Page 1

Weather Sensor

FD12P

USER'S GUIDE

M210296en-A

May 2002

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2002

No part of this manual may be reproduced in any form or by any means,

electronic or mechanical (including photocopying), nor may its contents be

communicated to a third party without prior written permission of the copyright

holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or

Conditions of Sale.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ..........................................................................11

About This Manual..................................................................11

Contents of This Manual......................................................11

Version Information................................................................12

Related Manuals .....................................................................12

Safety .......................................................................................12

General Safety Considerations............................................12

Product Related Safety Precautions ...................................13

Safety Summary ............................................................. 13

Ground the Equipment ...................................................13

Radio Frequency Interference Statement (USA) ...........15

ESD Protection .................................................................... 15

Trademarks .............................................................................16

Warranty ..................................................................................16

CHAPTER 2

PRODUCT OVERVIEW ................................................................................ 17

Introduction.............................................................................17

Hardware Structure .............................................................17

Sensing Elements ..........................................................19

Electronics Enclosure .....................................................20

Structural Elements ........................................................ 20

Operating Principle ..............................................................21

Using FD12P .......................................................................22

Equipment Nomenclature ......................................................23

Specifications .........................................................................24

Mechanical Specifications ...................................................24

Electrical Specifications.......................................................24

Optical Specifications ..........................................................25

Capabilities and Limitations ..................................................26

Visibility Measurement Specifications .................................26

Weather Sensing Specifications..........................................26

Environmental Specifications ..............................................27

CHAPTER 3

INSTALLATION ............................................................................................ 29

Organizing Installation ...........................................................29

Location and Orientation .......................................................30

Grounding and Lightning Protection....................................32

Equipment Grounding..........................................................32

Internal Grounding ............................................................... 34

VAISALA _________________________________________________________________________ 3

Page 4

User's Guide _______________________________________________________________________

Grounding for Testing Purposes......................................... 34

Grounding Remote Units and Communication Cable......... 34

Cable Selection ...................................................................... 35

Line Power Cabling............................................................. 35

Communication Cable......................................................... 35

Unloading and Unpacking..................................................... 36

Unpacking Procedure ......................................................... 36

Storage Information ............................................................ 36

Installation Procedures ......................................................... 37

Constructing the Foundation............................................... 37

Mounting When Casting the Pad................................... 38

Mounting to an Existing Surface.................................... 38

Assembling the FD12P ....................................................... 40

Attaching the DTS14B Temperature Sensor to the Mast ... 41

Connecting Cables.............................................................. 43

Basic Wiring ................................................................... 43

Communication Cable EMC-shielding........................... 46

Connecting a Background Luminance Sensor or a

Day/Night Switch to FD12P ........................................... 48

Communication Options ..................................................... 50

Serial Communications Settings.................................... 50

Serial Transmission RS-232.......................................... 50

Serial Multipoint Transmission RS-485 ......................... 51

Modem DMX21 .............................................................. 52

Indicators and Manual Controls..................................... 54

Indicators .................................................................. 54

Manual Controls ....................................................... 54

Analog Transmission ..................................................... 55

Connecting the Maintenance Terminal.......................... 55

Startup Testing.................................................................... 56

Initial Settings...................................................................... 56

CHAPTER 4

OPERATION ................................................................................................ 59

Introduction ............................................................................ 59

User Commands in Normal Operation................................. 59

Markings Used in This Manual ............................................. 61

Entering/Exiting the Command Mode .................................. 61

OPEN Command ................................................................ 61

CLOSE Command .............................................................. 62

Automatic Message Sending ................................................ 62

Message Types................................................................... 63

Message 0 ..................................................................... 64

Message 1 ..................................................................... 64

Message 2 ..................................................................... 65

Message 3 ..................................................................... 65

Message 4 ..................................................................... 66

Messages 5 and 6 ......................................................... 66

Message 7 ..................................................................... 68

Message Polling ..................................................................... 69

FD12P Command Set............................................................. 70

HELP Command ................................................................. 70

______________________________________________________ M210296en-A

4

Page 5

_________________________________________________________________________________

MES Command ...................................................................71

AMES Command............................................................71

Weather Related Commands ..............................................73

WPAR Command ........................................................... 73

WSET Command ...........................................................73

Precipitation Limit......................................................74

Weather Update Delay..............................................74

Haze Limit .................................................................74

Rain Intensity Scale................................................... 75

Violent Rain Limit ......................................................75

Heavy Rain Limit .......................................................75

Light Rain Limit.......................................................... 75

Drizzle Limit...............................................................75

Heavy Drizzle Limit....................................................76

Light Drizzle Limit ......................................................76

Snow Limit.................................................................76

Heavy Snow Limit......................................................76

Light Snow Limit ........................................................76

Snow Pellets Limit .....................................................77

Snow Grains Limit .....................................................77

Ice Crystals Limit .......................................................77

Hail Limit.................................................................... 77

DRD Scale................................................................. 77

Warm Limit ................................................................77

PRW Command..............................................................77

CLRS Command ............................................................78

WHIS Command.............................................................78

System Configuration Commands....................................... 79

PAR Command............................................................... 79

CONF Command............................................................80

BAUD Command ............................................................84

BLSC Command.............................................................84

Maintenance Commands..................................................... 85

STA Command ...............................................................85

CAL Command ...............................................................87

TCAL Command.............................................................87

CLEAN Command .......................................................... 88

CHEC Command............................................................89

FREQ Command ............................................................ 89

DRY and WET Commands ............................................89

AN Command .................................................................90

Analog Output Commands ..................................................91

Analog Output Calibration ..............................................91

Data Scaling ................................................................... 92

Hardware Check.............................................................92

Other Commands ................................................................93

TIME Command .............................................................93

DATE Command ............................................................93

RESET Command .......................................................... 94

CHAPTER 5

FUNCTIONAL DESCRIPTION .....................................................................95

General.....................................................................................95

Optical Measurement .............................................................96

VAISALA _________________________________________________________________________ 5

Page 6

User's Guide _______________________________________________________________________

Optical Arrangement ........................................................... 96

FDT12B Transmitter Unit .................................................... 96

FDR12 Receiver Unit .......................................................... 98

Additional Measurements ..................................................... 99

General ............................................................................... 99

DRI21 Interface Board ........................................................ 99

DRD12 Rain Detector ....................................................... 100

DTS14B Temperature Sensor .......................................... 101

FDP12 Control Unit .............................................................. 101

Measurement Signal Processing........................................ 103

Optical Signal Processing................................................. 103

DRD12 Signal Processing ................................................ 104

Algorithm Description ......................................................... 105

Visibility ............................................................................. 105

Detecting Precipitation ...................................................... 106

Precipitation Intensity........................................................ 106

Precipitation Accumulation ............................................... 107

Present Weather ............................................................... 108

Precipitation Types ...................................................... 108

Liquid Precipitation ................................................. 109

Frozen Precipitation................................................ 110

Mixed Precipitation ................................................. 111

Unknown Precipitation ............................................ 111

Visibility Types ............................................................. 111

Fog.......................................................................... 111

Haze and Mist......................................................... 112

Weather Classes ......................................................... 112

Weather Code Selection .............................................. 113

Applications.......................................................................... 113

Internal Monitoring .............................................................. 114

Built-in Tests ..................................................................... 114

Memory Tests ................................................................... 115

Signal Monitoring .............................................................. 115

Hardware Monitoring......................................................... 115

Contamination Monitoring................................................. 116

CHAPTER 6

MAINTENANCE ......................................................................................... 117

General.................................................................................. 117

Cleaning ................................................................................ 118

Cleaning Lenses and Hoods............................................. 118

Cleaning DRD12 Rain Detector........................................ 118

Calibration ............................................................................ 119

General ............................................................................. 119

Visibility Calibration........................................................... 119

Calibration Check Procedure....................................... 120

Calibration Procedure .................................................. 123

Calibrating the DTS14B Temperature Sensor............. 124

Removing and Replacing.................................................. 126

Removing and Replacing Optical Units ....................... 126

Removing and Replacing the DRD12 Rain Detector .. 129

______________________________________________________ M210296en-A

6

Page 7

_________________________________________________________________________________

Calibrating FD12P Weather Sensor after Unit

Replacement ................................................................130

CHAPTER 7

TROUBLESHOOTING................................................................................133

Warnings ...............................................................................133

Troubleshooting Examples..................................................133

Message Indicating Warning or Alarm .............................133

Message Missing ............................................................... 134

Visibility Value is Missing...................................................135

Visibility Value is Continuously Too Good ......................... 135

Visibility is Constantly Too Low .........................................136

FDP12 Reports Precipitation When There Is None........... 136

FD12P Reports Frozen Precipitation during Rain ............. 136

Have Jumper Settings Been Changed? ............................137

Values for Internal Monitoring.............................................137

Getting Help ..........................................................................140

Return Instructions...............................................................140

APPENDIX A

NWS AND WMO CODES USED IN FD12P ...............................................143

The NWS Codes ....................................................................143

APPENDIX B

JUMPER SETTINGS AND INTERNAL WIRING........................................147

CPU Board.............................................................................149

DC-Regulator.........................................................................149

DRI21 Interface Board ..........................................................149

APPENDIX C

TRANSMITTER AND RECEIVER TEST POINTS .....................................151

INDEX .........................................................................................................153

List of Figures

Figure 1 FD12P Weather Sensor Site ....................................................18

Figure 2 DRD12 Rain Detector and DTS14B Temperature Sensor .......19

Figure 3 FD12P Block Diagram ..............................................................21

Figure 4 Recommended Location for the FD12P ................................... 31

Figure 5 FD12P Equipment Grounding ..................................................33

Figure 6 Casting a Concrete Foundation................................................37

Figure 7 Constructing the FD12P Foundation ........................................ 39

Figure 8 Tilting the Pole Mast ................................................................. 41

Figure 9 DTS14B and the Sensor Holder Assembly to Mast .................42

Figure 10 Connecting Internal Grounding.................................................43

Figure 11 Cabling Principle.......................................................................44

Figure 12 Line Voltage and ON/OFF Switches.........................................45

Figure 13 Electronics Enclosure Feedthroughs........................................46

Figure 14 Cable Grounding Instructions ...................................................47

VAISALA _________________________________________________________________________ 7

Page 8

User's Guide _______________________________________________________________________

Figure 15 Wiring the Connector for the LM11 Background Luminance

Meter ........................................................................................ 49

Figure 16 Wiring the Day/Night Photo Switch .......................................... 50

Figure 17 Communication Option ............................................................ 51

Figure 18 RS-485 Communication Option ............................................... 52

Figure 19 Wiring the Modem.................................................................... 53

Figure 20 Analog Current Loop Option .................................................... 55

Figure 21 FD12P Optical System............................................................. 96

Figure 22 FDT12B Transmitter Block Diagram........................................ 97

Figure 23 FDR12 Receiver Block Diagram .............................................. 98

Figure 24 DRI21 Block Diagram in the FD12P Application.................... 100

Figure 25 DRD12 Block Diagram........................................................... 101

Figure 26 FDP12 Control Unit Block Diagram ....................................... 102

Figure 27 Optical Raw Data (in Rain) .................................................... 103

Figure 28 Optical Signal Amplitude Distribution (in Rain) ...................... 104

Figure 29 DRD12 Surface Signal (Heavy Rain Beginning).................... 104

Figure 30 Precipitation Type Determination Principle ............................ 109

Figure 31 Assembling the FDA13 Calibrator.......................................... 122

Figure 32 DTS14 Sensor Holder Assembly to Mast .............................. 125

Figure 33 Removing the Optical Units ................................................... 127

Figure 34 Replacing the Optical Units.................................................... 128

Figure 35 Removing the DRD12 Rain Detector ..................................... 129

Figure 36 Basic Electronics Enclosure Wiring ....................................... 148

Figure 37 Test Points, Transmitter......................................................... 151

Figure 38 Test Points, Receiver ............................................................. 152

List of Tables

Table 1 Manual Revisions..................................................................... 12

Table 2 Related Manuals ...................................................................... 12

Table 3 Basic Set .................................................................................. 23

Table 4 Options..................................................................................... 23

Table 5 Mains Cable Selection ............................................................. 35

Table 6 Communication Cable Lengths................................................ 35

Table 7 Transmit Frequencies of the DMX21 Modem Board ............... 53

Table 8 LED Indicators of the DMX21 Modem ..................................... 54

Table 9 Manual Controls of the DMX21 Modem................................... 54

Table 10 Default Communication Settings.............................................. 57

Table 11 Commands for Changing the Default Settings ........................ 57

Table 12 Commands for Displaying and Changing the Parameters ...... 57

Table 13 Settings and Corresponding Commands................................. 60

Table 14 Routine Command for Maintenance ........................................ 60

Table 15 Status Report Command ......................................................... 60

Table 16 Transmitter Status Correspondence between MITRAS and

FD12P ...................................................................................... 67

Table 17 Receiver Status Correspondence between MITRAS and FD12P67

Table 18 HELP Command Sets .............................................................. 70

Table 19 Commands for Displaying or Setting Weather Analysis

Parameters............................................................................... 73

______________________________________________________ M210296en-A

8

Page 9

_________________________________________________________________________________

Table 20 Commands for Displaying System Parameters and Editing the

Current System Configuration ..................................................79

Table 21 Maintenance Commands..........................................................85

Table 22 Hardware Error Texts ...............................................................86

Table 23 Hardware Warning Texts ..........................................................86

Table 24 Parameters for Optical Measurement.....................................131

Table 25 Parameters for DRD12 Precipitation Detector .......................131

Table 26 Parameters for DTS14 Temperature Sensor..........................131

Table 27 Updating Parameters..............................................................131

Table 28 Parameters and Commands...................................................132

Table 29 Values for Internal Monitoring.................................................138

Table 30 Internal Weather Types, NWS Code .....................................143

Table 31 WMO SYNOP Codes (4680, W

Table 32 WMO SYNOP Codes (4680, W

Table 33 WMO SYNOP Codes (4680, W

) ......................................143

aWa

) ......................................144

aWa

) ......................................144

aWa

Table 34 WMO Code Table 4678. Codes Used by FD12P ...................145

Table 35 CPU Board Jumpers...............................................................149

Table 36 CPU Board Connectors ..........................................................149

Table 37 DC-regulator Connectors........................................................149

Table 38 DRI21 Interface Board Jumpers ............................................. 149

Table 39 DRI21 Interface Board Connectors ........................................150

Table 40 Electronics Enclosure/Transducer Cable Signals ..................150

Table 41 Transmitter Test Points........................................................... 151

Table 42 Receiver Test Points............................................................... 152

VAISALA _________________________________________________________________________ 9

Page 10

User's Guide _______________________________________________________________________

This page intentionally left blank.

______________________________________________________ M210296en-A

10

Page 11

Chapter 1 _________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

About This Manual

This manual is a general information source as well as a detailed

operational guide to the FD12P Weather Sensor.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides important safety, revision

history, contact, and warranty information for the product.

- Chapter 2, Product Overview, introduces the FD12P Weather

Sensor features, advantages, and the product nomenclature.

- Chapter 3, Installation, provides you with information to help you

install this product.

- Chapter 4, Operation, contains information needed to operate this

product.

- Chapter 5, Functional Description, gives a functional description on

the product.

- Chapter 6, Maintenance, describes the overall maintenance of the

product.

- Chapter 7, Troubleshooting, deals with troubleshooting

information.

- Appendix A, NWS and WMO Codes Used in FD12P

- Appendix B, Jumper Settings and Internal Wiring

- Appendix C, Transmitter and Receiver Test Points

VAISALA ________________________________________________________________________ 11

Page 12

User's Guide _______________________________________________________________________

Version Information

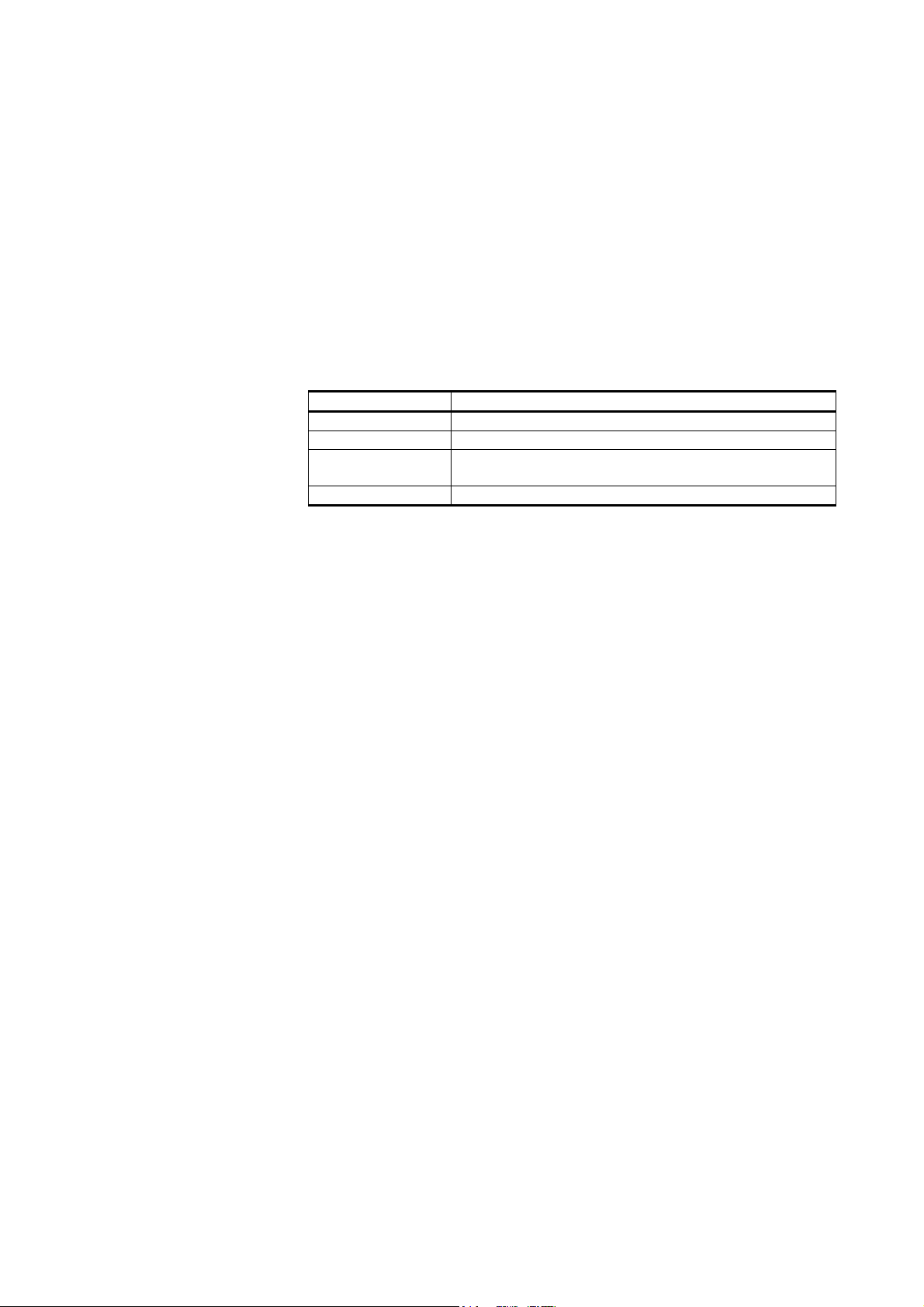

Table 1 Manual Revisions

Manual Code Description

FD12P-U106en-1.2 Weather Sensor, User's Guide

M210296en-A This manual.

Related Manuals

Table 2 Related Manuals

Manual Code Manual Name

DMX21T0496-1.1 DMX21 CCITT Modem

LM11T0545-1.2 LM11 Background Luminance Meter

Safety

WARNING

CAUTION

General Safety Considerations

Throughout the manual, important safety considerations are

highlighted as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or

even death.

Caution warns you of a potential hazard. If you do not read and

follow instructions carefully at this point, the product could be

damaged or important data could be lost.

NOTE

______________________________________________________ M210296en-A

12

Note highlights important information on using the product.

Page 13

Chapter 1 _________________________________________________________ General Information

Product Related Safety Precautions

The FD12P Weather Sensor delivered to you has been tested for

safety and approved as shipped from the factory. Note the following

precautions:

WARNING

CAUTION

WARNING

Ground the product, and verify outdoor installation grounding

periodically to minimize shock hazard.

Do not modify the unit. Improper modification can damage the

product or lead to malfunction.

Safety Summary

The following are general safety precautions must be observed during

all phases of installation, operation and maintenance.

Neglecting to follow these precautions or specific warnings and

cautions elsewhere in this manual violates safety standards of design,

manufacture and intended use of the instrument. Vaisala Oyj. and its

Subsidiaries do not answer for the consequences if the customer

neglects to follow these requirements.

Ground the Equipment

To minimize the hazard of electrical shock, follow accurately the

installation procedure in Chapter 3, Installation, on page 29.

NOTE

VAISALA ________________________________________________________________________ 13

Note that the chassis of the FD12P Weather Sensor must be

connected to a good electrical earth. The instrument is equipped with

a three-conductor AC power cable. Be sure that the earth wire of the

cable is connected to an electrical ground.

There is also a grounding clamp at the bottom of the electronics

enclosure of Weather Sensor FD12P. Good grounding with a 16-mm

2

Page 14

User's Guide _______________________________________________________________________

cable must be provided. Besides increasing safety, this also protects

the Weather Sensor against lightning induced voltages.

To prevent operator injury or damage to the Weather Sensor, check

that the LINE VOLTAGE SETTING is correct before connecting the

line power (See Figure 12 on page 45.) Also ensure that the line power

outlet is provided with a protective ground contact.

WARNING

WARNING

WARNING

Do not operate in an explosive atmosphere.

Do not operate the equipment in the presence of flammable gases or

fumes. Operation of any electrical instrument in such an environment

constitutes a definite safety hazard.

Do not service or adjust alone.

Do not attempt internal service or adjustment unless another person,

capable of rendering first aid and resuscitation, is present.

Keep away from live circuits.

Component replacement or internal adjustments must be made by

qualified maintenance personnel. Operating personnel must not

remove instrument covers. Do not remove or replace any components

with the power cable connected. Under certain conditions, dangerous

voltages may exist even with the power cable disconnected. To avoid

injuries disconnect power, and discharge all circuits before touching

them.

WARNING

______________________________________________________ M210296en-A

14

Do not substitute parts or modify the instrument.

Because of the danger of introducing additional hazards, do not

modify or substitute parts in the instrument. Contact Vaisala or its

authorized representative for repairs to ensure that safety features are

maintained.

Page 15

Chapter 1 _________________________________________________________ General Information

CAUTION

The component boards including CMOS microchips should be

transported and stored in conductive packages. Although new CMOS

devices are protected against overvoltage damages caused by static

electric discharge of the operator, careful handling is recommended:

the operator should be properly grounded. Unnecessary handling of

component boards should be avoided.

Radio Frequency Interference Statement (USA)

The United States Federal Communications Commission (in 47 CFR

15.838) has specified that the following notice must be brought to the

attention of users of this kind of a product in the USA:

Federal communications commission radio frequency interference

statement

This equipment generates and uses radio frequency energy and if not

installed and used properly, that is in strict accordance with the

manufacturer's instructions, may cause interference to radio and

television reception. The Weather Sensor is designed to provide

reasonable protection against such interference in an airport

installation. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment causes

interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

- reorient the receiving antenna

- relocate this device with respect to the receiver

- move this device away from the receiver

If necessary, the user should consult the dealer or an experienced

radio/television technician for additional suggestions.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage

to electronic circuits. Vaisala products are adequately protected

against ESD for their intended use. However, it is possible to damage

the product by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

VAISALA ________________________________________________________________________ 15

Page 16

User's Guide _______________________________________________________________________

To make sure you are not delivering high static voltages yourself, take

the following precautions:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench. When this is not possible, ground

yourself to the equipment chassis before touching the boards.

Ground yourself with a wrist strap and a resistive connection cord.

When neither of the above is possible, touch a conductive part of

the equipment chassis with your other hand before touching the

boards.

- Always hold the boards by the edges and avoid touching the

component contacts.

Trademarks

Intel® is a registered trademark of the Intel Corporation in the U.S.

and other countries.

Warranty

For certain products Vaisala normally gives a limited one-year

warranty. Please observe that any such warranty may not be valid in

case of damage due to normal wear and tear, exceptional operating

conditions, negligent handling or installation, or unauthorized

modifications. Please see the applicable supply contract or conditions

of sale for details of the warranty for each product.

______________________________________________________ M210296en-A

16

Page 17

Chapter 2 ___________________________________________________________Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the FD12P Weather Sensor features,

advantages, and the product nomenclature.

Introduction

The FD12P Weather Sensor is an intelligent, multi-variable sensor for

automatic weather stations and airport weather observing systems.

The sensor combines the functions of a forward scatter visibility meter

and a present weather sensor. In addition, the sensor can measure the

intensity and amount of both liquid and solid precipitation.

The FD12P can be used to automatically determine the visibility and

precipitation related weather codes in the World Meteorological

Organization (WMO) standard SYNOP and METAR messages. The

sensor can also be employed as an observer's aid in a semi-automatic

weather observing system. The sensor is also suitable for other

weather observing systems providing valuable information, for

example, to road and harbor authorities.

The versatility of the FD12P is achieved with a unique operating

principle. The FD12P measures precipitation water content with a

capacitive device and combines this information with optical scatter

and temperature measurements. These three independent

measurements together provide data sufficient for an accurate

evaluation of current visibility and weather type.

Hardware Structure

The structural basis of the FD12P is the pole mast that supports the

transducer crossarm (FDC115). The crossarm contains the optical

VAISALA ________________________________________________________________________ 17

Page 18

User's Guide _______________________________________________________________________

units, FDT12B Transmitter and FDR12 Receiver. The DRD12 Rain

Detector is fastened to the crossarm. The electronics enclosure with

the main data processing and interface units is mounted to the pole

mast as seen in Figure 1 below.

0201-085

Figure 1 FD12P Weather Sensor Site

The following numbers are related to Figure 1 above:

1 = Transducer crossarm

2 = DRD12 Rain Detector

3 = DTS14 Temperature Sensor

4 = Pole mast

5 = Electronics enclosure

The FD12P Weather Sensor consists of three parts: sensing elements,

electronics enclosure, and structural elements. They are described in

detail on the next page.

______________________________________________________ M210296en-A

18

Page 19

Chapter 2 ___________________________________________________________Product Overview

Sensing Elements

The FDT12B Transmitter emits pulses of near infrared light. It is

permanently tilted 16.5º downwards. The optical power is stabilized

by a closed hardware loop. The unit also includes a receiver circuit for

monitoring lens contamination.

The FDR12 Receiver measures the scattered part of the FDT12B light

beam. The FDR12 contains also an additional light transmitter for

monitoring lens contamination. Like the transmitter, the receiver is

also tilted 16.5º downwards. Therefore, the receiver unit measures

light scattered at an angle of 33°.

The DRD12 Rain Detector outputs a signal proportional to the amount

of water on two RainCap™ sensing elements. These elements consist

of thin wires protected by an insulating glass coating. The presence of

water changes the capacitance of the elements. The combined

capacitance of the plates is measured by the DRD12 electronics.

Integrated heating resistors keep the elements dry when, for example,

fog and melt snow fall on them. The Rain Detector is protected by a

windshield to decrease the effect of wind on the measurement results.

The DRD12 is illustrated in Figure 2 below.

The DTS14B Temperature Sensor is a Pt100 thermistor that is used to

measure the crossarm temperature. See Figure 2 below.

0201-086

Figure 2 DRD12 Rain Detector and DTS14B Temperature

Sensor

VAISALA ________________________________________________________________________ 19

Page 20

User's Guide _______________________________________________________________________

The following numbers refer to Figure 2 on page 19:

1 = Two RainCapTM elements

2 = DRD12 Rain Detector

3 = Wind shield

4 = Assembly clamp

5 = DTS14 Temperature sensor

Electronics Enclosure

The FDP12 Control Unit is the main data processor and

communication unit of the FD12P.

The DRI21 Interface Board is a Vaisala, general-purpose sensor

interface, with several analog and digital input channels. In the

FD12P, one of the DRI21 Interface Board channels is used for

measuring the crossarm temperature and the DRD12 analog signal. In

addition, the DRI21 controls the DRD12 heating and reads the

precipitation ON/OFF status.

The FDW13 Mains Power Supply converts the mains voltage to

24 VAC power for the FDS12 regulator and the heater elements. The

FDW13 includes also the mains voltage selector and the mains

ON/OFF switch, which also functions as an automatic fuse.

The FDS12 DC Voltage Regulatorconverts the AC or DC input

voltage (min. 18 V) to 12 VDC power used by FD12P electronics. The

FDS12 also includes one relay used to control heater power.

The DMX21 Modem (optional) is a standard, 300-baud modem used

only in the leased line mode with the FD12P.

The FDE12 Backup Temperature Sensor is included.

Structural Elements

The structural elements include the pole mast with a standard height

of 2 meters and the FDC115 Transducer Crossarm with a length of

1.5 meters, which is also the total width of the FD12P.

______________________________________________________ M210296en-A

20

Page 21

Chapter 2 ___________________________________________________________Product Overview

Operating Principle

The FD12P Weather Sensor is a microprocessor controlled, intelligent

sensor combining optical forward scatter measurement, capacitive

precipitation sensing, and temperature measurement. The main units

of the FD12P are shown in Figure 3 below.

9502-091

Figure 3 FD12P Block Diagram

The FD12P evaluates Meteorological Optical Range (MOR) by

measuring the intensity of infrared light scattered at an angle of 33°.

The scatter measurement is converted to the visibility value (MOR)

after a careful analysis of the signal properties. Special processing is

used in case of precipitation.

The FD12P software detects precipitation droplets from rapid changes

in the scatter signal. The droplet data is used to estimate optical

precipitation intensity and amount. In addition to the optical signal,

the analog output of the DRD12 Rain Detector is used to estimate the

precipitation intensity and type.

VAISALA ________________________________________________________________________ 21

Page 22

User's Guide _______________________________________________________________________

The output of the DRD12 is proportional to the water amount on the

capacitive sensing surfaces while the optical intensity is proportional

to the total volume of the reflecting particles. The ratio of optical and

capacitive intensities is used to determine the basic precipitation type.

The crossarm temperature (TS) is measured with the DTS14B

Temperature Sensor connected to the DRI21 interface card. The

temperature data together with the optical signal profile and the

DRD12 surface sensor data are used to determine the actual weather

code.

The software performs all signal analyses in the FD12P except the

DRD12 Rain ON/OFF status, which is hardware-based and is used as

an auxiliary parameter. The FD12P has a fixed program that is divided

into tasks executed under control of a real-time operating system

kernel. Each task is like an endless loop with a limited function. The

operating system kernel controls the timing of the tasks and the

interactions between the tasks.

Using FD12P

The FD12P is typically used as a component of a weather observing

system. The final weather message (SYNOP, METAR) is then coded

in the central unit of a weather observation system (for example,

Vaisala MILOS 500) or by a human observer using the FD12P as an

observation aid.

The FD12P output is a digital serial interface, which can be

configured into two different operating modes: the sensor can be set to

send a data message automatically at selected intervals, or the FD12P

can be polled by the host computer. The same serial line is also used

as an operator interface.

The operator controls and checks the operation of the FD12P by using

a maintenance terminal. A set of built-in commands and test routines

is provided for configuring and monitoring the multiple functions of

the FD12P.

The standard data messages contain a status character for indicating

faults detected by the internal diagnostics. If the error status is set, the

operator can view a special status message. It contains detailed results

of the diagnostics and a written description of the fault. Using this

information, the operator can take corrective action or provide the

maintenance personnel with valuable advice.

______________________________________________________ M210296en-A

22

Page 23

Chapter 2 ___________________________________________________________Product Overview

Equipment Nomenclature

The standard equipment nomenclature and common names are listed

in Table 3 and Table 4 below.

Table 3 Basic Set

Type Name Description

FDC115 Transducer Crossarm Optics, analog, monitoring

assembly

FDT12B Transmitter

FDR12 Receiver

16614ZZ Crossarm Cable

FDB12 Electronics Enclosure Power, conversions, interfacing

assembly

FDP12 Processor Board

FDS12 DC Voltage Regulator

FDW13 Mains Power Supply

DRI21 Interface Board

16615ZZ Transducer Cable

16737ZZ I/O Bus Cable

DRD12 Rain Detector

FD30513 Pole Mast Standard 2-m mast

13145 Base Plate and

Installation Set

Table 4 Options

Type Name Description

FDA13 Visibility Calibration Set

FD45094 Maintenance cable RS232 cable with 9-pin D-

connector.

Termbox-48 Mains and Signal

Junction Box

FD12MODEM Modem Option For remote communication.

FD12PLM11 LM11 Option For ambient light

16616ZZ Extended Transducer

Cable

Adapting/extending the local

cable. Contains heavy-duty

transient protection circuitry.

measurement.

For optional high-mast

mounting.

VAISALA ________________________________________________________________________ 23

Page 24

User's Guide _______________________________________________________________________

Specifications

Mechanical Specifications

- Dimensions: 2.3 m × 1.6 m × 0.6 m (H × W × D)

- Weight: 35 kg, excluding the installation plate for the pole

mast

- Mounting: on a concrete foundation with three ∅16-mm

bolts

- Material: anodized aluminum, natural gray

Electrical Specifications

- Mains supply: 115/230 VAC ± 20 %, 45 ... 65 Hz

- Maximum power consumption: 35 W + 100 W defrosting

heaters (in cold weather)

The sensor electronics:

- Lock-in amplifier

- LED power stabilizer

- Contamination monitor

- Lens heater

The control unit:

- Intel 8031 microprocessor

- Program memory, 64 Kbytes

- Read/write memory, 32 Kbytes

Outputs:

- Serial data line may be used either as RS-232 level signals or

interfaced via an optional data modem

- RS-485 (2-wire)

- 4 - 20 mA analog current (sink) output

______________________________________________________ M210296en-A

24

Page 25

Chapter 2 ___________________________________________________________Product Overview

The output data:

- Automatic or polled data message

- Visibility, present weather, precipitation and status data

- Automatic message type and interval is selectable at 15

seconds to n × 15 seconds (n < 18) intervals

The analog visibility output:

- Selectable range and mode (linear or logarithmic)

- Status control bit for remote alarm relay, etc.

- Alarms and warnings (hardware failures, visibility limits)

Optical Specifications

Operating principle:

- Forward scatter at an angle of 33o and capacitive rain sensor.

The light transmitter:

- Light source: near-infrared LED

- Peak wavelength: 875 nm

- Modulation frequency: 2.3 kHz

- Transmitter lens diameter: 71 mm

- Reference photodiode: for light source control

- Backscatter photodiode: for contamination and blockage

measurement

The light receiver:

- Photodiode: PIN 6 DI

- Spectral response: max. responsivity at 850 nm, 0.55 A/W

(in range 550 ... 1050 nm over 0.3 A/W)

- Reception lens diameter: 71 mm

- Backscatter light source: near-infrared LED for

contamination and blockage measurement

VAISALA ________________________________________________________________________ 25

Page 26

User's Guide _______________________________________________________________________

Capabilities and Limitations

Visibility Measurement Specifications

Measurement range of Meteorological Optical Range (MOR):

- 10 ... 50 000 m according to a 5 % Contrast Threshold

Definition

Accuracy:

- ± 10 %, range 10 ... 10 000 m

- ± 20 %, range 10 000 ... 50 000 m

Instrument consistency:

- + 4 %

Update interval:

- 15 seconds

Weather Sensing Specifications

Precipitation detection sensitivity:

- 0.05 mm/h or less, within 10 minutes

Weather type identification:

- 11 different types of precipitation

- Fog (mist) and haze (smoke, sand)

Weather type reporting:

- WMO code table 4680 (with some additions from code table

4677)

- Code letters for precipitation, NWS

- WMO code table 4678 (supported codes are shown in Table

34 on page 145).

______________________________________________________ M210296en-A

26

Page 27

Chapter 2 ___________________________________________________________Product Overview

Precipitation intensity measurement:

- Range 0.00 ... 999 mm/h

- Accuracy ± 30 % (range 0.5 ... 20 mm/h, liquid precipitation)

Environmental Specifications

Operating temperature range:

- − 40 ... +55 oC

Operating humidity range:

- Up to 100 % RH

Wind speed:

- Up to 60 m/s (standard mast)

Sun orientation:

- Direct and reflected sunlight into the light receiver must be

avoided.

VAISALA ________________________________________________________________________ 27

Page 28

User's Guide _______________________________________________________________________

This page intentionally left blank.

______________________________________________________ M210296en-A

28

Page 29

Chapter 3 ________________________________________________________________ Installation

CHAPTER 3

INSTALLATION

This chapter provides you with information to help you install this

product.

NOTE

Before installation, read section Product Related Safety Precautions

on page 13.

Organizing Installation

Before you begin to install the FD12P Weather Sensor, make a plan of

the installation steps. The following is an example of how to organize

the installation process.

1. Surveying the site:

- Find the most representative measurement site.

- Determine orientation of the Weather Sensor.

2. Cabling plan is required for the following:

- Grounding cabling layout and cable type.

- Power supply cabling layout and cable type.

- Modem/signal cabling layout and cable type.

3. Ordering the construction materials and cables.

4. Digging for cables and foundation.

5. Casting the concrete:

- Prepare concrete blocks by using a casting mold.

- Cast the fixing bolts in their places at the same time.

VAISALA ________________________________________________________________________ 29

Page 30

User's Guide _______________________________________________________________________

6. Installing the base plate and the pole mast:

- Install the base plate with the bolts on the concrete block.

- Level the plate.

- Mount the pole mast on the base plate.

- Mount the junction box to the pole mast (optional). Junction

boxes are available from Vaisala.

7. Connecting cables:

- Connect the mains and signal cables of the site to the junction

box or have them ready for direct connection to the sensor.

8. Final installation:

- Install the electronics enclosure and the crossarm of the

FD12P to the pole mast.

- Connect the power and signal cables of the FD12P.

- Connect the modem/signal line to the host computer, display,

etc.

9. Start-up tests for the system.

Location and Orientation

The main requirements for the location of the FD12P are as follows:

1. Place the FD12P at a site where the measurements will be

representative of the surrounding weather conditions.

The ideal site has a minimum clearance of 100 meters from all

large buildings and other constructions that generate heat and/or

obstruct precipitation droplets. Also avoid shading of trees as

this may cause changes in the microclimate.

2. Make sure the site is free of obstacles and reflective surfaces,

which disturb the optical measurements and act as obvious

sources of contamination.

There must not be any obstacles in the line-of-sight of the

transmitter and receiver units (see Figure 4 on page 31). If the

transmitter beam is reflected from obstacles back to the receiver

unit, the sensor will indicate too low MOR values as the

reflected signal cannot be distinguished from the real scatter

signal. Reflections are detected by rotating the sensor crossarm.

They will change depending on the crossarm orientation. Also

the visibility reading will change accordingly.

______________________________________________________ M210296en-A

30

Page 31

Chapter 3 ________________________________________________________________ Installation

The receiver and transmitter optics should not point towards

powerful light sources or, in bright daylight, reflective surfaces

such as snow or sand. The receiver should point north in the

Northern Hemisphere and south in the Southern Hemisphere.

The receiver circuit may become saturated in bright light, and

the built-in diagnostics will indicate a warning. Intense light can

generate false contamination alarms from the transmitter unit.

Bright daylight will also increase the noise level in the receiver.

The transmitter and receiver should face away from any obvious

source of contamination such as spray from passing vehicles.

Dirty lenses will cause the sensor to report too high visibility

values. Excessive contamination is automatically detected by the

sensor.

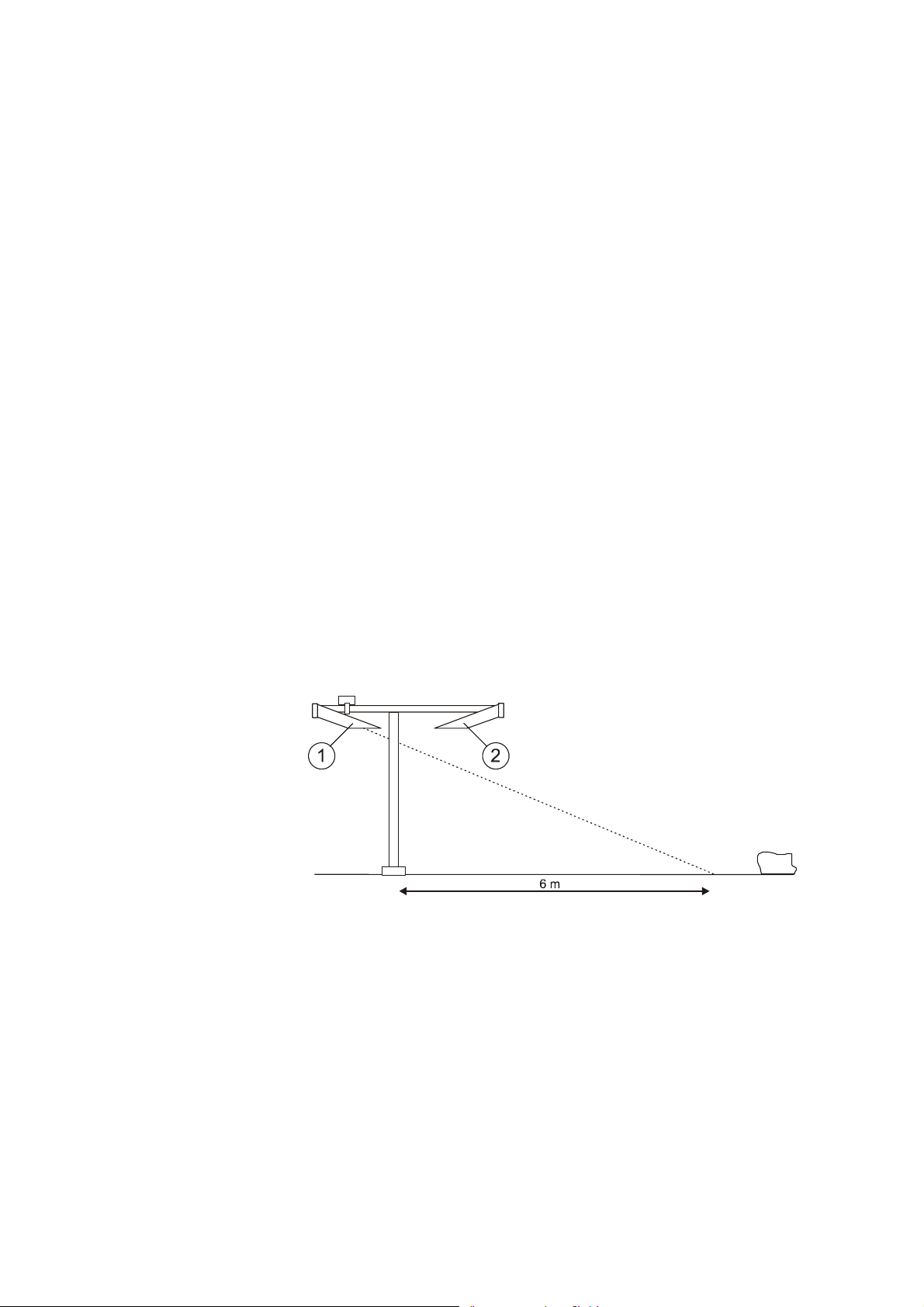

Harmful reflections are typically avoided if the transmitter beam

is directed towards a surface, which will reflect most of the light

away from the sensor. The distance of 6 meters shown in Figure

4 below is only for guidance; it is not an absolute requirement.

There should be no flashing lights near the sensor. A flashing

light can cause errors in detecting precipitation towards

No obstacles or reflecting surfaces

Figure 4 Recommended Location for the FD12P

The following numbers refer to Figure 4 above.

0110-178

1 = Transmitter

2 = Receiver

VAISALA ________________________________________________________________________ 31

Page 32

User's Guide _______________________________________________________________________

3. Power supply and communication lines must be available.

When the site for the FD12P is selected, take into consideration

the available power supply and communication lines. This

influences the amount of work and accessories needed and thus,

the actual installation costs.

Grounding and Lightning Protection

Equipment Grounding

Equipment grounding protects the electrical modules of the FD12P,

for example, against lightning and prevents radio frequency

interference. The FD12P equipment is grounded using a jacketed

grounding cable and conductive grounding rod(s).

The FD12P must be grounded by means of the grounding clamp,

which is located under the cable flange (See Figure 5 on page 33). A

16-mm² jacketed grounding cable is connected to the clamp.

Depending on the need, one to four copper-sheathed steel rods are

driven into the ground. If several rods are needed, the alignment from

the foot of the base plate must be radial.

The grounding principles are the following:

- The grounding rod must be isntalled as close to the pole mast

as possible to minimize the length of the grounding cable.

The grounding cable can be also cast inside the concrete base.

- The length of the grounding rod depends on the local

groundwater level. The lower end of the grounding rod must

continuously touch moist soil.

The grounding quality can be checked with a georesistance meter. The

resistance must be less than 10 ohms. This way the lowest possible

resistance is achieved.

The junction box must be also grounded via the grounding cables in

the same way as the electronics enclosure (Figure 5 on page 33). The

junction box is optional.

______________________________________________________ M210296en-A

32

Page 33

Chapter 3 ________________________________________________________________ Installation

0111-001

Figure 5 FD12P Equipment Grounding

The following numbers refer to Figure 5 above:

1 = Electronics enclosure

2 = Junction box (optional)

3 = Mains cable

4 = Cable tubing

5 = Grounding rods

6 = Signal cable

7 = 16 mm² grounding cables

8 = Grounding clamp

VAISALA ________________________________________________________________________ 33

Page 34

User's Guide _______________________________________________________________________

Internal Grounding

The electronics enclosure and the bottom plate of the FD12P are

secured by a 1.5-mm², yellow-green ground cable and the crossarm is

grounded through the transducer cable shield. The other parts of the

crossarm are in galvanic contact with each other.

CAUTION

When installing the FD12P, the grounding flat connector must be

plugged to the ground terminal socket, which is located beside the

MIL-connector in the crossarm. See instructions in section

Assembling the FD12P on page 40 and Figure 10 on page 43.

Grounding for Testing Purposes

The FD12P is provided with a two-meter mains cable. The cable has a

grounded plug. The plug must be connected only to an outlet that has

a ground terminal. This grounding is sufficient when the instrument is

used indoors, for example, for testing purposes.

Grounding Remote Units and Communication Cable

Remote units, such as, the PC data logger, must be grounded and

protected against lightning.

WARNING

______________________________________________________ M210296en-A

34

A lightning strike through a communication wire can cause a voltage

surge dangerous to life at remote sites if the remote units are not

properly grounded.

Page 35

Chapter 3 ________________________________________________________________ Installation

Cable Selection

Line Power Cabling

The FD12P is supplied with a two-meter power cable. If a local

terminal for 115/230 VAC power supply is not available, use an

extended mains cable from the FD12P to the nearest power source.

This cable should be armored and of underground type. The armored

reinforcing acts as a mechanical shield and also provides protection

against lightning. Ground the cable screen at both ends.

The recommended mains wire cross sections are shown in Table 5

below for mains voltage 230 VAC. For 115 VAC, divide the

maximum distances by four.

Table 5 Mains Cable Selection

Maximum

Distance from

Voltage Source

2 km 1.5 mm

4 km 2.5 mm

8 km 4.0 mm

One-wire

Cross-section

Area

2

2

2

Nearest

AWG-gauge

No 15 AWG 10 mm

No 13 AWG 14 mm

No 11 AWG 18 mm

Typical Nonarmored Cable

Diameter

NOTE

Cables with diameters more than 12 mm require a separate junction

box which is also available from Vaisala.

Communication Cable

The FD12P provides the RS-232C, RS-485, CCITT V.21 modem, and

analog transmission interfaces. Consider your needs for

communication before the installation. The communication method

depends on the distance between the computer or display and the

FD12P and the number of the FD12P sensors. Table 6 below describes

the possibilities.

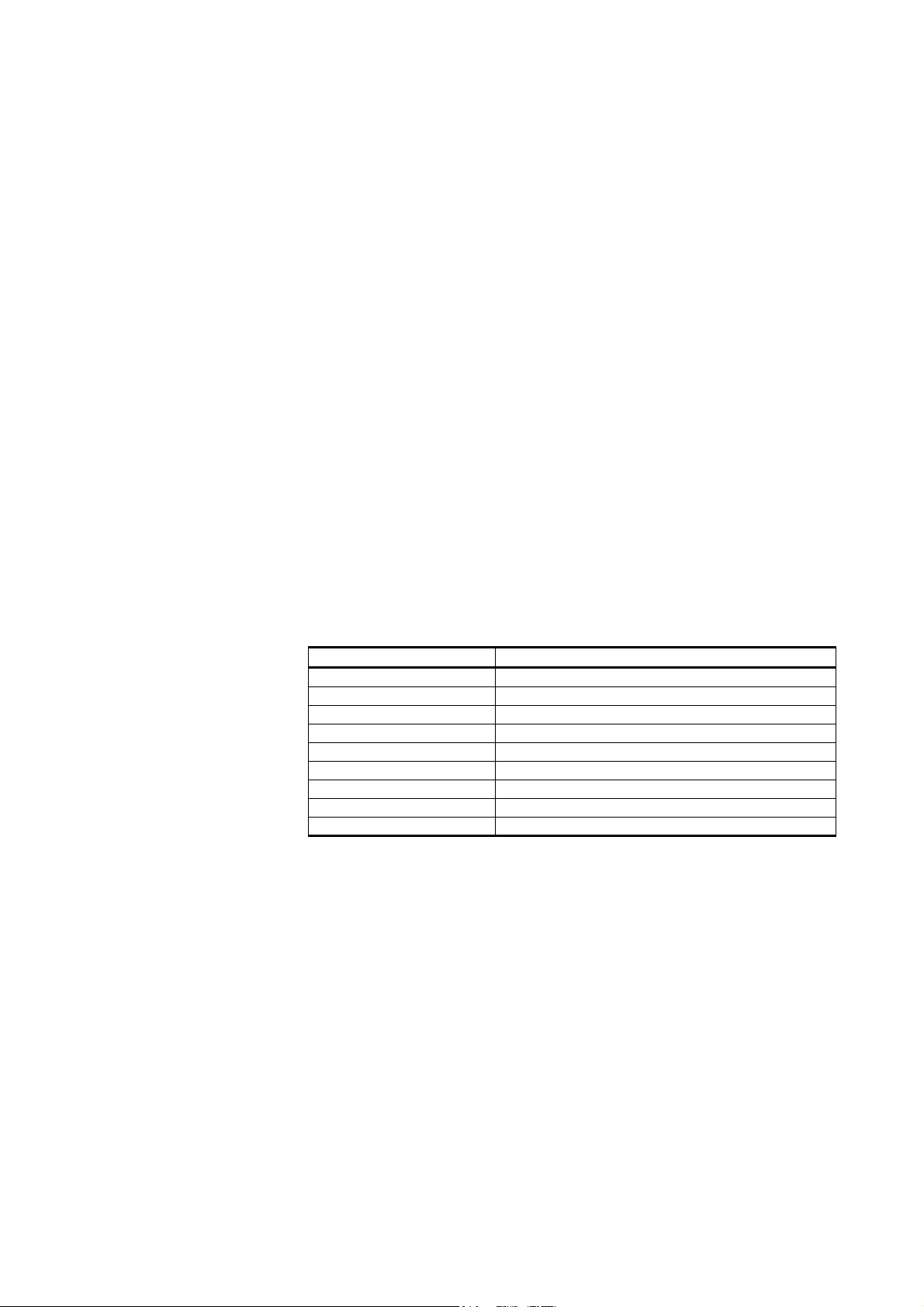

Table 6 Communication Cable Lengths

Cable Length One FD12P Several FD12Ps on line

< 150 m RS-232 RS-485, modem

< 500 m RS-485, modem RS-485, modem

> 500 m Modem Modem

VAISALA ________________________________________________________________________ 35

Page 36

User's Guide _______________________________________________________________________

For a modem and RS signal cable, use a screened, 2 × 0.22-mm²

twisted pair cable with a minimum diameter of 5 mm. For details, see

section Communication Options on page 50.

Unloading and Unpacking

The contents of the delivery in question are specified in the packing

list included with the delivery documents. The FD12P equipment is

normally delivered in three cases containing the following parts:

- Crossarm FDC115 containing the optics.

- Electronics enclosure FDB12 with radiation shield.

- Pole mast.

Two persons can easily move the cases from a truck to the installation

site.

NOTE

Handle gently the case containing the optical parts. Do not drop either

end of the case.

Unpacking Procedure

1. Read the packing list supplied within the delivery documents.

Compare the packing list against the purchase order to make

sure that the shipment is complete.

2. Open the covers.

3. In case of any discrepancies or damage, contact the supplier.

4. Place the packing materials and covers back in the cases and

store them for possible reshipment.

Storage Information

Store the FD12P in its packages in dry conditions, not in the open air.

The storage conditions are as follows:

- Temperature −40 oC ... 70 oC.

- Relative humidity up to 95 %.

______________________________________________________ M210296en-A

36

Page 37

Chapter 3 ________________________________________________________________ Installation

Installation Procedures

Constructing the Foundation

Cast a concrete foundation or use an existing construction that is level

and rigid. The recommended minimum dimensions for the foundation

are illustrated in Figure 6 below. It is easiest to mount the foundation

screws while casting the pad. If the pad was casted earlier, drill three

holes into the concrete for the wedge bolts.

0110-179

Figure 6 Casting a Concrete Foundation

VAISALA ________________________________________________________________________ 37

Page 38

User's Guide _______________________________________________________________________

The following numbers and letters refer to Figure 6 on page 37:

A = Watertight plastic for conducting rainwater away

(recommended)

1 = Concrete block

2 = Surface horizontal to ±0.5°

3 = Ground level

4 = Reinforcing steel

5=

The Installation Set included in the FD12P delivery contains the

required equipment both for mounting when casting the pad and

mounting to an existing surface. Use the triangle shaped template as

an auxiliary device and remove it before mounting the base plate.

Reinforcing steel or use steel mesh 150 × 150 mm

Mounting When Casting the Pad

1. Fasten the three reinforcing plates to the lower end of the

foundation screws with six M16 nuts. See Figure 7 (C, top view)

on page 39.

2. Fix the template to the upper ends of the foundation screws with

six nuts.

3. Embed the assembly in the concrete foundation as shown in

Figure 7 on page 39.

4. After the concrete has set, remove the template.

Mounting to an Existing Surface

1. Drill three, ∅20-mm holes using the template, minimum depth

65 mm. Refer to Figure 7 on page 39.

2. Remove the template.

3. Clean the holes.

4. Fasten the foundation screws to the wedge bolts by hand.

5. Protect the tops of the screws with two nuts tightened together.

6. Then place the wedge bolt and foundation screw combinations

in the holes, wedge bolts down, and hammer the combinations

down.

7. Tighten the foundation screws as tight as possible.

______________________________________________________ M210296en-A

38

Page 39

Chapter 3 ________________________________________________________________ Installation

0110-180

Figure 7 Constructing the FD12P Foundation

VAISALA ________________________________________________________________________ 39

Page 40

User's Guide _______________________________________________________________________

The following numbers and letters refer to Figure 7 on page 39:

A = Mounting when casting the pad

1 = A10.5 DIN125, 4 pieces

2 = M10 x 30 DIN933, 4 pieces

3 = A17 DIN125, 3 pieces

4 = M16 DIN934, 3 pieces

5 = Template

6 = Foundation screw M16 x 250, 3 pieces

7 = Base level

B = Mounting to an existing surface

6 = Foundation screw M16 x 250, 3 pieces

8 = Template

9 = Wedge bolt M16, 3 pieces

C = Top view

10 = M10, 4 pieces

11 = Baseplate

Assembling the FD12P

1. Mount the base plate and level it with the six M16 nuts.

2. Mount the pole mast pedestal and the tilting support on the base

plate with four M10 bolts (Figure 7 on page 39, C, top view).

3. Attach the electronics enclosure to the pole mast with two

clamps and four M6 Allen screws.

4. Tilt the mast. See Figure 8 on page 41.

5. Feed the crossarm cable and temperature sensor DTS14B cables

inside the pole mast.

6. Check that a thin rubber gasket is on the insertion neck of the

crossarm.

7. Connect the crossarm cable plug to the MIL-connector (see

Figure 10 on page 43).

8. Connect the grounding flat connector to the other pin of the

ground terminal socket as shown in Figure 10 on page 43.

______________________________________________________ M210296en-A

40

Page 41

Chapter 3 ________________________________________________________________ Installation

0110-181

Figure 8 Tilting the Pole Mast

The following numbers refer to Figure 8 above:

1 = Pole mast. For tilting, loosen the upper and remove the lower

M10 × 100 bolts.

2 = Tilting supporters. To be installed under the fastening screws.

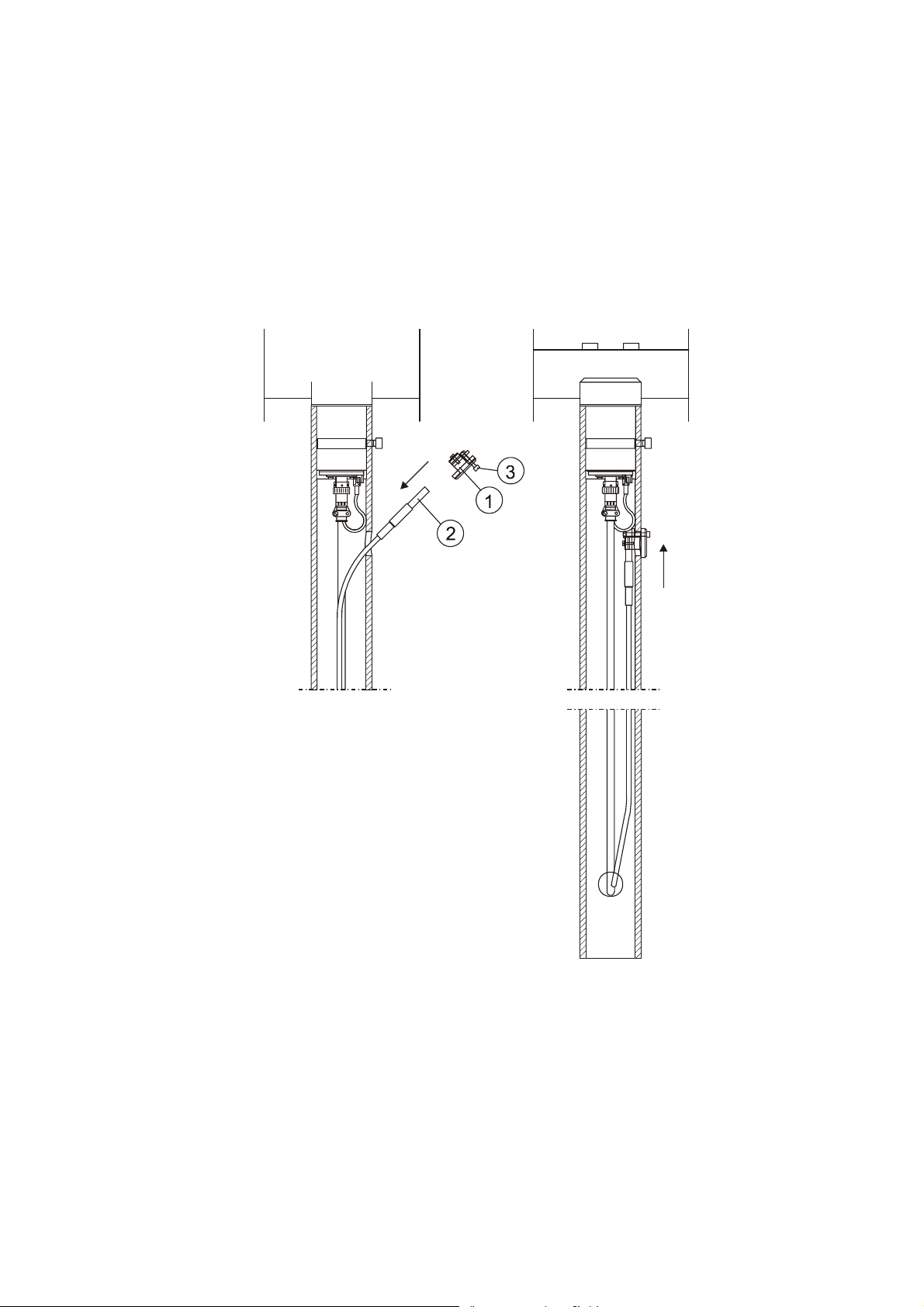

Attaching the DTS14B Temperature Sensor to the Mast

To attach the DTS14B Temperature Sensor to the mast, do the

following:

1. Pull the DTS14B temperature sensor out of the side hole of the

mast.

2. Then attach the holder to the mast in the following way:

- Open the fixing screw fully (part 3 below).

- Push the screw head to the holder with you finger.

- Put the holder to the hole in the mast pole.

- Slide the holder upwards as long as it goes and hold it there.

- Tighten the fixing screw firmly.

VAISALA ________________________________________________________________________ 41

Page 42

User's Guide _______________________________________________________________________

- Insert the crossarm to the pole mast and lock it in the right

position with two 8-mm bolts.

- Erect the mast.

- Lift the DRD12 Rain Detector to an upright position. Tighten

the clamp.

0201-088

Figure 9 DTS14B and the Sensor Holder Assembly to Mast

The following numbers refer to Figure 9 above:

1 = Sensor holder

2=DTS14

3 = Fixing screw

______________________________________________________ M210296en-A

42

Page 43

Chapter 3 ________________________________________________________________ Installation

0110-182

Figure 10 Connecting Internal Grounding

The following numbers refer to Figure 10 above:

1 = Crossarm

2 = Ground terminal socket

3 = Grounding flat connector

4 = Pole mast

5 = MIL-connector

Connecting Cables

Basic Wiring

To do the basic wiring, do the following:

1. The electronics enclosure includes a power cable. Remove the

plug.

VAISALA ________________________________________________________________________ 43

Page 44

User's Guide _______________________________________________________________________

If you use another, longer cable, make sure to connect the wires

in a correct way, especially the protective ground wire (usually

yellow-green). Refer to Figure 11 below.

2. Connect the power cord to the screw terminals in a junction box

or bring the power line directly to the electronics enclosure. The

selected method depends on the thickness of the power cable,

which should be checked before the installation. The electronics

enclosure has a cable outlet with a diameter of 10 - 12 mm.

3. Feed Neutral N (normally blue) and protective earth PE

(normally yellow-green) via separate conductors.

4. Feed the communication cable through one of the two cable

feedthroughs. For cable shield connections, see instructions in

section Communication Cable EMC-shielding on page 46.

5. Wire the communication cable according to instructions in

section Communication Options on page 50.

9509-011

Figure 11 Cabling Principle

______________________________________________________ M210296en-A

44

Page 45

Chapter 3 ________________________________________________________________ Installation

NOTE

If the line voltage used differs from 230 V (the initial setting at the

factory), check the voltage setting of the FDW13 Mains Power

Supply (alternatives 115 VAC and 230 VAC). You can find the line

voltage setting switch on the left side of the FDW13 unit (see Figure

12 below).

0110-183

Figure 12 Line Voltage and ON/OFF Switches

The following numbers are related to Figure 12 above:

1 = Electronics enclosure

2 = Pole mast

3 = DMX21 modem

4 = DC regulator FDW13

5 = ON/OFF switch

6 = Line voltage setting

7 = FD12P control unit

VAISALA ________________________________________________________________________ 45

Page 46

User's Guide _______________________________________________________________________

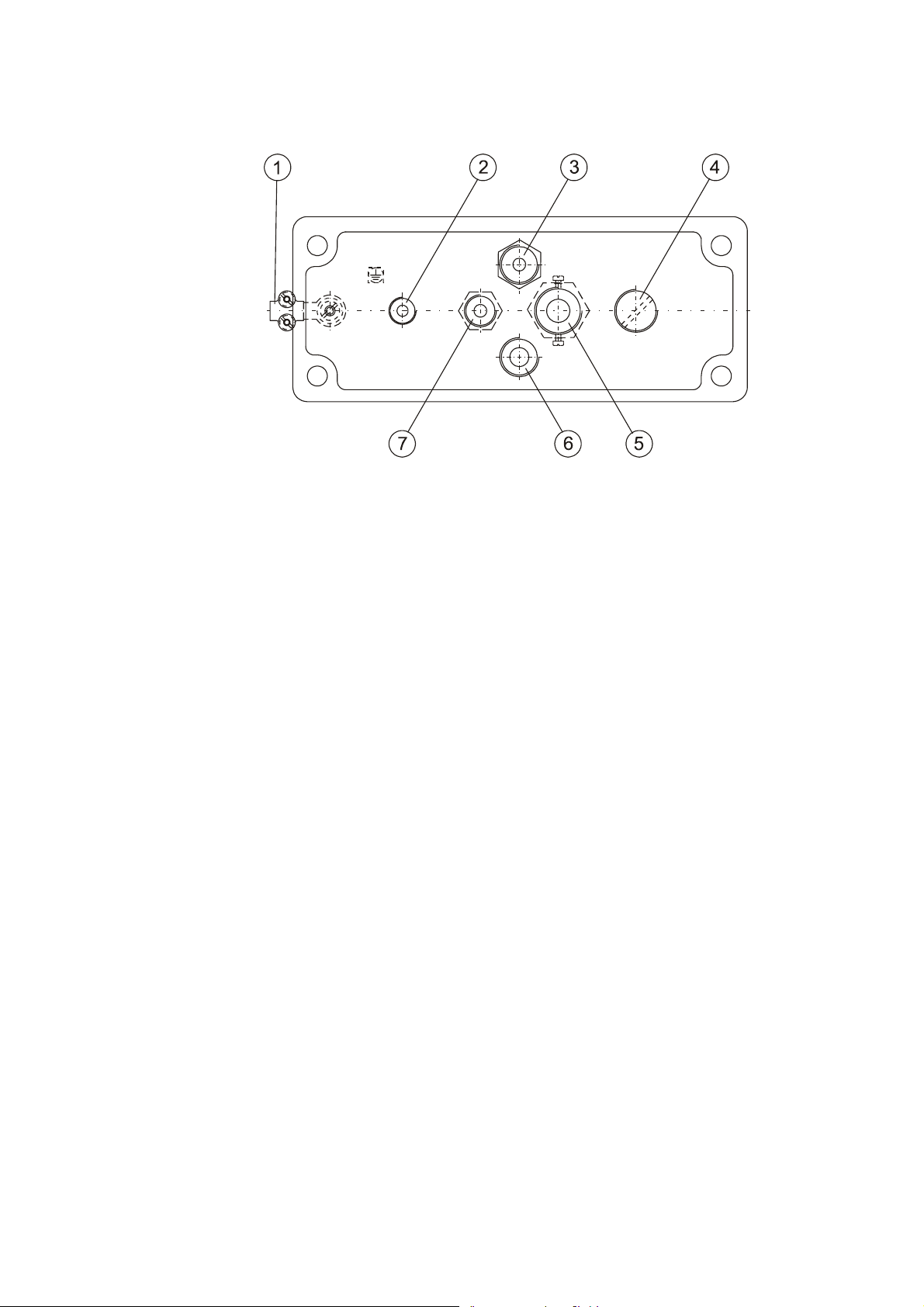

0110-184

Figure 13 Electronics Enclosure Feedthroughs

The following numbers refer to Figure 13 above:

1 = Grounding

2 = DTS14 cable feedthrough

3 = Temperature sensor (TE)

4 = Cap (Pg 13.5) of optional opening for the LM11

background luminance meter

5 = Main power cable

6 = FDC115 transducer cable feedthrough

7 = Standard communication cable feedthrough

Communication Cable EMC-shielding

The electronics enclosure has one cable outlet for a cable diameter

from Ø7 to Ø10 mm, which is reserved for a signal or modem cable.

Although the shielding of the cable may be just grounded after cable

inlet, an efficient procedure against RF-interference requires special

care. Ground the cable gland to keep EMI levels within specifications.

For a proper RF-grounding of any jacketed cable, the instructions are

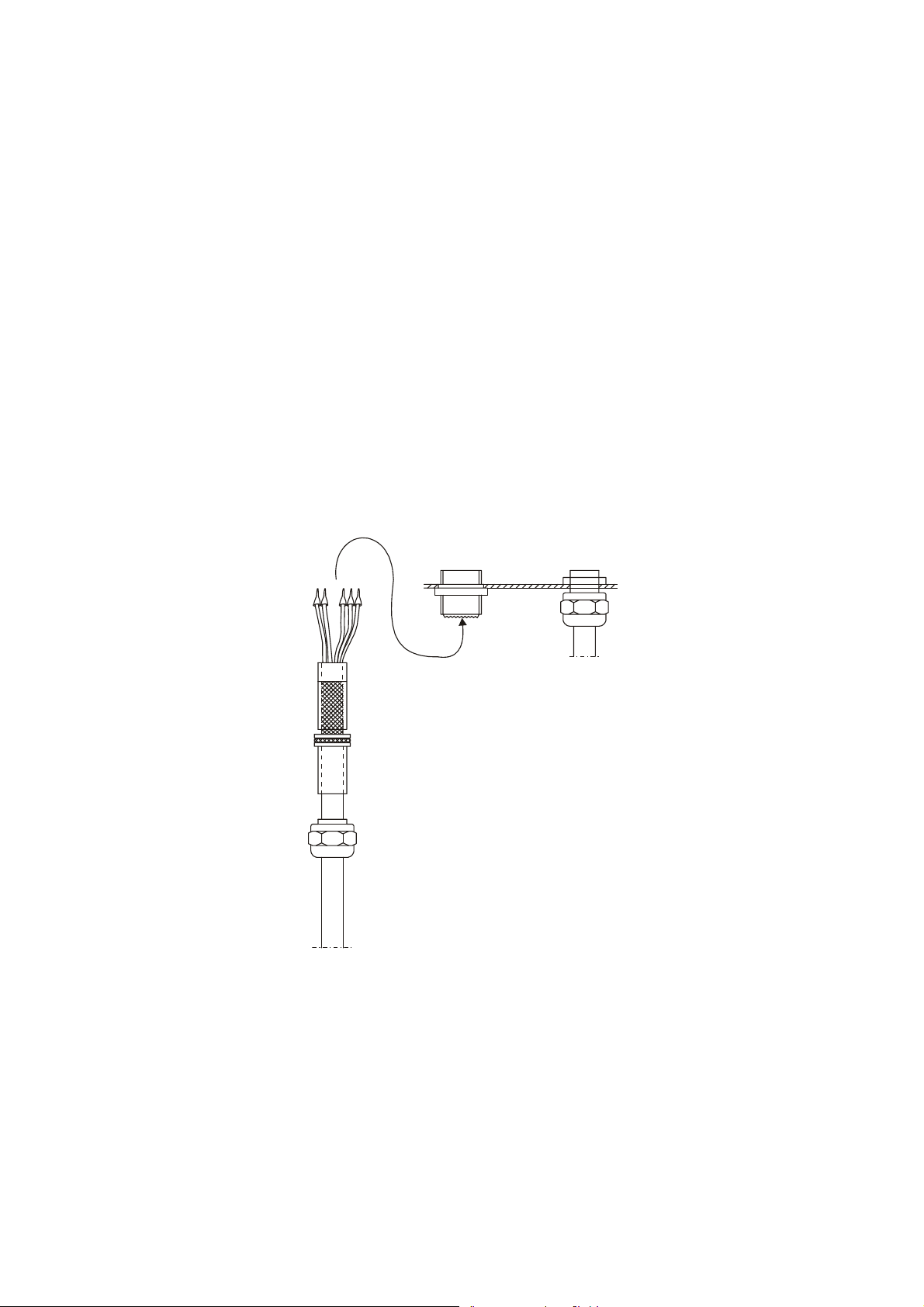

the following:

1. Lead the signal cable through the cable inlet. If the field cable is

thicker than 10 mm, use a separate signal junction box. See

Figure 14 on page 47.

2. Strip 80 mm of the cable sheath leaving approximately 40 mm

of the shield.

______________________________________________________ M210296en-A

46

Page 47

Chapter 3 ________________________________________________________________ Installation

3. Remove the cap of the cable gland, including the rubber cylinder

and the metal rings. Slide the cap with rubber cylinder onto the

cable.

4. For a thin cable, add a shrinkable tube to increase cable

diameter.

5. Slide two metal rings on the shielding and squeeze it evenly

between the rings.

6. Secure with a shrinkable tube.

7. Tighten the cable with the cable gland and proceed with the

wiring.

8. Connect the signal cable to the screw terminals in the electronics

enclosure.

9. Ground the signal cable with the same method at both ends.

0205-006

Figure 14 Cable Grounding Instructions

VAISALA ________________________________________________________________________ 47

Page 48

User's Guide _______________________________________________________________________

Connecting a Background Luminance Sensor or a Day/Night Switch to FD12P

The FD12P Weather Sensor supports two different methods for

ambient light sensing. The Background Luminance Meter LM11 can

be connected to the FD12P for accurate ambient light measurement.

The LM11 sensor and necessary wiring are included in option

FD12PLM11 (see Figure 15 on page 49 for the wiring details). The

background luminance measurement is typically used in the RVR

systems.

The LM11 output frequency is measured with the DRI21 interface

board and then converted into background luminance by the FD12P

software. The conversion uses a scaling factor, which needs to be

configured by the user. For details, see section BLSC Command on

page 84.

In certain applications it is necessary to calculate night visibility

separately using a formula that differs from MOR. In these cases a

simple day/night photo switch is sufficient for discerning between day

and night ambient light conditions. The switch can be connected to the

serial line control input on the FDP12 processor board. For wiring

details, see Figure 16 on page 50.

Positive voltage is interpreted as a night condition and the background

luminance value in the FD12P output message is set to 0. Negative

voltage or an open circuit is interpreted as a day condition and the

luminance value is set to 1. For details, see section BLSC Command

on page 84.

______________________________________________________ M210296en-A

48

Page 49

Chapter 3 ________________________________________________________________ Installation

9610-006

Figure 15 Wiring the Connector for the LM11 Background

Luminance Meter