Page 1

Overview

This Operating Manual covers information on safety and

cautions. Please read the relevant information carefully

and observe all the Warnings and Notes strictly.

Warning

To avoid electric shock or personal injury, read the

“Safety Information” carefully before using the

Meter.

Unpacking Inspection

Open the package case and take out the Meter. Check

the following items carefully for any missing or

damaged part:

In the event you find any missing or damaged item,

please contact your dealer immediately.

Item

1

2

3

Description

English Operating Manual

Test Leads

Holster

Qty

1 pc

1 pair

1 pc

Safety Information

This Meter complies with IEC61010 Overvoltage Cate

-gory(CAT.II1000V, CAT. III 600V), Double Insulation

and Pollution Degree 2 standards.

Use the Meter only as specified in this operating manual,

otherwise the protection provided by the Meter may be

impaired.

In this manual, a Warning identifies conditions and

actions that pose hazards to the user, or may damage

the Meter or the equipment under test.

A Note identifies the information that user should pay

attention to.

To avoid possible electric shock or personal

injury, and to avoid possible damage to the Meter or

to the equipment under test, adhere to the following

rules:

z Before using the Meter inspect the case. Do

not use the Meter if it is damaged or the case

(or part of the case) is removed. Look for cracks

or missing plastic. Pay attention to the insulation

around the connectors.

z Inspect the test leads for damaged insulation

or exposed metal. Check the test leads for

continuity. Replace damaged test leads with

identical model number or electrical specifications

before using the Meter.

z When using the test leads, keep your fingers

behind the finger guards.

z Do not apply more than the rated voltage, as

marked on the Meter, between the terminals or

between any terminal and grounding.

z When the Meter is working at an effective voltage

over 60V in DC or 30V in AC, special care should

be taken from there is danger of electric shock.

z Use the proper terminals, function, and range

for your measurements.

z The rotary switch should be placed in the right

position and no any changeover of range shall

be made during measurement to prevent damage

of the Meter.

z Disconnect circuit power and discharge all high

-voltage capacitors before testing current,

resistance, diodes, continuity or capacitance.

z Start charging as soon as the power indicator

appears. With a low battery, the Meter might

produce false readings that can lead to electric

shock and personal injury.

z When servicing the Meter, use only the replacement

parts with the same model or identical electrical

specifications.

z The internal circuit of the Meter shall not be

altered at will to avoid damage of the Meter and

any accident.

z Soft cloth and mild detergent should be used to

clean the surface of the Meter when servicing.

No abrasive and solvent should be used to

prevent the surface of the Meter from corrosion,

damage and accident.

z Turn off the Meter when it is not in use

z Do not use or store the Meter in an environment

of high temperature, humidity, explosive,

inflammable and strong magnetic field. The

performance of the Meter may deteriorate after

dampened.

z The Meter is suitable for indoor use.

International Electrical Symbols

AC (Alternating Current).

DC (Direct Current).

AC or DC.

Grounding.

Double Insulated.

Low Battery Indication.

Continuity Test.

Diode.

Fuse.

Warning. Refer to the Operating Manual.

Conforms to Standards of European Union.

Capacitance Test

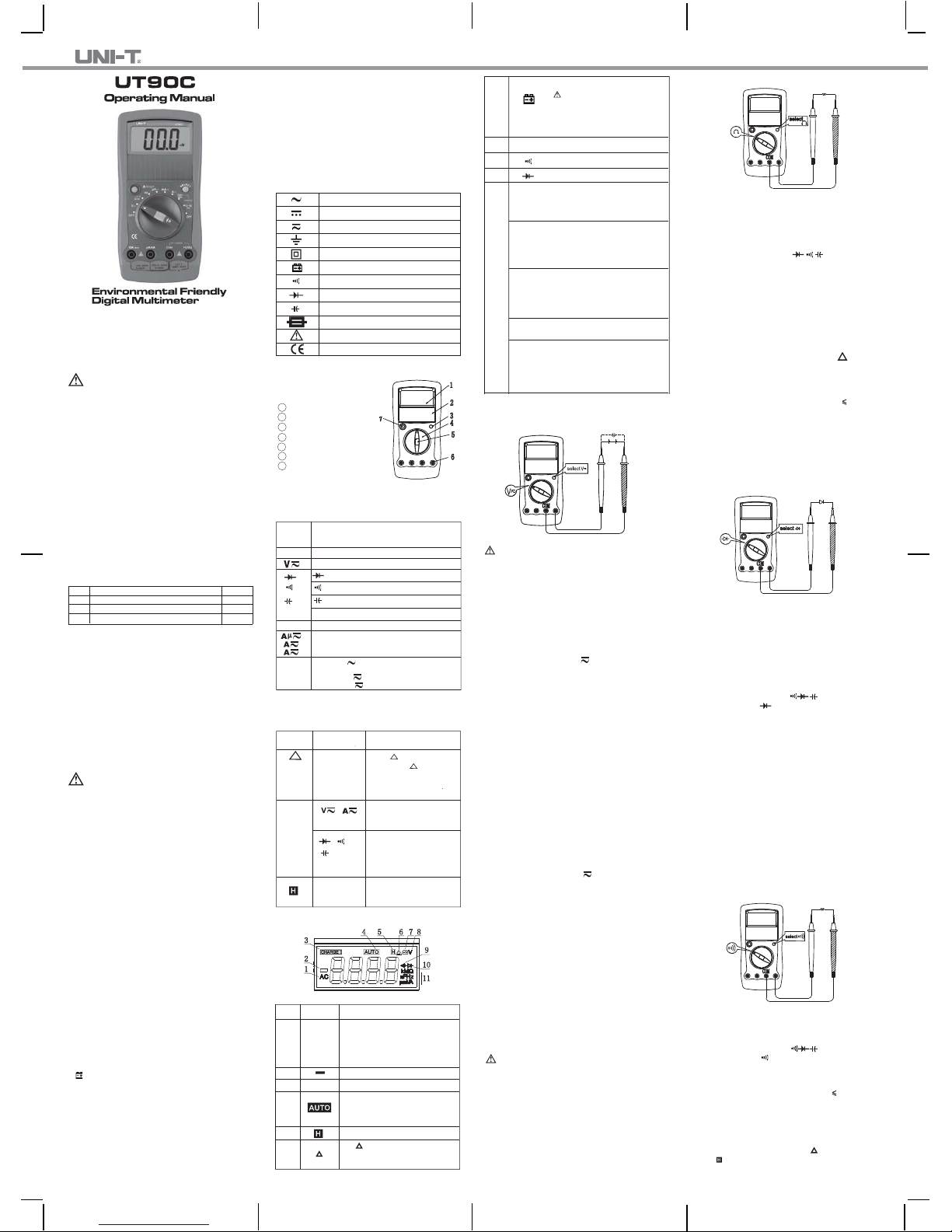

The Meter Structure (See Figure 1)

Fgure 1

1 LCD Display.

2 Solar Panel.

3 SELECT Button.

4 Rotary Switch.

5 HOLD Button.

6 Input Terminals

7 Relative Mode & RESET

Button

Rotary Switch

The table below offers information about the rotary

switch positions.

Rotary

Switch

Position

Function

AC/DC voltage measurement.

: Diode test.

: Resistance measurement.

Ω

AC or DC Current Measurement

Power is turned off.OFF

: Continuity test.

: Capacitance test.

Ω

Hz Frequency Test.

z 230V MAX:

Charge at 220VAC.

z 12-36V : Charge at

12-36V .

CHARGE

Functional Buttons

The table below offers information about the functional

button operations.

Button

Measuring

Function

Operation

Performed

RESET

Any rotary

switch position

except Hz and

CHARGE

Press RESET to enter

and exit the mode in any

measuring mode except in

frequency and charge

mode; the Meter beeps.

SELECT

Switches between AC and

DC voltage/current; the

Meter beeps. DC is default.

Switches between resistance,

diode, continuity and

capacitance measurements;

the Meter beeps. Resistance

is default.

Ω

Any rotary

switch

position

Press to enter and exit the

Hold mode in any mode,

the Meter beeps.

Display Symbols (See Figure 2)

Figure 2

No. Symbol Meaning

1

2

4

Indicates negative reading.

CHARGE

3

AC

Indicator for AC voltage or current.

The displayed value is the mean

value.

The battery is low.

Warning: To avoid false readings,

which could lead to possible electric

shock or personal injury, replace the

battery as soon as the battery

indicator appears.

Charge indicator.

The Meter is in the auto range

mode in which the Meter

automatically selects the range with

the best resolution.

Data hold is active.

5

The mode is on, under which

the stored value will be subtracted

from the displayed reading.

6

7

8

The voltage unit when charging is on.

V

Ω: Ohm. The unit of resistance.

kΩ: kilohm.1 x 10

3

or 1000 ohms.

MΩ: Megaohm. 1 x 10

6

or

1,000,000 ohms.

μA, mA, A

A: Amperes (amps). The unit of

current.

mA: Milliamp. 1 x 10

-3

or 0.001

amperes.

μA: Microamp. 1x 10

-6

or 0.000001

amperes.

V: Volts. The unit of voltage.

mV: Millivolt. 1 x 10

-3

or 0.001 volts.

Ω,kΩ,MΩ

mV, V

9

The continuity buzzer is on.

Test of diode.

10

11

μF, nF

F:

μF:

nF:

Farad. The unit of

capacitance.

Microfarad. 1 x 10-6or

0.000001 farads.

Nanofarad. 1 x 10-9 or

0.000000001 farads.

Hz:

kHz:

MHz:

Hertz.The unit of frequency

in cycles/second.

Kilohertz. 1 x 103 or 1,000

hertz.

Megahertz.1 x 10

6

or

1,000,000 hertz.

Hz,

kHz,

MHz

Measurement Operation

A.

Measuring DC&AC Voltage (See Figure 3)

Figure 3

Warning

To avoid harm to you or damage to the Meter from

electric shock, please do not attempt to measure

voltages higher than 1000VDC / 750VAC RMS although

readings may be obtained.

Measuring AC Voltage

The AC voltage ranges are: 4.000V, 40.00V, 400.0V

and 750.0V. To measure AC Voltage, connect the Meter

as follows:

1. Insert the red test lead into the HzVΩ terminal and

the black test lead into the COM terminal.

2. Set the rotary switch to V and press SELECT

button to select AC measurement mode.

3. Connect the test leads across with the object being

measured.

The measured value shows on the display,which

is effective value of sine wave (mean value response).

red black

Note

z At 400mV range, the Meter has an input impedance

of 4000MΩ At all the other ranges the Meter has an

input impedance of 10MΩ This loading effect can

cause measurement errors in high impedance circuits.

If the circuit impedance is less than or equal to 10kΩ,

the error is negligible (0.1% or less).

z When AC voltage measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test.

Measuring DC Voltage

The DC Voltage ranges are: 400.0mV, 4.000V, 40.00V,

400.0V and 1000V. To measure DC voltage, connect

the Meter as follows:

1. Insert the red test lead into the HzVΩ terminal and

the black test lead into the COM terminal.

2. Set the rotary switch to V ; DC measurement is

default or press SELECT button to select DC

measurement mode.

3. Connect the test leads across with the object being

measured.

The measured value shows on the display.

Note

z At 400mV range, the Meter has an input impedance

of 4000MΩ At all the other ranges,the Meter has

an input impedance of 10M Ω . This loading effect

can cause measurement errors in high impedance

circuits. If the circuit impedance is less than or equal

to 10k Ω , the error is negligible (0.1% or less).

z When DC voltage measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test.

B.Measuring Resistance, Diodes, Continuity &

Capacitance

Figure 4

Warning

To avoid harms to you, never attempt to input over

60V in DC or 30V rms in AC.

To avoid damages to the Meter or to the devices

under test, disconnect circuit power and discharge

all the high-voltage capacitors before measuring

resistance, diodes, continuity & capacitance

For testing capacitance, use the DC Voltage function

to confirm that the capacitor is discharged.

Measuring Resistance

(See Figure 4)

The resistance ranges are: 400.0Ω, 4.000kΩ, 40.00kΩ,

400.0kΩ , 4.000MΩ

and 40.00MΩ. To measure resistance,

connect the Meter as follows:

red black

1. Insert the red test lead into the HzVΩ terminal and

the black test lead into the COM terminal.

2. Set the rotary switch toΩ

,

resistance

measurement (Ω) is default or press SELECT button

to select Ω measurement mode.

3. Connect the test leads across with the object being

measured.

The measured value shows on the display.

Note

z The test leads can add 0.1Ωto 0.2Ωof error to

resistance measurement. To obtain precision readings

in low-resistance measurement, that is the range of

400.0Ω, short-circuit the input terminals beforehand,

using the relative value function button RESET to

automatically subtract tthe shorted value from the

reading.

z

For high-resistance measurement (>1MΩ), it normally

takes

several seconds to obtain a stable reading.

z IfΩ reading with shorted test leads is not 0.5Ω,

check for loose test leads, incorrect function selection,

or enabled Data Hold function.

z The LCD displays OL indicating open-circuit for the

tested resistor or the resistor value is higher than the

maximum range of the Meter.

z When resistance measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test.

Testing Diodes (See Figure 5)

Figure 5

Use the diode test to check diodes, transistors, and other

semiconductor devices. The diode test sends a current

through the semiconductor junction, and then measures

the voltage drop across the junction. A good silicon junction

drops between 0.5V and 0.8V.

To test a diode out of a circuit, connect the Meter as

follows:

1. Insert the red test lead into the HzVΩ terminal and

the black test lead into the COM terminal.

2. Set the rotary switch toΩ and press SELECT

button to select measurement mode.

3.

For forward voltage drop readings on any semiconductor

component, place the red test lead on the component’s

anode and place the black test lead on the component’s

cathode.

The measured value shows on the display.

Note

z In a circuit, a good diode should still produce a forward

voltage drop reading of 0.5V to 0.8V; however, the

reverse voltage drop reading can vary depending

on the resistance of other pathways between the

probe tips.

red black

Figure 6

z Connect the test leads to the proper terminals as

said above to avoid error display. The LCD will

display OL indicating open-circuit for wrong connection.

The unit of diode is Volt (V), displaying the positive-

connection voltage-drop value.

z When diode testing has been completed, disconnect

the connection between the testing leads and the

circuit under test.

Testing for Continuity

(See Figure 6)

To test for continuity, connect the Meter as below:

1. Insert the red test lead into the HzVΩ terminal and

the black test lead into the COM terminal.

2. Set the rotary switch toΩ and press

SELECT

button to select measurement mode.

3. The buzzer does not sound if the circuit is disconnected

with resistance value is > 100Ω

The buzzer sounds continuously if the circuit is in

good condition with resistance value 10Ω.

4. The nearest circuit resistance value shows on the

display, the unit isΩ.

Note

z The LCD displays OL indicating the resistance of

the circuit being tested is higher than 400Ω.

z The buzzer sounds once if the RESET, SELECT

or is pressed on.

red black

UT90C is a new generation of environment friendly

instrument, which can be powered by 220VAC, 12-36V

(DC or AC) or solar energy without need of battery and

therefore doesn’t pose chemical impact to the environ

-ment. The packing is toxic-free , recyclable and totally

safe to the environment.

The Multimeter is 4000-count auto-ranging digital multi

-meter(hereafter referred to as “the Meter”) and can

measure DC&AC voltage, DC&AC current, resistance,

capacitance, frequency, diode and continuity. It also

offers large LCD display, full icon display, overload pro

-tection, data hold, Relative mode features.

Page 2

P/N :110401104421X

** END **

This operating manual is subject to change without notice.

Figure 7

z When continuity testing has been completed,

disconnect the connection between the testing leads

and the circuit under test.

Measuring Capacitance

(See Figure 7)

The capacitance ranges are: 40.00nF, 400.0nF,4.000μF,

40.00μF, and 100.0μF. To measure capacitance,connect

the Meter as follows:

red black

1. Insert the red test lead into the HzVΩ terminal and

the black test lead into the COM terminal.

2. Set the rotary switch toΩ and press SELECT

button to select measurement mode. The existing

of the Meter built-in equalized capacitance will affect

the accuracy. To increase the accuracy of capacitance

measurement, press button before measuring to

reset the display to 0.

3. Connect the test leads across with the object being

measured.

The measured value shows on the display.

Note

z The LCD displays OL indicating the capacitor is short

-circuited or the capacitor value being tested is overload.

Figure 8

z For testing the capacitor with polarity, connect the

red test lead to anode & black test lead to cathode.

z It takes a longer time when testing a capacitor value

which is higher than 10μF range.

z When capacitance measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test.

C.Measuring Frequency

(See Figure 8)

Warning

To avoid harm to you, please do not attempt to

input frequency voltage being tested higher than 30V.

red black

The measurement ranges are from 10Hz to 10MHz.

To measure frequency, connect the Meter as follows:

1. Insert the red test lead into the HzVΩ terminal and

the black test lead into the COM terminal.

2. Set the rotary switch to Hz.

3. Connect the test leads across with the object being

measured.

The measured value shows on the display.

Figure 8

black red

Note

z When Hz measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test.

D.Measuring DC&AC Current

(See Figure 9)

Warning

Never attempt an in-circuit current measurement

where the open-circuit voltage between the circuit

and ground is greater than 250V.

If the fuse burns out during measurement, the Meter

may be damaged or the operator himself may be hurt.

Use proper terminals, function, and range for the

measurement. When the testing leads are connected

to the current terminals, do not parallel them across

any circuit.

The current measurement has 3 measurement positions

on the rotary switch: μA , A and mA

.

TheμA has a 400.0μA and 4000μA range, with auto

ranging; the mA has a 40.00mA and 400.0mA range,

with auto ranging; A position has a 4.000A and 10.00A

range, with auto ranging.

To measure current, do the following:

1. Turn off power to the circuit. Discharge all high voltage capacitors.

2. Insert the red test lead into the μAmA or 10A terminal

and the black test lead into the COM terminal.

Use the 10A terminal and A range if the current

value to be tested is unknown.

3. Set the rotary switch to μA , mA orA .

4. The Meter defaults to DC current measurement mode.

To toggle between DC andAC current measurement

function, press SELECT button. AC current is

displayed as an mean value (calibrated against RMS

value of sine wave

5. Break the current path to be tested. Connect the red

test lead to the more positive side of the break and

the black test lead to the more negative side of the

break.

6. Turn on power to the circuit.

The measured value shows on the display.

Note

z For safety sake, the measuring time for high current

should be less than 10 seconds for each measurement

and the interval time between 2 measurements

should be greater than 15 minutes.

z When current measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test, and remove the testing

leads away from the input terminals of the Meter.

Figure 10

E.Power Charging (See Figure 10)

red black

Warning

Start charging as soon as the power indicator

appears. With a low battery, the Meter might produce

false readings that can lead to electric shock and

personal injury.

To avoid damage to the Meter, please do not attempt

to turn the rotary switch during charging.

To set up charging as follows:

z Charge at 220V AC

1. Insert the red test lead into the HzVW terminal and

the black test lead into the COM terminal.

2. Set the rotary switch to 230V MAX.

3. Connect the test leads to two ends of 220VAC

power supply.

4. CHARGE shows on the display.

5. The charging time is around 15minutes. Then the

Meter can work continuously for more than 90 minu

-tes(eg: under DCV ranges)

z Charge by Solar Power

Charging through the solar panel from sunshine.

Remarks:

z When 0.7V displays on the display, it means the rated

charging voltage.

z The LCD will be closed when the power is low.

When the LCD is turned on for the first time during

charging or after 5-minute charging, please press

RESET in order to make the meter display the current

correct charging value.

z When power charging has been completed, disconnect

the connection between the testing leads and the

supply power.

z Charge at 12-36V

1. Insert the red test lead into the HzVΩ erminal and

the black test lead into the COM terminal.

2. Set the rotary switch to 12-36V .

3. Connect the test leads to two ends of 12-36V power

supply.

4. CHARGE shows on the display.

5. The charging time is around 30 minutes. Then the

Meter can work continuously for more than 90 minu

-tes(eg: under DCV ranges)

Operation of Hold Mode

Warning

To avoid possibility of electric shock, do not use Hold

mode to determine if circuits are without power. The

Hold mode will not capture unstable or noisy readings.

The Use of Relative Value Mode

The mode applies to all measurement functions except

frequency and charge function,it subtracts a stored

value from the present value and displays the relative

value ( ) as the result

The Hold mode is applicable to all measurement functions.

z Press to enter Hold mode; the Meter beeps.

z Press again to exit Hold mode; the Meter beeps.

z In Hold mode, is displayed.

The definition is as follows:

z Relative value ( ) = present value – stored value

For instance, if the stored value is 20.0V and the

present measurement value is 22.0V, the reading

would be 2.0V. If a new measurement value is equal

to the stored value then display 0.0V.

To enter or exit mode:

z Use rotary switch to select the measurement function

before selecting RESET. If measurement functions

change manually after RESET is selected, the Meter

exits the mode.

z Press RESET to enter mode, and the present

measurement range is locked and display the last

measurement value as “0” as the stored value.

z Press RESET again to reset the stored value and

exit Mode.

z Turn the rotary switch back and forth one time to return

to auto ranging mode. This only applies to those

functions having auto ranging.

z Safety/Compliances : IEC61010: CAT. II 1000V,

CAT. III 600V overvoltage

and double insulation

standard.

z Certification :

Accuracy: (a% reading + b digits),guarantee for 1 year.

Operating temperature:23oC

5oC.

Relative humidity:<75%.

Temperature coefficient: 0.1 x(specified accuracy) / 1

o

C.

Remarks:

z Input impedance: approx. 10MΩ.

z Frequency response: 40Hz ~ 400Hz.

z Displays RMS value of sine wave (mean value

response).

B. DC Voltage

Remark:

z Input impedance:

At 400mV range: above 4000MΩ.

All other ranges: approx. 10MΩ.

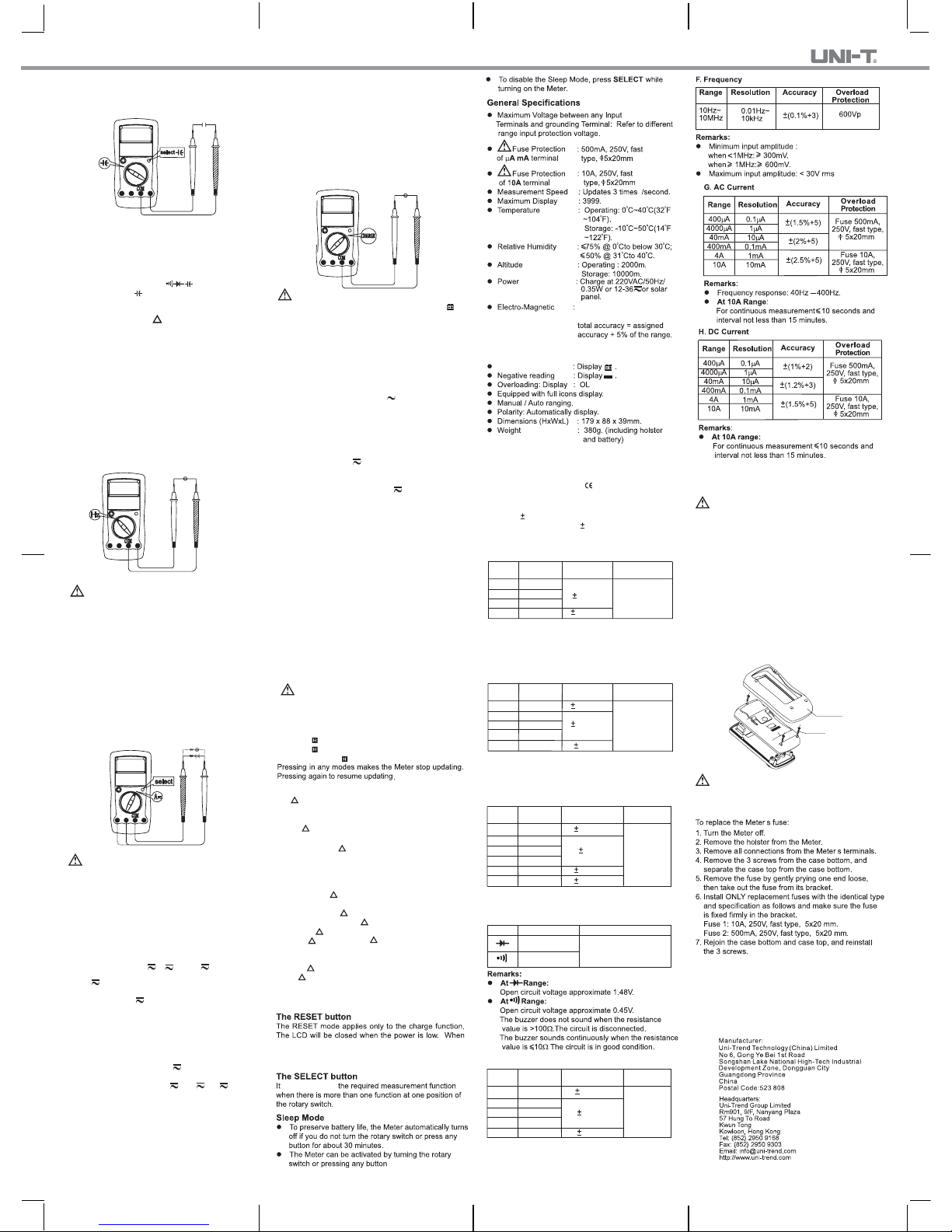

A.AC Voltage

4V

40V

400V

750V

1mV

10mV

100mV

1V

Range Resolution

(1%+5)

Overload

Protection

Accuracy

(1.2%+5)

1000V DC

or 750V AC

continuous.

Accuracy Specification

400mV

4V

40V

400V

1000V

0.1mV

1 mV

10 mV

100mV

1V

Range Resolution

Overload

Protection

Accuracy

(0.8%+3)

1000V DC

or 750V AC

continuous.

(1%+3)

(0.8%+1)

C. Resistance

Range Resolution

Overload

Protection

Accuracy

400Ω

4kΩ

40kΩ

400kΩ

4MΩ

40MΩ

0.1Ω

1Ω

10Ω

100Ω

1kΩ

10kΩ

(1%+2)

600Vp

(1.2%+2)

(1.5%+2)

(1.2%+2)

Remarks:

z Open circuit voltage: approx. 0.45V

D. Diode & Continuity

1mV

1Ω

Range Resolution Overload Protection

600Vp

E. Capacitance

Range Resolution

Overload

Protection

Accuracy

40nF

400nF

4μF

40μF

100μF

10pF

100pF

1nF

10nF

100nF

(3%+5)

600Vp

(3%+10)

(4%+5)

Maintenance

This section provides basic maintenance information

including fuse replacement instruction.

Warning

Do not attempt to repair or service your Meter unless

you are qualified to do so and have the relevant

calibration, performance test, and service information.

To avoid electrical shock or damage to the Meter,

do not get water inside the case.

A. General Service

z Periodically wipe the case with a damp cloth and

mild detergent. Do not use abrasives or solvents.

z To clean the terminals with cotton bar with detergent,

as dirt or moisture in the terminals can affect readings.

z Turn the Meter off when it is not in use and take out

the battery when not using for a long time.

z Do not store the Meter in a place of humidity, high

temperature, explosive, inflammable and strong

magnetic field.

B.Replacing the Fuses

(See Figure 11)

Screw

Holster

Figure 11

Warning

To avoid electrical shock or arc blast, or personal

injury or damage to the Meter, use specified fuses

ONLY in accordance with the following procedure.

Replacement of the fuses is seldom required. Burning

of a fuse always results from improper operation.

’

’

the LCD is turned on for the first time during charging or

after 5-minute charging, please press RESET in order to

make the meter display the current correct charging value.

is used to select

Performance over 1V/m is

not specified.

Low Battery Indicator

When under RF field of

1V/m,

Loading...

Loading...