Page 1

INVERTER

ARC

WELDER

MODEL 185TSW AC/DC CC

STICK

TIG - Lift Start

HF START

OPERATING MANUAL

November 13, 2003 Manual No. 430429-503

Page 2

Page 3

CONTENTS

SYMBOL LEGEND .......................................................................................................................................................5

STATEMENT OF WARRANTY...................................................................................................................................6

1.0 GENERAL INFORMATION....................................................................................................................................7

1.01 Notes, Cautions and Warnings...........................................................................................................................7

1.02 Important Safety Precautions..............................................................................................................................7

1.03 Publications........................................................................................................................................................8

1.04 Note, Attention et Avertissement........................................................................................................................9

1.05 Precautions De Securite Importantes..................................................................................................................9

1.06 Documents De Reference.................................................................................................................................11

2.0 INTRODUCTION AND DESCRIPTION ..............................................................................................................13

2.01 Description ........................................................................................................................................................13

2.02 Functional Block Diagrams...............................................................................................................................14

2.03 Transporting Methods........................................................................................................................................14

3.0 Installation Recommendations.................................................................................................................................15

3.01 Environment......................................................................................................................................................15

3.02 Location.............................................................................................................................................................15

3.03 Electrical Input Connections..............................................................................................................................16

3.03.01 Electrical Input Requirements..................................................................................................................16

3.03.02 Input Power ..............................................................................................................................................18

3.03.03 High Frequency Introduction....................................................................................................................19

3.03.04 High Frequency Interference....................................................................................................................19

3.04 Specifications ....................................................................................................................................................20

3.05 Duty Cycle.........................................................................................................................................................21

4.0 OPERATOR CONTROLS......................................................................................................................................23

4.01 Pro-Wave 185TSW Controls.............................................................................................................................23

4.02 Weld Process selection for Pro-Wave 185TSW................................................................................................25

4.03 Weld Parameter Descriptions for Pro-Wave 185TSW......................................................................................26

4.04 Weld Parameters for Pro-Wave 185TSW..........................................................................................................28

4.05 Power Source Features......................................................................................................................................29

5.0 SET-UP FOR SMAW (STICK) AND GTAW (TIG) .............................................................................................31

6.0 SEQUENCE OF OPERATION...............................................................................................................................32

6.01 Stick Welding....................................................................................................................................................33

6.02 AC or DC HF TIG Welding..............................................................................................................................34

6.02.01 Slope Mode Sequence ..............................................................................................................................35

6.02.02 Slope Mode with repeat sequence ............................................................................................................35

6.02.03 Pulse Controls...........................................................................................................................................36

7.0 BASIC TIG WELDING GUIDE.............................................................................................................................37

7.01 Explanation of “Fluttery Arc” when AC TIG Welding on Aluminum..............................................................37

7.02 Electrode Polarity........................................................................................................ ......................................38

7.03 Tungsten Electrode Current Ranges ..................................................................................................................38

7.04 Tungsten Electrode Types .................................................................................................................................38

7.05 Guide for Selecting Filler Wire Diameter..........................................................................................................39

7.06 Shielding Gas Selection.....................................................................................................................................39

7.07 TIG Welding Parameters for Low Carbon & Low Alloy Steel Pipe.................................................................39

7.08 Welding Parameters for Aluminum................................................................................................................... 40

7.09 Welding Parameters for Steel............................................................................................................................40

8.0 Basic Arc Welding Guide........................................................................................................................................41

8.01 Electrode Polarity........................................................................................................ ......................................41

8.02 Effects of Stick Welding Various Materials...................................................................................................... 41

9.0 ROUTINE MAINTENANCE .................................................................................................................................42

10.0 BASIC TROUBLESHOOTING............................................................................................................................43

10.01 TIG Welding Problems....................................................................................................................................43

10.02 Stick Welding Problems..................................................................................................................................45

10.03 Power Source Problems...................................................................................................................................47

11.0 Voltage Reduction Device (VRD).........................................................................................................................49

11.01 VRD Specification...........................................................................................................................................49

11.02 VRD Maintenance...........................................................................................................................................49

12.0 Power Source Error Codes....................................................................................................................................50

3

Page 4

13.0 PARTS LIST......................................................................................................................................................... 53

APPENDIX A – INTERCONNECT DIAGRAM ........................................................................................................ 56

APPENDIX B - AUTOMATION................................................................................................................................. 58

4

Page 5

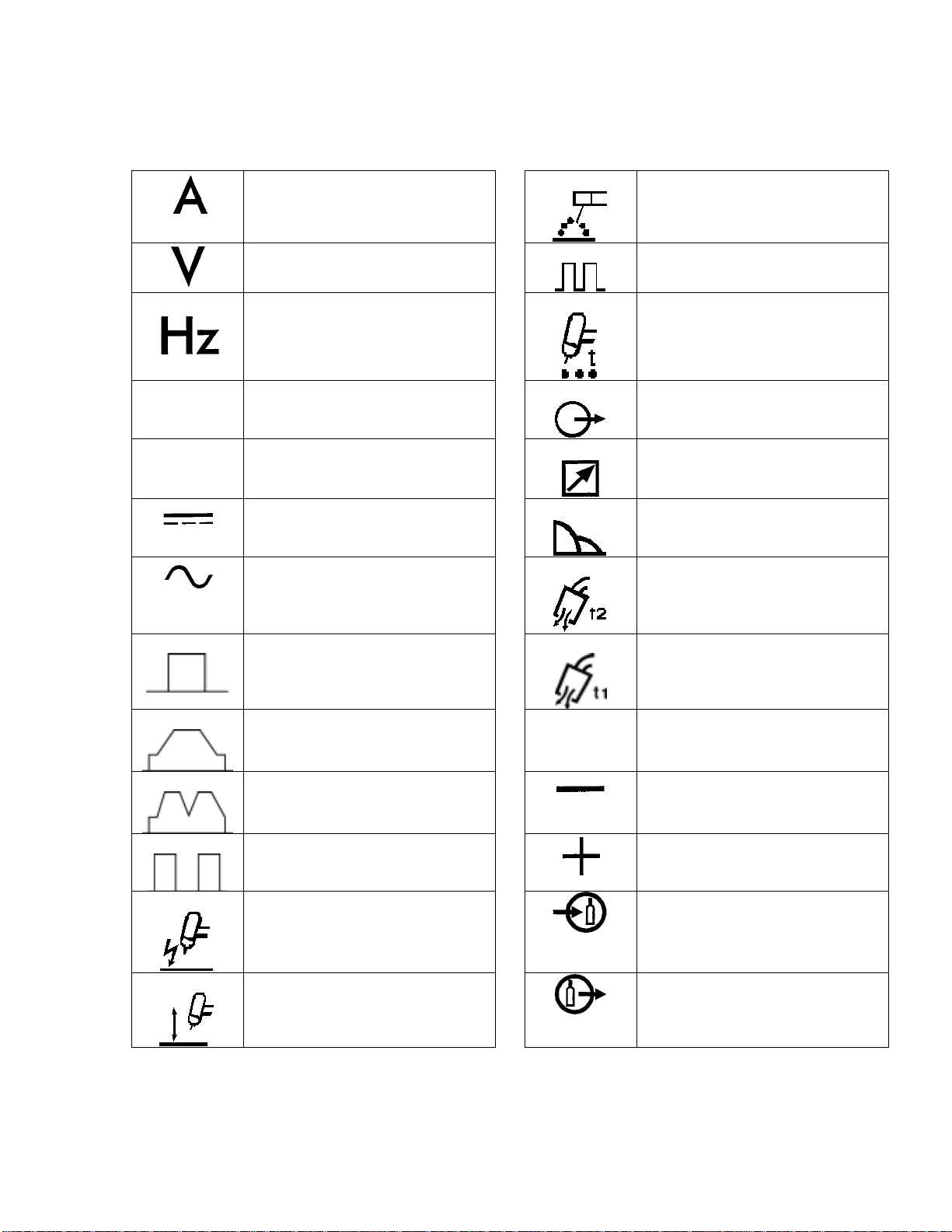

SYMBOL LEGEND

Amperage STICK (Shielded Metal Arc

Voltage Pulse Current Function

Hertz (frequency) Spot Time (GTAW)

SMAW)

SEC

%

Seconds Remote Control (Panel/Remote)

Percent Remote Function

DC (Direct Current) Arc Control (SMAW)

AC (Alternating Current Gas Post-Flow

Standard Function Gas Pre-Flow

Slope Function

VRD

Slope W/Repeat Function Negative

Voltage Reduction Device

Circuit

Spot Function Positive

Impulse Starting (High

Frequency GTAW)

Touch Start (Lift Start TIG

circuit GTAW)

5

Gas Input

Gas Output

Page 6

STATEMENT OF WARRANTY

LIMITED WARRANTY: Thermal Arc

authorized distributors here after “Thermal; Arc” that its pr oducts will be free of defects in work manship or material. Should any

failure to con form to thi s wa rr anty a ppear with i n th e time p er iod a ppl ica bl e to th e Th er mal Ar c pr od ucts as s tate d bel ow, Th ermal Arc

shall, upon notifi cation ther eof and substanti ation that th e product ha s been store d, instal led, opera ted, and mai ntained in accordance

with Thermal Arc’s specifications, instructions, recommendations and recognized standard industry practice, and not subject to

misuse, repair, neglect, alteration, or accident, correct such defects by s uitable repair or replacement, at Thermal Ar c’s sole option, of

any components o r parts of the product d etermined by Thermal Arc to be defective.

THERMAL ARC MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED. THIS WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHERS, INCLUDING, BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: Thermal Arc shall not under any cir cumstan ces be liable for s pecial, ind ire ct or con sequentia l d amages,

such as, but not l imited to, lost profi ts and busi ness in terruption . The re medies of the Pur chaser set forth h erein ar e exclus ive and the

liability of Thermal Arc with respect to any contract, or anything done in connection therewith such as the performance or breach

thereof, or from the manufacture, sale, delivery, resale, or use of any goods covered by or furnished by Thermal Arc whether arising

out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not, except as expressly provided herein, exceed the

price of the goods upon which such liability is based. No employee, agent, or representative of Thermal Arc is authorized to change

this warranty in any way o r grant any other warranty.

PURCHASER'S RIGHTS UNDER THIS WARRANTY ARE VOID IF REPLACEMENT PARTS OR ACCESSORIES ARE USED

WHICH IN THERMAL ARC’S SOLE JUDGEMENT MAY IMPAIR THE SAFETY OR PERFORMANCE OF ANY THERMAL ARC

PRODUCT.

PURCHASER'S RIGHTS UNDER THIS WARRANTY ARE VOID IF THE PRODUCT IS SOLD TO PURCHASER BY NONAUTHORIZED PERSONS.

®

, Inc., A Thermadyne Company, hereafter, “Thermal Arc” warrants to customers of its

The warran ty is effective fo r the time stated below beginnin g on the date that th e authoriz ed distributor delivers the products to the

Purchaser. Notw iths tan ding the for egoin g, in no even t shal l the wa rra nty per iod ex tend more tha n the time sta ted plus one year from

the date Thermal Arc delivere d the product to the a u thorized distributor.

POWER SUPPLIES POWER SUPPLIES & WIRE FEEDERS LABOR

MAIN POWER MAGNETICS (STATIC & ROTATING) 3 YEAR 3 YEAR

ORIGINAL MAIN POWER RECTIFIER 3 YEAR 3 YEAR

POWER SWITCHING SEMI-CONDUCTORS & CONTROL PC BOARD 3 YEAR 3 YEAR

ALL OTHER CIRCUITS AND COMPONENTS INCLUDING 1 YEAR 1 YEAR

BUT NOT LIMITED TO, CONTACTORS, RELAYS,

SOLENOIDS, PUMPS, SWITCHES, MOTORS

ENGINES: ENIGINES ARE NOT WARRANTED BY THERMAL ARC, ALTHOUGH MOST ARE WARRANTED BY THE ENGINE

MANUFACTURER, SEE THE ENGINE MANUFACTUR ES WARRA NT Y FOR DE TAILS .

CONSOLES, CONTROL EQUIPMENT, HEAT 1 YEAR 1 YEAR

EXCHANGES, AND ACCESSORY EQUIPMENT

PLASMA TORCH AND LEADS, AND REMOTE CONTROLS

180 DAYS 180 DAYS

REPAIR/REPLACEMENT PARTS 90 DAYS 90 DAYS

Warranty repair s or replace ment cla ims under this limi ted warr anty must be s ubmitted to Th ermal Arc by an a uthoriz ed Thermal Arc

repair facility within thirty (30) days of purchaser’s notice of any Warranty Claim. No transportation costs of any kind will be paid

under this warranty. Transportation charges to send products to an authorized warranty repair facility shall be the responsibility of the

Purchaser. All returned goods shall be at the Purchaser’s risk and expense. This warranty supersedes all previous Thermal Arc

warranties.

Thermal Arc® is a Registered Trademark of Thermadyne Industries Inc.

Effective April 1, 2002

6

Page 7

1.0 GENERAL INFORMATION

1.01 Notes, Cautions and Warnings

Throughout this manual, notes, cautions, and

warnings are used to highlight important

information. These highlights are categorized as

follows:

NOTE

An operation, procedure, or

background information which

requires additional emphasis or is

helpful in efficient operation of the

system.

CAUTION

A procedure which, if not properly

followed, may cause damage to the

equipment.

WARNING

A procedure which, if not properly

followed, may cause injury to the

operator or others in the operating

area.

1.02 Important Safety Precautions

WARNING

OPERATION AND

MAINTENANCE OF ARC

WELDING EQUIPMENT CAN BE

DANGEROUS AND HAZARDOUS

TO YOUR HEALTH.

To prevent possible injury, read,

understand and follow all warnings,

safety precautions and instructions

before using the equipment. Call 1800-462-2782 or your local distributor

if you have any questions.

• Use an air-supplied respirator if ventilation is

not adequate to remove all fumes and gases.

• The kinds of fumes and gases from the arc

welding/cutting depend on the kind of

metal being used, coatings on the metal, and

the different processes. You must be very

careful when cutting or welding any metals

which may contain one or more of the

following:

Antimony Chromium Mercury

Arsenic Cobalt Nickel

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese

Vanadium

• Always read the Material Safety Data Sheets

(MSDS) that should be supplied with the

material you are using. These MSDSs will

give you the information regarding the kind

and amount of fumes and gases that may be

dangerous to your health.

• For information on how to test for fume s and

gases in your workplace, refer to item 1 in

Subsection 1.03, Publications in this manual.

• Use special equipment, such as water or

down draft welding/cutting tables, to

capture fumes and gases.

• Do not use the welding torch in an area

where combustible or explosive gases or

materials are located.

• Phosgene, a toxic gas, is generated from the

vapors of chlorinated solven ts and cleanser s.

Remove all sources of these vapors.

ELECTRIC SHOCK

Electric Shock can injure or kill. The arc welding

process uses and produces high voltage electrical

energy. This electric energy can cause severe or

fatal shock to the operator or others in the

workplace.

GASES AND FUMES

Gases and fumes produced during the Arc

welding/cutting process can be dangerous and

hazardous to your health.

• Keep all fumes and gases from the breathing

area. Keep your head out of the welding

fume plume.

• Never touch any parts that are electrically

“live” or “hot.”

• Wear dry gloves and clothing. Insulate

yourself from the work piece or other parts

of the welding circuit.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workpla ce

is moist or damp.

7

Page 8

• Install and maintain eq uipment according to

NEC code, refer to item 4 in Subsection 1.03,

Publications.

• Disconnect power source before performing

any service or repairs.

• Read and follow all the instructions in the

Operating Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag,

sparks, or the arc weld.

• Be sure there is no combustible or flammable

material in the workplace. Any material that

cannot be removed must be protec te d.

• Ventilate all flammable or explosive vapors

from the workplace.

• Do not cut or weld on containers that may

have held combustibles.

• Provide a fire watch when working in an

area where fire hazards may exist.

• Hydrogen gas may be formed and trapped

under aluminum workpieces when they are

cut underwater or while using a water table.

DO NOT cut aluminum alloys underwater

or on a water table unle ss the hydrogen ga s

can be eliminated or dissipated. Trapped

hydrogen gas that is ignited will cause an

explosion.

NOISE

Noise can cause permanent hearing loss. Arc

welding/cutting processes can cause noise levels

to exceed safe limits. You must protect your ears

from loud noise to prevent permanent loss of

hearing.

• To protect your hearing from loud noise,

wear protective ear plugs and/or ear muffs.

Protect others in the workplace.

• Noise levels should be measured to be sure

the decibels (sound) do not exceed safe

levels.

• For information on how to test for noise, see

item 1 in Subsection 1.03, Publications, in

this manual.

ARC WELDING RAYS

Arc Welding/Cutting Rays can injure your eyes

and burn your skin. The arc welding/cutting

process produces very bright ultra violet and infra

red light. These arc rays will damage your eyes

and burn your skin if you are not properly

protected.

• To protect your eyes, always wear a welding

helmet or shield. Also always wear safety

glasses with side shields, goggles or other

protective eye wear.

• Wear welding gloves and suita ble clothing to

protect your skin from the arc rays and

sparks.

• Keep helmet and safety glasses in good

condition. Replace lenses when cracked,

chipped or dirty.

• Protect others in the wor k area from the arc

rays. Use protective booths, screens or

shields.

• Use the shade of lens as recommended in

Subsection 1.03, item 4.

1.03 Publications

Refer to the following standards or their latest

revisions for more information:

1. OSHA, SAFETY AN D HEA L TH ST AN D ARDS,

29CFR 1910, obtainable from the

Superintendent of Documents, U.S.

Government Printing Office, Washington, D.C.

20402

2. ANSI Standard Z49.1, SAFETY IN WELDING

AND CUTTING, obtainable from the American

Welding Society, 550 N.W. LeJeune Rd, Miami,

FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC

WELDING AND GAS WELDING AND

CUTTING, obtainable from the Superintendent

of Documents, U.S. Government Printing

Office, Washington, D.C. 20402

4. ANSI Standard Z87.1, SAFE PRACTICES FOR

OCCUPATION AND EDUCATIONAL EYE

AND FACE PROTECTION, obtainable from

American National Standards Institute, 1430

Broadway, New York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN’S

SAFETY-TOE FOOTWEAR, obtainable from

the American National Standards Institute,

1430 Broadway, New York, NY 10018

8

Page 9

6. ANSI Standard Z49.2, FIRE PREVENTION IN

THE USE OF CUTTING AND WELDING

PROCESSES, obtainable from American

National Standards Institute, 1430 Broadway,

New York, NY 10018

7. AWS Standard A6.0, WELDING AND

CUTTING CONTAINERS WHICH HAVE

HELD COMBUSTIBLES, obtainable from

American Welding Society, 550 N.W. LeJeune

Rd, Miami, FL 33126

8. NFPA Standard 51, OXYGEN-FUEL GAS

SYSTEMS FOR WELDING, CUTTING AND

ALLIED PROCESSES, obtainable from the

National Fire Protection Association,

Batterymarch Park, Quincy, M A 02269

9. NFPA Standard 70, NATIONAL ELECTRICAL

CODE, obtainable from the National Fire

Protection Association, Batterymarch Park,

Quincy, MA 02269

10. NFPA Standard 51B, CUTTING AND

WELDING PROCESSES, obtainable from the

National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

11.CGA Pamphlet P-1, SAFE HANDLING OF

COMPRESSED GASES IN CYLINDERS,

obtainable from the Compressed Gas

Association, 1235 Jefferson Davis Highway,

Suite 501, Arlington, VA 22202

12. CSA Standard W117.2, CODE FOR SAFETY IN

WELDING AND CUTTING, obtainable from

the Canadian Standards Association, Standards

Sales, 178 Rexdale Boulevard, Rexdale, Ontario,

Canada M9W 1R3

13. NWSA booklet, WELDING SAFETY

BIBLIOGRAPHY obtainable from the National

Welding Supply Association, 1900 Arch Street,

Philadelphia, PA 19103

14. American Welding Society Standard AWSF4.1,

RECOMMENDED SAFE PRACTICES FOR

THE PREPARATION FOR WELDING AND

CUTTING OF CONTAINERS AND PIPING

THAT HAVE HELD HAZARDOUS

SUBSTANCES, obtainable from the American

Welding Society, 550 N.W. LeJeune Rd, Miami,

FL 33126

15. ANSI Standard Z88.2, PRACTICE FOR

RESPIRATORY PROTECTION, obtainable

from American National Standards Institute,

1430 Broadway, New York, NY 10018

des informations à caractère important. Ces mises

en relief sont classifiées comme suit :

NOTE

Toute opération, procédure ou

renseignement général sur lequel il

importe d’insister davantage ou qui

contribue à l’efficacité de

fonctionnement du sy stème.

ATTENTION

Toute procédure po uvant résulter

l’endommagement du matériel en cas

de non-respect de la procédure en

question.

AVERTISSEMENT

Toute procédure pouvant provoquer

des blessures de l’opérateur ou des

autres personnes se trouvant dans la

zone de travail en cas de non-respect

de la procédure en question.

1.05 Precautions De Securite Importantes

AVERTISSEMENT

L’OPÉRATION ET LA

MAINTENANCE DU MATÉRIEL

DE SOUDAGE À L’ARC AU JET

DE PLASMA PEUVENT

PRÉSENTER DES RISQUES ET

DES DANGERS DE SANTÉ.

Il faut communiquer aux o pérateurs et

au personnel TOUS les dangers

possibles. Afin d’éviter les blessures

possibles, lisez, comprenez et suivez

tous les avertissements, toutes les

précautions de sécurité et toutes les

consignes avant d’utiliser le matériel.

Composez le + 1-800-462-2782 ou

votre distributeur local si vous avez

des questions.

FUMÉE et GAZ

1.04 Note, Attention et Avertissement

Dans ce manuel, les mots “note,” “attention,” et

“avertissement” sont utilisés pour mettre en relief

La fumée et les gaz produits par le procédé de jet

de plasma peuvent présenter des risques et des

dangers de santé.

9

Page 10

• Eloignez toute fumée et gaz de votre zone de

respiration. Gardez votre tête hors de la

plume de fumée provenant du chalumeau.

• Utilisez un appareil respiratoire à

alimentation en air si l’aération fournie ne

permet pas d’éliminer la fumée et les gaz.

• Les sortes de gaz et de fumée provenant de

l’arc de plasma dépendent du genre de métal

utilisé, des revêtements se trouvant sur le

métal et des différents procédés. Vous devez

prendre soin lorsque vous coupez ou soudez

tout métal pouvant contenir un ou plusieurs

des éléments suivants:

antimoine cadmium mercure

argent chrome nickel

arsenic cobalt plomb

baryum cuivre sélénium

béryllium manganèse

vanadium

• Lisez toujours les fiches de données sur la

sécurité des matières (sigle américain

“MSDS”); celles-ci devraient être fournies

avec le matériel que vous utilisez. Les MSDS

contiennent des renseignements quant à la

quantité et la nature de la fumée et des gaz

pouvant poser des dangers de santé.

• Pour des informations sur la manière de

tester la fumée et les gaz de votre lieu de

travail, consultez l’article 1 et les documents

cités à la page 5.

• Utilisez un équipement spécial tel que des

tables de coupe à débit d’eau ou à courant

descendant pour capter la fumée et les gaz.

• N’utilisez pas le chalumeau au jet de plasma

dans une zone où se trouvent des matières

ou des gaz combustibles ou explosifs.

• Le phosgène, un gaz toxique, est généré pa r la

fumée provenant des solvants et des

produits de nettoyage chlorés. Eliminez

toute source de telle fumée.

CHOC ELECTRIQUE

Les chocs électriques peuvent blesser ou même

tuer. Le procédé au jet de plasma requiert et

produit de l’énergie électrique haute tension. Cette

énergie électrique peut produire des chocs graves,

voire mortels, pour l’opérateur et les autres

personnes sur le lieu de travail.

• Ne touchez jamais une pièce “sous tension”

ou “vive”; portez des gants et des vêtements

secs. Isolez-vous de la pièce de travail ou des

autres parties du circuit de soudage.

• Réparez ou remplacez toute pièce usée ou

endommagée.

• Prenez des soins particuliers lorsque la zone

de travail est humide ou moite.

• Montez et maintenez le matériel

conformément au Code électrique national

des Etats-Unis. (Voir la page 5, article 9.)

• Débranchez l’alimentation électrique avant

tout travail d’entretien ou de réparation.

• Lisez et respectez toutes les consignes du

Manuel de consignes.

INCENDIE ET EXPLOSION

Les incendies et les explosions peuvent résulter

des scories chaudes, des étincelles ou de l’arc de

plasma. Le procédé à l’arc de plasma produit du

métal, des étincelles, des scories chaudes pouvant

mettre le feu aux matières combustibles ou

provoquer l’explosion de fumées inflammables.

• Soyez certain qu’aucune matière combustible

ou inflammable ne se trouve sur le lieu de

travail. Protégez toute telle matière qu’il est

impossible de retirer de la zone de travail.

• Procurez une bonne aération de toutes les

fumées inflammables ou explosives.

• Ne coupez pas et ne soudez pas les

conteneurs ayant pu renfermer des matières

combustibles.

• Prévoyez une veille d’incendie lors de tout

travail dans une zone présentant des dangers

d’incendie.

• Le gas hydrogène peut se former ou

s’accumuler sous les pièces de travail en

aluminium lorsqu’elles sont coupées sous

l’eau ou sur une table d’eau. NE PAS couper

les alliages en aluminium sous l’eau ou sur

une table d’eau à moins que le gas

hydrogène peut s’échapper ou se dissiper.

Le gas hydrogène accumulé explosera si

enflammé.

RAYONS D’ARC DE PLASM A

Les rayons provenant de l’arc de plasma peuvent

blesser vos yeux et brûler votre peau. Le procédé à

l’arc de plasma produit une lumière infra-rouge et

des rayons ultra-violets très forts. Ces rayons d’arc

10

Page 11

nuiront à vos yeux et brûleront votre peau si vous

ne vous protégez pas correctement.

• Pour protéger vos yeux, portez toujours un

casque ou un écran de soudeur. Portez

toujours des lunettes de sécurité munies de

parois latérales ou des lunette s de pr otection

ou une autre sorte de protec tion oculaire.

• Portez des gants de soudeur et u n vêtement

protecteur approprié pour protéger votre

peau contre les étincelles et les rayons de

l’arc.

• Maintenez votre casque et vos lunettes de

protection en bon état. Remplacez toute

lentille sale ou comportant fissure ou

rognure.

• Protégez les autres pe rsonnes se tr ouvant sur

la zone de travail contre les rayons de l’arc

en fournissant des cabines ou des écrans de

protection.

• Respectez le teint de lentille recommandé

dans le article 4, page 5.

• Hydrogen gas may be present under

aluminum workpieces during the cutting

process when being cut underwater or using

a water table. DO NOT cut aluminum

underwater or on a water table unless the

hydrogen gas can be eliminated as the

hydrogen gas may detonate.

BRUIT

Le bruit peut provoquer une perte permanente de

l’ouïe. Les procédés de soudage à l’arc de plasma

peuvent provoquer des niveaux sonores

supérieurs aux limites normalement acceptables.

Vous dú4ez vous protéger les oreilles contre les

bruits forts afin d’éviter une perte permanente de

l’ouïe.

• Pour protéger votre ouïe contre les bruits

forts, portez des tampons protecteurs et/ou

des protections auriculaires. Protégez

également les autres personnes se trouvant

sur le lieu de travail.

• Il faut mesurer les niveaux sonores afin

d’assurer que les décibels (le bruit) ne

dépassent pas les niveaux sûrs.

• Pour des renseignements sur la manière de

tester le bruit, consultez l’article 1, page 5.

1.06 Documents De Reference

Consultez les normes suivantes ou les révision s les

plus récentes ayant été faites à celles-ci pour de

plus amples renseignements :

1. OSHA, NORMES DE SÉCURITÉ DU

TRAVAIL ET DE PROTECTION DE LA

SANTÉ, 29CFR 1910, disponible auprès du

Superintendent of Documents, U.S.

Government Printing Office, Washington,

D.C. 20402

2. Norme ANSI Z49.1, LA SÉCURITÉ DES

OPÉRATIONS DE COUPE ET DE

SOUDAGE, disponible auprès de la Société

Américaine de Soudage (American Welding

Society), 550 N.W. LeJeune Rd., Miami, FL

33126

3. NIOSH, LA SÉCURITÉ ET LA SANTÉ LORS

DES OPÉRATIONS DE COUPE ET DE

SOUDAGE À L’ARC ET AU GAZ,

disponible auprès du Superintendent of

Documents, U.S. Government Printing

Office, Washington, D.C. 20402

4. Norme ANSI Z87.1, PRATIQUES SURES

POUR LA PROTECTION DES YEUX ET DU

VISAGE AU TRAVAIL ET DANS LES

ECOLES, disponible de l’Institut Américain

des Normes Nationales (American National

Standards Institute), 1430 Broadway, New

York, NY 10018

5. Norme ANSI Z41.1, NORMES POUR LES

CHAUSSURES PROTECTRICES, disponible

auprès de l’American National Standards

Institute, 1430 Broadway, New York, NY

10018

6. Norme ANSI Z49.2, PRÉVENTION DES

INCENDIES LORS DE L’EMPLOI DE

PROCÉDÉS DE COUPE ET DE SOUDAGE,

disponible auprès de l’American National

Standards Institute, 1430 Broadway, New

York, NY 10018

7. Norme A6.0 de l’Association Américaine du

Soudage (AWS), LE SOUDAGE ET LA

COUPE DE CONTENEURS AYANT

RENFERMÉ DES PRODUITS

COMBUSTIBLES, disponible auprès de la

American Welding Society, 550 N.W.

LeJeune Rd., Miami, FL 33126

8. Norme 51 de l’Association Américaine pour

la Protection contre les Incendies (NFPA),

LES SYSTEMES À GAZ AVEC

ALIMENTATION EN OXYGENE POUR LE

SOUDAGE, LA COUPE ET LES PROCÉDÉS

11

Page 12

ASSOCIÉS, disponible auprès de la National

Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

9. Norme 70 de la NFPA, CODE ELECTRIQUE

NATIONAL, disponible auprès de la

National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

10. Norme 51B de la NFPA, LES PROCÉDÉS

DE COUPE ET DE SOUDAGE, disponible

auprès de la National Fire Protection

Association, Batterymarch Park, Quincy, MA

02269

11. Brochure GCA P-1, LA MANIPULATION

SANS RISQUE DES GAZ COMPRIMÉS EN

CYLINDRES, disponible auprès de

l’Association des Gaz Comprimés

(Compressed Gas Association), 1235

Jefferson Davis Highway, Suite 501,

Arlington, VA 22202

12. Norme CSA W117.2, CODE DE SÉCURITÉ

POUR LE SOUDAGE ET LA COUPE,

disponible auprès de l’Association des

Normes Canadiennes, Standards Sales, 178

Rexdale Boulevard, Rexdale, Ontario,

Canada, M9W 1R3

13. ivret NWSA, BIBLIOGRAPHIE SUR LA

SÉCURITÉ DU SOUDAGE, disponible

auprès de l’Association Nationale de

Fournitures de Soudage (National Welding

Supply Association), 1900 Arch Street,

Philadelphia, PA 19103

14. Norme AWSF4.1 de l’Association

Américaine de Soudage,

RECOMMANDATIONS DE PRATIQUES

SURES POUR LA PRÉPARATION À LA

COUPE ET AU SOUDAGE DE

CONTENEURS ET TUYAUX AYANT

RENFERMÉ DES PRODUITS DANGEREUX

, disponible auprès de la American Welding

Society, 550 N.W. LeJeune Rd., Miami, FL

33126

15. Norme ANSI Z88.2, PRATIQUES DE

PROTECTION RESPIRATOIRE, disponible

auprès de l’American National Standards

Institute, 1430 Broadway, New York, NY

10018

12

Page 13

2.0 INTRODUCTION AND DESCRIPTION

2.01 Description

The Thermal Arc™ Model 185TSW is a self contained single-phase AC/DC arc welding power source

with Constant Current (CC) output characteristics. This unit is equipped with a Digital Volt/Amperage

Meter, gas control valve, built in Sloper and Pulser, lift arc starter, and high-frequency arc starter for use

with Gas Tungsten Arc Welding (GTAW), Gas Tungsten Arc Welding-Pulsed (GTAW-P) Gas Tungsten

Arc Welding-Sloped (GTAW-S), and Shielded Metal Arc Welding (SMAW) processes. The power

source is totally enclosed in an impact resistant, flame retardant and non-conductive plastic case.

(V)

OCV

(V)

OCV

10V

160A5A (A)

STICK Process

(V)

OCV

185A25A (A)

5A

LIFT TIG Process HF TIG Process

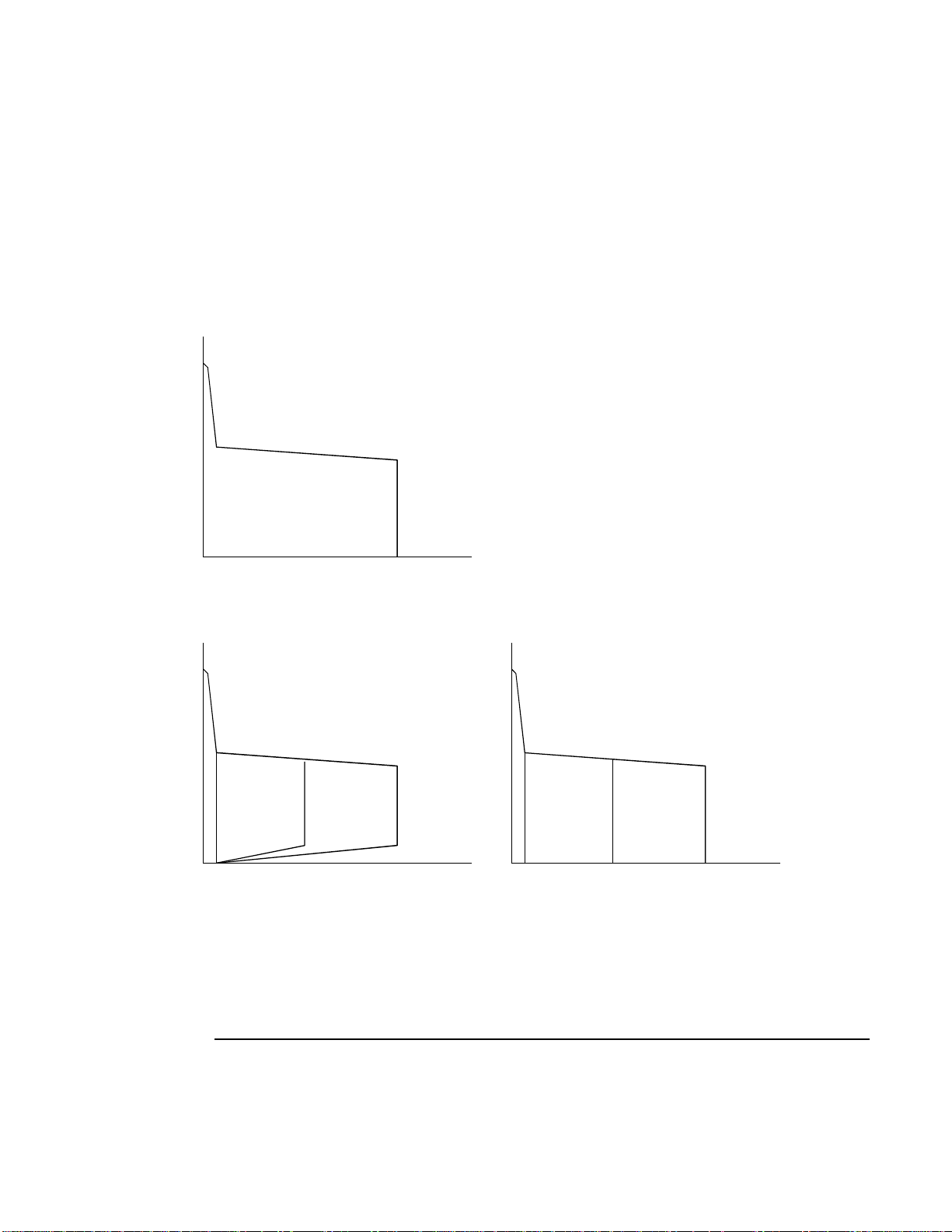

Figure 1. Model 185TSW Volt-Ampere curve

185A (A)

Note 1

Volt-Ampere curves show the maximum Voltage and Amperage output capabilities of the

welding power source. Curves of other settings will fall between the curves shown.

13

Page 14

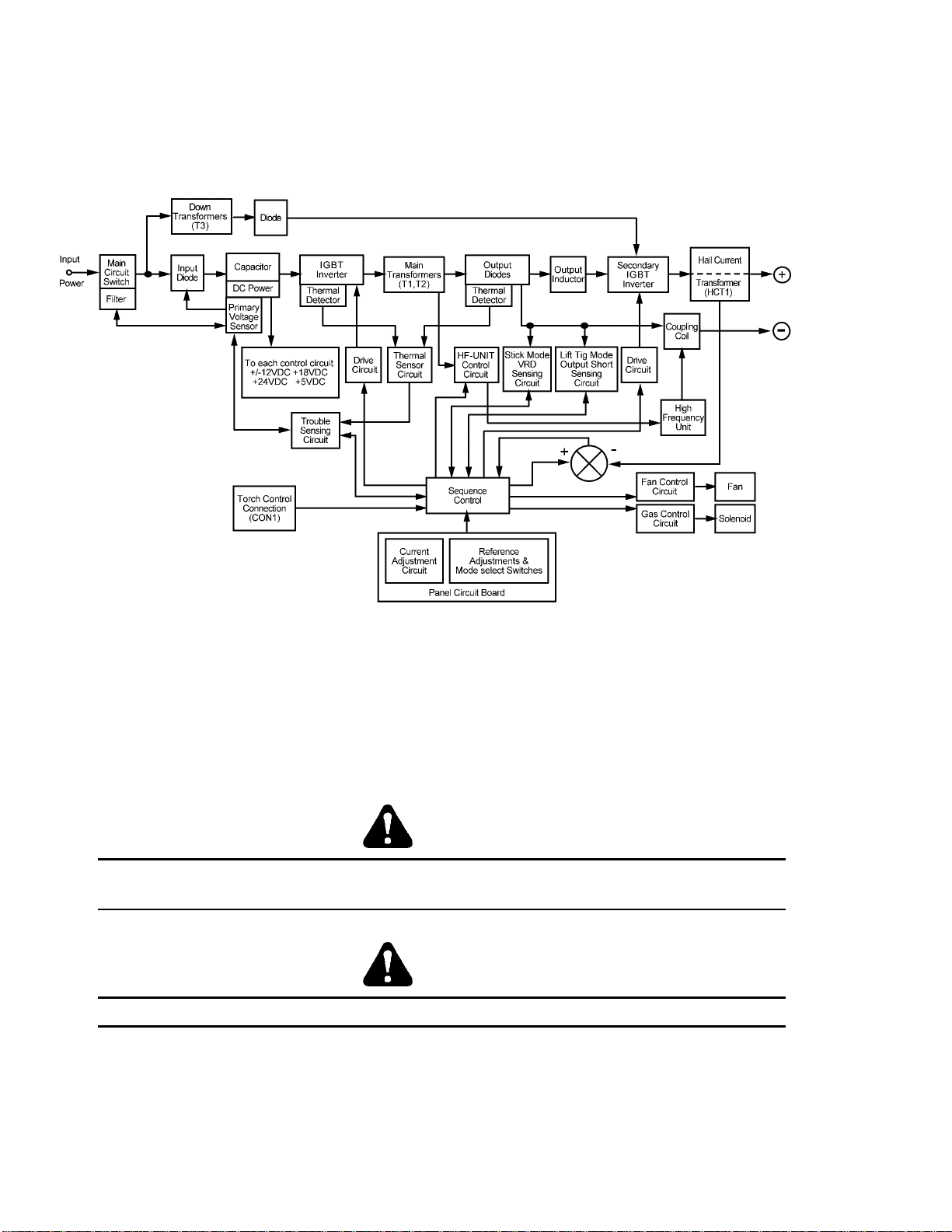

2.02 Functional Block Diagrams

Figure 2 illustrates the functional block diagram of the 185TSW-power supply.

Figure 2. 185TSW Model Functional Block Diagram

2.03 Transporting Methods

These units are equipped with a handle for carrying purposes.

WARNING 1

ELECTRIC SHOCK can kill. DO NOT TOUCH live electrical parts. Disconnect input

power conductors from de-energized supply line before moving the welding power source.

WARNING 2

FALLING EQUIPMENT can cause serious personal injury and equipment damage.

Lift unit with handle on top of case.

Use handcart or similar device of adequate capacity.

If using a fork lift vehicle, place and secure unit on a proper skid before transporting.

14

Page 15

3.0 Installation Recommendations

3.01 Environment

The Pro-Wave 185TSW is designed for u se in hazardous environments.

Examples of environments with increased hazardous environments are -

a) In locations in which freedom of movement is restricted, so that the operator is forced to

perform the work in a cramped (kneeling, sitting or lying) position with physical contact

with conductive parts;

b) In locations which are fully or partially limited by conductive elements, and in which

there is a high risk of unavoidable or accidental contact by the operator, or

c) In wet or damp hot locations where humidity or perspiration considerably reduces the

skin resistance of the human body and the insulation properties of accessories.

Environments with hazardous environments do not include places where electrically conductive

parts in the near vicinity of the operator, which can cause increased hazard, have been

insulated.

3.02 Location

Be sure to locate the welder according to the following guidelines:

• In areas, free from moisture and dust. • Ambient temperature between 0 degrees C

to 40 degrees C.

• In areas, free from oil, steam and

corrosive gases.

• In areas, not exposed to direct sunlight or

rain.

Thermal Arc advises that this equipment be electrically connected by a qualified

electrician.

• In areas, not subjected to abnormal

vibration or shock.

• Place at a distance of 12” (304.79mm) or

more from walls or similar that could

restrict natural airflow for cooling.

WARNING 3

15

Page 16

3.03 Electrical Input Connections

WARNING 4

ELECTRIC SHOCK can kill; SIGNIFICANT DC VOLTAGE is present after removal of

input power.

DO NOT TOUCH live electrical parts.

SHUT DOWN welding power source, disconnect input power employing lockout/tagging

procedures. Lockout/tagging procedures consist of padlocking line disconnect switch in

open position, removing fuses from fuse box, or shutting off and red-tagging circuit

breaker or other disconnecting device.

3.03.01 Electrical Input Requirements

Operate the welding power source from a single-phase 50/60 Hz, AC power supply. The input

voltage must match one of the electrical input voltages shown on the input data label on the unit

nameplate. Contact the local electric utility for information about the type of electrical service

available, how proper connections should be made, and any inspection required.

The line disconnect switch provides a safe and convenient means to completely remove all

electrical power from the welding power supply whenever necessary to inspect or service the unit.

Note 2

These units are equipped with a two-conductor with earth power cable that is connected at

the welding power source end for single-phase electrical input power.

Do not connect an input (WHITE or BLACK) conductor to the ground terminal.

Do not connect the ground (GREEN) conductor to an input line terminal.

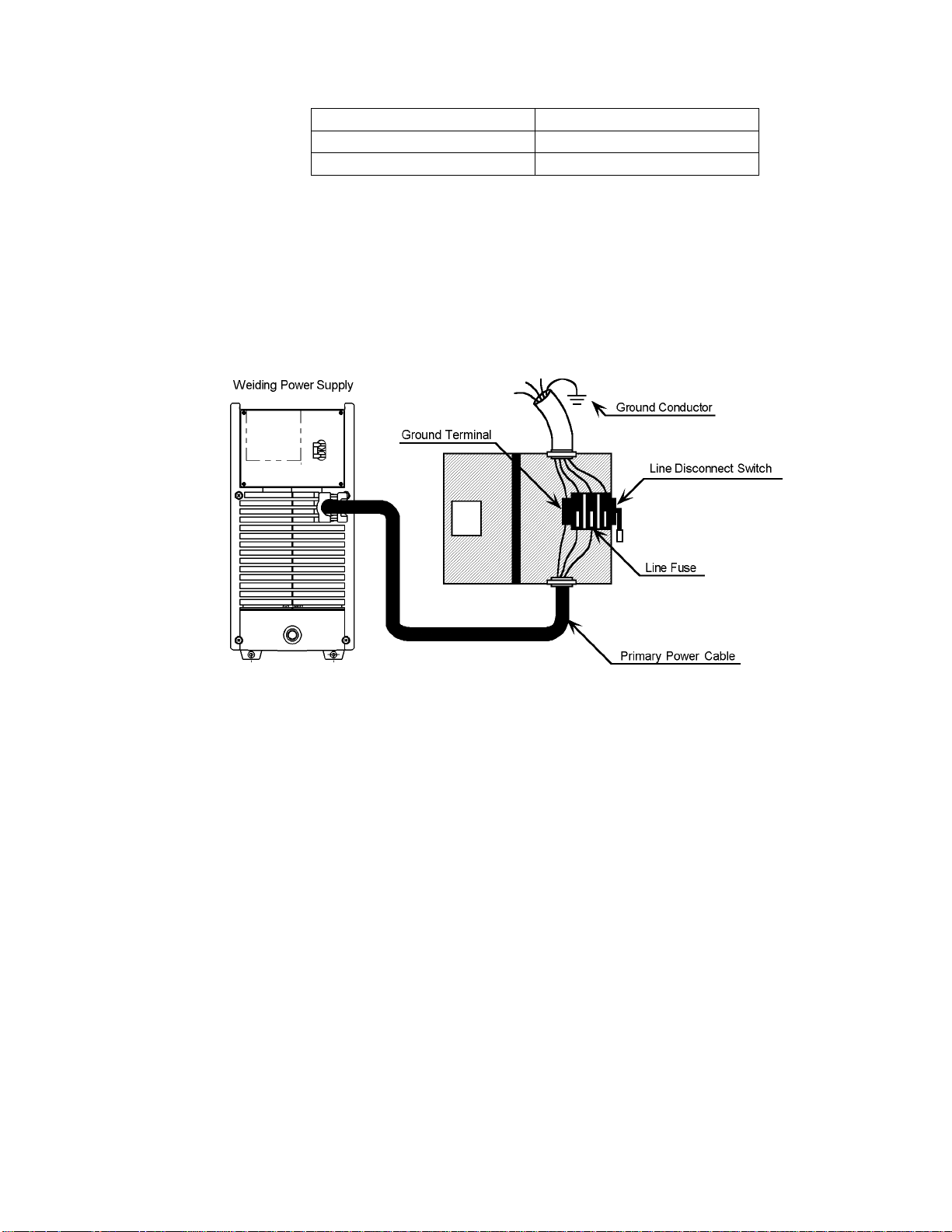

Refer to figure 3 and:

1. Connect end of ground (GREEN) conductor to a suitable ground. Use a grounding method that

complies with all applicable electrical codes.

2. Connect ends of line 1 (BLACK) and line 2 (WHITE) input conductors to a de-ene rgized line

disconnect switch.

3. Use Table 1 and Table 2 as a guide to select line fuses for the disconnect switch.

16

Page 17

Input Voltage Fuse Size

208V 45 Amps

230V 40 Amps

Table 1. Electrical Input Connections

NOTE: Fuse size is based on not more than 200 percent of the rated input amperage of the welding

power source (Based on Article 630, National Electrical Code).

Figure 3. Electrical Input Connections

17

Page 18

3.03.02 Input Power

Each unit incorporates an INRUSH circuit and input voltage sensing circuit. When the MAIN

CIRCUIT SWITCH is turned on, the inrush circuit provides a pre-charging of the input capacitors.

SCR’s in the Power Control Assembly (PCA) will turn on after the input capacitors have charged

to full operating voltage (after approximately 5 seconds).

Note 3

Note the available input power. Damage to the PCA could occur if 460VAC or higher is

applied.

The following 208/230V Primary Current recommendations are required to obtain the

maximum welding cur re nt and du ty cycle from this weldi ng e quip ment :

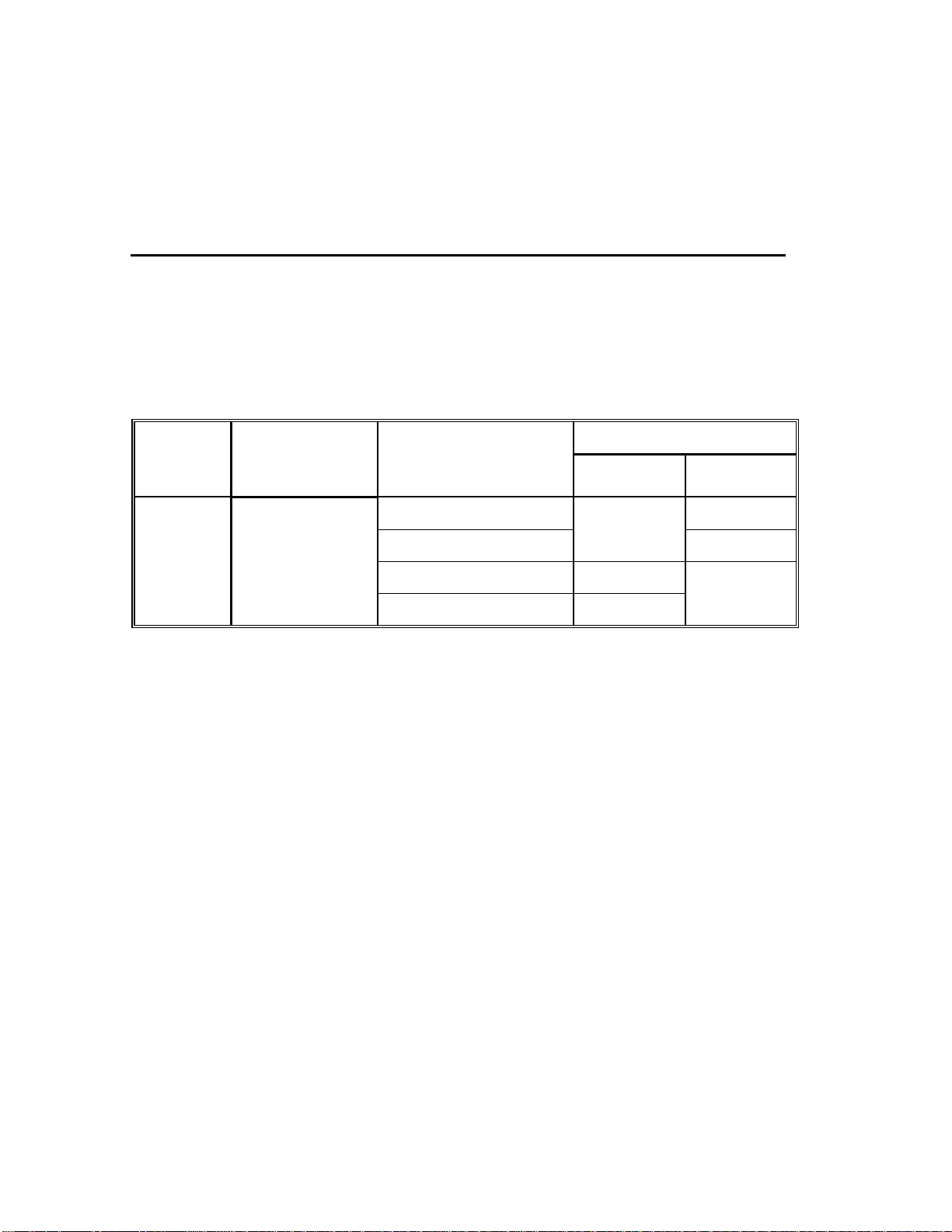

Current & Duty Cycle

TIG STICK

Model

Primary Supply

Lead Size

(Factory Fitted)

Minimum Primary

Current Circuit Size

(Vin/Amps)

230/29

185 @ 30%

Pro-Wave

185TSW

12/3 AWG

minimum

208/32

230/38 -

160 @ 40%

208/40 -

Table 2 – 208/230V Primary Current Circuit sizes to achieve maximum current

18

Page 19

3.03.03 High Frequency Introduction

The importance of correct installation of high frequency welding equipment cannot be overemphasized. Interference due to high frequency initiated or stabilized arc is almost invariably

traced to improper installation. The following information is intended as a guide for personnel

installing high frequency welding machi nes.

Warning

Explosives

The high frequency section of this machine has an output similar to a radio transmitter. The

machine should NOT be used in the vicinity of blasting operations due to the danger of

premature firing.

Computers

It is also possible that operation close to computer installations may cause computer

malfunction.

3.03.04 High Frequency Interference

Interference may be transmitted by a high frequency initiated or stabilized arc welding

machine in the following way s:

Direct Radiation

Radiation from the machine can occur if the case is metal and is not properly grounded. It

can occur through apertures such as open access panels. The shielding of the high frequency

unit in the Power Source w ill preve nt d irect radiat ion if t he equipmen t is pr operly grounded.

Transmission via the Supply Lead

Without adequate shielding and filtering, high frequency energy may be fed to the wiring

within the installation (mains) by direct coupling. The energy is then transmitted by both

radiation and conduction. A dequate sh ield ing and fil ter ing is provided in the Power S ource.

Radiation from Welding Leads

Radiated interference from welding leads, although pronounced in the vicinity of the leads,

diminishes rapidly with distance. Keeping leads as short as possible will minimize this type

of interference. Looping and sus pending of leads sho uld be avo ided where pos sib le.

Re-radiation from Unearthed Metallic Objects

A major factor contributing to interference is re-radiation from unearthed metallic objects

close to the welding leads. Effective grounding of such objects will prevent re-radiation in

most cases.

19

Page 20

3.04 Specifications

Parameter 185TSW

Rated Output

Amperes

Volts

Duty Cycle

Duty Cycle TIG 185A / 17.4V @ 30%

Output Current TIG 5 – 185 (DC)

Range STICK 5 – 160 (DC)

Open Circuit Voltage 69V

Dimensions

Width

Height

Length

Weight 41.8 lb. 19 kg

Output @ Rated Load

Output Amperes

Output Volts

Duty Cycle

KVA

KW

Output @ No Load

KVA

KW

Input Volts Single Phase

208V

230V

185

17.4

25%

160A / 16V @ 40%

130A / 15V @ 60%

100A / 14V @ 100%

STICK 160A / 26V @ 40%

130A / 25V @ 60%

100A / 25V @ 100%

5 – 185 (AC) @ 60Hz, 50% Cleaning

5 – 160 (AC) @ 60Hz, 50% Cleaning

7.08” (180mm)

14.7” (360mm)

16.54” (420mm)

160A

26V

40%

8.7

5.2

0.5

0.13

Amperage Draw @ Rated Load

40

38

No Load Amps

2.2

1.6

Thermal Arc continuously st r ives to produce the best product po ssible and therefore reserves the right to change, improve or revise t he

specifications or design of this or any product without prior notice. Such updates or changes do not entitle the buyer of equipment

previously sold or shipped to the corresponding changes, updates, improvements or replacement of such items.

20

Page 21

3.05 Duty Cycle

The duty cycle of a welding power source is the percentage of a ten (10) minute period that it can

be operated at a given output without causing overheating and damage to the unit. If the welding

amperes decrease, the duty cycle increases. If the welding amperes are increased beyond the

rated output, the duty cycle will decrease.

WARNING 5

Exceeding the duty cycle ratings will cause the thermal overload protection circuit to

become energized and shut down the output until the unit has cooled to normal operating

temperature.

CAUTION 1

Continually exceeding the duty cycle rat ings can cause damage to the welding power

source and will void the manufactures warranty.

NOTE 4

Due to variations that can occur in manufactured products, claimed performance,

voltages, ratings, all capacities, measurements, dimensions and weights quoted are

approximate only. Achievable capacities and ratings in use and operation will depend

upon correct installation, use, applications, maintenance and service.

21

Page 22

PAGE LEFT INTENTIONALLY BLANK

22

Page 23

4.0 OPERATOR CONTROLS

4.01 Pro-Wave 185TSW Controls

Figure 4– Pro-Wave 185TSW Power Source

1 Control Knob

This control sets the selected weld parameter, rotating it clockwise increases the parameter

that is indicated on the digital meter. Pushing the knob inward displays the actual welding

voltage.

2 Remote Control Socket

The 8 pin Remote Control S ocke t i s use d t o connec t remo te current con trol devices to the

welding Power Source. To make connect ion s, a lig n keyway, insert plug, and rotate threaded

collar fully cloc kwise.

Gnd.

21

543

876

12345678

Front view of 8-Sock et Receptacle

23

5k Ohms

Page 24

Socket Pin Function

1 Earth (Ground)

2

Torch Switch Input (24V) to energ ize we ld curren t.

(connect pins 2 & 3 to turn on wel ding current)

3

Torch Switch Input (0V) to e nergize weld current

(connect pins 2 & 3 to turn on wel ding current)

4

Connect pin 4 to pin 8 to instruct machine that a remote current control

device is connected (12V DC supply )

5 5k ohm (maximum) connection to 5k ohm rem ote co ntro l po tent io meter

6

Zero ohm (minimum) connection to 5k ohm re mote control

potentiometer

7 Wiper arm connection to 5 k oh m r em ote control potentiomete r

8 Connect pin 4 to pin 8 to instruct machine that a remote current control

device is connected (0V)

3 Positive Terminal

Welding current flows from the Power Source via heavy duty Dinse type terminal. It is

essential, however, that the male plug is inserted and turned securely to achieve a sound

electrical connection.

4 Negative Terminal

Welding current flows from the Power Source via heavy duty Dinse type terminal. It is

essential, however, that the male plug is inserted and turned securely to achieve a sound

electrical connection.

CAUTION 2

Loose welding terminal connections can cause overheating and result in the male plug

being fused in the bayonet terminal.

5 Gas Outlet

The Gas Outlet is a 5 /8 18 UNF f emale g as fitting.

6 ON/OFF Switch

This switch connects the Primary supply voltage to the inverter when in the ON position.

This enables the Power Sup ply.

WARNING 6

When the welder is connected to the Primary supply voltage, the internal electrical

components maybe at 240V potential with respect to earth.

7 Input Cable

The input cable connects the Primary supply voltage to the equipment.

24

Page 25

8 Gas Inlet

The Gas Inlet is a 5/8 18 UNF fe ma le g a s fit ti ng .

4.02 Weld Process selection for Pro-Wave 185TSW

Weld Mode

Weld Process

Selection STICK

STD

SLOPE

REPEAT

SPOT

PULSE ON/OFF

HF

TIG

LIFT

TIG Description

Yes Yes Yes 2T operation in TIG Modes using remote

devices to control contactor & current

No Yes Yes 4T operation in TIG Modes with crater fill

using a remote contactor device to control

sequence.

No Yes Yes 4T operation in TIG Modes with repeat

operation and crater fill using a remote

contactor device.

No Yes No 2T operation spot welding in HF TIG using

a remote contactor device.

No Yes Yes Pulse operation in TIG Modes

Yes Yes Yes Selects AC or DC weld current

Table 3 – Weld Process selection verses Weld Mode for Pro-Wave 185TSW

25

Page 26

4.03 Weld Parameter Descriptions for Pro-Wave 185TSW

Figure 5 Pro-Wave 185TSW Front Panel with Parameter Description

Parameter Description

This parameter operates in TIG modes only and is used to provide gas to

the weld zone prior to striking the arc, once the torch trigger switch has

been pressed. This control is used to dramatically reduce weld porosity at

PRE-FLOW

the start of a weld.

This parameter operates in all weld modes except Lift TIG mode and is

used to heat up the weld zone in TIG modes or improve the start

HOT START

characteristics for stick electrodes. e.g. low hydrogen electrodes. It sets

the peak start current on top of the BASE (WELD) current.

e.g. HOT START current = 130 amps when BASE (WELD) = 100 amps &

HOT START = 30 amps

INITIAL CUR.

This parameter operates in SLOPE or REPEAT (4T) TIG modes only and

is used to set the start current for TIG. The Start Current remains on until

the torch trigger switch is released after it has been depressed.

UP SLOPE

This parameter operates in TIG modes only and is used to set the time for

the weld current to ramp up, after the torch trigger switch has been

pressed then released, from INITIAL CUR to PEAK or BASE current

PEAK CUR.

WELD

This parameter sets the PEAK weld current when in PULSE mode

This parameter sets the TIG WELD current in STD, SLOPE, REPEAT and

SPOT modes when PULSE is off. This parameter also sets the STICK

weld current.

BASE

This parameter sets the Background current when in Pulse TIG mode.

(Background

Current)

26

Page 27

Parameter Description

SPOT TIME

PULSE WIDTH

PULSE FREQ.

AC FREQUENCY

WAVE BALANCE

This parameter sets the duration of the SPOT TIME in HF TIG mode only

This parameter sets the percentage on time of the PULSE FREQUENCY

for PEAK weld current when the PULSE is on.

This parameter sets the PULSE FREQUENCY when the PULSE is on.

This parameter operates in AC mode only and is used to set the frequency

for the AC weld current.

This parameter is used for aluminum AC TIG mode and is used to set the

penetration to cleaning action ratio for the AC weld current. Generally

WAVE BALANCE is set to 50% for AC STICK welding. The WAVE

BALANCE control changes the ratio of penetration to cleaning action of

the AC TIG welding arc. Maximum weld penetration is achieved when

the WAVE BALANCE control is set to 10%. Maximum cleaning of

heavily oxidised aluminium or magnesium alloys is achieved when the

WAVE BALANCE control is set to 65%.

WAVE BALA NCE=50%

WAVE BALA NCE=10%

10%50% 65%

WAVE BALA NCE=65%

(+ )(+ ) (+ )

DOWN SLOPE

CRATER CUR.

POST-FLOW

Table 4 – Weld Parameter Descriptions for Pro-Wave 185TSW

(- )(- ) (- )

90%50% 35%

Balanced with 50% pene trat ion

and 50% cleaning

This parameter operates in TIG modes only and is used to set the time for

the weld current to ramp down, after the torch trigger switch has been

pressed, to CRATER CUR. This control is used to eliminate the crater that

can form at the completion of a weld.

This parameter operates in SLOPE or REPEAT (4T) TIG modes only and

is used to set the finish current for TIG. The CRATER Current remains on

until the torch trigger switch is released after it has been depressed.

This parameter operates in TIG modes only and is used to adjust the post

gas flow time once the arc has extinguished. This control is used to

dramatically reduce oxidation of the tungsten electrode.

Maximum Penetration and

reduced cleaning

Maximum Cleani ng a nd

reduced penetr ation

27

Page 28

4.04 Weld Parameters for Pro-Wave 185TSW

Weld Mode

Weld

Parameter

Parameter

Range

Factory

Setting

Incremental

Unit STICK

HF

TIG

LIFT

TIG

PRE-FLOW 0.0 to 1.0 sec 0.1 sec 0.1 sec No Yes Yes

HOT START 0 to 70A 20A 1A Yes Yes No

INITIAL CUR. 5 to 185A 30A 1A No Yes Yes

UP SLOPE 0 to 15 sec 1 sec 0.1 sec No Yes Yes

PEAK CUR. 5 to 185A 120A 1A No Yes Yes

WELD CUR

(TIG)

WELD CUR

(STICK)

5 to 185A 80A 1A No Yes Yes

5 to 160A 80A 1A Yes No No

SPOT TIME 0.5 to 5.0 sec 2 sec 0.1 sec No Yes Yes

PULSE WIDTH 15 to 80% 50% 1% No Yes Yes

PULSE FREQ. 0.5 to 500Hz 100.0Hz

See

No Yes Yes

Table 6

AC FREQUENCY 15 to 150Hz 50Hz 1Hz Yes Yes Yes

WAVE BALANCE 10 to 65% 50% 1% Yes Yes Yes

DOWN SLOPE 0 to 25 sec 3 sec 0.1 sec No Yes Yes

CRATER CUR. 5 to 185A 30A 1A No Yes Yes

POST-FLOW 0.0 to 60 sec 10 sec 0.1 sec No Yes Yes

Table 5 – Weld Parameters for Pro-Wave 185TSW

PULSE FREQ. Range Incremental Unit

0.5 to 20Hz 0.1Hz

20 to 100Hz 1Hz

100 to 500Hz 5Hz

Table 6 – PULSE FREQ. Range and Incremental Units

28

Page 29

4.05 Power Source Features

Feature Description

New Digital Control

Touch Panel Switches

Front Control Cover

Digital Meter

Intelligent Fan Control

ON/OFF switch

Voltage Reduction Device (VRD)

• Almost all welding parameters are adjustable

• Touch switches eliminate mechanical damage

• Protects front panel controls

• Displays selected weld parameter value

• Displays weld current when welding

• Displays weld current for 20 seconds after weld

has been completed

• A selected weld parameter value can be adjusted at

any time even while welding

• The intelligent cooling system is designed to

reduce dust and foreign material build-up, whilst

providing optimum cooling.

• Fan speed reduces approximately 30 seconds after

machine is turned on

• Fan speed increases when internal components

reaches operating temperature

• Primary voltage Supply ON/OFF switch located

on rear panel

Reduces the OCV when the power supply is not in

use. Eliminates the need for add on voltage reducers

and has no effect on arc starting.

• VRD fully complies to IEC 60974-1

• When Stick mode is selected the green VRD light

is ON when not welding and red when welding.

• When in TIG modes VRD is off.

Control Knob

Self Diagnosis Using Error Codes

• For the selected weld parameter, rotating the knob

clockwise increases the parameter

• Rotating the knob counter-clockwise decreases the

parameter

• A selected weld parameter value can be adjusted at

any time even while welding

• Pushing the knob in displays actual arc voltage.

• An error code is displayed on the Digital Meter

when a problem occurs with Primary supply

voltage or internal component problems. Refer to

troubleshooting guide.

29

Page 30

PAGE LEFT INTENTIONALLY BLANK

30

Page 31

5.0 SET-UP FOR SMAW (STICK) AND GTAW (TIG)

Conventional operating procedures apply when using t he Welding Power Source, i.e. connect work

lead directly to work piece and electrode lead is used to hold electrode. Wide safety margins

provided by the coil design ensure that the Welding Power Source will withstand short-term

overload without adverse effects. The welding current range values should be used as a guide

only. Current delivered to the arc is dependent on the welding arc voltage, and as welding arc

voltage varies between different classes of electrodes, welding current at any one setting would

vary according to the type of electrode in use. The operator should use the welding current range

values as a guide, then finally adjust the cu rre n t se tting to s ui t t he app lic ati on.

Figure 6– 185TSW AC/DC Set-up

WARNING 7

Before connecting the work clamp to the

work and inserting the electrode in the

electrode holder make sure the Primary

power supply is switched off.

CAUTION 3

Remove any packaging material prior

Remove any packaging material prior

Remove any packaging material priorRemove any packaging material prior

to use. Do not block the air vents at

to use. Do not block the air vents at

to use. Do not block the air vents atto use. Do not block the air vents at

the front or rear or sides of the

the front or rear or sides of the

the front or rear or sides of thethe front or rear or sides of the

Welding Power Source.

Welding Power Source.

Welding Power Source.Welding Power Source.

CAUTION 4

DO NOT change the Weld Mode or

DO NOT change the Weld Mode or

DO NOT change the Weld Mode orDO NOT change the Weld Mode or

Weld Process Mode until after POST-

Weld Process Mode until after POST-

Weld Process Mode until after POST-Weld Process Mode until after POSTFLOW time has finished.

FLOW time has finished.

FLOW time has finished.FLOW time has finished.

31

Page 32

6.0 SEQUENCE OF OPERATION

123

NOTE: Scroll Buttons are used to select the parameters to be set. The

LED’s show which function is being adjusted on the weld sequence graph.

Refer to the Symbols Table located in the front of the manual for Symbol

descriptions.

Figure 7 185TSW Front Panel

4

7

6

32

Page 33

1. Pulse function – Pressing this button enables the TIG current pulse functions.

2. Scroll Buttons – used to select the parameters to be set. The LED’s show which function is being

adjusted on the Sequence Graph.

3. TIG Mode Functions – Pressing this button scrolls through the output TIG function modes (Standard,

Slope, Slope w/repeat, Spot).

4. Digital LED display – Welding amperage and parameter values are displayed in this window. Internal

warnings such as over temperature, low or high input voltage applied are signaled to the operator by a

warning sound and error message on the screen.

5. Control knob – allows the operator to adjust the output amperage within the entire range of the power

source, also used to set each parameter value.

Pushing the knob inward displays the actual welding

voltage.

6. Process Button – This button selects between STICK, Lift or HF TIG mode. A remote control

device is required for use during LIFT TIG and HF TIG operation. See section 4.01, section 2

“Remote Control Socket”, for complete details of the remote device.

7. AC/DC Button – Selects between AC or DC welding output.

6.01 Stick Welding

• Connect work lead to negative terminal

• Connect electrode lead to positive terminal

• Switch machine on

• Set AC or DC weld current. If AC is selected then set AC FREQ t o 60Hz & WAVE

BALANCE to 50%.

• Connect remote control device if required

Use the Scroll Button s t o m ove t o t he pa rame ter to be set . T he LED will show which

function is being adjusted on t he weld sequence g raph. Use the con trol kno b to adj us t each

parameter.

• Set HOT START

• Set WELD current

Commence welding

33

Page 34

6.02 AC or DC HF TIG Welding

• Connect work lead to positive terminal

• Connect TIG torc h to neg ative terminal

• Switch machine on

• Set AC or DC weld current. If AC is selected then set AC FREQ & WAVE BALANCE

• Connect remote control device. . See section 4.0 1, sec tio n 2 “ Remo te Control Socket”,

for complete deta il s of the remote device.

Use the Scroll Button s t o m ove t o t he pa rame ter to be set . T he LED will show which

function is being adjusted on t he weld sequence g raph. Use the con trol kno b to adj us t each

parameter.

• Set PRE-FLOW time

• Set HOT START current

• Set POST-FLOW time

• Set WELD current

• Set POST-FLOW time

Slope Mode Parameters if required

• Set INTIAL CUR current

• Set UP SLOPE time

• Set (WELD) PEAK CUR current

• Set BASE current

• Set DOWN SLOPE time

• Set CRATER CUR current

Pulse Mode parameters if required

• Set PULSE WIDTH % for PEAK CURRENT

• Set PEAK CURRENT

• Set PULSE FREQ

Commence welding

34

Page 35

6.02.01 Slope Mode Sequence

Switch

Closed

Preflow

Initial

Current

Up

Slope

Switch

Open

Weld Current

Down

Slope

Switch

Closed

Switch

Open

Final

Current

Postflow

Note 5

Slope function operates with a Remote ON/OFF device only.

1) To start Slope sequence Close remote switch contacts. Once the welding arc is established the

Power Source will maintain initial current setting as long as the remote switch contacts are

closed.

a) In the HF TIG mode, after Preflow time, High Frequency is present at the torch. When the

torch is positioned close to the work the welding current will transfer to the work and

establish the arc at the initial current setting.

b) In the Lift TIG mode, after Preflow time, Lift Start current is present at the torch. When the

electrode is touched to the work and lifted off, the welding arc is established at the initial

current setting.

2) Open Remote Switch – current increases to weld current. Once welding arc has reached weld

current the power source will maintain weld current as long as the remote switch contacts are

open.

3) Close Remote Switch – Welding current decreases to final current setting. Once final welding

current is reached the power source will maintain final current setting as long as the remote

switch contacts are closed.

4) Open Remote Switch – Welding arc stops and post flow begins.

6.02.02 Slope Mode with repeat sequence

The repeat function is operated during the down slope cycle of the Slope Sequence and is active

through the down slope period only. During the down slope period by opening the Remote Switch

contacts the current will increase back to weld current. Within the Down Slope period the repeat

function can operated as many times as desired. To continue slope cycle and end slope sequence

close remote switch contacts and allow weld current to reach final current setting. Once final current

setting is reached opening the Remote Switch again will turn off the welding arc and post flow

begins.

35

Page 36

6.02.03 Pulse Controls

(Pulse Width) (Pulse Frequency)

(Peak Current)

(Base)

Background

Current

The Pulse controls are used primarily to control heat input. Pulse offers a number of advantages as

follows:

1) Control puddle – size and fluidity (especially out of position).

2) Increase penetration

3) Travel speed control

4) Better consistent quality

5) Decreased distortion on lighter or thinner materials.

6.02.03 Puls e controls continued

Pulse-current provides a system in which the welding current continuously changes between two

levels. During the periods of Peak current, heating and fusion takes place, and during the

background (base) current periods, cooling and solidification take place. Pulse Width is the time in

one cycle the current remains at the peak current setting. Pulse Frequency, measured in Hertz, is the

number of cycles per second the current travels between peak and background current settings. It is

as if the foot rheostat were moved up and down to increase and decr ease the welding current on a

regular basis. The faster you moved the foot rheostat up and down the faster the frequency.

36

Page 37

7.0 BASIC TIG WELDING GUIDE

7.01 Explanation of “Fluttery Arc” when AC TIG Welding on Aluminum

The following will assist in understanding the phenomenon of Arc Flutter, also referred to as Arc

Rectification.

The basic thesis is that the flu tteri ng is caused by lack of oxide in the weld pool.

The oxide layer on the plate reduced the energy for electron emission. Electron emission from the

weld pool (DC+) causes the oxide layers to be disrupted, the so-called “cleaning action”.

However once the cleaning action has produced a mirror like surface weld pool the effect of the

oxide layer is limited because the oxide layer has dissipated. This makes electron emission from

the weld pool more difficult and increases the chance of arc instability.

This idea is supported by the observation that once fluttering starts it can be made to stop by

working the arc away from the mirror like weld pool to an area of oxide coated material. As soon

as this is done the arc settles back to a stable condition. So while the arc is “consuming” oxide

coated plate the instability does not occur. But once the arc is stationary, the pool becomes

thoroughly “cleaned” by election emiss ion, the f luttering beg ins .

Tests conducted on various types of AC TIG power sources, Fluttery Arc is not confined to one

type of power source or it’s design, both conventional and inverter types suffer from the same

problem.

AC TIG on aluminum

The Problem: Arc appears unstable and pulses or flutters. ie. appears to rapidly change welding

current.

Conditions that accentuate arc flutter: Conditions that minimizes arc flutter:

• Cold work piece, • Preheat the work piece,

• Very short arc length, • Increase the arc length,

• Weld pool crater about 0.39” to 0.47”

(10 to 12mm) diameter,

• Arc field in one spot to produce

“mirror” clean weld pool,

• Increased cleaning action.

ie. Prolonged oxide emission from a

stationary weld pool increases the

likelihood of arc flutter,

• Accentuated when tungsten running

near its current capacity, ie. Molten

ball on end.

• Introduce filler rod material to the

weld pool, which introduces oxides.

• Move the weld pool around to

introduce oxides to the weld pool.

• Decrease the cleaning action by

turning the WAVE BALANCE to below

50% or move the weld pool around.

• Use a larger diameter tungsten

electrode.

Table 7 – Reduction of Arc Flutter

Conclusion: Fluttery arc in AC TIG is a physical phenomenon independent of machine design.

37

Page 38

7.02 Electrode Polarity

Connect the TIG torch to the - / TORCH terminal and the work lead to the + / WORK

terminal for direct current straight po larity. Direct current straight polarity is the most widely

used polarity for DC TIG welding. It allows limited wear of the electrode since 70% of the

heat is concentrated at the work piece.

7.03 Tungsten Electrode Current Ranges

Electrode Diameter AC Current (Amps) DC Current (Amps)

0.040” (1.0mm) 30 – 70 30 – 60

1/16” (1.6mm) 60 – 95 60 – 115

3/32” (2.4mm) 125 – 150 100 – 165

1/8” (3.2mm) 130 – 225 135 – 200

5/32” (4.0mm) 190 – 280 190 – 280

3/16” (4.8mm) 250 – 340 250 – 340

Table 8 – Current ranges for varies tungsten electrode sizes

7.04 Tungsten Electrode Types

Electrode Type

Welding Application Features Color

(Ground

Finish)

DC welding of mild steel,

Thoriated 2%

stainless steel and copper.

High quality AC welding of

Zirconated 1%

aluminium, magnesium and

their alloys.

AC & DC welding of mild

Ceriated 2%

steel, stainless steel, copper,

aluminium, magnesium and

their alloys

Table 9 – Tungsten electrode types

Excellent arc starting, Long

life, High current carrying

capacity.

Self cleaning, Long life,

Maintains balled end, High

current carrying capacity.

Longer life, More stable arc,

Easier starting, Wider current

range, Narrower more

concentrated arc.

Code

Red

White

Grey

38

Page 39

7.05 Guide for Selecting Filler Wire Diameter

Filler Wire Diameter

1/16” (1.6 mm) 30-95 20 - 90

3/32” (2.4 mm) 125-160 65 - 115

1/8” (3.2 mm) 180-240 100 - 165

3/16” (4.8 mm) 220-320 200-350

Table 10 – Filler wire selection guide

The filler wire diameter specified in

Table 10 is a guide only, other diameter wires may be used according to the welding

application.

7.06 Shielding Gas Selection

Alloy Shielding Gas

AC Current Range

(Amps)

DC Current Range

(Amps)

NOTE 6

Argoshield is a registered trademark of BOC Gases

Limited.

Aluminium & alloys Welding Argon, Argoshield 80T, 81T

Carbon Steel Welding Argon

Stainless Steel Welding Argon, Argoshield 71T, 80T, 81T

Nickel Alloy Welding Argon, Argoshield 71T

Copper Welding Argon, Argoshield 81T

Titanium Welding Argon, Argoshield 80T, 81T

Table 11 – Shielding gas selection

7.07 TIG Welding Parameters for Low Carbon & Low Alloy Steel Pipe

Electrode Type &

Diameter

Thoriated 2%

3/32” (2.4 mm)

Thoriated 2%

3/32” (2.4 mm)

Thoriated 2%

3/32” (2.4 mm)

Current Range DC

Amperes

120 - 170 Yes

100 - 160 Yes

90 - 130 No

Filler Rod for

Root Pass

Joint Preparation

Table 12 – TIG welding parameters for low carbon & low alloy steel pipe

39

Page 40

7.08 Welding Parameters for Aluminum

Base Metal

Thickness

0.040”

1.0mm

0.045”

1.2mm

1/16”

1.6mm

1/8”

3.2mm

3/16”

4.8mm

¼”

6.4mm

AC Current

for Aluminum

30-45 Butt/Corner

35-50

40-60 Butt/Corner

45-70

60-85 Butt/Corner

70-95

125-150 Butt/Corner

130-160

Tungsten

Electrode

Diameter

0.040”

1.0mm

0.040”

1.0mm

1/16”

1.6mm

3/32”

2.4mm

Filler Rod

Diameter

(if required)

1/16”

1.6mm

1/16”

1.6mm

1/16”

1.6mm

3/32”

2.4mm

Argon Gas

Flow Rate

Liters/min

5-7

5-7

7

10

Joint Type

Lap/ Fillet

Lap/ Fillet

Lap/ Fillet

Lap/ Fillet

1/8”

3.2mm

180-225 Butt/Corner

190-240

240-280 Butt/Corner

250-320

1/8”

3.2mm

3/16”

4.8mm

1/8”

3.2mm

3/16”

4.8mm

10

Lap/ Fillet

13

Lap/ Fillet

Table 13 – AC TIG welding parameter

7.09 Welding Parameters for Steel

Base Metal

Thickness

0.040”

1.0mm

0.045”

1.2mm

1/16”

1.6mm

1/8”

3.2mm

3/16”

4.8mm

¼”

6.4mm

DC Current

for Mild

Steel

DC Current

for Stainless

Steel

35-45 20-30 Butt/Corner

40-50 25-35

45-55 30-45 Butt/Corner

50-60 35-50

60-70 40-60 Butt/Corner

70-90 50-70

80-100 65-85 Butt/Corner

90-115 90-110

115-135 100-125 Butt/Corner

140-165 125-150

160-175 135-160 Butt/Corner

170-200 160-180

Tungsten

Electrode

Diameter

0.040”

1.0mm

0.040”

1.0mm

1/16”

1.6mm

1/16”

1.6mm

3/32”

2.4mm

1/8”

3.2mm

Filler Rod

Diameter

(if required)

1/16”

1.6mm

1/16”

1.6mm

1/16”

1.6mm

3/32”

2.4mm

1/8”

3.2mm

5/32”

4.0mm

Argon Gas

Flow Rate

Liters/min

5-7

5-7

7

7

10

10

Joint Type

Lap/ Fillet

Lap/ Fillet

Lap/ Fillet

Lap/ Fillet

Lap/ Fillet

Lap/ Fillet

Table 14 – DC TIG welding parameters

40

Page 41

8.0 Basic Arc Welding Guide

8.01 Electrode Polarity

Stick electrodes are generally connected to the ‘+’ terminal and the work lead to the ‘−’

terminal but if in doubt consu lt the electrode manufacturers literature.

8.02 Effects of Stick Welding Various Materials

High tensile and alloy steels

The two most prominent effects of welding these steels are the formation of a hardened zone in

the weld area, and, if suitable precautions are not taken, the occurrence in this zone of under-bead

cracks. Hardened zone and under-bead cracks in the weld area may be reduced by using the

correct electrodes, preheating, using higher current settings, using larger electrodes sizes, short

runs for larger electrode deposits or tempering in a furnace.

Manganese steels

The effect on manganese steel of slow cooling from high temperatures is to embrittle it. For this

reason it is absolutely essential to keep manganese steel cool during welding by quenching after

each weld or skip welding to distribute the heat.

Cast Iron

Most types of cast iron, except white iron, are weldable. White iron, because of its extreme

brittleness, generally cracks when attempts are made to weld it. Trouble may also be experienced

when welding white-heart malleable, due to the poros ity caused by gas held in this ty pe of iron.

Copper and alloys

The most important factor is the high rate of heat conductivity of copper, making preheating of

heavy sections necessary to give proper fusi on of wel d an d base meta l.

Types of Electrodes

Arc Welding electrodes are classified into a number of groups depending on their applications.

There are a great number of electrodes used for specialized industrial purposes, which are not of

particular interest for everyday general work. These include some low hydrogen types for high

tensile steel, cellulose types for welding large diameter pipes, etc. The range of electrodes dealt

with in this publica ti on w il l cove r the vast majority of a pplications likely to be encounter ed; are all

easy to use and all will work on even the most basic of welding machines.

41

Page 42

9.0 ROUTINE MAINTENANCE

The only routine maintenance required for the power supply is a thorough cleaning and inspection,

with the frequency depending on the usag e and the operat ing enviro nmen t.

WARNING 8

Disconnect primary power at the source before opening the enclosure. Wait at least two

minutes before opening the enclosure to allow the primary capacitors to discharge.

To clean the unit, open the enclosure (please refer to Section 8.01.01, Opening the Enclosure in the

185TSW Service Manual P/N 430429-512) and use a vacuum cleaner to remove any accumulated

dirt and dust. The unit should also be wiped clean, if necessary; with solvents that are