VACUUBRAND ME 2SI User Manual

Technology for Vacuum Systems

Instructions for use

ME 2SI

Attention: Please observe the notes in the supplementary sheet.

69 61 30

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 69 61 30 - 99 56 52 / 18/10/2007

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 69 61 30 - 99 56 52 / 18/10/2007

Notice

Date: 18.10.2007

Equipment (Product): ME 2SI 100-120/200-230 V 50/60 Hz

Material No.: 69 61 30

Instructions for use for the standard equipment: ME 2

The following differences have to be considered:

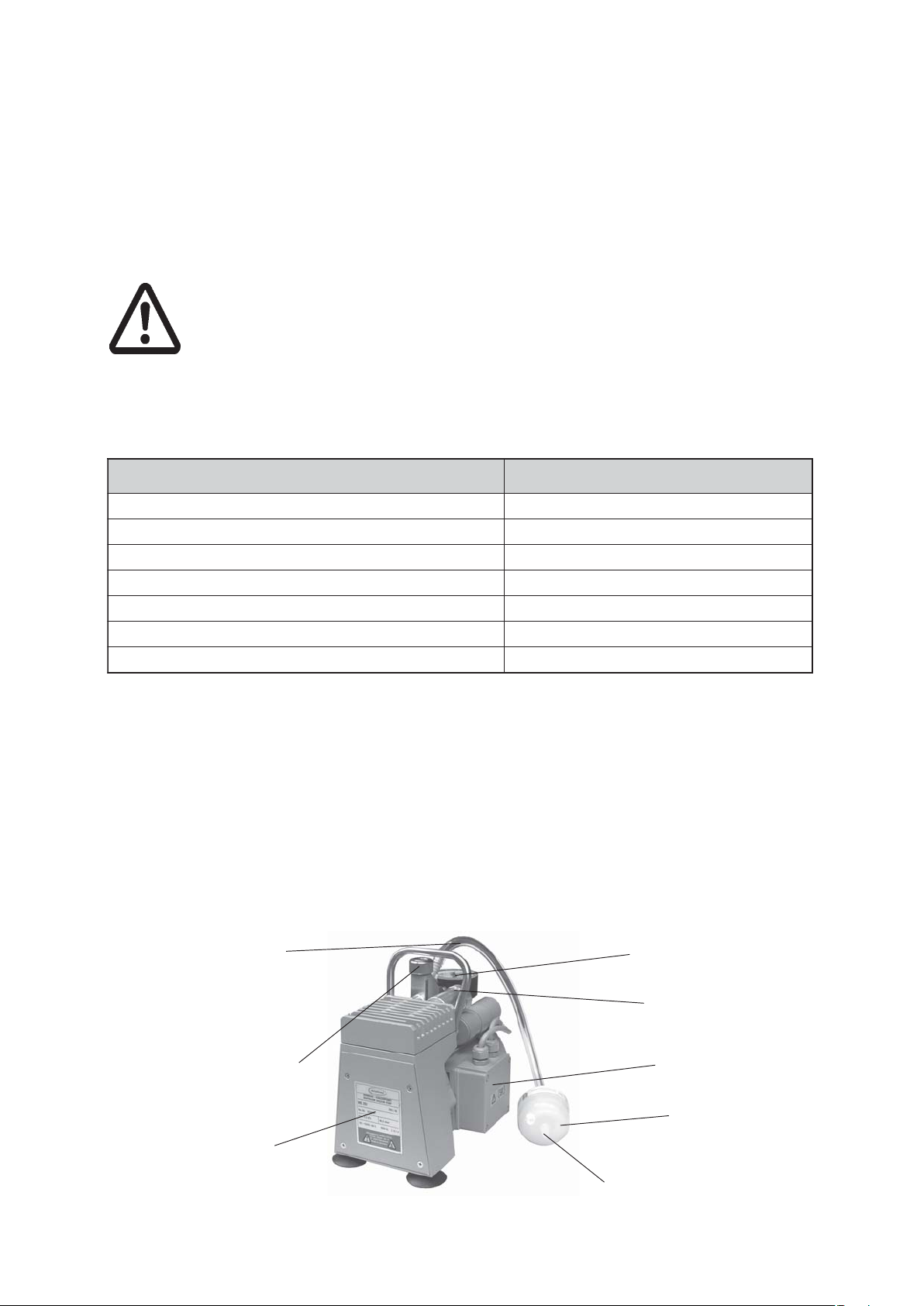

The diaphragm pump is equipped with a silencer at the outlet and a vacuum adjustment device at the inlet.

Inlet via a protective filter.

stnenopmoC strapdetteW

esoHCVP

elzzonesoHSPP

gnir-ORBN

kcolbevlaVyollamuinimula

retemonamgnirlaeSreppoc

)ecivedtnemtsujda(gnirlaeSmuini

)ecivedtnemtsujda(wercsgnisnepsid,tlobwolloHleetssselniats

mula

1x Silencer .................................................................................................................................. 63 96 91

1x Face wrench ...........................................................................................................................63 75 80

Set of seals (diaphragm, valves) ................................................................................................. 69 68 10

Attention: The insert of the silencer is made of rubber foam.

➨ Check the compatibility of the material of the insert with the pumped substances.

☞ If the specified values are not attained: Silencer clogged?

PVC hose 12,8/6,4

lenth: 36 cm

vacuum adjustment device

pump rating plate

manometer

outlet

silencer

terminal box

protective filter

inlet

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 69 61 30 - 99 56 52 / 18/10/2007

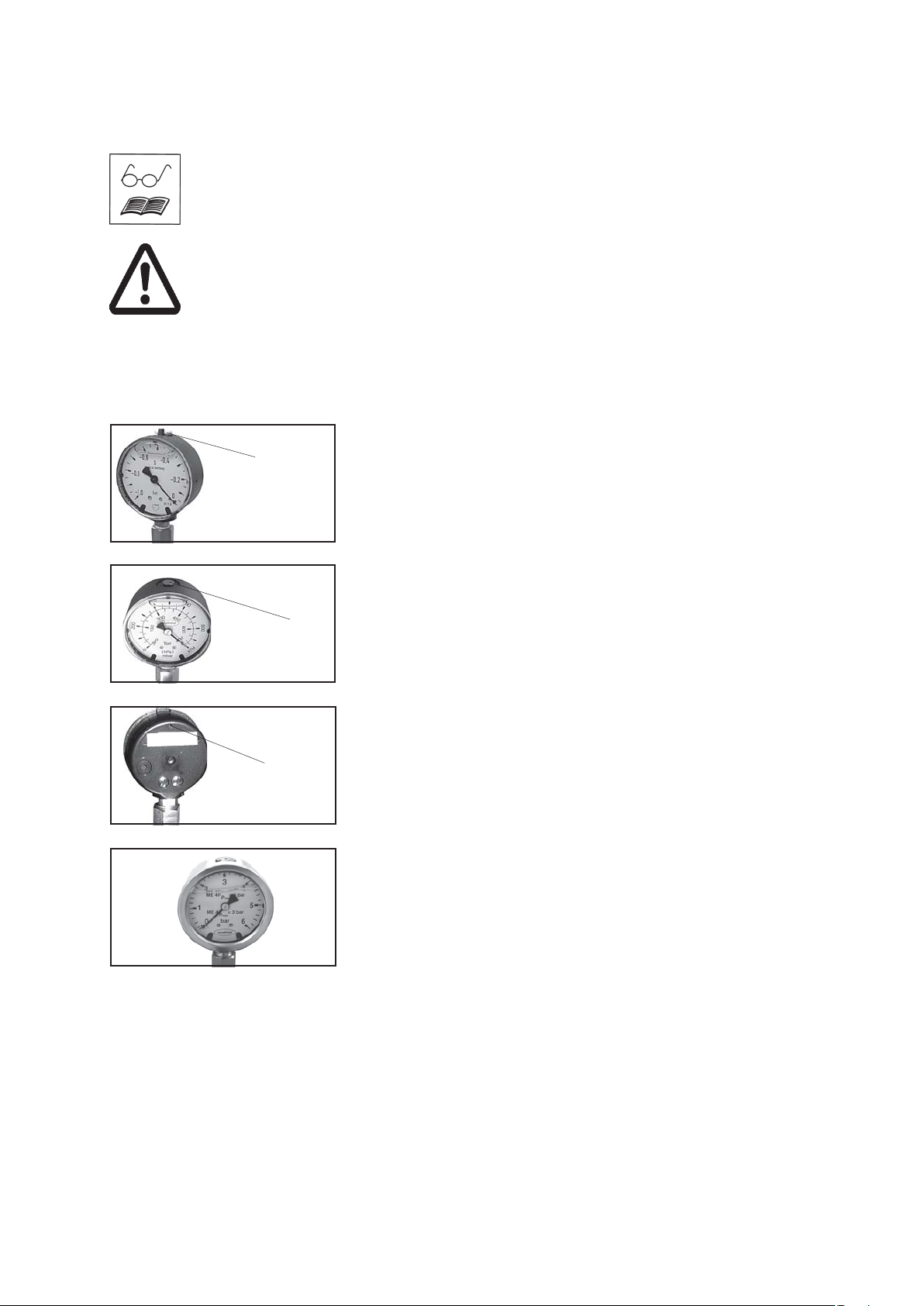

Notes prior to the use of the manometers:

The manometers used are vacuum meters or overpressure manometers with glycerin

filling. The overpressure manometer indicates the overpressure relative to the atmospheric pressure at the place of installation. The vacuumeter indicates the absolute

pressure.

➨ Install and tighten the manometers first (see instructions for use of the pump) or

install the pump with manometer in the room of operation.

➨ Prior to use the reference chambers of some of the manometers (depending on the

model of manometer) have to be ventilated.

☞ Else, not ventilating the manometer may lead to a systematic measuring error.

There are different types of manometers. To ventilate the reference chamber check

which types of manometers are installed at the pump and proceed according to the

given instructions:

A: Manometer with pressure compensation valve

Ventilate the manometer using the pressure compensation valve.

pressure

compensation

valve

pin

Close the valve after ventilation.

☞ Repeat if necessary until dial shows zero with measuring

connection ventilated to atmosphere.

B: Manometer with pin

Ventilate the manometer by lifting the pin. Do not remove the

pin completely!

Pierce hole

after installation

hole

C: Manometer with bore at the rear side

Pierce the hole at the rear side of the manometer. Some outflow

of liquid is normal.

☞ Do not tilt pump during transport.

D: Manometer without bore, pin or pressure compensation

valve

Do not ventilate the reference chamber of this manometer!

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 69 61 30 - 99 56 52 / 18/10/2007

page 1 of 24

Technology for Vacuum Systems

Instructions for use

ME 2 - ME 4 - MZ 2 - MZ 2D

Diaphragm pumps

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 56 52 / 10/07/2007

page 2 of 24

Dear customer,

Your VACUUBRAND diaphragm pump shall support you at your work for a long time without any trouble and

with full load output. Thanks to our large practical experience we attained much information how you could

add to an efficient application and to personal safety. Please read these instructions for use prior to the

initial start-up of your pump.

VACUUBRAND diaphragm pumps are the result of many years of experience in construction and practical

operation of these pumps combined with the latest results in material and manufacturing technology.

Our quality maxim is the ”zero fault principle”:

Every delivered diaphragm pump is tested extensively including an endurance run of 18 hours. Due to this

endurance run, also faults, which occur rarely, are reported an can be corrected. Every single diaphragm

pump is tested on achievement of the specification after the endurance run.

Every VACUUBRAND pump leaving our factory achieves the specification. We feel obliged to this

high quality standard.

We are aware that the vacuum pump should not draw a part of the real work and we hope to contribute with

our products to an effective and troublefree realisation of your work.

Yours

VACUUBRAND GMBH + CO KG

After sales service: Contact your local dealer or call (++49) 9342/808-193.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 56 52 / 10/07/2007

page 3 of 24

Contents

Safety information! ....................................................................................................4

Technical data ............................................................................................................ 7

Use and operation ................................................................................................... 11

Accessories - Installation .......................................................................................13

Troubleshooting ...................................................................................................... 15

Replacing diaphragms and valves ........................................................................16

Notes on return to the factory ................................................................................ 21

Health and safety clearance form ..........................................................................22

Attention! Important notes!

Not permitted! Misuse may cause damage.

Caution! Hot surface!

Isolate equipment from mains.

Note.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 56 52 / 10/07/2007

Safety information!

Remove all packing material, remove the product from its packing-box, remove the

protective covers from the inlet and outlet ports and keep, inspect the equipment.

If the equipment is damaged, notify the supplier and the carrier in writing within three

days; state the item number of the product together with the order number and the

supplier’s invoice number. Retain all packing material for inspection.

Do not use the equipment if it is damaged.

If the equipment is not used immediately, replace the protective covers. Store the

equipment in suitable conditions.

☞ Read and comply with this manual before installing or operating the equip-

ment.

☞ Transport the pump at the provided handles.

Use the equipment for the intended use only (for generation of vacuum).

☞ Prevent any part of the human body from coming in contact with the vacuum.

☞ Comply with notes on correct vacuum and electrical connections, see section ”Use

and operation”.

☞ Make sure that the individual components are only connected, combined and oper-

ated according to their design and as indicated in the instructions for use.

page 4 of 24

Comply with national safety regulations and safety requirements concerning the

use of vacuum and electrical equipment.

☞ Equipment must be connected only to a suitable fused and protected electrical

supply and a suitable earth point. Failure to connect the motor to ground may result

in deadly electrical shock.

☞ The supply cable may be fitted with a moulded European IEC plug or a plug suitable

for your local electrical supply. If the plug has been removed or has to be removed,

the cable will contain wires colour coded as follows: green or green and yellow:

earth; blue or white: neutral; brown or black: live.

☞ Check that mains voltage and current conform with the equipment (see rating

plate):

Pumps with dual-voltage motor (100-120 V / 200-230 V; 50/60 Hz):

☞ The equipment must be connected to a suitable fused and protected electrical

supply and a suitable earth point only, provide slow-blow fuse according to voltage

supply (see ”Technical data”).

☞ Check that the voltage changeover switch is positioned correctly.

Attention: If the pump is switched on with the voltage not correctly selected,

the motor may be damaged!

☞ If the equipment is brought from cold environment into a room for operation, allow

the equipment to warm up (pay attention to water condensation on cold surfaces).

☞ Make sure ventilation is adequate if pump is installed in a housing or if ambient

temperature is elevated.

Comply with all relevant safety requirements (regulations and guidelines) and adopt

suitable safety measures.

☞ Provide a firm level platform for the equipment and check that the system to be

evacuated is mechanically stable and that all fittings are secure.

Attention: Flexible elements tend to shrink when evacuated.

Due to the high compression ratio of the pumps, pressure at the outlet port might be

generated being higher than the max. permitted pressure compatible with the mechanical stability of the system.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 56 52 / 10/07/2007

page 5 of 24

☞ Comply with maximum permitted pressures and pressure differences, see sec-

tion ”Technical data”. Do not operate the pump with overpressure at the inlet.

Do not permit any uncontrolled pressurizing (e. g. make sure that the exhaust pipeline cannot become blocked). If you have an exhaust-isolation valve, make sure that

you cannot operate the equipment with the valve closed. Risk of bursting!

☞ Ensure that the system design does not allow the exhaust pipeline to become

blocked.

☞ Avoid overpressure of more than 0.2 bar in case inert gas is connected.

☞ The diameter of the inlet and outlet pipeline should be at the least as large as the

diameter of the pump connection pipelines.

To the best of our knowledge the equipment is in compliance with the requirements of

the applicable EC-directives and harmonized standards (see ”Declaration of conformity”) with regard to design, type and model, especially directive IEC 1010. This directive

gives in detail conditions, under which the equipment can be operated safely (see also

IP degree of protection).

☞ Adopt suitable measures in case of differences, e. g. using the equipment outdoors,

installation in altitudes of more than 1000 m above mean sea level, conductive

pollution or dewiness.

Pay attention to symbol ”hot surfaces” on the equipment (according to IEC 1010 recommendation).

☞ Adopt suitable measures to prevent any danger arising from the formation of hot

surfaces or electric sparks.

The pumps have no approval for operation in or for pumping of potentially explosive atmospheres.

If pumping different substances, purge the pump with inert gas prior to changing the

pumped media in order to pump out residues and to avoid reactions of the pumped

substances with each other with and the pump material. Ensure that the materials of

the wetted parts are compatible with the pumped substances, see section ”Technical

data”.

Take into consideration interactions and chemical reactions of the pumped media.

The pumps are not suitable for pumping substances which may form deposits inside

the pump.

☞ If there is a danger of the formation of deposits in the pump chamber (check inlet

and outlet of the pump) inspect the pump chamber regularly and clean if necessary.

The pumps are not suitable to pump unstable substances and substances which

react explosively under impact (mechanical stress) and/or when being exposed to

elevated temperatures without air.

The pumps are not suitable to pump self inflammable substances, substances which

are inflammable without air and explosive substances.

The pumps are not suitable for pumping dust and have no approval for operation

below ground.

Ensure that the materials of the wetted parts are compatible with the pumped substances, see section ”Technical data”.

☞ Adopt suitable measures to prevent the release of dangerous, explosive, corrosive

or polluting fluids.

☞ Use inert gas for gas ballast or venting if necessary.

☞ The user must take suitable precautions to prevent any formation of explosive mixtures

in the expansion chamber or at the outlet. In case of a diaphragm crack, mechanically

generated sparks, hot surfaces or static electricity may ignite these mixtures.

☞ Take adequate precautions to protect people from the effects of dangerous sub-

stances (chemicals, thermal decomposition products of fluoroelastomers), wear

appropriate safety-clothing and safety glasses.

☞ Comply with applicable regulations when disposing of chemicals. Take into consid-

eration that chemicals may be polluted.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 56 52 / 10/07/2007

Loading...

Loading...