Unitec American Parking Equipment User Manual

Unitec APE Gate and Gate Controller

For Multi-Lane Applications

Installation Guide

Unitec

www.StartwithUnitec.com

UNITEC GATE CONTROLLER FOR MULTI-LANE

APPLICATIONS INSTALLATION GUIDE

This document provides comprehensive operational procedures for the Unitec Gate

Controller. In this manual, we will discuss the setup, operation and maintenance of

the gate controller, which is only used in multi-lane applications.

If further assistance is needed, please contact the distributor from which the product

was purchased.

When calling for assistance, you must have the following information available:

Serial Number:

Distributor Name:

COPYRIGHT

© 2008 Unitec, Incorporated. All rights reserved. No part of this book, including text,

screen examples, diagrams, or icons, may be reproduced or transmitted in any form,

by any means (electronic, photocopying, recording, or otherwise) without prior written

permission of Unitec, Incorporated.

TRADEMARKS

Portal TI, Wash Select II. Unitec, and the Unitec Logo are trademarks, service marks,

or registered trademarks of Unitec, Incorporated.

All other products, services, and company names are trademarks or registered

trademarks of their respective owners.

Document Number: GC1001 2

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

Table of Contents

1 Gate Installation with Gate Controller........................................................ 1

1.1 Electrical Planning..........................................................................................................1

1.1.1 Signal Wires...........................................................................................................1

1.1.2 Conduit Runs .........................................................................................................1

1.2 Mechanical Planning.......................................................................................................2

1.3 Mechanical Installation ...................................................................................................3

1.3.1 Gate Reset Loop....................................................................................................3

1.3.2 Merge Loop............................................................................................................4

1.3.3 Installing the Gate..................................................................................................4

1.3.4 Installing the Gate Controller .................................................................................5

1.4 Electrical Installation.......................................................................................................6

1.4.1 Wire the AC power to the Gate Controller.............................................................6

1.4.2 Wire the WSII/Portal Units.....................................................................................7

2 Merge Zone Loop Guidelines.................................................................... 19

2.1 Installation of the Merge Zone Loop or Loops..............................................................19

2.1.1 Loop Placement...................................................................................................19

2.1.2 Determining the Number of Required Merge Loops............................................20

2.2 Loop Installation Tips....................................................................................................22

2.2.1 Loop Wire Installation ..........................................................................................22

2.3 Other Useful Information...............................................................................................22

2.4 APE Gate Merge Loop Detector Card..........................................................................23

2.5 Wiring the Merge Zone Loop........................................................................................24

3 Entry System Configuration ..................................................................... 27

3.1 Wash Select II Settings.................................................................................................27

3.1.1 Enable Barrier Gate interface ..............................................................................27

3.1.2 Tunnel Mode........................................................................................................28

3.2 Portal TI Settings..........................................................................................................29

4 APE Gate Test-Out Procedure.................................................................. 31

5 System Test-Out Procedure...................................................................... 33

5.1 Testing System Interface for Lane 1.............................................................................33

5.2 Testing System Interface for Lane 2.............................................................................34

5.3 Testing System Interface for Lane 3.............................................................................34

5.4 Testing System Interface for Lane 4.............................................................................35

5.5 Test for Merge Area......................................................................................................36

6 Gate Frequency Settings........................................................................... 37

7 Gate Terminal Block Signal Definitions................................................... 39

8 Gate Controller I/O Definitions ................................................................. 41

Document Number: GC1001 i

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

Index of Figures

Figure 1. Gate Position .................................................................................................................................2

Figure 2. Sample Site Layout........................................................................................................................3

Figure 3. Gate Reset Loop Dimensions........................................................................................................4

Figure 4. Gate Base Bolt Positioning............................................................................................................5

Figure 5. Wire the AC Power to the Gate Controller.....................................................................................6

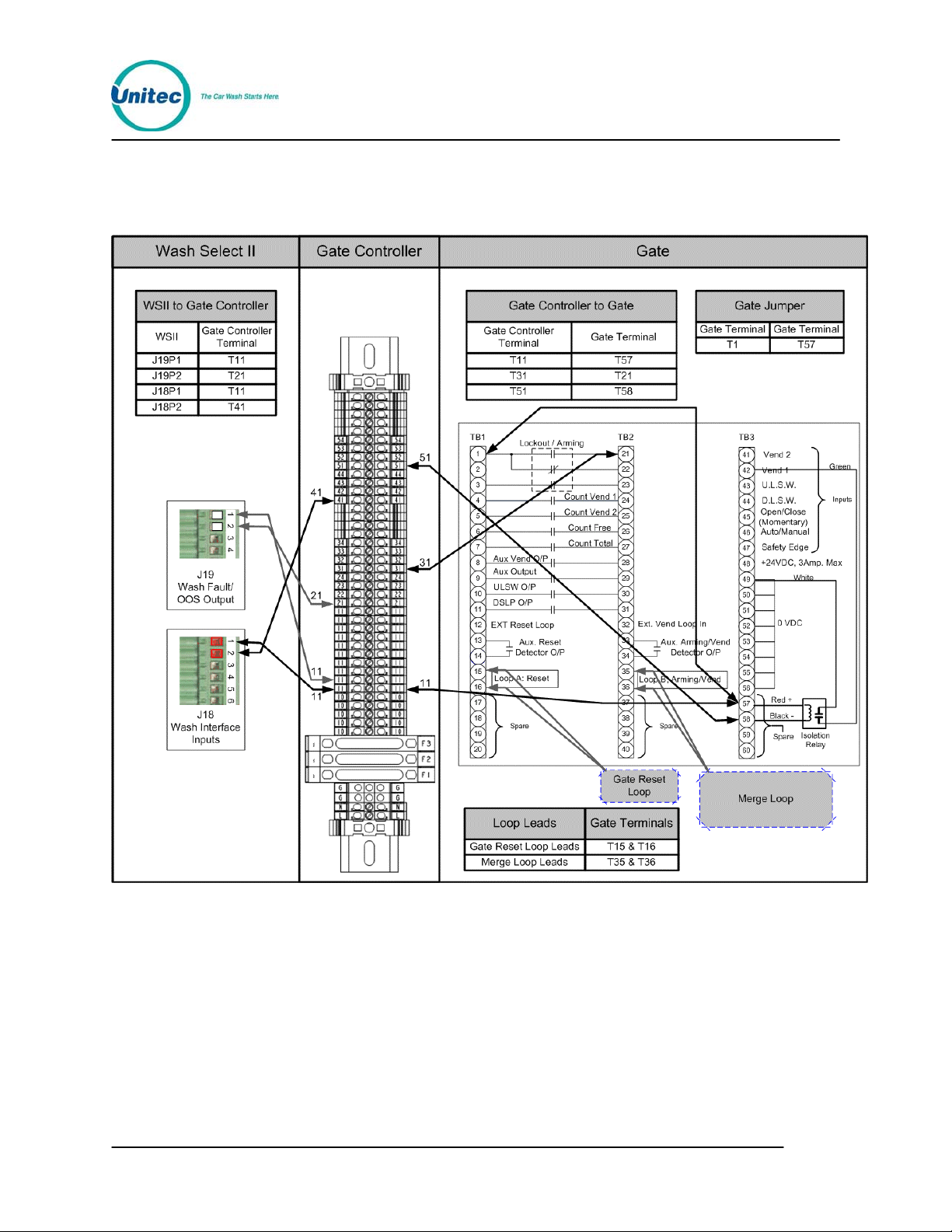

Figure 6. Unit 1 Gate Controller to Gate Wiring Diagram.............................................................................7

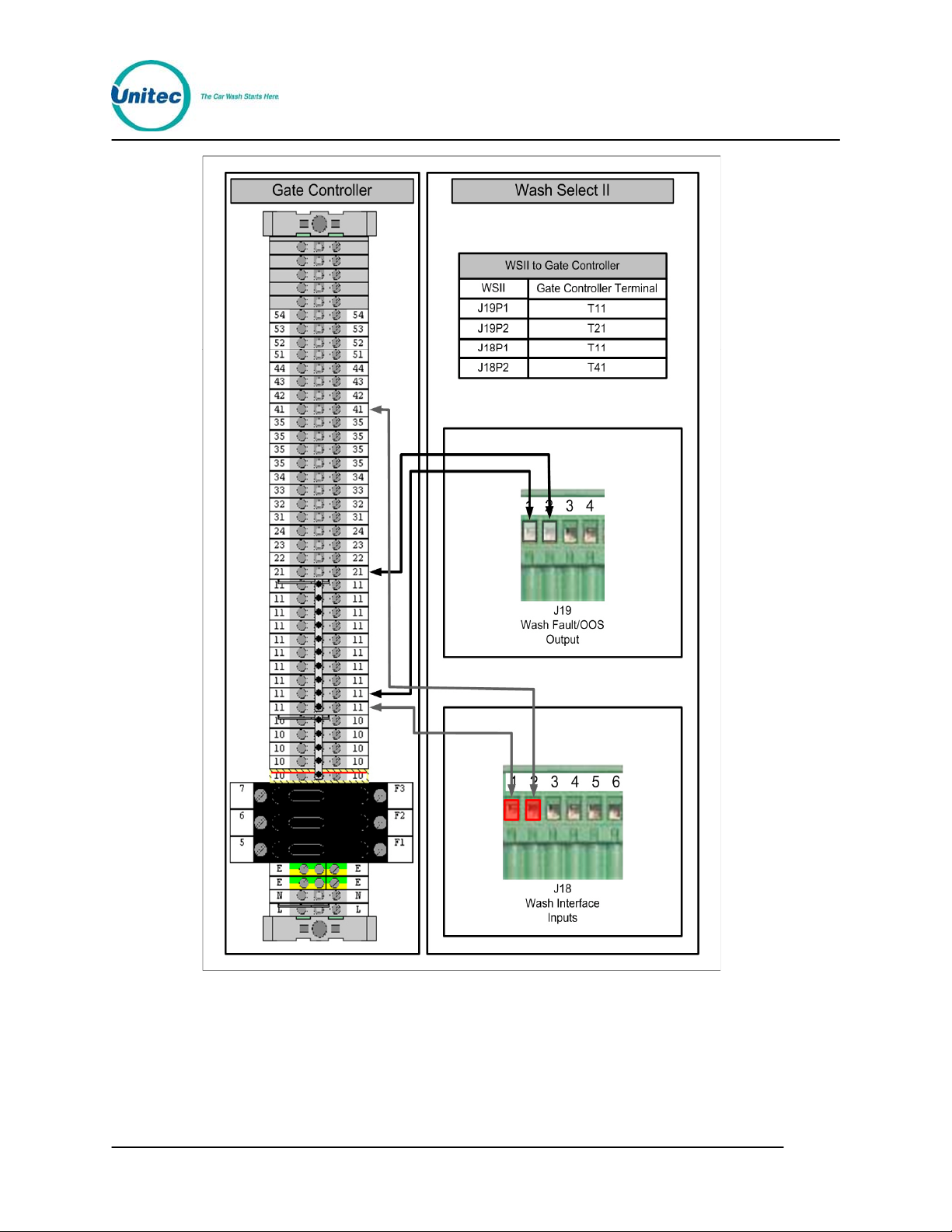

Figure 7. Unit 1 Gate Controller to Wash Select II Wiring Diagram..............................................................8

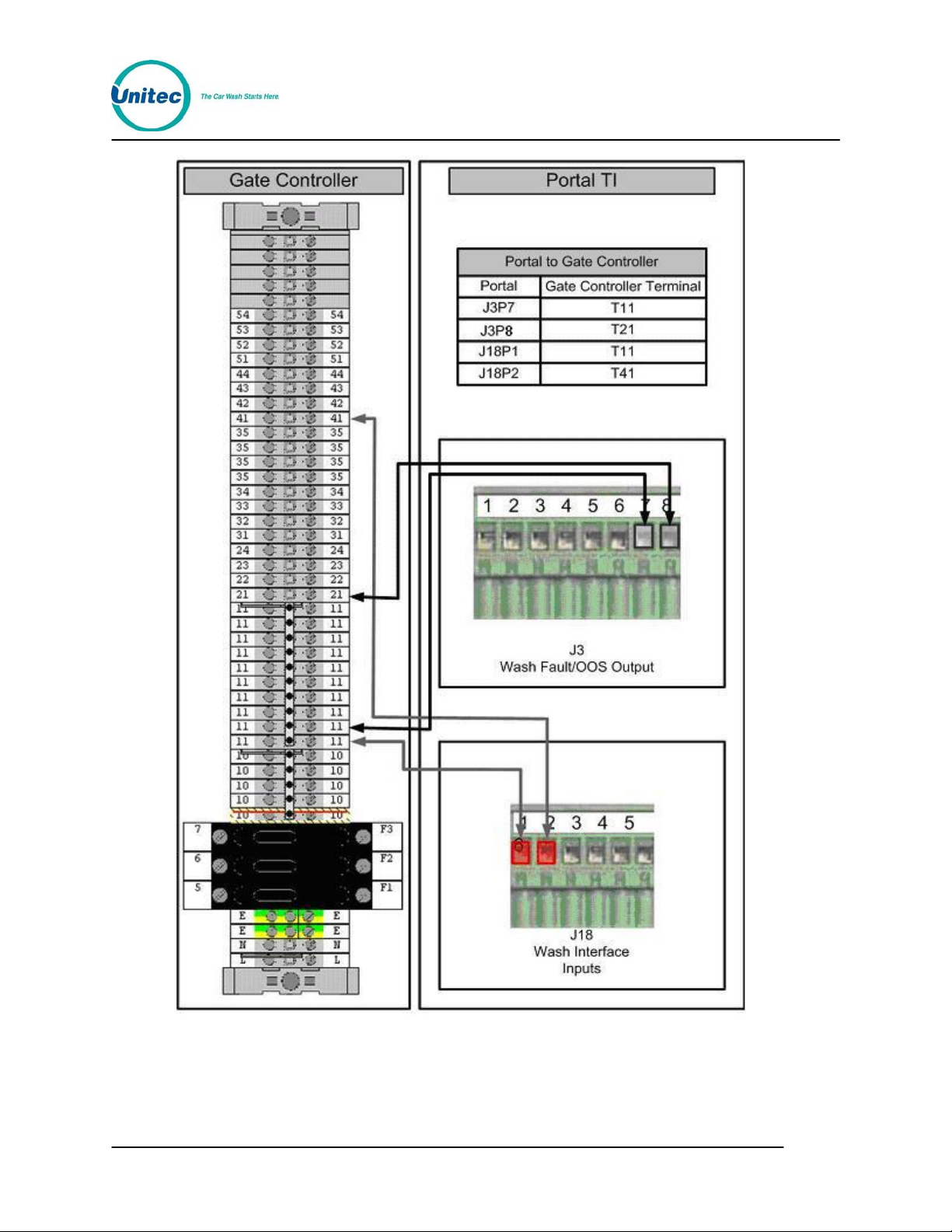

Figure 8. Unit 1 Gate Controller to Portal TI Wiring Diagram .......................................................................9

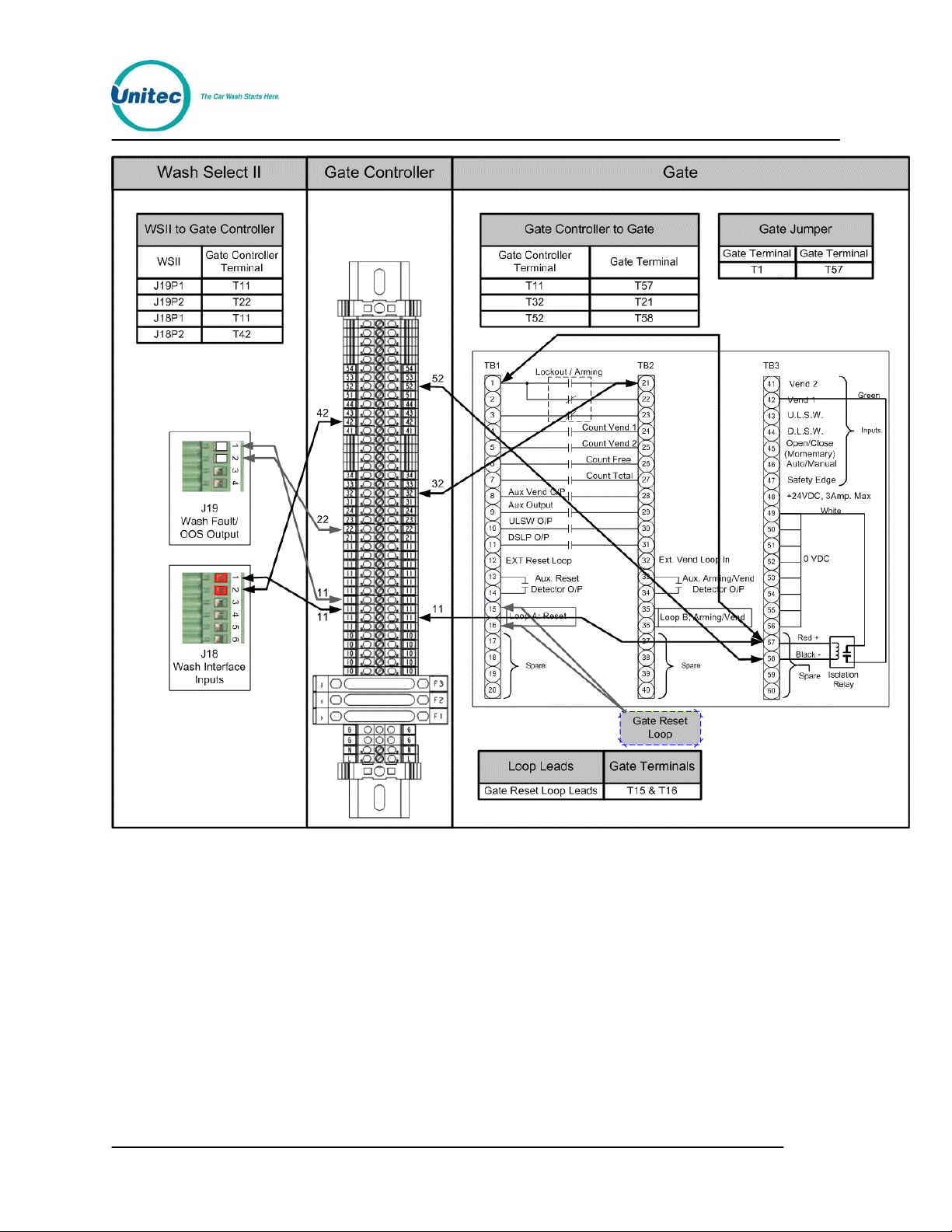

Figure 9. Unit 2 Gate Controller to Gate Wiring Diagram...........................................................................10

Figure 10. Unit 2 Gate Controller to Wash Select II Wiring Diagram..........................................................11

Figure 11. Unit 2 Gate Controller to Portal TI Wiring Diagram ...................................................................12

Figure 12. Unit 3 Gate Controller to Gate Wiring Diagram.........................................................................13

Figure 13. Unit 3 Gate Controller to Wash Select II Wiring Diagram..........................................................14

Figure 14. Unit 3 Gate Controller to Portal TI Wiring Diagram ...................................................................15

Figure 15. Unit 4 Gate Controller to Gate Wiring Diagram.........................................................................16

Figure 16. Unit 4 Gate to Wash Select II Wiring Diagram ..........................................................................17

Figure 17. Unit 4 Gate to Portal TI Wiring Diagram....................................................................................18

Figure 18. 2 Lane Short Merge Zone Loop.................................................................................................20

Figure 19. Three Lane Merge Zone Loops.................................................................................................21

Figure 20. Merge Loop Detector Circuit......................................................................................................25

Figure 21. Wash Select II CPU Board ........................................................................................................27

Figure 22. Bay Management Options Screen.............................................................................................29

Index of Tables

Table 1. Reset Loop and Merge Loop Settings..........................................................................................24

Table 2. Gate Terminal Block Signal Definitions ........................................................................................39

Table 3. Gate Controller I/O Definitions......................................................................................................41

Document Number: GC1001 ii

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

1 Gate Installation with Gate Controller

A Barrier Gate allows you to place gates in front of the Wash Select II (WSII) or Portal

TI units to control the flow of traffic into your car wash.

The Gate installation process consists of installing the conduit runs, cutting in the gate

loops (and optionally the merge loops), mounting the gate(s), installing the Gate

Controller, and then wiring the gate, the WSII/Portal and the Gat e Controller.

In this document, the term “Gate” refers to the device that opens to let

Note:

1.1 Electrical Planning

Each barrier gate requires a 115-120 VAC on a 5-Amp dedicated breaker, which

should be provided during wash construction. Most installers will have power supplie d

directly from one of the three phases used to power the wash motors and controllers.

If this method is used, special attention should be given to proper grounding at the

unit, as well as in the breaker panel.

customers drive into th e car wa sh when a wash is purchased. “Gate Controller”

refers to the box inside the equipment room that controls th e opening and

closing of the gates.

Note:

Follow all local and National Electric Codes.

1.1.1 Signal Wires

• The barrier gate control signal wires should be a minimum of 18awg.

• You will need to pull 4 control wires from the gate controller to each

WSII/Portal and 3 control wires from the Gate Controller to each gate.

• These wires can be run in the same conduit.

Since each lane will require 8 total signal wires, it’s a good idea to color-code

Hint:

them to eliminate confusion when connecting the wires to the WSII/Portal and

the gates.

1.1.2 Conduit Runs

Plan your conduit runs so that the barrier gate control signal wiring and the gate reset

loop wiring come up through the bottom of the base of the gate.

Warning:

The AC Power conduit must be positioned a minimum of 12” a way

from the gate reset and merge loops to prev ent electromag netic

interference.

Document Number: GC1001 1

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

You will need the following 1” conduit runs in place:

• A conduit between the gate controller (located in the equipment room) and

the WSII/Portal units to carry communication wiring.

• A conduit between the breaker and the WSII/Portal units to carry 115120VAC wiring.

• A conduit between the gates and the WSII/Portal units to carry gate signal

wiring.

• A conduit between the gates and the WSII/Portal units to carry 115-120VAC

wiring.

• If there is a merge zone loop installed, a conduit to carry the merge zone loop

leads to the gate. Each merge loop must be connected to its respective gate.

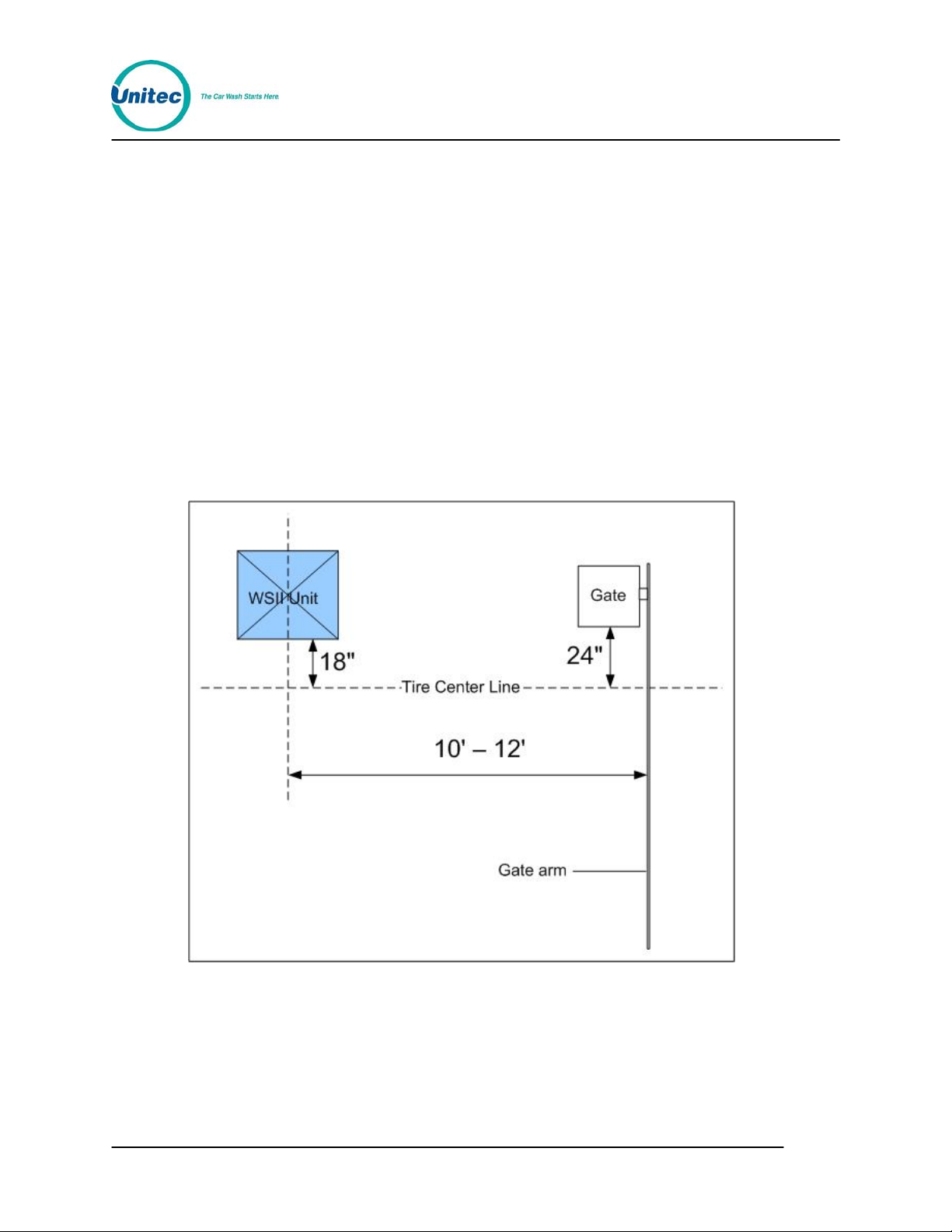

1.2 Mechanical Planning

Position the gate so that the gate arm is 10’-12’ from the WSII/Portal centerline in line with

the WSII/Portal unit.

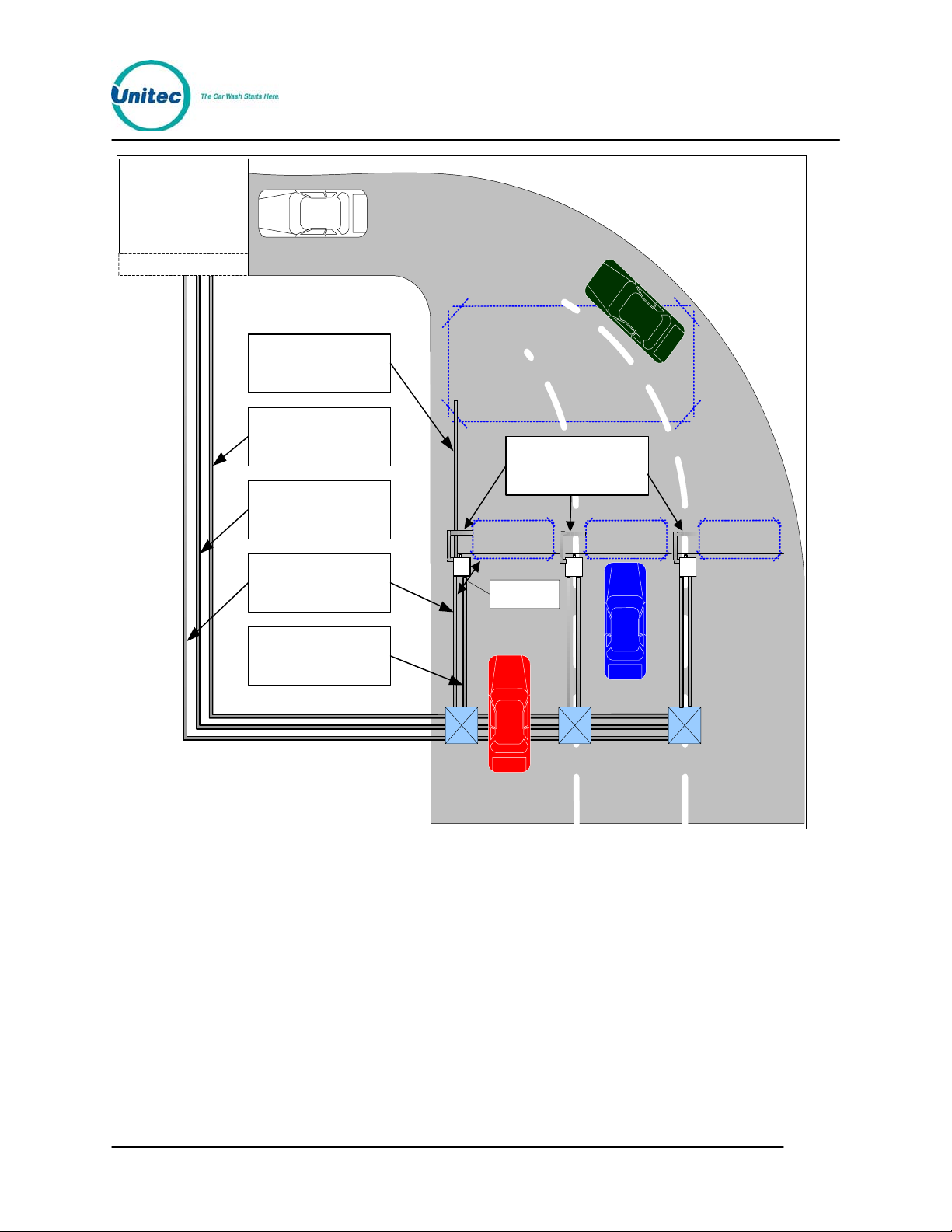

Figure 1. Gate Position

The following figure illustrates a sample site layout.

Document Number: GC1001 2

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

Car Wash

Equipment Room

Merge Loop

Conduit

Com munications

Conduit

Wash C ontrol

Conduit

AC Power

Conduit

Gate Reset Loop

Conduit

at least 12"

Gate Control

Conduit

Figure 2. Sample Site Layout

1.3 Mechanical Installation

You will be installing the gate directly into the concrete slab. Mark the po sitio n of the gate ,

and then cut the gate reset loops appropriately.

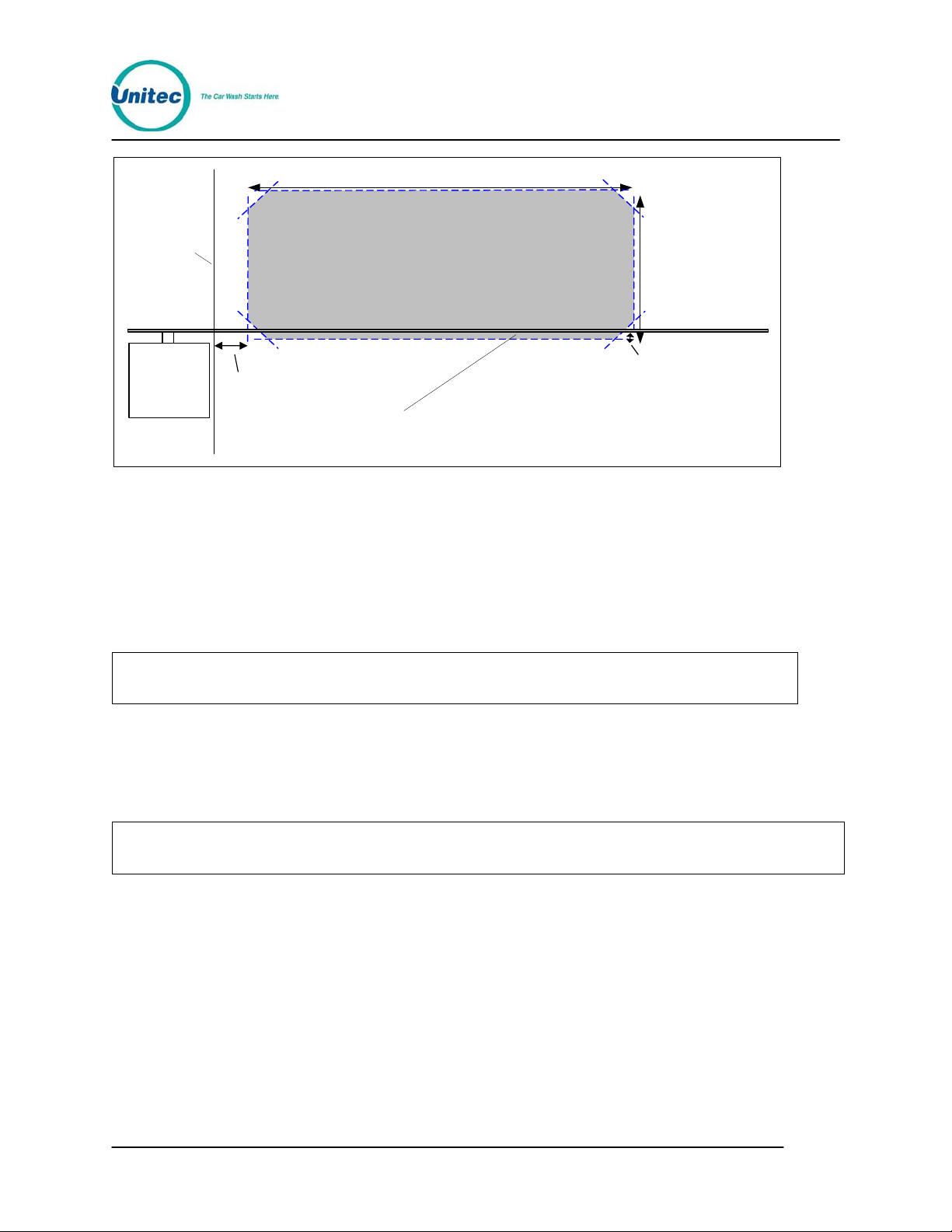

1.3.1 Gate Reset Loop

Each gate requires one gate reset loop. The gate reset loop should be 6’ long by 2.5’

wide. The loop should be positioned so that the edge closest to the approaching car

extends 2.5” beyond the forward edge of the gate arm. The loop should be positioned at

least 7.5” away from the gate as shown in the following figure.

Document Number: GC1001 3

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

6'

Curb

7.5"

With the dimensions as specified above, you will need to loop the wire 5 times around the

loop.

Cut the loop according to the guidelines provided in the installation documentation that

comes with the gate.

1.3.2 Merge Loop

Note:

If you are not installing a merge loop, skip to Section 1.3. 3 Installing the Gate.

2.5'

2.5"

Gate arm

Figure 3. Gate Reset Loop Dimensions

You will wire the Merge Loop to terminals 35 and 36 in the barrier gate. The gate must

have an additional Loop Detector Card installed if you are installing a merge loop. Refer

to Section 2 for more detailed information on the Merge Loop.

1.3.3 Installing the Gate

Document Number: GC1001 4

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

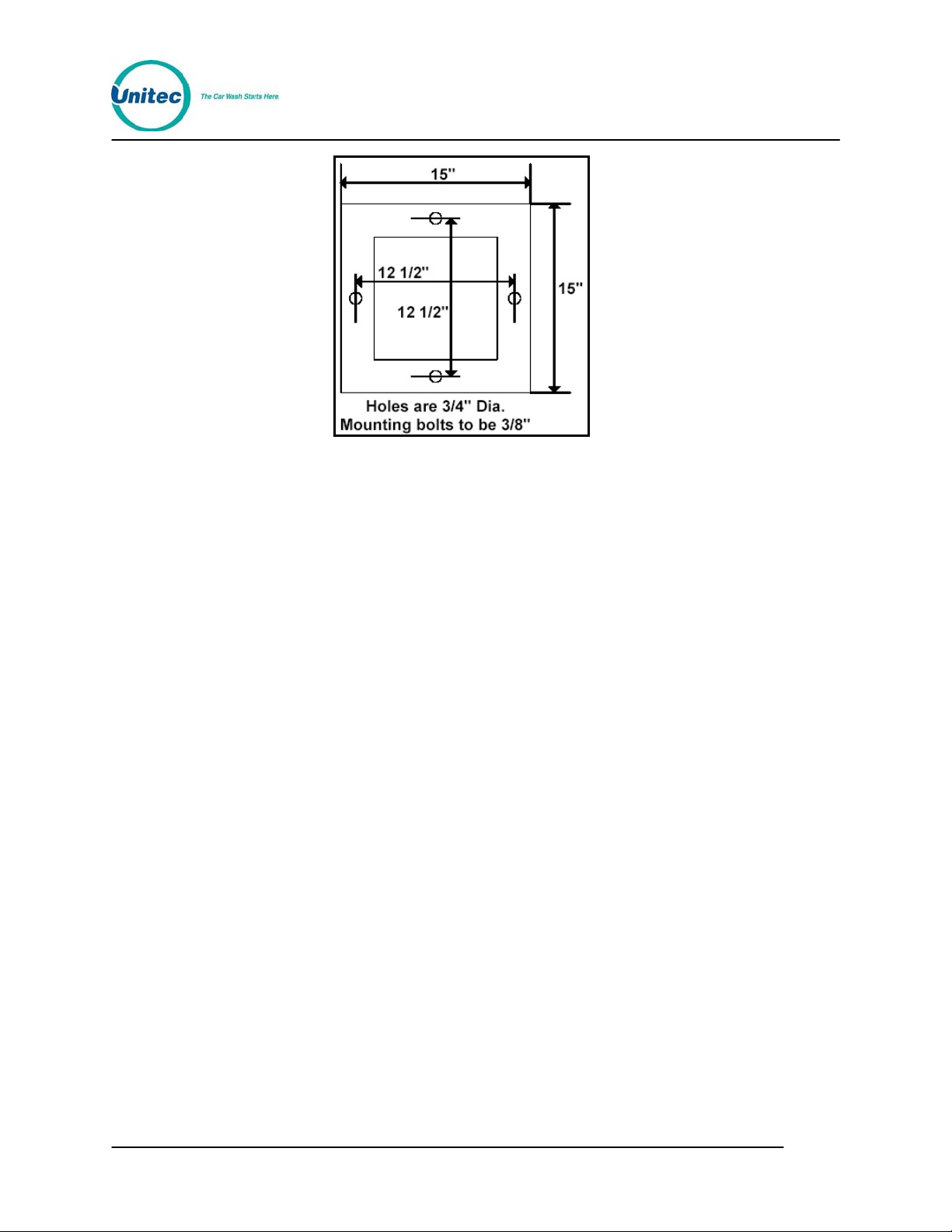

Note:

The holes in the base of the gate are 3/4" in diameter. The mou nting bolts m ust be 3/ 8” in

diameter.

Merge Loop conduit must be run to gate 1 pri or to installing th e gate.

Figure 4. Gate Base Bolt Positioning

1.3.4 Installing the Gate Controller

Mount the Gate Controller to the wall in the equipment room.

Document Number: GC1001 5

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

1.4 Electrical Installation

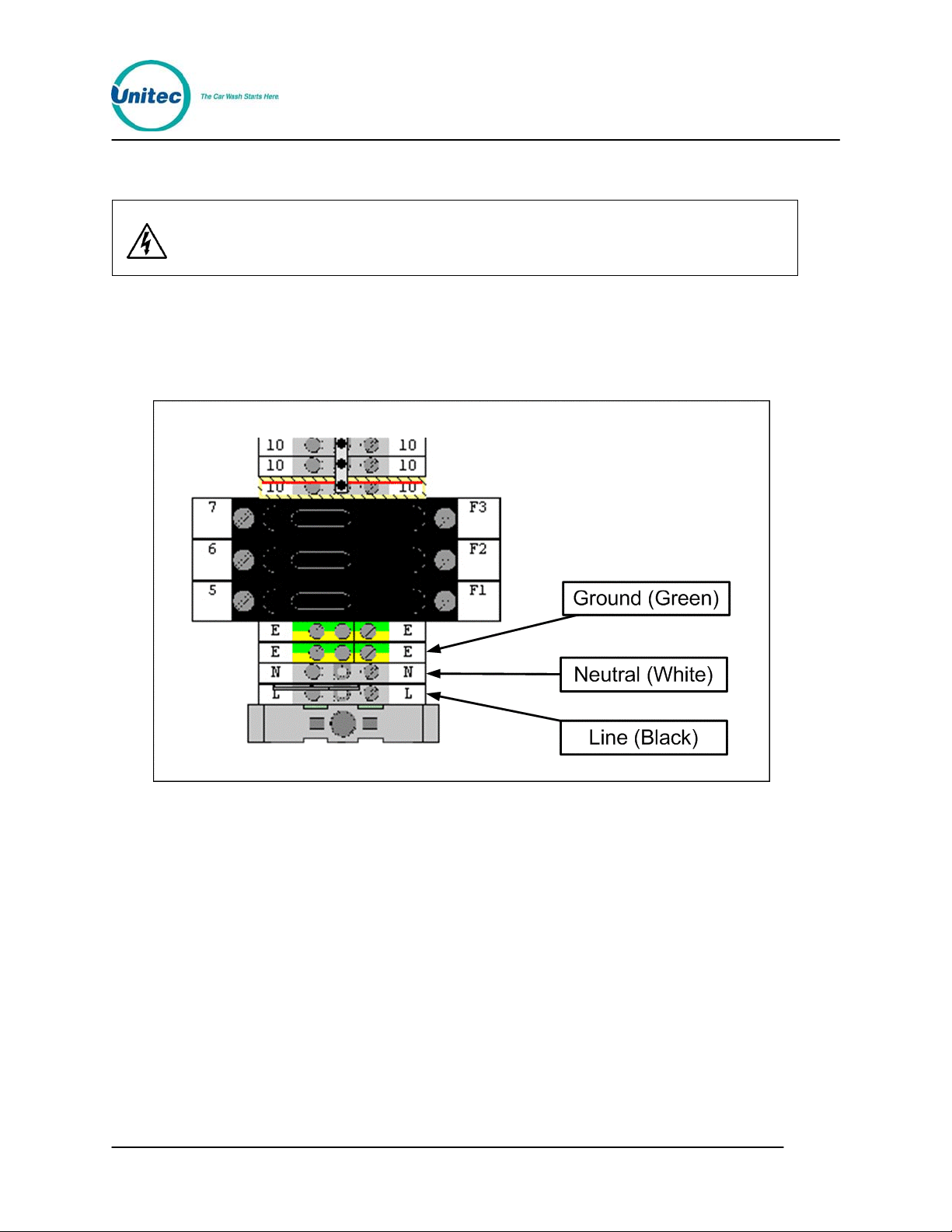

Warning:

Disconnect 115VAC-120VAC po wer from the m ain po wer lines at the

panel box before continuing!

1.4.1 Wire the AC power to the Gate Controller

Wire the AC Power to the Gate Controller. Line, Neutral, and Ground (Earth) are labeled

L, N, and E respectively on the Gate Controller strip.

Figure 5. Wire the AC Power to the Gate Controller

Document Number: GC1001 6

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

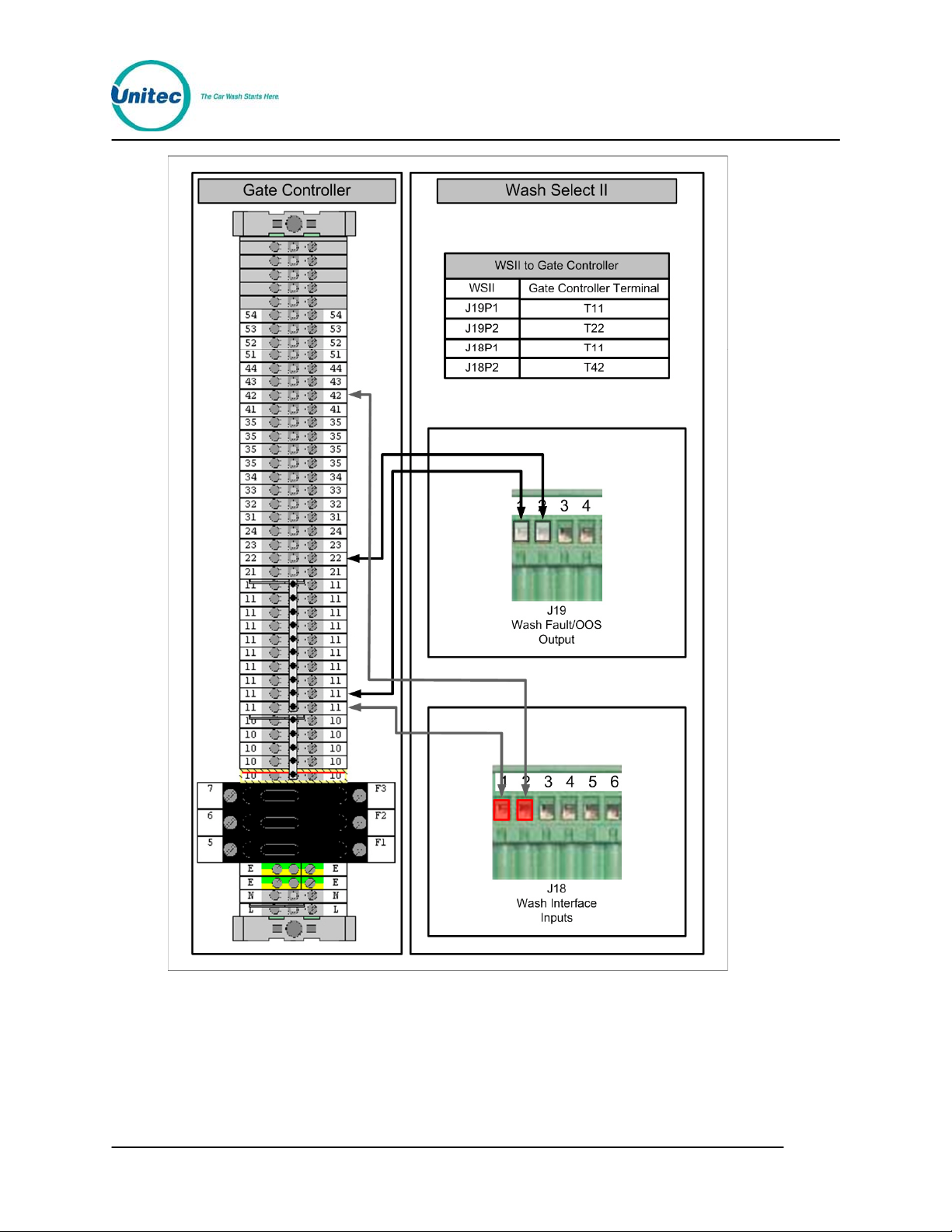

1.4.2 Wire the WSII/Portal Units

Refer to the following diagrams when wiring the WSII/Portal units and gates to the Gate

Controller.

Figure 6. Unit 1 Gate Controller to Gate Wiring Diagram

Document Number: GC1001 7

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

Figure 7. Unit 1 Gate Controller to Wash Select II Wiring Diagram

Document Number: GC1001 8

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

Figure 8. Unit 1 Gate Controller to Portal TI Wiring Diagram

Document Number: GC1001 9

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

Figure 9. Unit 2 Gate Controller to Gate Wiring Diagram

Document Number: GC1001 10

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

Figure 10. Unit 2 Gate Controller to Wash Select II Wiring Diagram

Document Number: GC1001 11

Document Title: Unitec APE Gate and Gate Controller for Multi-Lane Applications Installation Guide

Loading...

Loading...