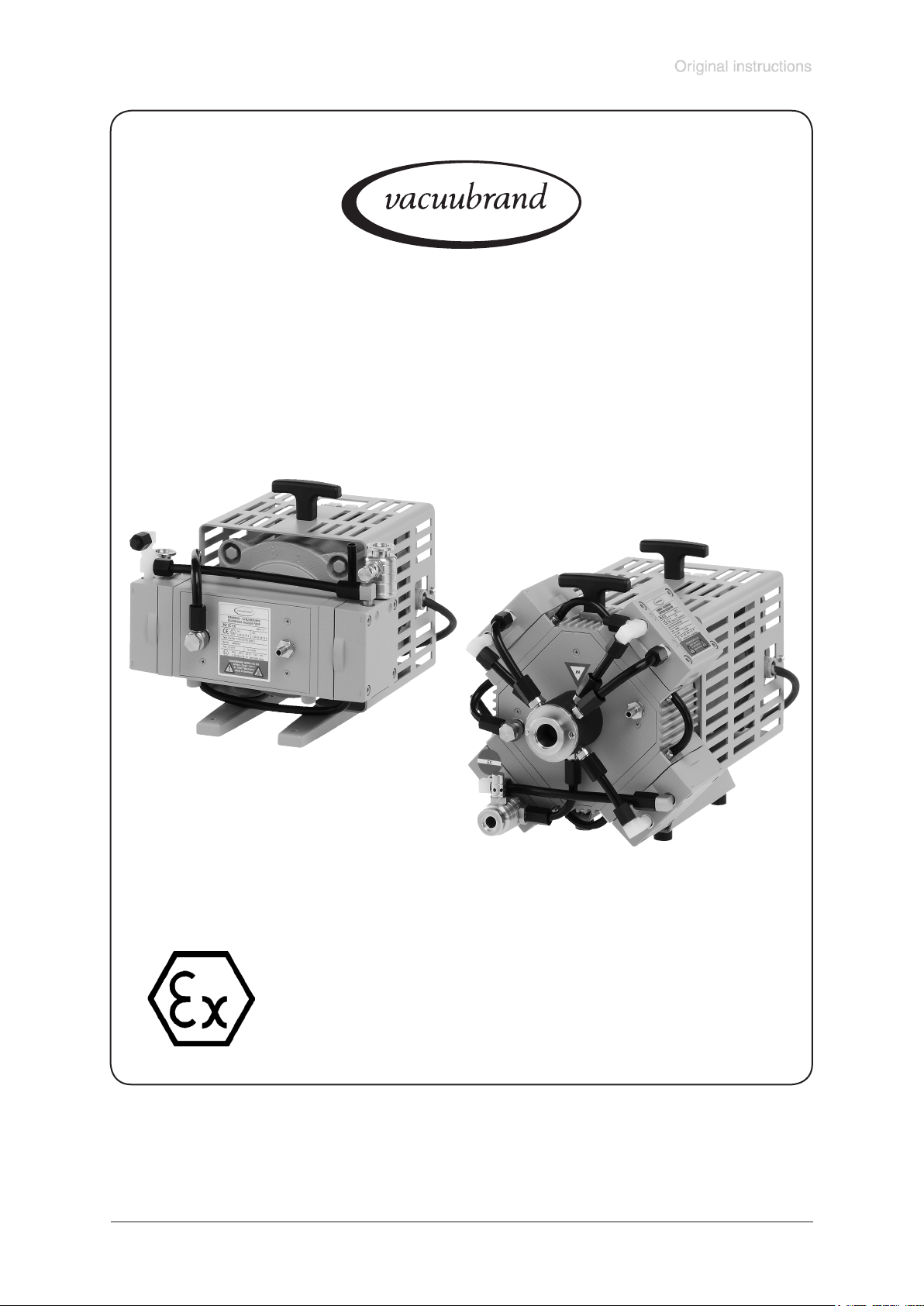

VACUUBRAND MZ 2C EX+IK+EK User Manual

page 1 of 75

Technology for Vacuum Systems

Instructions for use

MZ 2C EX

MD 4C EX

MV 10C EX

MZ 2C EX + AK + EK

MZ 2C EX + IK + EK

MD 4C EX + AK + EK

MV 10C EX + AK + EK

Chemistry diaphragm pumps

with

ATEX conformity

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 2 of 75

Dear customer,

Your VACUUBRAND diaphragm pump shall support you at your work for a long time without any trouble

and with full load output. Thanks to our large practical experience we attained much information how you

could add to an efcient application and to personal safety. Please read these instructions for use prior

to the initial start-up of your pump.

VACUUBRAND diaphragm pumps are the result of many years of experience in construction and practical operation of these pumps combined with the latest results in material and manufacturing technology.

Our quality maxim is the ”zero fault principle”:

Every delivered diaphragm pump is tested extensively including an endurance run of 14 hours. Due to

this endurance run, also faults, which occur rarely, are reported an can be corrected. Every single dia-

phragm pump is tested on achievement of the specication after the endurance run.

Every VACUUBRAND pump leaving our factory achieves the specication. We feel obliged to

this high quality standard.

We are aware that the vacuum pump should not draw a part of the real work and we hope to contribute

with our products to an effective and trouble-free realisation of your work.

Yours

VACUUBRAND GMBH + CO KG

After sales service: Contact your local dealer or call +49 9342 808-5500.

Attention: This manual is not available in all languages of the

EU. The user must not operate the device if he does not understand this manual. In this case a technically correct translation

of the complete manual has to be available. The manual must

be completely read and understood before operation of the device and all required measures must be applied.

Trademark index:

VACUU•LAN® (US-Reg.No 3,704,401), VACUU•BUS®, VACUU•CONTROLTM, chemistry-HYBRIDTM,

Peltronic®, TURBO•MODETM, VARIO® (US-Reg.No 3,833,788), VARIO-SPTM, VACUUBRAND® (US-

Reg.No 3,733,388) and also the shown company logos are trademarks of VACUUBRAND GMBH + CO

KG in Germany and/or other countries.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 3 of 75

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 4 of 75

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 5 of 75

Contents

Safety information! .....................................................................................................6

General information ............................................................................................................................6

Intended use .......................................................................................................................................6

Setting up and installing the equipment .............................................................................................6

Ambient conditions ...........................................................................................................................10

Operating conditions ........................................................................................................................10

Safety during operation ....................................................................................................................12

Maintenance and repair ....................................................................................................................13

Notes regarding devices with ATEX conformity ....................................................14

Technical data ...........................................................................................................16

Wetted parts ....................................................................................................................................18

Pump parts ......................................................................................................................................18

Use and operation ....................................................................................................23

Installing in a vacuum system ..........................................................................................................23

During operation ...............................................................................................................................28

Shutdown .........................................................................................................................................30

Troubleshooting .......................................................................................................31

Replacing diaphragms and valves..........................................................................32

Inspecting the overpressure safety valve .............................................................51

Notes on return to the factory .................................................................................53

Health and safety clearance form ...........................................................................54

EC Declaration of Conformity of the Machinery .......................................................71

➨ DANGER indicates a hazardous situation which, if not avoided, will re-

☞ WARNING indicates a hazardous situation which, if not avoided, could

• CAUTION indicates a hazardous situation which, if not avoided, could

NOTICE

NOTICE is used to address practices not related to personal injury.

Caution! Hot surface!

Isolate equipment from mains before removing the cover.

sult in death or serious injury.

result in death or serious injury.

result in minor or moderate injury.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

Safety information!

General information

☞ Read and comply with this manual before installing or operating the equip-

NOTICE

ment.

☞ Transport the pump at the provided handle.

Remove all packing material, remove the product from its packing-box, remove the

protective covers from the inlet and outlet ports and keep, inspect the equipment.

If the equipment is damaged, notify the supplier and the carrier in writing within three

days; state the item number of the product together with the order number and the

supplier’s invoice number. Retain all packing material for inspection.

Do not use the equipment if it is damaged.

If the equipment is not used immediately, replace the protective covers. Store the

equipment in suitable conditions.

Intended use

☞ Use the equipment for the intended use only according to the ATEX conformity, e.

g. for pumping gas atmosphere without aerosol in a range form 0.1 to 1000 mbar

and a maximum inlet pressure (dynamic pressure) and outlet pressure of 1100

mbar (absolute).

☞ The pump and all system parts must not be used on humans or animals.

☞ Prevent any part of the human body from coming into contact with vacuum.

☞ Ensure that the individual components are only connected, combined and oper-

ated according to their design and as indicated in the instructions for use.

☞ Comply with notes on correct vacuum and electrical connections, see section

”Use and operation”.

page 6 of 75

NOTICE

NOTICE

The pumps are marked with ”X” (according to EN 13463-1), i. e. restrictions of the

operation conditions:

• The pumps are designated for a low degree of mechanical stress and have to be

installed in a way so that they can not be damaged from outside.

Pumping units have to be installed protected against shocks from the outside and

against glass splinters in the event of breaking (implosion).

• The pumps are designated for an ambient and gas inlet temperature during operation of +10 to +40°C. Never exceed these ambient and gas inlet temperatures.

Use the equipment for the intended use only, i.e. for generation of vacuum in vessels designed for that purpose.

Setting up and installing the equipment

Before system start-up of the pump or the complete system the user has to evaluate

in its entirety the explosion risks and takes adequate measures in application of the

principle of risk assessment.

The evaluation and the measures have to be laid down in an explosion protection

document before system start-up.

The pump/system must not be operated until operation without danger in explosive

atmosphere is ensured. Provide suitable control, protection and warning systems

even in the event of failure.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 7 of 75

The inner (pumped media) and outer part of the pump have to be evaluated

separately because of their different conformity (see also section ”Technical

data” and ”Notes regarding devices with ATEX conformity”).

The pumps are not suitable for pumping dust and have no approval for operation

below ground.

The pumps are not suitable for pumping self inammable substances, for substances which are inammable without air and explosive substances.

☞ Electrical and vacuum components might require a separate approval.

☞ Include the components in the recurrent tests of tightness for pressure vessels, in

the case of hits and beats an intermediate leak test is required.

☞ Due to the high compression ratio of the pumps, pressure at the outlet port might

be generated being higher than the max. permitted pressure compatible with the

mechanical stability of the system.

☞ Always provide a free and pressureless exhaust pipeline.

☞ Do not permit any uncontrolled pressurizing (e.g. make sure that the exhaust

pipeline cannot become blocked). If there is an exhaust isolation valve, make sure

that you cannot operate the equipment with the valve closed. Risk of bursting!

• Secure coolant hoses at the hose nozzles (e.g. with hose clip) to prevent their

accidental slipping.

• Comply with maximum permissible pressures at inlet and outlet and pressure

differences, see section ”Technical data”. Do not operate the pump with overpressure at the inlet.

• Attention: Flexible elements tend to shrink when evacuated.

NOTICE

Provide a rm level platform for the equipment and check that the system to be

evacuated is mechanically stable and that all ttings are secure. Ensure a stable po-

sition of the pump without any mechanical contact except of the pump feet. Comply

with all applicable safety regulations.

Pumping units (pumps with vapour condenser) have to be installed protected

against hits from outside and protected against splinters (against implosion).

Adopt suitable measures prior to the rst use.

Obey all relevant requirements (regulations and guidelines) and adopt suitable safety measures.

☞ Pay attention to the max. permitted ambient temperature and make sure

ventilation is adequate especially if pump is installed in a housing or if

ambient temperature is elevated, install an external automatic ventilation

system if necessary.

If pumping hot process gases make sure that the maximum permitted gas inlet

temperature is not exceeded.

☞ If the equipment is brought from cold environment into a room for operation,

allow the equipment to warm up (pay attention to water condensation on cold

surfaces).

☞ The work clothing of the user must not lead to electrostatic discharge which may

ignite the explosive atmosphere.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 8 of 75

Inlet

☞ Connection lines at the pump inlet have to be performed conductive grounded

and gas tight (designation of the pump connections see gures).

☞ The diameter of the inlet pipeline should be at the least as large as the diameter

of the pump connection pipelines.

☞ Obey max. inlet pressure (see ”Technical data”).

☞ If there is a risk of ignition of gases or gas mixtures before or behind the pump the

user has to provide suitable safety devices against incoming of ames according

to EN 12874. The user must ensure the suitability concerning gas ow, chemical

resistance and safeness against clogging prior to use.

Outlet

☞ Connection lines at the pump outlet (small ange) have to be performed conduc-

tive grounded and gas tight (designation of the pump connections see gures).

☞ The diameter of the inlet pipeline should be at the least as large as the diameter

of the pump connection pipelines.

☞ Obey max. inlet pressure (see ”Technical data”).

Due to the high compression ratio of the pumps, pressure at the outlet port might

be generated being higher than the max. permitted pressure compatible with the

mechanical stability of the system.

☞ Obey maximum permitted pressures and pressure differences, see section ”Tech-

nical data”. Do not operate the pump with overpressure at the inlet.

☞ Do not permit any uncontrolled pressurizing (e. g. make sure that the exhaust

pipeline cannot become blocked). If you have an exhaust-isolation valve, make

sure that you cannot operate the equipment with the valve closed. Risk of bursting!

☞ Ensure that the system design does not allow the exhaust pipeline to become

blocked. Lead away exhaust gas or condensate at the outlet of the pump and the

overpressure safety valve under consideration of all applicable safety measures.

Avoid backow of gases or condensate denitely.

☞ Ensure that the system design does not allow the coolant outlet pipeline to be-

come blocked.

☞ Escaped and/or intentional or unintentional released inammable gases or va-

pours which may lead to danger of explosion have to be lead away safely or lead

to an appropriate place. If not possible enclose the gasses, vapours or mist safely

or dispose in an other way. In case of mixtures or different gases the measures

must consider the highest risk.

☞ If there is a risk of ignition of gases or gas mixtures before or behind the pump the

user has to provide suitable safety devices against incoming of ames according

to EN 12874. The user must ensure the suitability concerning gas ow, chemical

resistance and safeness against clogging prior to use.

Check the overpressure safety valve at the outlet regularly.

☞ Attention: If the exhaust pipeline is blocked the pumped gases may escape into

the environment through the overpressure safety valve. If necessary take appropriate measures.

If pumping dangerous gases install a second completely independent exhaust

pipeline instead of the overpressure safety valve. If necessary assemble a hose

nozzle instead of the overpressure safety valve to lead away the gases through

a second exhaust pipeline. Attention: Never combine the exhaust pipelines, i. e.

provide a sperate line for each exhaust.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 9 of 75

Inert gas purge

☞ The user must take suitable precautions to prevent any formation of explosive

mixtures in the expansion chamber using inert gas to purge the housing. Otherwise in case of a diaphragm crack, mechanically generated sparks, hot surfaces

or static electricity may ignite these mixtures.

☞ Inert gas connection lines (inlet and outlet) have to be performed conductive

grounded and gas tight (designation of the pump connections see gures).

☞ Connect the inert gas connections at the crankcase not serial but parallel.

☞ We recommend an inert gas purge of ≥ 1 l per minute.

☞ Provide an external pressure limitation to a pressure of 1.1 bar absolute if inert

gas is connected to the pump or at an air admittance valve. The inert gas has

to be dry and pure. It could be recommendable to provide an appropriate control

system to supervise the inert gas ow which switches off the pump in case of

failure (e. g. absence of inert gas) if necessary.

☞ To control the faultless function of the diaphragm it could be recommendable

install a gas specic detector at the outlet of the inert gas purge. A signal from

the detector indicates a diaphragm crack. Switch off the pump immediately and

check diaphragms.

☞ It is possible to leave out the inert gas purge if the surrounding of the pump is

zone 2 or not an explosive atmosphere.

☞ Without inert gas purge the pump outer part has the specication II 3G IIB T4 X.

Gas ballast

☞ Use only inert gas for gas ballast.

☞ We recommend the use of gas ballast when pumping condensable media.

☞ Gas ballast connection lines (inlet and outlet) have to be performed conductive

grounded and gas tight (designation of the pump connections see gures).

☞ Connect the inert gas connections at the gas ballast and the crankcase not serial

but parallel.

☞ Provide an external pressure limitation to a pressure of 1.1 bar absolute if inert

gas is connected to the pump or at an air admittance valve. The inert gas has

to be dry and pure. It could be recommendable to provide an appropriate control

system to supervise the inert gas ow which switches off the pump in case of

failure (e. g. absence of inert gas) if necessary.

Pumping at high inlet pressure may lead to overpressure at the gas ballast valve.

☞ Pumped gases or condensate might be pushed out in case the valve is open.

☞ The inert gas lines have to be chemical resistent due to possible backow.

Electrical connection

☞ Electrical connection of the pump must be performed only by a suitable trained

and supervised personnel.

☞ The motor cable for pumps in 230V version contains wires colour coded as fol-

lows: green or green and yellow: earth; blue or white: neutral; brown or black:

live.

☞ Provide a fuse for the mains cable (L and N) according to the current draw of the

motor, see ”Technical data”.

☞ The earth connection of the device (potential equalization) has to be performed

only using the green or green/yellow earth connection wire. Connect the earth

connection wire of the device to the earth connection of the power supply line and

the potential equalization point of the environment of the device.

☞ When using pumps with two motors absolutely connect both motors as described

above. Ensure that always both motors are running.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 10 of 75

Attention: Never use the antistatic connection at the housing of the device to

connect the device to ground, use only the green or green and yellow connection

wire of the motor. Use the antistatic connection at the housing only to perform an

antistatic connection of other non-electronic devices and components, e. g. inlet

and outlet vacuum hoses or something similar. Never lead away short-circuit currents using this connection. External electric devices have to be connected at the

potential equalization point of the environment separately and independent of this

device.

☞ Equipment must be connected only to a suitable fused and protected electrical

supply and a suitable earth point by suitable trained personnel. Failure to connect

the motor to ground may result in deadly electrical shock.

☞ Check that mains voltage and current conform with the equipment (see rating

plate).

☞ Obey notes regarding the motor in section ”Instructions manual: Explosion

proof motors”, see below.

The motor is protected by a thermal cutout with manual reset combined with an

overcurrent protection.

☞ Avoid reliable high heat supply (e. g. due to hot process gases). Maximum per-

mitted gas and ambient temperature se ”Technical data”.

☞ Make sure ventilation is adequate especially if pump is installed in a housing or if

ambient temperature is elevated, install an external automatic ventilation system

if necessary.

☞ Ensure that in case of pumps with two motors both motors are switched on at

the same time, if not possible switch on the motor of the pump at the outlet rst.

Ambient conditions

To the best of our knowledge the equipment is in compliance with the requirements

of the applicable EC-directives and harmonized standards (see ”Declaration of conformity”) with regard to design, type and model, especially directive EN 61010-1.

This directive gives in detail conditions, under which the equipment can be operated

safely (see also IP degree of protection).

Adopt suitable measures in case of differences, e. g. using the equipment outdoors,

installation in altitudes of more than 1000 m above mean sea level, conductive pollution or dewiness.

Pay attention to the permissible maximum ambient and gas inlet temperatures

(see ”Technical data”).

Operating conditions

The pumps have a conformity according to their specication to be installed in areas

and to pump out of areas which contain under normal operation conditions occasion-

ally a potential explosive atmosphere as a mixture of air with inammable gases or

vapours (category 2). Class of ignition and temperature see ”Technical data”.

The specication for category 2 for the outer part of the pump is only valid when purging the crankcase with inert gas. Without inert gas purging the

pump has the specication II 3G IIB T4 X for the outer part.

Ensure that the materials of the wetted parts are compatible with the pumped substances, see section ”Technical data”.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 11 of 75

☞ Adopt suitable measures to prevent the release of dangerous, explosive, corro-

sive or polluting uids.

☞ If pumping different substances, it is recommended to purge the pump with air

or inert gas prior to changing the pumped media in order to pump out residues

and to avoid reactions of the pumped substances with each other and with the

pump materials.

Take into consideration interactions and chemical reactions of the pumped

media. Ensure that the materials of the wetted parts are compatible with the

pumped substances, see section ”Technical data”.

☞ The valves and the diaphragms are wear parts. Replace the diaphragms and

valves at the latest at 90% of the typical lifetime or immediately at higher noise

level. The typical lifetime of a diaphragm is 15000 operation hours when pumping

non-corrosive or non-condensable gases, if necessary provide an operation time

counter.

☞ Check the overpressure safety valve between the pump stages (only pumps with

four cylinders) regularly and replace at the latest at 90% of the typical lifetime

(typical lifetime: 15000 operation hours).

☞ Take adequate precautions to protect people from the effects of dangerous sub-

stances (chemicals, thermal decomposition products of uoroelastomers), wear

appropriate safety-clothing and safety glasses.

☞ Obey applicable regulations when disposing of chemicals. Take into considera-

tion that chemicals may be polluted.

☞ Adopt suitable measures to prevent contamination of the pumped substances or

the environment.

Electronic equipment is never 100% fail-safe. This may lead to an indenite status of

the equipment. Provide protective measures against malfunction and failure.

☞ Operating the pump, stand still of the pump or operating the air admittance valve

must not lead to a critical dangerous situation under any circumstances.

Ensure that in case of failure the pump and the vacuum system always will turn into

a safe status.

☞ In case of leaks in the manifold or diaphragm cracks pumped substances might

be released into the environment or into the pump housing. To reduce the risk of

leaks, ask for a diaphragm pump with additional safety diaphragm.

☞ Obey especially notes on operation and use and maintenance.

☞ Failure of the pump (e. g. by power failure) or connected components, parts of

the supply (e. g. coolant) or change of parameters (e. g. increase of pressure

in the coolant system) must not lead to a critical dangerous situation under any

circumstances.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 12 of 75

Safety during operation

➨ Adopt suitable measures to prevent the release of dangerous, toxic, explosive,

corrosive, noxious or polluting uids, vapours and gases. In case install an appropriate collecting and disposal system and take protective action for pump and

environment.

➨ Prevent any part of the human body from coming into contact with vacuum.

➨ Potentially explosive mixtures at the outlet of the pump have to be drained ap-

propriately, sucked off or diluted with inert gas to non-explosive mixtures.

☞ Pay attention to the symbol ”hot surfaces” on the equipment. Adopt suitable

measures to prevent any danger arising from the formation of hot surfaces or

electric sparks. Provide a suitable protection against contact if necessary.

☞ Always provide free and pressureless exhaust pipelines.

☞ Ensure that the coolant outlet pipeline is always free and that it cannot get

blocked.

Check liquid level in both catchpots regularly and drain condensate in time.

☞ Pumping at high inlet pressure may lead to overpressure at the gas ballast

valve. Pumped gases or condensate might be pushed out in case the valve is

open. If an inert gas supply is connected, ensure that the inlet pipeline is not contaminated.

• Comply with applicable regulations when disposing of chemicals. Take into consideration that chemicals may be polluted.

Take adequate precautions to protect people from the effects of dangerous sub-

stances (chemicals, thermal decomposition products of uoroelastomers), wear

appropriate safety-clothing and safety glasses.

Use only genuine spare parts and accessories.

☞ Otherwise safety and performance of the equipment as well as the electromag-

netic compatibility of the equipment might be reduced.

☞ If not using genuine spare parts the ATEX conformity becomes invalid.

Do not start the pump if the pressure difference between inlet and outlet port exceeds 1.1 bar at maximum.

Prevent the backpressure of gases and the backow of condensates.

Never suck liquids or dust into the pump.

Ensure that in case of failure the pump and the vacuum system always will turn into

a safe status.

Provide appropriate protective measures (i.e. precautions which allow for the requirements of the respective application) even for the case of failure and malfunc-

tion.

Failure of the pump (e.g. due to power failure) or of connected components, parts

of the supply or change of parameters must not lead to a critical dangerous situation under any circumstances. In case of diaphragm cracks or leaks in the manifold

pumped substances might be released into the environment or into the pump housing or motor. Comply especially with notes on operation and use and maintenance.

• Due to the residual leak rate of the equipment, there might be an exchange of

gas, albeit extremely slight, between the environment and the vacuum system.

Adopt suitable measures to prevent contamination of the pumped substances or

the environment.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 13 of 75

Maintenance and repair

Wear parts have to be replaced regularly. In normal use, the lifetime of the diaphragms and valves is typically 15,000 operating hours. Bearings have a typical durability of 40000 h.

• The motor capacitors have to be replaced after 200000 start/stop cycles at the

latest. If an overaged motor capacitor fails it might get hot and even melt and may

cause a ame to form which could be dangerous for persons and equipment

in the vicinity. The capacitors have to be replaced only at the factory.

Use only genuine spare parts and accessories.

☞ Otherwise safety and performance of the equipment as well as the electromag-

netic compatibility of the equipment might be reduced.

☞ If not using genuine spare parts the ATEX conformity becomes invalid.

Ensure that maintenance is done only by suitable trained and supervised technicians.

➨ Isolate equipment from mains and wait two minutes before starting mainte-

nance to allow the capacitors to discharge.

• Before starting maintenance vent the pump, isolate the pump and other components from the vacuum system. Allow sufcient cooling of the pump. Drain con-

densate, if applicable.

☞ Ensure that the pump cannot be operated accidentally. Never operate the

pump if covers or other parts of the pump are disassembled. Never operate

a defective or damaged pump.

☞ Attention: The pump might be contaminated with process chemicals which have

been pumped during operation. Ensure that the pump is decontaminated before

maintenance and take adequate precautions to protect people from the effects of

dangerous substances if contamination has occurred.

☞ Take adequate precautions to protect people from the effects of dangerous sub-

stances (chemicals, thermal decomposition products of uoroelastomers), wear

appropriate safety-clothing and safety glasses.

☞ To avoid danger due to electrostatic ignition wipe the device or parts of the de-

vice only with a humid cloth.

In order to comply with law (occupational, health and safety regulations, safety at

work law and regulations for environmental protection) vacuum pumps, components

and measuring instruments returned to the manufacturer can be repaired only when

certain procedures (see section ”Notes on return to the factory”) are followed.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 14 of 75

Notes regarding devices with ATEX conformity

This information sheet does not replace the instructions for use!

In directive 89/391/EWG the European Union has dened requirements for safety at work, which later

have been detailed for explosive atmospheres in the directive 1999/92/EG.

The requirements to equipment for operation in explosive atmospheres have been dened in the directive 94/9/EG (also known as ATEX 100a or ATEX 95). In 1996 this directive was implemented into German law (11. Geräteschutzverordnung).

Concerning technology these directives only state general requirements. Technical details and test procedures are „recommended“ in European standards (e.g. for equipment with ATEX conformity: EN 1127,

E50014ff, EN 60079, EN 13463ff.).

Since July 1st 2003 equipment intended for use in potentially explosive atmospheres shall only be sold

if the equipment is in accordance with directive 94/9/EG (ATEX). This applies only to new equipment.

The repair of equipment sold prior to July 1st, 2003 is not affected. Pumps of prior design (pumps with

Ex-approved motor only) must not be brought to the market anymore.

Requirements to user and manufacturer of equipment according to ATEX:

The user of a system according to ATEX has to analyse the overall explosion risks according to directive 1999/92/EC and has to take adequate measures by means of a risk assessment. The evaluation

and validation of measures has to be documented in an explosion protection document, specifying

among other things the areas classied as potentially explosive (see below). The inner part of the pump

(pumped gases) and the environment of the pump (outer explosion protection) have to be evaluated

separately. Often the requirements will be different.

The responsibility for the classication of areas with potentially explosive atmospheres into

zones and for the specication of requirements to the equipment (category of equipment, class

of ignition, temperature class etc.) is accountable strictly to the operator of the system.

The equipment used has to comply with these requirements. VACUUBRAND does not advise

customers concerning requirements to the equipment under the specic aspects of the cus-

tomers applications.

Equipment with ATEX-conformity is to be used by appropriately instructed personnel only.

ATEX marking, intended use:

The marking of the equipment corresponding with the standards (see above) gives the areas in which

the equipment may be used according to its intended use.

Technical data, safety notes and intended use:

See instructions for use!

The equipment must only be used if the instructions for use are read, fully understood and

obeyed.

Clean, check and maintain equipment regularly.

Do never operate a defective equipment.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 15 of 75

Electrical connection:

VACUUBRAND diaphragm pumps with ATEX-conformity are equipped with a 230 V / 50 Hz singlephase motor and are protected by a thermal cutout with manual reset combined with an overcurrent

protection.

See instructions for use concerning notes on electrical connection

Where applicable the motors can be connected directly to an appropriate power supply by suitably

trained and authorised personnel (electrician). It is the responsibility of the user to meet the requirements of explosion protection in the power supply and connection area.

Vacuum and outlet connections:

See instructions for use: Make sure that all mechanical connections

are always gas tight and electrically conducting.

The exhaust pipeline must be designed in a way that it cannot become blocked.

If the exhaust pipeline becomes blocked, the overpressure safety device at the pump releases potentially dangerous gases into the environment. Take appropriate safety measures (see instructions for

use).

Evaluate the risk of explosion for the release of pumped gases at the outlet of the pump.

Use and connection of inert gas supply:

For external ATEX equipment category 2G (e.g. for use in Ex-zone 1) the crank case of the pump has to

be ushed with inert gas (e.g. nitrogen). A ow of approx. 1 l/min (at atmospheric pressure) is sufcient.

If necessary the ow should be monitored using a ow meter. Without inert gas purge the pump has

external equipment category 3G. This means the pump has to be used in this case only in a surrounding

with Ex - zone 2 (or no Ex-zone).

It is recommended to install a gas detector (specic to the pumped gas) at the outlet of the inert gas tubing. The maximum permitted overpressure at the inert gas outlet is 0.1 bar (Check the ow rate through

the gas detector!). A positive signal from the detector indicates a diaphragm failure. In this event switch

off the pump immediately and check the pump.

In the case of pumping condensable vapours, use gas ballast. Connect inert gas with maximum

overpressure of 0.1 bar to the gas ballast inlet (see instructions for use).

Inlet of air into the gas ballast must never lead to formation of an explosive mixture inside the

pump or at the outlet of the pump!

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 16 of 75

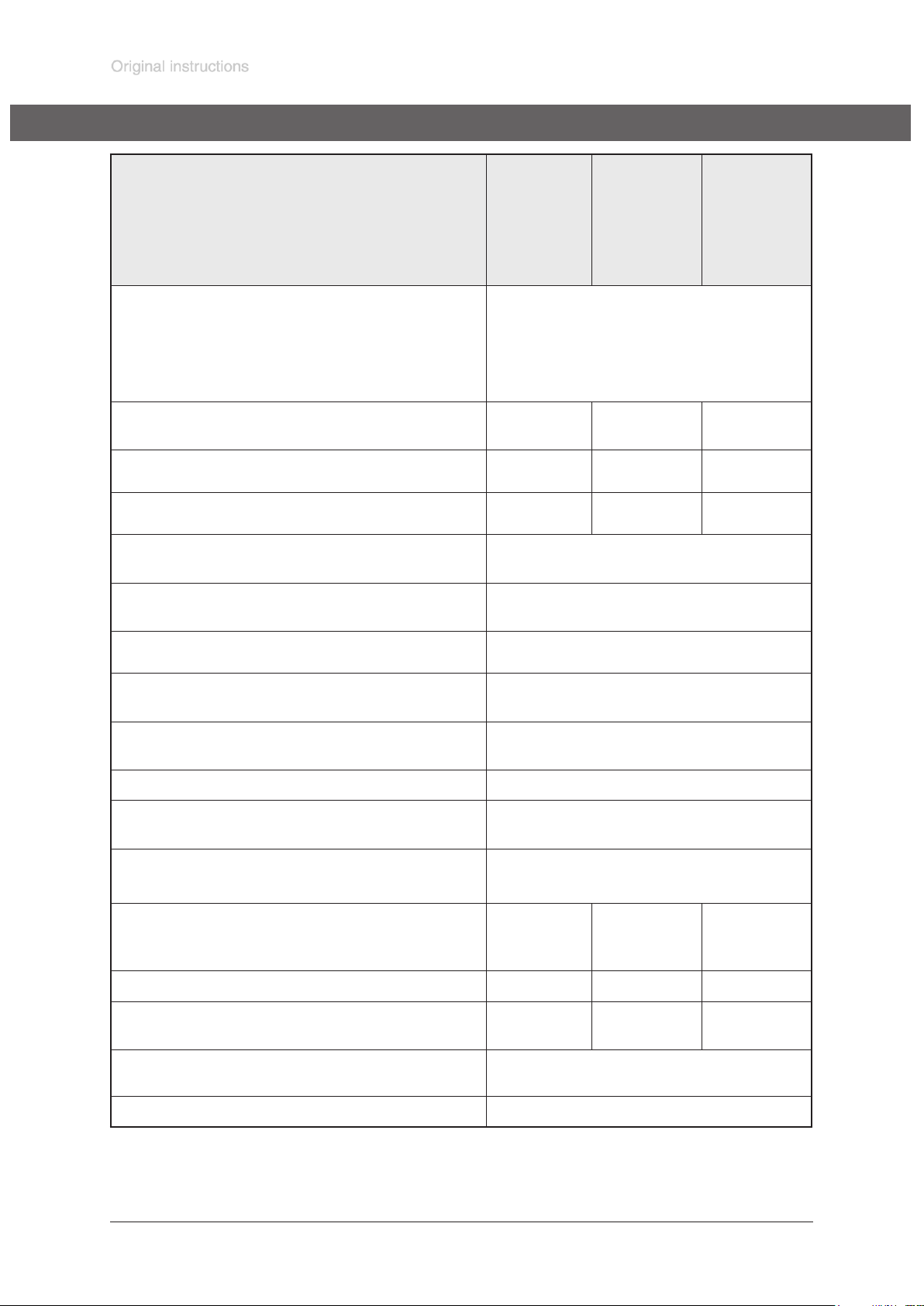

Technical data

Type

ATEX approval

Inner part (pumped gases)

Outer part

Surrounding of the pump with inert gas purge

Surrounding of the pump without inert gas purge

Motor

MZ 2C EX

MZ 2C EX

+ AK + EK

MZ 2C EX

+ IK + EK

MD 4C EX

MD 4C EX

MV 10C EX

MV 10C EX

+ AK + EK

II 2G IIC T3 X

II 2G IIB T4 X

II 3G IIB T4 X

see motor rating plate

+ AK + EK

Max. pumping speed* according to

ISO 21360

Ultimate vacuum* (absolute) without

gas ballast

Ultimate vacuum* (absolute) with

gas ballast

Max. permitted pressure at the inlet

and the outlet (absolute)

Max. permitted pressure difference

between inlet and outlet

Max. permitted pressure at inert gas

connection (absolute)

Max. permitted ambient temperature

during operation

Max. permitted ambient temperature

during storage

Permitted gas inlet temperature °C +10 to +40

Max. surface temperature of the

pump (outer part)

Max. permitted atmospheric moisture

during operation

(no condensation)

m3/h 1.9 3.7 8.1

mbar 12 3 2

mbar 18 10 10

bar 1.1

bar 1.1

bar 1.1

°C +10 to +40

°C -10 to +60

°C 110

% 30 to 85

Degree of protection of the pump IEC 529

Pump

Pump + AK + EK / Pump + IK + EK

Nominal current draw A 1.2 2 2 x 2

Maximum start-up current /

Start-up duration

Max. permitted range of voltage supply / frequency

Integral leak rate mbar*l/s 0.1

* Technical data according to EN 61010-1 and EN 1012-2 recommendation. The pump achieves its ultimate pumping speed and ultimate vacuum only at operating

temperature (after approx. 15 min.).

** Only when positioning the pump horizontal.

We reserve the right for technical modications without prior notice!

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

IP 54**

IP 52**

5.5 A /

125 ms

IP 54**

IP 54**

10.2 A /

125 ms

230V ± 10% / 50 Hz

IP 54**

IP 54**

2 x 10.2 A /

125 ms

page 17 of 75

MZ 2C EX

Type

MZ 2C EX +

AK + EK

MZ 2C EX +

MD 4C EX

MD 4C EX +

AK + EK

MV 10C EX

MV 10C EX +

AK + EK

IK + EK

Motor power kW 0.15 0.25 2 x 0.25

No-load speed min

A-weighted emission sound

pressure level***

(uncertainty KpA: 3 dB(A))

Inlet

Pump

Pump + IK + EK

Outlet

Pump

Pump + AK + EK / Pump + IK + EK

-1

dB(A) 50 53 53

KF 16

hose nozzle

DN 13 mm

hose nozzle 10 mm

1500

KF 25

-

KF 16

KF 25

-

Gas ballast connection hose nozzle 10 mm

Inert gas purge connection hose nozzle 8 mm

Recommended ow of inert gas l/min ≥ 1

Overall dimensions L x B x H,

approx.

Pump

Pump + AK + EK

Pump + IK + EK

Mass, approx.

Pump

Pump + AK + EK

Pump + IK + EK

*** Measurement according to EN ISO 2151:2004 and EN ISO 3744:1995 at 230V/50Hz and ultimate vacuum with exhaust tube

at outlet.

mm

mm

340 x 290 x 250

357 x 308 x 470

357 x 308 x 470

kg

kg

on request

21.6

25.4

440 x 265 x 305

600 x 365 x 420

-

29.3

37.4

-

560 x 430 x 410

on request

-

63.2

on request

-

We reserve the right for technical modications without prior notice!

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 18 of 75

Wetted parts

Components Wetted parts

Inlet stainless steel*

Outlet

Pump

Pump + AK + EK

Hoses PTFE, antistatic

Fittings ETFE / stainless steel*

Housing cover insert PTFE, carbon reinforced

Head cover ETFE, carbon reinforced

O-ring in head cover FPM

Diaphragm clamping disc ETFE, carbon reinforced

Valve FFKM or PTFE

Diaphragm PTFE

stainless steel**

PBT

Overpressure safety relief device

Separator cover plate PTFE, carbon reinforced

Catchpot, collecting ask,

vapour condenser

* stainless steel 1.4404

** stainless steel 1.4541

*** stainless steel 1.4404 and 1.4310

stainless steel***, PTFE, carbon reinforced,

FFKM

borsilicate glass

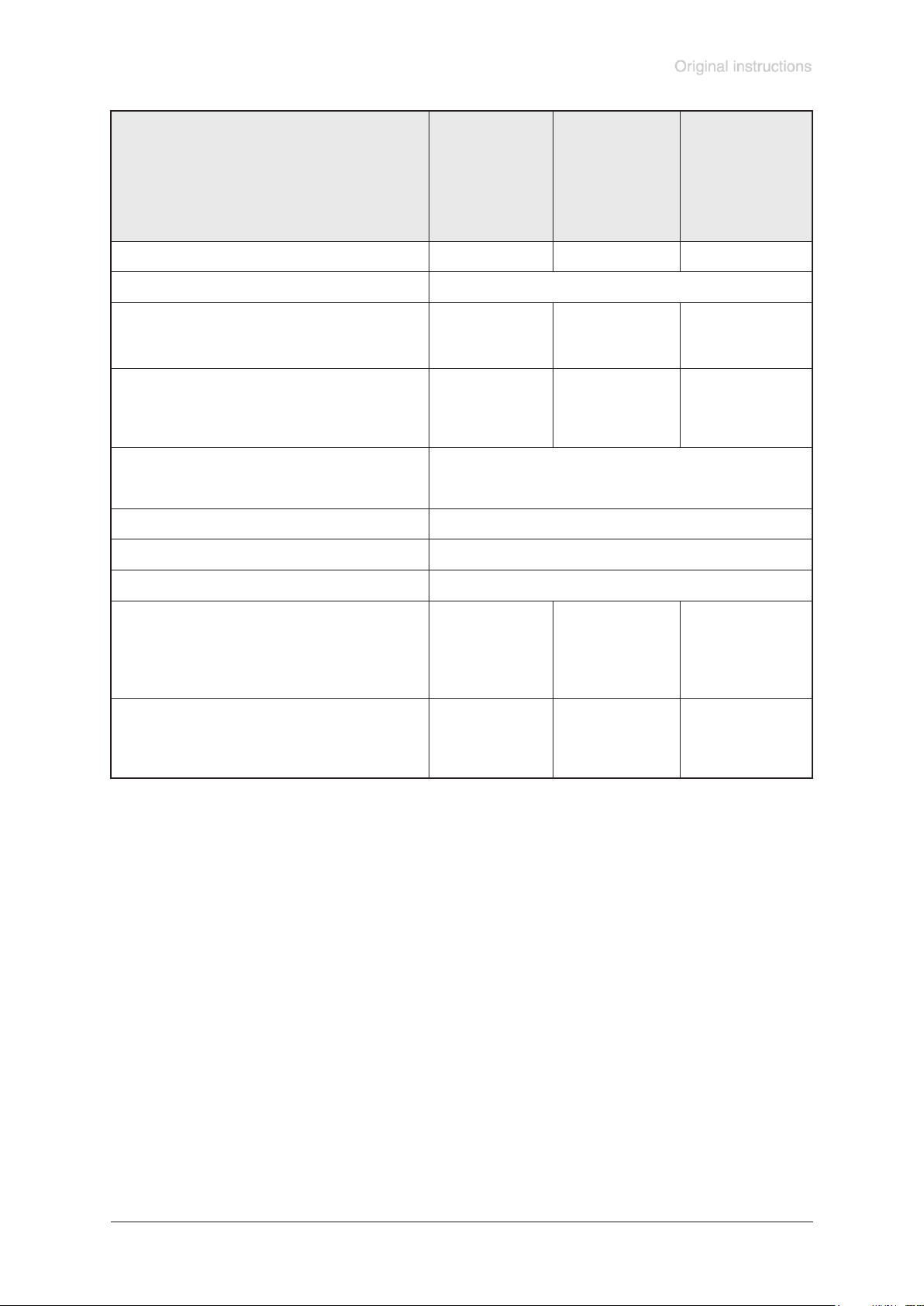

Pump parts

Position Component

1 inlet (vacuum connection)

2 outlet (gas!)

3 on/off switch (0: off, 1: on)

4 rating plate

5 handle

Position Component

12 exhaust waste vapour condenser

13

14

15 catchpot

coolant inlet

(hose nozzle 6 mm)

coolant outlet

(hose nozzle 6 mm)

6

7 inlet inert gas purge

8 outlet inert gas purge

9 overpressure valve

10 antistatic connection

11 mains cable

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

gas ballast connection

(only inert gas)

We reserve the right for technical modications without prior notice!

16 cover plate

17 collecting ask

18 immission condenser

MZ 2C EX

page 19 of 75

5

1

6

4

3

8

2

9

10

11

7

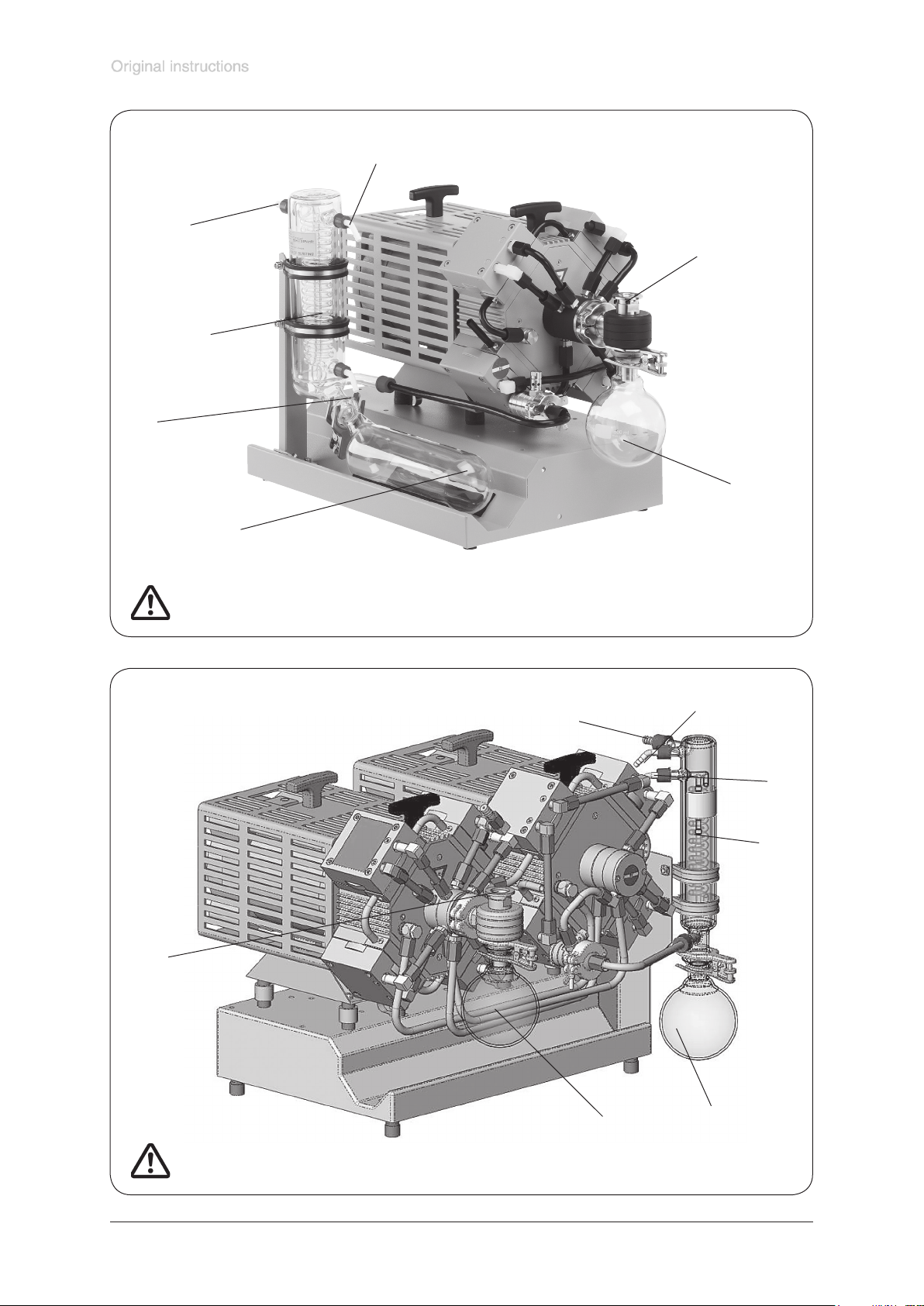

MD 4C EX

8

1

9

2

5

6

3

4

10

11

7

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 20 of 75

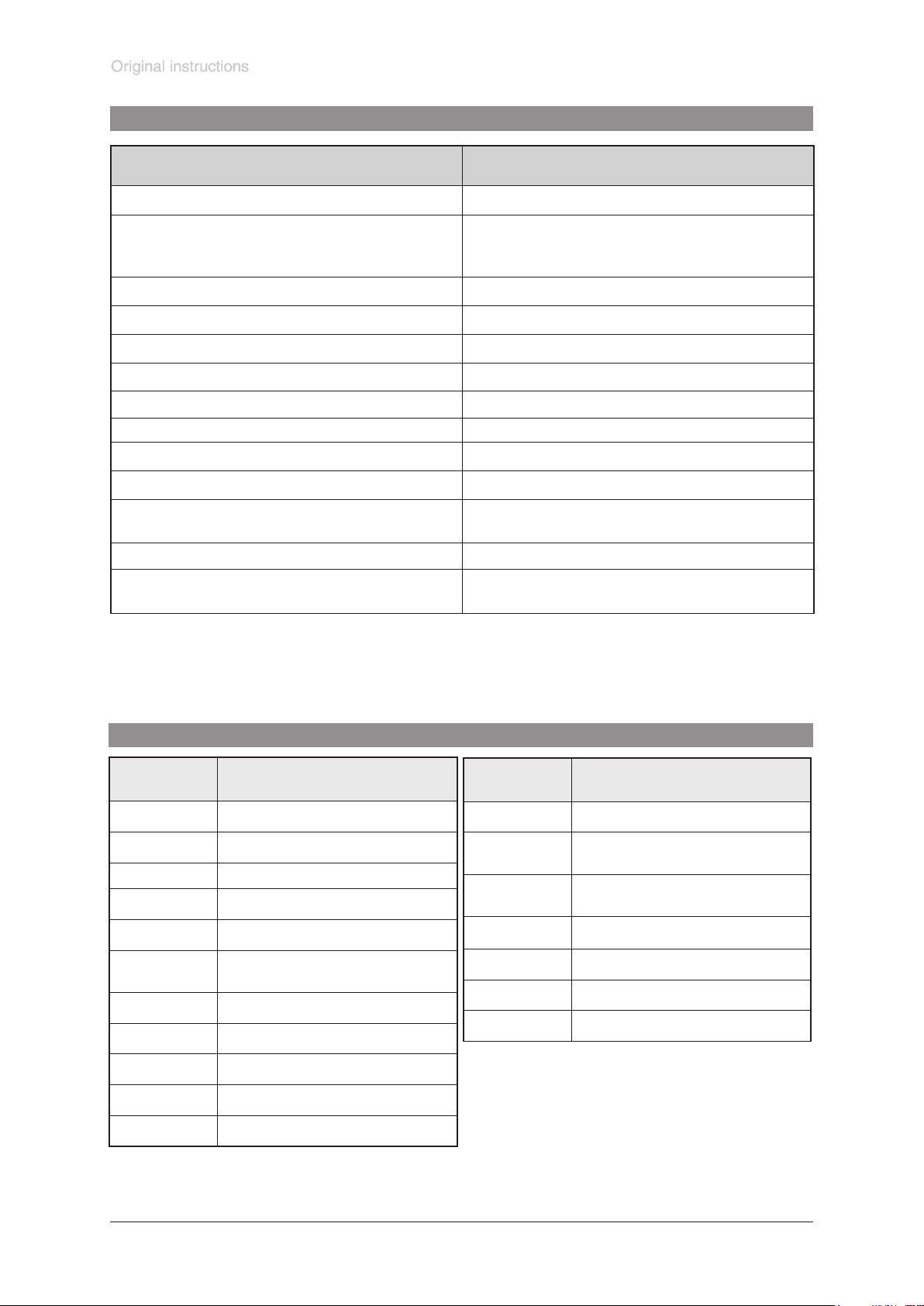

MV 10C EX

6

1

8

5

3

5

3

4

10

11

(2x !)

7

2

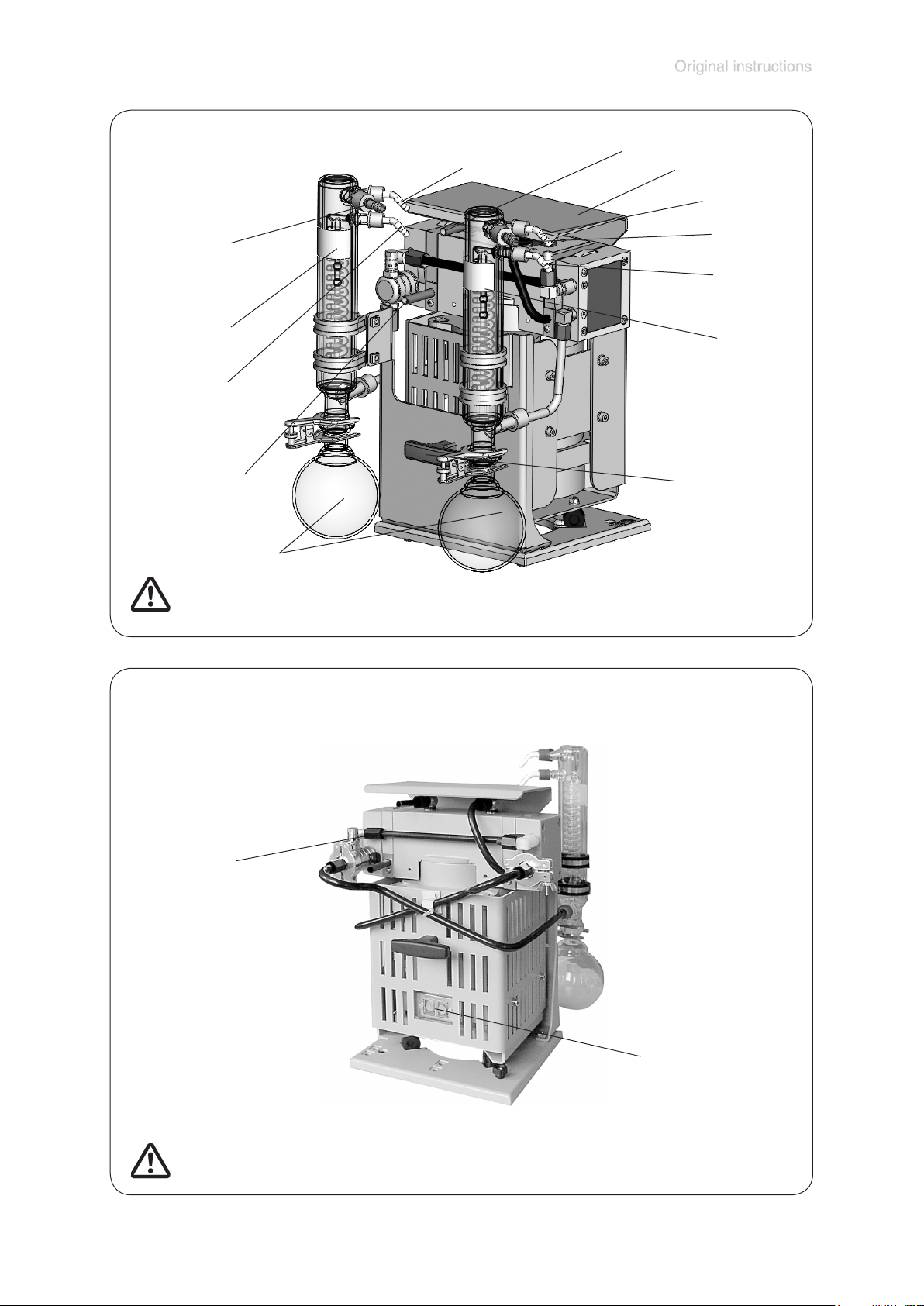

MZ 2C EX + AK + EK

2

12

13

8

9

7

14

16

1

5

15

Attention: Further designation of the pump components see gure MZ 2C EX

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

page 21 of 75

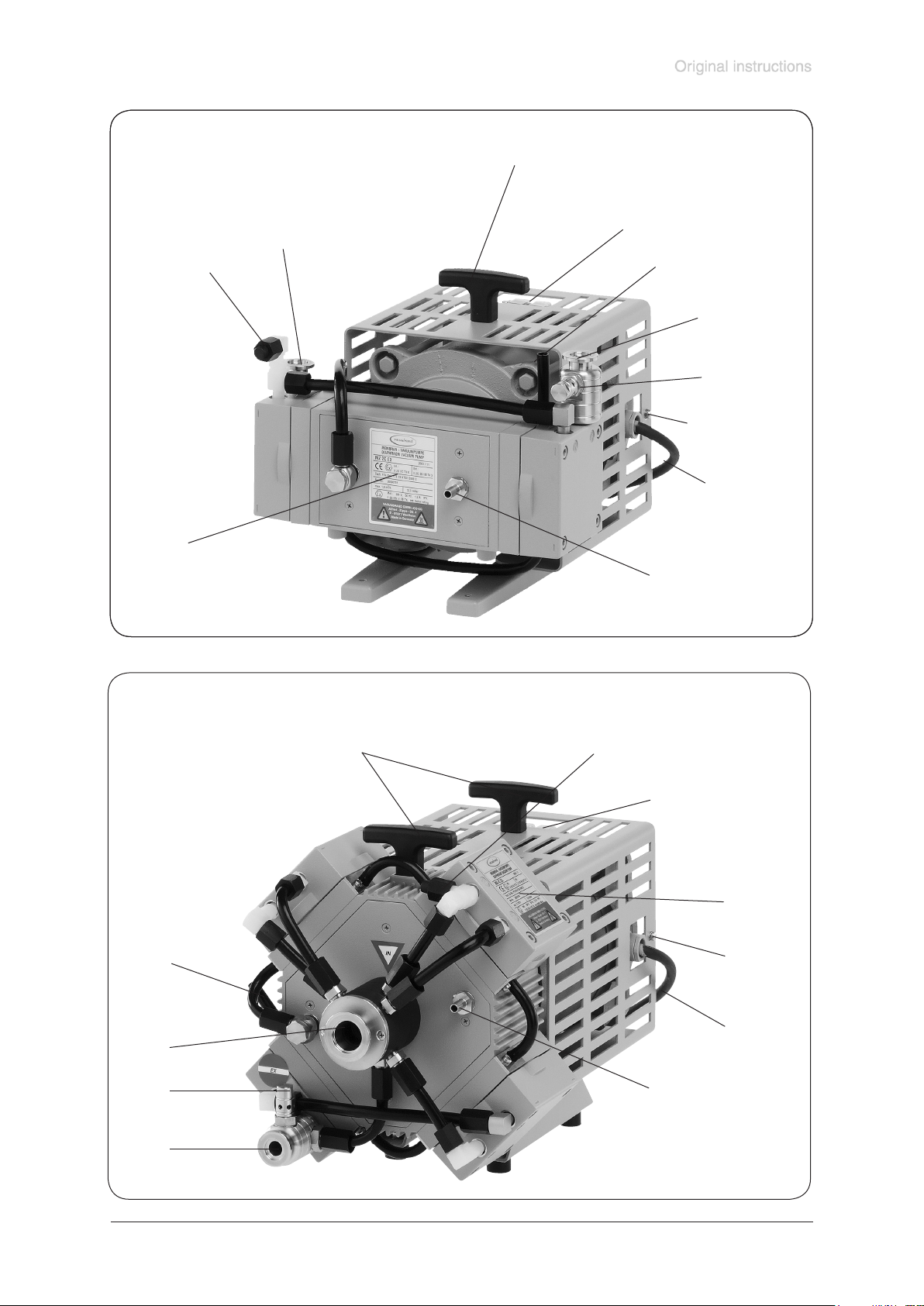

MZ 2C EX + IK + EK

2

12

13

8

15

14

7

16

14

1

13

18

5

Attention: Further designation of the pump components see gure MZ 2C EX

MZ 2C EX + AK + EK / MZ 2C EX + IK + EK (rear side)

9

3

Attention: Further designation of the pump components see gure MZ 2C EX

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

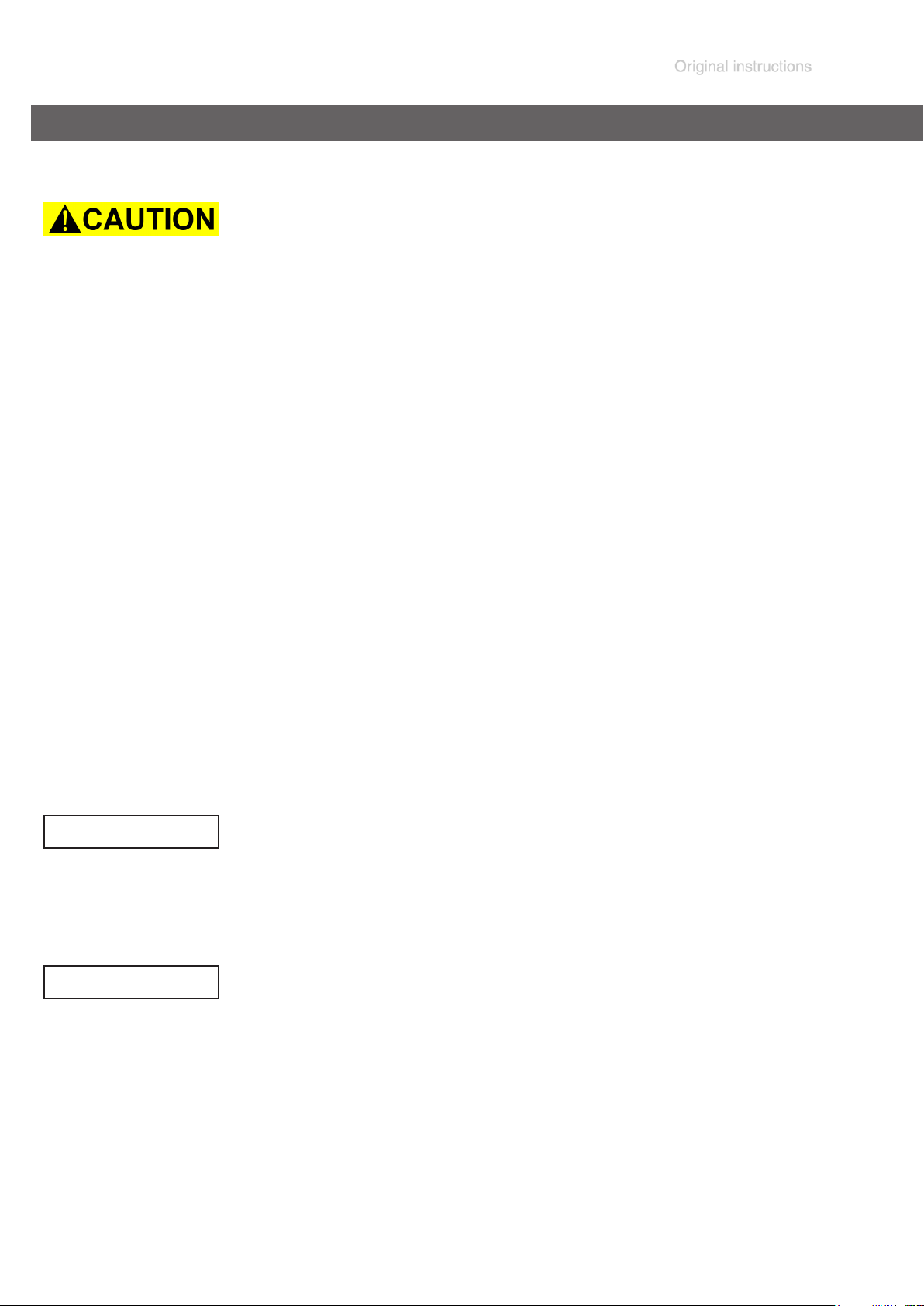

MD 4C EX + AK + EK

2

12

13

page 22 of 75

14

1

15

17

Attention: Further designation of the pump components see gure MD 4C EX

MV 10C EX + AK + EK

2

1

14

13

12

15

Attention: Further designation of the pump components see gure MV 10C EX

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

17

Use and operation

Installing in a vacuum system

• All connection lines at the pump (e. g. inlet, outlet, gas ballast connection, inert

gas connection) have to be performed conductive grounded.

• Connect pump and all connected components to ground.

• Avoid contact of the pump with rusty metal parts, e. g. by positioning the pump

with sufcient distance to surrounding parts.

• The pump is designated for a low degree of mechanical stress. Protect the pump

from damage and beats. In case of damage switch off the pump immediately,

check leak rate if necessary.

• Connection lines at the pump inlet have to be gas tight. Particles and dust must

not be aspirated, the user has to provide appropriate lters if necessary. The user

must ensure their suitability concerning gas ow, chemical resistance and safe-

ness against clogging prior to use.

• Connect an exhaust line gas tight at the pump outlet if necessary. Always dispose

of exhaust gases appropriately (e.g. into a fume hood). If there is risk of release of

dangerous or polluting uids, install an appropriate system to catch and dispose

of those uids.

• Reduce the transmission of vibration and prevent mechanical load due to rigid pipelines. Insert elastic hoses or exible elements as couplings between the

pump and rigid pipes. Attention: Flexible elements tend to shrink when evacuated.

• Use of a suitable valve to isolate the pump from the vacuum system is recommended to allow the pump to warm up before pumping condensable vapours or

to clean the pump before it is switched off.

• The gas outlet must never be blocked. The exhaust line has always to be free

(pressureless) to ensure an unimpeded discharge of gas.

• Especially if the gas ballast valve is open, a power failure may cause accidental

ventilation of the pump. In case this constitutes a potential source of danger, take

appropriate safety measures.

• Make sure ventilation is adequate especially if the pump is installed in a housing

or if the ambient temperature is elevated. Provide external ventilation if neces-

sary. Keep a distance of minimum 20 cm between fan and ambient parts.

page 23 of 75

NOTICE

NOTICE

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999128 / 29/04/2014

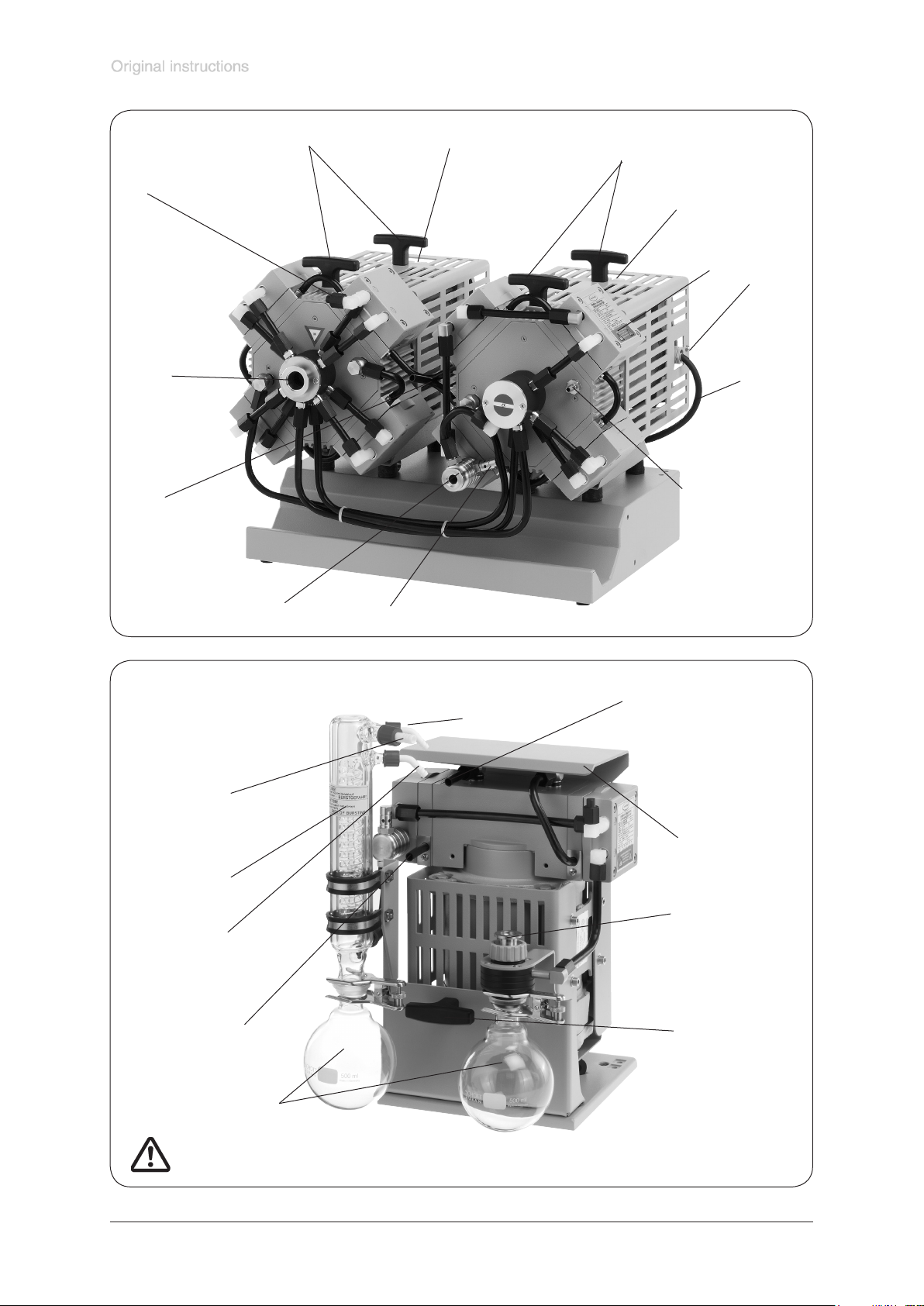

Avoid throttling losses by using connecting pipes with large diameter and by keeping

them as short as possible.

In case of perturbing exhaust noise connect an exhaust hose. Install outlet pipelines

always falling to avoid backow of condensate towards the pump.

When assembling, ensure vacuum-tightness. After assembly, check the whole system for leaks. Secure hose connections at the pump appropriately against accidental

detaching.

Attach the pipelines of the coolant circuit to the respective hose nozzles (hose nozzles 6-8 mm, see image) at the vapour condenser. Check hose connections prior to

starting operation of the cooling system.

Secure coolant hoses at the hose nozzles (e.g. with hose clip) to prevent their accidental slipping.

Loading...

Loading...