Page 1

Unitec CAME Gate and Gate Controller

For Multi-Lane Applications

Installation Guide

Unitec

www.StartwithUnitec.com

Page 2

UNITEC GATE CONTROLLER FOR MULTI-LANE

APPLICATIONS INSTALLATION GUIDE

This document provides comprehensive operational procedures for the Unitec Gate

Controller. In this manual, we will discuss the setup, operation and maintenance of

the Came gate and gate controller, which is only used in multi-lane applications.

If further assistance is needed, please contact the distributor from which the product

was purchased.

When calling for assistance, you must have the following information available:

Serial Number:

Distributor Name:

COPYRIGHT

© 2011 Unitec, Incorporated. All rights reserved. No part of this book, including text,

screen examples, diagrams, or icons, may be reproduced or transmitted in any form,

by any means (electronic, photocopying, recording, or otherwise) without prior written

permission of Unitec, Incorporated.

TRADEMARKS

Sentinel, Portal TI, Wash Select II. Unitec, and the Unitec Logo are trademarks,

service marks, or registered trademarks of Unitec, Incorporated.

All other products, services, and company names are trademarks or registered

trademarks of their respective owners.

Document Number: GC1004

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 3

Table of Contents

Introduction ...........................................................................................................................................1

Site Planning .........................................................................................................................................1

Electrical Planning................................................................................................................................3

Power Requirements........................................................................................................................3

Conduit Requirements......................................................................................................................3

Wiring Requirements........................................................................................................................3

Loop Planning and Installation............................................................................................................3

General.............................................................................................................................................3

Gate Reset Loop...............................................................................................................................4

Merge Loops.....................................................................................................................................5

System Wiring.......................................................................................................................................5

General.............................................................................................................................................5

Gate Controller Power......................................................................................................................6

Gate Power.......................................................................................................................................7

Gate to Gate Controller Wiring.........................................................................................................8

Control Signal Wiring........................................................................................................................8

Configuration settings........................................................................................................................11

Portal/Sentinel Settings..................................................................................................................11

Wash Select II Settings ..................................................................................................................12

System Test Procedure......................................................................................................................14

Testing System Interface for Lane 1 ..............................................................................................14

Testing System Interface for Lane 2 ..............................................................................................15

Testing System Interface for Lane 3 ..............................................................................................15

Testing System Interface for Lane 4 ..............................................................................................16

Test for Merge Area........................................................................................................................16

Gate Controller I/O Definitions ..........................................................................................................18

Document Number: GC1004 i

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 4

Index of Figures

Figure 1. Example Multi-Lane Site Plan........................................................................................................2

Figure 2. Gate Reset Loop Dimensions........................................................................................................4

Figure 3. Multi-Lane Merge Loop Placement................................................................................................5

Figure 4. Wire the AC Power to the Gate Controller.....................................................................................6

Figure 5. Gate Power....................................................................................................................................7

Figure 6. Came Gate to Gate Controller Connections..................................................................................8

Figure 7. WSII to Gate Controller to Gate Connections...............................................................................9

Figure 8. Portal/Sentinel to Gate Controller to Gate Connections..............................................................10

Figure 9. Wash Interface Screen................................................................................................................11

Figure 10. Wash Select II CPU Board ........................................................................................................12

Index of Tables

Table 1. Gate Controller I/O Definitions......................................................................................................18

Document Number: GC1004 ii

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 5

Introduction

This document provides instructions for installing the Unitec gate controller for use with the Sentinel, Portal or

WashSelect II entry units and Unitec supplied gates. Topics covered in this manual include:

• Conduit and wiring requirements for the gate controller and gates

• Guidelines for locating and installing vehicle detection loops (required for safe gate opera tion)

• Connection schematics for the gate and gate controller wirin g.

Additional instructions for installing the entry units and gates are available in the installation manuals that are

provided with those products.

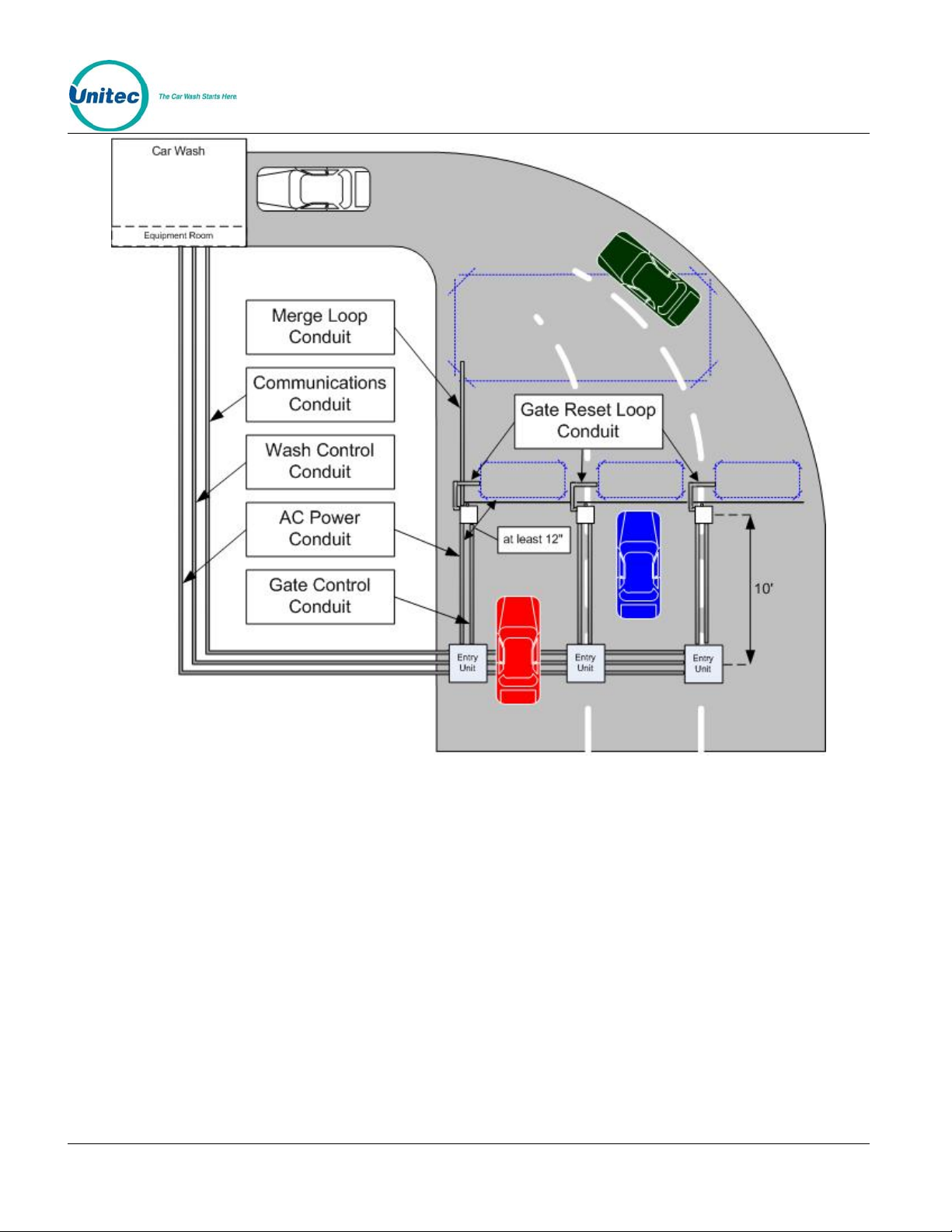

Site Planning

Figure 1 depicts a typical multi-lane gated installation. The gates are located approximately 10 ft past the

entry units and positioned on the same centerline as the terminal. Vehicle detection loops are required

after each arm to prevent the arm from closing on a vehicle. Additional loops may be required in the

‘merge’ area to ensure accurate queuing of vehicles. Additional details on planning and installation of

loops are provided later in this document.

The gate controller is supplied in NEMA enclosure and should be mounted on a wall in

room.

the equipment

Document Number: GC1004 1

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 6

Figure 1. Example Multi-Lane Site Plan

Document Number: GC1004 2

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 7

Electrical Planning

Power Requirements

Each barrier gate requires a 115-120 VAC on a 5-Amp dedicated breaker, which should be provided

during wash construction. Most installers will have power supplied directly fr om one of the three phases

used to power the wash motors and controllers. If this method is used, special attention should be

given to proper grounding at the unit, as well as in the brea ker panel.

Note: Follow all local and national electrical codes!

Conduit Requirements

Plan your conduit runs so that the barrier gate control signal wiring and the loop wiring enter through

the bottom of the base of the gate. Figure 1 shows a typical sit e layout with the followin g conduit runs:

• A conduit between the AC service panel and the entry units for power wiring.

• A conduit between the entry units and gates for power wiring.

• A conduit between the gate controller (located in the equipment room) and the entry units

for control signal wiring.

• A conduit between the entry units and the gates for contro l signal wiring.

• Conduit between the gates and loops the loop leads.

Wiring Requirements

Wires to be pulled through the conduits are listed in the following tables. Wires should be 18

AWG (minimum) and color-coded to facilitate installation and troubleshooting. The quantities

shown are per lane.

Qty From To Function

3 AC Service Panel Gate Gate Power (115 VAC)

4 Gate Controller Entry Units Control wires

3 Gate Controller Gate Control wires

Loop Planning and Installation

General

Unitec provides 18-foot vehicle detection loops that can be used for the gate arm reset or merge

loops. Two loop types are available: direct burial and saw cut installation. Direct burial loops

Document Number: GC1004 3

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 8

would only be used in new construction (where concrete is not yet poured). Saw cut loops are

used in pre-existing concrete and installed in a rectangular groove that is cut into the concrete.

Refer to the loop installation instructions for detailed installation procedures.

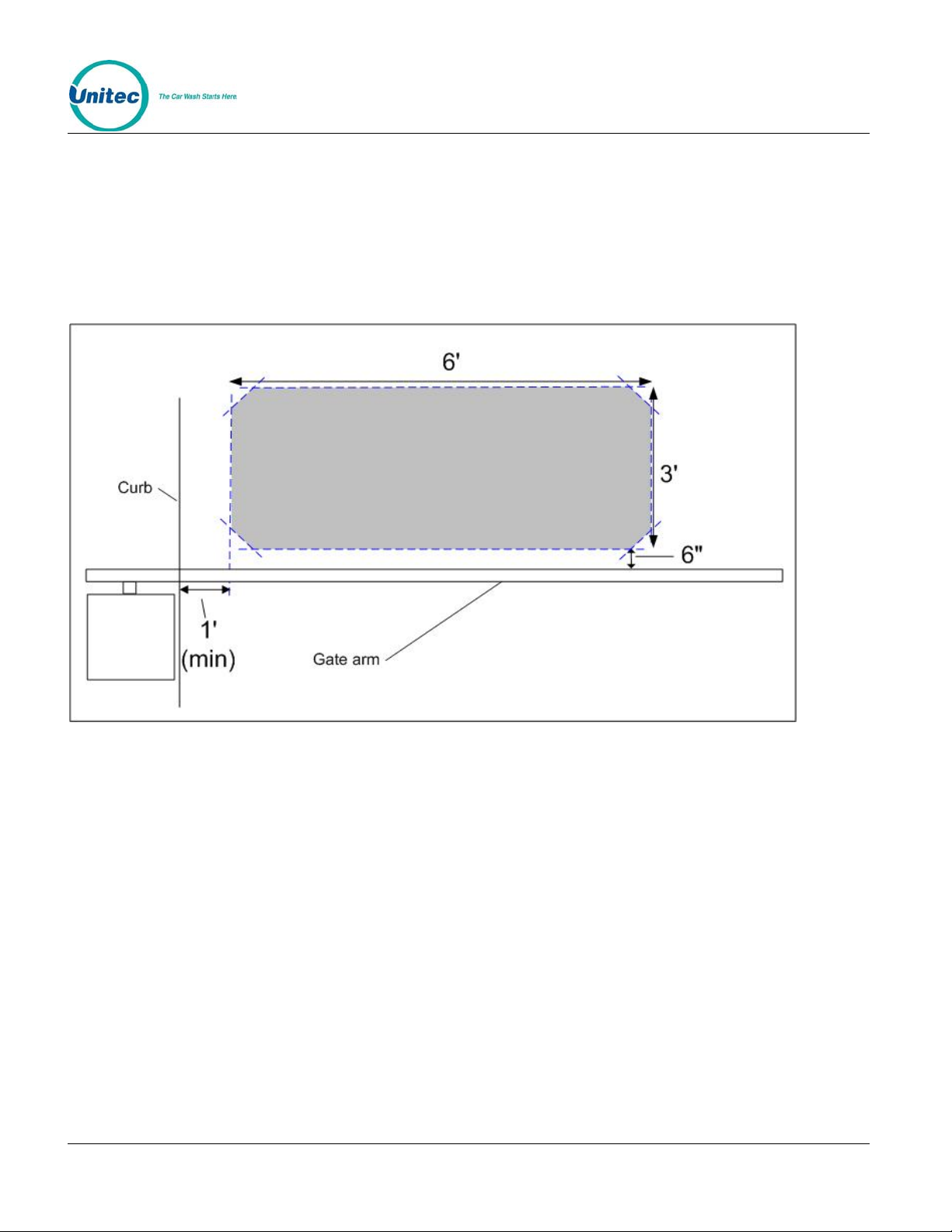

Gate Reset Loop

Each gate requires one gate reset loop. The reset loop should be formed into a 6’ long by 3’ wide

rectangle and located as shown in

Figure 2.

Figure 2. Gate Reset Loop Dimensions

Document Number: GC1004 4

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 9

Merge Loops

Merge loops are recommended to prevent vehicle queuing errors. These loops prevent a gate from

opening until all paid vehicles have merged into a single line at the tunnel en trance.

The number and size of loops required depends on the size of the merge zone area. The loop

detector in each gate has can accommodate (1) merge loop so the maximum number of merge loops

can not exceed the number of gates installed.

The front edge of a merge loop should be no more than 9 feet away from the back edge of the gate

reset loop to ensure proper detection of vehicles (see Figure 3). If the standard (18 foot) loop available

from Unitec is too small, larger loops can be provided as special orders.

Figure 3. Multi-Lane Merge Loop Placement

System Wiring

General

The payment system should be connected to the wash controller as described in its manual

except, the wash in use signal is not to be connected (as this signal is will be provided by the

gate controller). The following sections provide instructions on connecting the gate and gate

control power and the gate control signal wires.

Document Number: GC1004 5

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 10

Gate Controller Power

Warning:

Disconnect 115VAC-120VAC po wer from the m ain po wer lines at the

panel box before continuing!

The power connections are located at the bottom of the main terminal strip within the gate controller.

The Line, Neutral, and Ground (Earth) connections are labeled L, N, and E respectively.

Figure 4. Wire the AC Power to the Gate Controller

Document Number: GC1004 6

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 11

Gate Power

Connect the hot and neutral line to the red phoenix connector at the top of the gate, according the

installation manual included with the gate. Connect the ground wire to the cable lug on the base p late.

Figure 5. Gate Power

Document Number: GC1004 7

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 12

Gate to Gate Controller Wiring

Figure 6. Came Gate to Gate Controller Co nnections

There are 3 control wires that run from the gate to the gate controller. The gate reset loop and merge

loop wiring (if applicable) is also illustrated, above. You must remove the loop detector block to access

the block base for connecting the loop wires. The connections for each gate to the gate controller are

illustrated on the left sides of Figures 7 and 8.

Control Signal Wiring

There will be (4) control wires connected to each entry unit and (3) wires for each gate. For Portal and

Sentinel entry units, the control wires will terminate at connectors J3 and J18 on the Wash I/O board.

For the Wash Select II, the wires connect to J18 and J19 of the CPU board. The connections from the

gate controller to the gate are illustrated on the right sid e of Figures 7 and 8.

Figures 7 and 8 show controller wiring for up to four entry units and four gates. For installations with

fewer lanes, simply refer to the parts of the diagrams labeled for the numbers of units and gates you

are installing on site.

Document Number: GC1004 8

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 13

Figure 7. WSII to Gate Controller to Gate Connections

Document Number: GC1004 9

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 14

Figure 8. Portal/Sentinel to Gate Controller to Gate Connections

Document Number: GC1004 10

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 15

Configuration settings

Portal/Sentinel Settings

To configure the Portal or Sentinel, login to the Sierra Management Application then follow this

path to navigate to the configuration screen:

Setup>Device Profiles>(Edit next to device)>Wash Interface

Figure 9. Wash Interface Screen

1.

Enter the appropriate information in the following fields:

• Wash-in-Use Handshaking – Select this option when using a gate.

• Relay Latching –This needs to be unchecked if an entry gate is being used in conjunction

with the Portal or Sentinel.

• Fault OOS Detection – Check this box if a fault signal is available from the wash

equipment.

• Auto OOS Detection – Check this box to activate the Portal or Sentinel’s monitoring of the

out of service inputs from the wash.

• Relay Stacking –This needs to be checked if an entry gate is being used in conjunction

with the Portal.

Document Number: GC1004 11

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 16

• Start Button (over conveyor) – Used for Tunnel applications. This needs to be “off” if an

entry gate is being used in conjunction with the Portal.

Click OK to save your changes and return to the Bay Setup screen.

Wash Select II Settings

Before a Wash Select II (WSII) unit will operate with the Gate Controller, some configuration settings on

the Wash Select II must be changed. Refer to the WSII Operations Manual, Section 2.8.8: Wash

Interface Settings Tunnel mode for more information.

You must enable the Barrier gate interface of the WSII in order for the WSII to communicate with the

gate controller.

Figure 10. Wash Select II CPU Board

1.

Using the toggle switch at the top of the CPU board, place the Wash Select II in setup

mode by moving the switch toward the back of the Wash Select II case. (The CPU board is

located on the inside right wall of the Wash Se lect II case .)

2. On the WSII keypad, use the (3) key to scroll forward and the (1) key to scroll back. Scroll

through the main menu until the “Wash Interface” option is displayed. Press the (*) key to

enter.

3. Scroll through this menu until the “Barrier Gate” option is displayed, and then press the (*)

key to enter.

4. Press the (1) button to enable the option.

Document Number: GC1004 12

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 17

Depending on the interface of your WSII to the tunnel controller, you may need to put the WSII into

“Attended Tunnel Mode”

When the Tunnel Mode is set to “Attended,” each customer will receive a receipt to give to the

attendant, who will then arm the appropriate wash. For an interface to a Gate controller, you should

either use Roll Over or Attended mode. Do not use Mode 1 - Unattended mode.

1. Using the toggle switch at the top of the CPU board, place the Wash Select II in setup

mode by moving the switch toward the back of the Wash Select II case. (The CPU board is

located on the inside right wall of the Wash Se lect II case .)

2. On the WSII keypad, use the (3) key to scroll forward and the (1) key to scroll back. Scroll

through the main menu until the “Wash Interface” option is displayed. Press the (*) key to

enter.

3. Scroll through this menu until the “Tunnel Mode” option is displayed, and then press the (*)

key to enter.

4. Press the (2) button for “Attended Tunnel Mode” or (0) button to disable tunnel mode and

then press the (*) key.

Document Number: GC1004 13

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 18

System Test Procedure

The following section contains procedures for verifying the completed installation. The procedures are

written to cover up to 4 lanes of operation. Any lanes that do not have the wires connected will be

ignored by the Gate controller and do not need to be tested. The test procedure is to be performed in

lane sequence (i.e., test Lane 1, then Lane 2, etc.). If you chose to perform the procedures out of

sequence, follow the resetting of the entry unit power and Gate Controller as dictated in the init ia l step s

of testing for Lane 1.

Caution:

You may wish to do this test with the gate arms removed from the gates in order to

avoid damage to a vehicle if the Gate loops are malfu nctioning.

Testing System Interface for Lane 1

1. Reset power to all entry units.

2. Remove any vehicles below all gate loops and merge loop.

3. Verify that all Gates have power and the gates are down. Gates should be switched to

Automatic mode.

4. Reset Power to Gate controller. As you do, note the LCD screen display on it. It should

show the Gate controller software version then go to “Idle/Scanning.” The “Wash In Use”

output Y0,Y1,Y2,Y3 are the only output/input LEDs on the PLC that should be lit. They

provide the wash in use signal at each lane to hold the customer until the gate opens.

If this is not the case, check wiring of each terminal that is incorrect based on the Gate

Controller I/O Definitions chart in Section 5.

5. Verify that the “Wash In Use” LED on the associated board of the entry unit is lit. If not,

check the wiring from Y0/Terminals 41 and 11 to the entry unit.

6. Arm a wash at the entry unit in Lane 1.

7. Verify Gate at Lane 1 opens. If not, view the LCD screen on the PLC. If it shows

“IDLE/SCANNING” still, then it is not getting the signal into X0/terminal 21 from the entry

unit. Check the wiring from terminal 21 of the gate controller to the entry unit. If it shows

“Open Gate 1,” then check the wiring from the Gate Controller Y4/Terminal 51 to the Gate

terminal strip.

8. If everything is operating correctly, X4 LED on the PLC should be lit and the LCD screen

on the Gate controller should show “Wait for Gate 1”. If not, verify wiring from X4/Terminal

31 to the Gate terminal strip.

9. With the Gate for lane 1 open, drive a car through Lane 1. Validate that the Gate lowers after

the rear of the vehicle comfortably passes off the Gate Loop. If not, consult the Gate

Controller manual for Gate loop operation.

10. After the gate for Lane 1 closes, the LCD screen on the Gate controller should either show

“Car in Merge area” (if you have a Merge loop installed). Or “Idle/Scanning”

Document Number: GC1004 14

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 19

11. If you have connected the wash arming signals to your Tunnel controller, you should verify a

wash has been queued. If not, verify these connections.

Testing for Lane 1 is complete.

Testing System Interface for Lane 2

1. Remove any vehicles below all gate loops and merge loop.

2. Verify that all Gates have power and the gates are down. Gates should be switched to

Automatic mode.

3. Verify the “Wash In Use” LED is lit at the entry unit. If not, check the wiring from Y1/Terminals

42 and 11 to entry unit.

4. Arm a wash at the entry unit in Lane 2.

5. Verify Gate at Lane 2 opens. If not, view the LCD screen on the PLC. If it shows

“IDLE/SCANNING” still, then it is not getting the signal into X1/terminal 22 from the entry unit.

Check your wiring from terminal 22 of the Gate Controller to the entry unit. If it shows “Open

Gate 2” then check the wiring from the Gate Controller Y5/Terminal 52 to the Gate terminal

strip.

6. If everything is operating correctly, X5 LED on the PLC should be lit and the LCD on the Gate

controller should show “Wait for Gate 2”. If not, verify wiring from X5/Terminal 32 to the Gate

terminal strip.

7. With the Gate for lane 2 open, drive a car through Lane 2. Validate that the Gate lowers after

the rear of the vehicle comfortably passes off the Gate Loop. If not consult the Gate Controller

manual for Gate loop operation.

8. After the gate for Lane 2 closes, the LCD screen on the Gate controller should either show

“Car in Merge area” (if you have a Merge loop installed). Or “Idle/Scanning”

9. If you have connected the wash arming signals to your Tunnel controller, you should verify a

wash has been queued. If not, verify connections from the entry unit to the Tunnel controller.

Testing for Lane 2 is complete.

Testing System Interface for Lane 3

1. Remove any vehicles below all gate loops and merge loop.

2. Verify that all Gates have power and the gates are down. Gates should be switched to

Automatic mode.

3. Verify that the “Wash In Use” LED is lit at the entry unit. If not, check the wiring from

Y2/Terminals 43 and 11 to the entry unit.

4. Arm a wash at the entry unit in Lane 3.

5. Verify Gate at Lane 3 opens. If not, view the LCD screen on the PLC. If it shows

“IDLE/SCANNING” still, then it is not getting the signal into X2/terminal 23 from the entry unit.

Check your wiring from terminal 23 of the Gate Controller to the entry unit. If it shows “Open

Gate 3” then check the wiring from the Gate Controller Y6/Terminal 53 to the Gate terminal

strip.

Document Number: GC1004 15

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 20

6. If everything is operating correctly, X6 LED on the PLC should be lit and the LCD screen on

the Gate controller should show “Wait for Gate 3”. If not, verify wiring from X6/Terminal 33 to

the Gate terminal strip.

7. With the Gate for lane 3 open, drive a car through Lane 3. Validate that the Gate lowers after

the rear of the vehicle comfortably passes off the Gate Loop.

8. After the gate for Lane 3 closes, the LCD screen on the Gate controller should either show

“Car in Merge area” (if you have a Merge loop installed). Or “Idle/Scanning”

9. If you have connected the wash arming signals to your Tunnel controller, you should verify a

wash has been queued. If not, verify from the entry unit to the Tunnel controller.

Testing for Lane 3 is complete.

Testing System Interface for Lane 4

1. Remove any vehicles below all gate loops and merge loop.

2. Verify that all Gates have power and the gates are down. Gates should be switched to

Automatic mode.

3. Verify that the “Wash In Use” LED is lit at the entry unit. If not, check the wiring from

Y4/Terminals 44 and 11 of the Gate controller to the entry unit.

4. Arm a wash at the entry unit in Lane 4.

5. Verify Gate at Lane 4 opens. If not, view the LCD screen on the PLC. If it shows

“IDLE/SCANNING” still, then it is not getting the signal into X3/terminal 24 from the entry unit.

Check your wiring from the Gate Controller to the entry unit. If it shows “Open Gate 4” then

check the wiring from the Gate Controller Y7/Terminal 54 to the Gate terminal strip.

6. If everything is operating correctly, X7 LED on the PLC should be lit and the LCD screen on

the Gate controller should show “Wait for Gate 4”. If not, verify wiring from X7/Terminal 34 to

the Gate terminal strip.

7. With the Gate for lane 4 open, drive a car through Lane 4. Validate that the Gate lowers after

the rear of the vehicle comfortably passes off the Gate Loop.

8. After the gate for Lane 4 closes, the LCD screen on the Gate controller should either show

“Car in Merge area” (if you have a Merge loop installed). Or “Idle/Scanning”

9. If you have connected the wash arming signals to your Tunnel controller, you should verify a

wash has been queued. If not, verify connections from the entry unit to the Tunnel controller.

Testing for Lane 4 is complete.

Test for Merge Area

Using a vehicle, drive a small vehicle in all areas of the merge area, Verify that there are no dead zones.

Verify that in all areas, the PLC LCD shows “Car in Merge Area”. If not, determine if the issue is one of

the following:

• A merge loop signal from one of the gates is not functioning or being sent to Terminal 35.

• The merge area is not covered by merge loops completely.

Document Number: GC1004 16

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 21

[THIS PAGE INTENTIONALLY LEFT BLANK]

Document Number: GC1004 17

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 22

Gate Controller I/O Definitions

The following information is provided for troubleshooting purposes.

Table 1. Gate Controller I/O Definitions

Gate

Control

Signal name

Lane 1

Request

Lane 2

Request

Lane 3

Request

Lane 4

Gate

Control

Terminal

Number

21 X0 Input from Lane

22 X1 Input from Lane

23 X2 Input from Lane

24 X3 Input from Lane4

Gate

Control

PLC I/O

point

Device

Connection

1

2

3

Request

Gate 1 Open 31 X4 Input from Gate

1 Lockout

Gate 2 Open 32 X5 Input from Gate

2 Lockout

Gate 3 Open 33 X6 Input from Gate

3 Lockout

Gate 4 Open 34 X7 Input from Gate

4 Lockout

Merge Loop 35 X10 Input from one or

more merge

Loops from

Gates 1-4

Descriptive Use or

Operation

Terminal at lane 1 will hold this line at

24VDC when a customer at Lane 1

has purchased a wash. Terminal will

remove signal when Lane 1 Hold

turns off.

Terminal at lane 2 will hold this line at

24VDC when a customer at Lane 2

has purchased a wash. Terminal will

remove signal when Lane 1 Hold

turns off.

Terminal at lane 3 will hold this line at

24VDC when a customer at Lane 31

has purchased a wash. Terminal will

remove signal when Lane 1 Hold

turns off.

Terminal at lane 4 will hold this line at

24VDC when a customer at Lane 4

has purchased a wash. Terminal will

remove signal when Lane 1 Hold

turns off.

24VDC is present on this line when

Gate for Lane 1 is Open or Opening

24VDC is present on this line when

Gate for Lane 2 is Open or Opening

24VDC is present on this line when

Gate for Lane 3 is Open or Opening

24VDC is present on this line when

Gate for Lane 4 is Open or Opening

24VDC is present when any of the

merge loops from Gates 1-4 is active.

No gates will initiate an Open if a

Merge Loop is active.

Document Number: GC1004 18

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 23

Gate

Control

Signal name

Lane 1 Wash

in Use

Gate

Control

Terminal

Number

41 Y0 Output to Wash

Gate

Control

PLC I/O

point

Device

Connection

in use signal for

Lane 1

Lane 2 Wash

in Use

42 Y1 Output to Wash

in use signal for

Lane 2

Lane 3 Wash

in Use

43 Y2 Output to Wash

in use signal for

Lane 3

Lane 4 Wash

in Use

44 Y3 Output to Wash

in use signal for

Lane 4

Open Gate 1 51 Y4 Output to Vend

Input of Gate at

Lane 1

Open Gate 2 52 Y5 Output to Vend

Input of Gate at

Lane 2

Descriptive Use or

Operation

24VDC- is present when Gate

Controller is commanding Terminal at

Lane 1 to hold its current customer.

Signal turns off when Terminal is to

send customer through and fire wash

into queue. Note: This is a sinking

output. When testing, reference from

terminal 11(RED) to Y0. When Y0

light is on, Terminal 41(Black) to

11(Red) should measure 24VDC

24VDC- is present when Gate

Controller is commanding Terminal at

Lane 2 to hold its current customer.

Signal turns off when Terminal is to

send customer through and fire wash

into queue. Note: This is a sinking

output. When testing, reference from

terminal 11(RED) to Y1. When Y1

light is on, Terminal 42(Black) to

11(Red) should measure 24VDC

24VDC- is present when Gate

Controller is commanding Terminal at

Lane 3 to hold its current customer.

Signal turns off when Terminal is to

send customer through and fire wash

into queue. Note: This is a sinking

output. When testing, reference from

terminal 11(RED) to Y2. When Y2

light is on, Terminal 43(Black) to

11(Red) should measure 24VDC

24VDC- is present when Gate

Controller is commanding Terminal at

Lane 4 to hold its current customer.

Signal turns off when Terminal is to

send customer through and fire wash

into queue. Note: This is a sinking

output. When testing, reference from

terminal 11(RED) to Y3. When Y3

light is on, Terminal 44(Black) to

11(Red) should measure 24VDC

Tied to the Vend input of the Gate,

This line will become 24VDC- when

Gate 1 is triggered to open. Note:

This is a sinking output. When

testing, reference from terminal

11(RED) to Y4. When Y4 light is on,

Terminal 51(Black) to 11(Red) should

measure 24VDC

Tied to the Vend input of the Gate,

This line will become 24VDC when

Gate 2 is triggered to open. Note:

This is a sinking output. When

testing, reference from terminal

11(RED) to Y5. When Y5 light is on,

Terminal 52(Black) to 11(Red) should

measure 24VDC

Document Number: GC1004 19

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Page 24

Gate

Control

Signal name

Gate

Control

Terminal

Number

Gate

Control

PLC I/O

point

Device

Connection

Open Gate 3 53 Y6 Output to Vend

Input of Gate at

Lane 3

Open Gate 4 54 Y7 Output to Vend

Input of Gate at

Lane 4

Ground G N/A N/A

115V Line L N/A N/A

115V Neutral N N/A N/A

115V fused 5 N/A N/A

24VDC

6 N/A N/A

Regulated

24VDC Fused

F2 + N/A

for PLC

24VDC

Ground

24VDC Fused

10 -, C0, C1,

N/A

C0, C1

11 V+ N/A

for External

Descriptive Use or

Operation

Tied to the Vend input of the Gate,

This line will become 24VDC when

Gate 3is triggered to open. Note: This

is a sinking output. When testing,

reference from terminal 11(RED) to

Y6. When Y6 light is on, Terminal

53(Black) to 11(Red) should measure

24VDC

Tied to the Vend input of the Gate,

This line will become 24VDC when

Gate 4 is triggered to open. Note:

This is a sinking output. When

testing, reference from terminal

11(RED) to Y7. When Y7 light is on,

Terminal 54(Black) to 11(Red) should

measure 24VDC

Electrical Ground

115V Line (Hot)

115V Neutral (Common

Fused input power

Unfused 24VDC out of regulated PS

Fused power for PLC

Ground (24VDC-) for PLC power and

communications signals

Fused 24VDC signal power for

communications signals

Document Number: GC1004 20

Document Title: Unitec CAME Gate and Gate Controller Installation Guide

Loading...

Loading...