________________________________________________________ M211501EN-C

Page 29

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

If PuTTY is unable to open the serial port you selected, it will show you

an error message instead. If this happens, restart PuTTY and check the

settings.

Terminal Applic a tion Se t t ings

The steps below describe how to connect to the probe using the PuTTY

terminal application for Windows (available for download at

www.vaisala.com) and a USB computer connection cable:

1. Connect the USB serial interface cable between your PC and the

M12 connector of the probe.

2. Start the PuTTY application.

3. Select Connection > Serial & USB and check that the correct

COM port is selected in the Serial or USB line to connect to field.

If you are using the PuTTY terminal application supplied by

Vaisala, you can press the USB Finder button to open the Vaisala

USB Instrument Finder program.

4. Check that the other serial settings are correct for your connection,

and change if necessary. Flow control should be set to None unless

you have a reason to change it.

NOTE

5. Click the Open button to open the connection window and start

using the serial line.

6. You may need to adjust the Local echo setting in the Terminal

category to see what you are typing on the serial line. To access the

configuration screen while a session is running, click the right

mouse button over the session window, and select Change

Settings... from the pop-up menu.

Figure 11 PuTTY Terminal Application

VAISALA ________________________________________________________________________ 27

0807-004

Page 30

User's Guide _______________________________________________________________________

Command

Description

?

Show probe information.

CLOSE

Close connection to probe (POLL mode)

ECHO

Show or set remote echo mode.

ENV

Show or set environmental parameters.

ERRS

Show currently active errors .

FORM [modifier string]

Show or set output format.

HELP

Show list of currently available serial

commands.

INTV [0 ... 9999 s/min/h]

Set continuous output interval for R command.

OPEN [address]

Open connection to probe in POLL mode

PASS [1300]

Access advanced serial commands.

R

Start the continuous outputting.

RESET

Reset the probe.

S

Stop the continuous outputting.

SDELAY [0 ... 255]

Show or set serial line transmission delay in

milliseconds.

SEND

Output measurement message once.

SERI [baud data stop parit y]

Show or set the serial interface settings

SMODE [mode]

Show or set startup serial mode:

RUN, STOP, or POLL.

SNUM

Show probe serial number.

STANDBY [on/off]

Standby mode on/off (turn off measurement)

SYSTEM

Show probe firmware information

TIME

Show probe operation hours and uptime

VERS

Show probe firmware version.

Serial Commands

All commands can be issued either in uppercase or lowercase. In the

command examples, the keyboard input by the user is in bold type.

The notation <cr> refers to pressing the carriage return (Enter) key on

your computer keyboard. Enter a <cr> to clear the command buffer

before starting to enter commands.

Table 7 Basic Serial Commands

28 ___________________________________________________________________ M211501EN-C

Page 31

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

Command

Description

ADDR [0 … 254]

Show or set probe address.

AMODE

Show or set analog output mode.

AOVER

Show or set analog output overrange and

clipping behavior.

ASEL

Show or set analog output parameter.

ATEST

Test analog putput.

CCO2

Adjust CO2 measurement gain and offset.

CDATE

Show or set calibration date.

CP

Adjust pressure measurement offset.

CT

Adjust temperature measurement offset.

CTEXT

Show or set calibrati on inf o rmation.

FRESTORE

Restore probe to factory settings.

O2CMODE

Show or set oxygen compensation mode.

PCMODE

Show or set pressure compensation mode.

RHCMODE

Show or set humidity compensation mode.

TCMODE

Show or set temperature compensation mode.

Table 8 Advanced Serial Commands

Showing Device Information

Show Probe Information

The ? command outputs a listing of probe information.

?<cr>

Command ?? is a similar command that is designed to be used if the

probe is in POLL mode but its address is unknown. The probe will

respond to the ?? command even while in POLL mode. Do not use the ??

command if you have more than one probe on an RS-485 line.

Example:

?

Device : GMP231

Copyright : Copyright (c) Vaisala Oyj 2013. All rights reserved.

SW Name : GMP231

SW version : 1.0.1.1537

Snum : J1320082

Calibrated : 2014-03-11

Address : 1

Smode : STOP

VAISALA ________________________________________________________________________ 29

Page 32

User's Guide _______________________________________________________________________

Show Serial Number

SNUM<cr>

Example:

snum

Serial number : J1320082

Show Firmware Version

VERS<cr>

Example:

vers

GMP231 / 1.1.0.1537

Show Firmware Information

SYSTEM<cr>

Example:

system

Device Name : GMP231

SW Name : GMP231

SW version : 1.1.0.1537

Show Probe Uptime

Use the TIME command to show how long the probe has been in

operation, and what is the current uptime since last reset (in seconds).

The operation counter is in format ddddd:hh:mm:ss. Full days and hours

are retained in the counter, minutes and seconds are cleared at reset.

TIME<cr>

Example (cumulative uptime 23 hours, 56 minutes, and 49 seconds,

uptime since last reset 3409 seconds):

time

00000:23:56:49 Up time: 3409 s

30 ___________________________________________________________________ M211501EN-C

Page 33

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

Show Command List

Use the HELP command to show a list of the currently available serial

commands.

HELP<cr>

Example (shows basic commands, advanced commands are not enabled):

CLOSE

ECHO

ENV

ERRS

FORM

HELP

INTV

PASS

R

RESET

S

SDELAY

SEND

SERI

SMODE

SNUM

STANDBY

SYSTEM

TIME

VERS

Serial Line Output Commands

Start Measurement Output

Use the R command to start the continuous outputting of measurement

values as an ASCII text string to the serial line.

R<cr>

Example (measurement message in default format):

r

CO2= 490 ppm

CO2= 490 ppm

CO2= 491 ppm

CO2= 491 ppm

CO2= 491 ppm

...

The probe keeps outputting measurement messages at the interval that

has been set INTV command until stopped.

VAISALA ________________________________________________________________________ 31

Page 34

User's Guide _______________________________________________________________________

where

n = time interval, range 0 ... 255

xxx

=

time unit = "S", "MIN", or "H "

Stop Measurement Output

You can stop the measurement output by pressing the ESC key or with

the S command.

Set Output Interval

Use the INTV command to change the output interval of the

automatically repeat in g measu remen t mes s a ges. T he measu r emen t

messages are repeated in the RUN mode, or after the R command has

been given.

INTV [n xxx]<cr>

The shortest output interval (with n = 0) outputs the measurement

messages as quickly as the probe’s internal measurement cycle produces

them, without additional delay.

Example:

intv 5 s

Output interval : 5 S

Output a Reading Once

Use the SEND command to output a single measurement message.

SEND<cr>

Example:

send

CO2= 1702 ppm

32 ___________________________________________________________________ M211501EN-C

Page 35

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

where

modifier string

=

String of parameters and modifiers that defines the

output format, length 1 ... 15

See

Maximum length

may be shorter when text strings are used.

Measured Parameter

Abbreviation in FORM Command

Carbon dioxide in ppm

CO2

Carbon dioxide in percent

CO2%

Currently used temperature

compensation value

TCOMP

Currently used pressure

compensation value

PCOMP

Currently used oxygen concentration

compensation value

O2COMP

Currently used relative humidity

compensation value

RHCOMP

Modifier

Description

x.y

Length modifier (number of digits and decimal places)

#t

Tabulator

#r

Carriage-return

#n

Line feed

""

String constant, length 1 ... 15 characters

#xxx

ASCII code value (decimal) of a special character;

for example, #027 for ESC

ADDR

Probe address (0 ... 254)

SN

Probe serial number

TIME

Cumulative operating hours of the probe.

Ux

Shows the name of the measurement unit using “x” number

measurement unit with three characters

CS4

Modulus-65536 checksum of message sent so far, ASCII

encoded hexadecimal notation

CSX

NMEA xor-checksum of message sent so far, ASCII encoded

hexadecimal notation

Set Measurement Output Format

Use the serial line command FORM to change the measurement message

sent by the probe. You can freely define the output message to include

the desired parameters, formatting options, text strings, and additional

fields.

FORM [modifier string]<cr>

0 characters.

Table 9 and Table 10 below.

You can return to the default format using the "FORM /" command.

Table 9 FORM Co m ma n d Parameters

Table 10 FORM Command Modifiers

of characters. For example, U3 shows the name of the

VAISALA ________________________________________________________________________ 33

Page 36

User's Guide _______________________________________________________________________

FORM Command Examples

Example of default output (continuous output from RUN mode):

CO2= 860 ppm

CO2= 861 ppm

CO2= 861 ppm

...

Command to set output format as %CO2:

form 3.1 "CO2=" CO2% " " U4 #r #n

Output example:

CO2= 5.1 %CO2

CO2= 5.1 %CO2

CO2= 5.0 %CO2

...

Command to set output format as CO2 ppm with Modulus-65536

checksum:

form 6.0 "CO2=" CO2 " " U3 " " CS4 #r #n

Output example:

CO2= 3563 ppm 9F

CO2= 3562 ppm 9E

CO2= 3559 ppm A4

...

Command to set output format as CO2 ppm, with start of text (ASCII

character 002) and end of text (003) ASCII codes, and without line feed

and carriage return at the end:

form #002 6.0 "CO2=" CO2 " " U3 #003

Output example (ASCII codes not visible here):

CO2= 866 ppm CO2= 866 ppm CO2= 867 ppm CO2= 867 ppm

CO2= 867 ppm CO2= 868 ppm CO2= 868 ppm CO2= 869 ppm

...

34 ___________________________________________________________________ M211501EN-C

Page 37

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

where

on = Compensation enabled using setpoint value.

off = Compensation disabled, neutral value used.

measured

=

Compensation enabled using internal measurement.

Available only for pressure and temperature

compensations.

Changing Measurement Settings

Set Compensation Modes

You can change the mode of each environmental compensation type

using a dedicated serial command. The commands are:

- PCMODE for pressure compensation mode.

- TCMODE for temperature compensation mode.

- O2CMODE for oxygen compensation mode.

- RHCMODE for relative humidity compensation.

Command syntax is as follows:

PCMODE [on | off | measured]<cr>

TCMODE [on | off | measured]<cr>

O2CMODE [on | off]<cr>

RHCMODE [on | off]<cr>

Example (check temperature compensation mode):

pass 1300

tcmode

T COMP MODE : ON

Example (change temperature compensation mode to use internal

measurement):

pass 1300

tcmode measured

T COMP MODE : MEASURED

VAISALA ________________________________________________________________________ 35

Page 38

User's Guide _______________________________________________________________________

temp

=

Compensation temperature. Range -40 ... 100 °C.

pres

=

Compensation pressure. Range 500 ... 1150 hPa.

oxy

=

Oxygen content of background gas. Range 0 ... 100%.

hum

=

Relative humidity of background gas. Range 0 ... 100%.

xtemp

=

Compensation temperature that is stored in RAM.

xpres

=

Compensation pressure that is stored in RAM.

xoxy

=

Oxygen content of background gas that is stored

in RAM.

xhum

=

Relative humidity of background gas that is stored

in RAM.

Change Compensation Setpoint Values

Use the ENV command to show or set the setpoint values of the

environmental compensation parameters. To chan ge a value, giv e the

parameter name and value as arguments to the ENV command.

ENV [temp|pres|oxy|hum|xtemp|xpres|xoxy|xhum] [value]<cr>

There are four compensation parameters. Values of the parameters are

stored in two places: eeprom (non-volatile memory, values retained

during power off) and RAM (volatile memory that loses the values when

probe is reset, and where values are loaded from non-volatile memory at

startup). As the number of writes to eeprom is limited to 30000 cycles by

memory implementation, you must write all continuously updated values

to RAM to avoid wearing out the eeprom. A second set of parameters

(with X prefix in the name) is provided for this purpose.

When writing permanent values to eeprom, use these parameter names.

Note that updating these parameters does not update the parameters in

RAM (the values that are currently used by the probe).

When writing to RAM, use the parameter names below. The ranges are

the same as for the permanent parameters.

Example (Show current compensation values; all compensations are

enabled. Note that temperature and pressure compensations use internal

measurement, so the value in use is constantly changing):

env

Temperature (C) : 37.00

Pressure (hPa) : 1013.20

Oxygen (%O2) : 19.70

Humidity (%RH) : 93.00

In use:

Temperature (C) : 23.10

Pressure (hPa) : 1011.28

Oxygen (%O2) : 19.70

Humidity (%RH) : 93.00

36 ___________________________________________________________________ M211501EN-C

Page 39

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

If temperature and pressure compensations are

internally measured values, they will continuously update the values in

RAM, overriding any temperature and pressure values that are written to

RAM

Example below sets temperature compensation to setpoint mode, and

changes temperature setpoint value to 37.2 in RAM.

pass 1300

tcmode on

T COMP MODE : ON

env xtemp 37.2

In eeprom:

Temperature (C) : 37.00

Pressure (hPa) : 1013.20

Oxygen (%O2) : 19.70

Humidity (%RH) : 93.00

In use:

Temperature (C) : 37.2

Pressure (hPa) : 1013.20

Oxygen (%O2) : 19.70

Humidity (%RH) : 93.00

NOTE

configured to use

with the ENV command.

Set Measurement to Standby Mode

Use the STANDBY command to set the probe to standby mode. In

standby mode, the CO2 measurement is disabled. Probe returns to the

normal measurement when the command STANDBY OFF is given or

the probe is reset.

STANDBY [on | off]<cr>

Example (enable standby mode):

standby on

Standby mode : ON

VAISALA ________________________________________________________________________ 37

Page 40

User's Guide _______________________________________________________________________

where

mode

=

STOP, RUN, or POLL.

Mode

Measurement Output

Available Commands

STOP

Only with the SEND command.

All (default mode).

RUN

Automatic output.

Only command S.

POLL

Only with the SEND [addr]

SEND [addr] and OPEN [addr].

same line.

Configuring Serial Line Operation

Set Serial Line Op er at ing Mode

Use the SMODE command to set the start-up operating mode of the

serial line.

SMODE [mode]<cr>

Table 11 Selection of Output Modes

command.

Other commands available after

opening a line to the probe using

the OPEN command.

Use with RS-485 buses wh er e

multiple probes can share the

Selected output mode will be activated at next reset or power up.

Example:

smode poll

Serial mode : POLL

38 ___________________________________________________________________ M211501EN-C

Page 41

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

where

b = baud rate (9600, 19200, or 19200)

p = parity (n = none, e = even, o = odd)

d = data bits (7 or 8)

s = stop bits (1 or 2)

where

aaa

=

Device address of the probe, range 0 ... 254 (default = 0)

Set Serial Line Settings

Use the SERI command to set the serial line settings. The new settings

will be taken into use when the probe is reset or powered up.

SERI [b p d s]<cr>

Example (shows default settings):

seri

Com1 Baud rate : 19200

Com1 Parity : N

Com1 Data bits : 8

Com1 Stop bits : 1

Example (set serial line to 9600 baud, even, 7 data bits, and 1 stop bit):

seri 9600 e 7 1

OK

seri

Com1 Baud rate : 9600

Com1 Parity : E

Com1 Data bits : 7

Com1 Stop bits : 1

Set Probe Address

Use the ADDR command to set the device address of the probe.

Addresses are required for POLL mode.

ADDR [aaa]<cr>

Example (change probe address to 52):

pass 1300

addr 52

Address : 52

VAISALA ________________________________________________________________________ 39

Page 42

User's Guide _______________________________________________________________________

where

delay

=

Serial line delay, range 0 … 255 (milliseconds).

Set Serial Line Response Time

With the SDELAY command you can set delay (response time) of the

serial line, or view the currently set delay value.

SDELAY [delay]<cr>

Example (set delay to 50 milliseconds):

sdelay 50

Serial delay : 50

Set Serial Line Echo

Use the ECHO command to enable or disable the echoing of characters

received by the probe.

ECHO [on/off]<cr>

Example:

echo

Echo : OFF

40 ___________________________________________________________________ M211501EN-C

Page 43

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

Before calibrating GMP231 using serial line commands, read the

instructions in section

Make sure that the environmental compensation settings of the GMP231

are properly set for your calibration environment; see section

Measurement Settings

where

-lo = Select low concentration for adjustment. Adjusts

measurement offset.

-hi = Select high concentration for adjustment. Adjusts

measurement gain.

co2

=

CO2 concentration reference in ppm.

-save

=

Save currently entered adjustments.

-cancel

=

Cancel currently entered adjustments.

-reset

=

Clear user adjustments, set Gain to 1 and offset to 0.

Calibration Commands

NOTE

Calibration and Adjustment on page 73.

Changing

on page 35.

Adjust CO2 Measurement

Use the CCO2 command to adjust CO2 measurement in one or two

points. You can use either a low or high concentration reference

(one-point adjustment), or both (two-point adjustment).

The idea is to let the probe stabilize in the desired CO2 concentration, and

then input the real CO2 concentration using the CCO2 command. If you

are performing a two-point correction, repeat for the second point. Then

commit the adjustment by giving the CCO2 –SAVE command. Note that

successfully saving the adjustment clears the calibration date (CDATE)

and calibration text (CTEXT) that have been stored in the probe. Use

those commands to enter a new calibration date and text.

CCO2 [-lo | -hi] [co2] <cr>

CCO2 [-save | -cancel]<cr>

CCO2 [-reset]<cr>

VAISALA ________________________________________________________________________ 41

Page 44

User's Guide _______________________________________________________________________

where

yyyy

=

Year of calibration in four digits

mm

=

Month of calibration in two digits

dd = Day of calibration in two digits

Example (show current user adjustment status – no adjustment done):

pass 1300

cco2

1.Ref. point low 0

1.Meas. point low 0

2.Ref. point low 200000

2.Meas. point low 200000

Gain : 1.0000

Offset : 0.0000

Example (one-point adjustment in 5% concentration (50000 ppm)):

pass 1300

cco2 –lo 50000

OK

cco2 –save

OK

Set Calibration Date

Use the CDATE command to view the date when the probe was last

calibrated, or set a new date.

CDATE [yyyy mm dd]<cr>

Example (show currently stored calibration date):

>pass 1300

>cdate

Calibration date : 2013-10-03

Example (set calibration date to 2014-03-10):

>pass 1300

>cdate 2014 03 10

Calibration date : 2014-03-10

42 ___________________________________________________________________ M211501EN-C

Page 45

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

where

text

=

Calibration information text string, max 19 characters. If

you want to use spaces in the string, enclose the text in

quotes.

where

temp

=

Correct temperature in degrees Celsius (°C).

Set Calibration Info Text

Use the CTEXT command to view or set calibration information text.

CTEXT [text]<cr>

Example (shows the text “Calibrated at” followed by the currently stored

calibration text):

pass 1300

ctext

Calibrated at Vaisala

Example (set calibration text to “Lab_1”):

pass 1300

ctext Lab_1

Calibrated at Lab_1

Adjust Temperature Measurement

Use the CT command to perform an offset correction to the internal

temperature measurement. The correction is done by providing the

correct temperature as an argument to the CT command.

CT [temp]<cr>

CT [-reset]<cr>

Example (adjust the internal temperature measurement to 23 °C at the

current conditions):

pass 1300

ct 23

OK

Example (clear the offset adjustment from internal temperature

measurement):

pass 1300

ct -reset

OK

VAISALA ________________________________________________________________________ 43

Page 46

User's Guide _______________________________________________________________________

where

pressure

=

Correct pressure in hectopascals (hPa).

Adjust Pressure Measu rement

Use the CP command to perform an offset correction to the internal

pressure measurement. The correction is done by providing the correct

pressure as an argument to the CP command.

CP [pressure]<cr>

CP [-reset]<cr>

Example (adjust the internal pressure measurement to 990 hPa at the

current conditions):

pass 1300

cp 990

OK

Example (clear the offset adjustment from internal pressure

measurement):

pass 1300

cp -reset

OK

44 ___________________________________________________________________ M211501EN-C

Page 47

Chapter 4 ____________________________________________________ Vaisala Industrial Protocol

where

channel

=

Analog output channel, only 1 can be selected.

parameter

=

Parameter that is output on analog channel.

Only parameter available is CO2.

lowlimit

=

Lower limit of channel scaling in ppm.

highlimit

=

High limit of channel scaling in ppm.

where

channel

=

Analog output channel, only 1 can be selected.

lo_value

=

Low limit of the channel.

hi_value

=

High limit of the channel.

error_value

=

Error value of the channel.

Configuring Analog Output

Set Analog Output Scaling

Use the ASEL command to show or set the scaling of the analog output.

ASEL [channel] [parameter lowlimit highlimit]<cr>

Example (change channel scaling to 0 … 5%):

pass 1300

asel 1 co2 0 50000

Aout 1 quantity : CO2(0 ... 50000)

Set Analog Output Mode

Use the AMODE command to set the analog output limits and error

level.

AMODE [channel lo_value hi_value error_value]<cr>

Example (show current configuration):

pass 1300

amode 1

Aout 1 range (mA) :4.00 ... 20.00 (error :21.00)

Example (set channel to 4 … 20 mA, and error level to 3.6 mA):

pass 1300