Page 1

200

™

ULTRA-CUT

PLASMA CUTTING SYSTEM

& AUTOMATED GAS CONTROL

Art# A-08586_AC

Operating Manual

Rev. AK Date: March 13, 2013 Manual # 0-5133

Operating Features:

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Thermal Dynamics product. We are

proud to have you as our customer and will strive to provide you

with the best service and reliability in the industry. This product is

backed by our extensive warranty and world-wide service network.

To locate your nearest distributor or service agency call 1-800426-1888, or visit us on the web at www.thermal-dynamics.com.

This Operating Manual has been designed to instruct you on the

correct use and operation of your Thermal Dynamics product.

Your satisfaction with this product and its safe operation is our

ultimate concern. Therefore please take the time to read the entire

manual, especially the Safety Precautions. They will help you to

avoid potential hazards that may exist when working with this

product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators Worldwide.

Thermal Dynamics is a Global Brand of manual and automation

Plasma Cutting Products for Thermadyne Industries Inc.

We distinguish ourselves from our competition through marketleading, dependable products that have stood the test of time.

We pride ourselves on technical innovation, competitive prices,

excellent delivery, superior customer service and technical

support, together with excellence in sales and marketing expertise.

Above all, we are committed to developing technologically

advanced products to achieve a safer working environment within

the welding industry.

Page 3

!

WARNINGS

Read and understand this entire Manual and your employer’s safety practices before

installing, operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement, the Manufacturer assumes no liability for its use.

Plasma Cutting Power Supply, Ultra-Cut® 200

Automated Gas Control DFC-3000

Operating Manual No. 0-5133

Published by:

Thermadyne Corporation

82 Benning Street

West Lebanon, New Hampshire, USA 03784

(603) 298-5711

www.thermal-dynamics.com

© Copyright 2009, 2010, 2011, 2012, 2013 by

Thermadyne Corporation

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to

any party for any loss or damage caused by any error or omission

in this Manual, whether such error results from negligence, accident, or any other cause.

Licensed under U. S. Patent No. 5,070,227

Original Publication Date: June 24, 2009

Revision Date: March 13, 2013

Record the following information for Warranty purposes:

Where Purchased: ___________________________________

Purchase Date:______________________________________

Power Supply Serial #:_______________________________

Torch Serial #:_____________________________________

Page 4

This page intentionally blank

Page 5

TABLE OF CONTENTS

SECTION 1:

GENERAL INFORMATION ................................................................................................ 1-1

1.01 Notes, Cautions and Warnings ...................................................................... 1-1

1.02 Important Safety Precautions ....................................................................... 1-1

1.03 Publications .................................................................................................. 1-2

1.04 Note, Attention et Avertissement .................................................................. 1-3

1.05 Precautions De Securite Importantes ........................................................... 1-3

1.06 Documents De Reference ............................................................................. 1-5

1.07 Declaration of Conformity ............................................................................. 1-6

1.08 Statement of Warranty .................................................................................. 1-7

SECTION 2: SPECIFICATIONS ................................................................................................. 2-1

2.01 General Description Of The System .............................................................. 2-1

2.02 Plasma Power Supply ................................................................................... 2-1

2.03 Remote Arc Starter ...................................................................................... 2-1

2.04 Gas Control Module ...................................................................................... 2-1

2.05 Precision Plasma Cutting Torch .................................................................... 2-1

2.06 Specifications & Electrical Requirements ..................................................... 2-2

2.07 System Component Layout .......................................................................... 2-3

2.08 Power Supply Dimensions ............................................................................ 2-4

2.09 Power Supply Rear Panel Features ............................................................... 2-5

2.10 Gas Requirements ........................................................................................ 2-6

2.11 Gas Applications .......................................................................................... 2-6

2.12 XTTM-300 Torch Specifications .................................................................... 2-7

SECTION 3: INSTALLATION ...................................................................................................... 3-1

3.01 Installation Requirements ............................................................................. 3-1

3.02 System Layout ............................................................................................. 3-2

3.03 Cables & Leads Identification ....................................................................... 3-3

3.04 Lift the Power Supply .................................................................................... 3-4

3.05 Remove the Connections Cover ................................................................... 3-5

3.06 Connect Work Cable and Pilot and Negative Leads....................................... 3-8

3.07 Ground Connections ..................................................................................... 3-9

3.08 Connect Coolant Leads ................................................................................3-12

3.09 Connect Control Cables for CNC, Remote Arc Starter, and DMC-3000 ........ 3-13

3.10 Connect TSC-3000 Cable and DMC-3000 Fiber Optic Cable to CCM ............ 3-14

3.11 Set Switches on the Command - Control Module ......................................... 3-16

3.12 Height Control Connections ......................................................................... 3-18

3.13 DMC-3000 Gas Manifold Control Installation ................................................ 3-18

3.14 DPC-3000 Gas Pressure Control Installation ............................................... 3-22

3.15 Fiber Optic Cable Installation from CCM to DMC-3000. ............................... 3-25

3.16 Fiber Optic Cable Installation From DMC-3000 to DPC-3000........................3-28

3.17 Install TSC-3000 Touch Screen Control ........................................................ 3-30

3.18 Install Remote Arc Starter ...........................................................................3-31

3.19 Connecting Torch ......................................................................................... 3-40

3.20 Install Consumable Torch Parts .................................................................... 3-41

3.21 Complete the Installation ............................................................................. 3-45

Page 6

TABLE OF CONTENTS (continued)

SECTION 4: OPERATION .......................................................................................................... 4-1

4.01 Power Supply Control Panel .......................................................................... 4-1

4.02 Start-Up Sequence ....................................................................................... 4-2

4.03 TSC-3000 Navigation Functions ................................................................... 4-2

4.04 TSC-3000 Initial Setup ONLY ........................................................................ 4-3

4.05 TSC-3000 Selecting New Process ................................................................ 4-4

4.06 TSC-3000 Selecting Recently Used Process ................................................ 4-5

4.07 TSC-3000 Creating a Custom Process ......................................................... 4-6

4.08 Back up and Restoration of Custom Processes. ........................................... 4-8

4.09 Sequence of Operation ................................................................................ 4-11

4.10 Gas Selection .............................................................................................. 4-14

4.11 Power Supply Status Codes ........................................................................ 4-16

4.12 DMC-3000 Status Codes ............................................................................. 4-19

4.13 DPC-3000 Status Codes .............................................................................. 4-21

SECTION 5: MAINTENANCE .................................................................................................... 5-1

5.01 Periodic Checks ............................................................................................ 5-1

5.02 External Coolant Filter Cleaning Procedure ................................................... 5-1

5.03 Internal Coolant Filter Cleaning Procedure .................................................... 5-2

5.04 Coolant Replacement Procedure ................................................................... 5-2

5.05 Remote Arc Starter: Service Chart .............................................................. 5-3

5.06 Remote Arc Starter: Spark Gap Adjustment ................................................ 5-4

SECTION 6: REPLACEMENT ASSEMBLIES & PARTS ........................................................... 6-1

6.01 Main Component / System Replacement ...................................................... 6-1

6.02 System Layout ............................................................................................. 6-2

6.03 Recommended Gas Supply Hose ................................................................. 6-2

6.04 Leads and Cables ......................................................................................... 6-3

6.05 Power Supply External Replacement Parts .................................................. 6-10

6.06 Power Supply Replacement Parts - Right Side ............................................6-11

6.07 Power Supply Replacement Parts - Right Side ............................................6-12

6.08 Power Supply Replacement Parts - Right Side ............................................6-13

6.09 Power Supply Replacement Parts - Front Panel ........................................... 6-14

6.10 Power Supply Replacement Parts - Front Panel ........................................... 6-15

6.11 Power Supply Replacement Parts - Right Side ............................................6-16

6.12 Power Supply Replacement Parts - Rear Panel ............................................6-17

6.13 Power Supply Replacement Parts - Right Side ............................................6-18

6.14 Power Supply Replacement Parts ................................................................ 6-19

6.15 Power Supply Replacement Parts - Right Side ............................................6-20

6.16 Power Supply Replacement Parts ................................................................ 6-21

6.17 Power Supply Replacement Parts - Right Side ............................................6-22

6.18 DFC-3000 Automated Gas Control System Replacement Componants ........6-23

6.19 DMC-3000 Gas Control Module Replacement Parts ..................................... 6-24

6.20 DPC-3000 Gas Control Module Replacement Parts ..................................... 6-25

6.21 TSC-3000 Touch Screen Control Remote and Internal Replacement Parts ...6-26

6.22 Remote Arc Starter (RAS-1000) Replacement Parts....................................6-27

6.23 Remote Arc Starter (RAS-1000) Replacement Parts....................................6-28

6.24 Command & Control Module - Replacement Parts .................................... 6-29

Page 7

TABLE OF CONTENTS (continued)

SECTION 7: TORCH MAINTENANCE.................................................................................... 7-1

7.01 Consumable Removal ................................................................................... 7-1

7.02 O-Ring Lubrication ........................................................................................ 7-2

7.03 Parts Wear.................................................................................................... 7-2

7.04 Torch Consumables Installation .................................................................... 7-3

7.05 Coolant Leak Trouble-Shooting ...................................................................... 7-5

APPENDIX 1: Remote Arc Starter Schematic .......................................................................... A-1

APPENDIX 2: DMC-3000 PCB Layout ...................................................................................... A-2

APPENDIX 3: DPC-3000 PCB Layout ...................................................................................... A-3

APPENDIX 4: TSC-3000 PCB Layout ...................................................................................... A-4

APPENDIX 5: CCM Input / Output PCB Layout ........................................................................ A-5

APPENDIX 6: CCM CPU PCB Layout ..................................................................................... A-6

APPENDIX 7: CNC .................................................................................................................... A-8

A7.01 CNC functions ............................................................................................ A-8

A7.02 NC Input / Output Descriptions ................................................................... A-9

A7.03 Simplified CNC Circuit. ............................................................................ A-10

A7.04 CNC Connections. ................................................................................... A-11

APPENDIX 8: SERIAL COMMUNICATIONS ........................................................................... A-12

A8.01 Cables and Switch Settings for 2 and 4 Wire ........................................... A-12

APPENDIX 9: Schematic, 230-460V, Chopper Pilot ................................................................. A-14

APPENDIX9: Schematic, 230-460V, Chopper Pilot Cont. ......................................................... A-16

APPENDIX 10: Schematic, CCC 400V, w/ Chopper Pilot ......................................................... A-18

APPENDIX 10: Schematic, CCC 400V, w/ Chopper Pilot Cont. ................................................ A-20

APPENDIX 11: Schematic, CE 400V, Chopper Pilot ................................................................ A-22

APPENDIX 11: Schematic, CE 400V, Chopper Pilot Cont. ....................................................... A-24

APPENDIX 12: Schematic, CSA 600V, Chopper Pilot .............................................................. A-26

APPENDIX 12: Schematic, CSA 600V, Chopper Pilot Cont. ..................................................... A-28

APPENDIX 13: Schematic, DFC-3000 Auto Gas Box System ................................................. A-30

APPENDIX 14: PUBLICATION HISTORY................................................................................ A-32

Page 8

NOTE

Section 8, Torch operation, is provided separately.

Page 9

ULTRA-CUT 200

!

SECTION 1:

GENERAL INFORMATION

1.01 Notes, Cautions and Warnings

Throughout this manual, notes, cautions, and warnings are used to

highlight important information. These highlights are categorized as

follows:

NOTE

An operation, procedure, or background information

which requires additional emphasis or is helpful in efficient operation of the system.

CAUTION

A procedure which, if not properly followed, may cause

damage to the equipment.

WARNING

A procedure which, if not properly followed, may cause

injury to the operator or others in the operating area.

1.02 Important Safety Precautions

• Use an air-supplied respirator if ventilation is not adequate to

remove all fumes and gases.

• The kinds of fumes and gases from the plasma arc depend on the

kind of metal being used, coatings on the metal, and the different

processes. You must be very careful when cutting or welding

any metals which may contain one or more of the following:

Antimony Chromium Mercury

Arsenic Cobalt Nickel

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese Vanadium

• Always read the Material Safety Data Sheets (MSDS) that should

be supplied with the material you are using. These MSDSs will

give you the information regarding the kind and amount of fumes

and gases that may be dangerous to your health.

• For information on how to test for fumes and gases in your

workplace, refer to item 1 in Subsection 1.03, Publications in

this manual.

• Use special equipment, such as water or down draft cutting

tables, to capture fumes and gases.

• Do not use the plasma torch in an area where combustible or

explosive gases or materials are located.

• Phosgene, a toxic gas, is generated from the vapors of chlorinated solvents and cleansers. Remove all sources of these vapors.

• This product, when used for welding or cutting, produces fumes

or gases which contain chemicals known to the State of California to cause birth defects and, in some cases, cancer. (California

Health & Safety Code Sec. 25249.5 et seq.)

WARNINGS

OPERATION AND MAINTENANCE OF PLASMA ARC

EQUIPMENT CAN BE DANGEROUS AND HAZARDOUS

TO YOUR HEALTH.

Plasma arc cutting produces intense electric and magnetic emissions that may interfere with the proper function of cardiac pacemakers, hearing aids, or other electronic health equipment. Persons who work near plasma

arc cutting applications should consult their medical health

professional and the manufacturer of the health equipment to determine whether a hazard exists.

To prevent possible injury, read, understand and follow

all warnings, safety precautions and instructions before

using the equipment. Call 1-603-298-5711 or your local

distributor if you have any questions.

GASES AND FUMES

Gases and fumes produced during the plasma cutting process can be

dangerous and hazardous to your health.

• Keep all fumes and gases from the breathing area. Keep your

head out of the welding fume plume.

ELECTRIC SHOCK

Electric Shock can injure or kill. The plasma arc process uses and

produces high voltage electrical energy. This electric energy can cause

severe or fatal shock to the operator or others in the workplace.

• Never touch any parts that are electrically “live” or “hot.”

• Wear dry gloves and clothing. Insulate yourself from the work

piece or other parts of the welding circuit.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workplace is moist or damp.

• Install and maintain equipment according to NEC code, refer to

item 9 in Subsection 1.03, Publications.

• Disconnect power source before performing any service or repairs.

• Read and follow all the instructions in the Operating Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag, sparks, or the plasma arc.

• Be sure there is no combustible or flammable material in the

workplace. Any material that cannot be removed must be protected.

• Ventilate all flammable or explosive vapors from the workplace.

• Do not cut or weld on containers that may have held combustibles.

Manual 0-5133

1-1

Page 10

ULTRA-CUT 200

• Provide a fire watch when working in an area where fire hazards

may exist.

• Hydrogen gas may be formed and trapped under aluminum

workpieces when they are cut underwater or while using a water

table. DO NOT cut aluminum alloys underwater or on a water

table unless the hydrogen gas can be eliminated or dissipated.

Trapped hydrogen gas that is ignited will cause an explosion.

1.03 Publications

Refer to the following standards or their latest revisions for more information:

1. OSHA, SAFETY AND HEALTH STANDARDS, 29CFR 1910,

obtainable from the Superintendent of Documents, U.S.

Government Printing Office, Washington, D.C. 20402

NOISE

Noise can cause permanent hearing loss. Plasma arc processes can

cause noise levels to exceed safe limits. You must protect your ears

from loud noise to prevent permanent loss of hearing.

• To protect your hearing from loud noise, wear protective ear

plugs and/or ear muffs. Protect others in the workplace.

• Noise levels should be measured to be sure the decibels (sound)

do not exceed safe levels.

• For information on how to test for noise, see item 1 in Subsection 1.03, Publications, in this manual.

PLASMA ARC RAYS

Plasma Arc Rays can injure your eyes and burn your skin. The plasma

arc process produces very bright ultra violet and infra red light. These

arc rays will damage your eyes and burn your skin if you are not

properly protected.

• To protect your eyes, always wear a welding helmet or shield.

Also always wear safety glasses with side shields, goggles or

other protective eye wear.

• Wear welding gloves and suitable clothing to protect your skin

from the arc rays and sparks.

• Keep helmet and safety glasses in good condition. Replace

lenses when cracked, chipped or dirty.

• Protect others in the work area from the arc rays. Use protective

booths, screens or shields.

• Use the shade of lens as suggested in the following per ANSI/

ASC Z49.1:

Minimum Protective Suggested

Arc Current Shade No. Shade No.

Less Than 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

* These values apply where the actual arc is clearly seen.

Experience has shown that lighter filters may be used

when the arc is hidden by the workpiece.

LEAD WARNING

This product contains chemicals, including lead, or otherwise produces chemicals known to the State of California to cause cancer, birth

defects and other reproductive harm. Wash hands after handling.

(California Health & Safety Code § 25249.5 et seq.)

1-2

2. ANSI Standard Z49.1, SAFETY IN WELDING AND CUTTING,

obtainable from the American Welding Society, 550 N.W.

LeJeune Rd, Miami, FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC WELDING AND GAS

WELDING AND CUTTING, obtainable from the Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402

4. ANSI Standard Z87.1, SAFE PRACTICES FOR OCCUPATION

AND EDUCATIONAL EYE AND FACE PROTECTION, obtainable from American National Standards Institute, 1430

Broadway, New York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN’S SAFETY-TOE

FOOTWEAR, obtainable from the American National Standards Institute, 1430 Broadway, New York, NY 10018

6. ANSI Standard Z49.2, FIRE PREVENTION IN THE USE OF

CUTTING AND WELDING PROCESSES, obtainable from

American National Standards Institute, 1430 Broadway,

New York, NY 10018

7. AWS Standard A6.0, WELDING AND CUTTING CONTAINERS WHICH HAVE HELD COMBUSTIBLES, obtainable from

American Welding Society, 550 N.W. LeJeune Rd, Miami,

FL 33126

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS FOR

WELDING, CUTTING AND ALLIED PROCESSES, obtainable

from the National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

9. NFPA Standard 70, NATIONAL ELECTRICAL CODE, obtainable from the National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

10. NFPA Standard 51B, CUTTING AND WELDING PROCESSES,

obtainable from the National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

11. CGA Pamphlet P-1, SAFE HANDLING OF COMPRESSED

GASES IN CYLINDERS, obtainable from the Compressed

Gas Association, 1235 Jefferson Davis Highway, Suite 501,

Arlington, VA 22202

12. CSA Standard W117.2, CODE FOR SAFETY IN WELDING

AND CUTTING, obtainable from the Canadian Standards

Association, Standards Sales, 178 Rexdale Boulevard,

Rexdale, Ontario, Canada M9W 1R3

13. NWSA booklet, WELDING SAFETY BIBLIOGRAPHY obtainable from the National Welding Supply Association, 1900

Arch Street, Philadelphia, PA 19103

14. American Welding Society Standard AWSF4.1, RECOMMENDED SAFE PRACTICES FOR THE PREPARATION FOR

WELDING AND CUTTING OF CONTAINERS AND PIPING

Manual 0-5133

Page 11

THAT HAVE HELD HAZARDOUS SUBSTANCES, obtainable

!

from the American Welding Society, 550 N.W. LeJeune Rd,

Miami, FL 33126

ULTRA-CUT 200

FUMÉE et GAZ

15. ANSI Standard Z88.2, PRACTICE FOR RESPIRATORY PROTECTION, obtainable from American National Standards

Institute, 1430 Broadway, New York, NY 10018

1.04 Note, Attention et Avertissement

Dans ce manuel, les mots “note,” “attention,” et “avertissement” sont

utilisés pour mettre en relief des informations à caractère important.

Ces mises en relief sont classifiées comme suit :

NOTE

Toute opération, procédure ou renseignement général sur

lequel il importe d’insister davantage ou qui contribue à

l’efficacité de fonctionnement du système.

ATTENTION

Toute procédure pouvant résulter l’endommagement du

matériel en cas de non-respect de la procédure en

question.

AVERTISSEMENT

Toute procédure pouvant provoquer des blessures de

l’opérateur ou des autres personnes se trouvant dans la

zone de travail en cas de non-respect de la procédure en

question.

1.05 Precautions De Securite Importantes

AVERTISSEMENTS

L’OPÉRATION ET LA MAINTENANCE DU MATÉRIEL DE

SOUDAGE À L’ARC AU JET DE PLASMA PEUVENT

PRÉSENTER DES RISQUES ET DES DANGERS DE

SANTÉ.

La fumée et les gaz produits par le procédé de jet de plasma peuvent

présenter des risques et des dangers de santé.

• Eloignez toute fumée et gaz de votre zone de respiration. Gardez

votre tête hors de la plume de fumée provenant du chalumeau.

• Utilisez un appareil respiratoire à alimentation en air si l’aération

fournie ne permet pas d’éliminer la fumée et les gaz.

• Les sortes de gaz et de fumée provenant de l’arc de plasma dépendent

du genre de métal utilisé, des revêtements se trouvant sur le métal et

des différents procédés. Vous devez prendre soin lorsque vous

coupez ou soudez tout métal pouvant contenir un ou plusieurs des

éléments suivants:

antimoine cadmium mercure

argent chrome nickel

arsenic cobalt plomb

baryum cuivre sélénium

béryllium manganèse vanadium

• Lisez toujours les fiches de données sur la sécurité des matières

(sigle américain “MSDS”); celles-ci devraient être fournies avec le

matériel que vous utilisez. Les MSDS contiennent des

renseignements quant à la quantité et la nature de la fumée et des gaz

pouvant poser des dangers de santé.

• Pour des informations sur la manière de tester la fumée et les gaz de

votre lieu de travail, consultez l’article 1 et les documents cités à la

page 5.

• Utilisez un équipement spécial tel que des tables de coupe à débit

d’eau ou à courant descendant pour capter la fumée et les gaz.

• N’utilisez pas le chalumeau au jet de plasma dans une zone où se

trouvent des matières ou des gaz combustibles ou explosifs.

• Le phosgène, un gaz toxique, est généré par la fumée provenant des

solvants et des produits de nettoyage chlorés. Eliminez toute source

de telle fumée.

• Ce produit, dans le procéder de soudage et de coupe, produit de la

fumée ou des gaz pouvant contenir des éléments reconnu dans

L’état de la Californie, qui peuvent causer des défauts de naissance et

le cancer. (La sécurité de santé en Californie et la code sécurité Sec.

25249.5 et seq.)

Coupant à l’arc au jet de plasma produit de l’énergie

électrique haute tension et des émissions magnétique qui

peuvent interférer la fonction propre d’un “pacemaker”

cardiaque, les appareils auditif, ou autre matériel de santé

electronique. Ceux qui travail près d’une application à

l’arc au jet de plasma devrait consulter leur membre

professionel de médication et le manufacturier de matériel

de santé pour déterminer s’il existe des risques de santé.

Il faut communiquer aux opérateurs et au personnel TOUS

les dangers possibles. Afin d’éviter les blessures

possibles, lisez, comprenez et suivez tous les

avertissements, toutes les précautions de sécurité et toutes

les consignes avant d’utiliser le matériel. Composez le +

603-298-5711 ou votre distributeur local si vous avez

des questions.

Manual 0-5133

CHOC ELECTRIQUE

Les chocs électriques peuvent blesser ou même tuer. Le procédé au jet de

plasma requiert et produit de l’énergie électrique haute tension. Cette

énergie électrique peut produire des chocs graves, voire mortels, pour

l’opérateur et les autres personnes sur le lieu de travail.

• Ne touchez jamais une pièce “sous tension” ou “vive”; portez des

gants et des vêtements secs. Isolez-vous de la pièce de travail ou des

autres parties du circuit de soudage.

• Réparez ou remplacez toute pièce usée ou endommagée.

• Prenez des soins particuliers lorsque la zone de travail est humide

ou moite.

1-3

Page 12

ULTRA-CUT 200

• Montez et maintenez le matériel conformément au Code électrique

national des Etats-Unis. (Voir la page

• Débranchez l’alimentation électrique avant tout travail d’entretien

ou de réparation.

• Lisez et respectez toutes les consignes du Manuel de consignes.

INCENDIE ET EXPLOSION

Les incendies et les explosions peuvent résulter des scories chaudes,

des étincelles ou de l’arc de plasma. Le procédé à l’arc de plasma

produit du métal, des étincelles, des scories chaudes pouvant mettre le

feu aux matières combustibles ou provoquer l’explosion de fumées

inflammables.

• Soyez certain qu’aucune matière combustible ou inflammable ne se

trouve sur le lieu de travail. Protégez toute telle matière qu’il est

impossible de retirer de la zone de travail.

• Procurez une bonne aération de toutes les fumées inflammables ou

explosives.

• Ne coupez pas et ne soudez pas les conteneurs ayant pu renfermer

des matières combustibles.

• Prévoyez une veille d’incendie lors de tout travail dans une zone

présentant des dangers d’incendie.

• Le gas hydrogène peut se former ou s’accumuler sous les pièces de

travail en aluminium lorsqu’elles sont coupées sous l’eau ou sur

une table d’eau. NE PAS couper les alliages en aluminium sous

l’eau ou sur une table d’eau à moins que le gas hydrogène peut

s’échapper ou se dissiper. Le gas hydrogène accumulé explosera si

enflammé.

5,

article 9.)

• Utilisez la nuance de lentille qui est suggèrée dans le recommendation qui suivent ANSI/ASC Z49.1:

Nuance Minimum Nuance Suggerée

Courant Arc Protective Numéro Numéro

Moins de 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

* Ces valeurs s’appliquent ou l’arc actuel est observé

clairement. L’experience a démontrer que les filtres moins

foncés peuvent être utilisés quand l’arc est caché par

moiceau de travail.

BRUIT

Le bruit peut provoquer une perte permanente de l’ouïe. Les procédés

de soudage à l’arc de plasma peuvent provoquer des niveaux sonores

supérieurs aux limites normalement acceptables. Vous dú4ez vous

protéger les oreilles contre les bruits forts afin d’éviter une perte

permanente de l’ouïe.

• Pour protéger votre ouïe contre les bruits forts, portez des tampons

protecteurs et/ou des protections auriculaires. Protégez également

les autres personnes se trouvant sur le lieu de travail.

• Il faut mesurer les niveaux sonores afin d’assurer que les décibels

(le bruit) ne dépassent pas les niveaux sûrs.

• Pour des renseignements sur la manière de tester le bruit, consultez

l’article 1, page 5.

RAYONS D’ARC DE PLASMA

Les rayons provenant de l’arc de plasma peuvent blesser vos yeux et

brûler votre peau. Le procédé à l’arc de plasma produit une lumière

infra-rouge et des rayons ultra-violets très forts. Ces rayons d’arc nuiront

à vos yeux et brûleront votre peau si vous ne vous protégez pas

correctement.

• Pour protéger vos yeux, portez toujours un casque ou un écran de

soudeur. Portez toujours des lunettes de sécurité munies de parois

latérales ou des lunettes de protection ou une autre sorte de protection oculaire.

• Portez des gants de soudeur et un vêtement protecteur approprié

pour protéger votre peau contre les étincelles et les rayons de l’arc.

• Maintenez votre casque et vos lunettes de protection en bon état.

Remplacez toute lentille sale ou comportant fissure ou rognure.

• Protégez les autres personnes se trouvant sur la zone de travail

contre les rayons de l’arc en fournissant des cabines ou des écrans

de protection.

PLOMB AVERTISSEMENT

Ce produit contient des produits chimiques, comme le plomb, ou

engendre des produits chimiques, reconnus par l’état de Californie

comme pouvant être à l’origine de cancer, de malformations fœtales ou

d’autres problèmes de reproduction. Il faut se laver les mains après

toute manipulation. (Code de Californie de la sécurité et santé,

paragraphe 25249.5 et suivants)

1-4

Manual 0-5133

Page 13

1.06 Documents De Reference

Consultez les normes suivantes ou les révisions les plus récentes ayant

été faites à celles-ci pour de plus amples renseignements :

1. OSHA, NORMES DE SÉCURITÉ DU TRAVAIL ET DE PROTECTION

DE LA SANTÉ, 29CFR 1910, disponible auprès du Superintendent

of Documents, U.S. Government Printing Office, Washington, D.C.

20402

2. Norme ANSI Z49.1, LA SÉCURITÉ DES OPÉRATIONS DE COUPE ET

DE SOUDAGE, disponible auprès de la Société Américaine de

Soudage (American Welding Society), 550 N.W. LeJeune Rd., Miami, FL 33126

3. NIOSH, LA SÉCURITÉ ET LA SANTÉ LORS DES OPÉRATIONS DE

COUPE ET DE SOUDAGE À L’ARC ET AU GAZ, disponible auprès du

Superintendent of Documents, U.S. Government Printing Office,

Washington, D.C. 20402

4. Norme ANSI Z87.1, PRATIQUES SURES POUR LA PROTECTION

DES YEUX ET DU VISAGE AU TRAVAIL ET DANS LES ECOLES,

disponible de l’Institut Américain des Normes Nationales (American

National Standards Institute), 1430 Broadway, New York, NY 10018

5. Norme ANSI Z41.1, NORMES POUR LES CHAUSSURES

PROTECTRICES, disponible auprès de l’American National Standards Institute, 1430 Broadway, New York, NY 10018

ULTRA-CUT 200

14. Norme AWSF4.1 de l’Association Américaine de Soudage,

RECOMMANDATIONS DE PRATIQUES SURES POUR LA

PRÉPARATION À LA COUPE ET AU SOUDAGE DE CONTENEURS

ET TUYAUX AYANT RENFERMÉ DES PRODUITS DANGEREUX ,

disponible auprès de la American Welding Society, 550 N.W. LeJeune

Rd., Miami, FL 33126

15. Norme ANSI Z88.2, PRATIQUES DE PROTECTION RESPIRATOIRE,

disponible auprès de l’American National Standards Institute, 1430

Broadway, New York, NY 10018

6. Norme ANSI Z49.2, PRÉVENTION DES INCENDIES LORS DE

L’EMPLOI DE PROCÉDÉS DE COUPE ET DE SOUDAGE, disponible

auprès de l’American National Standards Institute, 1430 Broadway,

New York, NY 10018

7. Norme A6.0 de l’Association Américaine du Soudage (AWS), LE

SOUDAGE ET LA COUPE DE CONTENEURS AYANT RENFERMÉ DES

PRODUITS COMBUSTIBLES, disponible auprès de la American

Welding Society, 550 N.W. LeJeune Rd., Miami, FL 33126

8. Norme 51 de l’Association Américaine pour la Protection contre les

Incendies (NFPA), LES SYSTEMES À GAZ AVEC ALIMENTATION

EN OXYGENE POUR LE SOUDAGE, LA COUPE ET LES PROCÉDÉS

ASSOCIÉS, disponible auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269

9. Norme 70 de la NFPA, CODE ELECTRIQUE NATIONAL, disponible

auprès de la National Fire Protection Association, Batterymarch Park,

Quincy, MA 02269

10. Norme 51B de la NFPA, LES PROCÉDÉS DE COUPE ET DE

SOUDAGE, disponible auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269

11. Brochure GCA P-1, LA MANIPULATION SANS RISQUE DES GAZ

COMPRIMÉS EN CYLINDRES, disponible auprès de l’Association

des Gaz Comprimés (Compressed Gas Association), 1235 Jefferson

Davis Highway, Suite 501, Arlington, VA 22202

12. Norme CSA W117.2, CODE DE SÉCURITÉ POUR LE SOUDAGE ET

LA COUPE, disponible auprès de l’Association des Normes

Canadiennes, Standards Sales, 178 Rexdale Boulevard, Rexdale,

Ontario, Canada, M9W 1R3

13. Livret NWSA, BIBLIOGRAPHIE SUR LA SÉCURITÉ DU SOUDAGE,

disponible auprès de l’Association Nationale de Fournitures de

Soudage (National Welding Supply Association), 1900 Arch Street,

Philadelphia, PA 19103

Manual 0-5133

1-5

Page 14

ULTRA-CUT 200

1.07 Declaration of Conformity

Manufacturer: Thermal Dynamics Corporation

Address: 82 Benning Street

West Lebanon, New Hampshire 03784

USA

The equipment described in this manual conforms to all applicable aspects and regulations of the ‘Low Voltage Directive’ (2006/95 EC) and to the

National legislation for the enforcement of this Directive.

The equipment described in this manual conforms to all applicable aspects and regulations of the “EMC Directive” (European Council Directive 89/

336/EEC) and to the National legislation for the enforcement of this Directive.

Serial numbers are unique with each individual piece of equipment and details description, parts used to manufacture a unit and date of manufacture.

National Standard and Technical Specifications

The product is designed and manufactured to a number of standards and technical requirements. Among them are:

* CSA (Canadian Standards Association) standard C22.2 number 60 for Arc welding equipment.

* UL (Underwriters Laboratory) rating 94VO flammability testing for all printed-circuit boards used.

* CENELEC EN50199 EMC Product Standard for Arc Welding Equipment.

* ISO/IEC 60974-1 (BS 638-PT10) (EN 60 974-1) (EN50192) (EN50078) applicable to plasma cutting equipment and associated accessories.

* For environments with increased hazard of electrical shock, Power Supplies bearing the ‘S’ mark conform to EN50192 when used in

conjunction with hand torches with exposed cutting tips, if equipped with properly installed standoff guides.

* Extensive product design verification is conducted at the manufacturing facility as part of the routine design and manufacturing process. This

is to ensure the product is safe, when used according to instructions in this manual and related industry standards, and performs as specified.

Rigorous testing is incorporated into the manufacturing process to ensure the manufactured product meets or exceeds all design specifications.

Thermal Dynamics has been manufacturing products for more than 30 years, and will continue to achieve excellence in our area of manufacture.

Manufacturers responsible representative: Steve Ward

Operations Director

Thermadyne Europe

Europa Building

Chorley N Industrial Park

Chorley, Lancashire,

1-6

England PR6 7BX

Manual 0-5133

Page 15

ULTRA-CUT 200

1.08 Statement of Warranty

LIMITED WARRANTY : Thermal Dynamics® Corporation (hereinafter “Thermal”) warrants that its products will be free of defects in workmanship

or material. Should any failure to conform to this warranty appear within the time period applicable to the Thermal products as stated below ,

Thermal shall, upon notification thereof and substantiation that the product has been stored, installed, operated, and maintained in accordance

with Thermal’s specifications, instructions, recommendations and recognized standard industry practice, and not subject to misuse, repair ,

neglect, alteration, or accident, correct such defects by suitable repair or replacement, at Thermal’s sole option, of any components or parts

of the product determined by Thermal to be defective.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY WARRANTY OF MERCHANT ABILITY OR FITNESS FOR A P ARTICULAR

PURPOSE.

LIMIT A TION OF LIABILITY : Thermal shall not under any circumstances be liable for special or consequential damages, such as, but not

limited to, damage or loss of purchased or replacement goods, or claims of customers of distributor (hereinafter “Purchaser”) for service

interruption. The remedies of the Purchaser set forth herein are exclusive and the liability of Thermal with respect to any contract, or anything

done in connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery, resale, or use of any goods

covered by or furnished by Thermal whether arising out of contract, negligence, strict tort, or under any warranty , or otherwise, shall not,

except as expressly provided herein, exceed the price of the goods upon which such liability is based.

THIS WARRANTY BECOMES INVALID IF REPLACEMENT P ARTS OR ACCESSORIES ARE USED WHICH MA Y IMP AIR THE SAFETY OR

PERFORMANCE OF ANY THERMAL PRODUCT .

THIS WARRANTY IS INV ALID IF THE PRODUCT IS SOLD BY NON-AUTHORIZED PERSONS.

The limited warranty periods for this product shall be: A maximum of three (3) years from date of sale to an authorized distributor and a

maximum of two (2) years from date of sale by such distributor to the Purchaser, and with further limitations on such two (2) year period (see

chart below).

AutoCut

Parts

©

and UltraCut© Power Supplies and Components 2 Y ears 1 Y ear

Labor

Torch And Leads

TM

XT

-300 / XTTM-301 T orch (Excluding Consumable Parts) 1 Y ear 1 Y ear

Repair/Replacement Parts 90 Days 90 Days

Warranty repairs or replacement claims under this limited warranty must be submitted by an authorized Thermal Dynamics® repair facility

within thirty (30) days of the repair. No transportation cost s of any kind will be paid under this warranty. Transportation charges to send

products to an authorized warranty repair facility shall be the responsibility of the customer. All returned goods shall be at the customer’s risk

and expense. This warranty supersedes all previous Thermal warranties.

Effective August 19, 2005

Manual 0-5133

1-7

Page 16

ULTRA-CUT 200

1-8

Manual 0-5133

Page 17

SECTION 2: SPECIFICATIONS

2.01 General Description Of The System

A typical Ultra-Cut® 200 system configuration includes:

• One Power Supply

• Remote Arc Starter

• Gas Control Module

• Torch Valve Assembly

• Precision Plasma Cutting Torch

• Set Of Connecting Leads

• Torch Spare Parts Kit

The components are connected at installation.

2.02 Plasma Power Supply

The power supply provides the necessary current for cutting operations. The power supply also monitors system

performance, and cools and circulates the liquid coolant for the torch and leads.

2.03 Remote Arc Starter

This unit produces a temporary HF pulse to start the pilot arc. The pilot arc creates a path for the main arc to

transfer to the work. When the main arc is established, the pilot arc shuts off.

2.04 Gas Control Module

This module allows remote setting of gas selection, pressures, and flows together with setting of cutting current.

2.05 Precision Plasma Cutting Torch

The torch delivers the controlled current to the work through the main arc, causing the metal to be cut.

Manual No. 0-5133 Ultra-Cut 200 2-1 SPECIFICATIONS

Page 18

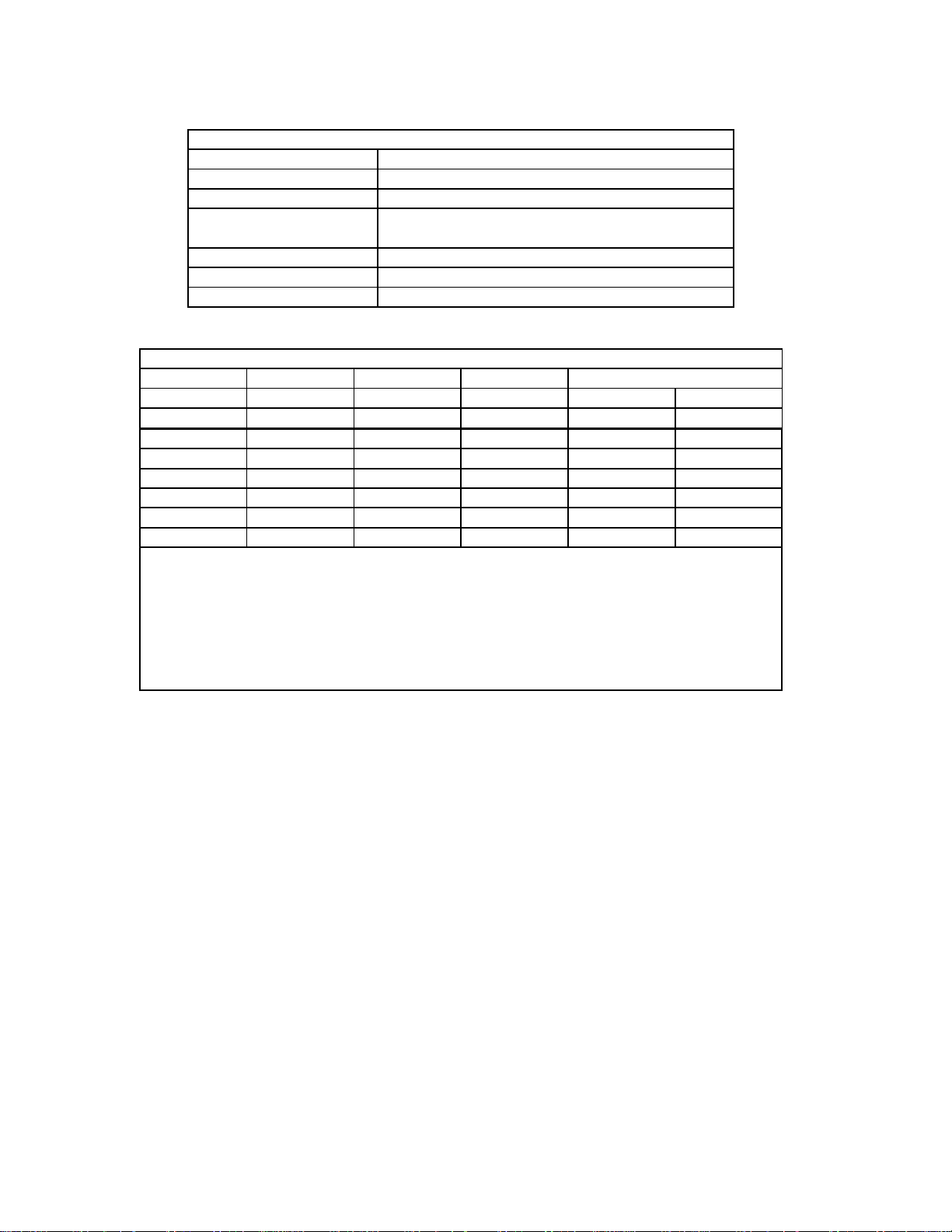

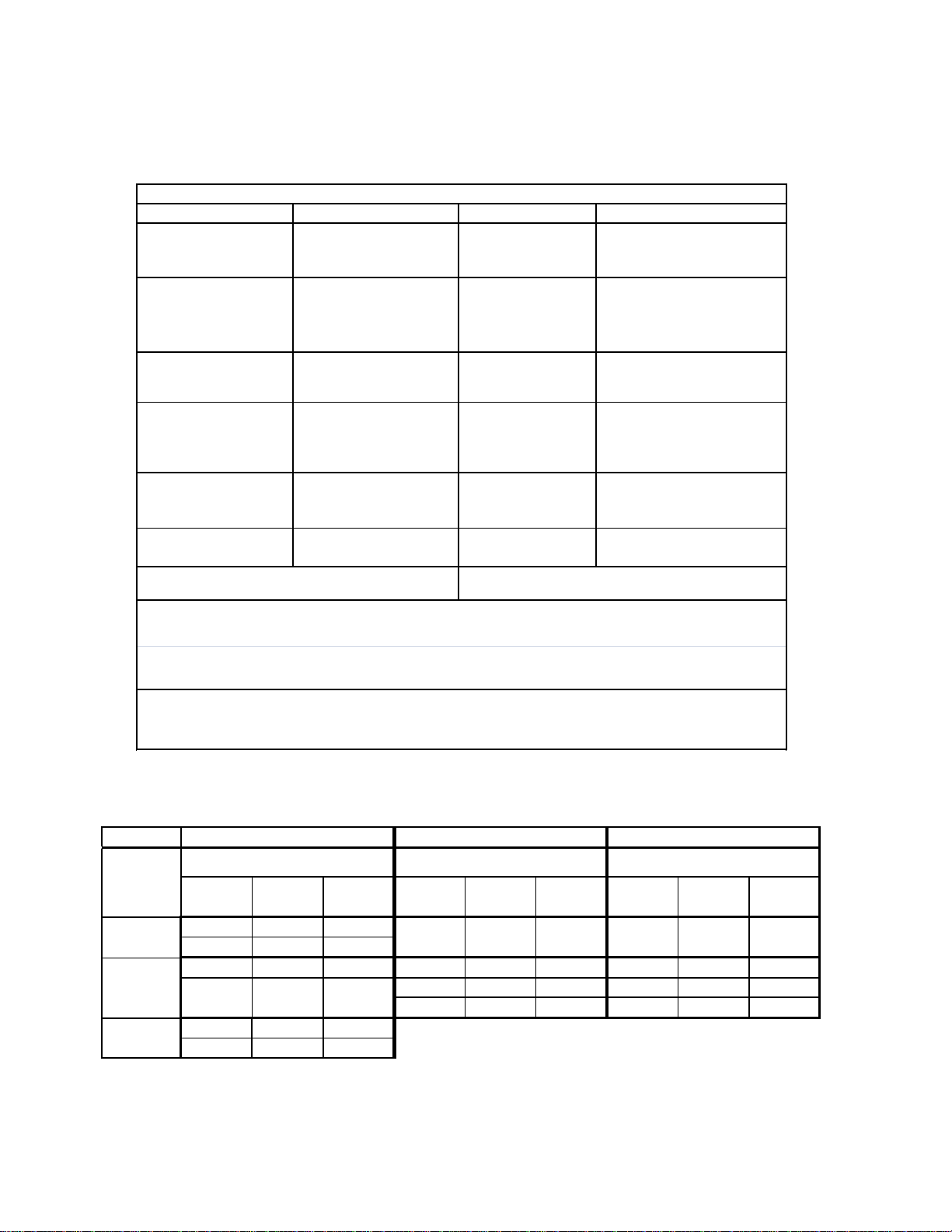

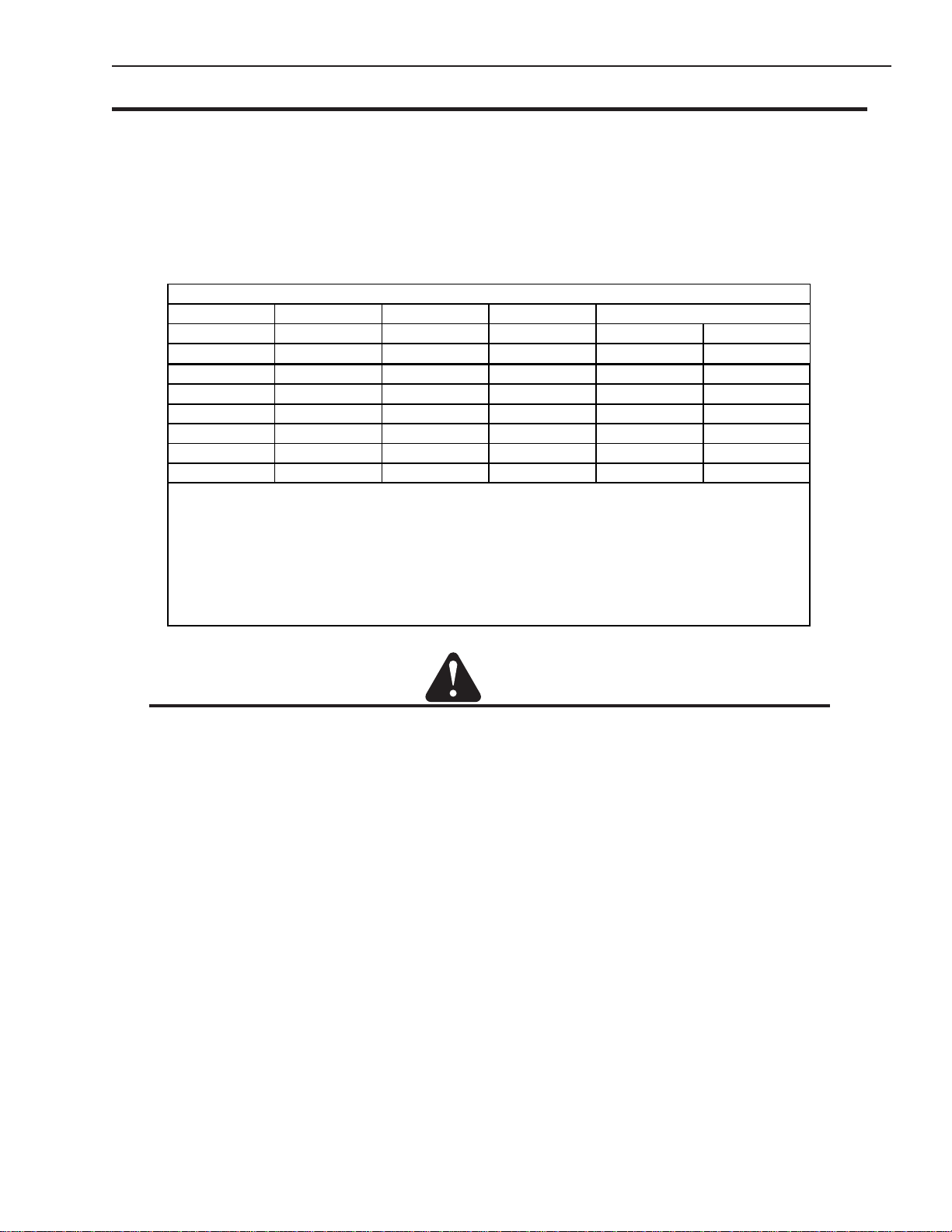

2.06 Specifications & Electrical Requirements

s

Ultra-Cut® 200 Power Supply Specifica tions

Maximum OCV (U0) 380 vdc

Maximu m Output C urrent 200 Amp s

Max im um Out put Voltage 230 vdc

Duty Cy cle Rating

Operating range 14°F to 122°F (-10°C to + 50°C)

Power Factor 0.70 @ 100 ADC Output

Cooli ng Forced Ai r (Cl a ss F )

Ultra-Cut 200 Powe r Suppl y Electrical I nput

Input Power Input Current

Volt age Freq. 3-Ph 3-Ph F us e (A m ps) Wire (AWG)

(Volts) (Hz) (kVA) (Amps) 3-Ph 3-Ph

208 50/60 46 130 160 #1

230 50/60 49 125 150 #1

380 50/60 52 81 100 #4

400 (CE) 50/60 52 77 90 #4

460 50/60 59 75 90 #4

600 50/60 52 51 60 #6

* Sugges t ed wire s i ze based on United S t at es NFPA 70 Nat i onal E l ec trical Code 2005 edit ion

publi shed by the Nat i ona l Fire Prevention A sso ciat i on .

Lis t ings are from rable 400.5(B ) for flexible cord of c ert ai n t ypes rated for 75 deg. C in ambient

temperat ures up t o 30 deg. C. Using wires of lower temperature rati ng or different insul at i on

ty pe m ay require larger wire s i ze. Derate for higher ambient t em perature.

W ire s i zes are sugges tions only. A lway s refer t o your local and nati onal codes t hat apply to

you r l ocati on for correc t wi re s izes.

100% @ 200A, 180vdc (32 kW),

@ 104F° (40°C) Ambient Temperature

Sugges t ed S i z es (See Note)

Manual No. 0-5133 Ultra-Cut 200 2-2 SPECIFICATIONS

Page 19

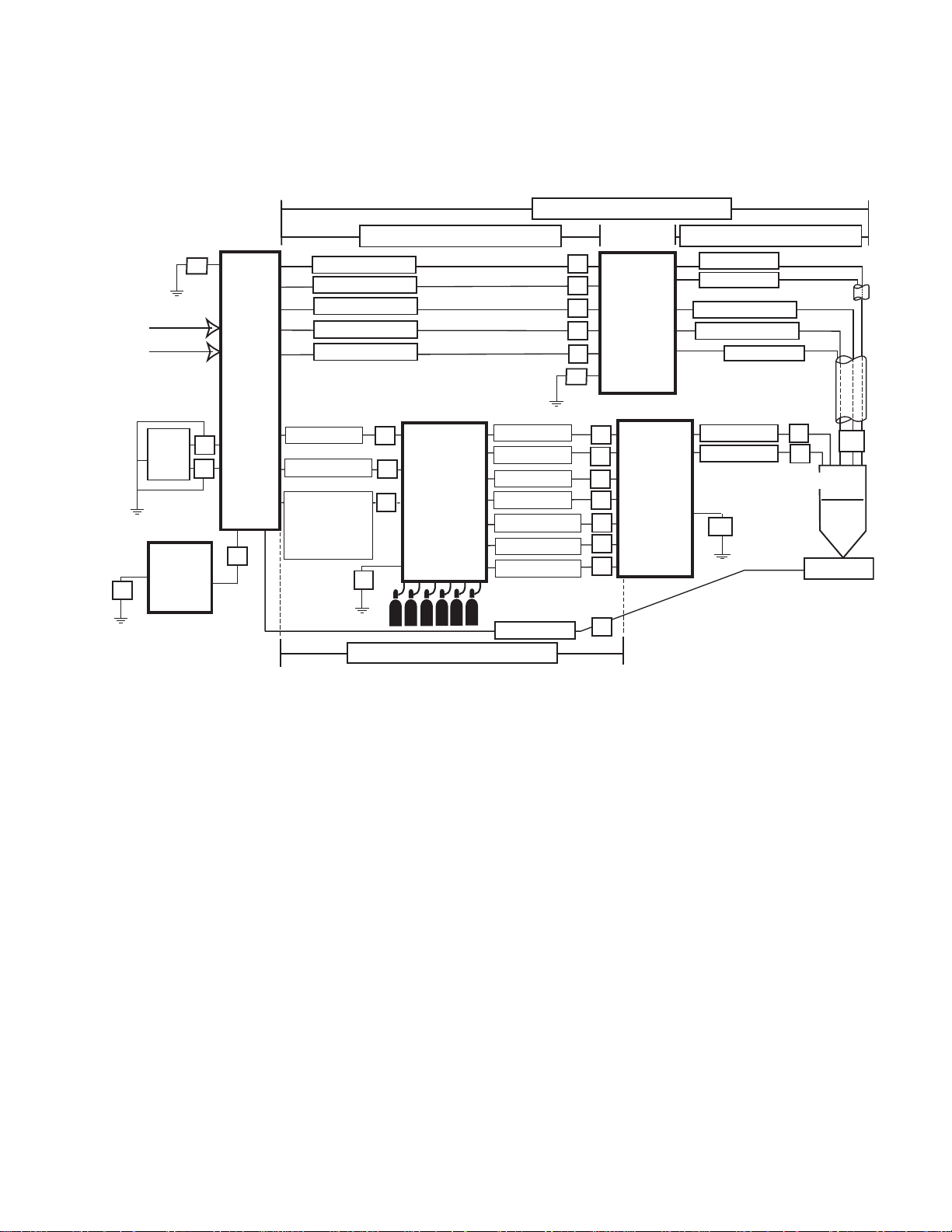

2.07 System Component Layout

Refer to section 3.11 for ground connections and ground cables.

175’ / 53.3 m Maximum Length

F

F1

Primary power

CNC

To uch

Screen

Controller

Art # A-09124_AB

W

P

Pilot Return

Ultra-Cut

Power

Supply

Fiber Optic

Control Cable

Ground Cable

Only When

DMC Mounted

On Top Of PS

V

125’ / 38.1 m Maximum Length

Negative

Coolant Supply

Coolant Return

Control Cable

L

K

DMC-3000

F

F

175’ / 53.3 m Maximum Length

Gas

Console

Plasma Gas

Fiber Optic

Shield Gas

Preflow

Control Cable

Water Shield

Marking

Work Cable

F1

100’ / 30.5 m Maximum Length

A

B

C

D

E

H

L

Q

R

S

T

U

O

Pilot Return

Remote

Arc

Starter

DPC-3000

Gas

Control

Shield

Coolant Supply

Coolant Return

Shield

Plasma Gas

Shield Gas

Positioning Tube

F

I

J

G

To r ch

Work

Manual No. 0-5133 Ultra-Cut 200 2-3 SPECIFICATIONS

Page 20

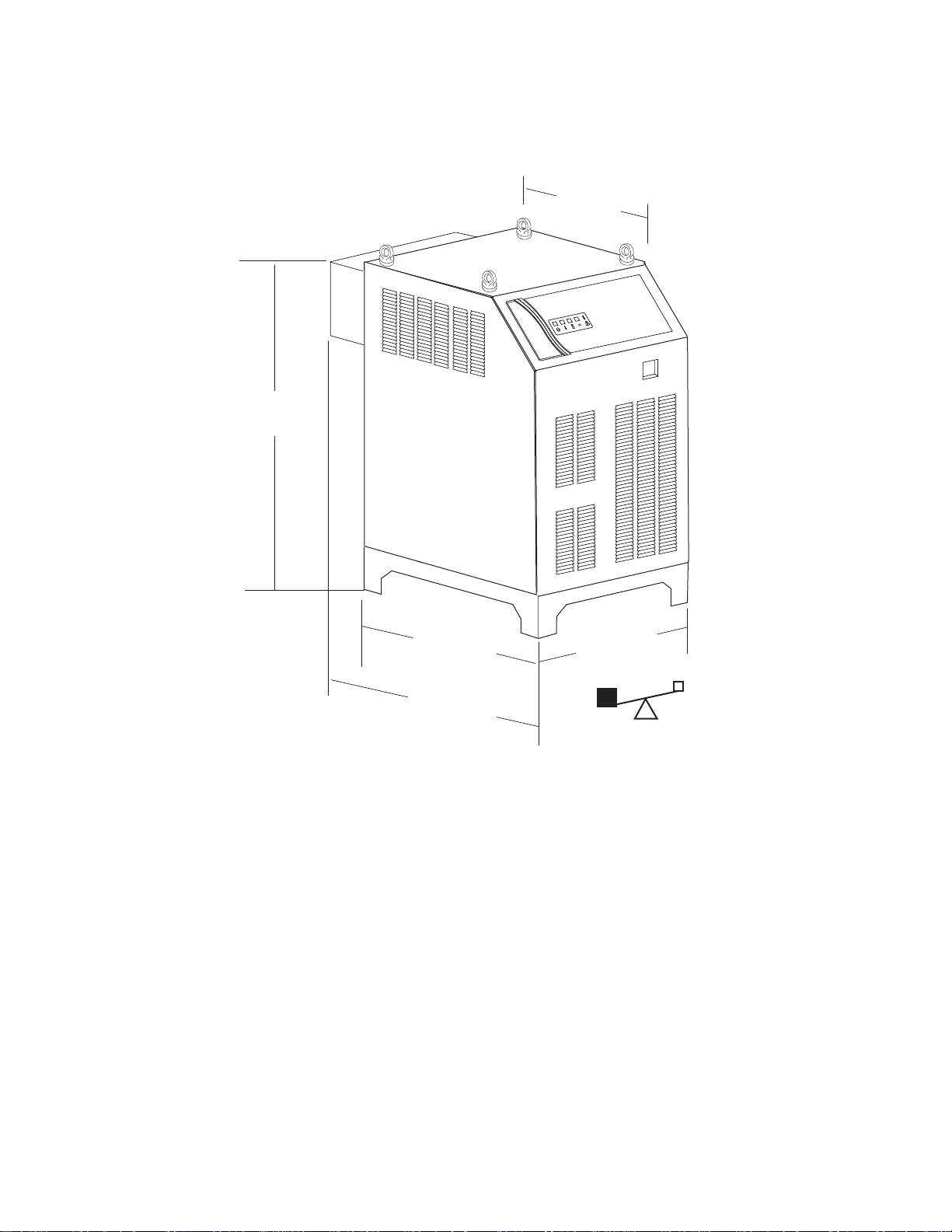

2.08 Power Supply Dimensions

41.25 inch

1050 mm

27 inch

680 mm

Art # A-07182

33 inch

840 mm

37.75 inch

960 mm

27.5 inch

700 mm

433 lb / 196 kg

Manual No. 0-5133 Ultra-Cut 200 2-4 SPECIFICATIONS

Page 21

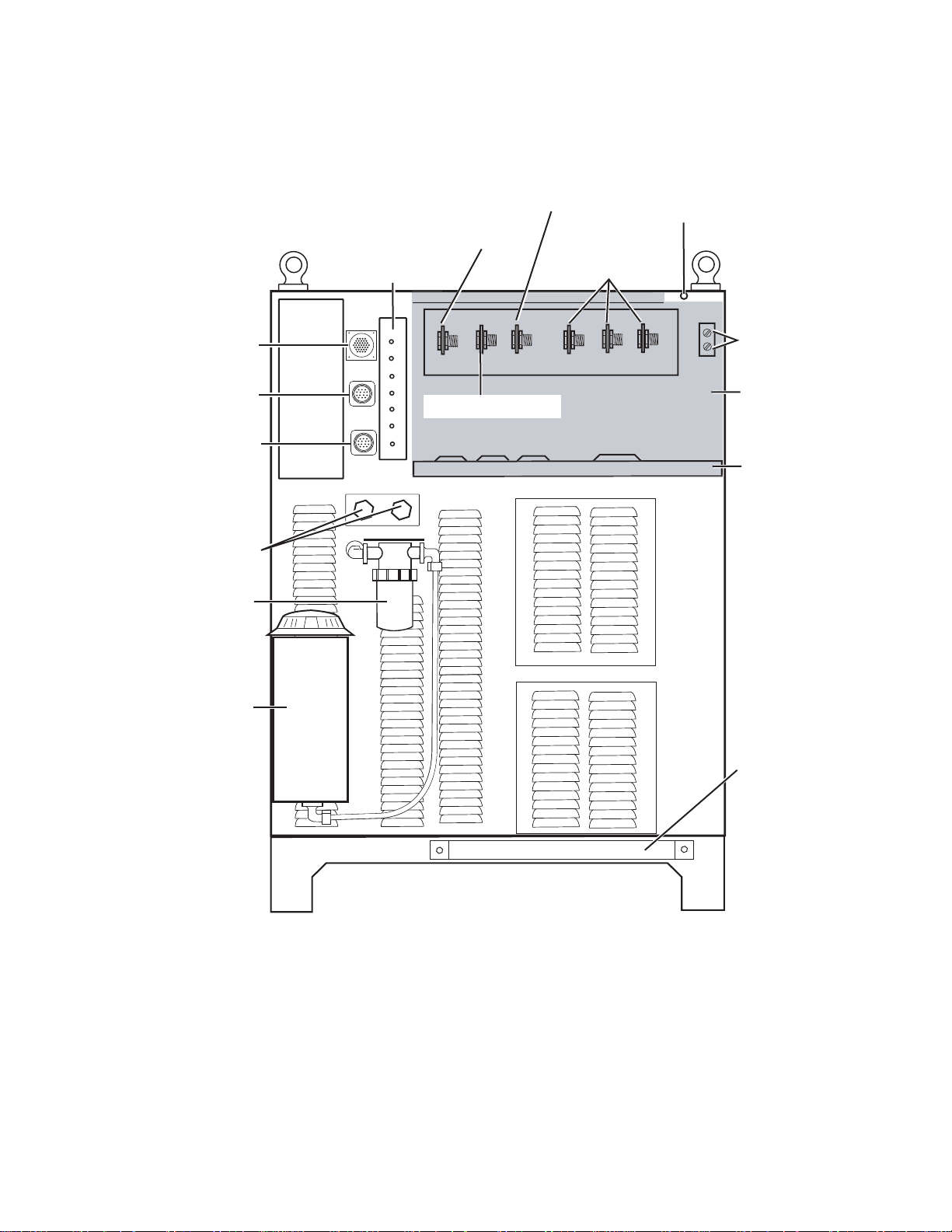

2.09 Power Supply Rear Panel Features

Gas Control

Console Connector

CNC Connector

Remote Arc Starter

Connector

Coolant Connections

Coolant Filter

Pilot (Pos) Terminal

Circuit Breaker

Panel

RETURN

SUPPLY

Torch (Neg) Terminal

AC Power Lamp

Input Power

Terminals

Ground Terminals

Terminal Cover

Work Cable Terminal

Terminal Cover

Support Panel

Coolant Tank

Leads

Bracket

Art # A-04794

Manual No. 0-5133 Ultra-Cut 200 2-5 SPECIFICATIONS

Page 22

2.10 Gas Requirements

pp

)

s

The customer will provide all gases and pressure regulators. Gases must be of high quality. Pressure regulators

shall be double stage.

Ultra-Cut 200 Powe r Suppl y: Gas Pre ssures, Fl ows, a nd Qua l ity Requirem ent

Gas Qualit y Minimum P res s ure Flow

O2 (Oxy gen)

N2 (Nitrogen)

Compressed

or Bottled Air

H35 (A rgon -Hydrogen)

H35 = 35% Hy drogen,

65% A rgon

Ar (Argon)

H2O (Wate r) See Not e 2

Note 1:

cont am inat ion from c om pres s ed or bott led ai r c an c aus e fires i n c onjunc t i on wit h ox y gen.

For filtering, a c oal es c i ng filter able t o filter t o 0. 01 m ic rons s houl d be ins t all ed as c l os e as

poss i ble t o t he gas inl ets on the Gas Control M odule.

Note 2

ext remel y high m i neral cont ent a wat er s oftener is rec omm ended. Tap water with high levels of

partic ulat e m at t er mus t be filt ered.

The air source mus t be adequat ely filt ered to rem ove all oil or greas e. Oil or grease

: The tap water sourc e does not need t o be deioniz ed, but in wat er s y stems wit h

99.5% P urit y

(Liquid recom m ended)

99.5% P urit y

(Liquid recom m ended)

<1000 ppm O2, < 32

m H2O

Clean, Dry ,

Free of Oil (see Note 1)

99.995% P urit y

(gas liquid

recommended)

99-995% Puri t y

(gas recom m ended)

120 psi

8.3 bar / 827 k P a

120 psi

8.3 bar / 827 k P a

120 psi

8.3 bar / 827 k P a

120 psi

8.3 bar / 827 k P a

80 psi

5.5 bar / 550 k P a

50 psi (3. 5 bar)

See Note 3

Max im um Input P res s ure 135 ps i (9.3 bar)

75 sc fh (2123 l/h)

180 sc fh (5097 l/h)

185 sc hf (5238 l/h)

85 sc fh (2406 l/h)

55 sc fh (1560 l/h)

10 gph (38 lph)

2.11 Gas Applications

MATERIAL

CUTTING

OUTPUT

FLOW

55 A

100 A

200 A

Manual No. 0-5133 Ultra-Cut 200 2-6 SPECIFICATIONS

MILD STEEL STAINLESS STEEL ALUMINUM

GAS TYPEGAS TYPE

PLASMA SHIELD

PRE-

PLASMA SHIELD

Air Air Air

Air O

2 Air

GAS TYPE

PRE-

FLOW

Air Air Air A ir

PLASMA SHIELD

Air Air

PRE-

FLOW

Air Air Air Air Air Air Air Air Air

Air

O

2

Air

N2 N

N2 H

2 H20N2 N2 H20

35

N

2

N2 H

35

Air Air Air

Air O

2

Air

N

2

Page 23

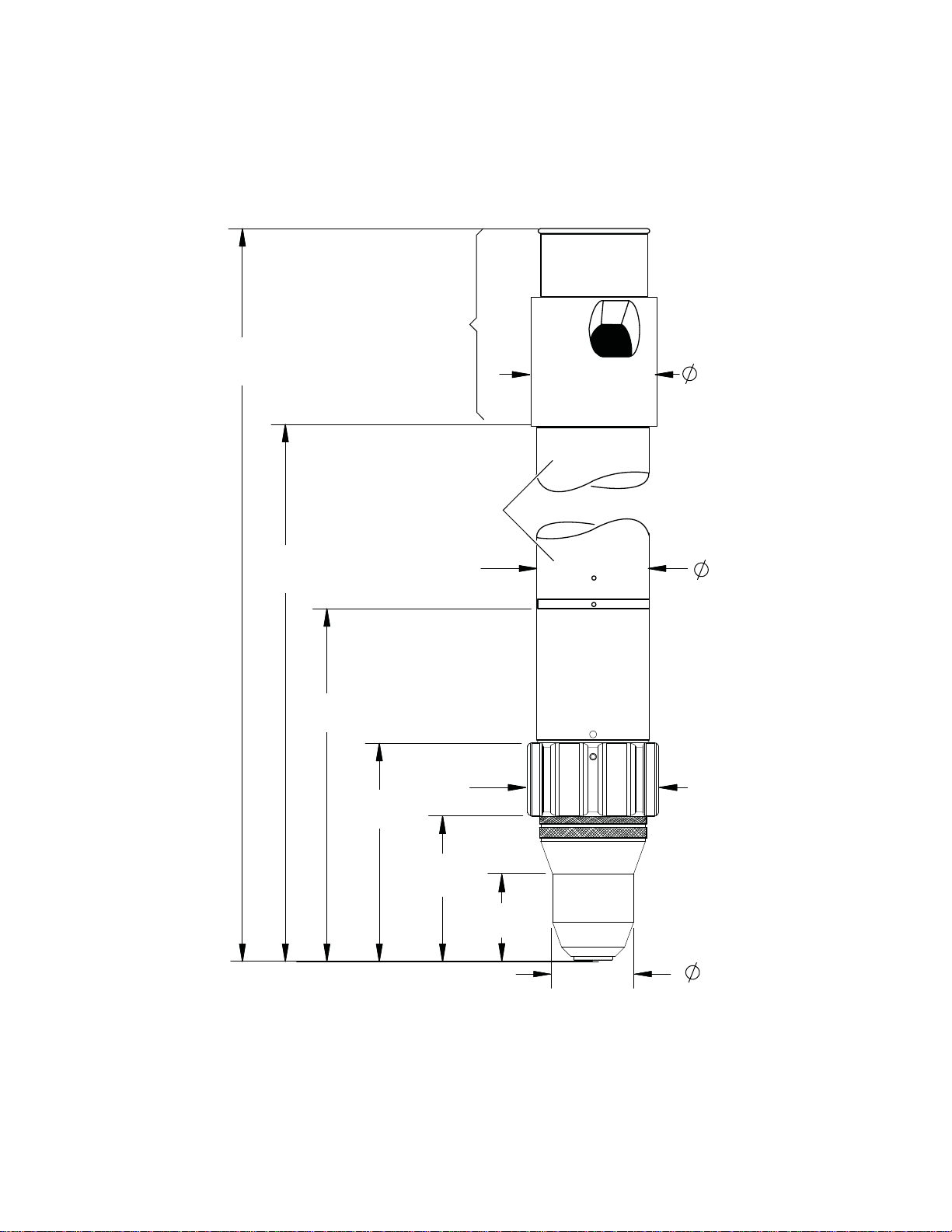

2.12 XTTM-300 Torch Specifications

A. Torch Dimensions

End Cap

Art # A-08301

19.00"

482.68 mm

393.78 mm

15.50"

160.10 mm

6.30"

3.98"

101.1 mm

2.25"

57.15 mm

Mounting Tube

2.0"

50.8 mm

2.39"

60.81 mm

2.63"

66.8 mm

1.57"

39.96 mm

1.49"

37.8 mm

Manual No. 0-5133 Ultra-Cut 200 2-7 SPECIFICATIONS

Page 24

B. Torch Leads Lengths

Gas Lead Assemblies

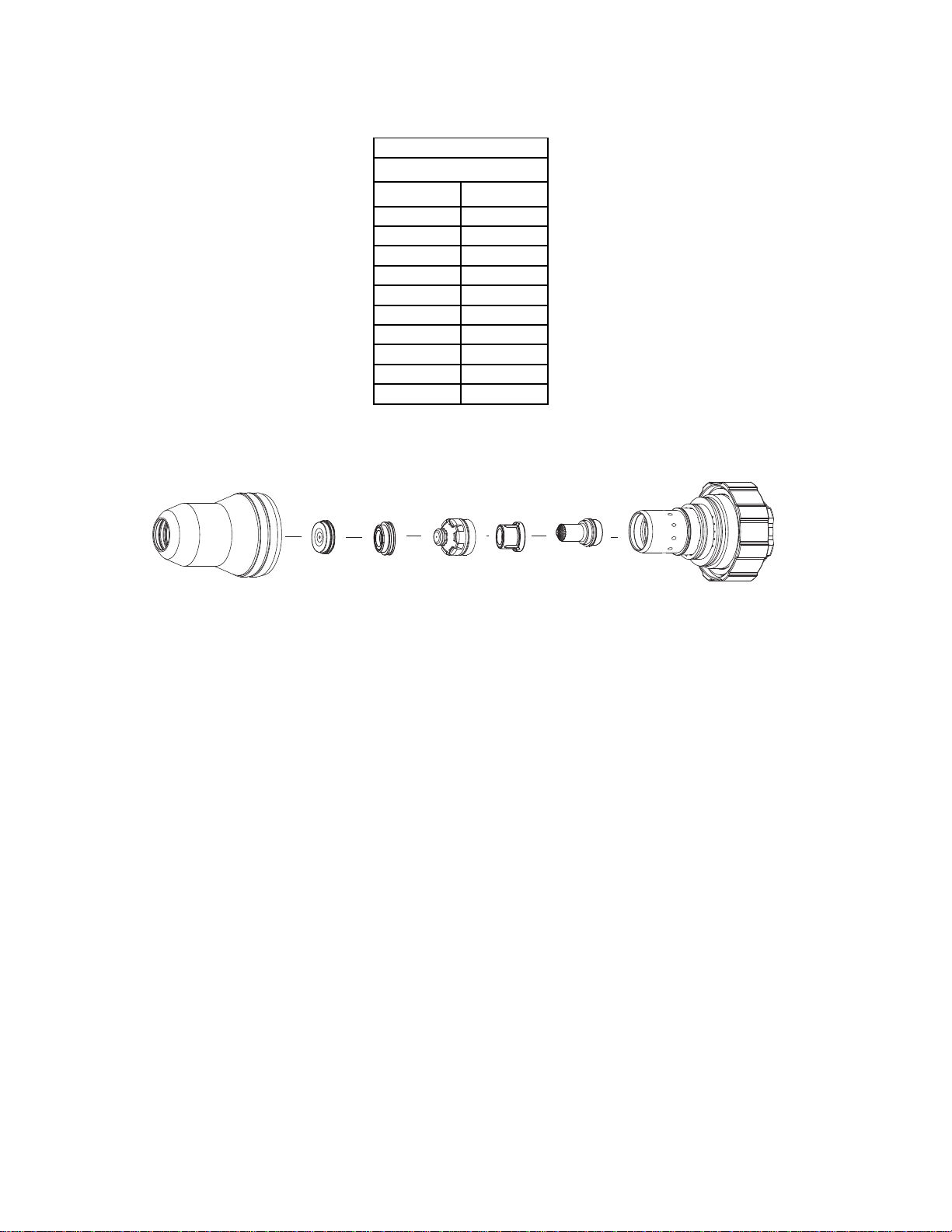

C. Torch Parts (Generic Parts Shown)

Length

Feet Meters

10 3.05

15 4.6

25 7.6

35 10.6

50 15.2

75 22.8

100 30.4

125 38.2

150 45.7

175 53.3

Art # A-04741

Shield Gas

Distributor

Shield Cap

Shield Cup

Tip

Plasma Gas

Distributor

Electrode

Cartridge

D. Parts - In - Place (PIP)

The torch is designed for use with a power supply which senses coolant return flow to confirm that torch

parts are in place. If coolant return flow to the power supply is absent or insufficient the power supply will

not provide power to the torch. Coolant leakage from the torch also indicates that torch parts are absent

or installed improperly.

E. Type of Cooling

Combination of gas stream through torch and liquid cooling.

Manual No. 0-5133 Ultra-Cut 200 2-8 SPECIFICATIONS

Page 25

F. XTTM-300 Torch Data (with Ultra-CutTM 200 Power Supply)

TM

XT

-300 Torch Ratings

for use wi th Ultra-Cut 200 Power S upp ly

Ambient

Tempera ture

Duty Cycle 100% @ 200 Am ps

Maxi m um Current 150 Amps

Volt age (V

)500V

peak

Arc Striking Voltage 10kV

Current

TM

XT

-300 Torch Gas Specifications

Plasma Gases:

Shield Gases:

Marking Gas A rgon

Operating Pres sure

Maxi m um Input P ressure 135 ps i / 9. 3 bar

104° F

40° C

Up to 200 Amps, DC,

Straight Polarity

Compress ed Ai r, Oxygen,

Nitrogen, H35

Compress ed Ai r, Oxygen,

Nitrogen, Water

125 ps i ± 10 psi

8.6 bar ± 0.7 bar

Manual No. 0-5133 Ultra-Cut 200 2-9 SPECIFICATIONS

Page 26

This Page Intentionally Blank

Manual No. 0-5133 Ultra-Cut 200 2-10 SPECIFICATIONS

Page 27

SECTION 3: INSTALLATION

s

3.01 Installation Requirements

Electric Supply

The electrical supply network, the gas and water supply system must meet local safety standards. This

conformity shall be checked by qualified personnel.

Ultra-Cut 200 Powe r Suppl y Electrical I nput

Input Power Input Current

Volt age Freq. 3-Ph 3-Ph F us e (A m ps) Wire (AWG)

(Volts) (Hz) (kVA) (Amps) 3-Ph 3-Ph

208 50/60 46 130 160 #1

230 50/60 49 125 150 #1

380 50/60 52 81 100 #4

400 (CE) 50/60 52 77 90 #4

460 50/60 59 75 90 #4

600 50/60 52 51 60 #6

* Sugges t ed wire s i ze based on United S t ates NFPA 70 Nat i onal E l ectric al Code 2005 edition

publi shed by the Nat i ona l Fire Prevention A ss ociat i on .

Lis t ings are from rable 400.5(B ) for flexible cord of certain types rated for 75 deg. C in ambient

temperat ures up t o 30 deg. C. Using wires of lower temperature rati ng or different insul at i on

ty pe m ay require larger wire s i ze. Derate for higher ambient t em perature.

W ire s i zes are sugges tions only. A lway s refer t o your local and nat ional codes t hat apply to

you r l ocati on for correc t wi re s izes.

ULTRA-CUT 200

Sugges t ed S i z es (See Note)

CAUTION

Fuse and wire sizes are for reference only. The installation must conform to national and local codes for the type

and method of wire being used.

Gas Supply

The customer must supply all gases and pressure regulators. Gases must be of high quality. Pressure

regulators must be double-stage and installed as close as possible to the gas console. Contaminated gas

can cause one or more of the following problems:

• Reduced cutting speed

• Poor cut quality

• Poor cutting precision

• Reduced consumables life.

• Oil or grease contamination from compressed or bottled air can cause fires in conjunction with oxygen.

Manual No. 0-5133 3-1 INSTALLATION

Page 28

ULTRA-CUT 200

Cooling System Requirements

Coolant must be added to the system on installation. The amount required varies with torch leads length.

Thermal Dynamics recommends the use of its coolants 7-3580 and 7-3581 (for low temperatures).

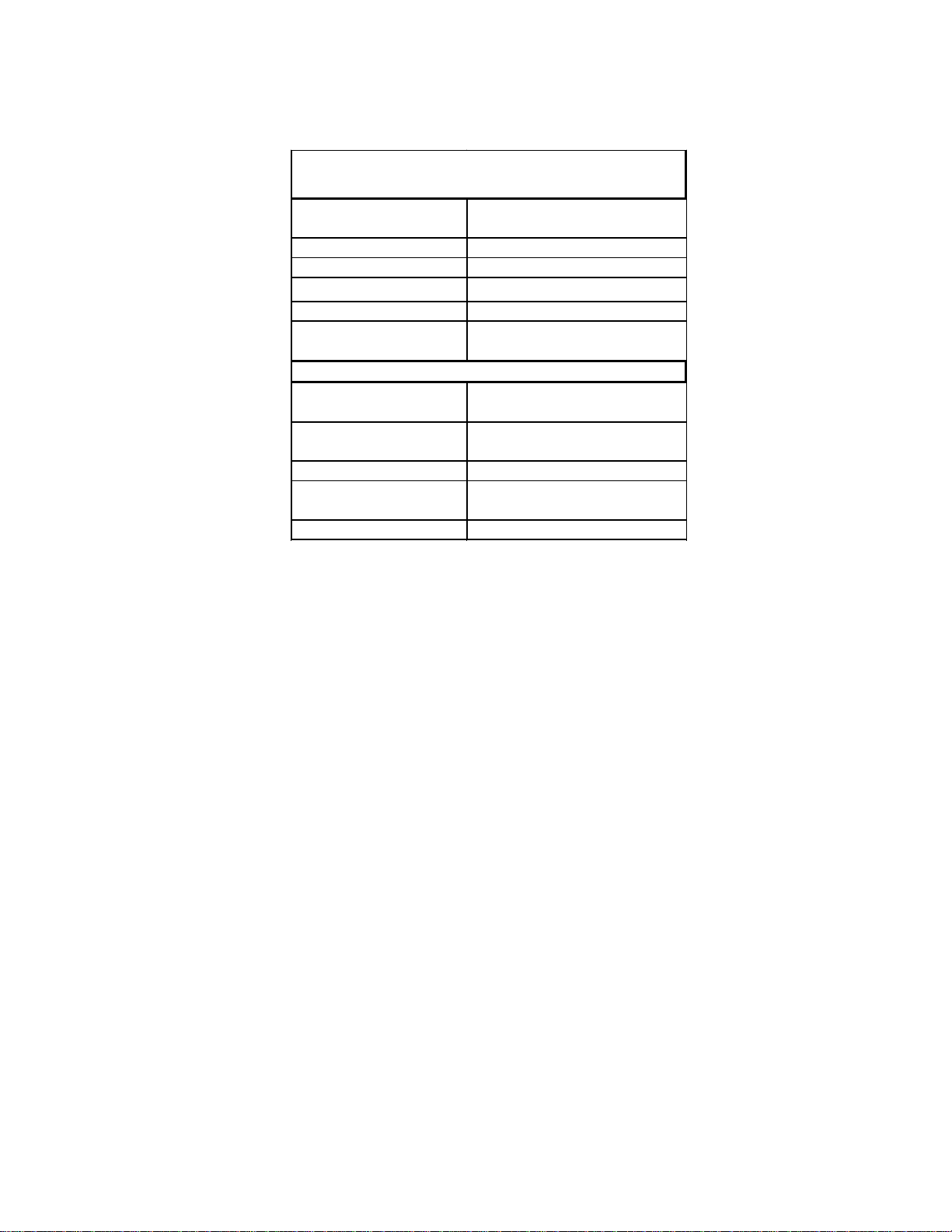

Coolant Capabilit i es

Cat. Number and Mixture Mixture Protects To

7-3580 'Extra-Cool

7-3581 'Ultra-Cool

7-3582 'Ext reme Cool

* For mixing with D-I Cool

TM

'

TM

'

TM

' Concent rate* -76° F / -60° C

TM

7-3583

3.02 System Layout

Refer to section 3.05 for ground connections and ground cables.

25 / 75 10° F / -12° C

50 / 50 -27° F / -33° C

Primary power

F

F1

W

CNC

P

To uch

Screen

Controller

Art # A-09124_AC

Pilot Return

Ultra-Cut

Power

Supply

Fiber Optic

Control Cable

Ground Cable

Only When

DMC Mounted

On Top Of PS

V

125’ / 38.1 m Maximum Length

Negative

Coolant Supply

Coolant Return

Control Cable

L

K

DMC-3000

F

F

175’ / 53.3 m Maximum Length

Gas

Console

175’ / 53.3 m Maximum Length

A

B

Remote

C

D

E

F1

Plasma Gas

Fiber Optic

Shield Gas

Preflow

Control Cable

Water Shield

Marking

Work Cable

Starter

H

L

Q

R

S

T

U

O

Arc

DPC-3000

100’ / 30.5 m Maximum Length

Pilot Return

Shield

Coolant Supply

Coolant Return

Plasma Gas

Shield Gas

Gas

Control

F

Shield

I

J

Positioning Tube

Torch

Work

G

INSTALLATION 3-2 Manual No. 0-5133

Page 29

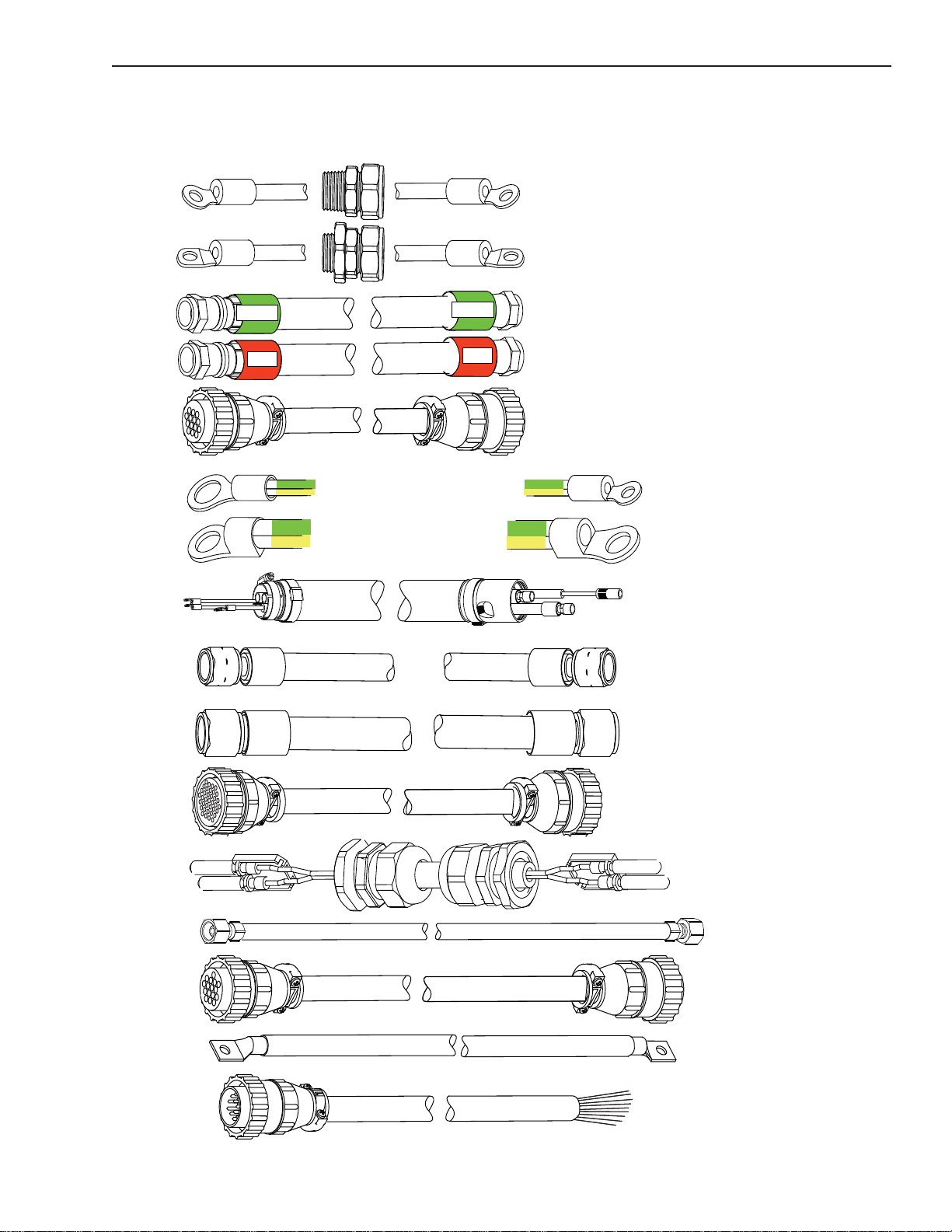

3.03 Cables & Leads Identification

ULTRA-CUT 200

B

C

D

E

F

F1

G

#8 AWG Cable

A

#1 AWG Cable

Green

Red

14

Green / Yellow #4 AWG (16 mm2)

Green / Yellow 1/0 (50 mm2)

Green

Red

Pilot Return, Power Supply

to Arc Starter

Negative Lead, Power Supply

to Arc Starter

Coolant Supply Lead,

Power Supply to Arc Starter

Coolant Return Lead,

Power Supply to Arc Starter

Control Cable, Power Supply

to Arc Starter

Ground Cable

Ground Cable,

Remote Arc Starter

To Earth Ground

Shielded Torch Lead

Assembly, Remote

Arc Starter to Torch

Art # A-09125_AC

I

J

K

L

H, Q,

R, T, U

S,V

16 pin

O

P, W

37

14/11

1/0 Cable (50 mm2 )

Plasma Gas Lead,

Torch Valve to Torch

Shield Gas Lead,

Torch Valve to Torch

Control Cable,

From Power Supply

Fiber Optic Cable,

Power Supply to

DMC-3000

For use with

DFC-3000

S - Control Cable,

DMC-3000

V - TSC-3000 to PS

Work Cable

P - CNC Cable (14 Wire)

W - CNC Communitcation

Cable (11 Wire)

to

DPC-3000

Manual No. 0-5133 3-3 INSTALLATION

Page 30

ULTRA-CUT 200

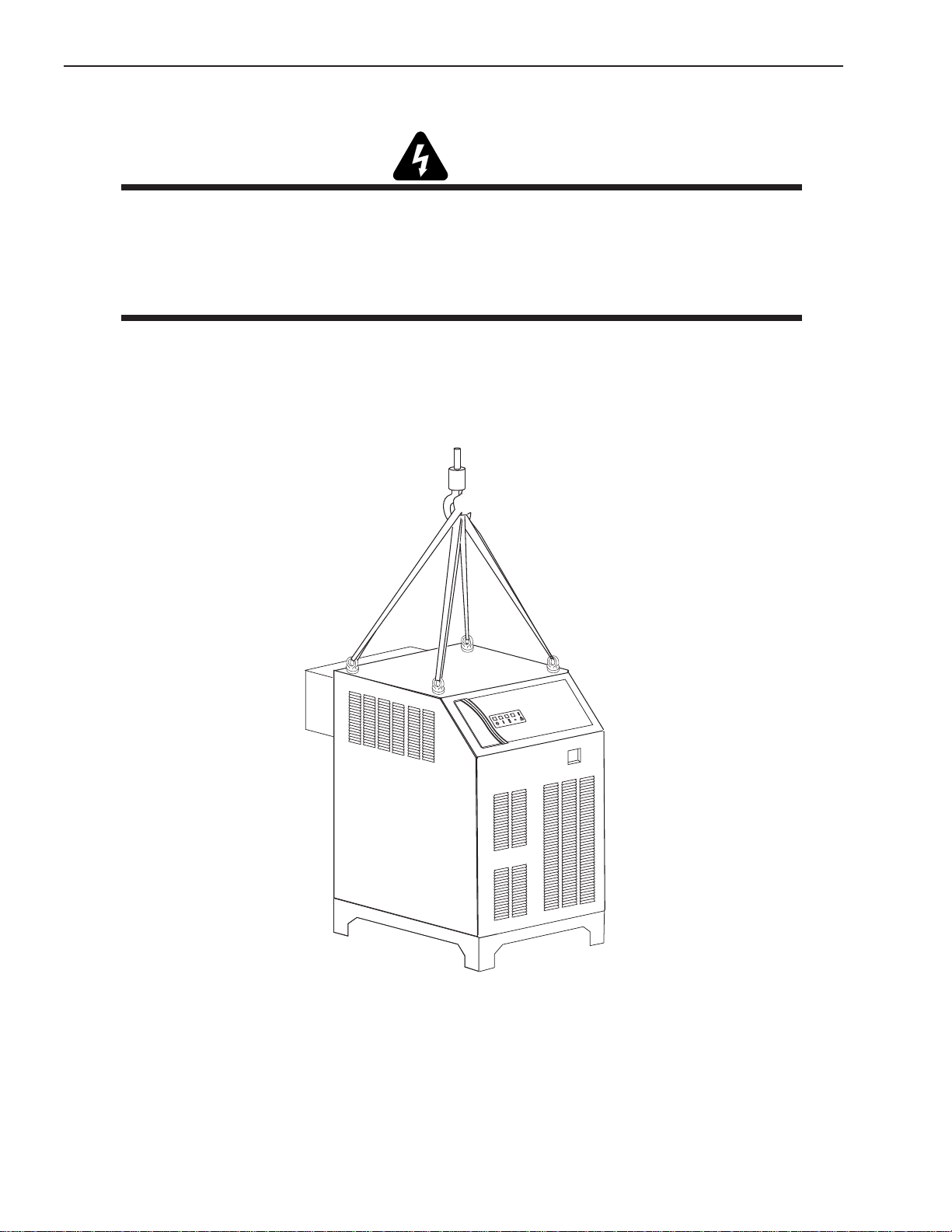

3.04 Lift the Power Supply

WARNINGS

Do not touch live electrical parts.

Disconnect input power conductors from de-energized supply line before moving unit.

FALLING EQUIPMENT can cause serious personal injury and equipment damage.

Use all four lifting eyes when using lifting straps to lift the power supply.

Use a forklift, crane, or hoist to lift the unit off the shipping pallet as shown. Keep the power supply steady and

vertical. Do not lift it any further than necessary to clear the shipping pallet. Ensure all panels and screws are

secure prior to lifting.

Art # A-04796

Set the power supply on a solid, level surface. The installer may fasten the power supply to the floor or a

supporting fixture with hardware passing through the horizontal parts of the power supply feet.

INSTALLATION 3-4 Manual No. 0-5133

Page 31

ULTRA-CUT 200

3.05 Remove the Connections Cover

The primary power cable must be supplied by the end user and connected to the power supply.

Remove the connections cover on the rear of the Power Supply. Use caution when removing the panel; there is a

ground wire connected to the inside of the panel. Do not disconnect this wire.

Connections Cover

(Removed)

Connection Panel

Art # A-04797

Manual No. 0-5133 3-5 INSTALLATION

Page 32

ULTRA-CUT 200

Check / Adjust Input Voltage Configuration for 208/230 and 460V Systems

1. The 208/230 and 460 V power supply includes a voltage configuration board which must be positioned to

match the primary input voltage. Remove the power supply left side panel and locate the voltage configuration

board. The input voltage configuration is shown at the top of the board.

2. If necessary, disconnect the jumper at the top right corner of the board, remove the board and re-install it with

the correct input voltage shown at the top of the board.

3. Re-connect the jumper. Re-install the power supply side panel.

Inverter Module

1. Unplug connector

208/230V / 460V

Input Voltage Board

(Shown in 460V Position)

2. Remove bolts.

3. Invert board.

4. Re-install board.

5. Plug in connector.

Art # A-04856_AB

INSTALLATION 3-6 Manual No. 0-5133

Page 33

ULTRA-CUT 200

Connect Input Power and System Ground Cables

1. Carefully cut back the outer sheath on the primary input power cable to expose the individual wires. Cut back

the insulation on the individual wires. Route the cable upward through leads bracket at the bottom of the rear

panel, then through the connections cover support panel on the rear panel of the power supply.

2. Install stripped end of 3 phase wires into the terminal block L1, L2 and L3.

3. Connect the individual cables as shown. Connect the power cable ground cord to the ground terminal block.

CAUTION

The clear connections cover must remain in place.

4. If required pass a system ground cable (F1) through the last opening in the connections cover support panel

next to the input power cable. Connect the cable to the ground terminal block on the power supply rear panel.

Refer to the Ground Connections Section for full details and procedures on proper system grounding.

Ground Terminal Block

Connections Cover

Connection Panel

3

to Remote Arc Starter

AC INPUT

L1 L2 L

PILOT

Art # A-07659_AB

K TORCH

OR

W

to Remote Arc Starter

L2

L1

Input power cable

L3

System Ground Cable

Input power cable ground

Connections Cover

Support Panel

System Ground Cable

Leads Bracket

Manual No. 0-5133 3-7 INSTALLATION

Page 34

ULTRA-CUT 200

3.06 Connect Work Cable and Pilot and Negative Leads

1. Pass the ends of the work cable and pilot and negative leads upward through the leads bracket at the

bottom edge of the rear panel, then through the openings in the connections cover support panel.

2. Refer to the illustration. Connect the leads as shown. Tighten securely. Do not overtighten.

CAUTION

The clear connections cover must remain in place.

Pilot

Connections Cover

Torch

Work

PILOT WORK TORCH

Work Lead

Pilot Lead To Remote Arc Starter

Connection Panel

Torch Lead -

AC INPUT

L3

1 L2

L

To Remote Arc Starter

Connections Cover

Support Panel

Lead Connection Detail

Art # A-07660_AB

To Cutting Table

Leads Bracket

3. Re-install the connections cover on the power supply. Snug the hardware securely by hand. Do not overtighten.

INSTALLATION 3-8 Manual No. 0-5133

Page 35

3.07 Ground Connections

Star Ground on Cutting Table

ULTRA-CUT 200

Remote Arc

Starter (RAS-1000)

To rch

Cutting Machine / Gantry

Cutting Table

1/0

Ground Cable

(F1)

1/0

Ground Cable

Customer supplied

Earth Ground

Rod

0 - 10 ft (0 - 3 m) Ideal

20 ft (6 m) Maximum

DPC-3000 Gas Control

Primary location

TSC-3000

Remote

(F)

TSC-3000 Internal

#4 AWG

Ground

(F)

1/0 Work Cable

1/0 Ground Cable

Power

Supply

‘Star’

Ground

Note: The DMC-3000 gas control

can be mounted on top of the

power supply.

If it is, it should be grounded

directly to the power supply with

#4 AWG ground, (F).

This alternate location requires

grounding the power supply to the

‘Star’ ground with the 1/0 Ground

Cable (F1).

Art # A-09128

A. Electromagnetic Interference (EMI)

Pilot arc starting generates a certain amount of electromagnetic interference (EMI), commonly called RF noise.

This RF noise may interfere with other electronic equipment such as CNC controllers, remote controls, height

controllers, etc. To minimize RF interference, follow these grounding procedures when installing mechanized

systems:

B. Grounding

1. The preferred grounding arrangement is a single point or “Star” ground. The single point, usually on the cutting

table, is connected with 1/0 AWG (European 50 mm2) or larger wire to a good earth ground (measuring leass

than 3 ohms; an ideal ground measures 1 ohm or less. Refer to paragraph ‘C’, Creating An Earth Ground. The

ground rod must be placed as close as possible to the cutting table, ideally less than 10 ft (3.0 m), but no more

than 20 ft (6.1 m) from the cutting table.

NOTE

All ground wires should be as short as possible. Long wires will have increased resistance to RF

frequencies. Smaller diameter wire has increased resistance to RF frequencies, so using a larger

diameter wire is better.

2. Grounding for components mounted on the cutting table (CNC controllers, height controllers, plasma remote

controls, etc.) should follow the manufacturer’s recommendations for wire size, type, and connection point

locations.

For Thermal Dynamics components (except Remote Arc Starter and Gas Control Module) it is recommended

to use a minimum of 10 AWG (European 6 mm2) wire or flat copper braid with cross section equal to or greater

than 10 AWG connected to the cutting table frame. The Remote Arc Starter uses 1/0 earth ground wire and the

Gas Control Module should use minimum # 4 AWG wire. The connection point must be to clean bare metal; rust

and paint make poor connections. For all components, wires larger than the recommended minimum can be

used and may improve noise protection.

Manual No. 0-5133 3-9 INSTALLATION

Page 36

ULTRA-CUT 200

3. The cutting machine frame is then connected to the “Star” point using 1/0 AWG (European 50 mm2) or larger

wire.

4. The plasma power supply work cable (see NOTE) is connected to the cutting table at the single point “Star” ground.

NOTE

Do Not connect the work cable directly to the ground rod. Do not coil up excess ground or power cables.

Cut to proper length and reterminate as needed.

5. Make sure work cable and ground cables are properly connected. The work cable must have a solid connection

to the cutting table. The work and ground connections must be free from rust, dirt, grease, oil and paint. If

necessary grind or sand down to bare metal. Use lock washers to keep the connections tight. Using electrical

joint compound to prevent corrosion is also recommended.

6. The plasma power supply chassis is connected to the power distribution system ground as required by electrical codes. If the plasma supply is close to the cutting table (see NOTE) a second ground rod is not usually

needed, in fact it could be detrimental as it can set up ground loop currents that cause interference.

When the plasma power supply is far away from the ground rod and interference is experienced, it may help to

install a second earth ground rod next to the plasma power supply. The plasma power supply chassis would

then be connected to this ground rod.

NOTE

It is recommended that the Plasma Power Supply be within 20 - 30 ft (6.1 – 9.1 m) of the cutting table,

if possible.

7. The plasma control cable should be shielded with the shield connected only at the cutting machine end.

Connecting the shield at both ends will allow ground loop currents which may cause more interference than with

no shield at all.

Creating An Earth Ground

1. To create a solid, low resistance, earth ground, drive a 1/2 in (12 mm) or greater diameter copper clad ground

rod at least 6 - 8 ft (1.8 - 2.4 m) into the earth so that the rod contacts moist soil over most of its length.

Depending on location, a greater depth may be required to obtain a low resistance ground (see NOTE). Ground

rods, typically 10 ft (3.0 m) long, may be welded end to end for greater lengths. Locate the rod as close as

possible to the work table. Install a ground wire, 1/0 AWG (European 50 mm2) or greater, between the ground

rod and the star ground point on the cutting table.

NOTE

Ideally, a properly installed ground rod will have a resistance of three ohms or less.

To test for a proper earth ground, refer to the following diagram. Ideally, the reading on the multimeter should be as

shown.

CAUTION

No other connections should be made at the ground rod being tested.

INSTALLATION 3-10 Manual No. 0-5133

Page 37

This test assumes the 115 or 230 VAC source neutral is connected to the utility earth ground.

ULTRA-CUT 200

NEUTRAL

Earth Grounded

NEUTRAL

PROBE

WARNING

Use extreme caution. This

test uses live voltage.

HOT

100W Incandescent

light bulb*

HOT

PROBE

* Can replace light bulb with

a 100w resistor.

Use 100 ohm for 115VAC.

Use 500 ohm for 230VAC

Ground Rod

with other

connections removed

On 115V AC Line:

3VAC = 3 ohms

1VAC = 1 ohm

VAC

On 230V AC Line:

1.5VAC = 3 ohms

0.5VAC = 1 ohm

Art # A-07252

Ground Testing

2. Increasing the ground rod length beyond 20 - 30 ft (6.1 – 9.1 m) does not generally increase the effectiveness

of the ground rod. A larger diameter rod which has more surface area may help. Sometimes keeping the soil

around the ground rod moist by continuously running a small amount of water into it will work. Adding salt to the

soil by soaking it in salt water may also reduce its resistance. You may also try a chemical ground rod devise.

When these methods are used, periodic checking of the ground resistance is required to make sure the ground

is still good.

D. Routing Of Torch Leads

1. To minimize RF interference, position torch leads as far as possible from any CNC components, drive motors,

control cables, or primary power lines. If cables have to pass over torch leads, do so at an angle. Do not run the

plasma control or other control cables in parallel with the torch leads in power tracts.

2. Keep torch leads clean. Dirt and metal particles bleed off energy, which causes difficult starting and increased

chance of RF interference.

Manual No. 0-5133 3-11 INSTALLATION

Page 38

ULTRA-CUT 200

3.08 Connect Coolant Leads

1. Connect the color-coded coolant hoses to the coolant connections on the power supply rear panel. The

supply line (out) is flagged green, the return line (in) is flagged red.

COOLANT

RETURN

SUPPLY

RETURN

SUPPLY

Coolant Connections

RED

GREEN

To Remote Arc Starter

Art # A-04800

INSTALLATION 3-12 Manual No. 0-5133

Page 39

ULTRA-CUT 200

3.09 Connect Control Cables for CNC, Remote Arc Starter, and DMC-

3000

1. Connect one end of each cable to the power supply.

2. Connect the other end of the CNC cable to the CNC device.

3. The CNC cable shield must be attached to ground.

Customer Wiring

Access Hole

To DMC-3000

To CNC Control

To Remote Arc Starter

RETURN

SUPPLY

Art # A-09129

Manual No. 0-5133 3-13 INSTALLATION

Page 40

ULTRA-CUT 200

3.10 Connect TSC-3000 Cable and DMC-3000 Fiber Optic Cable to CCM

1. Remove the plastic plug in the CCM at the rear of the Power Supply labelled GCM/DCM.

To TSC-3000

Fiber Optic

To DMC-3000

RETURN

SUPPLY

Art # A-09134

CAUTION

Avoid kinking, twisting, or bunching the fiber optic cable. The cable can be damaged by being forced

into tight-radius turns.

2. Remove outer thin nut from through hole protector at one end of Fiber Optic Cable (L) that connects between

the CCM portion of the Power Supply and the DMC-3000.

INSTALLATION 3-14 Manual No. 0-5133

Page 41

ULTRA-CUT 200

3. Feed the Fiber Optic Cable plug and wires through the hole where the plastic plug was removed labelled

GCM/DCM and slide the thin nut back over the Fiber Optic Cable.

4. Secure the thin nut on the through hole protector so both nut faces are tight against the sheet metal inside

and out.

5. Plug the Fiber Optic Cable into the PCB as shown below. Make sure the locking tabs are engaged.

Fiber Optic

Cable

Plug

Thin nut securing

the through hole

protector

Art # A-09136

6. Notice the alignment pin and then connect the TSC-3000 cable (V) to the rear of the CCM as shown below.

TSC-3000 Cable

DMC-3000 Fiber

Optic Cable

Art # A-09137

Manual No. 0-5133 3-15 INSTALLATION

Page 42

ULTRA-CUT 200

3.11 Set Switches on the Command - Control Module

Compare the command - control module to the illustration. Follow instructions in this section for a module

without an external connection cover.

Remove the power supply right side. Set switches on the CCM (Command-Control Module) per the illustrations.

Switch settings and connection details are provided in the Appendix.

CAUTION

Printed circuit boards in the Command - Control Module are static - sensitive. Discharge any built-up static

charges in your body or surroundings before touching the printed circuit boards.

Future Use

O

N

SW-1-1: Auto Pilot Restart. 1 = ON = Auto Pilot Function enabled.

1 = OFF = Auto Pilot Function disabled (Factory default setting).

SW-1-2: Pilot Delay 2 = OFF, 3 = OFF, 4 = OFF: 0 Seconds (Factory default setting).

SW-1-3: Pilot Delay 2 = ON, 3 = OFF, 4 = OFF: 0.1 Seconds

SW-1-4: Pilot Delay 2 = OFF, 3 = ON, 4 = OFF: 0.2 Seconds

2 = ON, 3 = ON, 4 = OFF: 0.4 Seconds

2 = OFF, 3 = OFF, 4 = ON: 0.8 Seconds

2 = ON, 3 = OFF, 4 = ON: 1.0 Seconds

2 = OFF, 3 = ON, 4 = ON: 1.5 Seconds

2 = ON, 3 = ON, 4 = ON: 2.0 Seconds

SW-3: Gas Preflow Time 1 = Off, 2 = OFF: 2 seconds

1 = ON, 2 = OFF: 4 seconds

1 = OFF, 2 = ON: 6 seconds

1 = ON, 2 = ON: 8 seconds

SW-4: Postflow Time 1 = OFF, 2 = OFF: 10 Seconds (Factory default setting).

1 = ON, 2 = OFF: 20 Seconds

1 = OFF, 2 = ON: 5 Seconds

1 = ON, 2 = ON: 0 Seconds

SW-5-1: Tip Saver Reserved for Factory use.

SW-5-2: Off Plate Reserved for Factory use.

SW 8-1: Pilot Time OFF = Short (85 ms.) (Factory default setting).

ON = Long (3 s.)

SW 8-2: Remote Current OFF = Disabled (Factory default setting).

ON = (Remote Analog Current Control)

*SW 8-3: Auto Transfer Retry OFF = Enabled Up to 3 tries (Factory default setting).

ON = Disabled

SW 8-4: Remote Marking OFF = Disabled (Factory default setting).

ON = Remote Marking SW Enabled at TB3-1&2

SW1

1

3

2

SW3 SW4

1

4

SW5

2

1

1

2

2

SW8

4

1

3

2

1

O

N

2

Active only when

SW-1-1 is set to O

* SW 8-3 is reserved for

Factory use prior to

Firmware V3.5

Art # A-09166

N.

INSTALLATION 3-16 Manual No. 0-5133

Page 43

ULTRA-CUT 200

CAUTION

Printed circuit boards in the Command - Control Module are static - sensitive. Discharge any built-up static

charges in your body or surroundings before touching the printed circuit boards.

SW11

SW6

SW12

SW13

SW-6: OK-to-Move: Contact closure, 120VAC @ 1A (Factory default setting) or