Page 1

Remote Code POS4000

Installation and Operations Manual

Unitec

www.StartwithUnitec.com

Page 2

POS4000

REMOTE CODE POS4000

OPERATIONS MANUAL

Software Version 8.25

This document provides comprehensive operational procedures for the Remote Code POS4000

Carwash Marketing System. In this manual, we will discuss the installation and operations of the

POS4000, along with cashier and management operations.

If further assistance is needed, please contact the distributor from which the product was

purchased.

When calling for assistance, you must have the following information available:

POS4000 Serial Number:

Distributor Name:

COPYRIGHT

© 2012 Unitec, Incorporated. All rights reserved. No part of this book, including text, screen

examples, diagrams, or icons, may be reproduced or transmitted in any form, by any means

(electronic, photocopying, recording, or otherwise) without prior written permission of Unitec,

Incorporated.

TRADEMARKS

Wash Select II, POS4000, Unitec, and the Unitec Logo are trademarks, service marks, or

registered trademarks of Unitec, Incorporated.

All other products, services, and company names are trademarks or registered trademarks of

their respective owners.

Document Number: POS4010

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 3

POS4000

Table of Contents

Quick Start Guide..................................................................................................................................1

Quick Reference Guide.........................................................................................................................1

1 Overview of Remote Code POS4000 ............................................................................................1

1.1 Requirements and Limitations...............................................................................................1

1.1.1 Remote Code Changes That Affect Configuration.........................................................1

1.1.2 Remote Code Changes That Affect Reporting...............................................................2

1.2 Enable and Setup Remote Code...........................................................................................2

1.2.1 Setting Up the Primary/Master POS4000.......................................................................2

1.2.2 Setting Up the Secondary/Slave POS4000s..................................................................3

1.3 Sierra Server Integration........................................................................................................3

1.4 Wash Select II POS System..................................................................................................4

1.4.1 Enable and Setup Remote Code....................................................................................4

1.4.2 Remote Code Utilities.....................................................................................................5

1.4.3 Changes to Code Entry on Wash Select II.....................................................................5

1.4.4 Accounting Report Changes ..........................................................................................6

2 Installation.......................................................................................................................................7

2.1 Pre-Installation Requirements ...............................................................................................7

2.2 Wiring.....................................................................................................................................8

2.3 POS4000 Function Lines/Car Wash Features ......................................................................9

2.4 Installing/Upgrading the EPROM Chip................................................................................10

2.5 Keypad Layout.....................................................................................................................13

3 Management Control (Command Reference)............................................................................15

3.1 System Configuration ..........................................................................................................15

3.1.1 Set System Time and Date...........................................................................................17

3.1.2 Configuring a Group.....................................................................................................18

3.1.3 Set Code Age Warning.................................................................................................19

3.1.4 Set Code Length...........................................................................................................19

3.1.5 Disable Cashier Keys...................................................................................................20

3.1.6 Set Serial Baud Rate....................................................................................................21

3.1.7 Set Languages .............................................................................................................22

3.1.8 Set Program Relays .....................................................................................................22

3.1.9 External POS MENU->.................................................................................................23

3.1.10 Multiple Unit MENU->.................................................................................................27

3.1.11 Relay Latching............................................................................................................30

3.1.12 Relay Stacking............................................................................................................30

Document Number: POS4010 i

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 4

POS4000

3.2 Accounting Report...............................................................................................................30

3.2.1 POS4000 Accounting Report.......................................................................................30

3.2.2 Print Accounting Report................................................................................................33

3.3 Set Prices.............................................................................................................................33

3.3.1 Set Regular or Discount Prices ....................................................................................34

3.3.2 Print Pricing Report ......................................................................................................34

3.3.3 Set Tax Rate.................................................................................................................35

3.3.4 Enable TAX Round Off.................................................................................................35

3.4 Service Routines..................................................................................................................35

3.4.1 System Configuration Report .......................................................................................36

3.4.2 Link Test.......................................................................................................................36

3.4.3 LED Test.......................................................................................................................37

3.4.4 Set Print To display (Non printer Mode).......................................................................37

3.4.5 Display POS Diags.......................................................................................................38

3.5 Clear Audit Counts...............................................................................................................38

3.6 Set Messages......................................................................................................................38

3.6.1 Change Header Message.............................................................................................39

3.6.2 Change Postscript 1-5..................................................................................................40

3.6.3 Change Footer Message..............................................................................................40

3.6.4 Print Current Message Configuration...........................................................................41

3.7 Set Passwords.....................................................................................................................41

3.7.1 Change a Specific Password .......................................................................................42

3.8 Setup a Feature...................................................................................................................42

3.8.1 Change Feature Name.................................................................................................43

3.8.2 Assign a Postscript Message to a Feature...................................................................43

4 Cashier Operations ......................................................................................................................45

4.1 Issuing A Customer Ticket...................................................................................................45

4.2 Issuing Multiple Customer Tickets.......................................................................................46

5 Customer Access .........................................................................................................................47

5.1 Customer Stacking ..............................................................................................................47

6 Printer Instructions ......................................................................................................................49

6.1 Instructions for Citizen Model CD-S500 ..............................................................................49

7 Backup Operations.......................................................................................................................51

7.1 Programming the Change-Codes Password.......................................................................52

7.2 Programming Backup Customer Codes..............................................................................52

7.3 Programming the Output Relays .........................................................................................53

8 Troubleshooting ...........................................................................................................................54

8.1 Printer Doesn't Print.............................................................................................................54

8.2 System Locked Up...............................................................................................................54

Document Number: POS4010 ii

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 5

POS4000

8.3 Customer Buzzer Failure.....................................................................................................55

8.4 Code Stacking Does Not Work............................................................................................55

8.5 "Enter Wash" Signal Does Not Work...................................................................................56

8.6 "Reenter Code" Signal Does Not Work ...............................................................................56

8.7 Bill, Coin or Audit Inputs Do Not Work.................................................................................56

8.8 Main Console Keys Do Not Work........................................................................................56

8.9 System Resets Each Time Power Is Turned On.................................................................56

8.10 Main Console Is "DEAD"...................................................................................................57

Appendix A. Interfacing to an External Point-of-Sale..................................................................58

Appendix B. Multiple Unit Configuration ......................................................................................64

Appendix C. Reconciliation of Sales When Connected to an EXTPOS Device.........................67

Appendix D. Application Notes for Using Default Discounts Function.....................................69

Appendix E. Application Notes for Using the Rev erse Orde r Function.....................................71

Document Number: POS4010 iii

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 6

POS4000

Index of Figures

Figure 1. POS4000 Connections.....................................................................................................8

Figure 2. POS EPROM Location ...................................................................................................11

Figure 3. EPROM and Socket........................................................................................................12

Figure 4. POS4000 Keypad...........................................................................................................13

Index of Tables

Table 1. Function Lines....................................................................................................................9

Table 2. Citizen CDS500 Printer Settings......................................................................................49

Table 3. Password Types...............................................................................................................51

Table 4. Output Relays ..................................................................................................................53

Document Number: POS4010 iv

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 7

POS4000

Quick Start Guide

(Pull Out Reference)

Document Number: POS4010 QSG-1

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 8

POS4000

[THIS PAGE INTENTIONALLY LEFT BLANK]

Document Number: POS4010 QSG-2

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 9

POS4000

The following commands are lists of steps that would typically be performed on a new

POS4000 prior to use. For further information, see Section 4, Management Operations.

ENABLE REMOTE CODE (At Primary/Master POS4000)

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Remote Code" is displayed

[ENTER]

[1] (Enable)

[ENTER]

SET DATE AND TIME

Example to set time to Monday 04:30PM on 05/06/08:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Set System Time" is displayed

[ENTER]

[0][5][0][6][0][8][1][6][3][0]

[ENTER]

[2] (Monday)

[ENTER]

NAME WASH FEATURES

Example to change the name of feature 1 to "ECONO-WASH":

[CMD]

[FEATURE 1] (cashier key)

[1] (password 1)

[MENU UP/DOWN] until "Change Wash Name" appears

[ENTER]

[E][C][O][N][O][-][W][A][S][H]

[ENTER]

To type [-] you must press [SHIFT] to switch to upper characters then [-] (on the [R]

key) then [SHIFT] again to return to the lower characters).

Note:

CONFIGURE GROUPS (Not used in all configurations)

Example to set Group 3 to Program 1 and options 1, 2 & 4:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

Document Number: POS4010 QSG-3

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 10

POS4000

[ENTER]

[MENU UP/DOWN] until "Configure a Group" is displayed

[ENTER]

[3] (select group #3 to configure)

[ENTER]

[Prog 1] (select wash functions in group)

[Opt 1]

[Opt 2]

[Opt 4]

[ENTER]

SET PRICING

Example to set regular (full) price structure:

[CMD]

[SET PRICES]

[2] (password 2)

[ENTER]

[MENU UP/DOWN] until "Set Regular Prices" appears

[ENTER]

[3][5][0] (set feature 1 full price to $3.50)

[ENTER]

[4][7][5] (set feature 2 full price to $4.75)

[ENTER]

∗ (continue through all features)

∗

[ENTER]

DISABLE UNUSED CASHIER KEYS

Example to disable PROGRAM 5:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Disable Cashier Key" is displayed

[ENTER]

[Prog 5] (disable program 5)

[ENTER]

DEFINE HEADER MESSAGE

Example to change header message text:

[CMD]

[SET MESSAGES]

[1] (password 1)

[ENTER]

Document Number: POS4010 QSG-4

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 11

POS4000

[MENU UP/DOWN] until "Change Header Msg." appears

[ENTER]

[9][9] (to change all lines of message)

[ENTER]

[T][H][I][S][ ][I][S][ ][A][ ][T][E][S][T]

[ENTER]

∗ (repeat for each line)

∗

∗

[ENTER]

DEFINE POSTSCRIPT MESSAGES

Example to change Postscript message 1:

[CMD]

[Set Messages]

[1] (password 1)

[ENTER]

[MENU UP/DOWN] until "Change Postscript 1" appears

[ENTER]

[9][9] (to change all lines of message)

[ENTER]

[T][H][I][S][ ][I][S][ ][A][ ][T][E][S][T]

[ENTER]

∗ (repeat for each line)

∗

[ENTER]

ASSIGN POSTSCRIPT MESSAGES

Example to assign postscript message 3 to Opt 2 at all price levels:

[CMD]

[Opt 2] (cashier key)

[1] (password 1)

[ENTER]

[MENU UP/DOWN] until "Set Postscript All $" appears

[ENTER]

[3] (select postscript message 3)

[ENTER]

ISSUE AND CHECK WASH TYPES (see Section 5.1)

Examples for cashier-issued wash tickets:

Example: Full price P1 & O1

[Prog 1]

Document Number: POS4010 QSG-5

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 12

POS4000

[Opt 1]

[ENTER]

Example: Full price-P2 & discount 1-O1

[Prog 2]

[DISC 1][Opt 1]

[ENTER]

Example: Discount 2-P2 & discount 2-O1 & discount 2-O2

[DISC 2][Prog 2]

[DISC 2][Opt 1]

[DISC 2][opt 2]

[ENTER]

CLEAR COUNTS

Example to clear AUDITOR level of counts:

[CMD]

[CLEAR REPORTS]

[MENU UP/DOWN] until "Clear Auditor Counts" appears

[ENTER]

[5] (password 5)

[ENTER]

Document Number: POS4010 QSG-6

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 13

POS4000

Quick R ef erence Guide

(Pull Out Reference)

Document Number: POS4010 QRG-1

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 14

POS4000

[THIS PAGE INTETNTIONALLY LEFT BLANK]

Document Number: POS4010 QRG-2

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 15

POS4000

The following examples demonstrate how to perform some of the most common

functions of the POS4000. For a complete list of commands, see Section 4.

CASHIER OPERATIONS

ISSUE A TICKET: (Code valid for Program 1 and Option 1)

[Prog 1]

[Opt 1]

[ENTER]

ISSUE MULTIPLE TICKETS: (print 5 tickets in this example)

[5] (key located on management keypad)

[Prog 1]

[Opt 1]

[ENTER]

PRINT ACCOUNTING REPORT: (but do not clear counts)

[CMD]

[PRINT REPORT]

[MENU UP/DOWN] (Scroll to Report Desired)

[ENTER] (report prints)

PRINT ACCOUNTING REPORT AND CLEAR COUNTERS:

[CMD]

[CLEAR REPORTS] (clear counters)

[MENU UP/DOWN] (Scroll to Report Desired)

[ENTER]

[1],[2] or [5] (passwords 1, 2 or 5 respectively)

[ENTER]

MANAGEMENT OPERATIONS

ENABLE REMOTE CODE (at Primary/Master POS4000 consoles)

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Remote Code" is displayed

[ENTER]

[1] (Enable)

[ENTER]

SET TIME

Example to set time to 07:15AM on 05/22/93

[CMD]

[SYSTEM SETUP]

Document Number: POS4010 QRG-3

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 16

POS4000

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Set System Time" appears

[ENTER]

[0][5][2][2][9][3][0][7][1][5] (MMDDYYHHMM)

[ENTER]

[2] (for Monday)

[ENTER]

SET PRICING

Example to set full price pricing

[CMD]

[SET PRICES]

[2] (password 2)

[ENTER]

[MENU UP/DOWN] until "Set Regular Prices" appears

[ENTER]

[3][5][0] (set 1st function full price to $3.50)

[ENTER]

[4][7][5] (set 2nd function full price to $4.75)

[ENTER]

*

*

*

[ENTER]

CHANGE HEADER MESSAGE TEXT

[CMD]

[SET MESSAGES]

[1] (password 1)

[ENTER]

[MENU UP/DOWN] until "Set Header Message" appears

[ENTER]

[9][9] (to change all lines of message)

[ENTER]

[T][H][I][S][ ][I][S][ ][A][ ][T][E][S][T]

[ENTER]

* (Repeat for each line)

*

*

[ENTER]

CHANGE FOOTER MESSAGE TEXT

[CMD]

[SET MESSAGES]

[1] (password 1)

[ENTER]

Document Number: POS4010 QRG-4

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 17

POS4000

[MENU UP/DOWN] until "Set Footer Message" appears

[ENTER]

[9][9] (to change all lines of message)

[ENTER]

[T][H][I][S][ ][I][S][ ][A][ ][T][E][S][T]

[ENTER]

∗ (Repeat for each line)

∗

∗

[ENTER]

DEFINE POSTSCRIPT MESSAGE TEXT

[CMD]

[SET MESSAGES]

[1] (password 1)

[ENTER]

[MENU UP/DOWN] until "Set Postscript Message 1" appears

[ENTER]

[9][9] (to change all lines of message)

[ENTER]

[T][H][I][S][ ][I][S][ ][A][ ][T][E][S][T]

[ENTER]

∗ (Repeat for each line)

∗

∗

[ENTER]

ASSIGN POSTSCRIPT MESSAGES TO WASH FUNCTIONS

Example to assign postscript message 3 to print on tickets that contain Opt 2 at any

price level

[CMD]

[Opt 2]

[1] (password 1)

[ENTER]

[MENU UP/DOWN] until "Set Postscript # All $" appears

[ENTER]

[3] (select postscript message 3)

[ENTER]

Document Number: POS4010 QRG-5

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 18

POS4000

SYSTEM CONFIGURATION COMMANDS

CHANGE A PASSWORD

CHANGE CASHIER KEY NAME

Example to change Option 1 to Wax

CONFIGURING A GROUP WASH

Example to Configure Group 3 to be Program 1 and Options 1 & 4

Example to change password 1 to "123"

[CMD]

[PASSWORDS]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Change Password 1" appears

[ENTER]

[1][2][3] (new password)

[ENTER]

[CMD]

[OPT 1] (this is the cashier key to re-label)

[1] (password 1)

[ENTER]

[MENU UP/DOWN] until "Change Wash Name" appears

[ENTER]

[W][A][X]

[ENTER]

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Configure a Group" appears

[ENTER]

[3] (management keypad, select group #3 to configure)

[ENTER]

[Prog 1] (select wash functions in group)

[Opt 1]

[Opt 4]

[ENTER]

Document Number: POS4010 QRG-6

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 19

POS4000

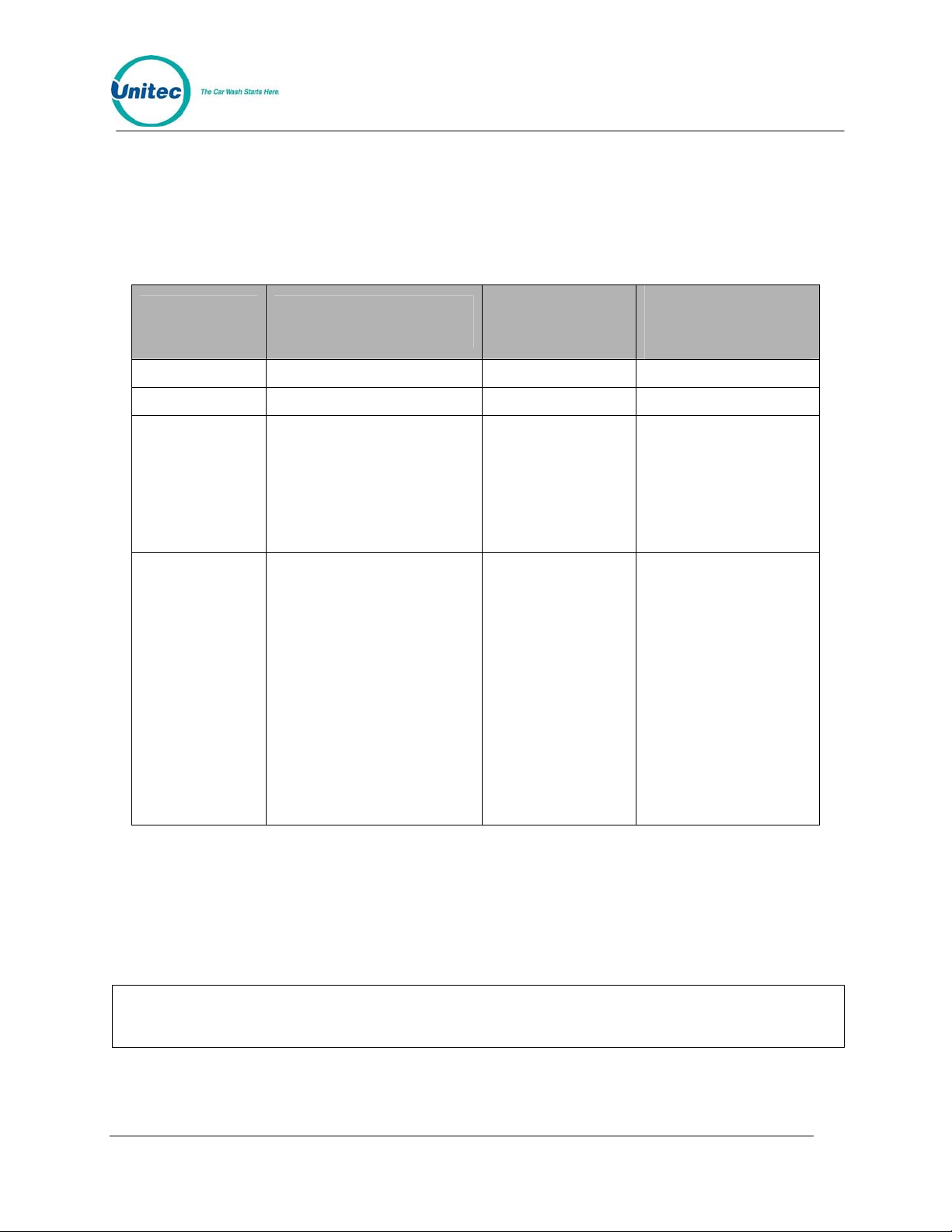

LIST OF COMMANDS

The primary commands and the required passwords are shown below along with their

secondary commands:

Primary/Secondary Command Key Label Password

System Configuration System Setup 3

Set System Time

Relay Latching

Relay Stacking

Configure a Group

Set Code Age Warning

Set Code Length

Disable Cashier Key

Set Serial Baud Rate

Set Languages

Set Program Relays

External POS MENU->

Set POS Offset

Define EXT. POS Type

Set POS MAX WASHES

Multiple Unit MENU->

Set Unit Number

Controller/Remote

Set # Bays/Consoles

Prog Remote Consoles

Set modem rings

Remote Code

Each sub-menu also contains an option to "Return to SETUP MENU"

Print Audit Counts Print Report None

Print Shift/Manager

Print Auditor/Non R.

Set Pricing Set Prices 2

Set Regular Prices

Set Discount 1 Price

Set Discount 2 Price

Print Pricing Report

Set Tax Rate

Enable TAX Round Off

Document Number: POS4010 QRG-7

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 20

POS4000

Primary/Secondary Command

Key Label Password

Service Routines Service 4

Print Configuration

Link Test

LED Test

Print (codes) to display

Display POS Diags

Clear Audit Counts Clear Reports

Clear Shift Counts 1

Clear Manger Counts 2

Clear Auditor Counts 5

Set Messages Set Messages 1

Change Header Msg.

Change Postscript 1

Change Postscript 2

Change Postscript 3

Change Postscript 4

Change Postscript 5

Change Footer Msg.

Change Coinbox Msg. (E-4000 only)

Print Message Config

Set Passwords Passwords 3

Change Password 1

Change Password 2

Change Password 3

Change Password 5

Change Serial Pass

Summary of access provided by each password:

Password User Commands

Clear SHIFT level counters,

1 Cashier

2 Manager

3 Supervisor

4 Service Service Routines

5 Auditor Clear AUDITOR level counters

Document Number: POS4010 QRG-8

Document Title: Remote Code POS4000 Installation and Operations Manual

Void codes, Define Messages,

Setup Features

Clear MANAGER level

counters, Set Pricing, Memory

Information

System Configuration, Change

Passwords

Page 21

POS4000

1 Overview of Remote Code POS4000

The POS4000 is a car wash access controller that provides both a merchandising tool and cash

security. The system consists of a main console, which is typically located near the cashier, and

the Wash Select II (WSII) entry system that is typically locate d at the entran ce of the car wa sh.

The Remote Code POS4000 is used when an electronic connection to the Wash Select II is not

feasible. The Remote Code POS4000 generates a 6 or 7 digit code that also contains wash data

in it. This code is then entered into the WSII. The WSII extracts and validates the data, then

stores the code in a database and authorizes the wash. Remote codes can be sold by the

cashier at the console or through the external POS (e.g., gas pumps). The operations are the

same as that of regular codes.

The Wash Select II may be configured to interface to a POS4000 in order to be activated by

codes sold at one or multiple POS4000 units. This is how a Wash Select II/POS is configured to

operate. Any Wash Select II may also be upgraded in the field to interface to a POS4000 either

by direct wires or via encrypted codes from a Remote Code POS4000. The Wash Select II can

support having BOTH a direct (wired) POS4000 link AND Remote Code POS4000s enabled on

the unit. When both types of POS4000 links are enabled, we highly suggest that different code

lengths are assigned to the linked POS4000 and to the Remote Code POS4000 to limit the

chance of duplicate codes being generated. A code will fir st attempt to be ver ified by the R emote

Code POS4000, then it will be sent to the linked POS4000 for verification.

1.1 Requirements and Limitations

• The minimum version for the POS4000 is v8.25, and v5.53 f or the WSII.

• Code Length: 6 or 7 digits. Some exter nal POS systems that req uire a 5-digit code w ill

not work with the Remote Code POS4000 (i.e., Verifone Ruby).

Note: Unitec highly recommends using 7 digit codes if possible to reduce the chances of

jackpotting codes.

• Maximum number POS4000 consoles:

o 6 digit code – 3 Masters plus their remote consoles

o 7 digit code – 4 Masters plus their remote consoles

• External POS connection to POS4000: Allowed on ly on Master console

• Maximum number of WSII Units: 1 Primary and its’ secondary units

• Maximum code sales per day: 190

• Maximum code age: 60 days

• Capacity of used code history: 90 days after sales d ate or 12000 codes – whichever

comes first

1.1.1 Remote Code Changes That Affect Configuration

When the remote code is set to enable, the following set up functions are disabled (“Feature Not

Available” when accessed):

Document Number: POS4010 1

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 22

POS4000

• Fleet related functions (Account Info button)

• Void code (Void Code button)

• Code management functions (Memory button)

• Check code (Check Code button)

• Reprint Receipt

• Code Length (Maximum Code Length)

• Code Age (Enter # of Days Good)

• Cash Upgrades

• Ext POS Multi-use code setup

• Number of Bays under Set # Bays/Consoles

• Optioning - disabled only when using 6 digits codes

1.1.2 Remote Code Changes That Affect Reporting

On the System Configuration Report:

• Multi-use codes will not b e there with Remote Cod e enabled

• Remote Code parameters will be there with Remote Code en abled

Audit Counts

These items are still displayed when Remote Code is enabled:

• Code Usage and Wash Activation Summary

• Ext Pos Multi-Use Code Summary

• Vehicles Washed Summary

• Wash Time Info

• WSII Fleet Usage Info

• WSII Fleet Sales Info

• CIN Code Failures

• Codes Void

• Coin Box Summary

• Coin Box Pricing

1.2 Enable and Setup Remote Code

Note: A remote POS4000 running the “Ext POS at remote POS” software option cannot be

used as a remote unit with a Master POS using Remote Code.

1.2.1 Setting Up the Primary/Master POS4000

To enable the Remote Code function at the Primary/Master POS4000 console:

System Setup -> Remote Code: 1=enable, 0=no

The following parameters MUST be set in order for Remote Code to function properly:

Document Number: POS4010 2

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 23

POS4000

• POS4000 ID: 1-4

o Master POS consoles must set to 1

Note: If you are using 6-digit codes, you may only use 3 Master consoles.

o Secondary Consoles must be set to Units 2-4.

o Remote consoles POS IDs must match the corresponding master console.

• Code Age: number of days a code is g ood after purchase. 1 to 60 days, default 1 4

• Daily Limit: maximum number of codes can be issued per day: 10 to190, defa ult 100.

Note: When the Daily Limit is reached, the code issued will be 0, which is invalid.

• Security Code: used to encrypt the wash code, up t o 7 digits. U sing simp le numbers like

“1234567” or “3333333” is discouraged.

• Verify the time and date settings on the POS4000 and WSII involved to make sure they

match. The Remote Code function will not work properly if they are not sync hronized.

NOTE: You MUST complete all of the above settings until they print or the settings will not be

saved!

After completing the items, the settings are printed out. Keep this printout as the same settings

need to be programmed into the WSII and any remote POS4000 units.

1.2.2 Setting Up the Secondary/Slave POS4000s

If there are any remote units, the Remote Code feature needs to be enable d too.

System Setup -> Remote Code: 1=enable, 0=no

In the remote unit, only Code Age setting needs to be entered, the rest are not present. The

settings are not printed.

• Code Age: number of days a code is g ood after purchase. 1 to 60 days, default 1 4

Once the Remote Code is enabled, the connection to the WSII is automatically disabled. If the

system time is changed on the POS4000, the sequence ID counter function of Remote Codes

will be reset and result in duplicate codes.

Note: The Multi-unit Settings must be re-programmed manually if the Remote Code feature is

disabled.

1.3 Sierra Server Integration

The Portal, Sentinel, and WashPay system may be configured to interface with a Remote Code

POS4000 via the Sierra Management Application. Login to the Sierra Management Application

and go to Setup>Site>Select Standard for Server Mode>Click Server Parameters>Click Enable

under Remote Codes. Enter the following parameters so that they are an exact match to

Remote Code POS4000 configuration settings. Enter the Code Length, Terminal ID, Code

Expiration, Daily Limit, and Security Code, then assign the washes in the correct order listed in

the POS4000. Click Save.

Document Number: POS4010 3

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 24

POS4000

1.4 Wash Select II POS System

The Wash Select II may be configured to interface to a POS4000 in order to be activated by

Codes sold at one or multiple POS4000 units. This is how a Wash Select II/POS is configured to

operate. Any Wash Select II may also be upgraded in the field to interface to a POS4000 either

by direct wires or via RF (Radio Frequency) interface.

For Remote Code functions, make sure washes and options programmed in the WSII are same

as ones programmed in the POS4000 or the code will be declined. For example, a code sold

with an option will not be accepted in a WSII with optioning disabled. Also verify the date

settings on the WSII and the POS4000 involved to make sure they are accurate because the

Remote Code function depends on them.

Upgrading a Wash Select II to interface to a Remote Code POS4000 requir es the following:

• Version 5.50 or greater software installed into the Wash Select II

• POS4000 with Version 8.24 or greater installed.

• Wash Select II 485 communications module. This plugs into the top left corner of

the Wash Select II CPU board.

• RF transceivers (Optional if your cable connection between the POS4000 and

Wash Select II is not feasible)

The Wash Select II is mostly configured at the Wash Select II entry system. Most of the entry

system settings in the POS4000 are not used by the Wash Select II. You must configure the

Wash Select II to accept the Wash names and Prices of the POS4000.

Here is a list of functions and features that must always be programmed at the Wash Select II

entry system:

• Credit system

• Speech recordings and settings

• Receipt Header

• Wash Interface (Remote Code, Relay Stacking, Relay Latching, Out of Service

etc.)

• Customer Interface (Upgrades, for ced selection, Cu stomer stacking etc…)

• Paging functions

• Cash and Token setting s.

• System time, Printer config, Site ID, an d Service Phone #

• VIP Wash Coupons™

• Passcodes & Passcards

Note: You must program the names and prices directly into the Wash Select II and they must

match the POS4000 names and prices in order for Remote Codes to function properly.

1.4.1 Enable and Setup Remote Code

Before starting using remote code, make sure these requirements are met: on the WSII:

• Expansion memory installed

• Credit Mode is NOT set to credit mode 3

Document Number: POS4010 4

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 25

POS4000

• POS LINK is not set to POS4000 Link

To enable the Remote Code function in the WSII:

1. Using the toggle switch at the top of the CPU board, place the Wash Select II in

setup mode by moving the switch toward the back of the Wash Select II case.

(The CPU board is located on the inside right wall of the Wash Select II case.)

2. Using the (3) key to scroll forward and the (1) key to scroll back, scroll through the

main menu until the "Wash Interface" option is displayed. Press the (*) key to

enter.

3. Use the (3) key to scroll until the "Remote Code" option is displayed. Press the (*)

key to enter.

4. “Use Remote Code?” will be displayed. Press (1) for yes and (3) for no. Press (*)

to enter.

Once enabled, go to Parameter Setup and enter the following information:

• IDs of POS Where Codes Sold: enter the ID of the POS4000(s) where the code is sold.

Up to 4 POS4000 IDs are supported. Default = 1

• Code Expiration: number of days a code is good after purchase from1 to 60 days.

Default=14

• Daily Code limit: maximum number of codes can be issued per day from 10 to190.

Default = 100

• Security Code: used to decrypt the wash code and is up to 7 digits. Using default value

or simple numbers like “1234567” or “3333333” is discouraged.

Note:

After completing the items, the settings are printed out. Keep printout as the same settings are

entered into the POS4000(s).

For any Secondary Units connected to the Primary unit and using remote code, enable Remote

Code on that unit too. However, no parameters need to be programmed on those units.

1.4.2 Remote Code Utilities

To access the Remote Code utilities, go to the Wash In terface menu.

• Print Used Codes: Get a printout of the redemption of the codes sold on a

particular day. Enter the date when the code issue date in the MMDD format

(leading 0 required), then press ‘*’. Codes redeemed in any secondary units

connected are included too.

• Clear Used Codes: To clear the code redemption history.

1.4.3 Changes to Code Entry on Wash Select II

When Remote Code is enabled, these features apply to all codes en tered in the WSII ke ypad:

• DO NOT use 6 or 7 digit codes for fleet accounts when using Remote Code. The

Code Length may conflict with codes sold at the Remote Code POS4000.

• Zeros in code no longer serve as the Enter key, it can appear in any position for

any code.

Document Number: POS4010 5

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 26

POS4000

• Fleet Account codes which have less than 5 digits will require the * key to enter

the code. Although the code still requires the 0 at the end during setup, the 0 no

longer acts like the Enter key – you must press *. If you enter a fleet code less

than 5 digits and do not press *, the screen eventually resets back to Please

Enter Your Code – the code is not accepted.

• For codes longer than 5 digits, a 3 second pause will cause the code to be

entered automatically

1.4.4 Accounting Report Changes

When Remote Code is enabled the following data is omitted from the Site Summary section of

the WSII Accounting Report:

POS4000 SALES replaced with POS4000 CODE SALES

POS4000 REFUND replaced with POS4000 CODE USAGE

A new section has been added to the Accounting report – the REMOTE CODE REDEMPTION

section, which includes the source of codes, sorted by the ID of the POS where codes are sold,

as well as wash types, prices and number of redemptions. The number of codes rejected is

shown at the bottom. Here is an example:

POS 1:

Express $ 6.00 : 42

Super $ 7.00 : 23

Deluxe $ 8.00 : 15

Works $ 9.00 : 18

TOTAL : 98

POS 2:

Express $ 6.00 : 25

Super $ 7.00 : 23

Deluxe $ 8.00 : 17

Works $ 9.00 : 25

TOTAL : 90

Rejected : 3

A note on Accounting Reports at Multi Bay sites: The Primary WS2 Accounting report

contains the Remote Code Redemption Section which accounts for all bays. All codes

redeemed and rejected are reported on the Primary – This section should not appear on a

Secondary WSII report at all. The Activation Details, however, are reported at each unit under

the Activation Summary.

Document Number: POS4010 6

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 27

POS4000

2 Installation

These instructions should be used as a guideline. If the wash manufacturer you purchased the

system from provides more detailed wire and installation instructions then please use that

information instead.

2.1 Pre-Installation Requirements

If your system comes with separate entry system installation instructions then follow

Note:

them for the entry system and use the following references to POS4000 Console

installation only.

Warning:

• Dedicated duplex (120 Volts/60 Hz, 3 amps, grounded) receptacle at location of

• POS4000 main console, printer and wall transformer

• POS4000 interface board with keypad

• POS4000 main console/interface cable (3 conductor, 22 gauge with shield)

Note:

Never run the communications li nes in the same conduit as wires used in powering the

entry system or the carwash.

main console. One is required for the console and one for the printer. The socket

outlet shall be installed near the equipment and shall be readily acceptable.

Ground hole of receptacle must be properly connected to Earth Ground.

When installing multi-Console or Multi-Bay configurations refer to included drawings for

instructions on daisy chaining the communications cable. Never wire the

communications in a STAR configuration where spli ces occur at any point oth er than at

the Consoles or Entrance stands.

Document Number: POS4010 7

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 28

2.2 Wiring

POS4000

Figure 1. POS4000 Connections

The wall transformer plugs into a 3-prong earth grounded wall outlet, the connector at the end of

the cord attaches to the mating connector on the back of the main console. This cord connects

the power and Earth Ground connection to the Console.

You may have POS consoles set up as Primary and Remote (hard wired together), or you may

have totally separate/independent POS consoles (not wired together) issue codes to be

validated at the WSIIs. In this case, you must ensure the units have different POS IDs.

Document Number: POS4010 8

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 29

POS4000

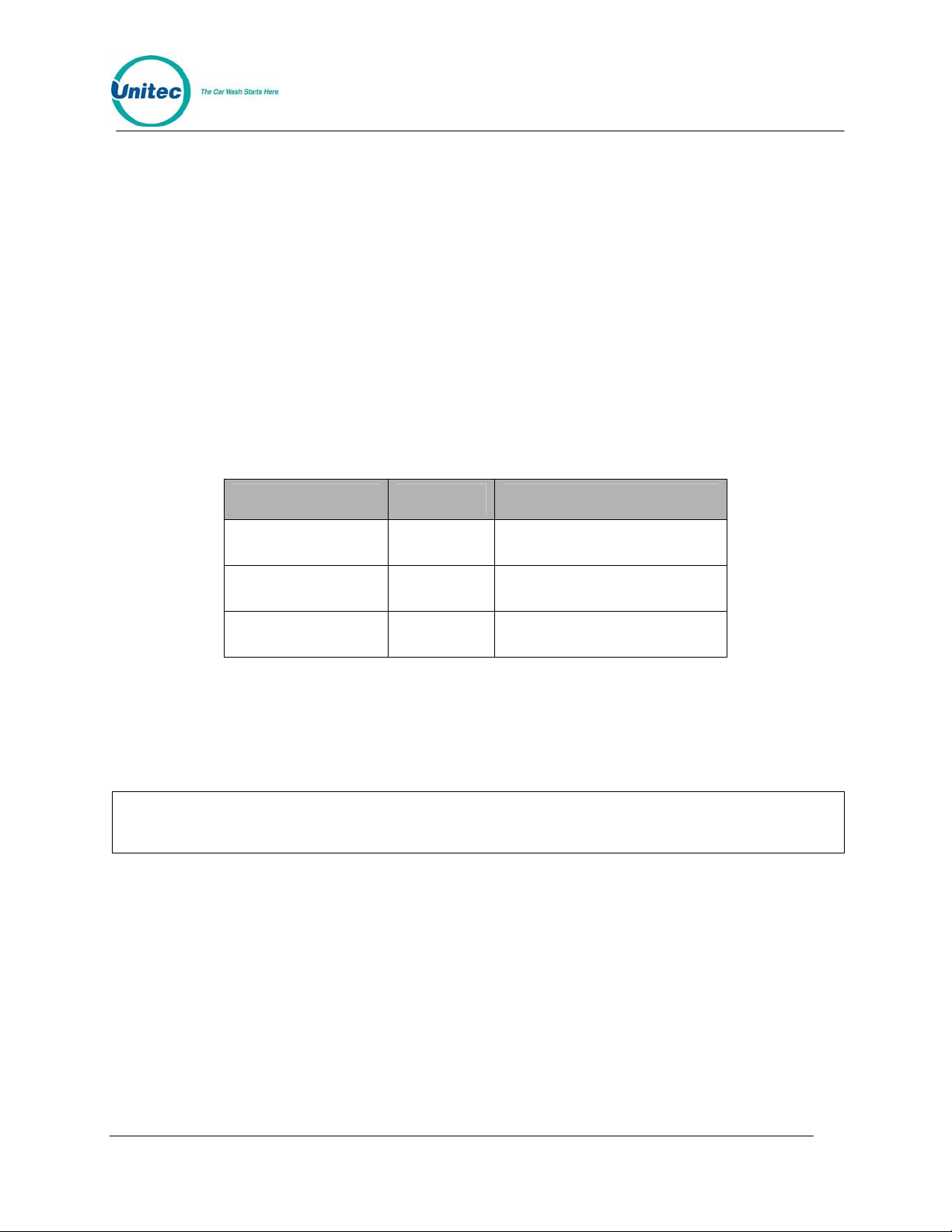

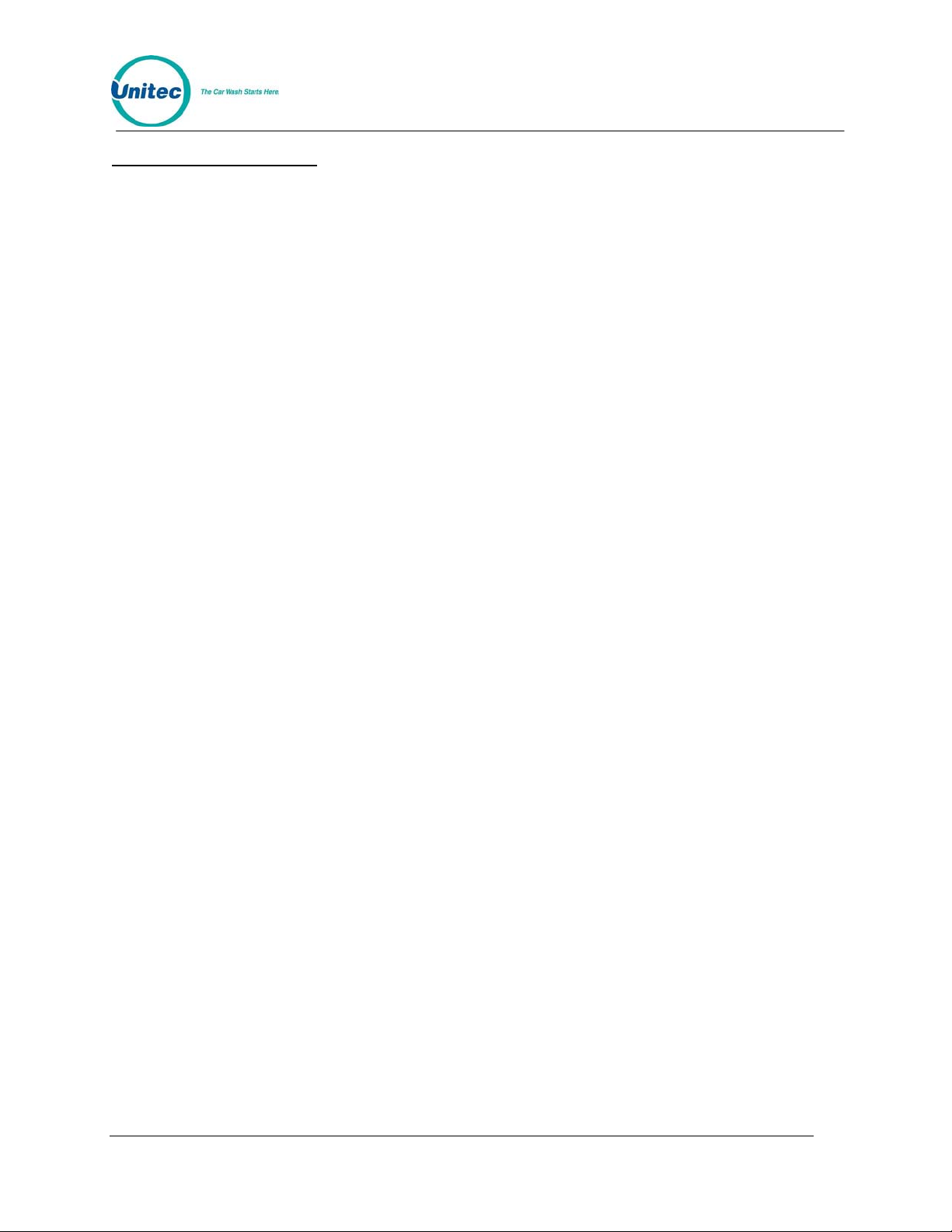

2.3 POS4000 Function Lines/Car Wash Features

The function control lines used to start the specific car wash features pu rchased by the customer

are identified as "function lines 1 - 8". The use of these lines is dependent on the specific

software program in the POS4000 console. The uses of the function lines are given in the table

on the following page by the type and number of program. To determine your POS4000

configuration, check the system configuration report

Table 1. Function Lines

# of

Programs

Multi-pulse* Pulsed Opt 1 Opt 2 Opt 3 Opt 4

1 Program Prog 1 Opt 1 Opt 2 Opt 3 Opt 4

2 Programs Prog 1 Prog 2 Opt 1 Opt 2 Opt 3

3 Programs Prog 1 Prog 2 Prog 3 Opt 1 Opt 2

4 Programs Prog 1 Prog 2 Prog 3

5 Programs Prog 1 Prog 2 Prog 3

6 Programs

7 Programs

8 Programs

* In multi-pulse operation, Function line 1 is pulsed 1, 2, 3 etc. times to issue different carwash programs.

Note:

1 2 3 4 5 6 7 8

Prog 1 Prog 2 Prog 3 Prog

Prog 1 Prog 2 Prog 3 Prog

Prog 1 Prog 2 Prog 3 Prog

If your configuration has fewer than the maximum options (as indicated in the table

above), then the upper function lines are not used. For example, if you have 3

programs and 3 options then lines 7 and 8 are not used.

Interface Function Line

Prog

4

Prog

4

4

4

4

Opt

5

Opt

5

Opt

4

Opt

3

Opt 1

Prog 5 Opt

Prog

5

Prog

5

Prog

5

Opt

2

1

Prog

6

Prog

6

Prog

6

Opt 6 Opt 7

Opt 6 Opt 7

Opt 5 Opt 6

Opt 4 Opt 5

Opt 3 Opt 4

Opt 2 Opt 3

Opt 1 Opt 2

Prog

7

Prog

7

Opt 1

Prog

8

Document Number: POS4010 9

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 30

POS4000

2.4 Installing/Upgrading the EPROM Chip

Depending upon the version of software that is currently in the console, this procedure

may delete ALL configuration information, including all codes and accounting

information. All setup configurations will be reset to factory defaults. To properly

facilitate reprogramming this information, you should print the following reports

Warning:

Perform the following steps to change the POS4000 console soft ware (EPROM):

5. Disconnect all cables to the console

6. Remove the plastic housing by removing the 2 screws from the rear and 2 screws

7. The upper chassis must be partially removed. Remove the middle and front

8. Find the EPROM chip, as indicated below:

BEFORE proceeding:

• System configuration

• Pricing report

• Accounting reports (those that are used)

• Message configurati on

from the bottom of the unit.

screws along the side of the metal chassis. Loosen the rear two screws on each

side of the chassis. This will allow the top piece to open up revealing the main

circuit board.

Document Number: POS4010 10

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 31

POS4000

Figure 2. POS EPROM Location

The EPROM chip has a small window on the top surface that may or may not be covered with

an adhesive label.

9. Carefully remove the EPROM chip from the socket. Use a small flat head screw

driver or an IC remover. Be careful to pry the chip from the socket and not the

socket from the board.

Document Number: POS4010 11

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 32

POS4000

Figure 3. EPROM and Socket

10.

Carefully install the new EPROM into the socket. Make sure that the Dimple on

the chip is facing the same direction as it was before (refer to previous drawing).

Also, make sure that pins can be properly inserted into the sockets without

bending. Component legs can be bent to fit sockets as follows:

• Lay the chip on its side with the pins fa cing away from you.

• Gently rock the chip away from you to bend t he pins.

• Lay chip on its other side and ro ck it aw ay from you.

• Repeat the above steps, alternating sides of the chip until the pins line up in

the socket without forcing the legs to fit.

7. Reconnect the power and printer connections and turn on the unit. As the system

powers up the message “!!SOFTWARE UPGRADE!!” will appear momentarily.

8. After the unit is powered up, you MUST then press the RESET BUTTON to reset

the system.

9. After pressing the reset button, the display will prompt you to press 99 or 55.

Press 55.

10. Reset the system two more times. If your system previously contained standard

version TG648 and above or Unicam version 656 and above, then the codes and

messages should be retained.

11. Replace all screws and plastic cover. Connect all other cables previously

attached.

Document Number: POS4010 12

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 33

POS4000

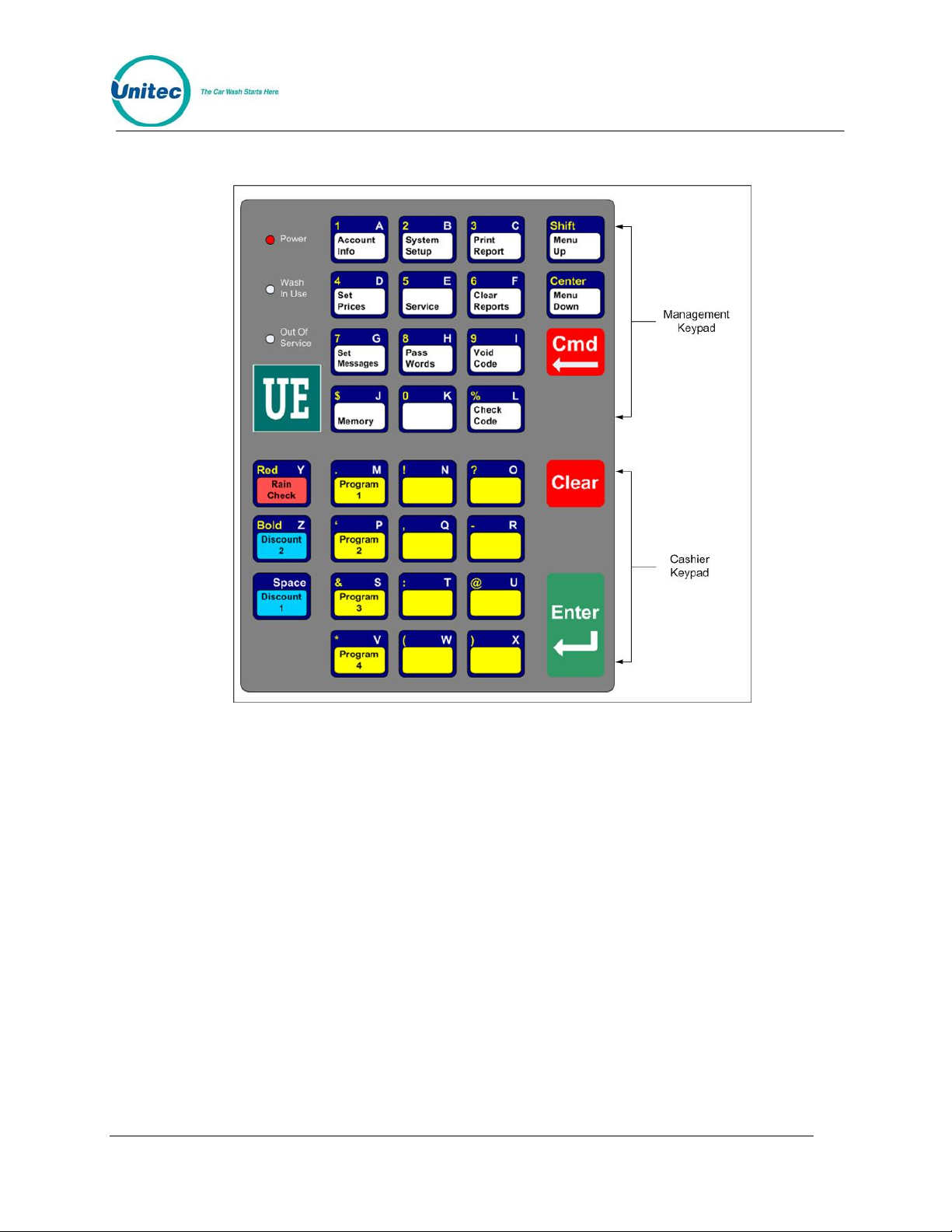

2.5 Keypad Layout

Figure 4. POS4000 Keypad

During various commands, you will be prompted to enter alphanumeric responses. To do this,

you must use the alternate characters printed on the right hand side of the keys. These alterna te

key values automatically become active when the console requires alphanumeric data entry.

Note that each alternate key has two characters printed on the t op and b otto m right han d side of

the key. When the console requests alphanumeric data, the bottom characters will initially be

active. You can switch back and forth between the top and bottom values by using the [SHIFT]

key.

Several special keys simplify alphanumeric data entry:

• [SHIFT] is used to toggle between the top and bottom selection on the alternated

keypad during alphanumeric data entry.

• [BACKSPACE] is used to erase the previous character .

• [CLEAR] has several uses depending upon what information the POS4000 is expect ing.

During alphanumeric text entry (i.e. header message), it is used to erase the entire line

of data entered and to start the line over. During feature selection, it clears all current

features. During numeric entry (e.g. passwords), it clears the number and allows you to

re-enter it.

Document Number: POS4010 13

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 34

• [SPACE] is used to add a blank space in the text.

• [ENTER] is used to end the current line of text.

• [CENTER] will center the text entered. Press once during the text entry of the line to

center.

• [RED] is used to print the text in red. Press once during the text entry of the line to print

the entire line in red.

[RED] is an upper function, therefore it may be necessary to press [SHIFT] prior to

pressing this key.

• [BOLD] is used to print the text in Bold (double high and double wide). Press it once

during the text entry of the line to print in bold. When a line of text is printed in bold, only

half the number of characters of text can be used in that line.

[BOLD] is an upper function, therefore it may be necessary to press [SHIFT] prior to

pressing this key

POS4000

Note:

Pressing both [RED] and [BOLD] during text entry will print that line in bold red.

Document Number: POS4010 14

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 35

POS4000

3 Management Control (Command Reference)

The management keys are used to access the various commands available. The management

keys are typically white and are located on the top half of the console keypad. They are used for

alpha-numeric entries as indicated by the large numeric characters located on the upper right

half of the keys and letters located on the lower right half of the keys. They are also used to

select commands as indicated by the text on the center of the ke ys.

Two methods are available to select a primary command. The first method allows you to scroll

through the primary menu list (by pressing the [MENU UP] or [MENU DOWN] key) and then

select the command of interest by pressing the [ENTER] key. The second method allows you to

directly access a particular primary menu command by simply pressing the [CMD] key followed

by the desired command function key (as identified by the text on the management keys). For

example, to print the wash counts report you either press the [MENU UP] and/or [MENU

DOWN] keys until the "Print Audit Counts" menu item appears on the disp lay and then pr ess the

[ENTER] key to select that command or you can simply press the [CMD] key followed by the

[PRINT REPORT] key. Both methods will activate that primary command.

Many of the console primary commands require a password. Those that do will prompt for a

specific password (password 1, password 2, ...) immediately after you select that command. To

continue with the command, type the appropriate password (using the numbers printed on the

management keys) followed by the [ENTER] key.

Many of the primary commands have a secondary command menu list. Once the primary

command has been selected and the appropriate password entered, you scroll through the

secondary menu list (using the [MENU UP] and/or [MENU DOWN] keys) and select the

secondary command of interest by pressing the [ENTER] key.

After a secondary command is executed, the primary command remains selected. This allows

several commands to be executed without having to re-enter the password. For example, all of

the passwords can be changed once the "Set Passwords" command has been activated. To exit

from a secondary menu and return the console to normal operation, scroll until "Press ENTER to

QUIT" appears and then press the [ENTER] key.

The password structure is intended to provide various levels of acce ss to th e conf iguration of the

POS4000 and the information that it maintains.

As you make numeric or character entries, the number/character is displayed. If a

mistake is made during numeric entry, it can be corrected prior to depressing the

Note:

[ENTER] key by pressing the [CLEAR] key and reentering the number. While entering

alpha-numeric data (i.e. entering header message), the [CMD] key can be used as a

backspace key.

3.1 System Configuration

The System Configuration command allows you to configure many aspects of the

console operation to your specification. To select this command press the [CMD]

key followed by the [SYS SETUP] key. You will be prompted to enter password

Document Number: POS4010 15

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 36

POS4000

3. After entering the correct password, you can scroll through the secondary

menu list that follows:

• Set System Time

• Configure a Group

• Set Code Age Warning

• Set Code Length

• Disable Cashier Key

• Set Serial Baud Rate

• Set Languages

• Set Program Relays

• Cash Upgrades MENU->

o Set BUYUP Mode

o Set Coin/Bill Values

o Set Dispense Value

• External POS MENU ->

o Set POS Offset

o Set EXT. POS Type

o Set POS Max Washes

o Set Send Code Age

o Reverse order

• Multiple Unit MENU ->

o Set Unit Number

o Controller/Remote

o Set # Bays/Consoles

o Prog Remote Consoles

To execute one of the secondary commands, scroll through the secondary menu until the

command of interest is displayed, and then press the [ENTER] key. The final three entries in the

secondary menu each allow access to a sub-menu. In addition to the choices shown for each

sub-menu, there is also an item that allows you to "Return to SETUP MENU".

The following information is provided in the System Configuration Report:

• Software Version and date of relea se

• Car Wash manufacturer compatibility

• Console language - used for text d isplayed on main console

Document Number: POS4010 16

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 37

• Customer language - used for tickets and customer display

• Number of Programs/options/groups

• Type of program: Multi-pulse or sing le line per progr am

• Relay Stacking status: Enabled/Disabled (see Note 1)

• Interface Relay Type: Momentary/Latched

• Type of Customer Buy up: None/Automatic/Selected/For ced

• E-system configuration (Change and Wash displays)

• Tax Rate

• Tax Round Off: Enabled/Disabled (only if tax rate is non-zero)

• Serial Baud Rate for EXT POS Device: 19200/9600/4800/ 2400/1200

• Code length (including zero: 6/7)

• Code Age Warning: 0-31

• Set Send Code age

• Reverse order of EXTPOS washes

POS4000

• Maximum number of valid codes stored in memory

• Maximum number of used codes stored in memory

• Default passwords (see Note 2)

• Cashier Key Status: All Enabled/Specific D isabled

• Group Configurations

• Customer interface type and version

The exact format of this information is subject to change a s new features are added.

If relay stacking is disabled, the function rel ays are cl ose d as so on as a code is e ntere d

(regardless of the wash in-use signal). If relay stacking is enabled, the function relays

will not be closed until the wash in-use signal is off. In either case, a second customer

can enter their code and/or deposit ca sh while a first cust omer is in the carwa sh.

The passwords listed are the default passwords (NOT necessarily the current

passwords). Once a password has been changed, the default passwords will no longer

work. The changed passwords are not listed for security reasons. It is the responsibility

of the user to know the current passwords if they are changed fro m the default values

Note 1:

Note 2:

3.1.1 Set System Time and Date

To set the system date and time scroll through the System Configuration main menu until "Set

System Time" appears. Once selected, the console will prompt for the date and time in the

Document Number: POS4010 17

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 38

POS4000

format MMDDYYHHMM (month, day, year, hour, minute). Two digits must be used for each

entry (i.e.. 3 = 03) and all entries must be completed. Time is entered in military format (i.e..

4:30PM is entered in the HHMM slot as 1630). After you enter the date and time, the con sole will

prompt for the day of the week where Sunday = 1, Monday = 2 ... Saturday = 7.

As of Version 7.00, the POS4000 is Year 2000 compliant. All printed dates are in 4-digit format.

However, whenever entering a date into the POS4000, 2-digit format is used. The 2-digit year

conversion is as follows: 00-89 = 2000-2089, 90-99 = 1990-1999. The POS4000 will calculate

the correct Date, Day of Week and Leap years until 2089.

As an example, Thursday May 6, 1999 4:37PM is entered as 0506991637 for MMDDYYHHMM

and 5 for the day of the week. If an invalid date/time is entered, the console will display "Time

Entry Error" and you will have to start over.

Example to set time to Thursday 04:37PM on 05/06/99:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Set System Time" is displayed

[ENTER]

[0][5][0][6][9][9][1][6][3][7]

[ENTER]

[5] (Monday)

[ENTER]

3.1.2 Configuring a Group

If "Groups" are available on the cashier keys, this command can be used to configure the

groups. A group is a car wash package that includes exactly one of the car wash programs and

any combination of options. For example, a "Works" group might include the deluxe wash

program and all options available on the car wash. This "group" or package would then be

available using a single key on the cashier keypad and would have its own pricing structure and

accounting information. As with all car wash functions, the group washes can be renamed to

match your nomenclature (see Section

To configure a group scroll through the configuration secondary menu until "Configure a Group"

is displayed and then press the [ENTER] key. You will then be prompted for the group number

(i.e.. 1 through 5 if five groups are available). Enter the number of the group to be configured

using the numbers printed on the management keypad followed by the [ENTER] key (do not use

the actual group key from the cashier keypad).

You will then be prompted to issue the wash type of this group. Issue the d esired wash u sing the

cashier keys as in a normal car wash transaction. For example, press the [Program 1] key,

[Option 1] key, [Option 2] key and then the [ENTER] key. Once the car wash type is entered, a

group ticket will be printed to confirm your selection. If an invalid set of features is entered, the

console will display "INVALID SELECTION" and wait for a valid set of features to be issued.

A carwash "group" cannot be used as a feature to configure another group, use only

specific wash programs and options.

Note:

3.8.1).

Document Number: POS4010 18

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 39

Example to set Group 3 to Program 1 and options 1, 2 & 4:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Configure a Group" is displayed

[ENTER]

[3] (select group #3 to configure)

[ENTER]

[Prog 1] (select wash functions in group)

[Opt 1]

[Opt 2]

[Opt 4]

[ENTER]

POS4000

3.1.3 Set Code Age Warning

This command allows you to change the code age warning message printed on customer

tickets. To select this command scroll through the configuration secondary menu until "Set Code

Age Warning" is displayed and press the [ENTER] key.

Once selected, you will be prompted to Enter # of Days Good. If 0 is entered, no message will

be printed on customer tickets; entering 0 disables code age enforcement, and the code will be

good until the customer uses the code. If 1 is entered, the message will be "Code is Good One

Time Today Only". If a number between 1 and 30 is entered, the message will be "Good Once

During Next # Days".

Note that with a multiple-console configuration, when code age is changed on the master

console, it is immediately downloaded to the remote consoles.

Note:

Important:

The default message is seven days.

Carwash codes are NOT automatically removed from memor y when this time expires.

If you wish to enforce the code age warning, you must use the Memory

Information/Clear Old Codes command

3.1.4 Set Code Length

This command allows you to change the maximum number of digits used in codes. Larger

customer codes reduce the probability of a jackpotting of the system by guessing random

numbers. For example, if the valid codes database is filled with 5,000 carwash codes and the

code length is set to 6 (maximum code is 999990) a 10% probability of jackpotting exists, or 10

random codes would have to be tried on average to jackpot the system. With the same 5,000

valid codes but a maximum code length of 7 (maximum code is 9999990) a 1% probability of

jackpotting exists, or 100 random codes would have to be tried on average to jackpot the

Document Number: POS4010 19

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 40

POS4000

system. Note that with a multiple-console configuration, when code length is changed on the

master console, it is immediately downloaded to the remote consoles.

To select this command scroll through the System Configuration secondary menu until "Set

Code Length" is displayed and press the [ENTER] key. Once selected, the console prompts you

to enter the maximum code length as 6 or 7. Press 6 or 7 as desired followed by the [ENTER]

key.

Example to set code length to 6 digits:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Set Code Length" is displayed

[ENTER]

[6]

[ENTER]

Note:

Important:

The code length includes the digit 0, which i s always the last digit in a code.

Setting the code length to 5 digits will result in reducing the number of valid codes

stored in memory from 5000 to 3000. This is necessary since there is a limited number

of 5 digit codes. If there are already more than 3000 co des i n mem o ry, you mu st delete

enough old codes to reduce the number in memory to fewer than 3000 or delete all

valid codes.

3.1.5 Disable Cashier Keys

This command allows you to disable specific cashier keys. If a key is disabled, it cannot be sold

as part of a customer transaction. All cashier keys for features that are not available on the

particular carwash installation should be disabled. This prevents a cashier from selling features

that are not available and is critical if you have the automatic buy up feature that allows

customers to upgrade or pay cash for a wash at the carwash entrance.

To select this command, scroll through the system configuration secondary menu until "Disable

Cashier Key" is display and press the [ENTER] key. Once selected you will be prompted Press

Cashier Keys to Disable, Then ENTER. Press all cashier keys that should be disabled and

then press the [ENTER] key. To enable all cashier keys, press only the [ENTER] key.

For example, if you have a console with 4 programs, 4 options and 4 groups and you don't use

group 4 and the carwash doesn't have program 4 or options 3 and 4, you disable the unused

keys as follows:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Disable Cashier Key" is displayed

[ENTER]

Document Number: POS4010 20

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 41

[Prog 4] (disable program 4)

[Opt 3] (disable option 3)

[Opt 4] (disable option 4)

[Group 4] (disable group 4)

[ENTER]

Example to re-enable all cashier keys:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[ENTER]

[MENU UP/DOWN] until "Disable Cashier Key" is displayed

[ENTER]

[ENTER] (no cashier keys pressed)

POS4000

Note:

Note:

Cashier keys that have been disabled MUST be re-e nabled using t he above steps.

All programs and options not available on your particular carwash and all group

packages not programmed and used by you must be disabled if the buy up option is

enabled.

3.1.6 Set Serial Baud Rate

This command allows you to change the serial baud rate of the cash register port on the

console. This rate only needs to be changed if you are connecting to an External Point of sale

device.

To select this command scroll through the configuration secondary menu until "Set Serial Baud"

is displayed and then press the [ENTER] key. You will then be prompted to enter the new baud

rate. Only standard baud rates are allowed: 1200, and 2400, 4800,9600, and 19200. If you enter

one of these rates, it will be saved. If you enter any other rate, an error message is displayed

and the baud rate is not changed.

Example for setting the baud rate to 9600:

[CMD]

[SYSTEM SETUP]

[MENU UP/DOWN] until "Set Baud Rate" appears

[ENTER]

[9][6][0][0]

[ENTER]

Note:

The new Baud Rate will not take effect until a power reset of the console occurs. To do

this, simply turn the ON/OFF switch in t he OFF positi on f or a mom ent and th en ret urn it

to the ON position.

Document Number: POS4010 21

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 42

Note:

POS4000

The factory default baud rate is dependent on what type of EXT POS interface is

configured on default. Serial Baud default for POS1 & POS2 is 19200, serial baud for

POS 0 (No EXT POS interface) and POS3 is 2400.

3.1.7 Set Languages

This command allows you to change the language used on the main console display and/or the

customer language (used on tickets and optional customer display at entrance of wash). To

select this command scroll through the system configuration main menu until "Set Language"

appears and then press [ENTER].

Once selected you are prompted to enter the desired console language. Press [0][ENTER] for

English or [1][ENTER] for French. Next, you are prompted to select the customer language in a

similar manner.

Example to set console language as English and the custo mer language a s German:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[MENU UP/DOWN] until "Set Languages" appears

[ENTER]

[0] for English

[ENTER]

[2] for German

[ENTER]

3.1.8 Set Program Relays

This command is only available on systems configured for a specific manufacturer. If a section

titled "OUTPUT Logic Block" does not appear on your SYSTEM CONFIGURATION report then

this option is not available on your system.

This command allows the output relays on the customer interface board to be configured for

Logic and Block values that correspond to each carwash program. To select this command,

scroll through the system configuration secondary menu until "Set Program Relays" is display

and press the [ENTER] key.

Once this item is selected, you will be prompted to Enter Program Number. Use the numbers

printed on the management keys to select the number of the program you wish to configure (do

not use the cashier keys) and then press [ENTER]. Next you will be prompted to Enter Logic &

Block. Again, use the management keys to enter the appropriate value. If you enter and invalid

logic or block value, the console will display the message "Invalid Logic/Block" and the

command will be terminated.

Example to configure Program 1 to have a logic & block value of 32:

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[MENU UP/DOWN] until "Set Program Relays" appears

[ENTER]

[1]

[ENTER]

Document Number: POS4010 22

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 43

[3][2]

[ENTER]

POS4000

3.1.9 External POS MENU->

This sub-menu is used to configure the external Point-of-Sale (POS) capabilities of your system.

It contains the following sub-menu items:

To execute one of the sub-menu commands, first select "External POS MENU->" from the

SYSTEM SETUP menu, and then scroll through the sub-menu until the command of interest is

displayed and then press the [ENTER] key.

Note that with the Optional Remote Extpos Connection Software, the master and each

secondary console can be set to interface to a different External POS system using different

configuration settings.

Note:

• Set POS Offset (direction and amount)

• Set EXT. POS Type

• Set POS MAX WASHES (for special circumstances only)

• Set Send Code age (for certain EXTPOS units only)

• Set Reverse order (to allow pumps to have wash 1 most expensive)

• Set Default Discounts

This command is used to configure an OPTIONAL FEATURE of the POS4000. If this

feature is not present in your system, you will not be able to execute these commands.

3.1.9.1 Set POS Offset

This command is used to convert an external POS system's wash "type" or "level" to a

POS4000 program or group key.

To select this command, scroll through the External POS sub-menu until "Set POS Offset"

appears and then press [ENTER].

Document Number: POS4010 23

Document Title: Remote Code POS4000 Installation and Operations Manual

Note:

Example to set the POS Offset as 5 UP:

This feature is for use with POS 1, 2 and 3.

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[MENU UP/DOWN] until "External POS MENU->" appears

[ENTER]

[MENU UP/DOWN] until "Set POS Offset" appears

[ENTER]

[1][ENTER] to select direction UP

[5][ENTER] to select amount of offset as 5

Page 44

POS4000

3.1.9.2 Define External POS Type

This command is used to define what type of external Point-of-Sale equipment is present and

connected to the POS4000. To select this command, scroll through the External POS su b-menu

until "Define EXT. POS Type" appears and then press [ENTER].

Note:

Note:

Example to set the external POS type as 3:

The default is for there to be no offset (i.e. 0 down).

The current EXT POS settings will print out with a mapping of the carwash type given

vs. the carwash type requested.

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[MENU UP/DOWN] until "External POS MENU->" appears

[ENTER]

[MENU UP/DOWN] until "Define EXT. POS Type" appears

[ENTER]

[3][ENTER]

3.1.9.3 Set POS MAX WASHES

Note:

Note:

This function is used to modify the commands received by an external point of

sale device such as pump equipment. These commands are configured to ask

for more wash types than are available. You should only change this value when

instructed to do so from an application note or a Unitec service technician. The

default value is 0 (disabled). This value only limits the number of wash types that

can be requested by an External POS device, not the number of wash types that

can be sold via the console or entry system (cash or buy ups).

If the external POS type is set to 1 or 2, the current EXT POS settings will print out with

a mapping of the Carwash type given vs. the carwash type re quested.

This feature is for use with POS 1 and 2 only.

Example to set the POS MAX WASHES to 3 (max of 3 washes allowed):

[CMD]

[SYSTEM SETUP]

[3] (password 3)

[MENU UP/DOWN] until "External POS MENU->" appears

Document Number: POS4010 24

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 45

POS4000

[ENTER]

[MENU UP/DOWN] until "Set POS MAX WASHES" appears

[ENTER]

[3][ENTER] to select maximum of 3 wash types to be given

3.1.9.4 Set Send Code Age

This command is used to enable the POS1 or POS2 protocol to include the response code for

code age and wash status. In some cases when this feature is not enabled (default) the receipt

printed out at the gas pump will show that the code is valid for 1 day only. Enabling this value

may cause the system to not work properly with some point of sale manufact urers. To select t his

command, scroll through the External POS sub-menu until “Set Send Code Age” appears and

then press the indicated function key.

Note:

Example to set send code age enabled:

[CMD] to select command mode

[2-System Setup] to select "System Setup" menu

Note:

The current EXT POS settings will print out with a mapping of the carwash type given

vs. the carwash type requested.

[3] Enter your password 3

[ENTER]

[Menu up] Until you see: "Ext. POS MENU->"

[Menu up] Until you see “Set Send Code Age”

[Enter] Select function

[ 1 ] To enable set send code age

[ENTER]

The default setting is 0, which is normal protocol.

3.1.9.5 Reverse Order

Note:

This feature is for use with POS 1 and 2 only.

Enabling the Reverse Order function will allow the order of carwashes configured

in the External POS device to be reversed. This function is often used when the

External POS has the prices configured in descending order (wash 1 on

EXTPOS is most expensive). Since the wash prices for an entry system that

uses cash must be in ascending order at the POS4000, this function allows the

re-mapping of the washes requested at the registers and pumps. This function

must be configured w/ POS MAX WASHES to determine how to reverse the

order.

Example:

Carwash is configured w/ 3 washes:

Document Number: POS4010 25

Document Title: Remote Code POS4000 Installation and Operations Manual

Page 46

POS4000

Wash 1 (program 1): Basic $4.00

Wash 2 (program 2): Deluxe $5.00

Wash 3 (program 3): Supreme $6.00

Register is configured to the opposite:

Wash 1 : Supreme $6.00

Wash 2 : Deluxe $5.00

Wash 3 : Basic $4.00

To make the system function properly you must configure POS MAX washes (See Section

3.1.9) to a value of 3 (3 washes). Set Reverse order to 1 (enabled).

After changing these values the current EXT POS settings will print out with a mapping of the

Carwash type given vs. the carwash type requested. This will show the relationship of the

mapping.

If you use groups, you must also set the POS OFFSET (Se Section 6.2.10.1).

This function only works with POS 1 & POS 2.

Example to set Reverse order to Enabled:

[CMD] to select command mode

[2-System Setup] to select "System Setup" menu

[3] Enter your password 3

[ENTER]

[Menu up] Until you see: "Ext. POS MENU->"

[Menu up] Until you see “Reverse order”

[Enter] Select function

[ 1 ][Enter]

To enable select 1

3.1.9.6 Set Default Discount Levels

Note:

This feature is for use with POS 1, 2 and 3.