Page 1

Vaisala Ceilometer

CL31

USER'S GUIDE

M210482EN-B

October 2004

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2004

No part of this manual may be reproduced in any form or by any means,

electronic or mechanical (including photocopying), nor may its contents be

communicated to a third party without prior written permission of the copyright

holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or

Conditions of Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION............................................................................7

About This Manual ................................................................... 7

Contents of This Manual ....................................................... 7

Related Manuals ................................................................... 8

Feedback............................................................................... 8

Safety......................................................................................... 8

General Safety Considerations ............................................. 8

Product Related Safety Precautions ..................................... 9

Laser Safety ........................................................................ 10

ESD Protection.................................................................... 11

Recycling ................................................................................ 12

Warranty..................................................................................12

CHAPTER 2

PRODUCT OVERVIEW................................................................................ 13

Introduction to Vaisala Ceilometer CL31............................. 13

Product Nomenclature........................................................... 15

CHAPTER 3

INSTALLATION............................................................................................ 19

Installation Procedure............................................................ 19

Unloading and Unpacking Instructions ............................... 19

Preparing a Concrete Foundation....................................... 20

Mounting the Ceilometer CL31 ...........................................22

Connecting the External Cables ......................................... 25

Data Line Connection.......................................................... 26

Grounding............................................................................ 28

Maintenance Terminal Connection .....................................29

Setting up Maintenance Terminal Connection............... 29

Operation of Maintenance Terminal Connection ........... 29

Using the Tilt Feature.......................................................... 29

Mobile Operation Aspects ................................................... 30

Startup..................................................................................... 31

Startup Procedure ............................................................... 31

Settings for Normal Operation ............................................ 34

Factory Settings of User Programmable Parameters ......... 35

CHAPTER 4

OPERATION................................................................................................. 37

Operation Modes .................................................................... 37

Serial Lines - Open and Closed Port .................................... 37

VAISALA ________________________________________________________________________ 3

Page 4

User's Guide ______________________________________________________________________

User Commands .....................................................................39

Data Messages........................................................................ 44

CL31 Data Messages No. 1 and 2 ......................................45

CRC16 Checksum..........................................................51

CL31 Status Message .........................................................52

CT12K Messages ................................................................ 55

CT12K Digital Message No. 2........................................ 55

CT12K Digital Message No. 3........................................ 59

CT25K Data Messages .......................................................60

CT25K Data Message No. 1 ..........................................60

CT25K Data Message No. 6 ..........................................62

CT25KAM Data Messages.................................................. 64

CT25KAM Data Message No. 60...................................64

CT25KAM Data Message No. 61...................................64

LD40 Standard Telegram ....................................................64

Telegram Structure Remarks .........................................66

Failure and Warning Messages .....................................66

Checksum Calculation....................................................69

Manual Message .................................................................70

Polling Mode ...........................................................................70

CHAPTER 5

FUNCTIONAL DESCRIPTION .....................................................................73

Theory of Operation ...............................................................73

Basic Principle of Operation ................................................ 73

Practical Measurement Signal.............................................74

Noise Cancellation ..............................................................74

Return Signal Strength ........................................................75

Height Normalization ...........................................................75

Backscatter Coefficient........................................................ 75

Extinction Normalization and Vertical Visibility....................77

CHAPTER 6

MAINTENANCE............................................................................................79

Periodic Maintenance............................................................. 79

Alarms and Warnings ..........................................................79

Window Cleaning.................................................................80

Calibration ......................................................................80

Checking the Door Gasket .................................................. 81

Battery Check ...................................................................... 81

Storage ................................................................................82

CHAPTER 7

TROUBLESHOOTING..................................................................................83

Accessing the Diagnostic Information.................................84

Equipment ...........................................................................84

Troubleshooting Instructions ............................................... 84

Warning and Alarm Messages ..............................................86

Technical Support .................................................................. 90

Vaisala Service Centers ......................................................... 90

4 ___________________________________________________________________ M210482EN-B

Page 5

________________________________________________________________________________

CHAPTER 8

REPAIR ........................................................................................................ 91

Replacing Window Assembly CLW311................................ 91

Replacing Ceilometer Laser Transmitter CLT311............... 93

Replacing Ceilometer Receiver CLR311.............................. 94

Replacing Ceilometer Engine Board CLE311.................... 100

Replacing No-break Battery 4592....................................... 101

Replacing AC Power CLP311.............................................. 102

Replacing Window Blower CLB311-115 / CLB 311-230.... 104

Replacing Ceilometer Optics CLO311................................ 105

Replacing Internal Heater CLH311-115 / CLH311-230 ......107

Replacing Internal Cable Set............................................... 109

Replacing Laser Monitor Board CLM311........................... 113

Replacing Modem Module DMX501 (Optional).................. 115

CHAPTER 9

TECHNICAL DATA .................................................................................... 117

Specifications ....................................................................... 117

Mechanical Specifications................................................. 117

External Connector J1 - Window Conditioner ................... 118

External Connector J2 - Power Input ................................ 118

Output Interface ................................................................ 118

External Connector J3 - Data Line............................... 119

External Connector J4 - Maintenance Line.................. 120

Modem Module DMX501 ..................................................121

Transmitter Specifications................................................. 121

Receiver Specifications..................................................... 122

Optical System Specifications........................................... 122

Performance Specifications .............................................. 122

Environmental Conditions Specifications.......................... 123

INDEX ......................................................................................................... 125

List of Figures

Figure 1 Vaisala Ceilometer CL31.......................................................... 14

Figure 2 Ceilometer CL31 Main Parts .................................................... 16

Figure 3 Measurement Unit Handle ....................................................... 20

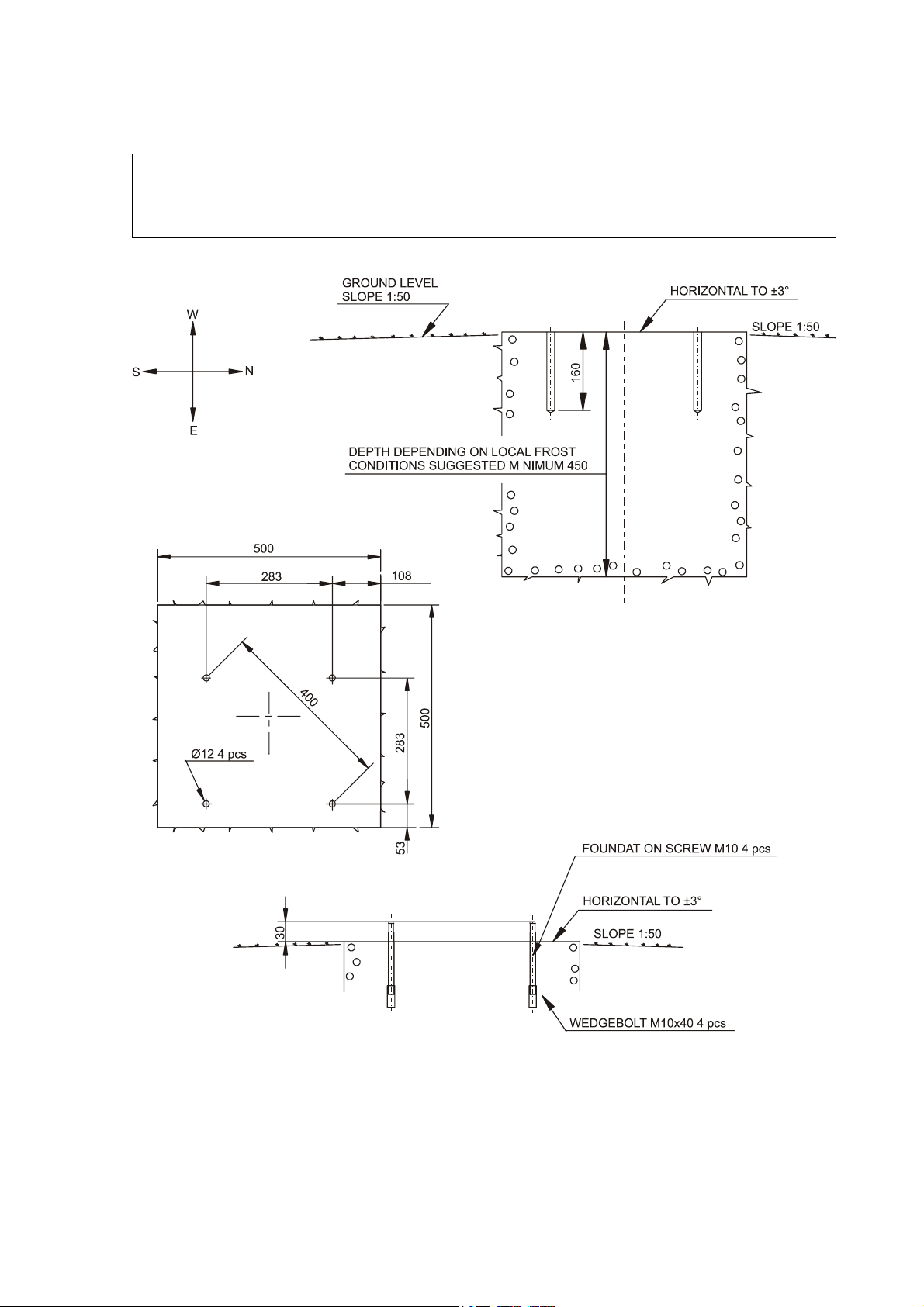

Figure 4 Foundation Construction .......................................................... 21

Figure 5 Removing and Attaching the Measurement Unit ..................... 23

Figure 6 Mounting the Shield.................................................................. 24

Figure 7 External Connectors (Bottom View) ......................................... 25

Figure 8 Data Line Modem Connection.................................................. 26

Figure 9 Data Line RS-485 Connection ................................................. 27

Figure 10 Data Line RS-232 Connection ................................................. 28

Figure 11 Subassembly Interconnections ................................................ 32

Figure 12 CL31 Switches ......................................................................... 33

Figure 13 Ceilometer Engine Board CLE311 ........................................... 34

Figure 14 Operation Modes...................................................................... 37

Figure 15 Open and Closed Port.............................................................. 39

Figure 16 Typical Measurement Signal.................................................... 74

VAISALA ________________________________________________________________________ 5

Page 6

User's Guide ______________________________________________________________________

Figure 17 CL31 ......................................................................................... 96

Figure 18 Main Components of Ceilometer CL31 .................................... 98

Figure 19 Ceilometer Engine Board CLE311 ........................................... 99

Figure 20 Grounding Wires of the Internal Cable Set (top view)............ 110

Figure 21 Internal Heater Wiring and Connector at the Left of the Optics

Frame .....................................................................................111

Figure 22 Optics Frame with Cable Set..................................................112

Figure 23 Connecting Mains Filters to the Cable Set .............................112

Figure 24 DMX501..................................................................................116

Figure 25 Pin Connections of Connector J4 ........................................... 120

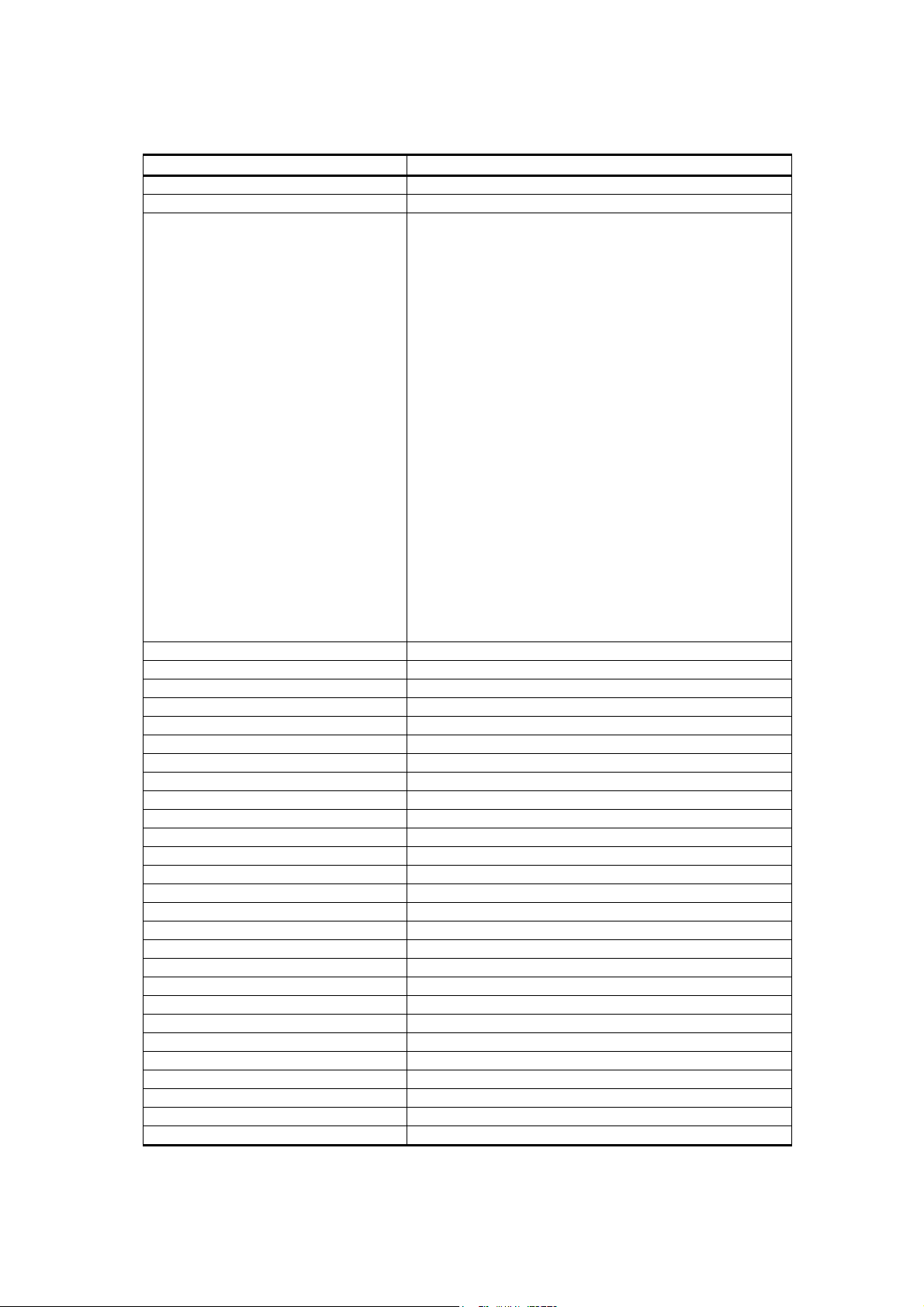

List of Tables

Table 1 Related Manuals......................................................................... 8

Table 2 Vaisala Ceilometer CL31 Main Parts .......................................15

Table 3 Vaisala Ceilometer CL31 Optional Parts..................................15

Table 4 Factory Defaults of User-Programmable Parameters ..............35

Table 5 User Level Commands .............................................................40

Table 6 Advanced Level Commands.....................................................43

Table 7 Messages with 10 m Resolution (Standard Mode)...................46

Table 8 Messages with 5 m Resolution (High Resolution)....................46

Table 9 Error Group Definition...............................................................67

Table 10 Error Group 1 (Byte 83) ............................................................67

Table 11 Error Group 2 (Byte 84) ............................................................67

Table 12 Error Group 3 (Byte 85) ............................................................67

Table 13 Error Group 4 (Byte 86) ............................................................68

Table 14 Error Group 5 (Byte 87) ............................................................68

Table 15 Error Group 6 (Byte 88) ............................................................ 68

Table 16 Error Group 7 (Byte 89) ............................................................68

Table 17 Command Telegram Description 'Polling Request' .................. 71

Table 18 Warnings...................................................................................86

Table 19 Alarms.......................................................................................88

Table 20 Miscellaneous Problems...........................................................89

Table 21 Ceilometer CL31 Mechanical Specifications.......................... 117

Table 22 Window Conditioner ...............................................................118

Table 23 Power Input.............................................................................118

Table 24 Data Line ................................................................................119

Table 25 Maintenance Line ................................................................... 120

Table 26 Modem Module DMX501 Specifications ................................121

Table 27 Transmitter Specifications ......................................................121

Table 28 Receiver Specifications ..........................................................122

Table 29 Optical System Specifications ................................................122

Table 30 Performance Specifications....................................................122

Table 31 Environmental Conditions Specifications ...............................123

6 ___________________________________________________________________ M210482EN-B

Page 7

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the product.

About This Manual

This manual provides information for installing, operating, and

maintaining Vaisala Ceilometer CL31.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides general notes for the

product.

- Chapter 2, Product Overview, introduces the features, advantages,

and the product nomenclature.

- Chapter 3, Installation, provides you with information that is

intended to help you install this product.

- Chapter 4, Operation, contains information that is needed to

operate this product.

- Chapter 5, Functional Description, describes the functionality of

the product.

- Chapter 6, Maintenance, provides information that is needed in the

basic maintenance of the product.

- Chapter 7, Troubleshooting, describes common problems, their

probable causes and remedies, and gives the contact information.

- Chapter 8, Repair, explains how to remove and replace different

parts of Vaisala Ceilometer CL31.

VAISALA ________________________________________________________________________ 7

Page 8

User's Guide ______________________________________________________________________

- Chapter 9, Technical Data, provides the technical data of the

product.

- INDEX

Related Manuals

Table 1 Related Manuals

Manual Code Manual Name

M210310EN-A Termination Box User's Guide

Feedback

Vaisala Customer Documentation Team welcomes your comments

and suggestions on the quality and usefulness of this publication. If

you find errors or have other suggestions for improvement, please

indicate the chapter, section, and page number. You can send

comments to us by e-mail: manuals@vaisala.com

Safety

WARNING

CAUTION

General Safety Considerations

Throughout the manual, important safety considerations are

highlighted as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or

even death.

Caution warns you of a potential hazard. If you do not read and

follow instructions carefully at this point, the product could be

damaged or important data could be lost.

NOTE

8 ___________________________________________________________________ M210482EN-B

Note highlights important information on using the product.

Page 9

Chapter 1 ________________________________________________________ General Information

WARNING

WARNING

Failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Vaisala Oyj

assumes no liability for the customer's failure to comply with these

requirements.

Product Related Safety Precautions

Vaisala Ceilometer CL31 delivered to you has been tested for safety

and approved as shipped from the factory. The following safety

precautions must be observed during all phases of operation, service,

and repair of this instrument:

To minimize shock hazard, the instrument chassis and cabinet must

be connected to an electrical ground. The instrument is equipped

with a three-conductor AC power connector. The power cable must

either be plugged into an approved three-contact electrical outlet or

the instrument must be carefully grounded to a low-resistance safety

ground.

WARNING

WARNING

WARNING

Do not operate the instrument in the presence of flammable gases or

fumes. Operation of any electrical instrument in such an environment

constitutes a definite safety hazard.

Do not attempt internal service or adjustment unless another person,

capable of rendering first aid and resuscitation, is present.

Because of the danger of introducing additional hazards, do not

install substitute parts or perform any unauthorized modification to

the instrument. Return the instrument to a Vaisala office or

authorized Depot for service and repair to ensure that safety features

are maintained.

VAISALA ________________________________________________________________________ 9

Page 10

User's Guide ______________________________________________________________________

WARNING

WARNING

Operating personnel must not remove instrument covers. Component

replacement and internal adjustments must be made by qualified

maintenance personnel. Do not replace components with the power

cable connected. Under certain conditions, dangerous voltages may

exist even with the power cable removed. To avoid injuries, always

disconnect power and discharge circuits before touching them.

High voltage will be present when the Laser Transmitter CLT311 or

Receiver CLR311 covers are removed and they are connected to a

powered unit. High voltage is present in AC Power Unit CLP311,

Internal Heater CLH311, Ceilometer Engine Board CLE311, and the

Window Blower CLB311 at the top of the Shield.

Laser Transmitter CLT311, Receiver CLR311, and AC Power Unit

CLP311 are equipped with the following warning label:

WARNING! HIGH VOLTAGE INSIDE THIS

ENCLOSURE

Internal Heater CLH311 can be hot and is equipped with the following

warning labels:

Laser Safety

Vaisala Ceilometer CL31 is classified as a Class 1M laser device in

accordance with International Standard IEC/EN 60 825-1. Complies

with 21 CFR 1040.10 and 1040.11 except for the deviations pursuant

to the Laser Notice No. 50, dated July 26, 2001. This means that

when CL31 is installed in a field environment with instrument covers

on and pointed vertically or near-vertically, it poses no established

biological hazard to humans.

10 __________________________________________________________________ M210482EN-B

Page 11

Chapter 1 ________________________________________________________ General Information

The device is equipped with the following label:

Ceilometer CL31 is intended for operation in an area restricted from

public access, and to be pointed vertically or near-vertically. The

following precautions must be followed during the service and

maintenance of the instrument:

WARNING

CAUTION

Never look directly into the Ceilometer Transmitter or Ceilometer

Optics with magnifying optics (such as glasses, binoculars, and

telescopes). Never remove the Ceilometer Transmitter from its

normal position without first switching off both the line and the

battery power and detaching the trasnmitter ribbon cable from the

Ceilometer Engine Board.

When operating, avoid looking at the ceilometer unit from the beam

direction. When tilting the unit, make sure that it is not being viewed

from the beam direction with magnifying optics.

Only trained personnel should perform maintenance functions.

Access to the work area by unauthorized persons during service

operations must be prevented.

ESD Protection

The equipment contains parts and assemblies sensitive to damage by

Electrostatic Discharge (ESD). Use ESD precautionary procedures

when touching, removing or inserting.

Electrostatic Discharge (ESD) can cause immediate or latent damage

to electronic circuits. Vaisala products are adequately protected

against ESD for their intended use. However, it is possible to damage

VAISALA _______________________________________________________________________ 11

Page 12

User's Guide ______________________________________________________________________

the product by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench. When this is not possible, ground

yourself to the equipment chassis before touching the boards.

Ground yourself with a wrist strap and a resistive connection cord.

When neither of the above is possible, touch a conductive part of

the equipment chassis with your other hand before touching the

boards.

- Always hold the boards by the edges and avoid touching the

component contacts.

Recycling

Warranty

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations.

Do not dispose of with regular household refuse.

For certain products Vaisala normally gives a limited one-year

warranty. Please observe that any such warranty may not be valid in

case of damage due to normal wear and tear, exceptional operating

conditions, negligent handling or installation, or unauthorized

modifications. Please see the applicable supply contract or Conditions

of Sale for details of the warranty for each product.

12 __________________________________________________________________ M210482EN-B

Page 13

Chapter 2 __________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the features, advantages, and the product

nomenclature.

Introduction to Vaisala Ceilometer CL31

Vaisala Ceilometer CL31 measures cloud height and vertical

visibility. The small and lightweight measurement unit suits well for

mobile operation.

Ceilometer CL31 employs pulsed diode laser LIDAR technology

(LIDAR = Light detection and ranging), where short, powerful laser

pulses are sent out in a vertical or near-vertical direction. The

reflection of light - backscatter - caused by haze, fog, mist, virga,

precipitation, and clouds is measured as the laser pulses traverse the

sky. The resulting backscatter profile, that is, the signal strength

versus the height, is stored and processed and the cloud bases are

detected. Knowing the speed of light, the time delay between the

launch of the laser pulse and the detection of the backscatter signal

indicates the cloud base height.

Ceilometer CL31 is able to detect three cloud layers simultaneously. If

the could base is obscured due to precipitation or ground-based fog,

CL31 reports vertical visibility. No adjustments in the field are

needed. The embedded software includes several service and

maintenance functions and gives continuous status information from

internal monitoring. The software is designed to give the full

backscatter profile.

To make Ceilometer CL31 easier to use and to ease the transfer from

old ceilometer versions to this new one, CL31 includes data messages

used in CT12K, CT25K, CT25KAM, and LD40.

VAISALA _______________________________________________________________________ 13

Page 14

User's Guide ______________________________________________________________________

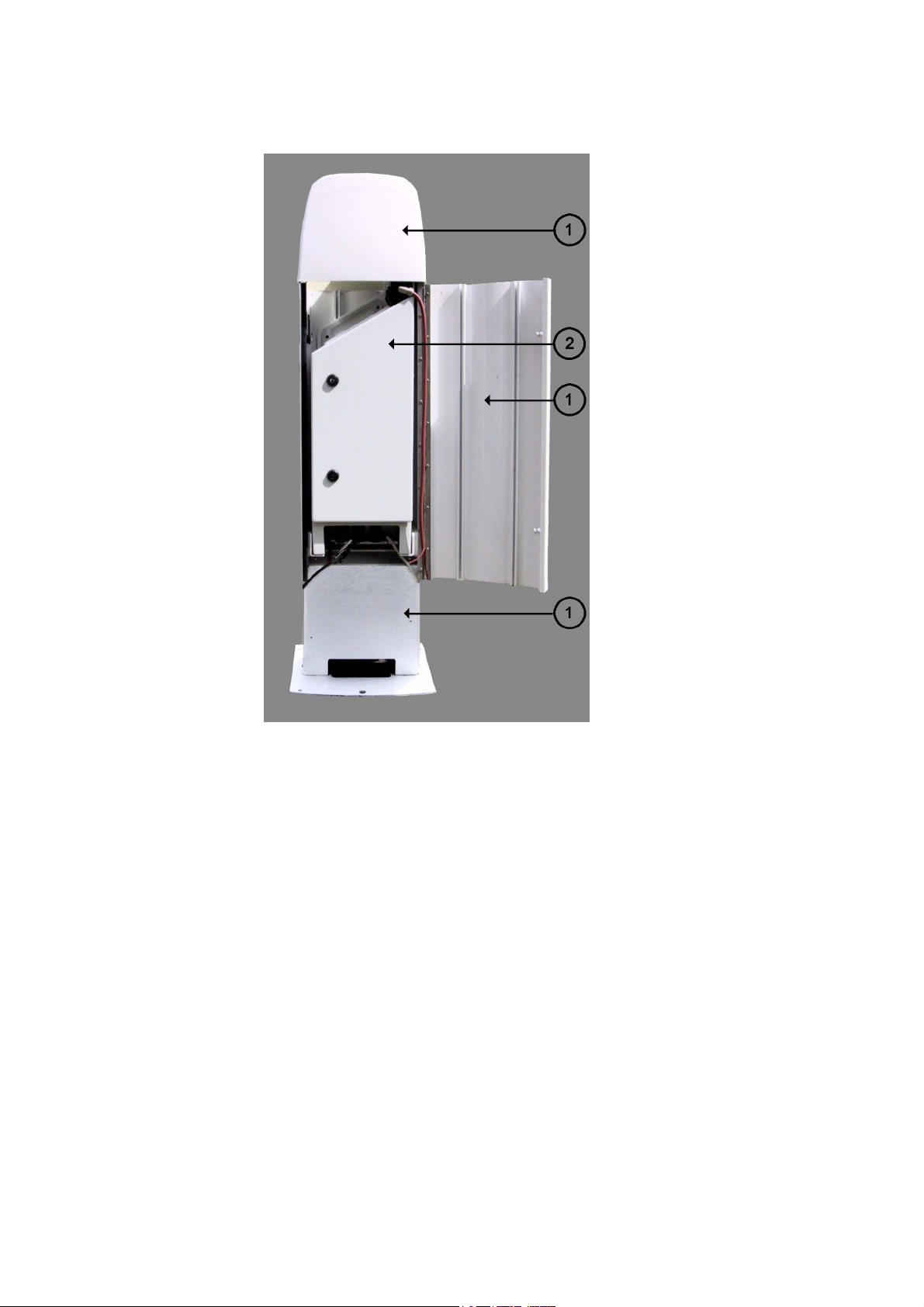

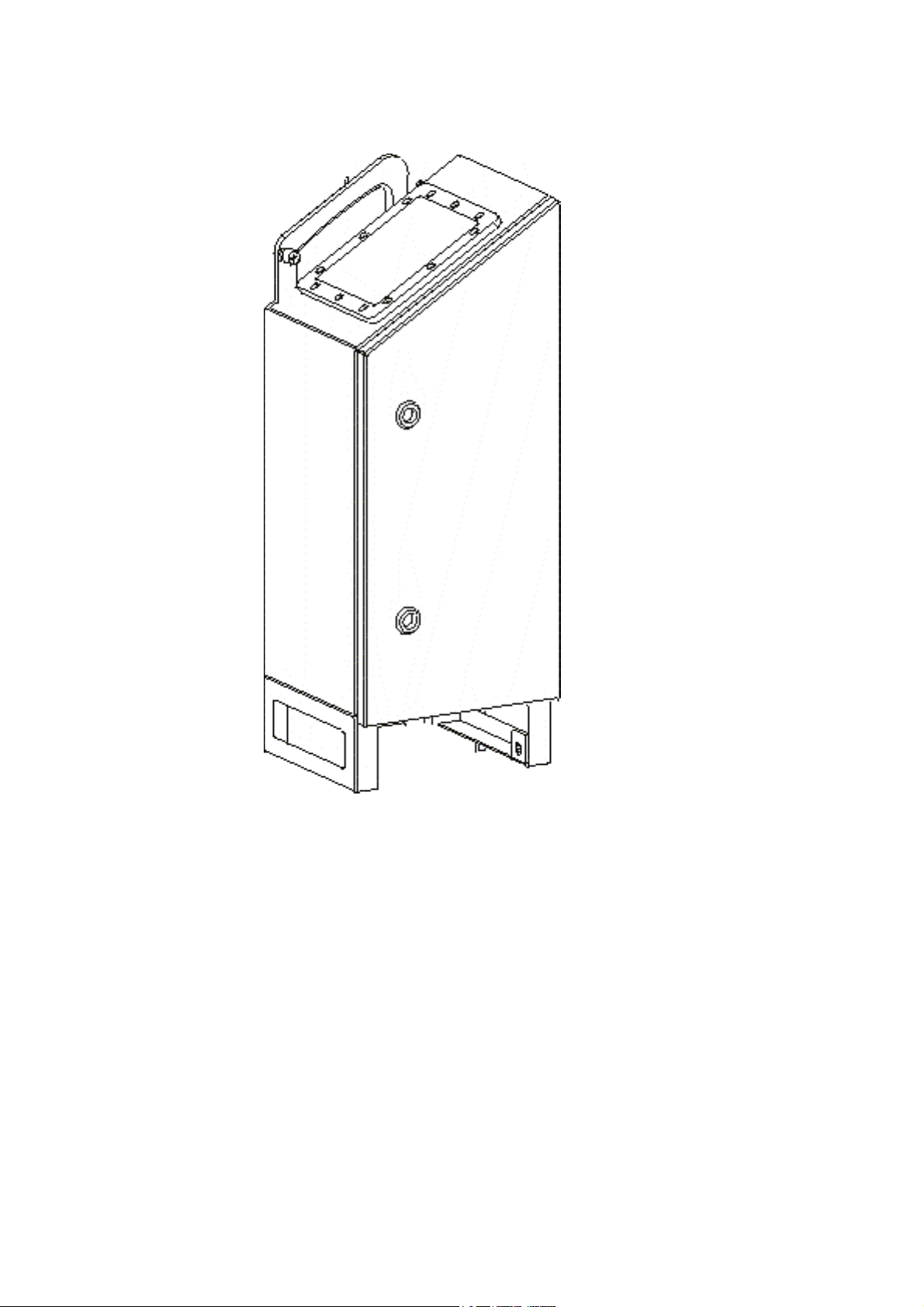

0406-052

Figure 1 Vaisala Ceilometer CL31

The following numbers refer to Figure 1 above:

1 = Shield

2 = Measurement Unit

14 __________________________________________________________________ M210482EN-B

Page 15

Chapter 2 __________________________________________________________ Product Overview

Product Nomenclature

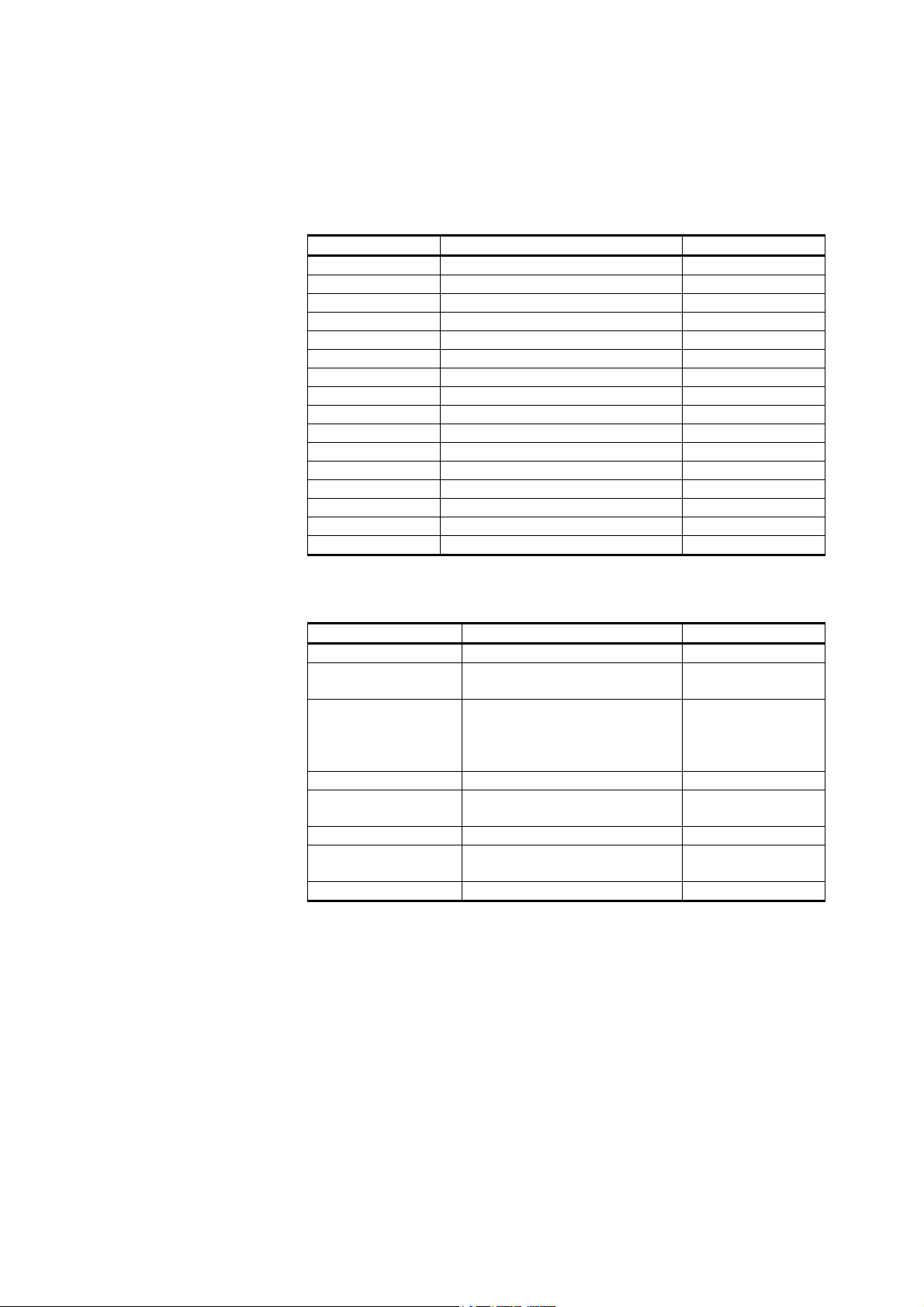

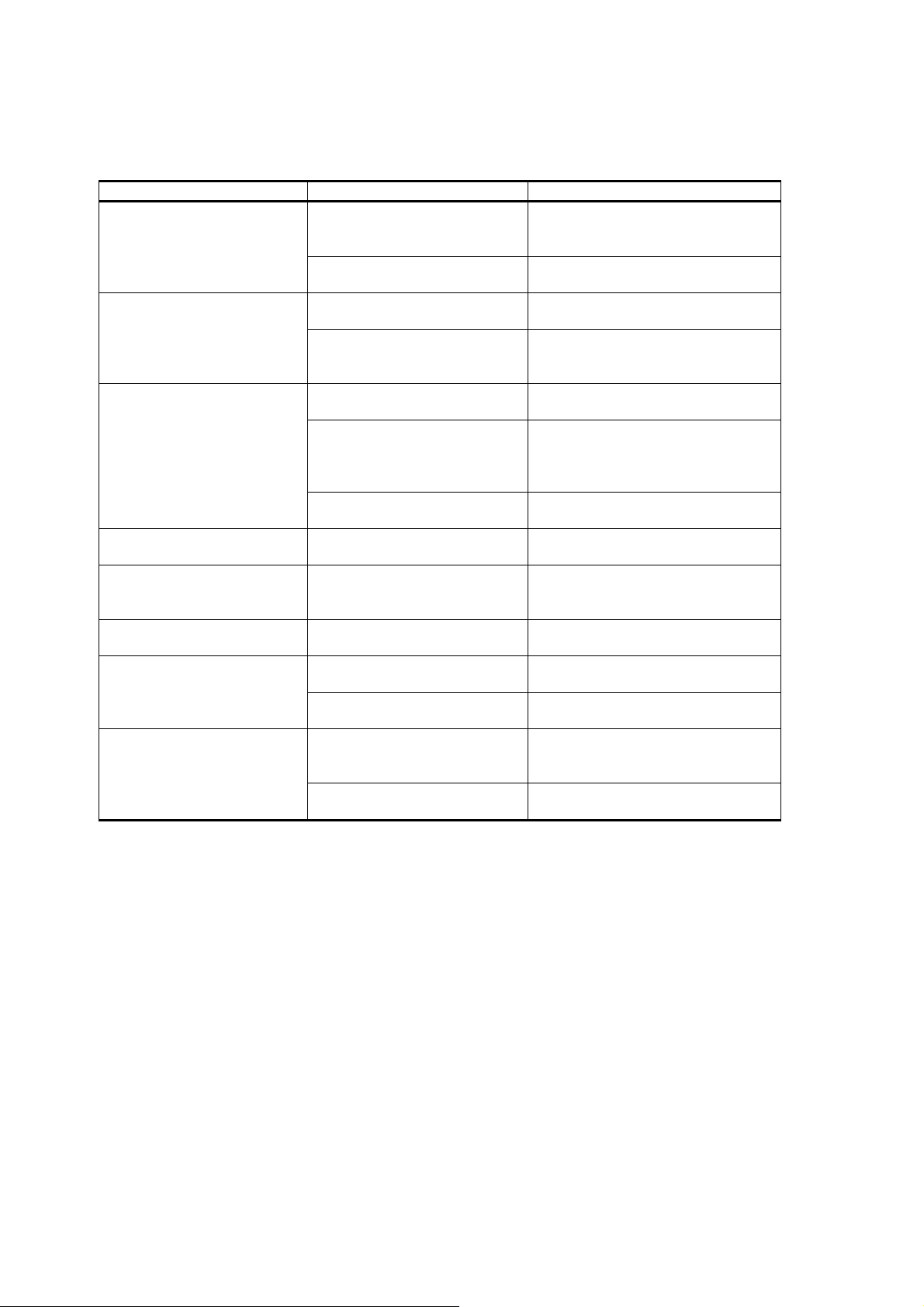

Table 2 Vaisala Ceilometer CL31 Main Parts

Code Common Name Description

CLO311 Optics Unit

CLW311 Window Assembly Spare part

CLT311SP Ceilometer Transmitter Spare part

CLR311 Ceilometer Receiver Spare part

CLM311 Laser Monitor Board Spare part

CLE311SP Ceilometer Engine Board Spare part

CLP311 AC Power Spare part

4592 No-break Battery Spare part

CLH311-115SP Inside Heater (100 ... 115 VAC) Spare part

CLH311-230SP Inside Heater (220 ... 240 VAC) Spare part

CLB311-115SP Window Blower (100 ... 115 VAC) Spare part

CLB311-230SP Window Blower (220 ... 240 VAC) Spare part

CT3839SP Power cable (230 V) Spare part

CT35324SP Power cable (115 V) Spare part

CT3838 Data cable Spare part

DRW217429 Coaxial Cable Spare part

Table 3 Vaisala Ceilometer CL31 Optional Parts

Code Common Name Description

DMX501 Modem Module Spare part

CLRADIOKIT Radio Modem Installation Kit Excl. radio modem

and antenna

TERMBOX-1200 Termination box, Mains and

signal

QMZ101 Maintenance cable

PSION Maintenance terminal

(palmtop computer)

CLTERMHOOD Optical Termination Hood

CT35022 Shock Absorber For ship

HMP50 UAB1A1A Internal Humidity Transmitter

For extended

surge and

overvoltage

protection

installations

The complete delivery also includes mating cables with connectors for

power and communication, installation hardware, a key for the

measurement unit door, and this CL31 User's Guide.

VAISALA _______________________________________________________________________ 15

Page 16

User's Guide ______________________________________________________________________

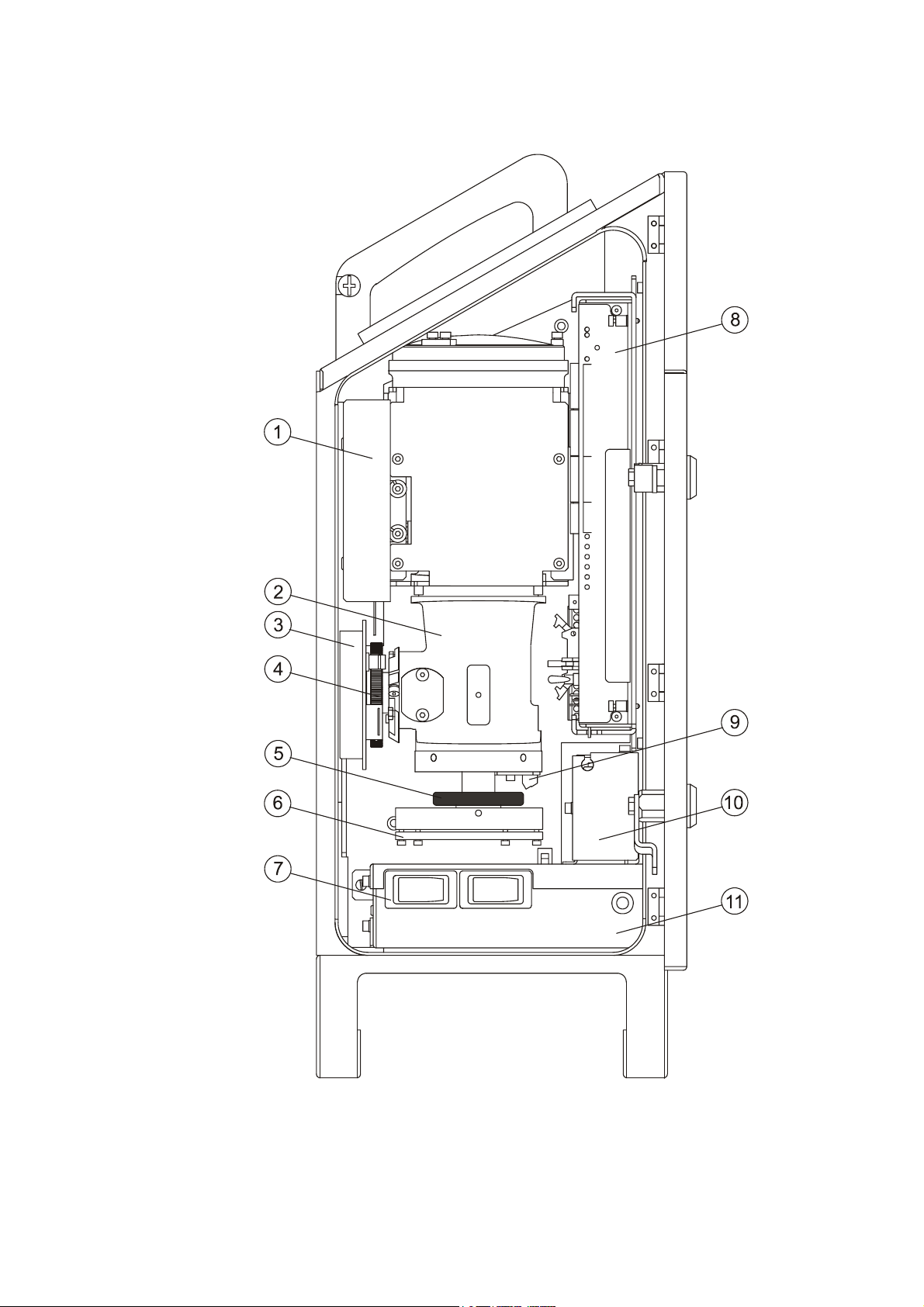

0311-057

Figure 2 Ceilometer CL31 Main Parts

16 __________________________________________________________________ M210482EN-B

Page 17

Chapter 2 __________________________________________________________ Product Overview

The following numbers refer to Figure 2 on page 16:

1 = Internal heater CLH311

2 = CLO311 Optics unit

3 = Ceilometer Receiver CLR311

4 = Receiver ring

5 = Transmitter ring

6 = Ceilometer Transmitter CLT311

7 = F1 Main circuit breaker

F2 Window blower circuit breaker

8 = Ceilometer Engine Board CLE311

9 = Laser Monitor Board CLM311

10 = Battery 4592

11 = AC Power CLP311

12 = Battery switch

VAISALA _______________________________________________________________________ 17

Page 18

User's Guide ______________________________________________________________________

This page intentionally left blank.

18 __________________________________________________________________ M210482EN-B

Page 19

Chapter 3 _______________________________________________________________ Installation

CHAPTER 3

INSTALLATION

This chapter provides you with information that is intended to help

you install this product.

Installation Procedure

This section describes the installation procedure of Vaisala Ceilometer

CL31.

Unloading and Unpacking Instructions

CL31 is shipped in one container that contains the shield, the

measurement unit inside the shield, and all the equipment, accessories,

and documentation needed for carrying out the installation. Store the

original packaging for possible later transport need.

For opening, the package should be placed on a flat surface with the

indicated top side up. You should open the container from the top side

and carefully remove the ceilometer and all the other equipment.

- Use proper gloves for protection against sharp edges, etc.

- Avoid touching the window or lens surfaces, unless you plan to

clean them properly afterwards.

- Keep the integral protective caps on the unused external connectors

(J4 Maintenance line).

- Use the measurement unit handle for lifting and carrying the

measurement unit. See Figure 3 on page 20.

VAISALA _______________________________________________________________________ 19

Page 20

User's Guide ______________________________________________________________________

0311-054

Figure 3 Measurement Unit Handle

If mishandling occurs during transit or installation, the instrument

should be returned to a Vaisala office or authorized Depot for

inspection.

Preparing a Concrete Foundation

The standard foundation for the CL31 ground installation is a concrete

foundation. The minimum dimensions suggested are presented in

Figure 4 on page 21. Mounting hardware is included with the delivery.

20 __________________________________________________________________ M210482EN-B

Page 21

Chapter 3 _______________________________________________________________ Installation

NOTE

In case CL31 is used to replace another ceilometer (CT25K, CT12K,

LD40, LD25, or LD12) the existing foundation and foundation

screws can be used.

9412-027

Figure 4 Foundation Construction

VAISALA _______________________________________________________________________ 21

Page 22

User's Guide ______________________________________________________________________

There are two alternative ways to create a concrete foundation for

Ceilometer CL31. You can either cast a new concrete foundation or

use an existing one.

NOTE

If the tilt feature will be used (see section Using the Tilt Feature on

page 29), observe this in the layout of the foundation screws and

shield placement.

Creating a New Concrete Foundation

1. Fasten the M10 × 40 wedge bolts to the lower ends of the

foundation screws (4 each).

2. Fix a drilling template to the upper ends of the foundation

screws with nuts.

3. Place the template with the attached foundation screws into the

hole in such a way that approximately 30 mm (1.25 inches) of

the foundation screw threads stand above the surface.

4. Pour in the concrete and finish the foundation.

Using an Existing Foundation

1. Drill four holes with a diameter of 12 mm and a depth of

165 mm (0.5 × 6.5 inches) into the concrete.

2. Fasten the M10 × 40 wedge bolts to the lower ends of the

foundation screws (4 each).

3. Place the wedge bolt and foundation screw combinations into

the holes, with the wedge bolts down, and hammer the

protruding threads down.

4. Tighten the foundation screws a few turns to attach the wedge

bolts to the hole walls.

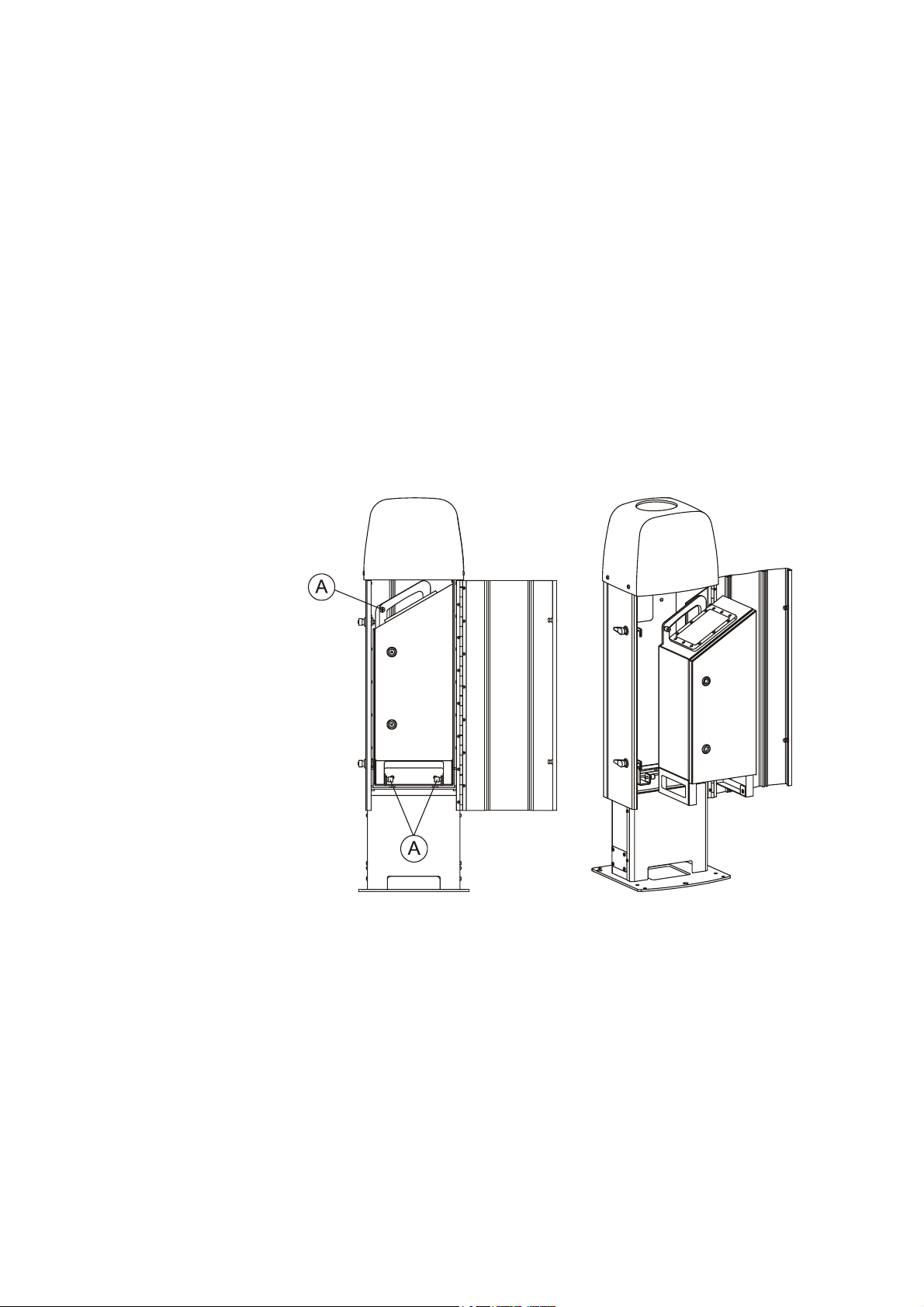

Mounting the Ceilometer CL31

Ceilometer CL31 is delivered with the measurement unit attached to

the shield. If two people are handling the installation, the shield can be

mounted with the measurement unit attached. It is, however,

recommended that you first remove the measurement unit, mount the

shield, and then reattach the measurement unit to the shield.

22 __________________________________________________________________ M210482EN-B

Page 23

Chapter 3 _______________________________________________________________ Installation

To mount Ceilometer CL31, proceed as follows:

1. Remove the measurement unit from the shield. To do this,

loosen the three attachment screws (marked A in Figure 5

below), disconnect the blower cable from connector J1 (see

Figure 7 on page 25), and pull out the unit.

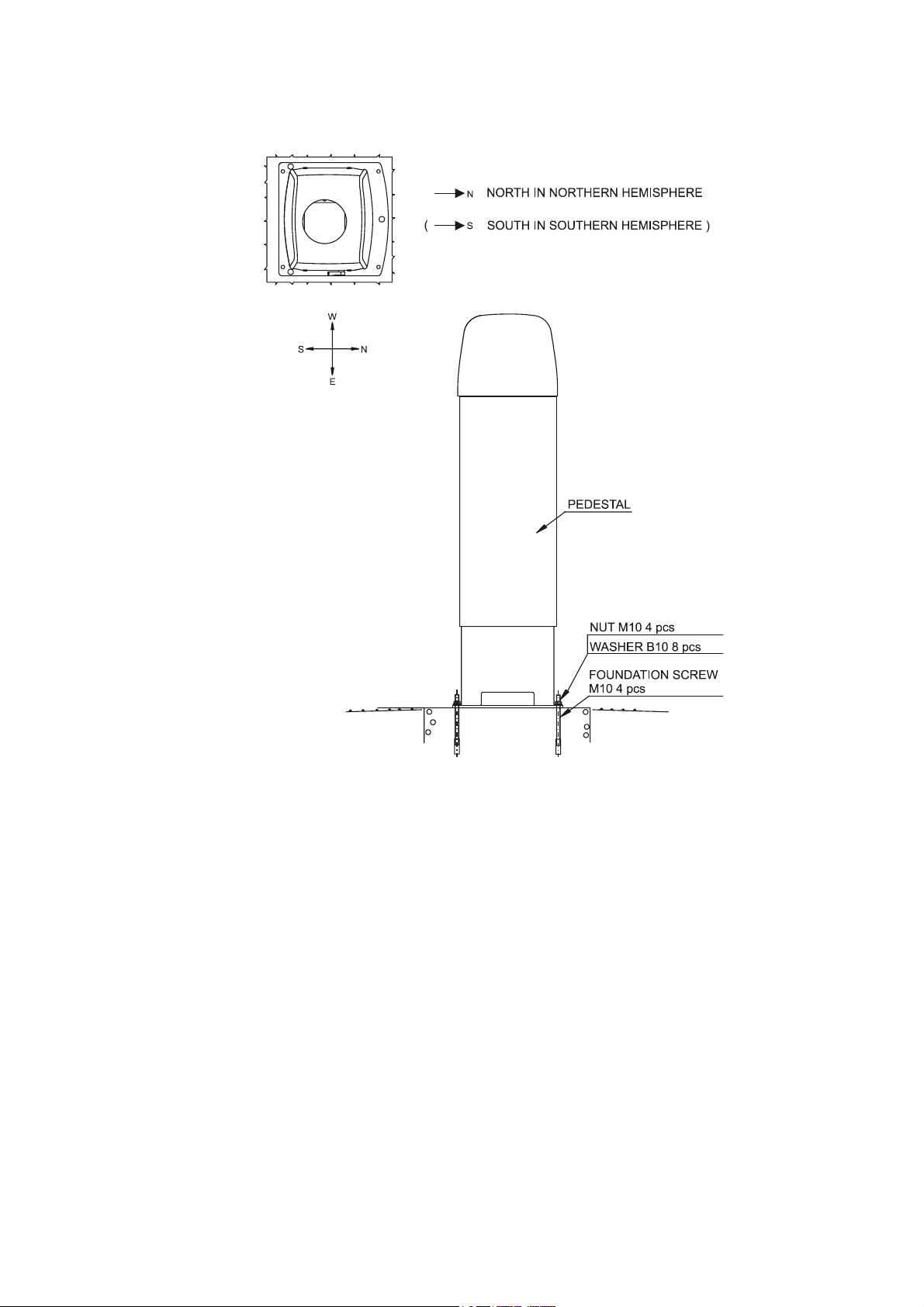

2. Place the shield on the foundation in such a way that the door

faces North in the Northern hemisphere and South in the

Southern hemisphere. Refer to Figure 6 on page 24.

3. Place the flat washers on the foundation screws and fix the nuts.

Refer to Figure 6 on page 24.

4. Place the measurement unit inside the shield, connect the blower

cable to connector J1, and tighten the three attachment screws

(marked A in Figure 5 below).

0311-055

Figure 5 Removing and Attaching the Measurement Unit

VAISALA _______________________________________________________________________ 23

Page 24

User's Guide ______________________________________________________________________

0311-056

Figure 6 Mounting the Shield

24 __________________________________________________________________ M210482EN-B

Page 25

Chapter 3 _______________________________________________________________ Installation

Connecting the External Cables

All external connectors to the measurement unit are located at the

bottom front edge as seen from the door direction. Figure 7 below

shows the external connectors J1, J2, J3, and J4.

0306-006

Figure 7 External Connectors (Bottom View)

The window blower mounted into the shield is connected to connector

J1. Line power input is connected to connector J2. Remote

communication is normally connected to connector J3. A local

maintenance terminal, a laptop or a palmtop for example, can be

connected to connector J4. A protective cap is included for covering

J4 when it is not used.

External mating connectors with 2 m (7 ft) cable are included for J2

and for J3. The power plug of the J2 cable can be cut when the unit is

permanently installed at the final site.

VAISALA _______________________________________________________________________ 25

Page 26

User's Guide ______________________________________________________________________

The wire connections and cable glands of the optional Termination

Box are presented in the Termination Box User's Guide (refer to

section Related Manuals on page 8).

NOTE

When the permanent line power installation is made, the maximum

size of the fuse protecting the power line is 10 A.

Data Line Connection

Vaisala Ceilometer CL31 offers three possible options for the data line

connection. These options are presented in the following figures.

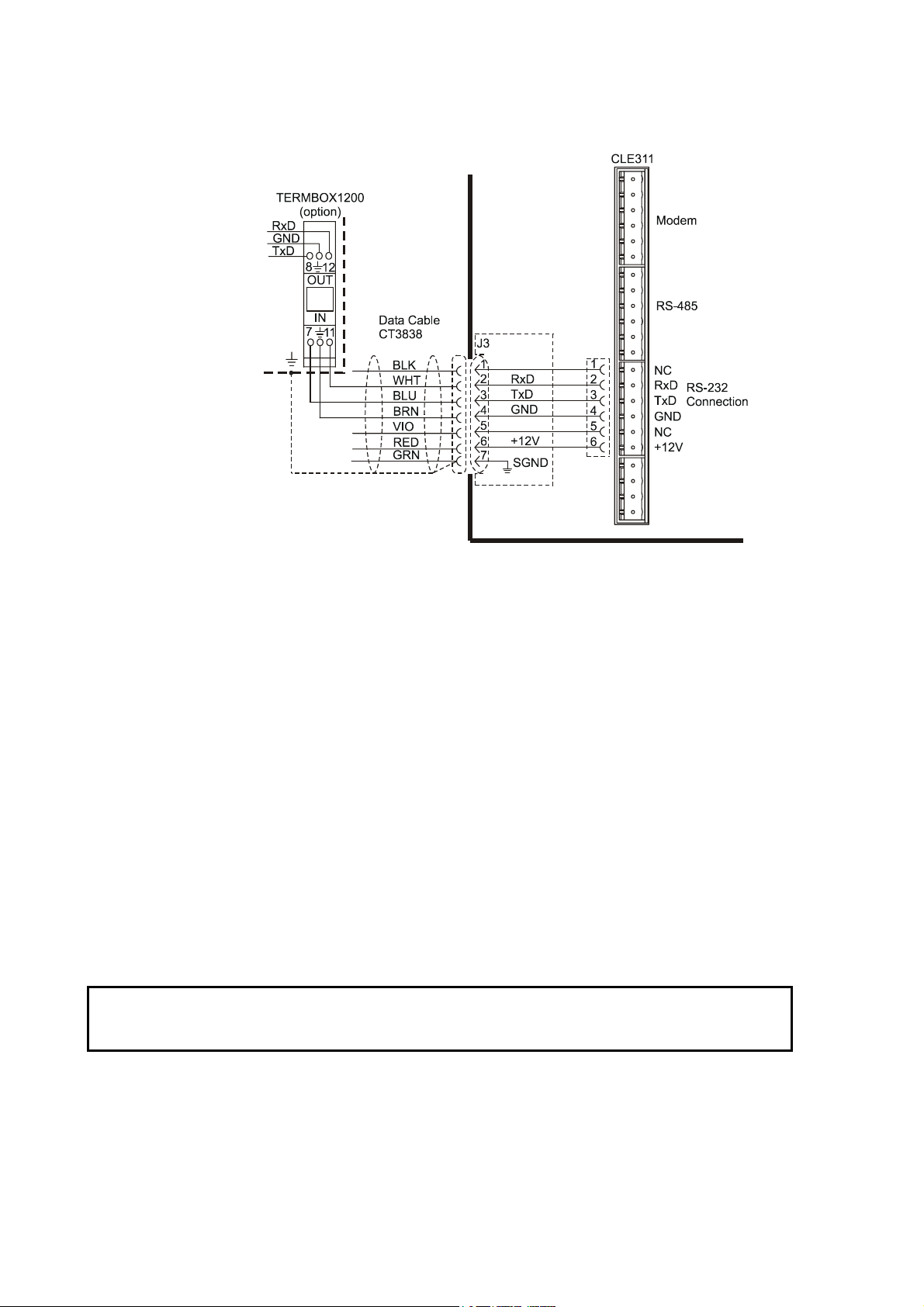

0311-060

Figure 8 Data Line Modem Connection

26 __________________________________________________________________ M210482EN-B

Page 27

Chapter 3 _______________________________________________________________ Installation

Default Settings for the Data Line Modem Connection

Modem mode V.22bis

Bit rate 2400

Data bits 8

Stop bits 1

Parity None

0311-061

Figure 9 Data Line RS-485 Connection

Default Settings for the Data Line RS-485 Connection

Bit rate 19200

Data bits 8

Stop bits 1

Parity None

VAISALA _______________________________________________________________________ 27

Page 28

User's Guide ______________________________________________________________________

0311-062

CAUTION

Figure 10 Data Line RS-232 Connection

Default Settings for the Data Line RS-232 Connection

Bit rate 19200

Data bits 8

Stop bits 1

Parity None

Handshake None

Grounding

The power supply connector J2 provides a standard protective ground

for the instrument chassis.

CL31 is equipped with a separate grounding screw for external

grounding at the bottom of the shield.

Connection to a solid earth ground at the installation site is

mandatory for adequate lightning and transient protection.

28 __________________________________________________________________ M210482EN-B

Page 29

Chapter 3 _______________________________________________________________ Installation

Maintenance Terminal Connection

Any terminal or PC with a serial interface and a terminal emulation

program can be used for operation and maintenance of Ceilometer

CL31. The maintenance terminal connection is established with the

QMZ101 maintenance cable, which connects the RS-232 port of the

PC to the maintenance port of the ceilometer.

A standard maintenance terminal option includes a PSION Palmtop

Computer and its Technical Manuals.

Setting up Maintenance Terminal Connection

1. Connect the RS cable to the ceilometer maintenance port

(connector J4) and the terminal computer.

2. Set the following settings for the terminal:

Bit rate 9600

Data bits 8

Stop bits 1

Parity None

Handshake None

Operation of Maintenance Terminal Connection

To operate the connection, do the following:

1. Turn the power on in CL31.

2. Open the CL31 maintenance with the open command.

3. The prompt CEILO > appears. For details, see Chapter 5,

Functional Description, on page 73.

Using the Tilt Feature

Ceilometer CL31 is designed to allow operation in a tilted direction.

The built-in tilt angle sensor detects the tilt angle, that is, the deviation

from vertical. The tilt feature allows three tilt angles: vertical, 12

degrees with the measurement unit door upwards, and 12 degrees with

the measurement unit door downwards. The cosine of the tilt angle is

used for an automatic correction of the detected cloud base height,

which enables accurate cloud base measurements also in a tilted

direction.

VAISALA _______________________________________________________________________ 29

Page 30

User's Guide ______________________________________________________________________

The tilt feature provides the following advantages:

- Protection in heavy weather conditions:

Using a tilt angle of 12 degrees protects the measurement unit

window from precipitation, thus enhancing the performance in

heavy weather conditions.

- Precision in aircraft approach detection:

The beam can be directed towards a direction that better represents

the approach of an aircraft than the straight vertical. This is useful,

for example, for helicopter approaches, and sites where the

ceilometer cannot be located exactly at the desired spot.

WARNING

NOTE

When tilting the unit, make sure that nobody is watching it with

binoculars or other magnifying optics.

To avoid direct sunlight, tilt the unit away from the sun. That is, tilt it

north in the northern hemisphere and south in the southern

hemisphere. Direct insolation exposure will not damage the unit but

will cause alarms and temporarily invalidate the data

As these advantages may be contradictory or cannot be realized

simultaneously, the user must decide the direction of the final

installation.

Mobile Operation Aspects

The small and lightweight measurement unit of Ceilometer CL31 is

also suitable for mobile operation. It has a built-in 12 V battery, which

enables operation without external power supply for about an hour in

normal room temperature.

NOTE

30 __________________________________________________________________ M210482EN-B

For switching the CL31 power fully off, also turn off the battery

switch in addition to the line power switch. Having the unit on with

the battery supply will only drain the battery.

Page 31

Chapter 3 _______________________________________________________________ Installation

NOTE

Startup

Do not attempt to carry a fully assembled unit alone, preferably, lift

the measurement unit from the shield. The two main parts, the

measurement unit (12 kg) and the shield (18.5 kg), can be lifted and

carried separately.

This section describes the different aspects of Ceilometer CL31 that

need to be considered before starting up the device.

Startup Procedure

Open the unit door with the key included in the delivery. Make a

visual check of the internal connectors and subassemblies (refer to

Figure 11 on page 32 for further information if necessary). Then

proceed as follows:

1. Turn the main circuit breaker F1 to the Off position (for

location, see Figure 12 on page 33).

NOTE

WARNING

2. Plug in the line supply cable to connector J2 (for location, see

Figure 7 on page 25) after checking the voltage of the power

supply cable connector.

3. Turn the Main Circuit Breaker F1, the Window Blower Circuit

Breaker F2, and the Battery Switch to the On position. After the

initialization routines, the Laser on LED starts blinking at

2-second intervals. Also the six diagnostic LEDs light up. For

location of the LEDs and switches, refer to Figure 12 on page 33

and Figure 13 on page 34.

For switching the CL31 power fully off, also turn off the battery

switch in addition to the line power switch. Having the unit on with

the battery supply will drain the battery.

Make sure that nobody is viewing the unit from the beam direction

with magnifying optics.

VAISALA _______________________________________________________________________ 31

Page 32

User's Guide ______________________________________________________________________

0311-058

Figure 11 Subassembly Interconnections

32 __________________________________________________________________ M210482EN-B

Page 33

Chapter 3 _______________________________________________________________ Installation

The following numbers refer to Figure 11 on page 32:

1 = Data line connection to AC power CLP311

2 = Coaxial cable connection to Ceilometer Receiver CLR311

3 = Connection to Ceilometer Transmitter CLT311

4 = Connection to Battery 4592

5 = Connection to Ceilometer Receiver CLR311

6 = Connection to Laser monitor board CLM311

7 = Connection to AC power CLP311

8 = Connection to Internal heater CLH311

9 = Battery switch

0406-053

Figure 12 CL31 Switches

The following numbers refer to Figure 12 above:

1 = F1 Main circuit breaker

2 = F2 Heater/Blower circuit breaker

VAISALA _______________________________________________________________________ 33

Page 34

User's Guide ______________________________________________________________________

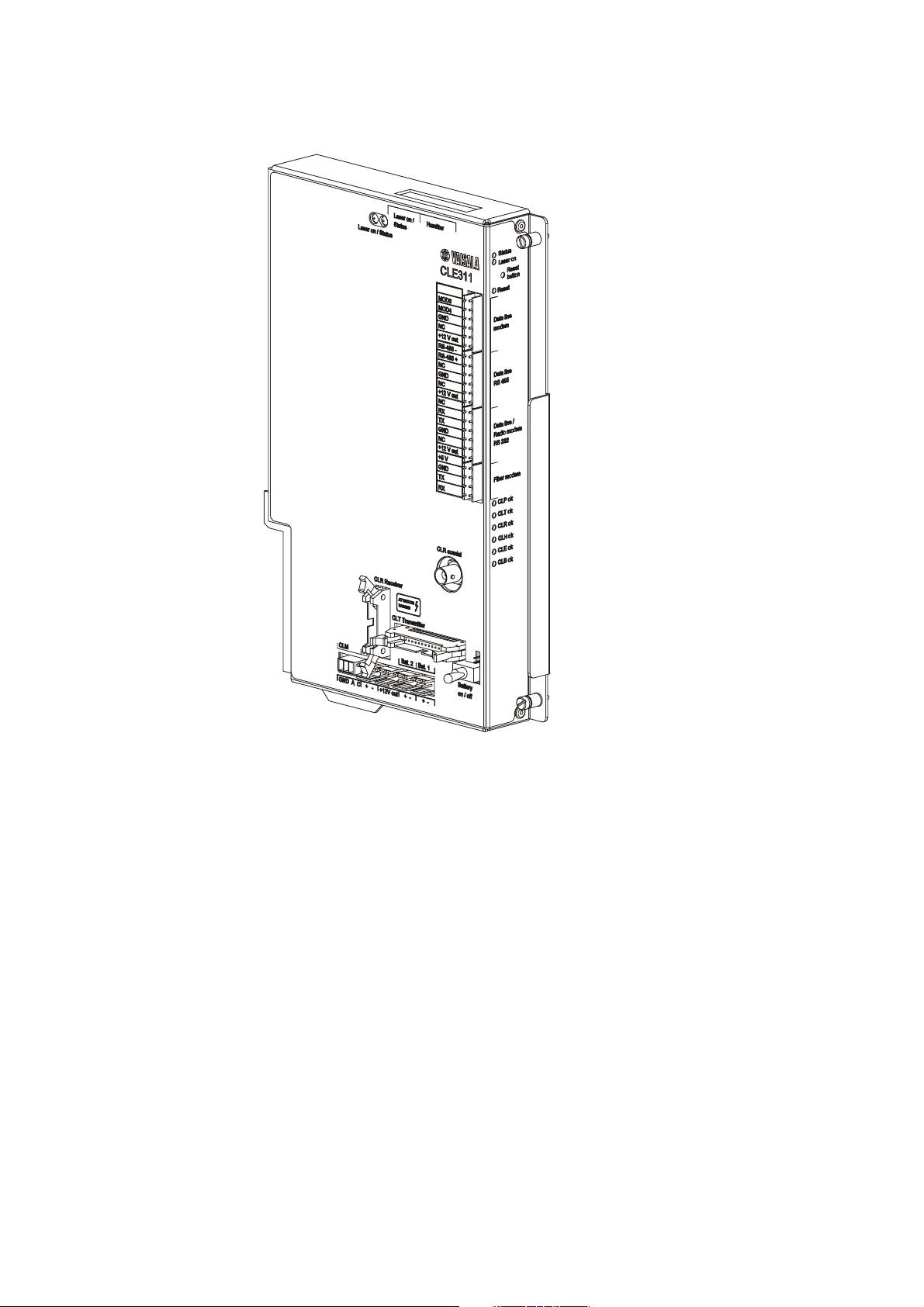

0311-059

Figure 13 Ceilometer Engine Board CLE311

Settings for Normal Operation

The switch settings for normal operation are as follows:

Main circuit breaker F1 ON

Heater/Blower circuit breaker F2 ON

Battery switch ON

The data message and interface configuration and the configuration of

measuring interval and transmission speed are standard factory

settings. When required, the settings can be changed by giving

commands with the terminal.

34 __________________________________________________________________ M210482EN-B

Page 35

Chapter 3 _______________________________________________________________ Installation

During the factory alignment procedure, the optical adjustments are

carefully carried out to fulfill the requirements and specifications of

the device. Optical adjustments have been made at the factory or

depot, thus there is no need to readjust them in the field.

Factory Settings of User Programmable Parameters

Table 4 below lists the factory defaults of user-programmable

parameters. The prevailing parameter settings of Ceilometer CL31 can

be seen with the following command:

get params parameter_group

The user-programmable parameters can be changed with the

following command:

set parameter_group parameter

Table 4 Factory Defaults of User-Programmable Parameters

Parameter Factory Default

Control blower Auto

Control inheater Auto

Data_acq power_save Disabled

Data_port baud 19200

Data_port mode RS232

Data_port parity 8N1

Maint_port baud 9600

Maint_port parity 8N1

Message angle_corr On

Message transmission Periodic

Message transmission delay 100 ms

Message height_offset 0

Message interval 2 s

Message port Data

Message profile scale 1.0

Message profile noise h2 Off

Message type msg2_20x385

Message units Feet

Message vv_limit ceiling 2000 m (6562 ft)

Message vv_limit sky_cond_percent 50

Oper_mode Normal

Port_timeout 2 min

Unit_id 0 (zero)

VAISALA _______________________________________________________________________ 35

Page 36

User's Guide ______________________________________________________________________

This page intentionally left blank.

36 __________________________________________________________________ M210482EN-B

Page 37

Chapter 4 ________________________________________________________________ Operation

CHAPTER 4

OPERATION

This chapter contains information that is needed to operate this

product.

Operation Modes

There are two operation modes, normal and standby. The set

oper_mode normal and set oper_mode standby commands are used

to switch between the modes. In the normal mode, continuous

measurement and message transmission occurs according to the

chosen parameters. The standby mode, which involves turning off the

wearing parts, can be used during periods when measurement is not

needed.

Figure 14 Operation Modes

Serial Lines - Open and Closed Port

0406-020

The two serial lines provided are called the maintenance line (external

connector J4) and the data line (external connector J3). The data line is

intended to be used for measurement data communication and can be

operated through a modem or baseband. The maintenance line is

intended for on-site maintenance access, and is used only as a

baseband. However, functionally the operation of the lines is identical,

VAISALA _______________________________________________________________________ 37

Page 38

User's Guide ______________________________________________________________________

the same commands, operations, and messages operate through any of

the lines, and the following description applies to both of them.

The factory default setting is 8 data bits, No parity, 1 Stop bit, and for

baseband lines, 9600 maint, 19200 data. The bit rate can be selected

from the user menu.

Both use the 7-bit USASCII character format. Both the UPPER and

lower letter cases can be used.

The standard operation of the serial lines requires no handshake

signals.

A communication port, in other words the serial line, has the

following two internal states (Figure 15 on page 39):

- CLOSED: This is the measurement data message transmitting state.

In this state, messages are transmitted as a response to a polling

input string or automatically at predetermined intervals, depending

on the corresponding settings (message transmission). User

commands are not accepted, except for the open command, which

turns the line into the OPEN state.

NOTE

- OPEN: This is the user dialog state. In this state, the user

commands are responded to and command input is echoed. A

command prompt CEILO > is displayed to indicate that CL31 is

ready for command input from the user. The commands are

executed by pressing ENTER, for example, OPEN 1 <enter>. No

automatic transmission of the measurement data message is

executed in the open state. The port reverts to the closed state with

the close command. An automatic, 2-minute time-out after the last

character input is applied. A 2 to 30-minute time-out may be set

with the set port_time_out command.

Only one of the ports can be open for commands at a time. Only one

of the ports transmits measurement messages at a time. Additionally,

in the RS-485 mode, a unit ID must be given with the open

command.

38 __________________________________________________________________ M210482EN-B

Page 39

Chapter 4 ________________________________________________________________ Operation

0406-066

Figure 15 Open and Closed Port

User Commands

User commands are described in Table 5 on page 40. User commands

are accessible after opening the line with the open command. No

password is needed.

The exact format of commands does not have to be remembered, as

the command line interpreter provides interactive support. At each

menu level, pressing ENTER provides an output of the available

menu. Inserting a letter followed by ENTER outputs all commands

starting with that letter. Inserting two letters followed by ENTER

outputs all commands that start with those two letters, etc., until only

the desired command is left. This command is then executed by

pressing the ENTER key.

In addition to the user menu and the user level command set, there is a

second in-depth maintenance and service level menu and command

set, which is intended for more profound system changes and

diagnostics. These advanced level commands are presented in a

separate table (see Table 6 on page 43). The password for this level is

"advanced". The commands on this level should only be used

according to the instructions in this manual.

VAISALA _______________________________________________________________________ 39

Page 40

User's Guide ______________________________________________________________________

Table 5 User Level Commands

Command Description

close Closes a user interface. Releases a port for message

transmission.

get diag contamination Prints diagnostic history of window contamination.

get diag angle Prints diagnostic history of inclinometer angle.

get diag battery Prints diagnostic history of battery voltage.

get diag int_temp Prints diagnostic history of internal temperature.

get diag l_power Prints diagnostic history of laser power.

get diag l_temp Prints diagnostic history of laser temperature.

get failure history Prints history of alarm and warning status.

get failure status Shows active alarms and warnings.

get params data_acq Prints data-acquisition related parameters.

get params factory Prints factory calibration values.

get params message Prints message related parameters.

get params port Prints serial port and modem parameters.

get sensors Prints data-acquisition values, tilt angles, and

humidity, if available.

get temperatures Displays temperatures.

get uptime Displays uptime clock.

get voltages Displays voltages.

name Displays device type, name, and ID.

open Opens a user interface.

reset Resets the ceilometer using the watchdog reset.

set control blower on Sets the window blower on.

set control blower off Sets the window blower off.

set control blower manual Sets manual control.

set control blower auto Sets automatic control.

set control inheater on Sets inheater on.

set control inheater off Sets inheater off.

set control inheater manual Sets manual control.

set control inheater auto Sets automatic control.

set control outheater on Sets outheater on.

set control outheater off Sets outheater off.

set data_port baud 115.2 k Data serial port speed.

set data_port baud 57.6 k Data serial port speed.

set data_port baud 38.4 k Data serial port speed.

set data_port baud 28.8 k Data serial port speed.

set data_port baud 19.2 k Data serial port speed.

set data_port baud 14.4 k Data serial port speed.

set data_port baud 9600 Data serial port speed.

set data_port baud 7200 Data serial port speed.

set data_port baud 4800 Data serial port speed.

set data_port baud 3600 Data serial port speed.

set data_port baud 2400 Data serial port speed.

set data_port baud 1800 Data serial port speed.

set data_port baud 1200 Data serial port speed.

set data_port baud 900 Data serial port speed.

set data_port baud 600 Data serial port speed.

set data_port baud 300 Data serial port speed.

set data_port mode RS-232 Data serial port mode.

set data_port mode RS-485 Data serial port mode.

set data_port parity 7E1 Data serial port settings.

40 __________________________________________________________________ M210482EN-B

Page 41

Chapter 4 ________________________________________________________________ Operation

Command Description

set data_port parity 7O1 Data serial port settings.

set data_port parity 8N1 Data serial port settings.

set defaults Restores the following default settings:

Operation mode: normal

Measurement mode: standard

Data acquisition autoadjustments: on

Blower control: auto

Inheater control: auto

Diagnostics intervals: 2 min

Power-save mode: disabled

Power-save sleep interval: 60 s

Message angle correction: on

Message transmission: periodic

Message transmission delay: 100 ms

Message height-offset: 0

Message interval: 2 s

Manual message: disabled

Message port: data

Message profile scale: 1.0

Message profile noise-h2: off

Message type: msg2_20x385

Message units: feet

Message VV limit ceiling: 6562 ft (2000 m)

Message VV limit sky-condition percentage: 50 %

Port timeout: 2 min

Unit ID: 0

set diag interval angle Sets diagnostic-data logging interval (min). 0 disables.

set diag interval battery Sets diagnostic-data logging interval (min). 0 disables.

set diag interval contam Sets diagnostic-data logging interval (min). 0 disables.

set diag interval int_temp Sets diagnostic-data logging interval (min). 0 disables.

set diag interval l_power Sets diagnostic-data logging interval (min). 0 disables.

set diag interval l_temp Sets diagnostic-data logging interval (min). 0 disables.

set diag interval clear Clears all diagnostic-data history.

set maint_port baud 115.2 k Maintenance serial port speed.

set maint_port baud 57.6 k Maintenance serial port speed.

set maint_port baud 38.4 k Maintenance serial port speed.

set maint_port baud 28.8 k Maintenance serial port speed.

set maint_port baud 19.2 k Maintenance serial port speed.

set maint_port baud 14.4 k Maintenance serial port speed.

set maint_port baud 9600 Maintenance serial port speed.

set maint_port baud 7200 Maintenance serial port speed.

set maint_port baud 4800 Maintenance serial port speed.

set maint_port baud 3600 Maintenance serial port speed.

set maint_port baud 2400 Maintenance serial port speed.

set maint_port baud 1800 Maintenance serial port speed.

set maint_port baud 1200 Maintenance serial port speed.

set maint_port baud 900 Maintenance serial port speed.

set maint_port baud 600 Maintenance serial port speed.

set maint_port baud 300 Maintenance serial port speed.

set maint_port parity 7E1 Maintenance serial port settings.

set maint_port parity 7O1 Maintenance serial port settings.

set maint_port parity 8N1 Maintenance serial port settings.

set message transmission delay Sets request-based delivery response delay (ms).

VAISALA _______________________________________________________________________ 41

Page 42

User's Guide ______________________________________________________________________

Command Description

set message transmission periodic Sets periodic message transmission.

set message transmission request Sets message request-based delivery.

set message interval 2 ... 120 Sets message delivery interval in seconds.

set message port data Delivers messages into data port.

set message port maintenance Delivers messages into maintenance port.

set message type msg1_10x770 Sets Msg1 with 10x770 profile.

set message type msg1_20x385 Sets Msg1 with 20x385 sample profile with 385

samples and 20 m resolution.

set message type msg1_5x1500 Sets Msg1 with 5x1500 profile.

set message type msg1_5x770 Sets Msg1 with 5x770 profile.

set message type msg1_base Sets Msg1 without a profile.

set message type msg2_10x770 Sets Msg2 with 10x770 profile.

set message type msg2_20x385 Sets Msg2 with 20x385 profile.

set message type msg2_ 5x1500 Sets Msg2 with 5x1500 profile.

set message type msg2_ 5x770 Sets Msg2 with 5x770 profile.

set message type msg2_base Sets Msg2 without a profile.

set message type status Sets status message.

set message type ct25k_msg1 Sets CT25K message 1.

set message type ct25k_msg6 Sets CT25K msg6 / CT25KAM msg60.

set message type ct25k_msg61 Sets CT25KAM msg61.

set message type ct12k_dmsg2 Set CT12K message no. 2.

set message type ct12k_dmsg3 Set CT12K message no. 3.

set message type ld40_std_tg Sets LD40 Standard Telegram.

set modem v21 answer Sets modem to answer with v21.

set modem v21 originate Sets modem to call with v21.

set modem v22 answer Sets modem to answer with v22.

set modem v22 originate Sets modem to call with v22.

set modem v22bis answer Sets modem to answer with v22bis.

set modem v22bis originate Sets modem to call with v22bis.

set modem off Disables the communication module and uses serial

line communication.

set name <string> Sets the unit name.

set oper_mode standby Sets standby mode. Profile sampling is inactive.

set oper_mode normal Sets normal operation.

set port_time_out 0 ... 30 Sets the command line time-out to 0 ... 30 minutes.

Zero disables.

set unit_id <character> Sets the unit ID.

status Prints the status message.

system Lists system information: type, ID, SW version, HW

modules, serial number.

version Displays the SW version.

42 __________________________________________________________________ M210482EN-B

Page 43

Chapter 4 ________________________________________________________________ Operation

Table 6 Advanced Level Commands

Command Description

back Go back one security level. Go back to the user level

commands.

get failure diag Show failure diagnostics data.

get params algorithm Prints cloud algorithm related parameters.

service replace_instr battery Prints service instructions for replacing a battery.

service replace_instr

cle_engine_board

service replace_instr clp_ac_power Prints service instructions for replacing a CLP311

service replace_instr clr_receiver Prints service instructions for replacing a CLR311

service replace_instr clt_transmitter Prints service instructions for replacing a CLT311

service self_check Runs the self-check.

service spare_part cle_engine mark Marks CLE spare part status.

service spare_part cle_engine clear Clears CLE spare part status.

service spare_part clt_transmitter

mark

service spare_part clt_transmitter

clear

service sw_update Updates the software.

set data_acq autoadj on Sets SW-control of data acquisition parameters.

set data_acq autoadj off Disables SW-control of data acquisition parameters.

set data_acq meas_mode standard Maximum range 7700 m, 10 m resolution, laser

set data_acq meas_mode high_res Maximum range 7550 m, 5 m resolution, laser pulse

set data_acq power_save disable Disables power-save mode.

set data_acq power_save enable Enables power-save mode.

set data_acq power_save interval

30 ... 30000

set data_acq receiver gain low Sets receiver to low gain.

set data_acq receiver gain high Sets receiver to high gain.

set data_acq transmit length_of_p short Sets transmitter to short pulse.

set data_acq transmit length_of_p long Sets transmitter to long pulse.

set data_acq transmit inlaser 0 ...

4095

set factory outlaser 0 .. 2500 Sets target outlaser.

set factory win_clean Sets window clean status for window cond.

set message angle_corr on Heights in messages are corrected for the tilt angle.

set message angle_corr off Heights in messages are not corrected for the tilt

set message height_offset <value> Sets height offset in current units.

set message manual_msg <string> Sets a manual message. Empty string disables.

set message profile scale Scaling factor for range gate data (%).

set message profile noise_h2 on Range gates data is always range normalized, even

Prints service instructions for replacing a CLE311

engine board.

power unit.

receiver.

transmitter.

Marks CLT spare part status.

Clears CLT spare part status.

pulse rate 10 kHz.

rate 8 kHz.

Power-save interval in seconds. Default is 60.

Sets control value for laser pulse.

calibration.

angle.

(Range is -304 ... 304 m or -1000 ... 1000 ft.)

Positive values are added to and negative values are

subtracted from the measured height.

noise.

VAISALA _______________________________________________________________________ 43

Page 44

User's Guide ______________________________________________________________________

Command Description

set message profile noise_h2 off Range gates data is range normalized, if backscatter

is

contained.

set message units feet Reported heights unit is feet.

set message units meters Reported heights unit is meters.

set message vv_limit ceiling 0 ... 7620 Sets vertical visibility ceiling limit (meters/feet). No

vertical visibility will be reported above this limit.

(Default: 2000 m).

set message vv_limit

sky_cond_percent 1 ... 100

set message units vv_limit ceiling Sets vertical visibility ceiling limit (meters/feet).

set option humitter on Enables the humitter option.

set option humitter off Disables the humitter option.

set option sky_cond off Disables the sky condition option.

set option sky_cond on 0 .. 99999 Enables the sky condition option with an activation

Sets vertical visibility reporting limit (%).

code.

Data Messages

To ease the use of Ceilometer CL31 and to ease the transfer from old

ceilometer versions to the new one, CL31 includes data messages used

in CT12K, CT25K, CT25KAM, and LD40. CL31 provides the

following data messages:

- CL31 Data messages 1 and 2

- CL31 Status message

- CT12K data messages No. 2 and No. 3

- CT25K data messages No. 1 and No. 6

- CT25KAM data messages No. 60 and No. 61

- LD40 Standard Telegram

Each port can be set to transmit a specified message automatically.

Alternatively, the port can be set to transmit the set message only

when polled by a predetermined polling string of characters, or the

polling string can contain the message identification.

The messages may provide a different resolution and require a

different measurement mode. A change of a message always switches

into a correct measurement mode automatically.

However, CL31 Status message and CL31 Data messages 1 and 2 of

subclass 5 (without profile data) may be used in both 10 m and 5 m

resolutions. A selection of these messages always activates the 10 m

44 __________________________________________________________________ M210482EN-B

Page 45

Chapter 4 ________________________________________________________________ Operation

resolution (standard mode). If needed, users can change into the 5 m

resolution (high resolution) by typing the following advanced level

command: set data_acq meas_mode high_res. Thus, the above

messages will work in 5 m resolution.

NOTE

All characters are 7-bit USASCII.

↵ symbolizes Carriage Return + Line Feed (2 characters) throughout

this document.

Start-of-Header, Start-of-Text, End-of-Text, End-of-Transmission,

Carriage Return, and Line Feed are non-printing characters in most

practical terminal use.

CL31 Data Messages No. 1 and 2

Data message No. 1 contains cloud height/vertical visibility

measurement and elementary status information that enables a host

system or operator to see that no warnings or alarms are present. This

message also includes a range and sensitivity normalized backscatter

profile, which makes it suitable, for example, for a graphical data

presentation or research purposes.

The data resolution is 5 m/10 m/20 m (16 ft/33 ft/66 ft) with distance,

and 20 bits (five hex-ASCII characters) with signal magnitude.

An example of CL31 data message No.1 is presented below:

CLA10011☺↵ 1st line 12 char.

30 01230 12340 23450 FEDCBA987654↵ 2nd line 35 char.

00100 10 0770 098 +34 099 12 0621 L0112HN15 139↵ 3rd line 49 char.

00000111112222233333 ... (5 x 770 bytes)↵ 4th line 3852 char.

1a3f♦↵ 5th line 8 char.

Total 3956 char.

An example of CL31 data message No. 2 is presented below:

CLA10021☺↵ 1st line 12 char.

30 01230 12340 23450 FEDCBA987654↵ 2nd line 35 char.

3 055 5 170 0 /// 0 /// 0 ///↵ 3rd line 37 char.

00100 10 0770 098 +34 099 12 0621 L0112HN15 139↵ 4th line 49 char.

00000111112222233333 ... (5 x 770 bytes)↵ 5th line 3852 char.

1a3f♦↵ 6th line 8 char.

VAISALA _______________________________________________________________________ 45

Total 3993 char.

Page 46

User's Guide ______________________________________________________________________

For data lines with low bandwidth, there is a short version of each

message. In the short version of message No.1, lines 3 and 4 are left

out. Correspondingly, in the short version of message No.2, lines 4

and 5 are left out. In the table below, the data message types are

summarized with the minimum bit rates and storage capacity. The

examples are divided into two measurement resolutions of 10 m and

5 m. They have different minimum reporting intervals, 2 s and

3 s.

Table 7 Messages with 10 m Resolution (Standard Mode)

Message

Number

and

Subclass

11 msg1_10x770 3956 28.8k 4890 MB 4800 815 MB

12 msg1_20x385 2031 14.4k 2510 MB 2400 418 MB

15 msg1_base 55 300 68 MB 300 11 MB

21 msg2_10x770 3993 28.8k 4940MB 4800 423 MB

22 msg2_20x385 2068 14.4k 2560 MB 2400 425 MB

25 msg2_base 92 600 114 MB 300 19 MB

Message Name Length

(bytes)

Min bps

(2 s)

Data/Month

(2 s)

Min bps

(12 s)

Data/Month

(12 s)

Table 8 Messages with 5 m Resolution (High Resolution)

Message

Number

and

Subclass

13 msg1_5x1500 7606 28.8k 6267 MB 9600 1253 MB

14 msg1_5x770 3956 14.4k 3260 MB 4800 625 MB

15 msg1_base 55 300 45 MB 300 9 MB

23 msg2_5x1500 7643 28.8k 6230 MB 9600 1260 MB

24 msg2_5x770 3993 14.4k 3290 MB 4800 660 MB

25 msg2_base 92 600 76 MB 300 15 MB

Message Name Length

(bytes)

Min bps

(3 s)

Data/Month

(3 s)

Min bps

(15 s)

Data/Month

(15 s)

The interpretation of the message lines is as follows:

1ST LINE

Example: CLA10011☺↵

where

= Start-of-Heading character

CL = Ceilometers' identification string; always CL

A = Unit identification character 0 ... 9, A ... Z

100 = Software level ID 100 ... 999

1 = Message number; message without sky condition data

is = 1, with sky condition data is = 2

46 __________________________________________________________________ M210482EN-B

Page 47

Chapter 4 ________________________________________________________________ Operation

where

1 = Character for subclasses of message

1 = 10 m x 770 samples, range 7700 m (msg1_10x770)

2 = 20 m x 385 samples, range 7700 m (msg1_20x385)

3 = 5 m x 1500 samples, range 7500 m (msg1_5x1500)

4 = 5 m x 770 samples, range 3850 m (msg1_5x770)

5 = without a backscatter profile

☺

= Start-of-Text Character

= Carriage Return + Line Feed

↵

2ND LINE

Example: 30 01230 12340 23450 FEDCBA987654↵

where

3 = First digit of line:

0

1

2

3

4

5

/

0 = Second digit of line:

0

W

A

01230 = If detection status is 1, 2, or 3:

If detection status is 4:

If detection status is 0 or 5:

12340 = If detection status is 2 or 3:

If detection status is 4:

If detection status is 0, 1, or 5:

Detection status as follows:

No significant backscatter

One cloud base detected

Two cloud bases detected

Three cloud bases detected

Full obscuration determined but no cloud base

detected

Some obscuration detected but determined to be

transparent

Raw data input to algorithm missing or suspect

Warning and Alarm information as follows:

Self-check OK

At least one Warning active, no Alarms

At least one Alarm active

Lowest cloud base height

Vertical Visibility as calculated

/////

Second lowest cloud base height

Highest signal detected

/////

23450 = If detection status is 3:

If detection status is 0, 1, 2, 4,

Highest cloud base height

/////

5:

VAISALA _______________________________________________________________________ 47

Page 48

User's Guide ______________________________________________________________________

FEDC

BA98

7654

= Alarm (A), Warning (W), and internal status (S) information. Each character is

a hexadecimal representation of four bits, i.e. values between 0 and 9 are

presented with respective numbers and values 10, 11, 12, 13, 14, and 15 are

presented with letters A, B, C, D, E, and F, respectively. As each of the 12

characters represent the sum of four individual bits, the total number of bits is

48 (b00-b47), with the following breakdown and interpretation:

F: b47 (8000 0000 0000) Transmitter shut-off (A)

b46 (4000 0000 0000) Transmitter failure (A)

b45 (2000 0000 0000) Receiver failure (A)

b44 (1000 0000 0000) Voltage failure (A)

E: b43 (0800 0000 0000) Alignment failure (A)

b42 (0400 0000 0000) Memory error (A)

b41 (0200 0000 0000) Light path obstruction (A)

b40 (0100 0000 0000) Receiver saturation (A)

D: b39 (0080 0000 0000) (spare) (A)

b38 (0040 0000 0000) (spare) (A)

b37 (0020 0000 0000) (spare) (A)

b36 (0010 0000 0000) (spare) (A)

C: b35 (0008 0000 0000) (spare) (A)

b34 (0004 0000 0000) (spare) (A)

b33 (0002 0000 0000) Coaxial cable failure (A)

b32 (0001 0000 0000) Ceilometer engine board failure (A)

B: b31 (0000 8000 0000) Window contamination (W)

b30 (0000 4000 0000) Battery voltage low (W)

b29 (0000 2000 0000) Transmitter expires (W)

b28 (0000 1000 0000) High humidity (W)

A: b27 (0000 0800 0000) (spare) (W)

b26 (0000 0400 0000) Blower failure (W)

b25 (0000 0200 0000) (spare) (W)

b24 (0000 0100 0000) Humidity sensor failure (W)

9: b23 (0000 0080 0000) Heater fault (W)

b22 (0000 0040 0000) High background radiance (W)

b21 (0000 0020 0000) Ceilometer engine board failure (W)

b20 (0000 0010 0000) Battery failure (W)

8: b19 (0000 0008 0000) Laser monitor failure (W)

b18 (0000 0004 0000) Receiver warning (W)

b17 (0000 0002 0000) Tilt angle > 45 degrees warning (W)

b16 (0000 0001 0000) (spare) (W)

7 b15 (0000 0000 8000) Blower is on (S)

b14 (0000 0000 4000) Blower heater is on (S)

b13 (0000 0000 2000) Internal heater is on (S)

b12 (0000 0000 1000) Working from battery (S)

6 b11 (0000 0000 0800) Standby mode is on (S)

b10 (0000 0000 0400) Self test in progress (S)

b09 (0000 0000 0200) Manual data acquisition settings are effective (S)

48 __________________________________________________________________ M210482EN-B

Page 49

Chapter 4 ________________________________________________________________ Operation

b08 (0000 0000 0100) (spare) (S)

5 b07 (0000 0000 0080) Units are meters if on, else feet (S)

b06 (0000 0000 0040) Manual blower control (S)

b05 (0000 0000 0020) Polling mode is on (S)

b04 (0000 0000 0010) (spare) (S)

4 b03 (0000 0000 0008) (spare) (S)

b02 (0000 0000 0004) (spare) (S)

b01 (0000 0000 0002) (spare) (S)

b00 (0000 0000 0001) (spare) (S)

For example, if no clouds are detected, if the window is contaminated,

the battery voltage is too low, the internal heater is on and units are

meters, a warning is given and the second line appears as follows:

0W ///// ///// ///// 0000C0002080

ADDITIONAL 3RD LINE IF MESSAGE NO. = 2

Example: __3_055__5_170__0_///__0_///__0_///↵

(space character indicated with '_' for clarity)

where

3 = First digit of line:

0 ... 8

9

-1

Detection status as follows:

Cloud amount of the first layer in oktas

Vertical visibility

Data missing, sky condition option not active or

the ceilometer is in standby mode

99

Not enough data (after start-up)

055 = Second digit of line: Height of the 1st cloud layer (550 m or 5500 ft

depending on the selection)

5 = Third digit of line: Cloud amount of the 2nd layer in oktas

170 = The fourth number of line: Height of the 2nd cloud layer (1700 m or 17000

ft depending on the selection)

0 = Fifth digit of line: Cloud amount of the 3rd layer in oktas

/// = Sixth digit of line: Height of the 3rd cloud layer

0 = Seventh digit of line: Cloud amount of the 4th layer in oktas