Page 1

TM

Service Manual

CAUTION: Read the instructions before using the machine.

©2014 TurboChef Technologies, Inc.

Page 2

Page 3

For further information, call

800.90TURBO

or

+1 214.379.6000

Page 4

Original Instructions

The information contained in this manual is important for the proper installation, use, maintenance,

and repair of this oven. Follow these procedures and instructions to help ensure satisfactory baking

results and years of trouble-free service.

Errors – descriptive, typographic, or pictorial – are subject to correction. Specifications are subject to

change without notice.

Please carefully read this manual and retain it for future reference.

Page 5

Table of Contents

Important Safety Instructions

General Safety Information i

Reducing Fire Risk ii

Grounding Instructions ii

Power Cord Replacement or Removal ii

Protective Earth (Ground) Symbol ii

Equipotential Bonding Symbol ii

Specifications and Installation

Performance 1

Dimensions 1

Certifications 2

Oven Construction 2

Electrical Specifications 2

Installation 2

Unpacking Instructions 2

Installation Warnings - Read Before Lifting Oven 2

Lifting and Placing the Oven 2

Installation Near Open Heat Source 3

Voltage Selection 3

Ventilation 3

Installing the Oven Handle 4

Daily Maintenance 5

Oven Operation

Oven Controls 7

Cooking 7

Setting the Temperatures 8

Setting the Timers 8

Setting the Parameters 8

Troubleshooting

Fault Code Er1 11

Fault Code Er2 11

Fault Code Ht 12

Oven Not Heating 12

Food Not Cooking Properly 13

Page 6

Oven Schematics 15

Appendix - Replacing Oven Components

Replacing Oven Components A-1

Replacing Items A-2

Page 7

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When operating this oven, strictly adhere to the following safety precautions to

reduce the risk of burns, electric shock, fire, injury, or damage to oven or property near oven.

WARNING: This appliance has hot surfaces! During use, the accessible parts of the oven can get very

hot. When opening the oven door, during, or after cooking, pay careful attention to the flow of hot air

and any steam that may be released from the cooking chamber. Move to the side or step back.

General Safety Information

a

To ensure proper use of the appliance, read all parts of this manual carefully and store safely. Before using

the appliance, clean all surfaces that will be coming into contact with food.

a

Read all instructions before using this appliance.

a

This appliance must be grounded. Connect only to a properly grounded outlet. See "Grounding

Instructions" on page ii.

a

Install or locate this appliance only in accordance with the provided installation instructions.

a

This appliance should be serviced by qualified service personnel only. Contact the nearest authorized

service facility for examination, repair, or adjustment.

a

Keep the cord away from heated surfaces.

a

Use this appliance only for its intended uses as described in this manual.

a

This appliance is designed for professional use. Only allow qualified or duly instructed personnel to use.

Always monitor the appliance during operation.

a

In the event of a failure, breakage or irregular function, switch the appliance off and disconnect the oven

from the power supply.

a

Always ensure the oven is disconnected from the power supply before servicing, repairing, or adjusting

any components or parts.

X

DO NOT use corrosive chemicals or vapors in this appliance; it is not designed for industrial/laboratory use.

X

WARNING: DO NOT heat liquids or other foods in sealed containers (e.g., jars, whole eggs, etc.) since

they are liable to explode.

X

DO NOT allow children to use this appliance.

X

DO NOT operate this appliance if it has a damaged cord or plug, is not working properly, has been

damaged or dropped. See “Power Cord Replacement or Removal” found on page ii.

X

DO NOT cover or block any openings on this appliance.

X

DO NOT store this appliance outdoors.

X

DO NOT use this appliance near water (e.g., near a kitchen sink, in a wet basement, near a swimming pool).

X

DO NOT immerse the cord or plug in water.

X

DO NOT let the cord hang over the edge of a table or counter.

X

DO NOT place the cord near heated surfaces.

X

DO NOT store or use flammable vapors or liquids (e.g., gasoline) in the vicinity of this appliance.

X

DO NOT use a water jet for cleaning. See page 5 in this manual for proper cleaning procedures.

X

This appliance is not to be used by children or persons with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction.

X

WARNING: Due to the nature of the apppliance, the floors around it may be slippery.

i

SAFETY INSTRUCTIONS

Page 8

ii SAFETY INSTRUCTIONS

Reducing Fire Risk

a

If materials inside the oven ignite, keep the oven door closed, turn the oven off, and disconnect the

power cord or shut off power at the fuse or circuit breaker panel.

a

If smoke is observed, switch off or unplug the oven. Keep the door closed to stifle any flames.

X

DO NOT put plastic or paper bags in the oven.

X

DO NOT use the cook cavity for storage purposes.

X

DO NOT overcook food. Carefully attend the oven if paper, plastic, or other combustible materials are

placed inside to facilitate cooking.

X

DO NOT leave paper products, cooking utensils, or food in the cavity when the oven is not in use.

Grounding Instructions

This appliance must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This oven is equipped with a cord that has

a grounding wire with a grounding plug, which must be plugged into an outlet that is properly installed and

grounded. Consult a qualified electrician or serviceman if uncertain about the ability to follow grounding

instructions or if doubt exists as to whether the appliance is properly grounded.

X

DO NOT use an extension cord. If the power cord is too short, have a qualified electrician or

serviceman install an outlet near the appliance.

WARNING: Improper grounding can result in risk of electric shock.

Power Cord Replacement or Removal

If the power cord is damaged, it must be replaced by the manufacturer, its service agent, or a similarly

qualified person.

WARNING: If the oven is unplugged during service or maintenance, the user must be able to access and

see the plug at all times to ensure that the oven remains unplugged. The plug must remain near the oven

and cannot be placed behind another appliance or in another room.

Protective Earth (Ground) Symbol

This symbol identifies the terminal which is intended for connecting an external conductor for

protection against electric shock in case of a fault, or the terminal of a protective earth (ground)

electrode.

Equipotential Bonding Symbol

This symbol identifies the terminals which, when connected together, bring the various parts of an

equipment or of a system to the same potential, not necesarily being the earth (ground) potential, e.g.

for local bonding.

Page 9

Specifications

and Installation

Page 10

Page 11

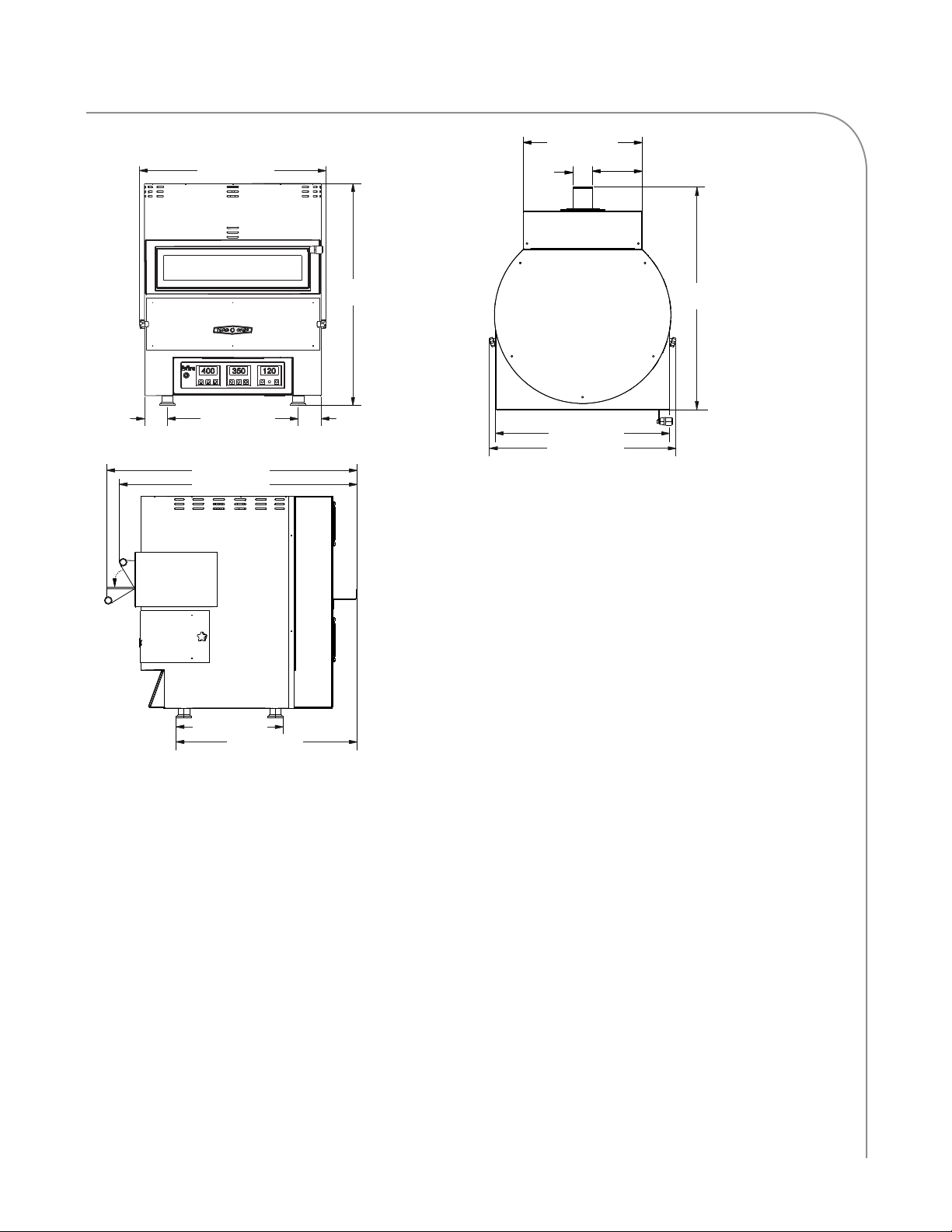

12.2” (309.9 mm)

2” (50.8 mm)

5.1”

(129.5 mm)

19.01” (482.9 mm)

19.01” (482.9 mm)

22.8”

(579.1 mm)

26.47” (672.3 mm)

24.39” (619.5 mm)

10.95” (278.1 mm)

18.11” (460 mm)18.55” (471.2 mm)

12.2” (309.9 mm)

2” (50.8 mm)

5.1”

(129.5 mm)

19.01” (482.9 mm)

22.8”

(579.1 mm)

18.11” (460 mm)

(579.1 mm)

12.2” (309.9 mm)

2” (50.8 mm)

(129.5 mm)

1

5.1”

2.35” (59.7 mm)

13.42” (340.9 mm)

26.47” (672.3 mm)

24.39” (619.5 mm)

10.95” (278.1 mm)

18.55” (471.2 mm)

(576.6 mm)

2.35” (59.7 mm)

22.7”

22.8”

18.11” (460 mm)

19.01” (482.9 mm)

Figure 1: Fire Oven Dimensions

Performance

The TurboChef Fire provides the artisan hearthstyle pizza experience anywhere. Cooking at

842°F/450°C, the Fire can cook 14-inch fresh

dough pizzas in as little as 90 seconds. The oven

is small and ventless, so it can be placed virtually

anywhere without type I or type II ventilation.

This manual includes instructions for installing,

cleaning, and operating the Fire oven. If you have

questions that are not addressed in this manual,

contact Customer Support at 800.90TURBO

(+1 214.379.6000) or your Authorized Distributor.

Dimensions

Oven Dimensions

Height: 22.7” (576.6 mm)

Width: 19.01” (482.9 mm)

Depth (footprint): 18.55” (471.2 mm)

Depth (door closed): 24.39” (619.5 mm)

Depth (door open): 26.47” (672.3 mm)

Weight: 75 lb. (34 kg)

Cook Cavity Dimensions

Width: 14.75” (374.7 mm)

Depth: 14.75” (374.7 mm)

Clearances

Top: 2” (51 mm)

Sides: 2” (51 mm)

SPECIFICATIONS AND INSTALLATION

Page 12

2 SPECIFICATIONS AND INSTALLATION

Certifications

cULus, UL EPH

Oven Construction

Exterior

- Powder coated, corrosion-resistant steel outer

wrap and door

- 430 stainless steel construction

Interior

- 430 stainless steel interior

- Double wall insulated cooling keeps external

temperatures cool

Electrical Specifications

TurboChef recommends a Type D circuit breaker

for all installations outside the United States.

Single Phase

3. Check the cook cavity thoroughly for

accessories and literature.

4. Discard any packaging in the cook cavity.

Installation Warnings - Read Before Lifting Oven

WARNING: The Fire oven weighs

approximately 75 lb. (34 kg). Never lift with

fewer than two people.

WARNING: The oven must be properly

placed on a food station at all times.

TurboChef will not recognize a fallen oven as

a warrantable claim and is not liable for any

injuries that may result.

WARNING: This oven is not intended for

built-in installation (i.e., installing the oven in

any structure that surrounds the oven by five

or more sides). Be sure to provide a minimum

of 2” (51 mm) clearance for all sides and 2”

(51 mm) clearance for the top.

WARNING: This oven is not intended to be

stacked.

North America: 208/240 VAC, 50/60 Hz,

3700/4800 W, 18/20 A, 30 A Plug

Europe/Asia/South America: 230 VAC, 50/60 Hz,

4500 W, 19.6 A, 32 A Plug

Australia: 230 VAC, 50/60 Hz, 4500 W, 19.6 A,

32 A Plug

Installation

Install or locate this appliance only in accordance

with the instructions below.

Unpacking Instructions

1. Remove the oven from its packaging.

2. Before discarding, check the packaging

thoroughly for accessories and literature.

NOTE: Packaging may also be retained in case the

oven may at some point be shipped somewhere

else or returned to the manufacturer.

Lifting and Placing the Oven

1. Prepare a surface at least 18.55” (471.2 mm)

deep and capable of supporting 80 lb (36.3 kg).

NOTE: Do not remove the oven legs.

2. Position one or more persons at the left and

right sides of the oven.

3. Place hands under the oven and lift.

4. Place the oven on the prepared surface,

ensuring no edges are hanging off the sides.

5. Ensure the lower access panel is properly

installed (thumbscrews are tight), refer to

Figure 6, Page 5 for illustration.

6. Plug in the oven.

Page 13

3

Installation Near Open Heat Source

When placing a TurboChef oven near an open

heat source (Figure 2), strictly adhere to the

following:

- If the oven is being placed near a grill or stove,

a divider must exist between the oven and the

open heat source, with a minimum of 6” (152

mm) between the oven and the divider.

- If the oven is being placed near a fryer, a

divider must exist between the oven and fryer,

with a minimum of 12” (305 mm) between

the oven and the divider.

- The height of the divider must be greater than

or equal to the height of the oven (22.7” or

576.6 mm).

- Verify the oven location has a minimum 2”

(51 mm) clearance on top and a minimum 2”

(51 mm) clearance on each side.

Voltage Selection

For North America oven models, the oven will

detect 208 or 240 incoming voltage.

Ventilation

The TurboChef Fire oven has been approved by

Underwriter’s Laboratory LLC for ventless

operation (UL® KNLZ listing) for all food items

except for foods classified as “fatty raw proteins.”

Such foods include bone-in, skin-on chicken, raw

hamburger meat, raw bacon, raw sausage, steaks,

etc. If cooking these types of foods, consult local

HVAC codes and authorities to ensure compliance

with ventilation requirements.

To ensure continued compliance with all health,

building, and fire codes, you are required to maintain clean and sanitary conditions around your

oven at all times.

NOTE: In no event shall the manufacturer assume

any liability for damages or injuries resulting from

installations which are not in compliance with the

instructions and codes previously listed. Failure to

comply with these instructions could result in the

issuance of a temporary cease and desist order from

the local health department until the environment

concerns are addressed.

Partition

22.7” (576.6 mm)

Above Counter Top

Grill

Figure 2: Installation Near Open Heat Source

6”

(152 mm)

Minimum

12”

(305 mm)

Minimum

Counter Top / Table

Partition

22.7” (576.6 mm)

Above Counter Top

Deep Fryer

SPECIFICATIONS AND INSTALLATION

Page 14

4 SPECIFICATIONS AND INSTALLATION

Installing the Oven Handle

1. While the oven is off and cool, open the oven

door (Figure 3).

2. Using a flat-head screwdriver, remove the two

screws on the outside of the oven door

(Figure 3).

3. Install the handle bracket as shown in Figure

4, using the screws removed in step 2.

4. Close the oven door.

5. Attach the handle to the bracket using the

provided screw and washer (Figure 5).

CAUTION: DO NOT over-tighten the

handle. The handle may break if over-tightened.

Oven Door Screws

Figure 3: Oven Door Screw Location

Handle

Screw

Washer

Bracket

Figure 4: Bracket Installed to Oven Door

Handle

Figure 5: Handle Installed

Page 15

Daily Maintenance

Page 16

Page 17

5

Daily Maintenance

Follow the steps below when cleaning your Fire oven.

Use only TurboChef ®-approved cleaning chemicals.

The use of any other cleaning products may damage

Supplies and Equipment

TurboChef ® Oven Cleaner (Product Number:

103180), nylon scrub pad, cleaning towel, disposable

gloves, protective eyewear, dust mask (optional)

critical oven components, resulting in a non-warranty

service call.

Oven Door

Thumbscrew

Figure 6: Maintenance

Thumbscrew

Lower Access Panel

Oven Interior

Step 1: Prepare the Oven

CAUTION: The oven operates at 842°F (450°C) and may cause injury if not allowed to cool properly.

• Turn off the oven by pressing the On/Off key.

• Cooling takes approximately two hours (or longer). DO NOT clean the oven until the oven is cool.

Step 2: Wipe the Oven Interior

• Remove the lower access panel by removing the two thumbscrews (see Figure 6, above).

• Use a food vacuum or damp towel to remove large particles from the oven interior.

Step 3: Clean the Oven Interior

• Spray TurboChef ® Oven Cleaner onto a clean towel or nylon scrub pad and scrub the interior of the oven and

the inside portion of the lower access panel.

CAUTION: DO NOT spray Oven Cleaner into any holes or openings in the oven interior. Doing

so can damage critical oven components, resulting in a non-warranty service call.

• Open the oven door and gently wipe down the inside of the Door.

• If necessary, spray a small amount of Oven Cleaner on stains and allow to penetrate for five minutes, then clean

with a nylon scrub pad.

Step 4: Rinse or Wipe the Oven Interior

CAUTION: DO NOT use a hose or water jet for cleaning. Doing so can damage critical oven components,

resulting in a non-warranty service call.

• Wipe down the oven interior with a clean damp towel.

• Dry the oven interior with a clean towel.

Step 5: Clean the Oven Exterior

• Reinstall the lower access panel and secure it with the two thumbscrews.

• Wipe the oven exterior with a clean, damp towel.

CAUTION: DO NOT spray chemicals into any openings, such as the vents on the side and front or

the perforation on the back. Doing so can damage critical oven components, resulting in a non-warranty

service call.

• The oven is ready to turn on.

DAILY MAINTENANCE

Page 18

6

DAILY MAINTENANCE

This page intentionally

left blank.

Page 19

Oven Operation

Page 20

Page 21

7

UPPER TEMPERATURE

65 7

1

TIME

PRESETS

Figure 7: Oven Controls

Oven Controls

1. On/Off Key

Press to turn the oven on or off.

2. Time Preset Keys

Press presets 1 through 6 to activate a timer.

3. Up and Down Keys

Press the Up and Down keys to change the oven

temperature (page 8), the time presets (page 8), or

the parameters (pages 8-9).

LOWER TEMPERATURE TIME

3 42

5. Upper Temperature Display

Displays the current Upper Temperature. A green

light in the lower-left corner of this display will

blink during warmup and turn solid once it has

reached the set temperature.

6. Lower Temperature Display

Displays the current Lower Temperature. A green

light in the lower-left corner of this display will

blink during warmup and turn solid once it has

reached the set temperature.

7. Time Display

4. Temperature Key

Press the Temperature Key to toggle between

setting the upper and lower temperatures (page 8).

Shows the amount of time left for the selected

preset. The time is displayed in seconds, up to

1,999 (33 minutes and 19 seconds).

Cooking

1. Press the On/Off key to turn the oven on.

2. Allow the oven to warm up. The green light in the bottom-left corner of the Upper Temperature

Display and the Lower Temperature Display will blink during warmup. Once the oven has finished

warming up, the lights will stop blinking and stay solid.

3. Open the oven door and using the provided paddle and cooking screen, slide the product into

the oven and close the oven door.

4. Press the desired timer (1 through 6).

NOTE: Once the timer reaches 0, the oven will begin beeping. To stop the beeping, press any of the

Time Preset keys.

5. Open the oven door and remove the product from the oven and close the oven door.

CAUTION: Dish and inside of oven/oven door are hot!

6. When finished cooking for the day, press the On/Off key to turn the oven off and begin cooling down.

OVEN OPERATION

Page 22

8 OVEN OPERATION

Setting the Temperatures

Two different temperatures can be set: one for the upper heating zone and one for the lower heating zone.

These temperatures range from off to 842°F (450°C).

NOTE: When a temperature is set to off, the display will read 32°F (0°C).

To set the temperature:

1. While the oven is on, press the Temperature key to access the upper temperature (the upper

temperature will begin flashing).

2. Use the Up and Down keys to set the upper temperature.

3. Press the Temperature key again to save the upper temperature and to access the lower temperature.

4. Use the Up and Down keys to set the lower temperature.

5. Press the Temperature key again to save the lower temperature.

NOTE: If changing only one temperature, simply press the Temperature key to bypass the upper or lower

temperature without changing it.

Setting the Timers

Six different timers can be set to accommodate different items.

To set a timer:

1. Make sure no timers are running.

2. While the oven is on, press and hold the desired timer button (1 through 6) for two seconds. The value

indicated on the Time display will begin flashing.

3. Use the Up and Down keys to set the time.

4. Press and hold the same timer button for two seconds to save the time.

NOTE: If you wait five seconds without pressing any buttons, the timer will save automatically.

To pause a timer:

- Press any of the Time Preset keys. The time on the Time Display will flash to indicate the timer

is paused.

- To resume the timer, press any of the Time Preset keys again.

- To reset the timer to 0, press and hold any of the Time Preset keys for two seconds. The oven will

begin beeping to indicate the timer has reached zero. To stop the beeping, press any of the Time

Preset keys.

Setting the Parameters

Access the parameter settings to change oven options. For a full list of parameters, descriptions, and

values, see page 9.

To set the parameters:

1. While the oven is off, simultaneously press and hold the Time Preset 2 and 3 keys for two seconds. The

Upper Temperature display will read “PA”.

2. Press the Down key until the Time display reads “-19” (negative nineteen).

3. Simultaneously press and hold the Time Preset 2 and 3 keys for two seconds. The Upper Temperature

display will now read “P0”.

4. Refer to the table on page 9 and use the Time Preset 2 and 3 keys (increase and decrease parameter

numbers) to navigate through the parameters.

5. Use the Up and Down keys to change the values.

6. When finished, press the On/Off key.

Page 23

9

Parameter Description

Temperatures shown in °C or °F.

P0

P1 Factory Use Only n/a n/a n/a 0

P2 Factory Use Only °F/°C n/a n/a 4°F/2°C

P3 Factory Use Only °F/°C n/a n/a 0°F/0°C

P4 Factory Use Only °F/°C n/a n/a 212°F/100°C

P5 Minimum Setting of Heater 1 °F/°C 32/0 P6 122°F/50°C

P6 Maximum Setting of Heater 1 °F/°C P5 842/450 842°F/450°C

P7 Factory Use Only °F/°C n/a n/a 0°F/0°C

P8 Factory Use Only °F/°C n/a n/a 212°F/100°C

P9 Minimum Setting of Heater 2 °F/°C 32/0 P10 122°F/50°C

P10 Maximum Setting of Heater 2 °F/°C P9 842/450 842°F/450°C

P11 Factory Use Only Minutes n/a n/a 30

P12 Factory Use Only Minutes n/a n/a 30

P13 Factory Use Only Minutes n/a n/a 30

0 = °C

1 = °F

Unit of

Measure

n/a 0 1 1

Minimum

Value

Maximum

Value

Default Value

P14 Preset Timer 1 Seconds P20 P21 80

P15 Preset Timer 2 Seconds P20 P21 90

P16 Preset Timer 3 Seconds P20 P21 100

P17 Preset Timer 4 Seconds P20 P21 110

P18 Preset Timer 5 Seconds P20 P21 120

P19 Preset Timer 6 Seconds P20 P21 130

P20 Minimum Settable Time Seconds 0 P21 0

P21 Maximum Settable Time Seconds P20 1,999 240

P22 Duration of Buzzer Sound Seconds 0 60 15

P23 Factory Use Only n/a n/a n/a 0

P24 Factory Use Only °F/°C n/a n/a 140°F/60°C

P25 Factory Use Only n/a n/a n/a 0

P26 Factory Use Only Seconds n/a n/a 20

P27 Factory Use Only % n/a n/a 67

P28 Factory Use Only % n/a n/a 67

P29

Time between selection and timer

start

Seconds 2 20 2

OVEN OPERATION

Page 24

10

OVEN OPERATION

This page intentionally

left blank.

Page 25

Troubleshooting

Page 26

Page 27

Troubleshooting: Fault Code Er1

Er1 is displayed on the upper temperature display and indicates a damaged upper

RTD. The oven will beep when this error occurs.

11

Is the wiring from the

upper RTD to the control

board OK? (See page 15

for schematic.)

YES

Is the top heater

element defective?

Resistance of

approximately 30 Ω

at room temperature.

NO

Correct

the wiring.

YES

Is the upper RTD

YES

NO

Replace the defective

heater element.

operating properly?

Resistance of

approximately 4 Ω at

room temperature.

Is the control board

operating properly?

NO

Replace the control

board.

Troubleshooting: Fault Code Er2

YES

NO

Ensure wiring is correct.

If necessary, replace the

upper RTD.

Replace the RTD.

Er2 is displayed on the lower temperature display and indicates a damaged lower RTD.

The oven will beep when this error occurs.

Is the wiring from the

lower RTD to the control

board OK? (See page 15

for schematic.)

YES

Is the bottom heater

element defective?

Resistance of

approximately 24 Ω

at room temperature.

YES

Is the lower RTD

YES

NO

NO

Replace the defective

heater element.

operating properly?

Resistance of

approximately 2 Ω at

room temperature.

Is the control board

operating properly?

NO

Replace the control

board.

NO

Correct the wiring.

YES

Replace the RTD.

Ensure wiring is correct.

If necessary, replace the

lower RTD.

TROUBLESHOOTING

Page 28

12 TROUBLESHOOTING

Ht is displayed on the upper temperature display and indicates that the temperature in

the controls compartment is too hot. The oven will beep when this error occurs.

Troubleshooting: Fault Code Ht

Is the wiring from the

controls compartment

cooling fan to the control

board OK? (See page 15

for schematic.)

YES

Replace the control

board.

Use the following troubleshooting steps when the oven is not heating properly.

Is the high-limit

thermostat tripped?

YES

NO

Correct

the wiring.

NO

Is the controls

YES

compartment cooling fan

operating properly?

Correct

the wiring.

NO

NO

Troubleshooting: Oven Not Heating

Is the oven receiving

YES

correct voltage from the

outlet?

NO

Is the wiring from the

controls compartment

cooling fan to the

contactor relay OK?

(See page 15 for

schematic.)

YES

Replace the controls

compartment

cooling fan.

Verify that the breakers

are not tripped, the outlet

is not damaged, and that

the electrical supply is

sucient for the oven.

Reset and

determine

why it tripped

- excess grease

buildup, etc.

Is either

fuse open/

blown?

YES

Replace and

determine

why it/they

opened/blew.

Replace the

control board.

Correct wiring.

NO

Are either heaters defective?

YES

Replace the

defective

heater(s).

Replace the

contactor relay

YES

NO

NO

Is the contactor

relay defective or

damaged?

YES

NO

Is the wiring from

the contactor relay

to the control board

OK? (See page 15

for schematic.)

Page 29

Use the following troubleshooting steps when the oven is not cooking properly.

YES

Are there any fault codes

present? See pages 10-11.

NO

Is the oven

heating

properly?

YES

Are the temperature

and timer settings set

properly?

NO

NO

Troubleshooting: Food Not Cooking Properly

Does the problem occur with all items?

For example, everything is undercooked/

overcooked/etc.?

Troubleshoot the

YES

Follow the “Troubleshooting: Oven

Not Heating” steps on page 11.

fault(s) using the

steps on pages 10-11.

YES

Ensure that the correct

amount is being cooked

- not more or less than

the recipe species.

Ensure the food item is

being properly stored/

prepared before cooking.

NO

13

NO

Is the food item in the

correct starting state

(e.g., frozen, fresh, etc.)?

NO

YES

Is the correct amount of

food being cooked?

YES

Correct the settings.

YES

Replace the

control board

NO

NO

Are the temperature

and timer settings set

properly?

YES

Dos the problem occur

EVERY time the food

item is cooked?

Is the food item being prepared correctly and

consistently? For example, ingredients are correct

thickness, pizza dough is correct consistency, etc.

YES

Are there any fault codes

present? See pages 10-11.

NO

Is the oven

heating

properly?

YES

NO

Ensure that the food item

is properly prepared.

Troubleshoot the

YES

NO

Follow the “Troubleshooting: Oven

Not Heating” steps on page 11.

fault(s) using the

steps on pages 10-11.

TROUBLESHOOTING

Page 30

14 TROUBLESHOOTING

This page intentionally

left blank.

Page 31

Oven Schematic

Page 32

Page 33

RED (L1)

NEMA 6-30

RED (L1)

RED (L1)

RED (L1)

RED (L1)

BLU (-)

RED (+)

RED (+)

33

32

31

30

29

28

27

26

25

24

23

22

21

18

17

16

15

14

13

12

11

10

15

BLU (L2)

S2

BOTTOM RTD

RED (+24)

BLK (-24)

RED (L1)

RED (L1)

RED (L1)

RED (L1)

WHT (L1)

S1

TOP RTD

VOLTAGE SELECTOR

OVEN LIGHT

INTERIOR

R1 TOP ELEMENT

1600 W

R2 BOTTOM ELEMENT

2100 W

RED (L1)

BLU (L2)

RED (L1)

BLK (L2)

RED (L1)

BLK (L2)

13

RED (L1)

BLK (L2)

BLU (L2)

A1

A2

RED (L1)

6146

4

2

BLU (L2)

BLU (L2)

RED (L1)

5

3

1

H1

CONTACTOR

9

8

7

6

5

4

3

2

1

WHT (L1)

WHT (L1)

GREEN (L1)

RED (L1)

COOLING FAN

M5

M3

TOP MOTOR

TOP BACK

COOLING FAN

REAR BOTTOM

OVER LIMIT

TS1

C)

NC (450

BLU (L2)

GREEN (L1)

BLK (L2)

C1

M1

Figure 8: Oven Schematic - Single Phase

RED (L1)

GREY (L1)

BOTTOM MOTOR

M2

COOLING FAN

KEYBOARD

M4

GREY (L2)

BLACK (L1)

WHITE (L2)

GREEN (GND)

F1-20 AMP

F2-20 AMP

F1

F2

L1 PE

L2

OVEN SCHEMATIC

Page 34

16 OVEN SCHEMATIC

This page intentionally

left blank.

Page 35

Appendix

Replacing Oven Components

Page 36

Page 37

Replacing Oven Components

This appendix provides illustrations for removing serviceable items, as well as the item numbers and

descriptions for those items. It also includes the item numbers and descriptions for the fasteners

used to secure each component to the oven chassis.

If you have any questions that are not addressed in this manual or appendix, please contact

TurboChef Customer Service at 800.90TURBO or +1 214.379.6000.

A-1

APPENDIX REPLACING OVEN COMPONENTS

Page 38

A-2 APPENDIX REPLACING OVEN COMPONENTS

Replacing Items

DANGER: Before replacing any oven component, ensure the oven is removed from any power

source. Replacing a component while the oven is plugged in can result in serious injury or death

CAUTION: Be careful to not tear the insulation when servicing components. Always reinstall the

insulation properly before reinstalling the outer shell.

NOTE: Fasteners listed are required for installing component to oven.

30

16

21

20

17

18

8

29

1

51212

2

24

5

2333

32

6

24

1

15

19

13

28

14

(x2)

27

26

10

4

31

11

7

9

22

(x4)

3

Figure

Reference #

1 Blower Motor* FRE-3001 (x2) Screw, PPH, SS, M5x25mm LGx .8mm 101344 (qty 2)

2 Catalytic Converter FRE-1019

3 Control Board FRE-3006 Screw, PFH, SS, M4x35mm LGx .8mm 101439 (qty 6)

4 Cooling Fan, Controls FRE-1046

5 Cooling Fan, Rear 100516 (x2)

Item Description Item Part Number Fastener Description

Screw, SH MTL, #8 x 1/2 Serrated PHTRH

Bracket, Catalyst Holder

Screw, PPH, SS, M4x30mm LGx .8mm

Nut, Hex, SS, M4

Screw, #10-32x1/2, Hex WSHR HD, Type 23

(Shared with Finger Guard)

*Ensure that the blower motor is properly aligned.

Fastener Part

Number(s)

101688 (qty 4)

FRE-1013 (qty 2)

101699 (qty 2)

101004 (qty 2)

101408 (qty 4)

Page 39

A3

Figure

Reference #

6 Cover, Back FRE-1016 Screw, M4x10mm LG, PPHD, S.S. 101671 (qty 8)

7 Cover, Bottom FRE-1133 Screw, M4x10mm LG, PPHD, S.S. 101671 (qty 7)

8 Cover, Top

9 Display Housing FRE-1112 Screw, M4x10mm LG, PPHD, S.S. 101671 (qty 2)

10 Display Housing, Cover FRE-1087 Screw, M4x10mm LG, PPHD, S.S. 101671 (qty 4)

11 Distribution Block FRE-1048 Screw, M5x12, Hex PPHD, CRES 101676 (qty 2)

12 Finger Guard 100087 (x2)

13 Fuse Holder 103548 Screw, M4x10mm LG, PPHD, S.S. 101671 (qty 2)

14 Fuse, F1 and F2, 20-amp 100599 None None

15

16

17

18

19 High Limit Thermostat FRE-1050 Screw, M4x10mm LG, PPHD, S.S. 101671 (qty 2)

Item Description Item Part Number Fastener Description

FRE-1059-1 (Red)

FRE-1059-2 (Green)

Handle, Kit

(kit includes bracket and hardware)

Hatch, Front

(kit includes thumb screws)

Heater, Bottom (approximately

24 at room temperature)

Heater, Top (approximately 30 at

room temperature)

FRE-1059-3 (Yellow)

FRE-1059-4 (White)

FRE-1059-5 (Black)

FRE-1059-6 (Blue)

FRE-3007 Included Included

FRE-3008-1 (Red)

FRE-3008-2 (Green)

FRE-3008-3 (Yellow)

FRE-3008-4 (White)

FRE-3008-5 (Black)

FRE-3008-6 (Blue)

FRE-3003 Included Included

FRE-3002 Included Included

Screw, M4x10mm LG, PPHD, S.S. 101671 (qty 5)

Screw, #10-32x1/2, Hex WSHR HD, Type 23

(Shared with Cooling Fan, Rear)

Included Included

Fastener Part

Number(s)

101408 (qty 4)

20 Keypad Back Panel FRE-1113 Screw, M4x10mm LG, PPHD, S.S. 101671 (qty 2)

21 Keypad Overlay FRE-1150 None None

22 Leg FRE-1055 None None

23 Light Bulb with Lens and Socket FRE-3005 None None

24 Magnet FRE-1162 (x2) Screw, FL HD Slot, SS, 90o M4x16mm LG, .7 Pitch 101428

25

26

27 Relay, Contactor FRE-1060 Screw, M4x8mm LG, PPHD, S.S. 101670

28

29

30 Screw, Thumb FRE-1163 None None

31 Voltage Module 100783

32 Window, Assembled FRE-3010 Included Included

33 Window, Glass FRE-3004 Included Included

34

Paint, Touch-Up Kit

(not shown)

Power Cord, Domestic

Power Cord, International

Power Cord, Australia

RTD, Lower (approximately 2 at

room temperature)

RTD, Upper (approximately 4 at

room temperature)

Wire Harness

(not shown)

FRE-3009 None None

100187

100195

i1-9136

FRE-1053 Screw, M4x10mm LG, PPHD, S.S. 101671

FRE-1052 Screw, M4x10mm LG, PPHD, S.S. 101671

FRE-1160 None None

None None

Screw, PPH, SS, M4x30mm LGx .8mm

Nut, Hex, SS, M4

101699

101004

APPENDIX REPLACING OVEN COMPONENTS

Page 40

For service or information:

Customer Support at 800.90TURBO

+1 214.379.6000 or Your Authorized Distributor

Part Number: FRE-1002 / Revision B / October 2014

Country Code: NA/EU

Global Operations

2801 Trade Center Drive

Carrollton, Texas 75007

TM

+1 214.379.6000

+1 214.379.6073

TurboChef International

Business & Technology

Centre

Bessemer Drive

Stevenage

Herts SG1 2DX

United Kingdom

+44 8456021544

+44 8456021636

Customer Support

800.90TURBO

+1 214.379.6000

turbochef.com

Loading...

Loading...