Page 1

Plasma Cutting

System

PAK 10

Instruction Manual

April 12, 2002 Manual No. 0-0515

Page 2

WARNINGS

Read and understand this entire Manual and your employer’s safety practices before installing, operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement, the

Manufacturer assumes no liability for its use.

Plasma Cutting System PAK 10

Instruction Manual Number 0-0515

Published by:

Thermal Dynamics Corporation

82 Benning Street

West Lebanon, New Hampshire, USA 03784

(603) 298-5711

www.thermal-dynamics.com

Copyright 1984 by

Thermal Dynamics Corporation

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to

any party for any loss or damage caused by any error or omission in

this Manual, whether such error results from negligence, accident, or

any other cause.

Printed in the United States of America

Publication Date: April 12, 2002

Record the following information for Warranty purposes:

Where Purchased:_________________________________________

Purchase Date:____________________________________________

Power Supply Serial #:_____________________________________

Torch Serial #:_____________________________________________

Page 3

Contents

SECTION 1:

GENERAL INFORMATION ....................................................................................................i

1.01 Notes, Cautions and Warnings ..........................................................................i

1.02 Important Safety Precautions............................................................................i

1.03 Publications...................................................................................................... ii

1.04 Note, Attention et Avertissement ..................................................................... iii

1.05 Precautions De Securite Importantes.............................................................. iii

1.06 Documents De Reference ............................................................................... v

1.07 Declaration of Conformity ............................................................................... vii

1.08 Statement of Warranty................................................................................... viii

SPECIFICATIONS ........................................................................................................................ 1

1.1. DESCRIPTION OF EQUIPMENT ................................................................... 2

1.2. SPECIFICATIONS........................................................................................... 2

1.3. PLASMA CUTTING........................................................................................ 3

1.4. THEORY OF OPERATION.............................................................................. 3

INSTALLATION............................................................................................................................. 5

2.1 UNPACKING ................................................................................................... 5

2.2 EQUIPMENT ASSEMBLY ............................................................................... 5

2.3 EQUIPMENT INST ALLATION ......................................................................... 6

OPERATION ................................................................................................................................. 9

3.1 OPERATING CONTROLS............................................................................... 9

3.2 PRE-OPERATION SET-UP ............................................................................. 9

3.3 OPERATION ................................................................................................. 10

3.4 CUTTING CURRENT AND SPEED SELECTION......................................... 13

SERVICE.................................................................................................................................... 15

4.1 TORCH MAINTENANCE .............................................................................. 15

4.2 TORCH LEADS AND LEADS EXTENSION PACKAGES .............................. 17

4.3 PAK UNIT MAINTENANCE ........................................................................... 18

4.4 GAS PRESSURE REGULATORS................................................................. 18

4.5 TROUBLE SHOO TING GUIDE..................................................................... 19

4.6 TEST PROCEDURES................................................................................... 21

PARTS LISTS ............................................................................................................................. 25

General Arrangement............................................................................................ 25

PAK 10 Cutting System ......................................................................................... 26

Equipment Board Assembly .................................................................................. 28

Control P.C. Board Assembly................................................................................. 29

Control Bridge and Main Bridge Assemblies ......................................................... 30

Torch Connection Panel Assembly ........................................................................ 32

Pilot Resistor and Rear Panel Assembly ............................................................... 34

Front P anel Assembly ........................................................................................... 36

Base Components Assembly ................................................................................ 38

Torch Leads, Leads Extension Packages, Torch Guide and

Circle Cutting Attachment, Remote Control Assembly .................................. 40

Series 4B Gas-Cooled Torches ............................................................................. 42

Gas Pressure Regulators...................................................................................... 44

Page 4

Page 5

SECTION 1:

GENERAL INFORMATION

1.01 Notes, Cautions and Warnings

Throughout this manual, notes, cautions, and warnings

are used to highlight important information. These highlights are categorized as follows:

NOTE

An operation, procedure, or backgr ound information which requires additional emphasis or is helpful in efficient operation of the system.

CAUTION

A procedure which, if not properly followed, may

cause damage to the equipment.

WARNING

A procedure which, if not properly followed, may

cause injury to the operator or others in the operating area.

1.02 Important Safety Precautions

WARNINGS

OPERATION AND MAINTENANCE OF

PLASMA ARC EQUIPMENT CAN BE DANGEROUS AND HAZARDOUS TO YOUR

HEALTH.

Plasma arc cutting produces intense electric and

magnetic emissions that may interfere with the

proper function of cardiac pacemakers, hearing

aids, or other electronic health equipment. Persons who work near plasma arc cutting applications should consult their medical health professional and the manufacturer of the health

equipment to determine whether a hazard exists.

To prevent possible injury, read, understand and

follow all warnings, safety precautions and instructions before using the equipment. Call 1-603298-5711 or your local distributor if you have any

questions.

GASES AND FUMES

Gases and fumes produced during the plasma cutting

process can be dangerous and hazardous to your health.

• Keep all fumes and gases from the breathing ar ea.

Keep your head out of the welding fume plume.

• Use an air-supplied respirator if ventilation is not

adequate to remove all fumes and gases.

• The kinds of fumes and gases from the plasma arc

depend on the kind of metal being used, coatings

on the metal, and the different pr ocesses. Y ou must

be very careful when cutting or welding any metals which may contain one or more of the following:

Antimony Chromium Mercury

Arsenic Cobalt Nickel

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese Vanadium

• Always read the Material Safety Data Sheets

(MSDS) that should be supplied with the material

you are using. These MSDSs will give you the information regarding the kind and amount of fumes

and gases that may be dangerous to your health.

• For information on how to test for fumes and gases

in your workplace, refer to item 1 in Subsection 1.03,

Publications in this manual.

• Use special equipment, such as water or down draft

cutting tables, to capture fumes and gases.

• Do not use the plasma torch in an area where combustible or explosive gases or materials are located.

• Phosgene, a toxic gas, is generated from the vapors

of chlorinated solvents and cleansers. Remove all

sources of these vapors.

• This product, when used for welding or cutting,

produces fumes or gases which contain chemicals

known to the State of California to cause birth defects and, in some cases, cancer . (California Health

& Safety Code Sec. 25249.5 et seq.)

ELECTRIC SHOCK

Electric Shock can injure or kill. The plasma arc process

uses and produces high voltage electrical energy. This

electric energy can cause severe or fatal shock to the operator or others in the workplace.

• Never touch any parts that are electrically “live”

or “hot.”

Date: No v ember 15, 2001 i GENERAL INFORMATION

Page 6

• Wear dry gloves and clothing. Insulate yourself

from the work piece or other parts of the welding

circuit.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workplace is

moist or damp.

• Install and maintain equipment according to NEC

code, refer to item 9 in Subsection 1.03, Publications.

• Disconnect power source before performing any

service or repairs.

• Read and follow all the instructions in the Operating Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag, sparks, or

the plasma arc.

• Be sure there is no combustible or flammable material in the workplace. Any material that cannot

be removed must be protected.

• Ventilate all flammable or explosive vapors from

the workplace.

• Do not cut or weld on containers that may have

held combustibles.

• Provide a fire watch when working in an area wher e

fire hazards may exist.

• Hydrogen gas may be formed and trapped under

aluminum workpieces when they are cut underwater or while using a water table. DO NOT cut

aluminum alloys underwater or on a water table

unless the hydrogen gas can be eliminated or dissipated. T rapped hydrogen gas that is ignited will

cause an explosion.

NOISE

Noise can cause permanent hearing loss. Plasma arc processes can cause noise levels to exceed safe limits. You

must protect your ears from loud noise to prevent permanent loss of hearing.

• T o protect your hearing from loud noise, wear pr otective ear plugs and/or ear muffs. Protect others

in the workplace.

• Noise levels should be measured to be sure the decibels (sound) do not exceed safe levels.

• For information on how to test for noise, see item 1

in Subsection 1.03, Publications, in this manual.

PLASMA ARC RAYS

Plasma Arc Rays can injure your eyes and burn your skin.

The plasma arc process produces very bright ultra violet

and infra red light. These arc rays will damage your

eyes and burn your skin if you are not properly pr otected.

• To protect your eyes, always wear a welding helmet or shield. Also always wear safety glasses with

side shields, goggles or other protective eye wear.

• Wear welding gloves and suitable clothing to protect your skin from the arc rays and sparks.

• Keep helmet and safety glasses in good condition.

Replace lenses when cracked, chipped or dirty.

• Protect others in the work area from the arc rays.

Use protective booths, screens or shields.

• Use the shade of lens as suggested in the following

per ANSI/ASC Z49.1:

Minimum Protective Suggested

Arc Current Shade No. Shade No.

Less Than 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

* These values apply where the actual arc is clearly

seen. Experience has shown that lighter filters

may be used when the arc is hidden by the workpiece.

1.03 Publications

Refer to the following standards or their latest revisions

for more information:

1. OSHA, SAFETY AND HEAL TH STANDARDS, 29CFR

1910, obtainable from the Superintendent of Documents, U.S. Government Printing Office, Washington,

D.C. 20402

2. ANSI Standard Z49.1, SAFETY IN WELDING AND

CUTTING, obtainable from the American Welding Society, 550 N.W. LeJeune Rd, Miami, FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC WELDING

AND GAS WELDING AND CUTTING, obtainable

from the Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402

4. ANSI Standard Z87.1, SAFE PRACTICES FOR OCCUP ATION AND EDUCA TIONAL EYE AND FACE PROTECTION, obtainable from American National Standards Institute, 1430 Broadway, New York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN’S

SAFETY -TOE FOOTWEAR, obtainable from the American National Standards Institute, 1430 Broadway, New

York, NY 10018

GENERAL INFORMATION ii Date: Nov ember 15, 2001

Page 7

6. ANSI Standard Z49.2, FIRE PREVENTION IN THE USE

OF CUTTING AND WELDING PROCESSES, obtainable from American National Standards Institute, 1430

Broadway, New York, NY 10018

7. AWS Standar d A6.0, WELDING AND CUTTING CONTAINERS WHICH HAVE HELD COMBUSTIBLES, obtainable from American Welding Society, 550 N.W.

LeJeune Rd, Miami, FL 33126

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS

FOR WELDING, CUTTING AND ALLIED PROCESSES, obtainable from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269

9. NFPA Standard 70, NATIONAL ELECTRICAL CODE,

obtainable from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269

10. NFP A Standar d 51B, CUTTING AND WELDING PROCESSES, obtainable from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269

11. CGA Pamphlet P-1, SAFE HANDLING OF COMPRESSED GASES IN CYLINDERS, obtainable from the

Compressed Gas Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202

12. CSA Standard W1 17.2, CODE FOR SAFETY IN WELDING AND CUTTING, obtainable from the Canadian

Standards Association, Standards Sales, 178 Rexdale

Boulevard, Rexdale, Ontario, Canada M9W 1R3

13. NWSA booklet, WELDING SAFETY BIBLIOGRAPHY

obtainable from the National Welding Supply Association, 1900 Arch Street, Philadelphia, PA 19103

14. American Welding Society Standard A WSF4.1, RECOMMENDED SAFE PRACTICES FOR THE PREPARATION FOR WELDING AND CUTTING OF CONT AINERS AND PIPING THAT HAVE HELD HAZARDOUS

SUBSTANCES, obtainable fr om the American Welding

Society, 550 N.W. LeJeune Rd, Miami, FL 33126

ATTENTION

Toute procédure pouvant résulter

l’endommagement du matériel en cas de nonrespect de la procédur e en question.

AVERTISSEMENT

Toute procédure pouvant provoquer des blessures

de l’opérateur ou des autres personnes se trouvant

dans la zone de travail en cas de non-respect de la

procédure en question.

1.05 Precautions De Securite Importantes

AVERTISSEMENTS

L’OPÉRATION ET LA MAINTENANCE DU

MATÉRIEL DE SOUDAGE À L’ARC AU JET

DE PLASMA PEUVENT PRÉSENTER DES

RISQUES ET DES DANGERS DE SANTÉ.

Coupant à l’arc au jet de plasma produit de l’énergie

électrique haute tension et des émissions

magnétique qui peuvent interférer la fonction

propre d’un “pacemaker” cardiaque, les appareils

auditif, ou autre matériel de santé electronique.

Ceux qui travail près d’une application à l’arc au

jet de plasma devrait consulter leur membre

professionel de médication et le manufacturier de

matériel de santé pour déterminer s’il existe des

risques de santé.

15. ANSI Standard Z88.2, PRACTICE FOR RESPIRATOR Y

PROTECTION, obtainable from American National

Standards Institute, 1430 Broadway, New York, NY

10018

1.04 Note, Attention et

Avertissement

Dans ce manuel, les mots “note,” “attention,” et

“avertissement” sont utilisés pour mettre en relief des

informations à caractère important. Ces mises en relief

sont classifiées comme suit :

NOTE

Toute opération, procédure ou renseignement

général sur lequel il importe d’insister davantage

ou qui contribue à l’efficacité de fonctionnement

du système.

Date: No v ember 15, 2001 iii GENERAL INFORMATION

Il faut communiquer aux opérateurs et au personnel TOUS les dangers possibles. Afin d’éviter les

blessures possibles, lisez, comprenez et suivez tous

les avertissements, toutes les précautions de sécurité

et toutes les consignes avant d’utiliser le matériel.

Composez le + 603-298-5711 ou votr e distributeur

local si vous avez des questions.

FUMÉE et GAZ

La fumée et les gaz produits par le procédé de jet de

plasma peuvent présenter des risques et des dangers de

santé.

Page 8

• Eloignez toute fumée et gaz de votre zone de respiration. Gardez votre tête hors de la plume de fumée

provenant du chalumeau.

• Utilisez un appareil respiratoire à alimentation en air

si l’aération fournie ne permet pas d’éliminer la fumée

et les gaz.

• Ne touchez jamais une pièce “sous tension” ou “vive”;

portez des gants et des vêtements secs. Isolez-vous

de la pièce de travail ou des autres parties du circuit

de soudage.

• Réparez ou remplacez toute pièce usée ou

endommagée.

• Les sortes de gaz et de fumée provenant de l’arc de

plasma dépendent du genre de métal utilisé, des

revêtements se trouvant sur le métal et des différ ents

procédés. Vous devez prendre soin lorsque vous

coupez ou soudez tout métal pouvant contenir un ou

plusieurs des éléments suivants:

antimoine cadmium mercure

argent chrome nickel

arsenic cobalt plomb

baryum cuivre sélénium

béryllium manganèse vanadium

• Lisez toujours les fiches de données sur la sécurité

des matières (sigle américain “MSDS”); celles-ci

devraient être fournies avec le matériel que vous

utilisez. Les MSDS contiennent des renseignements

quant à la quantité et la nature de la fumée et des gaz

pouvant poser des dangers de santé.

• Pour des informations sur la manière de tester la

fumée et les gaz de votre lieu de travail, consultez

l’article 1 et les documents cités à la page 5.

• Utilisez un équipement spécial tel que des tables de

coupe à débit d’eau ou à courant descendant pour

capter la fumée et les gaz.

• N’utilisez pas le chalumeau au jet de plasma dans une

zone où se trouvent des matières ou des gaz combustibles ou explosifs.

• Le phosgène, un gaz toxique, est généré par la fumée

provenant des solvants et des produits de nettoyage

chlorés. Eliminez toute source de telle fumée.

• Ce produit, dans le procéder de soudage et de coupe,

produit de la fumée ou des gaz pouvant contenir des

éléments reconnu dans L’état de la Californie, qui

peuvent causer des défauts de naissance et le cancer .

(La sécurité de santé en Californie et la code sécurité

Sec. 25249.5 et seq.)

CHOC ELECTRIQUE

• Prenez des soins particuliers lorsque la zone de travail est humide ou moite.

• Montez et maintenez le matériel conformément au

Code électrique national des Etats-Unis. (V oir la page

5, article 9.)

• Débranchez l’alimentation électrique avant tout travail d’entretien ou de réparation.

• Lisez et respectez toutes les consignes du Manuel de

consignes.

INCENDIE ET EXPLOSION

Les incendies et les explosions peuvent résulter des scories

chaudes, des étincelles ou de l’arc de plasma. Le procédé

à l’arc de plasma produit du métal, des étincelles, des

scories chaudes pouvant mettre le feu aux matières combustibles ou provoquer l’explosion de fumées

inflammables.

• Soyez certain qu’aucune matière combustible ou inflammable ne se trouve sur le lieu de travail. Protégez

toute telle matière qu’il est impossible de retirer de la

zone de travail.

• Procurez une bonne aération de toutes les fumées

inflammables ou explosives.

• Ne coupez pas et ne soudez pas les conteneurs ayant

pu renfermer des matières combustibles.

• Prévoyez une veille d’incendie lors de tout travail dans

une zone présentant des dangers d’incendie.

• Le gas hydrogène peut se former ou s’accumuler sous

les pièces de travail en aluminium lorsqu’elles sont

coupées sous l’eau ou sur une table d’eau. NE PAS

couper les alliages en aluminium sous l’eau ou sur

une table d’eau à moins que le gas hydrogène peut

s’échapper ou se dissiper . Le gas hydrogène accumulé

explosera si enflammé.

Les chocs électriques peuvent blesser ou même tuer. Le

procédé au jet de plasma requiert et produit de l’éner gie

électrique haute tension. Cette énergie électrique peut

produire des chocs graves, voire mortels, pour l’opérateur

et les autres personnes sur le lieu de travail.

GENERAL INFORMATION iv Date: Nov ember 15, 2001

Les rayons provenant de l’arc de plasma peuvent blesser

vos yeux et brûler votre peau. Le procédé à l’arc de

plasma produit une lumière infra-rouge et des rayons

RAYONS D’ARC DE PLASMA

Page 9

ultra-violets très forts. Ces rayons d’arc nuiront à vos

yeux et brûleront votre peau si vous ne vous protégez

pas correctement.

• Pour protéger vos yeux, portez toujours un casque ou

un écran de soudeur . Portez toujours des lunettes de

sécurité munies de parois latérales ou des lunettes de

protection ou une autre sorte de protection oculair e.

• Portez des gants de soudeur et un vêtement protecteur

approprié pour protéger votre peau contre les

étincelles et les rayons de l’arc.

• Maintenez votre casque et vos lunettes de protection

en bon état. Remplacez toute lentille sale ou

comportant fissure ou rognure.

• Protégez les autres personnes se trouvant sur la zone

de travail contre les rayons de l’arc en fournissant des

cabines ou des écrans de protection.

• Utilisez la nuance de lentille qui est suggèrée dans le

recommendation qui suivent ANSI/ASC Z49.1:

Nuance Minimum Nuance Suggerée

Courant Arc Protective Numéro Numéro

Moins de 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

* Ces valeurs s’appliquent ou l’arc actuel est observé

clairement. L ’experience a démontrer que les filtres

moins foncés peuvent être utilisés quand l’arc est

caché par moiceau de travail.

1.06 Documents De Reference

Consultez les normes suivantes ou les révisions les plus

récentes ayant été faites à celles-ci pour de plus amples

renseignements :

1. OSHA, NORMES DE SÉCURITÉ DU TRA VAIL ET DE

PROTECTION DE LA SANTÉ, 29CFR 1910,

disponible auprès du Superintendent of Documents,

U.S. Government Printing Office, Washington, D.C.

20402

2. Norme ANSI Z49.1, LA SÉCURITÉ DES

OPÉRATIONS DE COUPE ET DE SOUDAGE,

disponible auprès de la Société Américaine de

Soudage (American Welding Society), 550 N.W.

LeJeune Rd., Miami, FL 33126

3. NIOSH, LA SÉCURITÉ ET LA SANTÉ LORS DES

OPÉRATIONS DE COUPE ET DE SOUDAGE À

L’ARC ET AU GAZ, disponible auprès du Superintendent of Documents, U.S. Government Printing

Office, Washington, D.C. 20402

4. Norme ANSI Z87.1, PRATIQUES SURES POUR LA

PROTECTION DES YEUX ET DU VISAGE AU TRAV AIL ET DANS LES ECOLES, disponible de l’Institut

Américain des Normes Nationales (American National Standards Institute), 1430 Broadway, New Y ork,

NY 10018

5. Norme ANSI Z41.1, NORMES POUR LES

CHAUSSURES PROTECTRICES, disponible auprès

de l’American National Standards Institute, 1430

Broadway, New York, NY 10018

BRUIT

Le bruit peut provoquer une perte permanente de l’ouïe.

Les procédés de soudage à l’arc de plasma peuvent

provoquer des niveaux sonores supérieurs aux limites

normalement acceptables. V ous dú4ez vous pr otéger les

oreilles contre les bruits forts afin d’éviter une perte

permanente de l’ouïe.

• Pour protéger votre ouïe contre les bruits forts, portez

des tampons protecteurs et/ou des protections

auriculaires. Protégez également les autres personnes

se trouvant sur le lieu de travail.

• Il faut mesurer les niveaux sonores afin d’assurer que

les décibels (le bruit) ne dépassent pas les niveaux

sûrs.

• Pour des renseignements sur la manière de tester le

bruit, consultez l’article 1, page 5.

6. Norme ANSI Z49.2, PRÉVENTION DES INCENDIES

LORS DE L ’EMPLOI DE PROCÉDÉS DE COUPE ET

DE SOUDAGE, disponible auprès de l’American National Standards Institute, 1430 Broadway, New Y ork,

NY 10018

7. Norme A6.0 de l’Association Américaine du Soudage

(AWS), LE SOUDAGE ET LA COUPE DE

CONTENEURS A YANT RENFERMÉ DES PRODUITS

COMBUSTIBLES, disponible auprès de la American

Welding Society, 550 N.W. LeJeune Rd., Miami, FL

33126

8. Norme 51 de l’Association Américaine pour la Protection contre les Incendies (NFPA), LES SYSTEMES

À GAZ AVEC ALIMENTATION EN OXYGENE

POUR LE SOUDAGE, LA COUPE ET LES

PROCÉDÉS ASSOCIÉS, disponible auprès de la National Fire Protection Association, Batterymar ch Park,

Quincy, MA 02269

Date: No v ember 15, 2001 v GENERAL INFORMATION

Page 10

9. Norme 70 de la NFPA, CODE ELECTRIQUE NATIONAL, disponible auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA

02269

10. Norme 51B de la NFPA, LES PROCÉDÉS DE

COUPE ET DE SOUDAGE, disponible auprès de la

National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

11. Brochure GCA P-1, LA MANIPULATION SANS

RISQUE DES GAZ COMPRIMÉS EN CYLINDRES,

disponible auprès de l’Association des Gaz

Comprimés (Compressed Gas Association), 1235

Jefferson Davis Highway, Suite 501, Arlington, VA

22202

12. Norme CSA W117.2, CODE DE SÉCURITÉ POUR

LE SOUDAGE ET LA COUPE, disponible auprès

de l’Association des Normes Canadiennes, Standards Sales, 178 Rexdale Boulevard, Rexdale,

Ontario, Canada, M9W 1R3

13. Livret NWSA, BIBLIOGRAPHIE SUR LA

SÉCURITÉ DU SOUDAGE, disponible auprès de

l’Association Nationale de Fournitures de Soudage

(National Welding Supply Association), 1900 Arch

Street, Philadelphia, PA 19103

14. Norme AWSF4.1 de l’Association Américaine de

Soudage, RECOMMANDATIONS DE PRATIQUES

SURES POUR LA PRÉPARATION À LA COUPE ET

AU SOUDAGE DE CONTENEURS ET TUYAUX

AYANT RENFERMÉ DES PRODUITS

DANGEREUX , disponible auprès de la American

Welding Society, 550 N.W. LeJeune Rd., Miami, FL

33126

15. Norme ANSI Z88.2, PRA TIQUES DE PROTECTION

RESPIRATOIRE, disponible auprès de l’American

National Standards Institute, 1430 Broadway, New

York, NY 10018

GENERAL INFORMATION vi Date: Nov ember 15, 2001

Page 11

1.07 Declaration of Conformity

Manufacturer: Thermal Dynamics Corporation

Address: 82 Benning Street

W est Lebanon, New Hampshire 03784

USA

The equipment described in this manual conforms to all applicable aspects and regulations of the ‘Low Voltage Directive’

(European Council Directive 73/23/EEC as amended by Council Directive 93/68/EEC) and to the National legislation for

the enforcement of this Directive.

Serial numbers are unique with each individual piece of equipment and details description, parts used to manufacture a unit

and date of manufacture.

National Standard and Technical Specifications

The product is designed and manufactured to a number of standards and technical r equirements. Among them are:

* CSA (Canadian Standards Association) standard C22.2 number 60 for Arc welding equipment.

* UL (Underwriters Laboratory) rating 94VO flammability testing for all printed-circuit boar ds used.

* ISO/IEC 60974-1 (BS 638-PT10) (EN 60 974-1) (EN50192) (EN50078) applicable to plasma cutting equipment and associ-

ated accessories.

* Extensive product design verification is conducted at the manufacturing facility as part of the routine design and manufac-

turing process. This is to ensure the product is safe, when used according to instructions in this manual and related

industry standards, and performs as specified. Rigorous testing is incorporated into the manufacturing process to ensure

the manufactured product meets or exceeds all design specifications.

Thermal Dynamics has been manufacturing products for more than 30 years, and will continue to achieve excellence in our

area of manufacture.

Manufacturers responsible repr esentative: Giorgio Bassi

Managing Director

Thermal Dynamics Europe

Via rio Fabbiani 8A

40067 Rastignano (BO)

Italy

Date: No v ember 15, 2001 vii GENERAL INFORMATION

Page 12

1.08 Statement of Warranty

LIMITED WARRANTY: Thermal Dynamics® Corporation (hereinafter “Thermal”) warrants that its products will be free of defects in

workmanship or material. Should any failure to conform to this warranty appear within the time period applicable to the Thermal

products as stated below , Thermal shall, upon notification thereof and substantiation that the product has been stor ed, installed, operated,

and maintained in accordance with Thermal’s specifications, instructions, recommendations and recognized standard industry practice,

and not subject to misuse, repair , neglect, alteration, or accident, corr ect such defects by suitable r epair or replacement, at Thermal’s sole

option, of any components or parts of the product determined by Thermal to be defective.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PAR TICULAR PURPOSE.

LIMITATION OF LIABILITY: Thermal shall not under any circumstances be liable for special or consequential damages, such as, but

not limited to, damage or loss of purchased or replacement goods, or claims of customers of distributor (hereinafter “Purchaser”) for

service interruption. The remedies of the Purchaser set forth herein are exclusive and the liability of Thermal with respect to any

contract, or anything done in connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery,

resale, or use of any goods covered by or furnished by Thermal whether arising out of contract, negligence, strict tort, or under any

warranty, or otherwise, shall not, except as expressly provided herein, exceed the price of the goods upon which such liability is based.

THIS WARRANTY BECOMES INVALID IF REPLACEMENT PARTS OR ACCESSORIES ARE USED WHICH MAY IMPAIR THE

SAFETY OR PERFORMANCE OF ANY THERMAL PRODUCT.

THIS WARRANTY IS INVALID IF THE PRODUCT IS SOLD BY NON-AUTHORIZED PERSONS.

The limited warranty periods for Thermal products shall be as follows (with the exception of XL Plus Series, CutMaster Series , Cougar

and DRAG-GUN): A maximum of three (3) years from date of sale to an authorized distributor and a maximum of two (2) years from

date of sale by such distributor to the Purchaser, and with the further limitations on such two (2) year period (see chart below).

The limited warranty period for XL Plus Series and CutMaster Series shall be as follows: A maximum of four (4) years from date

of sale to an authorized distributor and a maximum of three (3) years from date of sale by such distributor to the Purchaser, and

with the further limitations on such three (3) year period (see chart below).

The limited warranty period for Cougar and DRAG-GUN shall be as follows: A maximum of two (2) years from date of sale to an

authorized distributor and a maximum of one (1) year from date of sale by such distributor to the Purchaser, and with the further

limitations on such two (2) year period (see chart below).

Parts

XL Plus & Parts Parts

PAK Units, Power Supplies CutMaster Series Cougar/Drag-Gun All Others Labor

Main Power Magnetics 3 Years 1 Year 2 Years 1 Year

Original Main Power Rectifier 3 Years 1 Year 2 Years 1 Year

Control PC Board 3 Years 1 Year 2 Years 1 Year

All Other Circuits And Components Including, 1 Year 1 Year 1 Year 1 Year

But Not Limited To, Starting Circuit,

Contactors, Relays, Solenoids, Pumps,

Power Switching Semi-Conductors

Consoles, Control Equipment, Heat 1 Year 1 Year 1 Year

Exchanges, And Accessory Equipment

Torch And Leads

Maximizer 300 Torch 1 Year 1 Year

SureLok Torches 1 Year 1 Year 1 Year

All Other Torches 180 Days 180 Days 180 Days 180 Days

Repair/Replacement Parts 90 Days 90 Days 90 Days None

Warranty repairs or replacement claims under this limited warranty must be submitted by an authorized Thermal Dynamics® repair

facility within thirty (30) days of the repair. No transportation costs of any kind will be paid under this warranty. Transportation

charges to send products to an authorized warranty repair facility shall be the responsibility of the customer. All returned goods shall

be at the customer’s risk and expense. This warranty supersedes all previous Thermal warranties.

Effective November 15, 2001

GENERAL INFORMATION viii Date: Nov ember 15, 2001

Page 13

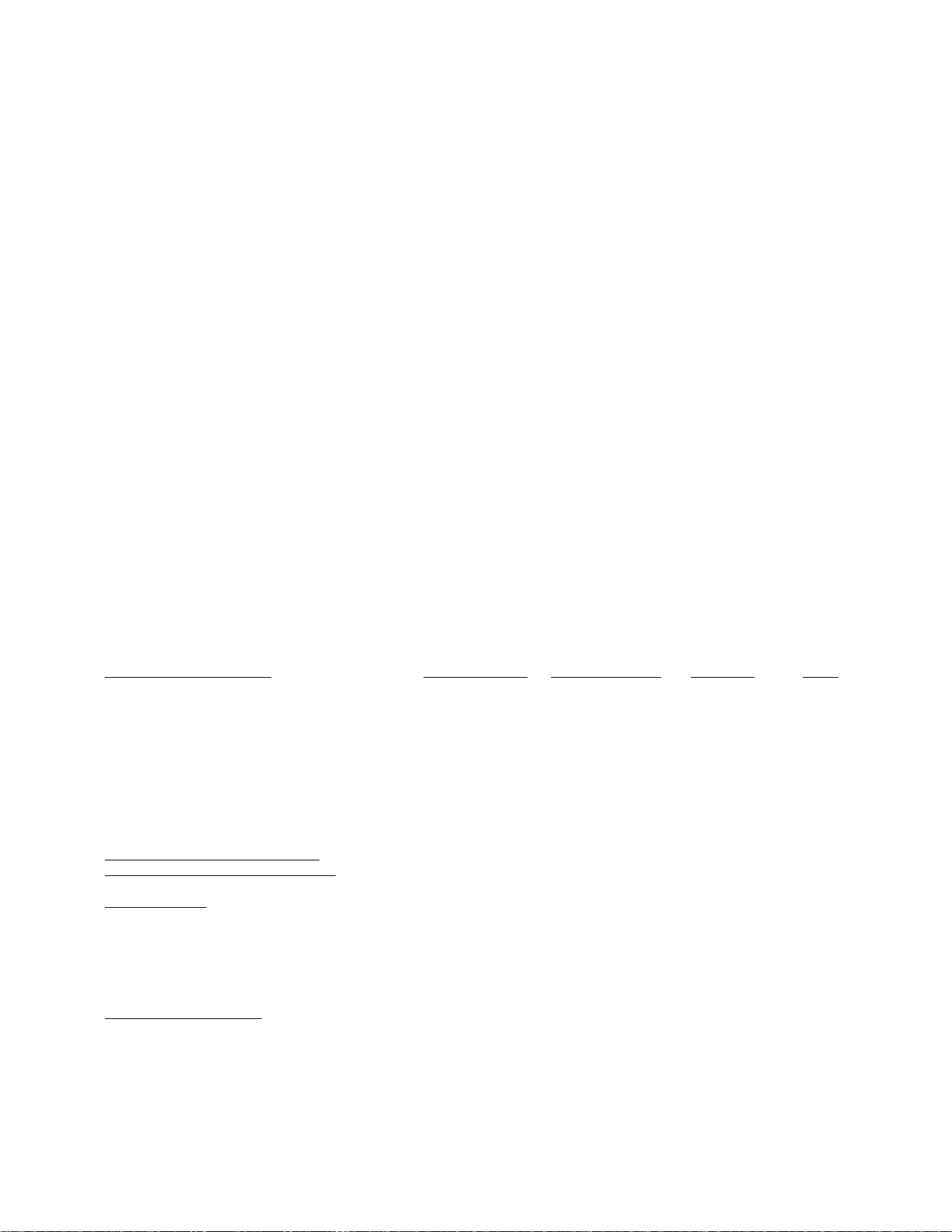

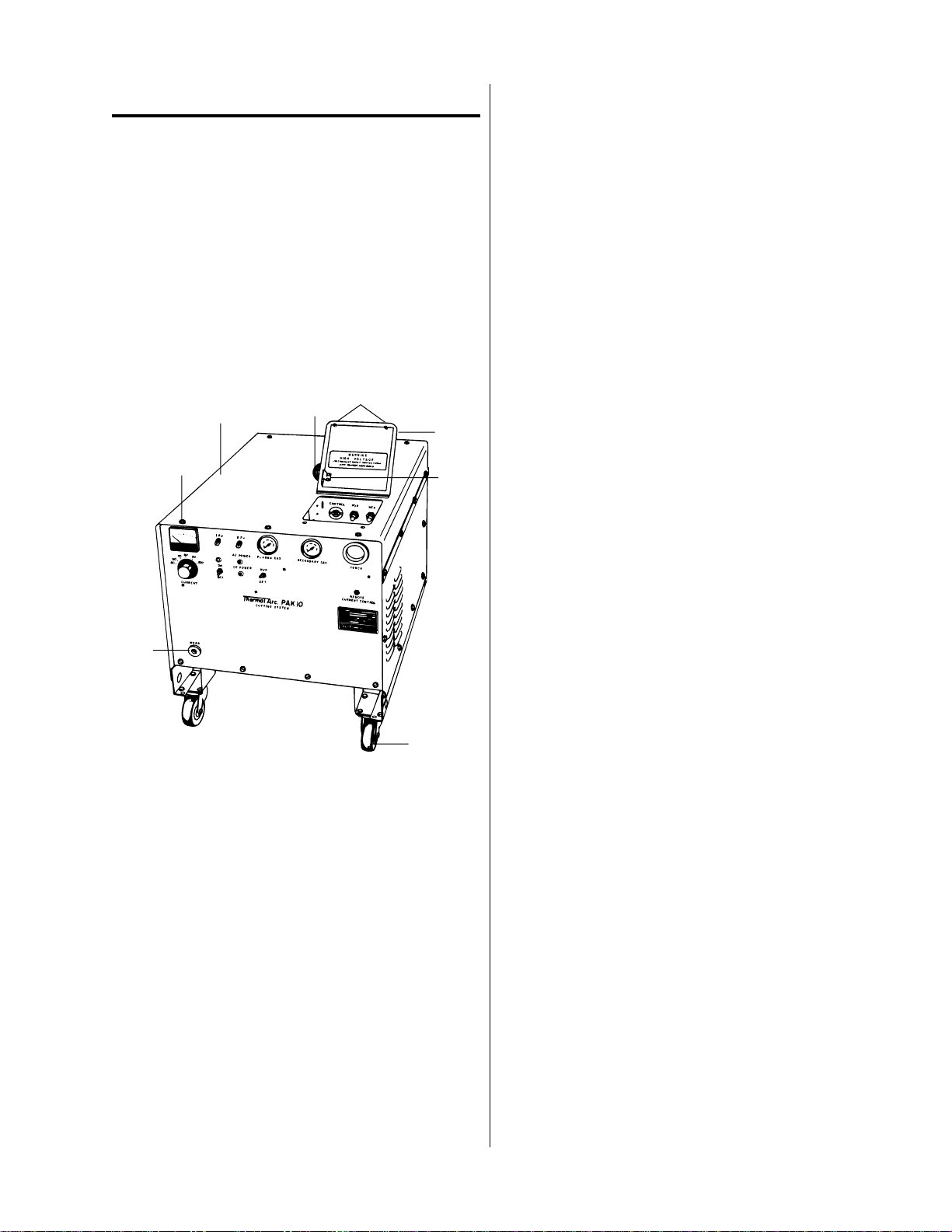

SPECIFICATIONS

A-03289

Pak 10

Gas Hoses

Gas

Regulators

Spare Parts

Kit

Work Cable

Torch and Leads

Figure 1-A Components of PAK 10 Cutting System

1

2

1

3

4

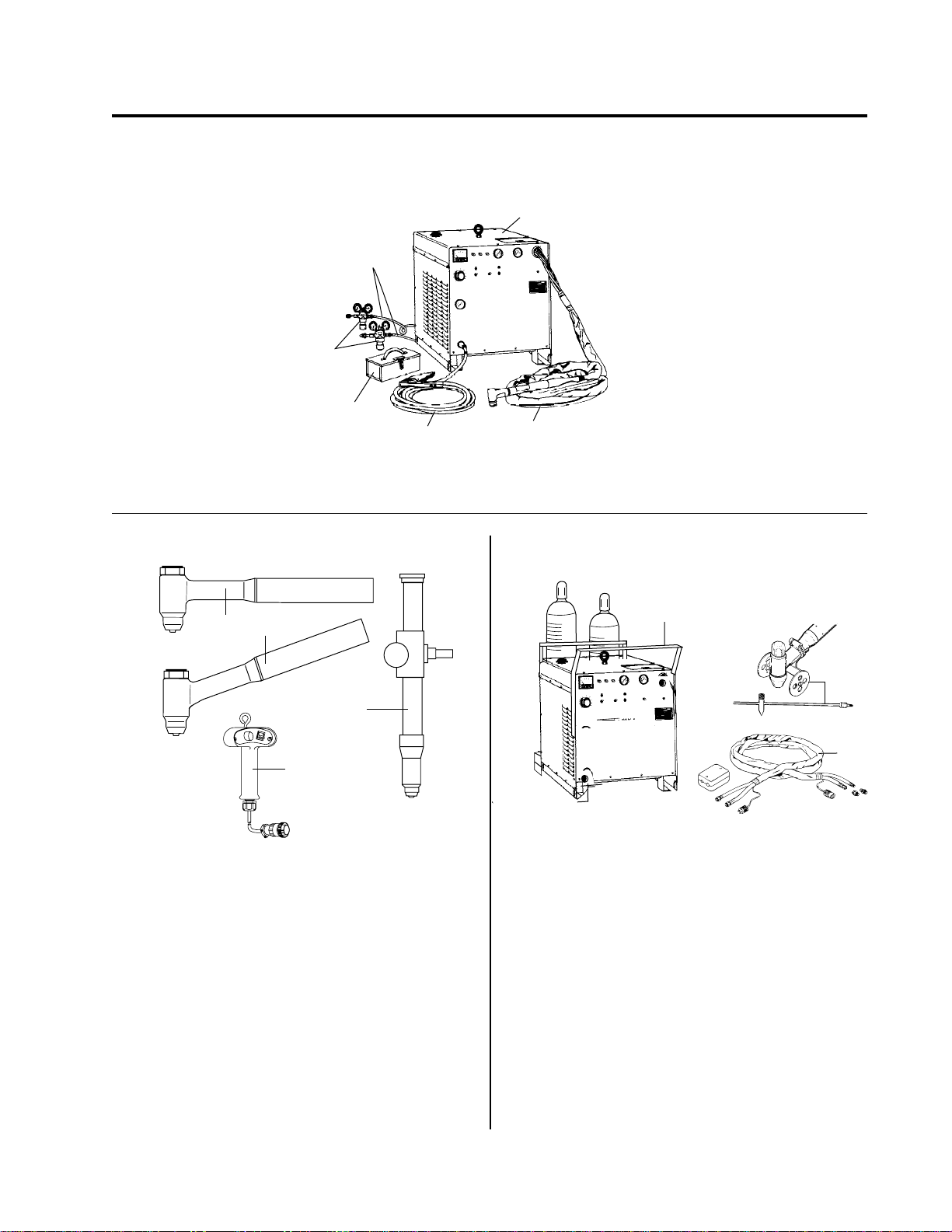

A-03290

Fig. 1-B Type 4B LO-AMP Gas Cooled Torches

1. 90° Hand cutting torch (PCH-4B 90°)

2. 70° Hand cutting torch (PCH-4B 70°)

3. Machine mounted cutting torch (PCM-4BT)

4. Remote control unit for machine mounted torch

10

K

A

rc P

al A

erm

Th

A-03291

Fig. 1-C Accessories

1. Cylinder Rack

2. Torch Guide & Circle Cutting Attachment

3. Leads Extension Package

2

3

Manual No. 0-0515 1 Specifications

Page 14

1.1. DESCRIPTION OF

EQUIPMENT

A complete PAK 10 system includes a PCH-4B hand

torch and/or PCM-4BT machine torch with 25 foot or

50 foot (7.62 m or 15.24 m) leads, a spare parts kit, a

PAK 10, gas supply, pressure regulators, 10 foot gas

supply hoses and a 25 foot work cable with clamp.

Three 4B torches are available (Figure 1-B): 90° hand

torch (1), 70° hand torch (2), and a machine mounted

torch (3). The 4BT machine mounted torch is controlled

by a remote control assembly (4, Figure 1-B) with an

ON/OFF switch and a remote current control. An initial supply of parts for the 4B is in the spare parts kit

(Figure 1-A).

PAK 10 UNIT

Power Input: 20 KVA, 50/60 Hertz, 3-phase in one of

the following standard voltage/amperage combinations:

1- 208/230/460 volts, 60/50/25 amps

2- 230/460/575 volts, 50/25/20 amps

3- 380/415/460 volts, 30/30/25 amps

4- 380/460/500 volts, 30/25/25 amps

5- 220/380/500 volts, 50/30/25 amps

6- 180/200/220 volts, 70/60/50 amps

Certain other special voltage combinations are avail-

able.

1.2. SPECIFICATIONS

TYPE 4B GAS COOLED TORCH

• Current Rating: 100 amperes maximum, DCSP , 80%

duty cycle

• Plasma Gas: Nitrogen (N2), 30 psi (2.2 kg/cm2), 15

SCFH (7.5 lpm); 65% Argon/35% Hydr ogen, 40 psi

(2.8 kg/cm2), 30 SCFH

• Secondary Gas: Carbon dioxide (C02), 50 psi (3.52

kg/cm2), 250 SCFH (125 lpm); compressed air, 50

psi (3.52 kg/cm2), 250 SCFH (125 lpm)

• Cutting Capacity (most metals): Maximum thickness- 1 inch (25.4 mm); production cutting- 5/8 inch

(15.9 mm); piercing- 3/4 inch (19 mm)

• Weight: Hand torch PCH-4B- 1-3/4 lbs. (0.79 kg);

Machine mounted torch PCM-4BT- 3 lbs. (1.36 kg)

without leads

C

• Rated Output: 100 amperes DC straight polarity

• Current Control: 50 to 100 amps continuously adjusted by feedback circuit

• Control Circuit: 24 volt AC

• Plasma and Secondary Gas Pressures: Controlled

by pressure regulator at gas supply

• Weight: 615 lbs. (279 kg)

• Dimensions: Width- 26 inches (66 cm); Depth- 36

inches (91 cm); Height- 24 inches (61 cm)

ACCESSORIES AVAILABLE:

• A cylinder rack (1, Figure 1-C) that holds two gas

cylinders

• A torch guide and cir cle cutting attachment (2, Figure 1-C)

• Torch lead extension packages to extend the torch

leads in increments of 25 or 50 feet (3, Figure 1-C)

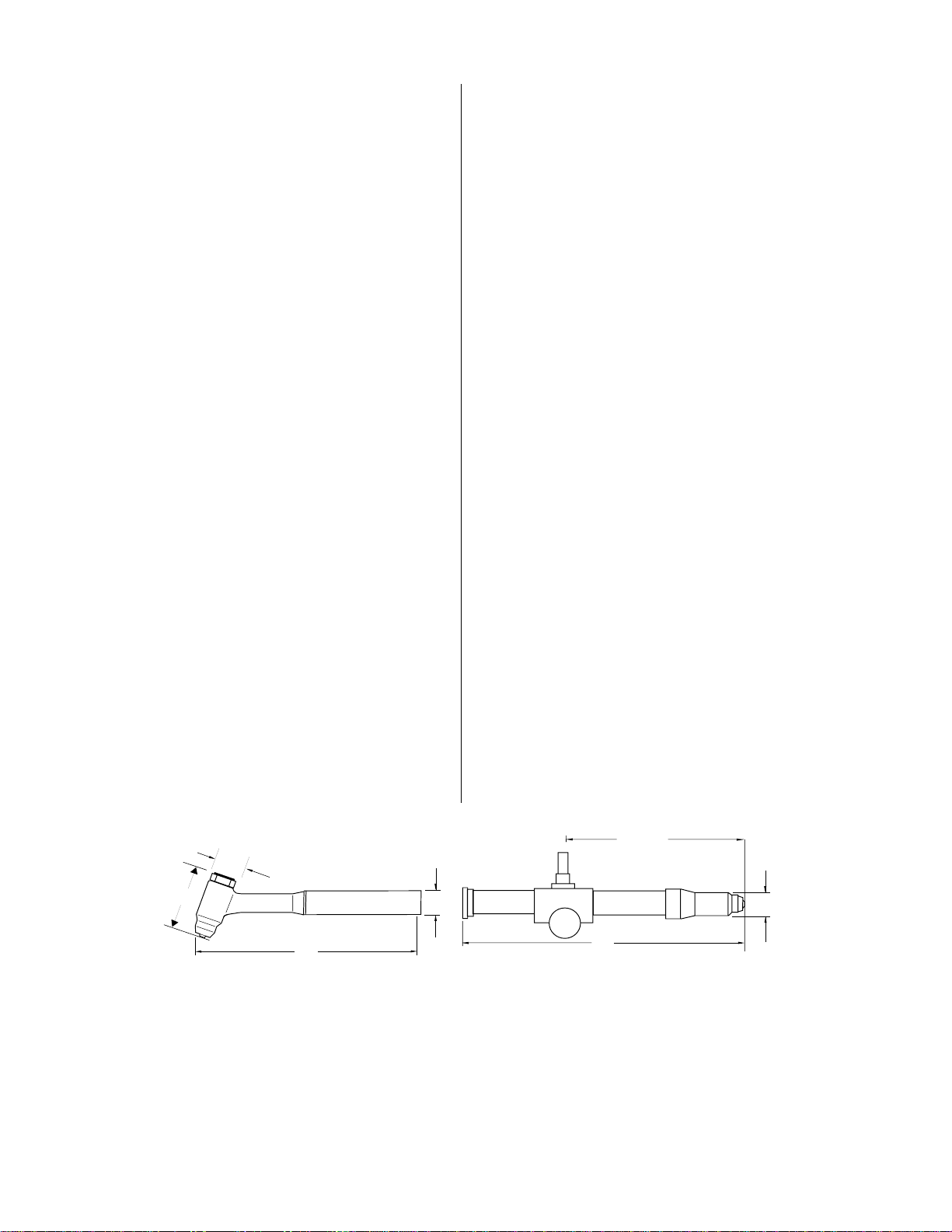

B MIN

C MAX

A-03292

B

A

D

A

D

TORCH DIMENSIONS

AB CD

PCH-4B (70°) 16.00” (406 mm) 3.98” (100 mm) 1.25” (32 mm) 1.32” (34 mm)

PCH-4B (90°) 15.25” (390 mm) 3.98” (100 mm) 1.25” (32 mm) 1.32” (34 mm)

PCM-4BT 18.38” (467 mm) 8.12” (206 mm) 16.00” (406 mm) 0.69” (17 mm)

Specifications 2 Manual No . 0-0515

Page 15

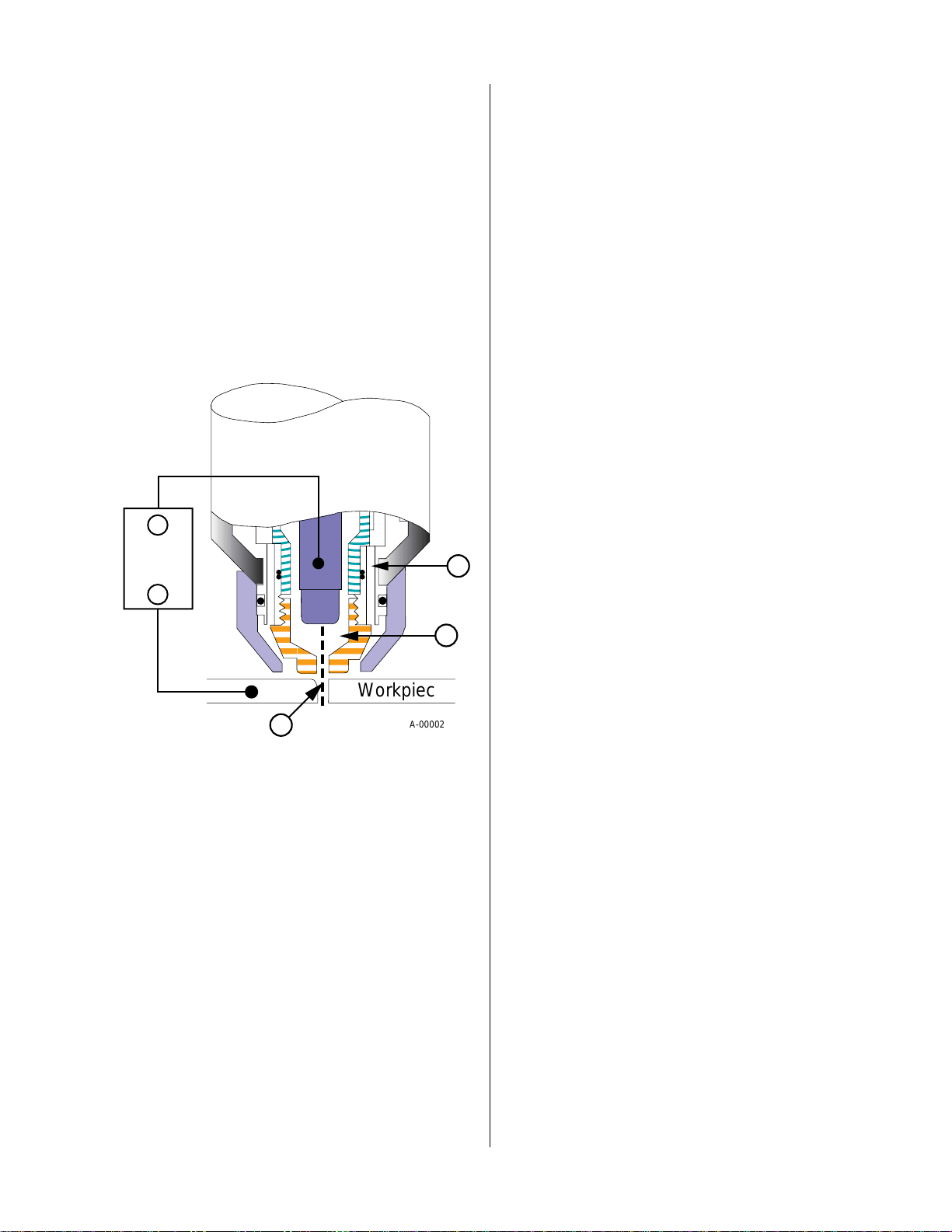

1.3. PLASMA CUTTING

1.4. THEORY OF OPERATION

Plasma is a gas which has been heated to an extremely

high temperature and ionized so that the gas becomes

electrically conductive. The plasma cutting process uses

this plasma to transfer an electric arc to the workpiece.

The metal to be cut is melted by the heat of the arc and

then blown away.

In a plasma torch, a cool gas such as nitrogen (N2) enters in Zone A, Figure 1-D. In Zone B a pilot arc between the electrode and the front of the tor ch heats and

ionizes the gas. An arc transfers to the workpiece

through a column of plasma gas in Zone C.

_

Power

Supply

A

+

The main components of the PAK 10 cutting system

are illustrated in the block diagram (Figure 1-E) and

their function is summarized below.

PLASMA AND SECONDARY GASES

Plasma and secondary gases flow through the P AK unit

to the cutting torch at pressures set at the external r egulators. The pressure of each gas is indicated on the fr ont

panel gauges. Solenoid valves turn the gases on and

off. The gas pressure interlocks shut the system down

if the plasma gas pressure falls below 25 psi (1.7 bar) or

the secondary gas pressure drops below 30 psi (2.0 bar).

The plasma gas flows through the green/black lead,

around the electrode and gas distributor, and out

through the tip orifice.

The secondary gas flows through the red/yellow tor ch

lead, down the outside of the torch liner, through the

holes at the base of the liner and out around the plasma

arc.

PILOT ARC

When the torch is started, the pilot arc contactor closes

and an arc is established between the electrode and

cutting tip. The pilot arc makes a path for transferring

the main arc to the work.

B

Workpiece

C

Figure 1-D Plasma Torch Operation

Plasma torches deliver a high concentration of heat to

a very small area. The stiff, constricted plasma arc is

shown in Zone C. Direct current straight polarity is

used for plasma cutting, as shown in the illustration.

Plasma cutting torches use a secondary gas, which assists the high velocity plasma gas in blowing the molten metal out of the cut. This results in fast, clean, dross

(slag)-free cuts. In the PAK l0 system, the secondary

gas also cools the cutting torch. CO2 or compressed air ,

supplied by either a cylinder or plant air system, is normally used as the secondary gas.

A-00002

HIGH FREQUENCY

Because direct current alone is not sufficient to strike

and maintain the pilot arc, high frequency is superimposed on the direct current.

CUTTING ARC

The main bridge rectifier converts the 3-phase AC

power to DC power for the pilot and main cutting arcs.

The negative output is connected to the torch electrode

through the torch lead. The positive output is connected

to the workpiece (through the work cable) and, through

a contactor and resistor to the torch tip.

CURRENT CONTROL

The desired cutting current is set on the CURRENT

ADJUST knob. A control circuit stabilizes cutting current against fluctuations due to changes in line voltages, material thickness, torch standoff and travel

speed. Changing the amount of saturating current in

the reactor changes the amount of AC power supplied

to the main bridge rectifier. The amount of saturating

current is controlled by a comparator which compares

the actual cutting current to the amperage selector potentiometer setting.

Manual No. 0-0515 3 Specifications

Page 16

POS.

(RED/YEL)

GAS

SECONDARY

PLASMA

3-PHASE

AC POWER

SECONDARY GAS PRESS

SOLENOID

VALVES

GAS PRESSURE

INTERLOCK

CONTROL

CIRCUITS

GAS

POWER

TRANS-

FORMER

SATURABLE

REACTOR

MAIN

CONTACTOR

SCR CONTROL

BRIDGE

RECTIFIER

PAK 10 POWER SUPPLY AND CONTROL UNIT

PLASMA

GAS PRESS

PILOT ARC

HIGH FREQUENCY

PILOT ARC

CONTACTOR

MAIN BRIDGE

RECTIFIER

COMPARATOR

(-)

SHUNT

(+)

AMP

AMPERAGE

SELECTOR POT

TORCH

LEADS

NEG.

(GR/BLK)

CUTTING

TORCH

WORK

CURRENT

SENSING COIL

(TOROID

TRANSFORMER)

A-03293

Figure 1-E Block Diagram of PAK 10 Cutting System

Specifications 4 Manual No . 0-0515

Page 17

INSTALLATION

2.1 UNPACKING

The P AK 10 is skid-mounted and pr otected with a car ton and padding material to prevent damage in shipment. The casters, lifting eye, gas hoses, work cable,

torch, torch leads and miscellaneous parts are packed

separately.

One copy of the P AK 10 Instruction Manual, in a transparent plastic envelope, is packed in with the PAK 10

unit.

2

3

4

5

2.2 EQUIPMENT ASSEMBLY

After removing the carton, turn the lifting eye (3,

Fig. 2-A) all the way into the threaded socket on top

of the unit and tighten it securely. The lifting eye

may then be used to lift the unit for removal of the

skids and installation of the casters (7). If no crane

or hoist is available for lifting, a fork lift or jack may

be used. Use care so that the base of the unit will

not be damaged. Lift the unit and remove the two

skids which are secured to the base assembly with

four bolts and hex nuts. Install the two swivel casters (7) at the front of the unit using four 5/16-18 x

3/4 inch cap screws and four 5/16-18 locknuts in

each. Install the two fixed casters at the rear in the

same manner. Lower the unit onto the casters and

remove the lifting device.

1

8

A-03356

1. Washer-head cover screws

2. Cover Assembly

3. Lifting eye

4. Access door fasteners

5. Lead connection access door assembly

6. Interlock switch actuator

7. Casters

8. Work cable receptacle

6

7

Figure 2-A Power Supply and Control Unit with

Access Door Open

Manual No. 0-0515 5 Installation

Page 18

2.3 EQUIPMENT INSTALLATION

Select a clean, dry location with good ventilation and

adequate working space. Be sure that the air flow into

the unit (from underneath) and out the back is not obstructed. A source of 3 phase power and a source of

gases with pressure regulators ar e r equired.

Review PRECAUTIONS in the first section of this

manual to be sure that location meets all safety requirements.

Most users prefer nitrogen (N2) as the plasma gas and

carbon dioxide (C0

easy to obtain good quality cuts with this combination.

Argon/Hydrogen (Ar/H2) (65% argon-35% hydrogen)

is sometimes preferred as the plasma gas when cutting

1/2" to 1" thick aluminum to improve cut finish and

reduce smoke and fumes. Compressed air (free of dirt

and oil) may also be used as the secondary gas.

) as the secondary gas, since it is

2

3. Check for possible loose connections and damage

that may have occurred during shipment.

4. Check the transformer (Figure 2-C) to be sure that

it is set up for the available power . Three terminals

(Figure 2-C) are provided for each phase. As shown

in Figure 2-C, to connect the unit for 460 volts, the

three wires from the input terminals attach to the

three terminals marked 460. For other voltages, the

three wires are connected to the appropriately

marked terminals.

1

A-03357

Figure 2-B Internal Packing Material

NOTE

A typical 50 lb. CO2 cylinder is capable of delivering 35 SCFH on a continuous basis. Therefore, the manifolding of several CO2 cylinders

may be necessary to obtain the required torch flow

rate, depending on application and duty cycle.

Connect the unit as follows:

1. Remove the top of the unit as follows:

a. Remove the screws holding the cover.

b. Open the lead connection access door (5, Fig-

ure 2-A).

Voltage Connections Transformer

A-03358

Figure 2-C Transformer Voltage Connections

CAUTION

Input voltage of the available three phase power

source must correspond to one of the three operating voltages of the PAK 10. If not properly

connected, damage to the equipment may result.

c. Lift off the cover of the unit.

2. Remove the paper band (1, Figure 2-B) stapled

around the main terminal board.

Installation 6 Manual No . 0-0515

Page 19

5. Check the three phase power service to be used.

Recommended fuse or circuit breaker sizes are given

in Table 2-A.

Power

Transformer

1

2

3

4

5

6

Line

Voltages

Accepted

208

230

460

230

460

575

380

415

460

380

460

500

220

380

500

180

200

220

Fuse or

Circuit

Breaker

Amperes

80

60

30

60

30

25

40

40

30

40

30

30

60

40

30

90

80

60

Recommended

Minimum

Primary

Wire size *

4

6

10

6

10

10

8

10

10

8

10

10

6

8

10

4

6

6

* From t he Nati onal E l ec t ri c Code, 1978

7. Connect the gases to be used to the fittings on the

back of the unit (2 & 3, Fig. 2-E). Pressure regulators for use with PAK units and specifically calibrated for use with nitrogen (Cat. #9-2722), argon/

hydrogen (Cat. #9-3053), carbon dioxide (Cat. #9-

2759), and compressed air (Cat. #9-3022) are available from Thermal Dynamics. The gas supplies

must be equipped with adjustable pressure regulators capable of being set between 0 and 60 psi (0-4.1

bar) and of delivering 15 Standard Cubic Feet per

Hour (SCFH) (7 lpm) of N2 and 250 SCFH (118 lpm)

of C02 or compressed air.

2

Table 2-A Line Voltages, Circuit Protection &

Recommended Wire Size

NOTE

Larger wires may be requir ed if the length is over

25 feet.

6. With the primary power disconnect switch open,

connect the electrical ground and primary power

leads to the terminals on the upper right hand side

(facing the unit from the front.) Recommended wir e

sizes are given in Table 2-A. The leads are led

through the “INPUT” fitting in the back (1, Figure

2-E). A proper gr ound connection must be made to

the brass stud as shown (2, Figure 2-D). The other

leads are attached to terminals L1, L2, and L3 (1,

Figure 2-D).

WARNING

Do Not Turn on Power Until Step 10.

1

A-03359

1. Primary Lead T erminals

2. Ground T erminal

Figure 2-D Primary Lead Connections

Manual No. 0-0515 7 Installation

Page 20

10. The work cable (Figure 1-A) is equipped with a

twist-lock plug on one end and a work clamp on

the other . The plug fits into the work receptacle on

the front of the unit (8, Figure 2-A) and the clamp

attaches to the workpiece. The unit is now ready

1

INPUT

for operation.

SEC

2

PLASMA

3

4FU

5A

A-03360

1. INPUT cable bushing

2. SECondary gas connection fitting

3. PLASMA gas connection fitting

Figure 2-E Rear Panel Connections

8. Check the torch to see that it is properly assembled

(Refer to Section 4.1.).

a. Pass the torch leads and control wire through

the bushing on the front panel (5, Figure 2-F)

and connect them to the appropriate fittings.

1

4

6

l. Actuator for Interlock Switch (SW3)

2. Negative (-) torch lead fitting

3. Positive (+) torch lead fitting

4. Torch control switch receptacle

5. Tor ch lead insulating bushing

6. Remote current control jack

3

2

5

A-03361

b. If the torch is machine-mounted, the remote

control assembly plug must also be inserted in

the remote current contr ol jack.

Figure 2-F Torch Connection Access Door and

Panel

9. Re-install the cover of the unit (the leads access door

must be open). Start the sheet metal screws but do

not tighten them until the cover is lined up.

Carefully close the leads access door, making sure

that the switch actuator (1, Figure 2-F) enters its slot

and activates the interlock switch. When the cover

is properly positioned, tighten the screws.

W ARNING

Do Not Operate the Unit unless all parts of the

enclosure are in place. This is important for

proper cooling as well as safety.

Installation 8 Manual No . 0-0515

Page 21

OPERATION

50

2

AMPERES

D.C.

70

60

80

39

90

100

1FU

10A

ON

4

2FU

5A

AC POWER

DC POWER

1

OFF

MIN.

CURRENT

Thermal Arc PAK 10

8

Figure 3-A PAK 10 Control Unit Operating Controls

3.1 OPERATING CONTROLS

1. Current Adjust Knob

Select desired cutting current. Calibrated from Min.

up to 100 amps.

2. Ammeter (A)

Indicates amperage supplied to torch.

3. READY Indicator (LT3)

Amber light indicates that the ON/OFF switch is

ON and that lead connection access door is closed.

4. AC POWER Indicator (LT1)

Red light indicates that 3 phase AC power is being

supplied to the system.

5

60

0

4

34

8

0

2

5

20

1

6

bar

psi

100

PLASMA GAS

RUN

SET

CUTTING SYSTEM

7. RUN/SET Switch (SW2)

Move up to RUN position for torch operation. Move

down to SET position for purging gas lines and setting gas pressures with external regulators.

8. DC Power Indicator (LT2)

Red light indicates that main contactor (W) has

closed to supply current to the main bridge rectifier

and that cutting current is available.

9. ON/OFF Switch (SW1)

Move up to ON position to activate the control cir-

cuits. Move down to OFF position to deactivate

control circuits.

3.2 PRE-OPERATION SET-UP

7

6

60

0

4

34

8

0

0

2

5

2

1

6

bar

psi

100

SECONDARY GAS

CURRENT CONTROL

TORCH

REMOTE

A-03309

NOTE

Fan is on when this light is on.

This procedure should be followed at the beginning of

each shift:

5. PLASMA GAS

WARNING

Indicates pressure at which plasma gas is being supplied to the torch.

Check to be sure main disconnect switch is open.

6. SECONDARY GAS

Indicates pressure at which secondary gas is being

supplied to the torch.

l. Check the torch to be sure it has the proper compo-

nents and is adjusted correctly . (Refer to Section 4.1).

2. Close the main disconnect switch supplying 3- phase

power to the unit.

Manual No. 0-0515 9 Operation

Page 22

3. Turn the ON/OFF switch ON (9, Figure 3-A). The

amber “READY” light will come on. (If the gas supply is on, the gases will flow for two seconds).

4. Turn the RUN/SET switch to the SET position.

Open the plasma gas supply valve at the source.

Adjust the pressure regulator on the gas supply until

the plasma gas pressure reads 30 psi (2.0 bar).

5. Purge for approximately 3 minutes by letting the

plasma gas run. This will remove any condensed

moisture that may have accumulated in the torch

or leads while the system was shut down.

6. Open the secondary gas supply valve at the source.

Adjust the pressure regulator at the gas supply until pressure reads 50 psi (3.4 bar).

A-01917

7. Return the RUN/SET switch to the RUN position.

8. Set the current adjust knob (l, Figure 3-A) to the desired amperage level.

The system is now ready for operation. The torch is

controlled by the switch mounted on the torch handle

(or the remote control switch for a machine mounted

torch).

3.3 OPERATION

HAND TORCH OPERATION

W ARNING

Be sure the operator is equipped with proper

gloves, clothing, eye and ear protection and that

all precautions at the front of this manual have

been followed.

l. Hold the torch comfortably , as shown in Figur e 3-B.

One hand should be close to the head assembly and

the other hand positioned so that the thumb can conveniently operate the control switch. Position the

torch over the workpiece, resting the front of the

cup on the edge of the workpiece at the point where

the cut is to start. This will positively locate the line

of the cut.

Figure 3-B Positioning the Hand Torch for a Cut

2. Lower the welding helmet and lift the torch about

1/8" (3 mm) from the workpiece. Then press and

hold the control switch on the torch. After a two

second gas purge, the pilot arc will come on and

remain on until the main cutting arc is established,

at which point the pilot arc circuit switches off automatically.

A-03310

Figure 3-C Hand Cutting Over a Line on the

Workpiece

3. The cutting arc will remain on as long as the control

switch is held down unless the torch is withdrawn

from the work or the torch motion is too slow . If the

cutting arc is interrupted, the pilot arc will come on

again. It will remain on until the cutting arc is again

established or the control switch is released.

4. Cut with the torch about 1/8" to 1/4" (3 to 6 mm)

from the workpiece, as shown in Figure 3-C. Keep

the torch perpendicular to the work.

Operation 10 Manual No. 0-0515

Page 23

MACHINE T ORCH OPERA TION

When cutting with a machine torch, the torch must be

at right angles to the plate to obtain a clean, vertical

cut. Use a square, as shown in Figure 3-D, to align the

torch. It is good to start a cut at a slow speed and increase the speed to obtain the desired cut quality. Table

3-B gives typical cutting speeds for various materials

and material thicknesses.

Rack and

Pinion Mounting

Assembly

Square

Direction Of

Travel

A-00175

Workpiece

Figure 3-D Using a Square to Set Up the Machine

Torch

To start a cut at the plate edge, line up the torch away

from the plate, and press the control switch. The transferred cutting arc will then be established at the plate

edge. Adjust cutting speed for good cutting performance, as indicated by a trailing arc of approximately

5° (Figure 3-E). When cutting expanded metal the cutting arc and pilot arc will alternate establishing themselves automatically.

5˚ Approximately

A-01919

Figure 3-E A Good Cut Will Produce a Trailing

Arc of Approximately 5°

PIERCING

In some cutting operations, it may be desirable to start

the cut within the plate area rather than at the plate

edge. Piercing the plate is not recommended on plates

thicker than 3/4" (19 mm), based on a 5/16" (7 mm)

standoff, using a mechanized torch with a “running

start” and a maximum time to complete pierce of 3 seconds). Blowback from the piercing operation can

shorten the life of torch parts. All pier cing should therefore be done as quickly as possible with current set at

100 amperes.

A method called “running start” is r ecommended when

piercing with a machine mounted torch. Position the

torch off the cutting line a sufficient distance to allow

the pierce to be made before reaching the cutting line.

This allowance depends on the thickness of the material and the travel rate of the mechanized torch.

Manual No. 0-0515 11 Operation

Page 24

Starting Pierce

Continue Cut After Pierce

W ARNING

It is not enough to simply move the ON/OFF

switch on the unit to its OFF position when cutting operations have been completed. Always

open the power supply disconnect switch 5 minutes after the last cut is made.

A-01920

Figures 3-F and 3-G Piercing with Hand Torch

When using a hand torch, tip the torch slightly to pierce

so that blowback particles blow away from the torch

tip rather than directly into it, as shown in Figure 3-F.

Pierce off the cutting line and then continue the cut as

shown in Figure 3-G. Spatter and scale should be

cleaned from the shield cup and the tip as soon as possible. Spraying or dipping the shield cup in anti-spatter compound will minimize the amount of scale which

adheres to it.

NOTE

The suggestions listed below should be followed

in all cutting operations.

1. Wait five minutes before opening the main disconnect switch at shut down. This permits the cooling

fan to run to remove operating heat from the unit.

2. For maximum parts life, do not operate the pilot

arc any longer than necessary.

3. Remember that cutting current can be adjusted at

any time. Learn to change the current output to

provide a comfortable working speed for the particular material being cut.

4. Handle torch leads carefully and protect them from

damage.

5. In continuous cutting applications, it is often necessary to manifold 4 to 6 C02 cylinders together to

maintain pressure at 50 psi (3.4 bar).

COMMON CUTTING FAULTS

Listed below are common cutting problems followed

by probable causes of each. If problems ar e caused by

the P AK 10, r efer to the Trouble Shooting Section (Section 4).

1. Insufficient Penetration

a. Cutting speed too high

b. Current too low

2. Main Arc Extinguishes

a. Cutting speed too low

b. Standoff too high

3. Dross Formation

a. Improper gas pressure or mixture

b. Improper cutting speed (Refer to Table 3-B)

c. Faulty electrode or tip

4. Burned-Out Tips

a. High cutting current

b. Damaged or loose cutting tip

c. Contact with work

d. Heavy spatter

e. Low plasma gas pressure

f. Back cap not tight

g. Spring not correctly installed

6. Because of the swirl of plasma gas in the torch, the

right hand side of the cut (in relation to torch travel)

is normally of better quality. Reverse swirl tips are

available for mirror image cutting.

FREQUENTLY REVIEW THE SAFETY PRECAUTIONS GIVEN AT THE FRONT OF THIS MANUAL.

Operation 12 Manual No. 0-0515

Page 25

3.4 CUTTING CURRENT AND SPEED SELECTION

The desired cutting current and the speed at which the

torch is moved along the line of the cut depend on the

thickness and composition of the workpiece. In hand

cutting, the speed is usually determined by how fast

the operator can comfortably and accurately follow the

line of the cut.

Most operators find that at speeds much above 30 ipm

it is difficult to accurately follow the line of the cut. For

machine cutting, faster speeds are often used. Refer to

Table 3-B.

This chart is intended as a guide to determining approximate conditions for making good quality cuts in

various thicknesses of material. Slower speeds may be

obtained on thin sections by reducing the current to

between 50 and 100 amperes.

The speeds shown are typical for cutting at 100 amperes using the 8-4153 (0.059) tip.

Plasma Gas - N2 at 30 psi (2.0 bar), 15 SCFH (7.1 lpm)

Secondary Gas - CO2 or Compressed Air at 50 psi (3.4

bar), 250 SCFH (125.0 lpm)

NOTE

This information represents our best judgment

but Thermal Dynamics Corporation assumes no

liability for its use.

INCHES/MINUTE (METERS/MINUTE)

THICKNESS 1/8" (3.2 mm) 1/4" (6.4 mm) 1/2" (12.7 mm) 3/4' (19 mm) 1" (25.4 mm)

Stainless

Steel

Alum i num 125 (3.18) 90 (2.29) 34 (0.86) 25 (0. 63) 12 (0. 30)

Carbon

Steel

Note: S peeds for Argon/ Hy drogen Pl asma Gas at 40 psi (2.7 bar), 30 S CFH (14.2 l pm )

with t he 8-4170 LO-AM P t i p at 100 amps are s l ightly faster. A rgon/Hy drogen is not

100 (2.54) 60 (1.52) 24 (0.61) 20 (0.50) 10 (0. 25)

75 (1.90) 45 (1.15) 24 (0. 61) 18 (0.46) 9 (0.23)

recomm ended for cut t i ng carbon st eel.

Table 3-B Recommended Cutting Speeds

Manual No. 0-0515 13 Operation

Page 26

PAK 10 - SEQUENCE OF OPERATION

System OFF

ACTION

1. Close external disconnect switch.

Red AC POWER indicator ON.

2. ON/OFF switch to ON.

RESULT

1. Amber ready indicator ON.

2. Coolant pressure switch closes.

3. Gases flow.

After two seconds:

4. Gas flow stops.

ACTION

1. RUN/SET switch to SET.

RESULT

1. Gas valves open, gases flow to

purge system and allow setting

of pressures.

2. Power circuits disabled.

ACTION

1. Lower helmet and close control switch on torch (or remote

control assembly).

RESULT

1. Gases flow and gas pressure switches close.

2. Main contactor closes. Red DC indicator ON.

After two seconds:

3. High frequency ON

4. Pilot arc relay closes.

5. Pilot arc comes ON.

System READY

ACTION

1. RUN/SET switch to RUN.

2. Select cutting amps with

CURRENT knob.

RESULT

1. Gas flow stops.

2. Power circuits ready.

PILOT ARC

ACTION

1. Torch moved away from workpiece,

or workpiece burns away under

torch.

RESULT

1. Cutting Arc stops.

2. Current sensing circuit turns ON high

frequency and pilot arc.

A-01892

ACTION

1. Torch brought close (within 1/4 inch)

to workpiece.

RESULT

1. Arc transfers to workpiece to

establish Cutting Arc.

2. Current sensing circuit turns OFF

pilot arc and high frequency.

Cutting Arc

NOTE:

To shut down system, allow fan and pump to run for

five minutes and then move On/OFF switch to OFF. Be

sure to open external disconnect switch.

ACTION

1. Open control switch on torch (or

remote control assembly)

RESULT

1. Red DC power indicator OFF.

2. Pilot arc stops.

After two seconds:

3. Gas flow stops.

System READY

NOTE

To shut down system, move ON-OFF switch to OFF. Wait 5 minutes to allow fan to remove heat from unit.

Then open external disconnect switch.

Manual No. 0-0515 14 Operation

Page 27

SERVICE

Torch Disassembly and Inspection

The Service Section is divided into six parts:

4.1 Torch Maintenance

4.2 Torch Leads and Leads Extension Packages

4.3 PAK Unit Maintenance

4.4 Gas Pressure Regulators

4.5 Trouble Shooting Guide

4.6 Test Procedur es

4.1 TORCH MAINTENANCE

The 4B and 4BT torch parts are interchangeable with

two exceptions. First of all, the 4BT collet is a different

design than the 4B. This is so that the collet can be

installed from the front of the torch. By installing the

collet from the front of the torch the back cap is eliminated in the 4BT design. These differences require

slightly different disassembly and assembly procedur es.

When a different pr ocedure is required, the tor ch model

will be specified, otherwise the step applies to both torch

models.

WARNING

Disconnect primary power before disassembling

the torch.

Disassemble the torch parts as follows:

1. Pull off the shield cup (1) and inspect it for damage.

Wipe it clean, or replace it if it appears to be damaged.

2. Use the tip wrench (17) to unscrew the tip (2). Check

the tip for wear as indicated by an elongated or oversize hole. Make sure that the tip is clean and that

threads have not been damaged. Replace the tip if

necessary.

3. Lift out the gas distributor (3). Remove the electrode (7) and check the end for pitting.

1

1

2

3

15

4

5

6

5

267

4

3

Figure 4-A Plasma Cutting Torch (PCH/M-4B), Exploded View

1. Shield Cup

2. Tip

3. Gas Distributor

4. Liner (includes 9-2960 O-ring)

5. O-ring (included with Liner)

6. Sleeve

7. Electrode

8. O-ring (included with Shield Cup)

9. Gasket

13

A-03311

14

10b

11

12

8

9

10a

16

12

13

9

8

17

7

10. Head Assembly:

a) PCH-4B

b) PCM-4BT

11. O-Ring: PCH-4B

12. Collet with 8-0525 O-Ring

13. Spring

14. Back Cap: PCH-4B

15. Liner Wrench

16. Tip W r ench

17. Collet Wrench: PCM-4BT

Manual No. 0-0515 15 Service

Page 28

If the end of the electrode is badly pitted (cavity

almost covers diameter) then that end of the electrode should no longer be used.

The electrode may then be reversed. When both

ends are pitted, the electrode should be replaced.

Do not attempt to repoint the electrode.

NOTE

Torch Assembly

WARNING

Disconnect primary power before assembling the

torch.

Remove the liner assembly (4) and sleeve (6), in

accordance with the following step, only if either appears to be damaged and requires replacement.

4. Remove the liner assembly (4) with the liner wrench

(16). After unscrewing the liner, slip out the sleeve

(6).

5. PCH-4B: Unscrew the back cap (14) and remove the

spring assembly (13) and collet assembly (12).

6. PCM-4BT: The collet (12) is removed by sliding the

collet wrench (17) into the torch cavity and unscr ewing it from the torch.

NOTE

The spring assembly (13) should come out with

the collet. Care must be taken not to lose this

spring.

6

1

3

1. PCM-4BT: Insert the spring assembly (13) into the

collet (12) and install the collet in the torch cavity.

Tighten down with collet wrench (17).

2. Insert the sleeve (6) in the liner (4). The sleeve should

be clean and dry and may be either end up.

3. O-ring (5) should be lightly lubricated with O-ring

lubricant (Cat. No. 8-4025) and installed just past

the threads on the liner. Install the liner (4) in the

torch using the liner wrench (16).

4. PCH-4B: Insert the spring assembly (13) in the collet

(12) and install the collet in the back of the torch

with the end with the O-ring toward the front.

5. PCH-4B: Check the O-ring (11) that seals the back

cap to be sure it is lightly lubricated (Cat. No. 8-

4025) and in good condition.

4

5

2

1

PCH-4B HAND TORCH

7

PCM-4B MACHINE TORCH

8

9

10

A-03312

Figure 4-B Hand and Machine Torch Heads, Exploded View

1. Head

2. Heat Shield

3. Handle

4. Torch Switch

5. Torch Switch Sheath

6. Back cap

7. Nut

8. Insulating Sleeve

9. Mounting tube

10. Pinion assembly

Service 16 Manual No. 0-0515

Page 29

6. PCH-4B: Install the back cap (14) and tighten it securely.

CAUTION

Use care to see that the back cap is turned all the

way down to hold the collet (12) securely. On

the machine torches this cap goes down inside

and may seem tight, but still may not be holding

the collet tightly. Arcing may result, welding

the collet to the torch and causing irreparable

damage.

7. Insert the electrode (7) in the torch from the front.

Push it back against the spring to make sure it slides

freely back and forth.

8. Install a gas distributor (3) in the tip (2) and install

the tip in the front of the torch. Tighten it securely

with a tip wrench (16).

9. Install a gasket (9) and two O-rings (8) on the front

of the torch. The O-rings must be lubricated with

O-ring lubricant (Cat. No. 8-4025).

10. Install the cup (1) on the front of the torch.

The torch is now ready for operation.

Use a ferrule (1) to secure the hose to the fitting or lock

the hose in place with a twisted wire. If a ferrule is

used, crimp (1) in place with 1/2 inch diameter crimping dies, Scovill No. 39 or equal. Crimp (1a) in place

with 5/8 inch diameter crimping dies, Scovill No. 34

or equal.

2

4

5

6

A-03313

1a

1

3

1a

1

Figure 4-C Torch Lead Fittings

4.2 TORCH LEADS AND LEADS

EXTENSION PACKAGES

Torch Leads Replacement

T o r eplace the tor ch leads on a hand torch separate the

leads covering from the torch handle by pulling the

torch switch sheath (5, Fig. 4-B) back over itself to expose where the leads covering is secured to the handle.

Remove the tape securing the covering to the handle.

Pull the covering away from the handle and disconnect the switch from the leads package. Unscrew the

handle from the torch and slide back to expose the leads

connections. Leads are connected to the appropriate

fittings on the torch in accordance with the color coding-red/yellow for secondary gas and green/black for

plasma gas. A plastic insulator is located between the

fittings in the handle.

The fittings (Figure 4-C) on the ends of the torch leads

may be replaced. Cut the hose close to the old fitting.

Cut the wire inside the hose and discard the old fitting.

Attach new fittings to the wire by crimping the tube,

on the fitting, onto the wire. Crimp the tube with a

Stakon size C crimping tool. It is important to crimp

the tube all the way back to the first hole to ensure adequate gas passage.

l. Ferrule

2. Fitting, console end (-)

3 Nut, console end (+)

4. Fitting, console end (+)

5. Fitting, torch end (+)

6. Fitting, torch end (-)

LEADS EXTENSION PACKAGES

Leads extension packages are available to extend the

torch leads in increments of 25 and 50 feet. The packages are available as follows:

PCH-4B 25': Cat. No. 4-2739 50': Cat. No. 4-2740

PCM-4BT 25': Cat. No. 4-2741 50': Cat. No. 4-2742

1. Lead Adapter

2. Insulator

3. Leads (25' or 50')

2

3

A-03314

1

Figure 4-D Leads Extension Package

Manual No. 0-0515 17 Service

Page 30

WARNING

4.4 GAS PRESSURE REGULATORS

Disconnect primary power before installing the

leads extension package. Do not turn on primary power to unit until all connections are

made and insulators are in place.

The leads that are furnished with the extension packages are the same as standard leads with the exception

of the control switch leads for the hand torch. On the

extension package the control switch leads terminate

in a receptacle for the 2 prong “Twist-Loc” plug. The

standard leads have a square plastic connector that

mates with the one on the torch leads.

NOTE

For leads extension over 100 feet the two-second

gas purge is not adequate. Replacement of TD2

Relay (Catalog No. 9-2694) with a Catalog No.

9-3528 Relay will increase the purge time to ten

seconds.

4.3 PAK UNIT MAINTENANCE

The only routine maintenance required for the PAK 10

system is a thorough cleaning and inspection of the unit.

This should be done on a regular basis, the frequency

depending on the amount of usage and the environment in which the unit is operated.

The Thermal Arc gas pressure regulators provide a

means of conveniently selecting and maintaining the

required working pressures of the gases. The regulator will hold this pressure constant. Inlet pressure is

reduced in one step to the working pressure by means

of a pressure balanced poppet valve controlled by a

spring loaded piston in a low pressure chamber . A lar ge

adjusting knob (6, Figure 4-E) provides for adjusting

spring pressure against the piston. A sinter ed stainless

steel filter , in the inlet connector (1), prevents dirt from

entering the regulator mechanism.

No regular maintenance of the gas pressure r egulators

is required, except an occasional lubrication of the adjusting screw thread and on its end, where it contacts

the adjusting spring. Lubricant is available from Thermal Dynamics for this purpose (Catalog No. 9-2871).

Replaceable parts in the regulator include the pressure

gauges, the O-ring seals on the piston and above the

poppet valve, and the poppet valve. (See Assembly

Parts List Fig. 5-10 for replacement parts).

CAUTION

Do not attempt to remove the sintered metal filter in the inlet connection. This is not a serviceable item.

WARNING

Removing the cover of a PAK 10 with a Running Gear also removes the retaining chains

making the gas cylinder free-standing. This cylinder must be restrained by some temporary

means until the cover and retaining bar are replaced and the retaining chains reconnected.

T o clean the P AK unit, first make sur e that the power is

disconnected and AC Power Light (LT1) off. Remove

the cover and side panels of the unit and blow out any

accumulated dirt and dust with compressed air. The

unit should also be wiped clean. If necessary, solvents

that are recommended for cleaning electrical apparatus may be used.

While the covers are off, inspect the wiring in the unit,

looking for any frayed wires or loose connections that

should be corrected. When cleaning the unit pay particular attention to the area around the high fr equency

spark gap points since accumulated dirt in that area

can weaken the high frequency starting current.

Service 18 Manual No. 0-0515

Page 31

2

3

4

WARNING

Removing the cover of a PAK 10 with a Running Gear also removes the retaining Chains

making the gas cylinders free standing. These

cylinders must be restrained by some temporary

1

means until the cover and the retaining bar are

replaced and the retaining chains reconnected.

When the external disconnect switch is closed, the red

5

“AC POWER” light goes on and the fan starts. When

the ON/OFF switch goes ON, the amber “READY”

light goes on and the gases flow for two seconds. If

this does not happen, check as follows:

A-01894

6