Page 1

Manual 0-4964

82 Benning Street, West Lebanon, NH 03784 USA

(603) 298-5711 • www.thermal-dynamics.com

Unpacking

The product is packaged and protected to prevent damage

during shipping. Inspect for possible shipping damage. If

damage is evident, contact your distributor and/or shipping

company before proceeding with installation.

General Information

This kit is for use only with Thermal Dynamics UltraCut®

Power Supplies and XT-300 Torches. Do not use this kit

with any other equipment.

This kit requires the C.C.M. (Communication Control Module) Firmware to have version 3.2 or higher and a change

in DIP switch settings. See your authorised service center

for this update.

This kit requires the GCM 2010 Firmware to be 3.1 or higher. See your authorised service center for this update.

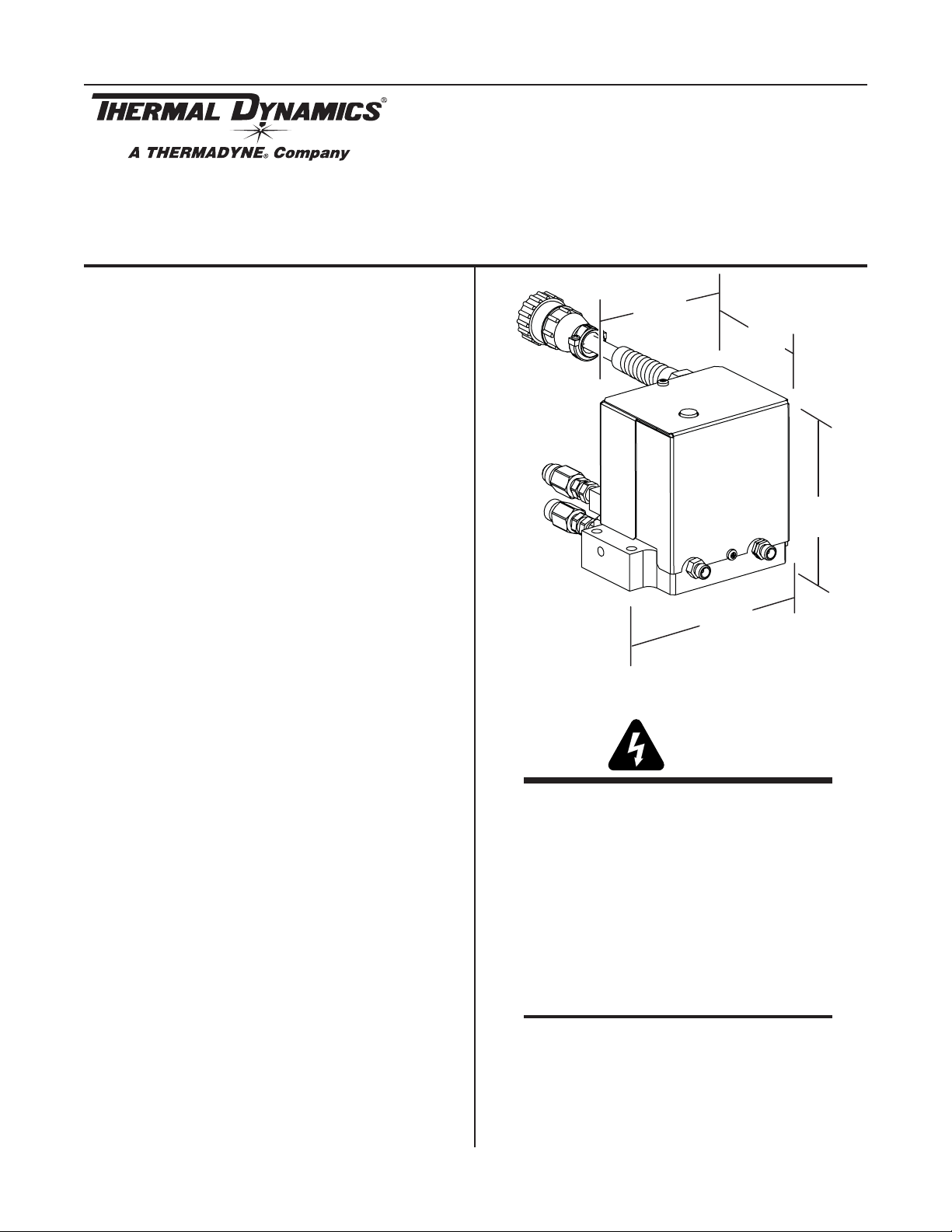

Art # A-07644

XTL Torch Valve Kit No. 4-3054

Installation Instructions

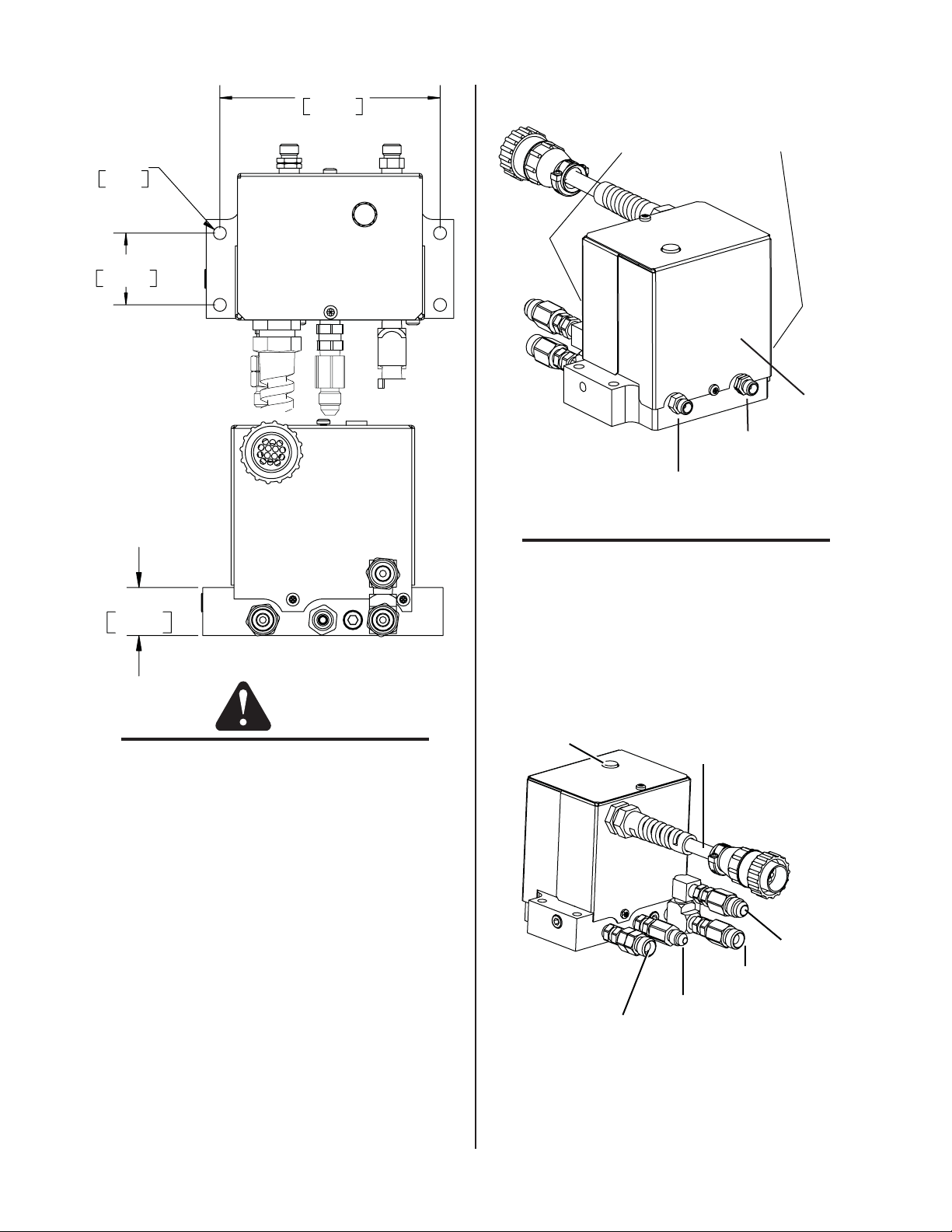

3.72 in

95 mm

2.9 in

73.66 mm

4.31 in

109 mm

5 in

127 mm

This kit accepts prefl ow, plasma, shield and Water Mist

Secondary™ gases from the Gas Control Module and

supplies these gases to the Torch.

Supplied Parts

• XTL Torch Valve Assembly

• 4’ Plasma Hose

• 4’ Shield Hose

• 4 Fuses

• Fuse Rating Label

• Installation Instructions

Installation

WARNINGS

Disconnect primary power at the source.

1. In most cases the XTL Valve Kit may be mounted in the

same location as the old one. If not, mount it as close

as possible to the Torch. The valve kit can be mounted

in any convenient position, provided the outlet side

(with two fi ttings) is closer to the torch than the inlet

side (with four fi ttings and a control cable connector).

Dimensions given in the following illustration are to assist in locating mounting holes and hardware length.

NOTE

Care must be taken when considering the

mounting location so the exhaust muffler

on top of the assembly is not covered or

blocked.

© 2007 Thermadyne Corp.

February 5, 2007

1

Manual 0-4964 Rev AA.01

Page 2

4.450 in.

113.03 mm

2. Connect the Valve Kit outlets to the torch leads as

shown.

.261 in Dia.

6.63 mm

1.450 in

36.83 mm

Art # A-07648

1.00 in.

25.40 mm

CAUTION

Place one wrench on the TVA fi tting and keep

it from turning before tightening or loosening

any hose fi ttings.

Art # A-07649

Do not remove brass plugs

Front and side

Outlet Side

Art # A-07645

Left-hand Thread:

To Torch Plasma Gas fitting

Right-hand Thread:

To Torch Shield Gas fitting

NOTE

Two 4’ hoses are provided in this kit. They

MUST be used if the existing hoses leak, have

any damage to them or are less than 4’ in

length. Do not use hoses that are not 4’ long.

3. Connect the gas supply lines and the control cable

connector from the Gas Control Module to the Valve

Kit as shown. Hold the check valves stationary while

attaching the gas lines.

Exhaust Muffler

Control Cable

Do not remove brass plugs from base.

February 5, 2007

WMS™ Inl

Shield Gas Inlet

Preflow Gas Inlet

Plasma Gas Inlet

2

Manual 0-4964 Rev AA.01

Art # A-07646

Page 3

4. Once all connections have been made, a careful check

m

of all fi ttings for leaks and function needs to be made. Use

a standard leak detection or soap based liquid to test for

leaks. Turn the system on and check setting displays for

each of the gasses.

Control Connector Pinout Diagram

2: To SOL16 (Btm)

1: To SOL16 (Top)

5: To SOL14 (Top)

& SOL18

8: To SOL15 (Top)

& SOL19

9: To SOL15 (Btm)

& SOL19

4

3: Ground

12

6: To SOL14 (Bt

& SOL18

7

11

10

14

13

WARNINGS

Disconnect primary power at the source before

starting the procedure.

Use caution when handling the printed circuit

board as damage can result from improper

handling or from electrostatic discharge. Wear

appropriate static-handling equipment and

grounding strap while performing this replacement procedure.

1. Remove the screws securing the cover panel to the gas

control module. Save the hardware for re-use.

2. Carefully remove the cover from the module noting

the attached ground wire. Remove the ground wire if

needed.

SOL15

SOL16

SOL19

SOL18

Fuse Update on Main PCB in GCM 2010

NOTE

Depending on version at time of purchase

or other updates some GCM 2010 units may

not need to have the fuses updated. It will be

necessary to verify this. One way to do that is

by removing the cover and inspecting the two

fuses at F14 and F15. The following explains

how to do that and update the two fuses.

SOL14

Gas Control Module Cover

Remove Ground

Wire

Do not remove

Art # A-07647

Art # A-06882

February 5, 2007

3. Locate the Main PCB mounted on the left side panel.

Remove the multi pin harness from the upper right at

J13.

3

Manual 0-4964 Rev AA.01

Page 4

4. Locate fuses at F14 and F15 shown below.

Art # A-07652

F15

J13

F14

New Fuse

Rating Label

Fuses F14 and F15 are

250V and .0250A

NOTE

Check the values of these fuses. If the fuses are

the same as those provided in this kit do not

replace them and go to step 7.

5. If the fuses at F14 and F15 are not 250VAC .0250A,

replace them with two of the four provided in this kit.

The other two are extra and should be saved for possible future use along with the two being removed. Do

not use the fuses in this kit in any other location on

this PCB.

February 5, 2007

6. Locate the new Fuse Rating Label supplied in this kit

and where it is to be applied shown above. Before applying the new Fuse Rating Label on the PCB ,clean

the surface using a clean cloth. If cleaning solution

is needed it must be approved for use on and around

electrical components. Once the surface is clean and

dry, apply the label.

7. Reconnect the harness plug to J13 and replace the

cover with the ground wire attached.

4

Manual 0-4964 Rev AA.01

Page 5

DIP Switch Selection

8. Locate the C.C.M. style in (with or without external box) that applies and SW13 as indicated in the following illustrations. Set the SW13 switches accordingly.

SW11

SW6

SW12

SW13

SW13: TVA and XTL Switch positions

1

2

TVA XTL-TVA

SW13

1

2

No external

connection cover

Art # A-07672

February 5, 2007

5

Manual 0-4964 Rev AA.01

Page 6

SW6

SW12

SW11

SW13

SW13: TVA and XTL Switch positions

TVA XTL-TVA

1

2

SW13

1

2

Art # A-07671

9. This ends the installation instructions for the XTL Torch Valve Assembly Kit.

NOTE

Operation of the Torch Valve is controlled by the Gas Control Module. The Torch Valve does not require

any adjustment or calibration.

NOTE

Every effort has been made to provide complete and accurate information in this manual. However,

the publisher does not assume and hereby disclaims any liability to any party for any loss or damage

caused by errors or omissions in this Manual, whether such errors result from negligence, accident, or

any other cause.

February 5, 2007

6

Manual 0-4964 Rev AA.01

Loading...

Loading...