VACUUBRAND ME 8SI User Manual

Technology for Vacuum Systems

Instructions for use

ME 8SI

Attention: Please observe the notes in the supplementary sheet.

696190

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 696190 - 999021 / 08/05/2008

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 69 61 90 - 99 90 21 / 08/05/2008

Notice!

Date: 08.05.2008

Equipment (Product): ME 8SI 100-230 V 50/60 Hz

Material No.: 696190

Instructions for use for the standard equipment: ME 8

In particular, the following differences have to be considered:

The diaphragm pump is equipped with silencers at the outlets and a vacuum adjustment device at the inlet.

Inlet via a protective filter.

The pump ME 8SI is equipped with a dual-voltage motor (100-120 V / 200-230 V; 50/60 Hz).

☞ The equipment must be connected to a suitable fused and protected electrical

supply and a suitable earth point (recommended slow-blow fuse according to

rated current, see ”Technical data”) only. Failure to connect the motor to ground

may result in deadly electrical shock.

☞ Before switching on the pump check that mains voltage and current conform

with the equipment.

☞☞

☞ Check that the voltage changeover switch is positioned correctly.

☞☞

Attention: If the pump is switched on with the voltage not correctly selected,

the motor may be damaged.

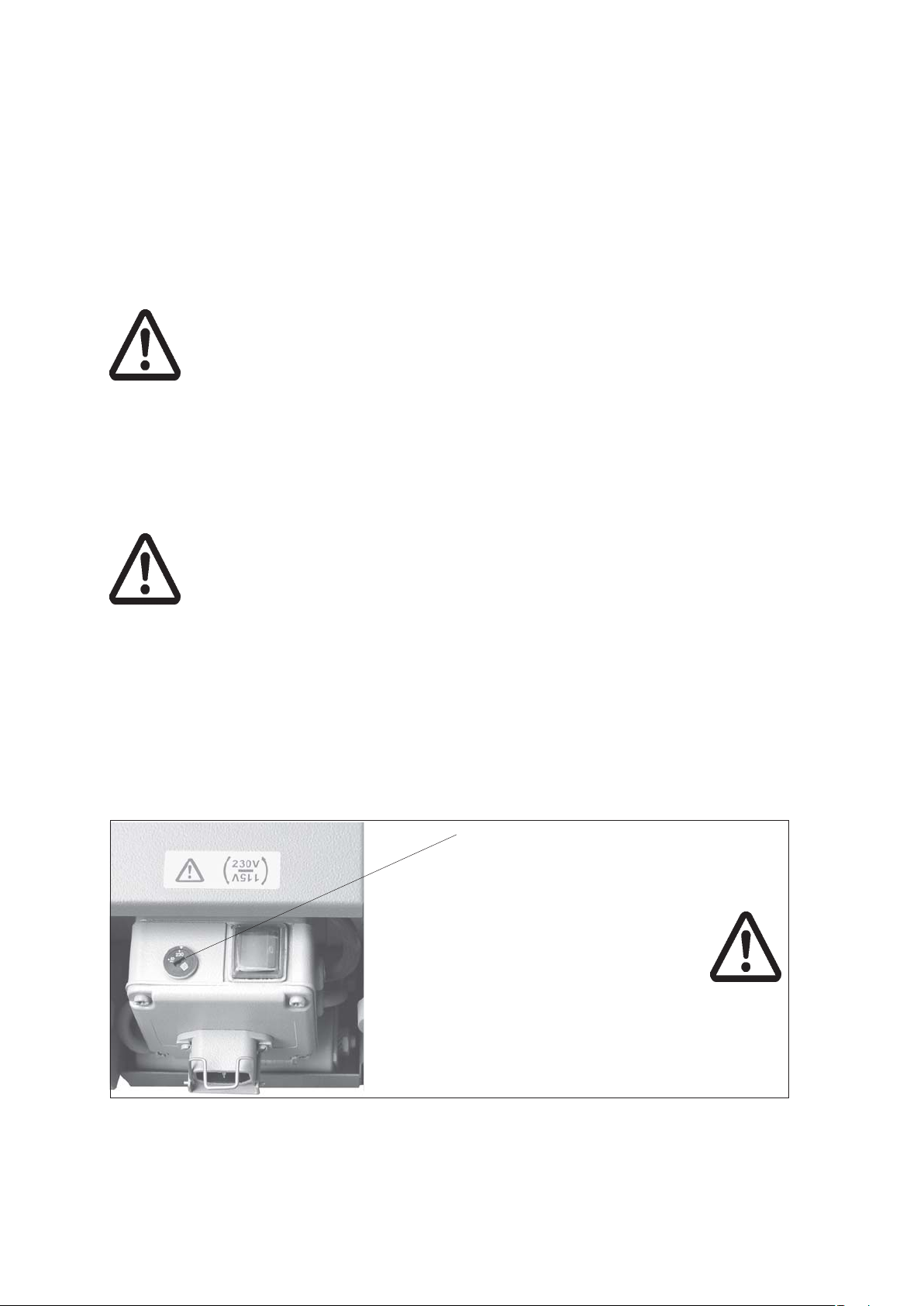

Selecting the supply voltage:

Attention:

Before starting the pump, check that

the voltage selection switch is

correctly positioned.

Change the selection at the voltage

changeover switch only if the pump

is separated from mains.

Voltage selection switch:

Use a screw driver to adjust the supply

voltage on the voltage changeover

switch at the terminal box of the pump:

”115” corresponds to 100-120V and

”230” corresponds to 200-240V.

Pumps with dual-voltage motor: The motor is shut down by a thermal cutout in the

winding.

☞ Manual reset is necessary. Switch off the pump or isolate the equipment from mains.

Wait approx. five minutes before restarting the pump.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 696190 - 999021 / 08/05/2008

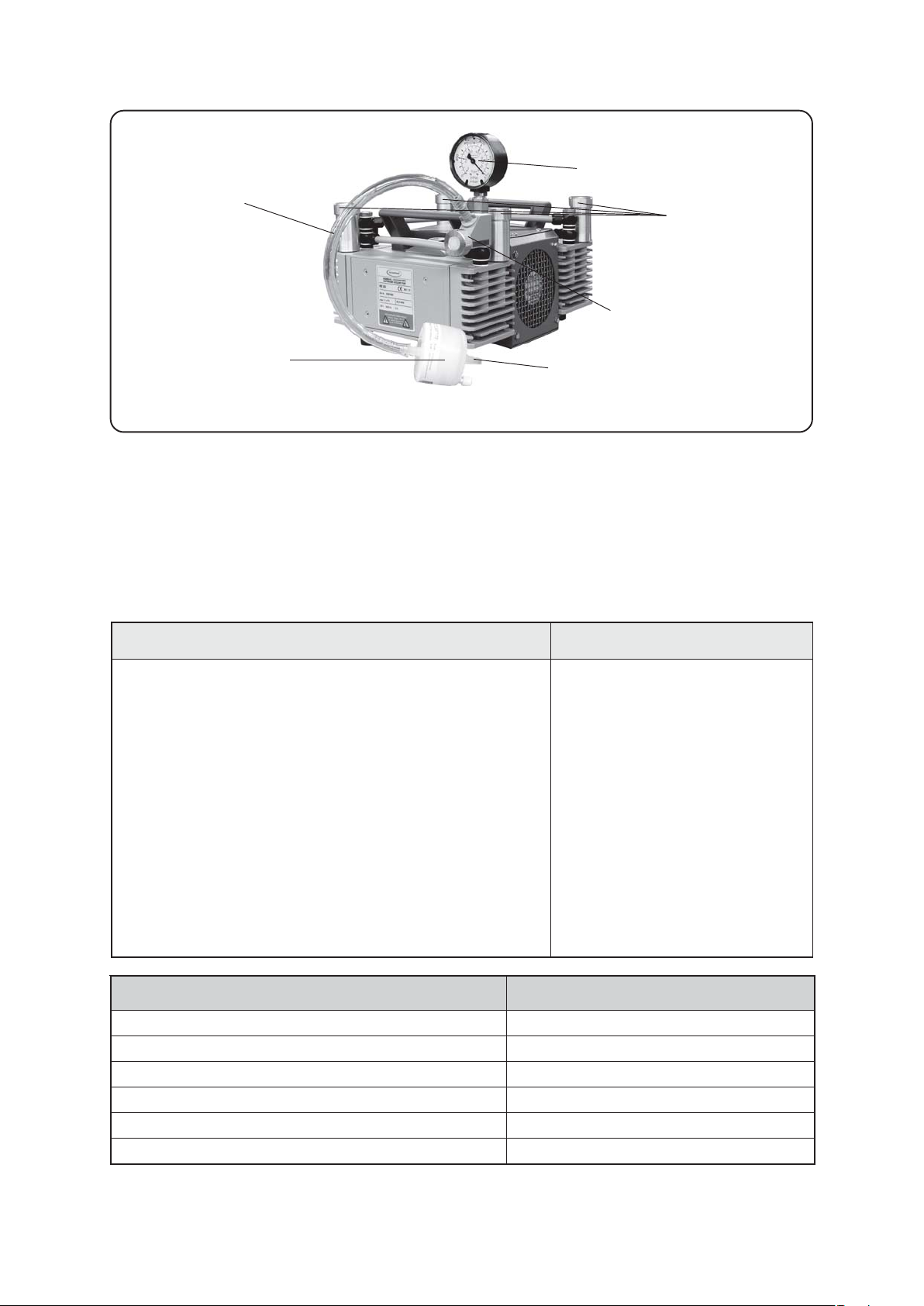

ME 8SI

PVC hose 12,8/6,4

length: 36 cm

manometer

outlet

vacuum adjustment device

protective filter

inlet

Technical data

epyT IS8EM

otgnidroccazH06/05deepsgnipmup.xaM

06312OSI

rewoprotoMWk2.0

tatnerrucdetaR

zH06/05~V021-001

zH06/05~V032-002

m3h/8.7/2.7

A

A

2.4/0.4

1.2/0.2

ardettimrep.xaM

telnI retl

HxWxLsnoisnemiDmm582x562x683

thgieWgk2.61

egatlovylppusfoegn

hctiwsnoitcelesegatlov:noitnettA

ifevitcetorpaiv

zH06-05%01-/5+~V021-001

zH06-05%01-/+~V032-002

stnenopmoC strapdetteW

esoHCVP

elzzonesoHSPP

gnir-ORBN

)ecivedtnenmtsujda(kcolbevlaVyollamuinimula

retemonamgnirlaeSreppoc

tsujda(wercsgnisnepsid,tlobwolloHleetssselniats

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 69 61 90 - 99 90 21 / 08/05/2008

)ecivedtnem

Spare parts

4x Silencer .................................................................................................................................... 639691

1x Face wrench ............................................................................................................................. 637580

Set of seals (diaphragms and valves) ........................................................................................... 696812

Attention: The inserts of the silencers are made of rubber foam.

➨ Check the compatibility of the material of the inserts with the pumped substances.

☞ If the specified values are not attained: Silencer clogged?

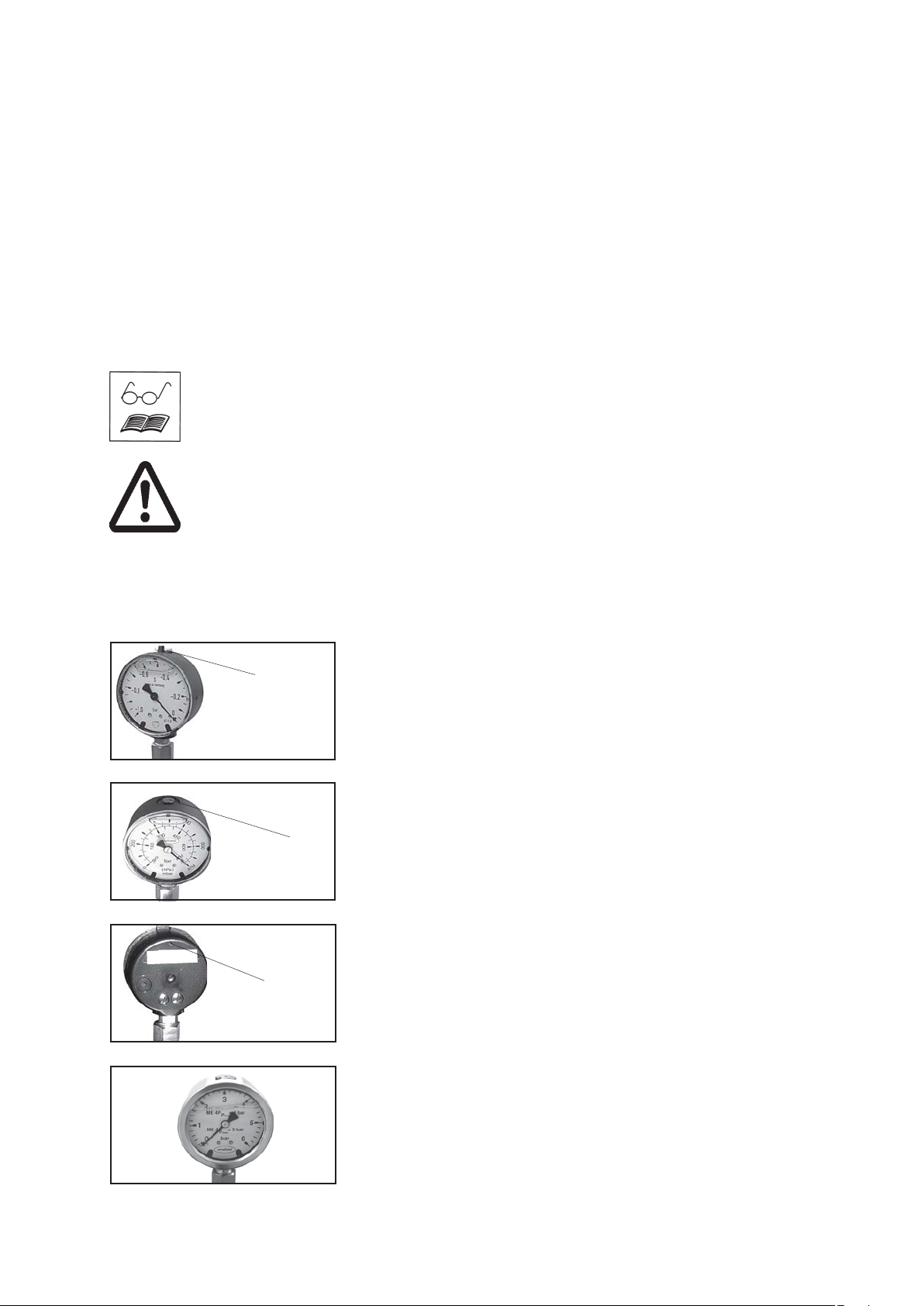

Notes prior to the use of the manometers:

The manometers used are vacuum meters or overpressure manometers with glycerin

filling. The overpressure manometer indicates the overpressure relative to the atmospheric pressure at the place of installation. The vacuumeter indicates the absolute

pressure.

➨ Install and tighten the manometers first (see instructions for use of the pump) or

install the pump with manometer in the room of operation.

➨ Prior to use the reference chambers of some of the manometers (depending on the

model of manometer) have to be ventilated.

☞ Else, not ventilating the manometer may lead to a systematic measuring error.

There are different types of manometers. To ventilate the reference chamber check

which types of manometers are installed at the pump and proceed according to the

given instructions:

Pierce hole

after installation

pressure

compensation

valve

pin

hole

A: Manometer with pressure compensation valve

Ventilate the manometer using the pressure compensation valve.

Close the valve after ventilation.

☞ Repeat if necessary until dial shows zero with measuring

connection ventilated to atmosphere.

B: Manometer with pin

Ventilate the manometer by lifting the pin. Do not remove the

pin completely!

C: Manometer with bore at the rear side

Pierce the hole at the rear side of the manometer. Some outflow

of liquid is normal.

☞ Do not tilt pump during transport.

D: Manometer without bore, pin or pressure compensation

valve

Do not ventilate the reference chamber of this manometer!

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 696190 - 999021 / 08/05/2008

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 69 61 90 - 99 90 21 / 08/05/2008

page 1 of 22

Technology for Vacuum Systems

Instructions for use

ME 8 - MZ 4 - MD 4 - MV 2

Diaphragm pumps

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999021 / 07/05/2008

page 2 of 22

Dear customer,

Your VACUUBRAND diaphragm pumps should support you for a long time without trouble and with maximal

power. Thanks to our long practical experience we have much information how you could ensure powerful

application and personal safety. Please read these instructions for use before the initial operation of your

pump.

VACUUBRAND diaphragm pumps are the result of many years of experience in construction and practical

operation of these pumps combined with the latest developments in material and manufacturing technology.

Our quality maxim is the ”zero fault principle”:

Every diaphragm pump, leaving our company, is tested intensively including an endurance run of 18 hours.

Therefore also faults, which occur rarely, are identified and can be eliminated immediately.

The achievement of the specifications after the endurance run is tested for every pump.

Every VACUUBRAND pump achieves the specifications. We feel obliged to this high quality standard.

We know that the vacuum pump can not take a part of your real work and hope that our products contribute

to an effective and trouble-free realisation of your work.

Yours

VACUUBRAND GMBH + CO KG

After sales service:Contact your local dealer or call +49 9342 808-193.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999021 / 07/05/2008

page 3 of 22

Contents

Safety information! ....................................................................................................4

Technical data ............................................................................................................ 7

Use and operation ................................................................................................... 11

Accessories - Installation .......................................................................................12

Troubleshooting ...................................................................................................... 14

Replacing diaphragms and valves ........................................................................15

Notes on return to the factory ................................................................................ 19

Health and safety clearance form ..........................................................................20

Attention! Important notes!

Not permitted! Misuse may cause damage.

Caution! Hot surface!

Isolate equipment from mains.

Note.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999021 / 07/05/2008

Loading...

Loading...