Page 1

Or i g i n a l

Op e r a t i n g i n s t r u c t i o n s • In s t r u c c i o n e s d e m a n e j o

M o d e d ‘ e m p l o i

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 2

C o n t e n t s Pa g e

Op e r a t i n g i n s t r u c t i o n s . . . . . . . . . . . . . . . . 5

In d i c e Pá g i n a

In s t r u c c i o n e s d e m a n e j o . . . . . . . . . . . . . 2 2

So m m a i r e Pa g e

M o d e d ’ e m p l o i . . . . . . . . . . . . . . . . . . . . . 3 9

Distributed exclusively by:

2 2 Ha r b o r Av e n u e , No r w a l k , C T 0 6 8 5 0 U SA

T o l l - F r e e : 8 0 0 - 7 0 0 - 5 9 1 9

Ph o n e : 2 0 3 - 8 5 3 - 9 5 2 2

F a x : 2 0 3 - 8 5 3 - 9 9 2 1

Em a i l : i n f o @ c s u n i t e c . c o m

w w w . c s u n i t e c . c o m

BA_MABasic_1501_A2 © 2015 BDS Maschinen GmbH

Page 3

5

4

3

2

1

9

1 0

8

1 1

6

7

Page 4

2 4 2 3 2 2

2 1

2 0

2 6 2 5

BA

Page 5

Ge n e r a l i n s t r u c t i o n s

T a b l e o f C o n t e n t s

Ge n e r a l i n s t r u c t i o n s . . . . . . . . . . . . . . . . . 7

Sa f e t y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

C o m p o n e n t s / d e l i v e r y c o n t e n t s . . . . . . 1 2

Before using for the rst time . . . . . . . . 1 3

Pr e p a r a t i o n . . . . . . . . . . . . . . . . . . . . . . . 1 3

U s e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 6

El i m i n a t i n g b l o c k a g e s . . . . . . . . . . . . . . 1 7

C l e a n i n g . . . . . . . . . . . . . . . . . . . . . . . . . . 1 8

M a i n t e n a n c e . . . . . . . . . . . . . . . . . . . . . . . 1 8

St o r a g e . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 8

T r o u b l e s h o o t i n g . . . . . . . . . . . . . . . . . . . 1 9

T e c h n i c a l d a t a . . . . . . . . . . . . . . . . . . . . . 2 0

EC D e c l a r a t i o n o f C o n f o r m i t y . . . . . . . . 2 1

Dear Customer,

Before using the machine, please read the

operating instructions contained in this user

manual on startup, safety, intended use as

well as cleaning and care.

The links and illustrations in these

instructions refer to the illustrations on the

inside of the cover.

Keep these operating instructions for later

use and pass them onto the next owner of

the machine.

Ge n e r a l i n s t r u c t i o n s

C o p y r i g h t

This document is copyrighted. Any

duplication or reprinting, in whole or in part,

and the reproduction of the illustrations, even

in modied form, is only permitted with the

written approval of the manufacturer.

Li a b i l i t y d i s c l a i m e r

All technical information, data and

instructions for commissioning, operation

and maintenance of the machine contained

in these operating instructions represent the

latest status at the time of printing.

The manufacturer assumes no liability

for damage or injury resulting from failure

to observe the operating instructions,

use for other than the intended purpose,

unprofessional repairs, unauthorized

modications or use of non-approved spare

parts and accessories, tools and lubricants.

In s t r u c t i o n s o n d i s p o s a l

The packaging materials used can be

recycled. When no longer required,

dispose of the packaging materials according

to local environmental regulations.

This product may not be disposed of in

the domestic refuse within the

European Union. Dispose of the

device via communal collection points.

ENGLISH

7M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 6

Ge n e r a l i n s t r u c t i o n s

Sa f e t y w a r n i n g s t r u c t u r e

The following warnings are used in these

operating instructions:

D ANGER

A w a r n i n g o f t h i s c a t e g o r y i n d i c a t e s a n

i m p e n d i n g d a n g e r o u s s i t u a t i o n .

If the dangerous situation is not avoided, it

may lead to serious injury or even death.

► Follow the instructions in this warning

ENGLISH

to avoid possible danger of serious

injury or even death.

W AR NING

A w a r n i n g o f t h i s c a t e g o r y i n d i c a t e s a

p o s s i b l e d a n g e r o u s s i t u a t i o n .

If the dangerous situation is not avoided, it

may lead to injuries.

► Follow the instructions in this warning

to avoid possible danger of serious

injury or even death.

ATTENTION

A w a r n i n g s t a t e m e n t f o r t h i s s a f e t y r i s k

c l a s s i n d i c a t e s a d a m a g e r i s k .

If the situation is not avoided, it may lead

to material damage.

► Follow the instructions in this warning

to avoid material damage.

In t e n d e d u s e

The machine is intended solely for drilling

operations in magnetic and non-magnetic

metals within the limits specied in the

technical data.

Any use other than previously stated is

considered as improper use.

W AR NING

D a n g e r r e s u l t i n g f r o m i m p r o p e r u s e !

If not used for its intended purpose and/or

used in any other way, the machine may

be or become a source of danger.

► Use the machine only for its intended

purpose.

► Observe the procedures described in

these operating instructions.

No claims of any kind will be accepted for

damage resulting from use of the appliance

for other than its intended purpose.

The risk must be borne solely by the user.

NOTE

► If used commercially, pay attention

to compliance with the accident

prevention and occupational safety

regulations.

NOTE

► A note indicates additional information

that simplies the use of the machine.

8

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 7

Sa f e t y

Sa f e t y

C AU T ION

W h e n u s i n g e l e c t r i c a l t o o l s , t h e f o l l o w i n g f u n d a m e n t a l p r e c a u t i o n s m u s t b e

t a k e n t o p r o t e c t a g a i n s t e l e c t r i c s h o c k

and the risk of injury and re!

F u n d a m e n t a l s a f e t y p r e c a u t i o n s

■ Do not use the machine in ammable or

potentially explosive environments.

■ Persons who are unable to operate the

machine due to their physical, mental or

motor response abilities may only use

the machine under supervision of or

instruction by a responsible person.

■ Persons with heart pacemakers or other

medical implants must not use this

machine.

■ Children must not be allowed to use the

machine.

■ Inspect the machine for visible signs

of damage before use. Do not use a

damaged machine.

■ Before beginning work, check the

condition of the Safety lashing strap

and the function of the switches on the

machine.

■ Repairs to the mains cable may only be

carried out by a qualied electrician.

■ Repairs to the machine may only be

carried out by an authorized specialist

workshop or by the works customer

service. Unqualied repairs can lead to

considerable danger for the user.

■ Repairs to the machine during the

warranty period may only be carried out

by a service centre authorized by the

manufacturer otherwise the guarantee

will be invalidated.

■ Defective parts may only be replaced

with original spare parts. Only original

spare parts guarantee that the safety

requirements are met.

■ Do not leave the machine unsupervised

during operation.

■ Store the machine in a dry, temperate

location out of the reach of children.

■ Do not leave the machine standing

outdoors and do not expose it to

moisture.

■ Make sure that your work area is

sufciently lit (>300 Lux).

■ Do not use low-power machines for

heavy working.

■ Make sure that your workplace is clean.

■ Keep the machine clean, dry and free of

oil and grease.

■ Follow the instructions on lubricating and

cooling the tool.

ENGLISH

9M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 8

Sa f e t y

D a n g e r o f e l e c t r i c s h o c k

D ANGER

El e c t r i c s h o c k h a z a r d !

C o n t a c t w i t h l i v e w i r e s o r c o m p o n e n t s

c a n l e a d t o s e r i o u s i n j u r y o r e v e n

d e a t h !

Observe the following safety precautions

to avoid any danger from electric current:

► Do not open the housing of the

ENGLISH

machine. Risk of electric shock if live

terminals are touched.

► Never immerse the machine or the

plug into water or other liquids.

► Only use extension cables or cable

drums with a cable cross-section of 1.5

mm².

► Only use extension cables that are

approved for the place of work.

► Check the condition of the extension

cable regularly and replace if

damaged.

► Avoid direct body contact with

grounded parts (e.g., tubes, radiators,

steel girders) to reduce the risk of

electric shock in the event of a defect.

R i s k o f i n j u r y

W AR NING

Im p r o p e r h a n d l i n g o f t h e m a c h i n e

i n c r e a s e s t h e r i s k o f i n j u r y !

Observe the following safety precautions

to avoid injuring yourself and/or others:

► Operate the machine only with the

protective equipment stipulated in

these operating instructions (see

Personal protective equipment

section).

► D o n o t wear protective gloves when

the machine is running. A glove can

be caught by the drilling machine and

torn off the hand. Risk of losing one or

more ngers.

► Remove loose jewellery before

beginning work. Wear a hair net if you

have long hair.

► Always switch off the machine

before changing tools, performing

maintenance or cleaning. Wait until

the machine has come to a complete

standstill.

► Always remove the plug from the

mains socket before changing tools,

cleaning or performing maintenance

work in order to avoid unintentional

starting of the machine.

► Do not put your hand into the machine

while it is in operation. Remove

swarf only when the machine is at a

standstill. Wear protective gloves when

removing swarf.

► When working on scaffolding, the

operator must be secured with a safety

belt as the machine can oscillate

dangerously in the event of interruption

to the power supply.

1 0

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 9

Sa f e t y

W AR NING

► Check for secure clamping of the

electromagnets on the substrate before

every use (see Preparation section).

► Secure the machine with the safety

lashing strap supplied when working

from an inclined or vertical position or

during overhead work. The machine

could fall down if the magnet is

loosened or the power fails.

► Check that the tool is tightened

securely before using (see Inserting

the tool section).

► Do not allow the connecting cable to

hang over edges (trip wire effect).

Pr e v e n t i n g d a m a g e

ATTENTION

Po t e n t i a l d a m a g e t o p r o p e r t y i f t h e

m a c h i n e i s i m p r o p e r l y u s e d !

Observe the following instructions to avoid

property to damage:

► Before connecting the machine,

compare the connection data (voltage

and frequency) on the rating plate with

those of your mains power supply. The

data must correspond in order to avoid

damage to the machine.

► Always use the handle to carry the

machine and not the connecting cable.

► Do not pull the mains cable to remove

the plug from the mains socket.

ATTENTION

► Do not crush the connecting cable.

► Do not expose the connecting cable to

heat or chemical liquids.

► Do not pull the connecting cable

across sharp edges or hot surfaces.

► Lay the connecting cable in such a way

that it cannot be caught and wound up

in the rotating part of the machine.

Sa f e t y a p p l i a n c e s

R e s t a r t p r o t e c t i o n

NOTE

► The machine stops automatically when

the magnetic clamp is switched off or if

the power supply is interrupted.

In order to prevent the machine from starting

unexpectedly after switching on the magnetic

clamp again or after reconnection following

interruption to the power supply ("restart

protection"), the machine must be switched

on using the ON/OFF switch.

Sy m b o l s o n t h e m a c h i n e

The symbols on the machine have the

following meaning:

Sy m b o l M e a n i n g

Electric shock hazard!

Read the operating instructions

before beginning work!

ENGLISH

Wear protective goggles and ear

protection!

1 1M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 10

C o m p o n e n t s / d e l i v e r y c o n t e n t s

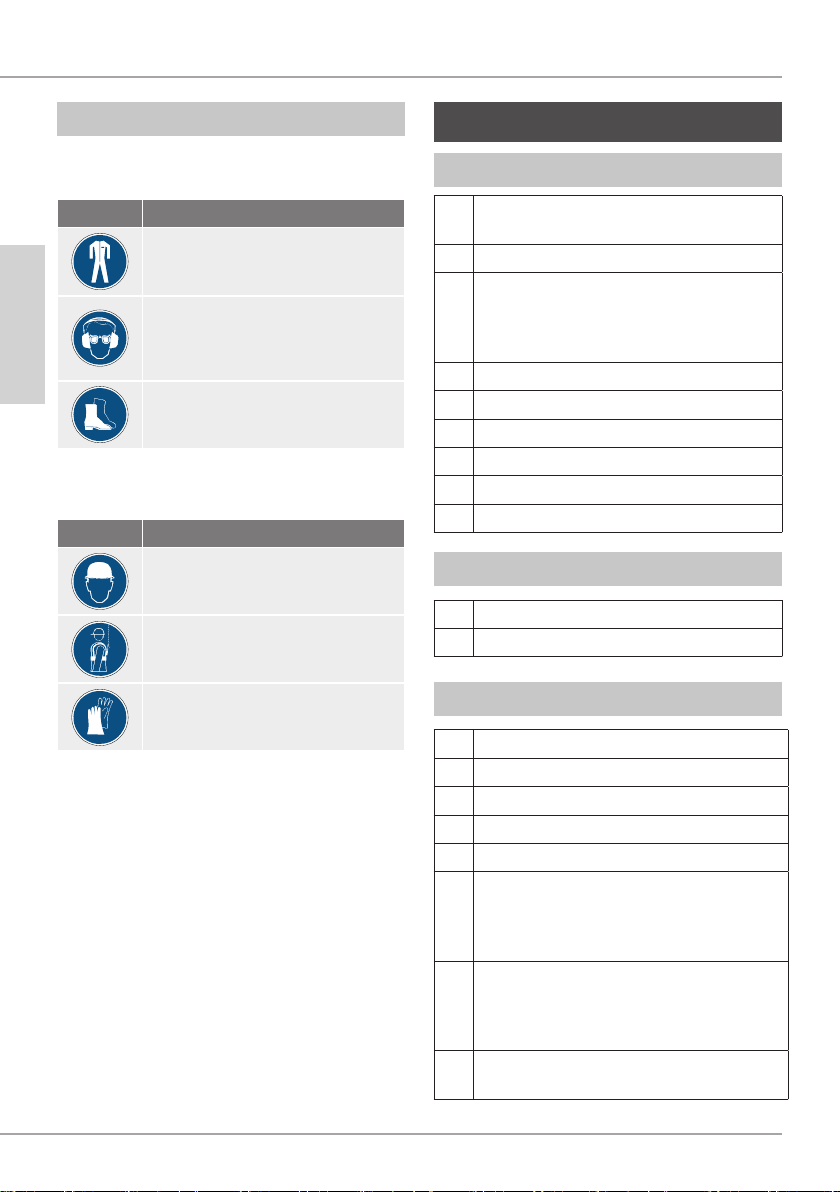

Pe r s o n a l p r o t e c t i v e e q u i p m e n t

Wear the following protective equipment at

all times when operating the machine:

Sy m b o l M e a n i n g

Close-tting work protection

clothing with a low tear strength

Goggles for protecting eyes

against ying parts and liquids

ENGLISH

Also wear the following protective equipment

during special work:

Sy m b o l M e a n i n g

and ear protection in areas with

noise emission >80 dB(A)

Safety shoes for protecting feet

against falling objects.

Helmet for protecting your head

against falling objects

Wear a harness where there is a

danger of falling.

Gloves for protection against

injuries

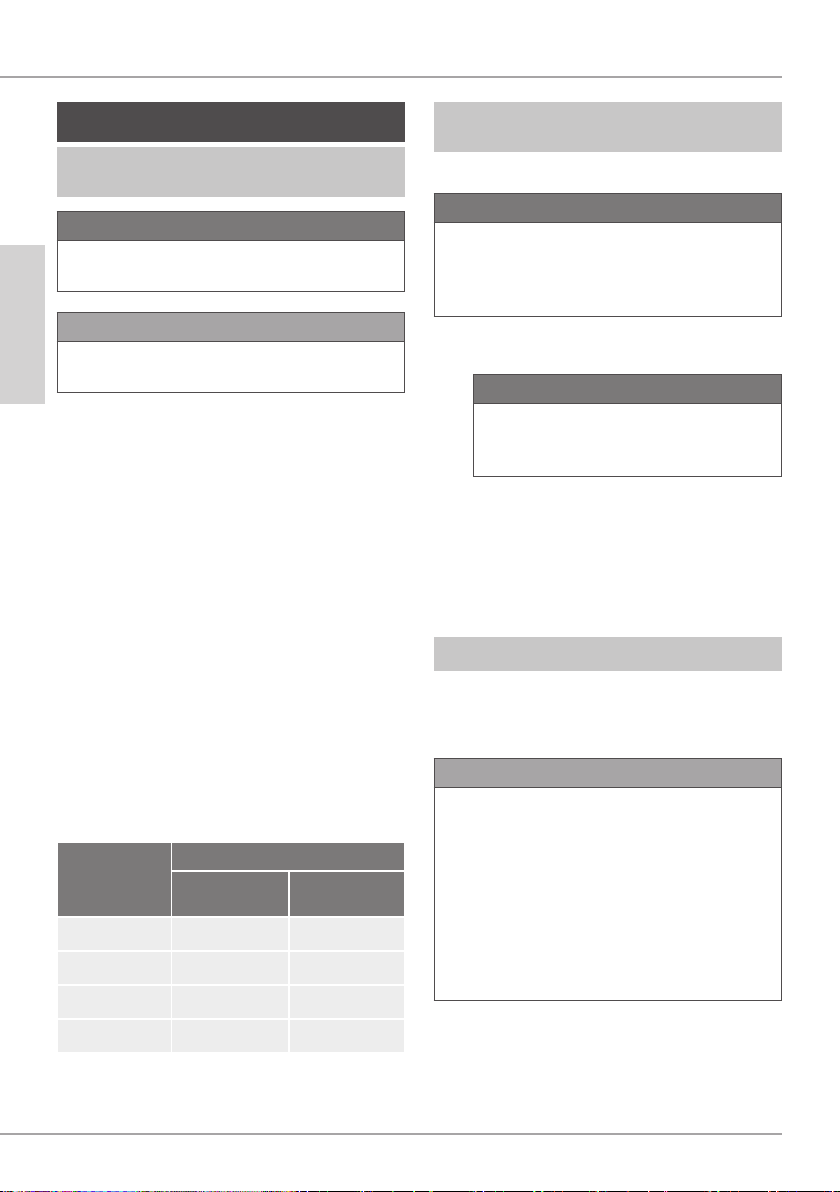

C o m p o n e n t s / d e l i v e r y c o n t e n t s

M a c h i n e o v e r v i e w

1 Core drill

(not supplied as standard)

2 Tool mounting

3 Gearbox

(with selector lever:

2-stage for MABasic400 and 450

4-stage for MABasic 850)

4 Drive motor

5 Handle

6 Hand lever

7 Operating panel

8 Magnetic foot

9 Machine slide and guide

Op e r a t i n g p a n e l

10 Motor ON/OFF switch

11 Magnet ON/OFF switch

D e l i v e r y c o n t e n t s

20 Core drilling machine

21 Safety lashing strap

22 ZKP100 cutting oil pump container

23 ZAK075 ejector pin

24 Transport case

25 Hexagonal offset screwdriver

SW 4 for MABasic 200/400

SW5 for MABasic 450

SW5 + SW6 for MABasic 850

26 Industrial holder

(ZIA219KN for MABasic 450

ZIA319KN and

ZIA32KN for MABasic 850)

Operating instructions/guarantee card

(not illustrated)

1 2

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 11

Before using for the rst time

Before using for the rst time

T r a n s p o r t i n s p e c t i o n

As standard, the machine is supplied

with the components indicated in the

Components/delivery contents"section.

NOTE

► Check for visible signs of damage or

missing items on delivery. Report an

incomplete or damaged delivery to

your supplier/retailer immediately.

Pr e p a r a t i o n

This section contains important instructions

on the required preparation before beginning

any work.

Ad d i t i o n a l s a f e t y m e a s u r e s f o r

c e r t a i n w o r k

Additional safety precautions must be taken

for the following operations with the machine:

No n - h o r i z o n t a l w o r k p o s i t i o n

W AR NING

R i s k o f i n j u r y f r o m a f a l l i n g m a c h i n e .

When working in an inclined or vertical

position or during overhead work, the

machine must be secured using the safety

lashing strap (21) supplied to prevent it

from falling.

► Before using, check the safety lashing

strap for proper function. A damaged

safety lashing strap may not be used.

Replace a damaged safety lashing

strap immediately.

W AR NING

► Attach the safety lashing strap in such

a way that the machine can fall away

from the operator if it slips.

► Lay the safety lashing strap as tightly

as possible around the handle of the

machine.

► Before beginning word, check that the

safety lashing strap and the lock is

rmly seated.

► Use the protective equipment

stipulated in the section Personal

protective equipment.

W o r k o n s c a f f o l d i n g

W AR NING

R i s k o f f a l l i n g f r o m s u d d e n o s c i l l a t i n g

m o v e m e n t s o f t h e m a c h i n e .

When working on scaffolding, the machine

can make a sudden oscillating movement

on starting or in the event of interruption to

the power supply.

► Secure the machine with the safety

lashing strap (21) supplied.

► Wear a safety harness to protect

yourself against falling.

ENGLISH

1 3M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 12

Pr e p a r a t i o n

C h e c k t h e c o n d i t i o n

o f t h e s u b s t r a t e

The magnetic clamping force is dependent

on the condition of the substrate. The

clamping force is signicantly reduced by

paint, zinc and scale coatings and rust.

The substrate must satisfy the following

conditions in order to achieve sufcient

magnetic clamping force:

■ The substrate must be magnetic.

ENGLISH

■ The clamping surface and the magnetic

foot (8) must be clean and grease-free.

■ The clamping surface must be

completely smooth and level.

NOTE

► Clean the substrate and the magnetic

foot (8) of the machine before use.

► Remove any unevenness and loose

rust from the substrate.

► The CS Unitec range of accessories

includes special holding devices.

The best clamping effect is obtained on low-

carbon steel substrate with a thickness of at

least 20 mm.

St e e l w i t h l o w t h i c k n e s s

When drilling into low thickness steel, an

additional steel plate (minimum dimensions

4” x 7-7/8” x 3/4” [100 x 200 x 20 mm]) must

be placed under the workpiece. Secure the

steel plate to prevent it from falling.

NF m e t a l s o r w o r k p i e c e s w i t h a n u n e v e n

s u r f a c e

A special holding device must be used when

drilling into NF metals or into workpieces with

an uneven surface.

NOTE

► CS Unitec offers a range of

accessories with special clamping

devices for tubes and non-magnetic

materials.

In s e r t i n g t h e t o o l

W AR NING

R i s k o f i n j u r y

► Do not use damaged, soiled or worn

tools.

► Change tools only when the machine

is switched off and at a standstill. Pull

the plug out of the mains socket.

► After inserting, check that the tool is

engaged securely.

► Only use tools, adapter and

accessories that match the machine.

1 4

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 13

Pr e p a r a t i o n

M AB a s i c 2 0 0 a n d 4 0 0

In s e r t t h e c o r e d r i l l i n t o t h e d i r e c t t o o l

m o u n t ( i l l u s t r a t i o n A)

Before mounting, clean the Weldon

shank and direct tool mount (2) of the

machine.

Check the the lead connection for

lubricant.

Unscrew the two Allen screws in the

direct tool mount using the hexagonal

offset screwdriver (25) supplied.

Insert the core drill in the direct tool

mount (2).

NOTE

► Insert the appropriate ejector pin (23)

before inserting the core drill.

Tighten the two Allen screws in

the direct tool mount (2) using the

hexagonal offset screwdriver (25)

supplied.

R e m o v i n g t h e t o o l

Unscrew the two Allen screws in the

tool mount (2) using the hexagonal

offset screwdriver (25) supplied and

remove the core drill from below.

M AB a s i c 4 5 0 a n d 8 5 0

In s e r t t h e c o r e d r i l l i n t o t h e i n d u s t r i a l

h o l d e r ( i l l u s t r a t i o n B )

Push the industrial holder (26) into the

spindle taper of the machine.

Before inserting, clean the Weldon

shank of the tool and the tool holder.

Check the the lead connection for

lubricant.

Unscrew both Allen screws in the tool

mount using the hexagonal offset

screwdriver (25) supplied.

Insert the core drill into the tool mount.

NOTE

► Insert the appropriate ejector pin (23)

before inserting the core drill.

Tighten both Allen screws in the tool

mount (2) using the hexagonal offset

screwdriver (25) supplied.

R e m o v i n g t h e t o o l

Unscrew the two Allen screws in the

tool mount (2) using the hexagonal

offset screwdriver (25) supplied and

remove the core drill from below.

ENGLISH

1 5M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 14

U s e

U s e

Se l e c t t h e r o t a t i n g s p e e d r a n g e

( o n l y M AB a s i c 4 0 0 , 4 5 0 a n d 8 5 0 )

ATTENTION

► Switch the gear stages only with the

machine at standstill.

NOTE

► Select the speed range according to

ENGLISH

the material and drilling diameter.

Se l e c t t h e g e a r M AB a s i c 4 0 0 / 4 5 0

The machine has a gearbox with two

mechanical gear stages. The rotation speeds

of the gear stages are specied in the

technical data.

To select the desired gear stage, set

selector lever on the gearbox (3) to

stage 1 or 2 with the machine switched

off.

Se l e c t t h e g e a r M AB a s i c 8 5 0

The machine has a gearbox with four

mechanical gear stages. The rotation speeds

of the gear stages are specied in the

technical data.

To select the desired gear stage, switch

the machine off and set both selector

levers on the gearbox (5) to the desired

stage as shown in the table below.

Se l e c t o r l e v e r

Ge a r s t a g e

Stage 1

Stage 2

Stage 3

Stage 4

a n t i - c l o c k -

w i s e

▼ ▲

▼ ▼

▲ ▲

▲ ▼

c l o c k w i s e

Ac t i v a t i n g / d e a c t i v a t i n g

t h e m a g n e t i c c l a m p

Ac t i v a t i n g t h e m a g n e t i c c l a m p

ATTENTION

► To prevent the magnet from

overheating, switch on the magnetic

clamp only when the machine is

standing on a magnetic substrate.

Turn on the switch (11). The indicator

lamp in the switch (11) lights up.

ATTENTION

► The maximum magnetic clamping

force is only available after

switching on the motor.

D e a c t i v a t i n g t h e m a g n e t i c c l a m p

Hold the handle tightly (5) to stop the

machine from slipping.

Turn off the switch (11). The indicator

lamp in the switch (11) extinguishes.

Sw i t c h i n g t h e m a c h i n e ON/ OF F

Using the ON/OFF switch (10), turn the

machine ON with the green button (I)

and OFF with the red button (O).

NOTE

► The machine can only be switched on

when the magnetic clamp has been

switched on.

► Allow a severely overheated machine

to run on at idle speed for approx. 2

minutes to cool it down.

► The machine switches off automatically

in the event of a power failure or if the

magnetic clamp is switched off.

1 6

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 15

El i m i n a t i n g b l o c k a g e s

D r i l l i n g w i t h t h e m a c h i n e

D r i l l i n g w i t h c o r e d r i l l s

When drilling with core drills, proceed as

follows:

Insert the corresponding ejector pin (23)

into the core drill.

Insert the core drill with the ejector pin

as described in chapter Inserting the

tool.

Place the machine at the working

location, align it and switch on the

magnetic clamps.

Switch the machine on.

Direct the drill with the handle (6) to the

material.

NOTE

Observe the following instructions when

drilling with core drills:

► Drilling with core drills does not require

great force. The drilling process is not

accelerated by higher pressure. The

drill wears faster and the machine can

be overloaded.

► Use CS Unitec’s high-performance

cutting oil in the cooling lubricant

system of the machine.

► The cooling lubricant system cannot be

used when working overhead. In this

case, use the high-performance ZHS

400 grease spray.Spray the drill on

the inside and outside before drilling.

Repeat this procedure when drilling

deeper holes.

► Make sure that swarf is removed

regularly. With larger drilling depths,

break the chip.

El i m i n a t i n g b l o c k a g e s

W AR NING

D a n g e r o f c u t i n j u r i e s f r o m b r o k e n t o o l

p a r t s o r s w a r f .

► Put protective gloves on before starting

work.

B l o c k a g e s c a u s e d b y a b r o k e n t o o l :

Switch off the machine. Remove plug

from the mains socket.

Use the handle to move the machine

slide to the upper position.

Replace defective tool. Remove swarf.

Ot h e r b l o c k a g e s :

Switch the machine off using the motor

switch. Leave the magnetic clamp

switched on.

Use the handle to move the machine

slide to the upper position.

Remove swarf and check tool.

ENGLISH

1 7M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 16

C l e a n i n g / M a i n t e n a n c e

C l e a n i n g

W AR NING

► Switch off the machine and pull the

plug out of the mains socket before

starting maintenance and cleaning.

► When using compressed air for

cleaning, wear protective goggles and

gloves and protect other persons in the

working area.

ENGLISH

ATTENTION

► Never immerse the machine in water

or other liquids.

Af t e r e v e r y u s e

Remove the inserted tool.

Remove swarf and coolant residues.

Clean the tool and the tool holder on

the machine.

Clean the guide of the machine slide.

Put the machine and accessories into

the transport case.

Ad j u s t i n g t h e m a c h i n e s l i d e g u i d e

If the machine slide guide (9) exhibits too

much clearance, it must be adjusted. To do

this, proceed as follows:

Loosen the clamping bolts.

Tighten the adjusting screws evenly.

Tighten the clamping bolts again.

R e p l a c i n g t h e c a r b o n b r u s h e s

Replacement of the carbon brushes

may only be carried out by CS Unitec or

by an authorized specialist workshop.

Unauthorized repairs will invalidate the

guarantee.

C u s t o m e r s e r v i c e / s e r v i c e

Should you have any questions on customer

service/service, please contact CS Unitec.

We will be happy to give you the address of

your nearest service partner.

St o r a g e

M a i n t e n a n c e

W AR NING

Danger caused by unqualied repairs!

Unqualied repairs can lead to considera-

ble danger for the user and cause damage

to the machine.

► Repairs to electrical appliances may

only be carried out by the works

customer service or by specialists

trained by the manufacturer.

1 8

St o r a g e

If you do not intend to use the machine for a

longer period of time, clean it as described in

the section Cleaning. Store the machine and

all its accessories in the transport case at a

dry, clean and frost-free location.

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 17

T r o u b l e s h o o t i n g

F a u l t Po s s i b l e c a u s e R e m e d y

Plug not inserted into socket. Insert plug.

T r o u b l e s h o o t i n g

The motor does not start after

pressing the ON/OFF switch

or stops during operation.

The automatic circuit breaker

in the electrical distribution

board trips.

The magnetic clamp does not

function.

The lubrication system does

not function.

Automatic circuit breaker

tripped.

The magnetic clamp is not

switched on.

Too many appliances connected to the same power

circuit.

The machine is defective. Contact customer service.

Magnet not switched on. Switch on the magnet.

The surface is not magnetic. Use a suitable base.

No lubricant available. Top up the lubricant.

Lubricant tap closed. Open the lubricant tap.

Connecting nipple clogged. Clean the tank and nipple.

Switch on the automatic circuit

breaker again.

Switch on the magnetic clamp.

Reduce the number of appliances on the power circuit.

NOTE

► If you cannot resolve the problem with the steps described above, please contact

customer service.

ENGLISH

1 9M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 18

T e c h n i c a l d a t a

T e c h n i c a l d a t a

M o d e l M AB a s i c 2 0 0 M AB a s i c 4 0 0 M AB a s i c 4 5 0 M AB a s i c 8 5 0

Dimensions

(L x W x H)

10-1/2" x 6-1/2" x

12-1/4"/18-1/2"

(269 x 163 x

310/470 mm)

11" x 6-1/2" x

14"/20-1/4"

(280 x 163 x

355/515 mm)

11" x 6-1/2" x

17"/23-1/4"

(280 x 163 x

430/590 mm)

12" x 9-1/2" x

19-1/3" /29-1/2"

(329 x 240 x

491/751 mm)

Magnetic foot

(L x W)

ENGLISH

Approx. net weight. 27 lbs. (12 kg) 27 lbs. (12 kg) 29 lbs. (13 kg) 53 lbs. (24 mm)

Operating voltage

(see type plate)

Power consumption

6-5/8" x 3-1/3"

(168 x 84 mm)

8.2 Amp /110 V

900 W

6-5/8" x 3-1/3"

(168 x 84 mm)

230 V / 50-60 Hz

or 110-125 / 50-60 Hz

9.5 Amp / 110 V

1050 W

6-5/8" x 3-1/3"

(168 x 84 mm)

10.5 Amp / 110 V

1150 W

8-5/8" x 4-1/3"

(220 x 110 mm)

16 Amp / 110 V

1700 W

Noise emission 87 db(A) 87 db(A) 87 db(A) 89 db(A)

Vibration 0.81 m/s² 0.81 m/s² 0.81 m/s² 0.77 m/s²

Stroke 6-1/3" (160 mm) 10" (255mm)

Core drill max. Ø 1-3/8" (32mm) 1-5/8" 1-5/8" (40 mm) 3" (75mm)

1-3/16" / 2-1/8" /

Cutting depth max. 1-3/16" / 2-1/8" (30 / 55 mm)

4-1/3"

(30 / 55 /110 mm)

Twist drill max. Ø 1/2" (13 mm) 5/8" (16 mm) 3/4" (18 mm)

= 600 min-1

n

Speed stage 1

0

n = 450 min

Speed stage 2 -

-1

n0 = 1050 min-1

n0 = 600 min-1

n = 430 min

n = 760 min

-1

-1

n0 = 400 min-1

n = 250 min

n0 = 730 min-1

n = 450 min

Speed stage 3 - - -

Speed stage 4 - - -

-1

-1

1-1/4"

(31.75 mm)

n0 = 215 min-1

n = 110 min

n0 = 330 min-1

n = 175 min

n0 = 460 min-1

n = 245 min

n0 = 680 min-1

n = 385 min

MT3 (MK3) /

Core drill assembly

Weldon

3/4" (19 mm)

Weldon

3/4" (19 mm)

MT2 (MK2) /

3/4" (19 mm)

industrial

3/4" (19 mm)

MT 3 (MK3) /

1-1/4" (32 mm)

industrial

Connecting cable

length

13 ft. (4 m) 13 ft. (4 m) 13 ft. (4 m) 13 ft. (4 m)

Protection class I I I I

-1

-1

-1

-1

2 0

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 19

EC D e c l a r a t i o n o f C o n f o r m i t y

EC D e c l a r a t i o n o f C o n f o r m i t y

Name/address of manufacturer: B D S M a s c h i n e n Gm b H

Martinstraße 108

D-41063 Mönchengladbach

We hereby declare that the product

Model: M a g n e t i c c o r e d r i l l i n g m a c h i n e

Type: M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

conforms to the following relevant regulations:

■ EC D i r e c t i v e 2 0 0 6 / 4 2 / EC o n m a c h i n e r y

■ EU D i r e c t i v e 2 0 0 4 / 1 0 8 / EU o n El e c t r o m a g n e t i c C o m p a t i b i l i t y .

The following harmonised standards were applied in whole or in part:

● DIN EN ISO 12100:2010

● DIN EN 61000-6-4:2007 + A1:2011

● DIN EN 55014-1:2006 + A1:2009 + A2:2011

● DIN EN 55014-2:1997 + Corr. 1997 + A1:2001 + A2:2008

● DIN EN 60745-1:2009

● DIN EN 60745-2-1:2010

Responsible person for documentation according to EC Directive 2006/42/EC - Annex II

Pt.A.2. was:

_____________________________________________________________________

(Surname, forename, position in company of the manufacturer)

ENGLISH

Mönchengladbach, 05st January 2015

Wolfgang Schroeder, Technical Director

________________________________________

(Legally binding signature of the issuer)

2 1M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 20

5

4

ESPAÑOL

3

2

1

9

1 0

8

1 1

6

7

2 2

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 21

2 4 2 3 2 2

2 1

2 0

2 6 2 5

ESPAÑOL

BA

2 3M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 22

In d i c a c i o n e s g e n e r a l e s

Í n d i c e

In d i c a c i o n e s g e n e r a l e s . . . . . . . . . . . . . . 2 4

Se g u r i d a d . . . . . . . . . . . . . . . . . . . . . . . . . 2 6

C o m p o n e n t e s / v o l u m e n d e

s u m i n i s t r o . . . . . . . . . . . . . . . . . . . . . . . . 2 9

An t e s d e u t i l i z a r p o r p r i m e r a v e z . . . . . . 3 0

Pr e p a r a t i v o s . . . . . . . . . . . . . . . . . . . . . . . 3 0

U t i l i z a c i ó n . . . . . . . . . . . . . . . . . . . . . . . . 3 3

ENGLISH

El i m i n a c i ó n d e b l o q u e o s . . . . . . . . . . . . 3 4

Li m p i e z a . . . . . . . . . . . . . . . . . . . . . . . . . . 3 5

M a n t e n i m i e n t o . . . . . . . . . . . . . . . . . . . . . 3 5

Al m a c e n a m i e n t o . . . . . . . . . . . . . . . . . . . 3 5

So l u c i ó n d e p r o b l e m a s . . . . . . . . . . . . . . 3 6

D a t o s t é c n i c o s . . . . . . . . . . . . . . . . . . . . . 3 7

D e c l a r a c i ó n d e c o n f o r m i d a d d e l a C E . 3 8

Distributed exclusively by:

22 Harbor Avenue, Norwalk, CT 06850 USA

Toll-Free: 800-700-5919 • Phone: 203-853-9522

Fax: 203-853-9921 • Email: info@csunitec.com

www.csunitec.com

Estimado cliente:

Antes de utilizar la máquina, le rogamos

que lea la información sobre la puesta

en servicio, seguridad, uso conforme a lo

previsto, limpieza y cuidado que encontrará

en estas instrucciones de servicio.

Las referencias a ilustraciones que se

utilizan en estas instrucciones se reeren a

las ilustraciones que hay en la cara interior

de la cubierta.

Guarde estas instrucciones de servicio como

referencia para el futuro y entréguelas junto

al aparato en caso de transferencia a otra

persona.

In d i c a c i o n e s g e n e r a l e s

D e r e c h o s d e a u t o r

Este documento está protegido por las leyes

de derechos de autor. Queda prohibida la

reproducción y reimpresión total o parcial

del manual, así como la copia de sus

ilustraciones, con o sin modicaciones, sin la

autorización por escrito del fabricante.

Ex e n c i ó n d e r e s p o n s a b i l i d a d e s

Toda la información técnica, datos e

indicaciones sobre la instalación, el

funcionamiento y el cuidado incluidas en

las presentes instrucciones de servicio se

corresponden al estado más actual en el

momento de su impresión.

El fabricante no se hace responsable de

los daños derivados del incumplimiento de

las instrucciones, del uso no conforme al

previsto, de las reparaciones indebidas,

de las modicaciones realizadas sin

autorización o del uso de accesorios

y piezas de repuesto, herramientas y

lubricantes no permitidos.

In f o r m a c i ó n s o b r e l a e l i m i n a c i ó n

Los materiales de embalaje utilizados

son reciclables. Elimine los materiales

de embalaje que no necesite de acuerdo con

la normativa en vigor.

En la Unión Europea no está permitido

eliminar este aparato junto con la

basura doméstica. El aparato debe

desecharse a través de los centros de

recogida municipales.

2 4

BA_MABasic_1501_A2 © 2015 BDS Maschinen GmbH

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 23

In d i c a c i o n e s g e n e r a l e s

C o m p o s i c i ó n d e l a s a d v e r t e n c i a s

En las presentes instrucciones de servicio se

utilizan las siguientes advertencias:

PELIGR O

La s i n d i c a c i o n e s d e e s t a c a t e g o r í a s e ñ a l a n u n a p o s i b l e s i t u a c i ó n d e p e l i g r o .

Si no se toman las medidas necesarias

para evitar esta situación, podría provocar

lesiones personales graves e incluso la

muerte.

► Las instrucciones contenidas en

esta indicación tienen la nalidad de

impedir la muerte o lesiones graves

para las personas.

AD V ER T ENC IA

La s i n d i c a c i o n e s d e e s t a c a t e g o r í a

s e ñ a l a n u n a s i t u a c i ó n d e p e l i g r o p o t e n c i a l .

Si no se toman las medidas necesarias

para evitar esta situación, podría provocar

lesiones personales.

► Las instrucciones contenidas en

esta indicación tienen la nalidad de

impedir lesiones para las personas.

ATENCIÓN

La s i n d i c a c i o n e s d e e s t a c a t e g o r í a s e ñ a l a n d a ñ o s m a t e r i a l e s p o t e n c i a l e s .

Si no se toman las medidas necesarias

para evitar esta situación, podría provocar

daños materiales.

► Las instrucciones contenidas en

esta indicación tienen la nalidad de

impedir daños materiales.

U s o c o n f o r m e a l o p r e v i s t o

La máquina ha sido diseñada para trabajos

de taladrado en metales magnéticos y no

magnéticos conforme a los límites indicados

en los datos técnicos.

Cualquier uso diferente o excedente se

considerará no conforme al previsto.

AD V ER T ENC IA

¡ Pe l i g r o d e r i v a d o d e u n u s o c o n t r a r i o a

l o p r e v i s t o !

Si la máquina no es utilizada de la forma

prevista y/o se utiliza para nes distintos

pueden producirse situaciones de peligro.

► Utilice el aparato únicamente conforme

a su uso previsto.

► Cumpla los procedimientos que se

describen en estas instrucciones de

servicio.

Las reclamaciones por daños derivados

del uso no conforme al previsto quedarán

invalidadas de forma inmediata.

El riesgo es responsabilidad única del

usuario.

INDICACIÓN

► Si usa la máquina para nes

profesionales, tenga en cuenta

las normativas de prevención de

accidentes y las disposiciones de

seguridad de la empresa.

ENGLISH

INDICACIÓN

► Una nota contiene informaciones

adicionales para facilitar el uso del

aparato.

2 5M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 24

Se g u r i d a d

Se g u r i d a d

AT ENC IÓ N

¡ D u r a n t e l a u t i l i z a c i ó n d e h e r r a m i e n t a s

e l é c t r i c a s d e b e n o b s e r v a r s e l a s s i g u i e n t e s m e d i d a s d e s e g u r i d a d b á s i c a s c o n

el n de evitar descargas eléctricas y

p e l i g r o s d e l e s i o n e s e i n c e n d i o !

In d i c a c i o n e s b á s i c a s d e s e g u r i d a d

ENGLISH

■ No utilice la máquina en ambientes con

riesgo de incendio o explosión.

■ Aquellas personas cuyas capacidades

físicas, psíquicas o motrices no les

permitan utilizar la máquina con plena

seguridad únicamente podrán usarla

bajo supervisión o con las instrucciones

de una persona responsable.

■ Queda prohibido el uso de la máquina a

las personas que lleven marcapasos o

cualquier otros implantes medicinales.

■ No se permite utilizar la máquina a los

niños.

■ Antes de utilizar la máquina, revise que

la máquina y el cable de conexión no

presenten daños externos. No ponga en

funcionamiento una máquina dañada.

■ Antes de empezar a trabajar, compruebe

que la correa de sujeción de seguridad

se encuentre en perfecto estado y que

el interruptor de la máquina funcione

correctamente.

■ Encargue las reparaciones del cable

de conexión únicamente a un técnico

electricista.

■ Encargue las reparaciones del aparato

sólo a un distribuidor autorizado o

al servicio técnico de fábrica. Una

reparación indebida puede provocar

situaciones graves de peligro para el

usuario.

■ Las reparaciones del aparato dentro

del periodo de garantía deberán ser

realizadas únicamente por un servicio

técnico autorizado por el fabricante, ya

que de lo contrario perderá el derecho a

la garantía.

■ Los componentes defectuosos se

deberán sustituir únicamente por piezas

de repuesto originales. Esta es la única

forma de garantizar que se cumplan los

requisitos de seguridad.

■ No deje la máquina desatendida cuando

esté en funcionamiento.

■ Guarde la máquina en un lugar seco y

con una temperatura agradable fuera del

alcance de los niños.

■ No deje la máquina al aire libre ni la

exponga a la humedad.

■ Asegúrese de que el lugar de trabajo

esté sucientemente iluminado (>300

Lux).

■ No utilice máquinas de baja potencia

para realizar trabajos pesados.

■ Mantenga el lugar de trabajo limpio.

■ Mantenga la máquina limpia, seca y libre

de residuos de aceite y grasa.

■ Respete las instrucciones de lubricación

y refrigeración de la herramienta.

2 6

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 25

Se g u r i d a d

Pe l i g r o s r e l a c i o n a d o s c o n

l a e l e c t r i c i d a d

PELIGR O

¡ Pe l i g r o d e m u e r t e d e b i d o a l a c o r r i e n t e

e l é c t r i c a !

¡ El c o n t a c t o c o n l o s c a b l e s y c o m p o n e n t e s c a r g a d o s c o n t e n s i ó n c o n s t i t u y e p e l i g r o d e m u e r t e !

A n de impedir situaciones de peligro re-

lacionadas con la electricidad, respete las

siguientes indicaciones de seguridad:

► No abra la carcasa de la máquina.

Si se tocan contactos sometidos a

tensión existe un riesgo de descarga

eléctrica.

► Nunca sumerja en agua o en otro

líquido la máquina o la clavija de red.

► Utilice exclusivamente prolongadores o

tambores portacables con una sección

de cable de 1,5 mm².

► Utilice únicamente cables alargadores

homologados para el lugar de uso de

la máquina.

► Revise el estado del cable alargador

de forma regular y sustitúyalo si está

deteriorado.

► Evite el contacto entre el cuerpo y las

piezas conectadas a tierra (p.ej. tubos,

radiadores o soportes de acero) para

reducir el peligro de descarga eléctrica

en caso de producirse una avería.

Pe l i g r o d e l e s i o n e s

AD V ER T ENC IA

¡ Pe l i g r o d e l e s i o n e s e n c a s o d e u n u s o

i n a d e c u a d o d e l a m á q u i n a !

A n de no resultar herido usted u otras per-

sonas, respete las siguientes indicaciones de

seguridad:

► Utilice la máquina sólo con el

equipamiento de protección (véase

capítulo Equipamiento de protección

personal) indicado en el presente manual.

► Cuando la máquina esté en marcha,

n o utilice guantes de protección. Los

guantes podrían quedarse enganchados

en la taladradora y ser arrancados de las

manos. Si esto llegara a suceder, podría

perder uno o varios dedos.

► Quítese las joyas sueltas antes de

empezar a trabajar. Si tiene el pelo largo,

recójaselo con una redecilla.

► Apague la máquina antes de proceder

a cualquier cambio de herramienta o de

cualquier trabajo de mantenimiento o

limpieza. Espere hasta que deje de girar la

máquina.

► Antes de cambiar una herramienta o de

realizar algún trabajo de mantenimiento o

limpieza, desenchufe la clavija de red de

la toma de corriente para impedir que la

máquina se pueda poner en marcha de

forma accidental.

► No acerque las manos a las piezas

móviles de la herramienta mientras esté

en marcha. Extraiga las virutas sólo con la

máquina parada. Para retirar las virutas,

utilice guantes de protección.

► Durante los trabajos sobre un andamio el

usuario deberá estar asegurado mediante

un arnés de sujeción contra caídas ya que

la máquina puede producir en caso de un

fallo de corriente un impacto pendular.

ENGLISH

2 7M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 26

Se g u r i d a d

AD V ER T ENC IA

► Compruebe antes de cada uso que

los imanes eléctricos tengan una

estabilidad segura sobre la base

(véase capítulo Preparativos).

► Asegure la máquina con la correa de

sujeción de seguridad suministrada

cuando se realicen trabajos en

posición vertical o inclinada y en los

trabajos por encima de la cabeza. La

ENGLISH

máquina podría desprenderse al soltar

el imán o por ausencia de tensión.

► Compruebe antes de cada uso el

asiento seguro de la herramienta

(véase capítulo Insertar herramienta).

► No deje el cable de conexión colgando

en esquinas (riesgo de tropezar).

Pr e v e n c i ó n d e d a ñ o s

ATENCIÓN

¡ Po s i b i l i d a d d e d a ñ o s m a t e r i a l e s s i e l

a p a r a t o s e m a n i p u l a i n c o r r e c t a m e n t e !

A n de impedir que se produzcan daños

materiales, respete las siguientes indicaciones:

► Antes de conectar la máquina,

compare los datos de conexión

(tensión y frecuencia) de la placa

de características con los de la red

eléctrica. Para que la máquina no

resulte dañada, deben coincidir estos

datos.

► Coja la máquina siempre por el asidero

y no por el cable de conexión.

► Para desenchufar el cable de conexión

de la toma de corriente, tire siempre

cogiéndolo por la clavija de red y

nunca por el cable de alimentación.

ATENCIÓN

► No aplaste el cable de conexión.

► No exponga el cable de conexión al

calor ni a productos químicos.

► No pase el cable de conexión

por encima de bordes alados ni

supercies calientes.

► Coloque el cable de conexión de

modo que no pueda ser capturado y

enrollado por piezas en rotación de la

máquina.

D i s p o s i t i v o s d e s e g u r i d a d

Pr o t e c c i ó n c o n t r a r e a r r a n q u e

INDICACIÓN

► La máquina se para automáticamente

al desconectar el imán de adherencia

o en caso de un fallo de corriente.

Para evitar un arranque inesperado de la

máquina al volver a conectar los imanes

de sujeción o bien al restablecerse la

alimentación de corriente (protección

contra rearranque), la máquina se ha de

volver a conectar mediante el interruptor de

conexión/desconexión.

Sí m b o l o s d e l a m á q u i n a

Los símbolos que hay colocados en la

máquina tienen el siguiente signicado:

Sí m b o l o

Signicado

¡Peligro de descarga eléctrica!

Lea las instrucciones de servicio

antes de empezar a trabajar.

Utilice protección auditiva y gafas

de protección.

2 8

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 27

C o m p o n e n t e s / v o l u m e n d e s u m i n i s t r o

Eq u i p a m i e n t o d e p r o t e c c i ó n

p e r s o n a l

Durante los trabajos con la máquina se

ha de llevar puesto el equipamiento de

protección personal siguiente:

Sí m b o l o Signicado

Ropa protectora de trabajo

ceñida con baja resistencia a la

rotura

Gafas de protección para protegerse los ojos contra las piezas

y los líquidos que pudieran salir

despedidos, y protección auditiva en los lugares con emisiones

acústicas > 80 dB(A)

Calzado de seguridad como

protección contra objetos desprendidos

Durante trabajos especiales con la máquina

se ha de llevar puesto el equipamiento de

protección personal adicional siguiente:

Sí m b o l o Signicado

Casco de protección como

protección contra objetos desprendidos

Llevar puesto un arnés de suje-

ción en caso de riesgo de caída

Guantes protectores como protección contra lesiones

C o m p o n e n t e s / v o l u m e n d e

s u m i n i s t r o

V i s i ó n g e n e r a l d e l a m á q u i n a

1 Broca de núcleo

(no contenida en el volumen de suministro)

2 Portaherramientas

3 Engranaje

(con palanca selectora:

bigradual para MABasic 400 y 450

de cuatro escalones para MABasic 850)

4 Motor de accionamiento

5 Mango

6 Palanca de mano

7 Panel de operación

8 Pie magnético

9 Carro de máquinas y guía

Pa n e l d e o p e r a c i ó n

10 Interruptor de encendido y apagado del

motor

11

Interruptor de encendido y apagado del

imán

V o l u m e n d e s u m i n i s t r o

20 Perforadora hueca

21 Correa de sujeción de seguridad

22 Depósito de bombeo de aceite de corte

ZKP100

23 Pasador de expulsión ZAK075

24 Maletín de transporte

25 Destornillador Allen acodado

SW 4 para MABasic 200/400

SW5 para MABasic 450

SW5 + SW6 para MABasic 850)

26 Adaptador industrial

(ZIA219KN para MABasic 450

ZIA319KN y

ZIA332KN para MAB 850)

Instrucciones de servicio/Tarjeta de

garantía (sin gura)

ENGLISH

2 9M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 28

An t e s d e u t i l i z a r p o r p r i m e r a v e z

An t e s d e u t i l i z a r p o r p r i m e r a

v e z

In s p e c c i ó n d e t r a n s p o r t e

De serie, la máquina está equipada con

los componentes indicados en el capítulo

Volumen de suministro.

INDICACIÓN

► Compruebe que el volumen de

ENGLISH

suministro esté completo y que

no presente daños visibles. Si el

suministro está incompleto o en mal

estado, informe inmediatamente al

proveedor/comercio.

Pr e p a r a t i v o s

El presente capítulo contiene indicaciones

importantes acerca de las actividades de

preparación necesarias antes de iniciar el

trabajo.

M e d i d a s d e s e g u r i d a d a d i c i o n a l e s

p a r a d e t e r m i n a d o s t r a b a j o s .

En los trabajos relacionados a continuación

se han de tomar las medidas de seguridad

adicionales siguientes:

Po s i c i ó n d e t r a b a j o n o h o r i z o n t a l

AD V ER T ENC IA

Pe l i g r o d e l e s i o n e s p o r c a í d a d e l a

m á q u i n a

Cuando se realicen trabajos en posición

vertical o inclinada o por encima de la

cabeza, la máquina ha de asegurarse

contra caídas con la correa de sujeción de

seguridad (21) suministrada.

► Compruebe que la correa de sujeción

de seguridad funcione correctamente

antes de utilizarla. No utilice nunca

una correa de sujeción de seguridad

en mal estado. Si está deteriorada,

sustituya la correa de sujeción de

seguridad inmediatamente.

AD V ER T ENC IA

► Coloque la correa de sujeción de

seguridad de modo que la máquina

se aleje del usuario en caso de

desprendimiento.

► En medida de lo posible, coloque la

correa de sujeción de seguridad sin

holgura alrededor del asidero de la

máquina.

► Antes de empezar a trabajar,

compruebe que la correa de sujeción

de seguridad y el cierre estén rmes.

► Utilice el equipamiento de protección

indicado en el capítulo Equipamiento

de protección personal.

T r a b a j o s s o b r e u n a n d a m i o

AD V ER T ENC IA

R i e s g o d e c a í d a d e b i d o a u n m o v i m i e n t o p e n d u l a r i n e s p e r a d o d e l a m á q u i n a .

Durante los trabajos sobre un andamio,

la máquina puede producir durante el

arranque o en caso de fallo de corriente

un movimiento pendular inesperado.

► Asegure la máquina con la correa de

sujeción de seguridad adjunta (21).

► Asegúrese contra caída llevando

puesto el arnés de sujeción.

3 0

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 29

Pr e p a r a t i v o s

C o m p r o b a r l a c o n s i s t e n c i a

d e l f u n d a m e n t o

La fuerza de sujeción magnética depende

de la naturaleza del fundamento. La fuerza

de sujeción es reducida notablemente por

capas de pintura, de cinc y de cascarilla así

como por óxido.

El fundamento para que se pueda establecer

una adherencia magnética suciente, deberá

cumplir las condiciones siguientes:

■ El fundamento deberá ser magnético.

■ La supercie de adherencia y el pie

magnético (8) deberán estar limpios y

libres de grasa.

■ La supercie de adherencia no deberá

ser irregular.

INDICACIÓN

► Antes de usar la máquina, limpie la

base y el pie magnético (8).

► Elimine las irregularidades y el óxido

suelto de la base.

► CS Unitec le ofrece en su gama

de accesorios útiles de sujeción

especiales.

El mejor efecto de adherencia se logra con

acero de bajo contenido en carbono y un

espesor mínimo de 20 mm.

Ac e r o d e e s p e s o r r e d u c i d o

Para taladrar en acero de espesor reducido,

se ha de colocar una placa de acero

adicional (dimensión mínima 100 x 200 x 20

mm) debajo de la pieza. Asegure la placa de

acero contra caída.

M e t a l e s n o f é r r i c o s o b i e n p i e z a s c o n

supercies no planas

Para taladrar en metales no férricos o bien

en piezas con supercies no planas, se ha

de utilizar un útil de sujeción especial.

INDICACIÓN

► CS Unitec le ofrece en su gama

de accesorios dispositivos de

sujeción para tubos y materiales no

magnéticos.

ENGLISH

In s e r t a r h e r r a m i e n t a

AD V ER T ENC IA

Pe l i g r o d e l e s i o n e s

► No utilice herramientas dañadas,

sucias o desgastadas.

► Realice el cambio de herramienta

solo con máquina parada y apagada.

Desenchufe la clavija de red de la

toma de corriente.

► Después de insertar la herramienta,

compruebe que esté asentada

rmemente.

► Utilice únicamente una herramienta,

adaptador y accesorio adecuados para

esta máquina.

3 1M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 30

Pr e p a r a t i v o s

M AB a s i c 2 0 0 y 4 0 0

C o l o c a r l a b r o c a d e n ú c l e o e n e l

adaptador directo (gura A)

Limpie antes de insertar el mango

Weldon la broca hueca y el adaptador

directo (2) de la máquina.

Compruebe la conexión del conducto

para el lubricante.

Suelte los dos tornillos Allen del

ENGLISH

adaptador directo utilizando el

destornillador Allen acodado (25)

suministrado.

Inserte la broca hueca en el adaptador

directo (2).

INDICACIÓN

► Antes de insertar la broca hueca,

inserte el pasador de expulsión (23)

apropiado.

Apriete los dos tornillos Allen en el

adaptador directo (2) utilizando el

destornillador Allen acodado (25)

suministrado.

Ex t r a e r h e r r a m i e n t a

Suelte los dos tornillos Allen del

adaptador directo (2) utilizando el

destornillador Allen acodado (25)

suministrado y extraiga la broca hueca

por abajo.

M AB a s i c 4 5 0 y 8 5 0

C o l o c a r l a b r o c a d e n ú c l e o e n e l

adaptador industrial (gura B)

Inserte el adaptador industrial (26) en el

cono de husillo de la máquina.

Antes de insertar, limpie el mango

Weldon de la herramienta y el

portaherramientas.

Compruebe la conexión del conducto

para el lubricante

Suelte los dos tornillos Allen del

portaherramientas utilizando el

destornillador Allen acodado (25)

suministrado.

Inserte la broca hueca en el

portaherramientas.

INDICACIÓN

► Antes de insertar la broca hueca,

inserte el pasador de expulsión (23)

apropiado.

Apriete los dos tornillos Allen en el

portaherramientas (2) utilizando el

destornillador Allen acodado (25)

suministrado.

Ex t r a e r h e r r a m i e n t a

Suelte los dos tornillos Allen del

portaherramientas (2) utilizando el

destornillador Allen acodado (25)

suministrado y extraiga la broca hueca

por abajo.

3 2

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 31

U t i l i z a c i ó n

U t i l i z a c i ó n

Se l e c c i o n a r e l r a n g o d e r e v o l u c i o n e s

( s o l o M AB a s i c 4 0 0 , 4 5 0 y 8 5 0 )

ATENCIÓN

► Realizar la conmutación del

engranajes sólo con máquina parada.

INDICACIÓN

► Seleccione el rango de revoluciones

en dependencia del material y el

diámetro de agujero.

Se l e c c i o n a r e l e n g r a n a j e s p a r a

M AB a s i c 4 0 0 / 4 5 0

La máquina dispone de un engranaje con

dos etapas de engranajes mecánicas. Los

regímenes de revoluciones de las etapas de

engranajes están especicados en los datos

técnicos.

Para ajustar nivel de engranaje,

coloque la palanca selectora del

engranaje (3) en el nivel 1 ó 2 con la

máquina apagada.

Se l e c c i o n a r e l e n g r a n a j e s p a r a

M AB a s i c 8 5 0

La máquina dispone de un engranaje con

cuatro etapas de engranajes mecánicas. Los

regímenes de revoluciones de las etapas de

engranajes están especicados en los datos

técnicos.

Para ajustar nivel de engranaje, apague

la máquina y ajuste las dos palancas

de selección del engranaje (3) al rango

de revoluciones deseado de acuerdo

con la siguiente tabla.

Et a p a d e

e n g r a n a j e

1ª marcha

2ª marcha

3ª marcha

4ª marcha

Pa l a n c a s e l e c t o r a

i z q u i e r d a d e r e c h a

▼ ▲

▼ ▼

▲ ▲

▲ ▼

C o n e c t a r / d e s c o n e c t a r i m á n d e

a d h e r e n c i a

C o n e c t a r i m á n d e a d h e r e n c i a

ATENCIÓN

► Con el n de evitar un

sobrecalentamiento de los imanes,

conecte los imanes de adherencia sólo

si la máquina está situada sobre una

base magnética.

Encienda el interruptor (11). El piloto de

control en el interruptor (11) se ilumina.

ATENCIÓN

► La fuerza de sujeción magnética

máxima estará disponible sólo

después de encender el motor.

D e s c o n e c t a r i m á n d e a d h e r e n c i a

Asegure la máquina en el asidero (5),

para evitar que pueda deslizarse la

máquina.

Apague el interruptor (11). El piloto de

control en el interruptor (11) se apaga.

En c e n d e r y a p a g a r l a m á q u i n a

Conecte la máquina en el interruptor de

conexión/desconexión (10) usando el

botón verde (I) y desconéctela con el

botón rojo (O).

INDICACIÓN

► La máquina sólo se podrá encender sí

previamente se ha conectado el imán

de adherencia.

► Para que se refrigere una máquina

calentada en exceso deberá dejarla

funcionando sin carga durante unos 2

minutos aproximadamente.

► La máquina se desconecta

automáticamente en caso de un fallo

de corriente o debido a la desconexión

de los imanes de adherencia.

ENGLISH

3 3M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 32

El i m i n a c i ó n d e b l o q u e o s

T a l a d r a r c o n l a m á q u i n a

T a l a d r a r c o n b r o c a s h u e c a s

Para taladrar con brocas huecas proceda del

modo siguiente:

Inserte el pasador de expulsión (23)

adecuado en la broca hueca.

Inserte la broca hueca con pasador de

expulsión tal como viene descrito en el

capítulo Insertar herramienta.

Emplace la máquina en el lugar

ENGLISH

de utilización y alinéela, conecte a

continuación los imanes de adherencia.

Conecte la máquina.

Desplace la broca con la palanca

manual (6) hacia el material.

INDICACIÓN

Durante el proceso de taladrar con brocas

huecas tenga en cuenta las indicaciones

siguientes:

► El taladrado con brocas huecas no

precisa aplicar grandes fuerzas. Con

mayor presión no acelera el proceso

de taladrado. Únicamente se produce

un desgaste más rápido de la broca y

sobrecargar la máquina.

► Utilice el dispositivo de lubricación y

refrigeración instalado en la máquina

con aceite de corte de alto rendimiento

CS Unitec.

► Cuando se realicen trabajos por

encima de la cabeza no se puede

utilizar el dispositivo de lubricación y

refrigeración. Use en tal caso el spray

de grasa de alto rendimiento ZHS 400.

Pulverice la broca antes de taladrar

con spray de grasa en su parte exterior

e interior. En caso de profundidades de

taladrado mayores repita este proceso.

► Preste atención a un ujo de viruta

regular. En caso de profundidades más

grandes deberá romper la viruta.

El i m i n a c i ó n d e b l o q u e o s

AD V ER T ENC IA

Pe l i g r o d e c o r t a r s e c o n l a s p i e z a s d e

h e r r a m i e n t a s r o t a s o l a s v i r u t a s .

► Antes de empezar a trabajar, póngase

unos guantes de protección.

Si s e p r o d u c e u n b l o q u e o a c a u s a d e u n a

r o t u r a e n l a h e r r a m i e n t a :

Apague la máquina. Desenchufe la

clavija de red de la toma de corriente.

Coloque el carro de máquina en la

posición superior con la palanca de

mano.

Sustituya la herramienta averiada.

Retire las virutas.

En c a s o d e o t r o t i p o d e b l o q u e o :

Desconecte el interruptor del motor de

la máquina. Deje conectado el imán de

adherencia.

Coloque el carro de máquina en la

posición superior con la palanca de

mano.

Retire las virutas y revise la

herramienta.

3 4

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 33

Li m p i e z a / M a n t e n i m i e n t o

Li m p i e z a

AD V ER T ENC IA

► Antes de proceder a cualquier

mantenimiento o limpieza, desconecte

la máquina y desenchufe la clavija de

red de la toma de corriente.

► Cuando utilice aire comprimido para

la limpieza póngase usted y otras

personas gafas protectoras y guantes

protectores con el n de protegerse en

la zona de trabajo.

ATENCIÓN

► Nunca sumerja en agua o en otro

líquido la máquina.

D e s p u é s d e c a d a u s o

Retire la herramienta aplicada

Retire las virutas y el resto de

lubricante.

Limpie la herramienta y el

portaherramientas en la máquina.

Limpie la guía del carro de máquina.

Vuelva a guardar la máquina y el

accesorio en su maleta de transporte.

R e a j u s t a r l a g u í a d e l c a r r o d e

m á q u i n a

Si la guía del carro de máquina (9) presenta

holgura, deberá reajustarse. Proceda del

modo siguiente:

Suelte los tornillos de apriete

Reapriete uniformemente los tornillos

de reglaje.

Vuelva apretar los tornillos de apriete.

C a m b i a r l a s e s c o b i l l a s

El cambio de escobillas sólo lo podrá realizar

un taller especializado y autorizado por

CS Unitec. En caso de reparaciones por

cuenta propia perderá el derecho a la

garantía.

As i s t e n c i a t é c n i c a / Se r v i c i o t é c n i c o

En caso de consultas a la asistencia técnica

/servicio técnico, póngase en contacto

con CS Unitec. Le podremos indicar un

representante del servicio técnico más

próximo.

Al m a c e n a m i e n t o

ENGLISH

M a n t e n i m i e n t o

AD V ER T ENC IA

¡ Pe l i g r o d e b i d o a r e p a r a c i o n e s i n d e b i d a s !

Reparaciones indebidas pueden provocar situaciones graves de peligro para el

usuario y daños en la máquina.

► Las reparaciones de los

electrodomésticos deben encargarse

al servicio técnico o a un técnico

cualicado por el fabricante.

Al m a c e n a m i e n t o

Si no tiene previsto utilizar la máquina

durante un periodo prolongado, límpiela de

acuerdo con las instrucciones del capítulo

Limpieza. Guarde la máquina y sus

accesorios en la maleta de transporte en un

lugar seco, limpio y libre de escarcha.

3 5M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 34

So l u c i ó n d e p r o b l e m a s

So l u c i ó n d e p r o b l e m a s

Pr o b l e m a C a u s a p o s i b l e So l u c i ó n

El motor no arranca después

de accionar el interruptor de

conexión/desconexión o se

para durante el funcionamiento.

La clavija no está enchufada. Enchufe la clavija.

Se ha disparado el interruptor

automático.

El imán de adherencia no está

conectado.

Conecte el interruptor automático.

Conectar imán de adherencia

ENGLISH

Se dispara el interruptor automático del cuadro eléctrico.

El imán magnético no funciona.

La lubricación no funciona.

Hay demasiados aparatos

conectados al mismo circuito

eléctrico.

La máquina está defectuosa.

El imán no está encendido. Encienda el imán.

No existe ninguna supercie

magnética.

No hay lubricante. Reponer lubricante

Grifo cerrado. Abrir el grifo.

Boquilla de conexión obstruida.

Reduzca el número de aparatos conectados al circuito

eléctrico.

Informe al servicio de atención

al cliente.

Utilizar un zócalo apropiado.

Limpiar depósito y boquilla

lubricante.

INDICACIÓN

► Si no logra solucionar el problema con estas acciones, póngase en contacto con el

servicio de atención al cliente.

3 6

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 35

D a t o s t é c n i c o s

D a t o s t é c n i c o s

M o d e l o M AB a s i c 2 0 0 M AB a s i c 4 0 0 M AB a s i c 4 5 0 M AB a s i c 8 5 0

Dimensiones

(F x A x A)

Pie magnético

(F x A)

Peso neto aprox. 12 12 13 24 kg

Tensión de servicio

(véase la placa de

características)

Consumo de

potencia

Emisión acústica 87 87 87 89 db(A)

Vibración 0,81 0,81 0,81 0,77 m/s²

Carrera 160 255 mm

Ø máx. de la broca

hueca

Profundidad de corte

máx.

Ø máx. de la broca

helicoidal

Revoluciones nivel 1

Revoluciones nivel 2 -

Revoluciones nivel 3 - - -

Revoluciones nivel 4 - - -

Portabrocas broca

hueca

Longitud del cable

de conexión:

Categoría de pro-

tección

269 x 163 x

310/470

168 x 84 168 x 84 168 x 84 220 x 110 mm

900 1050 1150 1700 W

32 35 40 75 mm

13 16 18 31,75 mm

n

= 600

0

n = 450

Weldon

19 mm (3/4“)

4 4 4 4 m

I I I I

280 x 163 x

355/515

o. 110-125 / 50-60 Hz

30 / 55 30 / 55 /110 mm

n0 = 600

n = 430

n0 = 1050

n = 760

Weldon

19 mm (3/4“)

280 x 163 x

430/590

230 V / 50-60 Hz

n0 = 400

n = 250

n0 = 730

n = 450

Adaptador

industrial

MK2/19 mm (3/4“)

329 x 240 x

491/751

n0 = 215

n = 110

n0 = 330

n = 175

n0 = 460

n = 245

n0 = 680

n = 385

Adaptador industrial

MK3/19 mm (3/4“)

MK3/32 mm (1-1/4“)

mm

RPM

RPM

RPM

RPM

ENGLISH

3 7M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 36

D e c l a r a c i ó n d e c o n f o r m i d a d d e l a C E

D e c l a r a c i ó n d e c o n f o r m i d a d d e l a C E

Nombre/dirección del fabricante: B D S M a s c h i n e n Gm b H

Martinstraße 108

D-41063 Mönchengladbach

Declaramos que el producto

ENGLISH

Artículo: Pe r f o r a d o r a h u e c a d e i m á n

Modelo: M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

cumple con las siguientes disposiciones especializadas:

■ D i r e c t i v a e u r o p e a d e m á q u i n a s 2 0 0 6 / 4 2 / C E

■ D i r e c t i v a e u r o p e a 2 0 0 4 / 1 0 8 / C E s o b r e l a c o m p a t i b i l i d a d e l e c t r o m a g n é t i c a

Se han aplicado total o parcialmente las siguientes normas armonizadas:

● DIN EN ISO 12100:2010

● DIN EN 61000-6-4:2007 + A1:2011

● DIN EN 55014-1:2006 + A1:2009 + A2:2011

● DIN EN 55014-2:1997 + Corr. 1997 + A1:2001 + A2:2008

● DIN EN 60745-1:2009

● DIN EN 60745-2-1:2010

Responsable de la documentación según la directiva europea 2006/42/CE - Anexo II

Punto A.2.:

_____________________________________________________________________

(Apellido, nombre, cargo en la empresa del fabricante)

Mönchengladbach, 05/01/2015

3 8

Wolfgang Schroeder, Director técnico

________________________________________

(Firma legal del expedidor)

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 37

5

4

3

2

1

9

8

6

7

F R ANÇ AIS

1 0

1 1

3 9M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 38

F R ANÇ AIS

2 4 2 3 2 2

2 1

2 0

2 6 2 5

BA

4 0

M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

Page 39

R e m a r q u e s g é n é r a l e s

T a b l e d e s m a t i è r e s

R e m a r q u e s g é n é r a l e s . . . . . . . . . . . . . . . 4 1

Sé c u r i t é . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

C o m p o s a n t s / é t e n d u e d e l a l i v r a i s o n . . 4 6

Av a n t l a p r e m i è r e u t i l i s a t i o n . . . . . . . . . 4 7

Pr é p a r a t i o n s . . . . . . . . . . . . . . . . . . . . . . 4 7

U t i l i s a t i o n . . . . . . . . . . . . . . . . . . . . . . . . . 5 0

É l i m i n a t i o n d e s b l o c a g e s . . . . . . . . . . . . 5 1

Ne t t o y a g e . . . . . . . . . . . . . . . . . . . . . . . . . 5 2

M a i n t e n a n c e . . . . . . . . . . . . . . . . . . . . . . . 5 2

En t r e p o s a g e . . . . . . . . . . . . . . . . . . . . . . . 5 2

É l i m i n a t i o n d e s d y s f o n c t i o n n e m e n t s . . 5 3

D o n n é e s t e c h n i q u e s . . . . . . . . . . . . . . . . 5 4

D é c l a r a t i o n d e c o n f o r m i t é C E . . . . . . . . 5 5

Distributed exclusively by:

22 Harbor Avenue, Norwalk, CT 06850 USA

Toll-Free: 800-700-5919 • Phone: 203-853-9522

Fax: 203-853-9921 • Email: info@csunitec.com

www.csunitec.com

R e m a r q u e s g é n é r a l e s

D r o i t s d ’ a u t e u r

Ce document est soumis à la protection

des droits d’auteur. Toute reproduction

ou impression ultérieure, même partielle,

ainsi que la retranscription d'illustrations,

même modiée, est seulement possible sur

autorisation écrite du fabricant.

Li m i t a t i o n d e l a r e s p o n s a b i l i t é

Toutes les informations techniques, données

et indications gurant dans le présent

mode d’emploi et relatives à la mise en

service, au fonctionnement et à l’entretien

correspondent à l’état le plus récent des

connaissances lors de l’impression.

Le fabricant décline toute responsabilité pour

les dommages survenus en cas de non-

respect de la présente notice, d’utilisation

non conforme, de réparations inappropriées,

de modications non autorisées ou

d’utilisation de pièces de rechange,

d’accessoires, d’outils et de graisses

interdits.

R e m a r q u e s r e l a t i v e s à l ' é l i m i n a t i o n

Cher client,

Avant d'utiliser la machine, veuillez lire les

instructions relatives à la mise en service, à

la sécurité, à l'utilisation conforme ainsi qu'au

nettoyage et à l'entretien contenues dans la

présente notice d'utilisation.

Les renvois aux gures utilisés dans la

présente notice se fondent sur les gures à

l'intérieur de l'enveloppe.

Bien conserver la présente notice d'utilisation

pour une utilisation ultérieure et la remettre

avec l'appareil au propriétaire suivant.

BA_MABasic_1501_A2 © 2015 BDS Maschinen GmbH

Les matériaux d’emballage utilisés sont

recyclables. Éliminer les matériaux

d’emballage non nécessaires conformément

aux directives locales en vigueur.

A l’intérieur de l’Union européenne, il

est interdit de mettre ce produit aux

ordures ménagères normales.

Éliminer l’appareil par l’intermédiaire des

points de collecte communaux.

4 1M AB a s i c 2 0 0 , 4 0 0 , 4 5 0 , 8 5 0

F R ANÇ AIS

Page 40

R e m a r q u e s g é n é r a l e s

St r u c t u r e d e s a v e r t i s s e m e n t s

La présente notice d’utilisation utilise les

avertissements suivants :

D ANGER

U n a v e r t i s s e m e n t d e c e t y p e d é s i g n e

u n e s i t u a t i o n d a n g e r e u s e i m m i n e n t e .

Si la situation dangereuse ne peut pas être

évitée, celle-ci peut entraîner des bles-

sures graves ou mortelles.

► Respecter les instructions de cet

avertissement an d'éviter tout risque

de blessures graves ou mortelles des

personnes.

AV ER T ISSEM ENT

U n a v e r t i s s e m e n t d e c e t y p e d é s i g n e

u n e é v e n t u e l l e s i t u a t i o n d a n g e r e u s e .

Si la situation dangereuse ne peut pas être

évitée, cela peut entraîner des blessures.

► Respecter les instructions de cet

avertissement an d’éviter toutes

blessures de personnes.

ATTENTION

U n a v e r t i s s e m e n t d e c e t y p e d é s i g n e

u n d o m m a g e m a t é r i e l p o s s i b l e .

Si la situation ne peut pas être évitée, cela

peut entraîner des dommages matériels.

F R ANÇ AIS

► Respecter les instructions de cet

avertissement an d'éviter tout

dommage matériel.

U t i l i s a t i o n c o n f o r m e à s a

d e s t i n a t i o n

La machine est uniquement prévue pour

le perçage des métaux magnétiques et

non magnétiques dans le cadre des limites

indiquées dans les données techniques.

Toute autre utilisation ou toute utilisation

dépassant ce cadre est considérée comme

non conforme.

AV ER T ISSEM ENT

D a n g e r e n r a i s o n d ' u n e u t i l i s a t i o n n o n

c o n f o r m e à s a d e s t i n a t i o n !

En cas d’utilisation non conforme et/ou

d’emploi autre, la machine peut présenter

des risques.

► Utiliser la machine uniquement de

façon conforme.

► Respecter les procédures décrites

dans le présent mode d’emploi.