Page 1

EZ T rak

Installation and Operations Manual

Unitec

www.StartwithUnitec.com

Page 2

EZTRAK

EZ TRAK INSTALLATION AND

OPERATIONS MANUAL

This manual provides comprehensive installation, setup, and operational procedures

for the EZ Trak Fleet Terminal.

If further assistance is needed, please contact the distributor from which the product

was purchased.

When calling for assistance, you must have the following information available:

EZ Trak Serial Number:

Distributor Name:

COPYRIGHT

© 2011 Unitec, Incorporated. All rights reserved. No part of this book, including text,

screen examples, diagrams, or icons, may be reproduced or transmitted in any form,

by any means (electronic, photocopying, recording, or otherwise) without prior written

permission of Unitec, Incorporated.

TRADEMARKS

EZ Trak, Unitec, and the Unitec Logo are trademarks, service marks, or registered

trademarks of Unitec, Incorporated.

Document Number: EZT1001 ii

Document Title: EZ Trak Installation and Operations Manual

Page 3

EZTRAK

Table of Contents

1 Introduction.....................................................................................................................................1

1.1 Electrical Planning......................................................................................................................1

1.1.1 Electrical Requirements of the EZ Trak........................................................................................1

1.2 Mechanical Planning..................................................................................................................2

1.2.1 Position of the Unit.......................................................................................................................2

1.2.2 Mechanical Requirements............................................................................................................3

1.3 EZ Trak – Standard Installation .................................................................................................3

2 Installation.......................................................................................................................................4

2.1 Mechanical Installation Tools.....................................................................................................4

2.2 Electrical Installation Tools ........................................................................................................4

2.3 Installation of the Terminal.........................................................................................................5

2.4 Electrical Installation ..................................................................................................................8

2.4.1 Wiring for the Interface Board......................................................................................................8

2.4.2 Wash Outputs..............................................................................................................................8

2.4.3 Wash-In-Use................................................................................................................................9

2.4.4 Wash Stacking.............................................................................................................................9

3 System Configuration..................................................................................................................10

3.1 Quick Setup..............................................................................................................................11

4 Operations.....................................................................................................................................12

4.1 Account Reports.......................................................................................................................13

4.2 List All Accounts.......................................................................................................................14

4.3 Setup/Change Accounts ..........................................................................................................15

4.4 One Use Codes........................................................................................................................16

4.5 Transaction Log .......................................................................................................................17

4.6 Administration ..........................................................................................................................18

4.6.1 Wash Account Counter Administration.......................................................................................19

4.6.2 Backup/Restore Data.................................................................................................................19

4.6.3 Change Dealer Name................................................................................................................19

4.6.4 Reset System Clock...................................................................................................................20

4.7 Password Administration..........................................................................................................20

Appendix A: 120 VAC Power Supply (Optional) ..............................................................................23

Appendix B: Connecting EZTrak to Network Hub or Switch..........................................................24

Appendix C: Configuring the EZ Trak on the LAN..........................................................................25

Document Number: EZT1001 iii

Document Title: EZ Trak Installation and Operations Manual

Page 4

EZTRAK

Index of Figures

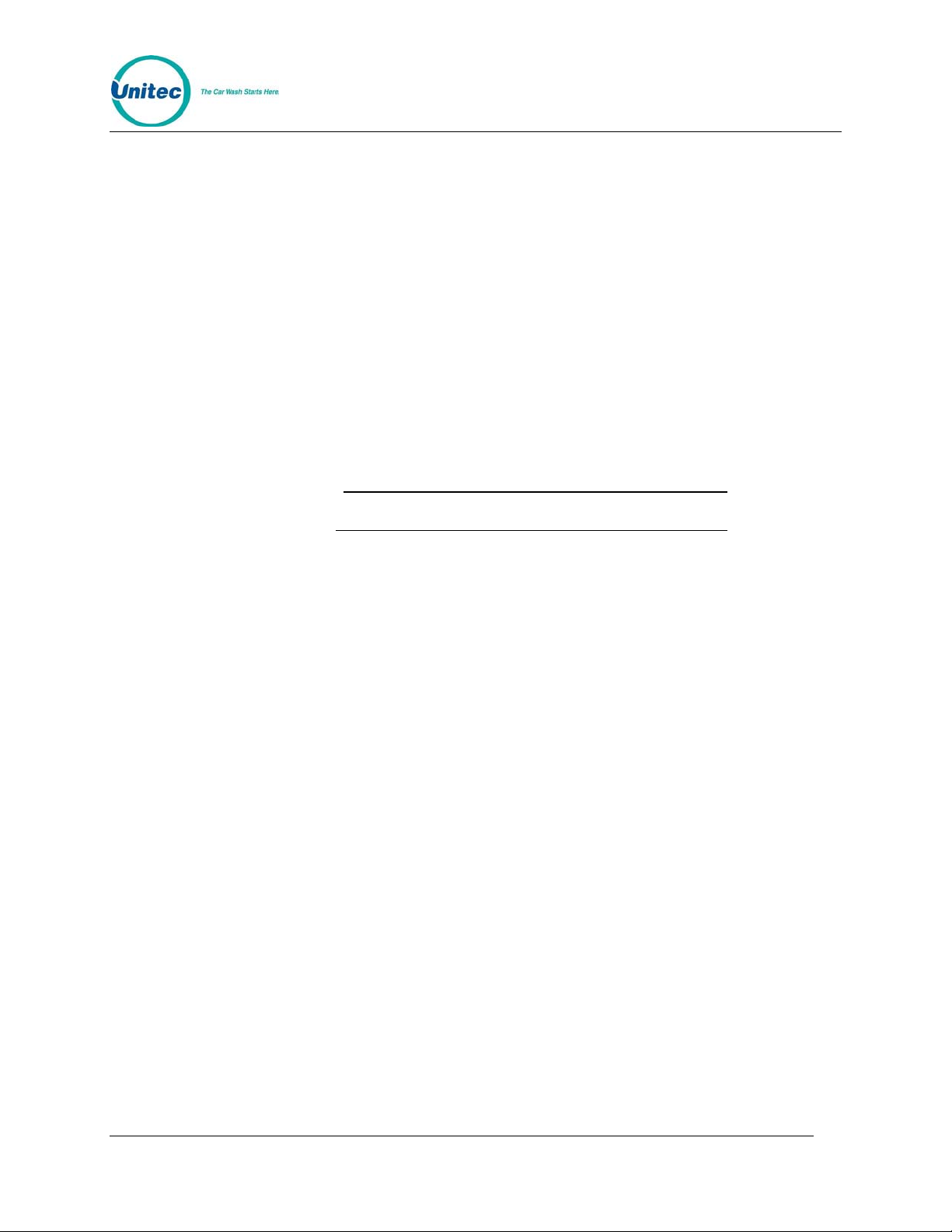

Figure 1. Conduits with Ethernet Cable Layout ...............................................................................2

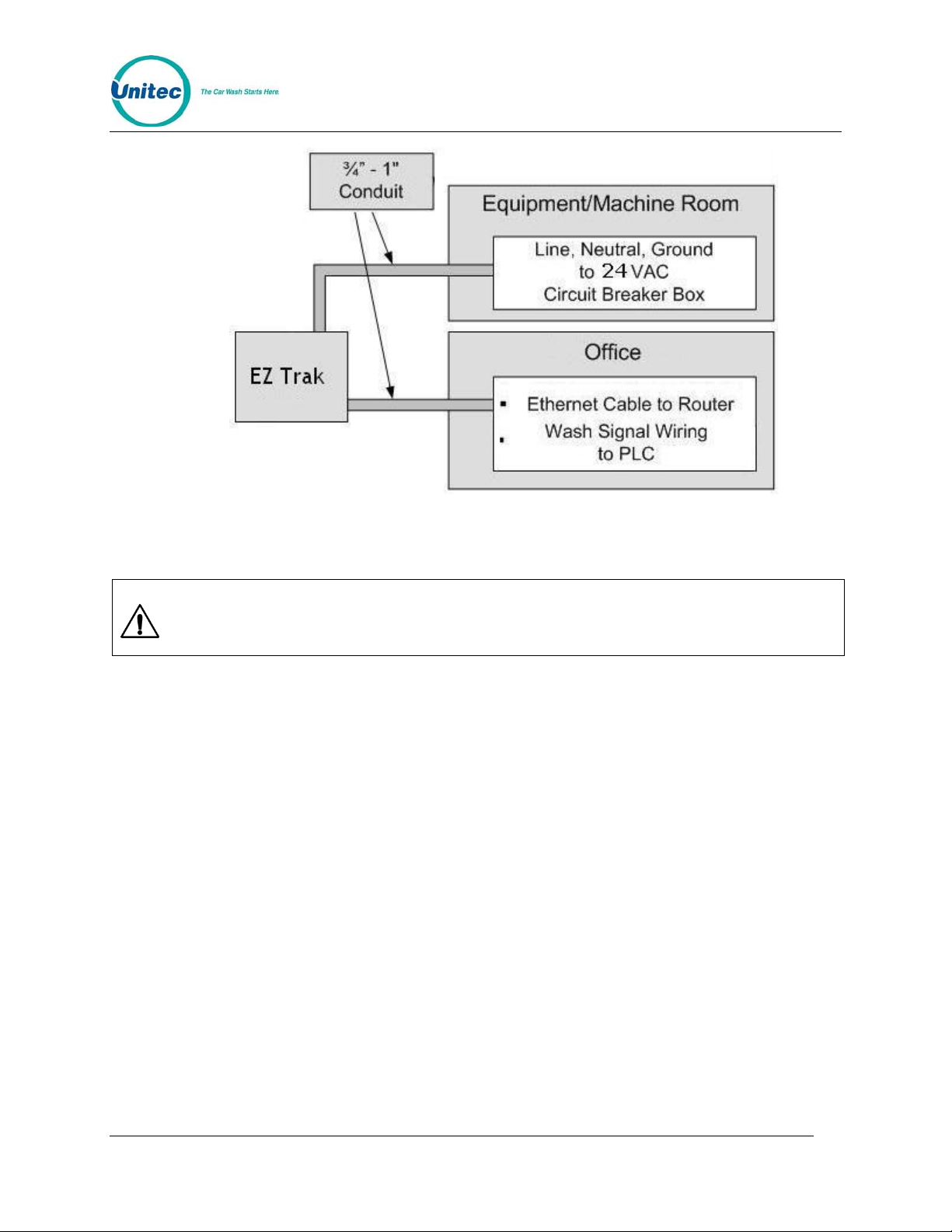

Figure 2. EZ Trak Base Placement..................................................................................................3

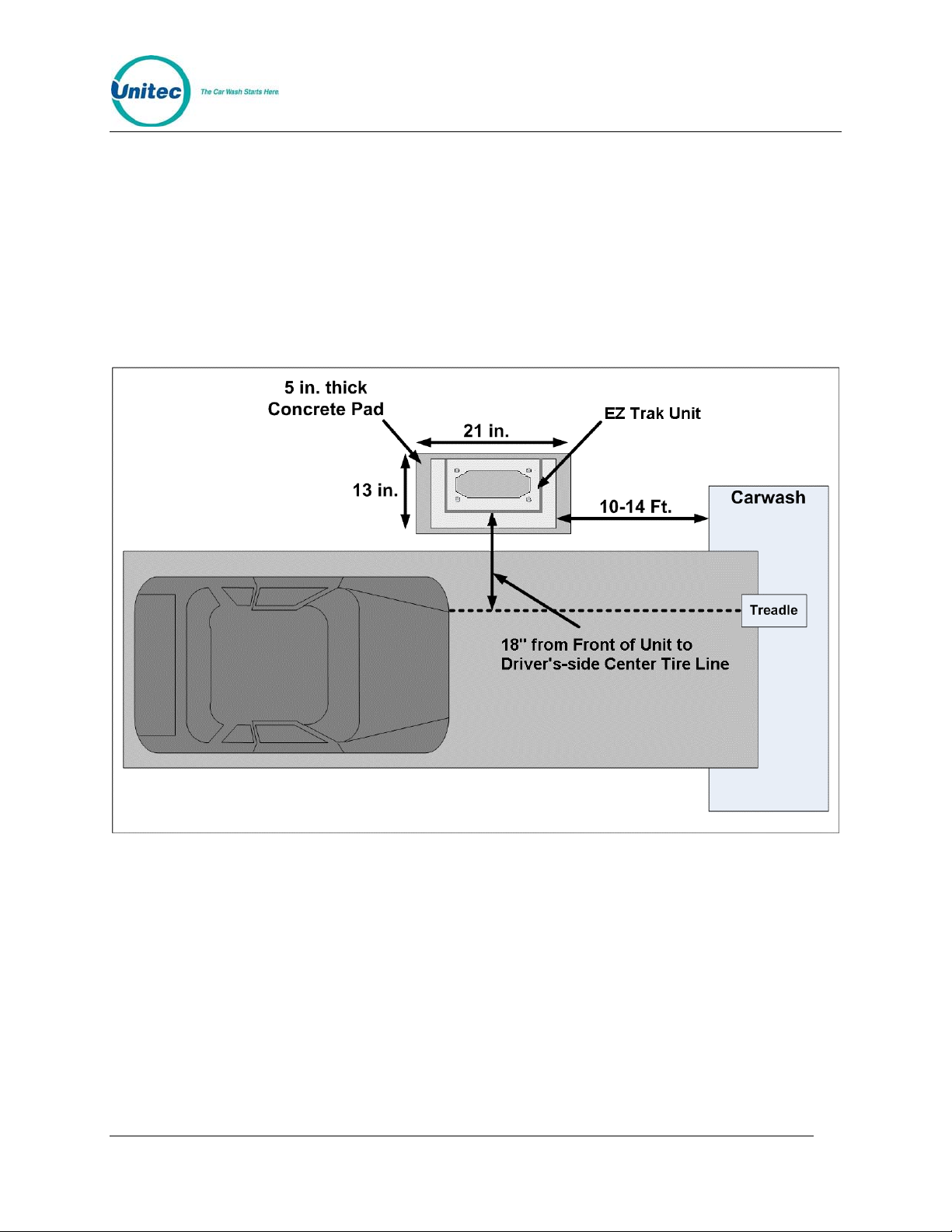

Figure 3. EZ Trak Terminal Base.....................................................................................................5

Figure 4. EZ Trak Terminal Base Dimensions.................................................................................6

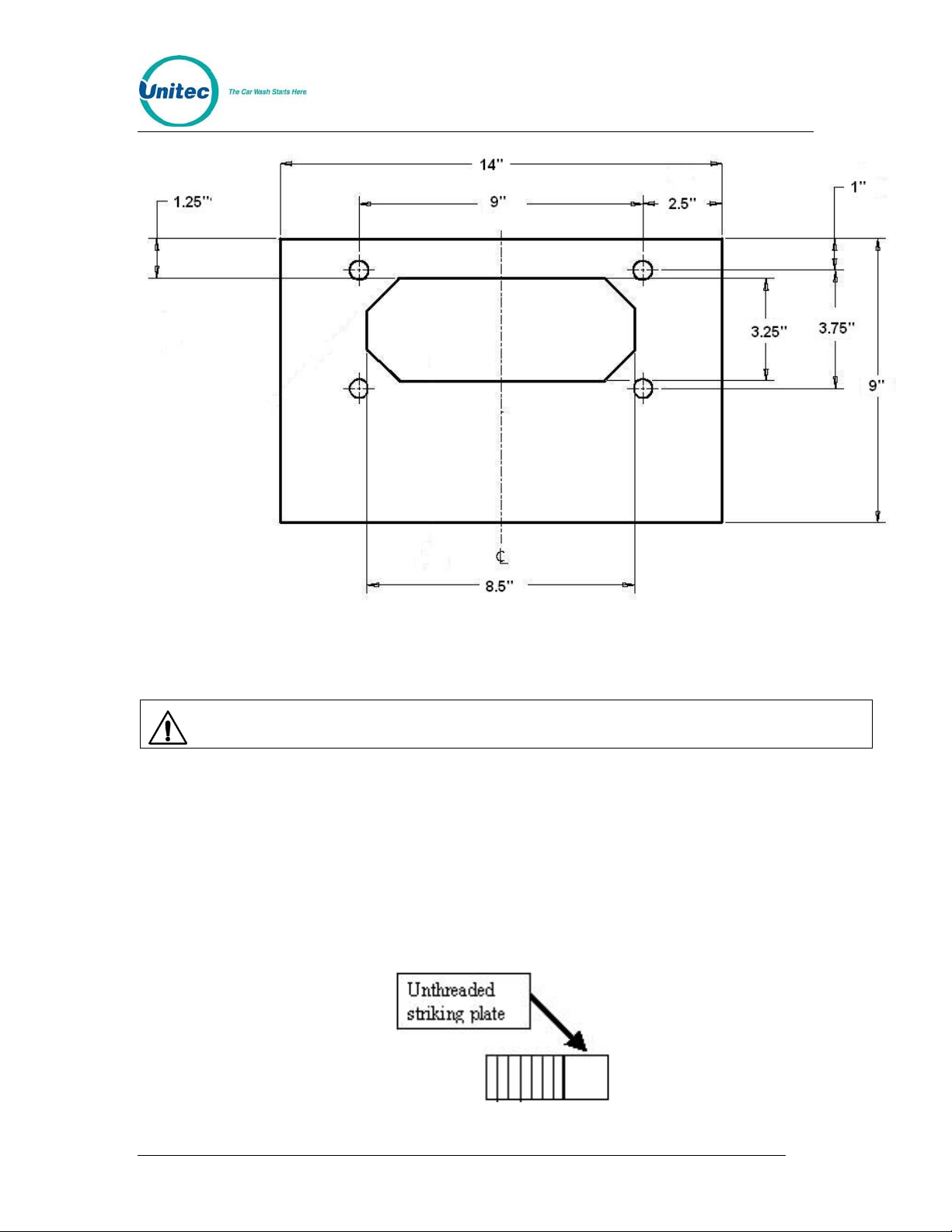

Figure 5. Setting Anchor Bolts .........................................................................................................6

Figure 6. Interface Board Connections............................................................................................8

Figure 7. Sample Account Report Screen .....................................................................................13

Figure 8. Sample List All Accounts Screen....................................................................................14

Figure 9. Setup/Change Account Screen ......................................................................................15

Figure 10. Sample One Use Codes Screen..................................................................................16

Figure 11. Sample Transaction Log Screen ..................................................................................17

Figure 12. Administration Screen...................................................................................................18

Figure 13. Password Administration Screen.................................................................................. 20

Index of Tables

Table 1. Wash Program Relays.......................................................................................................9

Table 2. Wash-In-Use Signal...........................................................................................................9

Document Number: EZT1001 iv

Document Title: EZ Trak Installation and Operations Manual

Page 5

EZTRAK

1 Introduction

The EZ Trak fleet terminal is a drive-up entry system developed specifically for the

automobile dealer market. EZ Trak cards and codes allow the dealer to track all wash use by

driver and department. EZ Trak can be used to track car wash use by rental companies,

neighboring dealerships and businesses.

EZ Trak is designed to integrate with the dealer’s local computer network. It requires 24 Volt

AC or DC power, Intranet (Ethernet) connection, and a web browser.

1.1 Electrical Planning

1.1.1 Electrical Requirements of the EZ Trak

The EZ Trak requires 24 VAC 1-amp service, which should be provided during wash

construction. Most installers will have power supplied directly from one of the three phases

used to power the wash motors and controllers. If this method is used, special attention

should be given to proper earth grounding at the unit, as we ll as in the breaker panel.

Make sure that the protective earth ground wire does not carry any

motor return current. Only

the neutral wire should carry return current.

The EZ Trak activates one wash type. The car wash’s Programmable Logic Controller (PLC)

activation voltage is routed to the EZ Trak interface board and back to the car wash

controller. In addition, a Wash-In-Use Hot and Wash-In-Use Neutral are required to properly

activate the EZ Trak operator interface and maintain accurate accounting information.

Typically, these are also provided by the PLC. It is important to consider this fact when

planning the conduit runs, because there will need to be 2 separ ate runs fro m the wash t o the

EZ Trak—one for AC power, and one for PLC Control Wires and the Ethernet cable. The

base of the EZ Trak terminal provides two knock-outs as well as the hole in the units' base to

accommodate various conduit installation options.

An Ethernet cable is required to program the EZ Trak. This cable should be standard CAT 5

or CAT 6. This cable can be pulled with the control wires. The cable is connected to the

Dealer’s Ethernet switch or router.

Document Number: EZT1001 1

Document Title: EZ Trak Installation and Operations Manual

Page 6

EZTRAK

Figure 1. Conduits with Ethernet Cable Layout

DO NOT RUN CABLE OUTSIDE OF A CONDUIT!

Important:

Follow all local and National Electric Codes.

Finally, it should be understood that the EZ Trak terminal is to be powered by wires of at least

18 AWG, or larger. Failure to adhere to this recommendation could result in a fire or injury.

When installing the conduit, it is suggested that it be a minimum of ¾” in size, and be made of

metal versus PVC.

1.2 Mechanical Planning

1.2.1 Position of the Unit

The proper positioning of the EZ Trak terminal is very important. Figure 2 of this section

should be used as a reference for good layout practices. There are several layout

considerations that follow, which may be a good idea to think about.

The EZ Trak terminal should be placed 10-14 feet from the car wash entrance to ensure the

proper timing and flow of customers. The wash’s treadle switch should be centered along the

horizontal plane, approximately 18” inches out from the front of the EZ Trak terminal. This will

ensure that the car/truck’s wheel is aligned with the treadle switch, as shown in Figure 2.

Finally, a concrete post can be positioned just to the front and left corner of the unit, to act as

a protective buffer. A typical size for this post is between 30 a nd 35 inches.

Document Number: EZT1001 2

Document Title: EZ Trak Installation and Operations Manual

Page 7

EZTRAK

1.2.2 Mechanical Requirements

It is strongly recommended that the unit be mounted on a concrete slab. The concrete should

be a minimum of 5” inches thick, 21” inches wide, and 13” inches long (Refer to Figure 2).

The dimensions and positioning of the mounting holes for the mounting plate will be covered

in the “Mechanical Installation” section of this manual.

The front edge of the unit should be 18 inches from the driver’s side tire centerline. This

provides the appropriate distance for customers to comfortably reach the unit to swipe their

card or enter their code.

Figure 2. EZ Trak Base Placement

1.3 EZ Trak – Standard Installation

EZ Trak Assembly with Keys

4 anchor bolts with washers (HW2061)

Installation & Operation Manual

100 EZ Trak Fleet Cards

Document Number: EZT1001 3

Document Title: EZ Trak Installation and Operations Manual

Page 8

EZTRAK

2 Installation

2.1 Mechanical Installation Tools

The following tools are recommended for the typical mechanical installation of this EZ Trak

unit:

6” inch or longer ratchet extension (for optional straight base)

¾” inch deep well socket and socket wrench

Small, thin blade, flat-tip screwdriver

Hammer drill

½” Concrete hammer drill bit

Hammer

Dual-plane Level

50’ foot tape measure

2.2 Electrical Installation Tools

Small, thin tipped, straight screwdriver (1/8” tip, for green Phoenix connectors)

Wire strippers (capable of handling 10-22 AWG wire)

Cable or wire tie wraps

Diagonal cutters

Needle nose pliers

5/16” nut-driver

¼” nut-driver

Phillips-head and flat-head screwdrivers

Document Number: EZT1001 4

Document Title: EZ Trak Installation Manual

Page 9

EZTRAK

2.3 Installation of the Terminal

The EZ Trak terminal is bolted onto the concrete base. Perform the f ollowing steps:

1. Center the EZ Trak terminal on the concrete base. Please note that the

bolt holes are inside the terminal, as shown in the pict ure the below.

Figure 3. EZ Trak Terminal Base

2.

Mark the 4 holes that you intend to drill in order to mount the EZ Trak.

Mark the holes with a marker as the terminal is sitting on top of the

concrete. It is important to keep in mind that the conduit run will need to

protrude through the cutout in the base by at least 3 inches.

Document Number: EZT1001 5

Document Title: EZ Trak Installation and Operations Manual

Page 10

EZTRAK

Figure 4. EZ Trak Terminal Base Dimensions

Warning:

3.

DO NOT BEGIN MOUNTING OF THE TERMINAL UNTIL ALL WIRES & CABLES

HAVE BEEN PULLED THROUGH THE CONDUITS!

Using the hammer drill, and the ½” inch concrete drill bit, drill the four

holes. Ensure that the holes are drilled deep enough to insert the anchor

bolts. A good depth is approximately 2”-2½” inches from the surface of

the concrete.

4. It should be noted that while the anchor bolts are rugged and durable,

they could become damaged if struck recklessly. Care should be given to

strike only the top of the anchors, where the force will be d istributed by the

provided area on top of the anchor bolt. Use the hammer to drive each of

the provided anchors into the drilled concrete holes.

Figure 5. Setting Anchor Bolts

Document Number: EZT1001 6

Document Title: EZ Trak Installation and Operations Manual

Page 11

EZTRAK

5. When all anchor bolts have been set, place one nut onto each of them,

and use the ratchet and socket to tighten it, until as many of the threads

from the bolts as possible are showing. There should also be sufficient

threads on the anchor bolts left to secure the plate in place with the

remaining 4 nuts. If this is not the case, the holes in the concrete were

drilled too deep, and the installer should use smaller, or n o leveling nuts.

6. Securely fasten the 4 nuts with the socket wrench. When this has been

successfully completed, there should be no movement in the EZ Trak

whatsoever.

NOTE: It is very important to allow at least 66” inches of wire to remain

draped over the top of the conduit, so that there is enough left to make all

of the electrical connections. It is also recommended that 3” or more of

conduit protrude the bottom of the terminal. This is to ensure that standin g

water will not accumulate in the conduit.

Document Number: EZT1001 7

Document Title: EZ Trak Installation and Operations Manual

Page 12

EZTRAK

2.4 Electrical Installation

2.4.1 Wiring for the Interface Board

Figure 6. Interface Board Connections

Notes on installation:

1. The carwash PLC activation voltage is applied to the program relay output in

order to activate the carwash.

2. The Wash-In-Use signal cannot exceed 110 VAC.

3. The heater is active when the red light (D2) is on.

2.4.2 Wash Outputs

1. Locate the small, thin-tipped screwdriver, and the EZ Trak power

distribution board, which is located on the inside of the EZ Trak front

Document Number: EZT1001 8

Document Title: EZ Trak Installation and Operations Manual

Page 13

EZTRAK

panel. You will be making connection to the interface board connector J7,

pins 3 and 4.

2. Use the screwdriver to open and/or secure the manufacturer wash wires

to each of the appropriate Unitec relay locations in accordance with the

following table:

Wash Program Relay Output J7, Pin 3

Wash Program Relay Input J7, Pin 4

2.4.3 Wash-In-Use

The EZ Trak will accept 24VAC, 24VDC or 115-120 VAC, Identify the signals

provided as a “Wash-In-Use Hot” and a “Wash-In-Use Common” coming from the

wash PLC. Install the two signal wires in accordance with the following table :

Table 1. Wash Program Relays

Signal: EZ Trak Interface Board

Table 2. Wash-In-Use Signal

Signal: EZ Trak Interface Board

Wash-In-Use Hot J7, Pin 1

Wash-In-Use Common J7, Pin 2

2.4.4 Wash Stacking

The EZ Trak unit stacks one wash if the wash in-use signal is on. If the wash-in-use

signal is on and a card/code is entered, that wash will be stacked and the customer

message is: “Account Valid, Wash Queued, Wait for Wash”. When the wash-in-use

signal turns off, the customer will be pr ompted to enter the wash.

A card/code entry will not activate a wash immediately following a wash activation.

The message displayed is: “Wait Until Previous Car is in Wash”. This is cleared by

the wash-in-use signal or a ~5 second timeout (the timeout is required in case the

carwash does not provide a wash-in-use signal).

If the in-use signal is on and a wash is queued, additional card/codes entrees will not

stack another wash. Customer message is: “Wash Already Queued – Waiting for

Wash”.

Document Number: EZT1001 9

Document Title: EZ Trak Installation and Operations Manual

Page 14

EZTRAK

3 System Configuration

Setup and configuration of the EZ Trak is completed via the Internet using a laptop or

desktop computer with Internet access. The network parameters for the EZ Trak

terminal are configured at the terminal itself.

The Fleet Terminal Ethernet interface comes shipped pre-configured with the

following settings:

• IP Address: 192.168.0.108

• Netmask: 255.255.255.0

• Gateway: 192.168.0.1

• DHCP: Off

To confirm these settings, enter the keypad code “123456789#”. The current: IP

address, Netmask, Gateway, MAC address, DHCP mode, DHCP Fallback mode and

Fallback IP address are displayed. Press the “#” key to return to operationa l mode.

If any of the preconfigured information conflicts with your router or network settings,

you will need to change the network parameters at the EZ Trak terminal. To leave a

parameter unchanged, press the “#” key to skip past that parameter. There is no

backspace key. Therefore, if you make a mistake you need to cycle through the

menu again and make the correct entry.

Note: This function does NOT time-out return to operational mode by default. You

MUST press the “#” key until the unit cycles back in to operational mode.

To change a parameter, perform the following steps:

1. Cycle the power on the EZ Trak. Upon boot up, enter the keypad code

“1397#” during the first 20 seconds.

2. Press “1#” to turn DHCP on or press “0#” to turn DHCP off. The default

setting for DHCP is off.

3. Enter the IP address. Use the “*” key as a “.”. The current value is displayed.

4. Enter the Gateway address. Use the “*” key as a “.”. The current value is

displayed.

5. Enter the Nameserver (Netmask) address. Use the “*” key as a “.”. The

current value is displayed.

6. All network parameters will then be displayed. Press the # key t o exit.

Document Number: EZT1001 10

Document Title: EZ Trak Installation and Operations Manual

Page 15

EZTRAK

3.1 Quick Setup

To access the EZ Trak main menu, connect the Ethernet port to you PC network hub

or router then enter

web browser address.

1. Login to the Main Menu using the Master login User Name: NADA and

Password: UE.

2. Login to the Password Administration Menu using the Master login. Enter all

screen user names and passwords. Check the box and click Submit.

3. Login to the Admin Menu. Enter the current date and time, check Set Current

Time then click Submit. Select all boxes under Reset System Counters then

click Submit. Return to the Main Menu.

4. Login to the One Use Codes Menu. Select Generate New One-Time-Use

Codes then click Submit. Print the One Use Codes page (using computer

print commands) for reference. Select Clear All One-Time-Use Codes but

keep the sheet for setting up pin numbers. Return t o the Main Menu.

5. Login to the Account Setup-Change menu. Select the number of accounts

you would like to add. Enter the Account name. Enter the Department. Enter

the number of Remaining Washes. Enter the card and/or keypad codes.

Select the Key/Card Status from the drop-down menu. Click Submit.

http://192.168.0.108 (or the IP address you programmed) into your

The EZ Trak system is now ready to operate. Test the accounts you entered by swiping a

programmed card or entering a code. Be sure the wash is fired.

Document Number: EZT1001 11

Document Title: EZ Trak Installation and Operations Manual

Page 16

EZTRAK

4 Operations

The EZ Track Fleet Terminal main menu includes the following functions, as defined

below:

• Account Reports – provides a detailed report of account usage for every

account or a summary of usage for each department.

• List All Accounts – provides a detailed list of all accounts plus a link to setup

accounts.

• Setup Change Accounts – used to add and deleted up to 100 accounts, set

the account name and department, set the account numeric code or VIP

Wash card code, and set the type of code activation: keypad, card, either, or

both. You can also disable an account with the option. Accounts are

displayed in groups of 10.

• One Use Codes -- provides 50 keypad codes that will activate t he wash on ce.

These codes are valid until used or until a new set of codes is generated.

When entering a keypad code at the terminal, the code is followed by the “#”

key which acts as the “enter” key.

• Transaction Log – provides a detailed list of the last 100 transactions at the

Fleet Terminal.

• Administration – used to reset accounting counters, backup and restore data,

change the carwash name, and set the current time in the Fleet Terminal.

• Password Administration – prevents unauthorized login of the EZ Trak

system by assigning a User Name and Password to each screen.

Document Number: EZT1001 12

Document Title: EZ Trak Installation and Operations Manual

Page 17

EZTRAK

4.1 Account Reports

Figure 7. Sample Account Report Screen

The Account Reports screen displays the information for the last counter reset, and washes

used for all accounts, departments, one use codes and summarizes the totals. One use

codes are included in the summary of totals of washes used. Invalid codes and cards are

displayed at the bottom of the screen. To refresh the report, click t he Submit button.

Note: The summary total of washes used in a particular counter will not equal the sum of

washes for all individual accounts if an account was deleted since the counter was last

cleared.

Document Number: EZT1001 13

Document Title: EZ Trak Installation and Operations Manual

Page 18

EZTRAK

4.2 List All Accounts

Figure 8. Sample List All Accounts Screen

The List All Accounts screen displays the account name, the department, the

remaining washes, the card code, the keypad code and the key/card status for each

account. You may also delete an account from this page by selecting the Delete

Account box then clicking Submit.

Document Number: EZT1001 14

Document Title: EZ Trak Installation and Operations Manual

Page 19

EZTRAK

4.3 Setup/Change Accounts

Figure 9. Setup/Change Account Screen

The Setup/Change Account function allows you to add, change and delete accounts

from the EZ Trak system. To add or change an account:

1. Click and select the number of accounts you wish to add under the Add

Accounts drop-down menu. Accounts are added below that row, allowing you

to arrange accounts in any order.

2. Enter an Account Name (max 20 characters).

3. Enter the Department Name (max 10 characters). If you want several

accounts to be rolled up in the Account Report, the Department names must

be identical. This includes upper/lower case and spaces

4. Enter the number of washes allowed to the account (up to 9999).

5. Enter the 8-digit code on the front of the account card, if required.

6. Enter the 5-digit keypad code.

7. Select one of the following options from the Key/Card Status drop-down

menu: Disable, Keypad Only, Card Only, Either, Both Required.

8. Click the Submit button to save your changes or click the Reset button to

discard your changes.

Document Number: EZT1001 15

Document Title: EZ Trak Installation and Operations Manual

Page 20

EZTRAK

9. To delete an account, select the Delete Account box next to the account you

wish to delete then click Submit.

4.4 One Use Codes

Figure 10. Sample One Use Codes Screen

The One Use Codes function provides 50 keypad codes that will activate the wash

once. These codes are valid until used or until a new set of codes is generated. When

entering a keypad code at the terminal, the code is followed by the “#” key which acts

as the “enter” key.

Note: Leading “0”s are not considered part of a code. I.E “01234” is stored as the

number “1234” not as the characters “01234”. Note that a “0” entr y is not a valid code.

1. Select Generate New One-Time-Use Codes then click Submit.

2. Print the One Use Codes page (using computer print commands) for

reference.

Document Number: EZT1001 16

Document Title: EZ Trak Installation and Operations Manual

Page 21

EZTRAK

4.5 Transaction Log

Figure 11. Sample Transaction Log Screen

The Transaction Log provides a detailed list of the last 100 transactions at the Fleet

Terminal, including the account name, department, washes left on the account, date

time and day of the week the account was used, any invalid codes and cards, and

system information, such as power cycling and memory resets.

Document Number: EZT1001 17

Document Title: EZ Trak Installation and Operations Manual

Page 22

EZTRAK

4.6 Administration

Figure 12. Administration Screen

Document Number: EZT1001 18

Document Title: EZ Trak Installation and Operations Manual

Page 23

EZTRAK

The Administration screen allows you to perform several administrative functions for

the EZ Trak system, including resetting system counters, backing up and restoring

data, changing the dealer name, and resetting the system clock.

4.6.1 Wash Account Counter Administration

The Wash Account Counter Administration function allows you to reset system

counters by day, week month, quarter or year or any other increment you chose. You

may rename any reset increment by typing a new name in the field and clicking

Submit. To reset system counters, select the box by the system counter and click

submit.

4.6.2 Backup/Restore Data

The “Backup” features saves all data normally held in memory to a serial flash. This

data includes: account information, user names/passwords, account usage data, one

use codes and the transaction log. You should backup your data at least every time

you make changes to the accounts or passwords.

The “Restore” feature replaces all current data in memory with the data from the

serial flash. Note that this restores all system information to the state it was in when

the last “Backup” was done.

The Restore function also restores all of the user names/passwords and other

information displayed on the administration web page. However, if you Restore data

and then click and submit from the administration web page before leaving that page

you will overwrite the restored data with the data on that page. For example, you can

keep your current user names/passwords after a restore by checking and submitting

the change passwords option immediately after the restore. If you do not click submit

from the administration web page, the user names/passwords at the time of the last

“backup” will be active.

Warning: All changes to the accounts, passwords, account usage, and transaction

log since the last Backup are lost!!! If you have never done a “Backup” the restore

function doesn’t work.

If memory fails in the unit when power is turned on (i.e. a dead battery), the unit will

automatically restore memory from the serial flash if a backup was previously done. If

no serial flash backup exists, all data in memory will be lost.

4.6.3 Change Dealer Name

You may customize the EZ Trak to display any dealer name you wish. Simply enter

the new dealer name and click the Submit button.

Document Number: EZT1001 19

Document Title: EZ Trak Installation and Operations Manual

Page 24

EZTRAK

4.6.4 Reset System Clock

The Reset System Clock function allows you to set the local time on the EZ Trak

system world-wide. Enter the date, time and day of the week and click the Submit

button. The system time does not automatically update, so it will need to be manually

updated for Daylight SavingsTime.

4.7 Password Administration

Figure 13. Password Administration Screen

The Password Administration screen allows you to manage access to the EZ Trak

system. Passwords are required to access all web pages (except the main menu).

Passwords provide access to one specific web page.

Once a web page is first accessed, a window will pop up and prompt for the user

name and password. If a valid username/password is entered, the web page will be

shown. Several attempts are given. If all attempts fail, a blank page will display. Once

the page is accessed, you will not be required to reenter the username and password

Document Number: EZT1001 20

Document Title: EZ Trak Installation and Operations Manual

Page 25

EZTRAK

during that session. If you terminate the browser and restart, the user name/password

will be required again.

A master username and password plus default usernames and passwords for each

web page are provided in the system. You may change any or all of user names and

passwords (max 15 characters each) on the Password Administration page. Once

the values are changed, you must click Submit to save the changes.

If you forget the master password, swipe the “Reset Password” card at the EZ TRAK

unit to return all passwords to the factory default.

Default values are as follows:

Master Username/Password: NADA/UE

Setup Account Username/Password: Setup/Setup

List Accounts Username/Password: List/List

One Use Codes Username/Password: Oneuse/Oneuse

Account Report Username/Password: Report/Report

Transaction Log Username/Password: Log/Log

Passwords Tips:

• The Master password provides access to all web pages and the

administration pages.

• No user names should be the same.

• No user passwords should be the same.

• Blanks spaces should not be used in the users name or passwords.

• Blanks and duplicate names/passwords will be accepted but the

names/passwords will not work.

• If a user name or password is blank, that password will not work. Only the

master will then have access to that page.

Document Number: EZT1001 21

Document Title: EZ Trak Installation and Operations Manual

Page 26

EZTRAK

Document Number: EZT1001 22

Document Title: EZ Trak Installation and Operations Manual

Page 27

EZTRAK

Appendix A: 120 VAC Power Supply (Optional)

The 120 VAC power supply is supplied as an option for those who wish to power their EZ

Trak system from a junction box. The power supply is attached to the DIN rail on the back

wall of the unit then connected to the junction box and power distribution board.

1. Connect the power supply to the DIN rail by centering the slot on the back of the

power supply on the DIN rail then push down firmly. Secure the power supply to the

DIN rail by pushing up the mounting pin on the back of the power supply.

2. Connect the hot wire from your power supply cable to the Line in conne ctor on the top

left side of the power supply.

3. Connect the common wire from your power supply cable to the Neutral connector on

the top left side of the power supply.

4. Connect the hot 24 VAC wire to the middle “+” connector on the top right o f the power

supply. Connect the other end to pin 5 “24V” on the J3 connector of the power

distribution board.

5. Connect the common 24 VAC wire to the middle “-“ connector on the top right of the

power supply. Connect the other end to pin 6 “Common” pin on the J3 connector of

the power distribution board.

Document Number: EZT1001 23

Document Title: EZ Trak Installation and Operations Manual

Page 28

EZTRAK

Appendix B: Connecting EZT rak to Network Hub or Switch

A standard Cat5 cable is used to connect the EZTrak to a network hub or switch using

standard “straight-through” wiring in the connectors. A straight through cable has both ends

with the same pin color code. These cables may be readily purchased from Radio Shack, but

you may also wire the connector yourself. In this case, wire the connectors as fo llows:

RJ45 Jack and Plug Pin Location

RJ45 Pin #

Wire Color

(T568B)

1 White/Orange

2 Orange

3 White/Green

4 Blue

5 White/Blue

6 Green

7 White/Brown

8 Brown

Straight-Through Cable Pinout for T568B

Wire Diagram

(T568B)

Document Number: EZT1001 24

Document Title: EZ Trak Installation and Operations Manual

Page 29

EZTRAK

Appendix C: Configuring the EZ Trak on the LAN

If your site does not have an existing Internet connection, you may configure the EZ Trak

with a laptop, a cross-over cable, and a CAT5 coupler. A cross-over cable is a Cat5

cable that has the wires reversed at opposite ends of the connector. These cables are

readily available at Radio Shack, but you may also wire the connectors yourself. In this

case, wire one for normal Cat5 communications and wire the other connector as follows:

RJ45 Pin #

(END 1)

Wire Color

1 White/Orange

2 Orange

3 White/Green

4 Blue

5 White/Blue

6 Green

7 White/Brown

8 Brown

Next, you must set up a TCP/IP connection on your laptop.

1. Confirm the default IP address on the EZ Trak unit. On the keypad enter

“123456789#”. Write down the EZ Trak settings.

2. Go to the Start button and select Control Panel.

3. Click on Network Connections.

Diagram End

#1

Cross Over Cable Pinouts

RJ45 Pin #

(END 2)

1 White/Green

2 Green

3 White/Orange

4 White/Brown

5 Brown

6 Orange

7 Blue

8 White/Blue

Wire Color

Diagram End

#2

4. Click on Local Area Connections.

NOTE: WRITE DOWN ALL EXISTING SETTING INFORMATION – YOU WILL NEED

TO RE-ENTER THIS INFORMATION AFTER THE EZ TRAK IS CONFIGURED OR

ELSE YOU WILL NOT BE ABLE TO ACCESS THE INTERNET.

Document Number: EZT1001 25

Document Title: EZ Trak Installation and Operations Manual

Page 30

EZTRAK

5. Select Internet Protocol (TCP/IP).

Document Number: EZT1001 26

Document Title: EZ Trak Installation and Operations Manual

Page 31

6. Click Properties.

EZTRAK

7. Select “Use the Following IP Address” then fill in the following network

information:

IP Address: 192.168.0.110

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.0.1

8. Leave the DNS information blank.

9. Click OK.

10. Plug the CAT5 cable from the pay node in the EZ Trak into the coupler. Plug one

end of the cross-over cable into the coupler and the other end int o your laptop.

11. Open an Internet browser window and enter the default IP address from Step 1

(http://192.168.0.108).

Document Number: EZT1001 27

Document Title: EZ Trak Installation and Operations Manual

Loading...

Loading...