Page 1

Sentinel

Installation Manual

Unitec

443-561-1200 • www.StartwithUnitec.com

Page 2

SENTINEL

SENTINEL INSTALLATION MANUAL

Revision A

This manual provides comprehensive installation procedures for the Sentinel. It

includes the process of site planning, site preparation, the mechanical installation of

the SentineI and the electrical wiring of the unit.

If further assistance is needed, please contact the distributor from which the Sentinel

was purchased.

When calling for assistance, you must have the following information available:

Sentinel Serial Number:

Distributor Name:

DECLARATION OF COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cau se harmful interference

in which case the user will be required to correct the interference at his own expense.

COPYRIGHT

© 2012 Unitec, Incorporated. All rights reserved. No part of this book, including text,

screen examples, diagrams, or icons, may be reproduced or transmitted in any form,

by any means (electronic, photocopying, recording, or otherwise) without prior written

permission of Unitec, Incorporated.

TRADEMARKS

Sentinel, Unitec, and the Unitec Logo are trademarks, service marks, or registered

trademarks of Unitec, Incorporated.

All other products, services, and company names are trademarks or registered

trademarks of their respective owners.

Document Number: SENT1001

Document Name: Sentinel Installation Manual

Page 3

SENTINEL

Table of Contents

1 Site Planning and Preparation ......................................................................................................1

1.1 Introduction............................................................................................................................1

1.2 Positioning the Sentinel.........................................................................................................2

1.2.1 In-Bay Applications ......................................................................................................................2

1.2.2 Express Wash Applications..........................................................................................................2

1.3 Electrical Preparation.............................................................................................................4

1.3.1 Conduit Installation.......................................................................................................................4

1.3.2 Power Requirements....................................................................................................................5

1.3.3 Site Wiring Requirements ............................................................................................................5

2 Mechanical Installation..................................................................................................................7

2.1 Hardware Required................................................................................................................7

2.2 Recommended Tools.............................................................................................................7

2.2.1 Mechanical Installation Tools.......................................................................................................7

2.3 Base Installation ....................................................................................................................8

2.4 Mounting the Sentinel............................................................................................................9

3 Electrical Installation....................................................................................................................10

3.1 Hardware Required..............................................................................................................10

3.2 Recommended Tools...........................................................................................................10

3.3 General................................................................................................................................10

3.4 Connecting Power ...............................................................................................................11

3.5 Network Connection ............................................................................................................12

3.6 Wash Control Wiring............................................................................................................13

3.6.1 Overview....................................................................................................................................13

3.6.2 Wiring the Wash Relay Interface................................................................................................13

3.6.3 Wiring the Wash-In-Use Interface..............................................................................................14

3.7 Intercom Systems................................................................................................................16

3.7.1 Overview....................................................................................................................................16

3.7.2 Intercom Connections................................................................................................................16

3.7.3 Intercom Adjustments................................................................................................................16

3.7.4 Connection Overview.................................................................................................................16

3.8 Camera Connection.............................................................................................................17

3.9 Gate Wiring..........................................................................................................................17

3.10 Connecting the Reach Free ID Option..............................................................................17

4 System Startup .............................................................................................................................18

5 System Test...................................................................................................................................18

Document Number: SENT1001 i

Document Name: Sentinel Installation Manual

Page 4

SENTINEL

Appendix A. Sentinel Base - Bo ttom Up View..............................................................................20

Appendix B. Sentinel Networking..................................................................................................21

Appendix C. POS Interface External POS Option.........................................................................27

Index of Figures

Figure 1. Express Exterior Island....................................................................................................3

Figure 2. Conduit Runs...................................................................................................................4

Figure 3. Bottom View of Base .......................................................................................................5

Figure 4. Top Plate of Base Frame..................................................................................................8

Figure 5. Sentinel Base with Mounting Plates ................................................................................9

Figure 6. Sentinel Interior............................................................................................................. 11

Figure 7. Neutral - Ground – Line Connections........................................................................... 12

Figure 8. 6-Pin Phoenix Connector..............................................................................................15

Figure 9. BNC Male Plug for Camera Connection........................................................................17

Document Number: SENT1001 ii

Document Name: Sentinel Installation Manual

Page 5

SENTINEL

1 Site Planning and Preparation

1.1 Introduction

This chapter provides guidelines for planning the Sentinel installation and preparing the site. Site

preparation includes:

• Determining how and where the Sentinel will be mounted

• Installing conduit runs and required wiring

These instructions serve as general guidelines only. If your wash manufacturer’s installation requirements

differ from these guidelines, always meet the wash manufacturer’s r equirements first.

Requirements specified in local electrical and building codes must be followed and shall take precedence

over the guidelines provided within this document. All units should be installed by a professiona l electr ician

ONLY.

The Sentinel is rated for the following environmental specifications:

• Temperature: -20° F to 115° F

• Humidity: 0% to 100%

The following symbol is used in the Sentinel:

This symbol represents the presence of earth-grounded eq uipment.

Document Number: SENT1001 1

Document Name: Sentinel Installation Manual

Page 6

SENTINEL

1.2 Positioning the Sentinel

1.2.1 In-Bay Applications

For in-bay automatics and other applications where the Sentinel is installed at the wa sh entrance, it should

be placed 10’-14’ from the wash to ensure the proper timing and flow of custom ers.

For curb mount applications, the front surface of t he Sentinel sh ould be even with the edge of the curb. To

achieve this dimension, the base frame should be installed so its leading edge is 7 in. fr om the edge of the

curb.

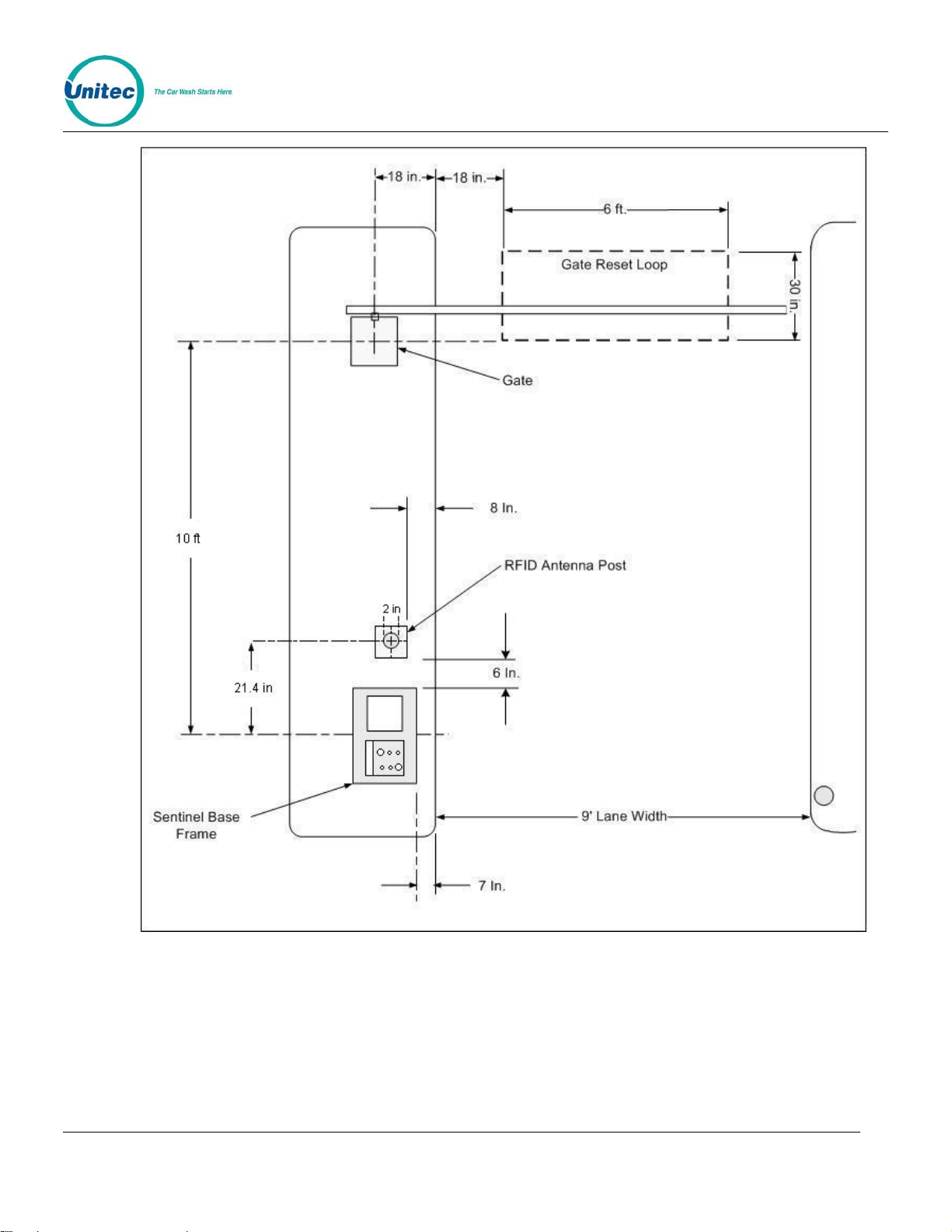

1.2.2 Express Wash Applications

Express Exterior sites should be designed to provide 9 ft. wide traffic lanes at the Sentinels. The traffic

control (or barrier) gate should be located approximately 10 ft. from the center of the Sentinel and an

underground vehicle detection loop is required under the gate arm. In some cases, it may be desirable to

install a 2

the vehicle queue.

If the Unitec Reach Free ID (RFID) option is included, the RF Antenna should be located adjacent to the

Sentinel.

(antenna) option. Refer to the installation instructions provide d with the gate and RFID option for guidance

in installing these devices.

nd

loop between the gate and tunnel entrance (referred to as the merge loop) to proper ly manage

Figure 1 provides guidelines for the design of an Express lane with the Sentinel, gate and RFID

Document Number: SENT1001 2

Document Name: Sentinel Installation Manual

Page 7

SENTINEL

Figure 1. Express Exterior Island

Document Number: SENT1001 3

Document Name: Sentinel Installation Manual

Page 8

SENTINEL

1.3 Electrical Preparation

1.3.1 Conduit Installation

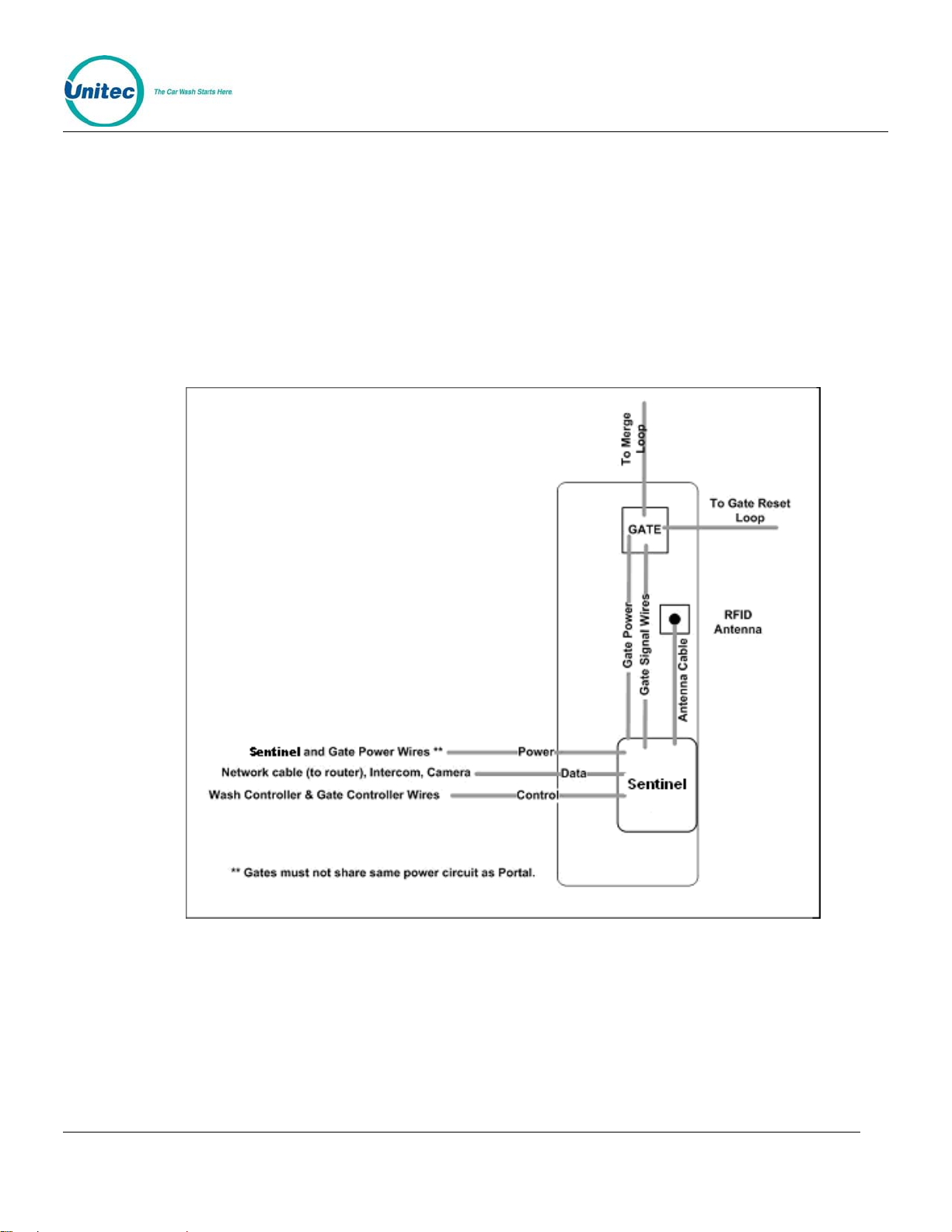

A typical installation will require 3 conduit runs for, power, data and wash control lines. DO NOT run data

wires in the AC Power or Wash Control conduits. Additional conduit runs may be needed when a gate or

the Sentinel RFID option are to be used. Conduit size should be at least ¾ in, a larger conduit may be

required depending on the quantity and gauge of wires to be installed. Refer to local and national

electrical codes to select the proper conduit type and size.

planning.

Figure 2 provides guidelines for conduit

Figure 2. Conduit Runs

Document Number: SENT1001 4

Document Name: Sentinel Installation Manual

Page 9

SENTINEL

Figure 3. Bottom View of Base

1.3.2 Power Requirements

The Sentinel requires 120 VAC, 8 Amps service. In applications where barrier gates are to be used, each

gate requires 120 VAC, 5 Amps service. The Sentinel and gate must be powered from se parate circuit s.

Ensure the protective earth ground wires do not carry any motor return current. Only

Note:

the neutral wire should carry retu rn current. Follow local electrica l code when wiring

the Sentinel. All units should be installed by a profe ssional ele ctrician ONLY.

1.3.3 Site Wiring Requirements

Wiring requirements will vary by site depending on the type of wash equipment and the Sentinel

configuration. The following table shows site wiring, which may be needed. As wires are pulled through

conduit, ensure there is at least 6 ft. of wire extending from the end of the conduit stu b.

Document Number: SENT1001 5

Document Name: Sentinel Installation Manual

Page 10

SENTINEL

Circuit Description Wire Qty Wire Requirements

Sentinel Power (115-120 VAC, 8 Amps). 3 16 AWG minimum, black/white/green

Gate Power (115-120 VAC, 5 Amps). 3 16 AWG minimum, black/white/green

Network connection (to router) 1 Cat 5 communications cable, 295 ft max length

Wash Signaling (required if the Sentinel will be

connected to the wash controller)

Intercom

(Required to interface with site intercom)

Camera

(Required for Sentinel camera option)

Gate Control – from gate controller to Sentinel

(Required if gate controller is use d)

Gate Control - from gate controller to gate

(Required if gate controller is use d)

Gate Control – from Sentinel to Gate

(Required if gate is used without gate controller)

RFID Option

(from RFID Antenna to Sentinel)

Varies

Refer to wash equipment manufacturer’s

instructions

4 22 AWG minimum

1 Type RG59/U coaxial cable

4 18 AWG minimum

3 18 AWG minimum

4 18 AWG minimum

1 Cable is supplied with RFID kit

Document Number: SENT1001 6

Document Name: Sentinel Installation Manual

Page 11

SENTINEL

2 Mechanical Installation

2.1 Hardware Required

Prior to beginning the installation, take the time to verify that all the following required parts are present

and accounted for.

Items supplied with the Sentinel:

• Allen Wrench For Door

• Key set for door

• Key set for vault door

• IEC-320-C14 Female AC Power Connector

Items supplied with the Base:

• (6) ½: Hex Nuts

• (6) ½” Flat Washers

• (6) ½” Lock Washers

2.2 Recommended T ools

2.2.1 Mechanical Installation Tools

The following tools are recommended for the typical mechanical installation of this Sentine l unit and base:

• ¾” deep well socket and socket wrench

• Open end 9/16” wrench

• Small, thin blade, flat-tip screwdriver

• Hammer

• Dual-plane Level

• 50’ foot tape measure

The following items may be required only when installing the Sentin el into a n existing concrete slab:

• 2.5” Concrete hammer drill bit

• Saw or Pipe cutter (capable of cutting 2 in. diamete r steel pipe)

Document Number: SENT1001 7

Document Name: Sentinel Installation Manual

Page 12

SENTINEL

2.3 Base Installation

Note:

The Sentinel base frame is designed to be embedded in a con crete pad , b u t ca n a lso be sur face mounted

in cases where concrete has already been poured. Unitec highly recommends that the base be

embedded into concrete, because using this method makes the unit more secure and less likely to be able

to be removed by a truck with a chain. Surface mounting is less secure.

In order to mount the base frame correctly, the conduit holes on the top plate of the base frame should be

located in the forward left position when the unit is facing the lane, as shown below, and in Figures 1 and

5.

Pull all wires through conduits before mounting the base. See Electrical Planning for

wiring requirements.

Figure 4. Top Plate of Base Frame

The frame includes (2) surface plates, as shown in Figure 4 below, to accommodate different mounting

heights. When installing the base on a curb, the frame should be set so that the upper mounting plate is

flush with the concrete surface. When no curb is used (standard height base), the frame should be set so

that the upper mounting plate is flush with the concrete surface.

Document Number: SENT1001 8

Document Name: Sentinel Installation Manual

Page 13

SENTINEL

Figure 5. Sentinel Base with Mounting Plates

When the base is to be surface mounted, the legs of the frame will need to be cut so that the appropriate

mounting plate can be bolted to the concrete surface. The cut edges of the pipe should be coated with a

rust preventative paint to deter corrosion. The frame is to be secured to the concrete using the (6)

concrete anchor bolts provided.

With the frame in place, the wires run through the conduit stubs should b e routed throug h the conduit plate

on the top left side of the frame. Flexible conduit should be installed between the conduit stub and

mounting plate to protect and separate the high and low voltage circuits. The flex conduit should be

secured to the conduit plate using a suitable nut.

2.4 Mounting the Sentinel

Before setting the Sentinel in place, ensure the fiel d-installed wires are ro uted to a po int where th ey can be

accessed and pulled through the wiring holes on the bottom of the Sentinel a nd that the p lastic sheath has

been fitted over the base.

1. Open the Sentinel and remove the bill dispenser.

Document Number: SENT1001 9

Document Name: Sentinel Installation Manual

Page 14

SENTINEL

2. Carefully set the Sentinel on top of the base so the (3) studs of the base pass through the

mounting holes on the bottom of the Sentinel.

3. Secure the Sentinel to the studs with the flat washer, lock washer and hex nut (in that order)

supplied with the base.

4. Pull the wires up through the cable entrance port s on the bottom of the Sentinel enclo sure.

5. Verify the unit’s final position.

6. Use the dual-plane level to verify that the unit is level. Make appropriate a djustments if necessary.

7. Tighten the 3 nuts with the socket wrench. When this has been successfully completed, there

should be no movement of the case whatsoever.

3 Electrical Installation

3.1 Hardware Required

Unitec does not provide connectors for terminating the field-installed wires. These wires will vary by

application but connectors that may be required include:

• RJ-45 Modular Plugs (for terminating the CAT-5 network cable).

• BNC Connectors (for terminating coaxial cable for the camera options)

3.2 Recommended Tools

In addition to the mechanical mounting of the Sentinel unit to the base (and the base to the concrete),

there will be a number of electrical connections that must be made. These connections will require the

use of the following common electrical tools:

• Small, thin tipped, straight screwdriver (1/8” tip, for green Phoen ix connectors)

• Wire strippers (capable of handling 10-23 AWG wire)

• Diagonal cutters

• Needle nose pliers

• Modular plug crimp tool (if CAT 5 or phone lines need to be term inated)

3.3 General

NOTE: Before starting, ensure all required wires have been routed to the Sentine l (as descr ibed in the Site

Preparation section).

The following figure shows the location insid e the Sentinel where the field wires will connect.

Document Number: SENT1001 10

Document Name: Sentinel Installation Manual

Page 15

SENTINEL

3.4 Connecting Power

1. Locate main power wires. There will be three 16 AWG (or greater) environmentally rated black,

white, and green colored wires.

2. Route the main power wires up through the condu it to the Sentinel’s power panel. Remove excess

wire length, leaving sufficient length to reach the power panel. Remove the plastic shield on the

power terminal block.

3. Secure the Neutral (White), Ground (Green), and Line (Black) wires to the appropriate terminal

screws on the power panel. (See figure below). Re-tighten the screws to hold the w ires in place.

Figure 6. Sentinel Interior

Document Number: SENT1001 11

Document Name: Sentinel Installation Manual

Page 16

SENTINEL

Figure 7. Neutral - Ground – Line Connections

4. Use wire ties to route and secure any extra cable. R eplace the plastic shield.

3.5 Network Connection

The Cat 5 cable will need to be terminated at each end with an RJ-45 modular plug. This termination

should be performed by a technician who is experienced in assembling network cables as a slight

misalignment in the wire termination can cause communications problems. For reference, Appendix B

provides guidelines for terminating a network cable with a modular RJ-45 plug.

The Network (Ethernet) port is located at the bottom edge of the mother board. There should be a surge

suppressor installed in the Ethernet port. Insert the terminated CAT 5 cable into t he other end of t he surge

protector. The facility end of the Cat-5 cable connects to one of the LAN ports on the Unitec router. The

router’s WAN port should be connected to the Internet Service device (e.g. DSL or Cable modem). Other

Unitec devices may need to be connected to the router’s LAN ports. Refer to

connecting devices to the router.

Appendix B for details on

Document Number: SENT1001 12

Document Name: Sentinel Installation Manual

Page 17

SENTINEL

3.6 Wash Control Wiring

3.6.1 Overview

In applications where the Sentinel will communicate with the Wash Controller, the wash control wires will

need to be connected to the Wash I/O Board.

Most wash manufacturers use a five-wire system to provide the arming signals for the selected wash

packages. One common line and four arming input wires are fed from the wash’s PLC to the Wash I/O

board. In addition to these five wires, a Wash-In-Use (WIU) Hot and W IU Ne utral are req uired to reset the

wash electronics. Typically, these are also provided by the PLC.

Each wash manufacturer has its own specific color code system and wash relay pin-outs; therefore, it is

important to review the appropriate wash documentation prior to beginning this portion of t he installatio n.

3.6.2 Wiring the Wash Relay Interface

To wire the wash relays, connect the wires that come from the PLC to the appropriate pin numbers in the

phoenix connector using the following procedures:

3.6.2.1 Preparation

Note:

• You will need a thin tipped, flat head screwdriver to open and tighten the relay connections of

• Review the wash manufacturer’s documentation to determine the color codes for the wiring of

• Phoenix connectors are shipped already inserted in the appropriate sockets on the Wash I/O

The wiring for the Sentinel Wash I/O board is the same as the wiring for the Wash

Select II wash interface.

the Phoenix connector.

the wash pin-outs for your wash equipment before beginning this installa tion.

board.

1. Remove the Carrier Board/Wash I/O Board Cover Plate using a 5/16” socket wrench.

2. Locate the Wash I/O board on the inside lower right-hand wall of the Sentinel case.

3. On the Wash I/O Board, locate the 10-pin Phoenix connector labeled J17 on the lower

right-hand corner of the Wash I/O board.

Document Number: SENT1001 13

Document Name: Sentinel Installation Manual

Page 18

SENTINEL

Note:

“Wash Output #”refers to the number associated with the arming wires. Refer to the

wash manufacturer documentation for more information.

4. Connect the wash relay arming wires, the wash relay common wire, and any spare option

relay wires to the appropriate pins, as indicated in the following table. Use the screwdriver

to open and/or secure the manufacturer wash wires to each of th e Unitec relay locat ions.

Table 1. Wash Relays

Pin Signal

Pin 1 Wash Output #1

Pin 2 Wash Output #2

Pin 3 Wash Output #3

Pin 4 Wash Output #4

Pins 5-8 Spare Option Relays (Outputs 5-8

respectively)

Pin 9 Wash Relay Common

Pin 10 N/A

5. Plug the Phoenix connector into the Wash I/O board socke t J17.

6. Continue to Wash-In-Use wiring procedures.

3.6.3 Wiring the Wash-In-Use Interface

3.6.3.1 Preparation

Note:

Wash equipment requires a reset circuit. This circuit is generally identified as the “Wash-In-Use” (WIU)

signal. It is not uncommon for values of this voltage to be as much as 115-120 VAC, so it is extremely

important to verify that there is no power applied to any of the wash components befo re proceeding.

Note:

Follow local electrical code when wiring the Senti nel.

Wash equipment wiring may vary, and not all equipment manufacturers use the washfault interface. Refer to the manufacturer’s document ation for additi onal information.

Document Number: SENT1001 14

Document Name: Sentinel Installation Manual

Page 19

SENTINEL

• Make sure all power is disconnected from the wash equipment prior to beginning this

procedure.

• You will need a thin tipped, flat head screwdriver to open and tighten the relay connections of

the Phoenix connector.

• Review the wash manufacturer’s documentation to determine the color codes for the wiring of

the wash pin-outs for your wash equipment before beginning this installa tion.

• Phoenix connectors are shipped already inserted in the appropriate sockets on the Wash I/O

board.

1. On the Wash I/O Board, locate the 6-pin Phoenix connector labeled J18 on the lower left-

hand corner of the Wash I/O board.

2. Remove the Phoenix connector from the socket.

3. Turn the connector so that the wire inputs are facin g up as shown below.

Figure 8. 6-Pin Phoenix Connector

4. Referring to the figure above, connect the following wires to the appropriate pins, as

indicated in the following table. Use the screwdriver to open and/or secure the

manufacturer wash wires to each of the Unitec relay locations.

Table 2. Wash-In-Use Connections

Pin Signal

Pin 1 Wash-In-Use Hot

Pin 2 Wash-In-Use Neutral

Pin 3 Wash-Fault-Hot

Pin 4 Wash-Fault-Neutral

Pin 5 Wash-Complete-Hot

Pin 6 Wash-Complete-Neutral

5. Plug the Phoenix connector into the Wash I/O board socke t J18.

6. Replace the protective metal plate that covers the Wash I/O board and the carrier board.

Document Number: SENT1001 15

Document Name: Sentinel Installation Manual

Page 20

SENTINEL

3.7 Intercom Systems

3.7.1 Overview

The use of an intercom system allows two-way communications between customers at the Sentinel and

staff elsewhere on site. A customer activates the Sentinel’s intercom output by pressing the help button.

Without an intercom, the intercom output can be used to activate a bell, light or other device to alert an

attendant that help is needed.

The intercom wires connect to the Display IO board on the back of the main door. Jumpers and

adjustments to control its operation are also located on that board. 2, 3, and 4 wire intercoms are

supported. A digital intercom is recommended if the intercom wiring is sharing conduit with other

communications wiring, but not required. Unitec does not supply intercom systems.

3.7.2 Intercom Connections

The Intercom has two connectors which control the way in which the intercom is wired and the mode of

operation. J16 is the interface and connects to the customer’s intercom unit. J35 is used to select mode of

operation (two, three, or four wire intercom systems). Twisted pair / fully shielded cable is recommended

for optimum performance.

3.7.3 Intercom Adjustments

The Intercom system has the ability to sense when voice band audio signals are present. This allows

the speakers in the unit to revert to a passive intercom mode. This bypasses the internal audio sectio n

and allows the left speaker to be used as an intercom.

3.7.4 Connection Overview

Call Function: The unit will initiate a call function by closing the contacts on RL5. By default, J16-Pin 1

(H1) and J16-Pin 2 (H2) will always reflect the contact closure of RL5. This is the default for the four-wire

mode when both the call function and audio are completely separated. More detailed instructions on this

follow.

Audio: When the Sentinel intercom mode is active, the audio section is floating and is not relative to

ground. By default, J16-Pin 3 (SP+) and J16-Pin 4 (SP-) will always be connected to the audio section.

Four Wire Intercom Configuration: Two separate pairs (four wires) are used for both the call function

and audio in the four-wire configuration. In this mode, J1 7 receives no jumpers.

3 Wire Intercom Configuration: This mode requires two conductors for audio and one additional

conductor for the call function. This mode uses a common ground for both audio and the call function (SP). Jumper pins 3&4 of J17 and connect H1, SP+ and SP- .

Document Number: SENT1001 16

Document Name: Sentinel Installation Manual

Page 21

SENTINEL

2 Wire Intercom Configuration: This type of intercom system has both the Call Function and audio

sharing the two conductors. Jumper pins 3&4 and 1&2 of J17 and connect the two conductors to SP+ &

SP-.

3.8 Camera Connection

The (optional) surveillance camera is attached to the front door of the Sent inel. The camera is inte nded for

use with a DVR or similar monitoring device installed at the site. The coaxial cable routed to the camera is

used to connect it to the monitoring device. The coax cable will need to be terminated with a BNC

connector similar to the one shown in

Figure 9.

Figure 9. BNC Male Plug for Camera Connection

3.9 Gate Wiring

In multi-lane applications, a Unitec or 3rd party gate controller is required. Refer to the instructions

provided with the gate controller for connecting wires between it and the Sentinel. If needed, a gate can

be used with a single Sentinel and no gate controller. Refer to for instructions on connecting the Sentinel

to the gate.

3.10 Connecting the Reach F ree ID Option

Refer to the installation instructions supplied with th is product op tion.

Document Number: SENT1001 17

Document Name: Sentinel Installation Manual

Page 22

SENTINEL

4 System Startup

For fully detailed instructions, please see the Sierra Management Application

Programming Manual on the

www.StartwithUnitec.com website.

1. Power up the Sentinel.

2. Using a laptop, login into the Sierra Management S ystem.

3. Enter the Site information and credit networking information, wash information, and

setup a device profile.

4. Download the device profile.

5. The Sentinel will reboot and be in full operationa l mode.

5 System T est

Once the installation is complete, a thorough test should be performed to ensure all

Sentinel functions are operational. This test should verify:

• Functionality of hardware devices (through diagnostic tests in maintenance

mode).

• Washes and added services are properly configured and wash outputs are

properly wired.

• The wash fault (out of service) signal places the Sentinel ou t of service.

• Sentinel Ethernet communications (through the Cat 5 cable).

• Credit card processing (Note: The merchant should confirm credit card

revenues are being properly deposited to their account).

• Functionality of peripherals (gate/gate controller, RFID Option, etc.).

Document Number: SENT1001 18

Document Name: Sentinel Installation Manual

Page 23

SENTINEL

[THIS PAGE INTENTIONALLY LEFT BLANK]

Document Number: SENT1001 19

Document Name: Sentinel Installation Manual

Page 24

Appendix A. Sentinel Base - Bottom Up V iew

Document Number: SENT1001 20

Document Name: Sentinel Installation Manual

Page 25

Appendix B. Sentinel Networking

Unitec supplies a pre-programmed router for connecting devices as a local network.

The networked devices will vary based on options ordered and may include:

• One or more Sentinel units

• A Sentinel Console

• A POS Interface device (to communicate with a C-store POS System)

• A print server (for connecting a local report printer)

In cases where there will be more than (4) Unitec devices on the network, an

Ethernet switch will need to be added. The WAN port of the switch connects to one

of the LAN ports of the Unitec router. The additional devices can then be connected

to the LAN ports of the switch.

The illustration below provides a sample network diagram.

Example of Networked Unitec Devices

Third party devices should not be connected directly to the Unitec router. The

broadband device supplied for Internet service (e.g. DSL or Cable modem) will often

have a built-in router that can be used to connect these devices. In some cases

however, a separate router will need to be installed between the broadband modem

and the Unitec router. The following illustration shows the use of a 2

nd

router for 3rd

party device connections.

Document Number: SENT1001 21

Document Name: Sentinel Installation Manual

Page 26

SENTINEL

When a router (or modem with built-in router) is used between the Unitec router and

broadband connection, it must be configured to allow external connections to and

from the Sentinel. The router should be configured to:

• Forward the ports assigned to the Sentinel(s) to the Unitec router. For a

single unit installation the port is 9810. In multi-unit sites, the ports would

increment for each Sentinel i.e. 9811, 9812 etc..).

• Provide a static/reserved IP address to the Unitec router reserved so that the

forwarded ports will always be directed to it.

Document Number: SENT1001 22

Document Name: Sentinel Installation Manual

Page 27

SENTINEL

• Terminating Ethernet Cables

1. Carefully remove the outer jacket of the cable. Be careful when stripping the

jacket as to not nick or cut the internal wiring. One good way to do this is to cut

lengthwise with snips or a knife along the side of the cable, away from yourself,

about an inch toward the open end. This reduces the risk of nicking the wires'

insulation. Locate the string inside with the wires, or if no string is found, use the

wires themselves to unzip the sheath of the cable by holding the sheath in one

hand and pulling sideways with the string or wire. Cut away the unzipped sheath

and cut the twisted pairs about 1 1/4" (30 mm). You will notice 8 wire s twist ed in 4

pairs. Each pair will have one wire of a certain color and another wire that is white

with a colored stripe matching its partner (this wire is ca lled a tracer).

2. Inspect the newly revealed wires for any cuts or scrapes that expose the copper

wire inside. If you have breached the protective sheath of any wire, you will need

to cut the entire segment of wires off and start over at step one. Exposed copper

wire will lead to cross-talk, poor performance or no connectivity at all. It is

important that the jacket for all network cables remains int act.

Document Number: SENT1001 23

Document Name: Sentinel Installation Manual

Page 28

SENTINEL

3. Untwist the pairs so they will lay flat between your fingers. The white piece of

thread can be cut off even with the jacket and disposed (see Warnings). For

easier handling, cut the wires so that they are 3/4" (19 mm) long from the base of

the jacket and even in length.

4. Arrange the wires in the following order (from left t o right):

• white/orange

• orange

• white/green

• blue

• white/blue

• green

• white/brown

• brown

Press all the wires flat and parallel between your thumb and forefinger. Verify the

colors have remained in the correct order. Cut the top of the wires even with one

another so that they are 1/2" (12.5 mm) long from the base of the jacket, as the jacket

needs to go into the 8P8C connector by about 1/8", meaning that you only have a

1/2" of room for the individual cables. Leaving more than 1/2" untwisted can

jeopardize connectivity and quality. Ensure that the cut leaves the wires even and

clean; failure to do so may cause the wire not to make contact inside the jack and

could lead to wrongly guided cores inside the plug.

Document Number: SENT1001 24

Document Name: Sentinel Installation Manual

Page 29

SENTINEL

5. Keep the wires flat and in order as you push them into the RJ-45 plug with the flat

surface of the plug on top. The white/orange wire should be on the left if you're

looking down at the jack. You can tell if all the wires made it into the jack and

maintain their positions by looking head-on at the plug. You should be able to see

a wire located in each hole, as seen at the bottom right. You may have to use a

little effort to push the pairs firmly into the plug. The cabling jacket should also

enter the rear of the jack about 1/4" (6 mm) to help secure the cable once the

plug is crimped. You may need to stretch the sleeve to the proper length. Verify

that the sequence is still correct before crimping.

6. Place the wired plug into the crimping tool. Give the handle a firm squeeze. You

should hear a ratcheting noise as you continue. Once you have completed the

crimp, the handle will reset to the open position. To ensure all pins are set, some

prefer to double-crimp by repeating this step.

7. Repeat all of the above steps with the other end of the cable. Test the cable to

ensure that it will function in the field. Mis-wired and incomplete network cables

Document Number: SENT1001 25

Document Name: Sentinel Installation Manual

Page 30

SENTINEL

could lead to headaches down the road. Also, crossed wire pairs could lead to

physical damage of computers or phone system equipment, making it even more

crucial that the pairs are in the correct order. A simple cable tester can quickly

verify that information for you. Should you not have a network cable tester on

hand, simply test connectivity pin to pin.

Document Number: SENT1001 26

Document Name: Sentinel Installation Manual

Page 31

SENTINEL

Appendix C. POS Interface External POS Option

The external POS option allows wash codes to be purchased at Point of Sale (POS

registers or gas pumps. This option includes a port conversion device, which

connects between the Unitec router and the C-store POS System. A 3ft Ethernet

cable is included for connecting the Ethernet port o f the converter to the Unitec r outer.

A standard 9-pin serial cable is included for conne cting the Serial port of the converter

to the C-Store POS however, some POS systems may require an alternate cable (or

adapter). Contact the POS manufacturer for their cabling requirements.

Port Converter of External POS Interface Option

Document Number: SENT1001 27

Document Name: Sentinel Installation Manual

Loading...

Loading...