VACUUBRAND BVC professional G User Manual

page 1 of 68

Technology for Vacuum Systems

Instructions for use

BVC control

BVC control G

BVC professional

BVC professional G

BioChem-VacuuCenter

page 2 of 68

Dear customer,

Your VACUUBRAND diaphragm pumps are designed to provide you with

many years of trouble-free service with optimal performance. Our many

years of practical experience allow us to provide a wealth of application

and safety information. Please read these instructions for use before the

initial operation of your pump.

VACUUBRAND diaphragm pumps combine our many years of experience in design, construction and practical operation, with the latest developments in material and manufacturing technology.

Our quality maxim is the ”zero defect” principle:

Every diaphragm pump, before leaving our factory, is tested intensively,

including an endurance run of 14 hours. Any faults, even those which occur rarely, are identied and can be eliminated immediately.

After completion of the endurance run, every pump is tested, and must

achieve specications before shipment.

We are committed to providing our customers only pumps that meet this

high quality standard.

While our pumps cannot eliminate all of your work, we design, manufacture and test them to ensure that they will be an effective and trouble-free

tool to assist you in that work.

Yours,

VACUUBRAND GMBH + CO KG

After sales service:

Contact your local dealer or call +49 9342 808-5500.

Trademark index:

VACUU•LAN® (US-Reg.No 3,704,401), VACUU•BUS®, VACUU•CONTROLTM,

chemistry-HYBRIDTM, Peltronic®, TURBO•MODETM, VARIO® (US-Reg.No

3,833,788), VARIO-SPTM, VACUUBRAND® (US-Reg.No 3,733,388) and also

the shown company logos are trademarks of VACUUBRAND GMBH +

CO KG in Germany and/or other countries.

page 3 of 68

Contents

Safety information! ........................................................................4

Important information! ...................................................................................... 4

General information .......................................................................................... 6

Intended use..................................................................................................... 6

Setting up and installing the system ................................................................. 7

Ambient conditions ........................................................................................... 8

Operating conditions ........................................................................................ 9

Safety during operation .................................................................................. 10

Maintenance and repair.................................................................................. 13

Technical data .............................................................................. 15

Wetted parts .................................................................................................. 17

System parts ................................................................................................. 18

Use and operation .......................................................................21

First steps: Installation ................................................................................... 21

Operation BVC control / BVC control G ........................................................ 22

Operation BVC professional / BVC professional G ....................................... 24

Level sensor of BVC professional / BVC professional G............................... 26

During operation ............................................................................................ 28

Filtration ......................................................................................................... 29

Filter and collection bottle.............................................................................. 31

Disinfection routine ........................................................................................ 33

Cleaning and decontaminating ..................................................35

Adjustment of the BVC level sensor to work properly

with a new bottle, or to correct false alarms.............................38

Assembling of components .......................................................42

Replacing the lter ......................................................................................... 42

Assembling a second VHC

Assembling quick coupling bottle - pump unit .............................................. 45

Assembling a hose nozzle at the bottle head of the BVC ............................. 46

Quick coupling sets ....................................................................................... 47

pro

connection set ................................................ 43

Accessories - spare parts ...........................................................48

Troubleshooting ..........................................................................50

Replacing diaphragms and valves.............................................52

Cleaning and inspecting the pump heads ..................................................... 54

Replacing the diaphragm .............................................................................. 56

Assembling the pump head ........................................................................... 58

Replacing the fuse......................................................................................... 61

Notes on return to the factory .................................................... 62

Health and safety clearance form ..............................................65

EC Declaration of Conformity of the Machinery .......................... 67

page 4 of 68

Safety information!

Important information!

+ Keep this manual complete and accessible to per-

sonnel at all times!

+ Read this manual carefully before installing or op-

erating the equipment. Observe the instructions

contained in this manual.

+ Do not modify the equipment without authorization.

NOTICE

This manual is an integral part of the equipment described therein. It describes the safe and proper use

of the vacuum pump.

Make operating personnel aware of dangers arising

from the pump and the pumped substances.

VACUUBRAND disclaims any liability for inappropriate use of these pumps and for damage from failure

to follow instructions contained in this manual.

This manual is only to be used and distributed in its complete and original form. It is strictly the users’ responsibility

to check carefully the applicability of the guidance in this

manual with respect to his product.

Manual-no.: 999263/ 09/04/2014

The following signal word panels and safety

symbols are used throughout this manual:

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury and death.

page 5 of 68

➨ DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

+ WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

• CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to per-

sonal injury.

Caution! Hot surface!

Disconnect equipment from AC power.

Formatting used in this manual:

Note: The signal word panels in all sections of this manual always refer

to all paragraphs of the same format (➨ / + / • / plain text) following each

signal word panel.

The document ”Safety information for vacuum equipment” is

part of this manual! Read the ”Safety information for vacuum

equipment” and observe the instructions contained therein!

page 6 of 68

General information

+ Read and comply with this manual before installing

or operating the equipment.

+ Before operating the equipment read and comply

with the section ”Cleaning and decontamination”!

NOTICE

Remove all packing material, remove the product from its

packing-box, remove the protective covers from the inlet

and outlet ports and keep, inspect the equipment.

If the equipment is damaged, notify the supplier and the

carrier in writing within three days; state the item number of the product together with the order number and the

supplier’s invoice number. Retain all packing material for

inspection.

Do not use the equipment if it is damaged.

Lift and transport the equipment at the provided handle.

Intended use

+ Prevent any part of the human body from coming in

contact with the vacuum.

+ Make sure that the individual components are only con-

nected, combined and operated according to their design and as indicated in the instructions for use. Use

only original VACUUBRAND accessories.

+ Comply with notes on correct vacuum and electrical

connections, see section ”Use and operation”.

• The systems are designed for ambient temperatures

during operation between +10°C and +40°C. Check

the maximum temperatures if installing the system in a

cabinet or a housing and make sure ventilation is adequate. Install an external automatic ventilation system

if necessary.

page 7 of 68

NOTICE

Ensure that the equipment and all components are suitable for the intended application. Use the system only for

aspiration of liquids and ltration.

Setting up and installing the system

➨ Equipment must be connected only to a suitable elec-

trical supply and a suitable ground point. Failure to

connect the motor to ground may result in deadly electrical shock.

The supply cable may be tted with a molded Euro-

pean IEC plug or a plug suitable for your local electrical supply. If the plug has been removed or has to be

removed, the cable will contain wires color coded as

follows: green or green and yellow: earth; blue or white:

neutral; brown or black: live. The device has an internal

fuse.

+ Do not permit any uncontrolled pressurizing (e.g., make

sure that an exhaust tubing cannot become blocked).

Risk of bursting!

+ Due to the high compression ratio of the pumps, pres-

sure at the outlet port may be generated that is higher

than the maximum permissible pressure compatible

with the mechanical stability of the system.

+ Always provide a free and pressureless exhaust line.

• Comply with maximum permissible pressures and

pressure differences; see section ”Technical data”. Do

not operate the pumping unit with overpressure at the

inlet or outlet.

• Check that line voltage and current conform with the

equipment. (See rating plate.)

• Avoid overpressure of more than 0.2 bar in instances in

which inert gas is connected.

page 8 of 68

NOTICE

Provide a rm level platform for the equipment. Ensure a

stable position of the pump without any mechanical contact except of the pump feet. Comply with all applicable

safety regulations.

Check fan regularly for dust/dirt, clean if necessary to

avoid reduced ventilation. Avoid high heat supply. If the

equipment is brought from cold environment into a room

for operation, allow the equipment to warm up. (Watch for

water condensation on cold surfaces.)

The diameter of the an outlet tubing should be at the least

as large as the diameter of the pump connections.

Comply with all applicable and relevant safety requirements (regulations and guidelines), implement the re-

NOTICE

quired actions and adopt suitable safety measures.

Ambient conditions

To the best of our knowledge the equipment is in compliance with the requirements of the applicable EC-directives and harmonized standards (see ”Declaration of conformity”) with regard to design, type and model, especially

directive DIN EN 61010-1. This directive gives, in detail,

conditions, under which the equipment can be operated

safely (see also IP degree of protection).

Adopt suitable measures in case of differences, e. g. using the equipment outdoors, installation in higher altitudes,

conductive pollution or bedewing.

Pay attention to the permissible maximum ambient

temperatures (see ”Technical data”).

page 9 of 68

Operating conditions

➨ The devices have no approval for operation in or

for pumping of potentially explosive atmospheres.

➨ The devices are not suitable to pump:

- unstable substances and substances which react

explosively under impact (mechanical stress) and/

or when being exposed to elevated temperatures

without air,

- self inammable substances,

- substances which are inammable without air and

- explosive substance

➨ The pumps have no approval for operation below

ground.

+ The pumps are not suitable for pumping dust.

• The devices are not suitable for pumping substances

which may form deposits inside the pump. Deposits

and condensate in the pump may lead to increased

temperatures even to the point of exceeding the maximum permitted temperatures! Increased temperatures

may cause ignition of inammable substances that may

have been deposited inside the pump during use.

• If there is a danger of the formation of deposits in the

pump chamber (check inlet and outlet of the pump), inspect the pump chamber regularly and clean if neces-

sary.

• Take into consideration interactions and chemical

reactions of the pumped media.

• Ensure that the materials of the wetted parts are com-

NOTICE

patible with the pumped substances, see section ”Technical data”.

If pumping different substances, it is recommended that

the pump be purged with air or inert gas prior to changing the pumped media in order to pump out residues and

to avoid reactions of the pumped substances with each

other and with the pump materials.

page 10 of 68

Safety during operation

➨ Avoid interactions of the media in the collection bottle

absolutely.

Comply with material safety data sheets and notes on

safe use of the manufacturer.

Do not mix incompatible disinfectants and/or in-

compatible reagents / solvents as well as unknown

substances.

For example sodium hypochlorite (chlorine bleach)

Incompatible chemicals and

agents

Acids or acidic compounds

(e. g. hydrochloric acid,

aluminium chloride)

Ammonia containing compounds

(e. g. ammonium hydroxide,

quarternary ammonium salts)

Organic chemicals

(e. g. solvents, polymers,

amines, oils)

Metals (e. g. copper, iron)

Hydrogen peroxide

Reducing agents

(e. g. sodium thiosulfate)

Possible results of mixing with

chlorine bleach

Release of chlorine gas

Formation of explosive compounds,

release of chlorine gas and other

hazardous gases

Formation of chlorinated organics,

release of chlorine gas and other

hazardous gases

Release of oxygen, overpressure,

rupture of a closed system

Production of heat, boiling

Guanidine salts

(e. g. guanidine hydrochloride,

guanidine thiocyanate)

➨ Avoid the formation of dangerous reactions / gases in

the BVC, especially in the collection bottle. If this is impossible dispose of dangerous gases at the outlet of

the pump appropriately.

Release of toxic gases, e. g. chlorine, chloramine, hydrogen cyanide

page 11 of 68

➨ Adopt suitable measures to prevent the release of dan-

gerous, toxic, explosive, corrosive, noxious or polluting

uids, vapors and gases. In such cases, install an appropriate collecting and disposal system and take protective action for pump and environment.

➨ If the equipment is used in combination with hazardous

materials (e. g., in medical-microbiological laborato-

ries) check all relevant safety and health requirements

and determine the applicability of regulatory limitations

prior to use if necessary.

➨ Use appropriate safety work materials and methods if

necessary, e. g., steam sterilization, sterilization indicators or germicides. For notes concerning the sterilization of wetted parts, see the “Technical Data” section

and “Cleaning and decontaminating”. It is the user´s

responsibility to ensure effective sterilization.

➨ Never operate a defective or damaged device.

➨ The user must take suitable precautions to prevent any

formation of explosive mixtures in the expansion chamber or in the housing. In case of a diaphragm crack, for

example, mechanically generated sparks, hot surfaces

or static electricity may ignite these mixtures. Use inert

gas for venting if necessary.

➨ Potentially explosive mixtures at the outlet of the pump

have to be drained appropriately evacuated, or diluted

with inert gas to non-explosive mixtures.

+ Check the collection bottle regularly for cracks. Do nev-

er use a collection bottle with cracks nor expose it to

vacuum.

+ Use the system only in combination with the integrated

hydrophobic lter (sterilizable) to protect pump and environment (people).

page 12 of 68

+ Comply with applicable regulations when disposing of

chemicals. Take into consideration that chemicals may

be polluted. Take adequate precautions to protect people from the effects of dangerous substances (chemicals, thermal decomposition products of uoroelastomers), wear appropriate safety-clothing and safety

glasses.

+ Use only OEM spare parts and accessories; other-

wise safety and performance of the equipment as well

as the electromagnetic compatibility of the equipment

might be reduced.

The CE mark or the cTUVus mark (see rating plate)

may become void if original equipment manufacturer

NOTICE

parts are not used.

+ In case of leaks in the manifold, aspirated substances

might be released into the environment. Comply especially with notes on operation and use and mainte-

nance.

+ Due to the residual leak rate of the equipment, there

may be an exchange of gas, albeit extremely slight, between the environment and the vacuum system.Adopt

suitable measures to prevent contamination of the

pumped substances or the environment.

Maximum liquid level in collection bottle: approx. 80

%, depending on the application. (When working with lowboiling liquids, or liquids that tend to foam, the maximum

liquid level might be reduced).

Ensure that, in case of failure, the system will always return to a safe status. Provide appropriate protective measures (i.e., precautions which allow for the requirements

of the respective application) even for the case of failure

and malfunction. When operating the pump, the loss of

pumping or venting must not lead to a critically dangerous

situation under any circumstances.

page 13 of 68

NOTICE

Electronic equipment is never 100% fail-safe. This may

lead to an indenite status of the equipment. Failure of the

pumping unit (e. g., by power failure) or connected components, or change of parameters must not lead to a critically

dangerous situation under any circumstances. In case of

diaphragm cracks or leaks in the manifold, pumped substances might be released into the environment or into the

pump housing. Comply especially with notes on operation

and use and maintenance.

• Pay attention to the safety symbol ”hot surfaces” on

the equipment. Hot parts may cause burns if touched.

Adopt suitable measures to prevent any danger arising

from hot surfaces or electric sparks. Ensure that hot

surfaces of the pump do not cause burns. Provide a

suitable contact guard if necessary.

In case of overload, the motor is shut down by a self-hold

thermal cutout in the winding. Attention: Reset possible

only manually. Switch off the pump or isolate the equipment from power supply. Identify and eliminate the cause

of failure. Wait approx. ve minutes before restarting the

pump.

• Attention: In case of supply voltage below 100V (100-

120V version), the lock of the cutout might be restricted

and the pump might restart on its own after sufcient

cooling down. Take suitable precautions if an automatic

restart of the pump may lead to a critical dangerous

situation.

Maintenance and repair

NOTICE

Wear parts have to be replaced regularly. Under typical operating conditions, the projected lifetime of the diaphragms and valves is > 15000 operating hours. Bearings

have a typical durability of 40000 h. Motor capacitors have

a typical durability in the range of 10000 to 40000 h depending strongly on the operating conditions like ambient

temperature, humidity or load.

page 14 of 68

➨ Never operate the pump if covers or other parts of the

pump are disassembled. Ensure that the pump cannot

be operated accidentally.

➨ Isolate equipment from power supply before re-

moving the cover!

➨ Before starting maintenance, unplug the equipment and

wait 5 seconds to allow the capacitors to discharge.

➨ Attention: The pump might be contaminated with nox-Attention: The pump might be contaminated with nox-

ious or otherwise dangerous process chemicals that

have been pumped during operation. Ensure that the

pump is decontaminated before maintenance.

+ Take adequate precautions to protect people from the

effects of dangerous substances if contamination has

occurred. Wear appropriate safety-clothing when you

come in contact with contaminated components.

+ Wear parts have to be replaced regularly.

+ Never operate a defective or damaged pump.

+ Check every motor capacitor regularly by measuring its

capacity and estimating its operation time. Exchange

old capacitors early enough to prevent a failure. When

motor capacitors fail, they can get hot enough to melt

or cause a ame which could be dangerous for per-

sons and equipment in the vicinity. Motor capacitors

have to be replaced by an electrician.

+ Before starting maintenance, vent the system and al-Before starting maintenance, vent the system and al-

low sufcient cooling of the pump. Drain condensate, if

applicable. Avoid the release of pollutants.

NOTICE

Ensure that maintenance is done only by suitably trained

and supervised technicians. Ensure that the maintenance

technician is familiar with the safety procedures which relate to the products processed by the pumping system.

In order to comply with law (occupational, health and safety regulations, safety at work law and regulations for environmental protection) vacuum pumps, components and

measuring instruments returned to the manufacturer can

be repaired only when certain procedures (see section

”Notes on return to the factory”) are followed.

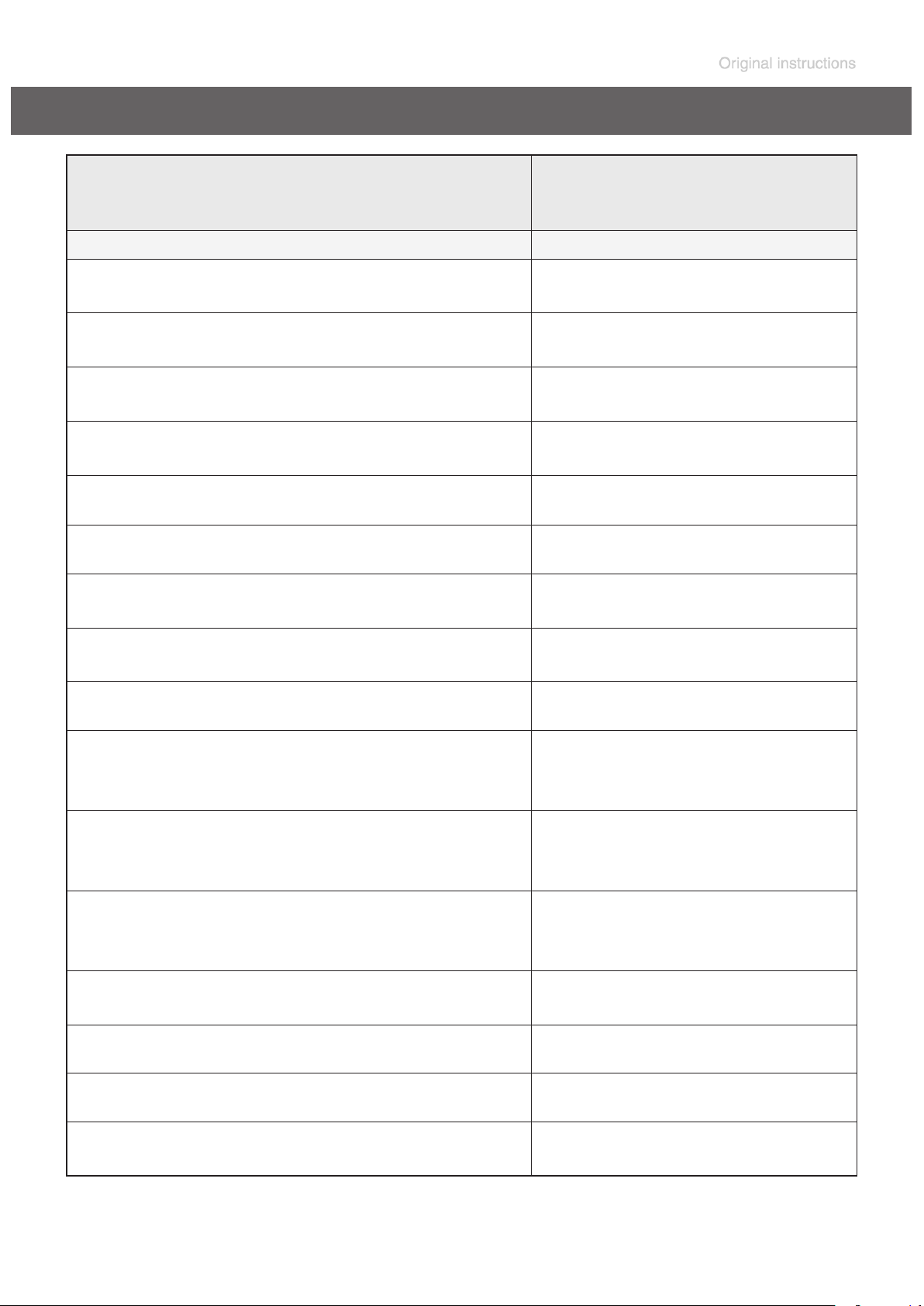

Technical data

page 15 of 68

Type

BVC control / G

BVC professional / G

Pump

Maximum pumping speed

(ISO 21360) at 50/60 Hz

Ultimate vacuum (absolute)

Maximum permissible inlet pressure

(absolute)

Maximum permissible outlet pressure

(absolute)

Rated power

No-load speed 50/60 Hz rpm 1500 / 1800

Control range

cfm

(m3/h)

Torr

(mbar)

psi

(bar)

psi

(bar)

hp

(kW)

Torr

(mbar)

0.4/ 0.5

(0.7 / 0.85)

112

(150)

16

(1.1)

16

(1.1)

0.054

(0.04)

112 - 637

(150 - 850)

Permissible ambient temperature

storage / operation

Maximum installation altitude m 2000 above mean sea level

Permissible relative atmospheric

moisture during operation

(no condensation)

Maximum permissible range of supply

voltage: Attention: Observe speci-

cations of rating plate!

Rated current at:

100-120 V~ 50/60 Hz

230 V~ 50/60 Hz

Fuse

Motor protection thermal cutout

°F

(°C)

% 30 to 85

A

A

14 to 140 / 50 to 104

(-10 to +60 / +10 to +40)

100-120 V~ ±10% 50/60 Hz

230 V~ ±10% 50/60 Hz

1.9 / 1.4

0.7 / 0.5

2 x 2.5 AT, 0.19 x 0.78 in

(5 x 20 mm)

Degree of protection IEC 529 IP 40

A-weighted emission sound pressure

level* (uncertainty KpA : 3 dB(A))

* Measurement according to EN ISO 2151:2004 and EN ISO 3744:1995 at 230V/50Hz and ulti-

mate vacuum with exhaust tube at outlet.

dB(A) 45

page 16 of 68

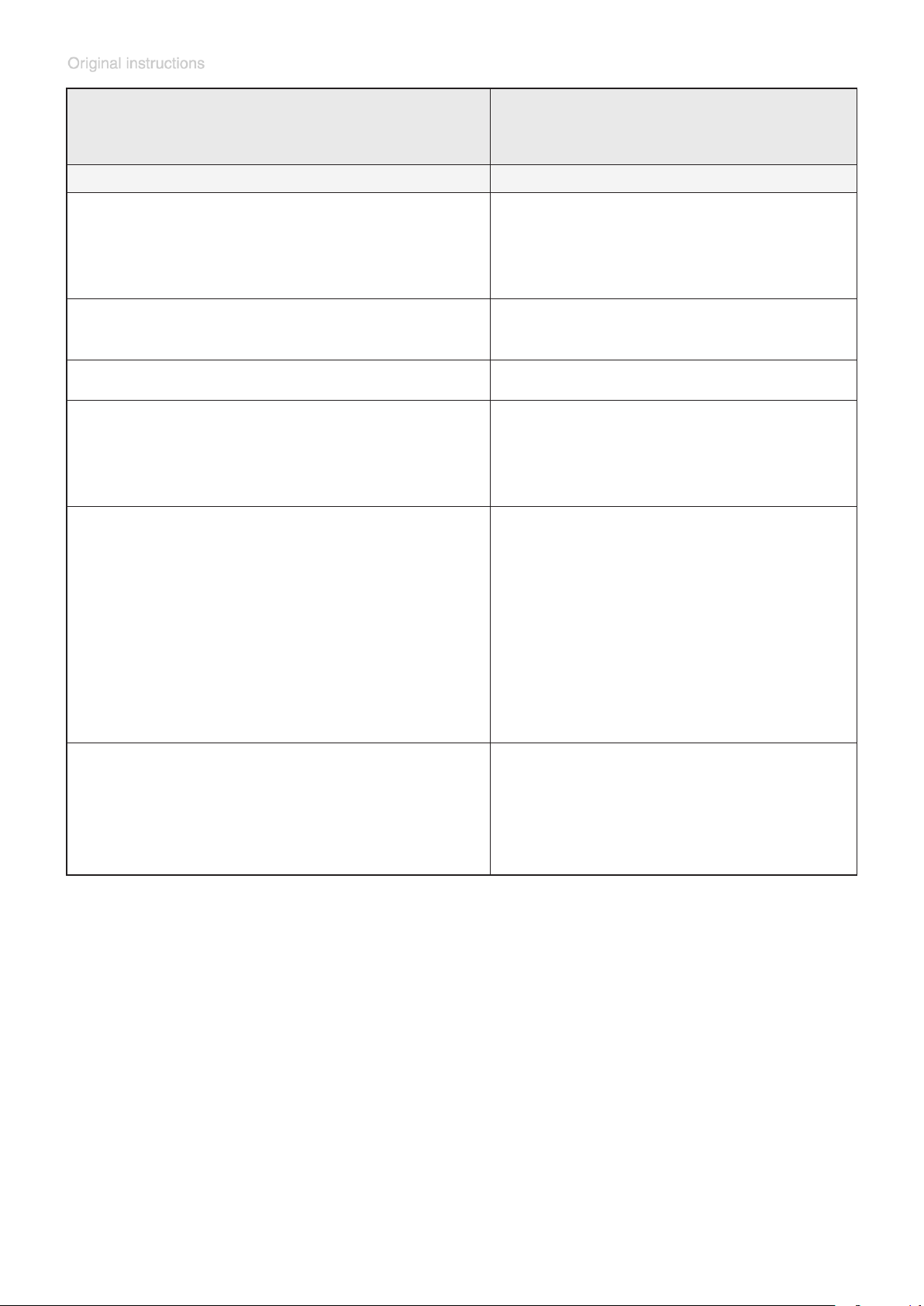

Type

gal

Volume of collection bottle

Connection at the inlet hose nozzle DN 3/5mm

Connection at the outlet hose nozzle DN 8 mm / silencer

Hydrophobic lter

Type

Manufacturer

Nominal pore diameter

Dimensions L x W x H approx.

BVC control

BVC control G

BVC professional

BVC professional G

BVC control

BVC control G

BVC professional

BVC professional G

(mm)

(mm)

(mm)

(mm)

1 (polypropylene) / 0.5 (borosilicate

(l)

(4 (polypropylene) / 2 (borosilicate

in

in

in

in

BVC control / G

BVC professional / G

System

glass)

glass))

Midisart® 2000

Sartorius stedim

0.2 µm

16.1 x 7.6 x 19.7

16.1 x 7.6 x 16.9

16.1 x 7.6 x 19.7

16.1 x 7.6 x 16.9

(408 x 194 x 500)

(408 x 194 x 430)

(408 x 194 x 500)

(408 x 194 x 430)

Weight approx.

BVC control / professional

BVC control G / professional G

BVC control / professional

BVC control G / professional G

lbs.

lbs.

(kg)

(kg)

16.1 (230V) / 17.0 (120V)

17.0 (230V) / 17.9 (120V)

(7.3 (230V) / 7.7 (120V))

(7.7 (230V) / 8.1 (120V))

We reserve the right for technical modications without prior notice!

page 17 of 68

Wetted parts

Components Wetted materials

Pump

Housing cover insert PTFE, carbon reinforced

Head cover ETFE, carbon bre reinforced

Diaphragm clamping disc ETFE, carbon bre reinforced

Diaphragm PTFE

Valve PTFE / FFKM

Inlet ETFE

Outlet ETFE

Silencer silicone rubber

Filter

Diaphragm PTFE

Housing PP

Tubing silicone rubber

Collection bottle 4l

Bottle / screw cap PP

Hose nozzle at bottle head (connection

pro

VHC

)

PP

Hose in bottle PTFE

Hose nozzle (connection lter) PPS, glass bre reinforced

Counter nut PP

Closing screw PPS, glass bre reinforced

Collection bottle 2l

Bottle Borosilicate glass

Cap insert PP

Flat seal EPDM

Hose nozzle at bottle head (connection

pro

VHC

)

PP

Hose in bottle PTFE

Hose nozzle (connection lter) PPS, glass bre reinforced

Closing screw PPS, glass bre reinforced

We reserve the right for technical modications without prior notice!

page 18 of 68

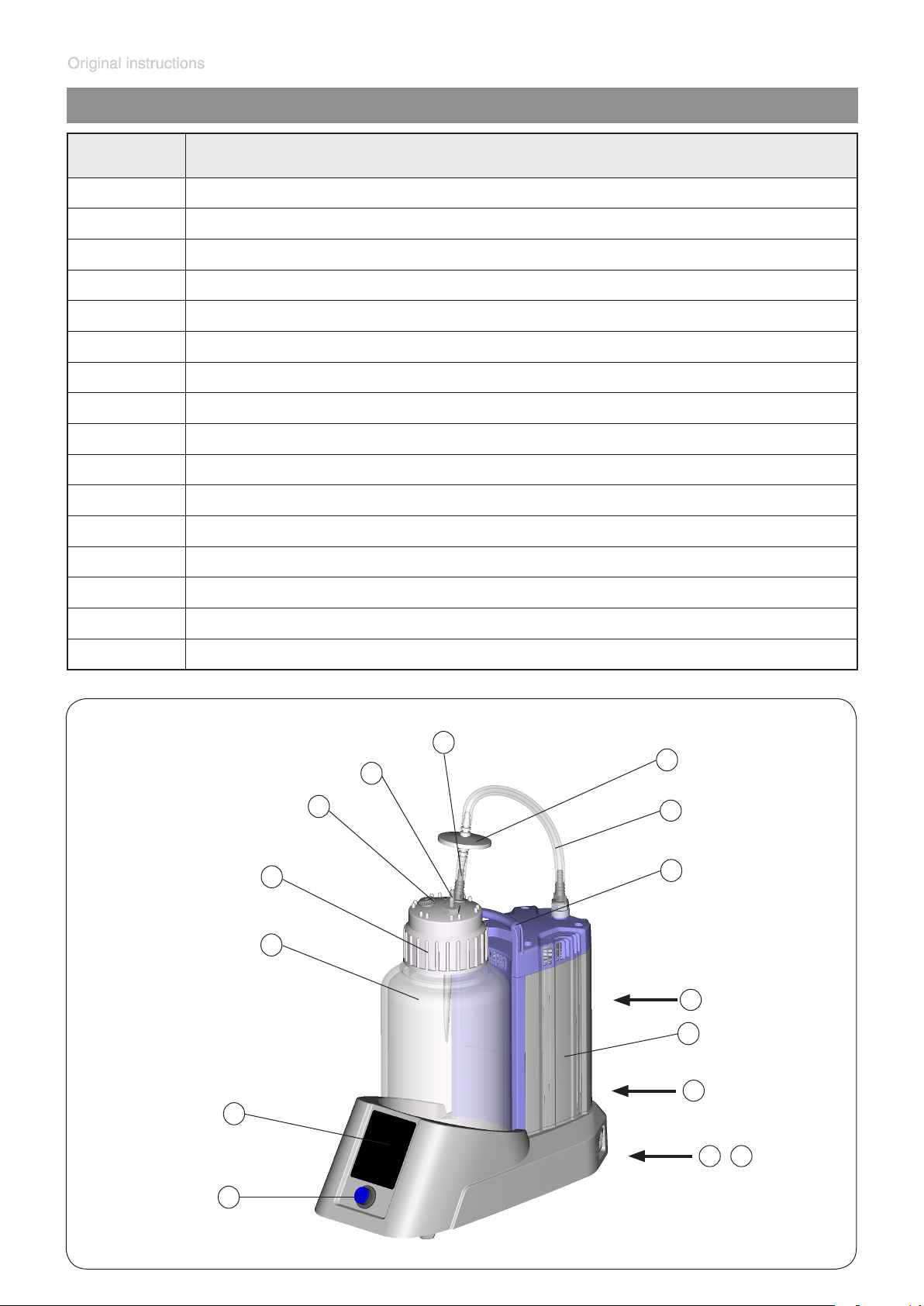

System parts

Position Designation

1 Pump ME 1C

2 Mains connection

3 Fuse holder

4 On / Off switch

5 Touch panel

6 Rating plate

7 Outlet

8 Connection tubing

9 Hydrophobic protection lter

10 Connection lter

11 Connection VacuuHandControl VHC

12 Closing screw (optional: connection second VHC

pro

pro

)

13 Screw cap / bottle cap with insert

14 Collection bottle

15 Handle

16 Level sensor

BVC control

13

14

12

10

9

11

8

15

7

1

6

5

2

3

4

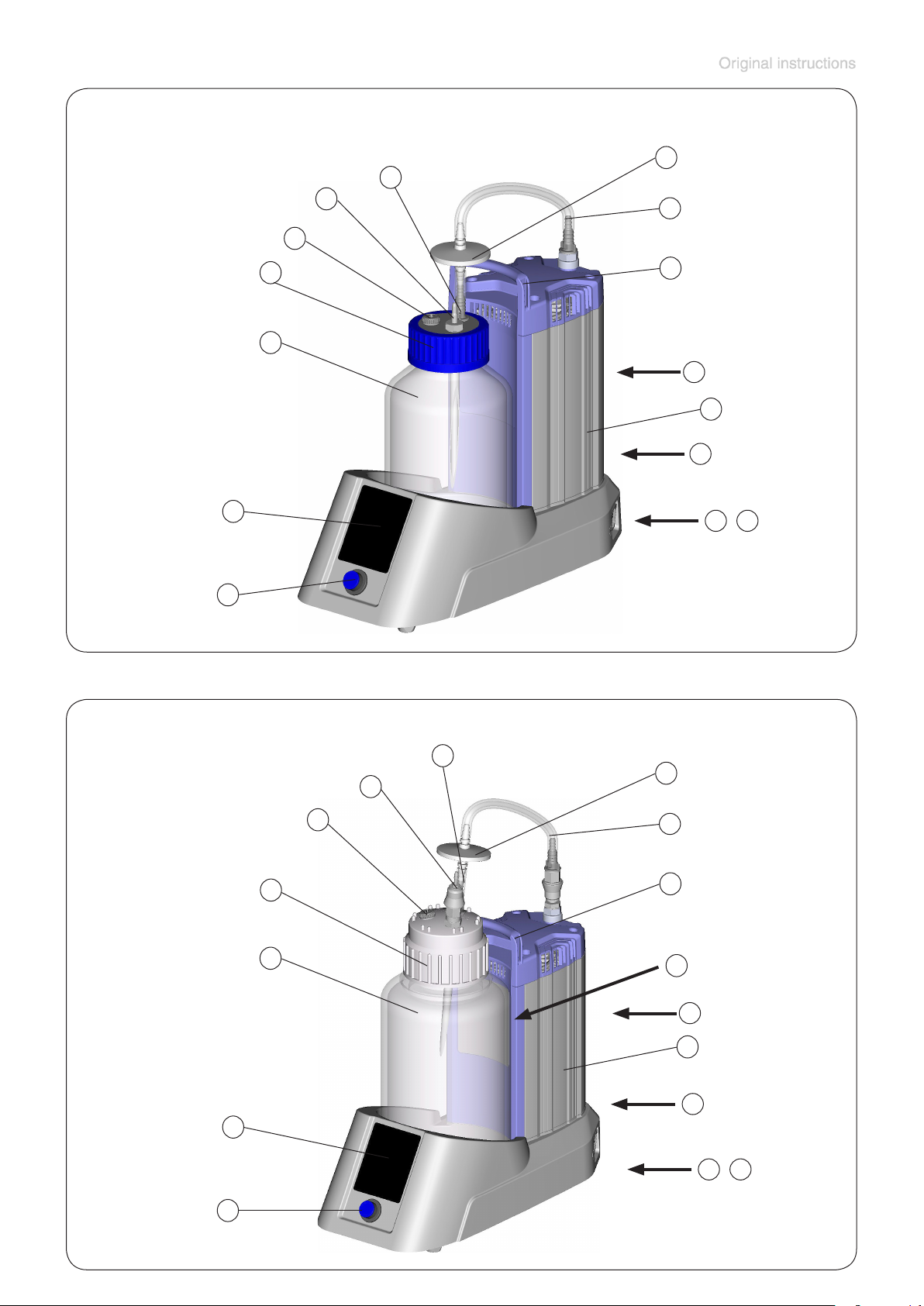

BVC control G

12

11

page 19 of 68

9

10

8

13

14

5

4

15

7

1

6

2

3

BVC professional

13

14

5

12

11

10

9

8

15

16

7

1

6

2

3

4

BVC professional G

12

11

page 20 of 68

9

10

8

13

14

5

4

15

16

7

1

6

2

3

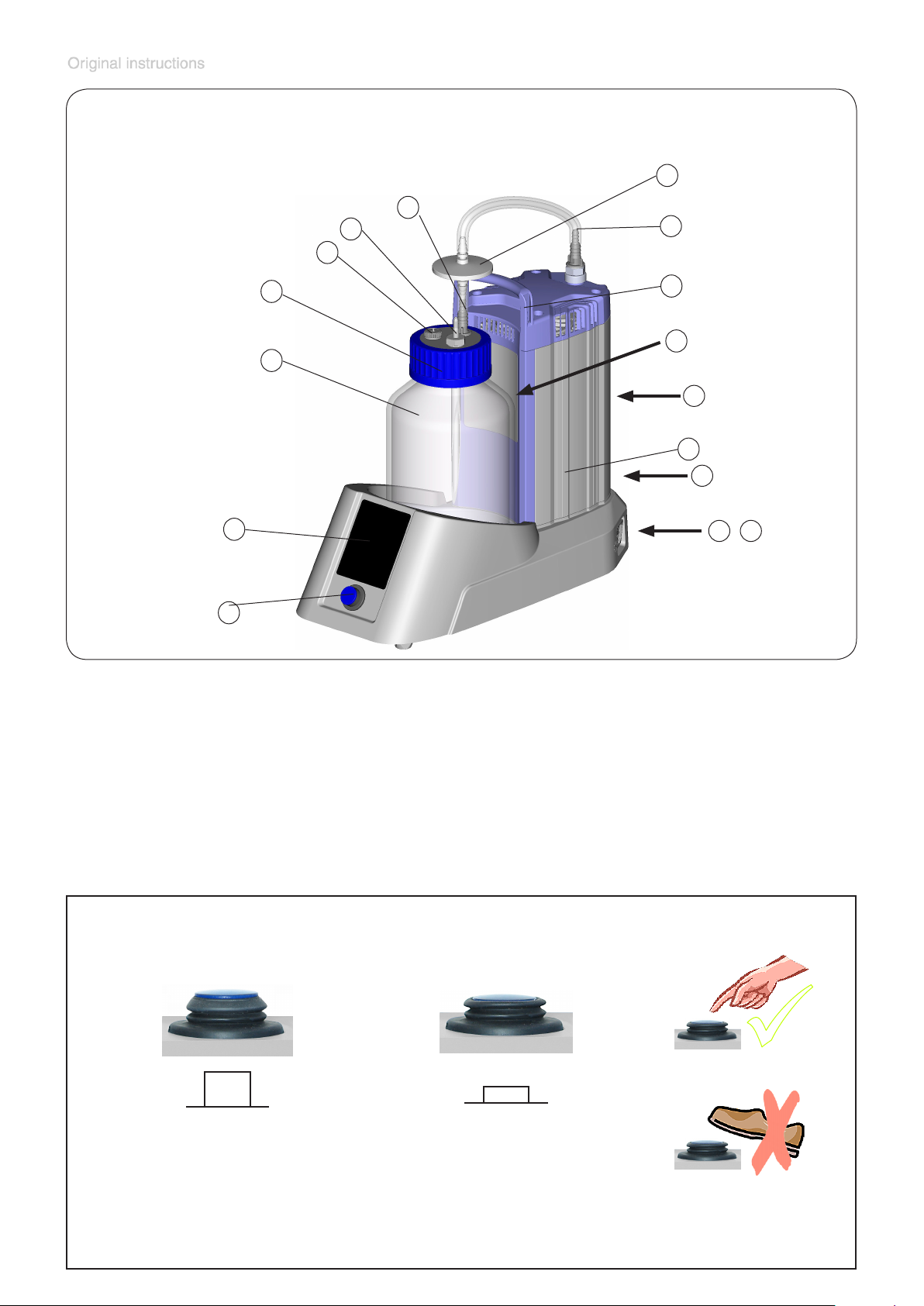

On / Off switch

System switched off

System switched on

Attention: Operate the on/off switch only by hand.

Use and operation

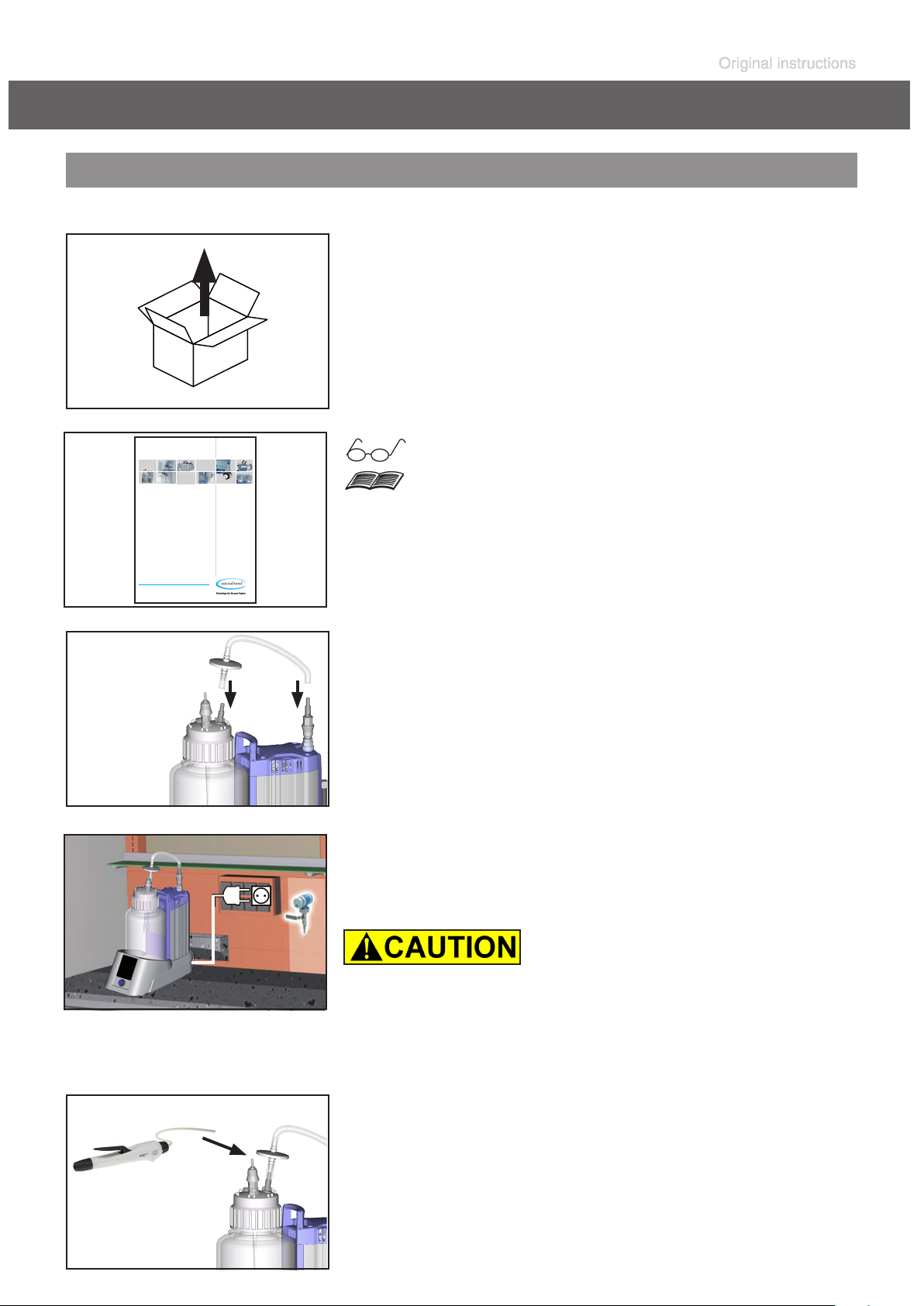

First steps: Installation

Unpack the equipment.

Safety information

for vacuum equipment

Sicherheitshinweise für Vakuumgeräte

DE

Safety information for vacuum equipment

EN

Avis de sécurité pour des dispositifs à vide

真空设备的安全信息

Sikkerhedsregler for vakuumudstyr

Ohutusnõuded vaakumseadmetele

Vakuumilaitteen turvallisuustiedot

Υποδείξεις ασφάλειας για αντλίες κενού

Sigurnosne napomene za vakuumske uređaje

真空装置を安全に取り扱うために

진공 장비에 대한 안전 정보

Vakuuminės įrangos saugos informacija

Vakuuma iekārtu drošības noteikumi

Säkerhetsinformation för vakuumutrustning

Varnostni nasveti za vakuumske naprave

Vakumlu cihazlar için güvenlik uyarıları

FR

BG

CN

CZ

DA

EE

ES

FI

GR

HR

HU

IT

JP

KR

LT

LV

NL

PL

PT

RO

RU

SE

SI

SK

TR

1

Read and comply with the document ”Safety

information for vacuum equipment - Sicher-Sicherheitshinweise für Vakuumgeräte”!

Указания за безопасност за вакуумни уреди

Bezpečnostní upozornění pro vakuové přístroje

Notas sobre la seguridad para equipos de vacío

A vákuum-készülékekkel kapcsolatos biztonsági tudnivalók

Istruzioni di sicurezza per apparecchi a vuoto

Veiligheidsvoorschriften voor vacuümapparaten

Wskazówki bezpieczeństwa do urządzeń próżniowych

Informação de Segurança para Equipamento que funciona a Vácuo

Instrucţiuni de siguranţă pentru aparatele de vidare

Указания по технике безопасности при работе с вакуумными устройствами

Bezpečnostné pokyny pre vákuové zariadenia

page 21 of 68

Assemble tubing with lter.

Setting up the BVC.

Connect to power supply.

Check line voltage and current prior to

switching on!

Attach tubing of the VacuuHandControl VHC

to the hose nozzle of the bottle head.

pro

Loading...

Loading...