Page 1

Art # A-09778

35

AMP

1

PHASE

DC

35A

™

CUTSKILL

PLASMA CUTTING SYSTEM

Operating Manual

Rev. AA Issue Date: January 7, 2011 Manual # 0-5180

Operating Features:

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Thermal Dynamics product. We are proud to

have you as our customer and will strive to provide you with the best service

and reliability in the industry. This product is backed by our extensive war

ranty and world-wide service network. To locate your nearest distributor

or service provider visit us on the web

(Americas and Europe).

This Operating Manual has been designed to instruct you on the correct

use and operation of your Thermal Dynamics product. Your satisfaction

with this product and its safe operation is our ultimate concern. There

fore please take the time to read the entire manual, especially the Safety

Precautions. They will help you to avoid potential hazards that may exist

when working with this product.

at www.thermal-dynamics.com

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators Worldwide.

-

-

Thermal Dynamics is a Global Brand of manual and automation Plasma

Cutting Products for Thermadyne Industries Inc.

We distinguish ourselves from our competition through market-leading,

dependable products that have stood the test of time. We pride ourselves

on technical innovation, competitive prices, excellent delivery, superior

customer service and technical support, together with excellence in sales

and marketing expertise.

Above all, we are committed to developing technologically advanced

products to achieve a safer working environment within the welding

industry.

Page 3

!

Read and understand this entire Manual and your employer’s safety practices before installing,

operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement, the

Manufacturer assumes no liability for its use.

Plasma Cutting Power Supply

CutSkill™ 35A

SL40 1Torch™

Operating Manual Number 0-5180

Published by:

Thermal Dynamics Corporation

82 Benning Street

West Lebanon, New Hampshire, USA 03784

(603) 298-5711

www.thermal-dynamics.com

Copyright 2011 by

Thermadyne Corporation

WARNINGS

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is

prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any loss or

damage caused by any error or omission in this Manual, whether such error results from negligence, accident, or any other cause.

Publication Date: January 7, 2011

Record the following information for Warranty purposes:

Where Purchased:_______________________________ ____________

Purchase Date:__________________________________ ____________

Power Supply Serial #:___________________________ _____________

Torch Serial #:___________________________________ ___________

Page 4

TABLE OF CONTENTS

SECTION 1:GENERAL INFORMATION ........................................................................................................ 1-1

1.01 Notes, Cautions and Warnings ................................................................................. 1-1

1.02 Important Safety Precautions ...................................................................................1-1

1.03 Publications .............................................................................................................. 1-3

1.04 Declaration of Conformity......................................................................................... 1-4

1.05 Statement of Warranty .............................................................................................1-5

SECTION 2 SYSTEM:INTRODUCTION ...................................................................................................... 2-1

2.01 Working Principle .....................................................................................................

2.02 Power Supply Specifications ....................................................................................

2.03 Input Wiring Specifications ...................................................................................... 2-2

2.04 Power Supply Features ............................................................................................. 2-3

SECTION 2TORCH:INTRODUCTION .......................................................................................................

2T.01 Scope of Manual

2T.02 Specifications ........................................................................................................ 2T-1

2T.03 Introduction to Plasma ........................................................................................... 2T-2

SECTION 3:INSTALLATION ....................................................................................................................... 3-1

3.01 Unpacking ................................................................................................................ 3-1

3.02 Lifting Options .......................................................................................................... 3-1

3.03 Primary Input Power Connections ............................................................................ 3-1

3.04 Air Supply Connections ............................................................................................ 3-2

SECTION 4 SYSTEM:OPERATION .............................................................................................................. 4-1

4.01 Control Panel ............................................................................................................

4.02 Preparations For Operating....................................................................................... 4-2

4.03 Sequence of Operation ............................................................................................. 4-5

4.04 Cut Quality ................................................................................................................ 4-7

4.05 General Cutting Information ..................................................................................... 4-8

..................................................................................................... 2T-1

2-1

2-1

2T-1

4-1

SECTION 5 SYSTEM: SERVICE .................................................................................................................

5.01 General Maintenance ................................................................................................ 5-1

5.02 Basic Troubleshooting Guide .................................................................................... 5-2

SECTION 5 TORCH:SERVICE ................................................................................................................... 5T-1

5T.01 General Maintenance .............................................................................................. 5T-1

5T.02 Inspection and Replacement of Consumable Torch Parts ....................................... 5T-1

SECTION 6:PARTS LISTS ..........................................................................................................................

6.01 Introduction .............................................................................................................. 6-1

6.02 Ordering Information ................................................................................................ 6-1

APPENDIX 1:CIRCUIT DIAGRAM .............................................................................................................A-1

GLOBAL CUSTOMER SERVICE CONTACT INFORMATION ............................................................ Rear Cover

5-1

6-1

Page 5

cutskill 35A

!

!

SECTION 1:

GENERAL INFORMATION

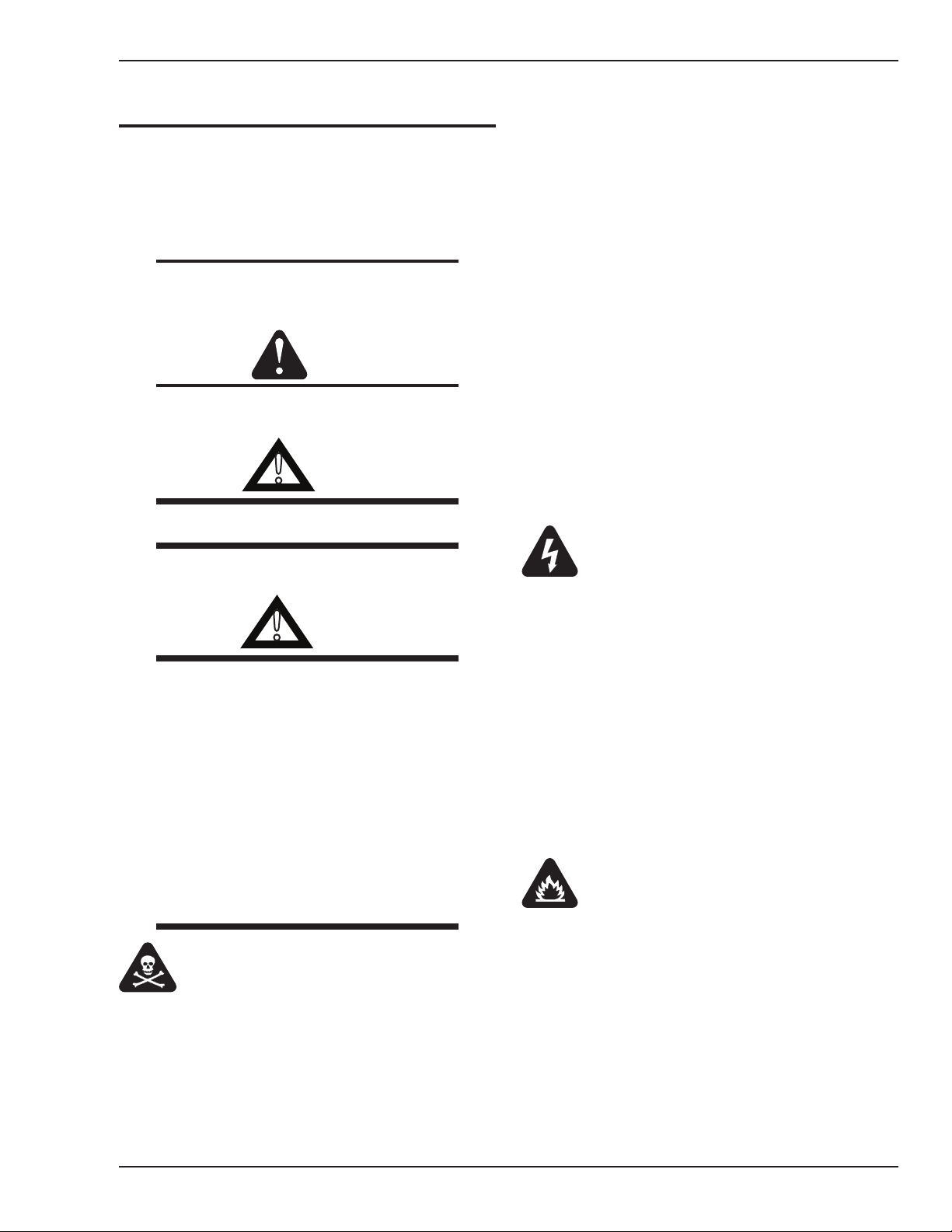

1.01 Notes, Cautions and Warnings

Throughout this manual, notes, cautions, and warnings are used to

highlight important information. These highlights are categorized as

follows:

NOTE

An operation, procedure, or background information

which requires additional emphasis or is helpful in ef

ficient operation of the system.

CAUTION

A procedure which, if not properly followed, may cause

damage to the equipment.

A procedure which, if not properly followed, may cause

injury to the operator or others in the operating area.

WARNING

-

or welding any metals which may contain one or more of the

following:

Antimony Chromium Mercury

Arsenic Cobalt Nickel

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese Vanadium

• Always read the Material Safety Data Sheets (MSDS) that should

be supplied with the material you are using. These MSDSs

will give you the information regarding the kind and amount of

fumes and gases that may be dangerous to your health.

• For information on how to test for fumes and gases in your

workplace, refer to item 1 in Subsection 1.03, Publications in

this manual.

• Use special equipment, such as water or down draft cutting

tables, to capture fumes and gases.

• Do not use the plasma torch in an area where combustible or

explosive gases or materials are located.

• Phosgene, a toxic gas, is generated from the vapors of chlo

rinated solvents and cleansers. Remove all sources of these

vapors.

• This product, when used for welding or cutting, produces

fumes or gases which contain chemicals known to the State

of California to cause birth defects and, in some cases, cancer.

(California Health & Safety Code Sec. 25249.5 et seq.)

-

1.02 Important Safety Precautions

WARNING

OPERATION AND MAINTENANCE OF PLASMA ARC

EQUIPMENT CAN BE DANGEROUS AND HAZARDOUS

TO YOUR HEALTH.

Plasma arc cutting produces intense electric and magnet

ic emissions that may interfere with the proper function

of cardiac pacemakers, hearing aids, or other electronic

health equipment. Persons who work near plasma arc

cutting applications should consult their medical health

professional and the manufacturer of the health equipment to determine whether a hazard exists.

To prevent possible injury, read, understand and follow

all warnings, safety precautions and instructions before

using the equipment. Call 1-603-298-5711 or your local

distributor if you have any questions.

GASES AND FUMES

Gases and fumes produced during the plasma cutting process can be

dangerous and hazardous to your health.

• Keep all fumes and gases from the breathing area. Keep your

head out of the welding fume plume.

• Use an air-supplied respirator if ventilation is not adequate to

remove all fumes and gases.

• The kinds of fumes and gases from the plasma arc depend on

the kind of metal being used, coatings on the metal, and the

different processes. You must be very careful when cutting

-

Electric Shock can injure or kill. The plasma arc process uses and

produces high voltage electrical energy. This electric energy can cause

severe or fatal shock to the operator or others in the workplace.

Fire and explosion can be caused by hot slag, sparks, or the plasma

arc.

ELECTRIC SHOCK

• Never touch any parts that are electrically “live” or “hot.”

• Wear dry gloves and clothing. Insulate yourself from the work

piece or other parts of the welding circuit.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workplace is moist or

damp.

• Install and maintain equipment according to NEC code, refer to

item 9 in Subsection 1.03, Publications.

• Disconnect power source before performing any service or

repairs.

• Read and follow all the instructions in the Operating Manual.

FIRE AND EXPLOSION

• Be sure there is no combustible or flammable material in the

workplace. Any material that cannot be removed must be

protected.

• Ventilate all flammable or explosive vapors from the work

place.

• Do not cut or weld on containers that may have held combus

tibles.

• Provide a fire watch when working in an area where fire hazards

may exist.

Manual 0-5180 1-1 GENERAL INFORMATION

-

-

Page 6

cutskill 35A

Pb!

Eye protection filter shade selector for welding or cutting

(goggles or helmet), from AWS A6.2-73.

Welding or Cutting

Operation

Electrode Size

Metal Thickness

Filter

Shade

Welding or Cutting

Operation

Electrode Size

Metal Thickness

Filter

Shade

Torch soldering 2

Gas metal-arc

welding (MIG)

Torch brazing 3 or 4 Non-ferrous base metal All 11

Oxygen Cutting Non-ferrous base metal All 12

Light Under 1 in., 25 mm 3 or 4 Gas tungsten arc welding All 12

Medium 1 to 6 in., 25-150 mm 4 or 5 (TIG) All 12

Heavy Over 6 in., 150 mm 5 or 6 Atomic hydrogen welding All 12

Gas welding Carbon arc welding All 12

Light Under 1/8 in., 3 mm 4 or 5 Plasma arc welding

Medium 1/8 to 1/2 in., 3-12 mm 5 or 6 Carbon arc air gouging

Heavy Over 1/2 in., 12 mm 6 or 8 Light 12

Shielded metal-arc

welding

(stick) electrodes

Under 5/32 in., 4 mm 10 Heavy 14

5/32 to 1/4 in.,

4 to 6.4 mm

12 Plasma arc cutting

Over 1/4 in., 6.4 mm 14 Light Under 300 Amp 9

Medium 300 to 400 Amp 12

Heavy Over 400 Amp 14

• Hydrogen gas may be formed and trapped under aluminum

workpieces when they are cut underwater or while using a water

table. DO NOT cut aluminum alloys underwater or on a water

table unless the hydrogen gas can be eliminated or dissipated.

Trapped hydrogen gas that is ignited will cause an explosion.

NOISE

Noise can cause permanent hearing loss. Plasma arc processes can

cause noise levels to exceed safe limits. You must protect your ears

from loud noise to prevent permanent loss of hearing.

• To protect your hearing from loud noise, wear protective ear

plugs and/or ear muffs. Protect others in the workplace.

• Noise levels should be measured to be sure the decibels (sound)

do not exceed safe levels.

• For information on how to test for noise, see item 1 in Subsec

tion 1.03, Publications, in this manual.

PLASMA ARC RAYS

Plasma Arc Rays can injure your eyes and burn your skin. The plasma

arc process produces very bright ultra violet and infrared light. These

arc rays will damage your eyes and burn your skin if you are not

properly protected.

• To protect your eyes, always wear a welding helmet or shield.

Also always wear safety glasses with side shields, goggles or

other protective eye wear.

• Wear welding gloves and suitable clothing to protect your skin

from the arc rays and sparks.

• Keep helmet and safety glasses in good condition. Replace

lenses when cracked, chipped or dirty.

• Protect others in the work area from the arc rays. Use protective

booths, screens or shields.

• Use the shade of lens as suggested in the following per ANSI/

ASC Z49.1:

Minimum Protective Suggested

Arc Current Shade No. Shade No.

Less Than 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

*These values apply where the actual arc is clearly

-

seen. Experience has shown that lighter filters may

be used when the arc is hidden by the workpiece.

LEAD WARNING

This product contains chemicals, including lead, or otherwise produces

chemicals known to the State of California to cause cancer, birth defects

and other reproductive harm. Wash hands after handling. (California

Health & Safety Code § 25249.5 et seq.)

GENERAL INFORMATON 1-2 Manual 0-5180

Table 1-1

Page 7

cutskill 35A

1.03 Publications

Refer to the following standards or their latest revisions for more

information:

1. OSHA, SAFETY AND HEALTH STANDARDS, 29CFR 1910,

obtainable from the Superintendent of Documents, U.S.

Government Printing Office, Washington, D.C. 20402

2. ANSI Standard Z49.1, SAFETY IN WELDING AND CUTTING,

obtainable from the American Welding Society, 550 N.W.

LeJeune Rd, Miami, FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC WELDING AND GAS

WELDING AND CUTTING, obtainable from the Superintendent

of Documents, U.S. Government Printing Office, Washington,

D.C. 20402

4. ANSI Standard Z87.1, SAFE PRACTICES FOR OCCUPATION

AND EDUCATIONAL EYE AND FACE PROTECTION, obtainable

from American National Standards Institute, 1430 Broadway,

New York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN’S SAFETY-TOE

FOOTWEAR, obtainable from the American National Standards

Institute, 1430 Broadway, New York, NY 10018

6. ANSI Standard Z49.2,

TING AND WELDING PROCESSES, obtainable from American

National Standards Institute, 1430 Broadway, New York, NY

10018

7. AWS Standard A6.0,

ERS WHICH HAVE HELD COMBUSTIBLES, obtainable from

American Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS FOR WELD

ING, CUTTING AND ALLIED PROCESSES, obtainable from

the National Fire Protection Association, Batterymarch Park,

Quincy, MA 02269

FIRE PREVENTION IN THE USE OF CUT-

WELDING AND CUTTING CONTAIN-

9. NFPA Standard 70, NATIONAL ELECTRICAL CODE, obtainable

from the National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

10. NFPA Standard 51B, CUTTING AND WELDING PROCESSES,

obtainable from the National Fire Protection Association, Bat

terymarch Park, Quincy, MA 02269

11. CGA Pamphlet P-1, SAFE HANDLING OF COMPRESSED

GASES IN CYLINDERS, obtainable from the Compressed

Gas Association, 1235 Jefferson Davis Highway, Suite 501,

Arlington, VA 22202

12. CSA Standard W117.2, CODE FOR SAFETY IN WELDING

AND CUTTING, obtainable from the Canadian Standards As

sociation, Standards Sales, 178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

13. NWSA booklet, WELDING SAFETY BIBLIOGRAPHY obtainable

from the National Welding Supply Association, 1900 Arch

Street, Philadelphia, PA 19103

14. American Welding Society Standard AWSF4.1, RECOM

MENDED SAFE PRACTICES FOR THE PREPARATION FOR

WELDING AND CUTTING OF CONTAINERS AND PIPING THAT

HAVE HELD HAZARDOUS SUBSTANCES, obtainable from the

American Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126

15. ANSI Standard Z88.2, PRACTICE FOR RESPIRATORY PRO

TECTION, obtainable from American National Standards

Institute, 1430 Broadway, New York, NY 10018

16. Safety in Welding and Allied Processes Part 2: Electrical,

AS1674.2-2007 from SAI Global Limited, www.saiglobal.

com

-

-

-

-

-

Manual 0-5180 1-3 GENERAL INFORMATION

Page 8

cutskill 35A

S

1.04 Declaration of Conformity

Manufacturer: Thermadyne Company

Address: 82 Benning Street

West Lebanon, New Hampshire 03784

USA

The equipment described in this manual conforms to all applicable aspects and regulations of the ‘Low Voltage Directive’ (European Council Directive

73/23/EEC as amended by Council Directive 93/68/EEC) and to the National legislation for the enforcement of this Directive.

The equipment described in this manual conforms to all applicable aspects and regulations of the "EMC Directive" (European Council Directive

89/336/EEC) and to the National legislation for the enforcement of this Directive.

Serial numbers are unique with each individual piece of equipment and details description, parts used to manufacture a unit and date of manufacture.

National Standard and Technical Specifications

The product is designed and manufactured to a number of standards and technical requirements. Among them are:

* CSA (Canadian Standards Association) standard C22.2 number 60 for Arc welding equipment.

* UL (Underwriters Laboratory) rating 94VO flammability testing for all printed-circuit boards used.

* CENELEC EN50199 EMC Product Standard for Arc Welding Equipment.

* ISO/IEC 60974-1 (BS 638-PT10) (EN 60 974-1) (EN50192) (EN50078) applicable to plasma cutting equipment and associated accessories.

* AS60974.1 Arc Welding Equipment Welding Power Sources.

For environments with increased hazard of electrical shock, Power Supplies bearing the

conjunction with hand torches with exposed cutting tips, if equipped with properly installed standoff guides.

* Extensive product design verification is conducted at the manufacturing facility as part of the routine design and manufacturing process.

This is to ensure the product is safe, when used according to instructions in this manual and related industry standards, and performs as

specified. Rigorous testing is incorporated into the manufacturing process to ensure the manufactured product meets or exceeds all design

specifications.

Thermadyne has been manufacturing products for more than 30 years, and will continue to achieve excellence in our area of manufacture.

Manufacturers responsible representative in Europe: Steve Ward

Thermadyne Europe

Europa Building

Chorley N Industrial Park

Chorley, Lancashire,

England PR6 7BX

Operations Director

mark conform to EN50192 when used in

GENERAL INFORMATON 1-4 Manual 0-5180

Page 9

cutskill 35A

1.05 Statement of Warranty

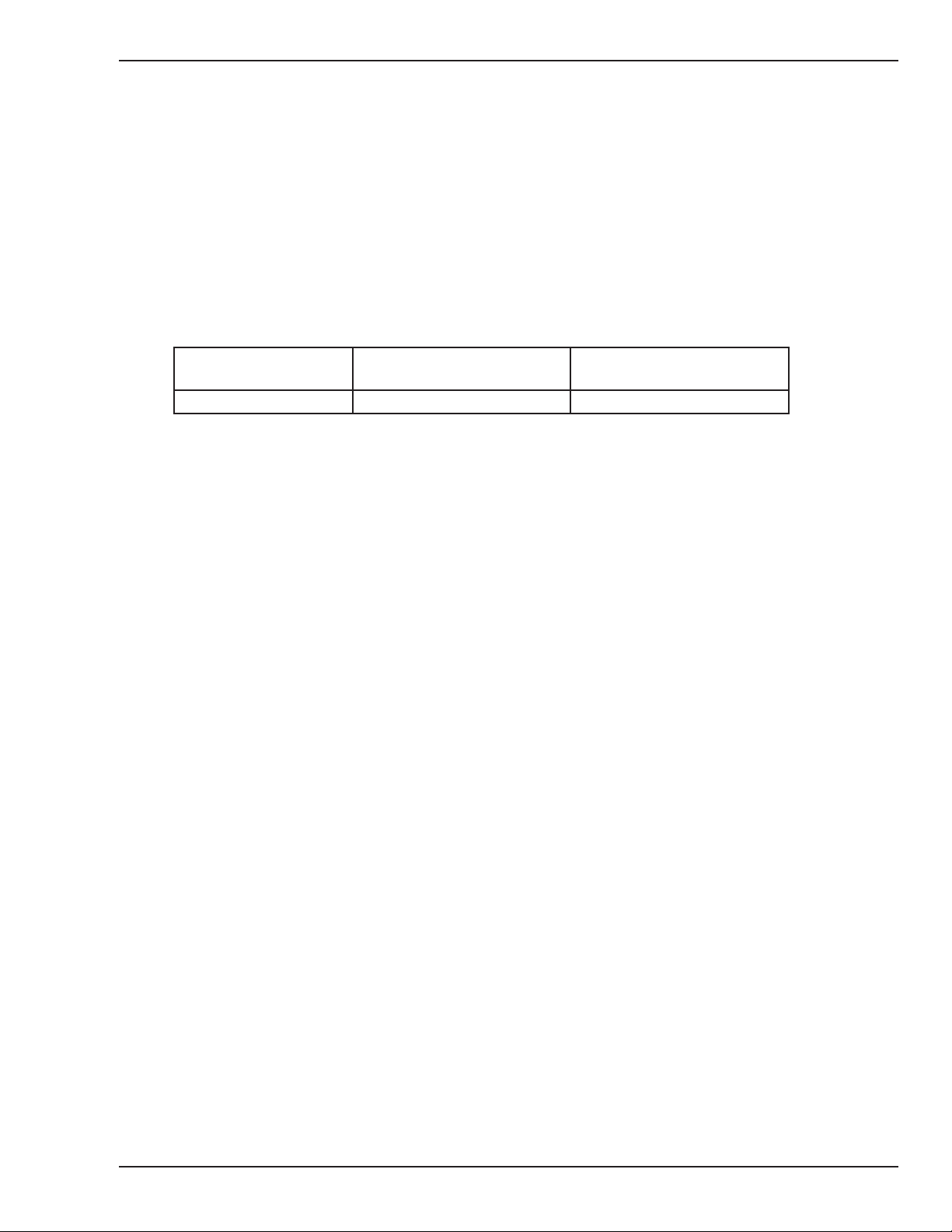

LIMITED WARRANTY: Subject to the terms and conditions established below, Thermadyne Company warrants to the original retail purchaser that new

Thermal Dynamics CUTSKILL™ plasma cutting systems sold after the effective date of this warranty are free of defects in material and workmanship.

Should any failure to conform to this warranty appear within the applicable period stated below, Thermadyne Company shall, upon notification thereof and

substantiation that the product has been stored operated and maintained in accordance with Thermadyne’s specifications, instructions, recommendations

and recognized industry practice, correct such defects by suitable repair or replacement.

This warranty is exclusive and in lieu of any warranty of merchantability or fitness for a particular purpose.

Thermadyne will repair or replace, at its discretion, any warranted parts or components that fail due to defects in material or workmanship within the

time periods set out below. Thermadyne Company must be notified within 30 days of any failure, at which time Thermadyne Company will provide

instructions on the warranty procedures to be implemented.

Thermadyne Company will honor warranty claims submitted within the warranty periods listed below. All warranty periods begin on the date of sale

of the product to the original retail customer or 1 year after sale to an authorized Thermadyne Distributor.

LIMITED WARRANTY PERIOD

Product

Power Supply Components

(Parts and Labor)

Torch and Leads

(Parts and Labor)

CUTSKILL 35A 2 Year 1 Year

This warranty does not apply to:

1. Consumable Parts, such as tips, electrodes, shield cups, o - rings, starter cartridges, gas distributors, fuses, filters.

2. Equipment that has been modified by an unauthorized party, improperly installed, improperly operated or misused based upon industry standards.

In the event of a claim under this warranty, the remedies shall be, at the discretion of Thermadyne Company:

1. Repair of the defective product.

2. Replacement of the defective product.

3. Reimbursement of reasonable costs of repair when authorized in advance by Thermadyne.

4. Payment of credit up to the purchase price less reasonable depreciation based on actual use.

These remedies may be authorized by Thermadyne and are FOB West Lebanon, NH or an authorized Thermadyne service station. Product returned

for service is at the owner’s expense and no reimbursement of travel or transportation is authorized.

LIMITATION OF LIABILITY: Thermadyne Company shall not under any circumstances be liable for special or consequential damages such as, but not

limited to, damage or loss of purchased or replacement goods or claims of customer of distributors (hereinafter “Purchaser”) for service interruption.

The remedies of the Purchaser set forth herein are exclusive and the liability of Thermadyne with respect to any contract, or anything done in

connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery, resale, or use of the goods covered by or

furnished by Thermadyne whether arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not, except as expressly

provided herein, exceed the price of the goods upon which liability is based.

This warranty becomes invalid if replacement parts or accessories are used which may impair the safety or performance of any Thermadyne

product.

This warranty is invalid if the Thermal Dynamics product is sold by non - authorized persons.

Effective December 10, 2010

Manual 0-5180 1-5 GENERAL INFORMATION

Page 10

Page 11

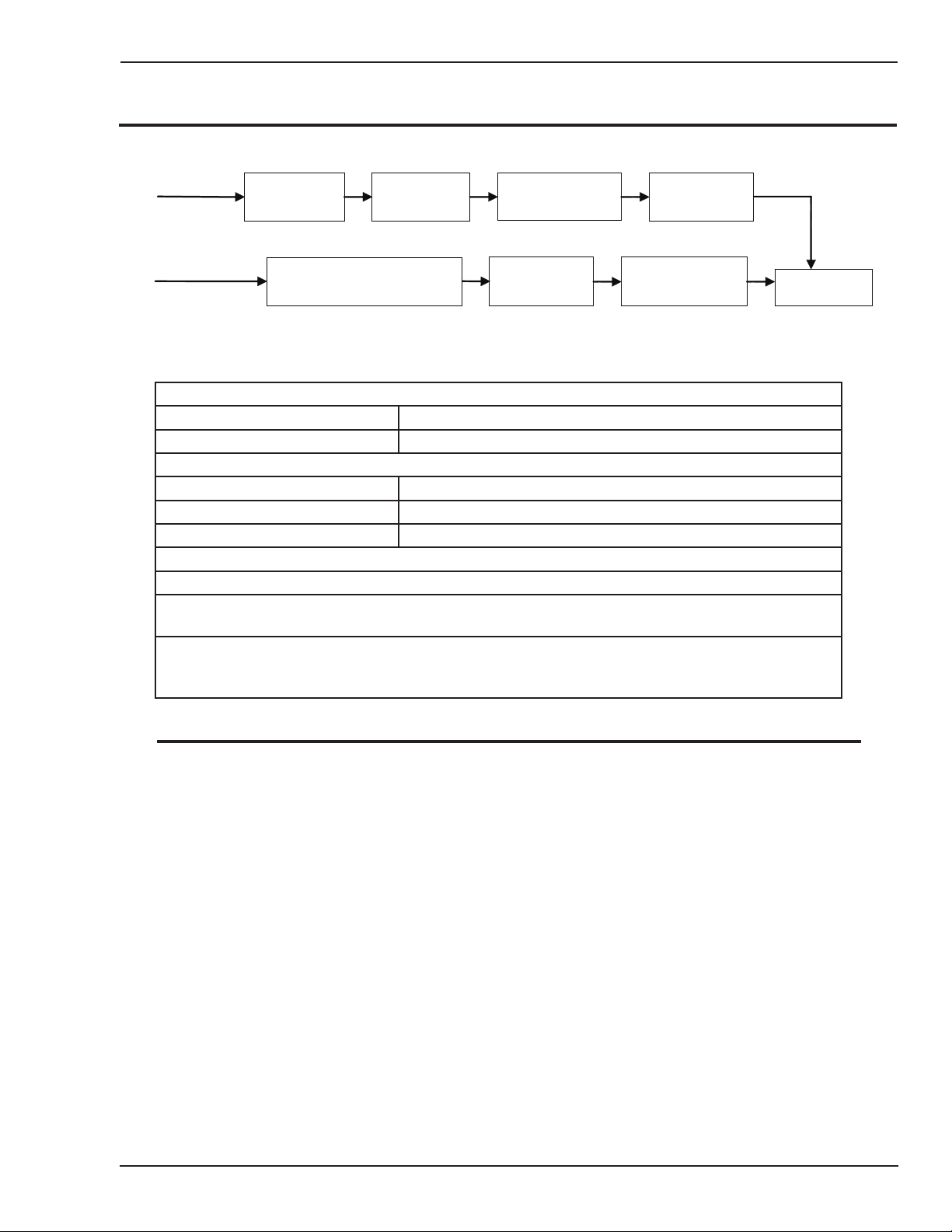

SECTION 2 SYSTEM:

Rectifier

Inverter

Transformer

Rectifier

Reduce pressure, filter

Gas valve Cutting torch

Workpiece

Compressed air

Art # A-09204_AB

INTRODUCTION

2.01 Working Principle

2.02 Power Supply Specifications

CutSkill 35A Power Supply Specifications

Input Power 230 VAC (± 15%), Single-Phase, 50 Hz

Output Current 15-35 Amps, continuously variable

CutSkill 35A Power Supply Duty Cycle (Note 1)

Ambient Temperature 104° F (40° C)

Duty Cycle

Current 35 Amps

SL 40 Torch Gas Requirements (see section 2T.03)

1. Duty Cycle is the percentage of time the system can be operated without overheating. Duty cycle is re

duced if primary input voltage (AC) is low or the DC voltage is higher than shown in this chart.

2. Air supply must be free of oil, moisture, and other contaminants. Excessive oil and moisture may cause

double-arcing, rapid tip wear, or even complete torch failure. Contaminants may cause poor cutting perfor

mance and rapid electrode wear. Optional filters provide increased filtering capabilities.

30%

Notes

NOTE

cutskill 35A

-

-

IEC Rating is determined as specified by the International Electro-Technical Commission. These specifica

tions include calculating an output voltage based upon power supply rated current. To facilitate comparison

between power supplies, all manufacturers use this output voltage to determine duty cycle.

TDC Rating is determined using an output voltage representative of actual output voltage during cutting

with a TDC torch. This voltage may be more or less than IEC voltage, depending upon choice of torch,

consumables, and actual cutting operation.

Manual 0-5180 2-1 INTRODUCTION

Page 12

cutskill 35A

26lb / 11.8kg

5 1/4"

133 mm

16 1/2"

419 mm

R

U

N

S

E

T

C

U

R

R

E

N

T

(

A

)

2

5

3

5

R

E

A

D

Y

A

I

R

O

V

E

R

H

E

A

T

P

O

W

E

R

11"

280 mm

Art # A-09174

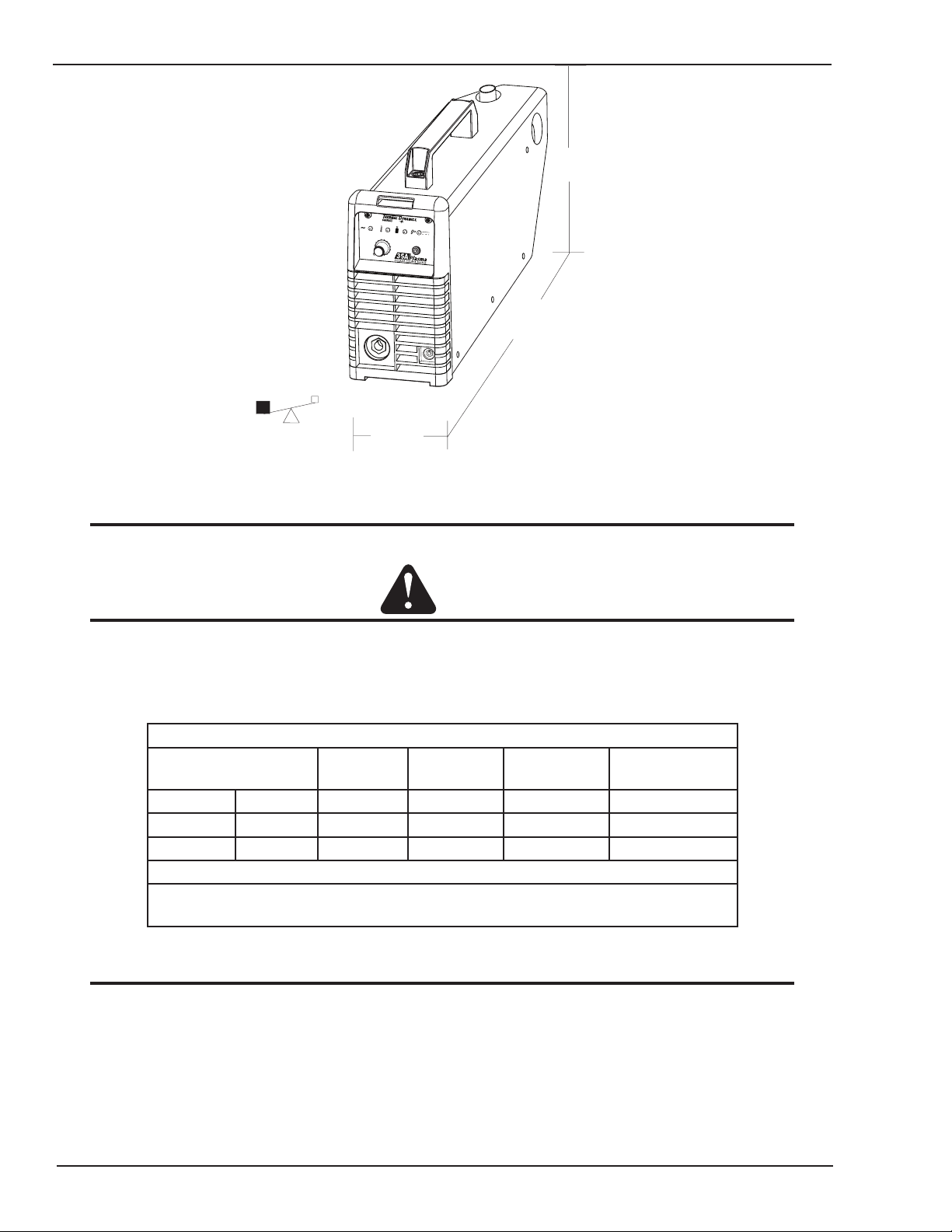

Figure 2-1 Power Supply Dimensions & Weight

NOTE

Weight includes torch & leads, input power cord, and work cable with clamp.

CAUTION

Provide clearance for proper air flow through the power supply. Operation without proper air flow will

inhibit proper cooling and reduce duty cycle.

2.03 Input Wiring Specifications

CutSkill 35A Input Power Requirements

Input Power Input Current Input Current Input

Voltage Freq. (kVA) Max (Amps) Ieff (Amps) Fuse (Amps)

(Volts) (Hz) 1-Ph 1-Ph 1-Ph 1-Ph

230 50 3.4 27.3 14 16

Line Voltages with Suggested Circuit Protection.

Motor start fuses or thermal circuit breakers are recommended for this application. Check

local requirements for your situation in this regard.

NOTE

Refer to Local and National Codes or local authority having jurisdiction for proper wiring requirements.

Cable size is de-rated based on the Duty Cycle of the equipment.

The suggested sizes are based on flexible power cable with power plug installations.

Suggested Sizes

(See Note)

Cable conductor temperature used is 167° F (75° C).

INTRODUCTION 2-2 Manual 0-5180

Page 13

2.04 Power Supply Features

Gas Pressure Regulator/

Filter Assembly

Control Panel

Torch Lead

R

U

N

SE

T

C

U

R

R

E

N

T

(A

)

25

35

R

E

A

D

Y

A

IR

O

V

E

RH

E

A

T

P

O

WE

R

230V AC Power Source

Work Cable and Clamp

Art # A-09779

Gas Pressure Regulator/

Filter Assembly

Gas Pressure Gauge

Art # A-09176

cutskill 35A

Manual 0-5180 2-3 INTRODUCTION

Page 14

This Page left blank intentionally.

Page 15

cutskill 35A

8.3" (210.82mm)

2.6"

(66.04mm)

.96" (24.38mm)

Art # A-09336

!

SECTION 2TORCH:

INTRODUCTION

2T.01 Scope of Manual

This manual contains descriptions, operating instructions and maintenance procedures for the SL40 Plasma

Cutting Torch. Service of this equipment is restricted to

properly trained personnel; unqualified personnel are

strictly cautioned against attempting repairs or adjust

ments not covered in this manual, at the risk of voiding

the Warranty. Read this manual thoroughly. A complete

understanding of the characteristics and capabilities of

this equipment will assure the dependable operation for

which it was designed.

2T.02 Specifications

A. Torch Configurations

1. Hand Torch, Model SL40

The hand torch head is at 75° to the torch handle.

The hand torches include a torch handle and torch

trigger assembly.

F. Torch Ratings

Ambient

Temperature

Duty Cycle 100% @ 40 Amps @ 193 scfh

Maximum Current 40 Amps

Voltage (V

Arc Striking Voltage

-

G. Current Ratings

SL40 Torch & Leads

Power Supply characteristics will determine

material thickness range.

H. Gas Requirements

SL40 Torch Gas Specications

Gas (Plasma and Secondary) Compressed Air

SL40 Torch Ratings

) 500V

peak

SL40 Current Ratings

Up to 40 Amps, DC,

Straight Polarity

NOTE

104° F

40° C

500V

B. Torch Leads Lengths

Hand Torches are available as follows:

• 15 ft / 4.6 m.

C. Torch Parts

Starter Cartridge, Electrode, Tip, Shield Cup

D. Parts - In - Place (PIP)

Torch has built-in switch.

12 vdc circuit rating

E. Type Cooling

Combination of ambient air and gas stream through

torch.

Minimum Input Pressure

Maximum Input Pressure 125 psi / 8.6 bar

Gas Flow

WARNING

75 psi

5.2 bar

193 scfh

91 lpm

This torch is not to be used with oxygen (O2).

This torch is not to be use with high frequency

starting systems.

Manual 0-5180 2T-1 INTRODUCTION

Page 16

CUTSKILL 35A

A-00002

Workpiece

Power

Supply

+

_

C

B

A

Torch Trigge

r

PIP Switch

Shield Cup

To Control

Cable Wiring

Torch Switch

A-09595

2T.03 Introduction to Plasma

A. Plasma Gas Flow

Plasma is a gas which has been heated to an extremely

high temperature and ionized so that it becomes electri

cally conductive. The plasma arc cutting and gouging

processes use this plasma to transfer an electrical arc

to the workpiece. The metal to be cut or removed is

melted by the heat of the arc and then blown away.

While the goal of plasma arc cutting is separation of

the material, plasma arc gouging is used to remove

metals to a controlled depth and width.

In a Plasma Cutting Torch a cool gas enters Zone B,

where a arc between the electrode and the torch tip

heats and ionizes the gas. The main cutting arc then

transfers to the workpiece through the column of

plasma gas in Zone C.

By forcing the plasma gas and electric arc through a

small orifice, the torch delivers a high concentration

of heat to a small area. The stiff, constricted plasma

arc is shown in Zone C. Direct current (DC) straight

polarity is used for plasma cutting, as shown in the

illustration.

Zone A channels a secondary gas that cools the torch.

This gas also assists the high velocity plasma gas in

blowing the molten metal out of the cut allowing for a

fast, slag - free cut.

B. Gas Distribution

The single gas used is internally split into plasma and

secondary gases.

-

The plasma gas flows into the torch through the

negative lead, through the starter cartridge, around

the electrode, and out through the tip orifice.

The secondary gas flows down around the outside

of the torch starter cartridge, and out between the tip

and shield cup around the plasma arc.

C. Pilot Arc

When the torch is started a pilot arc is established

between the electrode and cutting tip. This pilot

arc creates a path for the main arc to transfer to the

work.

D. Main Cutting Arc

DC power is also used for the main cutting arc. The

negative output is connected to the torch electrode

through the torch lead. The positive output is con

nected to the workpiece via the work cable and to the

torch through a pilot wire.

E. Parts - In - Place (PIP)

The torch includes a 'Parts - In - Place' (PIP) circuit.

When the shield cup is properly installed, it closes

a switch. The torch will not operate if this switch is

open.

-

INTRODUCTION 2T-2 Manual 0-5180

Typical Torch Head Detail

Parts - In - Place Circuit Diagram for Hand Torch

Page 17

cutskill 35A

!

SECTION 3:

INSTALLATION

3.01 Unpacking

1. Use the packing lists to identify and account for each item.

A. Contents List

Description Quantity

Power source 1

3 m power input cable (fitted) 1

SL40 (fitted) 1

Work cable and clamp (fitted) 1

Carry case 1

35 A Drag Tip (Located in power source handle) 2

Electrode (Located in power source handle) 1

Gas Regulator 1

Operating Manual 1

2. Inspect each item for possible shipping damage. If damage is evident, contact your distributor and / or shipping

company before proceeding with the installation.

3. Record Power Supply and Torch model and serial numbers, purchase date and vendor name, in the information

block at the front of this manual.

3.02 Lifting Options

The Power Supply includes a handle for hand lifting only. Be sure unit is lifted and transported safely and securely.

Do not touch live electrical parts.

Disconnect input power cord before moving unit.

FALLING EQUIPMENT can cause serious personal injury and can damage equipment.

HANDLE is not for mechanical lifting.

• Only persons of adequate physical strength should lift the unit.

• Lift unit by the handle, using two hands. Do not use straps for lifting.

• Use optional cart or similar device of adequate capacity to move unit.

• Place unit on a proper skid and secure in place before transporting with a fork lift or other vehicle.

WARNING

3.03 Primary Input Power Connections

CAUTION

Check your power source for correct voltage before plugging in or connecting the unit. The primary power

source, fuse, and any extension cords used must conform to local electrical code and the recommended

circuit protection and wiring requirements as specified in Section

Manual 0-5180 3-1 INSTALLATION

2.

Page 18

cutskill 35A

Art # A-09781

230V AC Power Source

Power Cord and Plug

This power supply comes installed with a input power cable with no plug, Single - Phase input power.

Figure 3-1 230V AC Power Source

When the power source input voltage is over or under the safe operating range, the alarm light will turn on, at the

same time the current output will be cut off.

If the power supply voltage continually goes beyond the safe work voltage range it will shorten the power source

life-span.

3.04 Air Supply Connections

A. Connecting Air Supply to Unit

The connection is the same for compressed air or industrial compressed air in gas cylinders.

1. Connect the gas line to the compressed air input inlet port at the appropriate pressure. The illustration shows

typical fittings as an example. (Minimum pressure should be 75 psi/5.2 bar)

For a secure seal, apply thread sealant to the fitting threads, according to manufacturer's instructions. Do

Not use Teflon tape as a thread sealer, as small particles of the tape may break off and block the small gas

passages in the torch.

NOTE

INSTALLATION 3-2 Manual 0-5180

Page 19

cutskill 35A

Gas Supply Hose

Adjustment knob

of compressed

air Pressure

Compressed air

pressure meter

Air filter

Compressed

air input

Art # A-09178

Hose Clamp

Fitting

Figure 3-2 Gas Connection to Compressed Air input

B. Using Industrial Compressed Air In Gas Cylinders

When using Industrial compressed air in gas cylinders as the gas supply:

1. Refer to the manufacturer’s specifications for installation and maintenance procedures for high pressure gas

regulators.

2. Examine the cylinder valves to be sure they are clean and free of oil, grease or any foreign material. Briefly open

each cylinder valve to blow out any dust which may be present.

3. The cylinder must be equipped with an adjustable high - pressure regulator capable of outlet pressures up to 100

psi (6.9 bar) maximum and flows of at least 193 scfh (91 lpm).

4. Connect gas supply hose to the cylinder.

NOTE

Pressure should be set at 75 psi (5.2 bar) at the high pressure gas cylinder regulator.

Supply hose must be at least 1/4 inch (6 mm) I.D.

For a secure seal, apply thread sealant to the fitting threads, according to manufacturer's instructions. Do

Not use Teflon tape as a thread sealer, as small particles of the tape may break off and block the small gas

passages in the torch.

Manual 0-5180 3-3 INSTALLATION

Page 20

This page left blank intentionally.

Page 21

4.01 Control Panel

RUN

SET

CURREN T (A)

15

25

35

READY

AIR

OVERHE AT

POWER

Cutting Current Control

Work Lead Connection

Power On Indicator

Torch Connection

Run/Set Switch

Over Heat Indicator

Air Indicator

DC Indicator

Art # A-09179

Adjustment knob

of compressed

air Pressure

Power switch

Compressed air

pressure meter

Power cable

input

Air filter

Compressed

air input

Art # A-09180

cutskill 35A

SECTION 4 SYSTEM:

OPERATION

The Front Panel The Rear Panel

1. ON / OFF Switch (Power Switch)

Controls input power to the power supply. I is ON, O is OFF.

2. RUN / SET Switch

RUN (up) position is for general torch operation. SET (down) position is for setting gas pressure and purging

lines.

3. (A) Output Current Control

Sets the desired output current. If the overload protection (fuse or circuit breaker) on the input power circuit

opens frequently, either reduce cutting output, reduce the cutting time, or connect the unit to more adequate

input power. Refer to Section 2 for input power requirements.

4.

Power ON Indicator (AC Indicator)

Steady light indicates power supply is ready for operation.

5.

OVERHEAT Indicator (TEMP Indicator)

Indicator is normally OFF. Indicator is ON when internal temperature exceeds normal limits. Allow the unit to

run with the fan on until the temp indicator turns off.

6.

AIR Indicator

AIR light should be ON when there is insufficient gas pressure (below 50 psi).

7.

READY (DC Indicator)

Indicator is ON when DC output circuit is active.

Manual 0-5180 4-1 OPERATION

Page 22

cutskill 35A

!

Art # A-09793_AC

Start Cartridge,

Cat. No. 9-0097

Electrode, Cat. No. 9-0096

Worn Electrode

Worn Tip

35 Amp Drag Tip, Cat. No. 9-0091

Shield Cup, Cat. No. 9-0098

8. Parts - in - place ( PIP)

This unit is fitted with a protective interlock mode (parts in place sensor), which serves to protect the user from

potentially dangerous voltages when changing consumables. If the shield cup is not correctly fitted, the output

will be disabled and the air indicator will flash.

NOTE

All consumables must be correctly fitted and maintained to ensure correct operation.

4.02 Preparations For Operating

At the start of each operating session:

WARNING

Disconnect primary power at the source before assembling or disassembling power supply, torch parts,

or torch and leads assemblies.

A. Torch Parts Selection

Check the torch for proper assembly and appropriate torch parts. The torch parts must correspond with the type

of operation, and with the amperage output of this power supply (35 amps maximum). Use only genuine Thermal

Dynamics parts with this torch.

OPERATION 4-2 Manual 0-5180

Page 23

cutskill 35A

Art # A-03387

Art # A-09181

RU N

SE T

CU RR EN T (A)

15

25

35

RE AD Y

AI R OV ER HE AT

PO WE R

NOTE

When operating the torch in a normal condition, a small amount of gas vents through the gap between

the shield cup and torch handle. Do not attempt to over tighten the shield cup as irreparable damage to

internal components may result.

B. Torch Connection

Check that the torch is properly connected.

C. Check Primary Input Power Source

1. Check the power source for proper input voltage. Make sure the input power source meets the power require

ments for the unit per Section 2, Specifications.

2. Connect the input power cable (or close the main disconnect switch) to supply power to the system.

D. Gas Selection

Ensure gas source meets requirements listed in section 2T. Check connections and turn gas supply on.

E. Connect Work Cable

Clamp the work cable to the workpiece or cutting table. The area must be free from oil, paint and rust. Connect

only to the main part of the workpiece; do not connect to the part to be cut off.

-

F. Power On

Place the power supply ON / OFF switch to the ON (I) position. Power indicator

turns on.

Front Panel With Power ON/OFF Indicator

Manual 0-5180 4-3 OPERATION

Page 24

cutskill 35A

Gas Pressure Regulator/

Filter Assembly

Gas Pressure Gauge

Art # A-09176

Art # A-09181

RU N

SE T

CU RR EN T (A)

15

25

35

RE AD Y

AI R OV ER HE AT

PO WE R

G. Set Operating Pressure

Place the power supply RUN / SET switch to the SET (down) position. Gas will flow. Adjust gas pressure to 65

psi / 4.5 bar. Air indicator

turns on.

NOTE

If gas regulator leaks, reset gas pressure to 0 psi, then reset to 65 psi / 4.5 bar.

H. Select Current Output Level

Place RUN / SET switch to RUN (up) position. Gas flow will stop. Set the desired current output level.

OPERATION 4-4 Manual 0-5180

Page 25

cutskill 35A

A-00024_AB

Shield Cup

Torch

Standoff Distance

1/8" - 3/8" (3 - 9mm)

Art # A-09342

Trigger

Trigger Release

3

4

Trigger

2

1

Trigger Release

Art# A-09341

4.03 Sequence of Operation

The following is a typical sequence of operation for this

power supply. Refer to Appendix 1 for block diagram.

1. Plug the input power cord into an active circuit.

a. AC power is available at the power supply.

2. Place the ON / OFF switch on the power supply

to ON (up) position.

a. AC indicator turns on; fan turns on.

NOTE

Gas will automatically flow from torch for 4

seconds, this is a safety circuit that makes

sure the torch tip is properly installed.

3. Set gas pressure.

a. Turn gas pressure adjustment knob to set

pressure to 75 psi / 5.2 bar.

NOTE

Minimum pressure for power supply opera

tion is lower than minimum pressure for torch

operation.

4. Wear protective clothing, including welding gloves

and appropriate eye protection (see table 1-1).

Place tip on work piece and pull trigger. Arc will

initiate and start cutting material.

• Standoff Cutting With Hand Torch

NOTE

-

b). For standoff cutting, hold the

torch tip on the work piece, pull the trigger.

After the arc is initiated lift the tip to 1/8"

- 3/8" (3-4mm) off the work.

Standoff Distance

For best performance and parts life, always use

the correct parts for the type of operation.

A. The torch can be comfortably held in one hand

or steadied with two hands. Position the hand

to press the Trigger on the torch handle. With

the hand torch, the hand may be positioned

close to the torch head for maximum control

or near the back end for maximum heat protection. Choose the holding technique that feels

most comfortable and allows good control

and movement.

NOTE

The tip should never come in contact with the

workpiece except during drag cutting opera

-

tions.

B. Depending on the cutting operation, do one

of the following:

a). For edge starts, hold the torch

perpendicular to the workpiece with the

front of the tip on the edge of the workpiece

at the point where the cut is to start.

C. Cut as usual. Simply release the trigger

assembly to stop cutting.

Manual 0-5180 4-5 OPERATION

Page 26

cutskill 35A

Shield Cup

Workpiece

Standoff Guide

Art # A-09790

Art # A-09342

Trigger

Trigger Release

3

4

Trigger

2

1

Trigger Release

Art# A-09341

D. Follow normal recommended cutting practices

as provided in the power supply operating

manual.

NOTE

When the shield cup is properly installed, there

is a slight gap between the shield cup and the

torch handle. Gas vents through this gap as

part of normal operation. Do not attempt to

force the shield cup to close this gap. Forcing

the shield cup against the torch head or torch

handle can damage components.

E. For a consistent standoff height from the

workpiece, install the standoff guide by sliding

it onto the torch shield cup. Install the guide

with the legs at the sides of the shield cup

body to maintain good visibility of the cutting

arc. During operation, position the legs of the

standoff guide against the workpiece.

C. Keep the torch in contact with the workpiece

during the cutting cycle.

D. Hold the torch away from your body.

E. Slide the trigger release toward the back of the

torch handle while simultaneously squeezing

the trigger. The arc will start.

F. Place the torch tip on the work. The main arc

will transfer to the work.

NOTE

The gas preflow and postflow are a character

istic of the power supply and not a function

of the torch.

• Drag Cutting With a Hand Torch

Drag cutting works best on metal 1/4"(6 mm) thick

or less.

NOTE

For best parts performance and life, always

use the correct parts for the type of opera

-

tion.

A. Install the drag cutting tip and set the output

G. Cut as usual. Simply release the trigger as-

sembly to stop cutting.

H. Follow normal recommended cutting practices

as provided in the power supply operating

manual.

5. Complete cutting operation.

NOTE

current.

B. The torch can be comfortably held in one hand

or steadied with two hands. Position the hand

to press the Trigger on the torch handle. With

the hand torch, the hand may be positioned

close to the torch head for maximum control

or near the back end for maximum heat protection. Choose the holding technique that feels

most comfortable and allows good control and

movement.

If the torch is lifted too far from the workpiece

while cutting, the main arc will stop and the

pilot arc will automatically restart.

OPERATION 4-6 Manual 0-5180

-

Page 27

6. Release the torch trigger.

Kerf Width

Cut Surface

Bevel Angle

Top Edge

Rounding

Cut Surface

Drag Lines

Dross

Build-Up

Top

Spatter

A-00007

a. Main arc stops.

7. Set the power supply ON / OFF switch to OFF

(down position).

a. AC indicator

turns OFF.

8. Set the main power disconnect to OFF, or unplug

input power cord.

a. Input power is removed from the system.

4.04 Cut Quality

NOTE

Cut quality depends heavily on setup and

parameters such as torch standoff, alignment

with the workpiece, cutting speed, gas pres

sures, and operator ability.

cutskill 35A

Nitride Build - Up

Nitride deposits can be left on the surface of the cut

when nitrogen is present in the plasma gas stream.

These buildups may create difficulties if the material

is to be welded after the cutting process.

Bevel Angle

The angle between the surface of the cut edge and

a plane perpendicular to the surface of the plate. A

perfectly perpendicular cut would result in a 0° bevel

angle.

Top - Edge Rounding

Rounding on the top edge of a cut due to wearing

-

from the initial contact of the plasma arc on the

workpiece.

Refer to appendix pages for additional infor

-

mation as related to the power supply used.

Cut quality requirements differ depending on application.

For instance, nitride build - up and bevel angle may be

major factors when the surface will be welded after cut

ting. Dross - free cutting is important when finish cut

quality is desired to avoid a secondary cleaning operation.

The following cut quality characteristics are illustrated in

the following figure:

Bottom Dross Buildup

Molten material which is not blown out of the cut area

and resolidifies on the plate. Excessive dross may

require secondary cleanup operations after cutting.

-

Kerf Width

The width of the cut (or the width of material removed

during the cut).

Top Spatter (Dross)

Top spatter or dross on the top of the cut caused by

slow travel speed, excess cutting height, or cutting

tip whose orifice has become elongated.

Cut Quality Characteristics

Cut Surface

The desired or specified condition (smooth or rough)

of the face of the cut.

Manual 0-5180 4-7 OPERATION

Page 28

cutskill 35A

!

Right Side

Cut Angle

Left Side

Cut Angle

A-00512

4.05 General Cutting Information

WARNING

Disconnect primary power at the source be

fore disassembling the power supply, torch,

or torch leads.

Frequently review the Important Safety Pre

cautions at the front of this manual. Be sure

the operator is equipped with proper gloves,

clothing, eye and ear protection. Make sure

no part of the operator’s body comes into

contact with the workpiece while the torch is

activated.\

CAUTION

Sparks from the cutting process can cause

damage to coated, painted, and other surfaces

such as glass, plastic and metal.

NOTE

Handle torch leads with care and protect them

from damage.

Torch Standoff

Improper standoff (the distance between the torch tip

and workpiece) can adversely affect tip life as well as

shield cup life. Standoff may also significantly affect

the bevel angle. Reducing standoff will generally

result in a more square cut.

Edge Starting

-

-

Side Characteristics Of Cut

To make a square - edged cut along an inside diameter

of a circle, the torch should move counterclockwise

around the circle. To keep the square edge along

an outside diameter cut, the torch should travel in a

clockwise direction.

Dross

When dross is present on carbon steel, it is com

monly referred to as either “high speed, slow speed,

or top dross”. Dross present on top of the plate is

normally caused by too great a torch to plate distance.

"Top dross" is normally very easy to remove and can

often be wiped off with a welding glove. "Slow speed

dross" is normally present on the bottom edge of the

plate. It can vary from a light to heavy bead, but does

not adhere tightly to the cut edge, and can be easily

scraped off. "High speed dross" usually forms a narrow bead along the bottom of the cut edge and is very

difficult to remove. When cutting a troublesome steel,

it is sometimes useful to reduce the cutting speed to

produce "slow speed dross". Any resultant cleanup

can be accomplished by scraping, not grinding.

-

For edge starts, hold the torch perpendicular to the

workpiece with the front of the tip near (not touching)

the edge of the workpiece at the point where the cut

is to start. When starting at the edge of the plate, do

not pause at the edge and force the arc to "reach" for

the edge of the metal. Establish the cutting arc as

quickly as possible.

Direction of Cut

In the torches, the plasma gas stream swirls as it

leaves the torch to maintain a smooth column of

gas. This swirl effect results in one side of a cut

being more square than the other. Viewed along the

direction of travel, the right side of the cut is more

square than the left.

OPERATION 4-8 Manual 0-5180

Page 29

SECTION 5 SYSTEM: SERVICE

Warning!

There are extremely dangerous voltage and power levels present inside

this product. Do not attempt to open or repair unless you are a qualified

electrical tradesperson and you have had training in power measurements

and troubleshooting techniques. If major complex subassemblies are faulty,

then the Cutting Power Source must be returned to an Thermadyne for

repair.

Each Use

Visual check of

torch tip and electrode

Weekly

Visually inspect the torch body tip,

electrode, start cartridge and shield cup

Visually inspect the

cables and leads.

Replace as needed

3 Months

6 Months

Replace all

broken parts

Visually check and

Carefully clean the

interior

Maintain more often

if used under severe

conditions

Art # A-00004

R

U

N

S

E

T

C

U

R

R

E

N

T

(

A

)

2

5

3

5

R

E

A

D

Y

A

I

R

O

V

E

R

H

E

A

T

P

O

W

E

R

Clean

exterior

of power supply

R

U

N

S

E

T

C

U

R

R

E

N

T

(

A

)

2

5

3

5

R

E

A

D

Y

A

I

R

O

V

E

R

H

E

A

T

P

O

W

E

R

5.01 General Maintenance

cutskill 35A

Manual 0-5180 5-1 SERVICE

Page 30

cutskill 35A

!

A. Every three months

Check external air filter, replace if necessary.

1. Shut off input power; turn off the gas supply.

sary.

Leave internal ground wire in place.

B. Every six months

1. Check the in-line air filter(s), clean or replace as required.

2. Check cables and hoses for leaks or cracks, replace if necessary.

3. Check all contactor points for severe arcing or pits, replace if necessary.

4. Vacuum dust and dirt out of the entire machine.

Bleed down the gas supply. Check air filter and replace if neces-

NOTE

5.02 Basic Troubleshooting Guide

WARNING

There are extremely dangerous voltage and power levels present inside this unit. Do not attempt to diagnose

or repair it unless you are an accredited service provider and you have had training in power electronics

measurement and troubleshooting techniques.

1. Common Faults symptom

A. Gas regulator leakage

1) Gas regulator on

a. Reset the regulator to 0 PSI and re-adjust it to 75 PSI (5.2 bar).

B. AC indicator

1) Main input power cord does not connect to power distribution net.

a. Connect the power cord.

2) Power ON/OFF switch in OFF (down) position.

a. Turn switch to ON (up) position.

3) Actual input voltage does not correspond to voltage of unit.

a. Verify that the input line voltage is correct.

4) Faulty components in unit

a. Return for repair or have qualified technician repair per service manual.

C. Torch will not pilot; When trigger is activated, Air indicator

1) Gas pressure too low. Adjust the pressure to 75 PSI/5.2 bar.

D. AC indicator ON, TEMP indicator

1) Air flow blocked

a. Check for blocked air flow around the unit and correct condition.

2) Fan blocked

a. Check for blocked status and correct condition.

OFF

ON.

ON.

SERVICE 5-2 Manual 0-5180

Page 31

cutskill 35A

3) Unit is overheated.

a. Keep the machine plugged in and turned on for five minutes. This will allow

the fan to run and cool the machine.

4) Faulty components in unit

a. Return for repair or have qualified technician repair per service manual.

E. Torch will not pilot, when torch trigger is activated.

1) The system is in SET mode.

a. Switch to RUN mode.

2) Faulty parts in torch

a. Check torch parts per section 4.02; replace as needed.

3) Gas pressure too high or too low

a. Adjust pressure to proper setting value.

4) Faulty components in unit

a. Return for repair or have qualified technician repair per service manual.

F. No cutting output when torch is activated; AC indicator

1) Torch is not connected properly to power supply.

a. Check torch connection to power supply.

2) Working cable not connected to work piece, or connection is poor.

a. Make sure that work cable has a proper connection to a clean, dry area of the

work piece.

3) Faulty components in unit

a. Return for repair or have qualified technician repair per service manual.

4) Faulty torch

a. Return for repair or have qualified technician repair.

G. Torch cuts but not adequately

1) Incorrect setting of output current control

a. Check and adjust to proper setting.

2) Working cable connection to work piece is poor.

a. Make sure that work cable has a proper connection to a clean, dry area of the

work piece.

3) Faulty components in unit

a. Return for repair or have qualified technician repair.

H. Output is restricted, and can not be controlled.

1) Input or output connection is poor.

a. Check all input and output connection leads.

2) Working cable connection to work piece is poor.

a. Make sure that work cable has a proper connection to a clean, dry area of the

work piece.

3) Faulty components in unit

a. Return for repair or have qualified technician repair per service manual.

I. Cutting output is unstable or inadequate.

1) Input or output connection is poor

a. Check all input and output connection leads.

ON, gas flows, fan turns.

Manual 0-5180 5-3 SERVICE

Page 32

cutskill 35A

2) Working cable connection is poor.

a. Make sure that work cable has a proper connection to a clean, dry area of the

work piece.

3) Fluctuations in input power

a. Have electrician check input line voltage.

J. Hard to startup

1) Torch parts worn (consumables)

a. Turn off input power, remove shield cup, tip, start cartridge, and electrode

and check them all. If the electrode or cutting tip is worn out, replace them.

If the start cartridge does not move freely, replace it. If there is too much spat ter on shield cup, replace it.

K. Arc goes out while operating. Arc can’t be restarted when torch trigger is activated.

1) Power Supply is overheated (TEMP indicator

a. Let unit cool down for at least 5 minutes. Make sure the unit has not been

operated beyond duty cycle limit.

2) Fan blades blocked (TEMP indicator

a. Check and clear blades.

3) Air flow blocked

a. Check for blocked air flow around the unit and correct condition.

4) Gas pressure is too low. (Air indicator

a. Check gas source, It should be set to at least 75 PSI/5.2 bar. Adjust it as

needed.

5) Torch parts worn

a. Check torch shield cup, cutting tip, start cartridge and electrode. Replace as

needed.

6) Faulty component in unit

a. Return for repair or have qualified technician repair per service manual.

L. Torch cuts but not well.

1) Current control is set too low.

a. Increase the current setting.

2) Torch is being moved too fast across work piece

a. Reduce cutting speed.

3) Excessive oil or moisture in torch

a. Hold torch 1/8 inch (3 mm) from clean surface while purging and observe

oil or moisture buildup (do not activate torch). If there are contaminants in the

gas, additional filtering may be needed.

ON).

ON).

ON when torch trigger is activated.)

SERVICE 5-4 Manual 0-5180

Page 33

cutskill 35A

Art# A-09345

Electrode

Start Cartridge

Tip

Shield Cup

Torch Head

Good Tip

Worn Tip

A-09791

SECTION 5 TORCH:

SERVICE

5T.01 General Maintenance

NOTE

Refer to Previous "Section 5 System" for com

mon and fault indicator descriptions.

Cleaning Torch

Even if precautions are taken to use only clean air with

a torch, eventually the inside of the torch becomes

coated with residue. This buildup can affect the arc

initiation and the overall cut quality of the torch.

WARNING

Disconnect primary power to the system be

fore disassembling the torch or torch leads.

Remove the consumable torch parts as follows:

NOTE

The shield cup holds the tip and starter car

tridge shield cup in place. Position the torch

with the shield cup facing upward to prevent

these parts from falling out when the cup is

removed.

-

1. Unscrew and remove the shield cup from the

torch.

NOTE

Slag built up on the shield cup that cannot

be removed may effect the performance of

the system.

2. Inspect the cup for damage. Wipe it clean or

replace if damaged.

-

DO NOT touch any internal torch parts while

the AC indicator light of the Power Supply is

ON.

The inside of the torch should be cleaned with electrical contact cleaner using a cotton swab or soft wet

rag. In severe cases, the torch can be removed from

the leads and cleaned more thoroughly by pouring

electrical contact cleaner into the torch and blowing

it through with compressed air.

CAUTION

Dry the torch thoroughly before reinstalling..

5T.02 Inspection and Replacement of

Consumable Torch Parts

WARNING

Disconnect primary power to the system be

fore disassembling the torch or torch leads.

DO NOT touch any internal torch parts while

the AC indicator light of the Power Supply is

ON.

Consumable Parts

3. Remove the tip. Check for excessive wear (indicated by an elongated or oversized orifice). Clean

or replace the tip if necessary.

-

Tip Wear

Manual 0-5180 5T-1 SERVICE

Page 34

cutskill 35A

Art A-09792

Worn Electrode

New Electrode

Art # A-09346

Art# A-09817

Electrode

Start Cartridge

Tip

Shield Cup

Torch Head

1

2

3

4

4. Remove the starter cartridge. Check for excessive

wear, plugged gas holes, or discoloration. Check

the lower end fitting for free motion. Replace if

necessary.

5. Pull the electrode straight out of the torch head.

Check the face of the electrode for excessive wear.

Refer to the following figure.

SL40 Replacement Parts

Item # Description Cat. No

1 Electrode 9-0096

2 Start Cartridge 9-0097

3 Tip, 20-35A Drag 9-0091

4 Shield Cup 9-0098

N/S SL40 Torch w/ 15ft (4.6m) leads 7-0041

6. Reinstall the electrode by pushing it straight into

7. Reinstall the desired starter cartridge and tip into

8. Hand tighten the shield cup until it is seated on the

Electrode Wear

the torch head until it clicks.

the torch head.

torch head. If resistance is felt when installing the

cup, check the threads before proceeding.

SERVICE 5T-2 Manual 0-5180

Page 35

SECTION 6:

1

3

4

2

5

Art # A-09930

6

7

8

9

10

11

PARTS LISTS

6.01 Introduction

A. Parts List Breakdown

The parts list provides a breakdown of all replaceable components.

Item # Qty Description Catalog #

1 1 Logic PCB assembly 9-0134

2 1 Control PCB assembly

3 1 Main PCB assembly 9-0137

4 1 Regulator 9-0139

5 1 Solenoid assembly 9-0140

6 1 Pressure Switch 9-0136

7 1 Current Transformer 9-0138

8 1 CS35 Machine Cover 9-0376

9 1 CS35 Front Panel 9-0377

10 1 CS35 Rear Panel 9-0378

11 1 CS35 Fan 9-0381

9-0135

cutskill 35a

B. Returns

If a product must be returned for service, contact your distributor. Materials returned without proper authorization

will not be accepted.

Manual 0-5180 6-1 PART LIST

Page 36

This page left blank intentionally.

Page 37

603-298-5711

THERMAL DYNAMICS

INDUSTRIAL OARK NO.2

WEST LEBANON,NH 03784

A THERMADYNE Company

Information proprietary to THERMAL DYNAMICS CORPORATION

Not for Release Reproduction or Distribution without written consent

NOTE:

Unless otherwise Specified resistors are in Ohms 1/4W 5%

Capacitors are in Microfarads (UF)

TITLE:

SCHEMATIC

35A 240V SINGLE PHASE 50/60 Hz

Date

By

Rev Revision

PILOT

WORK

T

ORC

H

WV OUTPUT

BLACK

RED

FAN

DC24V

AC240V

INPUT 50/60 Hz

AC240V

D & T

WV OUTPUT

FEEDBACK SIGNAL

N/A

DRIVE

POWER

OT

AIR

READY

CURRENT CONTROL

SET / RUN

DRIVE SIGNAL

N/A

SOURCE&TIP

SIGNAL

HF&QF

GAS SOLENOID

TEST

TORCH SW

PRESSURE SW

OVER TEMPERATURE

1

2

3

1

2

3

1

2

1

234

1

2

3

4

1

2

3

4

5

1

2

3

4

5

6

7

1

2

1

2

3

4

1

2

1

2

3

1

2

3

4

5

6

1

2

3

1

2

3

4

1

2

1

2

3

4

5

1

2

3

4

5

6

7

1

2

SW

1

2

3

+

-

+

-

+

+

Art # A-09193_AC

APPENDIX 1:

CIRCUIT DIAGRAM

cutskill 35a

Manual 0-5180 A-1 APPENDIX

Page 38

This page left blank intentionally.

Page 39

This Page Intentionally Blank.

Page 40

&ORª5SEªWITHª%UROPEANª,ITERATUREªLARGEªAREAªªªª

7 / 2 , $ ª ( % ! $ 1 5 ! 2 4 % 2 3 ª ª ª 3 W I N G L E Y ª 2 I D G Eª 2 O A D ª 3 U IT E ª ª ª s ª ª 3 T ª ,O U I S ª - I S S OU R I ª ª ª 5 3 !

A Global Cutting & Welding Market Leader

™

Customer Care UK: +44 (0)1257 261 755 / Fax: +44 (0)1257 224 800

Customer Care Italy +39 02 36546801 / Fax: +39 02 36546480

www.thermadyne.com

Denton, TX USA

U.S. Customer Care

*\Ê £nää{ÓÈ£nnnÊÌvÀii®

>Ý\Ê£nääxÎxäxxÇÊÌvÀii®

International Customer Care

*\Ê £{äÎn££Ó£Ó

>Ý\Ê£{ä{nÎn£Çn

Miami, FL USA

Sales Office, Latin America

*\Ê £x{ÇÓÇnÎÇ£

>Ý\Ê£x{ÇÓÇnÎÇÈ

Oakville, Ontario, Canada

Canada Customer Care

*\Ê £äxnÓÇ{x£x

>Ý\Ê£nääxnn£Ç£{ÊÌvÀii®

Chorley, United Kingdom

Customer Care

*\Ê ³{{Ê£ÓxÇÓÈ£Çxx

>Ý\ʳ{{Ê£ÓxÇÓÓ{nää

Milan, Italy

Customer Care

*\К ³ОКдУОИx{Иnд£

>Э\К³ОКдУОИx{Иn{д

Cikarang, Indonesia

Customer Care

*\К ИУУ£nдИдx

>Э\ККИУУ£nдИдИ

Rawang, Malaysia

Customer Care

*\К ³ИдОКИдУУnn

>Э\К³ИдОКИдУ£дnx

Melbourne, Australia

Australia Customer Care

*\Ê £ÎääÈx{ÈÇ{ÊÌvÀii®

*\Ê È£Î{Ç{Ç{ääÊ

>Ý\ÊÈ£Î{Ç{ÇΣ

International

*\Ê È£Î{Ç{Çxän

>Ý\ÊÈ£Î{Ç{Ç{nn

Shanghai, China

Sales Office

*\К ³nИКУ£И{дЗУИУИ

>Э\КК³nИКУ£И{{nОдОУ

Singapore

Sales Office

*\К ³ИxКИnОУnдИИ

>Э\К³ИxКИЗИОxn£У

&ORMª.OªXXªªªªªÊ ^ÊÓä£äÊ/iÀ>`ÞiÊ`ÕÃÌÀiÃ]ÊV°Ê ÜÜÜ°ÌiÀ>`Þi°VÊ *ÀÌi`ÊÊ1°-°°

THE AMERICAS EUROPE ASIA/PACIFIC

Loading...

Loading...