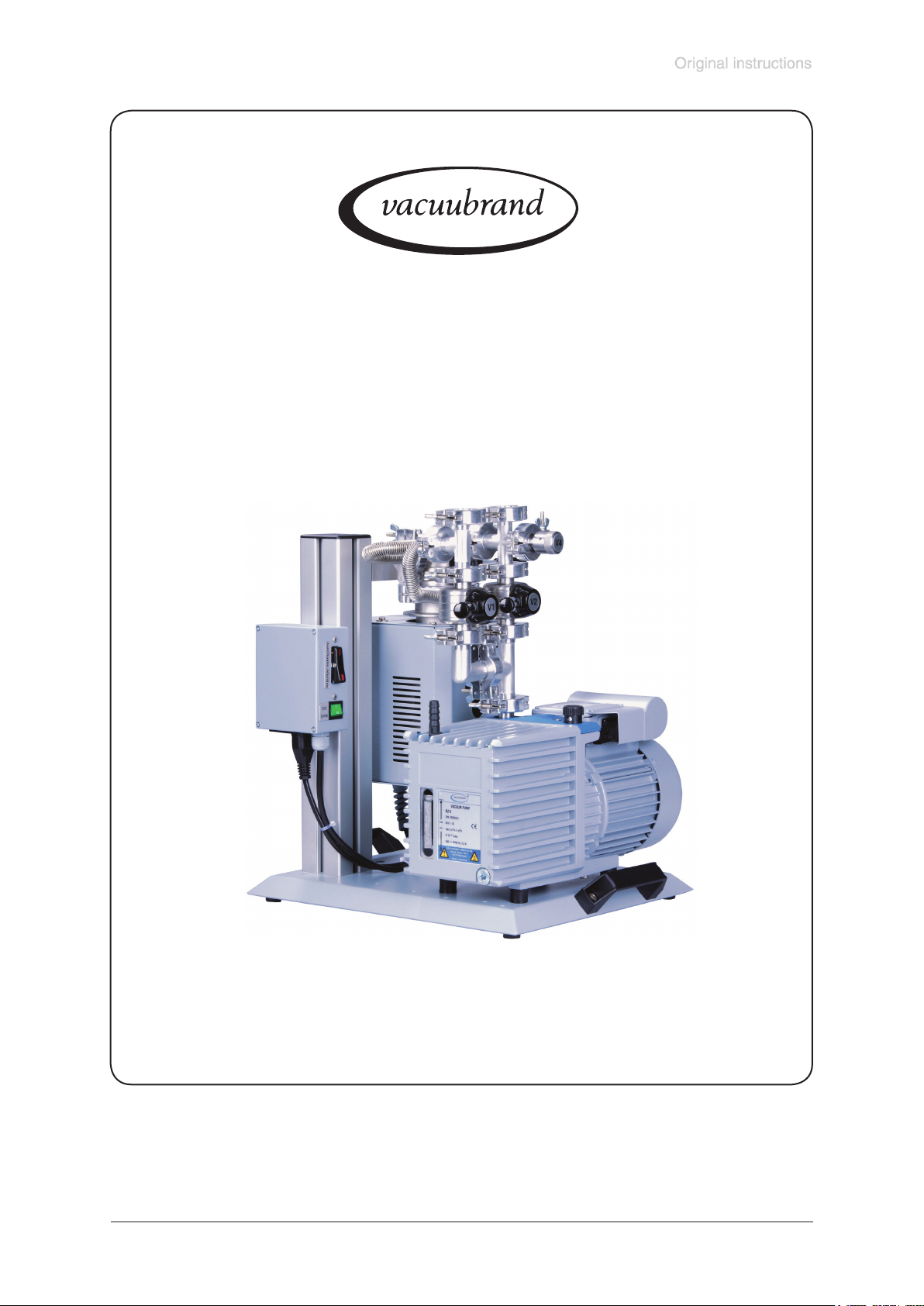

VACUUBRAND HP 63B2 User Manual

page 1 of 20

Technology for Vacuum Systems

Instructions for use

HP 40B2

HP 63B2

Vacuum pumping units

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999069 / 24/09/2014

page 2 of 20

Dear customer,

Your VACUUBRAND pumping unit is designed to provide you with many years of trouble-free service

with optimal performance. Our many years of practical experience allow us to provide a wealth of application and safety information. Please read these instructions for use before the initial operation of your

pumping unit.

VACUUBRAND vacuum pumps combine our many years of experience in design, construction and

practical operation, with the latest developments in material and manufacturing technology.

Our quality maxim is the ”zero defect” principle:

Every vacuum pumping unit, before leaving our factory, is tested intensively, including an endurance run

of 24 hours. Any faults, even those which occur rarely, are identied and can be eliminated immediately.

After completion of the endurance run, every pumping unit is tested, and must achieve specications

before shipment.

We are committed to providing our customers only pumps that meet this high quality standard.

While our pumps cannot eliminate all of your work, we design, manufacture and test them to ensure that

they will be an effective and trouble-free tool to assist you in that work.

Yours,

VACUUBRAND GMBH + CO KG

After sales service:

Contact your local dealer or call +49 9342 808-5500.

The document ”Safety information for vacuum equipment” is part of this

manual! Read the ”Safety information for vacuum equipment” and observe

the instructions contained therein!

Trademark index:

VACUU•LAN® (US-Reg.No 3,704,401), VACUU•BUS®, VACUU•CONTROL®, Peltronic®, VARIO® (US-

Reg.No 3,833,788), VACUUBRAND® (US-Reg.No 3,733,388) and also the shown company logos are

trademarks of VACUUBRAND GMBH + CO KG in Germany and/or other countries.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999069 / 24/09/2014

page 3 of 20

Contents

Safety information! .....................................................................................................4

General information ............................................................................................................................4

Intended use .......................................................................................................................................4

Setting up and installing the equipment .............................................................................................5

Ambient conditions .............................................................................................................................6

Operating conditions ..........................................................................................................................6

Safety during operation ......................................................................................................................7

Maintenance and repair ......................................................................................................................8

Technical data ...........................................................................................................10

Pump parts ...................................................................................................................................... 11

Use and operation ....................................................................................................14

Setting up and installing ..................................................................................................................14

Getting started .................................................................................................................................14

During operation ..............................................................................................................................15

Shutdown ........................................................................................................................................16

Accessories ..............................................................................................................16

Troubleshooting .......................................................................................................16

Maintenance ..............................................................................................................16

Notes on return to the factory .................................................................................17

Health and safety clearance form ...........................................................................18

EC Declaration of Conformity of the Machinery .......................................................19

NOTICE

➨ DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

+ WARNING indicates a hazardous situation which, if not avoided, could re-

sult in death or serious injury.

• CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

Caution! Hot surface!

Disconnect equipment from AC power.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999069 / 24/09/2014

Safety information!

General information

+ Read this manual carefully before installing or operating the equipment.

Observe the instructions contained in this manual.

+ Read the manuals of the rotary vane pump and of the diffusion

pump before installing or operating the equipment. Observe

the instructions contained in those manuals.

+ Do not use any damaged equipment.

• Use the handles when moving the pump.

Remove all packing material from the packing box. Remove the product from its

NOTICE

packing-box and retain all packaging until the equipment is inspected and tested.

Remove the protective caps from the inlet and outlet ports and retain for future use.

Inspect the equipment promptly and carefully.

If the equipment is damaged, notify the supplier and the carrier in writing within

three days. Retain all packing material for inspection. State the item number of the

product together with the order number and the supplier’s invoice number. Failure

to check and give notice of damage will void any and all warranty claims for those

deciencies.

Replace the protective caps, if the equipment is not used immediately. Store the

equipment in dry and non-corrosive conditions.

page 4 of 20

NOTICE

Intended use

+ Do not use the pump or any system parts on humans or animals.

+ Ensure that the individual components are only connected, combined and oper-

ated according to their design and as indicated in the instructions for use.

Use only original manufacturer’s spare parts and accessories. Otherwise the

safety and performance of the equipment, as well as the electromagnetic com-

patibility of the equipment might be reduced.

The CE mark may be voided if not using original manufacturer’s spare parts.

+ Comply with all notes on correct vacuum and electrical connections; see section

“Use and operation“.

+ The pumps are designed for ambient temperatures during operation between

+12°C and +40°C. Periodically check maximum temperatures if installing the

pump in a cabinet or a housing. Make sure ventilation is adequate to maintain

recommended operating temperature. Install an external automatic ventilation

system if necessary. If pumping hot process gases, make sure that the maximum

permitted gas inlet temperature is not exceeded. The maximum permitted gas

inlet temperature depends on several parameters like inlet pressure and ambient

temperature (see ”Technical Data”).

+ Particles and dust must not enter the pump.

+ Do not pump liquids.

Use the equipment only as intended, that is, for generation of vacuum in vessels

designed for that purpose. Any other use will automatically invalidate all warranty

and liability claims. Remain aware of safety and risks.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999069 / 24/09/2014

page 5 of 20

Setting up and installing the equipment

➨ Equipment must be connected only to a suitable electrical supply and a suit-

able ground point. As such, the plug must be plugged into an outlet that is proper-

ly grounded. Failure to connect the motor to ground may result in deadly electrical

shock.

The supply cable may be tted with a molded European IEC plug or a plug suit-

able for your local electrical supply. The cable contains wires color coded as fol-

lows: green or green and yellow: ground; blue or white: neutral; brown or black:

hot.

+ Due to the high compression ratio, the pump may generate overpressure at the

outlet. Check pressure compatibility with system components (e.g., exhaust pipe-

line or exhaust valve) at the outlet.

+ Do not permit any uncontrolled pressurizing. Make sure that the exhaust tub-

ing cannot become blocked to avoid a risk of bursting!

+ Keep the electrical power cord away from heated surfaces.

• Provide a rm, level platform for the equipment. Check that the system which you

are going to evacuate is mechanically stable. Check that all ttings are secure.

Ensure a stable position of the pumping unit.

• Comply with maximum permissible pressures at inlet and outlet and with max-

imum permissible pressure differences between inlet and outlet. See section

“Technical data“. Do not operate the pump with overpressure at the inlet.

• Avoid overpressure of more than 1.2 bar absolute in the event that inert gas is

connected to the pump, to the gas ballast or to a venting valve.

• Note: Flexible elements will shrink when evacuated.

• Connect hoses gas tight at inlet and outlet of the pump.

• Ensure that no foreign objects can be drawn into the pump.

• Check the power source and the pump’s rating plate to be sure that the power

source and the equipment match in voltage, phase, and frequency.

• Use only oil of the recommended type. Other oils or operating uids may cause

damage of the pump or danger.

Use special oils for the rotary vane pump, if, e.g.,

- the pump operates in the vicinity of potential ignition sources.

- oxygen or other ammable gases account for a large proportion of the evacu-

ated gases.

• Under normal operation conditions, pump oils and lubricants are not toxic and

their use entails no danger. Certain hazards are, however, associated with some

of these products.

• Take adequate precautions when handling pump uids, lubricants, and solvents.

Use appropriate protective clothing, safety goggles and protective gloves to avoid

excessive contact with the skin and possible skin irritations (including dermatitis).

Do not inhale or swallow. Maintain adequate levels of hygiene and cleanliness.

Ensure that the pump location is well ventilated and that possible toxic effects of

certain vapors are avoided.

• Comply with all relevant statutory requirements and regulations concerning the

handling, storage and disposal of oil.

Attention! Do not allow oils to be poured into or enter the drainage system or

other bodies of water.

Spillage can cause accidents, use suitable means of removing spilled oil.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999069 / 24/09/2014

NOTICE

page 6 of 20

Make sure ventilation is adequate to maintain recommended operating temperature.

Keep a minimum distance of 5 cm between the cooling fans and surrounding items

(e.g., housing, walls, etc.), or else install an external automatic ventilation system.

Check fans regularly for dust/dirt. Clean fan guard grills if necessary to avoid a reduction of ventilation.

Use only hoses at the inlet and outlet of the pump with an inner diameter at least as

large as the diameter of the pump’s tubing (to avoid overpressure at the outlet, and

reduction of pumping speed at the inlet).

Allow the equipment to equilibrate to ambient temperature if you bring it from cold

environment into a room prior to operation. Notice if there is water condensation on

cold surfaces.

The ON/OFF-switches are located at the terminal box. At rst, switch on the rotary

vane pump (backing pump), then switch on the diffusion pump. The diffusion pump

can be switched on only if the backing pump has been switched on.

Comply with all applicable and relevant safety requirements (regulations and

guidelines). Implement the required actions and adopt suitable safety mea-

sures.

NOTICE

Ambient conditions

• Adopt suitable measures in case of differences from recommended conditions,

e.g., using the equipment outdoors, installation in higher altitudes, conductive

pollution or external condensation on the pump.

• Do not operate this product near ames.

To the best of our knowledge the equipment is in compliance with the requirements

of the applicable EC-directives and harmonized standards (see ”Declaration of Conformity”) with regard to design, type and model. Directive EN 61010-1 gives in detail

the conditions under which the equipment can be operated safely (see also IP degree of protection).

Operating conditions

➨ These pumps are not approved for operation in potentially explosive atmos-

pheres. Do not operate the pumps in potentially explosive atmospheres.

➨ These pumps are not approved for the pumping of potentially explosive

atmospheres. Do not pump potentially explosive atmospheres.

➨ The pumps are not suitable to pump any of the substances listed below.

Do not pump:

- unstable substances

- substances which react explosively under impact (mechanical stress) without air

- substances which react explosively when being exposed to elevated tempera-

tures without air,

- substances subject to auto-ignition,

- substances which are inammable without air

- explosive substances.

➨ The pumps are not approved for operation below ground. Do not operate the

pump below ground.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999069 / 24/09/2014

Loading...

Loading...