Page 1

CO2 transmitter GMD20 and GMD20D M210292en-A

INTRODUCTION

Vaisala’s GMD20 uses silicon based CARBOCAP sensor technology providing

excellent stability and reliability. The GMD20 transmitters require almost no

maintenance: the recommended calibration interval is five years in HVAC and related

benign applications. Transmitters are available without a display (GMD20 version) and

with a display (GMD20D version).

MOUNTING

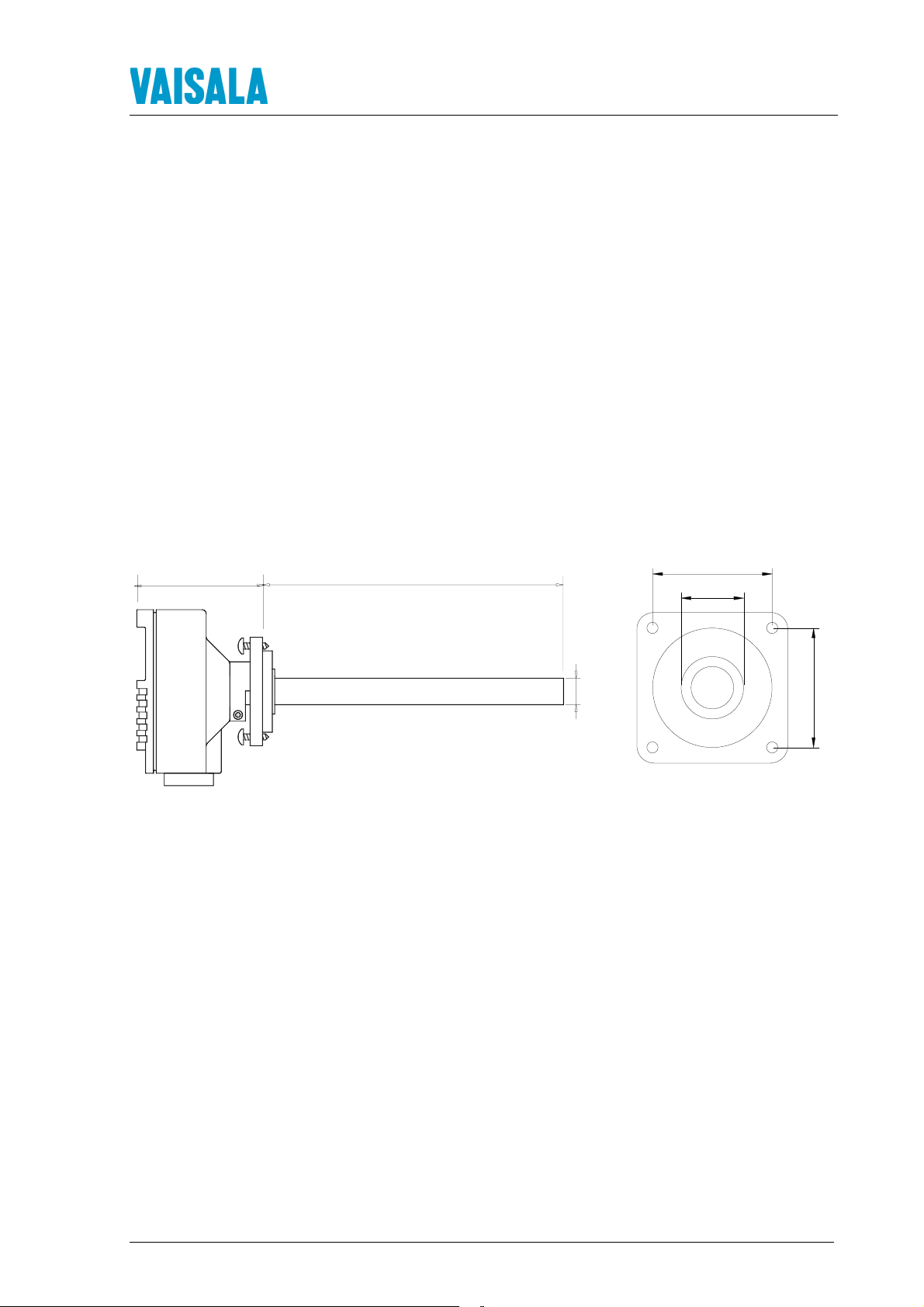

The GMD20 transmitters are truly duct mounted. The distance between the probe and the

duct wall is easily adjusted by using the mounting plate. The mounting plate is fastened

with four screws ST.4.2x16-C-Z/A4m DIN 7981. Note that four ∅3.2 holes on the duct

surface are needed, as well as one ∅22...25 mm hole in the middle (see figure below).

Insert the transmitter through the mounting plate and adjust the distance.

64

min 80 max 140

Ø15

42

22

42

Figure 1 Dimensions of the GMD20 and the mounting plate (in mm)

ELECTRICAL CONNECTIONS

Open the transmitter cover and remove the display board if there is one installed. The

cable is inserted through a rubber plug included in the package. Pierce the rubber plug

with a screwdriver or a similar instrument in order to open the hole for the cable. Then

insert the plug in the appropriate hole in the transmitter cover. Strip a few millimetres of

the cable insulation and insert the cable carefully through the rubber plug so that you can

connect the wires to the terminal block on the righthand side of the component board.

1

Page 2

CO2 transmitter GMD20 and GMD20D M210292en-A

The nominal 24 V supply must be connected between terminals + and -. The analogue

output is available at remaining terminals. The common wire is connected to terminal 0

and the other wire either to terminal V (voltage output) or to terminal mA (current

output). The current output type is chosen with the jumper 0/4mA (see Figure 2):

4...20mA is chosen by connecting the jumper (default) and the 0...20 mA is chosen by

disconnecting the jumper. If the relay output of the display board (in GMD20D ) is used,

connect the wires to the terminal block at the back of the display board before reinstalling it. The default relay trigger point has been set to 1000 ppm and it can be

changed with the optional software kit 19222GM. For further details, contact your local

Vaisala representative. If an optional LonWorks interface or a relay output option is

installed in the GMD20, please, refer to the corresponding manuals for details.

Note that during normal operation the green led (V10) at the lower righthand corner is

blinking. In case the self-diagnostics procedure comes across some abnormality, the red

led (V7) lights up (see Figure 2).

Figure 2 Electrical connections and leds V7, V10

SERVICE AND MAINTENANCE

The GMD20 transmitters have an excellent stability and require almost no maintenance.

In benign environments the recommended calibration interval is five years. If the reading

differs too much from the reference value during checking, the transmitter should be

removed and preferably sent to Vaisala or Vaisala distributor for re-calibration. In case

the user prefers to do the re-calibration himself, Vaisala's software Kit 19222GM and

accurate calibration gases are needed.

If full accuracy is required, the transmitter has to be calibrated against accurate and

traceable calibration gases in stable environmental conditions (temperature, pressure).

Accurate calibrations are usually performed in laboratories; in these calibrations,

temperature and pressure corrections have to be made. A full after sales calibration and

service facility is naturally provided by Vaisala and its distributors. For further details,

consult your local Vaisala representative.

2

Page 3

CONTROLLER

GM20

CO2 transmitter GMD20 and GMD20D M210292en-A

POWER SUPPLY REQUIREMENTS

The GMD20 transmitter is designed to operate from a nominal 24 VAC/VDC supply. The

power supply should maintain the voltage between 18...30 VDC or 20...26 VAC for all

load conditions and all mains voltages. The power input includes a halfwave rectifier. To

avoid current peaks, it is recommended to use a DC supply. The average transmitter current consumption is 85 mA maximum but peak currents of 170 mA may occur during

normal operation.

CONNECTION TO A 24 VAC SUPPLY

The GMD20 transmitters can also be connected to a 24 VAC supply without an external

rectifier. However, when more than one transmitter is connected to one 24 VAC

transformer, a common loop is formed and there is an increased risk of a short-circuit. To

avoid this, always use separate floating supply for each transmitter (see Figure 3A).

However, if several transmitters have to share one transformer, the phase (∼) must always

be connected to + connector in each transmitter (see Figure 3B).

A)

24VAC

Supply

voltage

GM20

24V OUT

GND

GM20

Supply

voltage

Supply

voltage

24V OUT

GND

24V OUT

GND

GM20

24V OUT

GND

B)

24VAC

24VAC

Supply

voltage

Figure 3 AC connections

Signal

output

Signal

output

CONTROLLER

Signal

output

Signal

output

SHARED

COMMON

LINE

3

Page 4

CO2 transmitter GMD20 and GMD20D M210292en-A

*M210292

EN

*

TECHNICAL DATA

Carbon dioxide

Measuring range 0...2000 ppm CO2 (nominal); with recalibration 0...5000 ppm CO2,

0...10 000 ppm CO

Accuracy at 20°C against

certified factory references <±[30 ppm + 2.0 % of the reading]

(including repeatability and calibration uncertainty)

Non-linearity <±1.0 %FS

Temperature dependence

of output (typical) < 0.15 %FS / °C (reference 25°C)

Long-term stability <±5 %FS / 5 years

Response time (0…63%) 1 minute

, 0...20 000 ppm CO

2

2

Operating conditions

Operating temperature -5...+45 °C

Storage temperature -20...+70 °C

Humidity range short term 0...85 %RH (non-condensing)

Air flow range 0...10 m/s

General

Analogue outputs 0...20 mA or 4...20 mA and 0...10 V

Resolution of analog outputs 0.5 % FS

Recommended external load:

current output max. 500 Ω

voltage output min. 1kΩ

Relay contact ratings max. 50 V 0.5 A

Power supply nominal 24 VDC/VAC (18...30 VDC)

Power consumption < 2.5 W average

Warm-up time < 15 minutes

Mechanics

Housing material ABS plastic

Housing classification IP65

(electronics housing)

Weight:

GMD20 140 g

GMD20D 170 g

ACCESSORIES

Order code Description

GMR20 Relay output option (not for the GMD20D)

GML20

GM35001 Calibration pipe

19222GM Calibration software kit (incl. disk and serial COM adapter)

LonWorksinterface option (not for the GMD20D )

GUARANTEE

Vaisala issues a guarantee for the material and workmanship of this product under

normal operating conditions for one (1) year from the date of delivery. Exceptional

operating conditions, damage due to careless handling and misapplication will void

the guarantee.

4

Loading...

Loading...